Modified asphalt, and production process and application thereof

A technology of modified asphalt and production process, which is applied in the direction of building components, building insulation materials, construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

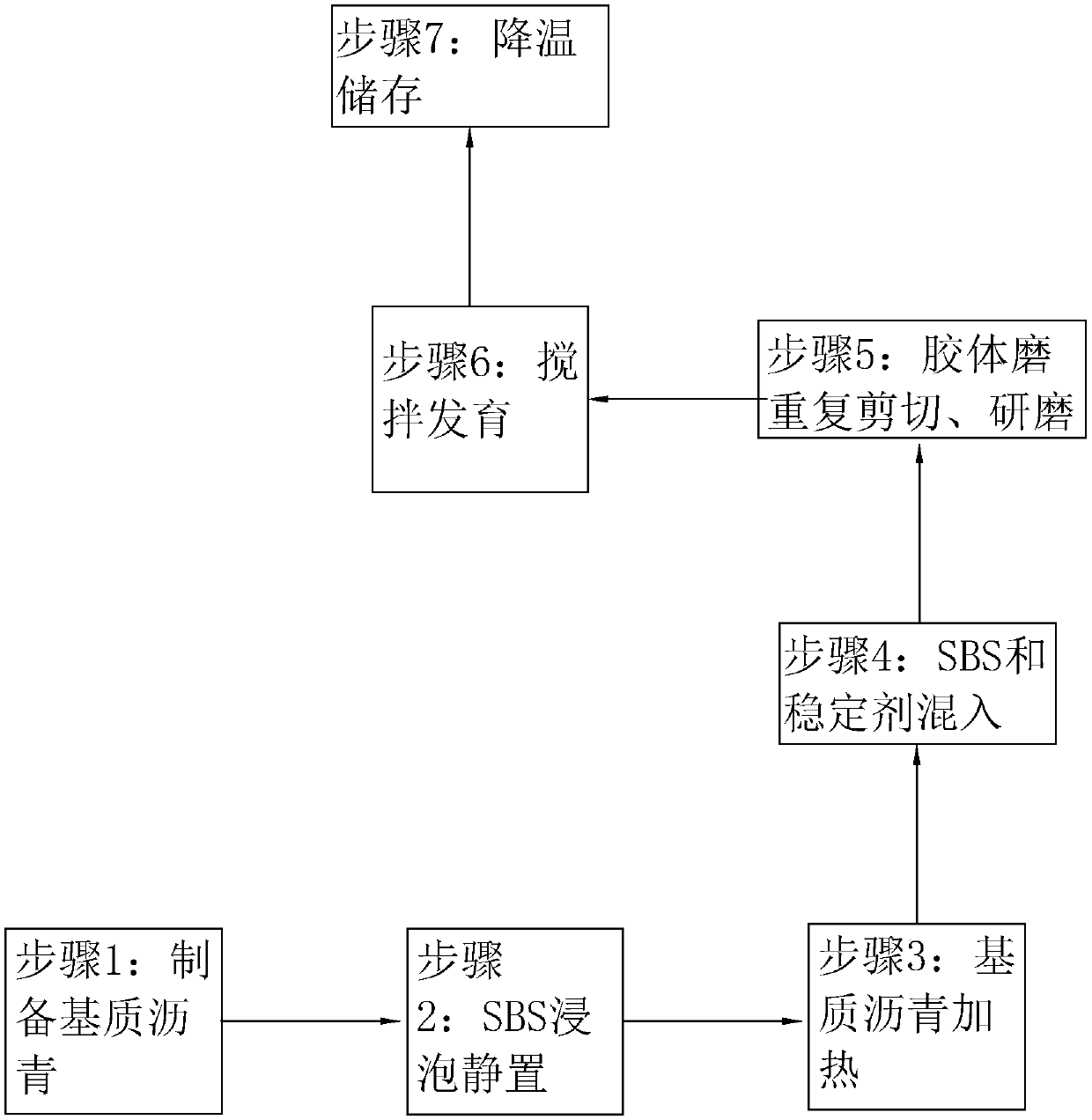

[0037] A modified asphalt production process, such as figure 1 shown, including the following steps:

[0038] Step 1: Prepare the base asphalt and keep stirring.

[0039] Step 2: Soak the SBS and let it stand for 10-50 minutes; cut the SBS into sheets of uniform size and then soak and swell. In this example, star-shaped SBS is used, and the density after swelling is 0.96-1.00g / cm 3 It is considered that the swelling is successful; then oil is poured into the swollen SBS, and the oil temperature is controlled to be 40-50°C, and the oil is naphthenic oil; the control standing time is 10 minutes in this embodiment, and the oil temperature is 40°C. ℃.

[0040] Step 3: Heat the base asphalt prepared in step 1 to 150-180°C, and pour it into the premixing tank. In this embodiment, the heating temperature is controlled to be 150°C.

[0041] Step 4: Pour the SBS and stabilizer processed in step 2 into the premix tank, mix and stir until evenly dispersed. In this embodiment, the st...

Embodiment 2

[0046] A modified asphalt production process, such as figure 1 shown, including the following steps:

[0047] Step 1: Prepare the base asphalt and keep stirring.

[0048] Step 2: Soak the SBS and let it stand for 10-50 minutes; cut the SBS into sheets of uniform size and then soak and swell. In this example, star-shaped SBS is used, and the density after swelling is 0.96-1.00g / cm 3 It is considered that the swelling is successful; then oil is poured into the SBS after it is swollen, and the oil temperature is controlled to be 40-50 ° C, and the oil adopts naphthenic oil; the control standing time is 50 minutes in the present embodiment, and the oil temperature is 50 °C. ℃.

[0049] Step 3: Heat the base asphalt prepared in step 1 to 150-180°C, and pour it into the premixing tank. In this embodiment, the heating temperature is controlled to be 180°C.

[0050] Step 4: Pour the SBS and stabilizer processed in step 2 into the premix tank, mix and stir until evenly dispersed. In...

Embodiment 3

[0055] A modified asphalt production process, such as figure 1 shown, including the following steps:

[0056] Step 1: Prepare the base asphalt and keep stirring.

[0057] Step 2: Soak the SBS and let it stand for 10-50 minutes; cut the SBS into sheets of uniform size and then soak and swell. In this example, star-shaped SBS is used, and the density after swelling is 0.96-1.00g / cm 3 It is considered that the swelling is successful; then oil is poured into the swollen SBS, and the oil temperature is controlled to be 40-50 ° C, and the oil is naphthenic oil; the control standing time is 20 minutes in this embodiment, and the oil temperature is 45 °C. ℃.

[0058] Step 3: Heat the base asphalt prepared in step 1 to 150-180°C and pour it into the premixing tank. In this embodiment, the heating temperature is controlled to be 165°C.

[0059] Step 4: Pour the SBS and stabilizer processed in step 2 into the premix tank, mix and stir until evenly dispersed. In this embodiment, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com