Rust-removing oil-removing wax-removing additive and preparation method thereof

An additive, oleic acid technology, applied in the field of pickling solution, can solve problems such as affecting the health of operators, affecting product quality, over-corrosion of workpieces, etc., to avoid hydrogen embrittlement, avoid over-corrosion of workpieces, and passivate the surface of workpieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

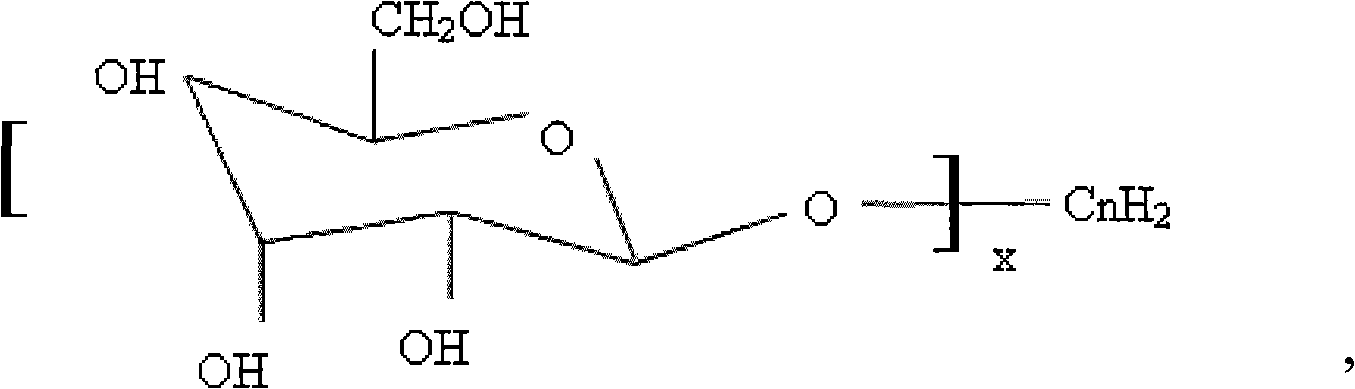

[0048] The rust, oil and wax removal additives of this embodiment are made up of the following raw materials: 10% of modified oleic acid, 3% of alkyl polyglucosanne, 3% of coconut acid diethanolamide, 1% of 65% ethanol, four Acetylethylenediamine 2%, the balance is water.

Embodiment 2

[0050] The rust-removing, oil-removing and wax-removing additive of the present embodiment is made up of following raw materials: modified oleic acid 20%, alkyl polyglucosanne 13%, coconut oil cavity acid diethanolamide 13%, 65% ethanol 10%, four Acetyl ethylenediamine 7%, the rest is water.

Embodiment 3

[0052] The present embodiment derusting, degreasing and dewaxing additive is made up of following raw materials: modified oleic acid 15%, alkyl polyglucosanne 8%, cocoacid diethanolamide 8%, 65% ethanol 5%, four 2% of acetylethylenediamine, and the rest is water; the additive is obtained by shearing with a shearing machine at a rotor speed of 10,000 rpm.

[0053] The invention also provides a preparation method of the rust-removing, oil-removing and wax-removing additive. The method includes:

[0054] Take 10%-20% of modified oleic acid, 3%-13% of alkyl polyglucosin, 3%-13% of coconut acid diethanolamide, 1%-10% of 65% ethanol, tetraacetyl ethyl alcohol 2%-7% of diamine, and the rest is water; dissolve the modified oleic acid with the 65% ethanol, and then mix it with the alkyl polyglucosan, the coconut acid diethanolamide, and the four Mix acetylethylenediamine and water evenly.

[0055] The preparation method of the rust-removing, oil-removing and wax-removing additive of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com