A method for magnetic nanospheres to adsorb vanadium oxide quantum dots to degrade rhodamine b

A magnetic nanosphere and magnetic nanoparticle technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve the problem of large material size, difficult separation, and the size of metal compounds Large and other problems, to achieve the effect of environmental friendliness, broad market prospects, and ingenious ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

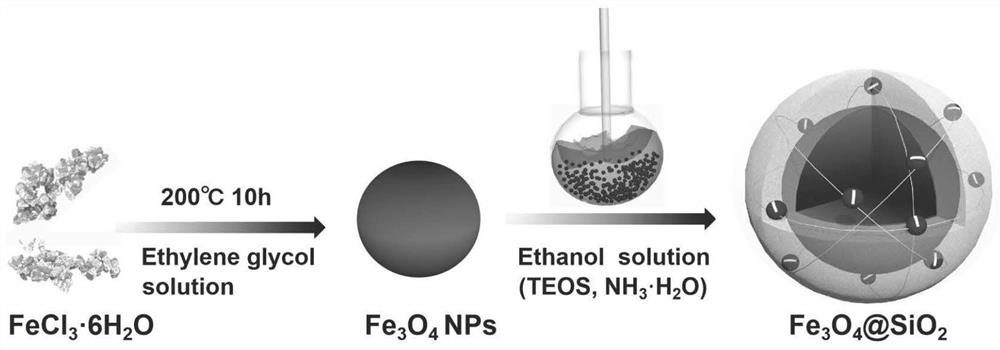

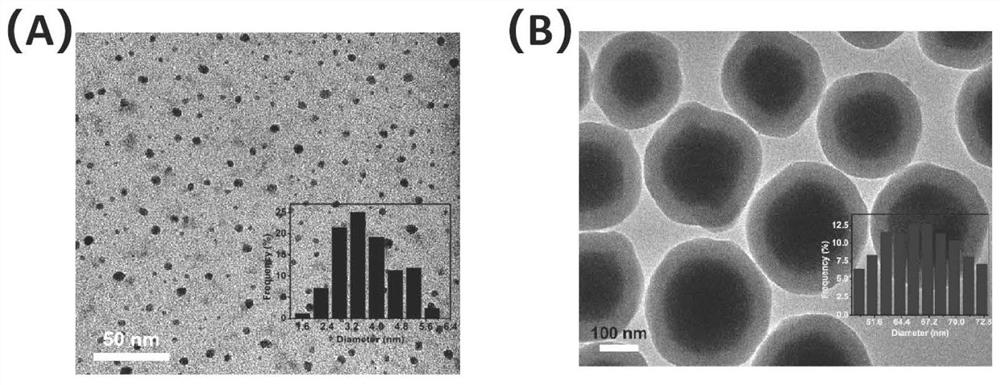

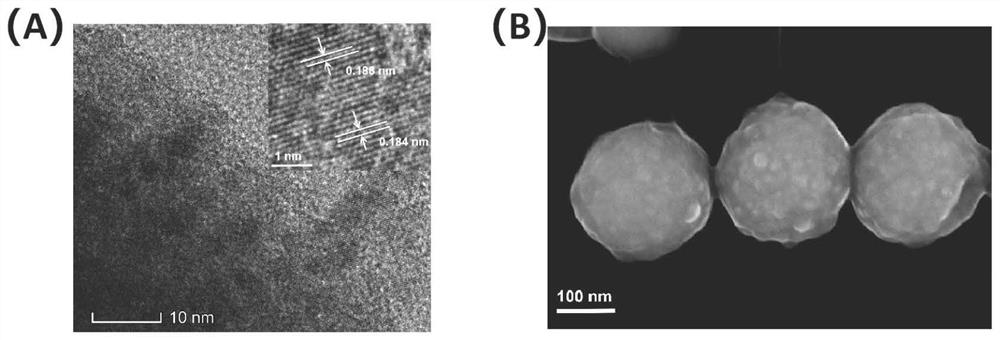

[0039] The preparation of the magnetic ferroferric oxide and the encapsulation of the silicon dioxide layer involved in this embodiment, the specific synthesis method is carried out according to the steps:

[0040] S1. Dissolve 1.5g PSSMA 1:1 in 80mL ethylene glycol (with FeCl 3 ·6H 2 O is the precursor, weigh 1.62g FeCl respectively 3 ·6H 2 O and 4.5g of anhydrous sodium acetate in the above alcohol solution, then transferred to a 100mL polytetrafluoro-lined reaction kettle, heated to 200°C in a blast drying oven, and maintained for ten hours, collected with a magnet The precipitate was washed three times with ethanol and deionized water, and then freeze-dried for 24 hours;

[0041] S2. Weigh 50 mg ferric oxide nanoparticles and disperse them in 5 mL of deionized water, then disperse them in a round bottom flask filled with 200 mL of absolute ethanol and 10 mL of deionized water to obtain a dispersion, and then ultrasonically treat the above dispersion 15 minutes; then ad...

Embodiment 2

[0044] This embodiment verifies the degradation conditions of rhodamine B, and the specific steps are carried out as follows:

[0045] Weigh 50mg Fe 3 o 4 @SiO 2 Powder, dispersed in 100ml 0.5M NaCl solution, ultrasonicated for 30 minutes, then added 0.75g polydiallyl ammonium chloride (PDDA), mechanically stirred for 1h and washed to remove excess PDDA; the same method was used to wrap polyphenylene Sodium ethylene sulfonate (PSS), PDDA-modified Fe 3 o 4 @SiO 2 It is represented by the letter FS (PDDA), and the modified PDDA and PSS is represented by the letter FS (P / S). After adsorbing quantum dots, it is represented by the letters VFS (PDDA), VFS (P / S), Figure 5 (A) As shown in the figure, a-h were respectively controlled as follows, and the UV absorbance was measured after 5 minutes of reaction, (a) Rh B; (b) Rh B+H 2 o 2 ;(c)FS+H 2 o 2 ;(d)VFS+H 2 o 2 ;(e)FS(PDDA)+H 2 o 2 ;(f)VFS(PDDA)+H 2 o 2 ;(g)FS(P / S)+H 2 o 2 ;(h)VFS(P / S)+H 2 o 2 ; When PDDA is wra...

Embodiment 3

[0048] This embodiment verifies the charge conditions of the silicon dioxide-wrapped iron ferric oxide and quantum dots in Example 1 and Example 2. The pure quantum dot alcohol solution has a positive charge at pH=2. The charged state of the dots realizes the adsorption of the negatively charged surface to the quantum dots. The potential difference of the surface before and after the adsorption of the magnetic silicon ball is as follows: Figure 4 As shown, it shows that the surface potential of the magnetic silicon sphere wrapped by silica is slightly lower than that of the material without adsorption, and the potential value at pH 1-7 is slightly lower, and the surface of the surface silicon sphere is indeed adsorbed with quantum dots.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com