A treatment method for improving the reusable performance of modified polytetrafluoroethylene fiber iron complex catalyst

A polytetrafluoroethylene, iron complex technology, applied in the direction of organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problem of unusable, need regeneration or replacement, It can not meet the problems of repeated reuse and the decolorization rate of dyes, and achieve the effects of easy industrialization, good adaptability and short processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

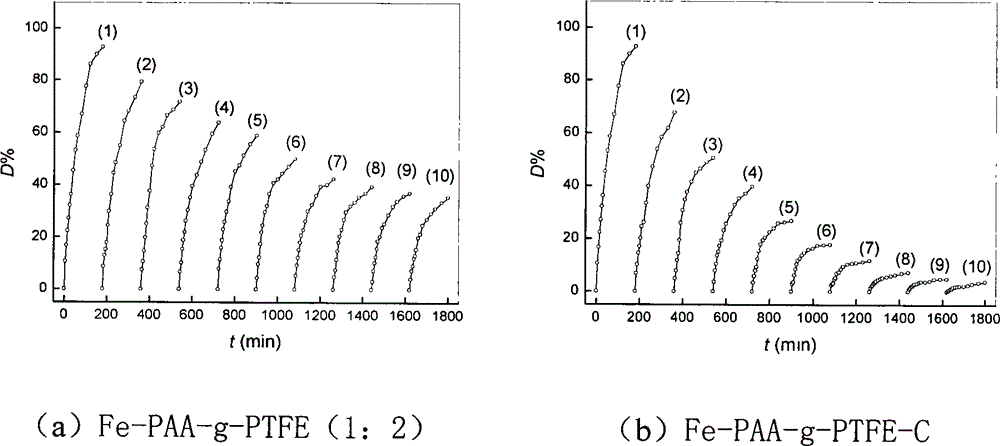

Embodiment 1

[0035]1. Pretreatment process: at room temperature, first immerse the catalyst in an aqueous solution containing a nonionic surfactant with a volume concentration of 2.0 g / L, and place it in an ultrasonic cleaner for 10 minutes, then take it out, and then Wash the catalyst 5 times with distilled water, and finally dry it under vacuum at 50-70°C for 24-48 hours;

[0036] 2. Preparation of reuse treatment solution: Add ferric sulfate and oxalic acid to distilled water to form a mixed solution, so that the molar concentration ratio of ferric sulfate and oxalic acid is 1:2, and the molar concentration of ferric sulfate is 1.0×l0 -4 mol / L, the molar concentration of oxalic acid is 2.0×10 -4 mol / L, stand for use. Add hydrogen peroxide to this mixed solution and make its molar concentration 4.0×10 before recycling. -3 mol / L, to prepare reused treatment solution.

[0037] 3. Reuse treatment process: immerse the above-mentioned pretreated catalyst in the reuse treatment solution, so...

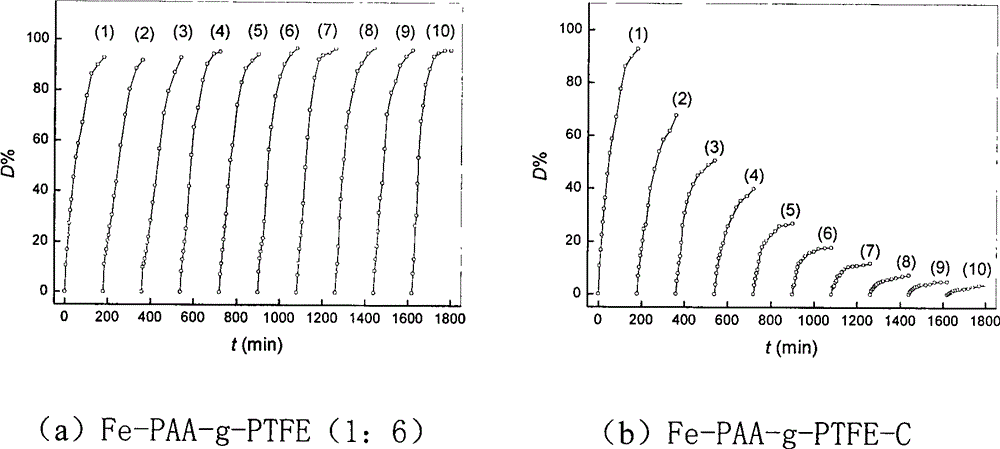

Embodiment 2

[0040] 1. The process is the same as the 1-step process in Example 1 respectively.

[0041] 2. The molar concentration ratio of ferric sulfate and oxalic acid in the mixed aqueous solution of ferric sulfate and oxalic acid is adjusted to 1:6, that is, the molar concentrations of ferric sulfate and oxalic acid in the aqueous solution are 1.0×10 -4 mol / L and 6.0×10 -4 mol / L. All the other are with 2 in embodiment 1.

[0042] 3. The process is respectively the same as the 3-step process in Example 1.

[0043] 4. The process is the same as the 4-step process in Example 1 respectively. The obtained catalyst is abbreviated as Fe-PAA-g-PTFE (1:6).

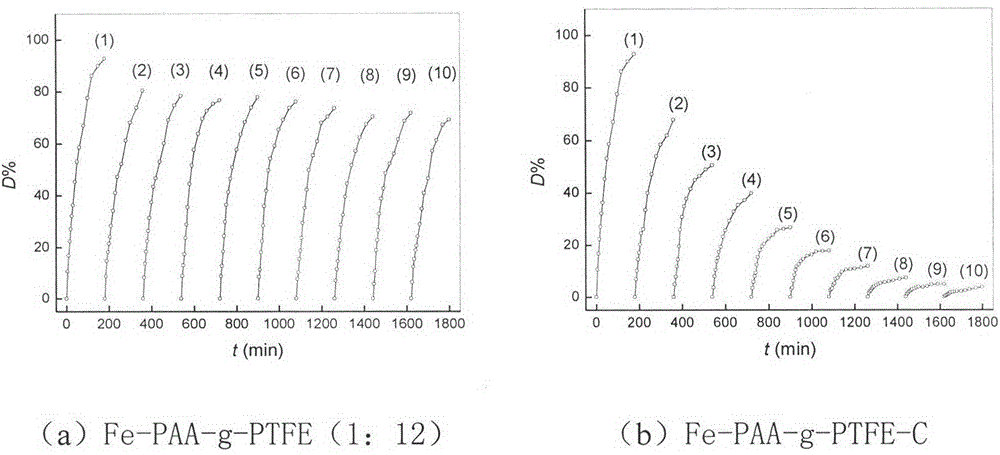

Embodiment 3

[0045] 1. The process is the same as the 1-step process in Example 1 respectively.

[0046] 2. The molar concentration ratio of ferric sulfate and oxalic acid in the mixed aqueous solution of ferric sulfate and oxalic acid is adjusted to 1:12, that is, the molar concentrations of ferric sulfate and oxalic acid in the aqueous solution are 1.0×10 -4 mol / L and 12.0×10 -4 mol / L. All the other are with 2 in embodiment 1.

[0047] 3. The process is respectively the same as the 3-step process in Example 1.

[0048] 4. The process is the same as the 4-step process in Example 1, and the obtained catalyst is abbreviated as Fe-PAA-g-PTFE (1:12).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com