Patents

Literature

282results about How to "Guaranteed shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Online self-sharpening metallic bond and super-hard abrasive precision grinding pellet and preparation method thereof

InactiveCN103009270ALow shrinkageHigh strengthAbrasion apparatusGrinding devicesPolyvinyl alcoholDecomposition

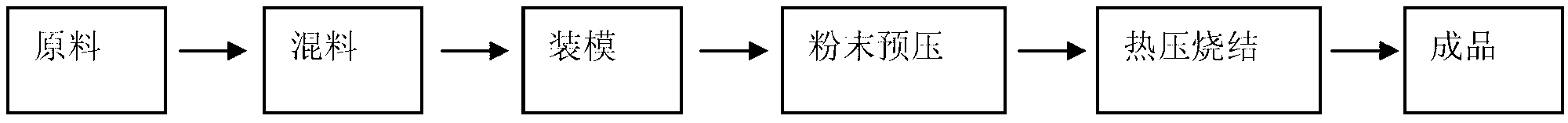

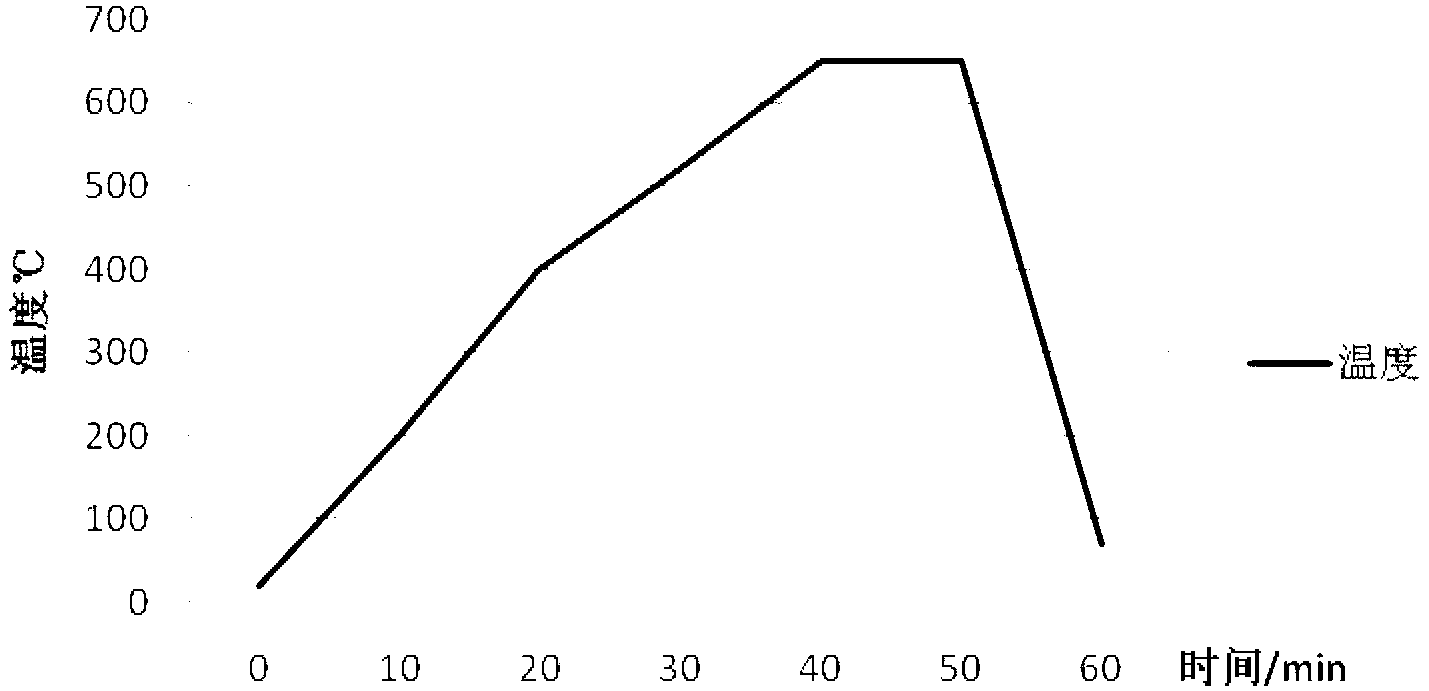

The invention provides an online self-sharpening metallic bond and super-hard abrasive precision grinding pellet and a preparation method thereof and belongs to the technical field of precision grinding pellets. Raw materials of the precision grinding pellet comprise a super-hard abrasive and a metallic bond, wherein the super-hard abrasive is diamond micro-powder; the diamond concentration falls within a range of 75-100 %; and the metallic bond uses a multicomponent alloy bond whose main components are copper powder, tin powder, aluminum powder, copper-clad ball shaped graphite powder, silicon dioxide and ferroferric oxide powder. The preparation method comprises the following steps: uniformly mixing and stirring the diamond micro-powder as well as the copper powder, the tin powder and the aluminum powder; adding polyvinyl alcohol to a mixture and mixing the polyvinyl alcohol and the mixture; adding the silicon dioxide, the copper-clad ball shaped graphite powder and the ferroferric oxide powder to an obtained mixture and mixing these materials and the obtained mixture; filling the mixture into a graphite mold; maintaining the pressure of the graphite mold for 5-10 minutes after pressurizing the graphite mold to 100-250 MPa; and carrying out hot pressing sintering on the graphite mold in a sintering furnace, wherein the sintering atmosphere is ammonia decomposition gas. Through the adoption of the online self-sharpening metallic bond and super-hard abrasive precision grinding pellet provided by the invention, online automatic sharpening can be achieved without blockage and offline repairing.

Owner:BEIJING UNIV OF TECH

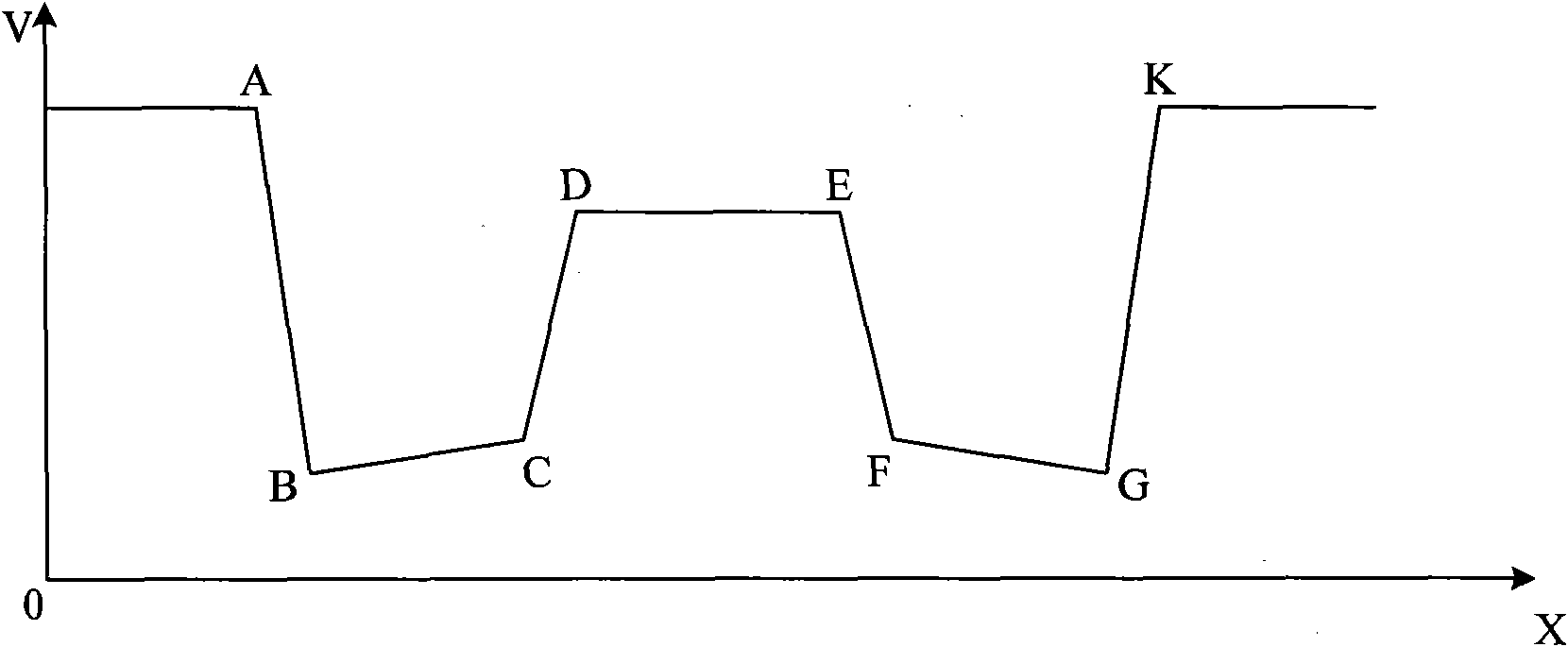

Control method for periodic variable-thickness strip rolling speed

ActiveCN101890434AGuaranteed shapeGuaranteed sizeMetal rolling arrangementsRoll speed control deviceVariable thicknessControl theory

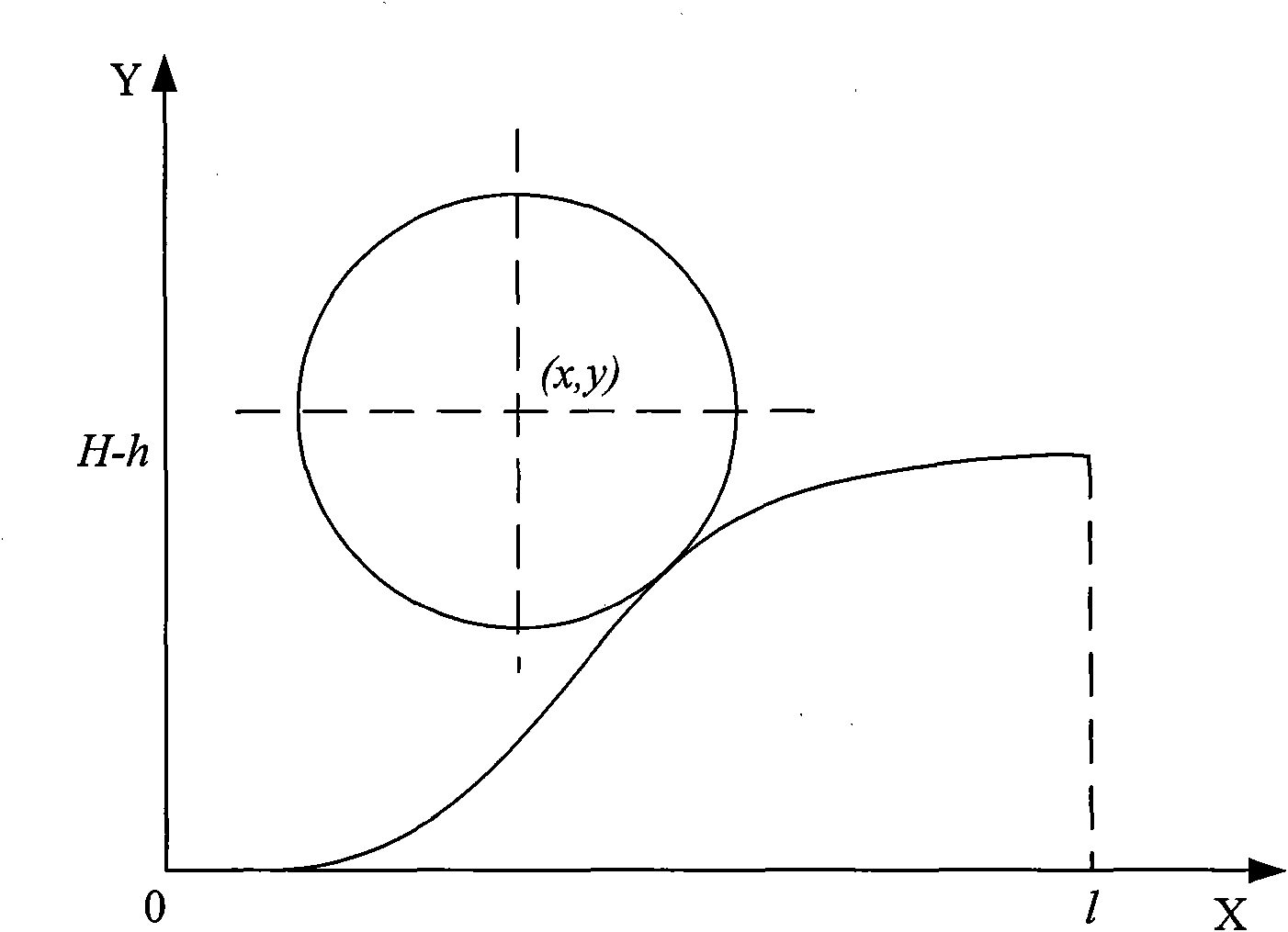

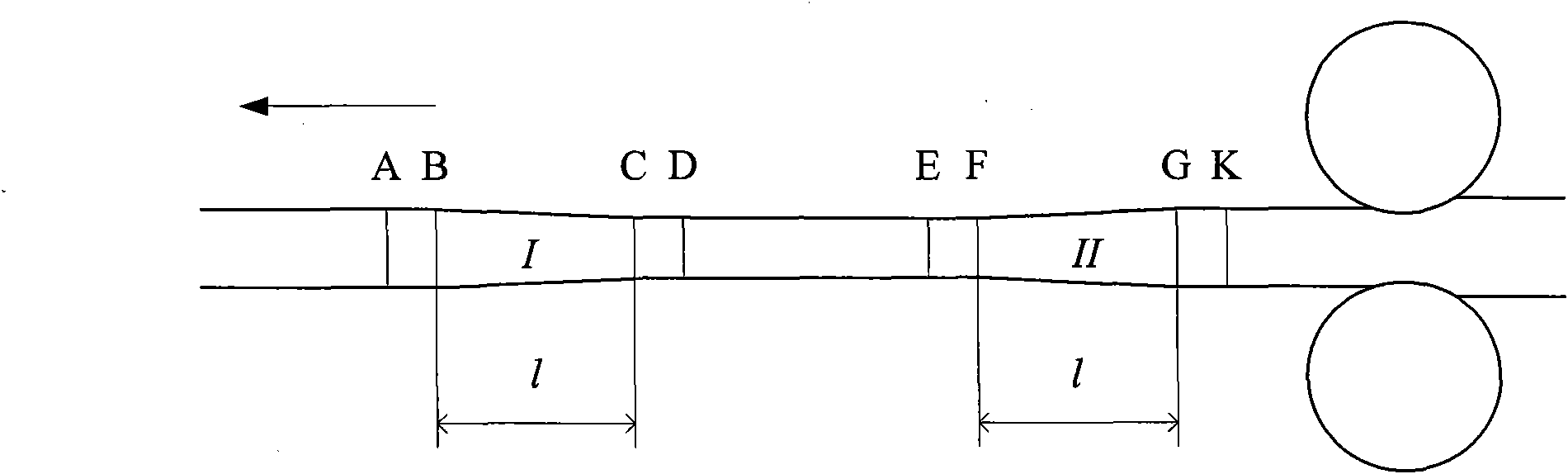

The invention discloses a control method for a periodic variable-thickness strip rolling speed, and belongs to the technical field of rolling. The control method comprises horizontal rolling speed control and the vertical rolling speed control of a roller, wherein the horizontal rolling speed control is performed in a way that: a thick region of a strip is rolled at a thick region rolling speed; the rolling speed starts to decrease at a near point A of a transition region and decreases to VB at a starting point B of the transition region; at the transition region, the horizontal rolling speed at the transition region is calculated according to a transition region curvilinear equation and a second flow equivalence principle; and the rolling speed starts to increase after an end point C of the transition region and increases to a thin region rolling speed at a far point D of the transition point to start to roll a thin region; the vertical rolling speed control of the roller is performed in the way that: the vertical rolling speed of the roller is 0 when the thick region of the strip is rolled; after the thick region is rolled and a rolled piece reaches the starting point B of the transition region, the roller starts downward pressing, and the vertical rolling speed of the transition region is Vdy(x); the Vdy(x) starts to decrease after reaching a maximum point Q1 and decreases to 0 at the end point C of the transition region; and the steps are repeated periodically.

Owner:SHENYANG DONGBAO HAIXING METAL MATERIAL TECH

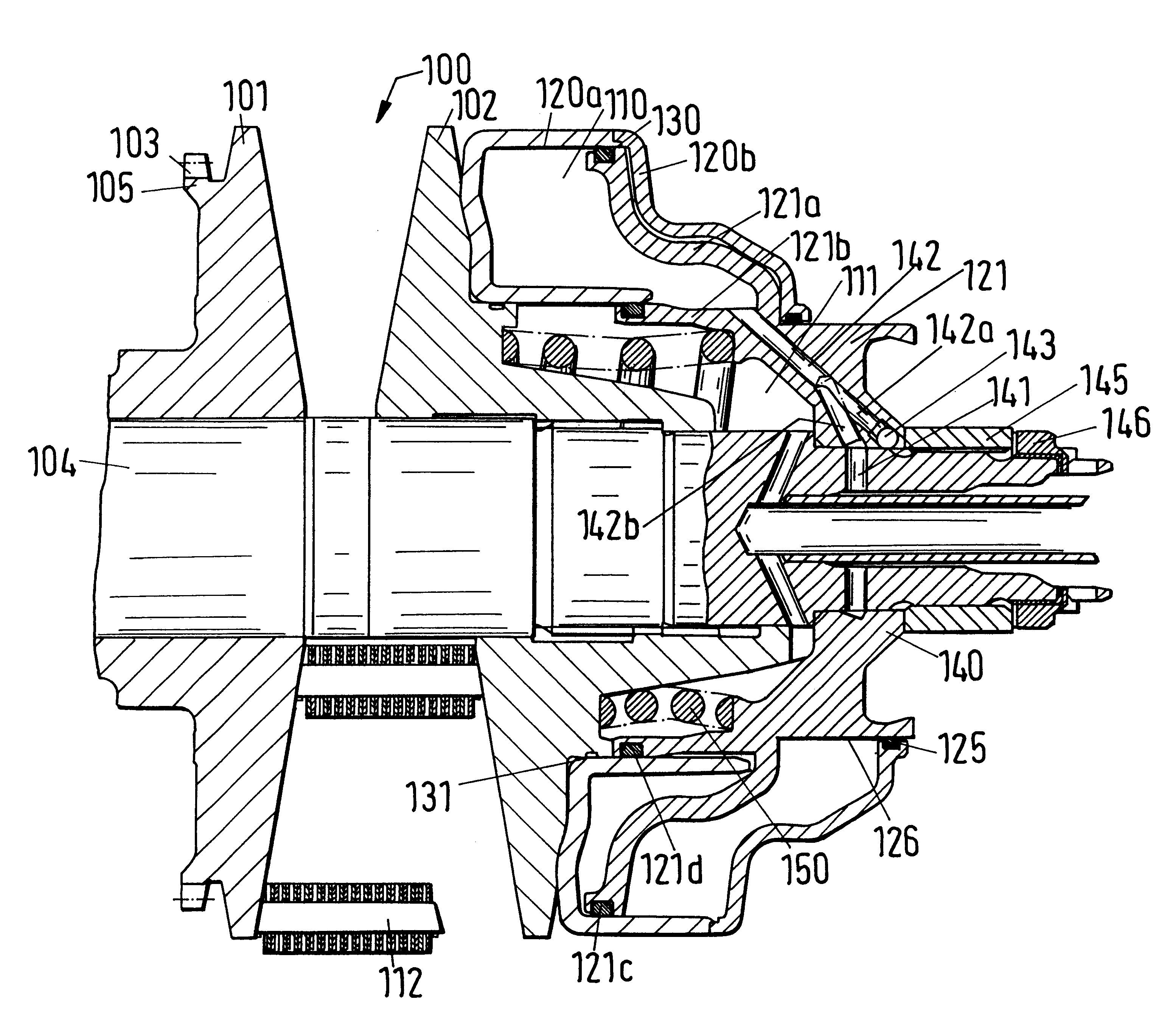

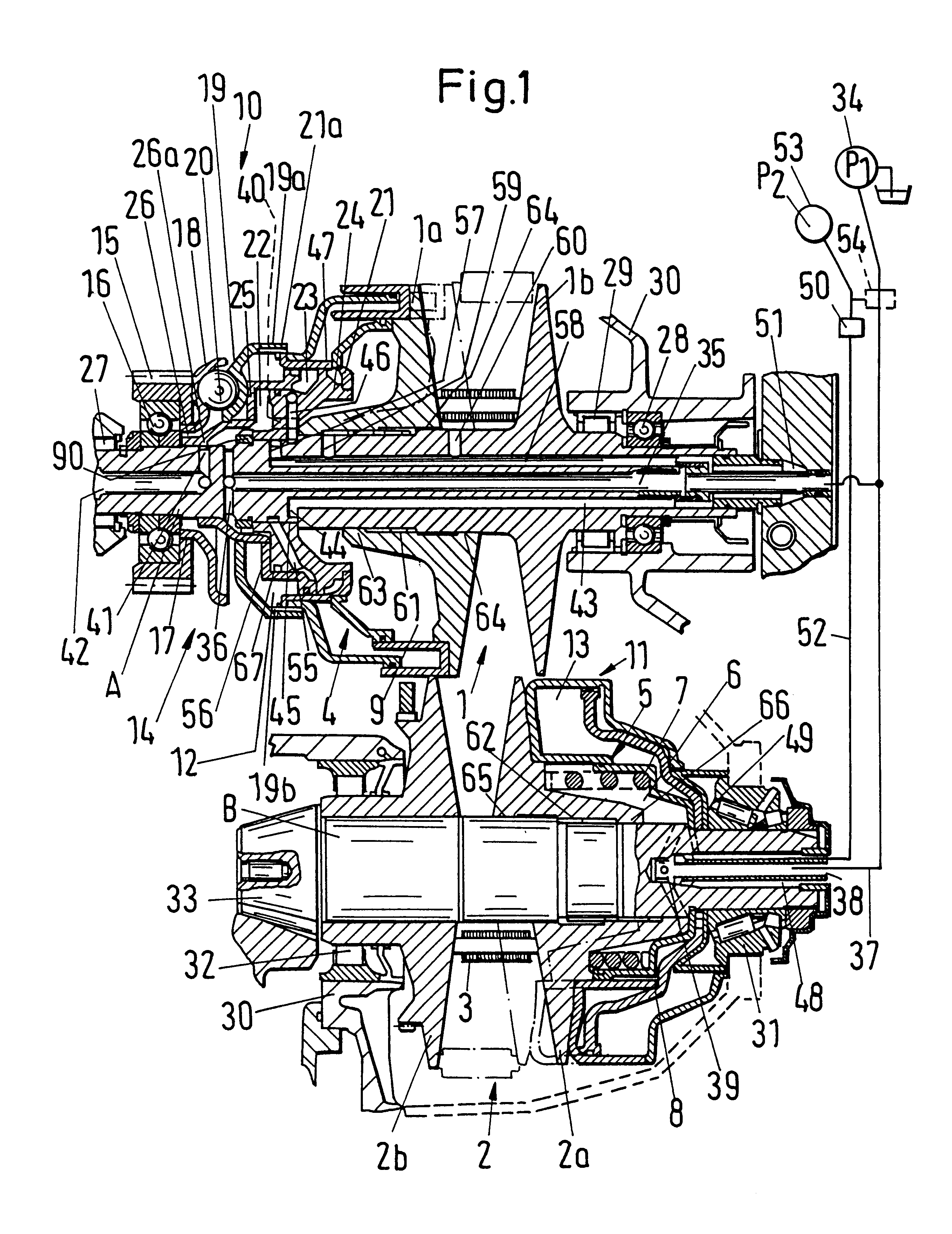

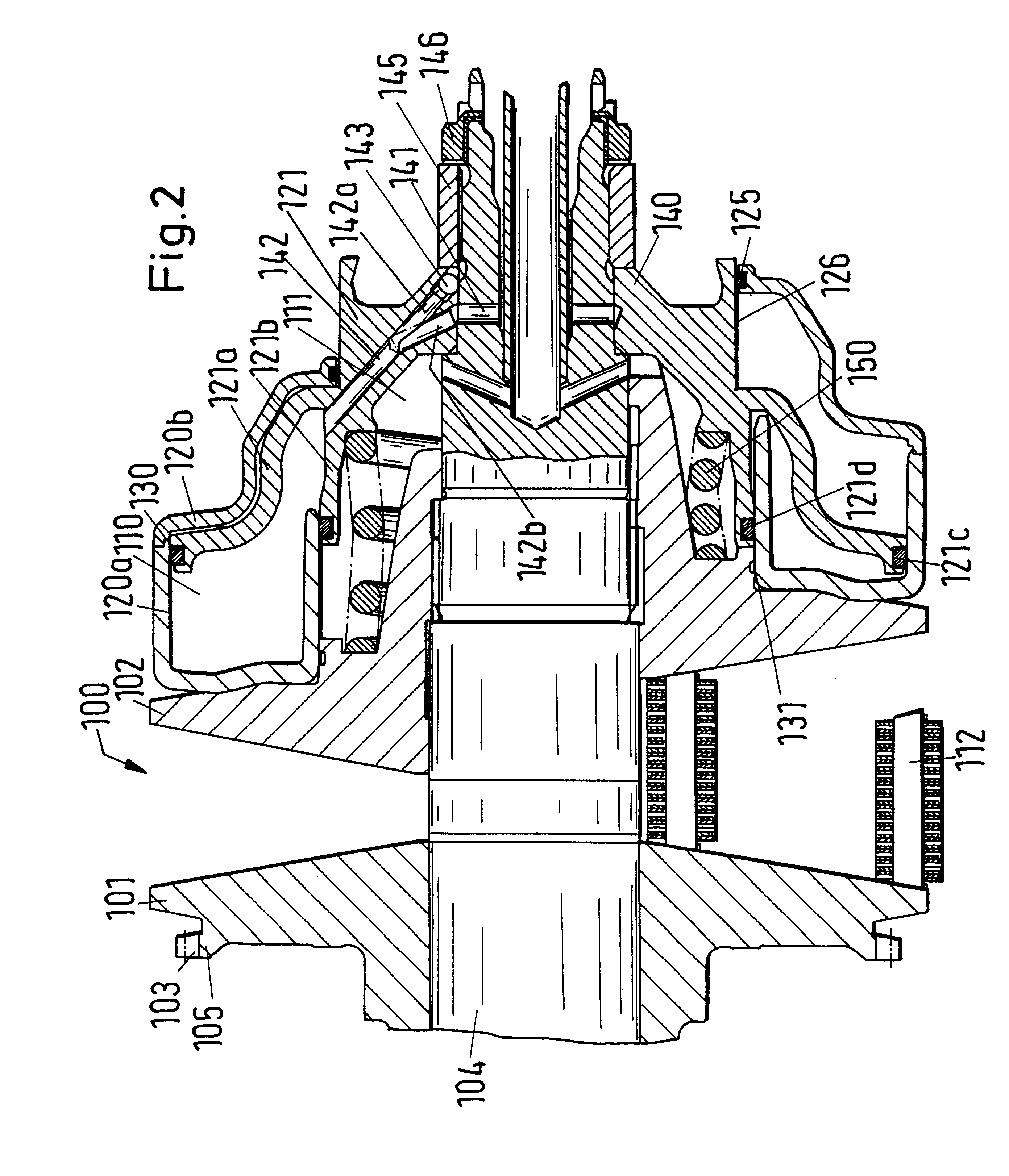

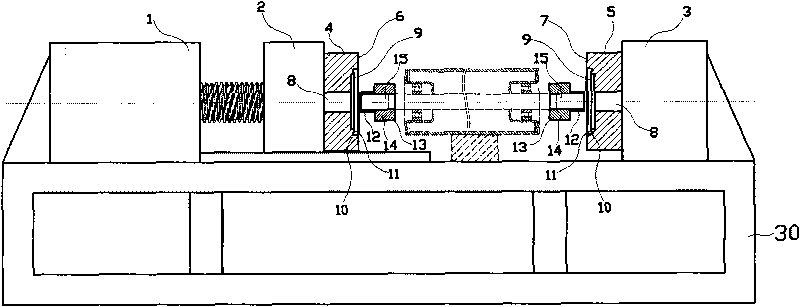

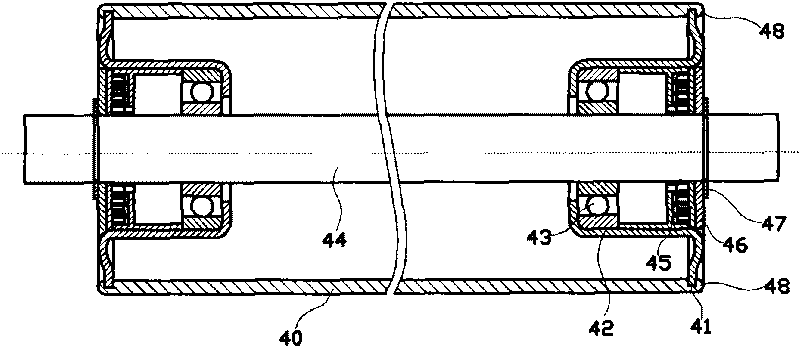

Transmission

A continuously variable speed transmission with a first adjustable pulley on an input shaft, a second adjustable pulley on an output shaft, and an endless chain or belt trained over the pulleys employs at least one coil spring which biases one flange of one of the pulleys axially of the respective shaft. The coil spring has larger-diameter end convolutions and smaller-diameter intermediate convolutions. A plenum chamber of a torque sensor or of at least one of several piston-cylinder units-which serve to adjust the axially movable flanges of the pulleys-is bounded in part by a check valve in the form of a composite seal having a rigid annular element and an elastic annular element. One of the annular elements surrounds the other element.

Owner:LUK GETRIEBE SYST

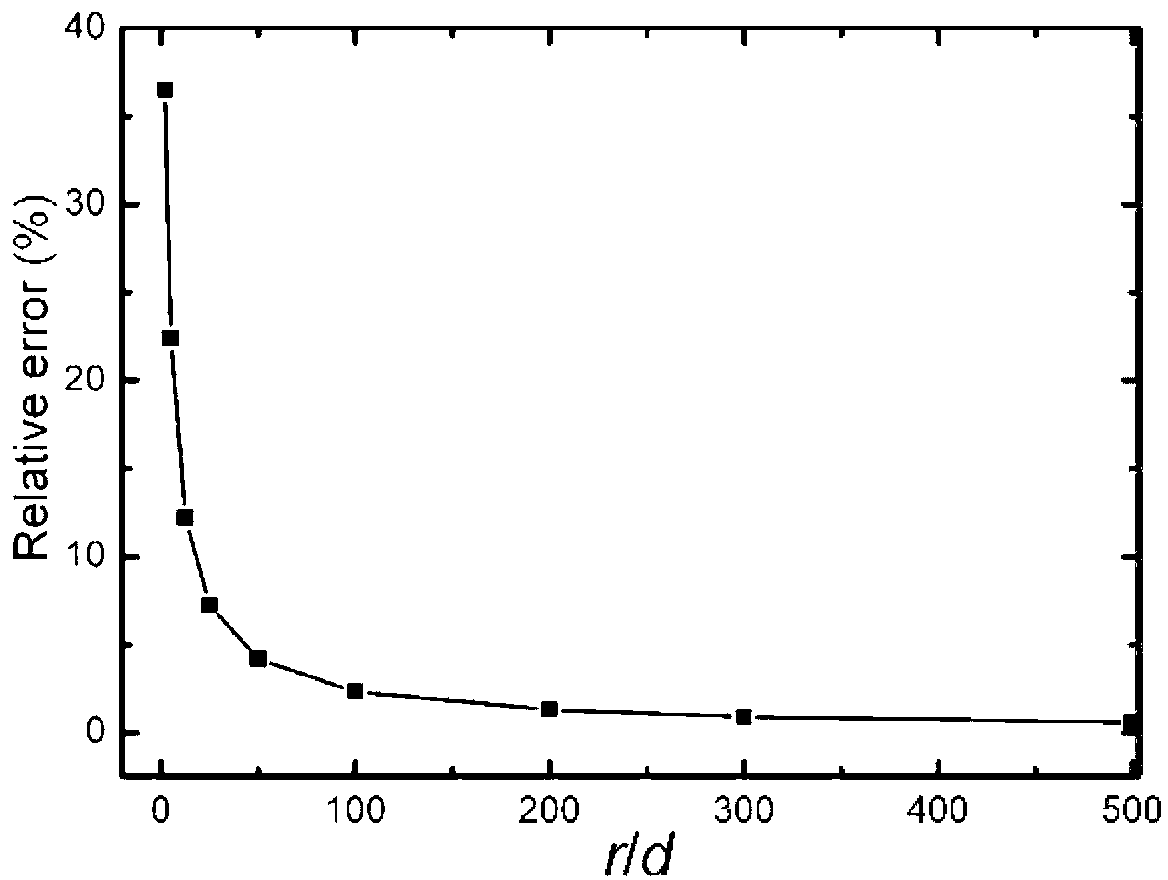

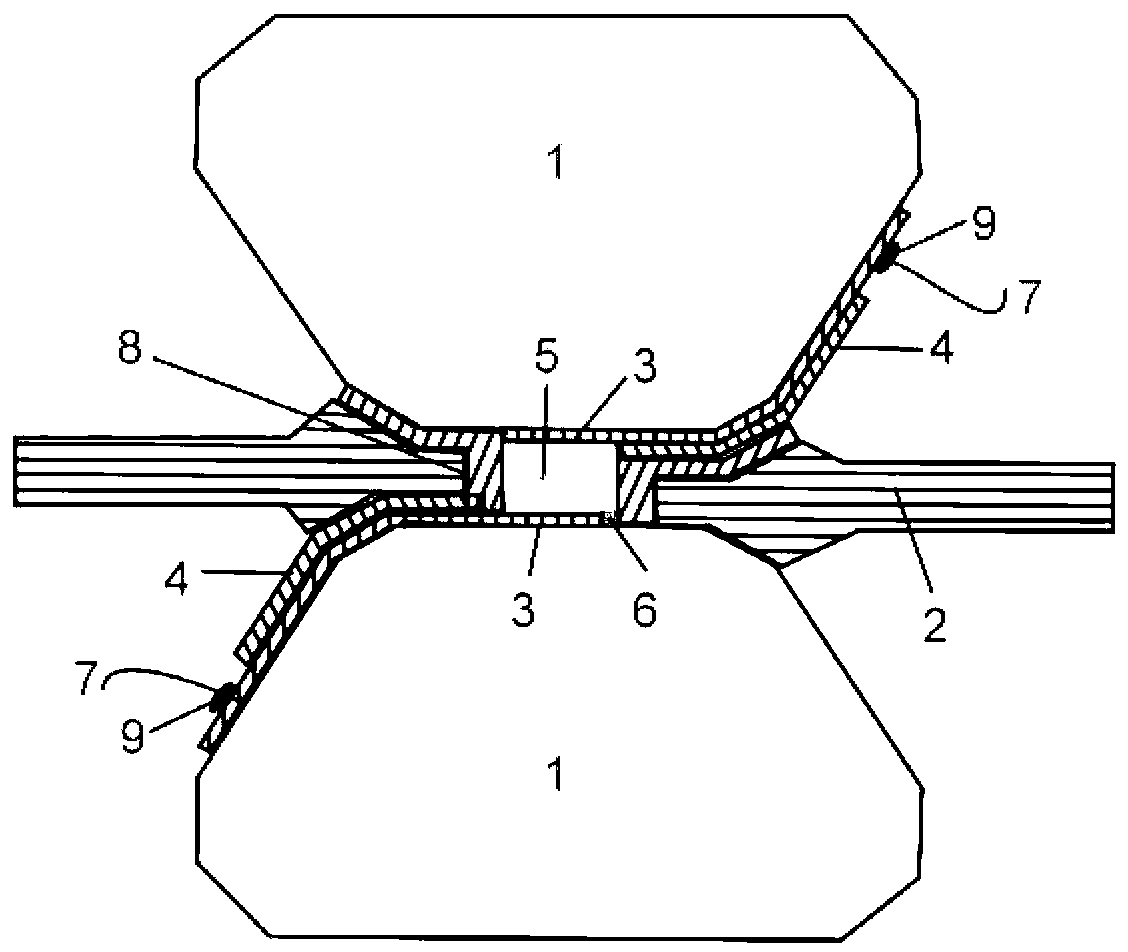

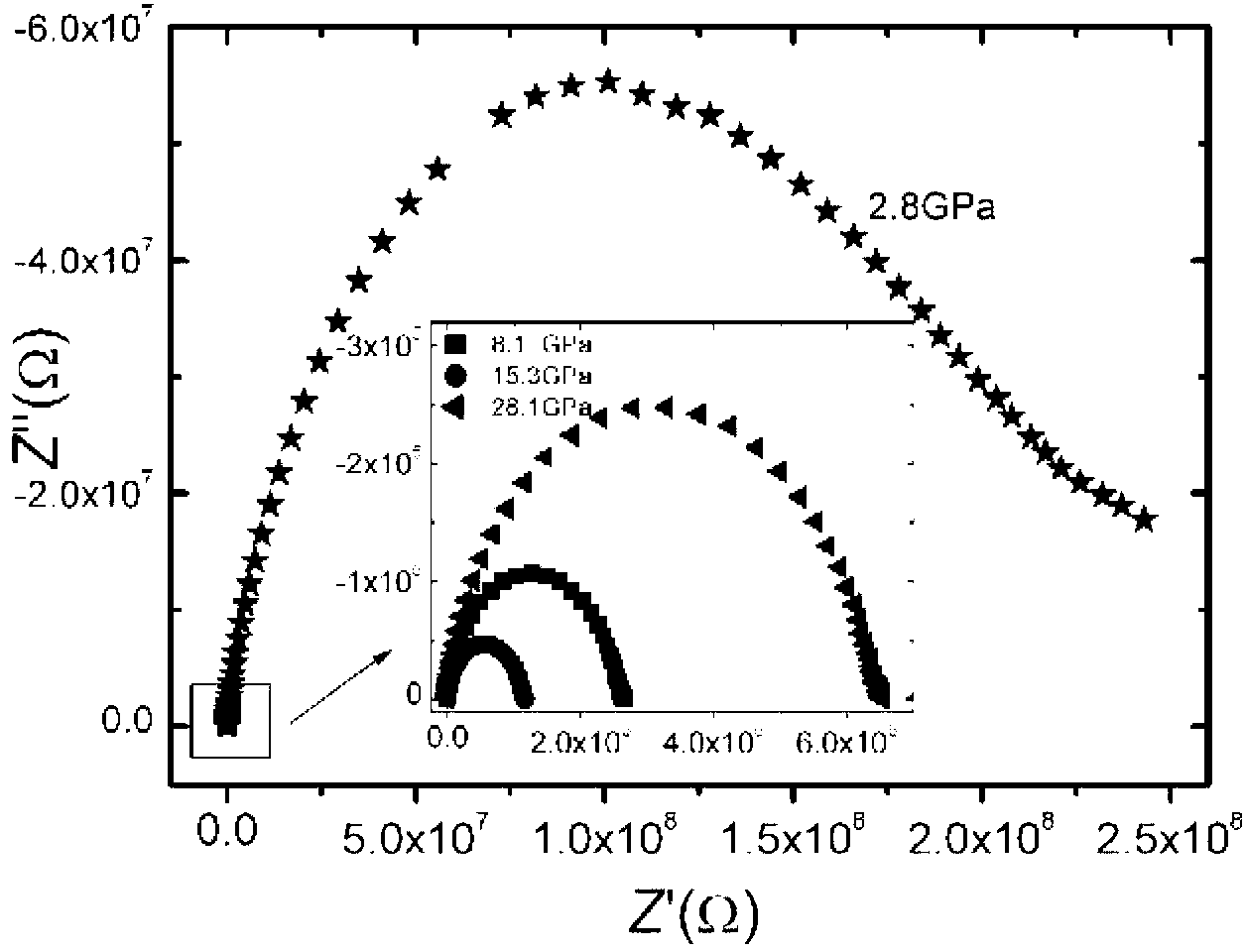

Method for measuring dielectric properties of diamond anvil cells in situ

InactiveCN103076501AGuaranteed shapeGuaranteed fixed effectResistance/reactance/impedenceElectromagnetismMaterials science

The invention discloses a method for measuring dielectric properties of diamond anvil cells in situ and belongs to the technical field of electromagnetic measurement under high voltage. The method comprises the following steps of firstly, assembling the diamond anvil cells, i.e. respectively forming round electrodes on the anvil surfaces of two diamond anvil cells, wherein an insulating layer is arranged on the inner side wall of a sample cavity of a composite insulating cushion; secondly, performing measurement, i.e. using a frequency response analysis meter to obtain relation patterns between an impedance real part and an impedance virtual part under different pressures; and finally, performing data processing, i.e. using Zview software and an electromagnetic metering formula related to dielectric properties to obtain the relative dielectric constant epsilon r, the dielectric constant real part epsilon', the dielectric constant virtual part epsilon'', the loss tan theta and the like. The shapes and the positions of the electrodes are fixed, and meanwhile, correction is performed because of the influence of fringe effect on a measuring result; and the prepared composite insulating cushion ensures complete insulation of the inner wall of a voltage cavity, so that the method for precisely measuring the dielectric properties of a material in situ under high voltage is realized.

Owner:JILIN UNIV

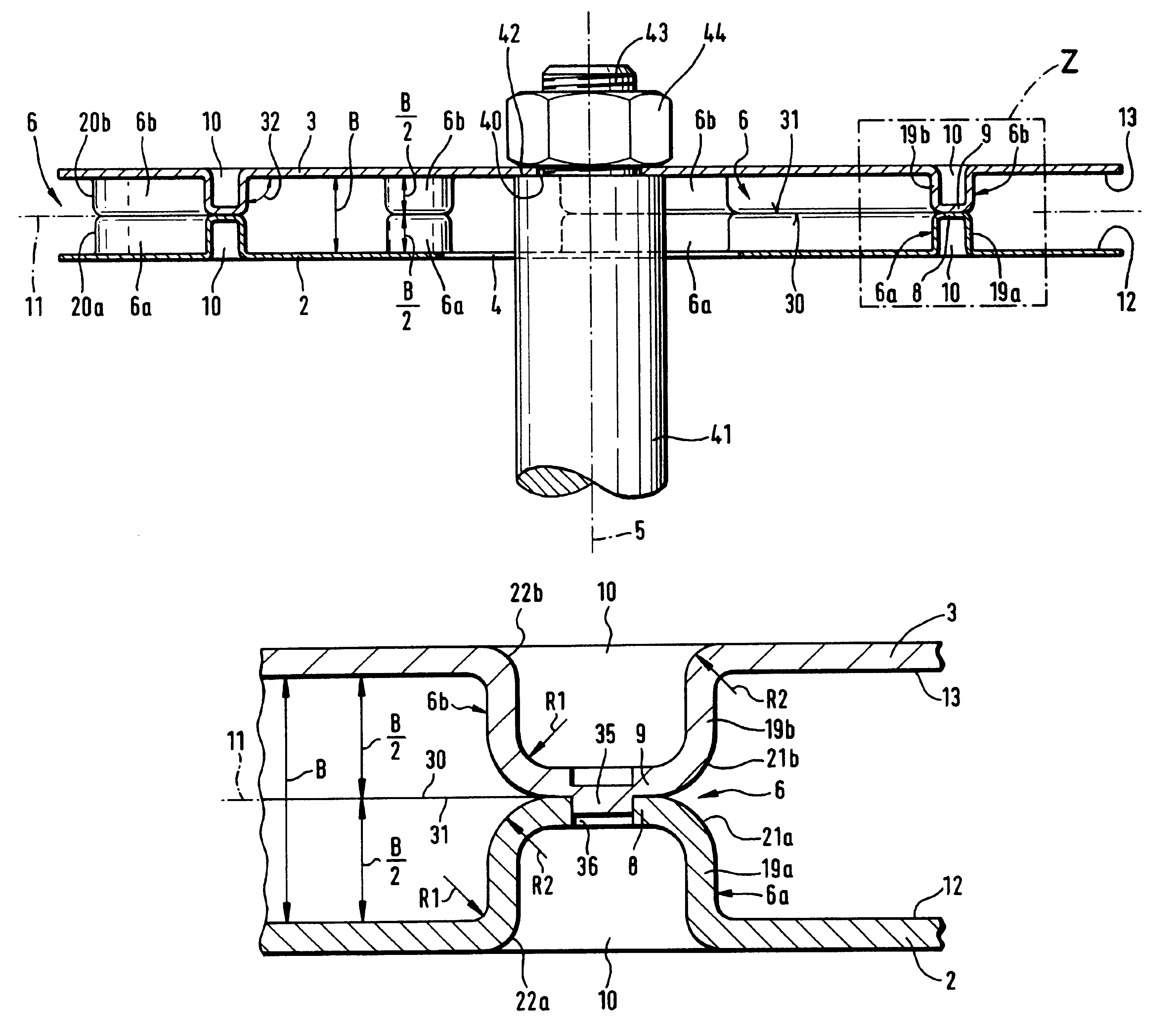

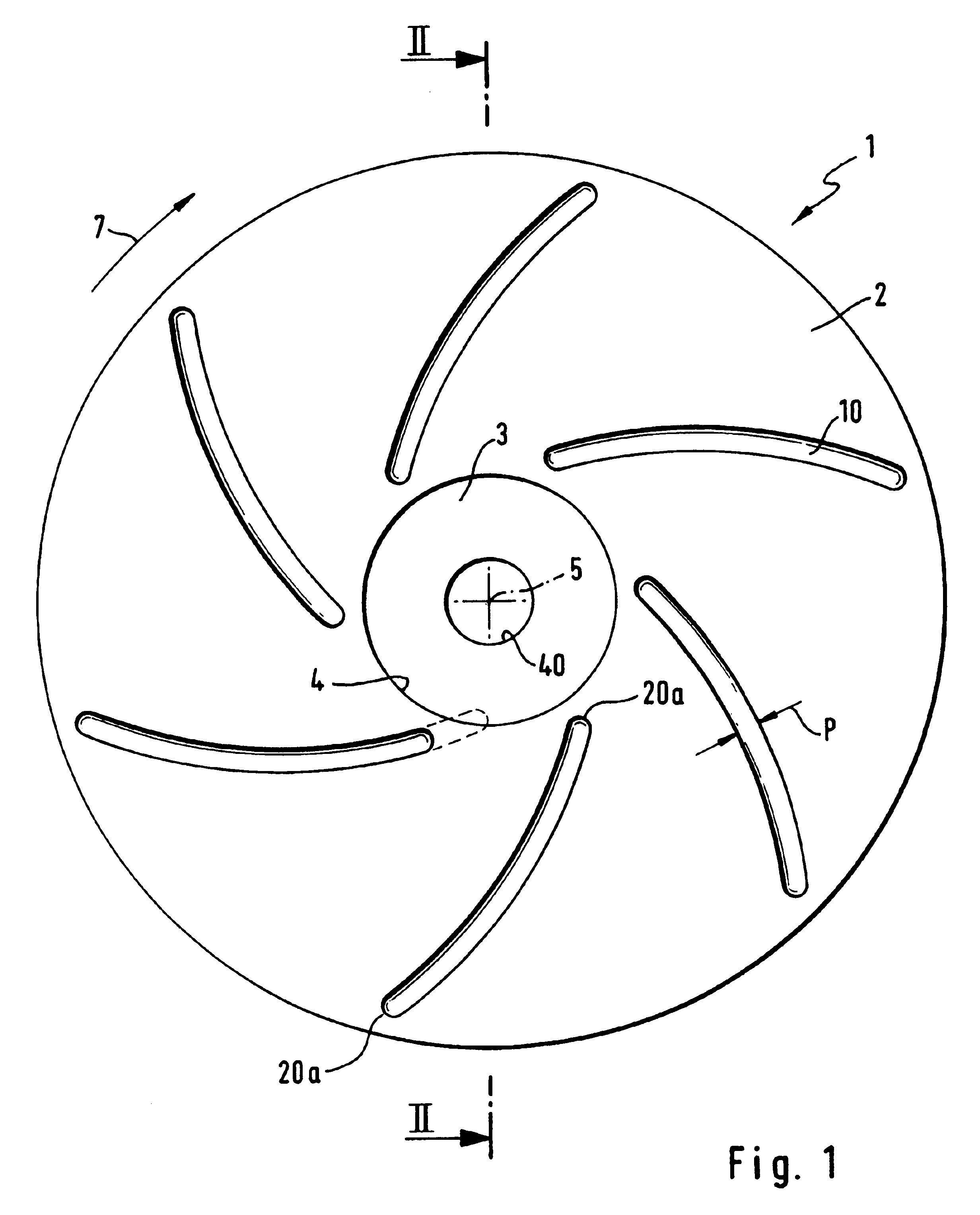

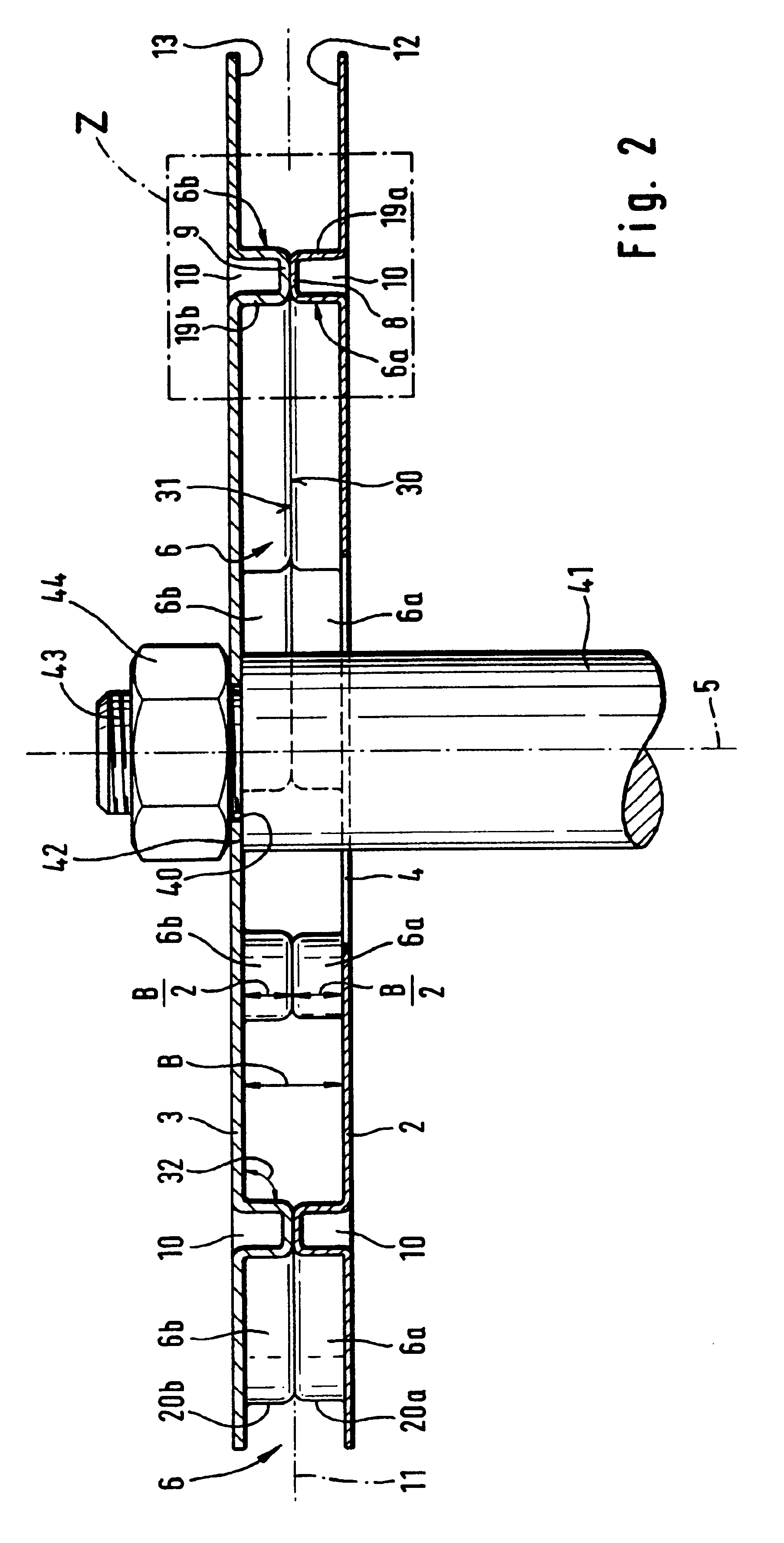

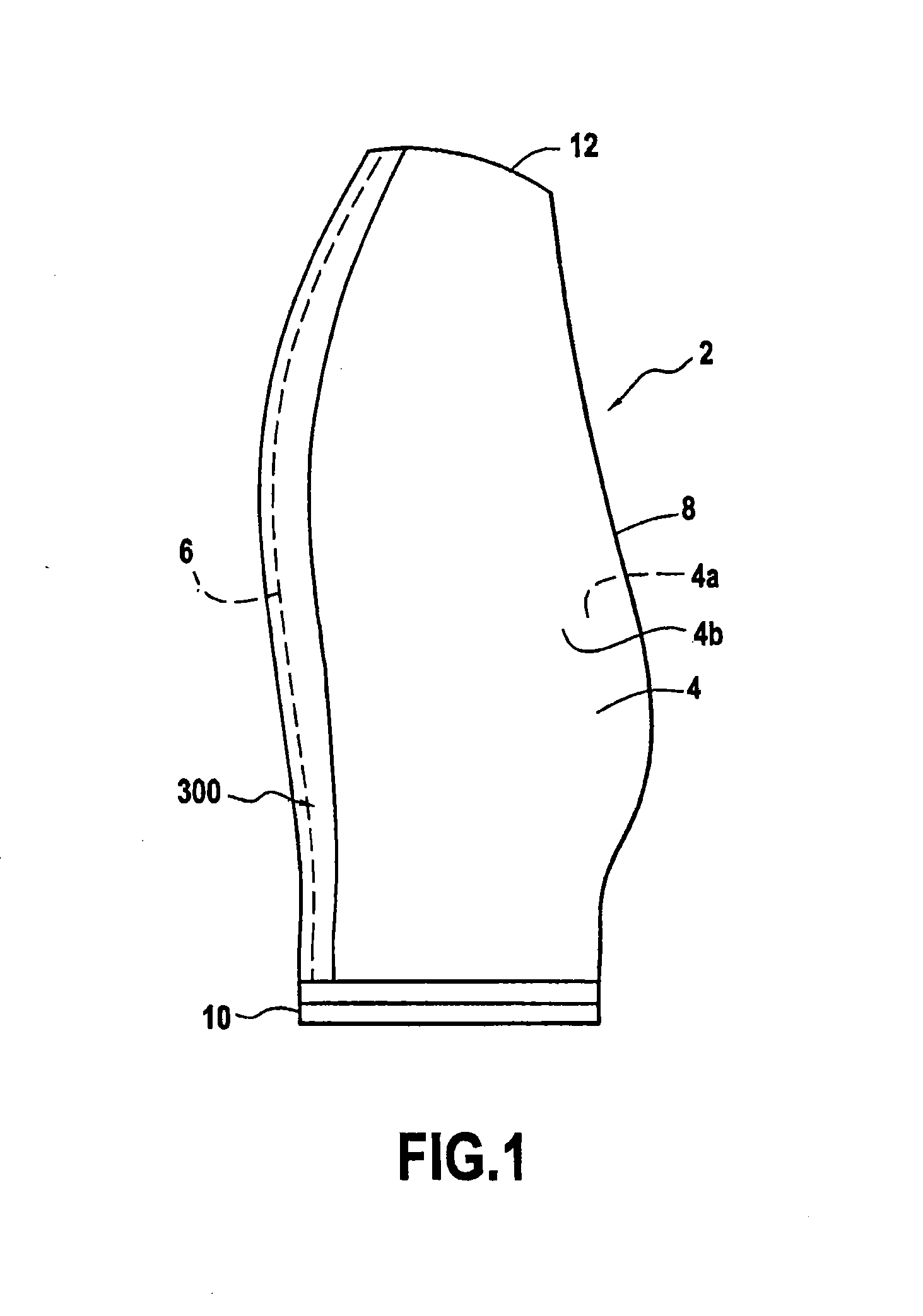

Fan wheel

The invention relates to a fan wheel for a turbo charger. The fan wheel (1) is comprised of a base body with a central axis of rotation (5) wherein the base body is assembled of two cover discs (2, 3) positioned approximately congruently opposite one another, between whose end faces (12, 13) facing one another fan blades (6) are arranged. The fan blades (6) are formed as monolithic parts on at least one of the cover discs (2, 3) and have an axial contact surface (30) against which an oppositely positioned axial contact surface (31) of the other cover disc (2,3) rests. Fastening means are provided in the area of the contact surfaces (8, 9) for non-detachably connecting the cover discs (2, 3) to one another. In order to produce the fan wheel (1) without balancing, the cover discs (2, 3) are embossed from a material that can be embossed and the fan blades (6) are embossed axially out of the material of a cover disc (2, 3), wherein the edge (22a, 22b) between the plane of the cover disc (2,3) and the sidewall (19a, 19b) of a fan blade (6) positioned substantially at a right angle to the plane of the cover disc (2, 3) as well as the edge (21a, 21b) between the sidewall (19a, 19b) of the contact surface (30, 31) are rounded with a radius (R1, R2) of approximately 0.5 to 2 mm.

Owner:HERMANN STAHL

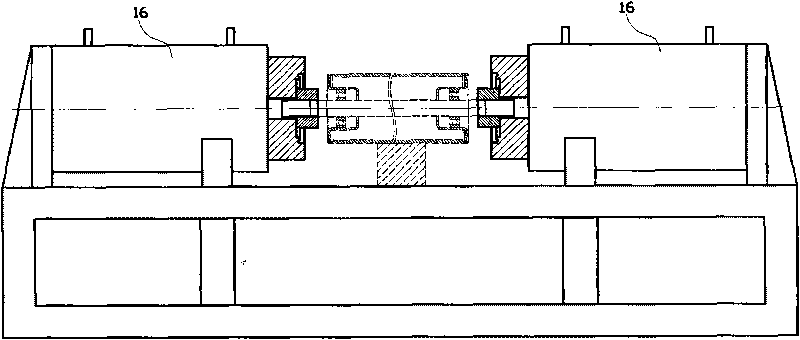

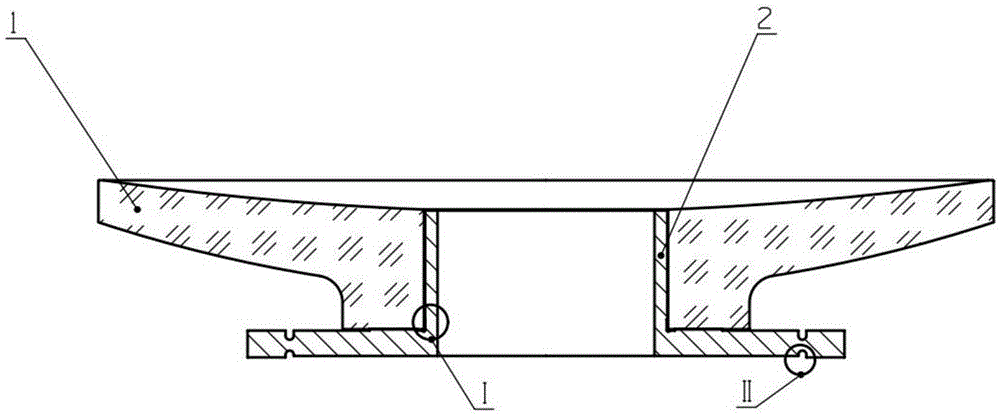

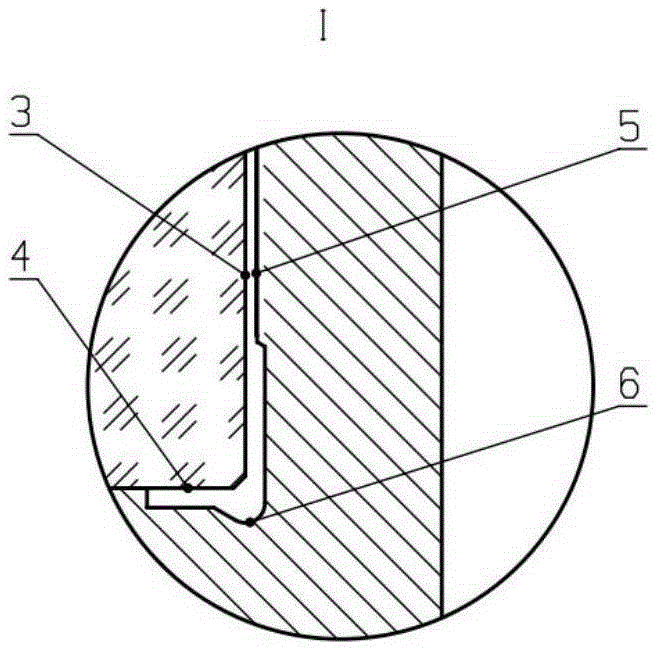

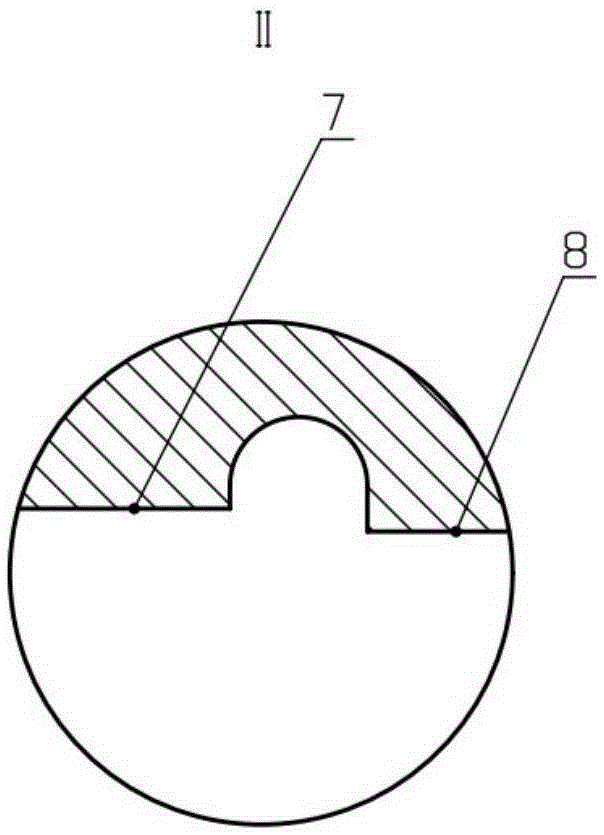

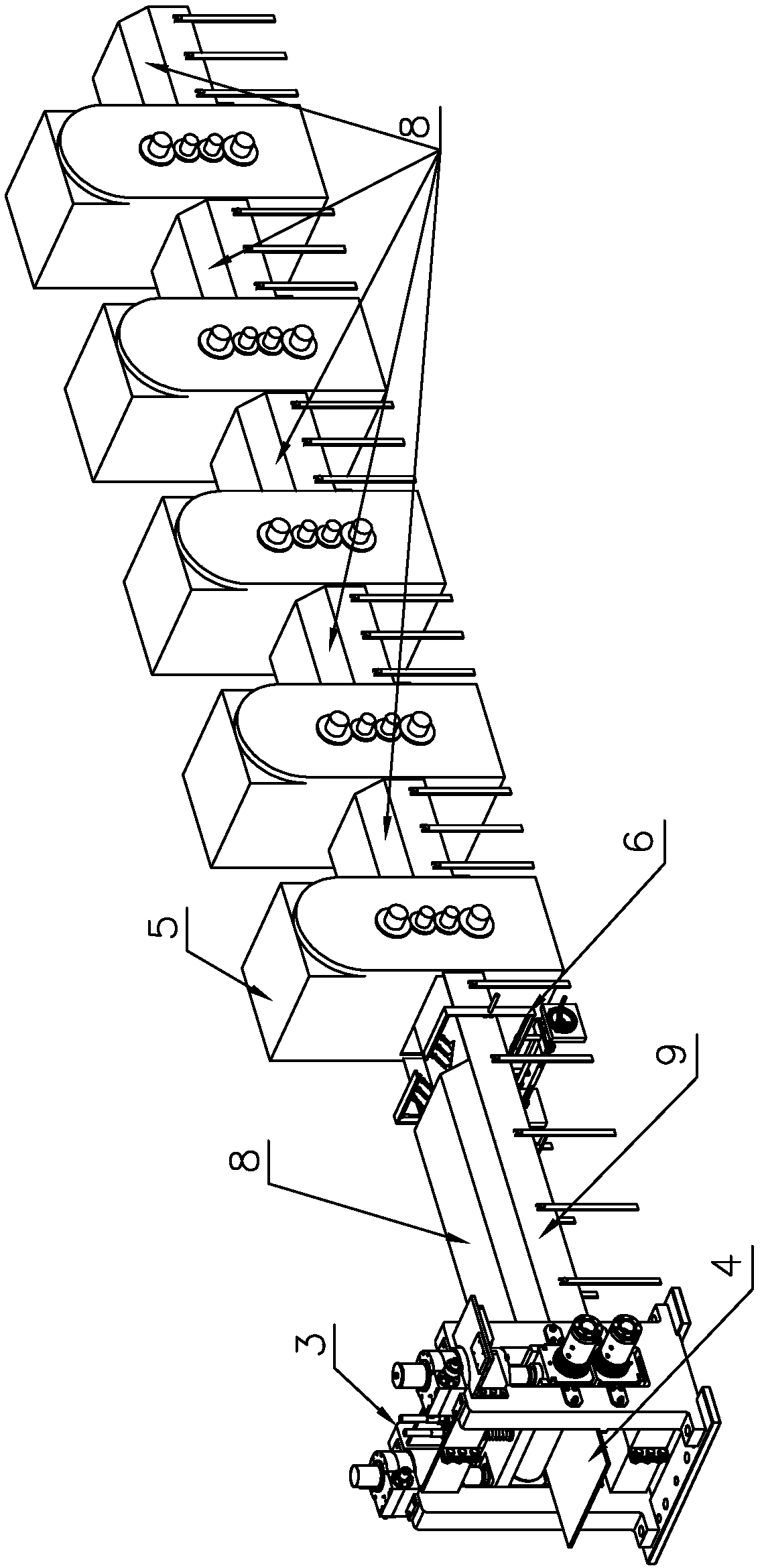

Buckling support roll and buckling support roll assembly machine

InactiveCN101723160ALow equipment costSimple methodConveyorsAssembly machinesSteel tubeMachine press

The invention discloses a buckling support roll and a buckling support roll assembly machine. An assembly stander is provided with a pressure machine; a pressure head and a base are provided with a buckling die respectively; a circular insertion hole of which axis is vertical to a buckling surface is formed in the buckling die; a flat-bottom circular groove of which axis is on the same straight line as the axis of the circular insertion hole is formed on the buckling surface; a stepped columnar bearing director of which the outer section is inserted in the circular insertion hole and which has a small outer section diameter and a large inner section diameter is arranged in the flat-bottom circular groove; and the bearing director is provided with a through hole of which axis is on the same straight line as the axis of a column of the bearing director. The manufacturing charge is low, the process for manufacturing the support roll is simple, particularly buckling bearing cups at two ends of a steel tube and bearings pushed to the bottoms of the bearing cups and a support roll shaft are combined by a buckling die, and the shape and position of the support roll are ensured after the combination; and the manufactured support roll has the advantages of higher coaxial degree, smooth two ends and lower processing cost. The buckling support roll assembly machine is a better device special for manufacturing a belt conveyor support roll.

Owner:赵士华 +1

Rolling method of titanium steel composite board

ActiveCN102794299AQuality assuranceReduce harmTemperature control deviceWork treatment devicesForeign matterWater flow

The invention provides a rolling method of a titanium steel composite board. The rolling method comprises the following steps of: 1, selecting the titanium steel composite board provided with a titanium plate as an upper layer and a steel plate as a lower layer; 2, pre-treating a surface; 3, heating and soaking in a heating furnace; and 4, rolling on a hot mill, and removing scale and cooling by utilizing high-pressure water. According to different physical characteristics of the titanium plate and the steel plate under the high-temperature state, through setting the proper heating and soaking processes, and adopting the high pressure water to remove the scale and cool in the rolling process, an oxide skin on the surface of the titanium steel composite board is greatly reduced, and sundries on the surface of the titanium steel composite board are eliminated, meanwhile, the titanium plate and the steel plate are cooled at different water flows, so that the deformation degree of the titanium plate corresponds to the deformation degree of the steel plate, head buckle or unwarp phenomenon of the titanium steel composite board in the rolling process can be effectively prevented, and damage about a roller is greatly reduced; and the titanium steel composite board, rolled by the invention, has the advantages of clean and tidy surface, no foreign matters to press and good plate cut.

Owner:WESTERN TITANIUM TECH

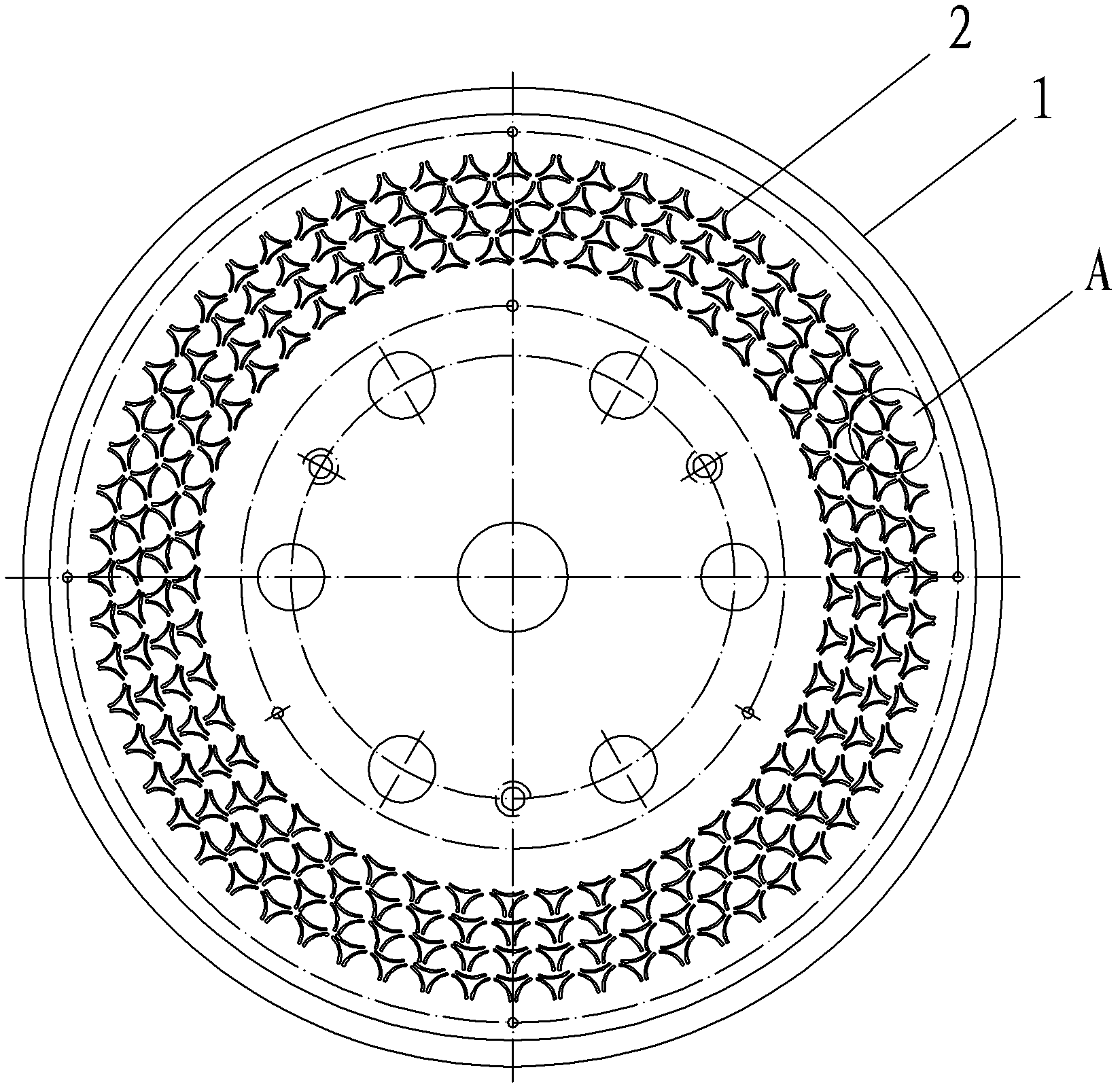

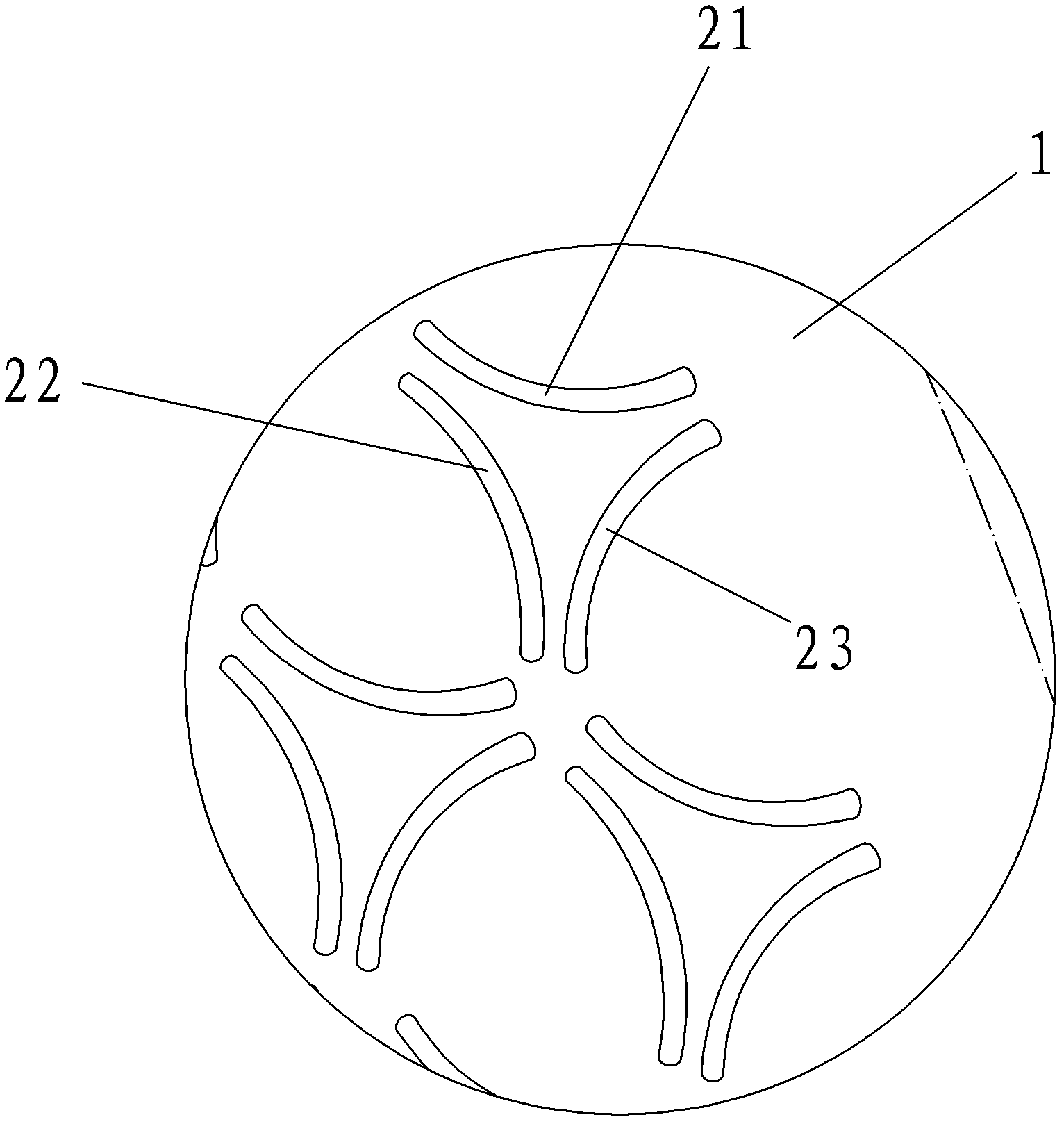

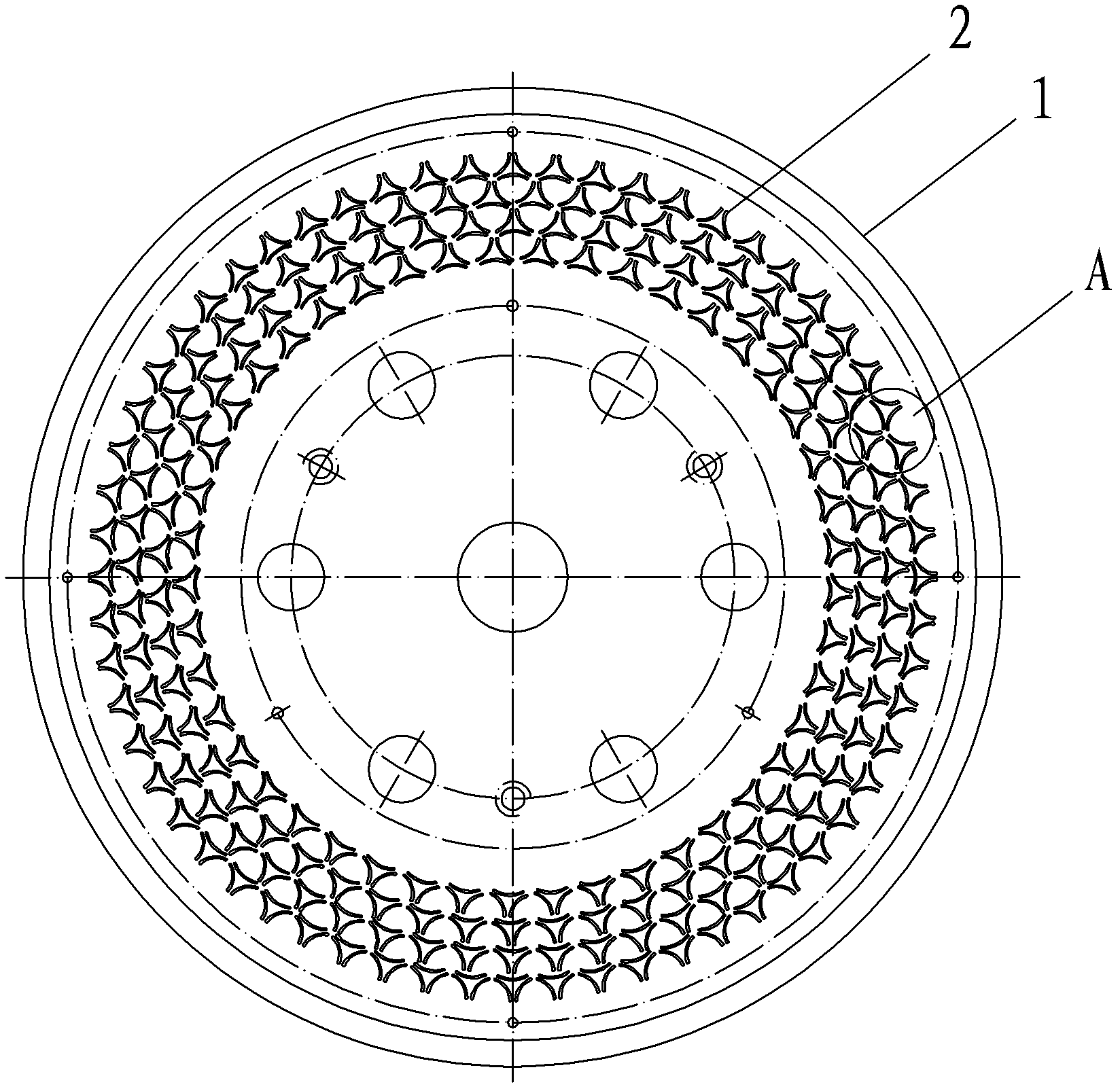

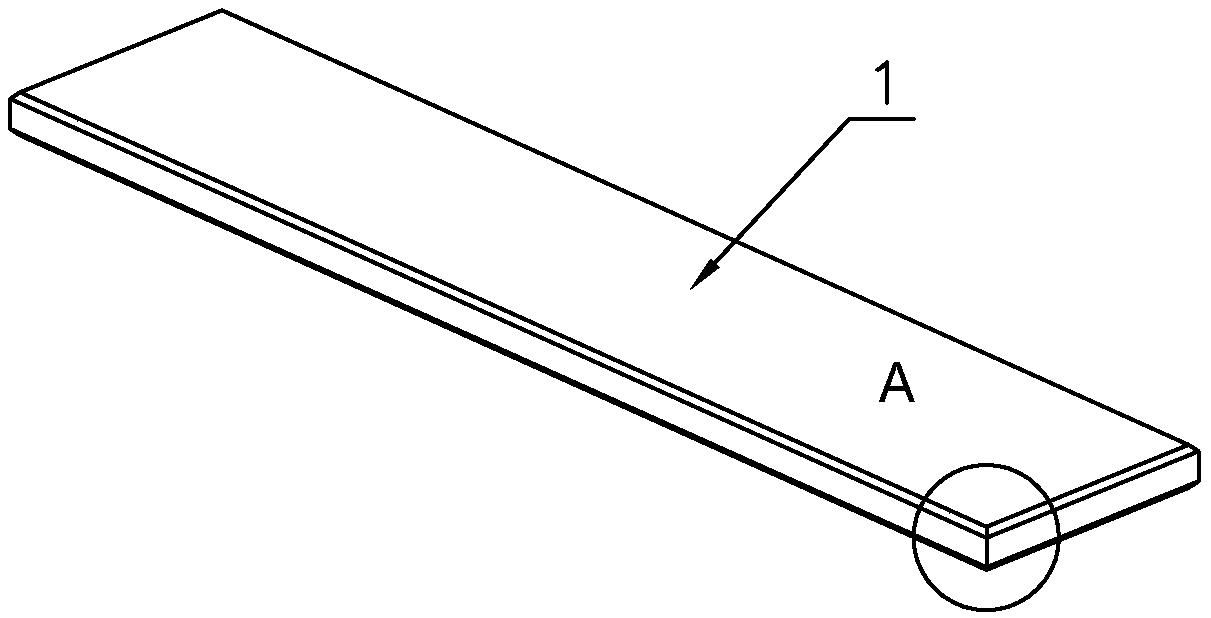

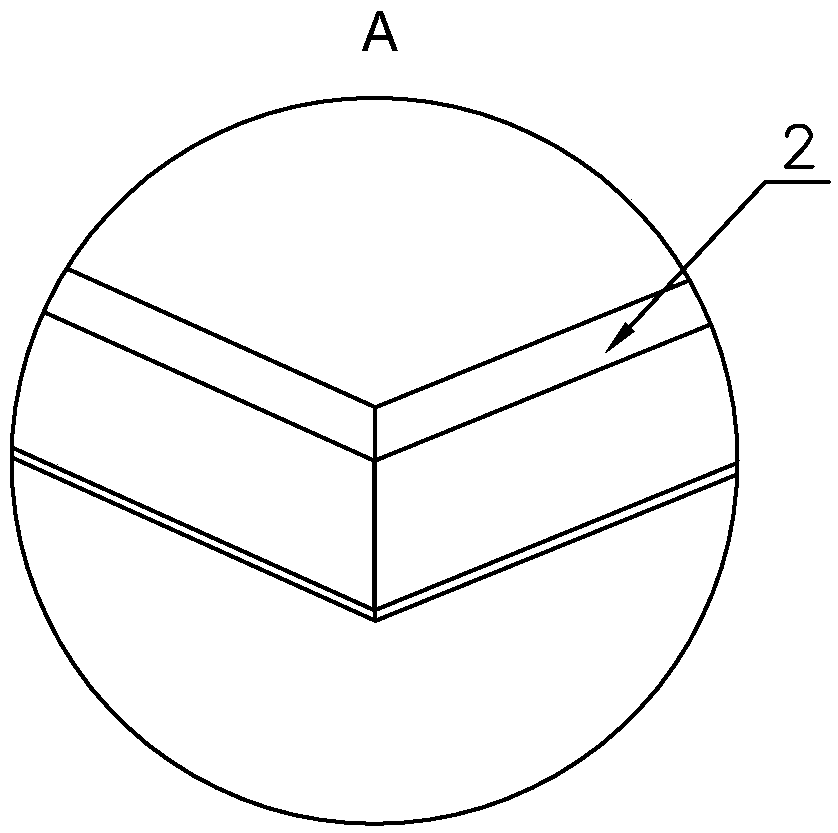

Preparation method of triangular hollow dacron short fiber and spinneret plate for preparing triangular hollow dacron short fiber

ActiveCN102517661AReduce heatLower extrusion swell ratioHollow filament manufactureFilament/thread formingThermal insulationLight reflection

The invention discloses a preparation method of a triangular hollow dacron short fiber and a spinneret plate for the preparing triangular hollow dacron short fiber. Melting spinning is performed after mixing and drying of a spinning raw material, a nascent fiber for preparing triangular hollow dacron is extruded through the special-shaped hole spinneret plate, winding, filament dropping and bunching are performed in sequence, and finally flabby heat setting is performed after oil bath drafting, steam drafting and curling. In the preparation method, an arc-shaped open hole is adopted on the spinneret plate, the concave surface is outward, extruding swelling occurs during the spinning process, the concave surface is substantially a plane, and a fiber section can maintain an equilateral triangle shape well. Compared with an existing special-shaped section hollow technology, the plane of the triangular hollow dacron produced by the preparation method is good in light reflection effect and glossiness, gloss and application effects of fabrics are improved, soft effects are improved, thermal insulation is excellent, stable and efficient low-frequency sound insulation functions are provided, hollow rate of the fiber can be 30%-40%, the special-shaped degree can be 50%-60%, the hollow rate and the special-shaped degree are stable, the volume density is low, and good advantages are provided.

Owner:福建鑫华股份有限公司

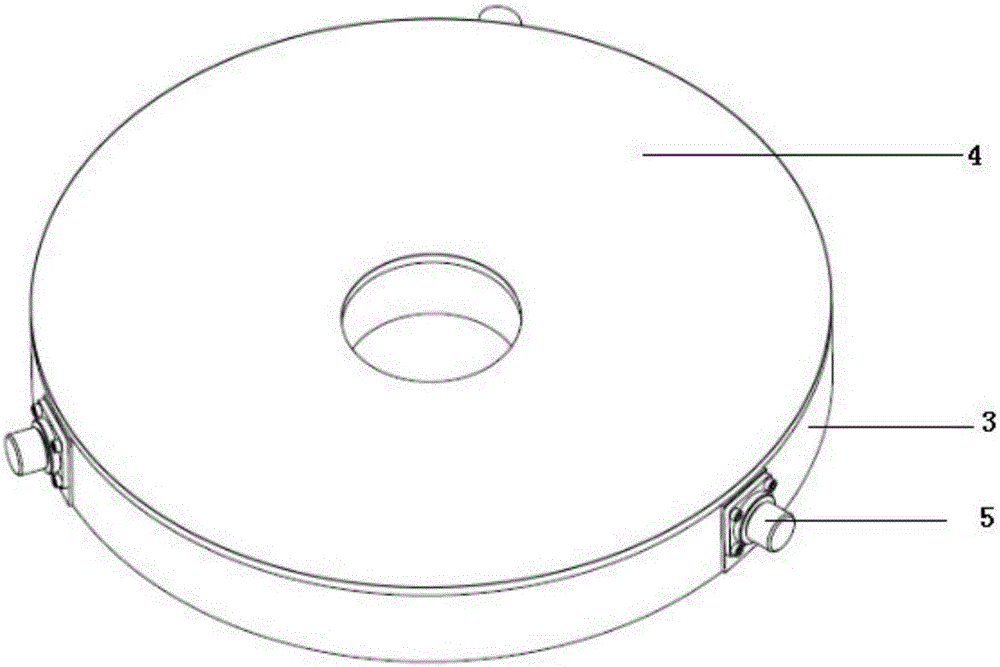

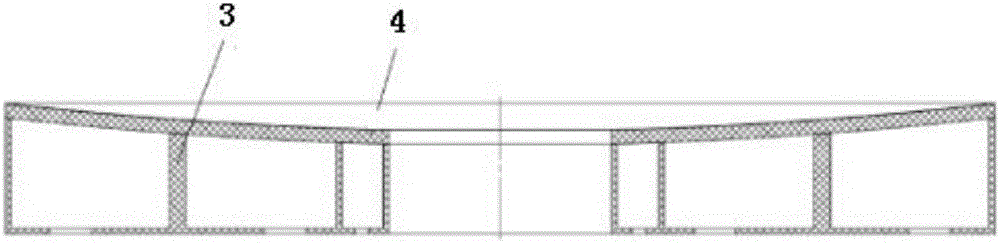

Space camera reflecting mirror center support device

A space camera reflecting mirror center support device relates to the technical field of a space camera. The space camera reflecting mirror center support device solves the problem of a poor reflecting mirror surface deformation resulted from a large adhesion area, which exists in an existing reflecting mirror support structure, of a reflecting mirror, the problem of low installation precision resulted from poor axial and radial positioning, which exist in the existing reflecting mirror support structure, when the reflecting mirror and the support structure are adhered, and other problems. The space camera reflecting mirror center support device comprises a flexible support structure, and the flexible support structure is directly obtained through a machining mode; the flexible support structure comprises a support structure and three flexible structures uniformly distributed in the circumferential direction of the support structure; and a reflecting mirror is accurately positioned and installed, and, through design of six glue grooves, adhesive stresses are small, and an influence of assembly on a surface shape of the reflecting mirror is reduced. Through design of multiple radial and axial flexile links, dynamic structural rigidity and static structural rigidity are guaranteed, influences of a borne force and a deformation of a machine body of the space camera on the reflecting mirror can be effectively eliminated, and influences of a temperature change, the gravity and other factors on the surface shape of the reflecting mirror are reduced.

Owner:CHANGGUANG SATELLITE TECH CO LTD

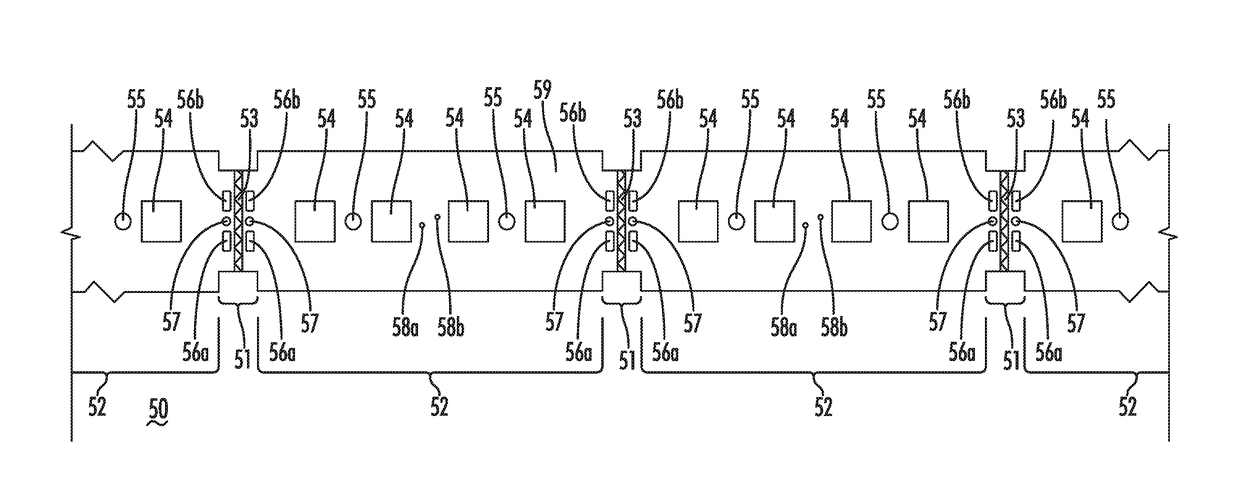

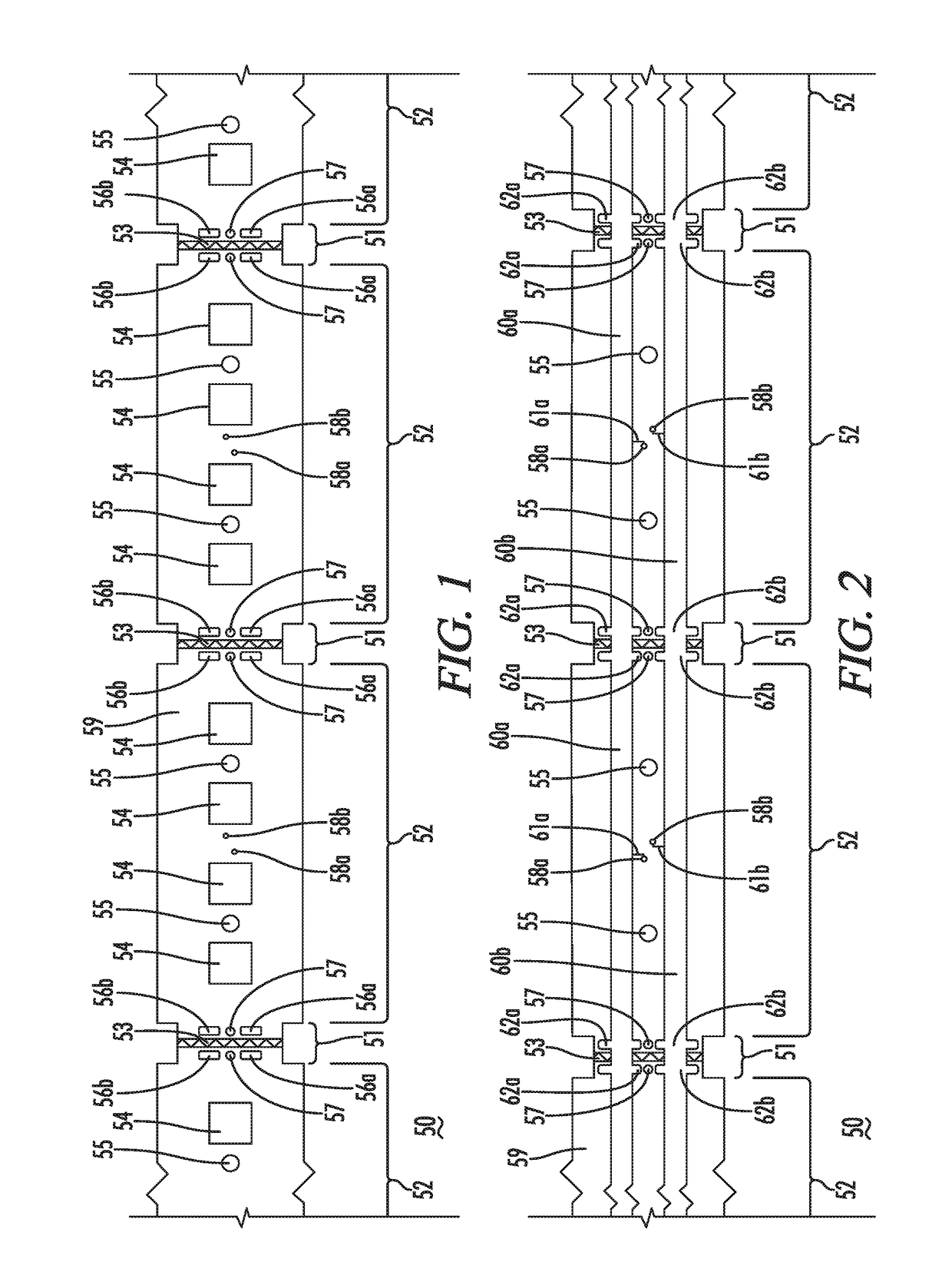

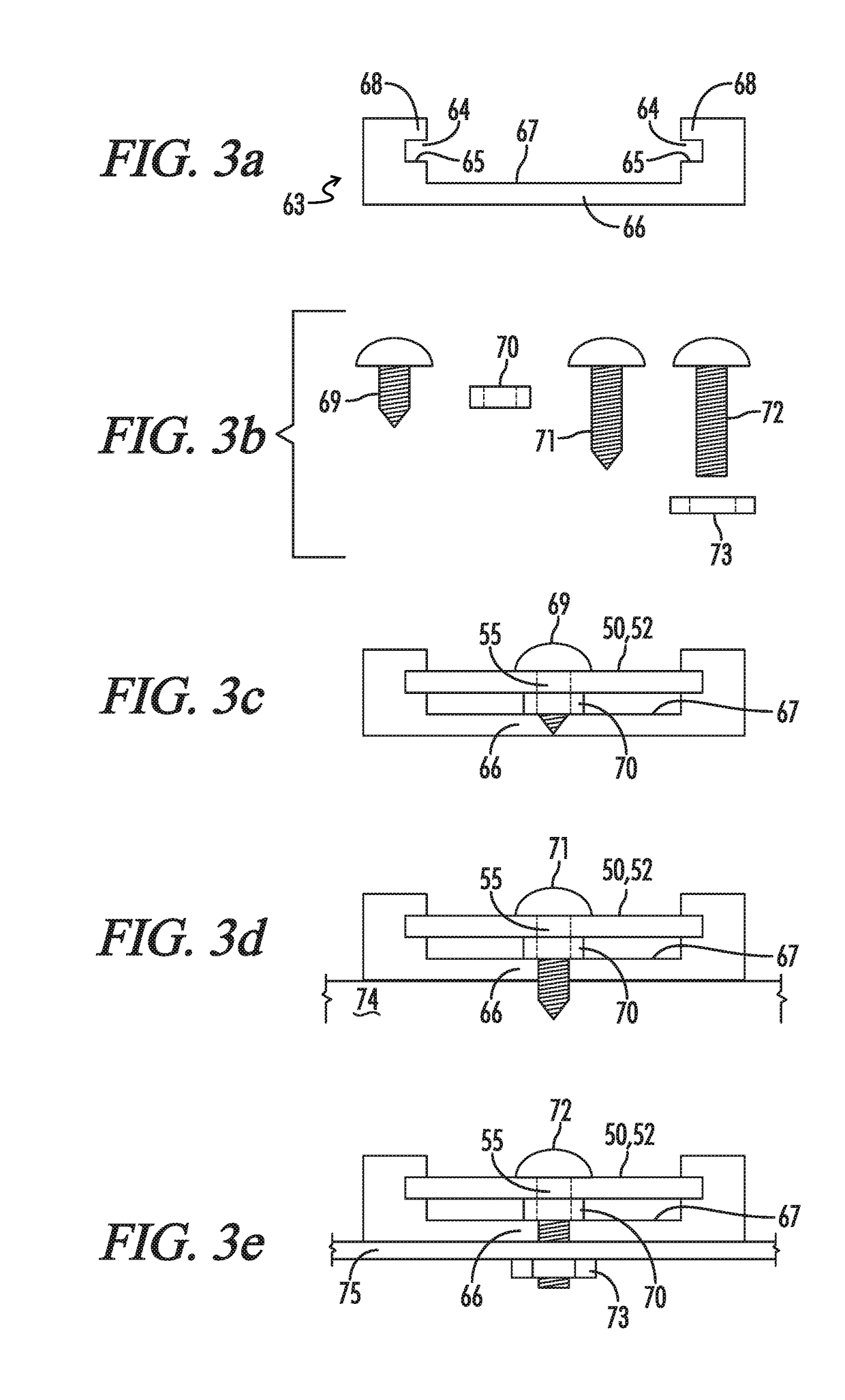

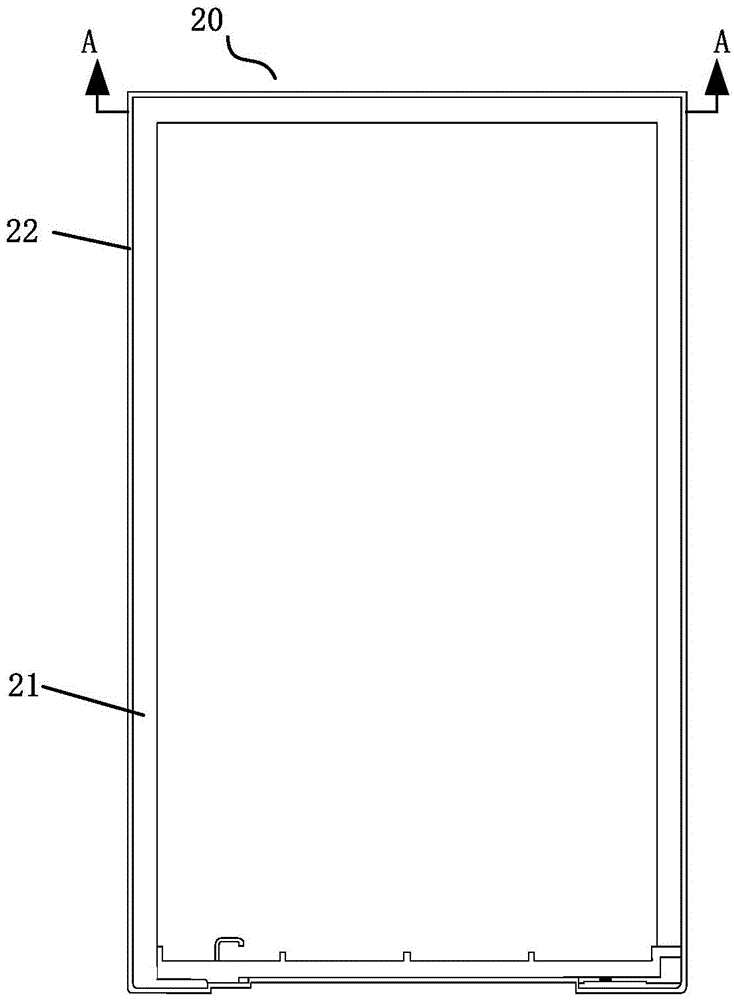

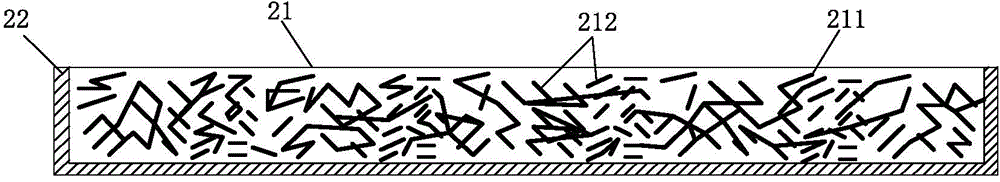

LED Light Linear Strip, Mounting Structure and Clip Assembly

ActiveUS20170122507A1Efficiently provideGuaranteed shapeElectrical apparatusLighting support devicesControl signalLED lamp

A system and method comprised of an LED light strip whose electrically insulating core structure is somewhat flexible and elastic and whose alternating light producing sections and narrower clip sections have a top side containing LED elements and control signals and an underside containing a high capacity voltage bus, and a three sided mounting structure where an installed LED light strip is the fourth side with LED elements facing out and the voltage bus protected inside, and a clip system of two halves which affix to each other around a narrower clip section with a lower half connecting electrically to the voltage bus under the narrower clip section and installing in one side of the mounting structure and an upper half connecting electrically to control signals on the top half of the narrower clip section and installing in the other side of the mounting structure.

Owner:HOFFMAN JEREMY P

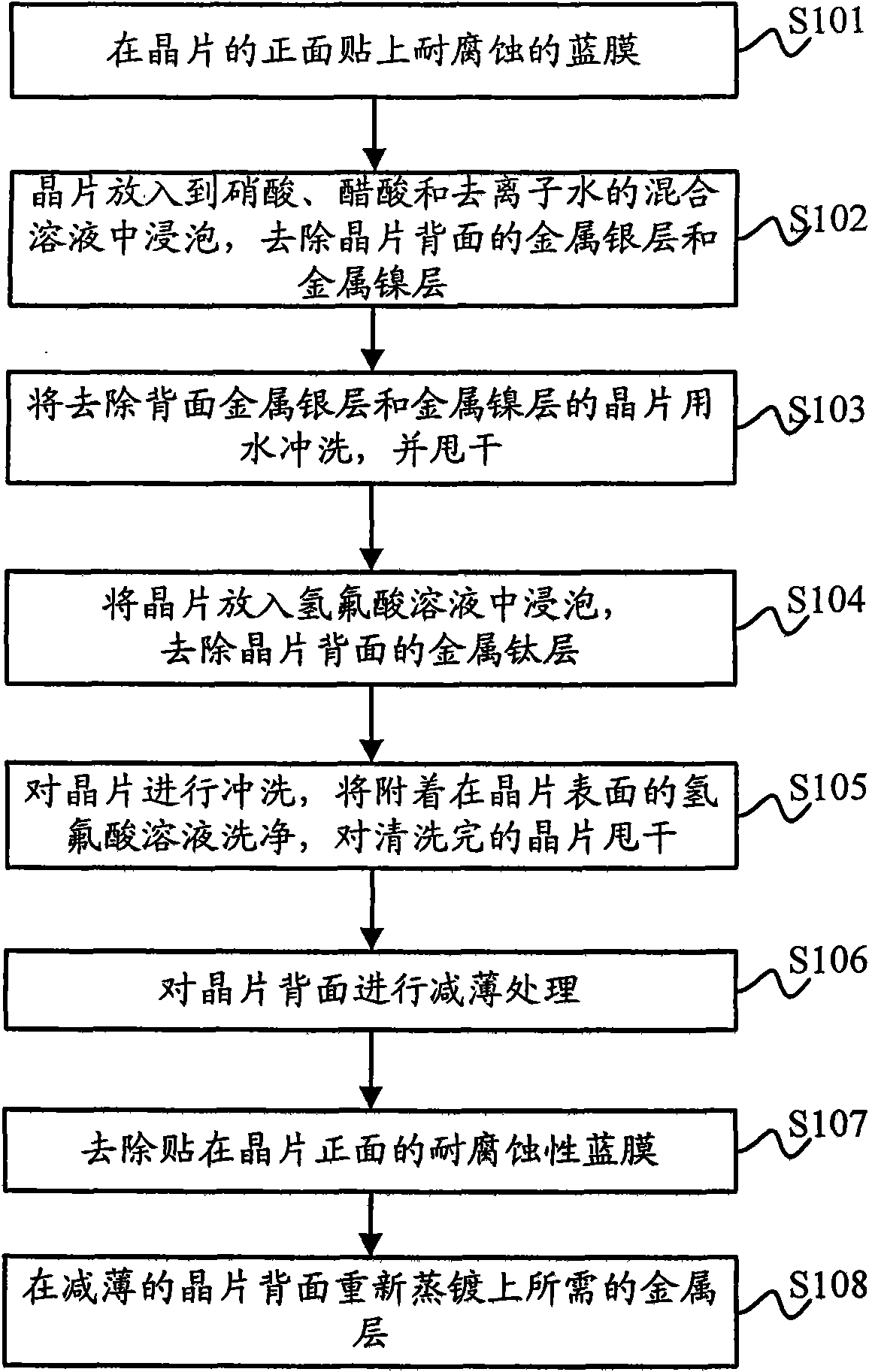

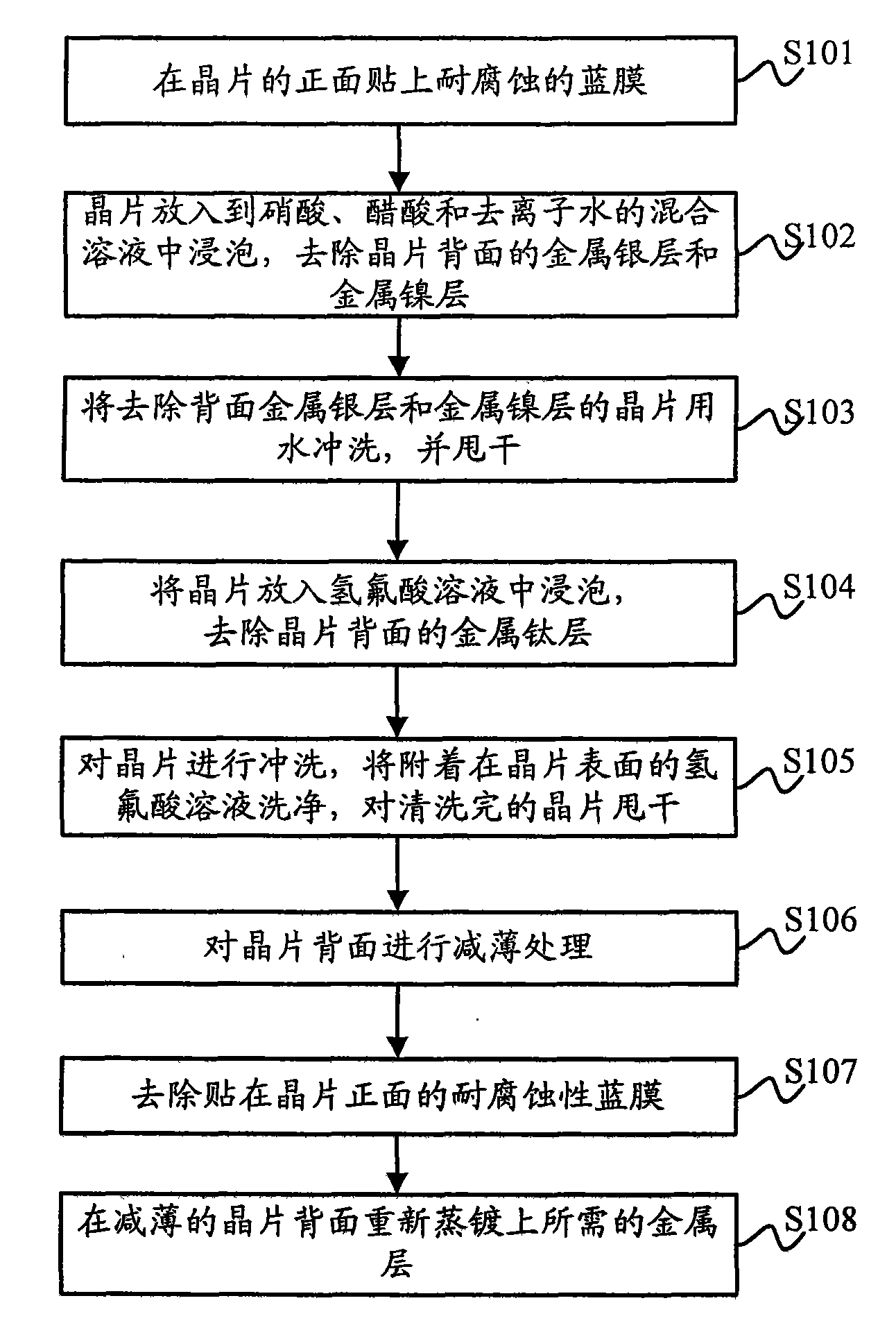

Rework method for back-side metal process

InactiveCN102097288AGuaranteed shapeQuality assuranceSemiconductor/solid-state device manufacturingEtchingEngineering

The invention discloses a rework method for a back-side metal process, comprising the following steps of: removing a metal layer on the back side of a wafer to be reworked by wet etching; thinning the back side of the wafer of which the metal layer is removed; and re-evaporating the required metal layer on the back side of the thinned wafer. By adopting the embodiment, the abnormal metal layer on the back side of the wafer can be removed, the appearance and the quality of the back side of the reworked and thinned wafer can be ensured and are consistent to those of the back side of the wafer after being thinned through a normal back gold process, and the problem of metal layer stripping caused by stress on the back side of the wafer is avoided. Due to the flow, reworking on a product with the abnormal back-side metal layer already appeared is realized, and the yield and the reliability of the final product are ensured.

Owner:PEKING UNIV FOUNDER GRP CO LTD +1

Paper making apparatus and method

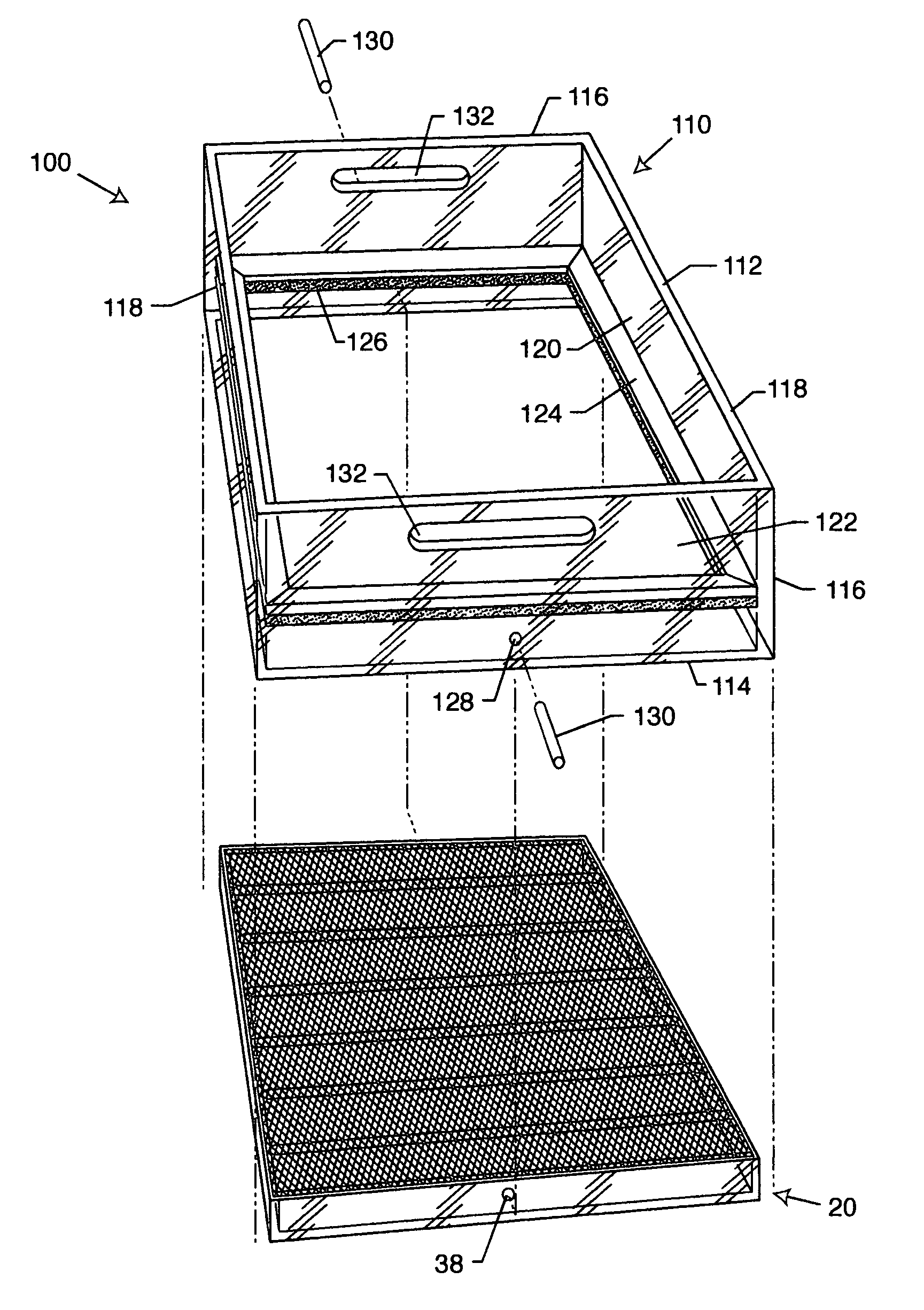

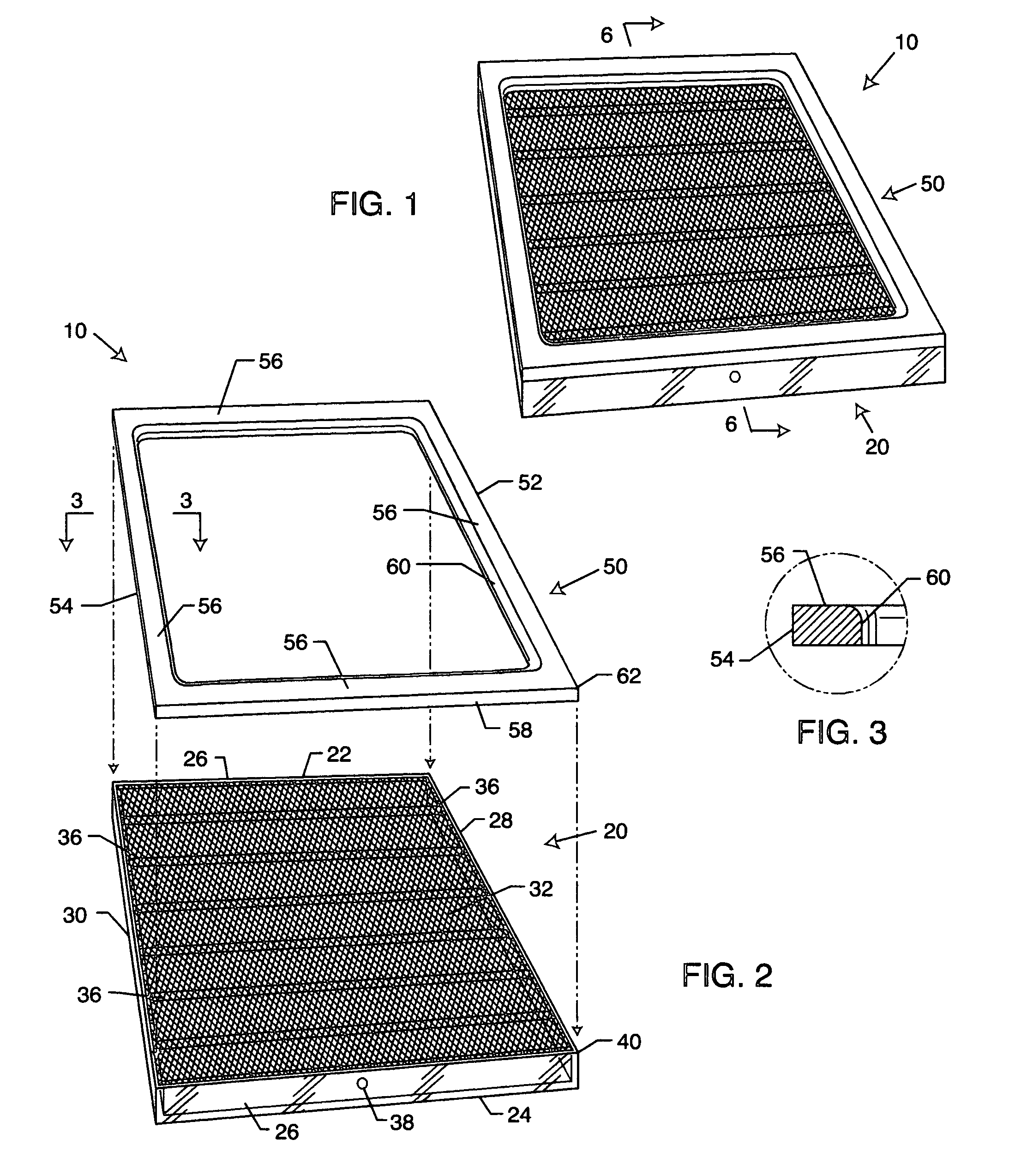

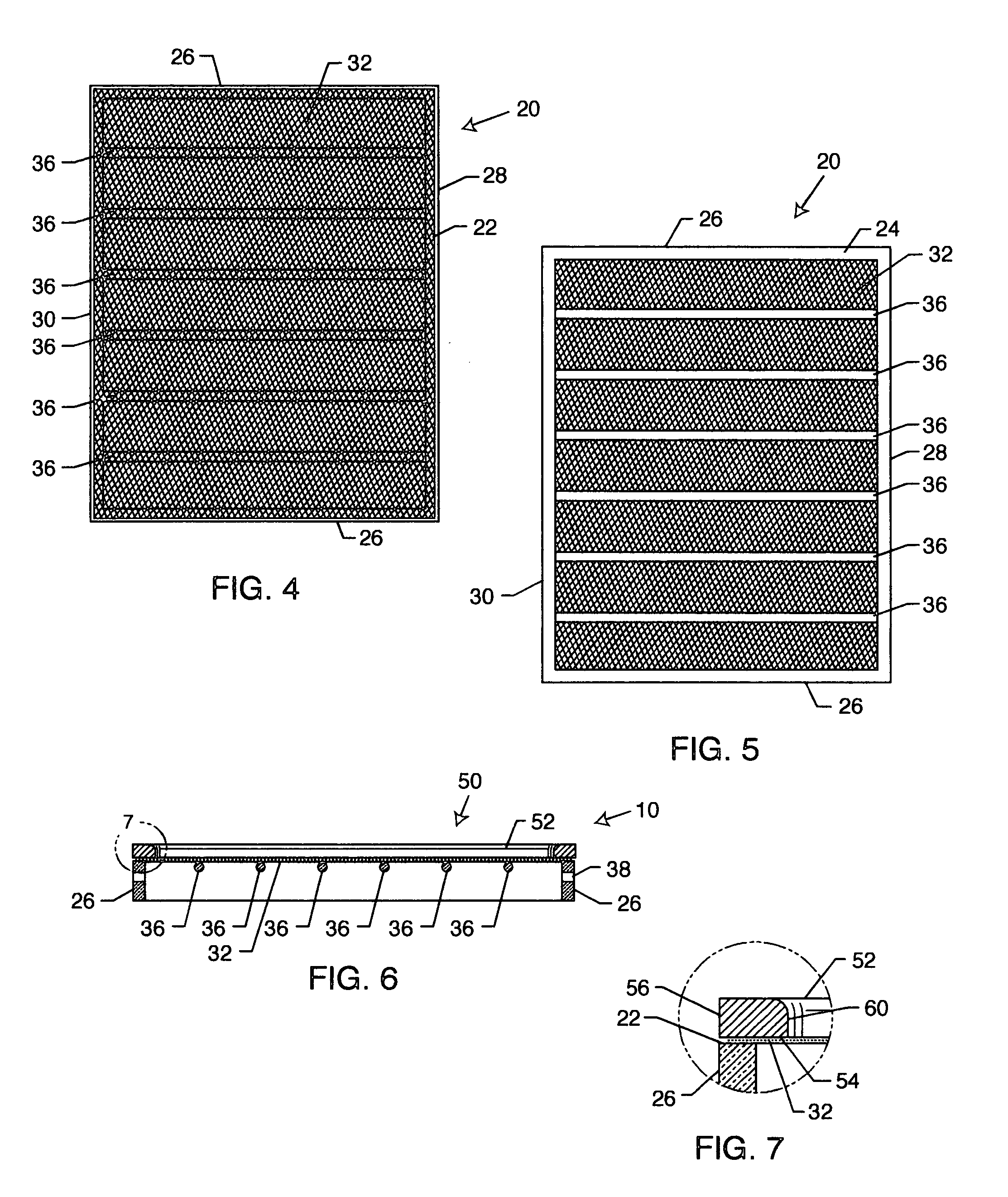

InactiveUS7507315B1Uniform shapeUniform thicknessPaper-making machinesCeramic shaping liningsComparable sizePulp and paper industry

A paper making apparatus includes a mould having a mesh screen and a deckle of comparable size. The deckle includes a shaped inner edge for directing pulp onto the screen. The mould and deckle are held together and dipped in a vat having a pulp and water slurry to form a sheet of paper. The mould and deckle are constructed of materials that will not warp, crack, twist, or otherwise deform from repeated use in water. The mould also includes structural ribs to hold its shape. An alternative embodiment of the invention includes a mould having a mesh screen and structural support ribs and a deckle box having a shaped inner lip and a sealing means attached to the lip. The combination of mould and deckle box may be dipped in water and does not require the presence of a vat having a pulp stock. Pulp may be poured into the mould and deckle box assembly. The mould and deckle box are constructed of materials that will not warp, crack, twist, or otherwise deform under normal use in water.

Owner:SEELENBINDER APKE MAXINE

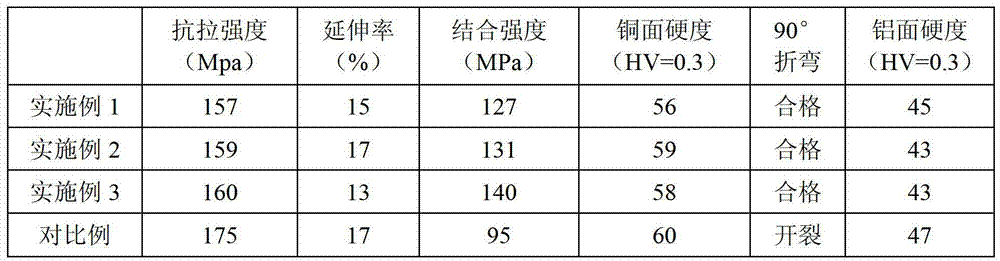

Aluminum substrate layer material of copper-aluminum composite metal strip, strip and machining method thereof

ActiveCN103029377AEasy to controlSuppress exceptionTension/compression control deviceMetal rolling arrangementsMetal stripsAluminum substrate

The invention discloses an aluminum substrate layer material of a copper-aluminum composite metal strip, a strip and a machining method of the strip. According to the invention, the aluminum substrate layer material of the copper-aluminum composite metal strip is formed by adding the elements of Si, Fe, Cu, Mn and Ti into an aluminum substrate layer material, so that the machining property of an aluminum substrate layer is improved effectively, the machinability of the aluminum substrate layer can accord with that of a copper covering layer. According to the invention, a copper covering layer material with the shop sign of TU2 and the state of TM is adopted by the copper-aluminum composite metal strip as the copper covering layer, so that the machining property of the aluminum substrate layer can further accord with that of the copper covering layer. The strip adopts multi-pass rolling, reduces single-pass machining rate, and adopts sectional type annealing, so that the reliability of annealing is improved, and the abnormality of copper and aluminum caused by the difference of properties is restrained. The copper-aluminum composite metal strip manufactured through the machining method has the advantages that the bonding strength is high, and the strip cannot easily crack because of bend.

Owner:LUOYANG TONGYI METAL MATERIAL DEV

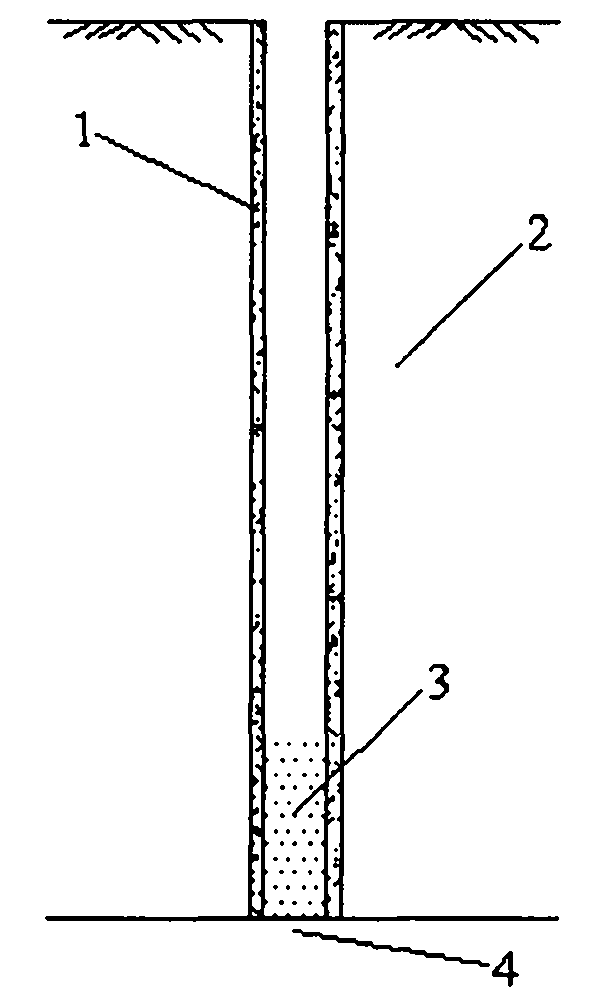

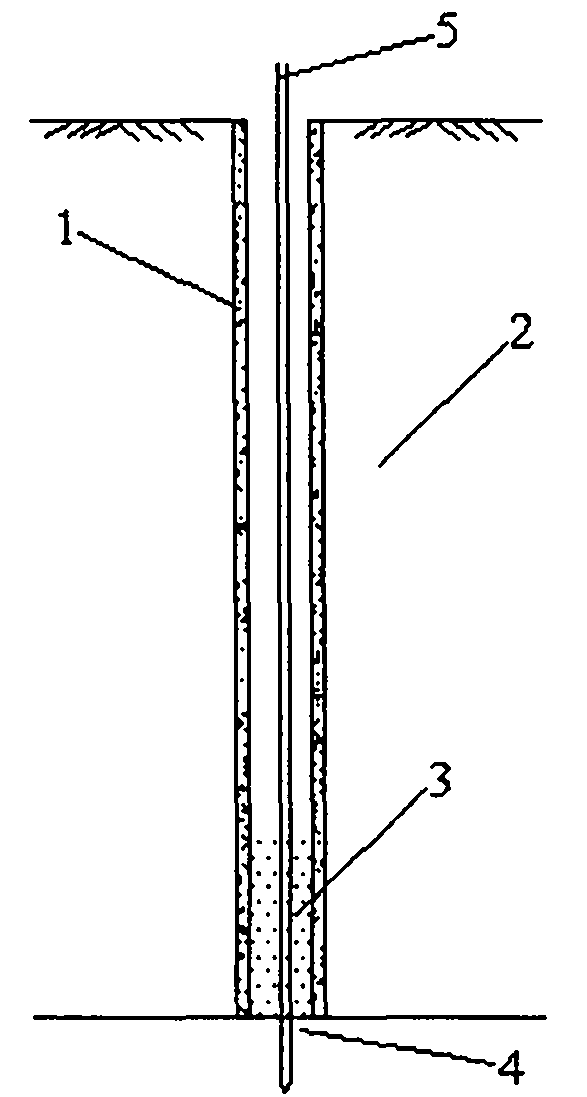

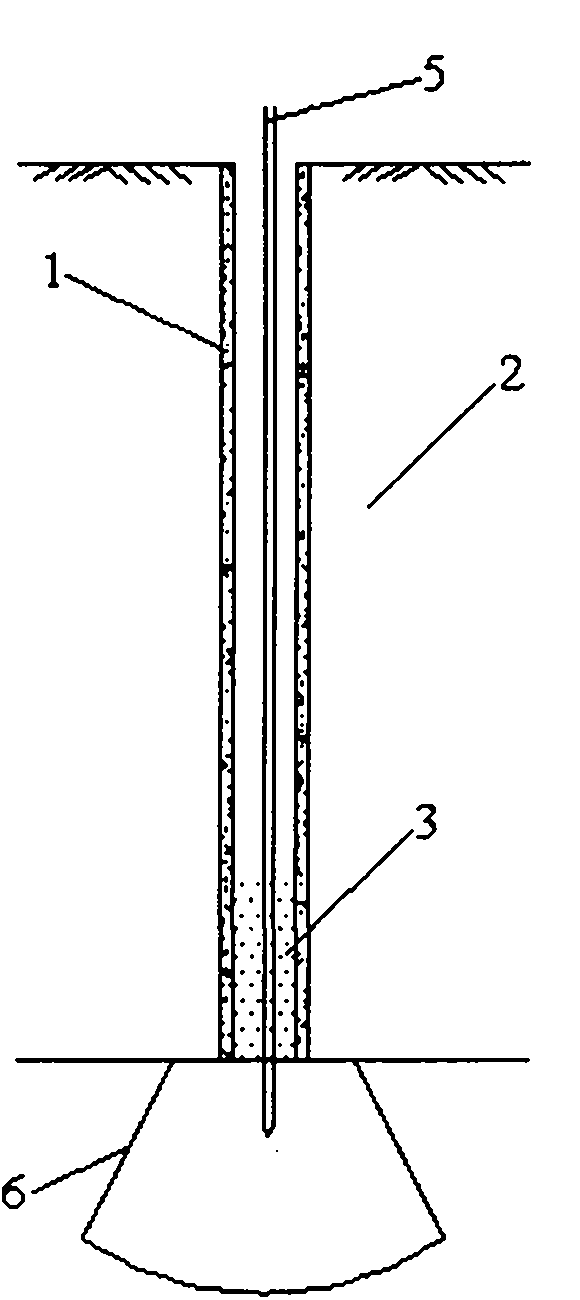

PHC pile-based multiple high jet pedestal pile construction method

The invention discloses a prestressed high-strength concrete (PHC) pile-based multiple high jet pedestal pile construction method, which comprises the following steps of: statically pressing a PHC pile to the designed depth of a soil layer, drilling to the depth below the bottom of the PHC pile through the hollow part of the PHC pile by a multiple high-pressure spiral jet drill rod, performing multiple tube construction at the bottom of the PHC pile to form an enlarged head cavity greater than the diameter of the PHC pile and in accordance with the design requirement, and then filling the enlarged head cavity to form an enlarged head. The method has obvious economic benefit; and compared with other pile types acquiring the same bearing capacity, the PHC pile-based multiple high jet pedestal pile has obvious economic advantage.

Owner:HENAN POLYTECHNIC UNIV

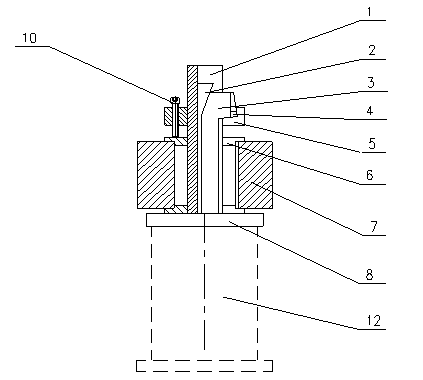

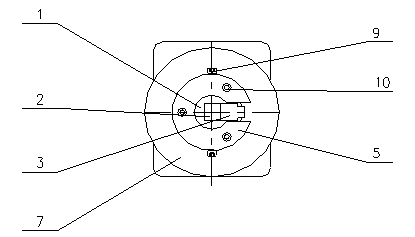

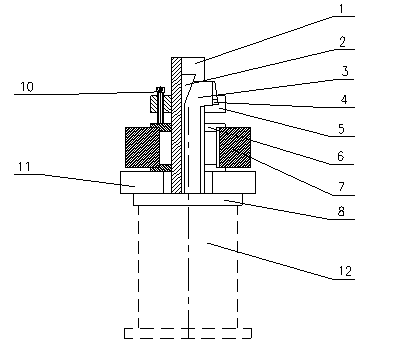

Precision cutting head for inner-hole keyways

ActiveCN102699442AEasy clampingHigh positioning accuracyFeeding apparatusLarge fixed membersEngineeringMetal cutting

The invention relates to metal cutting machinery and particularly relates to a precision cutting head for an inner-hole keyways. The cutting head comprises a cutter guide rail, a feeding rod, a cutter rod, a blade, a clamping block, an embedded lining, a work table, a fixed screw, a pressing screw, a precision dividing disc and a machine seat. The precision cutting head adopts a new processing concept to create a processing method which integrates the cutter with the clamper. The cutter guide rail is provided with a rectangular precision groove. The feeding rod and the cutter rod which can slide upwards and downwards along the rectangular precision groove are installed in the rectangular groove according to the precision sliding fit tolerance. The heads of the feeding rod and the cutter rod are provided with inclined surfaces which are mutually adhered with each other, and the slopes of the inclined surfaces are the same. The feeding rod and the cutter rod are driven by an external power source. A molded blade of which the width is the same as the keyway is installed on the cutter rod. The embedded lining of the cutter guide rail is embedded in the inner hole of the working piece to positioning, and the working piece is fixed by a manner of processing the embedded lining through the pressing bolt. The precision cutting head has the advantages of simple installation and clamping, accurate centering, high processing precision and high processing efficiency, so that the precision cutting head can be applied to the mechanical processing industry, in particular to the precision machinery industry.

Owner:HUBEI MINGCHENG PRECISION MACHINERY

Titanium plate hot continuous rolling large-scale manufacturing method

ActiveCN109317518AReduce drum distortionGuaranteed temperatureCleaning using toolsWork heating devicesMetallurgyIngot

The invention discloses a titanium plate hot continuous rolling large-scale manufacturing method. The titanium plate hot continuous rolling large-scale manufacturing method comprises the following steps of: step (1) heating; (2) carrying out rough rolling; step (3) carrying out finish rolling; step (4) crimping; step (5) welding; and step (6) pickling and annealing. According to the titanium platehot continuous rolling large-scale manufacturing method, the temperature required for rolling a titanium plate is ensured by arranging a heat preservation cover on a conveying roller; before an titanium ingot is heated, the edge of the titanium ingot is chamfered, and the chamfering reduces the drum type deformation of the edge of the titanium plate and ensures the shape of a plate formed by rolling the titanium plate.

Owner:山东盛阳金属科技股份有限公司

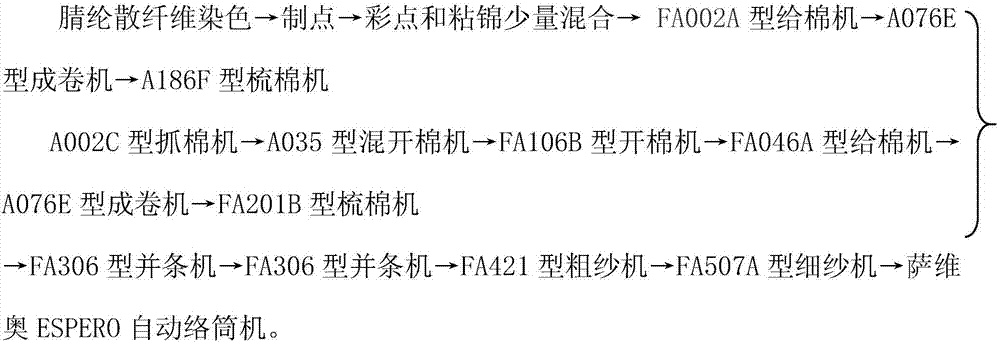

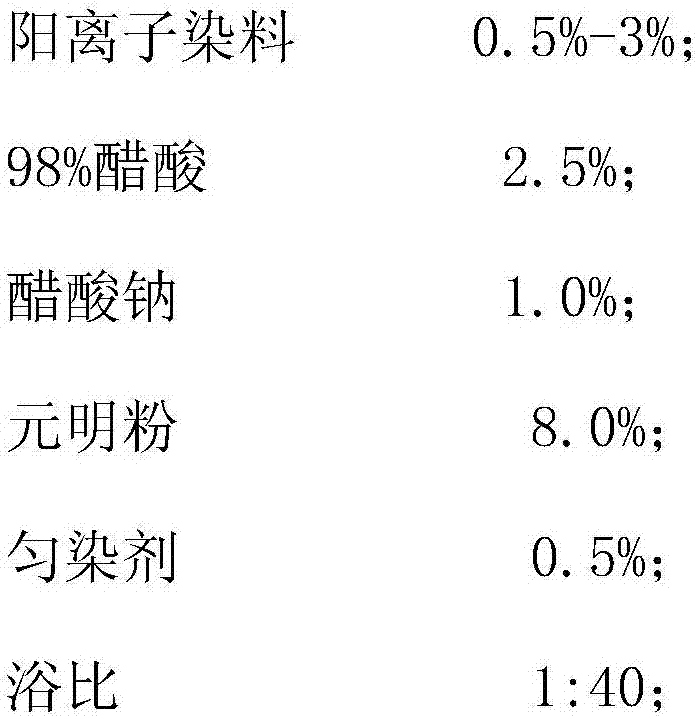

Method for producing PBT (Polythylene Terephthalate) color point core spun yarns

The invention discloses a method for producing PBT (Polythylene Terephthalate) color point core spun yarns. The method comprises the following steps: selecting yarn materials; performing process procedures of the PBT color point core spun yarns; implementing the specific production process. According to the method disclosed by the invention, acrylic fibers serve as raw materials of the points, the color point has rich colors, the color is bright, the stereoscopic impression is excellent, and the price can be saved by 20000 Yuan per tonnage compared with that of common chinlon points. A waterproof agent is diluted according to a ratio and uniformly sprayed onto the points, and the points are dried and roasted at a high temperature, so that the colored point achieves a water-repellent effect, the colored points are prevented from being loosened in the subsequent processing procedure, staining of dyes on the color points is reduced in the dyeing process, the shape and brightness of the color points can be guaranteed, and the quality of the yarns is improved. The PBT serves as the core yarn, viscose cotton serves as an outer packaging material, and the problems that the spandex core-spun yarns are poor in acid resistance and chlorine resistance and have non-ideal dyeing effect are solved. The color point core spun yarns produced by the method disclosed by the invention are excellent in fluffiness and crimpiness and high in elasticity and shape stability and have hand feel of cashmere.

Owner:IANGSU COLLEGE OF ENG & TECH

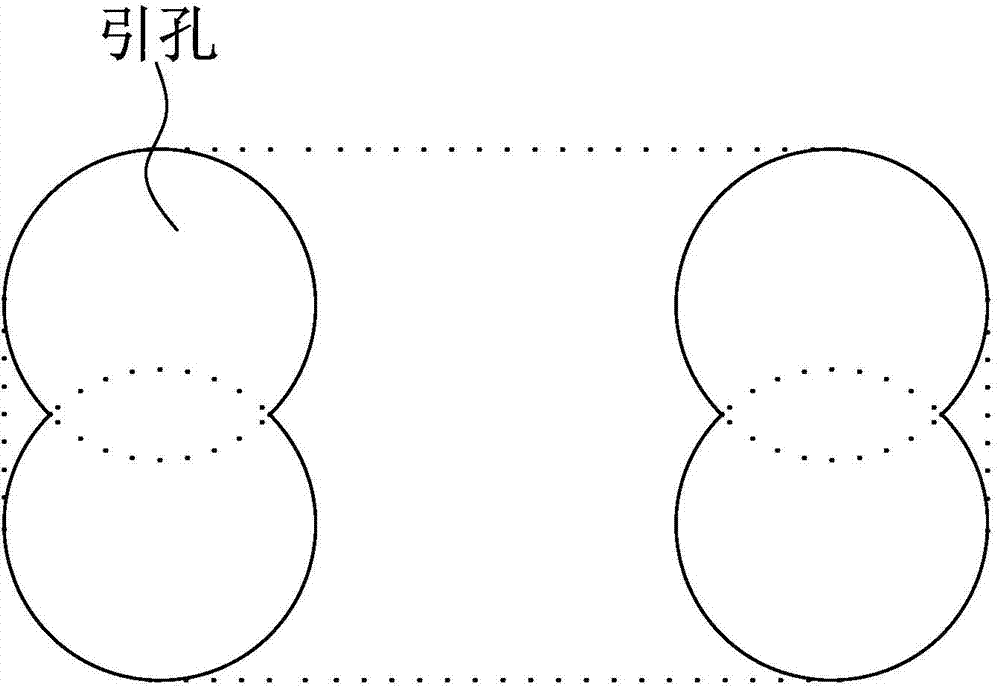

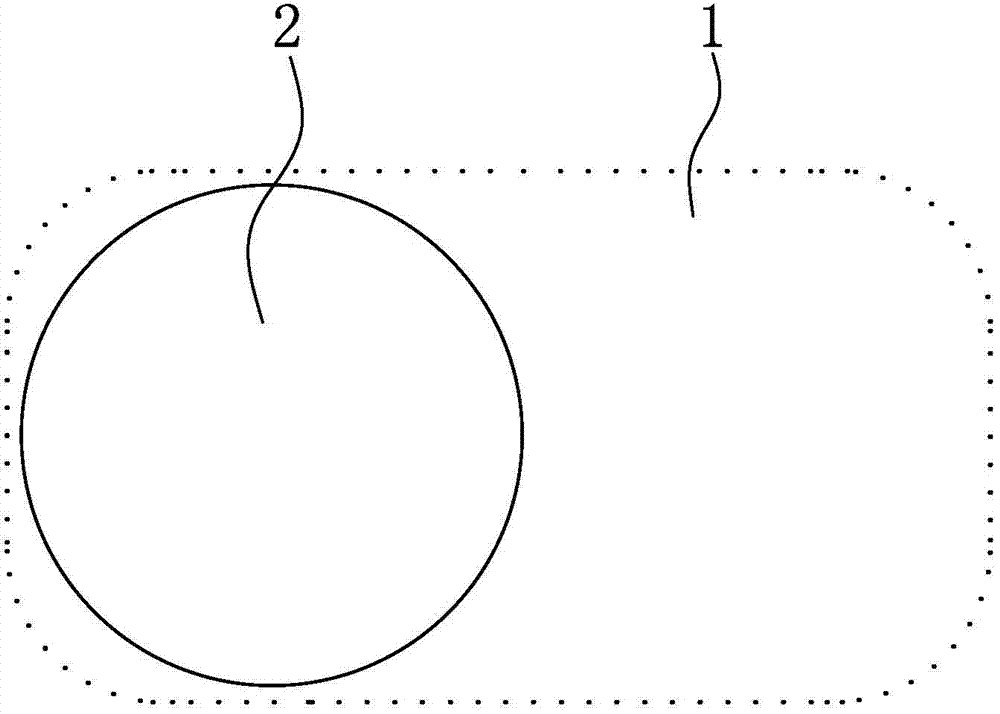

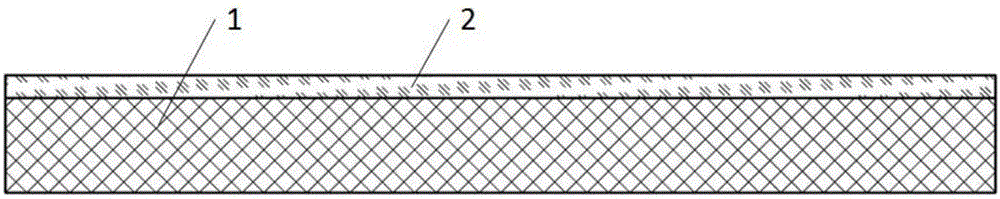

Method for manufacturing metallization groove holes in PCB

ActiveCN104717846AAvoid the problem of shaped holesImprove qualityPrinted circuit aspectsPrinted element electric connection formationMilling cutterEngineering

The invention relates to the technical field of manufacturing of PCBs, in particular to a method for manufacturing metallization groove holes in a PCB. The method comprises the steps that a guiding hole is drilled in each hole position where a metallization groove hole needs to be manufactured in a multilayer board, and then a milling cutter is used for conducting milling along the shape of the hole positions from the guiding holes to manufacture the groove holes. Due to the fact that only one guiding hole is formed in each hole position, the problem of asymmetry of the guiding holes does not exist, so that the problem that the manufactured groove holes are special-shaped holes due to the asymmetry of the positions of the drilled guiding holes is solved, it is ensured that the shape and the appearance of the metallization groove holes meet the design requirements, and the quality of the PCB is improved.

Owner:大连崇达电子有限公司

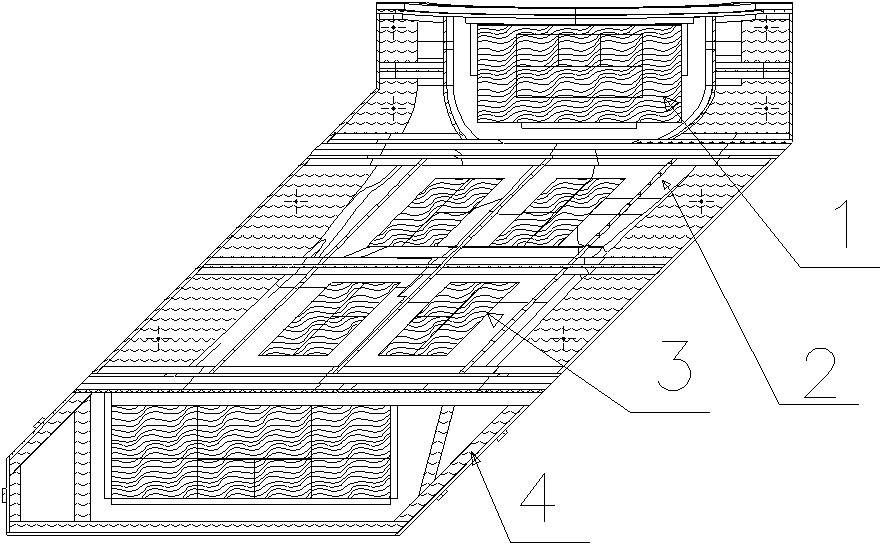

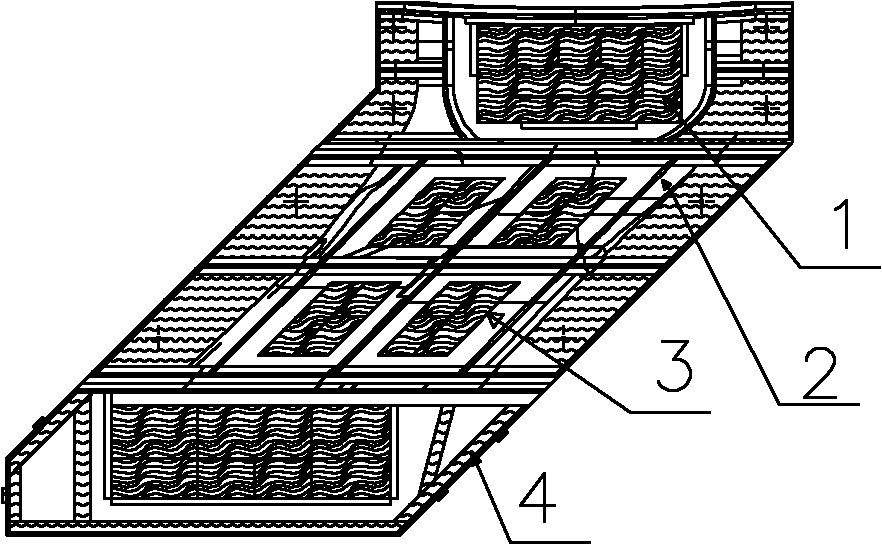

Manufacturing technology of carbon fiber reflecting mirror

The invention relates to a manufacturing technology of a carbon fiber reflecting mirror and belongs to the optical element manufacturing technology field. In the prior art, a manufacturing technology of a carbon fiber reflecting mirror is not suitable for manufacturing a large-caliber spherical mirror and an aspherical mirror, and surface shape precision of the manufactured carbon fiber reflecting mirror is low. By using the technology of the invention, the above technical problems are solved. The technology comprises the following steps of firstly, using a corresponding die to manufacture a reflecting mirror matrix and a reflecting mirror panel respectively; during a manufacturing process, using [Q6]s quasi isotropic layer mode to lay a carbon fiber layer, and using a vacuum injection molding technology so that a resin layer is attached to the reflecting mirror panel; then bonding the reflecting mirror matrix and the reflecting mirror panel to acquire a reflecting mirror billet; and finally carrying out detection, film coating and polishing successively so as to complete manufacturing of the carbon fiber reflecting mirror. The technology is simple to operate, is easy to copy and is not limited by a reflecting mirror shape. Manufactured carbon fiber reflecting mirror performance is reliable, stability is good, the surface shape precision is high and weight is light. The technology has a wide application prospect in the space remote sensing technology field.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Method for manufacturing space complicated curve surface core box mold

ActiveCN102430712AClever material selectionEasy to implementFoundry moulding apparatusRoughcastManufacturing efficiency

The invention relates to a mold manufacture method, in particular to a method for manufacturing a space complicated curve surface core box mold, which is applicable to ship support frames of deep water drilling ships and ocean exploration ships and is characterized in that the method comprises the following steps of: selecting materials, building a mold three-dimensional space model, manufacturing a main carrying steel frame, manufacturing a mold blank, processing the mold and carrying out mold detection. The method has the advantages that the method is unique, the intensity is high, the manufacture efficiency is high, the precision requirement of customers is met, the mold quality is improved, and in addition, the method is applicable to the ship support frames of the deep water drilling ships and the ocean exploration ships.

Owner:KOCEL EQUIP

Non-Oriented Electrical Steel Having High Magnetic Induction And High Intensity And Manufacturing Method Thereof

InactiveUS20120298267A1Prominent deterioration in magnetic propertyHigh magnetic inductionElectrical steelHigh intensity

A non-oriented electrical steel has relative high magnetic induction and high intensity without increasing manufacturing difficulty. The weight percentage of the compositions of the electrical steel are as follows: C≦0.0040%, Si is 2.50% to 4.00%, Al is 0.20% to 0.80%, Cr is 1.0 to 8.0%, Ni is 0.5 to 5.0%, Mn≦0.50%, P≦0.30%, S≦0.0020%, N≦0.0030%, Ti≦0.0030%, Nb≦0.010%, V≦0.010%, C+S+N+Ti≦0.010%, and a balance substantially being Fe and inevitable impurities.

Owner:BAOSHAN IRON & STEEL CO LTD

Preparation method of metal chalcogen compound thin film

ActiveCN103469274AEvenly distributedPrecise control is reasonableElectrolytic inorganic material coatingFilm materialWorking electrode

The invention relates to a preparation method of a metal chalcogen compound thin film and belongs to the technical field of optoelectronic film material preparation. The preparation method of combining electric deposition with chemical reaction is adopted comprises the following steps: firstly, putting a conductive substrate as a working electrode into an electrolyte solution, preparing desired single-component metal or an alloy thin-layer film by an electric deposition method, and then soaking the substrate into a precursor solution containing chalcogen anions so that the thin film reacts in the solution to generate a layer of target compound thin film, and then performing pre-annealing treatment on the obtained thin film; repeating the steps and controlling the times of circulation to obtain a prefabricated layer of the compound thin film of the desired thickness; finally, carrying out heat treatment on the prefabricated layer to form the metal chalcogen compound thin film. According to the preparation method, the problems that thin film components and thickness are not easy to control, and the flim is easy to crack when being subjected to drying and annealing process in the prior art are solved. Besides, the preparation method provided by the invention has the advantages of simple needed equipment, low preparation cost, and excellent performance of the obtained product and the like, and is convenient for industrial production.

Owner:CENT SOUTH UNIV

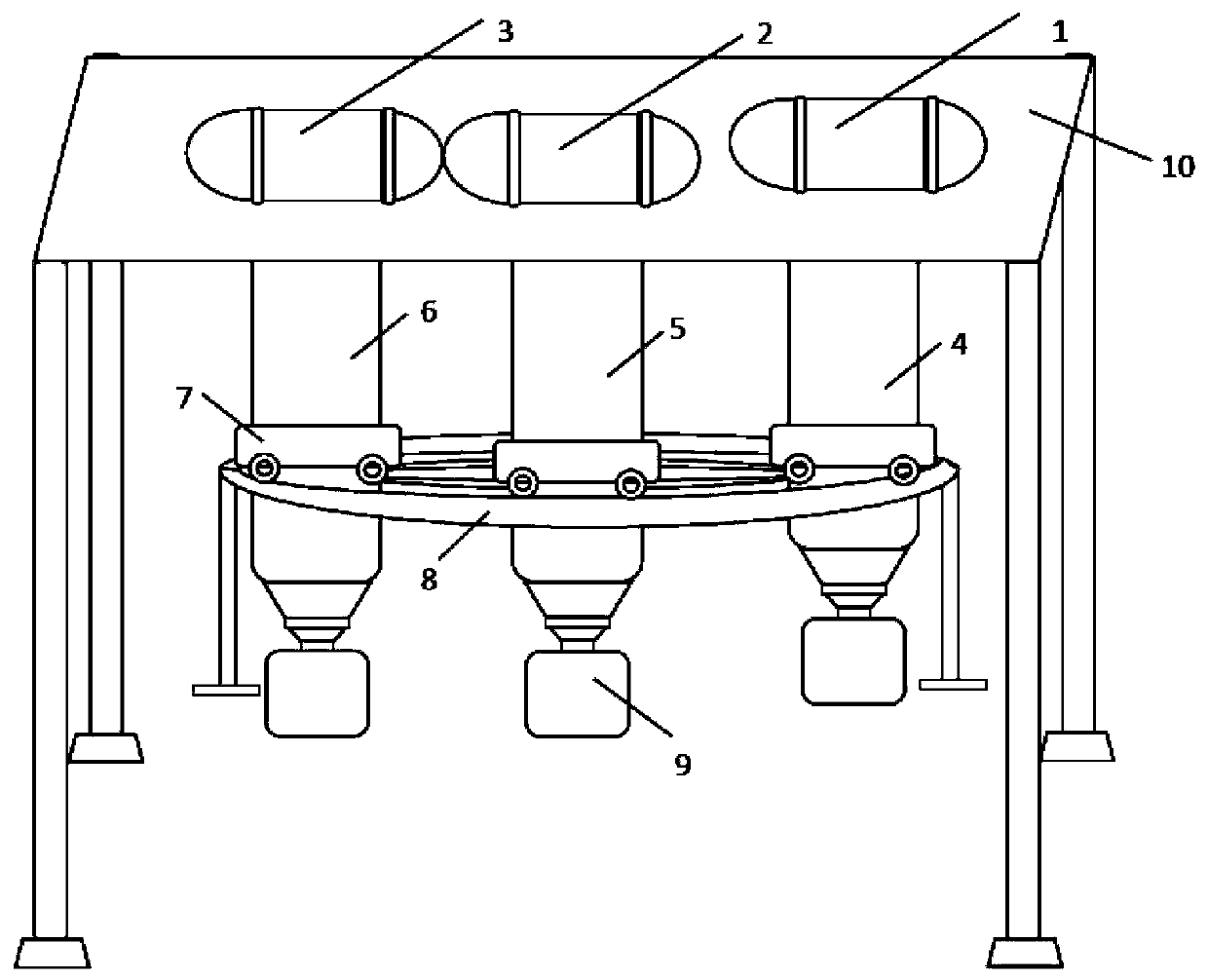

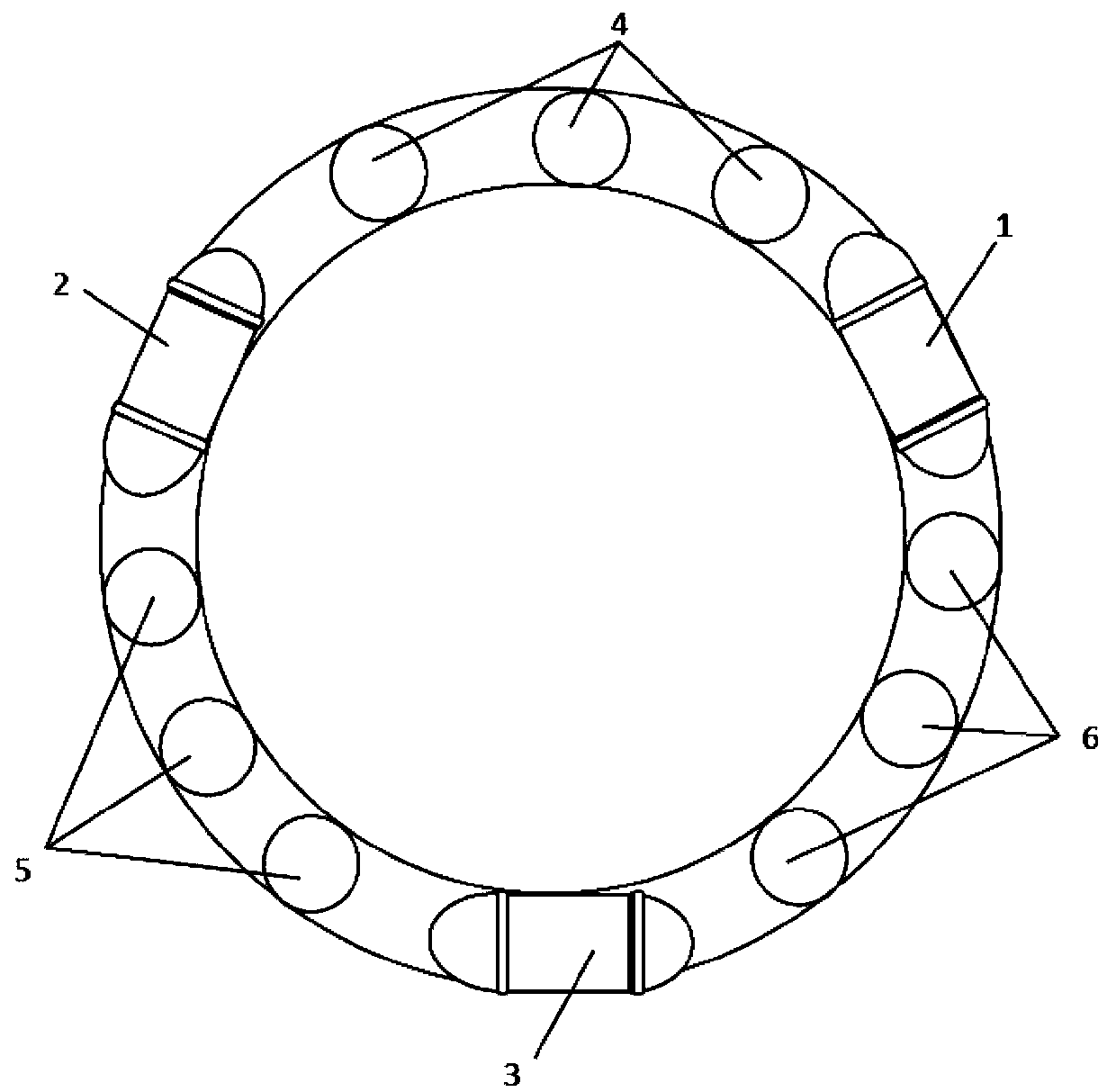

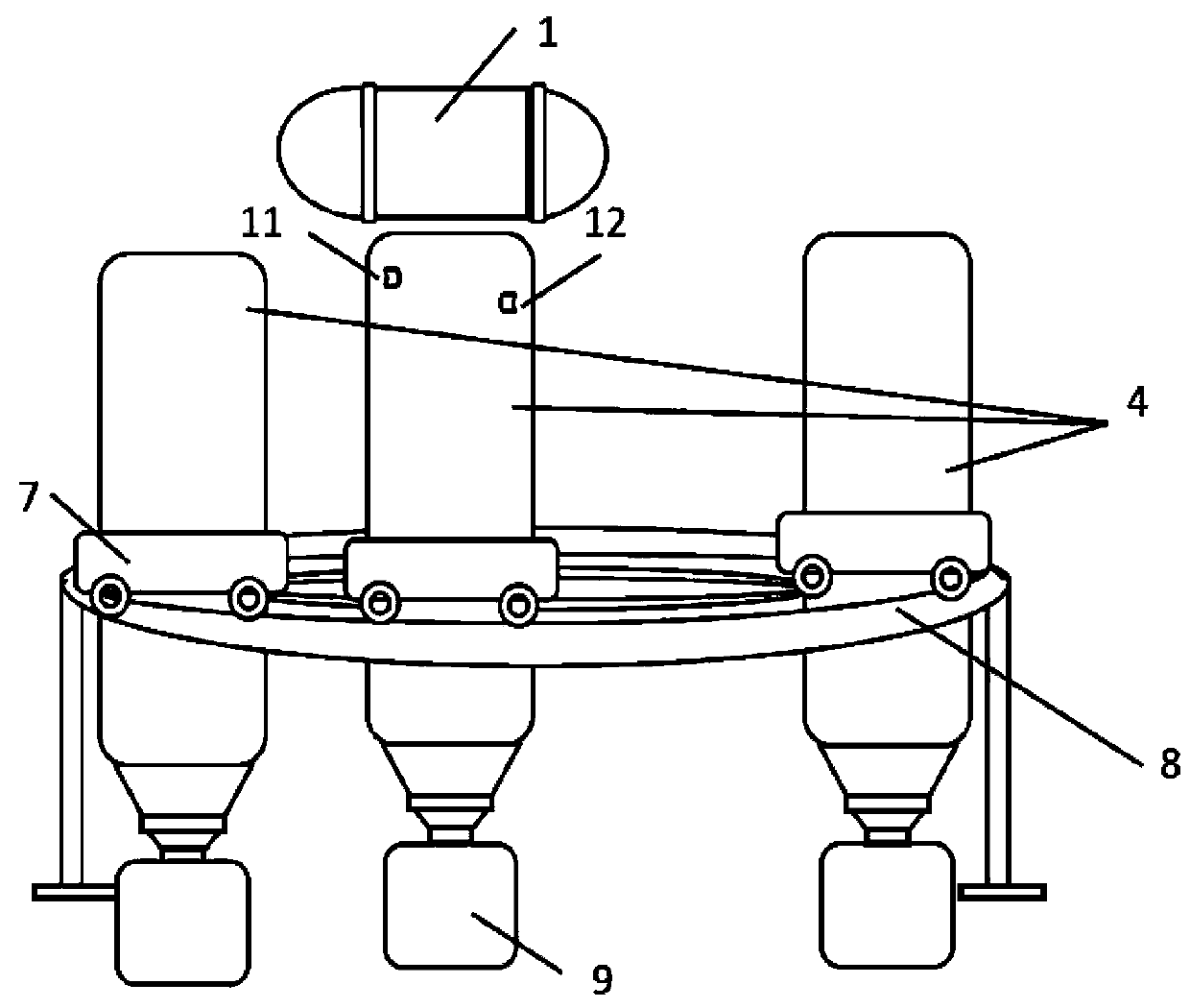

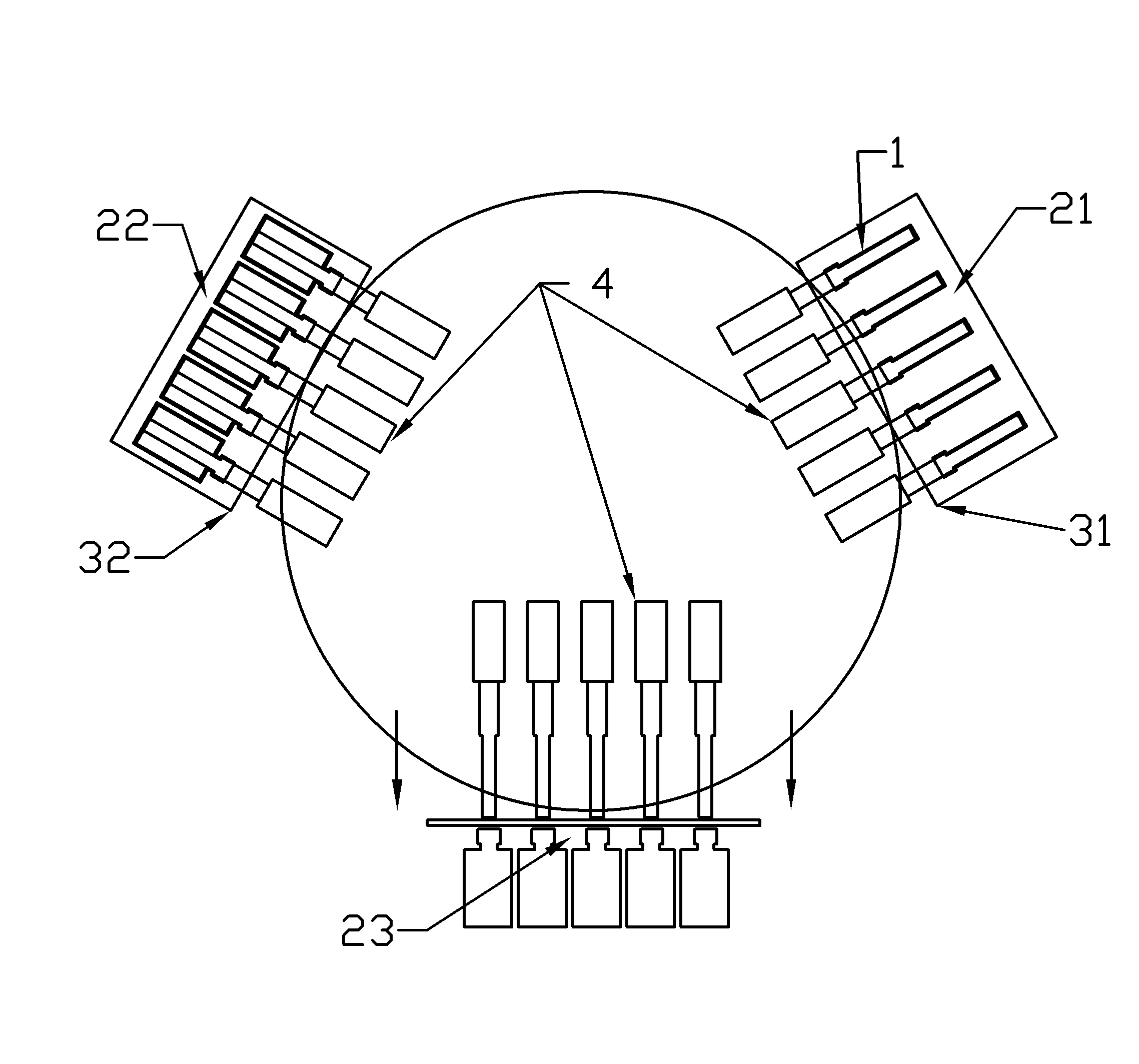

Combined device for preparing spherical metal powder by gas atomization method

ActiveCN109848429AConfiguration highGuaranteed purityAdditive manufacturing apparatusIncreasing energy efficiencyTowerMetal powder

The invention discloses a combined device for preparing spherical metal powder by a gas atomization method. The combined device comprises two or more different-types gas atomizing smelting furnaces, each smelting furnace is detachably and correspondingly connected with two or more atomizing towers, and each atomizing tower is provided with a detachable powder collecting device; and the combined device further includes an annular guide rail, the annular guide rail is provided with moving brackets corresponding to the atomizing towers, each atomizing tower penetrates through one moving bracket,and the two or more different-types gas atomizing smelting furnaces are distributed and erected above the guide rail. The combined device is not limited by the production conditions of the single gasatomizing smelting furnaces and atomizing towers, and the different gas atomizing smelting furnaces and atomizing towers can be quickly selected to be configured. In the case of ensuring the purity and morphology of the powder, it is possible to produce a plurality of types of powders in the same production system, and the production efficiency and the utilization rate of the equipment are improved.

Owner:HONG KONG PRODUCTIVITY COUNCIL

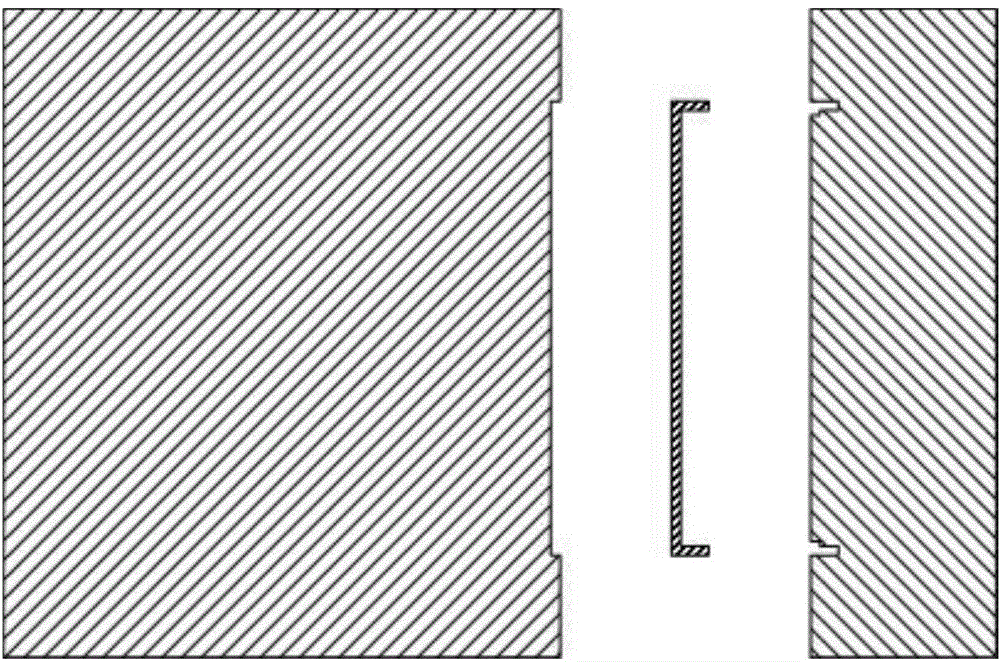

Injection molding composition for rubber and iron integrated frame, rubber and iron integrated frame and manufacture method of rubber and iron integrated frame

The invention discloses an injection molding composition for a rubber and iron integrated frame, the rubber and iron integrated frame and a manufacture method of the rubber and iron integrated frame. The injection molding composition for the rubber and iron integrated frame comprises a plastic granule and a solid additive, wherein the shrinking percentage of the solid additive is less than that of the plastic granule; the solid additive comprises at least one of a glass fiber, a carbon fiber or a boron fiber; when injection molding is carried out, the plastic granule and the solid additive are mixed and injection molded, so that the using volume of the plastic granule is reduced, the injection amount of the plastic granule is reduced and the shrinking percentage of the injection molding plastic of the rubber and iron integrated frame is reduced; the melting point of the solid additive is higher than that of the plastic granule, the injection molding temperature is controlled between the melting points of the solid additive and the plastic granule. The solid additive is kept in a solid state in the injection molding process so that the deformation degree after shaping the rubber and iron integrated frame is small or none.

Owner:SHENZHEN TECHASER TECH

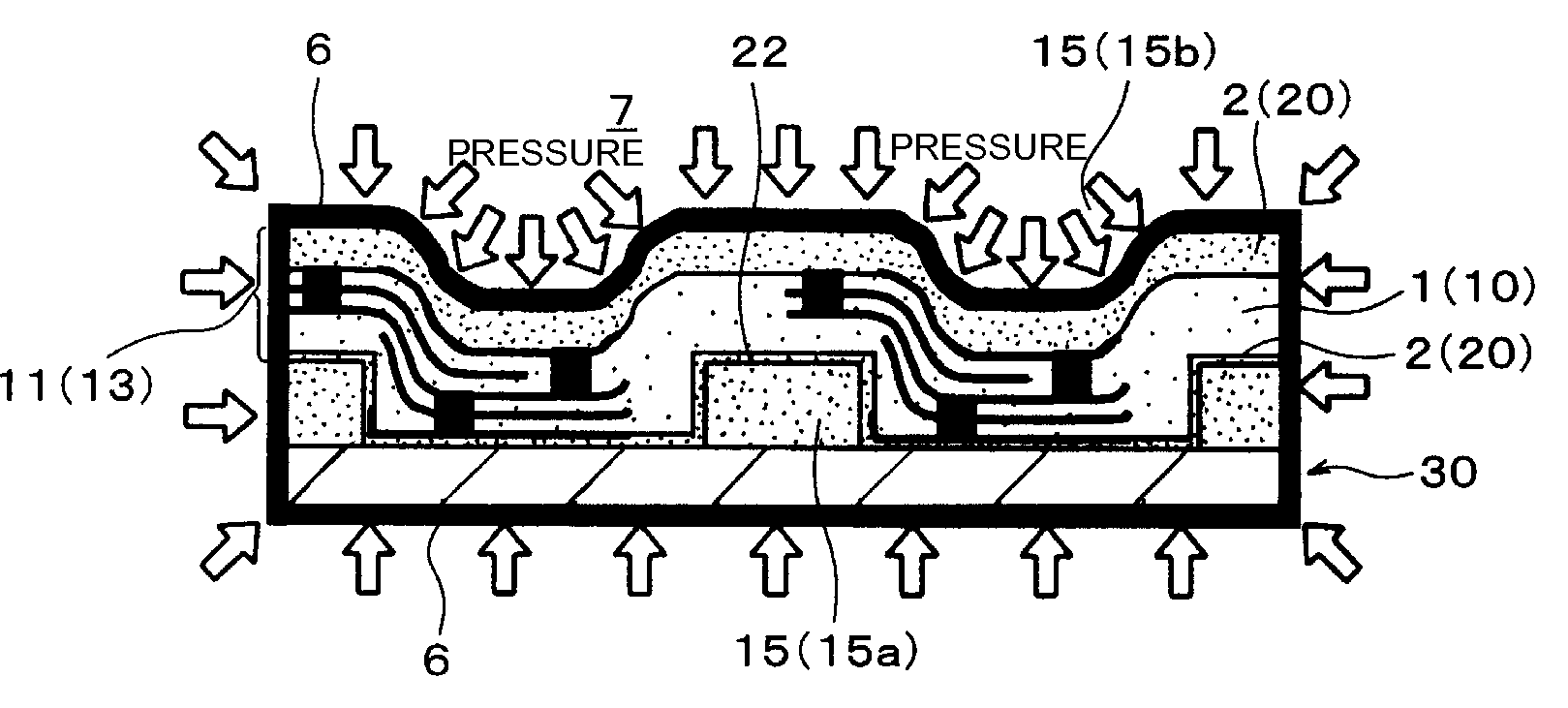

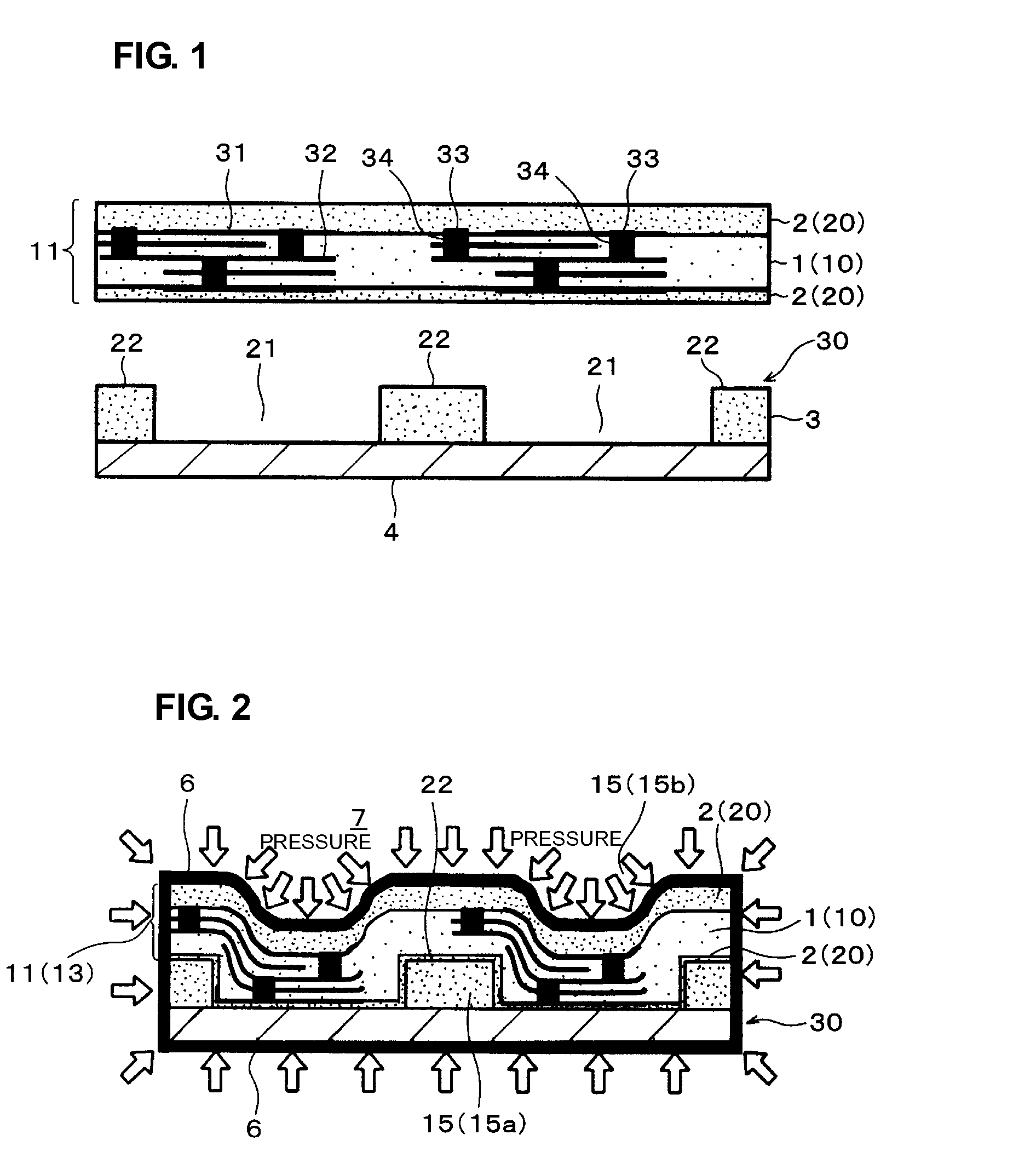

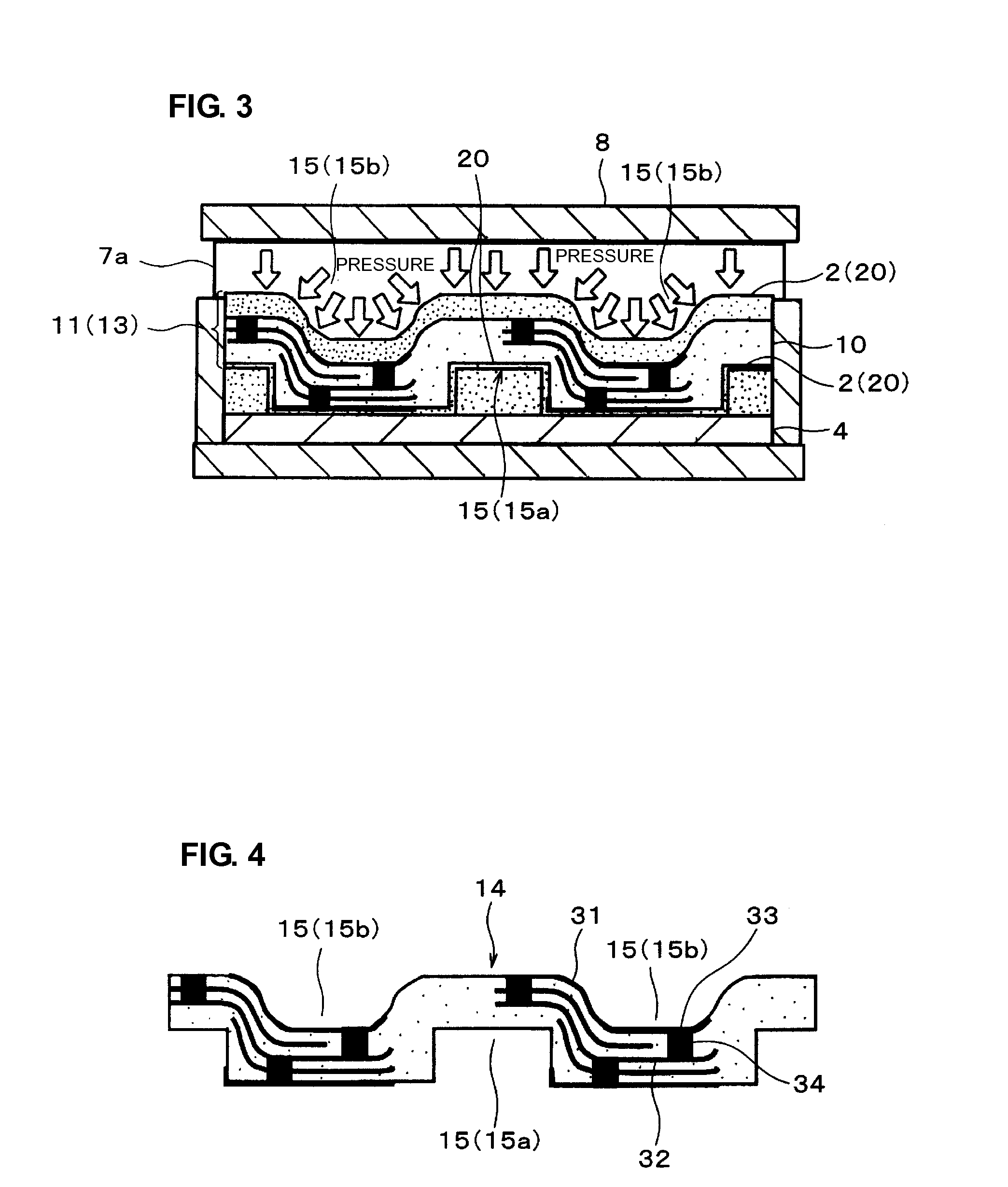

Ceramic substrate production process and ceramic substrate produced using the process

InactiveUS20080308976A1Improve versatilityEfficient production3D rigid printed circuitsLaminationMetallurgyCeramic substrate

A process for producing a multilayered ceramic substrate having a step portion of a desired shape does not require complicated process steps and equipment. An auxiliary-layer-lined unfired ceramic body, which has a step portion in a principal surface thereof, has an unfired ceramic body and an auxiliary layer which is adhered to one principal surface of the unfired ceramic body and which is made of a material that is substantially unsinterable at a temperature at which the unfired ceramic body is fired. The auxiliary-layer-lined unfired ceramic body is fired at a temperature at which the unfired ceramic body is sinterable but the auxiliary layer is substantially unsinterable, while the auxiliary layer remains adhered to the unfired ceramic body. A pressing operation is performed by using a die having a projection placed on the side of the auxiliary-layer-lined unfired ceramic body retaining the auxiliary layer, so that the step portion, having a shape corresponding to the outer shape of the die projection, is formed in the side of the auxiliary-layer-lined unfired ceramic body retaining the auxiliary layer.

Owner:MURATA MFG CO LTD

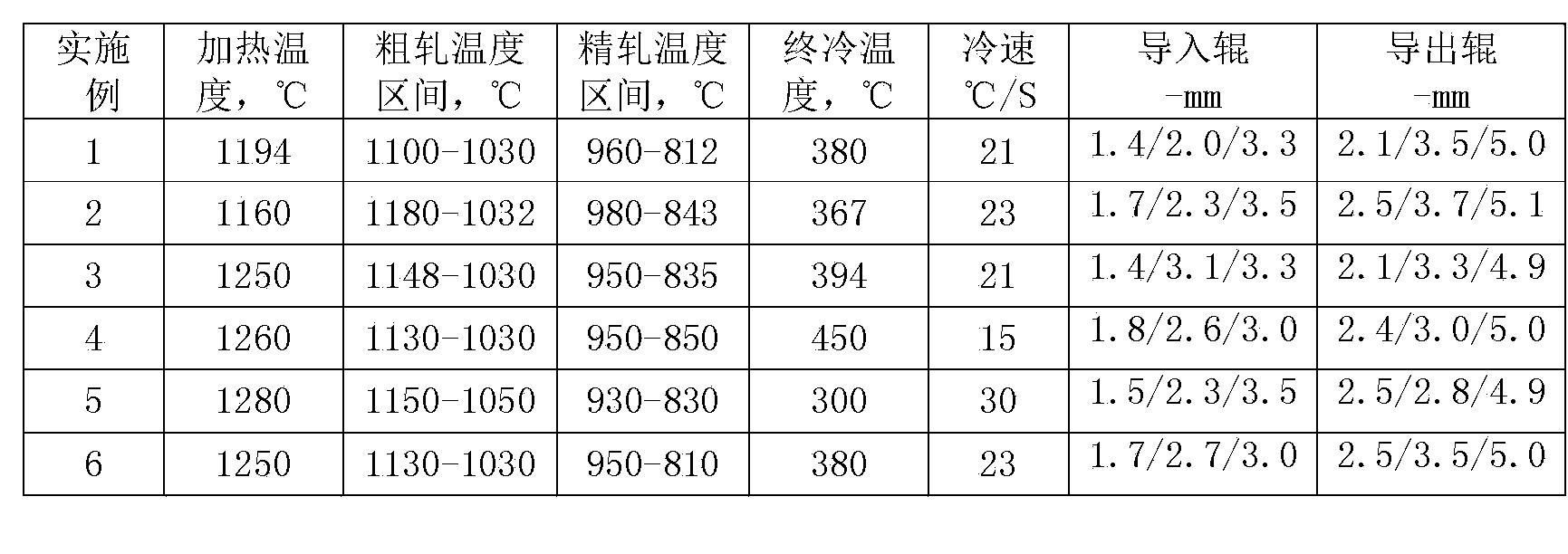

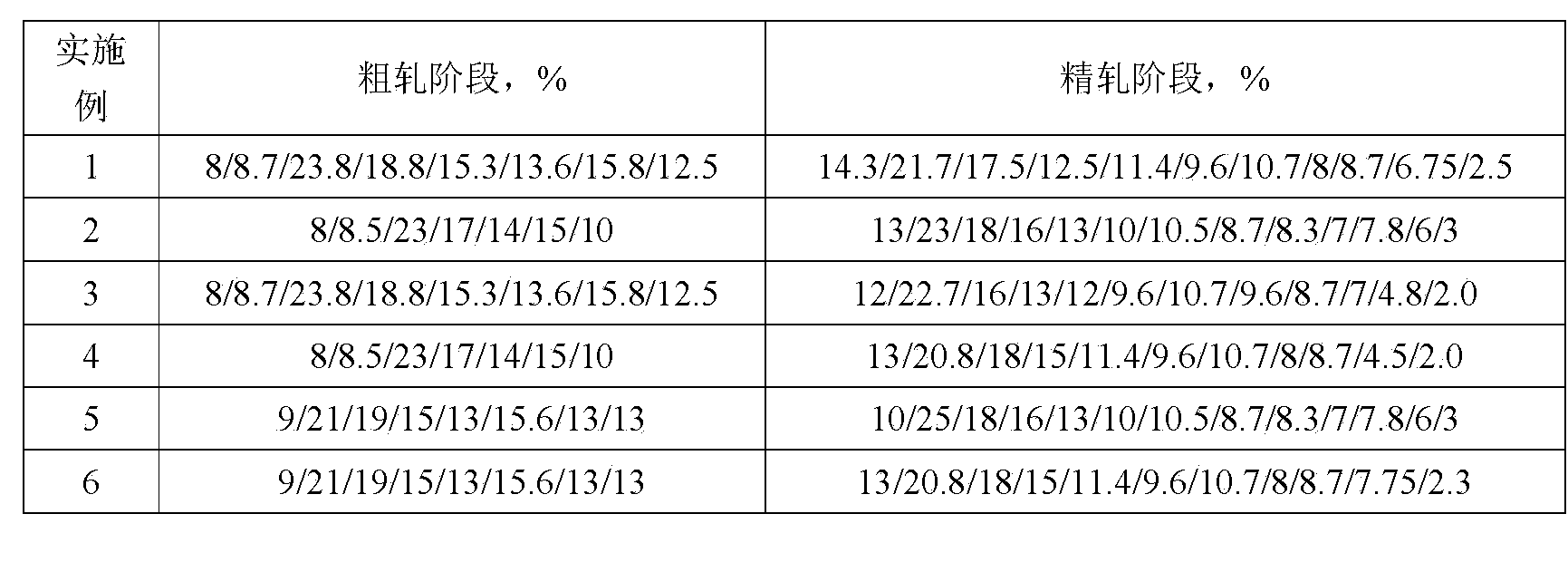

X70 flat plate used for gas-transmission longitudinal welded pipe and producing method thereof

ActiveCN103882334AReduce the amount addedLow costRoll mill control devicesMetal rolling arrangementsReduction rateToughness

The invention provides an X70 flat plate used for a gas-transmission longitudinal welded pipe and a producing method thereof. The flat plate comprises following chemical components: 0.06-0.10% of C, 0.10-0.35% of Si, 1.50-1.80% of Mn, 0.04-0.07% of Nb, 0.008-0.030% of Ti, 0.02-0.045% of Als, not more than 0.20% of Ni, not more than 0.20% of Cr, not more than 0.20% of Cu and 0.020-0.048% of V, with the balance being iron. The method includes: heating a slab is heated to 1160-1280 DEG C; performing rough rolling at 1030-1180 DEG C, wherein the reduction rate of one pass in the first three passes is higher than 20% and the reduction rate of one pass in the last three passes is not less than 15%; performing refined rolling at 810-980 DEG C, wherein the reduction rate in one pass in the first three passes is higher than 20% and the reduction rate in one pass in the last three passes is not less than 7%; raising the speed of rolling; cooling after rolling, with the cooling speed being 15-30 DEG C / s and the finish cooling temperature being 300-450 DEG C; performing air cooling; and performing three passes of straightening. The problems such as large rolling resisting power and large straightening resisting power are overcome. The plate shape of an ultra-wide plate can be guaranteed, and good comprehensive performances comprising ultrafine grains, high strength and high toughness can be obtained.

Owner:ANGANG STEEL CO LTD

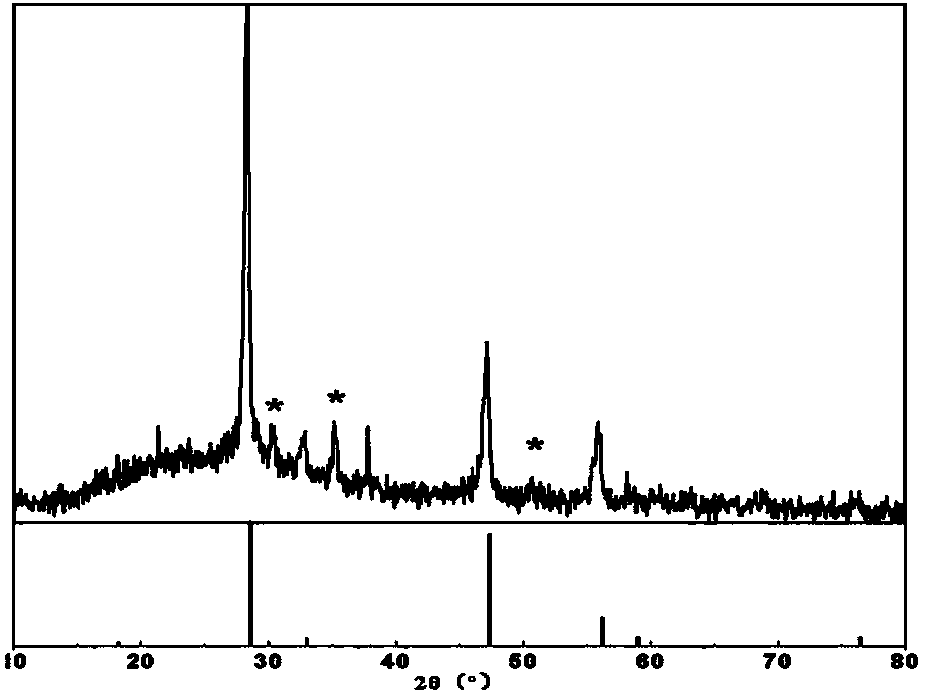

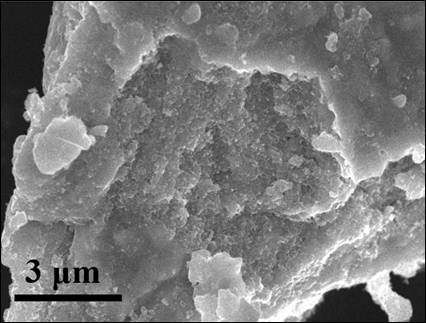

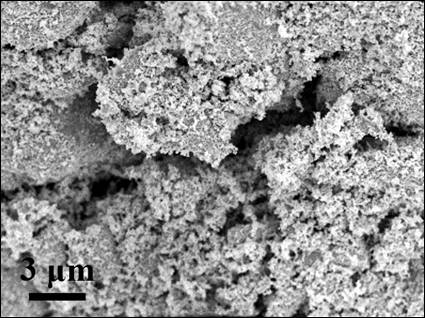

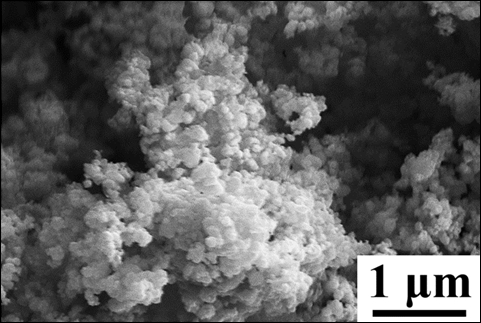

Preparation method and application of nano tungsten trioxide and nano tungsten powder

ActiveCN112222421AEasy to controlIncrease nucleation rateTungsten oxides/hydroxidesNanotechnologyAmmonium metatungstateMaterials science

The invention discloses a preparation method of nano tungsten trioxide and nano tungsten powder. The preparation method comprises the steps of firstly, dispersing carbon nanoparticles, then adding ammonium metatungstate, and uniformly stirring the materials to obtain a mixed solution; secondly, drying the mixed solution to obtain combined powder; thirdly, heating and decomposing the combined powder to obtain the nano tungsten trioxide; and fourthly, carrying out segmented hydrogen reduction on the nano tungsten trioxide to obtain the nano tungsten powder. In addition, the invention discloses application of the nano tungsten powder to preparation of superfine nano tungsten carbide and fine-grain tungsten alloy. According to the preparation method, the carbon nanoparticles are used as a nucleating agent and a pore-forming agent for decomposition of the ammonium metatungstate, and therefore the nucleation and growth processes of the tungsten trioxide are effectively controlled, the nucleation rate of the tungsten trioxide is increased, the granularity of the tungsten trioxide is reduced, the nano tungsten powder is obtained through hydrogen reduction, and the problems of regulation and control over the nucleation, the granularity and the dispersity in the ammonium metatungstate decomposition process are solved; and an application method of the nano tungsten powder is simple, crystal grains of a tungsten material are prevented from being coarse, and the high-performance tungsten material can be obtained advantageously.

Owner:西安稀有金属材料研究院有限公司

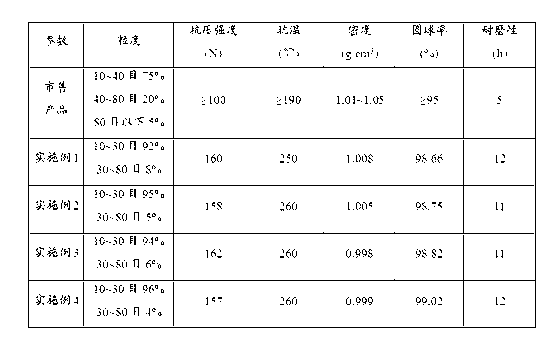

Plastic ball solid lubricating agent for drilling fluid and method for preparing plastic ball solid lubricating agent

ActiveCN103013462AAvoid stickingGuaranteed shapeDrilling compositionBenzoyl peroxidePolyvinyl alcohol

The invention discloses a plastic ball solid lubricating agent for drilling fluid and a method for preparing the plastic ball solid lubricating agent. The plastic ball solid lubricating agent for the drilling fluid is prepared from the raw materials in parts by weight: 35-56 parts of styrene, 6-10 parts of divinylbenzene, 5-10 parts of acrylic acid, 5-10 parts of polytetrafluoroethylene, 10-20 parts of paraffin, 10-15 parts of silicon dioxide, 0.5-1 part of benzoyl peroxide, 0.5-1 part of polyvinyl alcohol and 0.5-1.5 parts of dodecylbenzene sulfonic acid. The method for preparing the plastic ball solid lubricating agent comprises the following five steps of resistance removing, soaking, crosslinking, sepherical boiling and grading. The high temperature resistance and extrusion resistance of the plastic ball solid lubricating agent for the drilling fluid are improved, the density is close to water density, and the plastic ball solid lubricating agent can realize the purposes of effectively lubricating and preventing blockaged.

Owner:河北华运鸿业化工有限公司

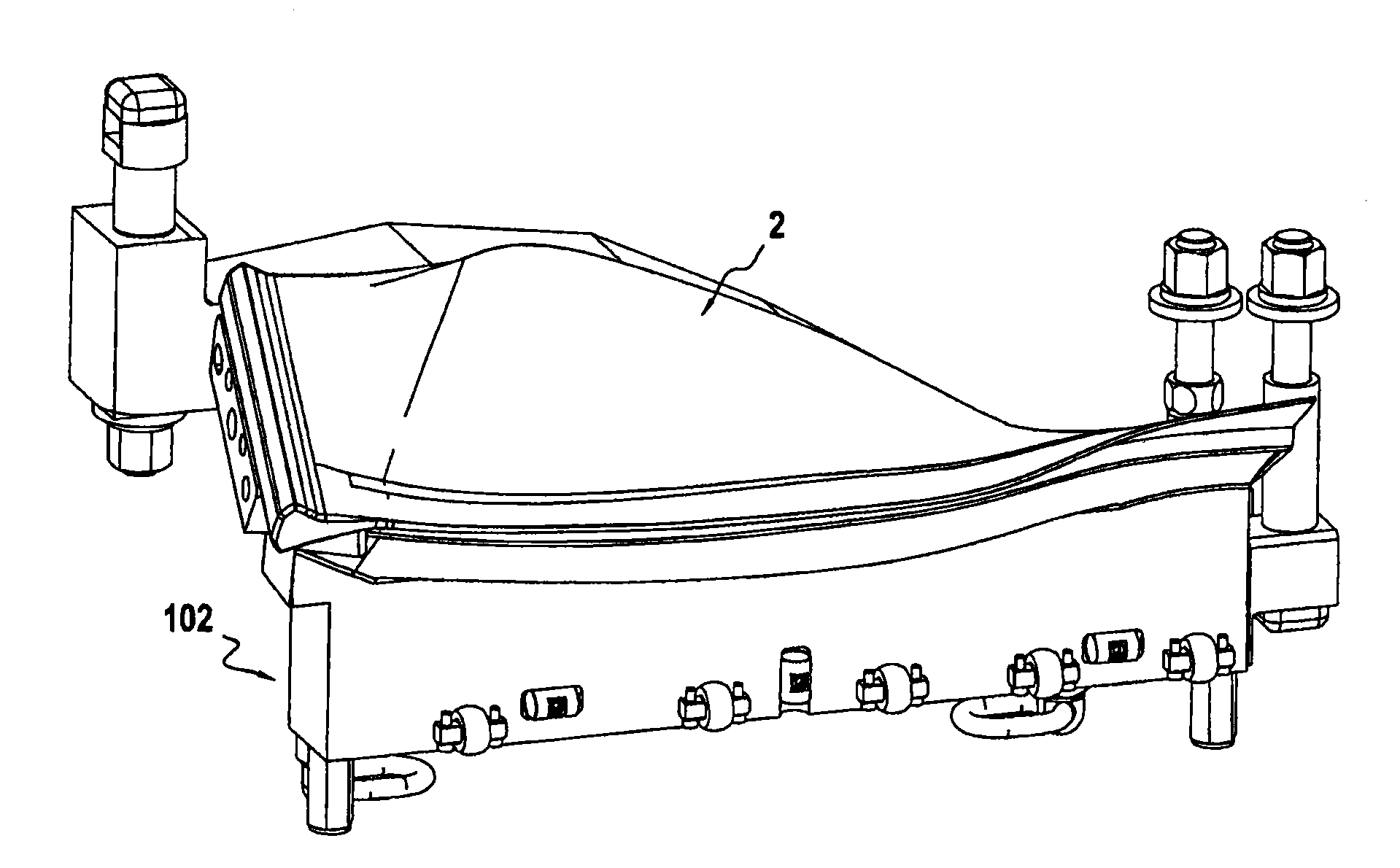

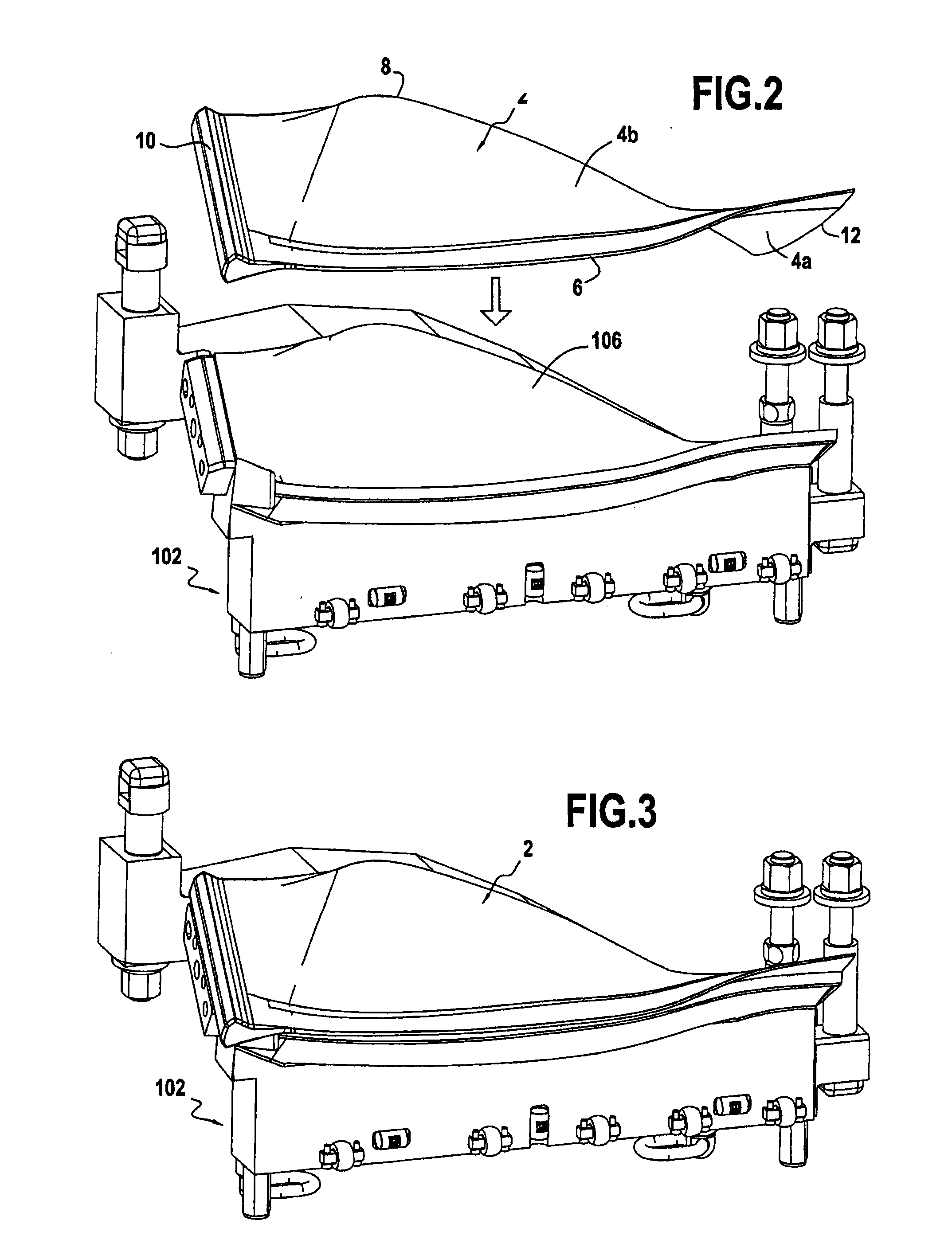

Tooling for fastening metal reinforcement on the leading edge of a turbine engine blade, and a method using such tooling

ActiveUS20160076387A1Avoid defectsReduce heat fatiguePump componentsBlade accessoriesLeading edgeTurbine

A tooling for fastening metal reinforcement on the leading edge of a turbine engine blade, the tooling including a blade support for receiving a blade while leaving surfaces of the leading edge of the blade disengaged; and a leading edge reinforcement support on which the blade support is designed to be mounted, and including two lateral wedges between which the metal reinforcement for the leading edge of the blade is positioned, the wedges being suitable for being capable of moving towards each other and apart from each other and each of them being provided with a suction grid for gripping the metal reinforcement, the leading edge reinforcement support further including heater elements for polymerizing an adhesive film applied on the leading edge surfaces of the blade.

Owner:SAFRAN +1

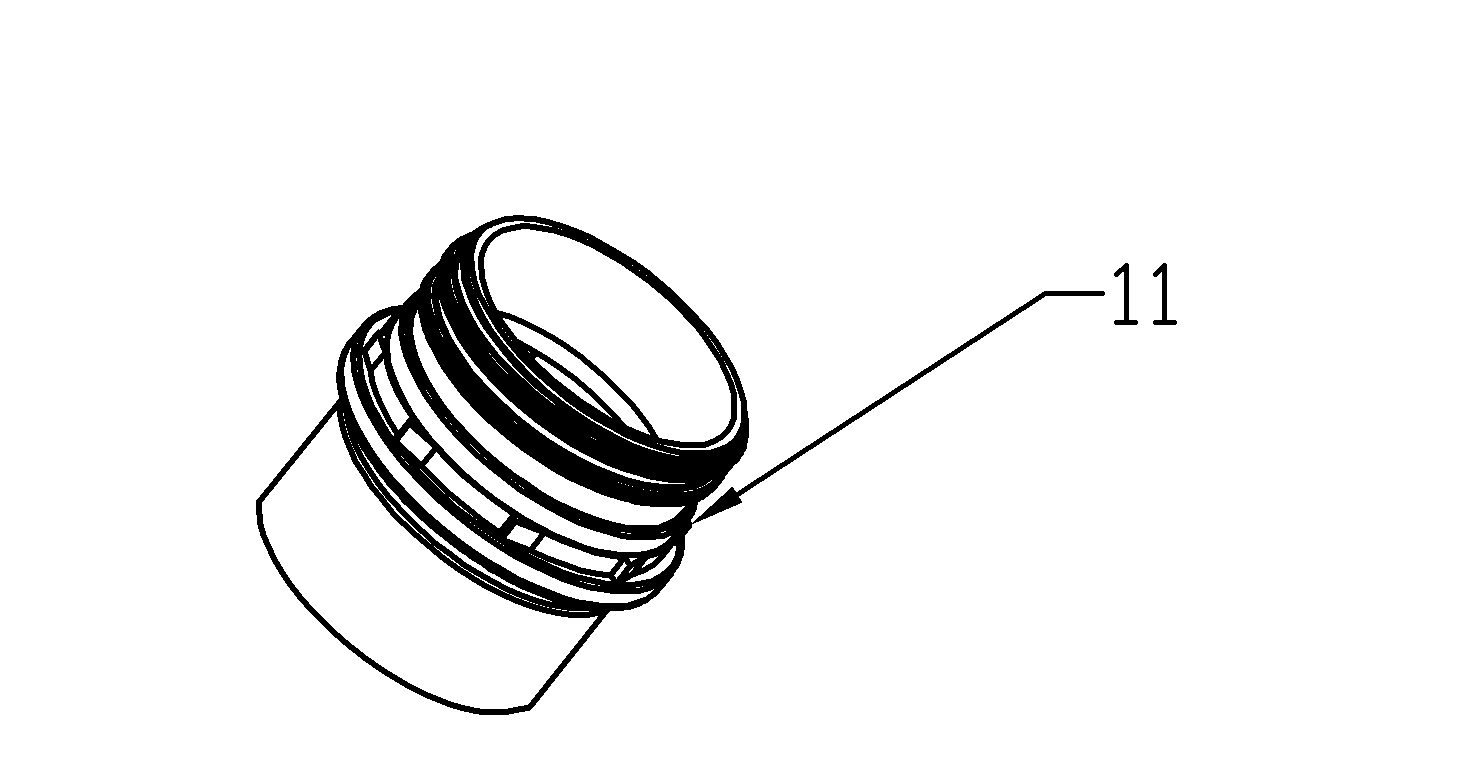

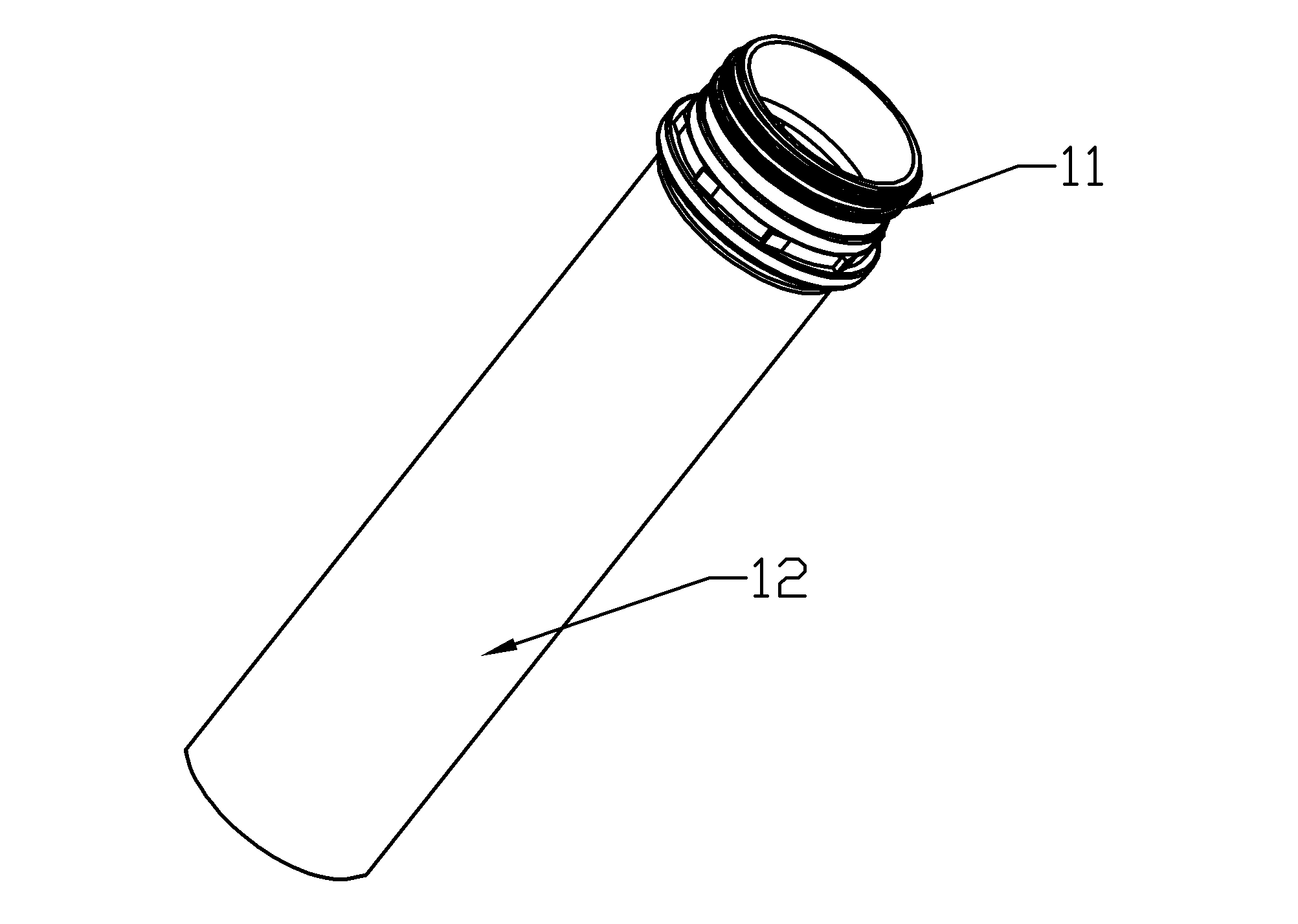

Method for manufacturing plastic bottle

The invention discloses a method for manufacturing a plastic bottle. The method comprises an injection molding process, a blow molding process and a demoulding process, namely comprises the following steps of: at a first station, performing accurate injection molding on a bottle blank material to obtain a bottle neck part, stretching a bottle body to obtain a prefabricated bottle, and placing a mold core and the prefabricated bottle into a second station; at the second station, producing the plastic bottle in a blow mold by a blow molding method, wherein the blow mold comprises an accommodating cavity which cannot be subjected to blow molding and a cavity which can be subjected to blow molding, and the shape and the size of the accommodating cavity are matched with those of the bottle neck part; placing the bottle body in the cavity, and placing into a third station after the blow molding is finished; and at the third station, demoulding. The method is suitable for producing the plastic bottle which has high bottle neck molding accuracy and conveniently meets sealing requirements together with a bottle cap.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com