Nylon fiber with low surface friction coefficient and improved hydrophobicity and preparation method thereof

A surface friction, nylon fiber technology, applied in the field of fiber manufacturing, can solve problems such as poor compatibility, poor durability, and shedding of nylon, and achieve the effects of improving dispersion uniformity, hydrophobicity, and compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

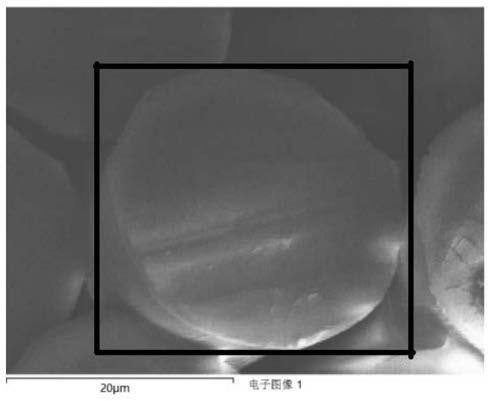

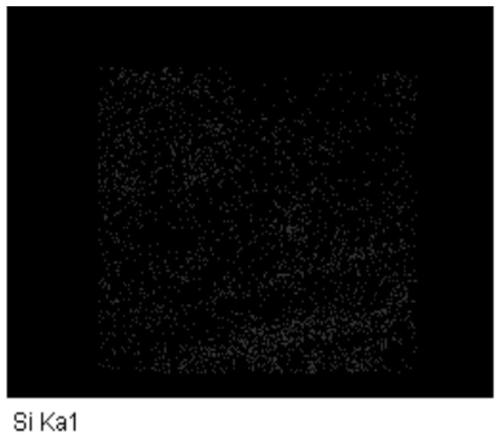

Image

Examples

Embodiment 1

[0030] A preparation method of nylon fibers with low surface friction coefficient and improved hydrophobicity, the steps are as follows:

[0031] (1) prepare modified nylon masterbatch;

[0032]First, add the mixture composed of nylon 66, PDMS with a number average molecular weight of 40w and aminoethylaminopropyl isobutyl cage silsesquioxane into a high-speed mixer and stir evenly. In the mixture, nylon 66, PDMS and aminoethyl The mass content of aminopropyl isobutyl cage silsesquioxane is 49.5wt%, 50wt% and 0.5wt% respectively, the rotation speed during stirring is 1500r / min, the temperature is 232°C, the time is 3min, and then transported to Melt extrusion and pelletizing in twin-screw extruder, the temperature of melt extrusion is 260°C;

[0033] (2) blending melt spinning;

[0034] The modified nylon masterbatch and nylon 66 slices were respectively placed in a vacuum oven and dried for 48 hours at a temperature of 120°C. The mass ratio of the modified nylon masterbatch...

Embodiment 2

[0039] A preparation method of nylon fibers with low surface friction coefficient and improved hydrophobicity, the steps are as follows:

[0040] (1) prepare modified nylon masterbatch;

[0041] First, add the mixture composed of nylon 66, PDMS with a number average molecular weight of 40w and aminoethylaminopropyl isobutyl cage silsesquioxane into a high-speed mixer and stir evenly. In the mixture, nylon 66, PDMS and aminoethyl The mass content of aminopropyl isobutyl cage silsesquioxane is 49.5wt%, 50wt% and 0.5wt% respectively, the rotation speed during stirring is 1500r / min, the temperature is 232°C, the time is 3min, and then transported to Melt extrusion and pelletizing in twin-screw extruder, the temperature of melt extrusion is 260°C;

[0042] (2) blending melt spinning;

[0043] The modified nylon masterbatch and nylon 66 slices were respectively placed in a vacuum oven and dried for 48 hours at a temperature of 120 ° C. The mass ratio of the modified nylon masterba...

Embodiment 3

[0046] A preparation method of nylon fibers with low surface friction coefficient and improved hydrophobicity, the steps are as follows:

[0047] (1) prepare modified nylon masterbatch;

[0048] First, add the mixture composed of nylon 66, PDMS with a number average molecular weight of 40w and aminoethylaminopropyl isobutyl cage silsesquioxane into a high-speed mixer and stir evenly. In the mixture, nylon 66, PDMS and aminoethyl The mass content of aminopropyl isobutyl cage silsesquioxane is 49.5wt%, 50wt% and 0.5wt% respectively, the rotation speed during stirring is 1500r / min, the temperature is 232°C, the time is 3min, and then transported to Melt extrusion and pelletizing in twin-screw extruder, the temperature of melt extrusion is 260°C;

[0049] (2) blending melt spinning;

[0050] The modified nylon masterbatch and nylon 66 slices were respectively placed in a vacuum oven and dried for 48 hours at a temperature of 120°C. The mass ratio of the modified nylon masterbatc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com