Method for degrading dye wastewater by using tetraacetylethylenediamine (TAED)/solid oxidant (SPS, SPC or SPB) catalytic oxidation system

A tetraacetylethylenediamine, dye wastewater technology, applied in chemical instruments and methods, oxidized water/sewage treatment, physical/chemical process catalysts, etc., can solve the problems of low utilization rate, accelerated dye degradation, increased energy consumption, etc., To achieve the effect of low cost, environmental friendliness and strong oxidation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

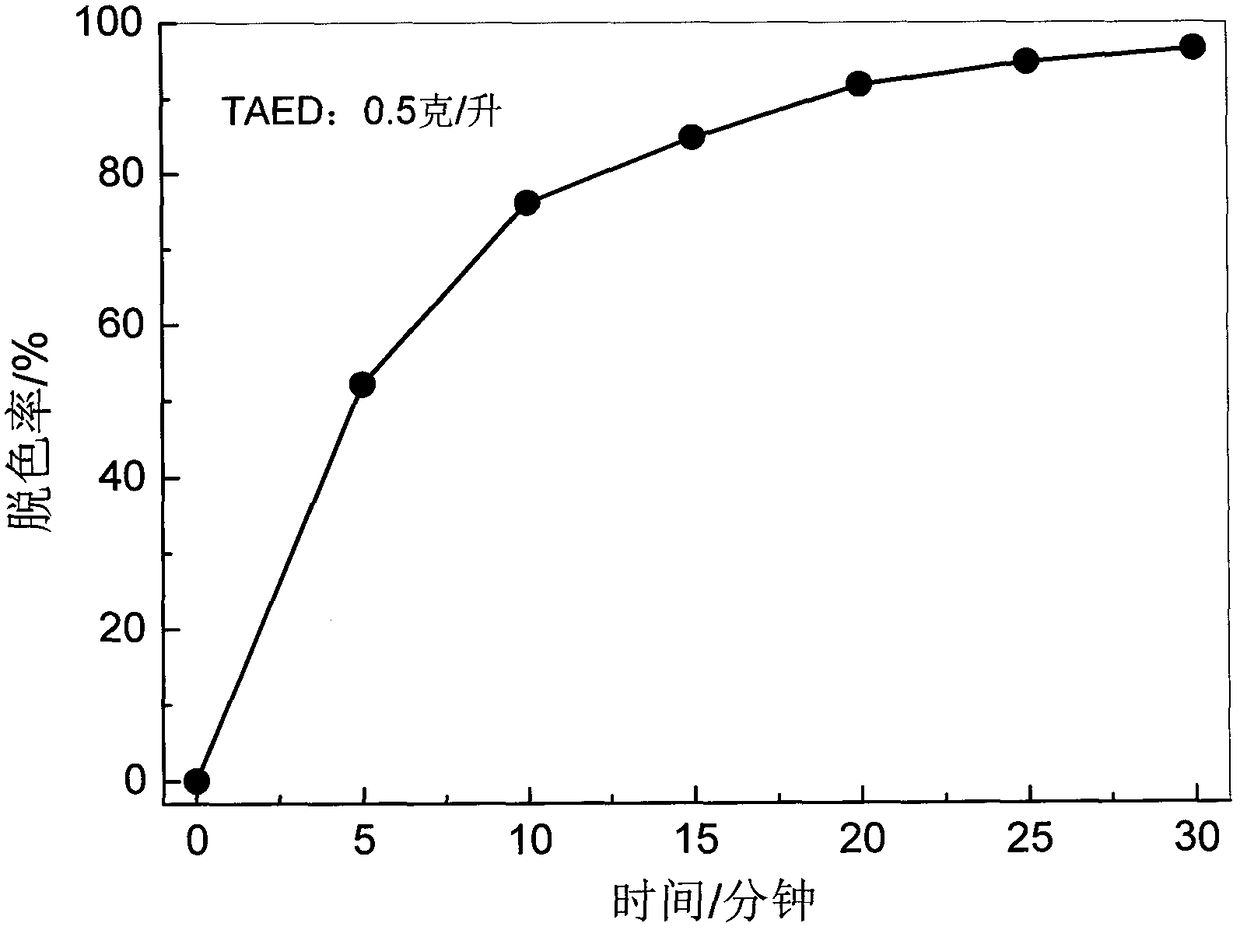

Embodiment 1

[0017] (1) Preparation of aqueous dye solution: Accurately weigh 1.25 grams of reactive red 195 in a 50-milliliter beaker, add a small amount of distilled water to dissolve it and transfer it to a 250-milliliter volumetric flask, then wash the beaker with a small amount of distilled water several times, and wash the solution completely Transfer to a volumetric flask, finally add distilled water to the specified scale and shake well to obtain a 5.0 g / L dye stock solution;

[0018] (2) Preparation of TAED aqueous solution: Accurately weigh 6.0 grams of TAED in a 1000 ml beaker, add a small amount of distilled water to dissolve it and transfer it to a 2000 ml volumetric flask, then wash the beaker with a small amount of distilled water several times, and transfer all the washing solution into In the volumetric flask, finally add distilled water to make the volume to the specified scale and shake well to obtain 3.0 g / L TAED aqueous solution;

[0019] (3) Preparation of SPS aqueous...

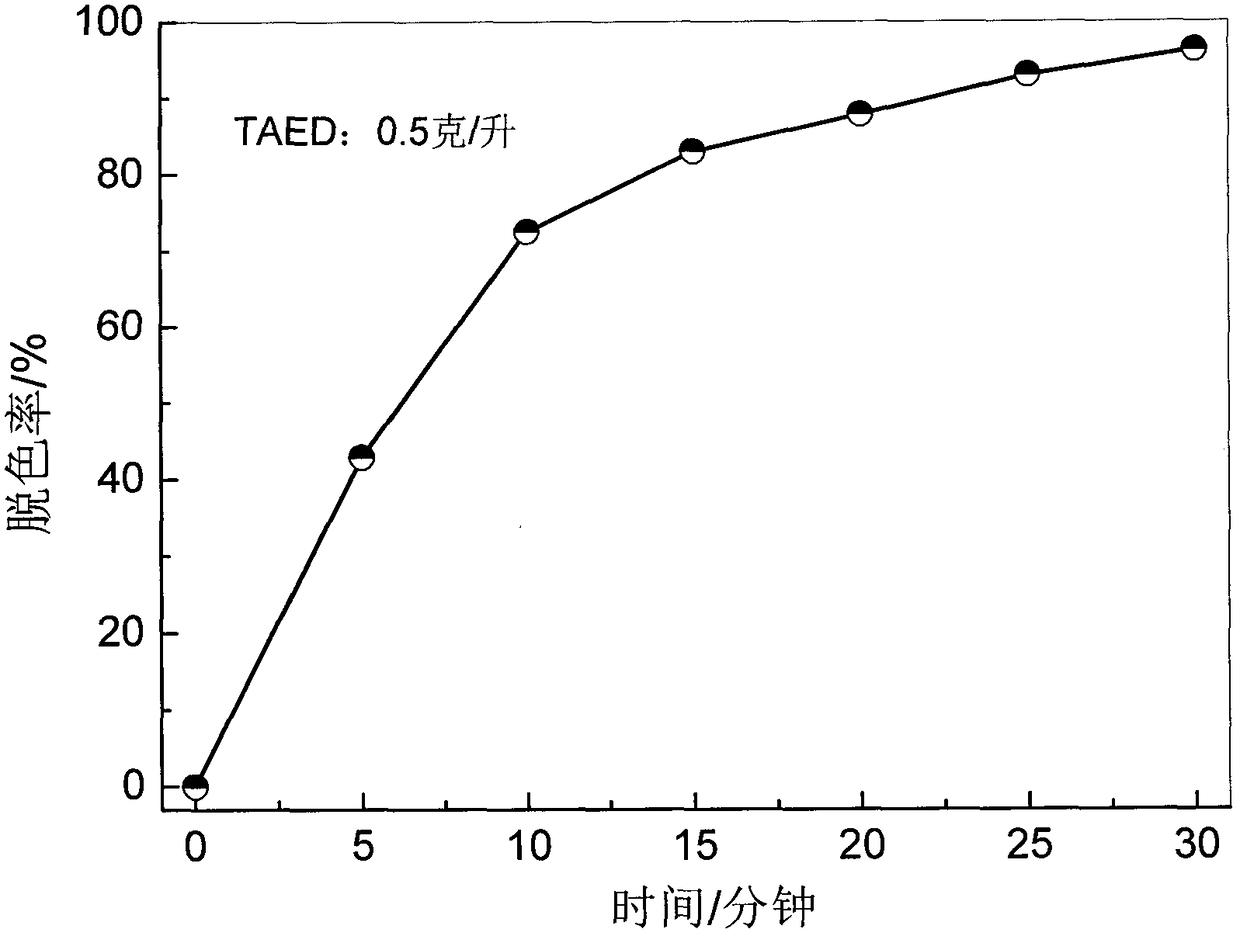

Embodiment 2

[0022] (1) process is identical with step (1) in embodiment 1;

[0023] (2) process is identical with step (2) in embodiment 1;

[0024] (3) Preparation of SPC aqueous solution: Accurately weigh 0.5 g of SPC in a 50 ml beaker, add a small amount of distilled water to dissolve it and transfer it to a 50 ml volumetric flask, then wash the beaker several times with a small amount of distilled water, and transfer all the washing solution into In the volumetric flask, finally add distilled water to the specified scale and shake to obtain 10.0 g / L SPC stock solution;

[0025] (4) Oxidative degradation reaction of dye: Measure 5 milliliters of reactive red 195 stock solution and add 34.2 milliliters of distilled water, then add 8.3 milliliters of TAED aqueous solution and 2.5 milliliters of SPC stock solution to form a 50 milliliter reaction system to make it active The concentration of Red 195 is 50 mg / L, the concentration of TAED is 0.5 g / L, and the concentration of SPC is 0.50 g / ...

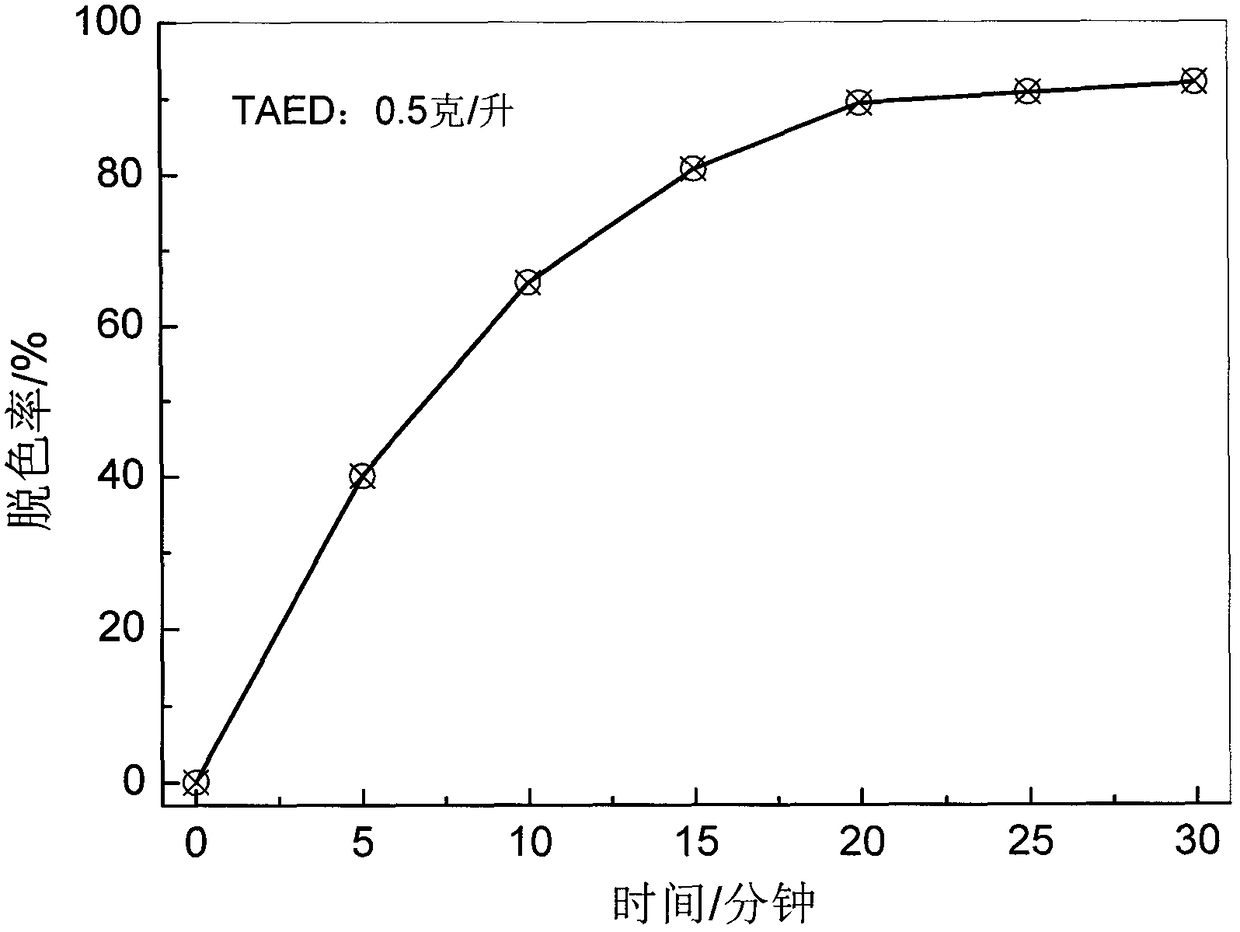

Embodiment 3

[0027] (1) process is identical with step (1) in embodiment 1;

[0028] (2) process is identical with step (2) in embodiment 1;

[0029](3) Preparation of SPB aqueous solution: Accurately weigh 0.5 g of SPB in a 50 ml beaker, add a small amount of distilled water to dissolve it and transfer it to a 50 ml volumetric flask, then wash the beaker several times with a small amount of distilled water, and transfer all the washing solutions into In the volumetric flask, finally add distilled water to the specified scale and shake up to obtain 10.0 g / L SPB stock solution;

[0030] (4) Oxidative degradation reaction of dyestuff: Measure 5 milliliters of reactive red 195 stock solution and add 34.2 milliliters of distilled water, then add 8.3 milliliters of TAED aqueous solution and 2.5 milliliters of SPB stock solution to construct 50 milliliters of reaction system, make it active The concentration of Red 195 was 50 mg / L, the concentration of TAED was 0.5 g / L, and the concentration of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com