Automobile safety air bag and its manufacturing method

An automobile safety and air bag technology, which is applied in vehicle safety arrangements, pedestrian/passenger safety arrangements, vehicle components, etc., can solve problems such as melted sutures, achieve tensile strength, and prevent the danger of high temperature melted sutures , the effect of preventing high fever wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

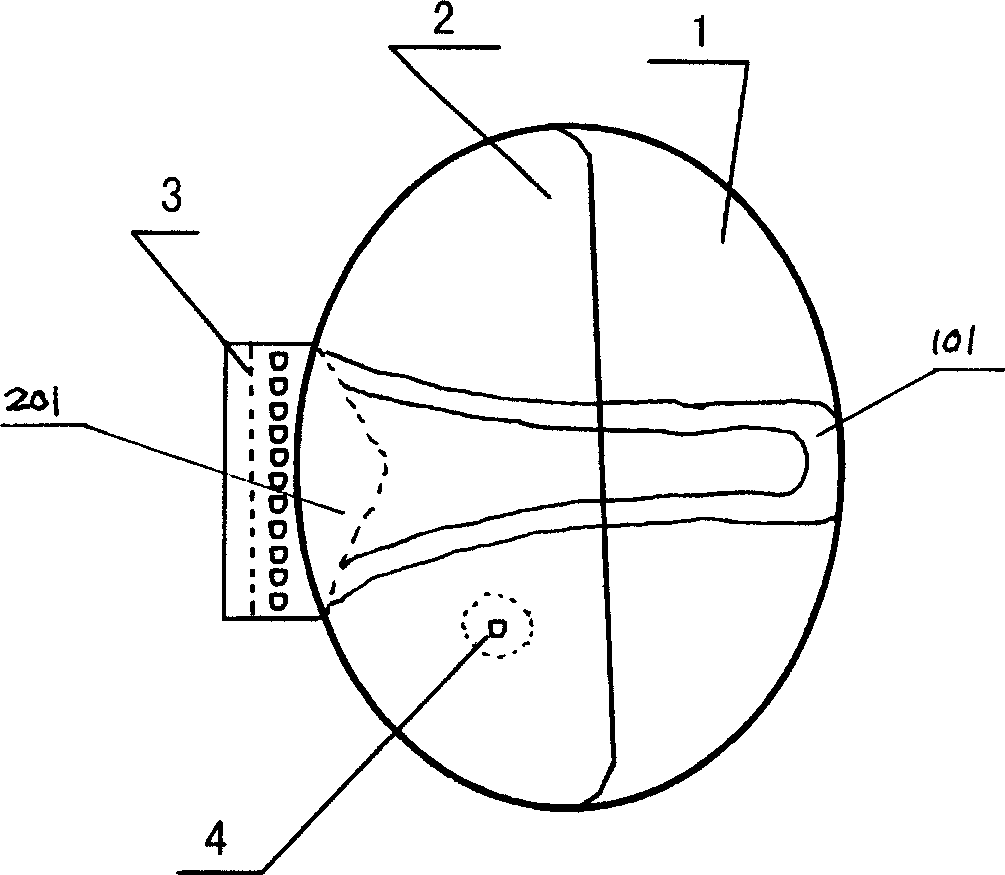

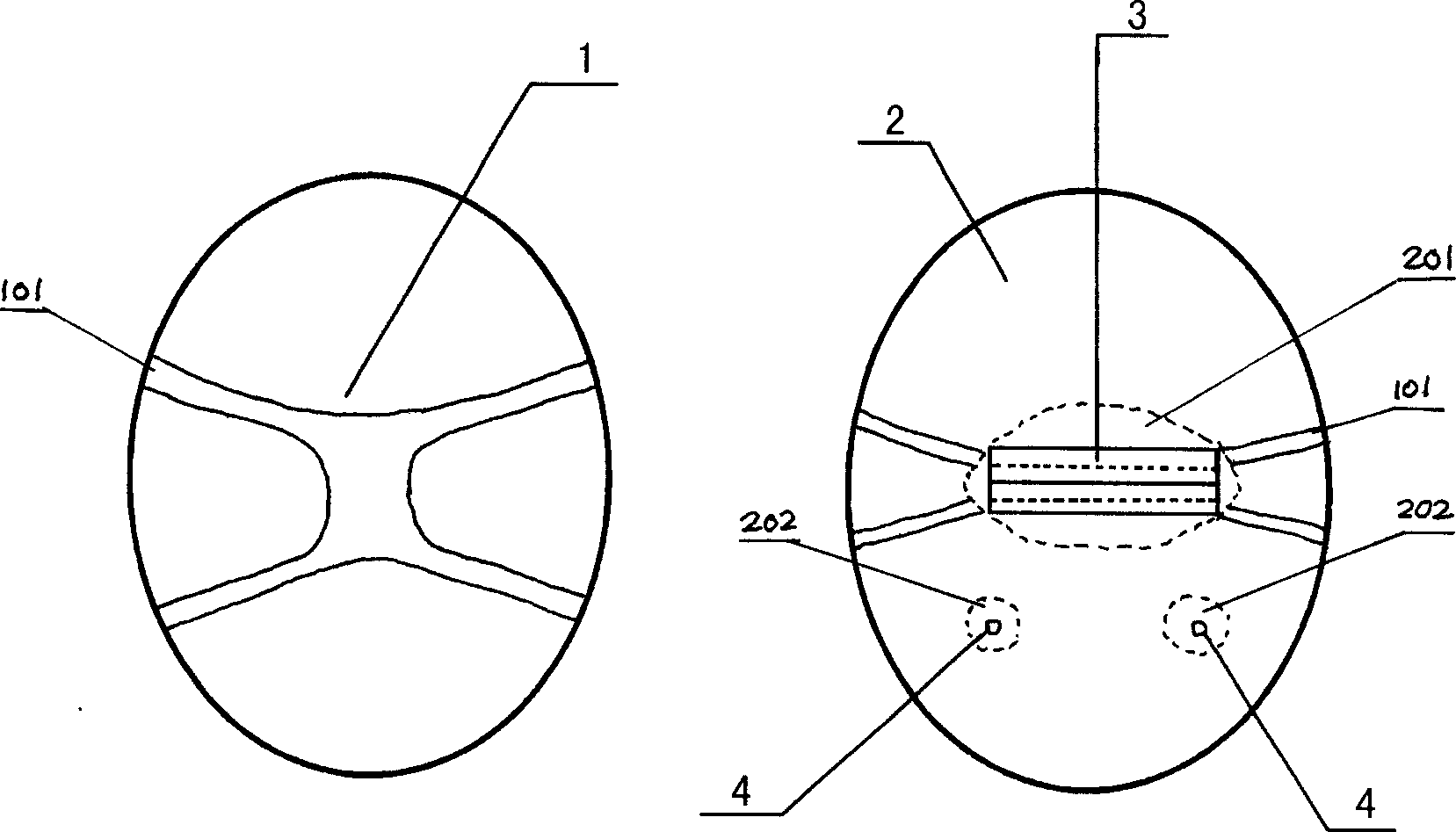

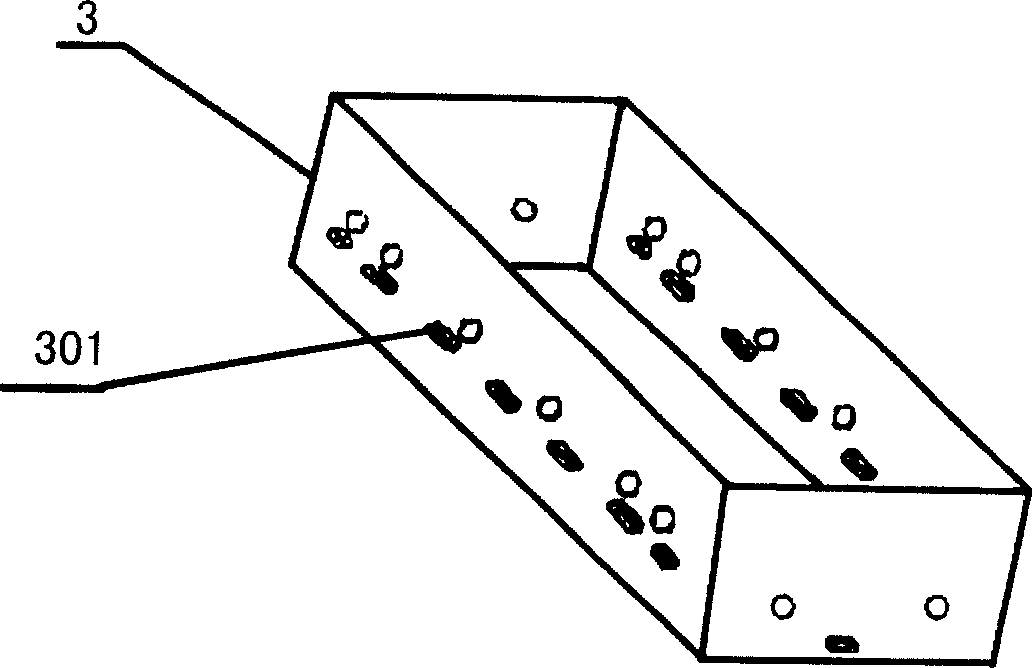

[0016] The present invention will be further elaborated below in conjunction with the accompanying drawings.

[0017] Automobile safety air bag, after the car collides, instantly opens a bag filled with gas immediately between the driver or passenger and the interior parts of the car, allowing the driver and passenger to pounce on the upper piece of the air bag. Exhaust through the vent hole of the air bag absorbs the function of the driver and passengers rushing forward, buffering the violent collision in the car, so as to protect the safety of the driver and passengers.

[0018] The airbag system for automobiles generally consists of sensors, electronic control units, gas generators and airbags. The sensor senses the collision intensity of the car and transmits it to the electronic control unit. The electronic control unit makes a judgment and sends an ignition signal in time to trigger the gas generator. After the air bag is detonated, the 2400CC air bag can be filled with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com