Patents

Literature

116results about How to "Avoid hydrogen embrittlement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Super-pressure hydrogen cylinder manufacture method

ActiveCN101187441AImprove plasticityImprove toughnessFurnace typesPressure vesselsNitrogen atmosphereNitrogen gas

The invention relates to a preparation method of a super-pressure hydrogen cylinder, which comprises choosing seamless steel pipe which is hot-roll-formed by high grade chrome-molybdenum steel whose wall thickness is not less 27mm, S is smaller 0.01.%, and P is smaller 0.020% as base material, no existing the weakness of wall thickness 5%line size through supersonic inspection, processing the form of the two end by rotationally pressing reducing, flattening the heads of the two ends, removing inner and outer folds on the shoulder portion, shot-blasting the inner side and the outer side of the bottle, heat hardening with heating temperature of 850-950 DEG C, tempering in 580-700 DEG C, accurately processing the end face of the bottle and inner threads and outer threads, shot-blasting the inner side and the outer side of the bottle in second time to remove remanent stress concentration area, proceeding 100% magnetic particle detection for the bottle, proceeding 100% ultrasonic detection to the two ends, carrying out secondary 100% supersonic inspection to the bottle after proceeded water pressure experiment and pressure-tight experiment according to mating installation specification, drying the inner portion of the bottle, processing rust prevention on the outer portion of the bottle, assembling bottleneck switches on bottlenecks on the two ends, and evacuating the inner portion to replace nitrogen atmosphere for storage for use.

Owner:SHIJIAZHUANG ENRIC GAS EQUIP

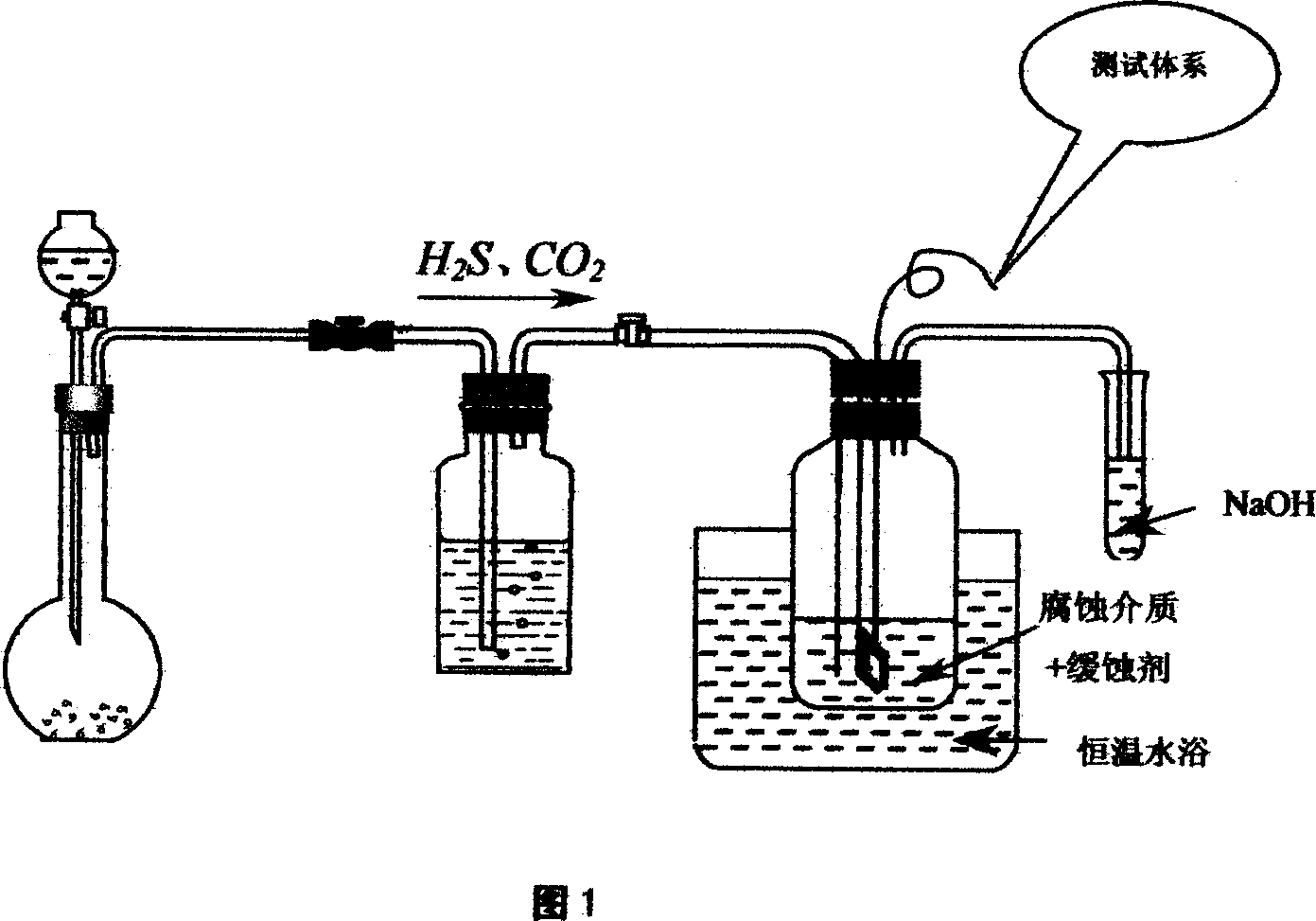

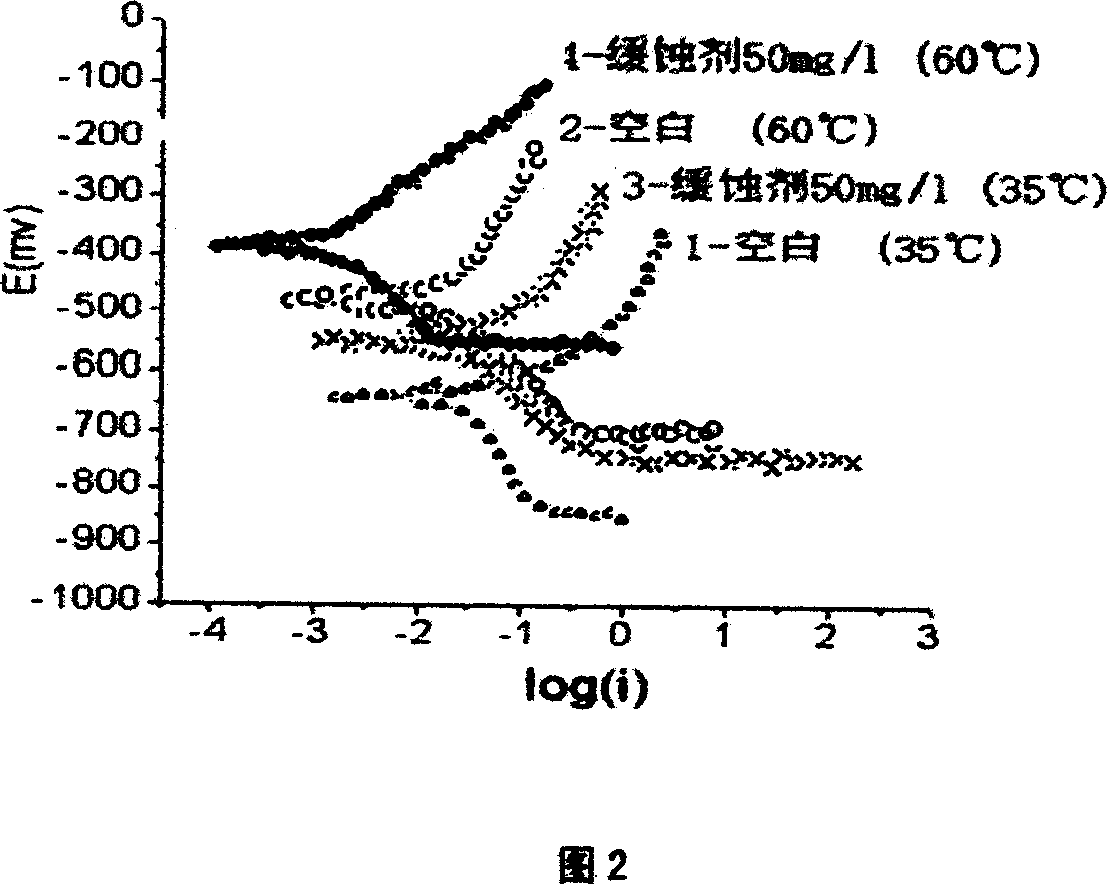

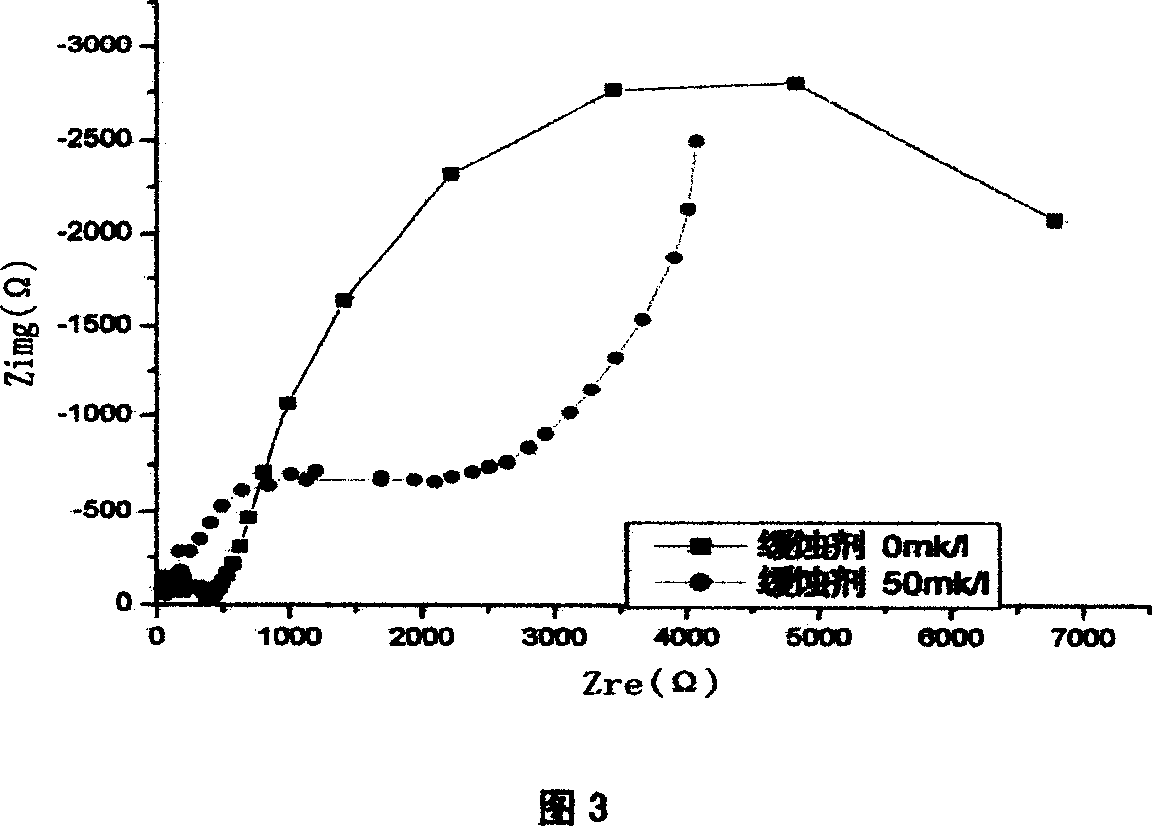

Corrosion inhibitor resistant to H2S and CO2

InactiveCN1966774ADoes not affect separation efficiencyGood corrosion inhibition effectBorehole/well accessoriesIsopropyl alcoholFatty alcohol

The invention relates the chemical engineering field, especially a H2 and CO2 inhibiter. H2 and CO2 are produced accompany to oil-gas field exploitation and transfusion process, and can corrode exploitation equipment. The inhibiter contains at least (by wt. %): isopropyl alcohol 10-30, fatty alcohol polyoxyethylene ether .1-0.5, and litol polyoxyethylene ether 0.1- 1.0. The inhibiter can be used in oil / water well with high temperature and pressure, and has the advantages of good corrosion resistance, low consumption, low cost and high efficiency.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

Copper alloy material for lead frame and preparation method thereof

The invention relates to a copper alloy material used for lead frame and the preparation method, belonging to the copper alloy material field; wherein nickel accounts for 0.9 to 3.5% (weight percentage), silicon accounts for 0.18 to 0.8%, phosphorus accounts for 0.02 to 0.1% and the rest is copper. The preparation method is that all the components according to the weight ratio are mixed and melted, after casting, hot forging, solid solution, multiple cold rolling, deformation and aging, the product is got. The copper alloy material used for lead frame has the advantages of tensile strength of 600 to 850MPa, conductivity of 45 to 65%IACS, elongation of 5 to 8% and softening temperature of 500 to 550 centigrade; thereby the requirements on the copper alloy material performance of the lead frame in electronic industrial field is well achieved; the copper alloy material can also be used in the copper alloy material field needing high strength and high conductive, such as contact lines in trolleys and electric locomotives, rotor bars of the high-speed turbine generator and inner liners of the large thrust rocket engines.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Corrosion inhibitor for hydrogenation plant

InactiveCN1754944AThe synthetic route is simpleSave raw materialsTreatment apparatus corrosion/fouling inhibitionImidazoline derivativesOrganic acid

The invention relates to corrosion inhibitor for hydrogenation device with constituent as: 10-30% fat nitrogen-containing compound, 10-20% aromatic sulfur-containing compound, 0-25% organic acid esters, 15-70% aromatics, and 0-25% imidazoline derivative. A little this product can effective inhibiting corrosion and salt dirty without any negative effect to product property and successive process fit to high-concentration H2S-HCl-H2O acidic or H2S-HCl-NH3-H2O basic system. It can form dense monomolecular layer protection membrane on metal surface to prevent hydrogen embrittlement phenomenon and fit to heat exchanger, air cooler and others.

Owner:上海贵通新材料科技有限公司

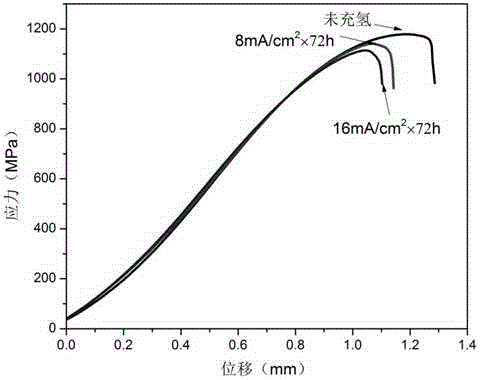

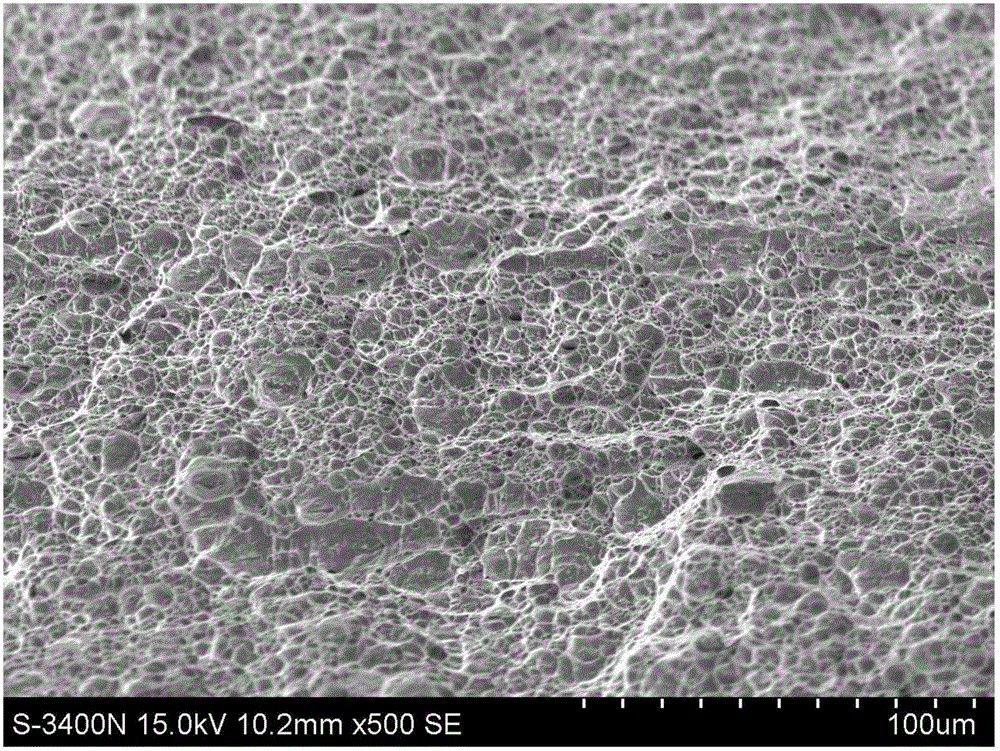

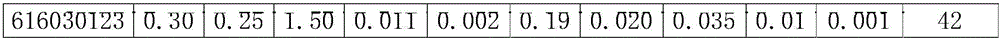

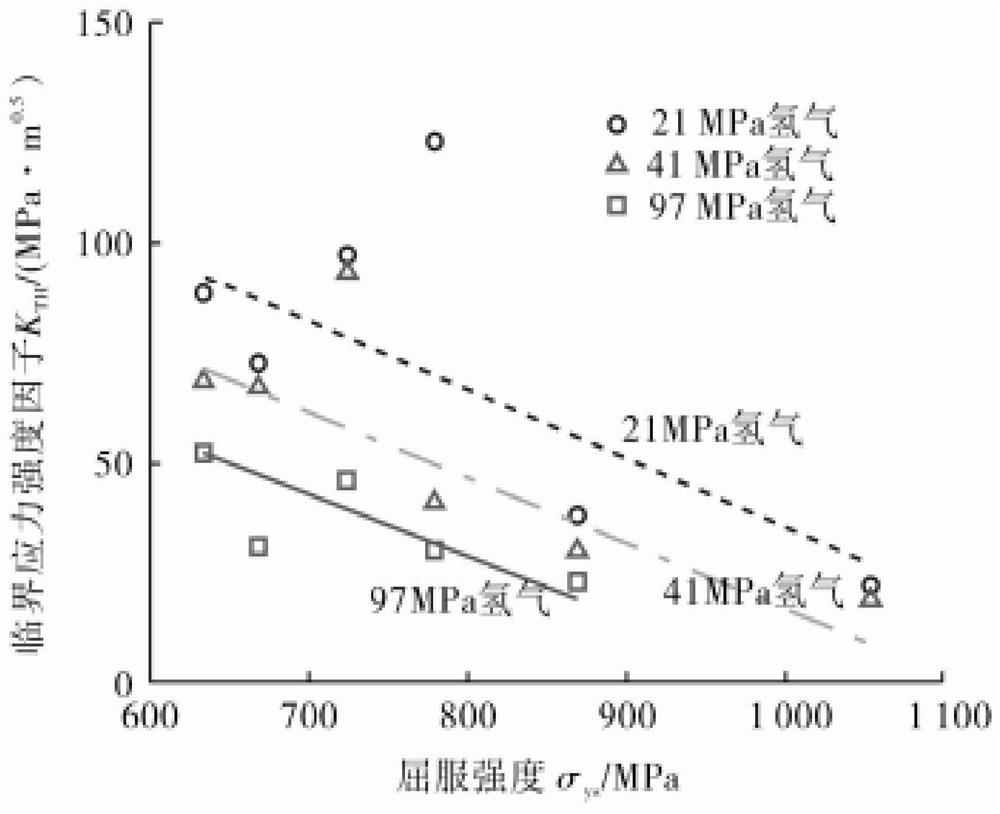

Dual phase steel with tensile strength of 1000 MPa and production method thereof

The invention discloses a dual phase steel with tensile strength of 1000 MPa and a production method thereof. The dual phase steel is composed of the following chemical components in percentage by weight: 0.08%-0.11% of C, 0.2%-0.6% of Si, 2.0%-2.5% of Mn, at most 0.01% of P, at most 0.01% of S, 0.02%-0.06% of Al, 0.4%-0.6% of Cr, 0.02%-0.05% of Ti, at most 0.003% of N, and the balance of Fe and inevitable impurities. The method solves the technical problem of how to lower the alloy cost and enhance the reaming property and delayed fracture resistance of the material on the premise of satisfying the strength requirement.

Owner:SHOUGANG CORPORATION

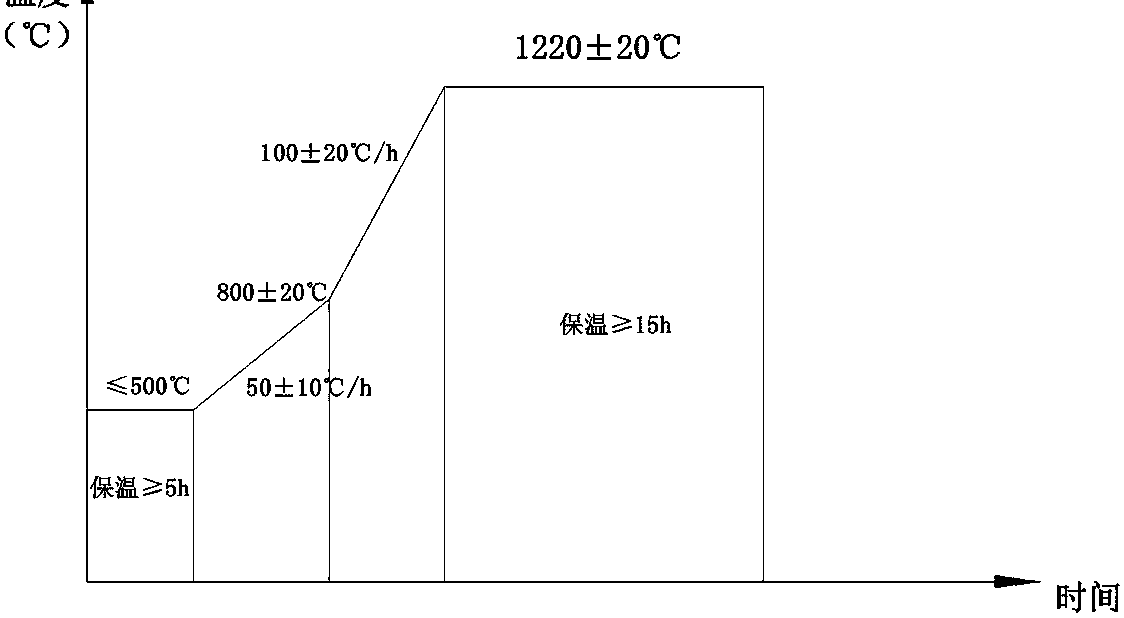

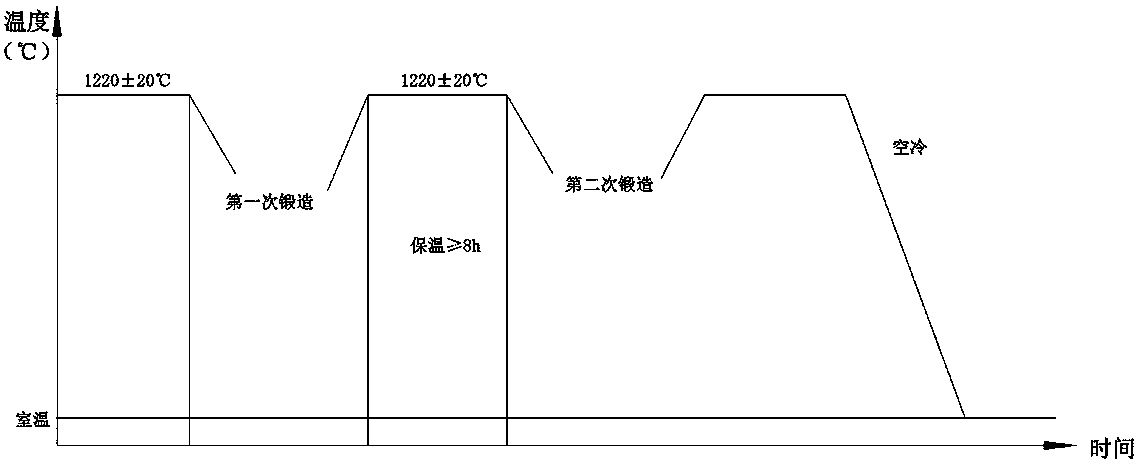

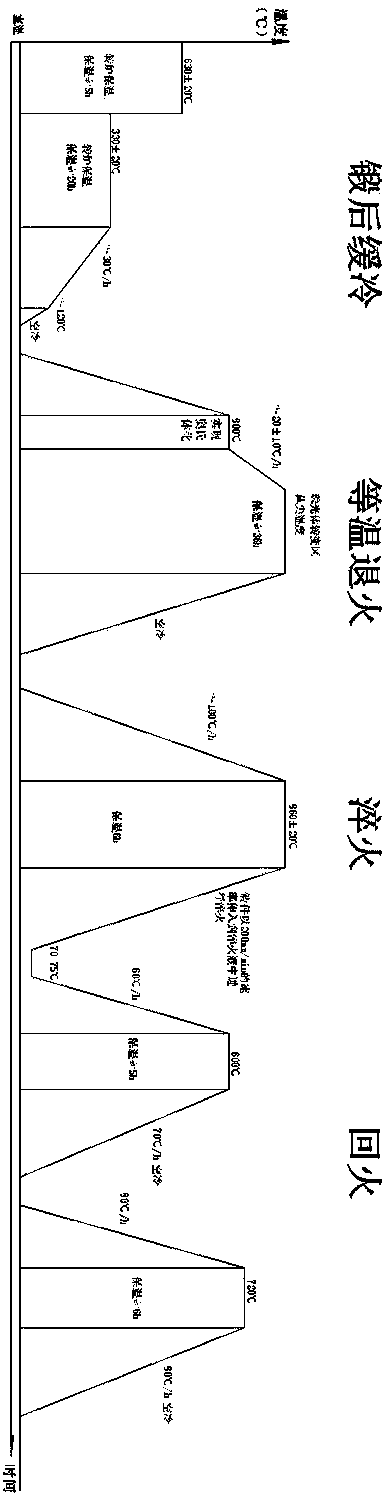

Manufacturing process for manufacturing large ship-used shafting forge pieces

InactiveCN108453202AEfficient crushingReasonable upsetting processMetal-working apparatusFurnace typesSolubilityHydrogen

The invention provides a manufacturing process for manufacturing large ship-used shafting forge pieces and belongs to the field of ship-used shafting forge pieces. The manufacturing process for manufacturing large ship-used shafting forge pieces specifically comprises the following steps: heat treatment before forging; two-time upsetting and stretching and forging (a WHF method); and thermal treatment on the forged shafting forge pieces. The two-time upsetting and stretching process is reasonable. Cast state tissues can be crushed effectively in first time stretching, and inner hole defects are forged; strip-type plastic inclusions of a core of a blank are fractured to smaller impurities in second time upsetting; the impurities are stretched to disperse impurity granules in the second stretching process, and the action of white points is eliminated effectively by the two-time upsetting process. As a result of temperature change condition in the two-time upsetting and stretching process, the solubility of hydrogen in the forge pieces changes continuously, and distribution and diffusion of hydrogen are facilitated well.

Owner:WUXI HONGDA HEAVY IND

Multifunctional environment protection metal degreasing derusting rust-proofing liquid

InactiveCN101082128ANo pollutionCause flammabilityMetallic material coating processesSodium bicarbonateThiourea

The functional environment friendly metal deoiling, derusting and antirusting fluid is prepared with polyoxyethylene alkyl ether, sodium dodecyl sulfate, 1.3-dibutyl thiourea, hexamethylidyene tetraamine, zinc dihydrogene phosphate, phosphoric acid, sodium butylnaphthalene sulfonate, sodium sulfosuccinate, triethanolamine, sodium bicarbonate, tartaric acid and 1.3-diethyl sulfourea in certain weight proportion, and through dissolving, diluting with water, mixing to react, and filtering. It has the synergistic effect of the components to deoil, derust, phosphorize, deactivate and antirust metal surface, no harm to human body and no environmental pollution.

Owner:彭文表

Metal part electroplating method

The invention discloses a metal part electroplating method. The metal part electroplating method includes the steps that a, film pasting is conducted, i.e., the surface of a metal part to be electroplated is covered with an anti-electroplating film coinciding with the portion, not needing electroplating, of the metal part; b, electroplating is conducted, i.e., the metal part with the surface covered with the anti-electroplating film is subjected to electrocoppering, electronickelling and electrogalvanizing, wherein an electrogalvanizing solution for electrogalvanizing is composed of 100-150 mg / L of sodium hydroxide, 5-10 mg / L of ethylenediamine, 25-30 mg / L of triethanolamine, 50-130 mg / L of alkaline tetra-iso-propyl amine, 10-15 mg / L of zinc sulfate, 40-59 mg / L of sodium citrate, 25-39 mg / L of phosphorous acid, 40-55 mg / L of dioctyl sodium sulfosuccinate and 25-67 mg / L of antimony potassium tartrate, and meanwhile electroplating parameters are set; and c, film removal is conducted, i.e., the anti-electroplating film on the metal part is removed after electroplating is completed. By means of the metal part electroplating method, the electroplating cost is reduced and the occurrence rate of hydrogen brittleness is also reduced.

Owner:WUXI QIAOYANG MACHINERY MFG

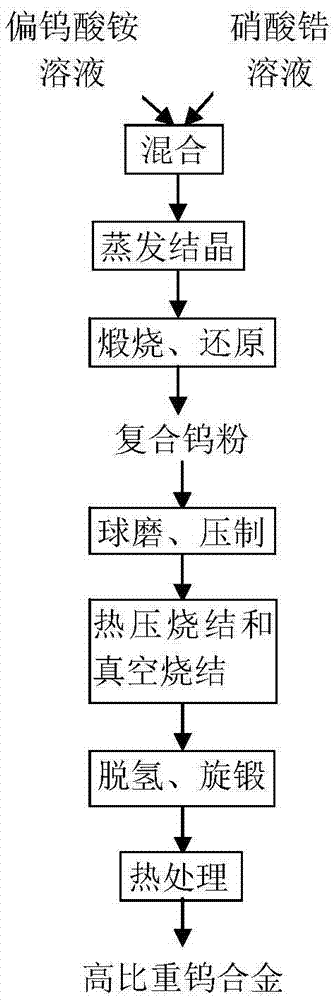

High-density tungsten alloy and preparation method thereof

The invention discloses a high-density tungsten alloy and a preparation method thereof, belonging to the field of metal materials. The tungsten alloy comprises the following components in percentage by mass: 95.0-99.0 percent of tungsten, 1.0-5.0 percent of zirconium oxide and inevitable impurities. The preparation method comprises the following steps: (1) respectively dissolving ammonium metatungstate and zirconium nitrate in water for mixing; drying the mixed liquid, and thus obtaining powder; calcining and reducing the powder, and thus obtaining composite tungsten powder; (2) after ball milling, carrying out compression molding and sintering for the composite tungsten powder, and thus obtaining a sintering billet; after dehydrogenation, carrying out deformation and thermal treatment for the sintering billet, and thus obtaining the high-density tungsten alloy. According to the preparation method, a ZrO2 strengthening phase is added in a tungsten matrix through a liquid-liquid doping method, and two segments of sintering processes, dehydrogenation and rotary swaging treatment are adopted to prepare the tungsten alloy. The preparation method solves the problems of uneven distribution of the strengthening phase of the traditional tungsten alloy, hydrogen embrittlement and low sintered density and provides a new direction for the application and development of the tungsten alloy in the new field.

Owner:HENAN UNIV OF SCI & TECH

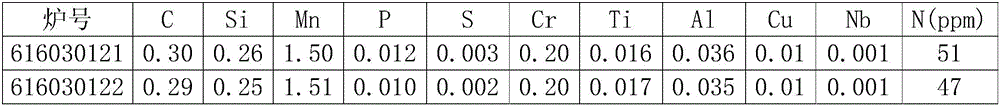

Production process for effectively preventing marine anchor chain round steel from generating cracks

InactiveCN106086595ASolve the problem of nozzle nodulationReduce inclusion contentProcess efficiency improvementElectric furnaceChemical compositionSlag

The invention relates to a production process for effectively preventing marine anchor chain round steel from generating cracks. A preparation method includes the steps of an electric furnace smelting procedure, a refining procedure outside an LF, a square billet continuous casting procedure and a rolling procedure. Chemical components are reasonably designed, the carbon equivalent is controlled, Ti microalloy reinforcement is added, the content of P and S is controlled to be smaller than or equal to 0.015%, the content of N is controlled to be smaller than or equal to 70 ppm, the content of residual elements of Cu, Nb and the like is reasonably controlled, the LF is well sealed, the soft blowing flow of argon is reasonably controlled, molten steel is prevented from absorbing nitrogen, aluminum deoxidation is enhanced, the soft blowing time of the argon is properly prolonged, whole-process protective casting is adopted for the continuous casting, the pulling speed and the superheat degree are low, proper protective slag is selected, the straightening temperature is raised, continuously cast billet enters a pit to be slowly cooled, the tapping interval is well controlled in a rolling manner, the compression ratio is increased, and a reasonable heat treatment process is selected. The marine anchor chain round steel produced through the method is simple in procedure and low in cost, vacuum treatment is not needed, and the technical problems that marine anchor chain round steel produced at present is bad in surface quality, high in crack occurrence ratio, not stable in quality and the like are solved.

Owner:ZENITH STEEL GROUP CORP

Aluminum alloy powder core wire for arc welding additive manufacturing

InactiveCN110181192AReduce porosityAvoid hydrogen embrittlementWelding/cutting media/materialsSoldering mediaPorosityMain group element

The invention discloses an aluminum alloy powder core wire for arc welding additive manufacturing. The aluminum alloy powder core wire comprises an aluminum alloy metal skin and a powder core; the powder core internally contains one or few of barium, strontium, or calcium of second main group elements, the powder core further comprises manganese nitride, and the content of manganese nitride is 5%or below of the total mass of the powder core. One or few of barium, strontium, or calcium of the second main group elements are added into the powder core of the aluminum alloy powder core wire for arc welding additive manufacturing, air holes generated by hydrogen in the manufactured finished product can be reduced, the porosity is reduced, and meanwhile, the hydrogen embrittlement caused by hydrogen can be avoided.

Owner:新乡市和光科技有限公司

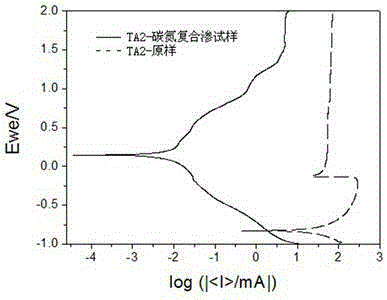

Titanium alloy parts protection and its preparation method and uses of hydrogen prevention crisp

ActiveCN101204861AAvoid hydrogen embrittlementUniform colorLiquid/solution decomposition chemical coatingSuperimposed coating processHydrogen atmosphereGold layer

The invention relates to a protective layer for titanium alloy parts, a preparation method and application thereof to prevent hydrogen brittleness. The preparation method mainly comprises the processes of oil removal, membrane removal, catalyzing, chemical nickel plating, gold electroplating and heat treatment. A fluoride membrane is formed on the surface of the prepared titanium alloy substrate;a nickel phosphorus transition layer is plated on the fluoride membrane; a dense gold layer with a thickness of 5 to 20Mum is plated on the transition layer. The invention can effectively prevent thetitanium alloy from hydrogen brittleness in hydrogen atmosphere.

Owner:中科西卡思(苏州)科技发展有限公司

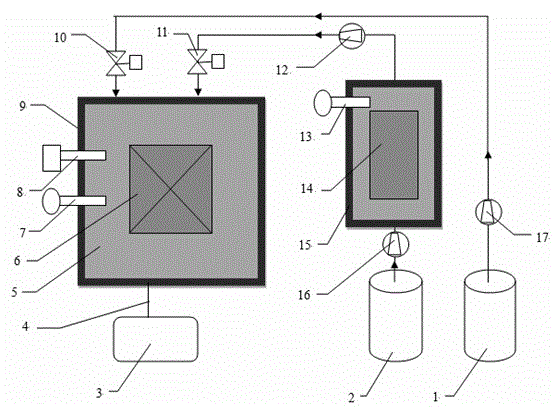

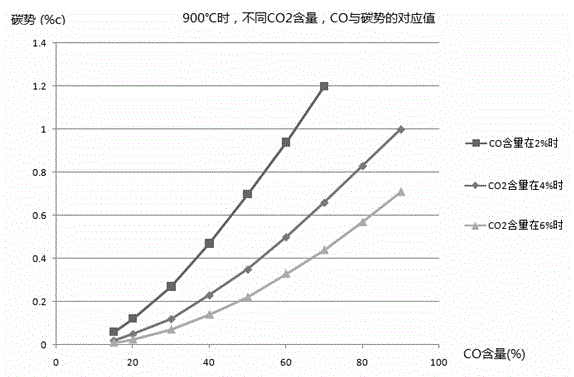

No-hydrogen atmosphere protection heat treatment process completely without decarburization for steel

The invention discloses a no-hydrogen atmosphere protection heat treatment process completely without decarburization for steel. CO2 is fed in a gas generation furnace with activated carbons, and is chemically reacted with the activated carbons; a reaction product a is fed in a sealing atmosphere furnace with workpieces to be thermally treated; then, N2 is fed in the sealing atmosphere furnace to dilute the reaction product a; the contents of the reaction product a and N2 in the sealing atmosphere furnace are adjusted through comparing a set value of a carbon controller with a carbon potential measurement value in the atmosphere in the sealing atmosphere furnace to form a no-hydrogen protection atmosphere; the workpieces can be located in the no-hydrogen environment in the heating and insulation process of the heat treatment; the carbon potential in the atmosphere is always kept the same with the carbon content of the workpieces in the furnace; the workpieces generate no decarburization or recarburization through long-time stop under high temperature; the complete protection of the steel in the no-hydrogen environment is realized; and the decarburization problem of large and ultralarge workpieces manufactured by high-strength steel and ultrahigh-strength steel in the heat treatment in the field of aerospace is solved.

Owner:XIAN BEIHENG IND CO LTD

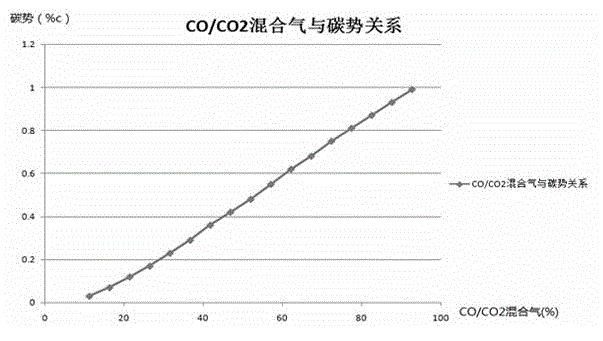

Process of preparing graphene coating on surface of metal

ActiveCN109183007AAvoid hydrogen embrittlementImprove uniformityNuclear energy generationGrapheneHydrogenGraphene coating

The invention belongs to the technical field of reactor engineering, and in particular relates to a process of preparing a graphene coating on the surface of a metal. The process comprises the following steps: (1) pre-treatment of the surface of the metal; (2) soaking, spraying or hang-brushing the metal with a graphene oxide aqueous solution; (3) roasting and drying the metal; (4) microwave reductive treatment; and (5) cleaning the metal with a cleaning agent and the like. The process has the beneficial effects of being free of introduction of hydrogen, simple to operate, good in compactnessof the coating, firm in combination of the coating and a matrix.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

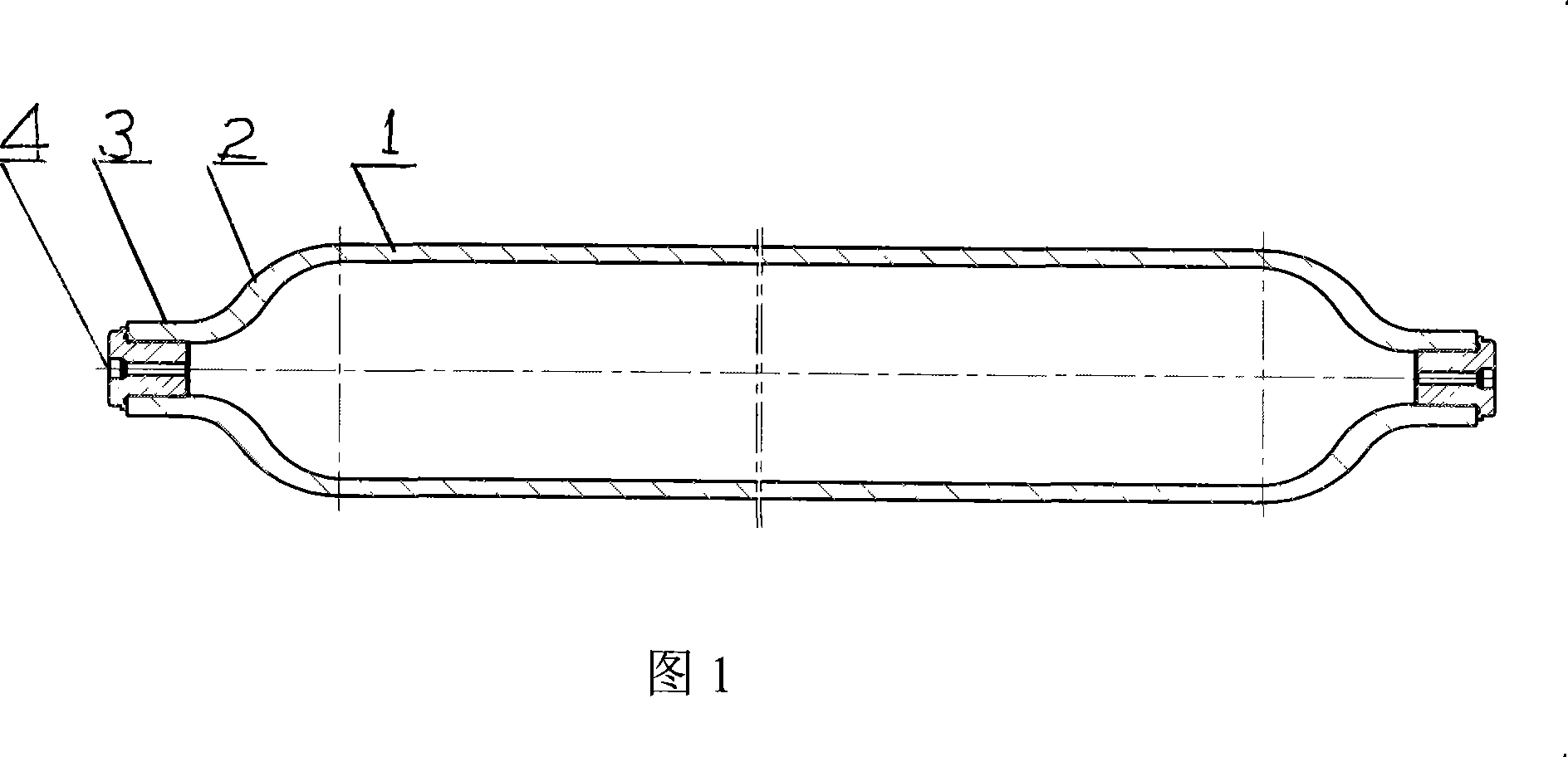

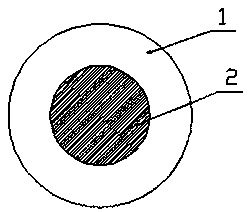

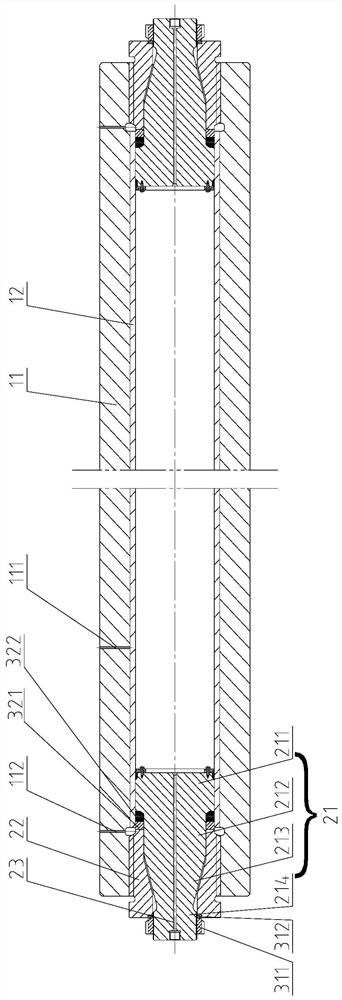

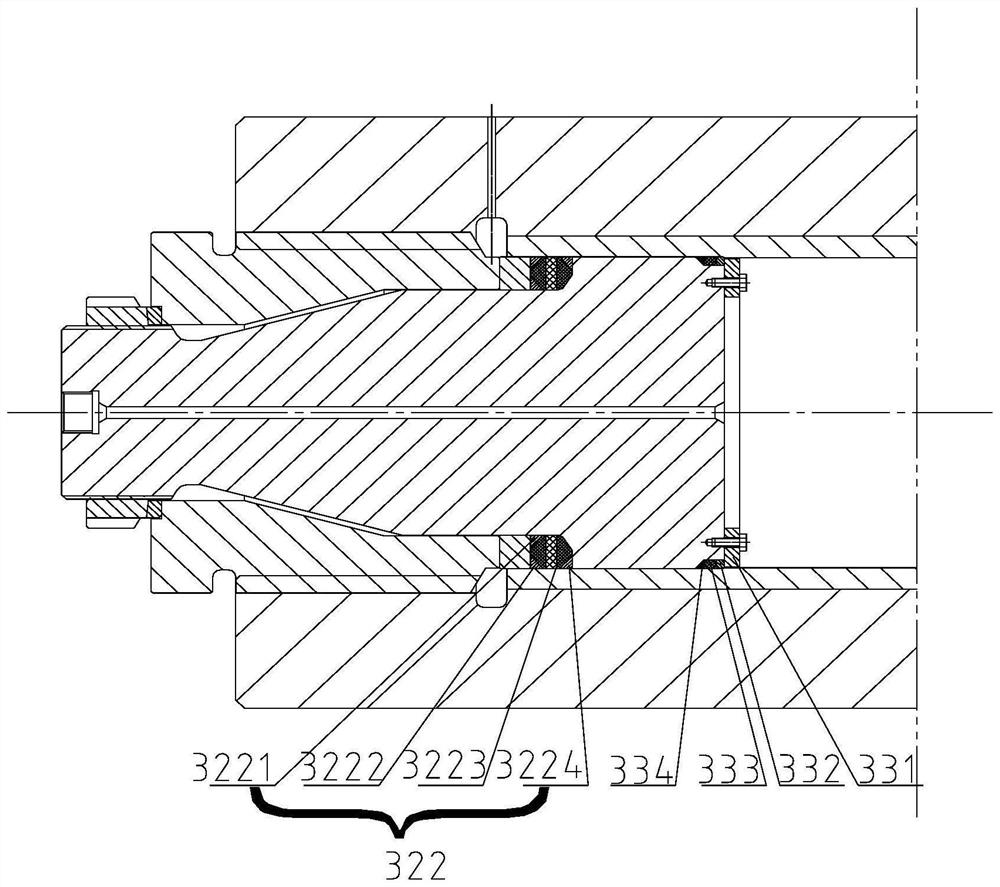

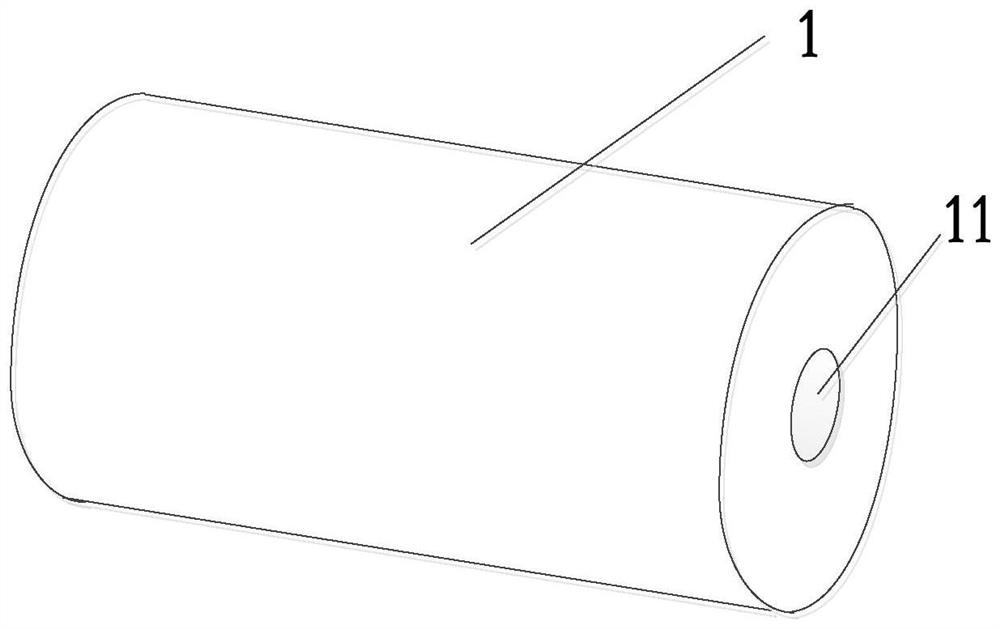

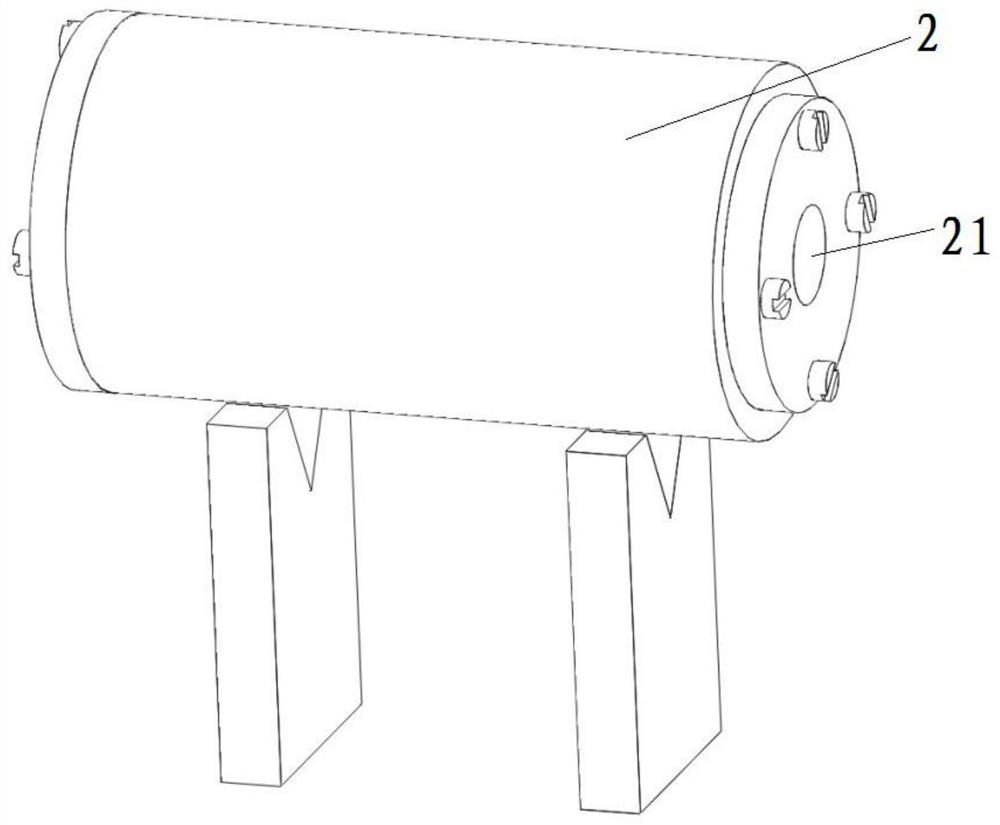

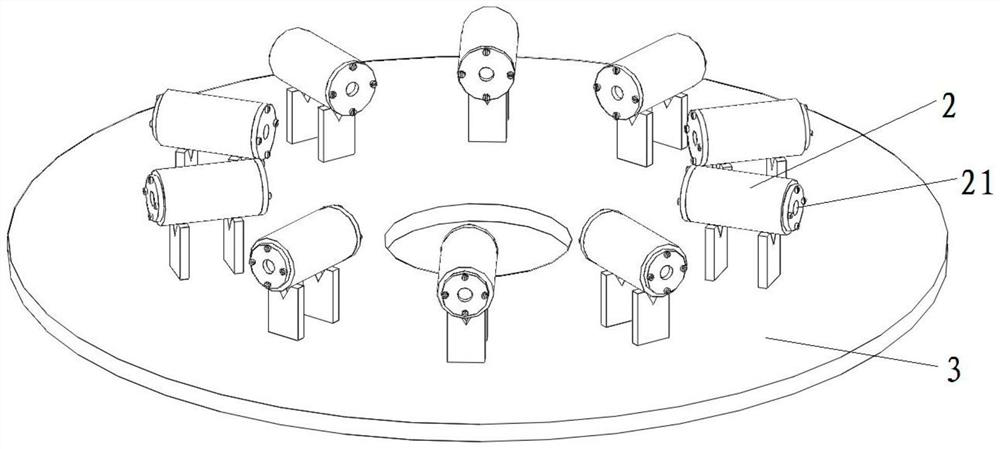

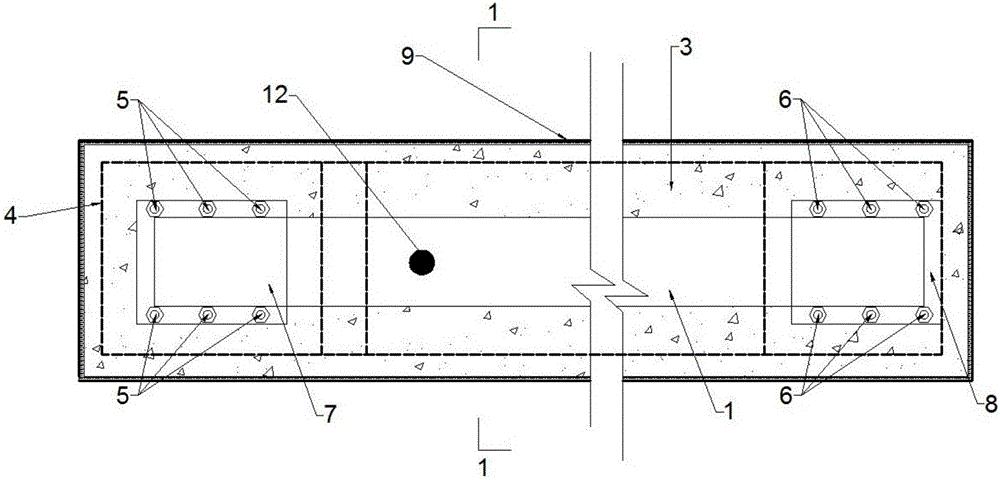

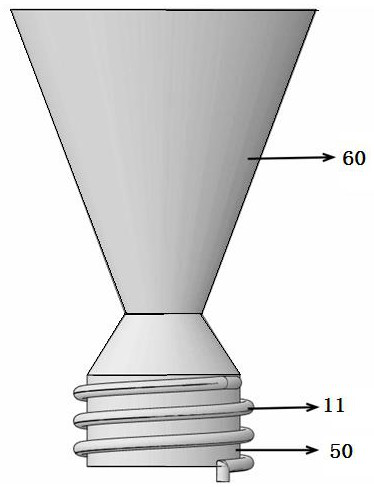

Ultra-high pressure hydrogen storage container

ActiveCN111963884AAvoid explosionImprove securityVessel geometry/arrangement/sizeContainer filling methodsUltra high pressureHigh pressure hydrogen

The invention relates to the technical field of hydrogen energy storage, in particular to an ultra-high pressure hydrogen storage container. The ultra-high pressure hydrogen storage container comprises a double-layer cylinder body, cover bodies arranged on the two sides of the cylinder body, and a self-tightening sealing assembly for connecting the double-layer cylinder body and the cover bodies at two ends, wherein the inner layer of the double-layer cylinder body is used for inhibiting the hydrogen atom penetration, and the outer cylinder body is used for ensuring the strength of the cylinder body, and a leakage hole is formed in the outer cylinder body of the double-layer cylinder body. The ultra-high pressure hydrogen storage container has the advantages that a double-layer structure is arranged, different effects are achieved by two layers, the leakage hole can release hydrogen under the condition of exceeding the set pressure to prevent the explosion of the container, and the safety performance of an ultra-high pressure hydrogen storage tank is greatly improved.

Owner:HEFEI GENERAL MACHINERY RES INST

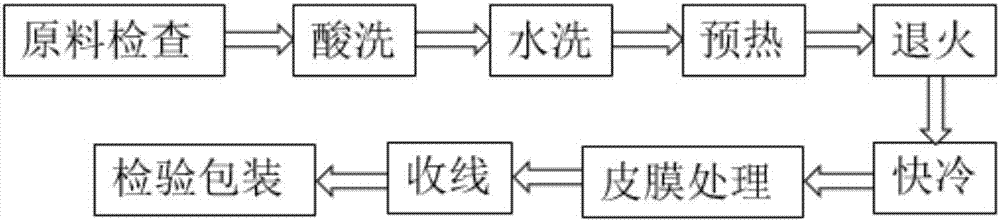

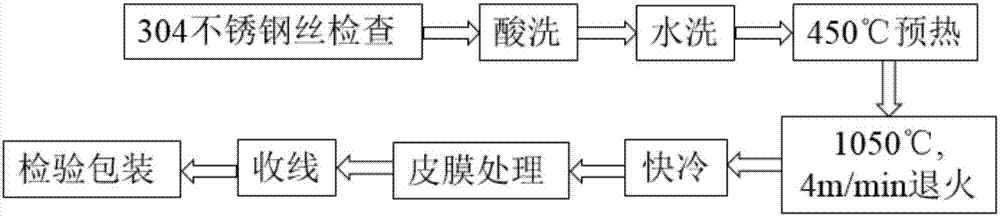

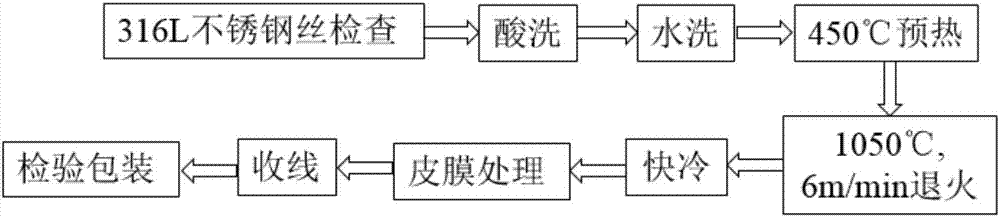

Heat treatment method for austenite stainless steel wire

InactiveCN107385189AAvoid air pollutionOptimal annealing temperatureFurnace typesProcess efficiency improvementAustenitic stainless steelAustenite

The invention mainly belongs to the field of metal smelting and particularly relates to a heat treatment method for an austenite stainless steel wire. The method comprises the steps that a material is pre-heated before annealing, and meanwhile the suitable annealing temperature is selected. The residual stress after drawing of the steel wire can be eliminated, the cold workability of the steel wire is improved, the shape of the steel wire is stabilized, meanwhile, the advantages of high technological practicability, low cost and the like are achieved, and the quality and production efficiency of the steel wire are improved significantly.

Owner:UNIV OF SCI & TECH BEIJING

Electroplating method of metal piece

The invention discloses an electroplating method of a metal piece. The electroplating method comprises steps as follows: a, film pasting: the to-be-electroplated metal piece is covered with an anti-electroplating film coinciding with the part which does not need electroplating; b, electroplating: the metal piece covered with the anti-electroplating film is electroplated with copper, nickel and zinc respectively, wherein an electroplating solution for zinc electroplating comprises 60-90 mg / L of benzyl pyridinium sodium carboxylate, 15-30 mg / L of triethanolamine, 50-130 mg / L of alkalized tetra-isopropylamine, 10-15 mg / L of zinc sulfate, 40-59 mg / L of sodium citrate, 25-39 mg / L of phosphorous acid, 40-55 mg / L of dioctyl sodium sulfosuccinate and 25-67 mg / L of antimony potassium tartrate, and meanwhile, electroplating parameters are limited; c, film removal: the anti-electroplating film on the metal piece is removed after electroplating. According to the electroplating method, the electroplating cost is reduced, and the phenomenon of hydrogen embrittlement is reduced.

Owner:WUXI JIABANG ELECTRIC POWER PIPE FACTORY

Novel tungsten alloy material and preparation method thereof

The invention discloses a novel tungsten alloy material and a preparation method thereof. The novel tungsten alloy material is composed of a tungsten matrix, carbonyl Ni and carbonyl Fe. The preparation method adopts a solid phase sintering process and a liquid phase sintering process, and the technological process includes: mixing, ball milling, isostatic pressing and sintering. The tungsten alloy has high strength, good plasticity, strong impact toughness and penetration ability, the sintering temperature and sintering time are controlled to inhibit the growth of crystal grains and improve the structure uniformity so as to improve comprehensive mechanical properties. The prepared low density tungsten alloy projectile cannot be destroyed after penetration, and is suitable to serve as a projectile body preparation material.

Owner:江西澳科新材料科技股份有限公司

Galvanizing technology for high-strength fastening piece

InactiveCN101984129AAvoid hydrogen embrittlementHigh surface friction coefficientHot-dipping/immersion processesPre treatmentFastener

The invention relates to a galvanizing technology for high-strength fastening pieces. The technology consists of oil removing process, surface pre-treatment process, passivation process, hot-dip zinc process, centrifugation process and cooling process successively. In hot-dip zinc process, high-strength fastening pieces are subject to passivation treatment and then are immersed in zinc liquid at a temperature of 470-480 DEG C. for 40-60 seconds. After being treated with the galvanizing technology, zinc layer thickness of high-strength fastening pieces can meet the corresponding standard and surface hardness and strength thereof will not change basically.

Owner:NINGBO YINZHOU JISHI METAL SURFACE TREATMENT FACTORY

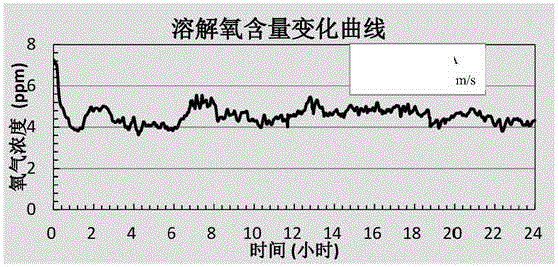

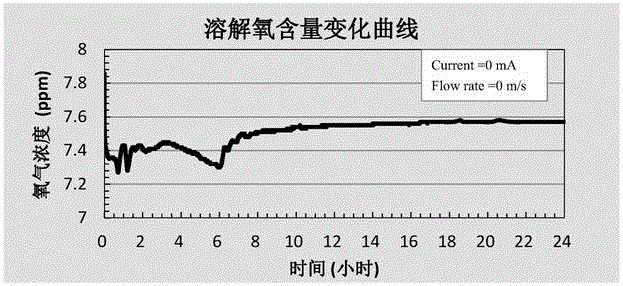

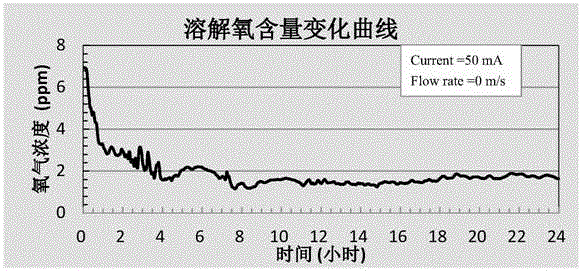

Electrochemical corrosion apparatus and electrochemical corrosion method of reinforcing steel bar in seawater full immersion zone reinforced concrete

The present invention discloses an electrochemical corrosion apparatus of reinforcing steel bar in seawater full immersion zone reinforced concrete. The electrochemical corrosion apparatus comprises a cathode for making dissolved oxygen in seawater obtain electron, an auxiliary anode and a direct current power supply, wherein the cathode, the auxiliary anode and seawater form an electrochemical oxygen filter after electrifying, the oxygen close to the concrete surface is converted into hydroxide radicals and / or hydrogen peroxide ions through the cathode, and the chlorine ions in the seawater move to close to the auxiliary anode under the effect of electric field force and generate chlorine gas under the effect of the auxiliary anode. According to the present invention, with the technical scheme, the dissolved oxygen in the reinforcing steel bar surface region is eliminated while the chlorine ions in the reinforcing steel bar surface passivation film can be damaged, such that the reinforcing steel bar can be used in the seawater for a long time; and during the diffusion process of the dissolved oxygen to the concrete structure, when the dissolved oxygen passes through the electrified low carbon steel net, the dissolved oxygen can be transferred to the carbon steel net surface as more as possible so as to be consumed, such that the oxygen is prevented from reaching the reinforcing steel bar surface.

Owner:DALIAN UNIV OF TECH

Method for local ion nitriding of deep cavity thread of titanium alloy part

ActiveCN111636046ANitriding is not affectedGuaranteed glow nitriding processSolid state diffusion coatingTitanium alloyVacuum annealing

The invention relates to a method for local ion nitriding of a deep cavity thread of a titanium alloy part, and belongs to the technical field of chemical heat treatment. The method comprises the steps of 1, manufacturing a nitriding tool according to the size and shape of the titanium alloy part; 2, carrying out vacuum annealing treatment on the nitriding tool; 3, wiping the titanium alloy part and the nitriding tool, and blow-drying the titanium alloy part and the nitriding tool through oil-free compressed air or nitrogen; 4, coating the outer wall of the titanium alloy part with the nitriding tool; 5, repeating the step 1 to the step 4 for n times, manufacturing n nitriding tools for coating the titanium alloy part, and enabling the n nitriding tools to be annularly and evenly arrangedon an ionization disc, wherein n is a positive integer; and 6, conducting nitriding treatment on the titanium alloy part. According to the method, the outer surface of the part and the non-nitrided part of the deep cavity are protected against a nitriding layer through tool design, and the temperature, time, atmosphere and electric parameters in the nitriding process are adjusted, so that the whole deep cavity thread obtains the hardness and nitriding depth of the nitriding layer meeting the technical requirements.

Owner:BEIJING SATELLITE MFG FACTORY

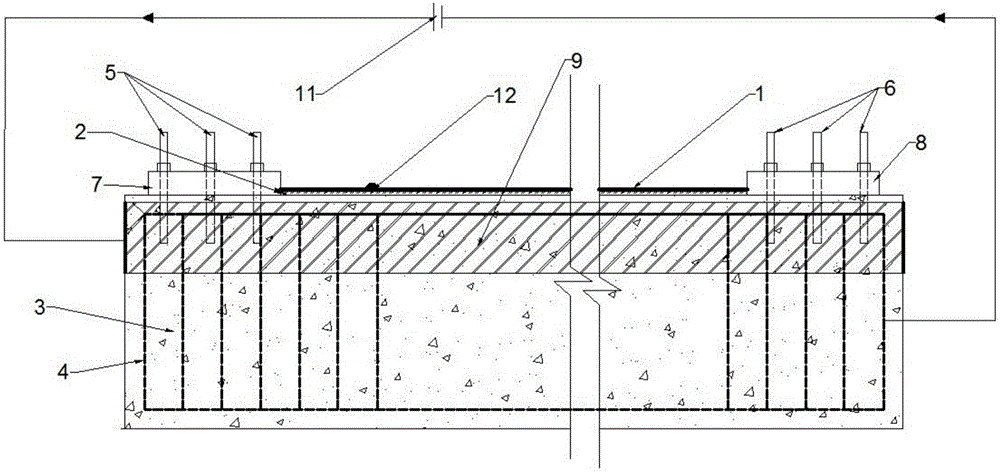

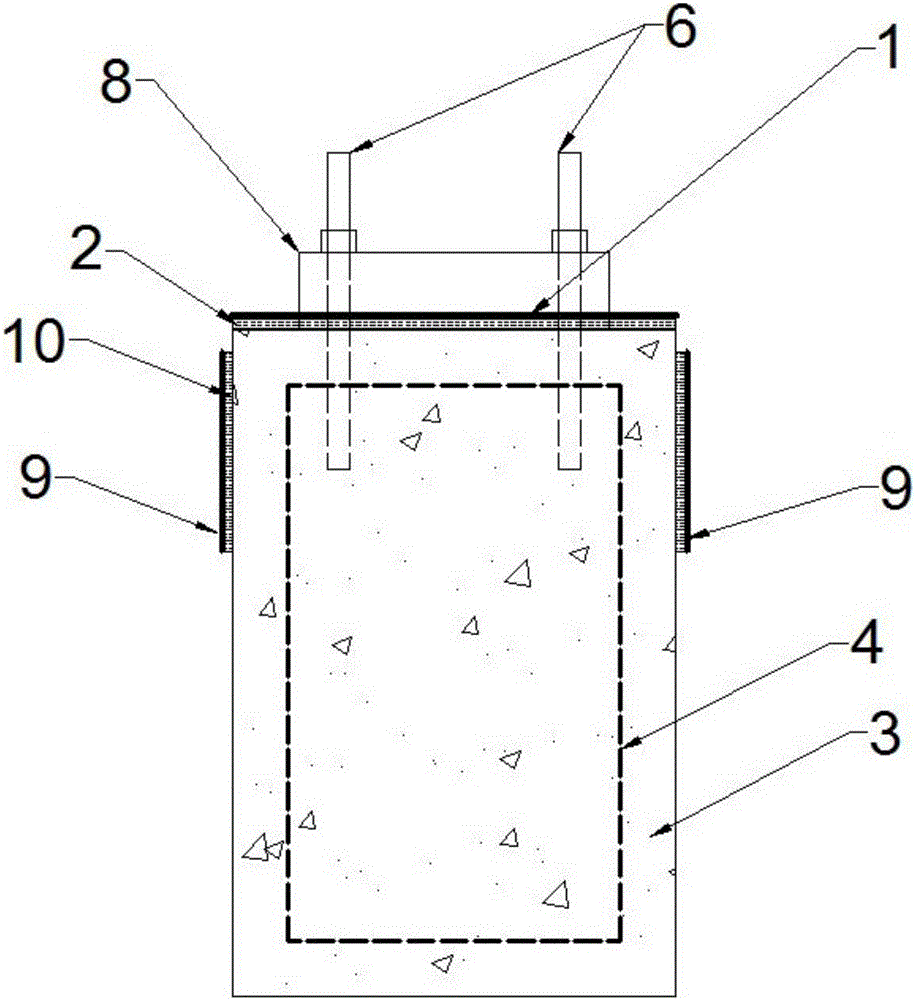

Structure for reinforcing corroded concrete through prestress fiber reinforced composite sheet and reinforcing method

InactiveCN106285036AIncreased durabilityImprove long-term reinforcement effectBuilding repairsBridge erection/assemblyPre stressFiber-reinforced composite

The invention discloses a structure for reinforcing corroded concrete through a prestress fiber reinforced composite sheet and a reinforcing method. The structure comprises a concrete member (3) to be reinforced, the prestress fiber reinforced composite sheet (1), stretching end anchorage device anchor bolts (5), a stretching end anchorage device (7), fixed end anchorage device anchor bolts (6), a fixed end anchorage device (8), non-prestress fiber reinforced composite sheets (9) and an external intermittent constant-current power source (11). The stretching end anchorage device (7) and the fixed end anchorage device (8) clamp the two ends of the prestress fiber reinforced composite sheet (1) correspondingly and fix the prestress fiber reinforced composite sheet (1) to the upper surface of the concrete member (3) to be reinforced. An inner reinforcement cage (4) is arranged in the concrete member (3) to be reinforced. According to the structure and the reinforcing method, the corrosion problem of steel bars and prestress anchorage devices in a concrete structure in the corrosive environment is solved, an auxiliary anode is resistant to corrosion and easy to replace, a reinforcing effect is achieved on the concrete structure, and the repairing cost is remarkably reduced.

Owner:GUANGDONG UNIV OF TECH

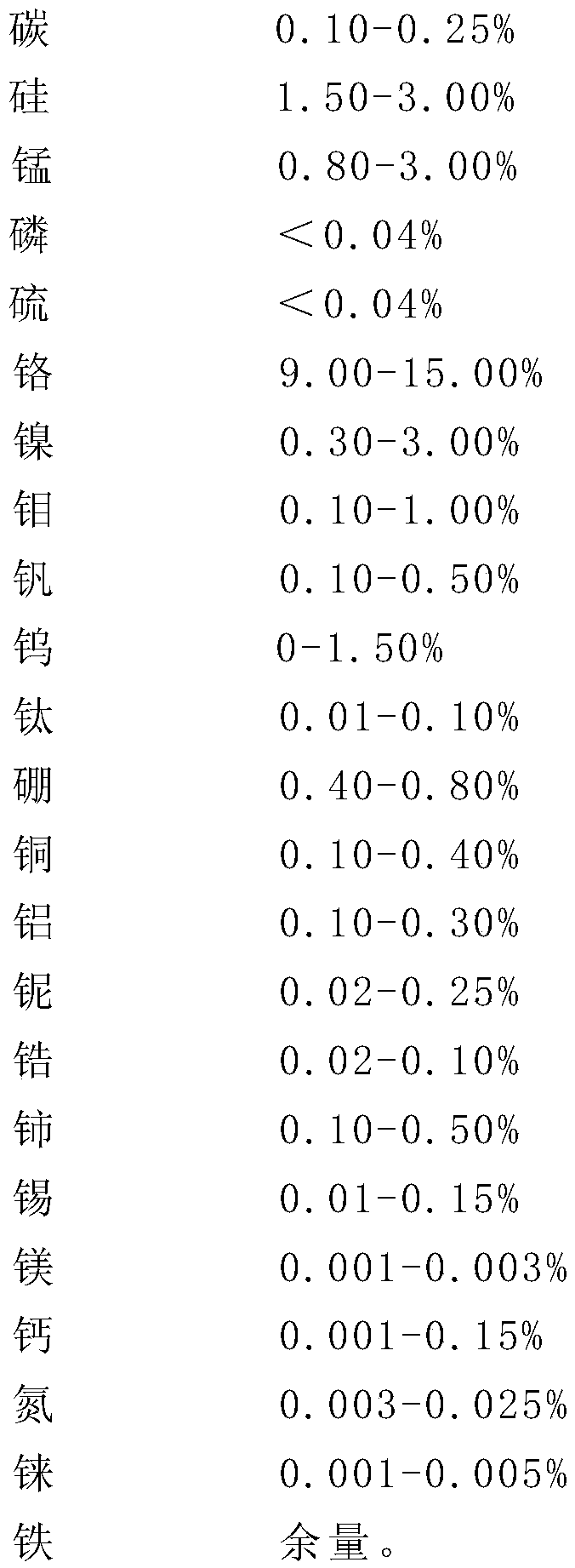

Micro-carbon high-chromium high-boron wear-resistant steel and preparation method thereof

InactiveCN109825778AHinder segregationAvoid hydrogen embrittlementProcess efficiency improvementWear resistantCerium

The invention discloses micro-carbon high-chromium high-boron wear-resistant steel and a preparation method thereof. The prepared wear-resistant steel comprises the following components of, in percentage by weight, 0.10-0.25% of carbon, 1.50-3.00% of silicon, 0.80-3.00% of manganese, less than 0.04% of phosphorus, less than 0.04% of sulfur, 9.00-15.00% of chromium, 0.30-3.00% of nickel, 0.10-1.00%of molybdenum, 0.10-0.50% of vanadium, 0-1.50% of tungsten, 0.01-0.10% of titanium, 0.40-0.80% of boron, 0.10-0.40% of copper, 0.10-0.30% of aluminum, 0.02-0.25% of niobium, 0.02-0.10% of zirconium,0.10-0.50% of cerium, 0.01-0.15% of tin, 0.001-0.003% of magnesium, 0.001-0.15% of calcium, 0.003-0.025% of nitrogen, 0.001-0.005% of rhenium, and the balance iron. The steel not only has the high hardness, also has the characteristics of certain toughness and high wear resistance at the same time.

Owner:陈章华

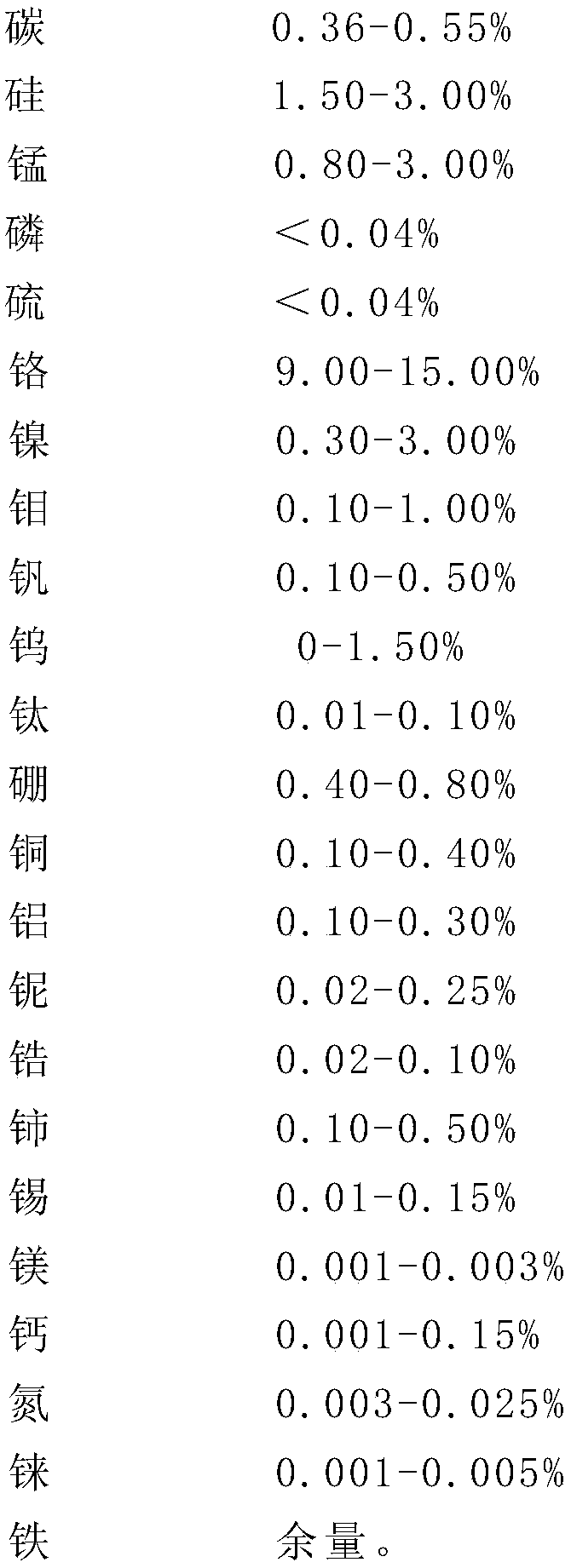

Medium-carbon high-chromium high-boron wear-resistant steel and preparation method thereof

The invention discloses medium-carbon high-chromium high-boron wear-resistant steel and a preparation method thereof. The prepared wear-resistant steel comprises, by weight percentage, 0.36-0.55% of carbon, 1.50-3.00% of silicon, 0.80-3.00% of manganese, smaller than 0.04% of phosphorus, smaller than 0.04% of sulfur, 9.00-15.00% of chromium, 0.30-3.00% of nickel, 0.10-1.00% of molybdenum, 0.10-0.50% of vanadium, 0-1.50% of tungsten, 0.01-0.10% of titanium, 0.40-0.80% of boron, 0.10-0.40% of copper, 0.10-0.30% of aluminum, 0.02-0.25% of niobium, 0.02-0.10% of zirconium, 0.10-0.50% of cerium, 0.01-0.15% of tin, 0.001-0.003% of magnesium, 0.001-0.15% of calcium, 0.003-0.025% of nitrogen, 0.001-0.005% of rhenium and the balance Fe. The obtained wear-resistant steel is high in hardness, good intoughness and resistant to wear.

Owner:陈章华

Method of electroplating graphene-metal composite material plating layer by using complex pulses, PCB and motor

PendingCN110636693AAvoid hydrogen embrittlementRegeneration is easyElectrolytic coatingsPrinted circuit manufactureIonCvd graphene

The invention relates to the technical field of material surface engineering, and provides a method of electroplating a graphene-metal composite material plating layer by using complex pulses, a PCB and a motor. The method specifically comprises the steps: ionic liquid serves as electroplating liquid, graphene oxide is dispersed in the ionic liquid, and the ionic liquid further contains metal ions; and the graphene-metal composite material plating layer is deposited on a cathode substrate through current or voltage control pulses, wherein the current or voltage control pulses comprise a forward pulse period, a reverse pulse period and a pause period. The method is simple in process, low in cost, free of environmental pollution of traditional electroplating and capable of being applied to large-area coating or film production. The PCB comprises a base material plate and a bottom conductive wire. The graphene-metal composite material plating layer and the conductive wire are manufacturedthrough the method. According to the invention, the graphene-containing conductive wire is printed and wound on a PCB to form a brushless motor stator, so that a novel motor is provided.

Owner:SICHUAN JUCHUANG SHIMOXI TECH CO LTD +1

Surface treatment method of titanium alloy carbon and nitrogen compound permeation

InactiveCN105420663AHigh affinityImprove surface propertiesSolid state diffusion coatingTitanium nitrideNitrogen

The invention discloses a surface treatment method of titanium alloy carbon and nitrogen compound permeation. The surface treatment method comprises a method of alternately and intermittently feeding a carburizing gas medium and a nitriding gas medium and combining the carburizing treatment with the nitriding treatment, and comprises a method of carburizing or nitriding inflation compound permeation treatment formed by combining the intermittent periodical repeated inflation and extraction treatment with the carburizing and nitriding treatment. The surface treatment method combines the gas carburizing with the gas nitriding to make up the defects caused by single gas carburizing, so that titanium nitrides, titanium carbides and titanium carbonitrides are generated on the surface of titanium alloy to facilitate improvement of the surface performance of the titanium alloy. The intermittent periodical repeated inflation and extraction treatment is adopted to enable acceleration of the absorption speed and the reaction speed of permeated elements on the surface of a workpiece. A medium of the compound permeation is high-purity acetylene gas or high-purity acetylene and high-purity argon, so that the surface performance of the titanium alloy can be further improved, and the hydrogen embrittlement is prevented.

Owner:GUIZHOU NORMAL UNIVERSITY

Nickel-based alloy wire for welding of LNG storage tank as well as preparation method and welding process

InactiveCN110480208AUniform compositionFlat surfaceWelding/cutting media/materialsSoldering mediaAlloyElectro-slag remelting

The invention relates to a nickel-based alloy wire for welding of an LNG storage tank as well as a preparation method and a welding process. The nickel-based alloy wire comprises the following components in percentage by mass: 20.0%-23.0% of Cr, 0.0%-10.0% of Mo, 3.15%-4.15% of Nb, not more than 5.0% of Fe, not more than 1.0% of Co, not more than 0.50% of Mn, not more than 0.40% of Al, not more than 0.40% of Ti, not more than 0.50% of Si, not more than 0.10% of C, not more than 0.015% of S and the balance of Ni. The preparation method comprises the following steps of A, alloy smelting and casting into electrode rods; B, electroslag remelting; C, hammer cogging; D, hot roll annealing; E, acid pickling and grinding; F, drawing; G, dehydrogenation and straightening after hydrogen annealing treatment; and H, winding to be disc-like. The welding process is that the welding current is 360-380 A, the voltage is 26-28 V, and the welding speed is 50-100 cm / min and the current type is alternating current.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Method for reducing coating hydrogen embrittlement degree

InactiveCN1632175ASmall molecule hydrogen reductionFacilitate depositionUltrasonic cavitationElectroplating

A method for reducing the degree of hydrogen embrittlement of the coating is to install an ultrasonic generator at the cathode end of the electroplating tank, and emit ultrasonic waves to the plated parts during the electroplating process. Utilize the cavitation effect generated by ultrasonic waves to bombard the small molecular hydrogen generated on the surface of the plated piece to make it detach, reduce the small molecular hydrogen on the surface of the plated piece, facilitate the deposition of metal atoms in the coating, produce a dense coating, and prevent hydrogen embrittlement. At the same time, it is beneficial to increase the speed of coating formation and improve production efficiency.

Owner:徐菁

Method for electroplating zinc in neodymium iron boron magnet ionic liquid

The invention relates to a method for electroplating zinc in neodymium iron boron magnet ionic liquid. According to the method, a neodymium iron boron magnet treated before plating is used as a cathode, a zinc sheet is used as an anode, the ionic liquid is adopted as electroplating liquid, under the magnetic stirring condition, a power supply is conducted, the temperature, the current intensity and the electroplating time are controlled for electroplating, and then, bright dipping, passivation and aging treatment are carried out. The method is applied to the neodymium iron boron magnet electroplating, the process is simple, the price of medicine is low, the operation temperature is low, more importantly, the hydrogen evolution reaction is avoided, the obtained plating layer is bright and compact, the combination of the plating layer and a base body is firm, and the corrosion resistance performance is good.

Owner:TAIYUAN UNIV OF TECH

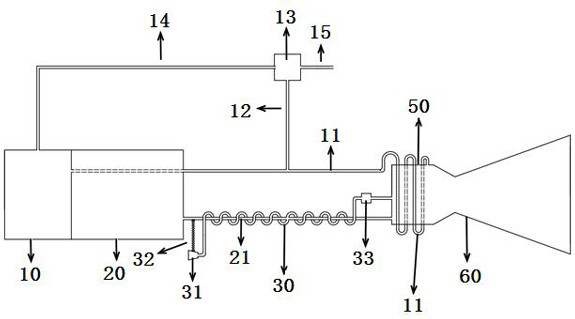

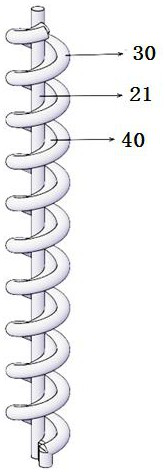

Cooperative air suction type liquid rocket engine propellant supply system

ActiveCN112431692AReduce power consumptionReduce demandRocket engine plantsThermodynamicsThrust chamber

The invention discloses a cooperative air suction type liquid rocket engine propellant supply system which comprises a liquid oxygen storage tank, a liquid hydrogen storage tank, a liquid oxygen pipeline, a liquid hydrogen pipeline, a high-temperature incoming flow air pipeline, a helium pipeline and a rocket thrust chamber. A rocket belly is formed between the liquid hydrogen storage tank and therocket thrust chamber; the liquid hydrogen pipeline is positioned at the rocket belly and is linearly arranged; the high-temperature incoming flow air pipeline and the helium pipeline are wound at the outer side of the liquid hydrogen pipeline in parallel, and the helium pipeline is located between the two pipelines; a telescopic arm with a telescopic length is mounted on the side wall of an airinlet; when the telescopic arm is lengthened, the air inlet is pushed out from the rocket belly to realize an air suction working mode; and when the length of the telescopic arm is shortened, the airinlet is stored in the rocket belly, and a pure rocket working mode is achieved. According to the cooperative air suction type liquid rocket engine propellant supply system, oxygen in the atmosphere can be utilized, the layout of internal pipelines of a traditional liquid rocket engine is optimized, the liquid rocket engine has the high specific impulse and the large thrust-weight ratio, and therefore the launching cost is reduced.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com