Two-component water epoxy radiation-resistant paint for nuclear power plant

A radiation coating, a two-component technology, is applied in the field of protection and decoration of the concrete surface of the containment of nuclear power plants and nuclear auxiliary powerhouses. Effects of reduced adverse effects, improved radiation resistance, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030]The aqueous amine-epoxy adduct of the amine termination in the preparation component A of embodiment 1

[0031] Concrete synthetic steps are as follows:

[0032] ① Preparation of raw materials for synthesis

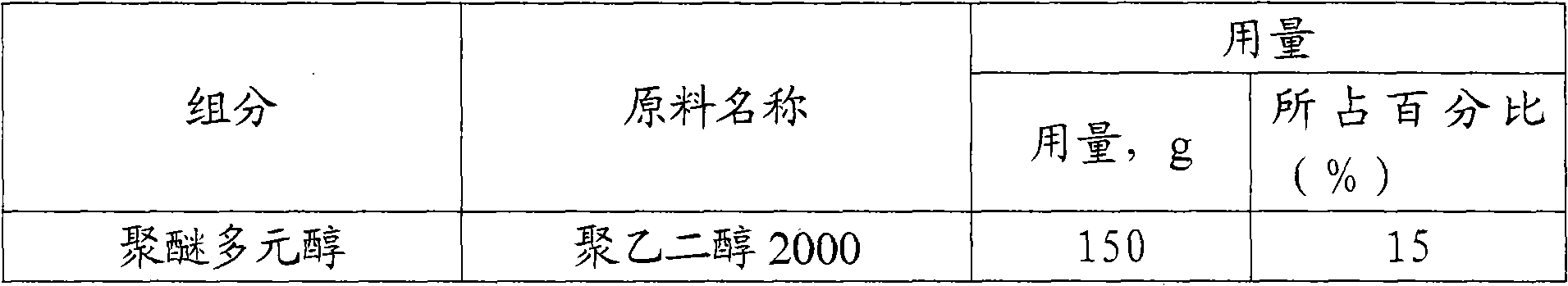

[0033] The percentages of the amount of each raw material in the total weight of raw materials are as follows: olefin-based polyamine 8-15%, monofunctional glycidyl ether 5-12%, polyether polyol 5-15%, bisphenol A diglycidyl ether 10% ~20%, co-solvent 10-20%, catalyst 0.1-1.0% and deionized water as the balance, the specific formula is shown in Table 1.

[0034] Table 1

[0035]

[0036]

[0037] Note: "Percentage" refers to the percentage of the amount of the raw material in the total weight of the raw material.

[0038] ②In a reactor equipped with stirring and heating equipment, a nitrogen conduit reflux condenser and a thermometer, add an appropriate amount of toluene solvent and a formula amount of bisphenol A diglycidyl ether and polyethylene glycol 20...

Embodiment 2

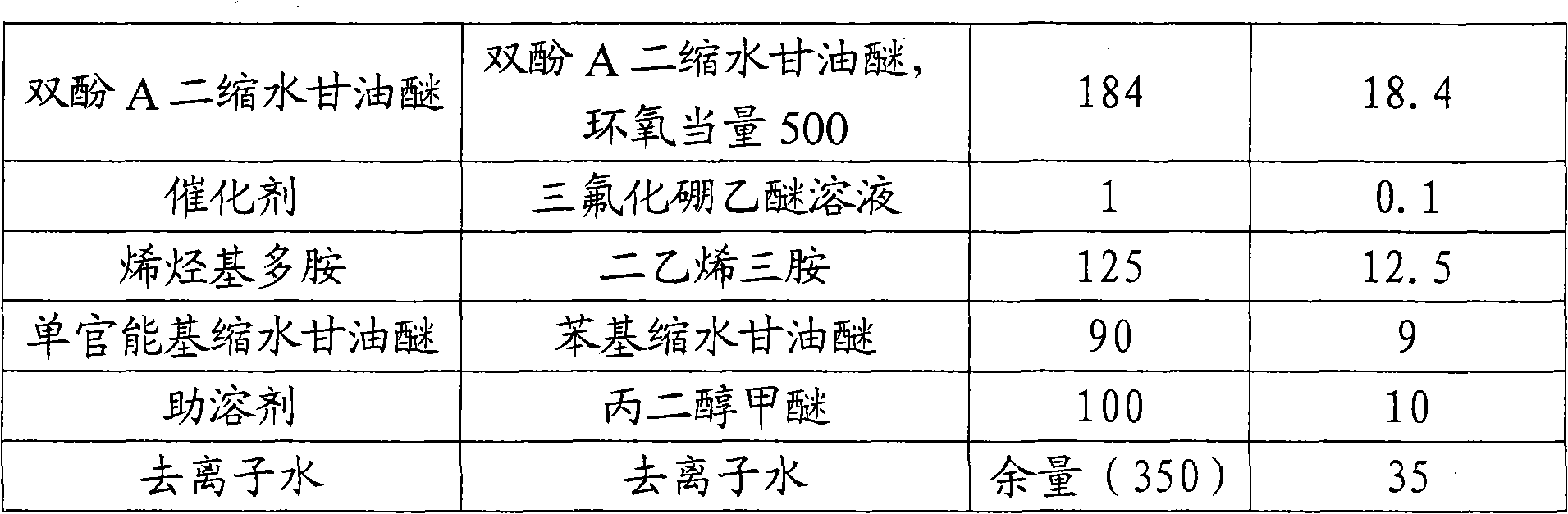

[0041] Embodiment 2 prepares the emulsifier in component B

[0042] 1. Formula

[0043] The percentages of the amount of each raw material in the total weight of raw materials are as follows: bisphenol A epoxy resin 3-14%, polyether polyol 35-47%, catalyst 0.2-1%, deionized water as the balance, the specific formula see Table 2.

[0044] Table 2

[0045]

[0046] Note: "Percentage" refers to the percentage of the amount of the raw material in the total weight of the raw material.

[0047] 2. Operation method

[0048] In a reactor equipped with stirring, heating equipment, nitrogen conduit and thermometer, add the formula amount of polyethylene glycol 4000 and epoxy E-51 and heat to 60-70°C, stir until the resin is completely dissolved, stop heating, and slowly drop Add boron trifluoride ether solution, the reaction is an exothermic reaction, when the temperature is stable, control the temperature at 70-80°C for 1 hour, then slowly raise the temperature to 90-100°C, and ...

Embodiment 3

[0049] The epoxy-polyacrylate interpenetrating network polymer in the preparation component B of embodiment 3

[0050] 1. Formula

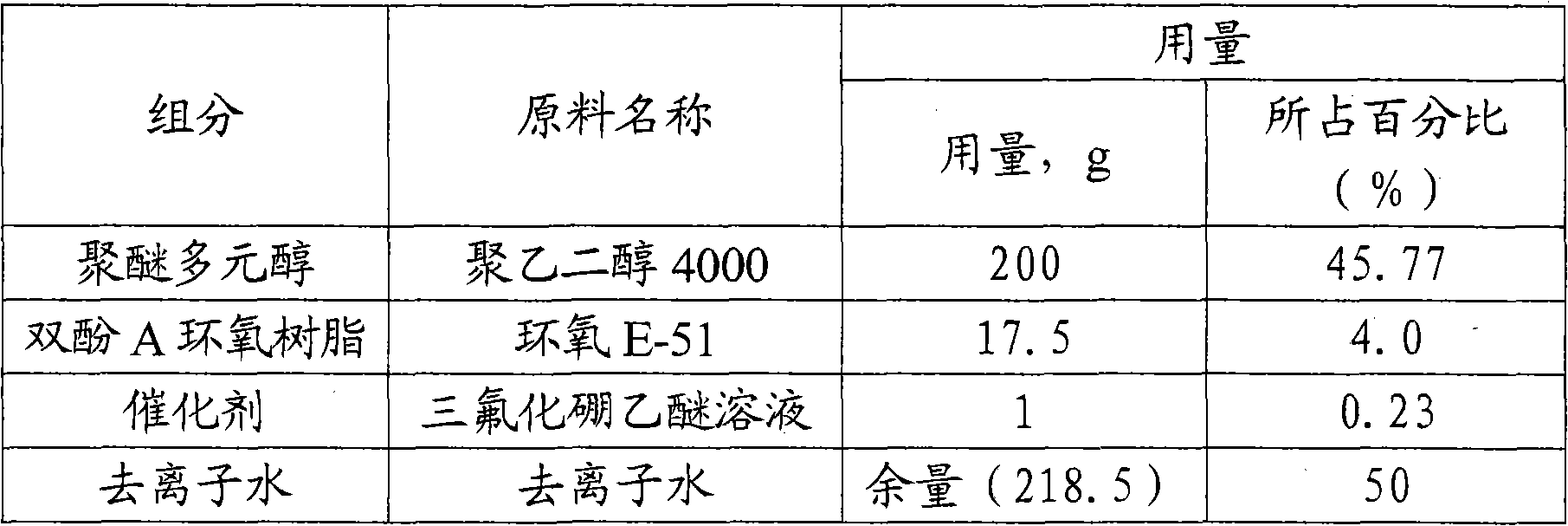

[0051] The percentages of the amount of each raw material in the total weight of the raw materials are as follows: 50-90% of bisphenol A epoxy resin, 10-50% of the total amount of acrylate monomer or acrylate monomer and styrene, and 0.3-50% of the initiator 1%, the specific formula is shown in Table 3.

[0052] table 3

[0053]

[0054] Note: "Percentage" refers to the percentage of the amount of the raw material in the total weight of the raw material.

[0055] 2. Operation method

[0056] In a reactor equipped with stirring, heating equipment, nitrogen conduit, condenser and thermometer, add the prescribed amount of epoxy E-51 and heat to 80-90°C, stir until the resin is completely dissolved, and then slowly drop each acrylate mono The mixed solution composed of body, styrene and catalyst, dripped in 2 hours; after the dropwise addition,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com