Patents

Literature

171 results about "Nylon fibre" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nylon is a manufactured fiber in which the fiber forming substance is a long-chain synthetic polyamide in which less than 85% of the amide-linkages are attached directly (-CO-NH-) to two aliphatic groups.

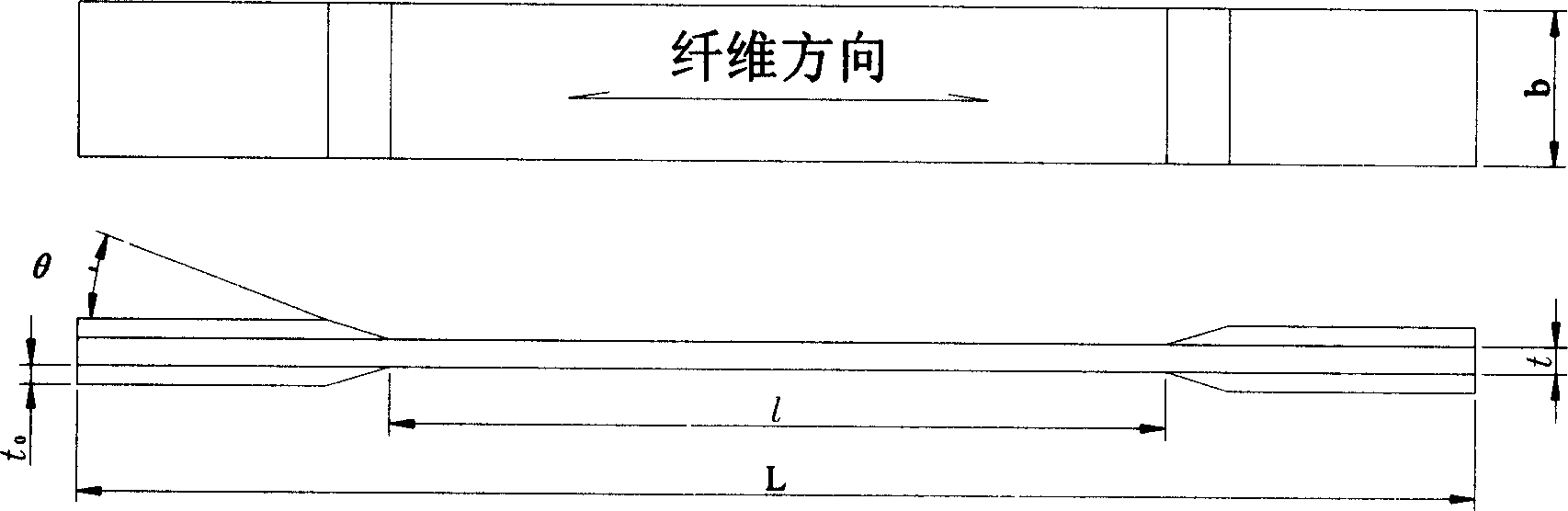

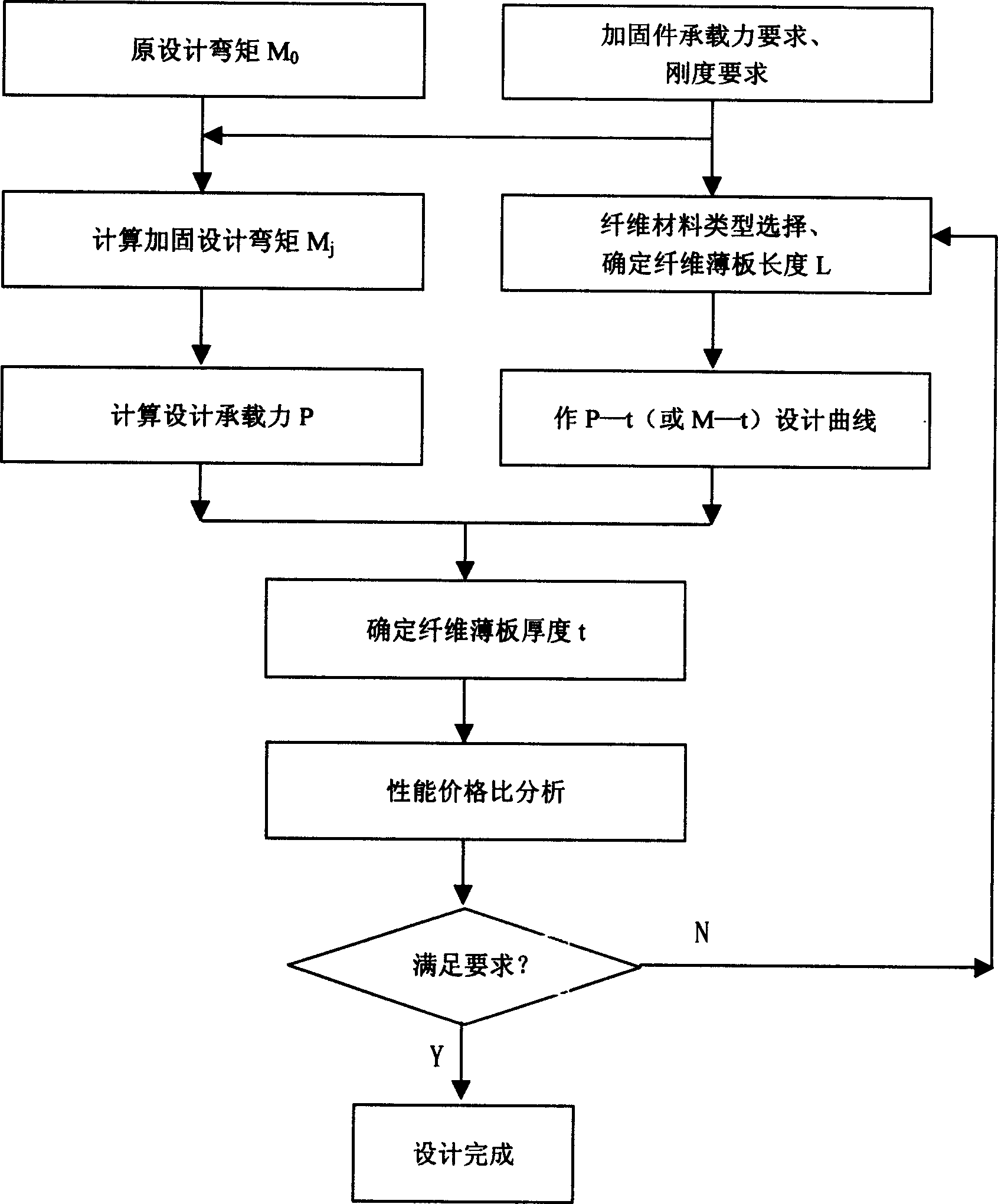

Fiber sheet plate and usage

ActiveCN1563557ASimple preparation processAdaptableBuilding repairsTextiles and paperGlass fiberEpoxy

This invention is a fibre sheet and its use. It contains: carbon fibre, aromatic nylon fibre or high strength glass fibre. After to weave them, soak them into soaking materials. This soaking liquid is composed with: liquid epoxy resin, solid epoxy resin and polyamide, the ratio of their weight is 0.8-1.3: 0.8-1.3: 0.8-1.3. This fibre sheet use for to reinforce the cement constructors. It contains: The surface treatment of cement; to provide the material for leveling. To glue the epoxy resin in the structural members they have crack or split. To compound the sticker and smear the glue on the fibre sheet surface.

Owner:SOUTH CHINA UNIV OF TECH

High performance concrete reinforced by assorted fiber

The present invention relates to a high-performance mixed fibre reinforced concrete, its composition includes (by volume %) high elastic modulas fibre 1%-5%, low elastic modulus fibre 0.2%-3% and the rest general concrete, the described high elastic modulus fibre is one of steel fibre, carbon fibre and glass fibre, and the described low elastic modulus fibre is one of vinylon fibre, polypropylene fibre, acrylic fibre, nylon fibre and polyethylene fibre. Said invention can be used for making manhole cover which not only has higher strength, but also has higher impact resistance.

Owner:SHANGHAI JIAO TONG UNIV

Layer-by-layer self-assembly polyaniline/nylon composite conductive fabric preparation method

InactiveCN101613943AEasy accessImprove conductivityFibre typesPolymer scienceHydrogen-Ion Concentrations

The invention relates a layer-by-layer self-assembly polyaniline / nylon composite conductive fabric preparation method, comprising the following steps: pretreating nylon fabric with 5-40g / L of sodium polystyrene sulfonate solution, performing two-dip-two-rolling, drying the fabric at 40-70 DEG C, soaking the fabric in a acid-doped mixed solution of aniline and ammonium persulfate, stirring the solution continuously, reacting for 15-40min, taking the fabric out to washing fully and drying, repeating the above operations n times (n is not less than 1), finally performing second doping for 15-40min in the acid solution of which the hydrogen ion concentration equals 1mol / L and washing and drying the fabric to obtain the polyaniline / nylon composite conductive fabric. The preparation method of the invention combines the padding technology which is frequently used in dyeing and finishing so that the reaction time is reduced, polyaniline can enter in the nylon fibre fast, the electric conductivity of the composite fabric is increased, and the cost and the pollution to the environment are lower.

Owner:DONGHUA UNIV

Fine denier or ultra-fine denier nylon fibre and production method thereof

ActiveCN101139749AImprove mechanical propertiesHigh strengthArtifical filament manufactureMonocomponent polyamides artificial filamentMasterbatchAntioxidant

The invention relates to a fine denier or super fine denier nylon fiber as well as relevant production method. The invention needs to solve the technical problem of providing a fine denier or super fine denier nylon fiber sized in smaller than 1 denier and relevant production methods. The invention fiber is characterized in that the fiber comprises nylon and a mixture of effective quantum of metal compound and effective quantum of assistant-antioxidant. The invented production method is as follows: Perform pre-smelting for the metal compound mixture and the nylon before mixing together and extrude to form additive shaped in masterbatch particles. The metal compound mixture shares 5 to 50 percent of total weight of additive; then, perform smelting filature for the additive masterbatch particles and nylon together.

Owner:HANGZHOU NORMAL UNIVERSITY +1

Ultraviolet-proof waterproof coating fabric

ActiveCN103774326AImproves UV resistanceImprove performanceFibre treatmentSynthetic resin layered productsYarnEmulsion

The invention provides an ultraviolet-proof waterproof coating fabric which comprises a base fabric layer and at least one coating, wherein one base layer and at least one coating, wherein the base fabric layer is interwoven by warps and yarns; the warps and yarns are respectively composed of 92-98wt% of nylon fibre and 2-8wt% of aluminium silicate fibre; the coating is coated on the base fabric layer and is composed of the following components in parts by weight: 40-60 parts of polyurethane emulsion, 3-6 parts of nano titanium oxide, 2-6 parts of nano zinc oxide, 3-7 parts of cross-linking agent, 5-8 parts of acrylate and 10-15 parts of solvent. According to the ultraviolet-proof waterproof coating fabric provided by the technical scheme, the base fabric layer has certain ultraviolet-proof performance; after being coated by the coating, the base fabric layer has high ultraviolet-proof capability; the coating has stable performance, can effectively adapt to strong ultraviolet environments and meanwhile has certain waterproof performance.

Owner:NANTONG QUANJI TEXTILE COATING

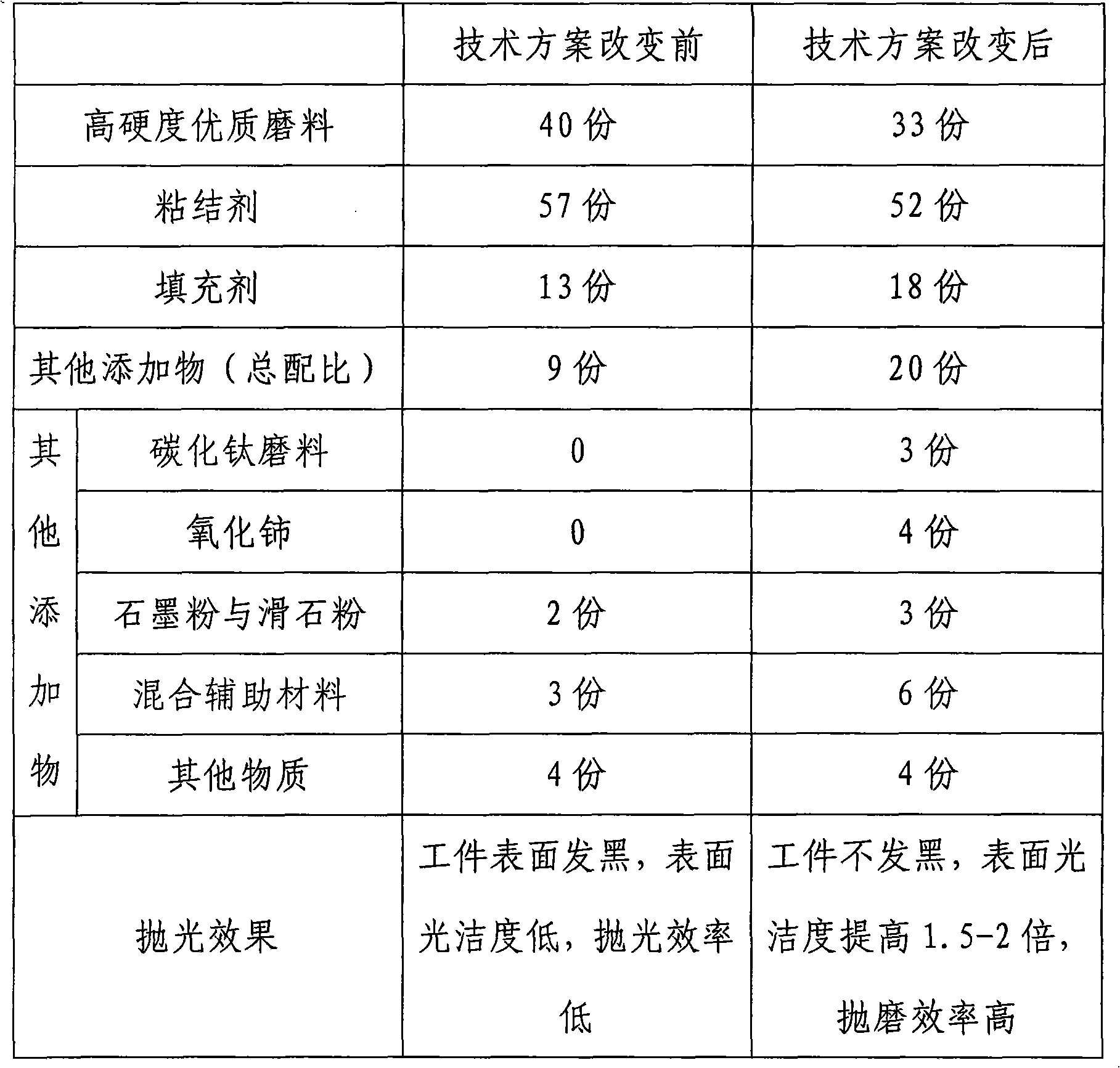

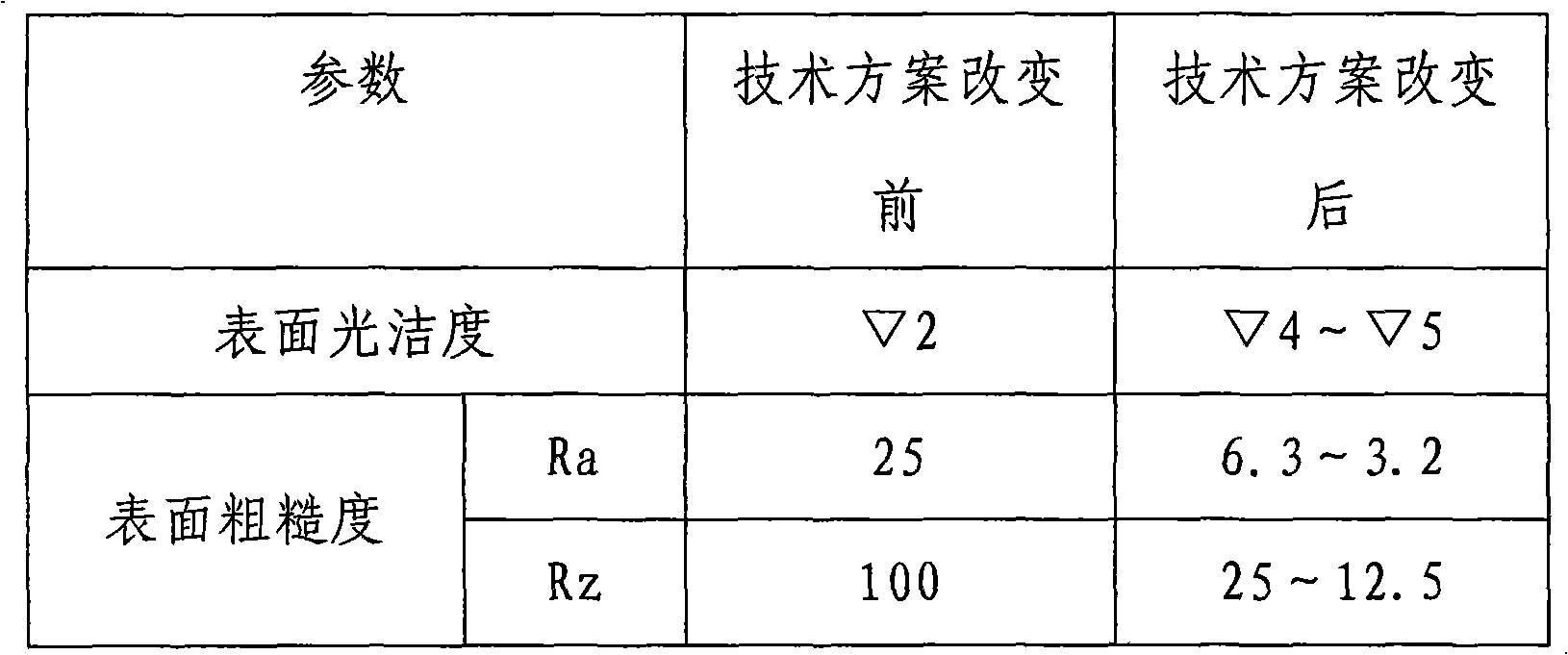

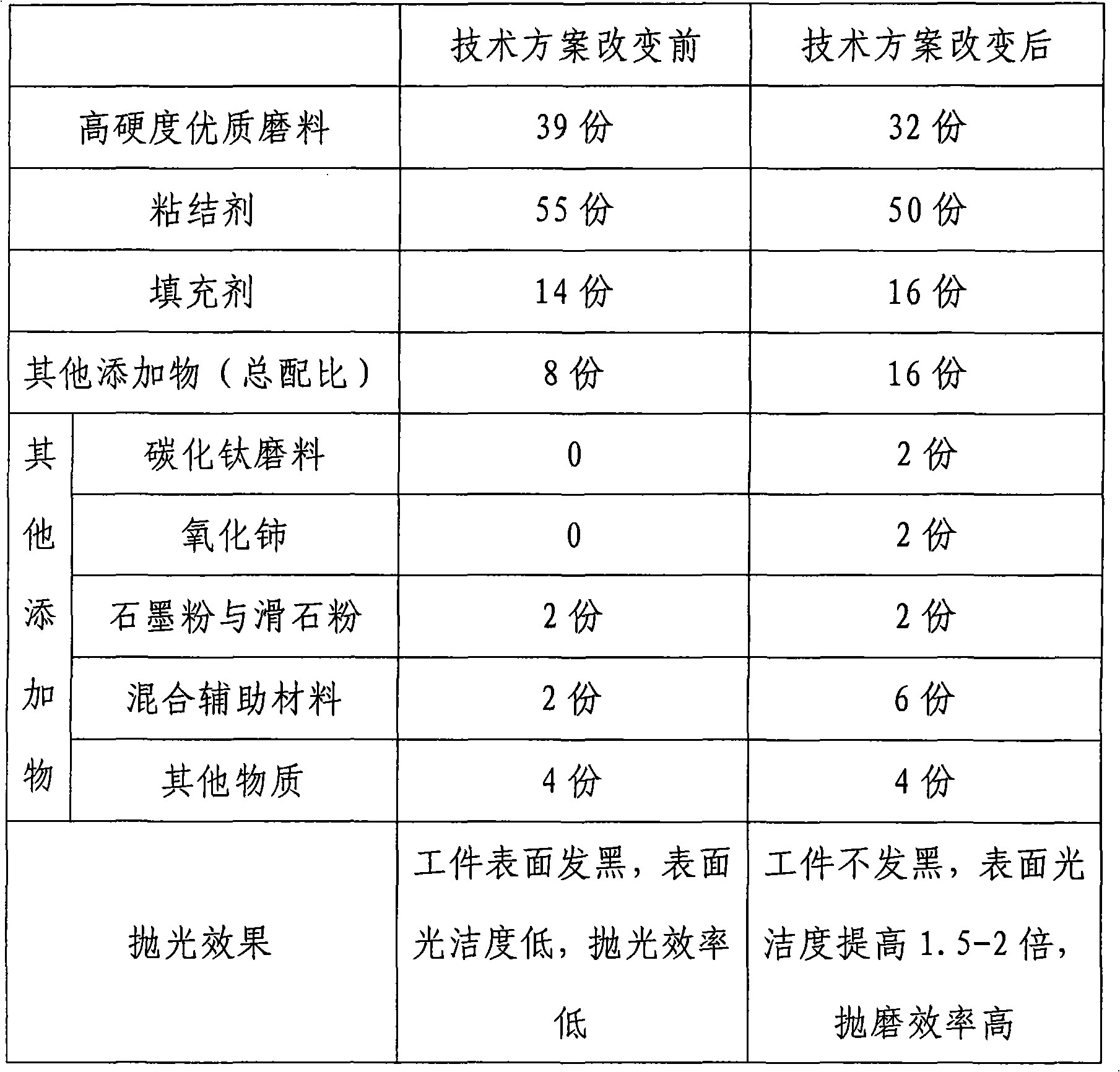

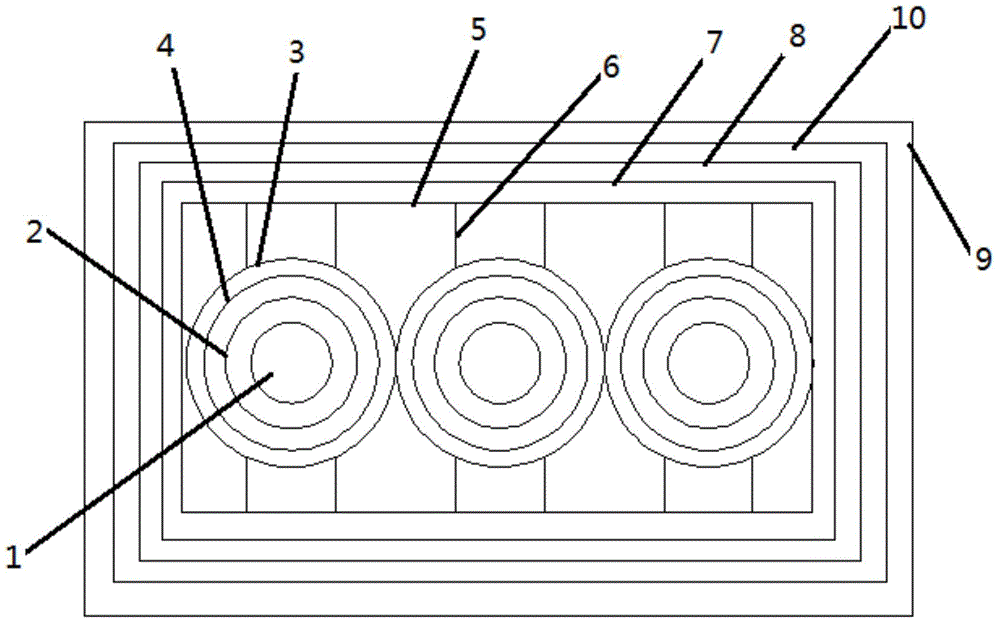

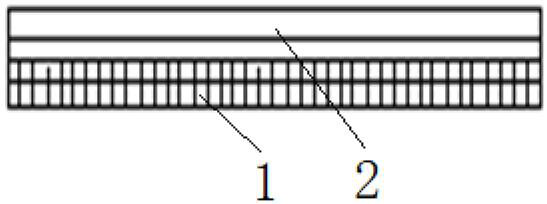

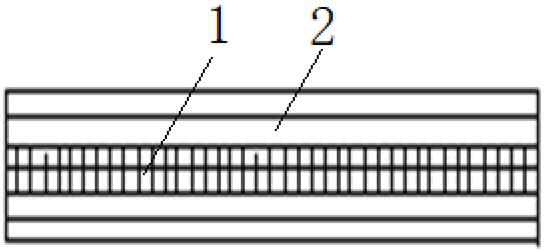

Nylon wheel and preparation method thereof

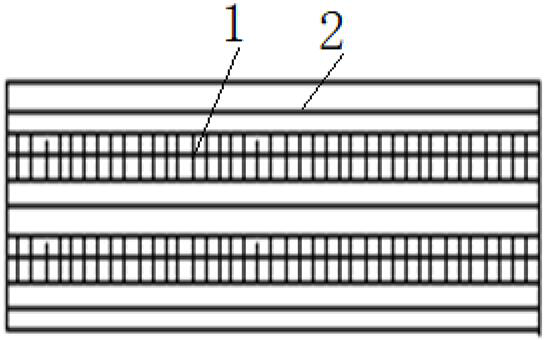

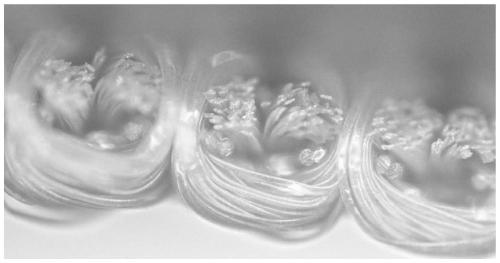

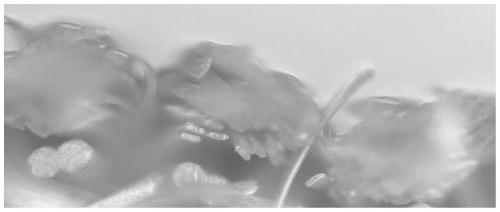

InactiveCN101570005AGood self-sharpeningGood polishing effectOther chemical processesFlexible-parts wheelsSurface finishPolymer science

The invention relates to a nylon wheel and a preparation method thereof. The nylon wheel comprises a nylon fiber silk screen (1) with a reticular fiber structure and a working layer (2) poured in the nylon fiber silk screen (1), wherein the working layer (2) is a mixture prepared from a high-hardness high-quality grinding material, a binding agent and a filling agent, and the weight proportion of the nylon fiber silk screen (1) to the mixture is 1:5-7. The method for preparing the nylon wheel comprises the following steps: 1) adding the high-hardness high-quality grinding material and the filling agent into the binding agent in an agitator tank in turn according to the sequence, stirring the mixture evenly under a condition of heating; 2) pouring the liquid mixture obtained in the step 1) into the nylon fiber silk screen, and performing an extrusion process so that the material is evenly distributed in the nylon fiber silk screen; and 3) according to the diameter and the thickness of the nylon wheel to be produced, performing laminating processing on the nylon fiber silk screen, cutting off and processing the nylon fiber silk screen into required shapes after standing, and performing hot working under a condition of heating to obtain the finished product. The nylon wheel has the advantages of low cost, long service life, capability of improving the surface finish quality of a workpiece, and high polishing efficiency. The method for preparing the nylon wheel has convenient manufacture and high production efficiency.

Owner:YANGJIANG WEIYI POLISHING MATERIAL

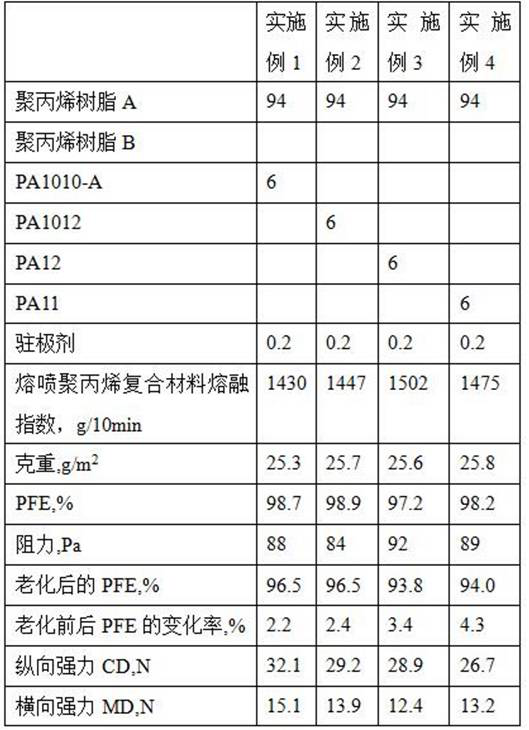

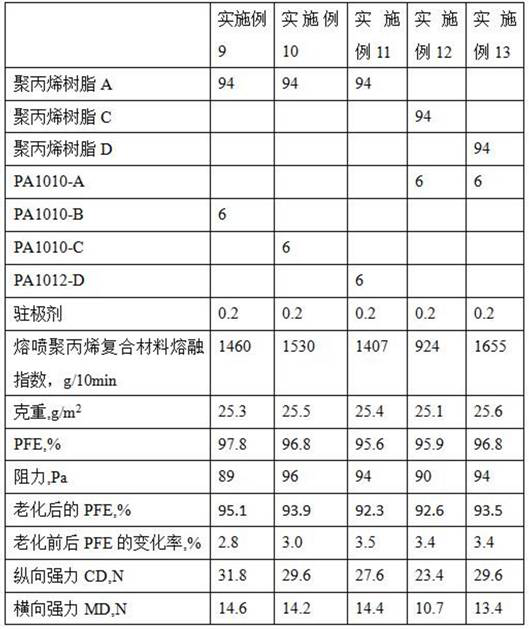

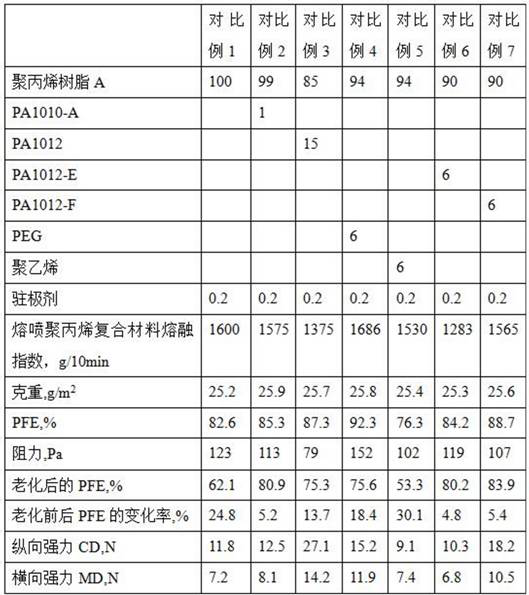

Melt-blown polypropylene composite material, and preparation method and application thereof

ActiveCN111732790AIncrease viscosityIncrease the rate of crystallizationNon-woven fabricsYarnPolypropylene composites

The invention discloses a melt-blown polypropylene composite material. The composite material comprises, by weight, 87-98 parts of polypropylene resin, 2-13 parts of long carbon chain nylon resin and0.1 to 5 parts of an electret agent. Firstly, by means of the low compatibility of polypropylene resin and the long carbon chain nylon resin and the relatively high crystallization speed of the long carbon chain nylon resin, thick long chain nylon resin filaments and thin polypropylene resin filaments can be obtained after melt-blowing filamentation, and the filtering efficiency can be improved while the filtering resistance is reduced; secondly, the long carbon chain nylon resin contains polar amido bonds, so that the dispersion effect of the electret is improved after the long carbon chain nylon resin is easily combined with the electret, meanwhile, the nylon fibers can be subjected to electret polarization and cooperate with the electret agent to improve the filtering efficiency; and thirdly, due to the existence of the long carbon chain nylon crude fiber yarns with higher strength, the breakage probability of the melt-blown cloth in the winding process can be reduced.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

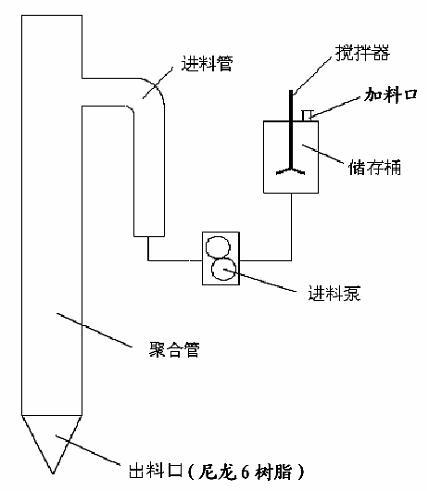

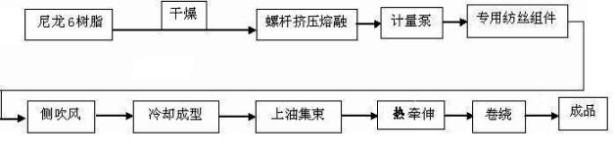

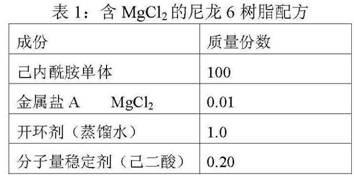

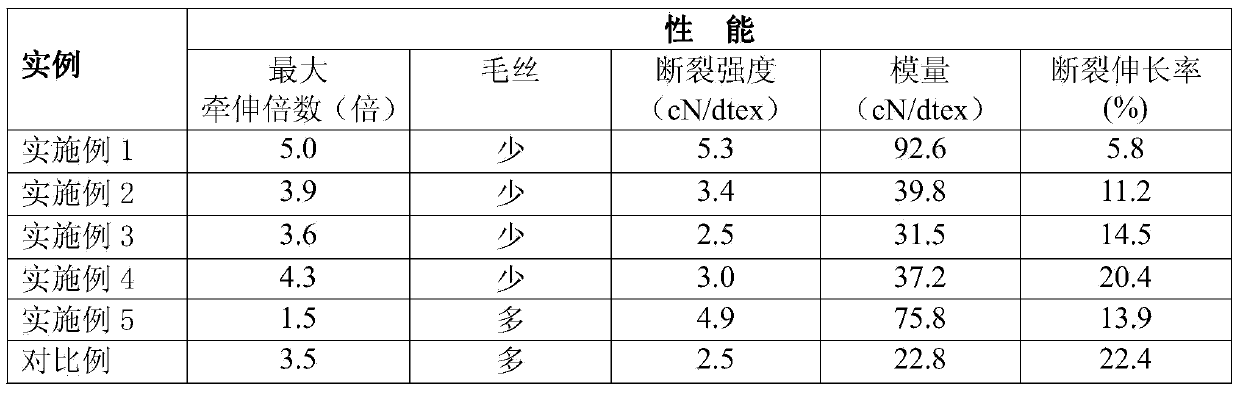

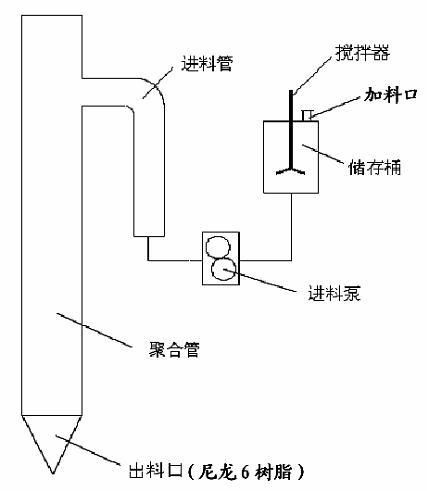

Nylon-6 resin, nylon-6 fiber and preparation method thereof

InactiveCN102161755AHigh tensile strengthSlow crystallization rateMelt spinning methodsArtifical filament manufacturePolymer scienceCaprolactam

The invention relates to the field of spinning materials, and firstly provides a nylon-6 resin which is prepared by the polymerization reaction of a caprolactam monomer and fixed melt of compounds of metals in the second main group, wherein based on the total weight of the caprolactam monomer, the weight of the compounds of metals in the second main group is 0.01-1.0%. The invention also provides a nylon-6 fiber which is prepared from the nylon-6 resin by melt spinning. By using the nylon-6 resin and the preparation method provided by the invention, the fine-denier or superfine-denier nylon-6 fiber with a fineness of about 0.10-1.0dtex can be obtained. Both the strength and the breaking elongation of the fiber conform to post-weaving requirements. Besides, the invention fills up the gap that the fine-denier / superfine-denier nylon-6 filament can not be produced by the conventional high-speed spinning method home and abroad, and increases the technological content and added value of the nylon-6 fiber product.

Owner:HANGZHOU NORMAL UNIVERSITY

Preparation method of LiCl modified nylon 6 fiber

InactiveCN103469346AIncrease draft ratioHigh breaking strengthFilament forming substance formingArtificial thread manufacturing machinesHydrogenSurface layer

The invention relates to a preparation method of LiCl modified nylon 6 fiber and particularly relates to a method for deeply coating LiCl by high-speed blending and then preparing the modified nylon 6 fiber. The method comprises the following steps: firstly slicing the LiCl and nylon 6, respectively drying, removing crystal water in the LiCl and water in nylon 6 slices, further deeply coating different contents of the LiCl in surface layers of the nylon 6 slices by using a high-speed blending machine to prevent the situation that the LiCl is exposed in air and absorbs the water to affect the smooth operation of spinning, then performing melt spinning and heat drawing on the treated nylon 6 slices, performing pressure washing to remove monomers in the nylon 6 fiber and simultaneously remove the LiCl to enable the nylon 6 fiber to reform hydrogen bonds, and finally performing vacuum heat setting. According to the method disclosed by the invention, the problem that the LiCl absorbs water before spinning, so that spinning processing is influenced, can be effectively solved, and the prepared nylon 6 fiber has the advantages of small fiber number, high strength and excellent comprehensive mechanical properties, and can be widely applied to the clothing field and the industrial field. The preparation process is simple, the production period is short, the cost is low, and the method is suitable for industrial production.

Owner:DONGHUA UNIV

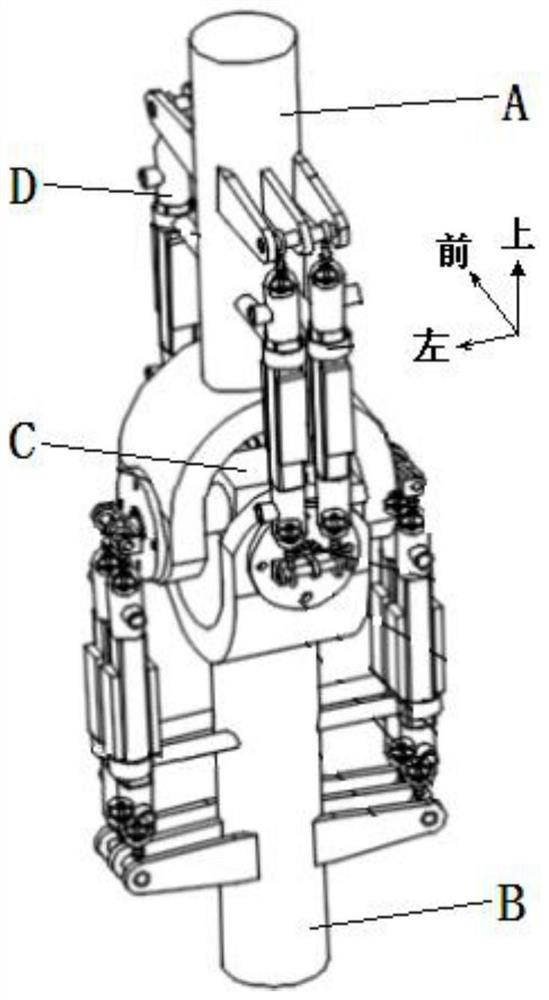

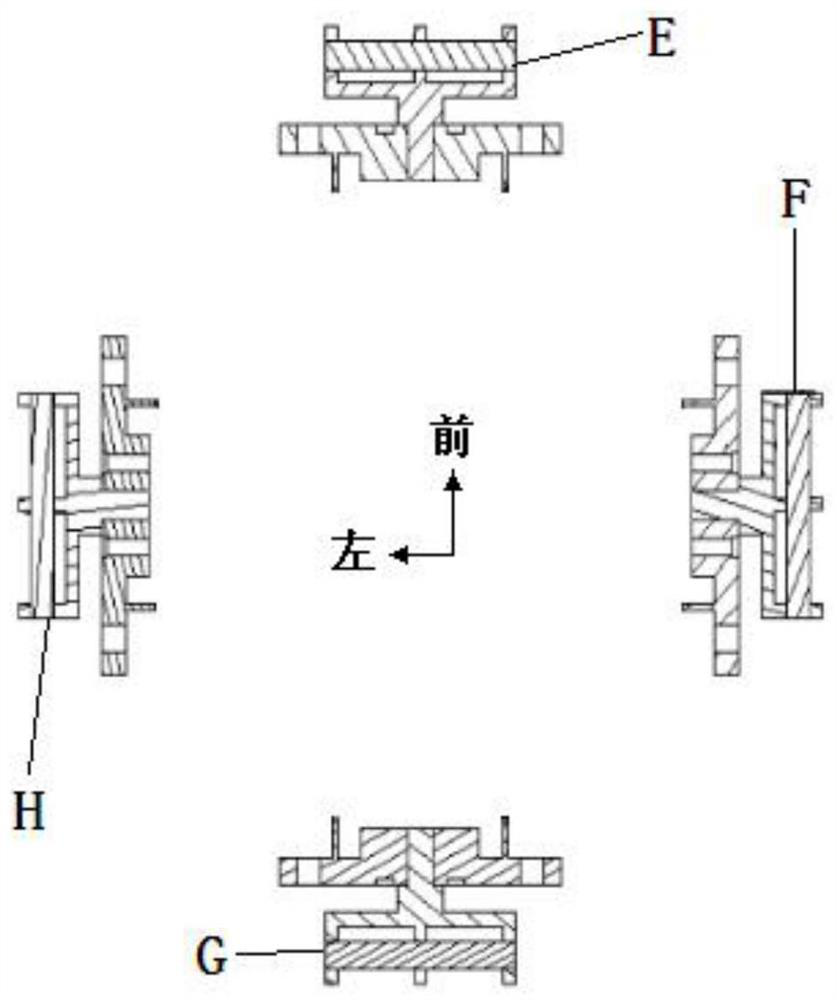

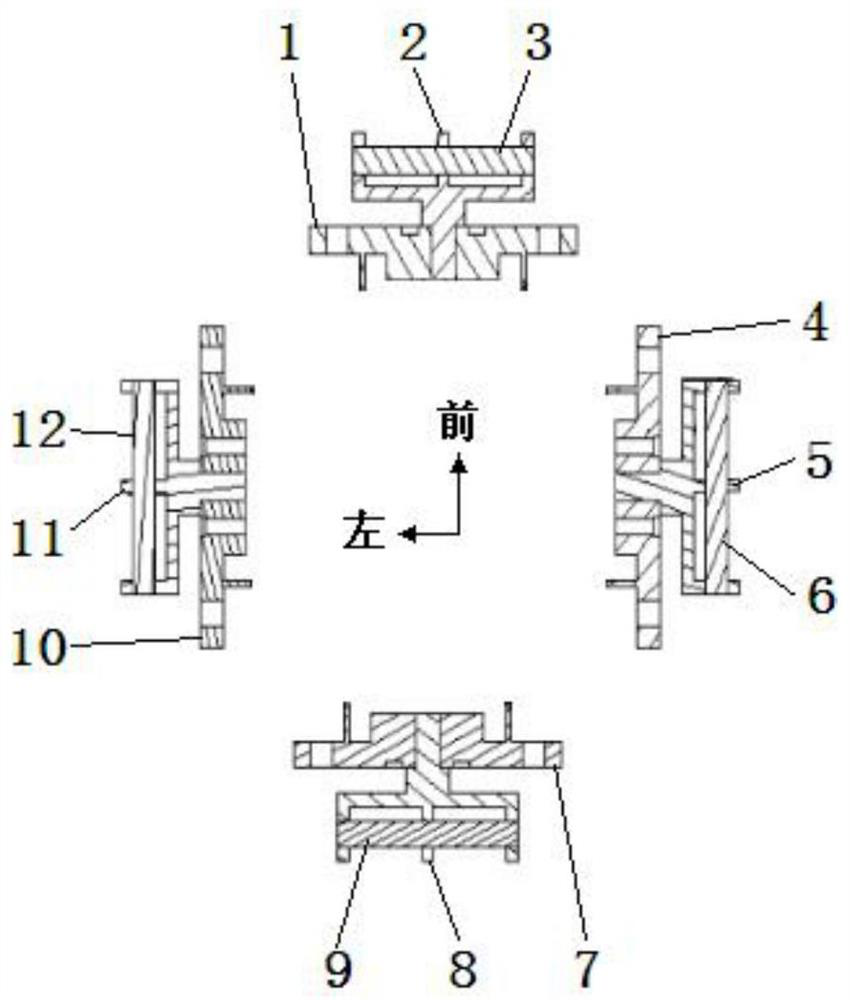

Knee joint driven by flexible driver

The invention discloses a knee joint driven by a flexible driver, and belongs to the technical field of biomimetic robots. According to the knee joint driven by the flexible driver, a biomimetic femurand a biomimetic tibia are arranged up and down, a simulated cruciate ligament is positioned between a biomimetic femoral condyle of the biomimetic femur and a biomimetic tibial condyle of the biomimetic tibia, and the biomimetic femur and the biomimetic tibia are separately provided with two bionic muscle pairs. Bionic muscle is attached to a biomimetic tendon and is fixed to a fixed ring. According to the knee joint driven by the flexible driver, super-spiral silver-plated nylon fibers are integrated into one driving unit to be applied to the knee joint, the spiral silver-plated nylon fibers are driven by electric heat to contract, and high-response, lag-free and easily-controlled linear contraction can be achieved; meanwhile, the rapid refrigeration effect of deionized water and semiconductor refrigeration is adopted, and high-frequency driving of the flexible driver can be achieved; and according to the knee joint driven by the flexible driver, the spiral silver-plated nylon fibers, the deionized water and semiconductor refrigeration equipment are integrated in one small silica gel, the deionized water is sealed by magnetofluid sealing equipment, so that the flexible driver iswell applied to the knee joint.

Owner:JILIN UNIV

Spinning process for antistatic and antibacterial nylon 6DTY high elastic filament

InactiveCN102766933AWith mechanical propertiesImprove antibacterial propertiesElectroconductive/antistatic filament manufactureMelt spinning methodsPolymer scienceNylon 6

The present invention relates to a spinning process for an antistatic and antibacterial nylon 6DTY high elastic filament, which is prepared from raw materials comprising nylon 6 chips and additives by a POY-DTY process. The prepared DTY high elastic filament has antistatic and antibacterial function and good stability, and can meet different requirements of post-weaving finishing.

Owner:WUJIANG YATAI CHEM TEXTILE

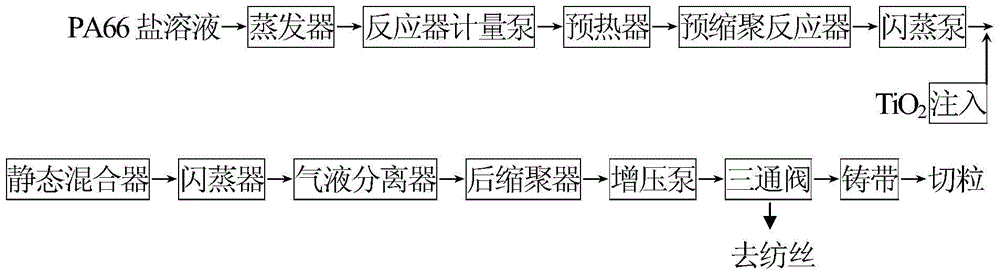

Method for preparing nano-TiO2 nylon 66 resin and fibre having anti-ultraviolet function

InactiveCN104629042AWith UV shielding functionWith sun protection and heat insulationMelt spinning methodsMonocomponent polyamides artificial filamentPolyesterYarn

The invention discloses a method for preparing nano-TiO2 nylon 66 resin and fibre having an anti-ultraviolet function, belonging to the technical field of fibre and textiles. The method disclosed by the invention comprises the following steps: injecting TiO2 suspension into a polymer melt at the outlet of a flash evaporation pump in the condensation polymerization process of nylon 66 at first, and then, carrying out post condensation polymerization of the polymer melt injected with the TiO2 suspension so as to obtain nano-TiO2 nylon 66 resin; and then, carrying out melt spinning of the nano-TiO2 nylon 66 resin so as to obtain nano-TiO2 nylon 66 fibre. The nylon 66 fibre having excellent properties and the anti-ultraviolet protection function can be manufactured from the nylon 66 resin manufactured by the invention through a POY-DTY (Polyester Pre-Oriented Yarn-Draw Texturing Yarn) spinning technology; and the fibre can be processed into high-quality clothes or costume materials having gentle lustre, soft hand feeling and comfort, good air permeability, abrasion resistance and easy rinsing property and having anti-ultraviolet and nursing functions.

Owner:LIAONING YINZHU CHEMTEX GROUP

Process for producing nylon fibre under low temperature

InactiveCN101311388ALower spinning temperatureReduce energy consumptionMelt spinning methodsArtifical filament manufactureRare earth metal compoundsEnergy consumption

The invention discloses a method for producing nylon fiber under low temperature, which includes adding a rare-earth metal compound before or when the nylon is in melted state and conducting the spinning of the molten mass under low temperature between 160 DEG C and 250 DEG C. The energy consumption and cost of the method are low with more convenient and safer industrial operations.

Owner:PEKING UNIV +1

High-strength nylon composite and preparation method thereof

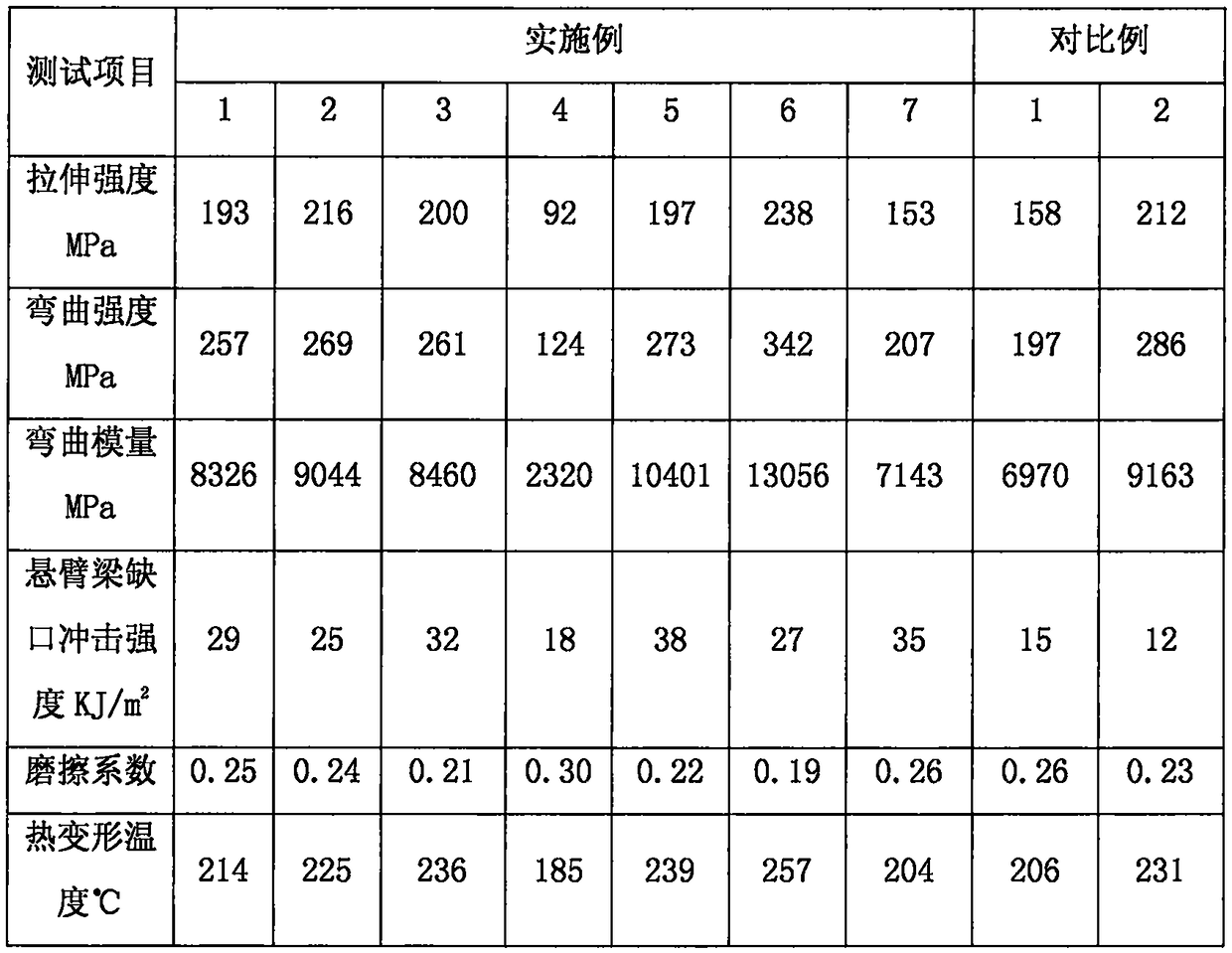

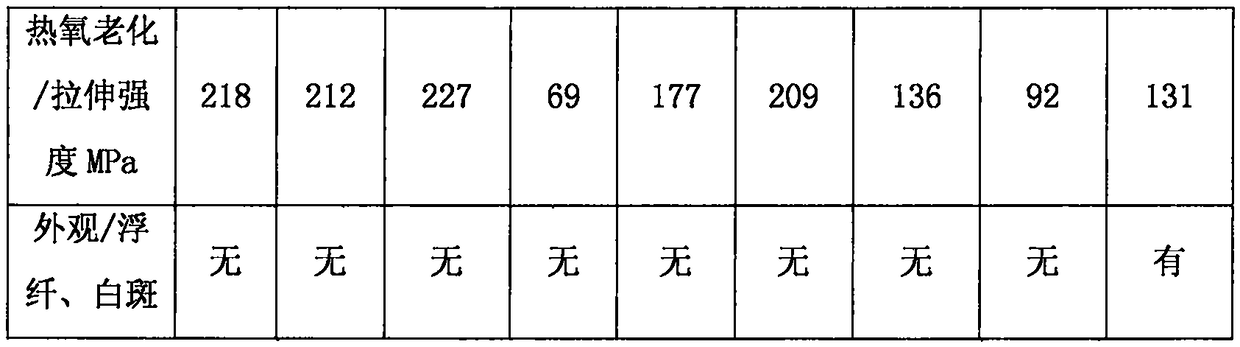

The invention discloses a high-strength nylon composite and a preparation method thereof. The composite is prepared from raw materials in percentage by mass as follows: 40wt%-99wt% of nylon, 0-40wt% of fiber, 0.05wt%-20wt% of a multifunctional material, 0.1wt%-2wt% of an oxidative aging resisting agent and 0.1wt%-2wt% of a lubricant. The preparation method of the composite comprises the steps as follows: nylon, the self-made multifunctional material, the oxidative aging resisting agent and the lubricant are uniformly mixed in a high-speed mixer in the mass ratio, a premix is obtained for lateruse, the premix is added from a main feeding port of a twin-screw extruder, short chopped fiber or continuous long fiber is added from a first side feeding port in proportion, for example, the self-made multifunctional material is added from a second side feeding port of the extruder in proportion in a filler form, the temperature of the extruder is controlled at 210-280 DEG C, the obtained material and drawn out, cooled and granulated, and the composite is obtained. Compared with the prior art, the composite has the advantages that the self-made multifunctional material has a synergistic effect with fiber after being added, the rigidity, toughness and thermal deformation of the prepared composite are substantially improved, meanwhile, the prepared composite material has no floating fiberand white spots in appearance, high wear resistance and lower strength reduction after thermo-oxidative aging.

Owner:BEIJING INST OF AEROSPACE TESTING TECH +1

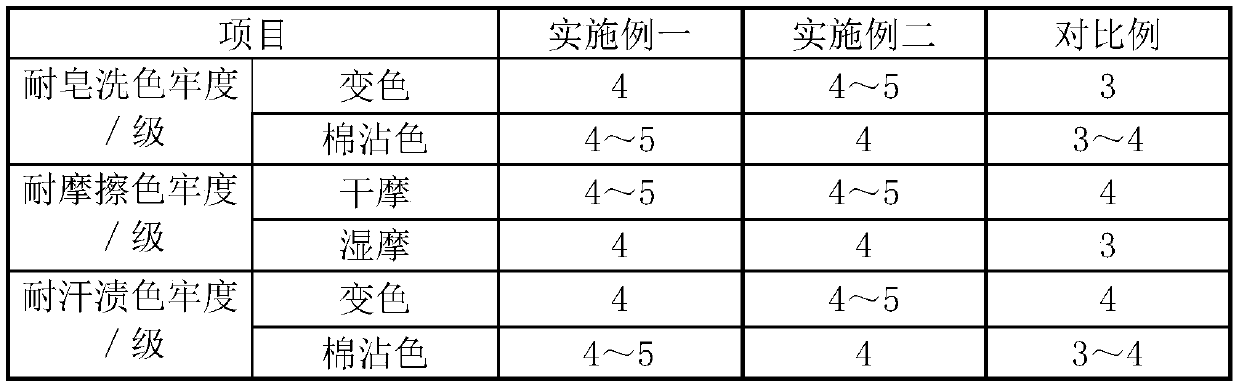

Production technology of beam-dyed double-layer two-way stretch fabric

The invention discloses a production technology of beam-dyed double-layer two-way stretch fabric. The production technology comprises the following steps: preparation of a surface beam, dyeing pretreatment of the surface beam, dyeing of the surface beam, soaping of the surface beam, foam slashing of the surface beam, preparation of a lining beam, pretreatment of the lining beam, dyeing of the lining beam, soaping of the lining beam, foam slashing of the lining beam, weaving and after finishing. According to the production technology of the beam-dyed double-layer two-way stretch fabric, the surface is formed by interweaving nylon fiber core spun yarn, and the lining is formed by interweaving corn spun yarn taking tencel and Coolmax as a coating layer. According to the double double-layer two-way stretch fabric, the surface has wear resistance of nylon fiber, the lining has moisture absorption and removal effect of the tencel and the Coolmax fiber, and the creativity and durability of the fabric are improved. Besides, yarn hairiness and neps on warp can be reduced by beam dyeing sizing, so that weaving is performed smoothly. The process of the production technology can be shortened and production efficiency can be improved.

Owner:浙江鸣春纺织股份有限公司

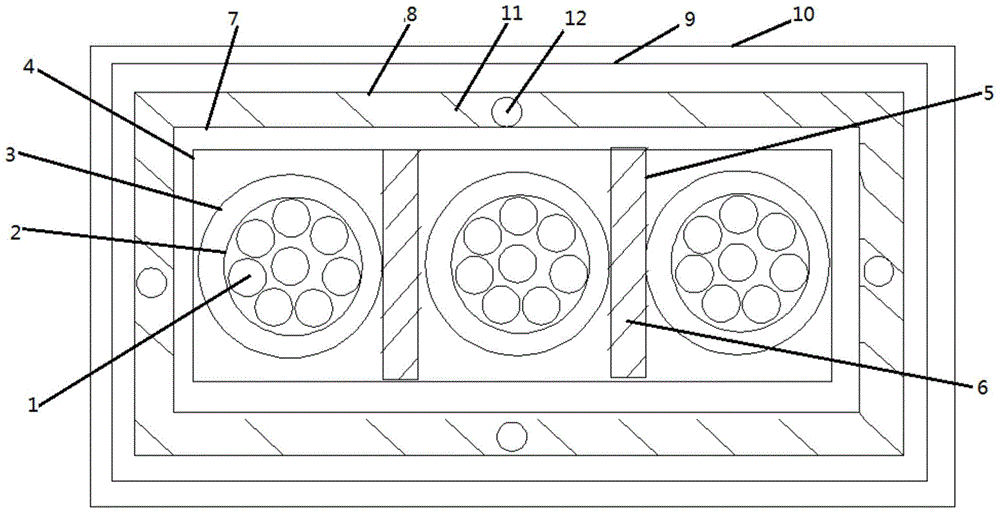

Mining cable of flat structure

InactiveCN103985447AImprove stress resistanceImprove practicalityFlat/ribbon cablesInsulated conductorsPolyesterFluoroplast

The invention discloses a mining cable of a flat structure. The mining cable comprises a plurality of wires. The wires are twisted and bundled into multiple sets. An isolating layer wraps each set of wires. Insulating layers wrap the isolating layers of the multiple sets of wires respectively. The multiple sets of wires are horizontally arrayed in parallel. An aluminum-polyethylene bonding layer wraps all the insulating layers of the multiple sets of wires. Vertical nylon fiber frameworks are arranged at the portions, between the adjacent sets of wires, in the aluminum-polyethylene bonding layer. High-temperature-resistant filaments are wound around the outer surfaces of the nylon fiber frameworks. A ceramic silicone rubber flame-retardant layer, a medal shielding layer, a tear-resistant layer and a fluoroplastic protective sleeve layer sequentially wrap the aluminum-polyethylene bonding layer, wherein the tear-resistant layer is formed by weaving polyester silks. The metal shielding layer is filled with magnesium oxide powder, and steel ropes are arranged in the magnesium oxide powder. The mining cable is simple in structure; the frameworks are added to the mining cable of the flat structure, and therefore pressure resistance of the whole cable is improved, practicability is higher, and meanwhile flame retardance and high temperature resistance are high.

Owner:ANHUI SAIHUA CABLE

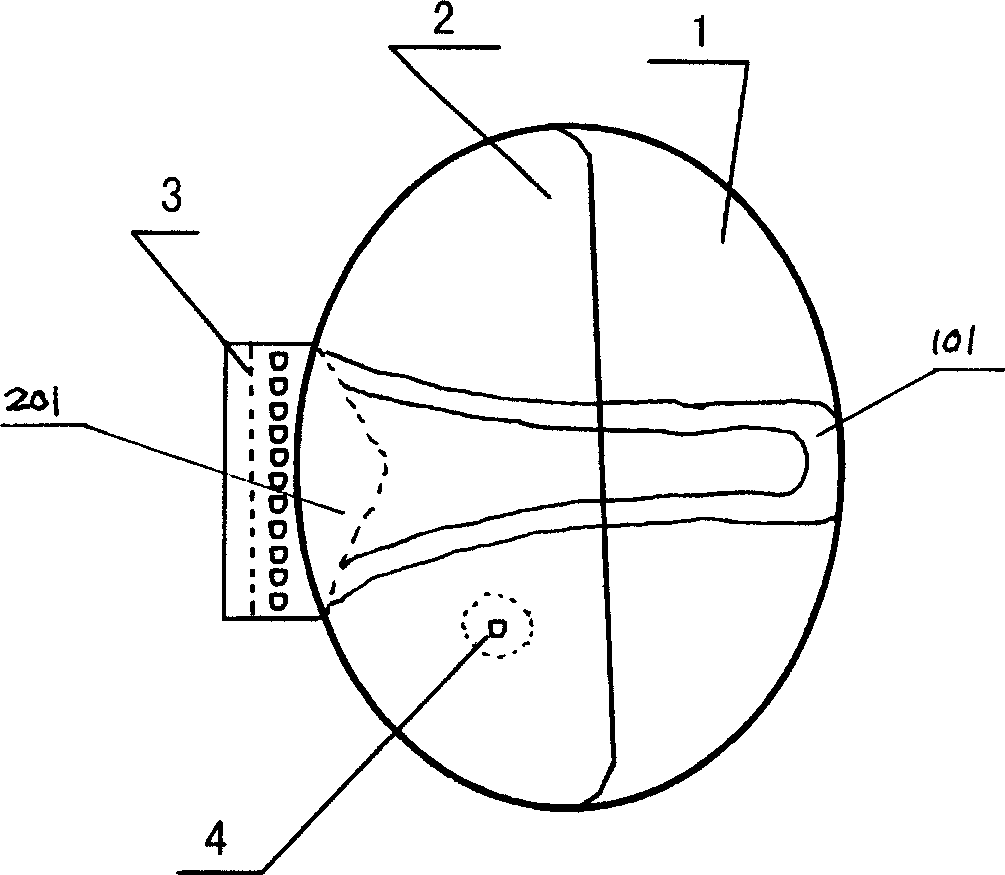

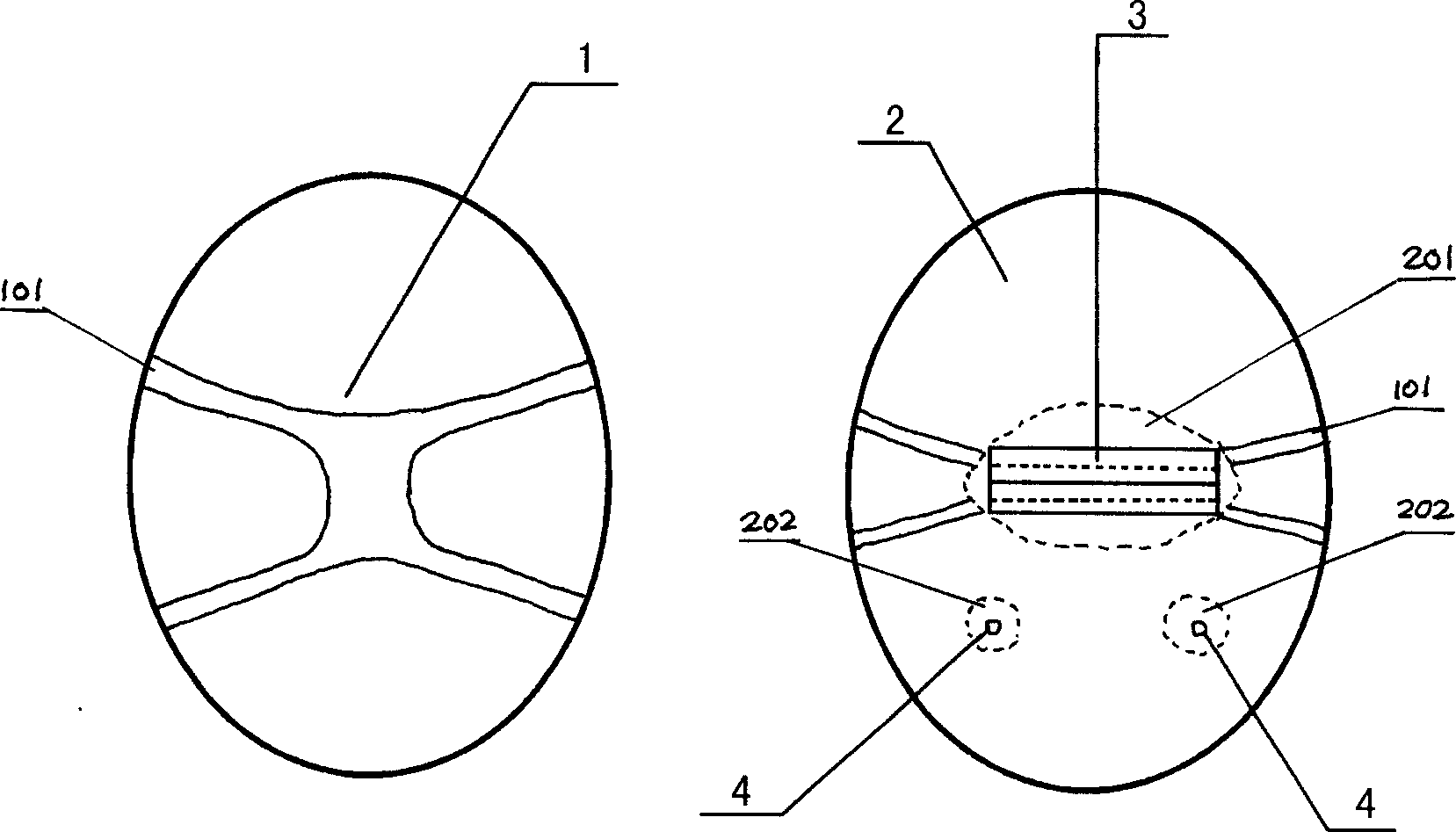

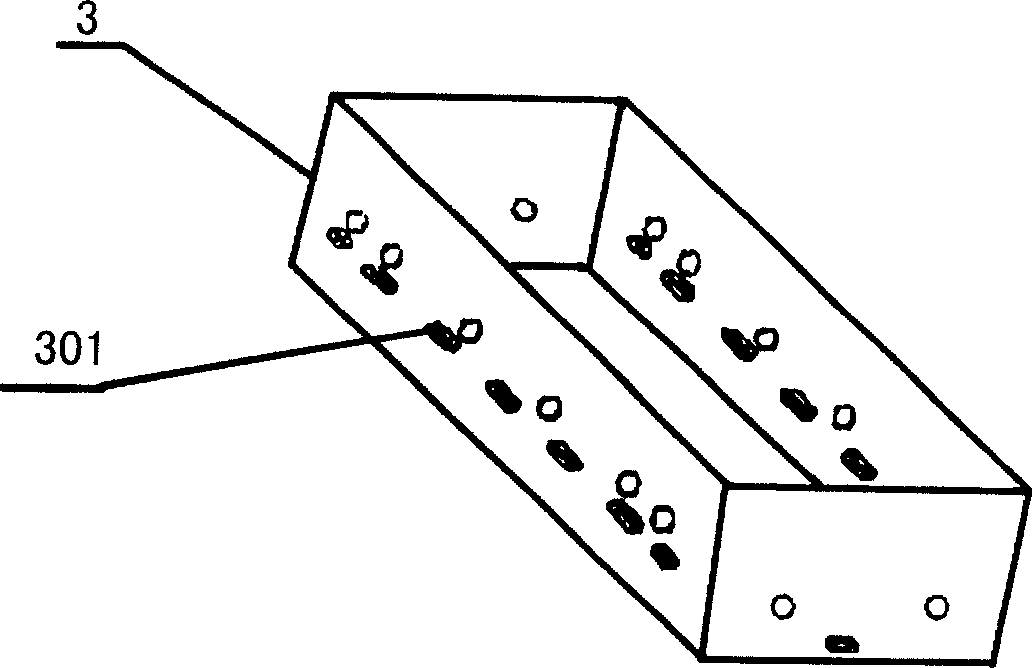

Automobile safety air bag and its manufacturing method

InactiveCN1830704AImprove interface designPrevent the risk of high temperature melting suturesPedestrian/occupant safety arrangementAutomobile safetyNylon 66

A safety air bag with elliptical shape for car is composed of upper half and lower half with an interface to gas generation, a gas releasing hole and a reinforcing ring for said interface. It is made up of nylon-66 fiber cloth and two halves are combined by sewing with the composite thread of refractory aramid fiber thread and nylon-66 thread.

Owner:上海惠太科技股份有限公司

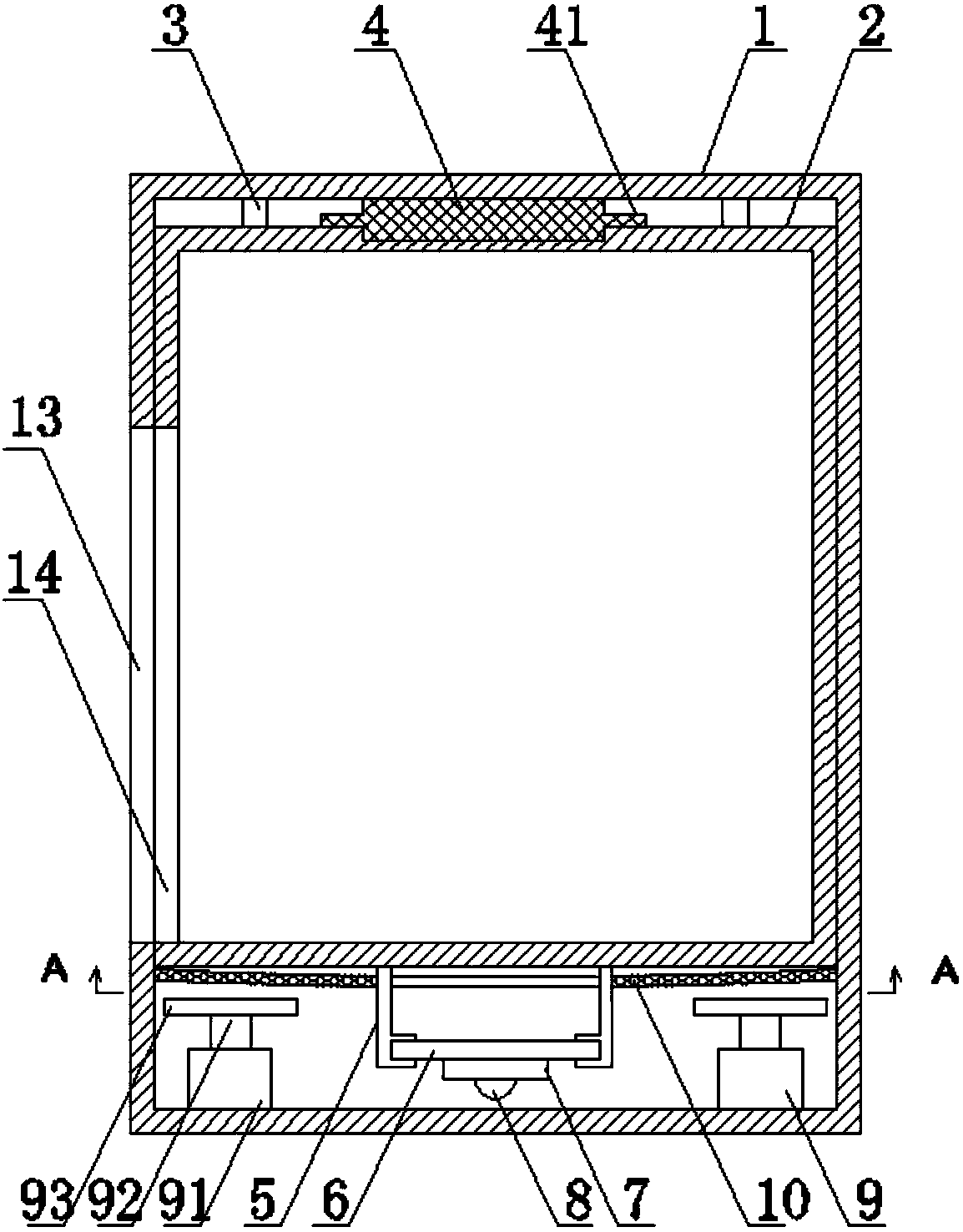

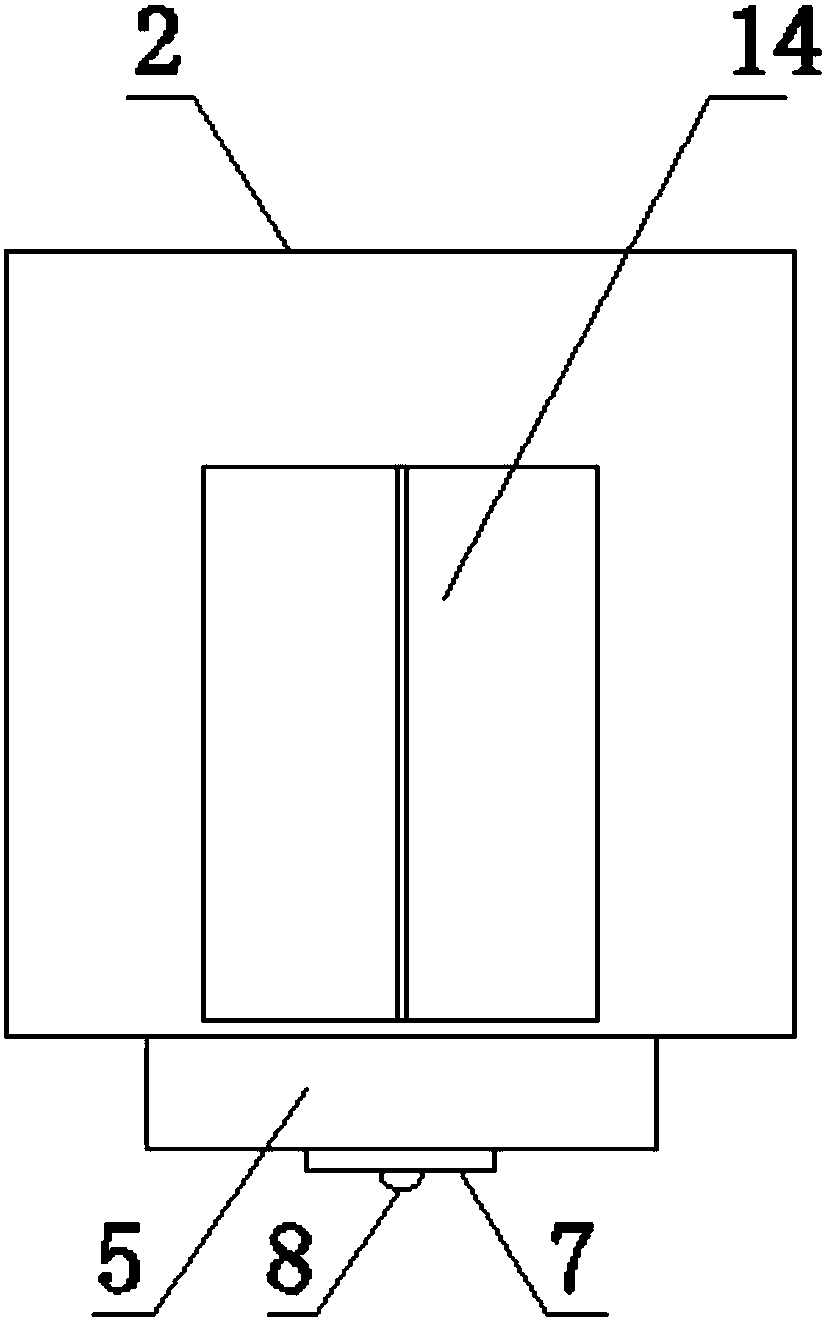

Fall protection car

PendingCN107902522AReduce safety incidentsGuarantee personal safetyElevatorsBuilding liftsFall protectionCushion

The invention discloses a fall protection car. The fall protection car comprises an outer car body and an inner car body; the inner car body is hung inside the outer car body through safety blocks; alimiting block is arranged between the top of the inner car body and the outer car body; a buffering air bag device is connected to the bottom of the inner car body through a mounting frame and comprises a nylon fiber air bag, an inflation device and an impact sensor, wherein the nylon fiber air bag is arranged in a folded mode, the inflation device is connected to the nylon fiber air bag, and theimpact sensor is electrically connected to the inflation device; air buffering devices are further arranged on the lower side of the inner car body and are fixed to the bottom surface of the outer car body; and vent holes are formed in the top and the bottom of the outer car body separately. The fall protection car has the advantages of being remarkable in buffering capacity and capable of reducing injuries to personnel.

Owner:KANGDA ELEVATOR CO LTD

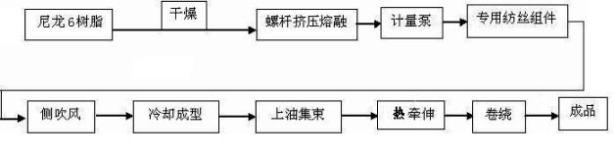

Spinning process for far infrared chinlon 6 FDY

InactiveCN102766934AIncreased durabilitySimple processing methodMelt spinning methodsArtifical filament manufacturePolymer scienceFar infrared

The present invention relates to a pinning process for a far infrared chinlon 6 FDY. The far infrared chinlon 6 FDY is prepared from raw materials comprising chinlon chips and additives by a process route comprising a screw extruder, a pre-filter, a static mixer, a metering pump, a spinning assembly, flow, side blowing, oil application, a spinning shaft, a first godet, a second godet, a third godet and winding. The process provided by the invention is simple and practical; and the prepared fiber nylon is added with composite far infrared particles, and combined with micro capsule technology to gain good durability.

Owner:WUJIANG YATAI CHEM TEXTILE

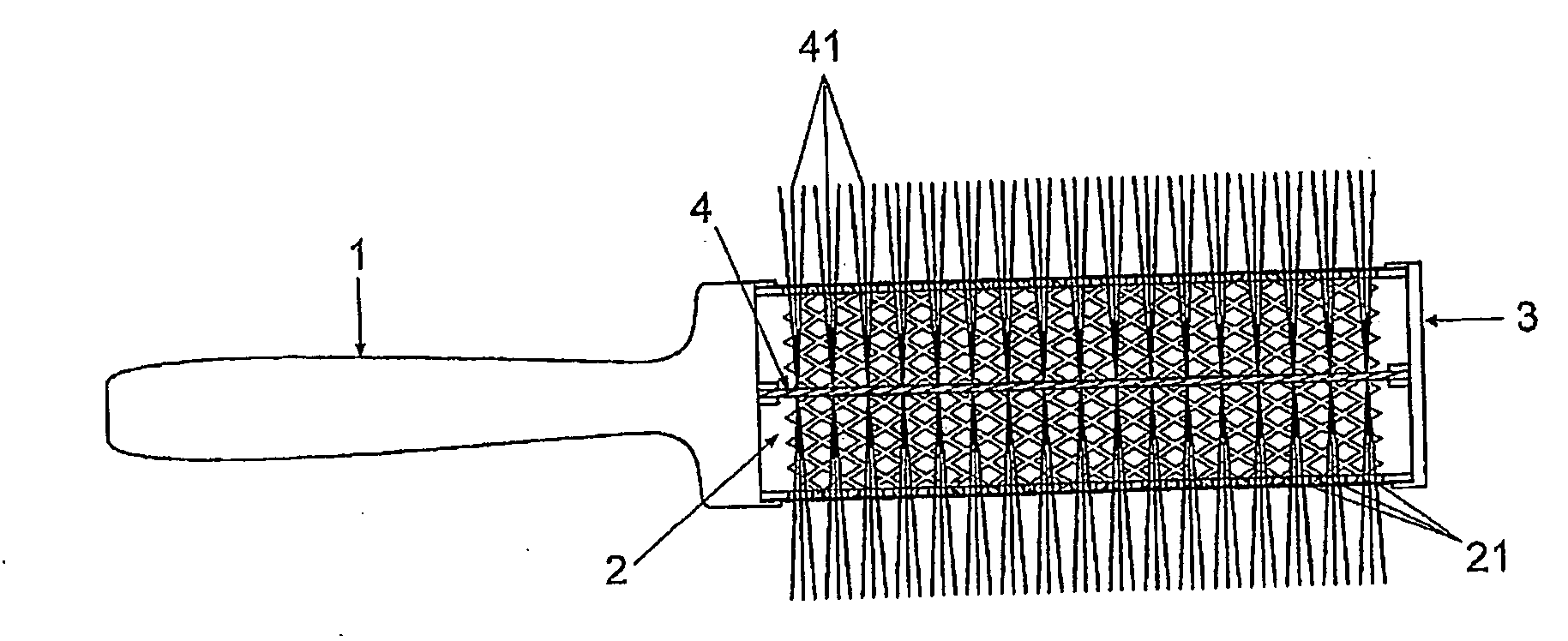

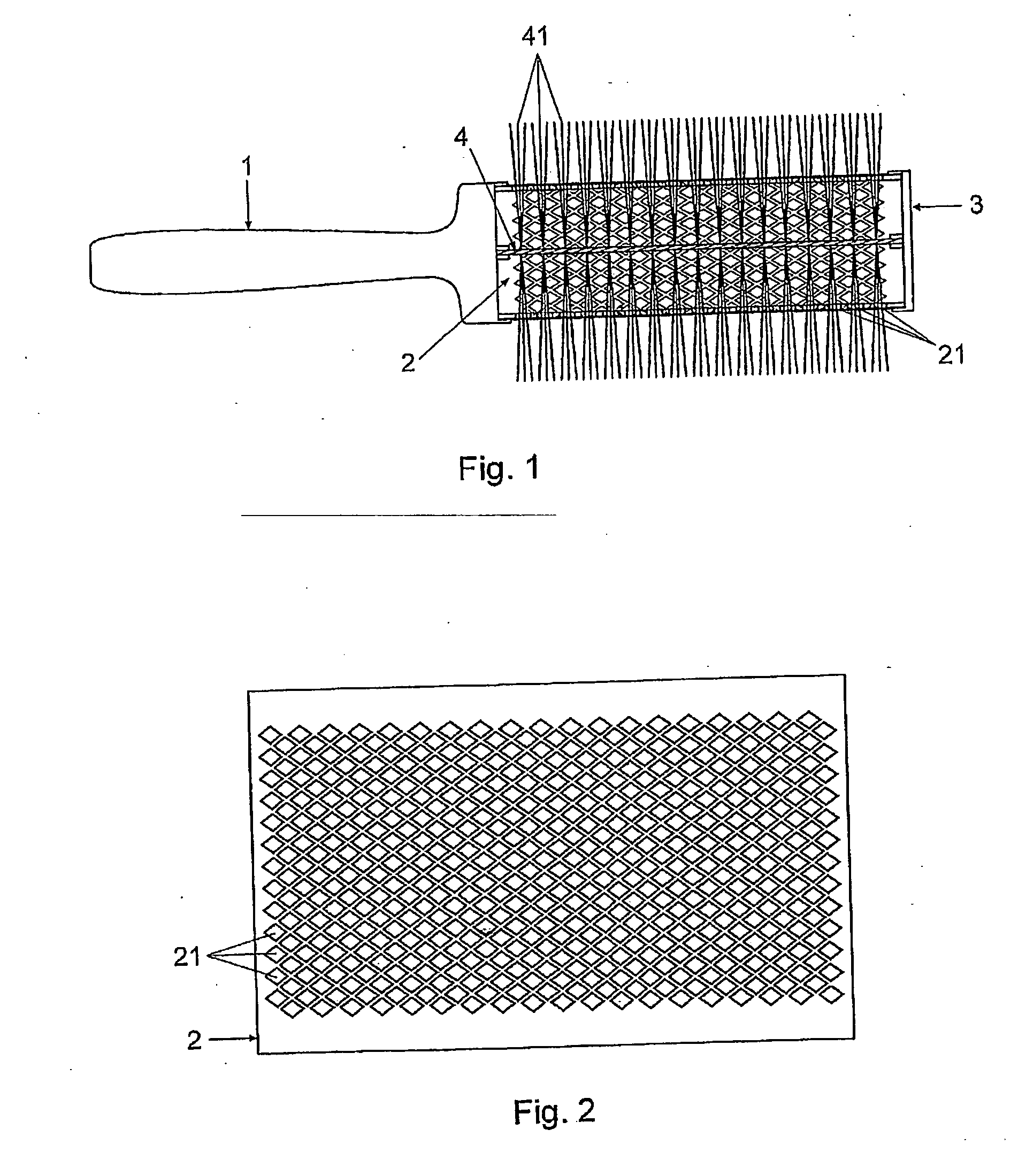

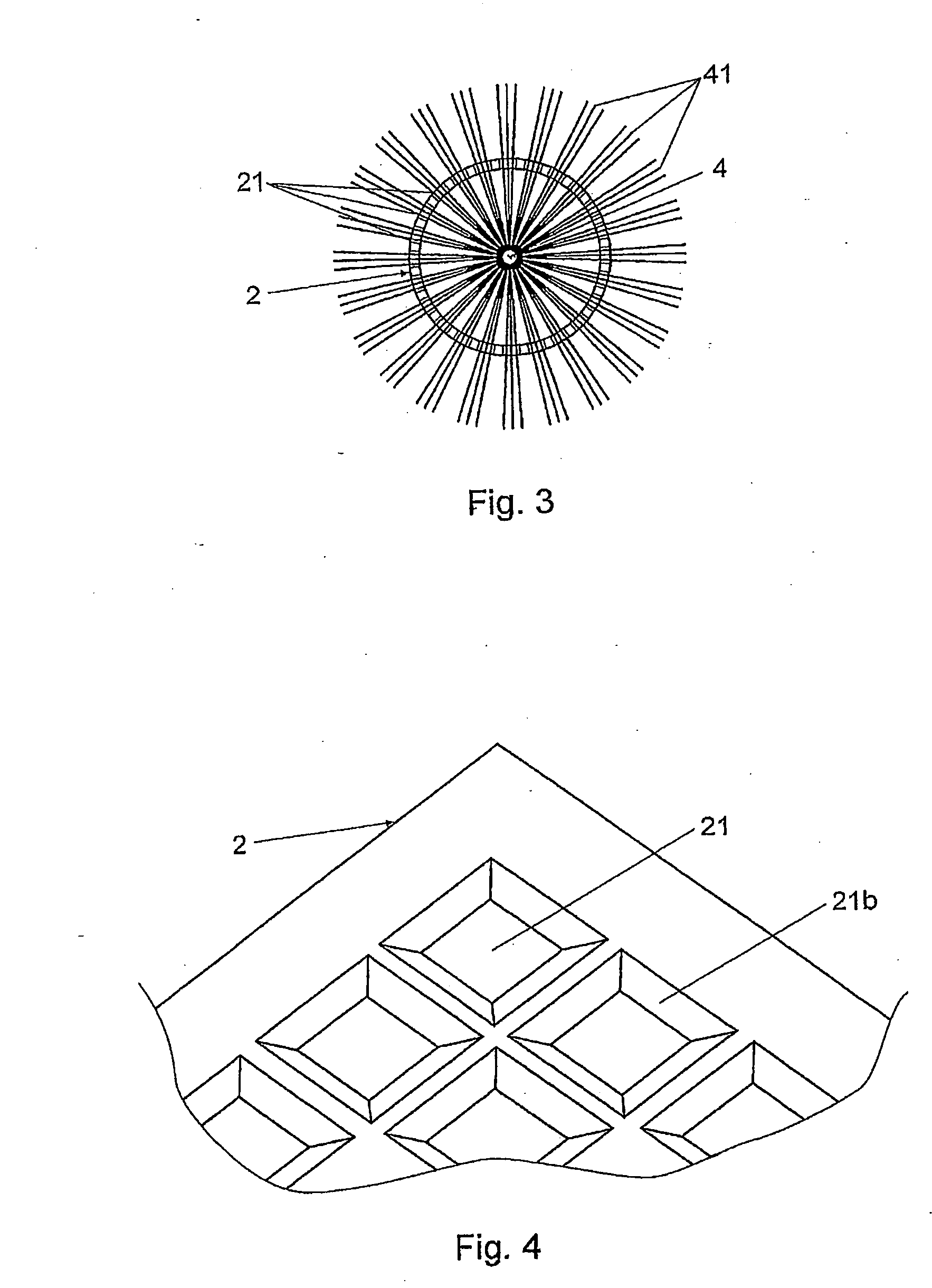

Hair Brush

ActiveUS20090165234A1Long useful lifeBrilliant and reinforced hairBrush bodiesBristle carriersPlastic materialsEngineering

This brush is made up of: a handle (1); an aluminium tubular body (2) which is coated with an artificial plastic material, vinyl fluoride polymer, and holes (21) with polygonal shape, arranged in a herringbone pattern, which end in bevelling (21, 21b) and are arranged forming oblique lines in respect of the longitudinal axle of the brush; nylon fibres (41), ionized by means of radiation, fixed helicoidally to a supporting centre (4), located inside the tubular body, emerging the said fibres (41) through the holes (21) of the tubular body, and a front top (3) that closes the fore end of the above said tubular body.

Owner:DOLS IND DE PELUQUERIA SA

Regenerated nylon 6 fiber manufacturing process

InactiveCN112853534AAchieve recyclingAvoid wastingPlastic recyclingArtifical filament manufacturePolymer sciencePtru catalyst

The invention relates to a fiber manufacturing process, in particular to a regenerated nylon 6 fiber manufacturing process. The regenerated nylon 6 fiber manufacturing process comprises the following steps of 1, crushing nylon 6 waste; 2, adding a catalyst and a mixed solvent of ethanol and dichloroethane; 3, filtering undissolved solids in the solution after the dissolution is finished; 4, cooling and crystallizing the nylon 6 in the filtered solution at a certain temperature to form a nylon 6 solid; 5, drying the nylon 6 solid in a drying oven at 100-120 DEG C for 3-4 hours until the water content is less than 5%; 6, adding an additive to obtain a mixture; and 7, performing melt spinning to obtain the regenerated nylon 6 fiber. The regenerated nylon 6 fiber is prepared from the nylon 6 waste material, so that the nylon 6 waste material is recycled, and resource waste and environmental pollution are fully avoided.

Owner:金华市广拓新材料科技有限公司

Far infrared DTY high-elastic filament for hosiery

InactiveCN102766922ASimple processing methodIncreased durabilityMelt spinning methodsArtifical filament manufactureFar infraredNylon fibre

The present invention relates to a far infrared DTY high-elastic filament for hosiery. The far infrared DTY high-elastic filament is prepared from raw materials containing chinlon 66 chips and additives by a POY-DTY process. The process provided by the invention is simple and practical; and the prepared fiber nylon is added with composite far infrared particles, and combined with micro capsule technology to gain good durability.

Owner:WUJIANG YATAI CHEM TEXTILE

Control cable of flat structure

InactiveCN103985448AImprove insulation performanceImprove toughnessFlat/ribbon cablesInsulated conductorsNitrile rubberEngineering

The invention discloses a control cable of a flat structure. The control cable comprises a plurality of wires. An inner butyronitrile rubber insulating layer and an outer butyronitrile rubber insulating layer wrap the wires. A reinforcing layer formed by weaving nylon fiber is arranged between the inner butyronitrile rubber insulating layer and the outer butyronitrile rubber insulating layer. An isolating layer formed by overlapping and wrapping high-flame-retardant fiber bands wraps the inner butyronitrile rubber insulating layer and the outer butyronitrile rubber insulating layer. Rubber frameworks are arranged on the portions, between the wires and the insolating layer, in the isolating layer formed by overlapping and wrapping the high-flame-retardant fiber bands. A zinc-coated steel wire knitted armor layer, a metal shielding layer and a flame-retardant external protective sleeve layer sequentially wrap the isolating layer which is formed by overlapping and wrapping the high-flame-retardant fiber bands. A reinforcing insulating layer is arranged between the metal shielding layer and the flame-retardant external protective sleeve layer. According to the control cable, the insulating layers high in insulation performance are designed, the isolating layer is also arranged, and therefore insulation performance and isolation performance are good, and practicability is high.

Owner:ANHUI SAIHUA CABLE

Nylon-6 resin, nylon-6 filament and preparation method thereof

ActiveCN102161756AHigh tensile strengthSlow crystallization rateMelt spinning methodsArtifical filament manufacturePolymer scienceCaprolactam

The invention relates to the field of spinning materials, and firstly provides a nylon-6 resin which is prepared by the polymerization reaction of a caprolactam monomer and fixed melt of compounds of metals in the first main group, wherein based on the total weight of the caprolactam monomer, the weight of the compounds of metals in the first main group is 0.03-1.0%. The invention also provides anylon-6 filament which is prepared from the nylon-6 resin by melt spinning. By using the nylon-6 resin and the preparation method provided by the invention, the fine-denier or superfine-denier nylon-6 filament with a fineness of about 0.30-1.0dtex can be obtained. Both the strength and the breaking elongation of the fiber conform to post-weaving requirements. Besides, the invention fills up the gap that the fine-denier / superfine-denier nylon-6 filament can not be produced by the conventional high-speed spinning method home and abroad, and increases the technological content and added value ofthe nylon-6 fiber product.

Owner:HANGZHOU NORMAL UNIVERSITY

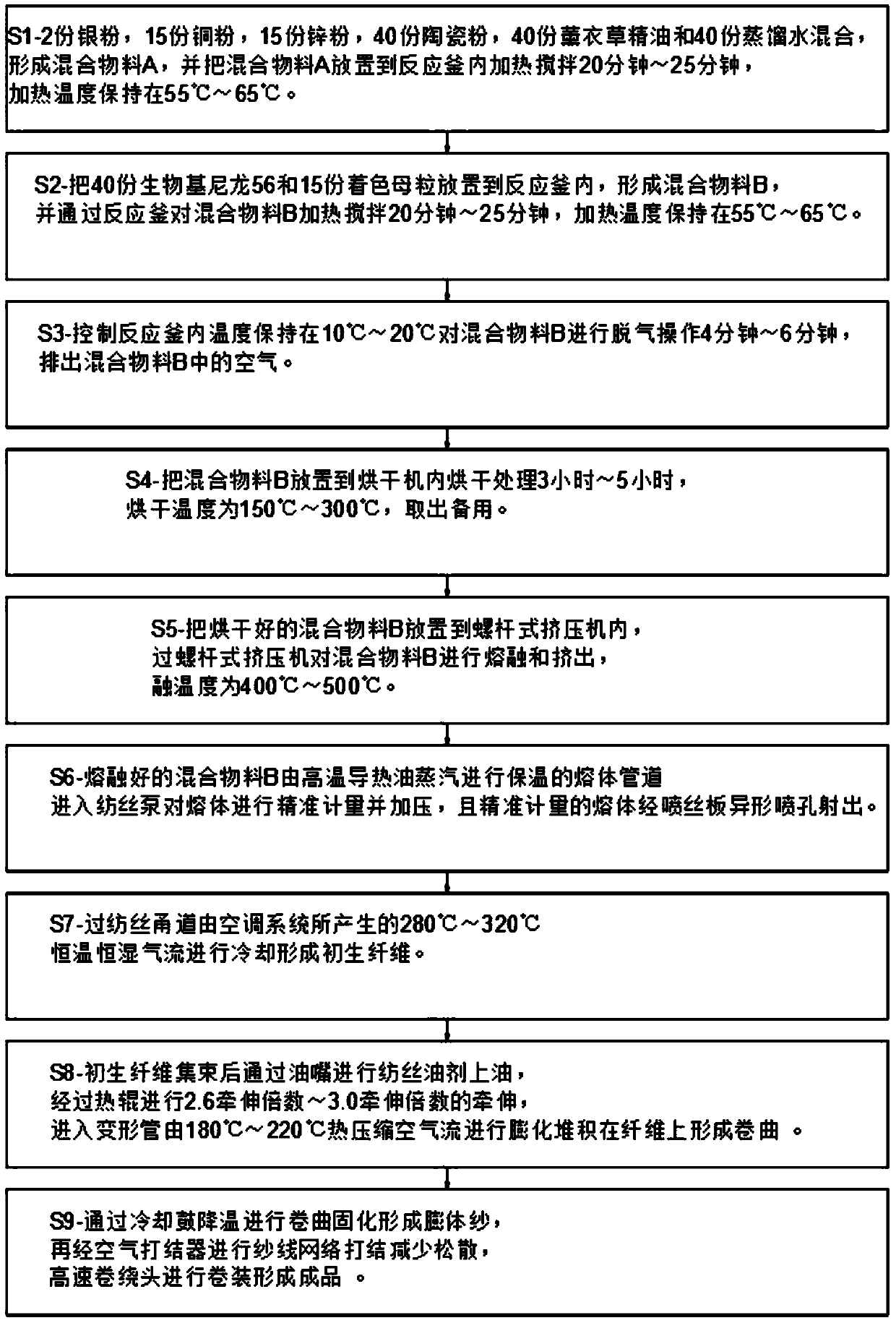

Process for producing bio-based nylon 56 fiber with antibacterial function

InactiveCN109629034AImprove antibacterial propertiesImprove blood vessel flowMelt spinning methodsArtifical filament manufactureFiberDistilled water

The invention belongs to the technical field of fiber processing, and particularly relates to a bio-based nylon 56 fiber with an antibacterial function. The fiber is prepared from, 30 parts-50 parts of bio-based nylon 56, 10 parts-20 parts of a coloring master batch, 30 parts-50 parts of distilled water, 1 part-3 parts of silver powder, 10 parts-20 parts of copper powder, 10 parts-20 parts of zincpowder, 30 parts-50 parts of ceramic powder and 30 parts-50 parts of lavender essential oil; the silver powder, the copper powder and the zinc powder are added into the nylon 56 fiber, the silver powder, the copper powder and the zinc powder are adhered through the ceramic powder, so that the silver powder, the copper powder and the zinc powder have synergistic effects, the bio-based nylon 56 fiber has a good antibacterial ability, the lavender essential oil is also added to the bio-based nylon 56 fiber, and the lavender essential oil can improve the blood vessel circulation of a user and bring convenience to the user.

Owner:南通东屹高新纤维科技有限公司

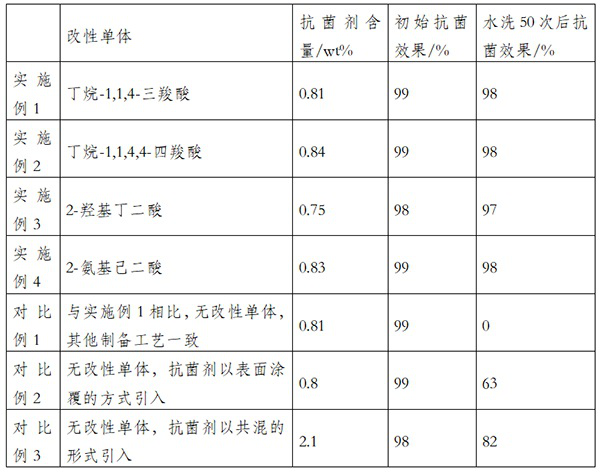

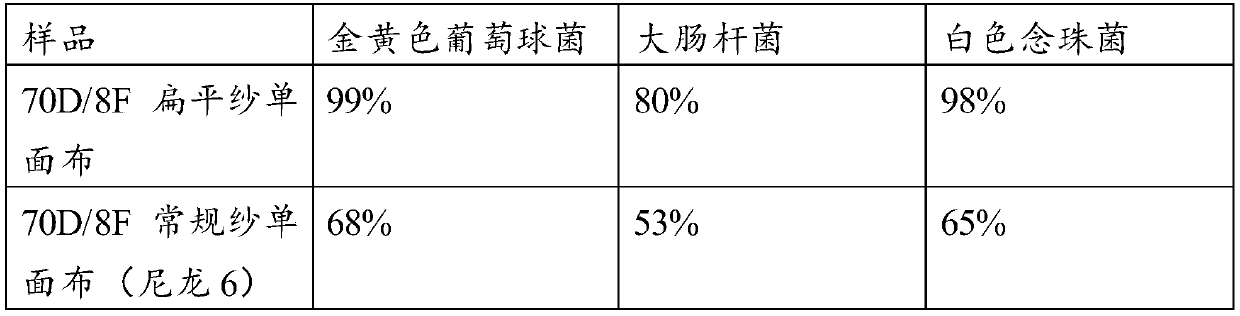

Preparation method of durable and efficient antibacterial nylon 6 fiber and product prepared from fiber

ActiveCN113802379AImprove antibacterial propertiesImprove performanceBiochemical fibre treatmentFibre typesPolymer scienceSide chain

Owner:POLY PLASTIC MASTERBATCH SUZHOU

Pressure-resistant corrosion-resistant rubber airbag cloth composite material and preparation method thereof

PendingCN111941968AImprove stress resistanceImprove corrosion resistanceSynthetic resin layered productsGlass/slag layered productsGlass fiberCarbon fibers

The invention discloses a pressure-resistant corrosion-resistant rubber airbag cloth composite material and a preparation method thereof. The pressure-resistant corrosion-resistant rubber airbag clothcomposite material comprises basic fiber cloth, a bonding rubber layer coating the basic fiber cloth, and a pre-vulcanized rubber composition sheet attached to the basic fiber cloth coated with the bonding rubber layer, wherein the basic fiber cloth comprises one selected from glass fiber cloth, carbon fiber cloth, high-strength nylon fiber cloth, ultra-high molecular weight fiber cloth and polyimide fiber cloth; and bonding rubber comprises one selected from liquid nitrile rubber, liquid polybutadiene rubber, carboxyl-terminated liquid nitrile rubber, hydroxyl-terminated liquid nitrile rubber, carboxyl-terminated liquid polybutadiene rubber, hydroxyl-terminated liquid polybutadiene rubber and chlorinated liquid paraffin. The rubber airbag cloth composite material in the scheme has the advantages of good pressure resistance and strong corrosion resistance, and can be used for processing and producing various inflatable airbag products applicabel to pipeline plugging, ships, shock absorption, bridges, constructional engineering, hollow constructs for pouring, civil fields and the like.

Owner:南京曼可新材料有限公司

Functional recycled nylon 6 fiber, preparing method thereof and fabric

InactiveCN111560659AEnvironmentally friendlyChange contact formMelt spinning methodsArtifical filament manufacturePolymer scienceSpinning

The invention relates to the technical field of recycled nylon fibers, and provides a functional recycled nylon 6 fiber, a preparing method thereof and fabric. The functional recycled nylon 6 fiber isformed by nylon 6 waste through pre-treatment, recycling granulation and spinning in sequence, the a functional recycled nylon 6 fiber is provided with a flat straight-line section, the fiber is madeof the nylon waste, and has the environment friendliness, the special-shaped section structure of the recycled nylon 6 fiber can change the contact form of the fiber surface and water molecules, therefore, the property of the final fabric on continuous cool sense wearing experiences is improved, popularization and application are facilitated, in addition, zinc oxide is added in to the fiber, thefiber has the anti-bacterial function, meanwhile, a tracking element-barium used for source tracing is added, and source tracing tracking managing and controlling of the material from the fiber to a final garment finished product is facilitated.

Owner:XIAMEN ANTA SPORTS GOODS CO LTD

Novel composite aging-resistant textile material and preparing method thereof

The invention discloses a novel composite aging-resistant textile material.The novel composite aging-resistant textile material comprises, by weight, 20-45 parts of polyester fibers, 20-45 parts of nylon fibers, 20-45 parts of hollow fibers, 10-25 parts of hydroxypropyl methyl cellulose, 20-45 parts of dacron, 20-45 parts of acrylon, 5-15 parts of sisal hemp, 15-25 parts of flax, 5-10 parts of lignin fibers, 15-25 parts of chitin fibers, 5-10 parts of wool, 5-10 parts of asbestos fibers, 2-5 parts of nanometer ceramic powder, 2-5 parts of nanometer graphite powder, 2-5 parts of nanometer silicon powder, 5-15 parts of tannic acid, 2-10 parts of poly-beta-hydroxybutyrate, 5-10 parts of poly-epsilon-caprolactone, 5-10 parts of stabilizer and 5-10 parts of adhesive.The prepared textile material has the good aging resistance.Meanwhile, the invention discloses a corresponding preparing method.

Owner:WUJIANG ZEWANG TEXTILE CO LTD

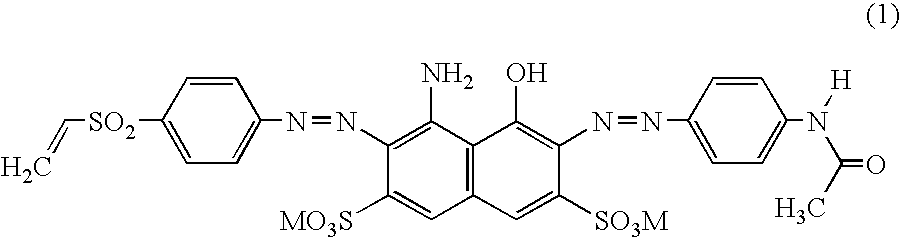

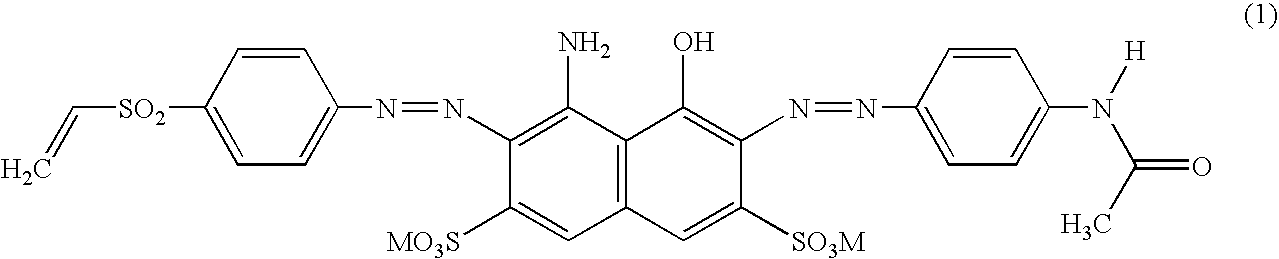

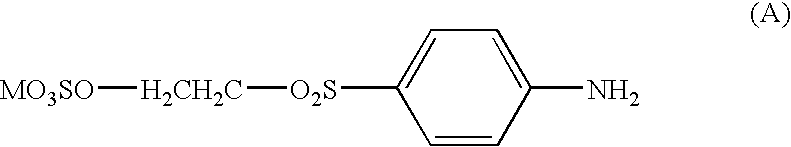

Reactive blue dye containing a vinyl sulfone group

The present invention relates to a reactive blue dye, and more particularly to a reactive blue dye represented by the following Formula 1, which is effective in black dyeing or printing of polyamide textiles, in particular, nylon fibre, wherein M is a hydrogen atom or an alkali metal atom. The blue dye of the present invention offers superior color yield, reactivity, fixing efficiency, light fastness, and washing fastness, substantivity, and superior cleaning properties over unfixed dyes.

Owner:KOREA RES INST OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com