Two-step method resource treatment process for sludge containing oil

A treatment process and resource recovery technology, which is applied in the field of oily sludge two-step resource recovery process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

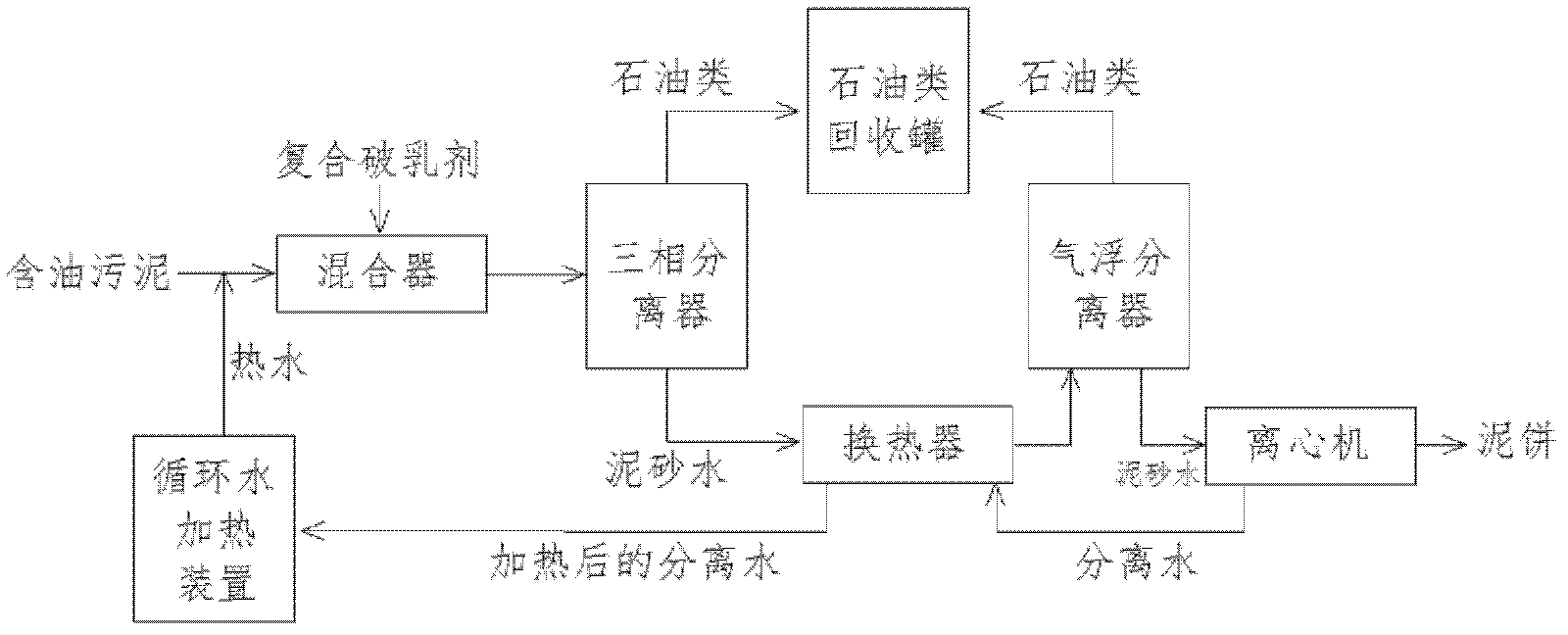

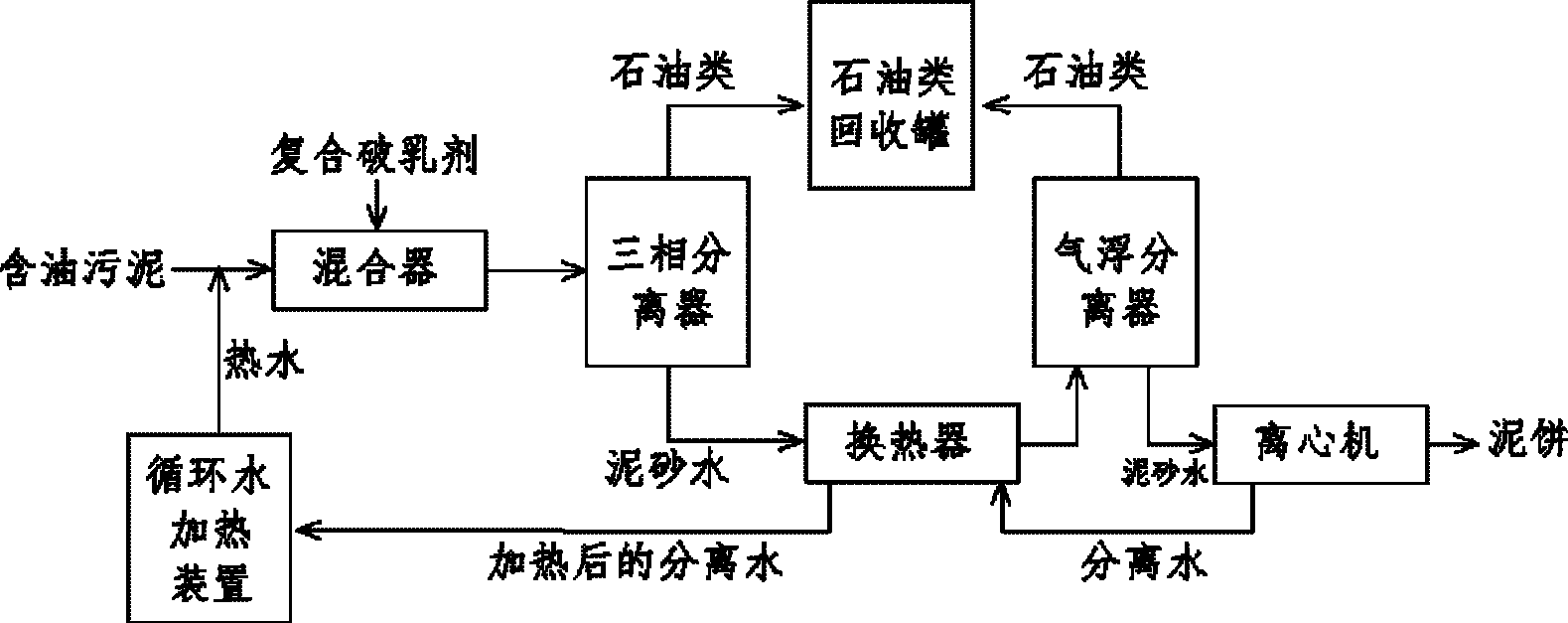

Image

Examples

Embodiment 1

[0036] The oily sludge obtained from Oil Production Plant A contains 38.5% oil, 51.9% solids and 9.6% water. The oily sludge after removal of impurities is melted with 4 times the volume of hot water, mixed with a compound demulsifier and then entered into a three-phase separator. The conditions in the three-phase separator are controlled as follows: temperature 70°C, pH=5.5, compound demulsifier concentration 3‰, stirring speed 200r / min, hydraulic retention time 20min. The crude oil in the upper layer is recovered, and the cement-sand mixture in the lower layer enters the air flotation separation tank for air flotation separation, and the hydraulic retention time of the air flotation separation tank is 15 minutes. After recovering the crude oil in the upper layer, the mud cake in the lower layer was centrifuged and the oil content was 1.8%, the water content was 32.1%, and the solid content was 66.1%. The recovery rate of crude oil was calculated to be 95.3%.

Embodiment 2

[0038] It is taken from the oily sludge of Oil Extraction Plant B, which contains 41.7% oil, 49.4% solid matter, and 8.9% water. The oily sludge after removing impurities is dissolved with 3 times the volume of hot water, and the mixed liquid is mixed with the compound demulsifier and then enters the three-phase separator. The conditions in the three-phase separator are controlled as follows: temperature 70°C, pH=7, compound demulsifier concentration 3‰, stirring speed 150r / min, hydraulic retention time 20min. The crude oil in the upper layer is recovered, and the cement-sand mixture in the lower layer enters the air flotation separation tank for air flotation separation, and the hydraulic retention time of the air flotation separation tank is 15 minutes. After recovering the crude oil in the upper layer, the mud cake in the lower layer contains 0.6% oil, 38.7% water and 60.7% solids after centrifugation of the mud-water mixture in the lower layer. The calculated oil recovery ...

Embodiment 3

[0040] The oily sludge obtained from Oil Production Plant C contains 30.5% oil, 55.9% solids and 13.6% water. The oily sludge after removing impurities is dissolved with 4 times the volume of hot water, and the mixed solution is mixed with the compound demulsifier and then enters the three-phase separator. The conditions in the three-phase separator are controlled as follows: temperature 70°C, pH=8, compound demulsifier concentration 3‰, stirring speed 300r / min, hydraulic retention time 20min. The crude oil in the upper layer is recovered, and the cement-sand mixture in the lower layer enters the air flotation separation tank for air flotation separation, and the hydraulic retention time of the air flotation separation tank is 15 minutes. After recovering the crude oil in the upper layer, the mud-water mixture in the lower layer was centrifuged and the mud cake contained 1.5% oil, 36.7% water and 61.8% solids, and the calculated oil recovery rate was 95.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com