Injection molding composition for rubber and iron integrated frame, rubber and iron integrated frame and manufacture method of rubber and iron integrated frame

A composition and an integrated technology, applied in optics, instruments, nonlinear optics, etc., can solve problems such as difficult assembly and affecting the display quality of display modules, and achieve the effect of cheap price and restrained deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

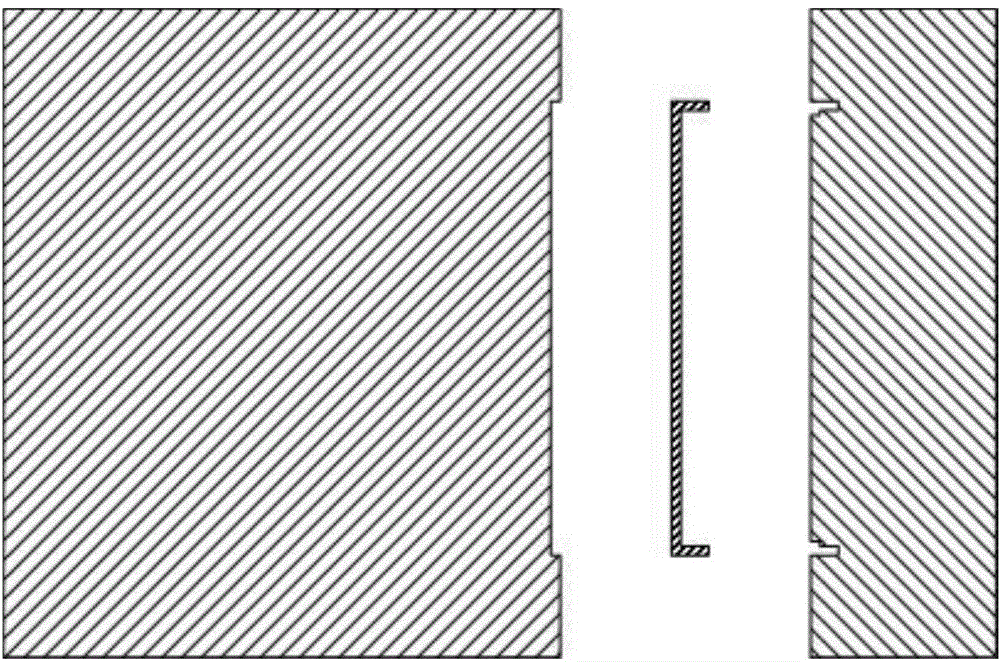

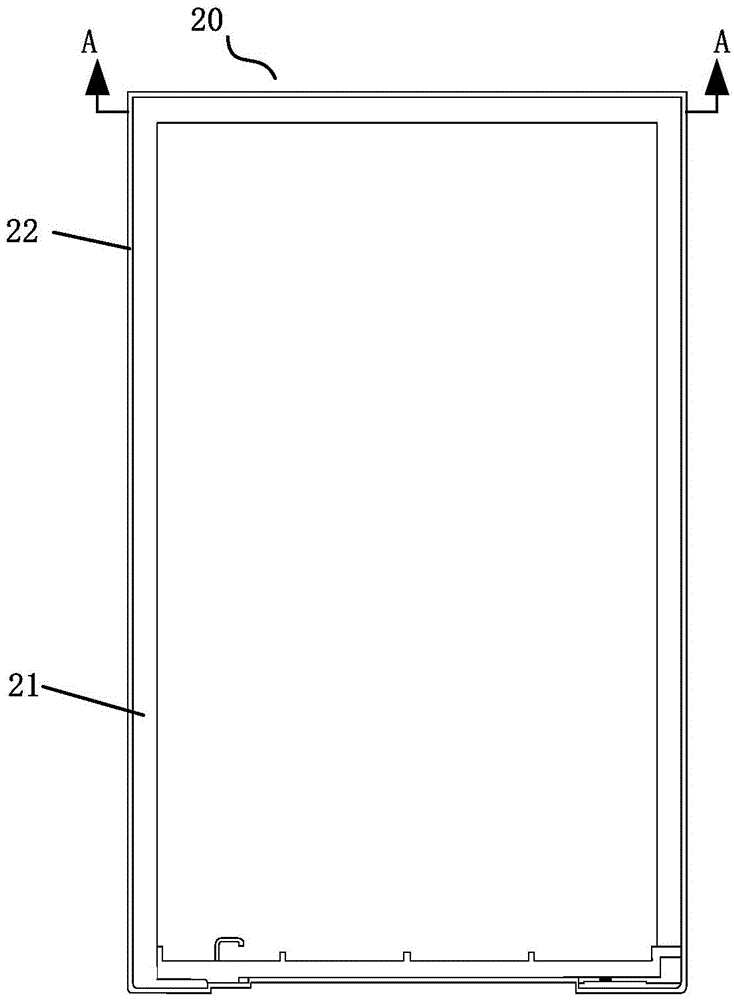

[0024] figure 2 It is a schematic diagram of the plastic-iron integrated frame structure, such as figure 2 As shown, in this embodiment, the plastic-iron integrated frame 20 includes a plastic frame 21 and an iron frame 22 , and the plastic frame 21 is arranged around the edge of the iron frame 22 .

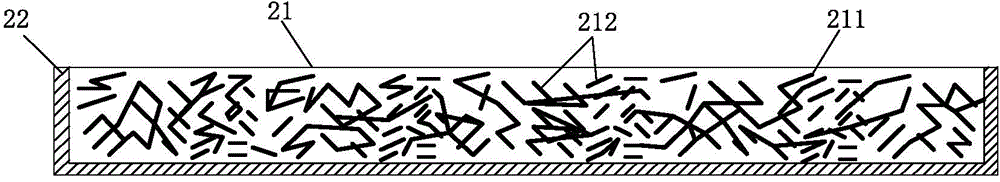

[0025] In this embodiment, the plastic frame is formed by mixed injection molding of plastic particles and solid additives, the material shrinkage rate of the solid additives is smaller than that of the plastic particles, and the melting point of the solid additives is higher than that of the solid additives. The melting point of the plastic particles, the plastic particles are mixed with the solid additives, so that the shrinkage rate of the plastic particles is reduced, and further, the plastic-iron integrated frame has little or no deformation after molding.

[0026] The melting point of the solid additive is greater than the maximum temperature of the injection molding pro...

Embodiment 2

[0038] Figure 4 It is a flow chart of the method for manufacturing the rubber-iron integrated frame provided by Embodiment 2 of the present invention, as shown in Figure 4 As shown, in this embodiment, the manufacturing method of the rubber-iron integrated frame provided by the present invention includes the following steps:

[0039] S401: Put the iron frame on the mold core of the injection mold for injection molding the plastic-iron integrated frame.

[0040] S402: Clamp the mold core, and inject plastic into the injection cavity formed by the iron frame and the mold core.

[0041] The mold core is molded together, the iron frame and the mold core form an injection cavity, and plastic is injected into the injection cavity to form a plastic frame. Plastics formed from injection molding compositions.

[0042] Further, specifically, the iron frame and the mold core form an injection cavity, and plastic is injected into the injection cavity to form a plastic frame. The plas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com