Patents

Literature

51results about How to "High surface friction coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

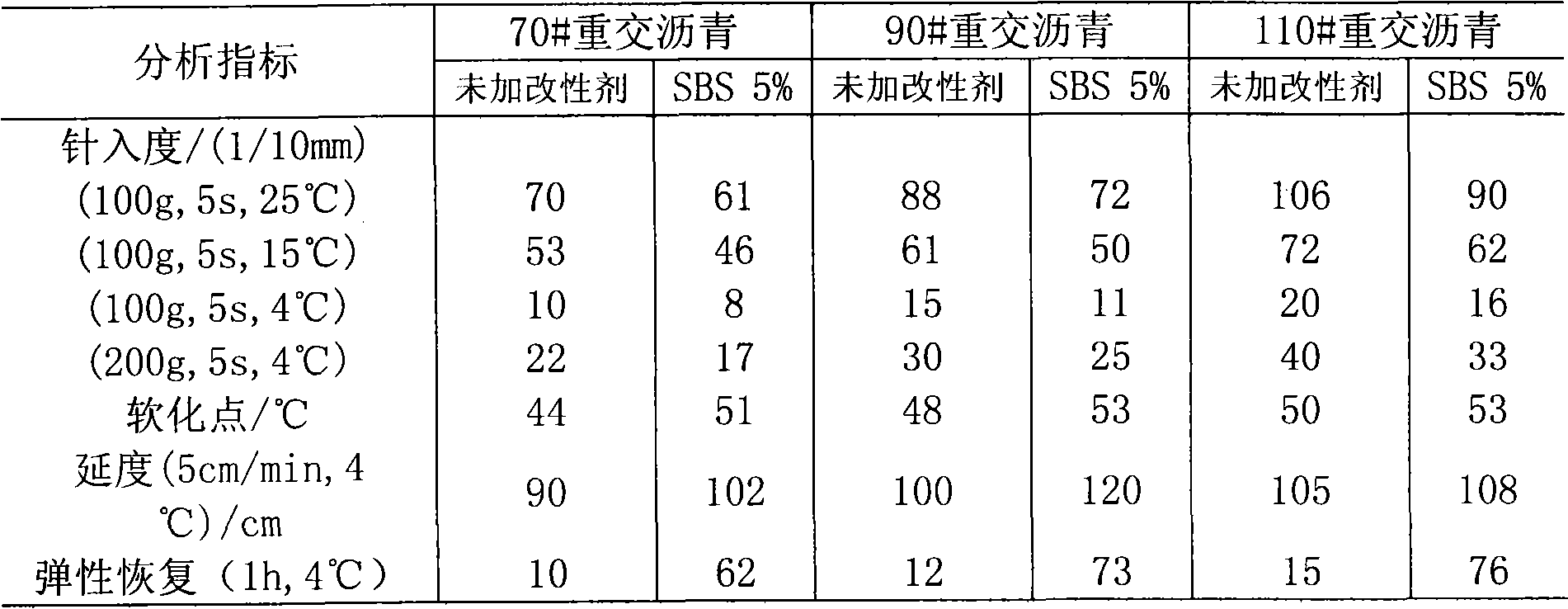

Preparation method of star-shaped SBS (styrene butadiene styrene block polymer)-modified asphalt and production method of waterproof coiled material

ActiveCN102220023AGood high and low temperature resistanceImprove stabilityBuilding insulationsBasementAdhesive

The invention provides star-shaped SBS (styrene butadiene styrene block polymer)-modified asphalt, which is a composition composed of asphalt, swelling star-shaped SBS, filler and aids and solves the problem that star-shaped SBS used as an asphalt modifier is difficult to process. The production method of the star-shaped SBS-modified asphalt involves the following steps: adding star-shaped SBS swelled by a non-polar solvent to asphalt, modifying at the temperature of 180-210 DEG C for 50-150 minutes by a colloid mill or a powerful high-speed shearing stirrer, adding the filler and aids and uniformly stirring so as to form the uniform and stable modified asphalt. The modified asphalt can be made into a waterproof coiled material with excellent performance as well as a waterproof and leak-proof adhesive used for building roofs, basements, expressways, sealants, tunnels or water conservancy facilities. The modified asphalt has the characteristics of better compatibility with asphalt and better high-temperature and low-temperature resistance, compared with existing SBS modified asphalt.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

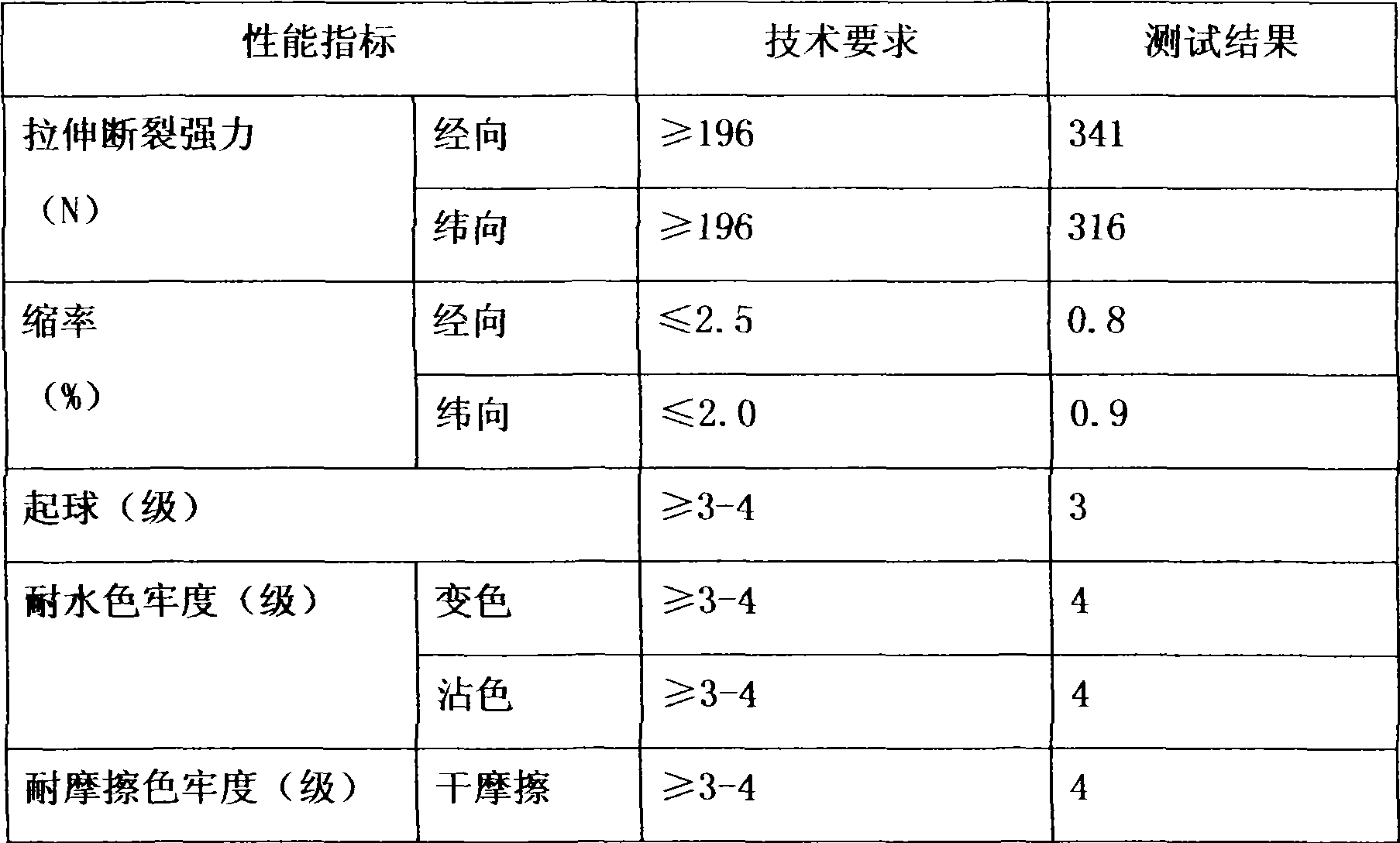

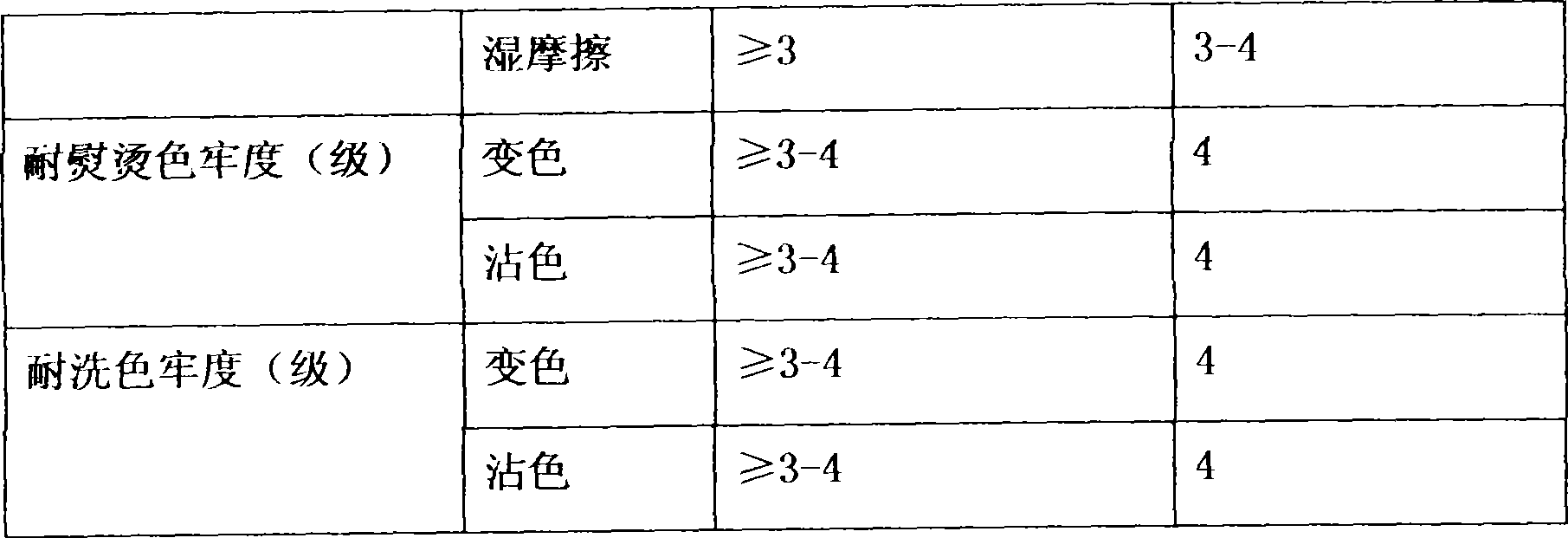

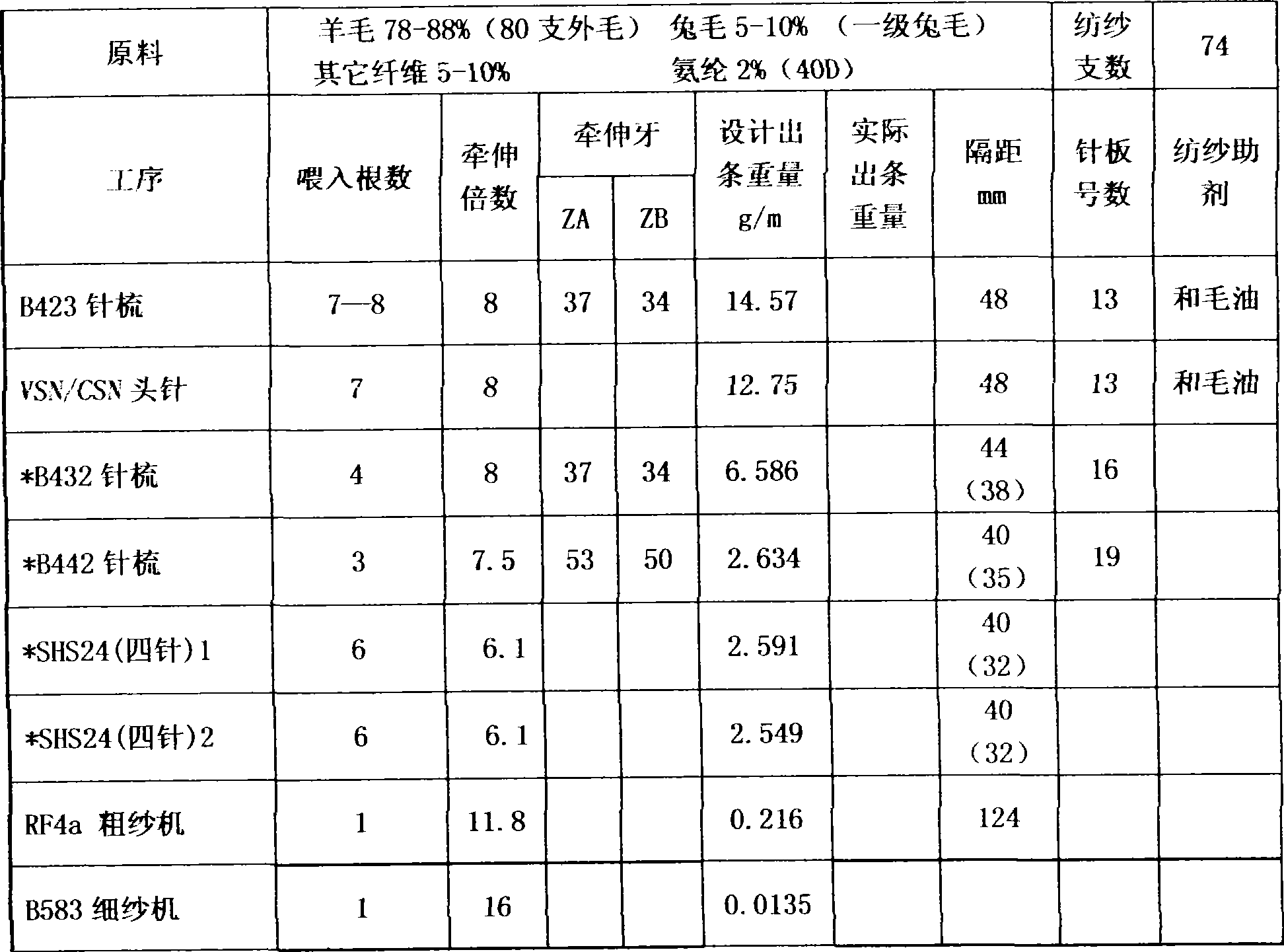

Method for producing sheep and rabbit hair combing elastic fabric

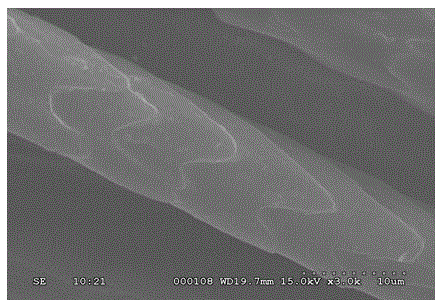

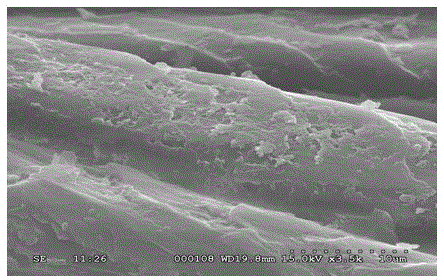

InactiveCN101418519AImprove spinnabilityIncreased scale angleBiochemical fibre treatmentWoven fabricsTextile technologyFiber

The invention discloses a method for producing a wool and rabbit hair combing elastic fabric and belongs to the field of textile technology. The method comprises raw material selection, a spinning process, a weaving process and fabric afterfinishing. The method is characterized in that before the spinning process, rabbit hair fiber is subjected to enzyme treatment, water washing and drying for spinning preparation; and the wool and the rabbit hair fibers are spun into wool and rabbit hair combed yarn through adopting the combination of combing spinning and semi-combing spinning; and the wool and rabbit hair combed yarn is interwoven to form the wool and rabbit hair combing elastic fabric. The method aims at the disadvantages that the rabbit hair fiber has poor spinnability and is easy to moult, creatively adopts oxidase to carry out pretreatment on the rabbit hair fiber in order to increase the angle of squama of the rabbit hair fiber, increase the friction coefficient of the surface of the rabbit hair fiber, have good spinnability and effectively improve the phenomena that a rabbit hair textile moults. The quality and added value of the product are greatly improved, and the product has good utility value and potential economic and social benefits.

Owner:SHAOXING UNIVERSITY

Preparation method of silver nanowire modified flexible fiber sensor electrode

ActiveCN107525832AHigh tensile strengthExcellent electrical performanceElectroconductive/antistatic filament manufactureFibre typesConductive materialsGraphene

The invention relates to the field of sensors, and discloses a preparation method of a silver nanowire modified flexible fiber sensor electrode. A flexible conductive fiber is prepared with a solution mixing method, wherein SBS (styrene-butadiene-styrene) is taken a as flexible substrate, poly 3,4-ethylenedioxythiophene-polystyrene sulfonate-graphene is taken as a conductive material, the electrode is modified with a silver nanowire, and the silver nanowire modified flexible fiber sensor electrode containing SBS / graphene / poly 3,4-ethylenedioxythiophene-polystyrene sulfonate is obtained. The sensor electrode can be applied in the fields of medical biological monitoring, environment and hygiene monitoring and the like.

Owner:ZHEJIANG SCI-TECH UNIV

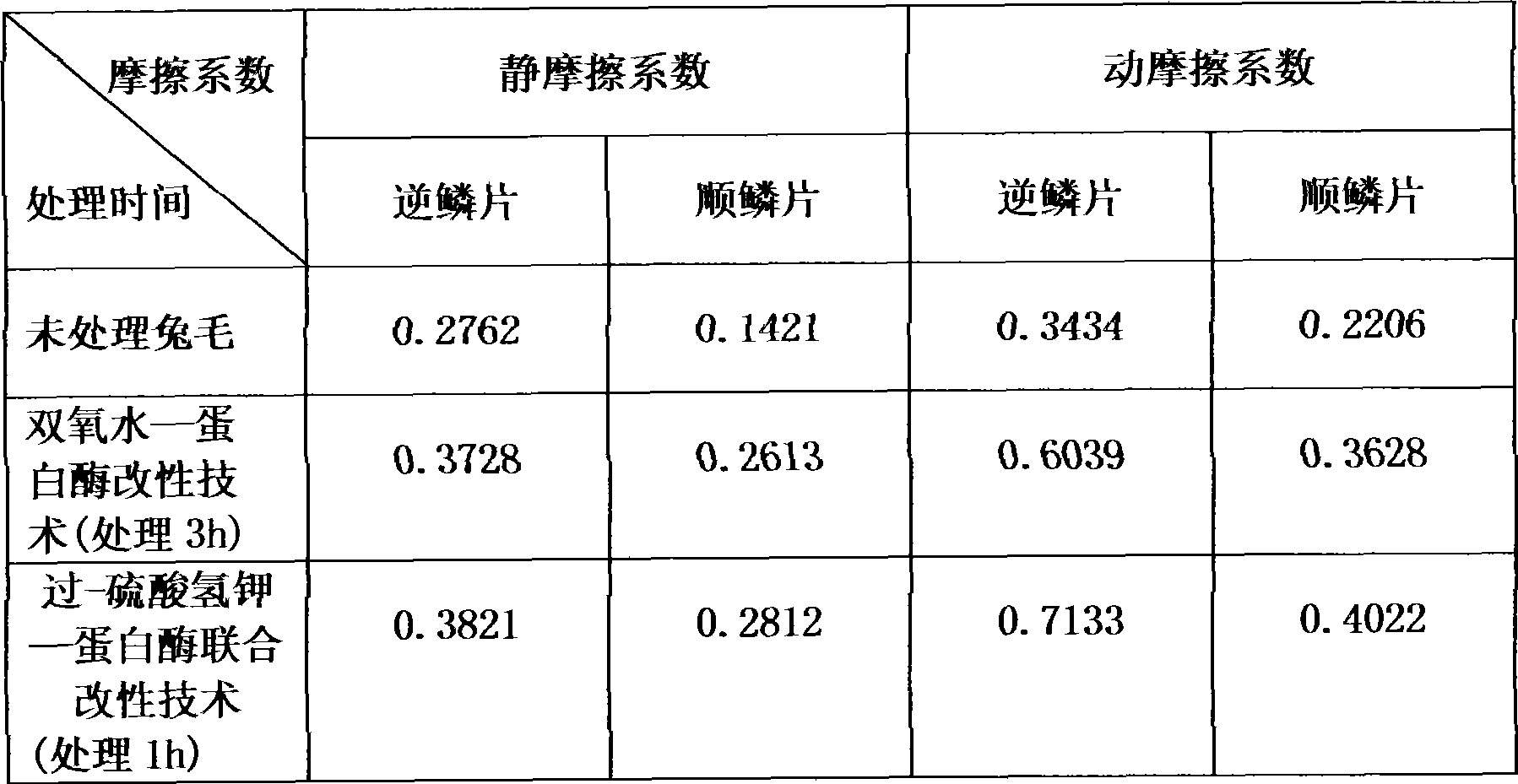

Rabbit hair fibre modification treatment process

InactiveCN101435152AHigh surface friction coefficientReduce hair lossBiochemical fibre treatmentAnimal fibresFiberProteinase activity

The invention disclose a rabbit hair fiber modification treatment process which belongs to the technical field of spinning pretreatment, adopts a per-acid potassium sulfate-protease jointed modification treatment technology and has the following process flow: the rabbit hair fiber is dipped for 25 to 30 minutes in per-acid potassium sulfate oxidation solution, then dipped in sodium sulfite reduction solution for 15 to 20 minutes and treated by hair protease for 50 to 60 minutes after water-washing, after enzyme treatment, enzyme inactivation is carried out for 8 to 12 minutes, and the rabbit hair fiber is dried after water-washing. The process improves the spinnability of the rabbit hair fiber under the condition of minimal strength loss of the rabbit hair fiber, thus effectively improving the quality of rabbit hair fiber fabrics.

Owner:NANTONG NTEC MONOFILAMENT TECH CO LTD

Method for preparing seepage brick by coal ash

InactiveCN101596737AImprove protectionSave natural resourcesCeramic shaping apparatusClay processing apparatusSodium BentoniteBrick

The invention relates to a method for preparing a seepage brick by coal ash. The coal ash, potash feldspar and kaolin are mixed and put into a ball mill for wet grinding to be even, so as to form mixed slurry; the mixed slurry is dried into powder material and then pressed into green body; the pressed green body is sintered and cooled naturally and then is put into an edge runner mill to be smashed into aggregate; waste glass is put into the ball mill for dry grinding, and then bentonite is added and grinding is continued, so as to form mixed material; arabic gum solution is added into the mixed material to form mixed slurry, and then the aggregate and the mixed slurry are stirred to be even, filtered by pumping by a circulation water vacuum pump and then put into a steel mould to be pressed into a green body; and the pressed green body is dried and sintered, cooled naturally and then taken out, thus obtaining the coal ash seepage brick. The invention takes industrial waste coal ash and waste glass powder as raw materials, which is beneficial for saving natural resources and reducing production cost; meanwhile the raw materials are sintered at high temperature, no harmful gas is produced in sintering except gas given off by the raw materials, and pollution of waste gas towards environment is reduced.

Owner:SHAANXI UNIV OF SCI & TECH

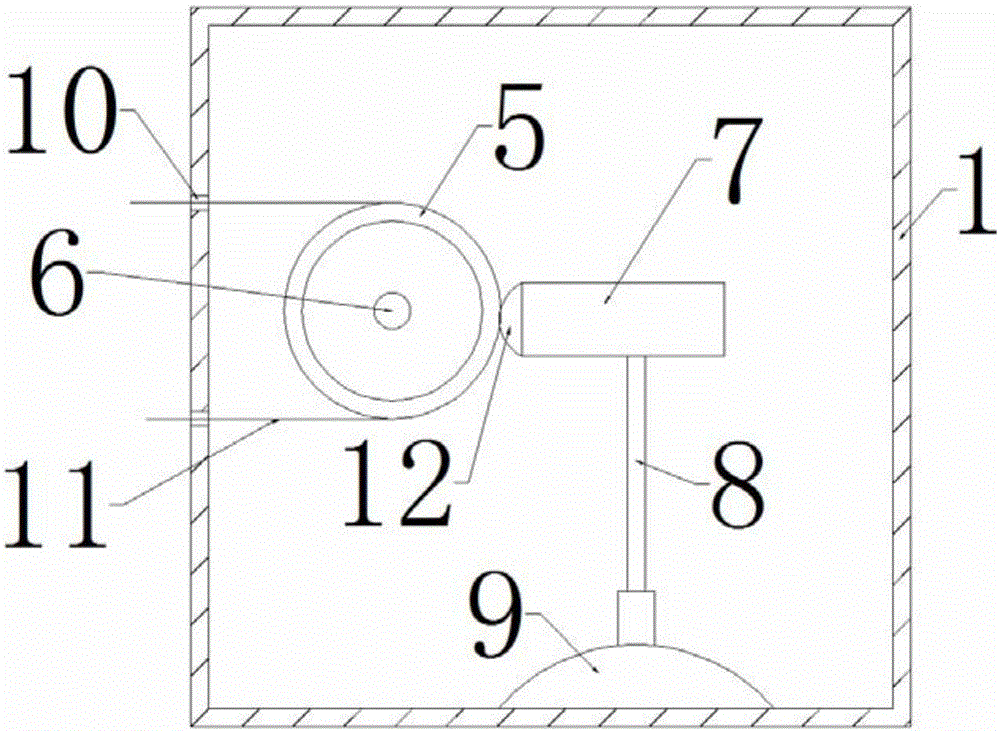

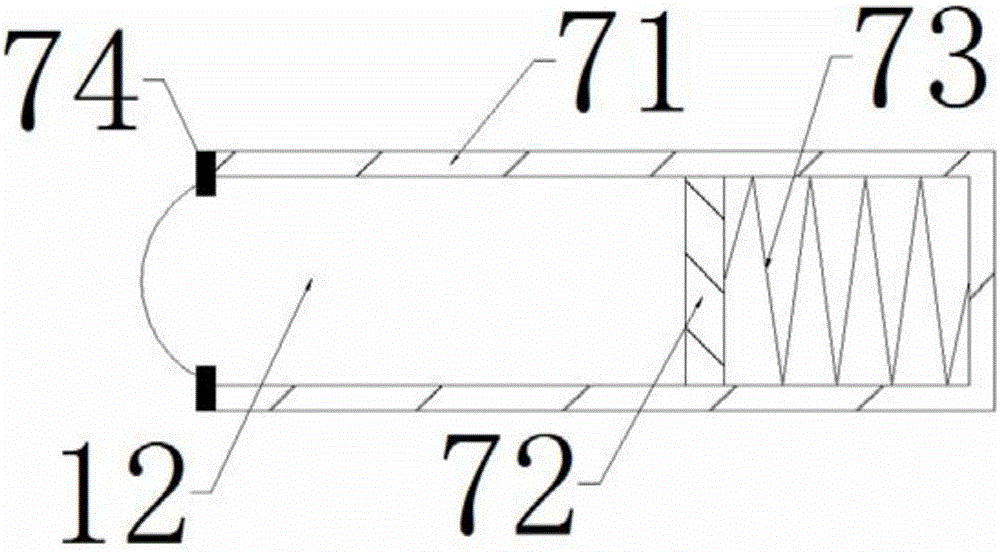

Textile yarn waxing device

The invention discloses a textile yarn waxing device, and relates to the field of textile equipment. The textile yarn waxing device comprises a shell, a panel, hinges, a handle, a yarn conveying wheel, a rotating shaft, a waxing machine, a connecting rod, a pneumatic device, yarn through holes and a piece of solid wax; the shell of the textile yarn waxing device is formed by casting aluminum alloy, thus being lighter in weight and good in shock absorption, and capable of guaranteeing the stable work of the waxing device; the panel is arranged at the front of the textile yarn waxing device, so that dust is prevented from entering the device, and the waxing quality is guaranteed; the pneumatic device is adopted to lift the waxing machine, so that the solid wax and yarns are convenient to replace; the spring pre-tightening type waxing machine is adopted, so that the waxing force is maintained from beginning to end, and the waxing of the waxing device is enabled to be uniform and good in quality; rubber tube sleeves are respectively arranged at the inner rings of the yarn through holes, so that the yarns are effectively prevented from being broken due to being worn by metal; a circle of rubber sleeve is arranged at the outer ring of the yarn conveying wheel, so that the surface friction coefficient is increased, the yarns are effectively prevented from slipping, and the waxing quality is guaranteed.

Owner:ANHUI SONGTAI PACKAGING MATERIALS

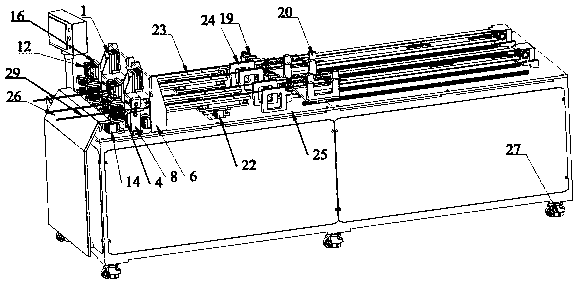

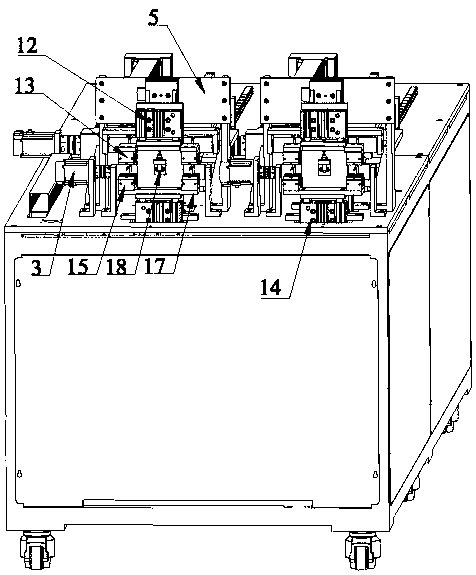

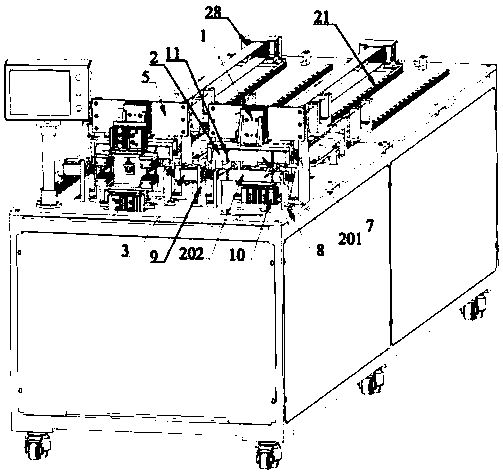

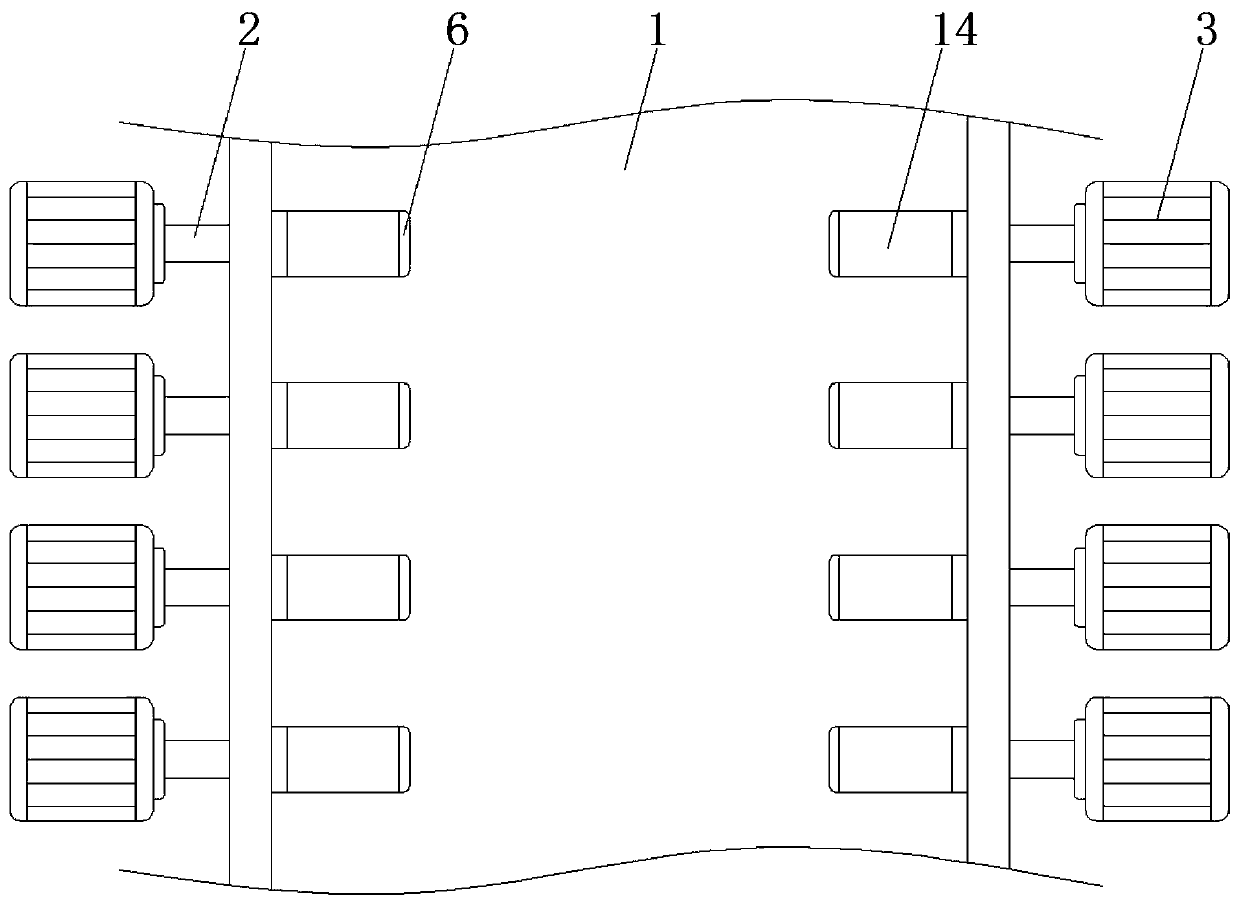

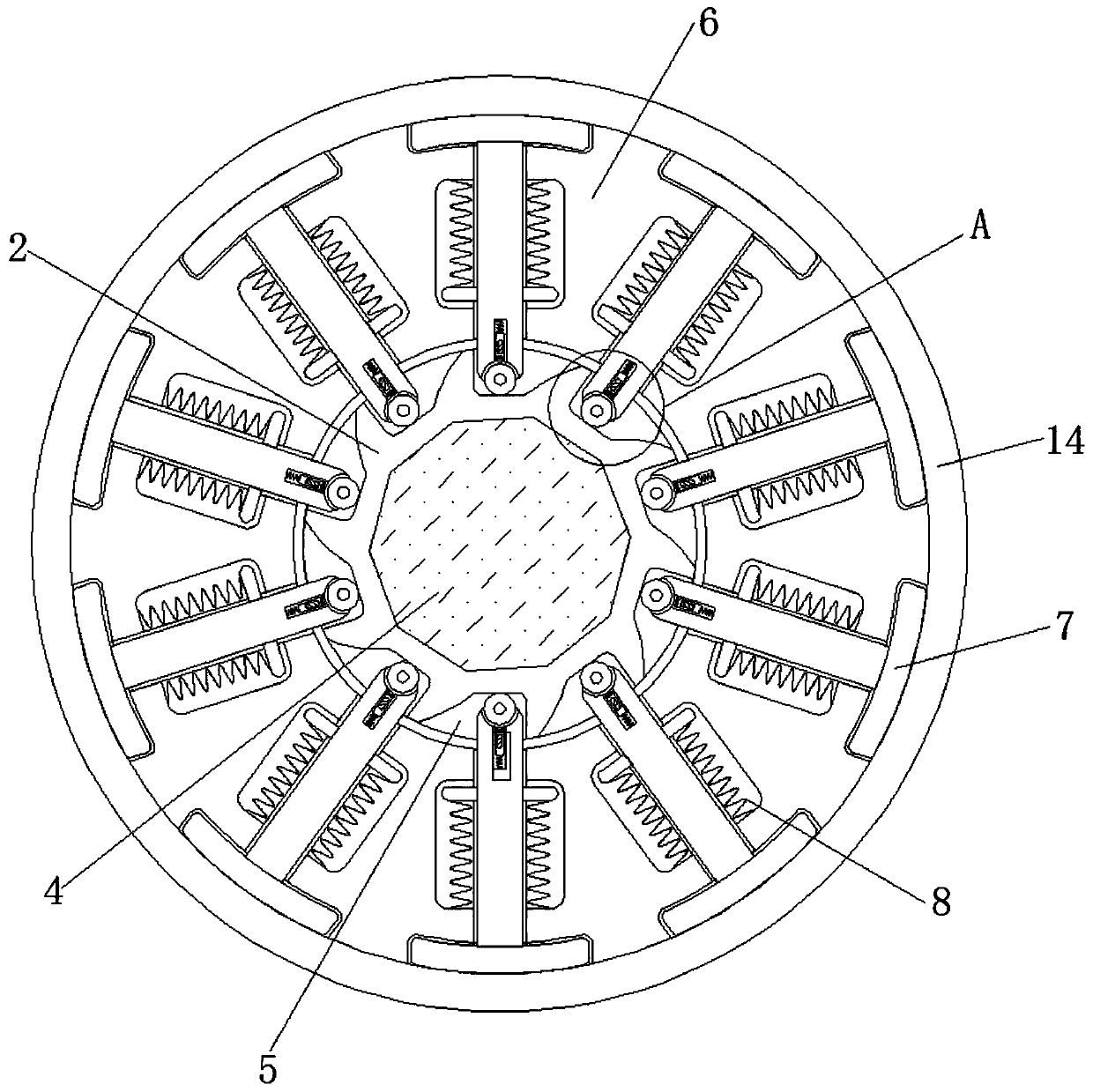

Wiring harness automatic penetration sleeve device

ActiveCN108400559AAvoid damageHigh surface friction coefficientApparatus for laying cablesEngineeringSilica gel

The invention discloses a wiring harness automatic penetration sleeve device; the end part of one end of a PVC sleeve penetrates into the front end of the wiring harness feeding rod, so that fixed length of the wiring harness feeding rod is achieved; after feeding, a sleeve pressing air cylinder is pressed down; a silica gel roller train presses the PVC sleeve; a servo motor is started to drive alower silica gel roller wheel to rotate, the PVC sleeve is completely inserted into a designated position on the wiring harness feeding rod, and the sleeve pressing air cylinder rises after the PVC sleeve is in place; two wiring harnesses are buckled into a bayonet at the front end of the wiring harness feeding rod; after the wiring harnesses are loaded, a starting button is pressed down, and thepressing air cylinder is pressed, so that the upper silica gel sheet holds the PVC sleeve which has already been loaded, and then, a power module drives the wiring harness feeding rod to pull the wiring harnesses into the PVC sleeve; the power module drives the wiring harness feeding rod to return to send out a finished product, and the finished product is sent out to an original position and unloaded, so that the automation process is realized, and the labor cost is reduced; the silica gel sheet made of silica gel and the roller train are adopted for grabbing and conveying the PVC sleeve, thefriction coefficient is increased, and the PVC sleeve is not easily damaged.

Owner:WUXI NIUKE ELECTRONICS SCI & TECH

Galvanizing technology for high-strength fastening piece

InactiveCN101984129AAvoid hydrogen embrittlementHigh surface friction coefficientHot-dipping/immersion processesPre treatmentFastener

The invention relates to a galvanizing technology for high-strength fastening pieces. The technology consists of oil removing process, surface pre-treatment process, passivation process, hot-dip zinc process, centrifugation process and cooling process successively. In hot-dip zinc process, high-strength fastening pieces are subject to passivation treatment and then are immersed in zinc liquid at a temperature of 470-480 DEG C. for 40-60 seconds. After being treated with the galvanizing technology, zinc layer thickness of high-strength fastening pieces can meet the corresponding standard and surface hardness and strength thereof will not change basically.

Owner:NINGBO YINZHOU JISHI METAL SURFACE TREATMENT FACTORY

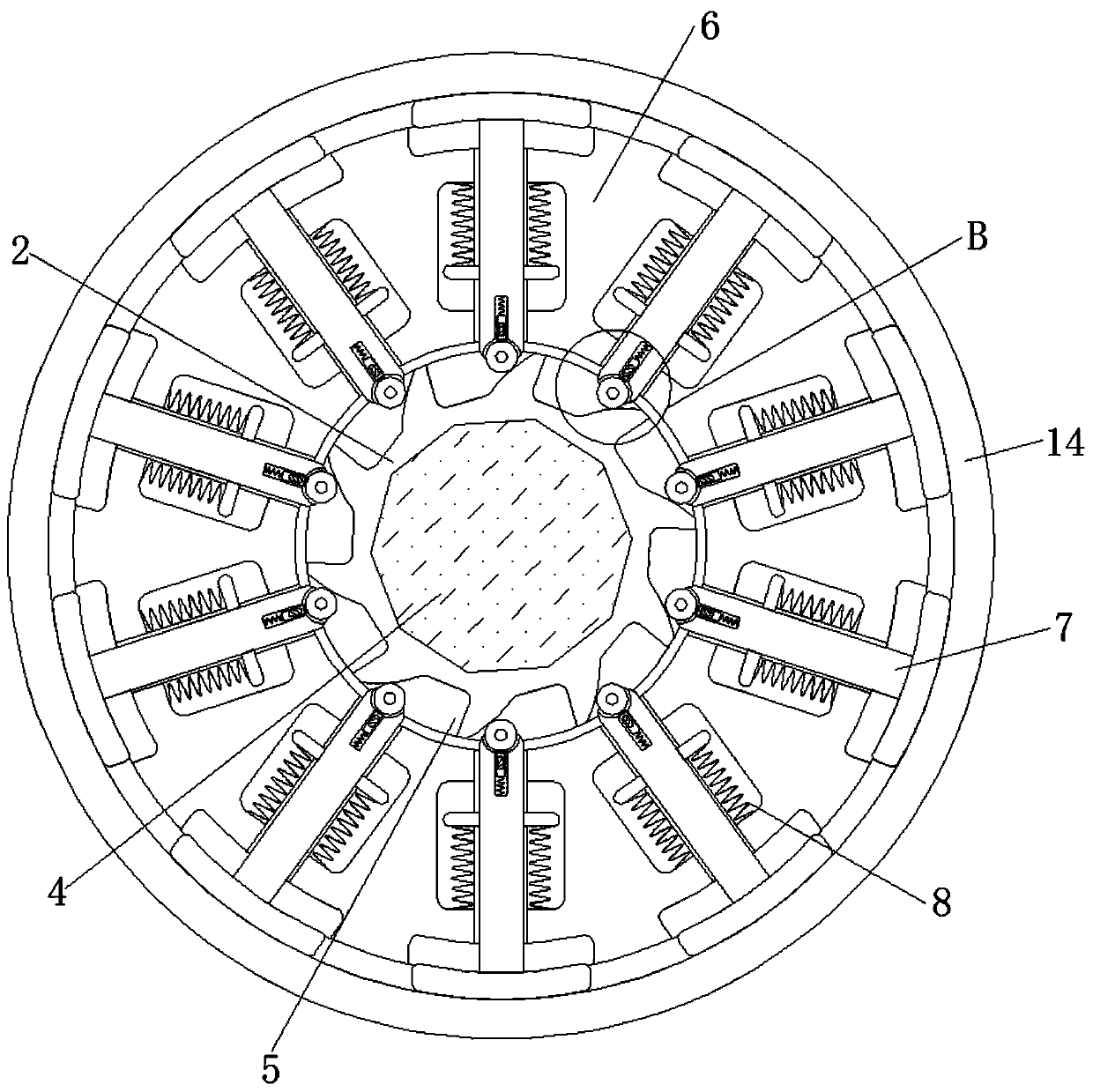

Conveying and paper-pressing device used for variable-diameter printing equipment

ActiveCN110759155AChange roller diameterImprove transmission efficiencyWebs handlingElectric machineryEngineering

The invention provides a conveying and paper-pressing device used for variable-diameter printing equipment, and relates to the technique field of printing. The device includes a conveying platform, the two sides of the conveying platform are rotationally connected with output shafts, the outer sides of the output shafts are fixedly connected with motors, the middles of the output shafts are fixedly connected with electric-magnetic devices, and the outer sides of the output shafts are provided with limiting grooves. According to the conveying and paper-pressing device used for the variable-diameter printing equipment, the limiting grooves and idler wheels cooperate in use, when the paper-pressing device is used, the output shafts are driven through the motors to rotate, the limiting groovesalso rotate, the positions of the idler wheels are changed, moving blocks are thus driven to stretch out and draw back, the maximum outer diameters of compression rollers are thus changed, the distance between the outer side of each compression roller to the conveying platform is changed, the moving blocks can support rubber rings to make the surface friction coefficients increase, the diametersof the compression rollers are thus changed, paperboards different in thickness are effectively and tightly pressed, the conveying efficiency is improved, and the steady operation of the conveying device is guaranteed.

Owner:海宁人民机械有限公司

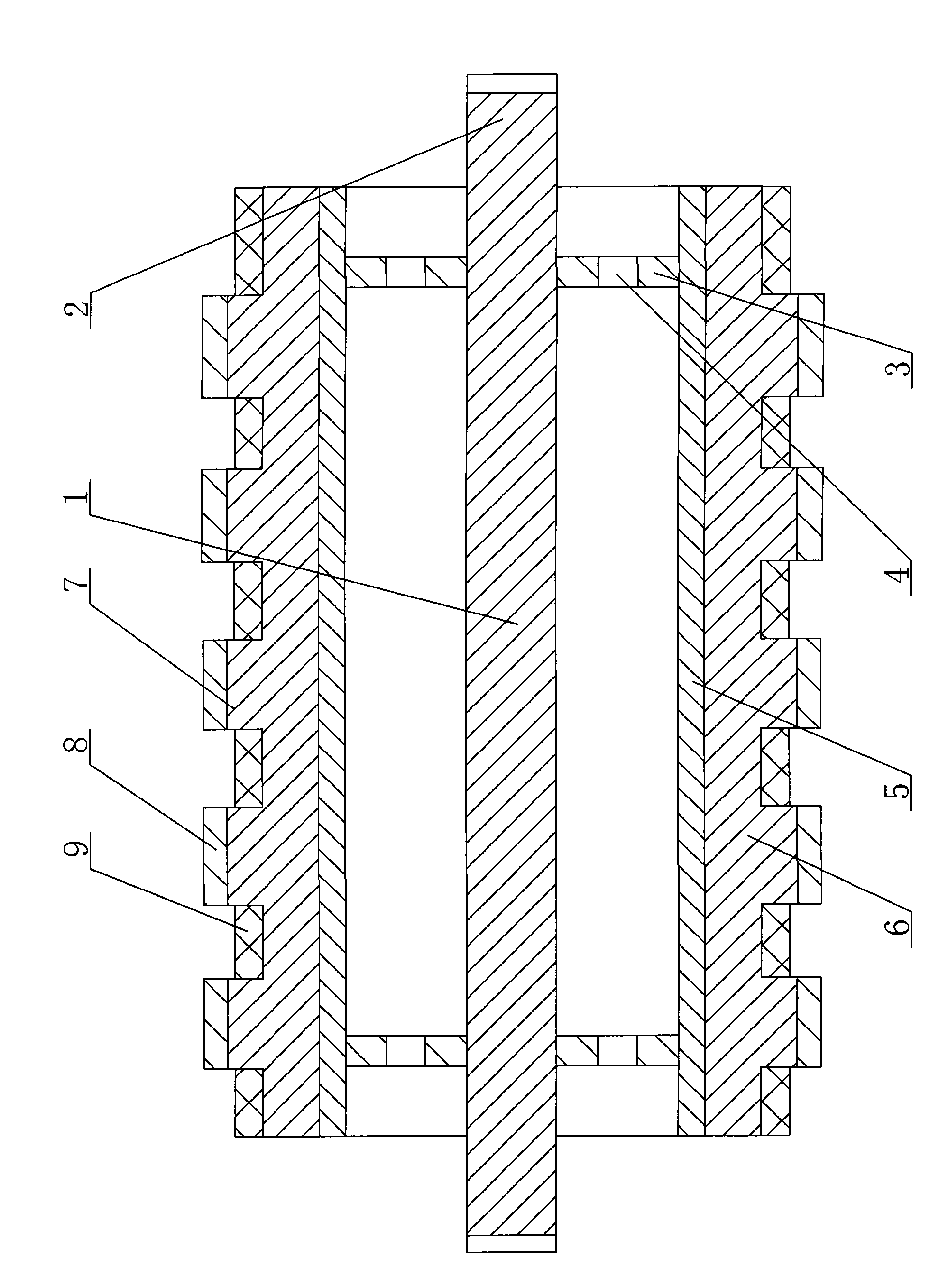

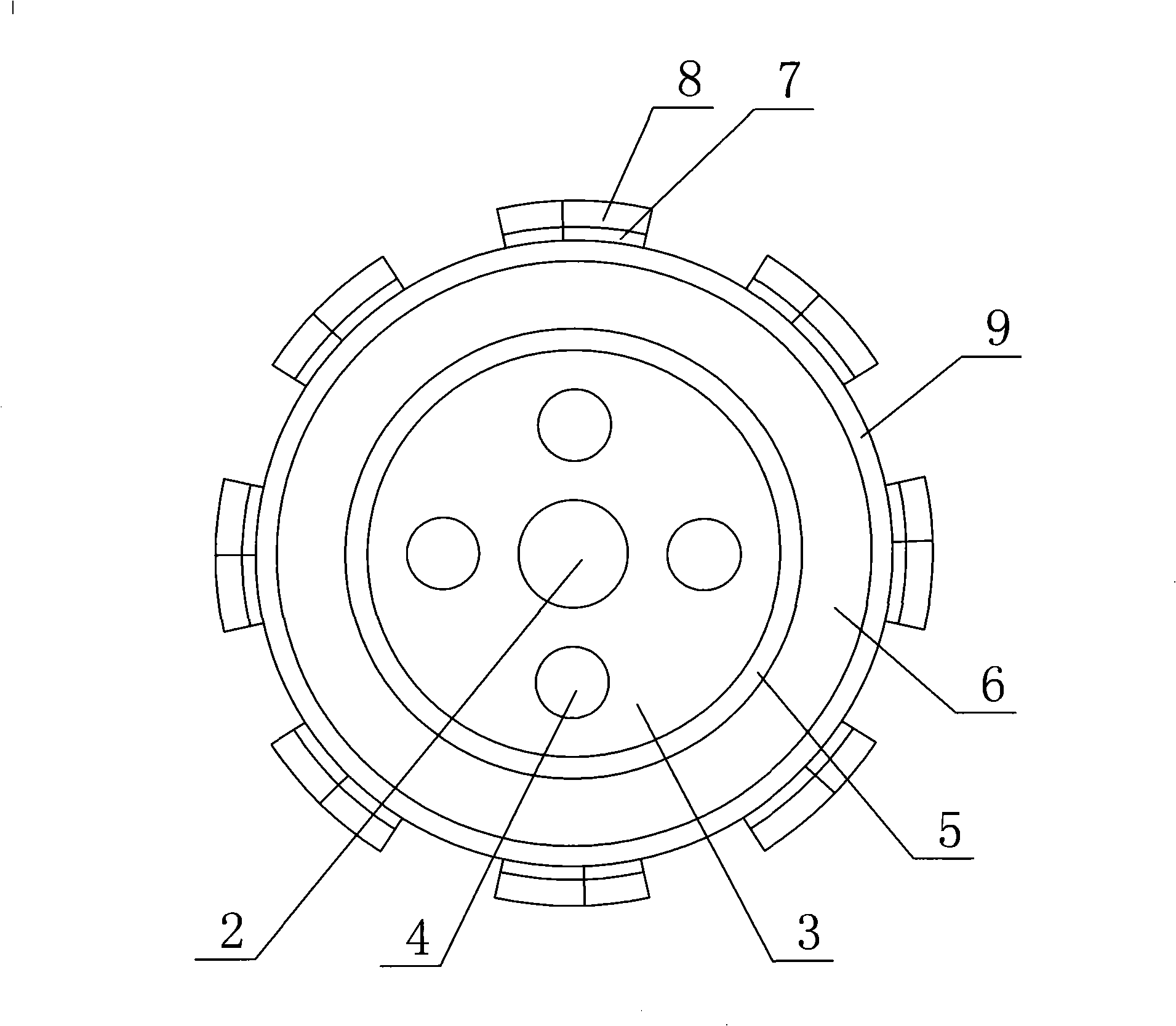

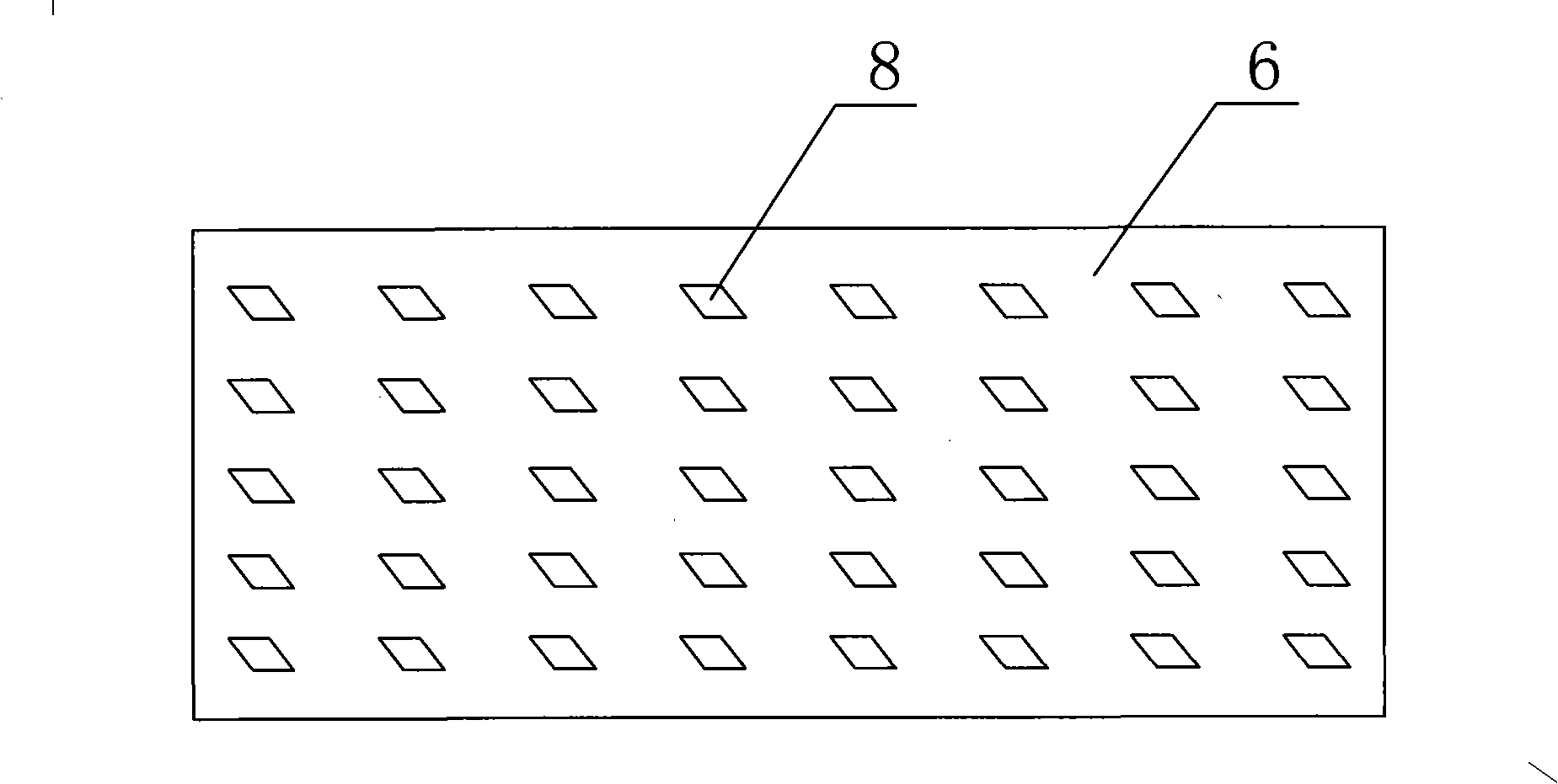

Fill type rubber rhombic conveying roll

InactiveCN101537930AHigh surface friction coefficientSafe and reliable operationRollersSurface frictionEngineering

The invention discloses a fill type rubber rhombic conveying roll with convenient maintenance, comprising a metal roll core. A roll neck and a connecting plate are respectively arranged on both ends of the metal roll core, a plurality of lightening holes are arranged on the connecting plate, a metal roller is supported on the metal roll core through the connecting plate, and a rhombic composite layer is arranged at the outer side of the metal roller. The rhombic composite layer comprises an inside glue layer, a plurality of rhombuses arranged on the inside glue layer and an outside glue layer, wherein the inside glue layer is arranged at the outer side of the metal roller, and the outside glue layer is arranged at the outer side of the rhombuses. A metal rhombic net is arranged on the rhombic composite layer in a matching way. The invention has the advantages that the surface of the conveying roll with the structure is in a rhombic shape, therefore, the surface friction coefficient of the conveying roll is increased, and a conveyor belt cannot slip when running in a rainy day with safe running and machine consumption reduction. After the conveying roll is damaged, the maintenance and dismantling time is short, thereby the normal use of a customer can be ensured, and the maintenance cost of the customer can be reduced.

Owner:ZHANGJIAGANG HUASHEN INDAL RUBBER PRODS

Device and method for regulating warping of glass plate

ActiveCN106242250AGuaranteed uptimeEliminate warpingGlass forming apparatusArchitectural engineeringOverflow downdraw method

The invention discloses a device and method for regulating warping of a glass plate. The device comprises overflow down-drawing forming equipment. Glass plate cutting equipment is arranged at the rear end of the overflow down-drawing forming equipment, and a traction roller is arranged between the overflow down-drawing forming equipment and the glass plate cutting equipment. The holding force of the traction roller to a glass plate is increased, in an overflow down-drawing method, the clamping force of the traction roller is greatly affected by friction force between the surface of a boss and the glass plate, the friction coefficient of the surface of the boss is increased, friction force is increased, therefore, the glass plate runs stably through the method of increasing the clamping force, and warping badness caused by back-and-forth running of the glass plate is eliminated.

Owner:RAINBOW (HEFEI) LIQUID CRYSTAL GLASS CO LTD

Nylon fiber with low surface frictional coefficient and improved hydrophobicity and preparation method thereof

ActiveCN109989128ASolve the problem that it is difficult to disperse evenly in the fiber matrixImprove dispersion uniformityArtifical filament manufactureMonocomponent polyamides artificial filamentPolymer scienceSide chain

The invention relates to a nylon fiber with low surface frictional coefficient and improved hydrophobicity and a preparation method thereof. The preparation method comprises mixing modified nylon masterbatch and nylon chips in a mass ratio of (0.5-5):(95-99.5), and performing melt spinning to obtain the nylon fiber with low surface frictional coefficient, wherein the modified nylon masterbatch ismainly composed of, by weight, 37-88.8% of nylon, 10-60% of PDMS (polydimethylsiloxane) and 0.2-3% of POSS with amino side chains and is made by adding the materials proportionally into a mixer, mixing well, transferring to a twin-screw extruder and dicing. The prepared nylon fiber with low surface frictional coefficient and improved hydrophobicity has both dynamic frictional coefficient and stationary frictional coefficient of less than 0.3, has an angle of contact with water being greater than 71 DEG, has good durability, spinnability and good mechanical properties, and has a good application prospect.

Owner:DONGHUA UNIV +1

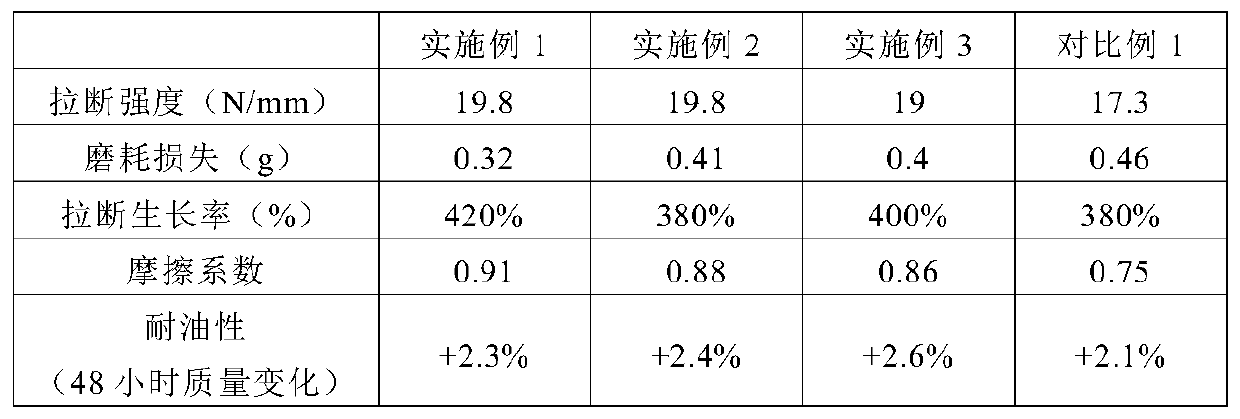

High-wear-resistance rubber friction layer for folder gluer conveying belt and preparation method of rubber friction layer

InactiveCN110041575AEasy to processGood compatibilityLamination ancillary operationsLaminationVulcanizationEngineering

The invention discloses a high-wear-resistance rubber friction layer for a folder gluer conveying belt and a preparation method of the rubber friction layer. The friction layer is prepared from raw materials in parts by weight as follows: 60-90 parts of butadiene rubber, 5-20 parts of natural rubber, 5-20 parts of NBR (nitrile butadiene rubber), 40-60 parts of a reinforcing agent, 3-5.5 parts of aprotective agent, 8-12 parts of a vulcanizing agent, 6-9 parts of a vulcanizing aid and 12-16 parts of rubber oil through plastifying, mixing, rolling and vulcanization. Three different types of rubber are combined and can make up defects of one another and play respective advantages, tensile strength, wear resistance and rebound resilience are significantly improved, the surface friction coefficient is increased, and wear resistance is enhanced, so that the overall performance of the folder gluer conveying belt is improved.

Owner:江阴市斯强传动科技有限公司

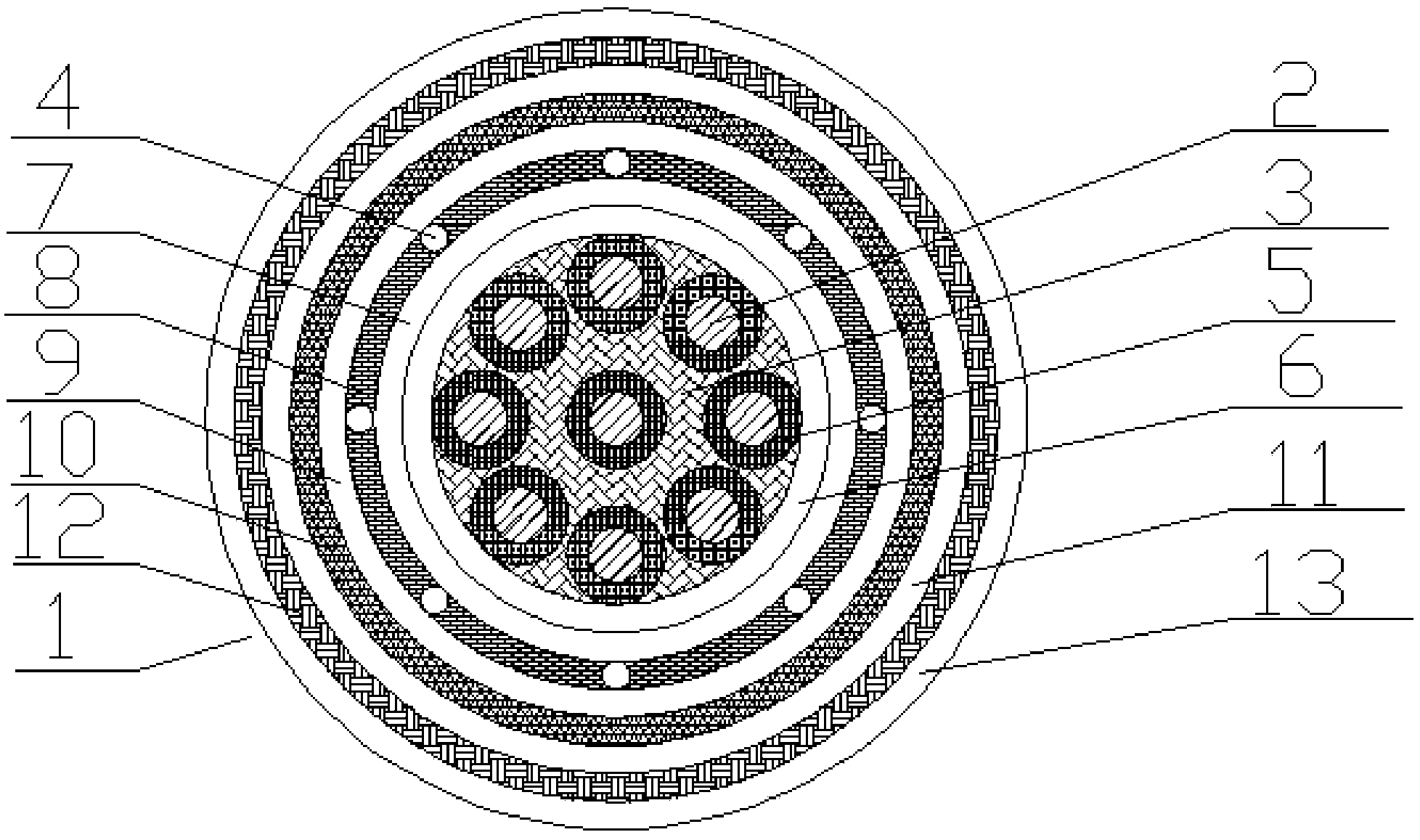

Environment-friendly, high-temperature-resistant and anti-shielding industrial control cable

InactiveCN104332227AReasonable structural designExtended service lifeInsulated cablesInsulated conductorsEnvironmental resistanceMetal coating

The invention discloses an environment-friendly, high-temperature-resistant and anti-shielding industrial control cable, comprising a cable body that includes conductors, an insulating layer, a shielding layer, an inner sheath and an outer sheath. The conductor is arranged inside the cable body; the section of the conductor is circular in shape; a copper foil layer is extruded outside the conductor; the insulating layer is tightly extruded outside the copper foil layers; the gap part between the insulating layer and the copper foil layers is filled with fillers; the shielding layer is tightly extruded outside the insulating layer; a plurality of uniformly arranged drainage cores are arranged inside the shielding layer; a resin bonding layer is arranged between the shielding layer and the insulating layer; a metal coating is arranged on the outer surface of the shielding layer; a reinforcing layer and a refractory layer are arranged outside the metal coating from inside to outside; the inner sheath is arranged on the outer surface of the refractory layer; the outer sheath is tightly extruded on the surface of the inner sheath. The environment-friendly, high-temperature-resistant and anti-shielding industrial control cable has the advantages of reasonable structural design, long service life and good shielding resistance.

Owner:CHENGDU GUANYU TECH

Prefabricated plastic runway coiled material and preparation method thereof

The invention discloses a prefabricated plastic runway coiled material and a preparation method thereof, and belongs to the field of plastic runways. The prefabricated plastic runway coiled material is prepared from SEBS, SBS, white oil, calcium carbonate, ethylene propylene diene monomer, grafted PP, silicone master batch, TPU, PP, an antioxidant and a pigment, wherein the model of SEBS is specifically CH1320; the model of SBS is specifically CH1303; the mesh number of calcium carbonate is 400 to 1250 meshes; the model of ethylene propylene diene monomer is 3080P; the model of PP is specifically K80; and the antioxidant is an antioxidant 1010. The prepared plastic runway coiled material is good in elasticity and impact capacity, the safety of athletes can be guaranteed, the sports effectof the athletes can be enhanced, and the plastic runway coiled material is safer and healthier.

Owner:玖德隆机械(昆山)有限公司

Particle rubber roll and manufacturing method thereof

InactiveCN104646434ANot easy to produce powder drop phenomenonExtended service lifeMetal rolling arrangementsRubber materialPolymer science

The invention discloses a particle rubber roll and a manufacturing method thereof. The particle rubber roll comprises a roll body, wherein a rubber layer coats the surface of the roll body, the outer surface of the rubber layer is a smooth arc-shaped surface, the rubber layer consists of base rubber and a plurality of rubber particles, the rubber particles are uniformly distributed in the base rubber, and the shore hardness of the rubber particle is 15 degrees more than the shore hardness of the base rubber. The particle rubber roll has the advantages that the rubber layer is made of two kinds of rubber material with different hardness; when the particle rubber roll is in contact with a steel plate, the friction coefficient of the surface of the rubber layer is increased because of hardness difference, and the slippage and expansion losing are avoided; as the rubber layer is in surface contact with the steel plate, the easiness in generation of rubber powder falling is avoided, the influence on the quality of the rubber layer caused by the rubber grinding chips falling onto the steel plate is avoided, and the service life of the rubber roll is longer.

Owner:苏州市宝苏矿冶设备有限公司

Preparation method of star-shaped SBS (styrene butadiene styrene block polymer)-modified asphalt and production method of waterproof coiled material

ActiveCN102220023BGood high and low temperature resistanceImprove stabilityBuilding insulationsPolymer scienceAdhesive

Owner:XI NIU PI WATERPROOFING TECH CO LTD

Modified asphalt, and production process and application thereof

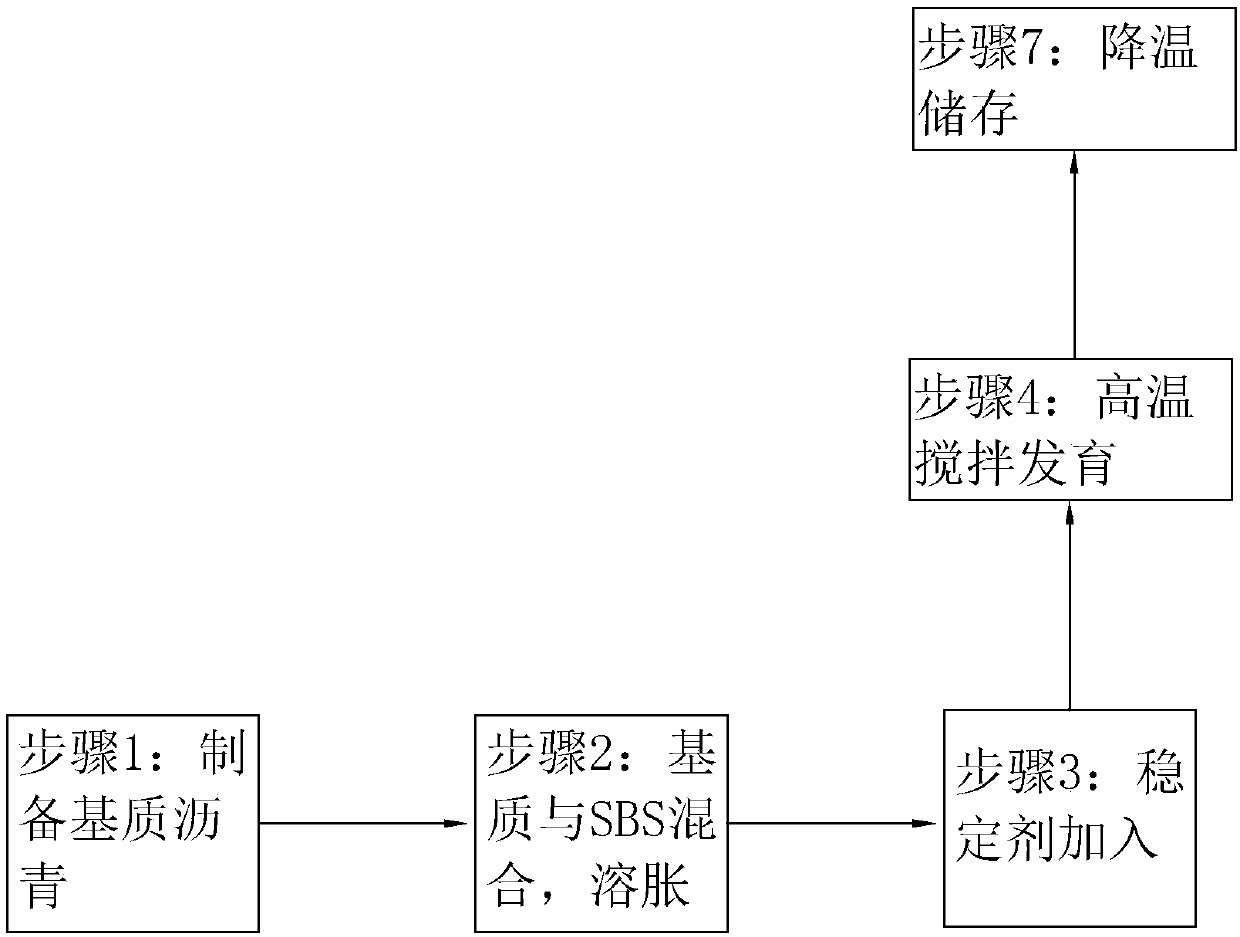

InactiveCN107815132AImprove natureImprove heat storage performanceBuilding insulationsChemical reactionAfter treatment

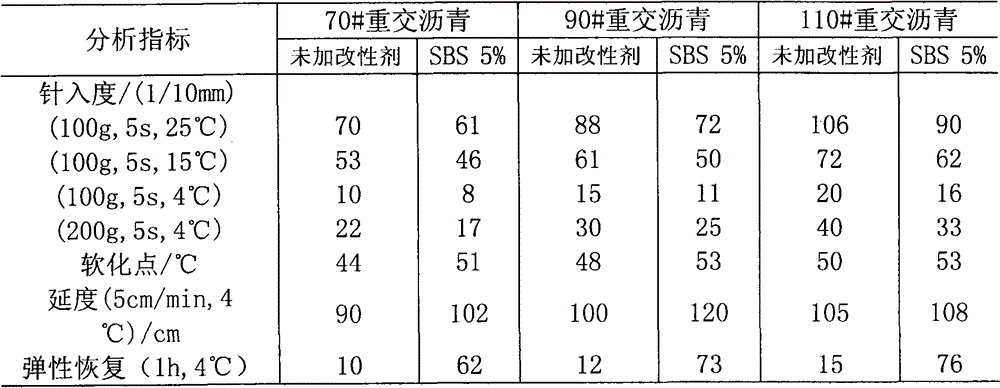

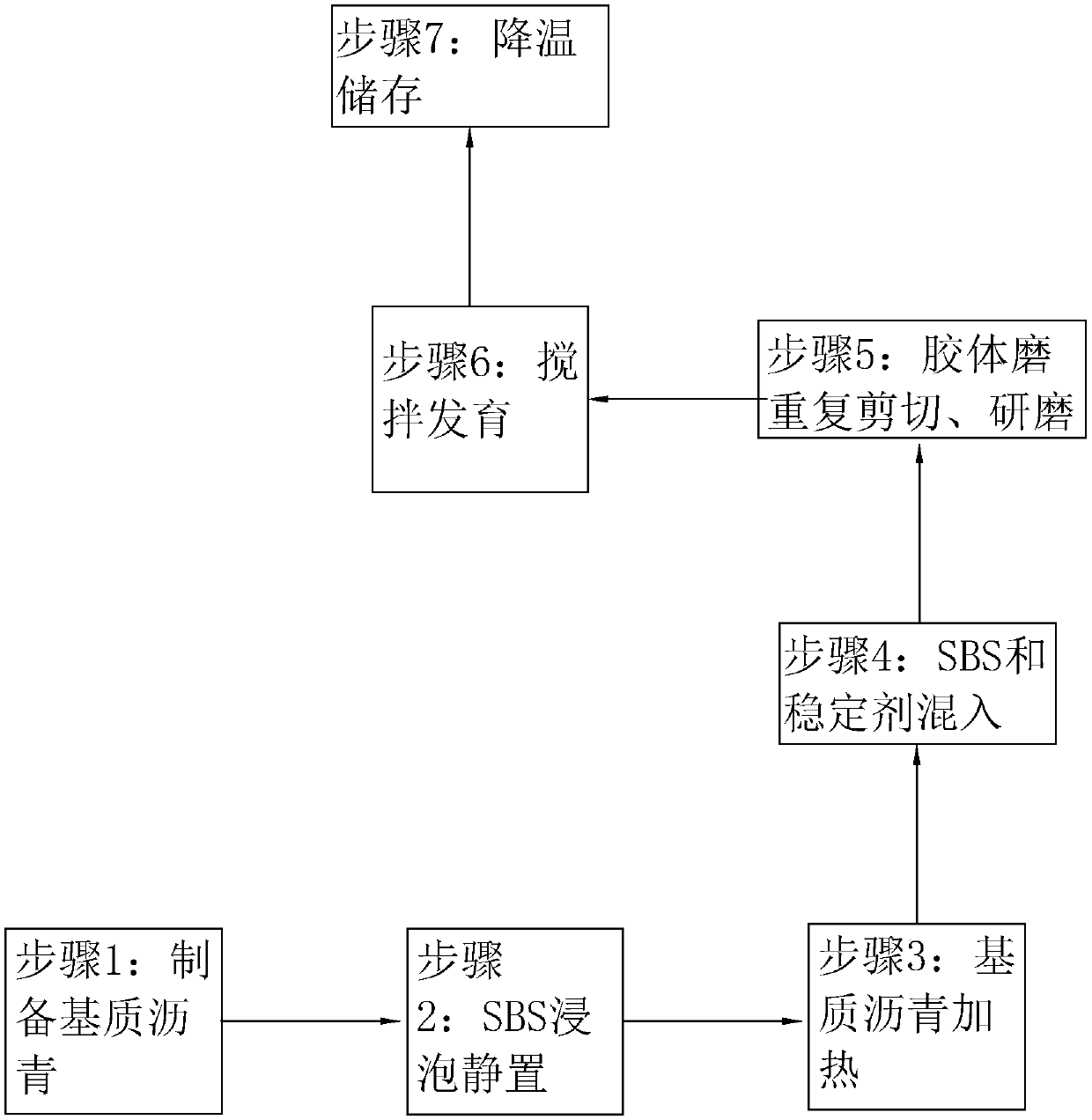

The invention relates to modified asphalt, and a production process and application thereof. The production process comprises the following steps of (1) preparing matrix asphalt for standby use; (2) soaking and standing SBS (Styrene Butadiene Styrene); (3) heating the matrix asphalt prepared in the step (1) to 150 to 180 DEG C, and pouring into a premixing tank; (4) pouring the SBS processed in the step (2) and a stabilizer into the premixing tank, and mixing and stirring to disperse uniformly; (5) repeatedly shearing and grinding the matter mixed uniformly in the step (4), and obtaining submicron particles; (6) placing the matter in the step (5) into a sealed container, stirring and developing for more than 30 hours, and controlling the temperature to be 170 to 200 DEG C. According to thescheme, during preparing and mixing, the SBS and the modified asphalt are subjected to physical mixing and chemical crosslinking, and along with the adding of the stabilizer, the SBS and the asphaltare subjected to crosslinking reaction or grafting reaction or other chemical reactions, so that a networked overall structure is formed, and the modified asphalt obtained after treatment is improvedin property and better in heat storage performance.

Owner:苏州三创路面工程有限公司

Asphalt modifier and preparation method thereof

InactiveCN108102281AHigh surface friction coefficientImprove low temperature performanceBuilding insulationsWeather resistanceCrack resistance

The invention belongs to the technical field of pavement composite materials, and provides an asphalt modifier and a preparation method thereof. The asphalt modifier comprises the following raw materials in parts by weight: 90-110 parts of a styrene-butadiene-styrene triblock copolymer (SBS), 8-15 parts of dimethicone, 12-30 parts of carbon black and 2-8 parts of silicon dioxide. The modifier cangreatly improve the weather resistance and the crack resistance of asphalt. The preparation method of the asphalt modifier comprises the following steps: (1), mixing the SBS, the dimethicone, the carbon black and the silicon dioxide, and then stirring to obtain a mixture; and (2), extruding the mixture at 160-190 DEG C according to a rotating speed of 20-120 r / min to obtain a cylindrical strip, then cooling, and then cutting into granules to obtain the asphalt modifier. The preparation method is simple, and can be widely applied to the field of asphalt roads, building waterproofing and the like.

Owner:中昊黑元化工研究设计院有限公司

Pressure-sensitive SEBS (Styrene-butadiene-styrene Block Copolymer) rubber binder and preparation process thereof

InactiveCN103881616AImprove aging resistanceMalleableNon-macromolecular adhesive additivesWax adhesivesPolymer scienceAging resistance

The invention discloses a pressure-sensitive SEBS (Styrene-butadiene-styrene Block Copolymer) rubber binder and a preparation process thereof. The pressure-sensitive SEBS rubber binder comprises the following components by mass percent: 10 to 25% of SEBS, 20 to 40% of SBR (Styrene Butadiene Rubber), 3 to 9% of SBS (Styrene Butadiene Styrene), 2 to 4% of Styrene Isoprene Styrene, 4 to 8% of nano calcium carbonate, 6 to 16% of rosin glycerol, and 20 to 35% of paroline. The pressure-sensitive SEBS rubber binder is outstanding in ageing resistance, high in plasticity and high in elasticity, can quickly bind, shows remarkable flame retardant performance and aging resistance, and is also high in shockproof performance and heat preserving performance, relatively high in elasticity, waterproof and airproof.

Owner:王勇

Wharve of spun yarn spindle

InactiveCN103572431AHigh surface friction coefficientPrevent slippingTextiles and paperYarnEngineering

The invention discloses a wharve of a spun yarn spindle. The spun yarn spindle comprises a spindle blade, wherein the wharve is arranged on the spindle blade; the wharve is connected with a spindle tape driving the spun yarn spindle to rotate; and an anti-slip structure is arranged on the surface where the wharve and the spindle tape are contacted. According to the wharve of the spun yarn spindle, the anti-slip structure can effectively increase the surface friction coefficient of a spindle tape wheel, the skid phenomenon of the spindle tape wheel and the spindle tape is prevented, and the transmission efficiency is improved; and at the same time, the difference of rotating speeds of all spindles of a whole spinning frame can be balanced, and the yarn quality is improved further.

Owner:TONGXIN TEXTILE MACHINERY WUHU

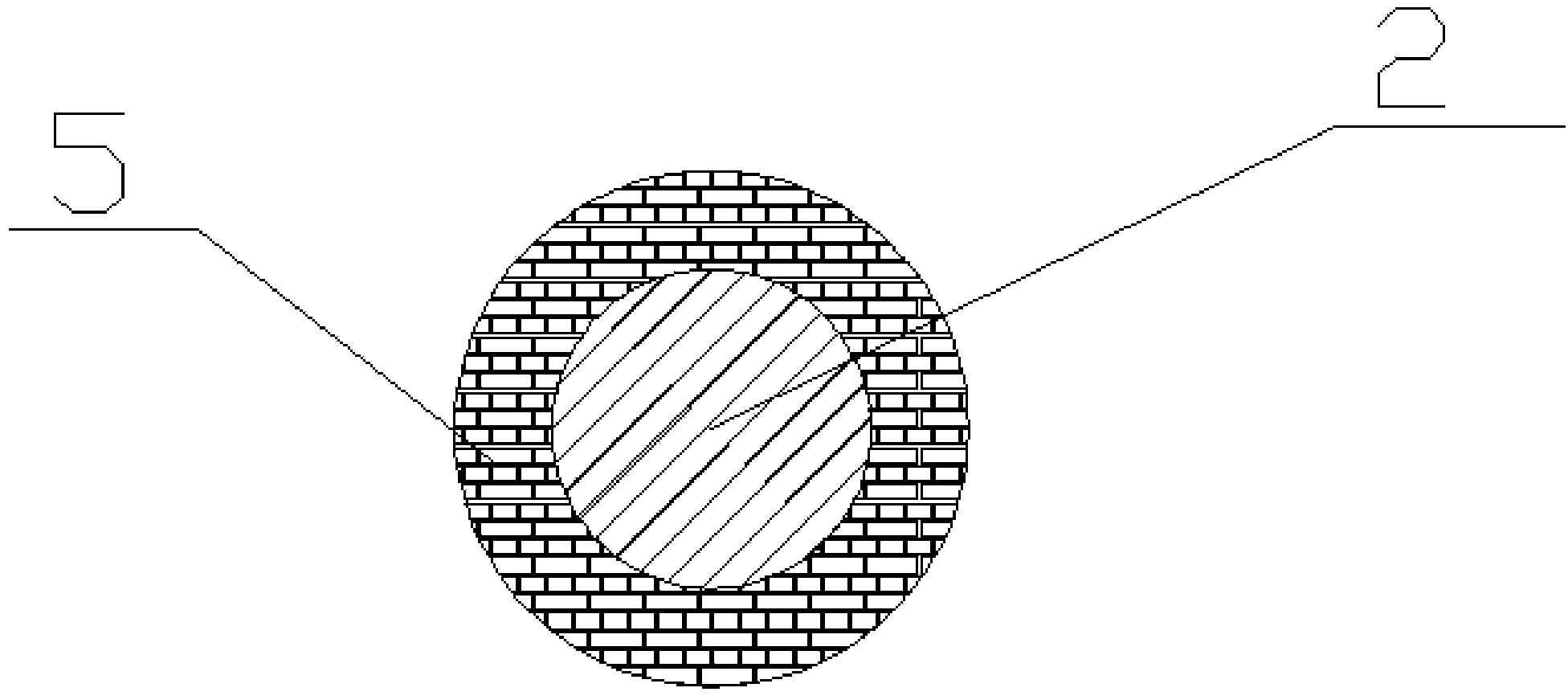

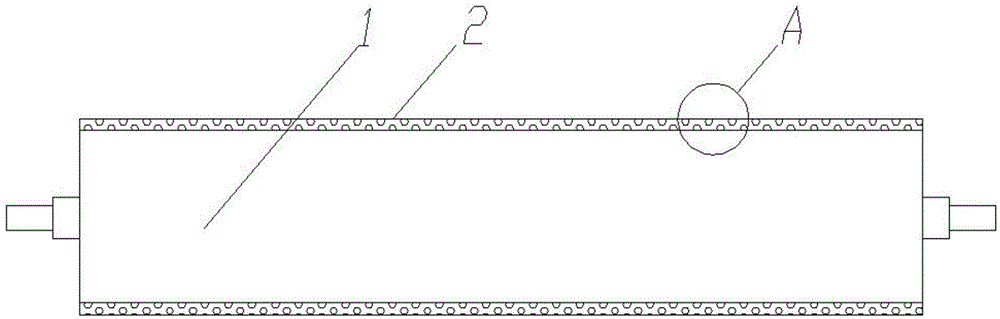

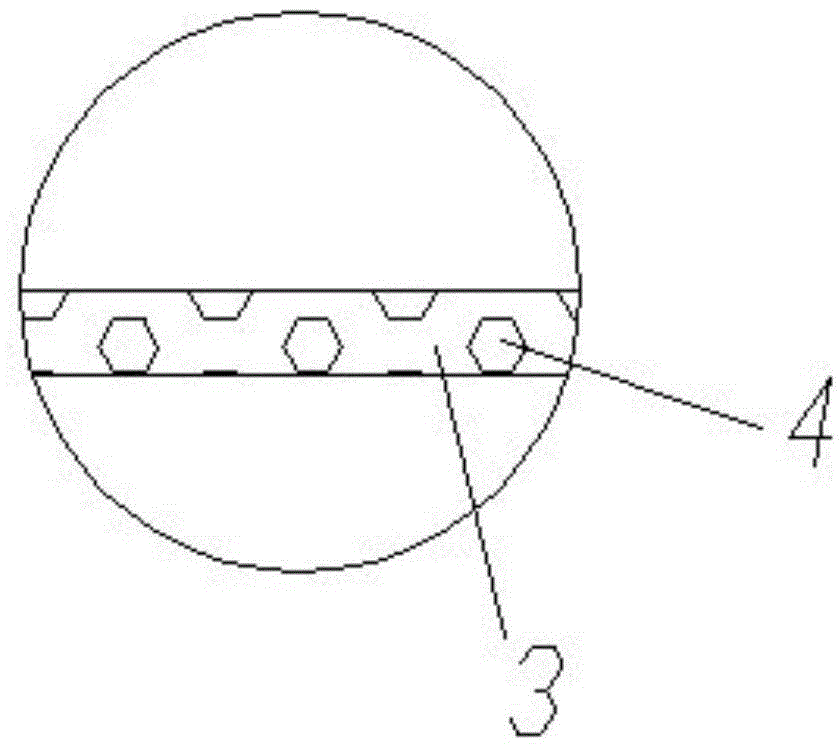

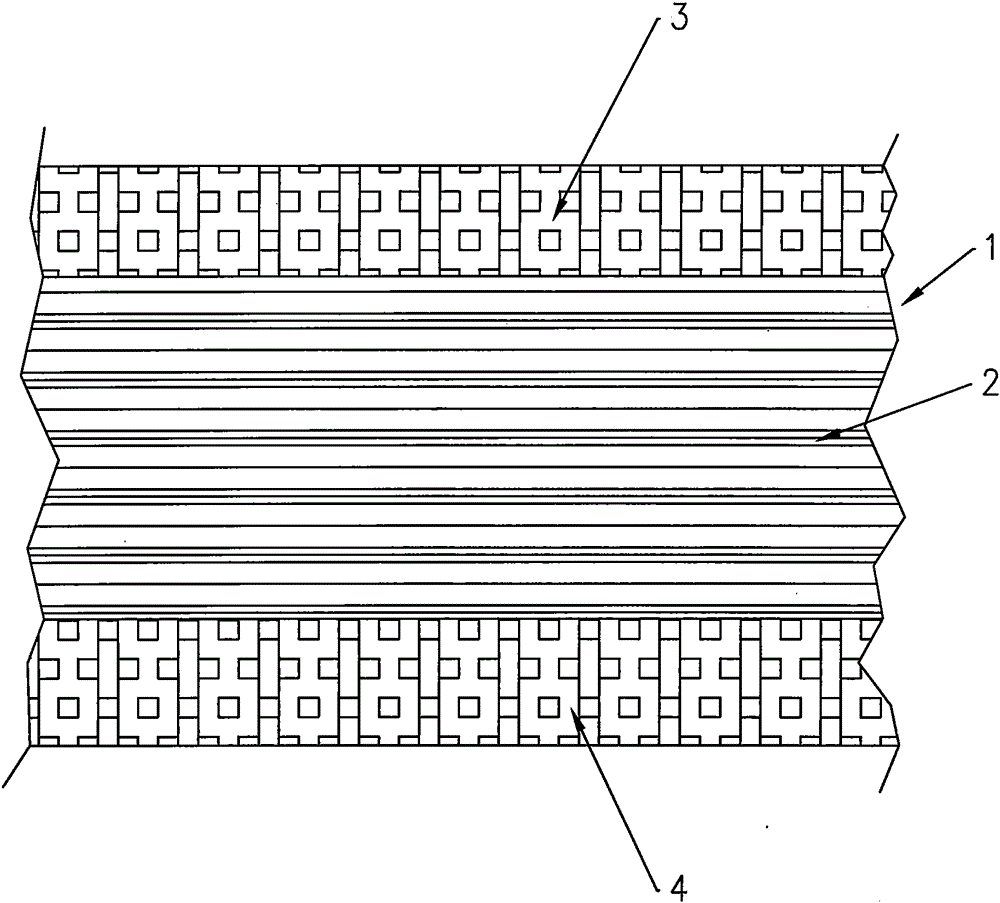

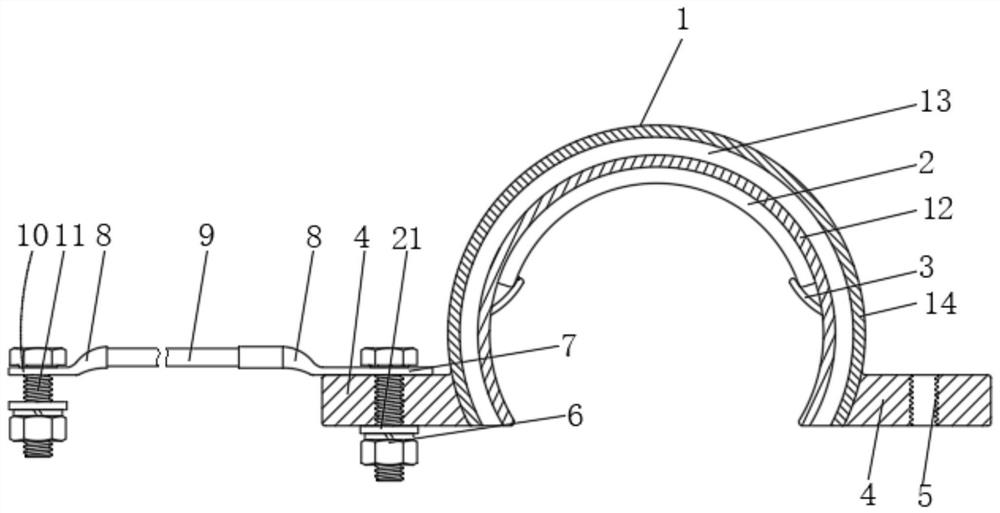

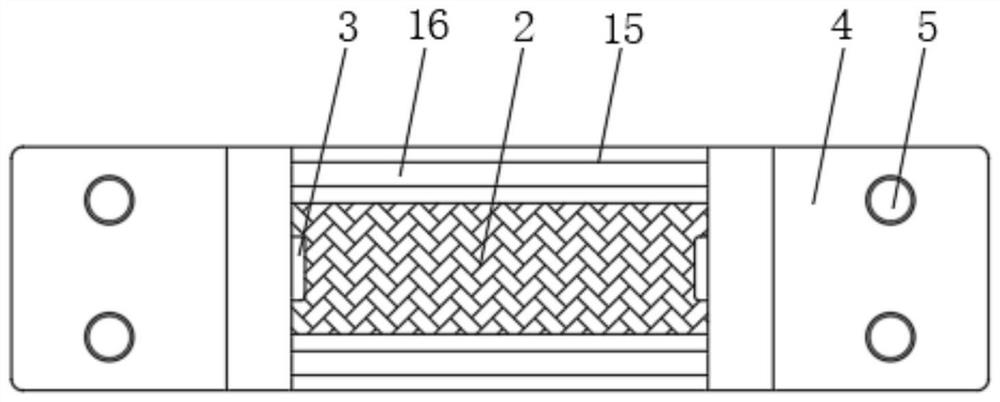

Railroad transport crawler belt equipment non-overrun device cloth layer rubber bearing body

ActiveCN105273658AWell mixedHighlight substantive featuresNatural rubber adhesivesNon-macromolecular adhesive additivesAdhesiveTear resistance

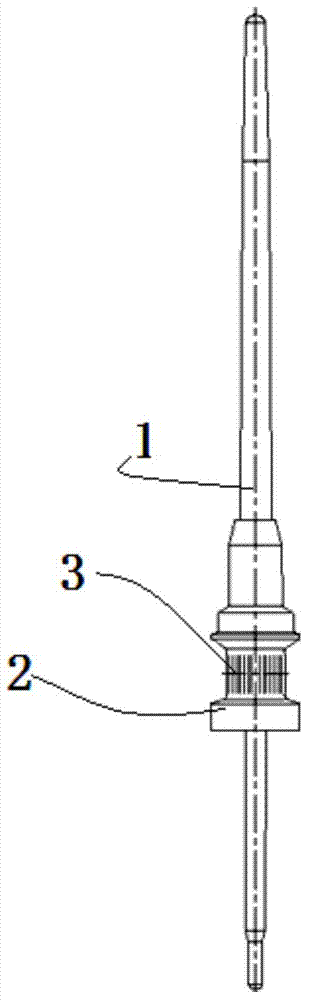

A railroad transport crawler belt equipment non-overrun device cloth layer rubber bearing body comprises a rectangular pad, the pad includes a power layer (1), the power layer (1) is arranged along the horizontal direction, the power layer (1) comprises 3-5 layers of EP canvas layers (2) which are arranged along the horizontal direction, the mutual adjacent surfaces of the 3-5 layers of EP canvas layers (2) are connected and bonded by 401 adhesive, the upper surface of the power layer (1) is bonded with an upper adhesive layer (3) by the 401 adhesive, the lower surface of the power layer (1) is bonded with a lower adhesive layer (4) by the 401 adhesive, the thickness of the power layer (1) is 60-80mm, the thickness of the upper adhesive layer (3) is 30-50mm, and the thickness of the lower adhesive layer (4) is 20-40mm. The purpose is to provide the railroad transport crawler belt equipment non-overrun device cloth layer rubber bearing body which has high strength and high tear resistance and large surface friction coefficient in the environment with a temperature of-40 DEG C to 60 DEG C, and can be well adapted to chilly condition and high temperature condition.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Preparation method of rubber concrete panel with rough surface

ActiveCN109265067AImprove driving safetyHigh surface friction coefficientShaping press ramRough surfacePolymer science

The invention provides a preparation method of a rubber concrete panel with a rough surface, and belongs to the field of compound materials. The method specifically includes the steps that treated stone and rubber compound particles are packed into a mold after being mixed evenly, then the mold is covered by a plastic panel with an area equal to that of an upper mold cavity and the thickness of 2-5 mm, an upper mold panel is closed, at 150-180 DEG C, firstly, preheating is conducted for 30-90 seconds, then mold pressing is conducted at 8-18 MPa, and finally, vulcanization is conducted for 10-40 minutes to prepare the rubber concrete panel with the rough surface. The preparation method of the rubber concrete panel with the rough surface has the beneficial effects that through the method, apart of stone on the rubber concrete surface can be made to be raised, not only is the rubber concrete material surface wear resistance improved, but also a surface friction coefficient of a materialcan be increased, and the anti-skid performance is improved, so that the safety of passengers and driving is improved; meanwhile, mold opening after vulcanization is conducted can be made to be easier.

Owner:XUZHOU COLLEGE OF INDAL TECH

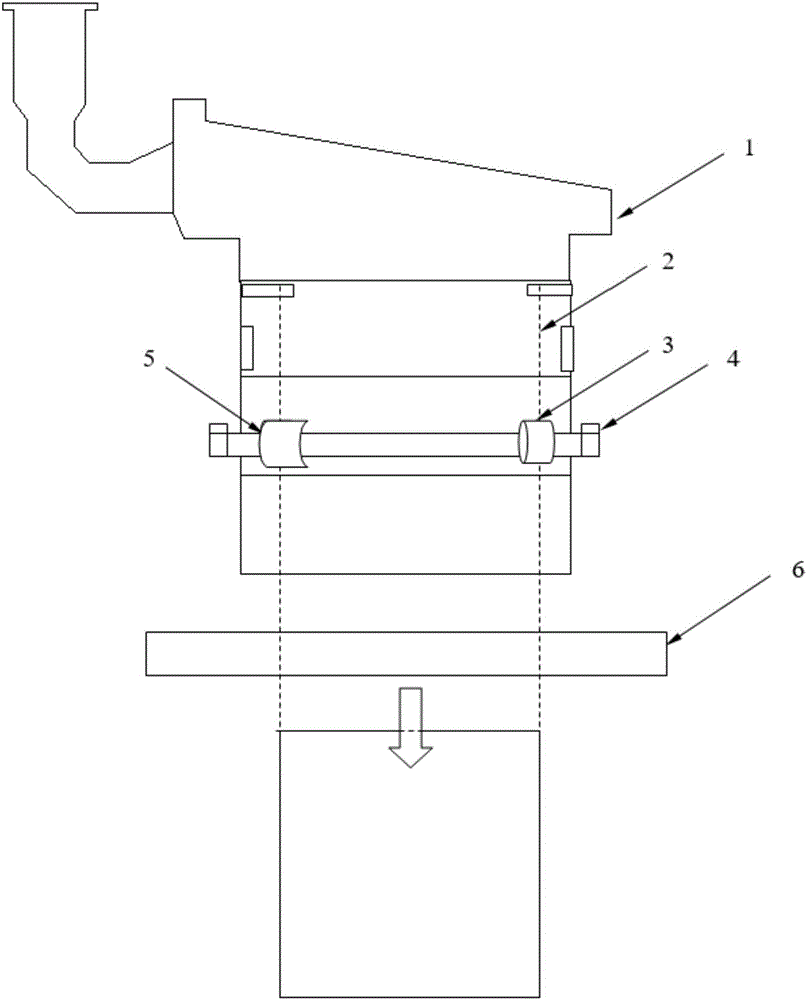

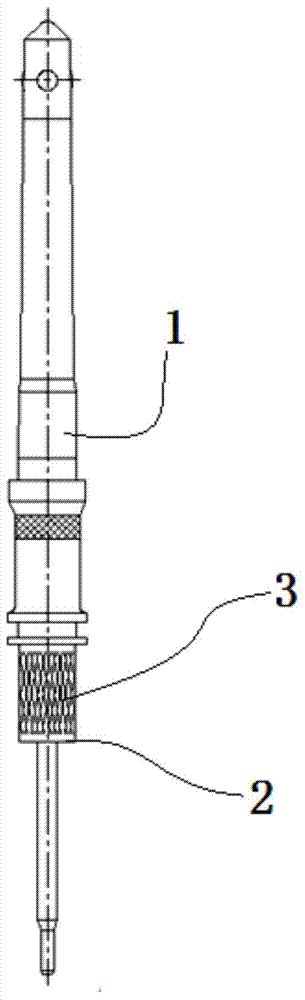

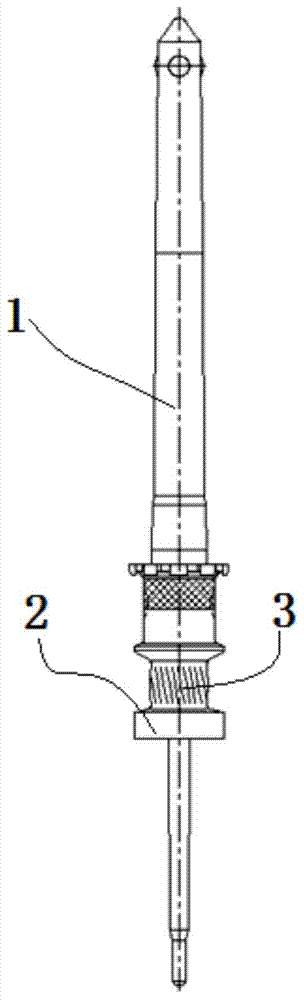

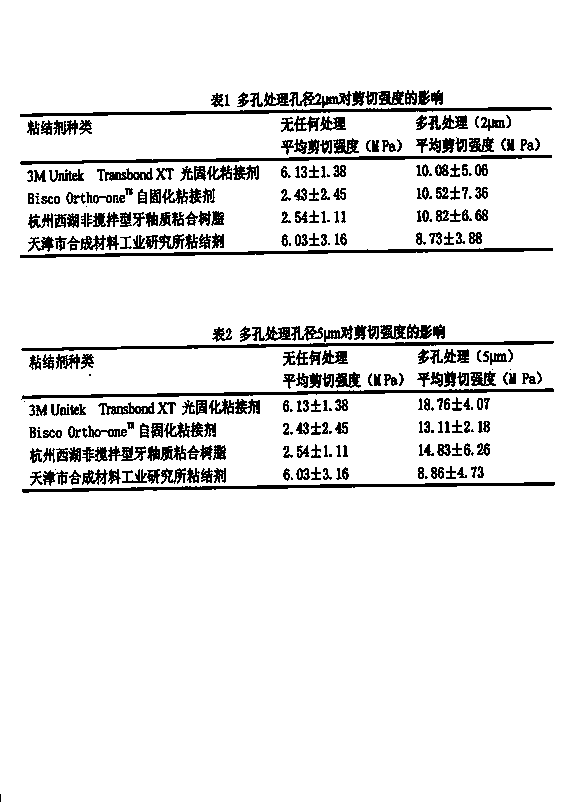

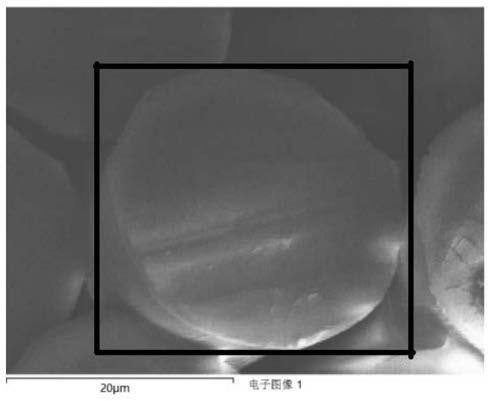

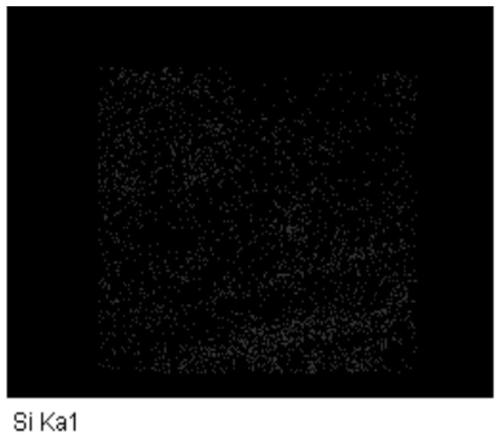

Manufacturing method of porous bottom surface of zirconium oxide ceramic bracket

ActiveCN102210612BHigh surface friction coefficientImprove mechanical strengthBracketsFrictional coefficientCeramic brackets

The invention relates to a method for manufacturing the porous bottom surface of a zirconia ceramic bracket. Zirconia, alumina and silicon dioxide are mixed and ball-milled according to different ratio requirements, and a solution is prepared and coated on the bottom of the ceramic bracket to form a porous surface on the bracket surface. Surface, increase the friction coefficient of the bracket surface, make it more firmly bonded. The invention enhances the adhesive strength of the ceramic bracket, and can control the size of the coarse-grained zirconia powder, the size of the aperture, and the adhesive force, so that the adhesive strength of the bracket can be controlled within a certain range, reducing the The bracket is less likely to fall off due to external force, and it is easy to remove.

Owner:SHENZHEN UPCERA DENTAL TECH

A method for preventing hair shedding of rabbit fur fabric

The invention relates to a method for preventing rabbit hair fabrics from hair shedding, which comprises the following steps: soaking the rabbit hair fabric to be treated in a sulfuric acid solution, performing pretreatment of the rabbit hair surface, then performing water bath of the rabbit hair fabric with a cross-linking agent with a mass fraction of 0.5-5% of the rabbit hair fabric, protein with a mass fraction of 0.5-10%, and a surfactant with a mass fraction of 0.5-10% according to a bath ratio of 1:50 at a temperature of 60 DEG C for 30 min-50 min, drying, and performing roasting and grafting at 90-110 DEG C for 20 min. The method of the invention prolongs the duration of the anti-hair shedding function of rabbit hair fabrics, causes no damage to the rabbit hair fabrics, and can improve fiber strength. The method is simple and easy to operate.

Owner:SOUTHWEST UNIV

Two-component coating type antiskid coating material and preparation method thereof

PendingCN113174777AIncrease coefficient of frictionImprove mechanical propertiesDefoamers additionPaper/cardboardNano al2o3Polyamide

The invention provides a two-component coating type antiskid coating material and a preparation method thereof. The antiskid coating material is composed of a component A solution and a component B solution, wherein the component A solution is composed of the following components by weight: 30-50% of waterborne polyurethane modified epoxy resin, 10-15% of a nano Al2O3 and CaCO3 dispersion liquid, 25-30% of fluff powder, and the balance of water, and the component B solution comprises the following components in percentage by weight: 30-50% of a polyamide curing agent, 1-2% of a defoaming agent, 1-2% of a flatting agent and the balance of water. According to the invention, the two-component anti-skid coating material is coated on the paper slide plate, so that the surface friction coefficient is increased, the anti-skid capability of the paper slide plate is enhanced, and the problems that the paper slide plate is easy to slip in the stacking and carrying processes, cannot be carried and loaded on equipment and the like are solved.

Owner:MYS GRP CO LTD

Waterproof skeleton grounding card for communication lightning protection

PendingCN114122754APrevent fallingImprove firm performanceCoatingsConnection contact member materialScrew threadGrounding line

The invention discloses a waterproof skeleton grounding card for communication lightning protection, and relates to the technical field of grounding cards, the waterproof skeleton grounding card comprises a body and a grounding wire, and also comprises a bolt, two sides of the body are provided with locking lugs, and the surface of each locking lug is provided with a threaded hole for the bolt to pass through and to be in threaded connection with the locking lug. The two ends of the grounding wire are connected with a first wiring lug and a second wiring lug respectively, the first wiring lug is fixedly connected with the locking lug through a bolt, a copper woven belt adheres to the inner side of the body, elastic pieces are arranged on the two sides in the body, the two elastic pieces abut against the copper woven belt, and the body comprises a high-temperature-resistant layer, a base material layer and a waterproof layer. According to the grounding card, the elastic sheet is arranged on the inner side of the body, so that the copper woven belt can be prevented from falling off, the firmness between the copper woven belt and the body is improved, and the waterproof layer is arranged on the body, so that the sealing and waterproof capability of the grounding card is improved.

Owner:MAXDAO

Nylon fiber with low surface friction coefficient and improved hydrophobicity and preparation method thereof

ActiveCN109989128BReduce apparent viscosityReduced effectArtifical filament manufactureMonocomponent polyamides artificial filamentPolymer scienceSide chain

The invention relates to a nylon fiber with low surface frictional coefficient and improved hydrophobicity and a preparation method thereof. The preparation method comprises mixing modified nylon masterbatch and nylon chips in a mass ratio of (0.5-5):(95-99.5), and performing melt spinning to obtain the nylon fiber with low surface frictional coefficient, wherein the modified nylon masterbatch ismainly composed of, by weight, 37-88.8% of nylon, 10-60% of PDMS (polydimethylsiloxane) and 0.2-3% of POSS with amino side chains and is made by adding the materials proportionally into a mixer, mixing well, transferring to a twin-screw extruder and dicing. The prepared nylon fiber with low surface frictional coefficient and improved hydrophobicity has both dynamic frictional coefficient and stationary frictional coefficient of less than 0.3, has an angle of contact with water being greater than 71 DEG, has good durability, spinnability and good mechanical properties, and has a good application prospect.

Owner:DONGHUA UNIV +1

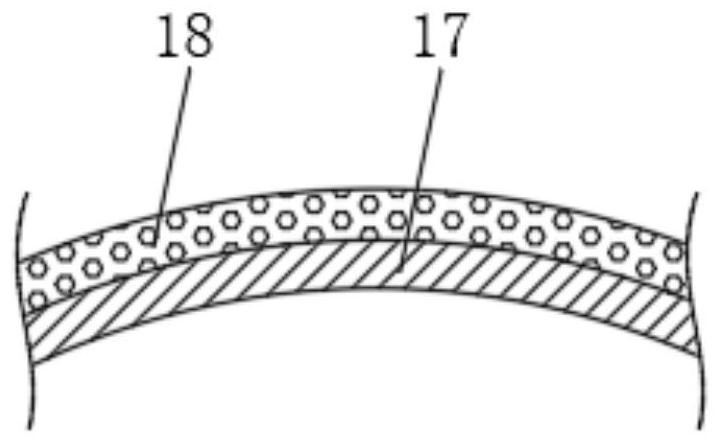

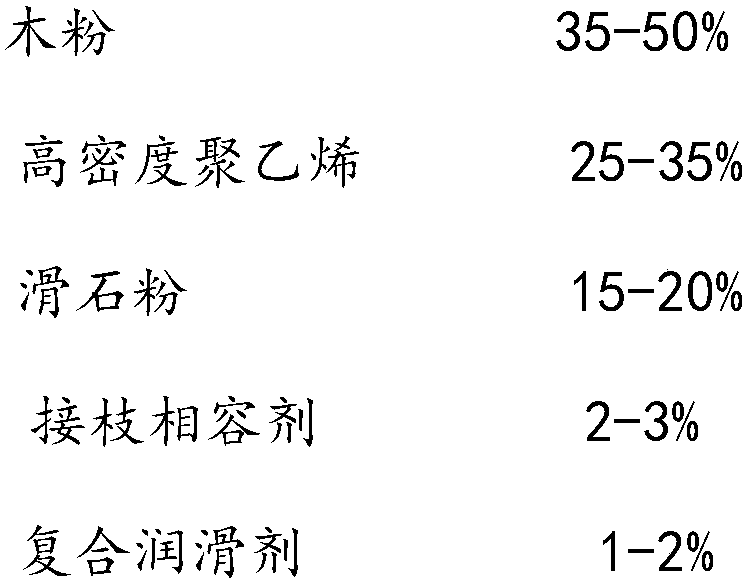

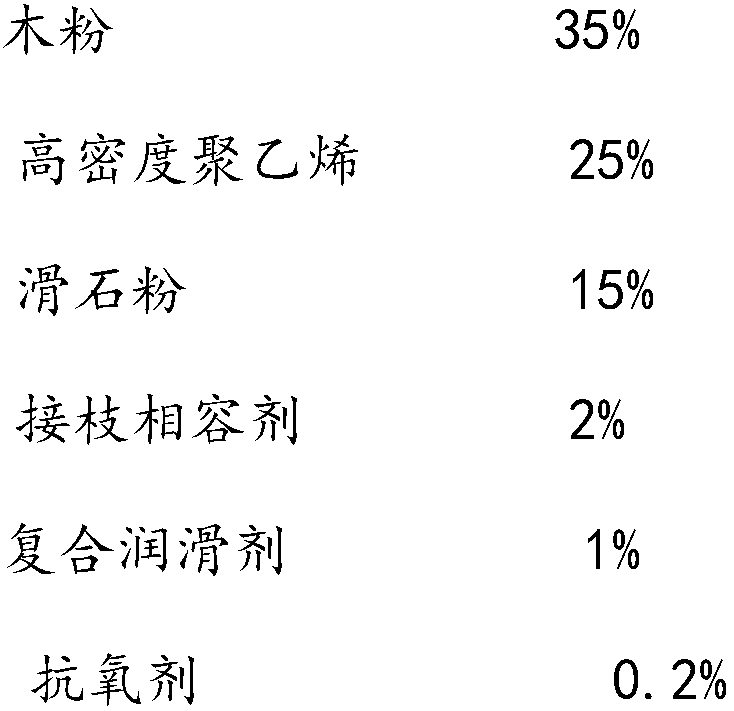

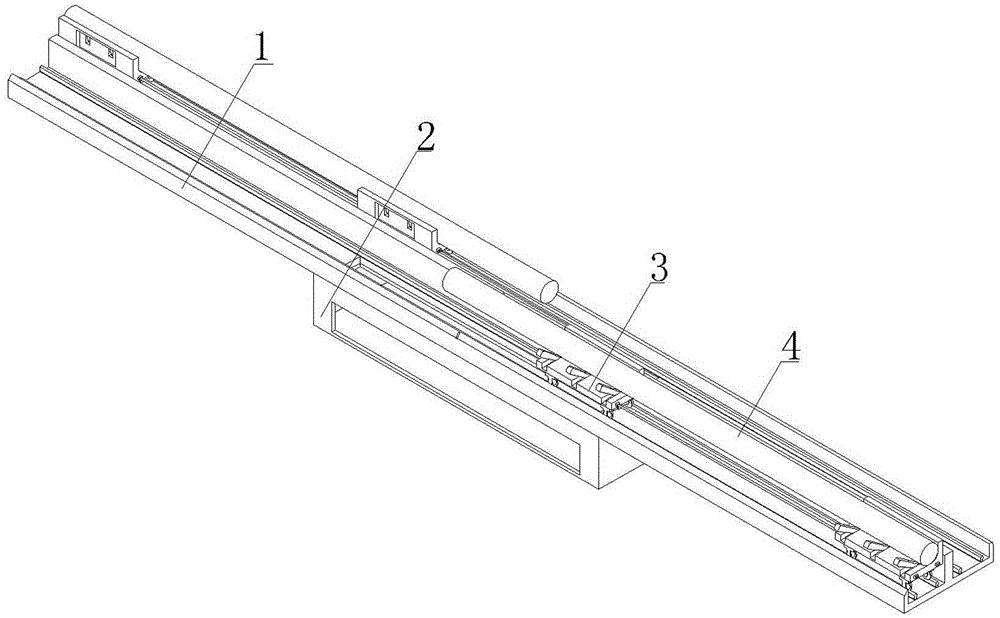

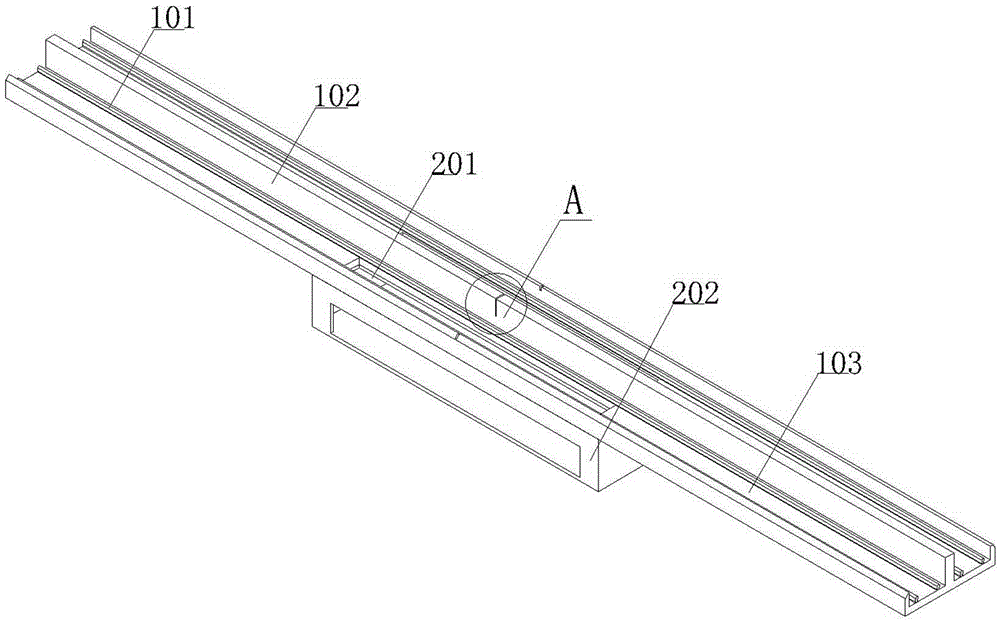

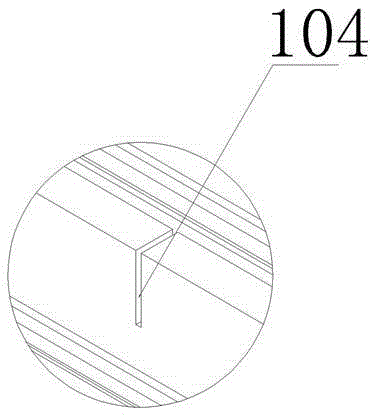

Skin-friendly wood-plastic composite board and molding process thereof

The invention discloses a skin-friendly wood-plastic composite board comprising the following components by mass: 35-50% of wood powder, 25-35% of high density polyethylene, 15-20% of talcum powder, 2-3% of a graft compatibilizer, 1-2% of a composite lubricant, 0.2-0.5% of an antioxidant, and 5-8% of an elastomer material. The end face of the composite board is divided into two layers, a surface layer is an elastomer material, the inner layer is a wood plastic material, and the two layers are firmly fused together. The surface layer has the characteristics of softness, high frictional force and good skin friendliness, people are not easy to slip when walking on the board, and the safety is high; the inner layer provides enough mechanical strength support to ensure long-term stable use of the product.

Owner:ANHUI RED FOREST NEW MATERIAL TECH

Aluminum bar constant-distance cutting and transporting mechanism

InactiveCN105290494AUniform lengthNo manual push requiredShearing machine accessoriesBogieDrive wheel

The invention discloses an aluminum bar constant-distance cutting and transporting mechanism in auxiliary cutting equipment. The aluminum bar constant-distance cutting and transporting mechanism comprises a base; multiple pairs of rails are laid on the base; the aluminum bar constant-distance cutting and transporting mechanism further comprises a reject chute and a traveling bogie set. The middle of the base is provided with a feed opening matched with the rails; the reject chute is arranged under the feed opening; a limiter is arranged in the middle of the rails. The traveling bogie set comprises a power bogie in rolling connection with the rails. The power bogie is mainly composed of an objective table, at least two rows of driving wheels arranged below the objective table and a driving mechanism connected with the driving wheels. The objective table is provided with grasps capable of fixing an aluminum bar. Each driving wheel is provided with a lap recording brake mechanism comprising a lap recorder and a brake portion connected with the driving wheel. By the adoption of the scheme, as the power bogie can accurately stop by reaching the appointed distance through cooperation of the lap recorders and the brake portions, the lengths of cut aluminum bars are uniform, the aluminum bars do not need to be pushed manually, and labor cost is reduced.

Owner:ZUNYI ZHIPENG HI TECH ALUMINUM COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com