Patents

Literature

160results about How to "Reduce the degree of deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

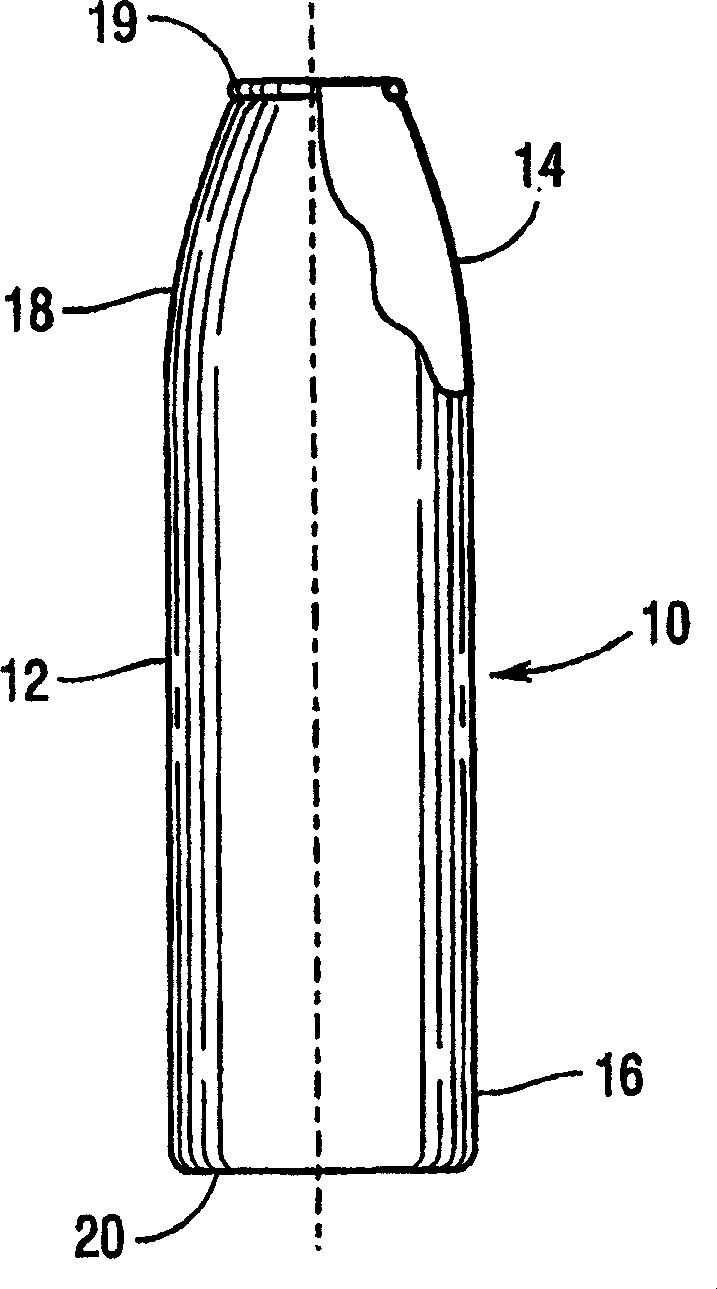

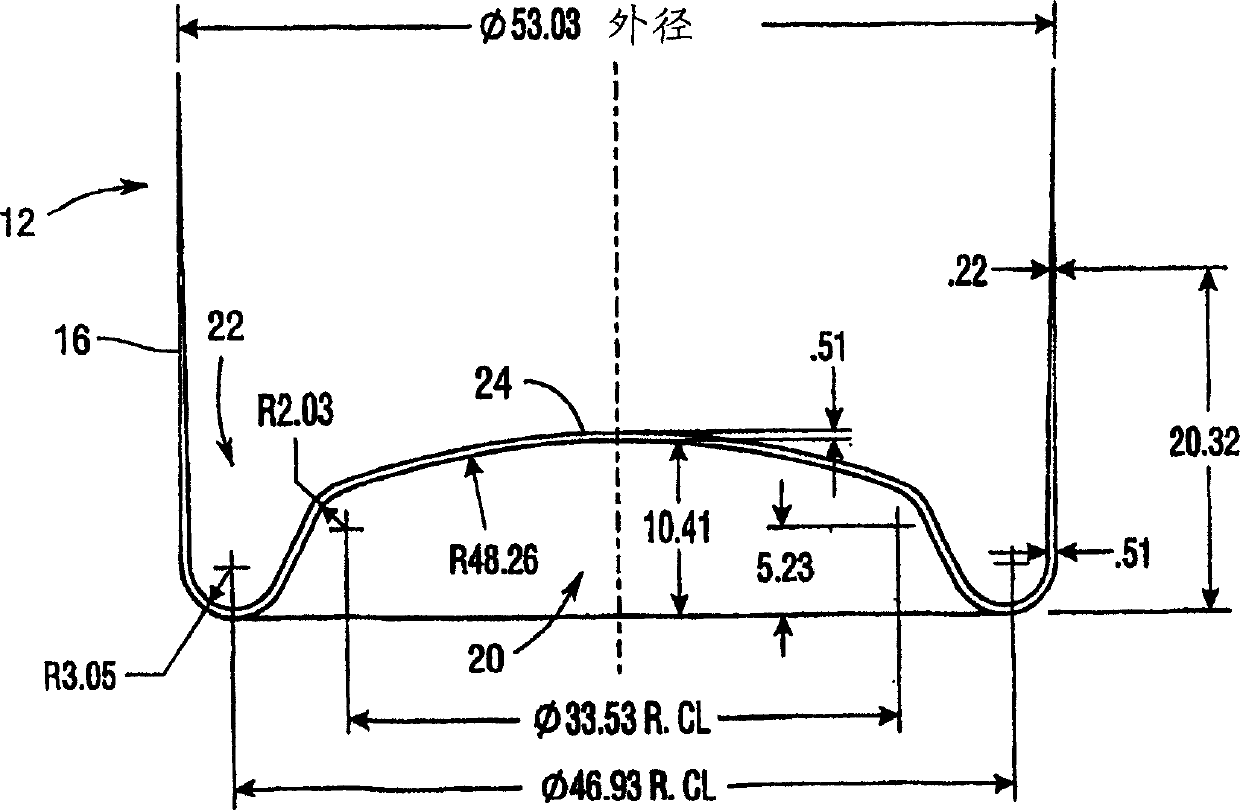

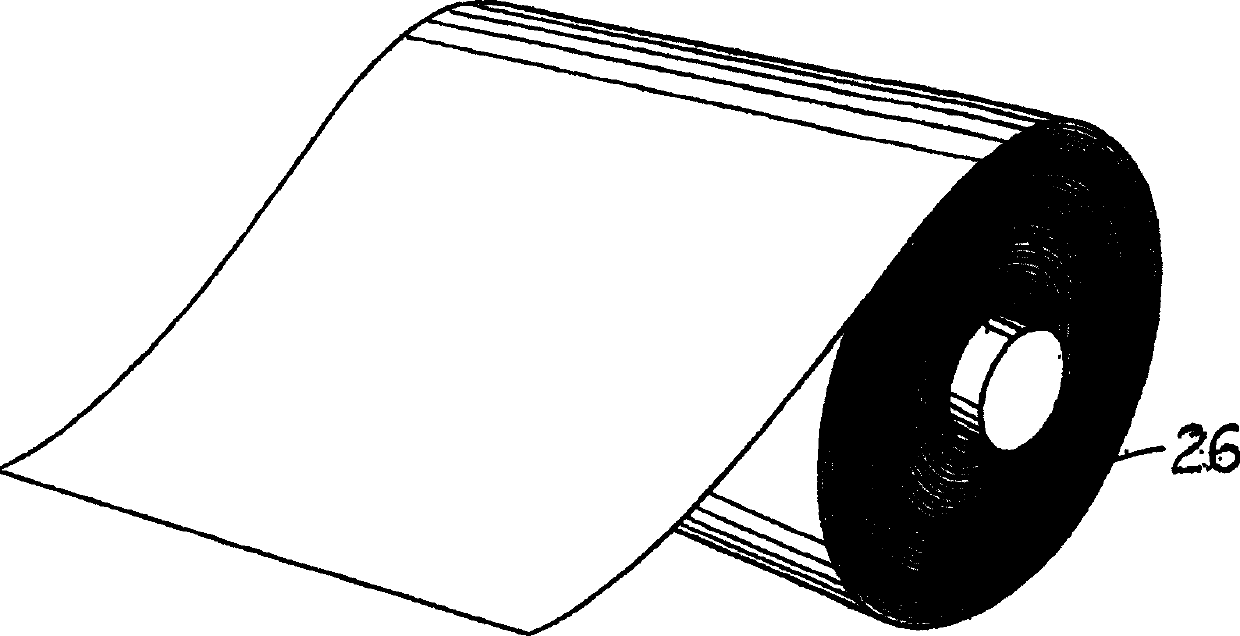

Aluminum aerosol can and aluminum bottle and method of manufacture from coil feedstock

InactiveCN1675010AIncrease the number ofReduce the degree of deformationCans/barrels/drumsLiquid dispensingBottleUltimate tensile strength

Owner:EXAL

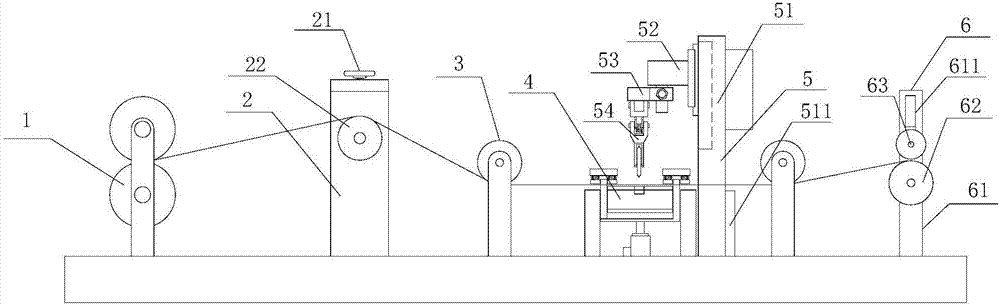

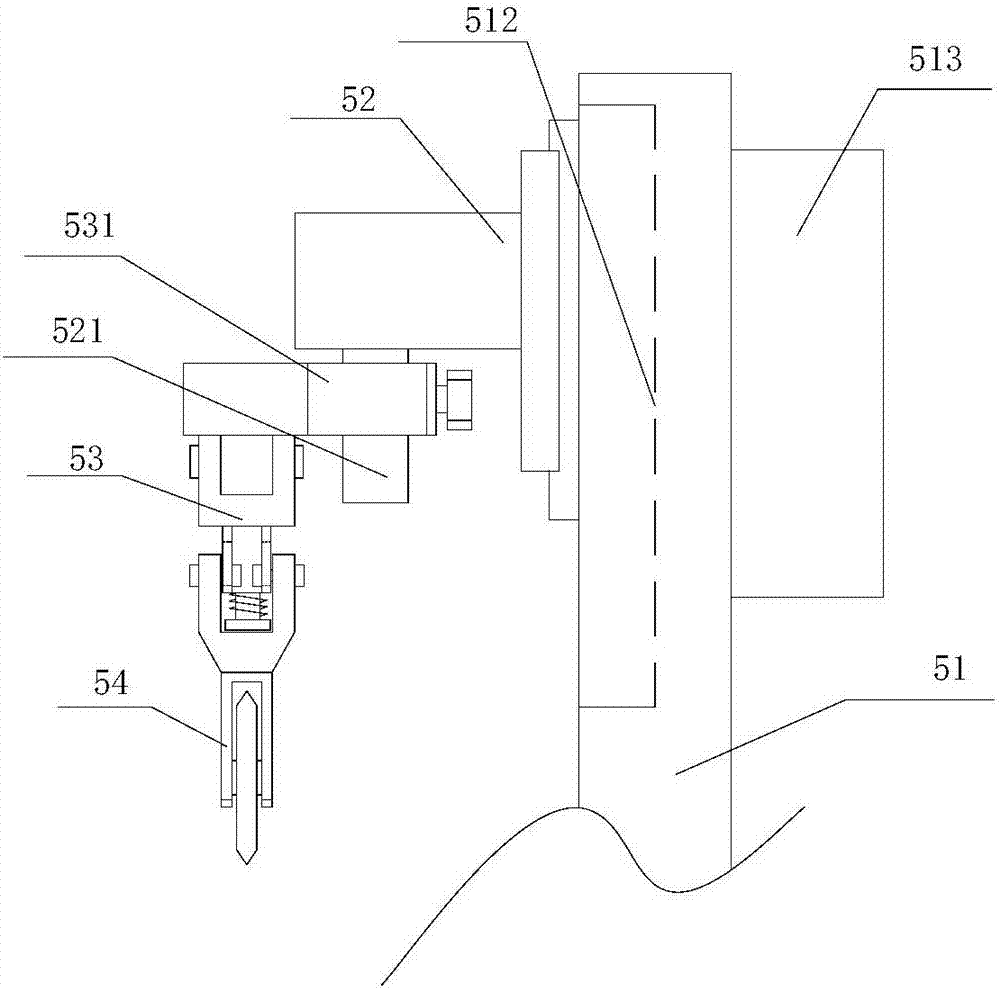

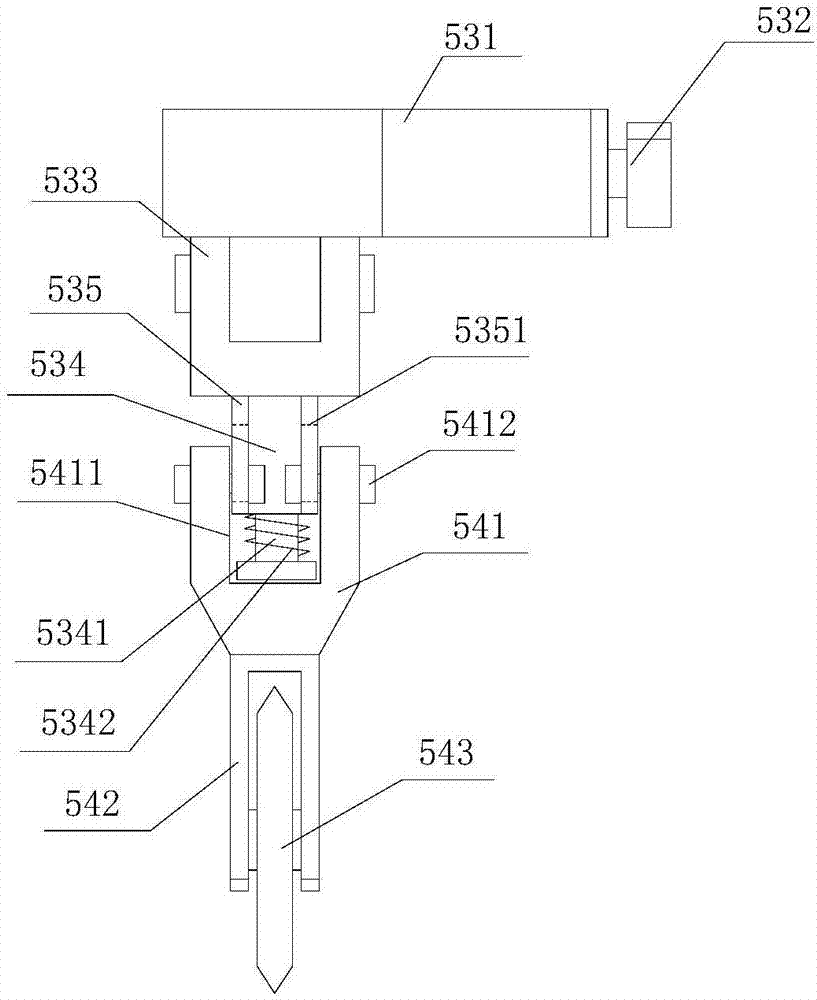

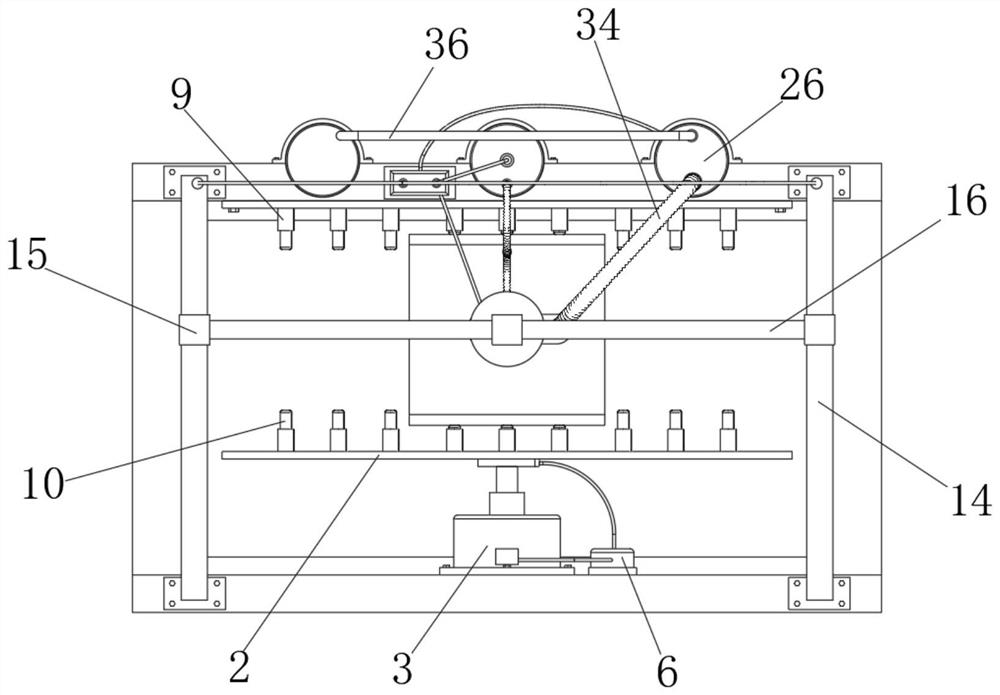

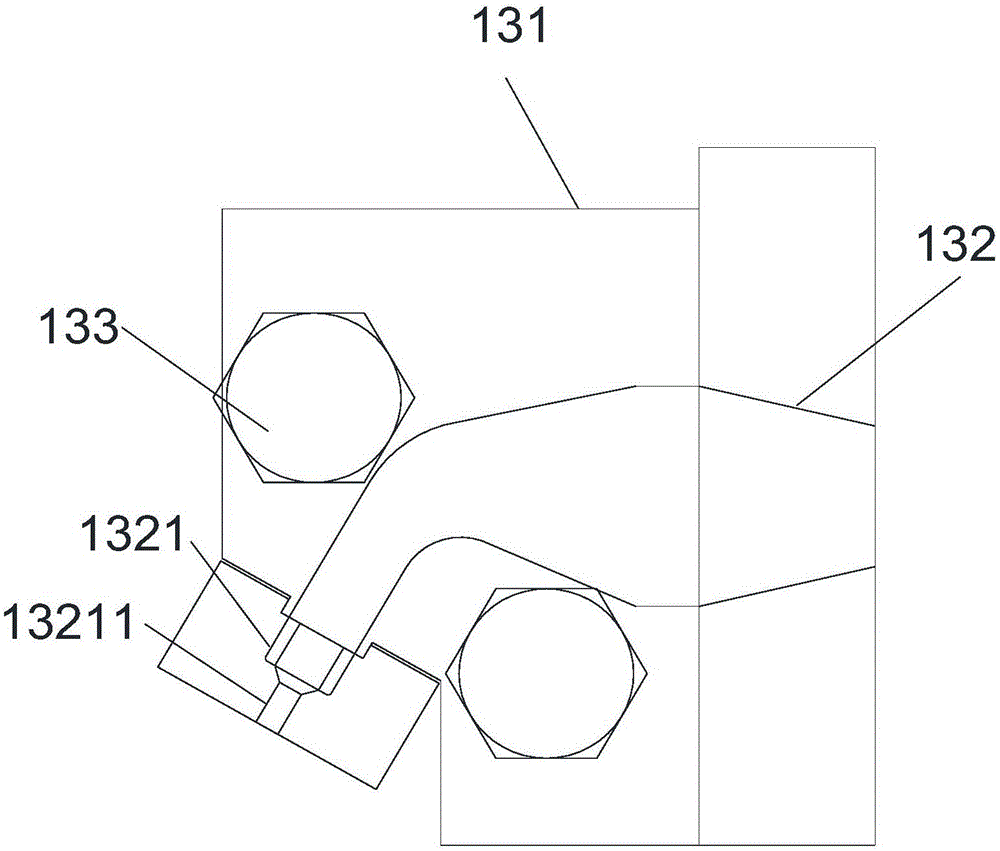

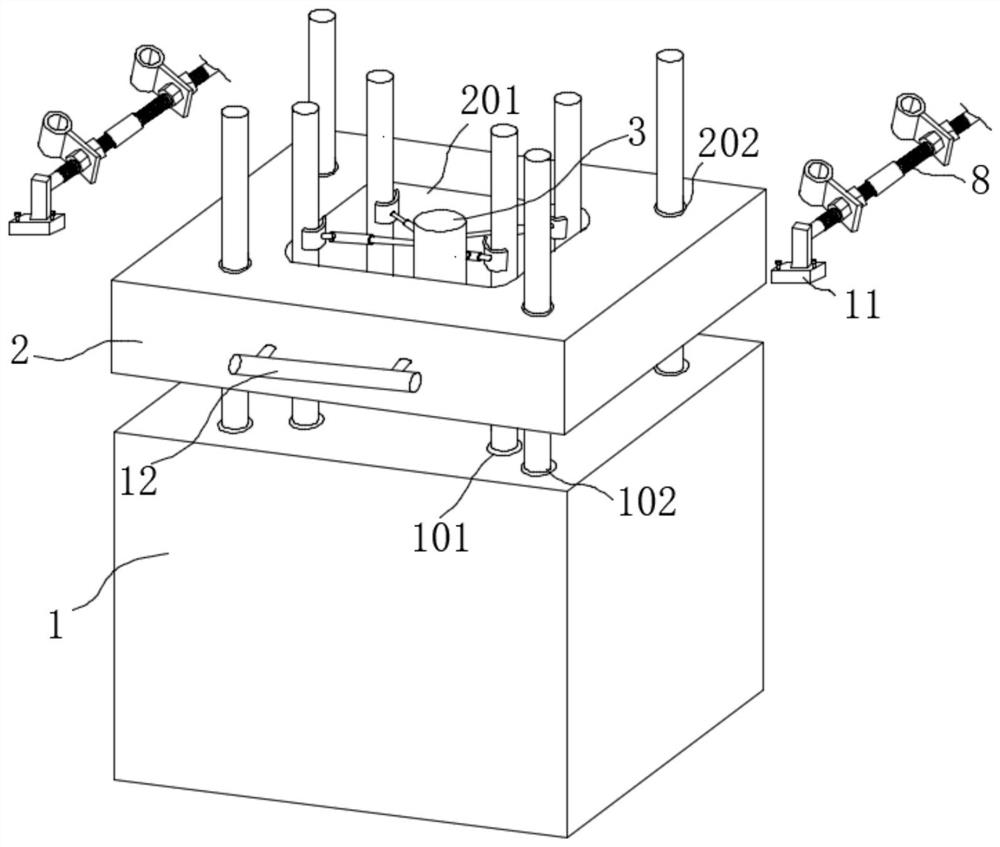

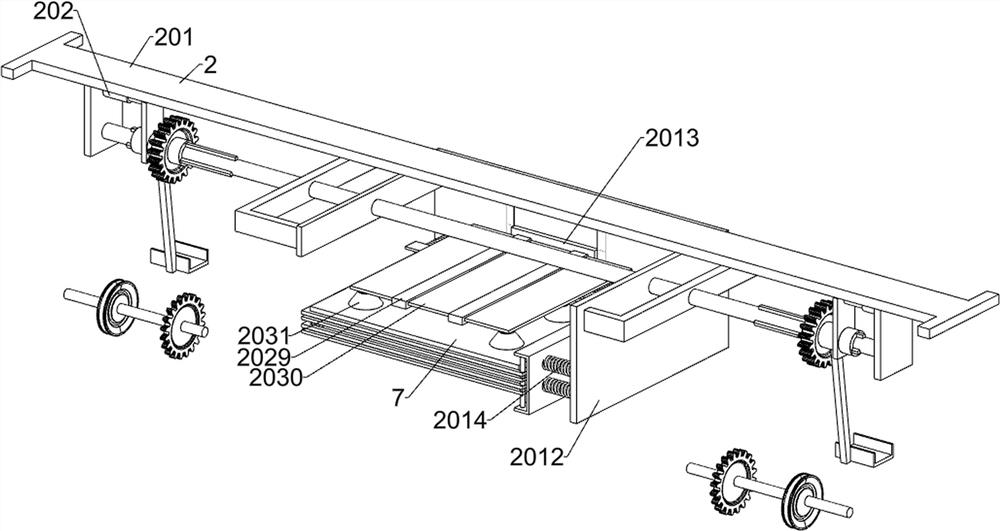

Cloth cutting device

ActiveCN107142704AReduce cloth deformationReduce impactSevering textilesEngineeringMechanical engineering

The invention provides a cloth cutting device comprising a transport roller device, an adjustable guide roller mechanism, an auxiliary roller assembly, a press unit, a cutter and a rolling device; the press unit is provided with a tool rest; two sides of the tool rest are provided with a press mechanism; the cutter is arranged above the press unit; two sides of the cutter are provided with the auxiliary roller assembly; the cutter is provided with a vertical slide seat; a transverse slide seat is arranged on the vertical slide seat; one side of the transverse slide seat is provided with a buffer mounting rack; a cutter assembly is arranged below the buffer mounting rack; the cloth on the transport roller device passes the guide roller assembly, the auxiliary roller assembly, the press unit and the rolling device in sequence along the transport direction; the press unit can press tight the cloth on two sides of the tool rest, thus maximumly reducing the cloth deformation level, and ensuring the cutting process to be stable; the cutter assembly is provided with the buffer mounting rack, thus reducing bumps between the cutter and the tool rest in a cutting process, and reducing the cutter wearing.

Owner:杭州世佳布艺有限公司

Polyurethane hard-foam composition and polyurethane hard-foam plastic prepared from same

The invention discloses a polyurethane hard-foam composition and a polyurethane hard-foam plastic prepared from the same. The polyurethane hard-foam composition comprises polyisocyanate, polyether glycol, polyester polyol I, additive flame retardant and foaming agent, wherein the polyester polyol I is flame-retardant polyester polyol. The flame-retardant polyester polyol is added in the polyurethane hard-foam composition, so that the consumption of the additive flame retardant can be reduced; and the plastification action of the additive flame retardant on the polyurethane hard-foam plastic can be reduced, the Van der Waals force among macromolecular chains of polyurethane can be increased, and the relative slippage among the macromolecular chains can be reduced, thereby reducing the sizes of foaming pores formed by the composition. Meanwhile, the Van der Waals force among the macromolecular chains is increased, so that the rigidity of the pore walls of the foaming pores in the polyurethane hard-foam plastic can be increased, thereby ensuring that the foaming pores are more regular in structure and the deformation degree of the foaming pores is weakened. The foaming pores are small in size and stable in structure, and can enhance the compression strength and creep property of the polyurethane hard-foam plastic.

Owner:北京碧海云智新材料技术有限公司

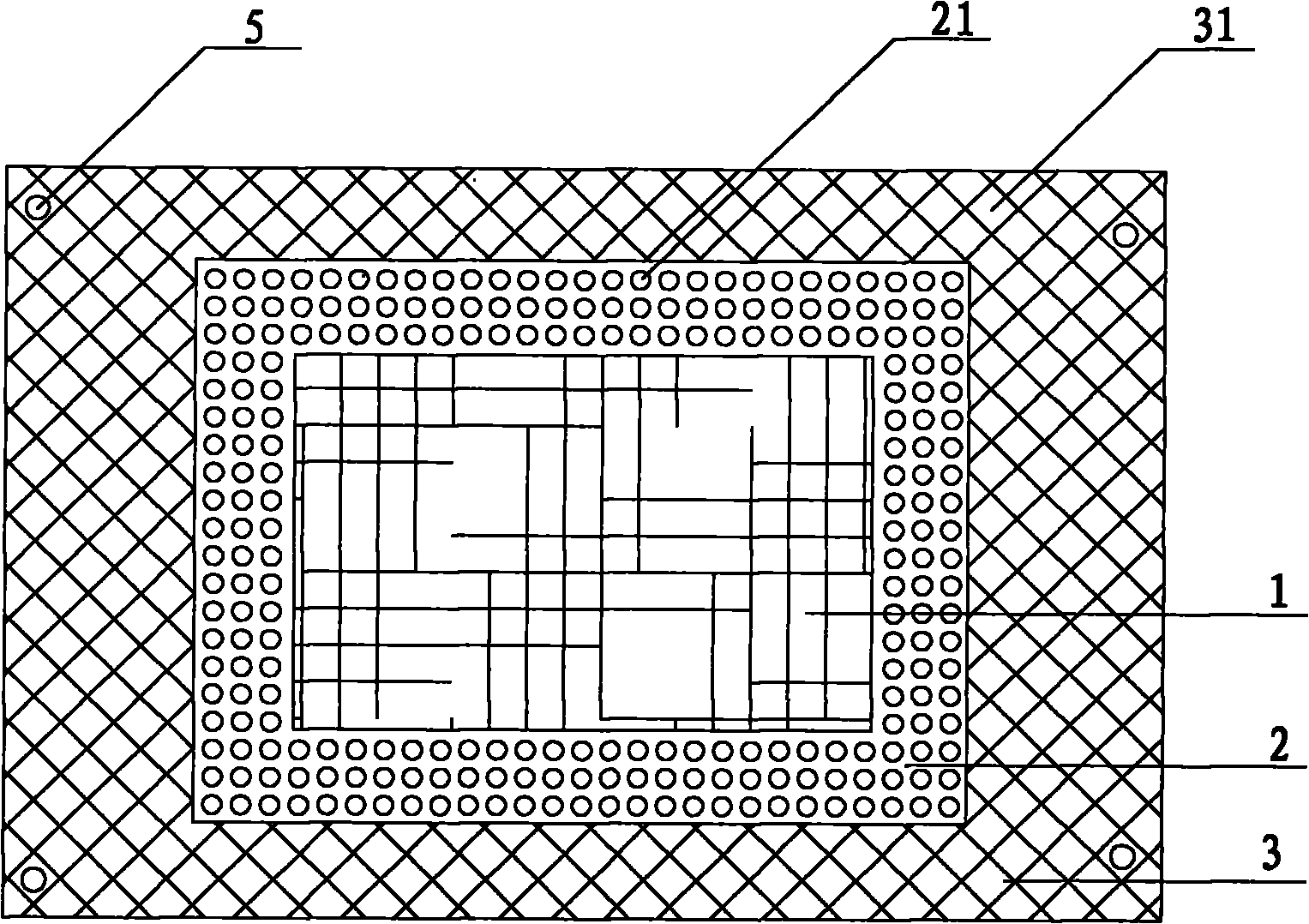

Multi-layer printed circuit board machining process

ActiveCN101778543AControl deformationHigh residual copper rateMultilayer circuit manufactureSolder maskEngineering

The invention discloses a multi-layer printed circuit board machining process, which sequentially comprises the following steps: 1) manufacturing a circuit diagram and frame diagrams on a copper clad board, wherein the frame diagrams comprise a frame diagram I and a frame diagram II, the circuit diagram, the frame diagram I and the frame diagram II are sequentially arranged from the central zone of the copper clad board to the outside, and the copper residual rate of the frame diagram I is smaller than the copper residual rate of the frame diagram II; 2) laminating the copper clad board into a multi-layer circuit board, and milling off the outer edge of the multi-layer circuit board comprising the frame diagram II; 3) manufacturing a through hole, an outer diagram and a solder mask of the multi-layer circuit board; and 4) milling the multi-layer circuit board into the designed finished size. By adopting the machining process of the invention, the machining precision of the PCB is high, and the size of the PCB is accurate.

Owner:SHENNAN CIRCUITS

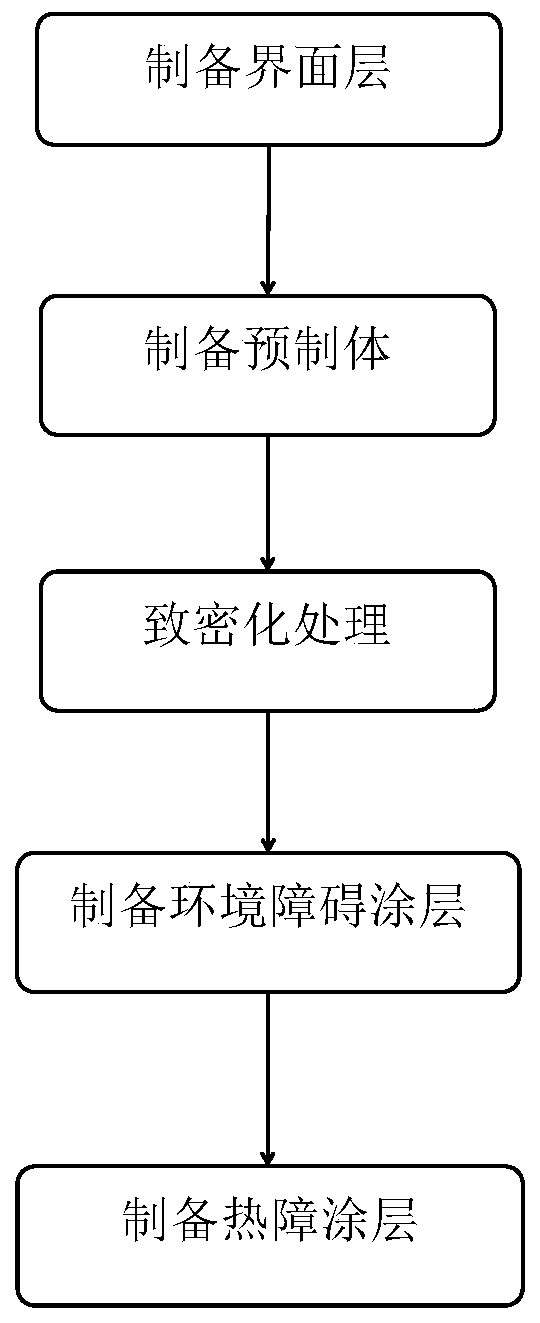

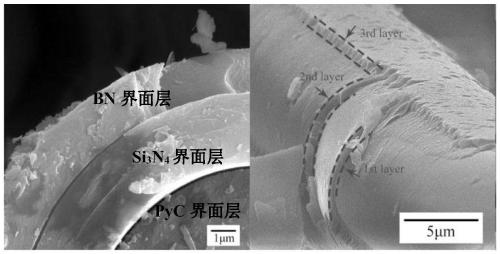

SiCf/SiC composite material flame tube and automatic preparation method thereof

ActiveCN110330353AHigh mechanical strengthCorrosion protectionContinuous combustion chamberCeramic layered productsPolymer scienceGas phase

The invention discloses an automatic preparation method of a SiCf / SiC composite material flame tube. The preparation method comprises the following steps: preparing an interface layer from SiC fibersby adopting chemical vapor deposition, so as to obtain SiC fibers with a continuous interface layer; performing unidirectional tape laying and filament winding on the SiC fibers with the continuous interface layer according to the fiber volume and fiber orientation obtained by simulation calculation, so as to obtain net size forming preform; performing densifying treatment on the obtained preformby adopting a reactive melt infiltration process and the chemical vapor deposition process; preparing an environmental barrier coating on the surface of the obtained preform; finally, continuously preparing a thermal barrier coating on the surface, thereby fully intelligently obtaining the high-density SiCf / SiC composite material flame tube. The SiCf / SiC composite material flame tube prepared withthe method disclosed by the invention has the characteristics of high temperature resistance and long service life and also has the advantages such as low thermal expansion coefficient, high thermalconductivity, high thermal shock resistance and excellent mechanical property. Meanwhile, the preparation method is high in degree of automation, short in production cycle, low in cost and controllable in quality.

Owner:CENT SOUTH UNIV

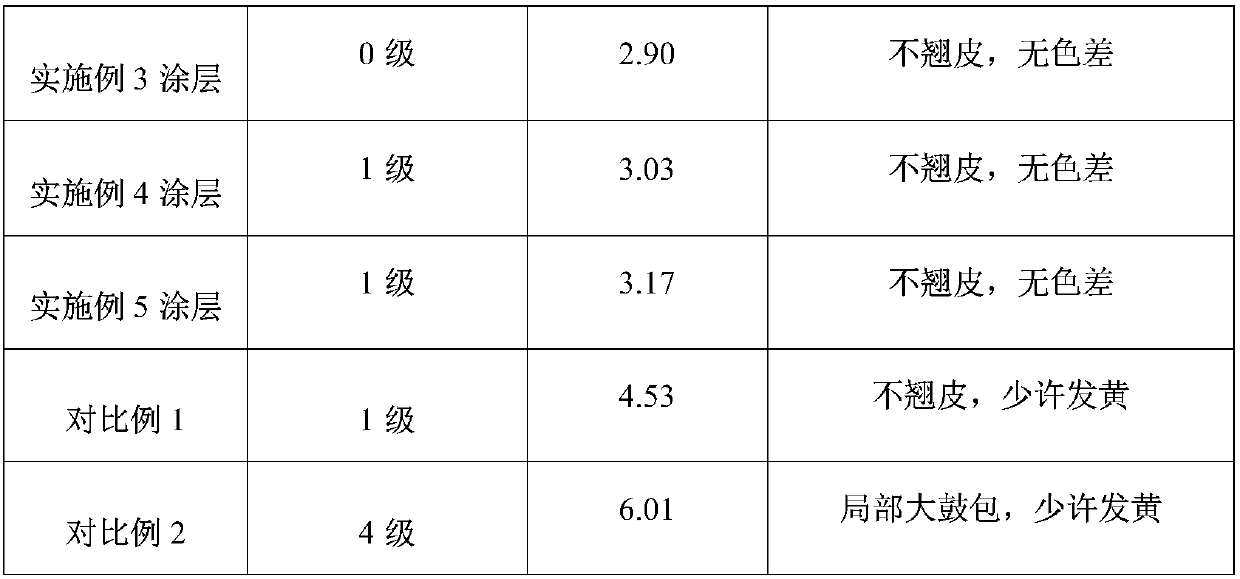

Photovoltaic backing plate refinishing paint as well as refinishing method and applications thereof

The invention discloses a photovoltaic backing plate refinishing paint as well as a refinishing method and applications thereof. The refinishing paint comprises the following raw materials in parts byweight: 40-60 parts of fluorine resin, 10-25 parts of silicone prepolymer, 1-19 parts of epoxy resin, 15-31 parts of inorganic filler, 1-13 parts of auxiliaries, 5-30 parts of diluent, and 5-34 partsof isocyanate curing agent; the refinishing method of a photovoltaic backing plate coating comprises the following steps: (1) cleanly treating the flaws of a photovoltaic backing plate; and (2) filling the prepared photovoltaic backing plate refinishing paint into the flaws, and drying; the applications comprise that the photovoltaic backing plate refinishing paint is applied in refinishing of coatings of coated type, compound type, co-extrusion type and PET type photovoltaic backing plates; and the photovoltaic backing plate refinishing paint not only can meet the strong hydrophobicity situation, but also has the advantages of being low in stress, yellowing-resistant, good in glossiness and strong in adhesivity.

Owner:SUZHOU FIRST PV MATERIAL CO LTD

Injection molding composition for rubber and iron integrated frame, rubber and iron integrated frame and manufacture method of rubber and iron integrated frame

The invention discloses an injection molding composition for a rubber and iron integrated frame, the rubber and iron integrated frame and a manufacture method of the rubber and iron integrated frame. The injection molding composition for the rubber and iron integrated frame comprises a plastic granule and a solid additive, wherein the shrinking percentage of the solid additive is less than that of the plastic granule; the solid additive comprises at least one of a glass fiber, a carbon fiber or a boron fiber; when injection molding is carried out, the plastic granule and the solid additive are mixed and injection molded, so that the using volume of the plastic granule is reduced, the injection amount of the plastic granule is reduced and the shrinking percentage of the injection molding plastic of the rubber and iron integrated frame is reduced; the melting point of the solid additive is higher than that of the plastic granule, the injection molding temperature is controlled between the melting points of the solid additive and the plastic granule. The solid additive is kept in a solid state in the injection molding process so that the deformation degree after shaping the rubber and iron integrated frame is small or none.

Owner:SHENZHEN TECHASER TECH

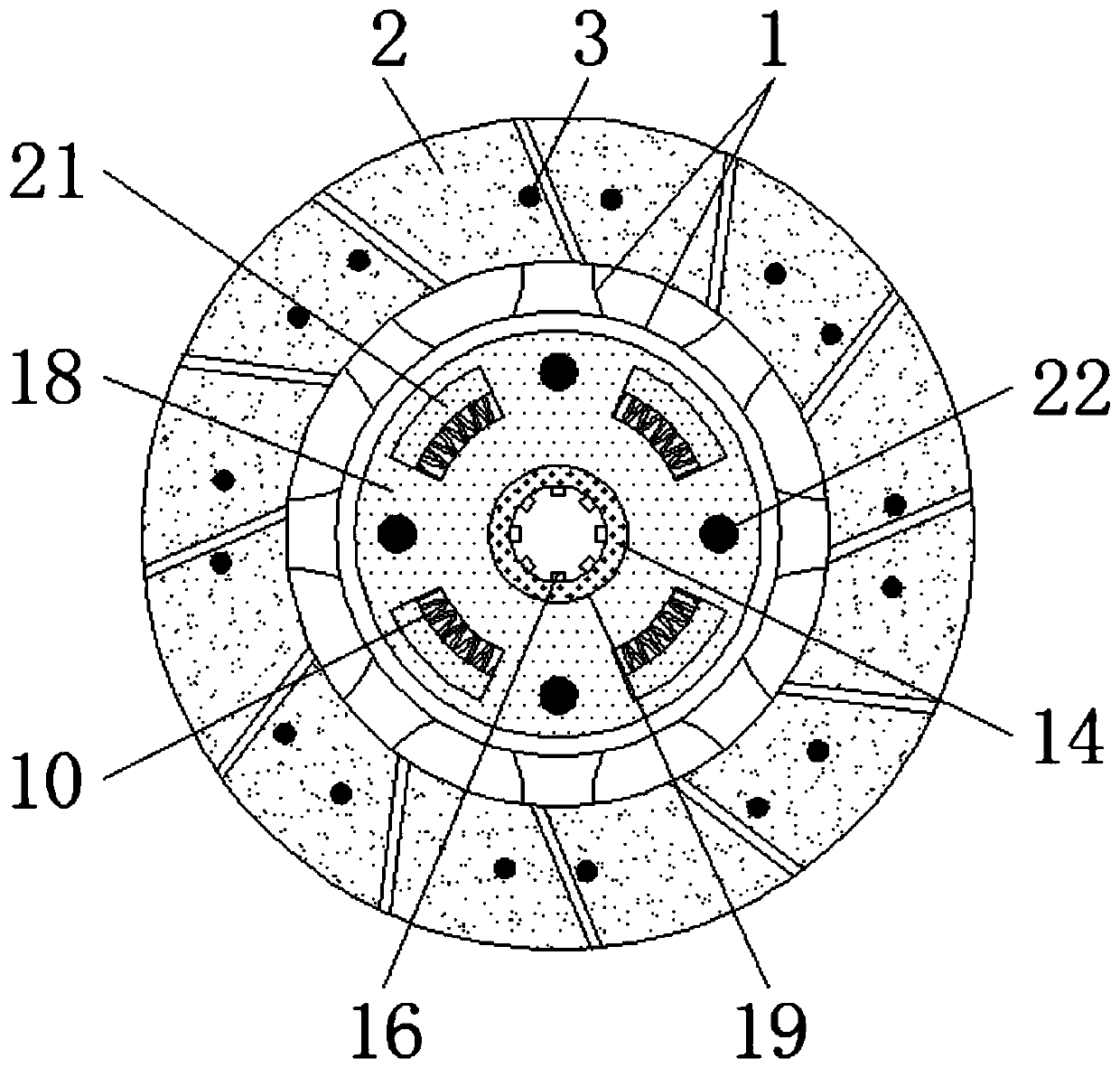

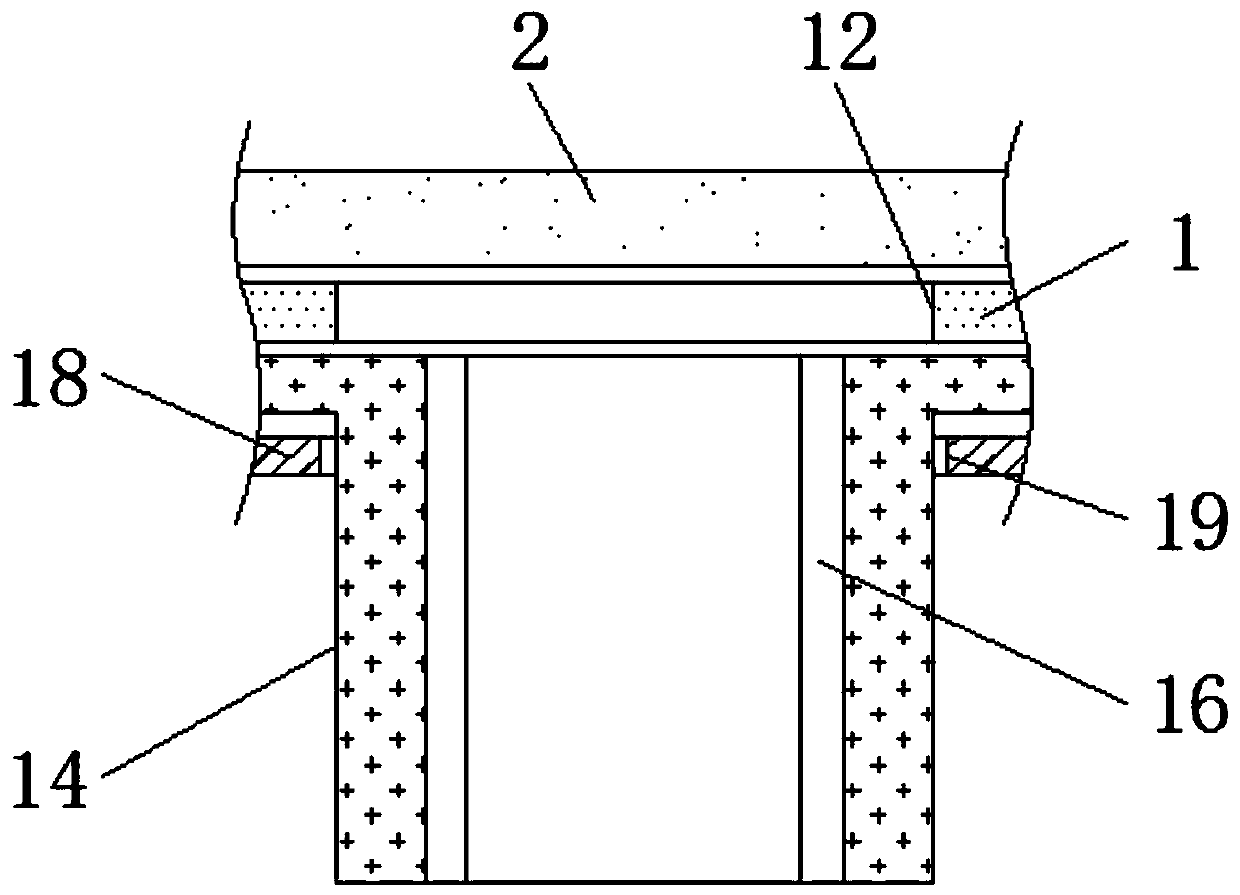

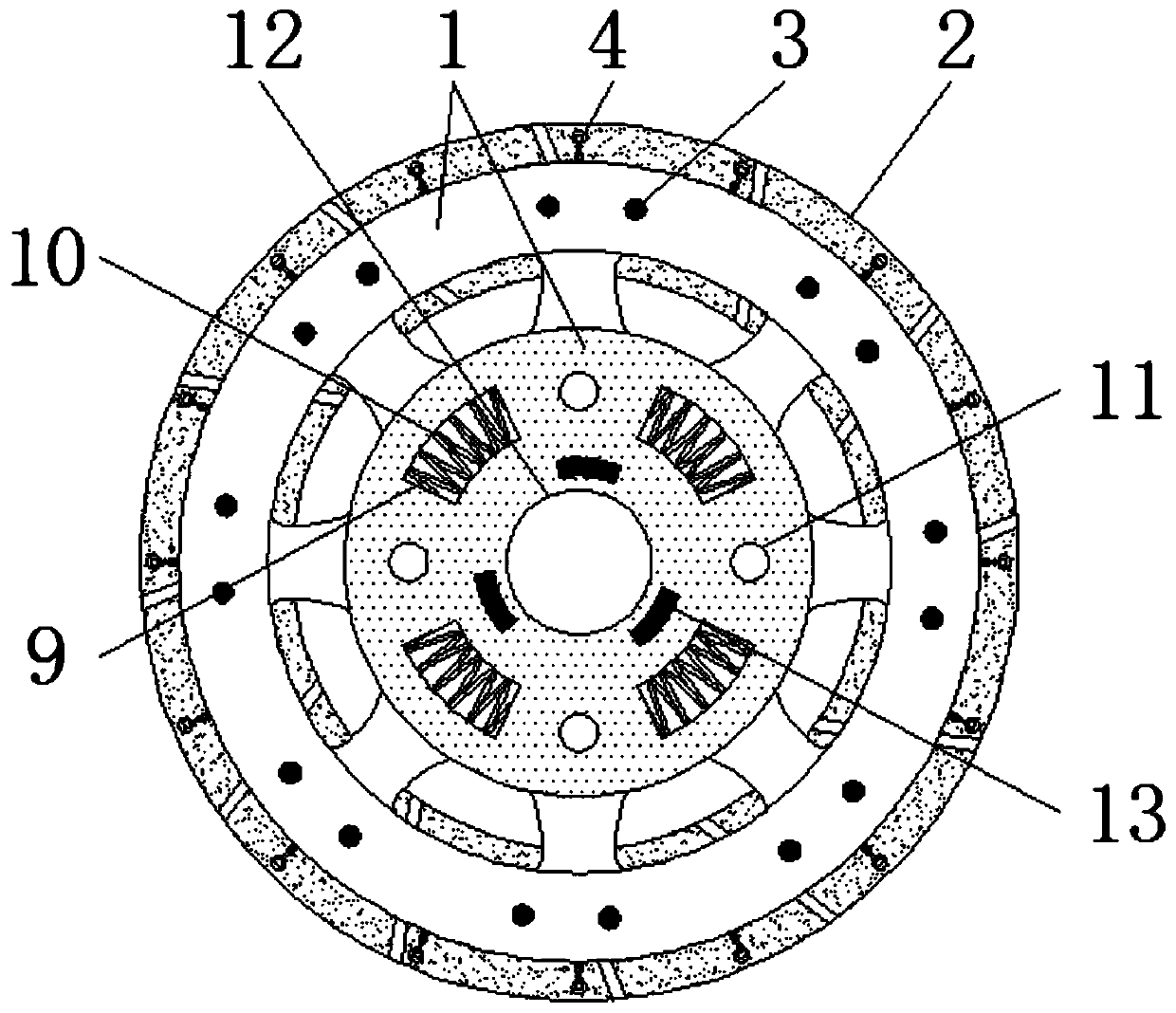

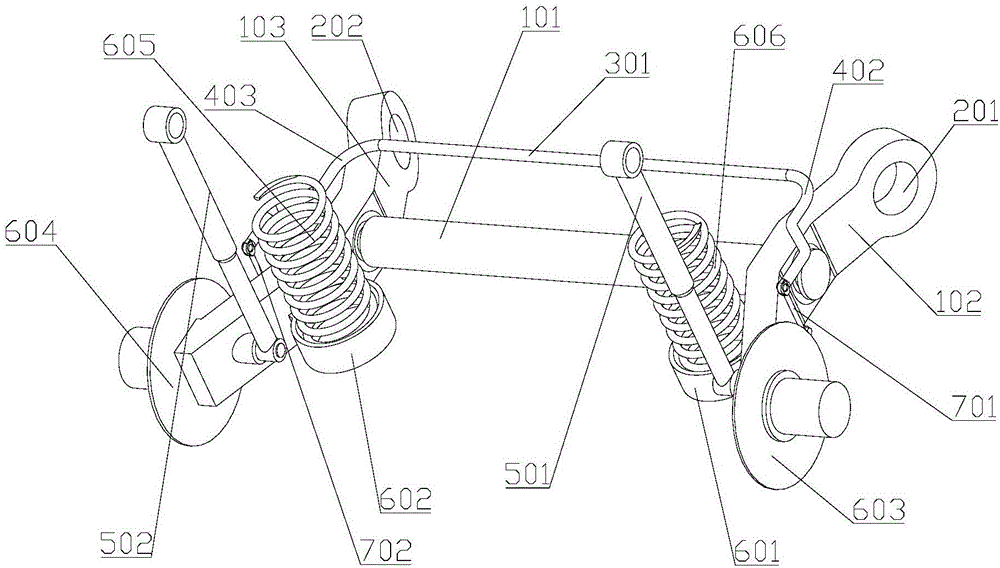

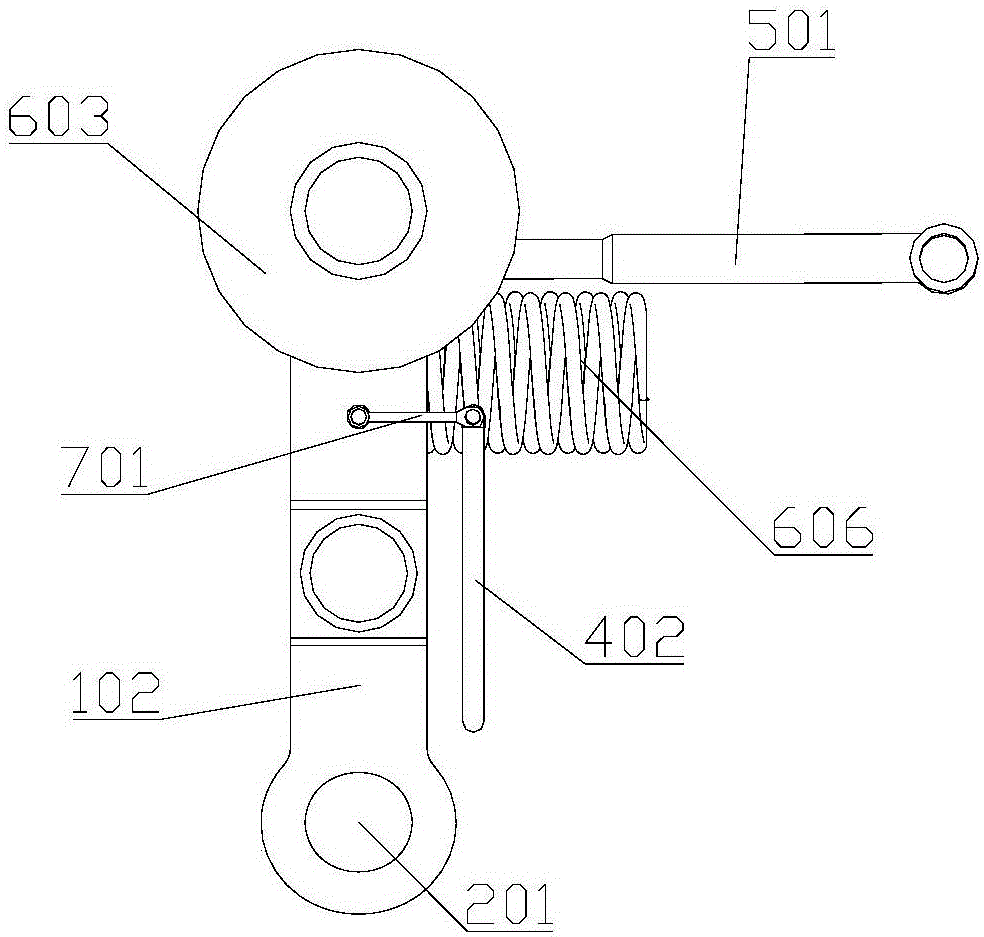

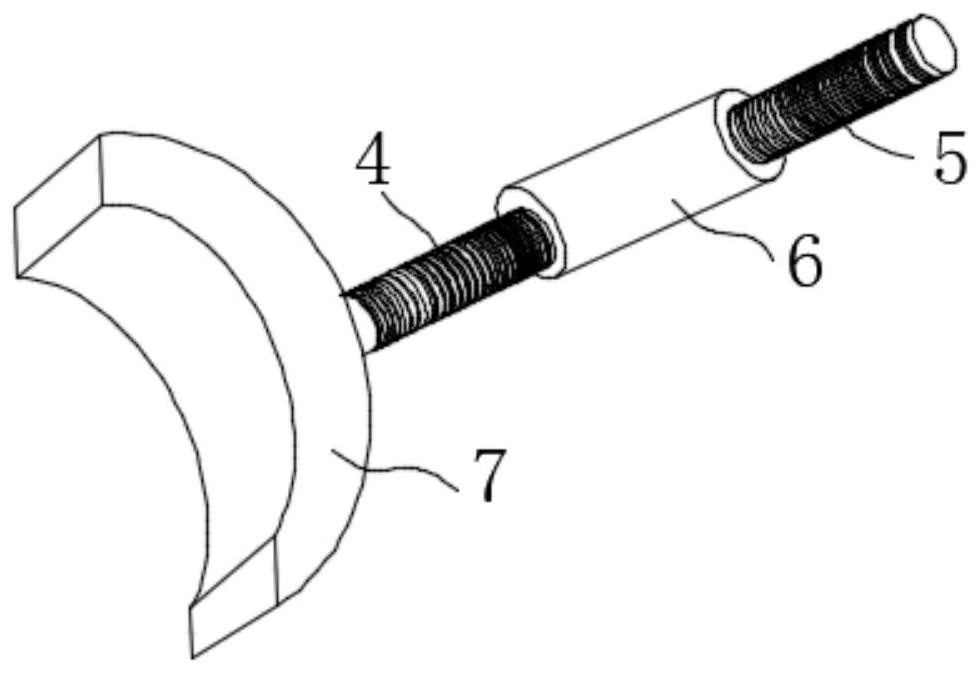

Novel nonlinearity wrench transmission clutch driven plate assembly

ActiveCN110043572AReduce the deformationReduce lossFriction clutchesVibration suppression adjustmentsEngineeringWrench

The invention discloses a novel nonlinearity wrench transmission clutch driven plate assembly. The novel nonlinearity wrench transmission clutch driven plate assembly comprises a clutch driven piece,friction pieces, a driven plate hub, a driven piece cover plate and connection rivets. The edge of the clutch driven piece is provided with the friction pieces. The clutch driven piece is provided with first rivet holes. The back face of the driven plate hub is fixedly provided with a second fixing protruding plate. A center hole is formed in the center position of the driven piece cover plate, and the driven piece cover plate is provided with second rivet holes and half-covered windows. The connection rivets are connected with the first rivet holes and the second rivet holes. According to thenovel nonlinearity wrench transmission clutch driven plate assembly, by means of the novel structural design, supporting damping can be carried out on the edge parts of the friction pieces through the device, it is guaranteed that in the stress process of the friction pieces, deformation amplitude is reduced, after the friction pieces are not stressed, recovering is rapid, meanwhile, through thedesigned structure of auxiliary damping springs for working, the loss of the damping springs is effectively reduced, and the service life of the whole device is prolonged.

Owner:浙江华信汽车零部件有限公司

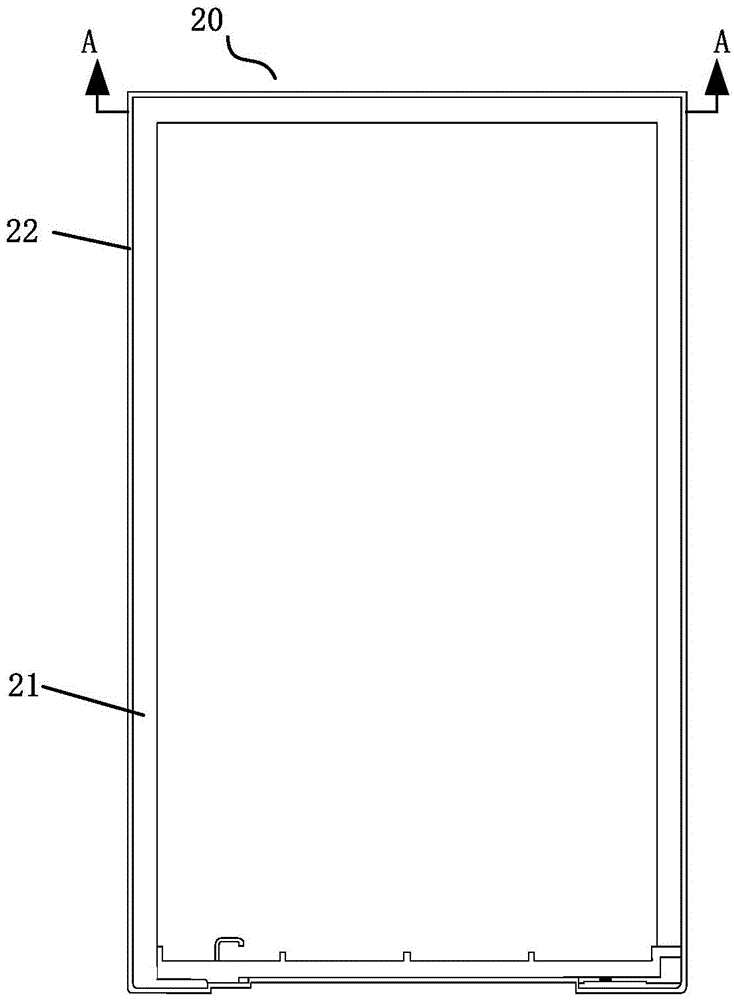

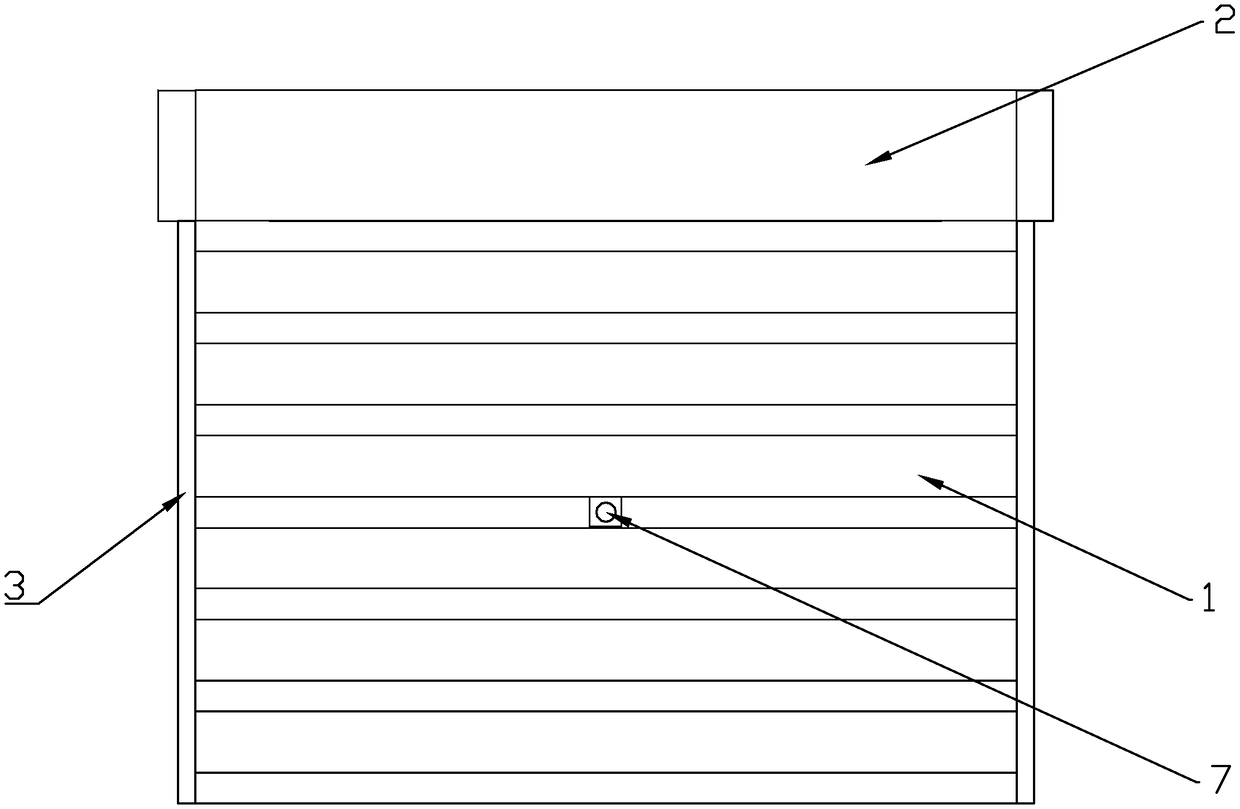

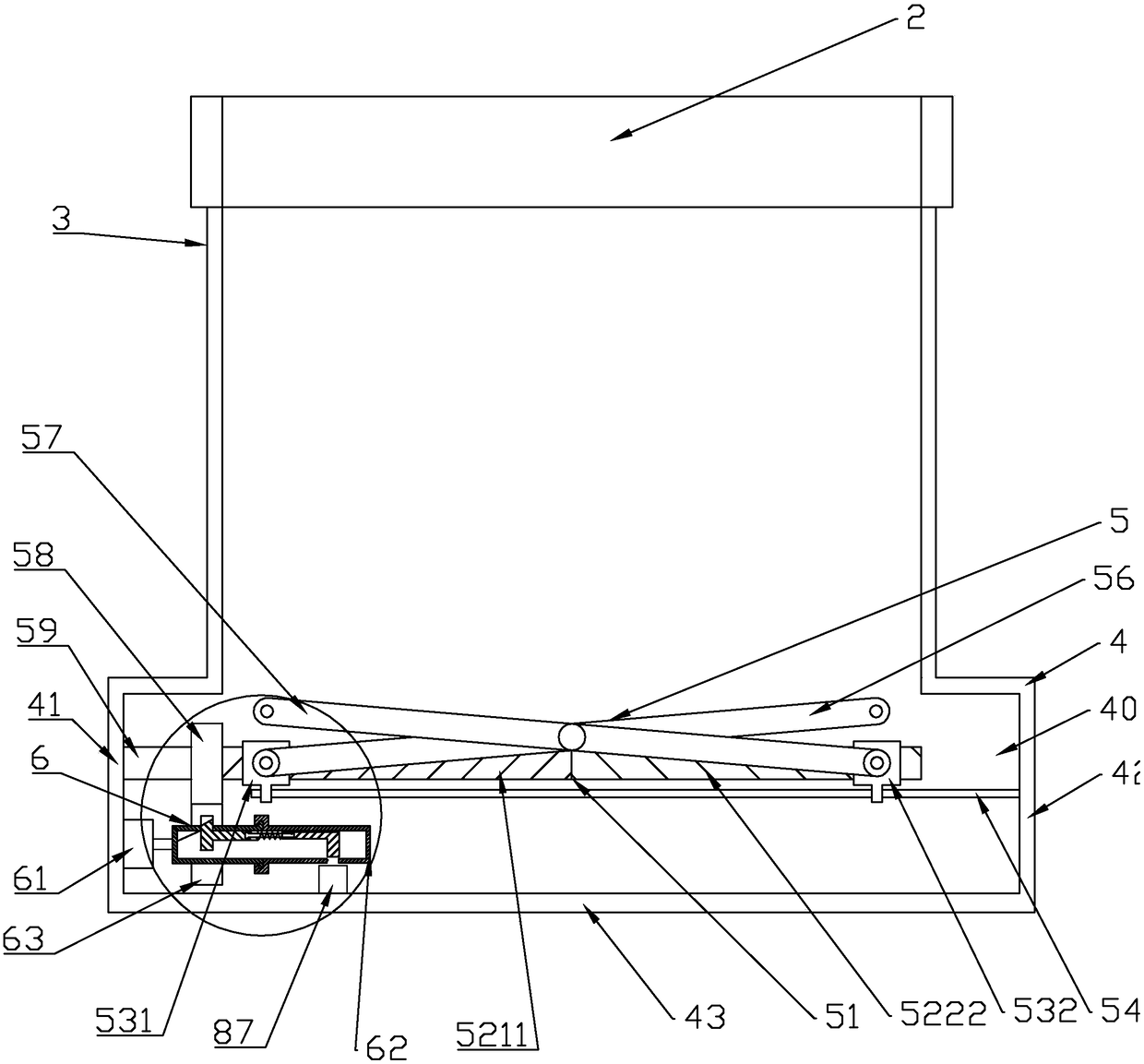

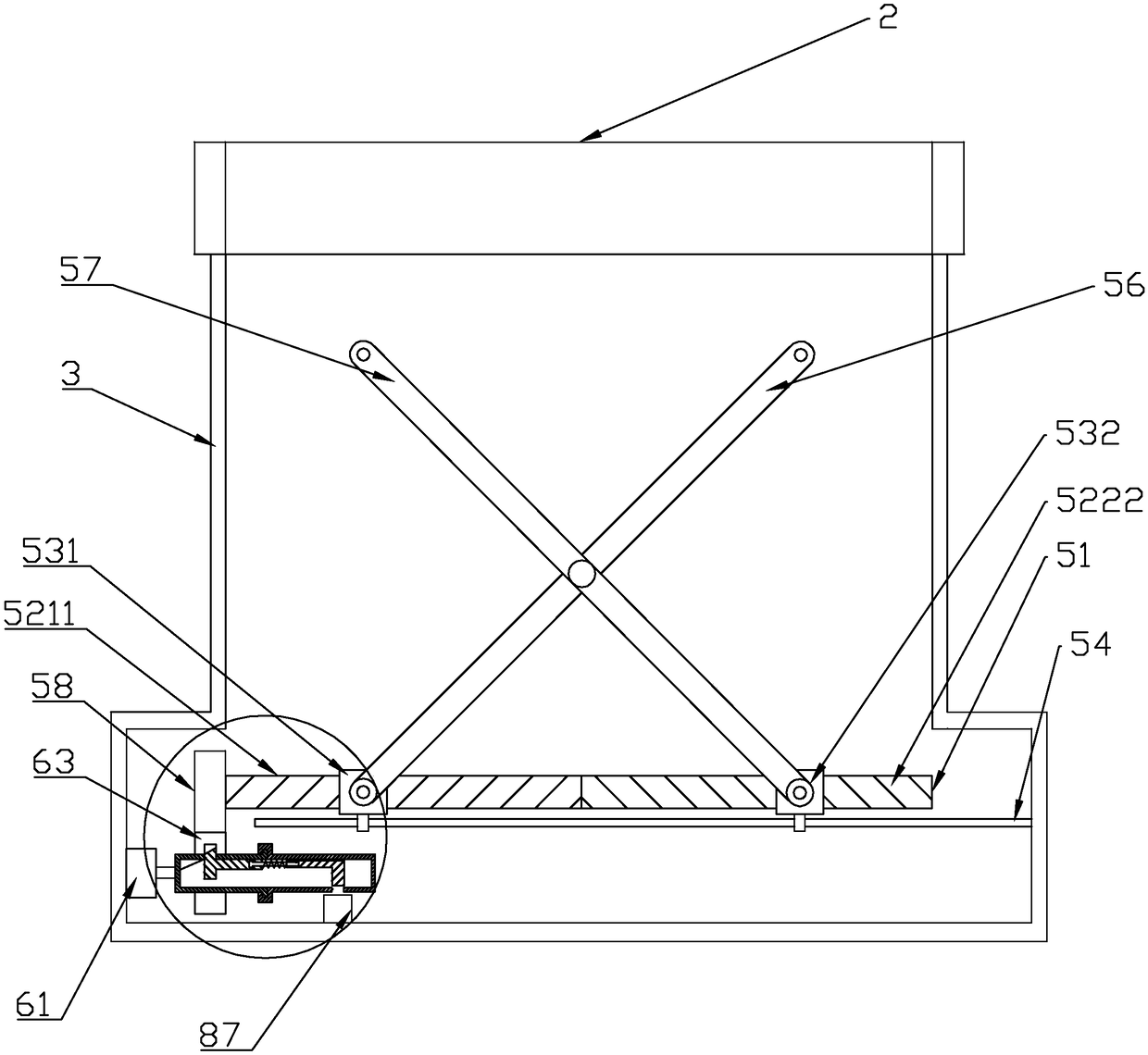

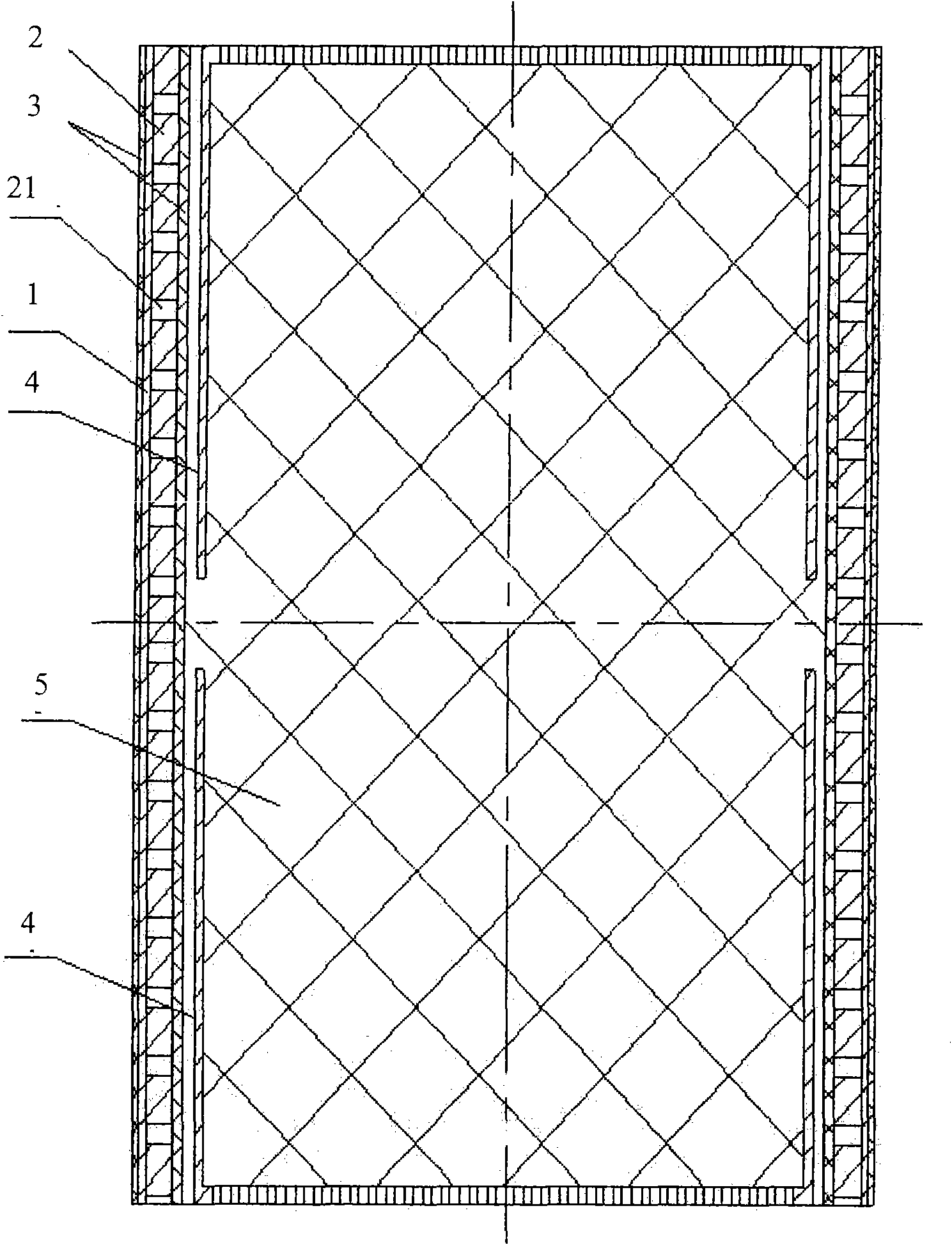

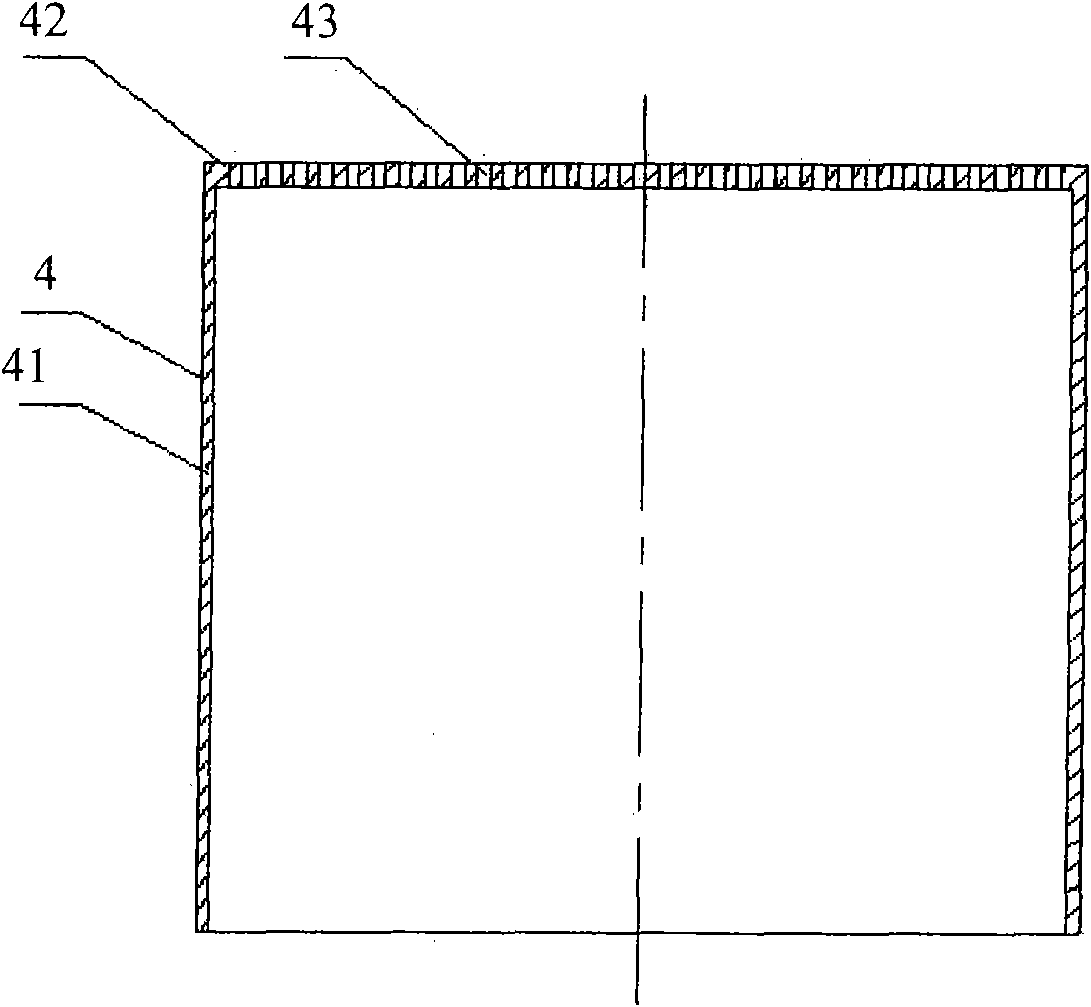

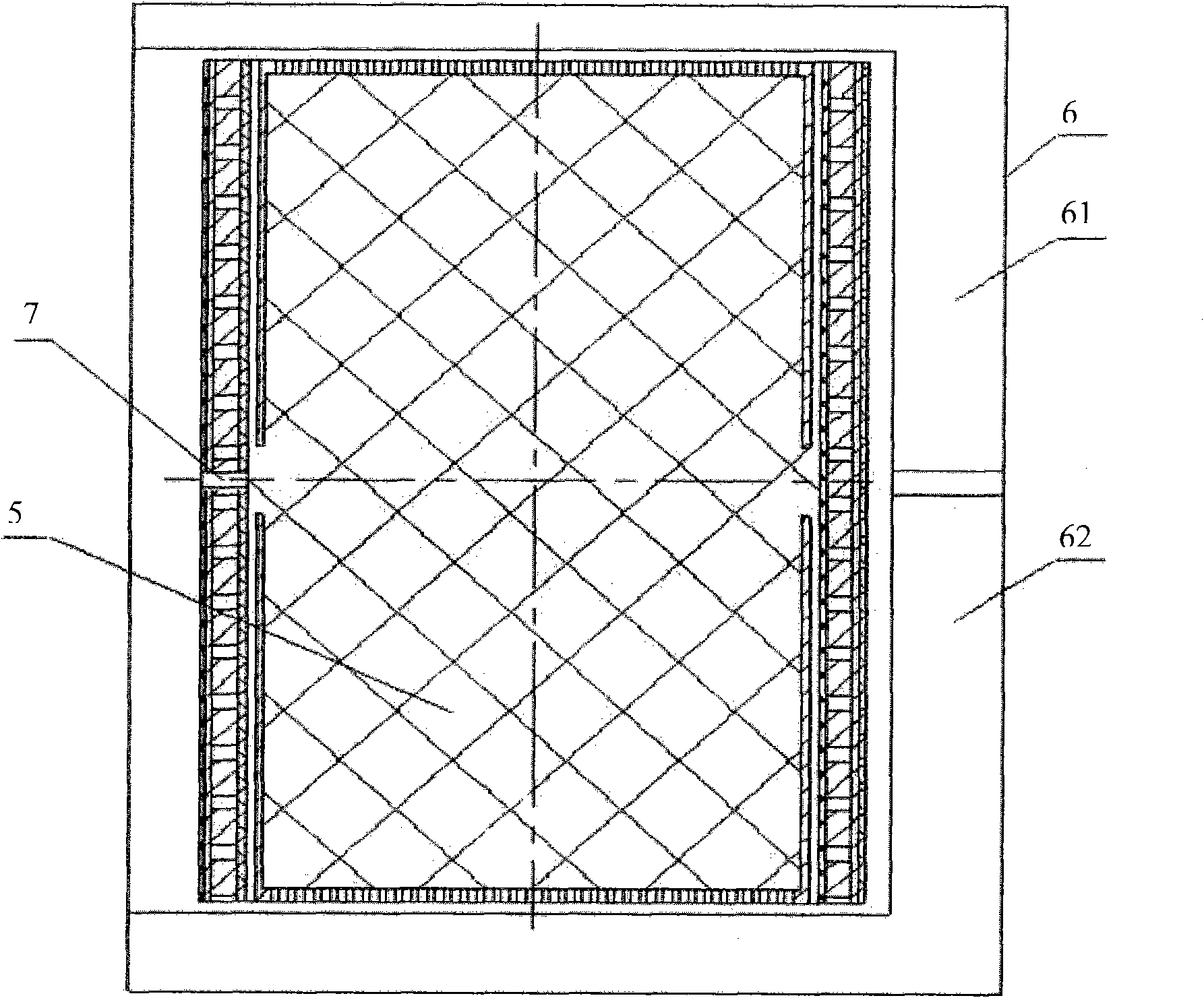

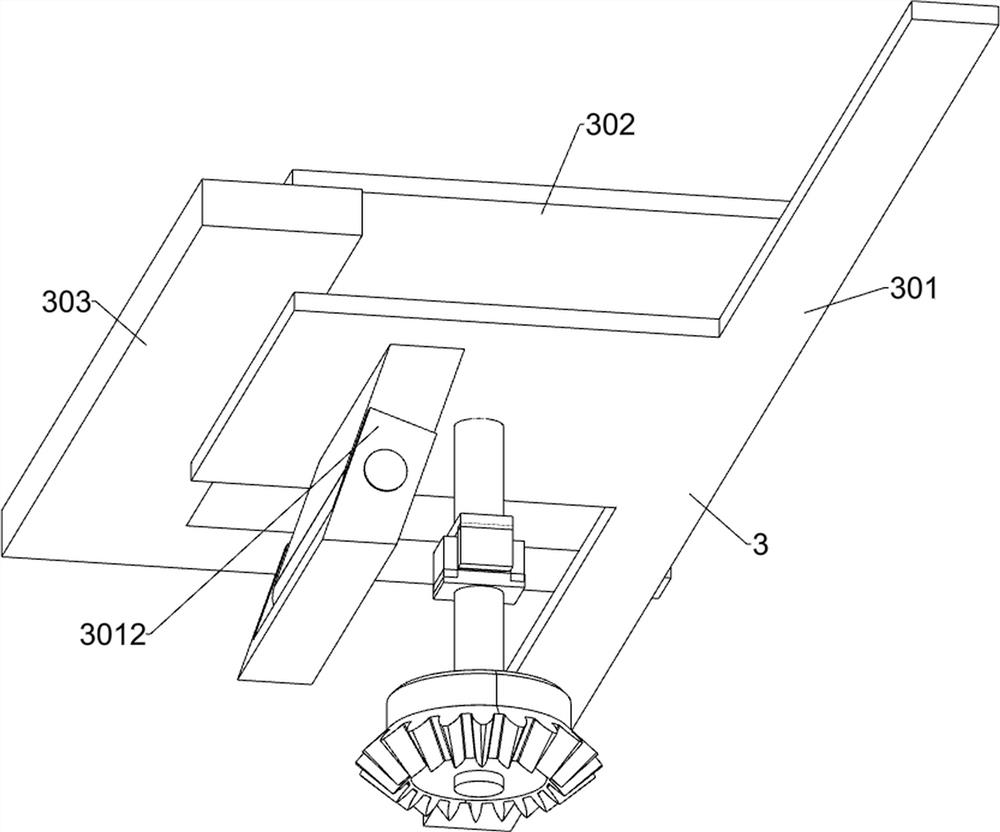

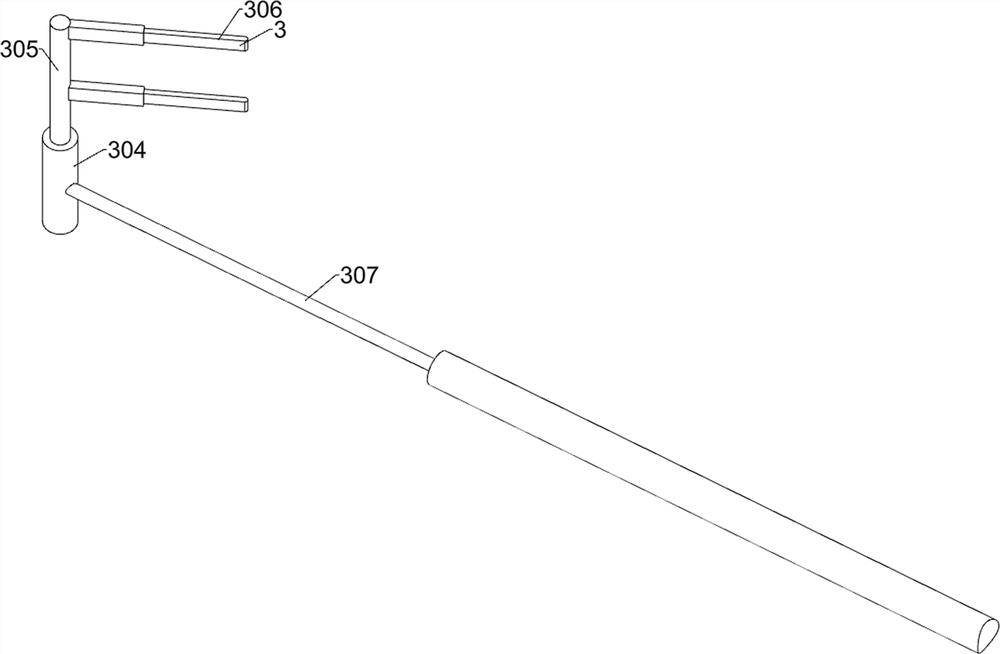

Wind resistance device for roller shutter door

ActiveCN109441321AReduce the degree of deformationStable supportShutters/ movable grillesDrive wheelEngineering

The invention discloses a wind resistance device for a rolling shutter door. The wind resistance device comprises a shutter door body and a winding drum, door frames are further arranged on the two sides of the shutter door body, a mounting seat is arranged on the side, back on to the winding drum, of the door frames, a mounting groove is formed in the mounting seat and comprises a first groove wall and a second groove wall, a supporting mechanism is arranged on the first groove wall and comprises a lead screw, a first thread and a second thread which are opposite in thread turning direction are arranged on the lead screw and are in threaded connection with a first sliding block and a second sliding block correspondingly, a guide rail is arranged on the second groove wall, and the first sliding block and the second sliding block are slidably connected to the guide rail; a first wind-resistant plate and a second wind-resistant plate which are centrally and mutually hinged are further arranged in the mounting groove, one end of the first wind-resistant plate is hinged to the first sliding block, one end of the second wind-resistant plate is hinged to the second sliding block, a driven wheel is arranged at the end, facing the first groove wall, of the lead screw and provided with a rotating shaft, and the rotating shaft is rotatably arranged on the first groove wall; and a drivingmechanism is arranged in the mounting groove, and a wind power sensor is arranged on the shutter door body.

Owner:WENZHOU UNIV OUJIANG COLLEGE

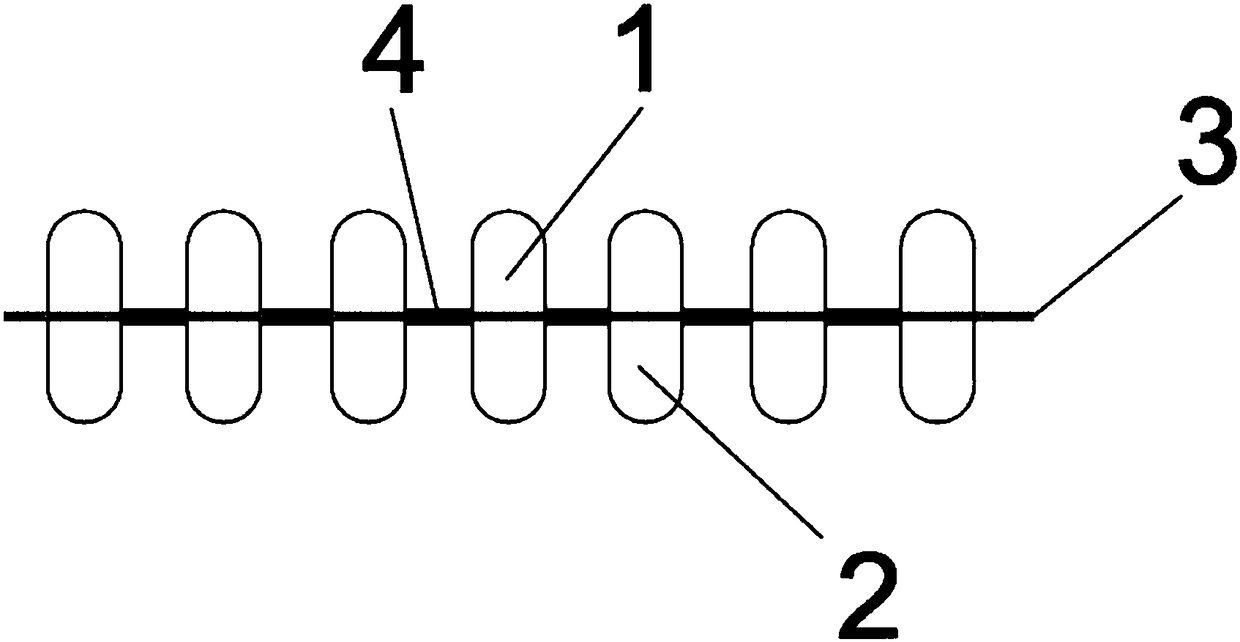

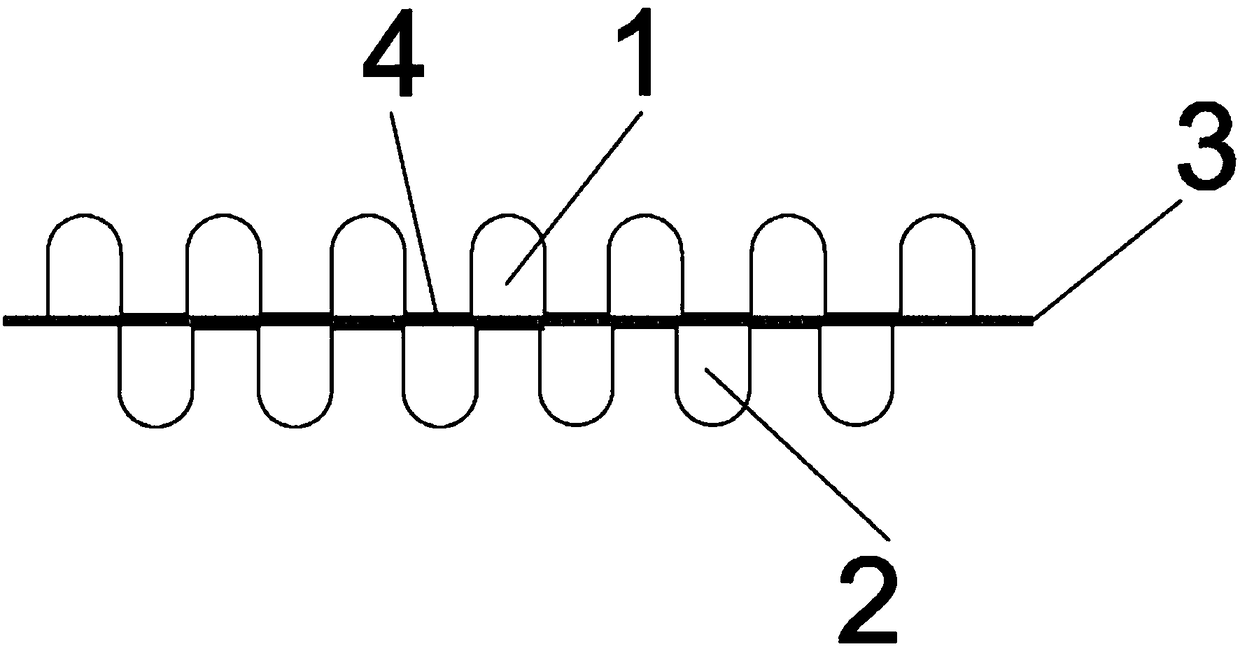

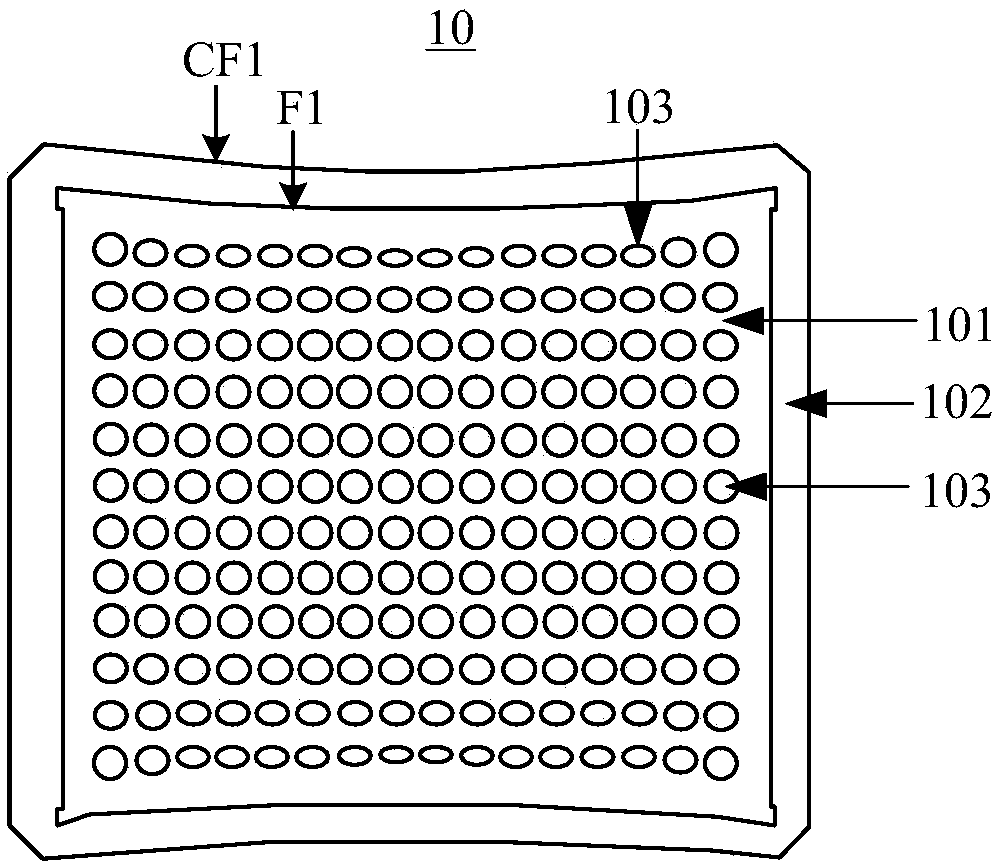

Device of titanium metal wire net cage compounded with titanium metal wire engineering bone and preparation method thereof

ActiveCN102085123ALightweight yet strongExuberant formationBone implantCoatingsTitanium metalInvestment material

The invention provides a device of a titanium metal wire net cage compounded with a titanium metal wire engineering bone and a preparation method thereof, and the device of the titanium metal wire net cage compounded with the titanium metal wire engineering bone comprises a piston type titanium metal wire net cage and a titanium metal wire engineering bone composite filled in the piston type titanium metal wire net cage; and the preparation method comprises the following steps: winding titanium metal wire non-woven fabric on the outer wall of a titanium metal cage body and sintering for preparing a titanium metal wire net cage body, then coating hydroxyapatite on the inner surface and the outer surface of the cage body, and then placing two piston type cap-shaped bodies in an inner cavityof the metal cage body for getting the piston type titanium metal wire net cage; and further uniformly mixing titanium metal wires, a morselized bone, a binding material and auxiliary materials, and filling into the piston type titanium metal wire net cage. The device has good elastic modulus coordination and high strength, and can be used in the field of bone surgery.

Owner:HARBIN MEDICAL UNIVERSITY

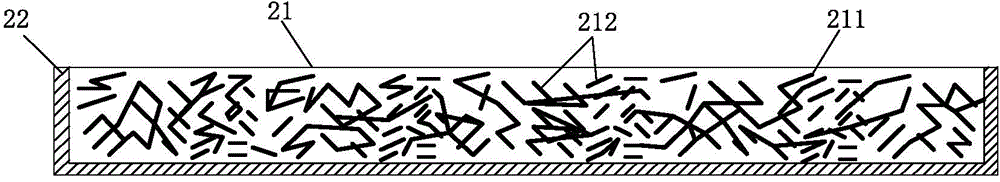

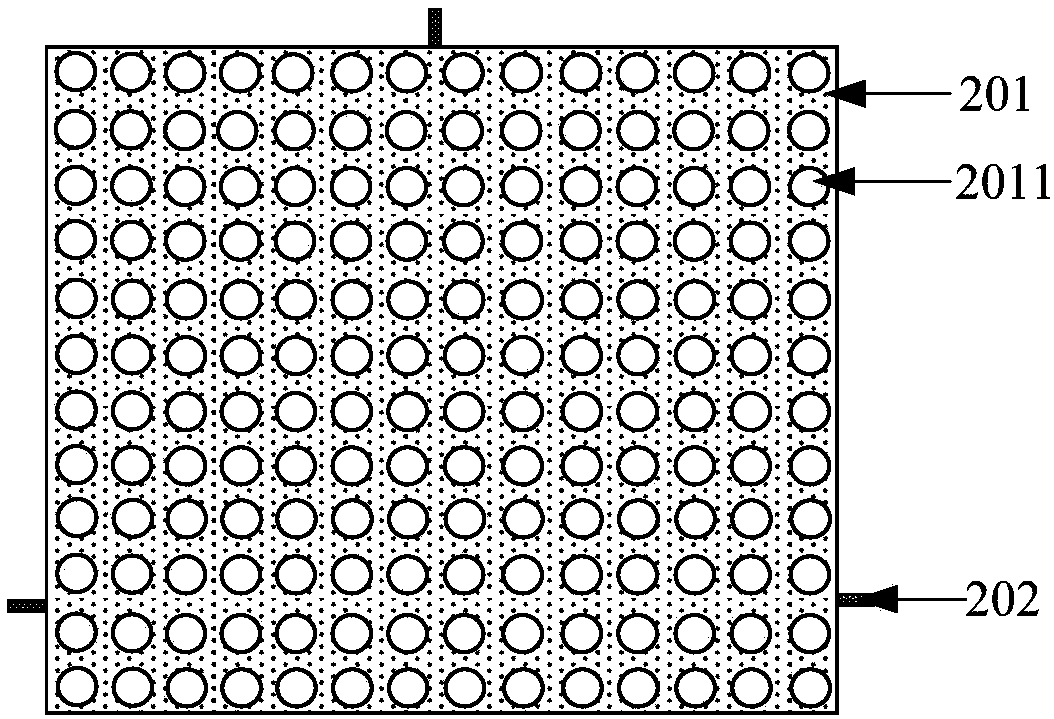

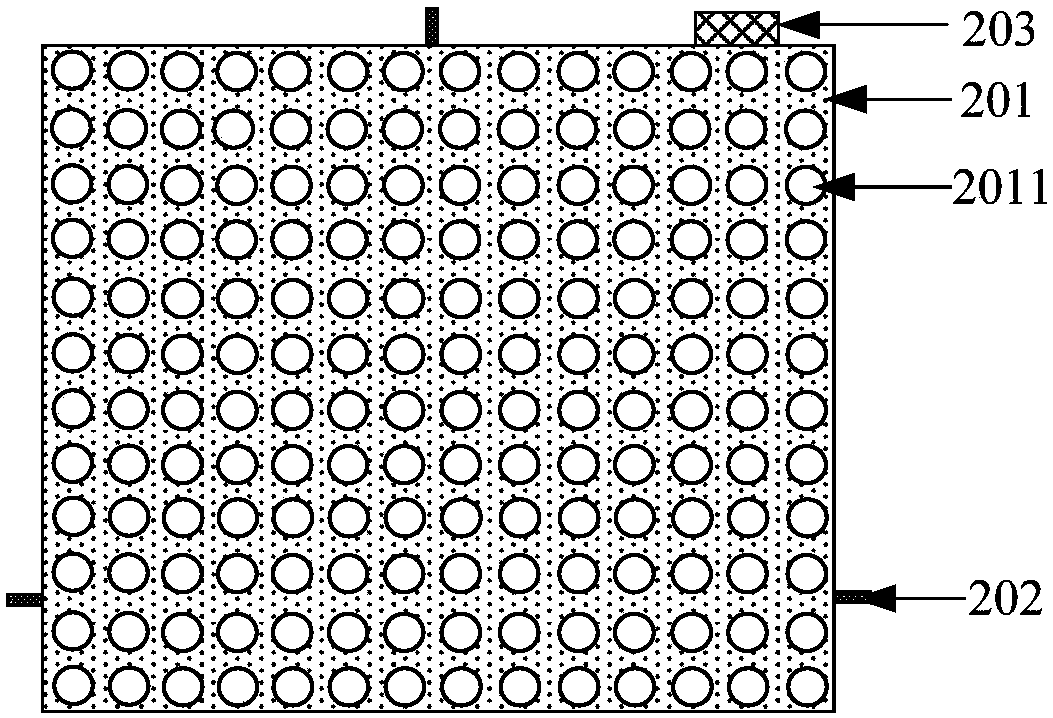

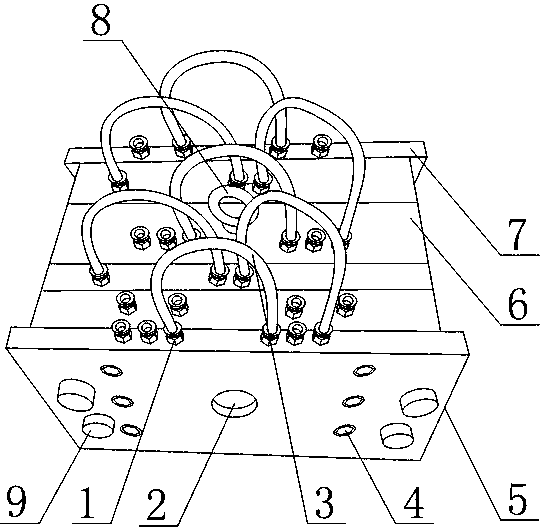

Inflation-free type double-side air bag and preparation method thereof

PendingCN108313519APlay a protective effectReduce impactDomestic articlesContainers to prevent mechanical damageAbsorbed energyEngineering

The invention belongs to the technical field of air bags, and specifically relates to an inflation-free type double-side air bag and a preparation method thereof. The inflation-free type double-side air bag comprises a plurality of upper air bags which are arranged in an array form and are interconnected to form a planar body, a plurality of air bags which are arranged in an array form and are interconnected to form a planar body, and an elastic material layer which is arranged between each upper air bag and the corresponding lower air bag; the upper surfaces of the elastic material layers areconnected to the upper air bags, and the lower surfaces of the elastic material layers are connected to the lower air bags; soft edge connecting parts are arranged between adjacent upper air bags andadjacent lower air bags; in case of being pierced, the air bag still remain the protection effect; in addition, when the inflation-free type double-side air bag is subjected to outside pressure, theelastic material layers are capable of buffering and absorbing energy, thus the deformation degree of the air bag can be reduced, and as a result, the impact force on an air bag body or a product canbe reduced. The preparation method comprises the steps of (1) molding single edge; and (2) sealing an opening, and forming. The preparation method is simple in processes, easy to operate, and high inproduction efficiency.

Owner:DONGGUAN ZHONGDING PLASTIC PROD CO LTD

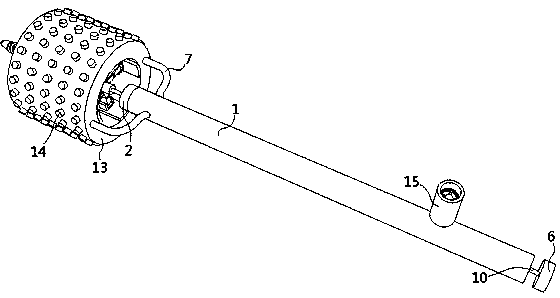

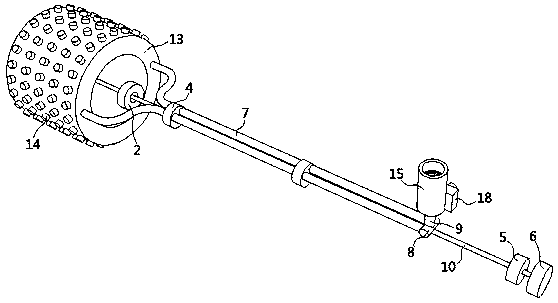

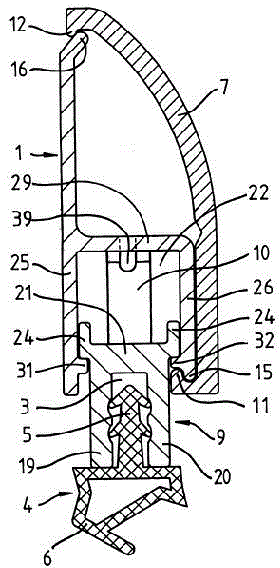

Biological balloon dilatation catheter

PendingCN108853694AReduce the degree of deformationProtection securityBalloon catheterSurgeryBalloon dilatation catheterBlood vessel

The invention discloses a biological balloon dilatation catheter and relates to the technical field of catheter. The biological balloon dilatation catheter disclosed by the invention comprises a firstcatheter body, a handle, a third catheter body, a fourth catheter body and a first fixed plate, wherein a group of second blocking plates and a third blocking plate are sequentially fixed to an innerwall of the first catheter body from left to right, a fifth catheter body and a fourth blocking plate are sequentially fixed to an inner wall of the fourth catheter body from top to bottom, and one end of the third catheter body penetrates through one surface of the fourth blocking plate and extends into the fourth catheter body. According to the biological balloon dilatation catheter disclosed by the invention, a steel wire is pulled to drive a first supporting rod to slide in an air bag, so that a second fixed plate is driven to rotate, the second fixed plate and a fourth fixed plate are matched, supporting plates are opened, the air bag is supported by the plurality of the supporting plates, and a blocked part can be better opened by the air bag; furthermore, a deformation degree of the air bag is protected to be smaller, and no secondary damage is generated to blood vessels; meanwhile, blood circulation cannot be blocked in a treating process, and safety of patients is protected.

Owner:杭州耕鑫生物科技有限公司

Filter press and filter pressing method

PendingCN110372170AHigh efficiency filter pressCompress usage amount and volumeSludge treatment by de-watering/drying/thickeningEngineeringMechanical engineering

The invention relates to a filter press and a filter pressing method, and belongs to the technical field of water removing equipment. The filter press comprises a first filter pressing system and a second filter pressing system, the first filter pressing system internally comprises a first filter belt, the second filter pressing system internally comprises a second filter belt, a section of an overlapping part formed by mutual attaching is arranged between the first filter belt and the second filter belt, pressing rollers are arranged on one side of the overlapping part, the pressing rollers extrude the overlapping part, thus objects to be subjected to filter pressing between the first filter belt and the second filter belt are extruded to filter liquid out; and the two or more pressing rollers are arranged, and the diameters of the pressing rollers located on the front filter pressing position are larger than the diameters of the pressing rollers located on the rear filter pressing position. The multiple pressing rollers with the diameters being decreased progressively are adopted to sequentially conduct pressure progressive increase type filter pressing on the overlapping part, the pressing rollers located on the front filter pressing position become the basis of further filter pressing of the pressing rollers located on the rear filter pressing position, high-efficiency filter pressing of overall filter pressing equipment is achieved, and the water outlet proportion of the objects, to be subjected to filter pressing, such as sludge and impurities is increased.

Owner:CHINA TIESIJU CIVIL ENG GROUP +1

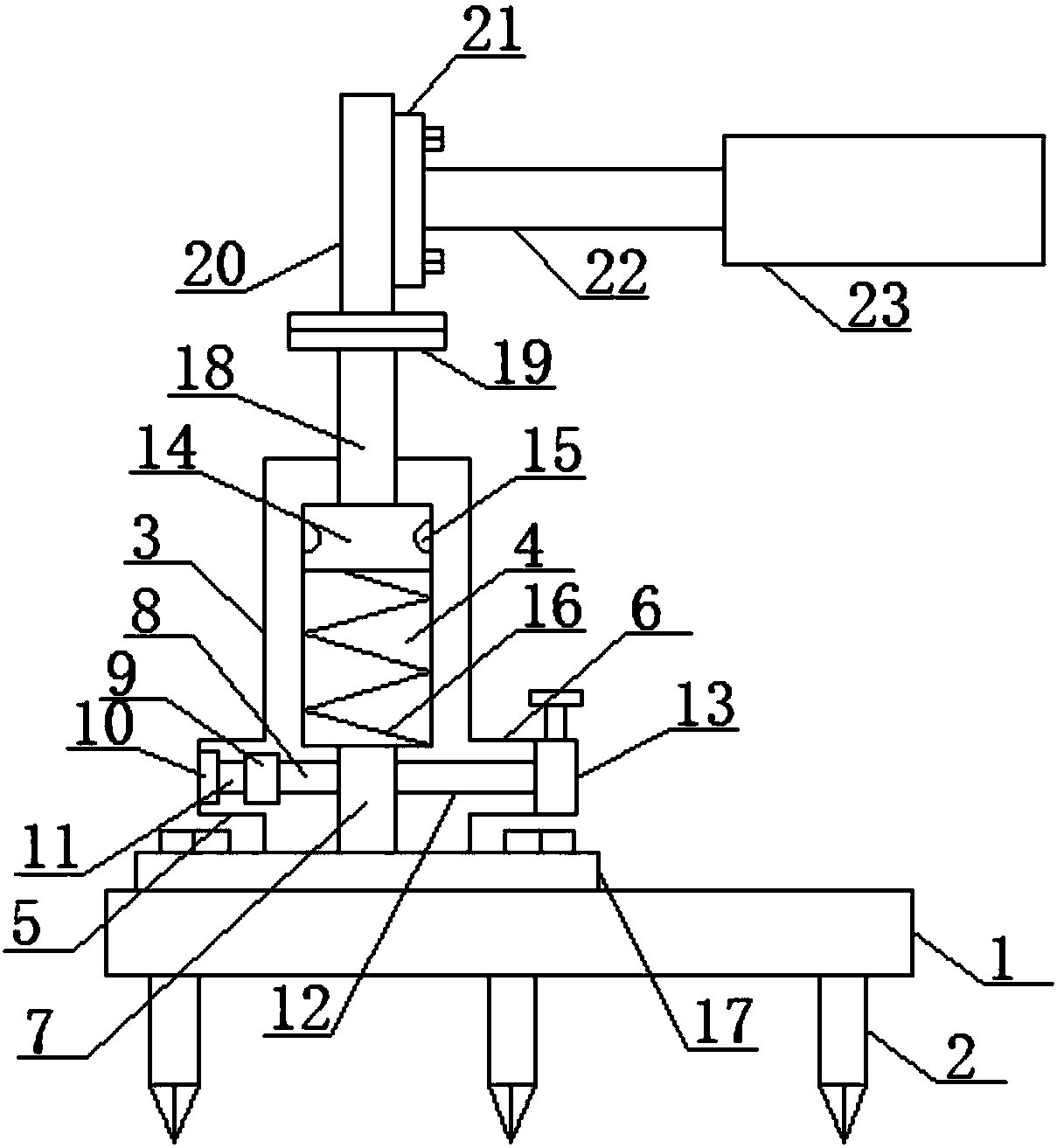

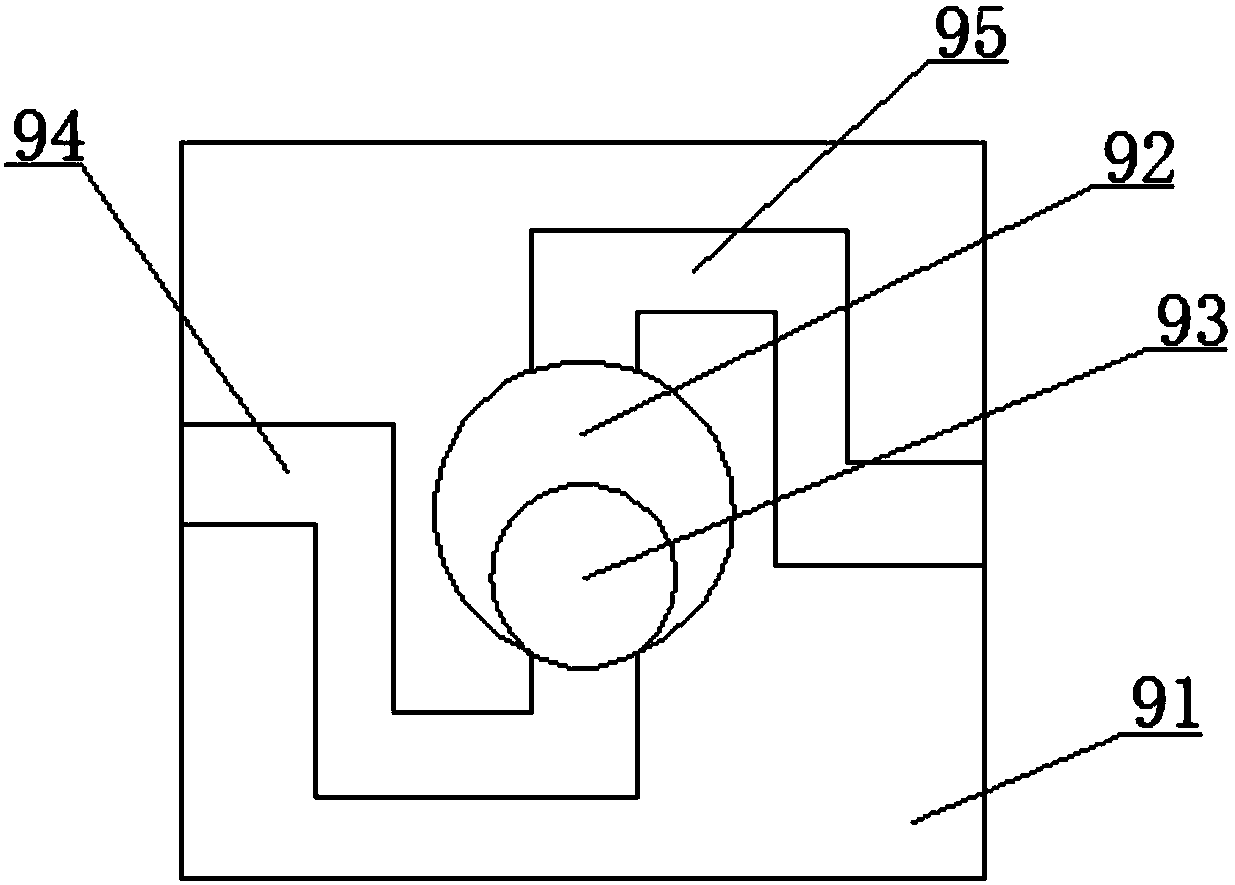

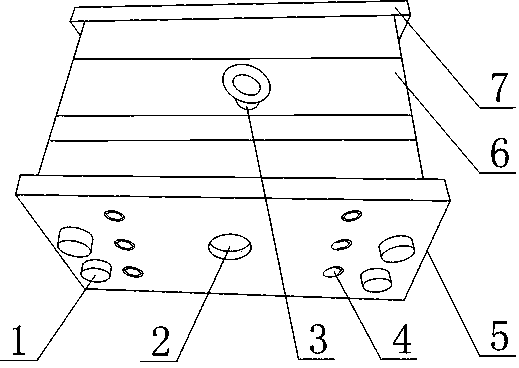

Large-pipeline storing bracket for building site

ActiveCN108506573AReduce the degree of deformationIncrease the internal contact areaPipe supportsOperating means/releasing devices for valvesBuilding unitMechanical property

The invention discloses a large-pipeline storing bracket for a building site. The large-pipeline storing bracket comprises a bottom supporting base plate. A plurality of ground inserting rods are mounted on the bottom surface of the bottom supporting base plate. The large-pipeline storing bracket is mainly used for supporting storing of a large pipeline, a supporting part makes contact with an inner ring of the pipeline, by increasing the internal contact area of the supporting part and the pipeline, the degree of deformation of the pipeline due to the gravity of the pipeline is reduced effectively, and the phenomena such as the mechanical property of the pipeline are protected effectively; the large-pipeline storing bracket is provided with a large air one-way flowing control mechanism, one-way air flowing can be achieved under the precise that the large air pressure is borne, accordingly, the pressure effect of the air pressure on vulnerable components such as a valve core at the mounting part is reduced, and the service life of the components is prolonged; and in addition, the large-pipeline storing bracket is provided with a thread-rotating-type air release flow control mechanism, discharging and closing functions of the air with the large air pressure can be controlled, and practicability is high.

Owner:马鞍山楚兴市政设施有限公司

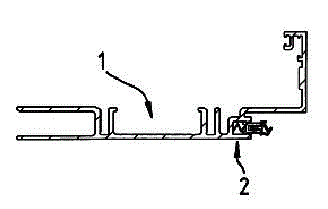

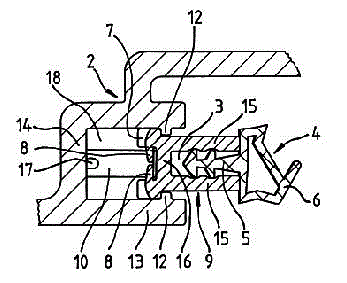

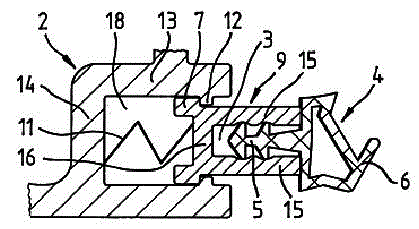

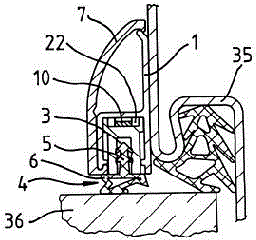

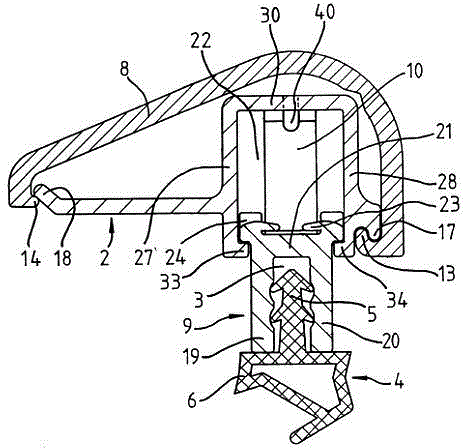

Door frame sealing device

The invention relates to a door frame sealing device, and the device is used for sealing a gap between a door frame and a door leaf. The device comprises an installation part, and an installation groove which is used for installing a sealing strip, wherein the installation part is located in a metal, plastic or wood door frame, and the sealing strip consists of a fixed part and a sealing part. The device is characterized in that the fixed part of the sealing strip is disposed in an installation groove of a built-in strip; the built-in strip is disposed in the installation part, is installed on a closing surface in a closing direction, and can be impelled in a parallel manner. The device enables the gap between the door frame and the door surface to be sealed as durably and completely as possible, and is not affected by the torque of a door structure or the concave-convex parts of the door surface.

Owner:ATHMER

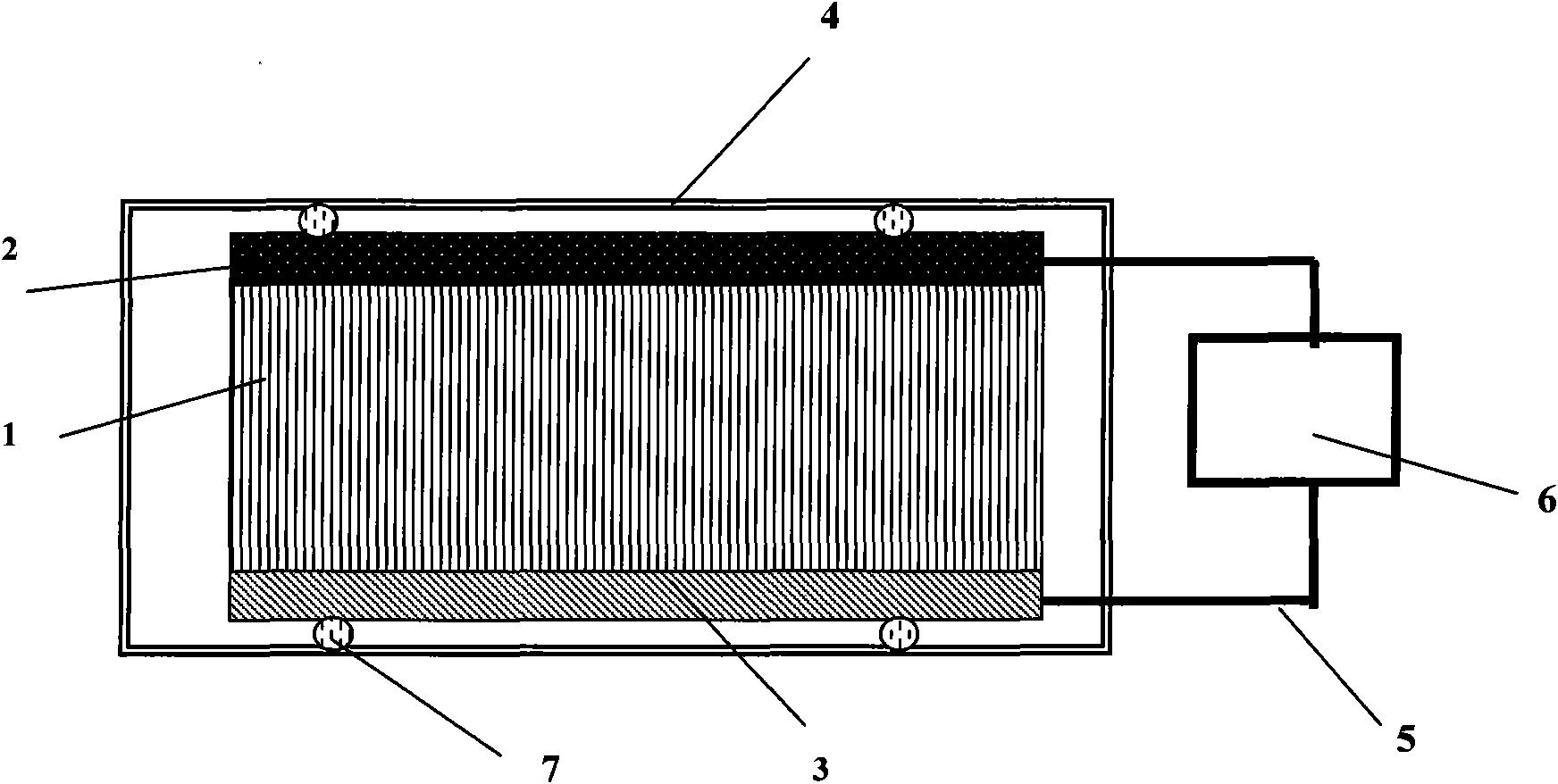

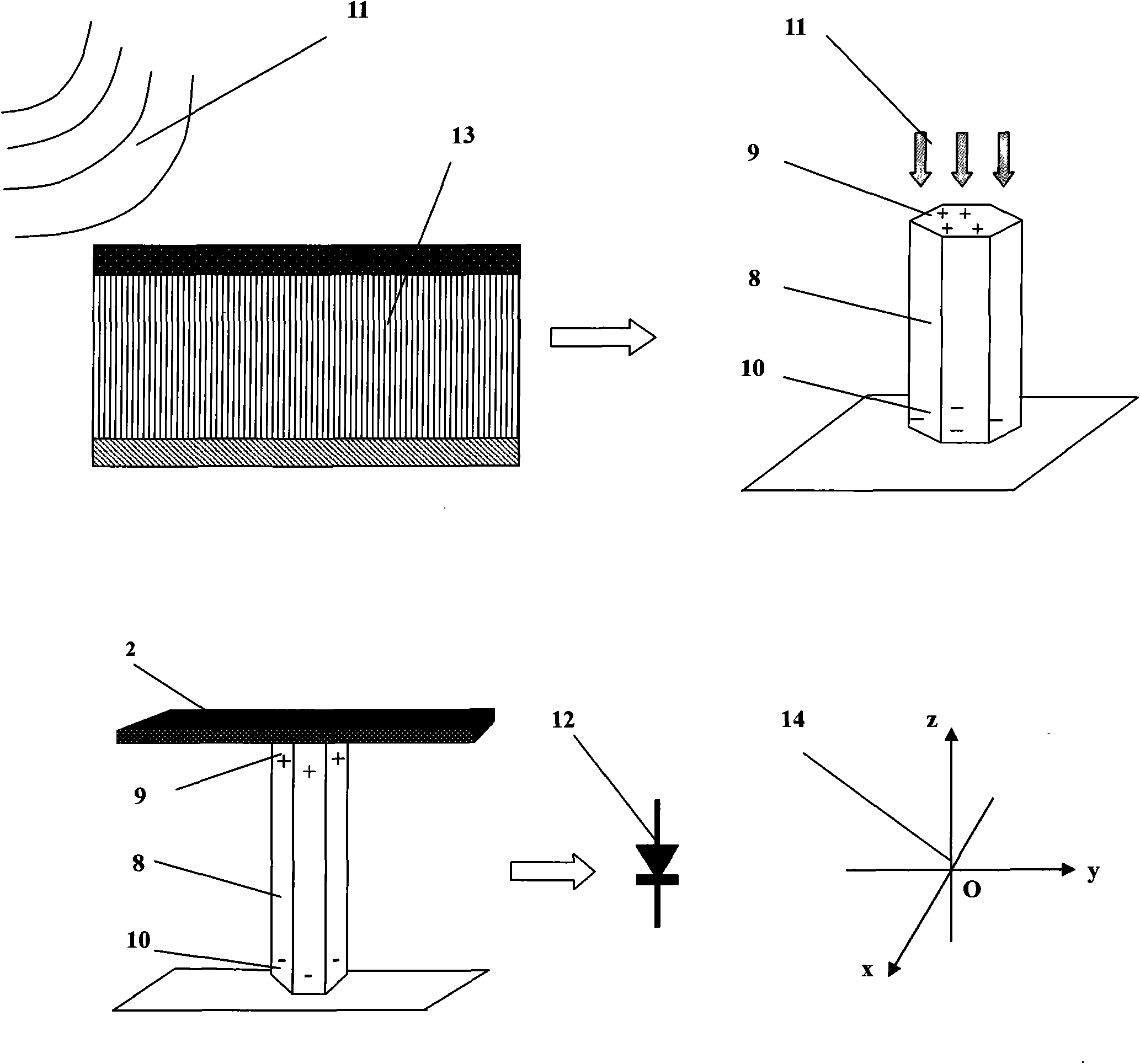

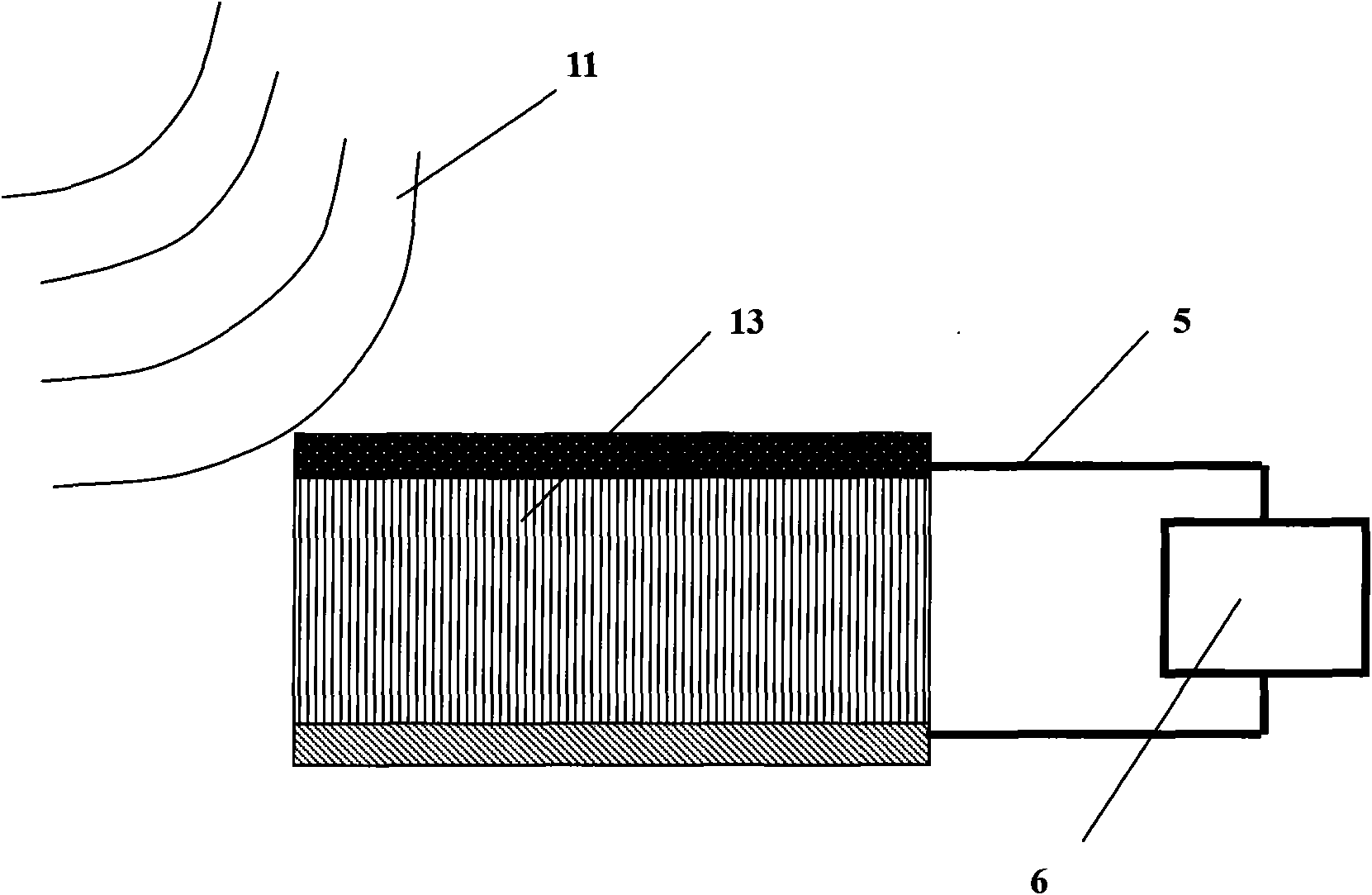

Inverse piezoelectric nano semiconductor generator

InactiveCN101860261AAvoid obstructionAchieve the effect of power generationPiezoelectric/electrostriction/magnetostriction machinesPolarization phenomenonElectromagnetic radiation

The invention discloses an inverse piezoelectric nano semiconductor generator, which comprises a semiconductor nano-wire array, a metal sheet, a shell and an external circuit. The nano-wire array consists of oriented semiconductor nano-wires with inverse piezoelectricity and polarization characteristics and is grown on a corresponding conductive metal substrate; the metal sheet is tightly contacted with the other side of the semiconductor nano-wire array; and the semiconductor nano-wire array and the metal sheet are directly fixed in the shell through a suspension spring system after up-and-down laminated contact and connected with the external circuit. When spatial electromagnetic radiation signals are acted on the nano-wires, the nano-wires generate inverse piezoelectricity and polarization phenomenon, and positive and negative charges are accumulated on the surfaces of the nano-wires. Meanwhile, Schottky contact effect causing unidirectional conduction of current is formed between the contact faces of a metal and an N-type semiconductor, and polarization charges on the surfaces of the nano-wires are directly output to the external circuit in a form of electronic current so as to finish energy conversion from electromagnetic radiation energy to electrical energy.

Owner:LIAONING NORMAL UNIVERSITY

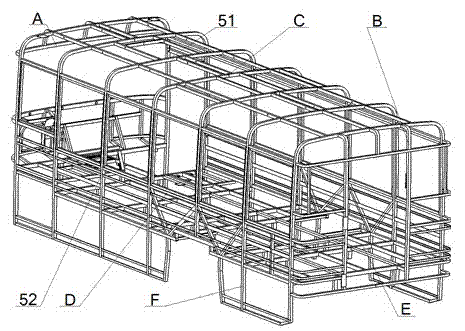

Birdcage type vehicle body skeleton structure

A birdcage type vehicle body skeleton structure comprises a front wall assembly, a rear wall assembly and a top cover assembly, wherein the two ends of the top cover assembly are connected with the upper ends of the front wall assembly and the rear wall assembly; the lower ends of the front wall assembly and the rear wall assembly are connected with a chassis assembly; the side part of the chassis assembly is connected with the top cover assembly through a side wall assembly; the top cover assembly comprises a plurality of parallel top cross beams; the side wall assembly comprises a plurality of parallel side wall vertical beams; two ends of the top cross beams are connected with tops of the side wall vertical beams, and the top cross beams and the side wall vertical beams form an integrated structure; a plurality of embedded beams are arranged on the side wall assembly and the rear wall assembly; and stiffening beams running through the periphery of a vehicle body are correspondingly arranged on the embedded beams. According to the design, the birdcage type vehicle body skeleton structure is firmer in connection and strong in impact resistance, and can disperse the impact force, reduces the deformation degree of the vehicle body and provides more survival space for passengers when being collided.

Owner:DONGFENG MOTOR CORP HUBEI

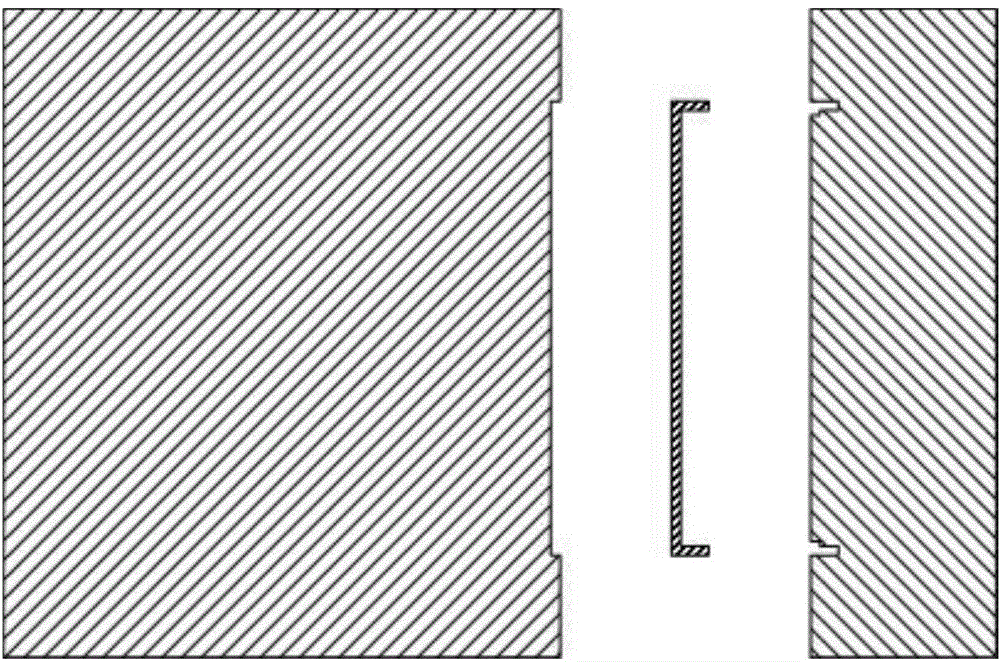

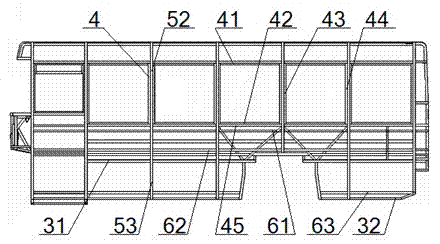

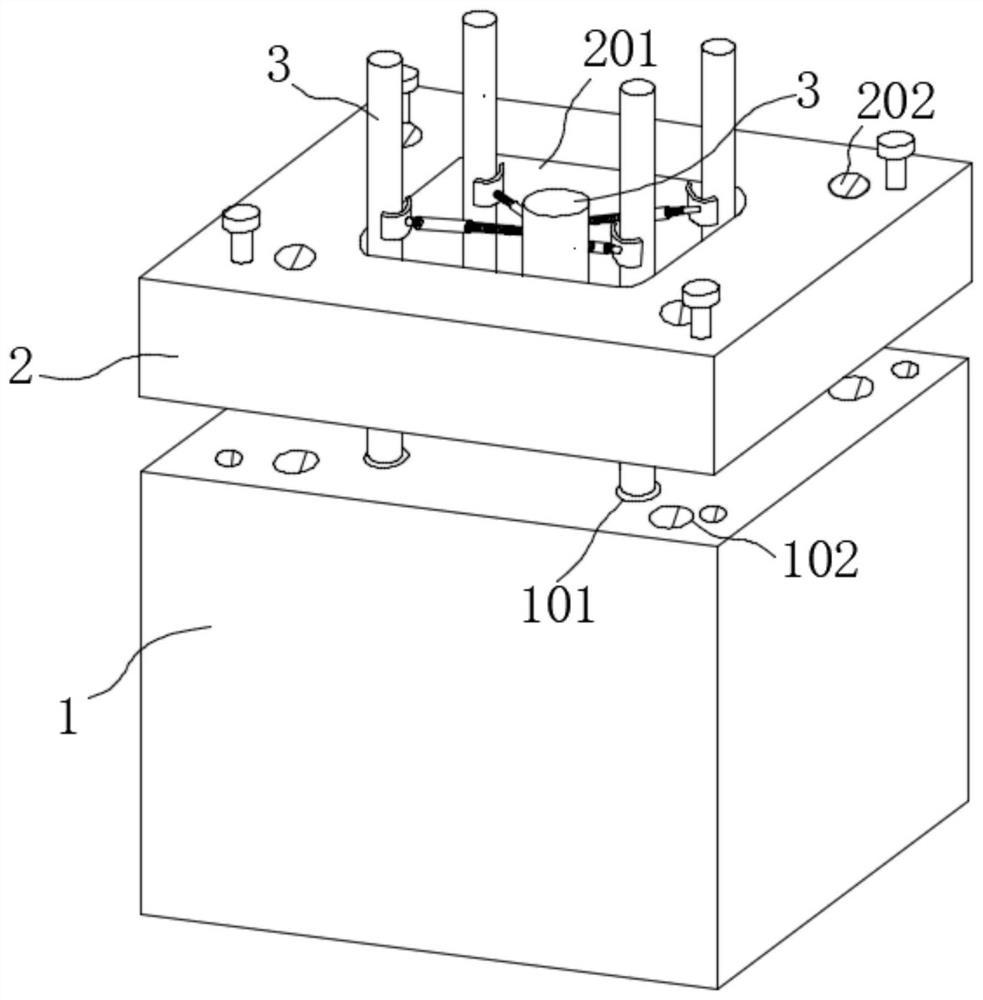

Injection mold device

InactiveCN103407077AReduce contact areaReduce the degree of deformationEngineeringInjection moulding

The invention discloses an injection mold device which comprises a front baffle (5), a plurality of cavity plates (6) with cavities on the inner sides, and a rear baffle (7), wherein the cavity plates (6) are positioned between the front baffle (5) and the rear baffle (7), and are arranged in sequence; the side surfaces of the two adjacent cavity plates, the side surfaces of the front baffle and one cavity plate (6) as well as the side surface of another cavity plate (6) and the rear baffle (7) are attached to each other; an injection hole (2) is formed in the front baffle (5); an exhaust hole is formed in the rear baffle (7). Compared with the prior art, the cavity part of a mold cavity comprise a plurality of parts, the mold unloading is still smoothly completed after the cavity body of the mold cavity is arranged in a more complex shape, and the injection precision of plastic products of more complex shapes in the injection molding process is beneficial to improvement, so that the subsequent reprocessing is avoided or reduced, and the enterprises' production efficiency is beneficial to improvement.

Owner:成都万顺达模具零件有限公司

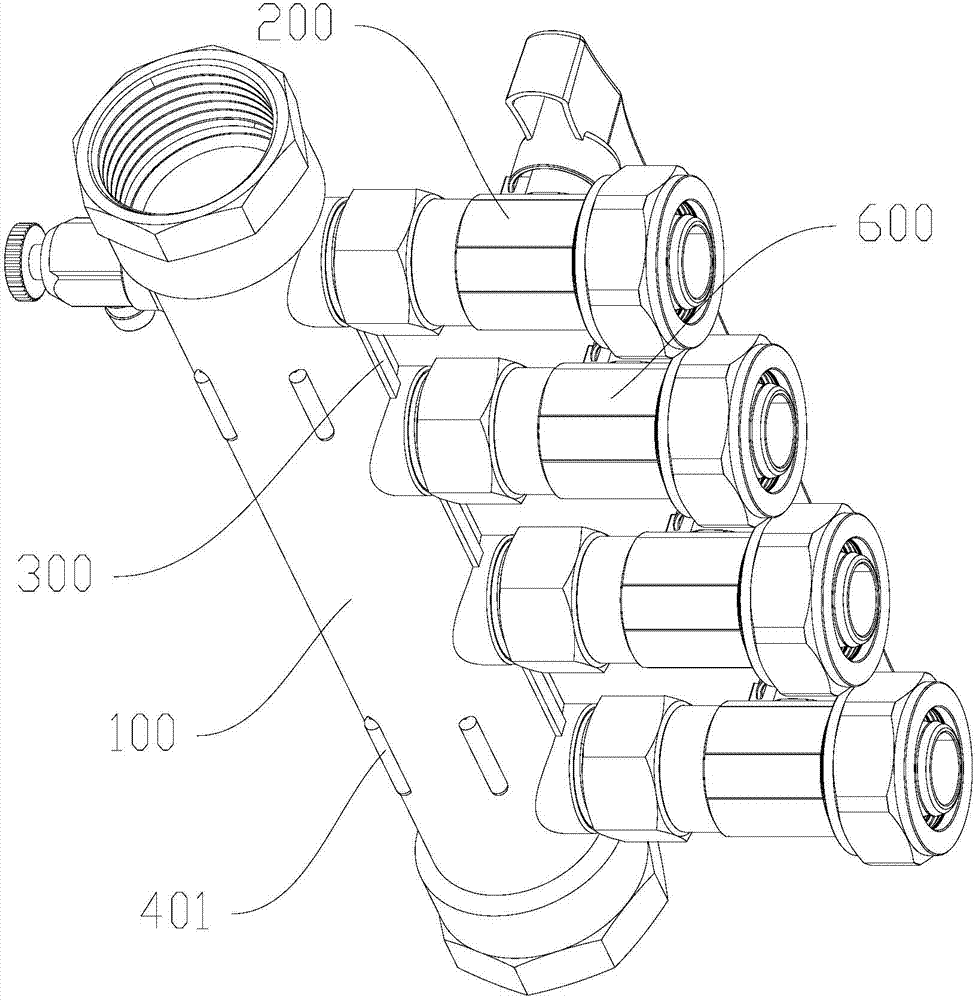

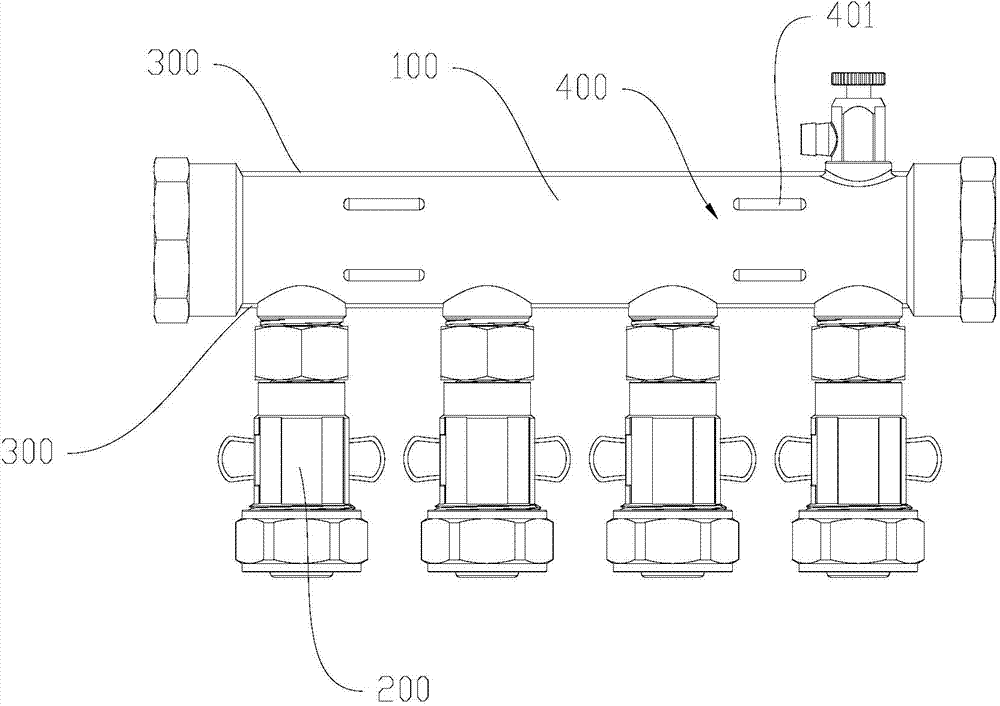

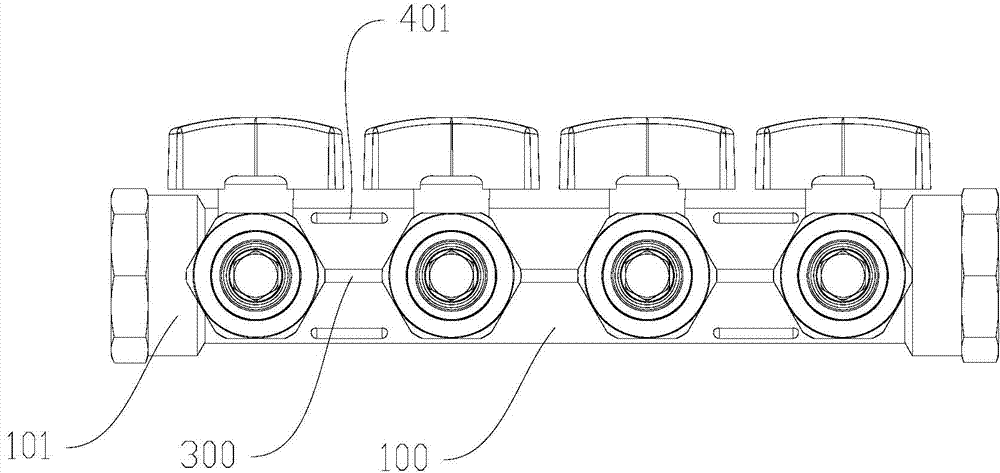

Conjoined loose-joint ball valve water segregator

InactiveCN103672012AGood technical effectHigh strengthPlug valvesBranching pipesEngineeringBall valve

The invention relates to the field of pipeline connecting, and discloses a conjoined loose-joint ball valve water segregator which comprises a main lever and at least two distributive pipes. The distributive pipes are connected with the outer side face of the main lever, at least two protrusion edges are arranged on the outer side face of the main lever, the protrusion edges extend in the axial direction of the main lever, the length of the protrusion edges is equal to that of the main lever, at least one auxiliary edge set is further arranged on the outer side face of the main lever, each auxiliary edge set comprises two or more auxiliary edges, the number of the auxiliary edges is even, the auxiliary edges extend in the axial direction of the main lever, and the auxiliary edges belonging to the same auxiliary edge set are symmetrically distributed on the two sides of the main lever. The conjoined loose-joint ball valve water segregator has the advantages of being high in strength, long in service life, simple in fixation, easy to mount, convenient to machine after forging, few in working procedure, and low in manufacturing cost and having good application value.

Owner:ZHEJIANG HONGXIA HVAC ENG CO LTD

Mask and mask assembly

ActiveCN107768551ASmall stressReduce the degree of deformationSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringWelding process

The invention provides a mask, and belongs to the technical field of display. The mask comprises a mask main body, wherein a hollow region is arranged on the mask main body, n bulges are arranged at an edge of the mask main body in an upward extension way, and n is more than or equal to 3. By the mask, the problem that the mask can be deformed under an effect of stress generated by welding duringthe welding process of the mask and a mask frame to further cause that the hollow region in the mask also can be deformed is solved. The mask is used for manufacturing a mask assembly.

Owner:BOE TECH GRP CO LTD +1

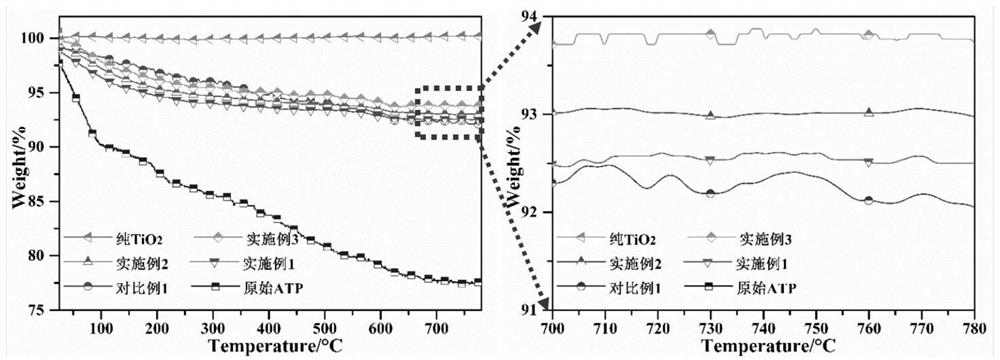

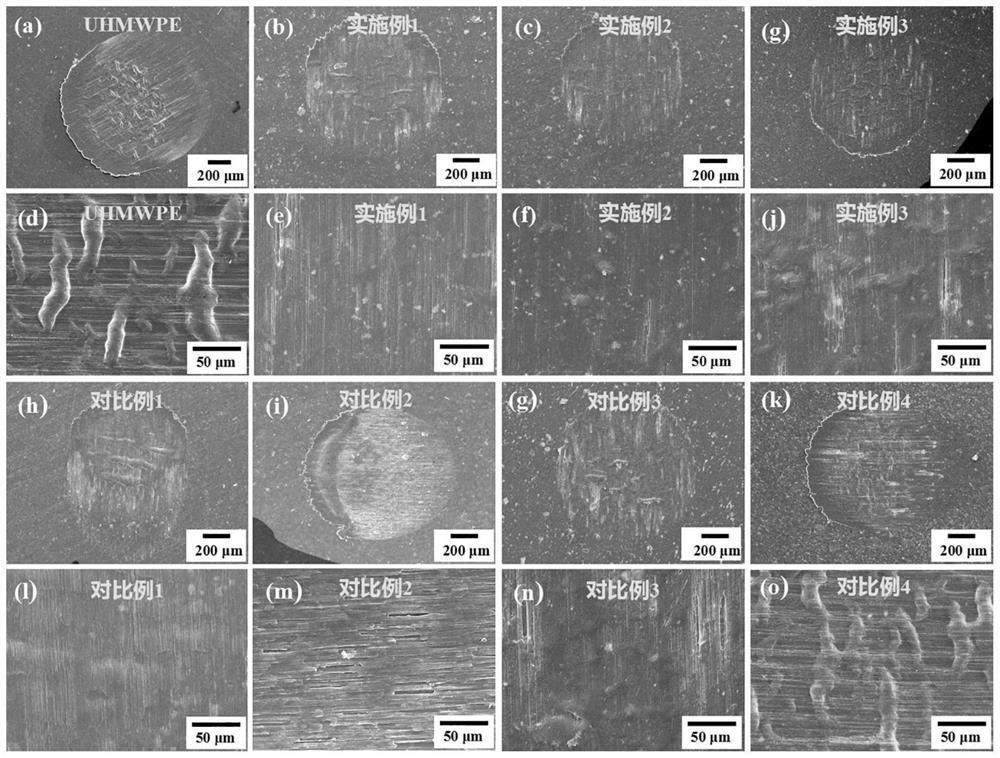

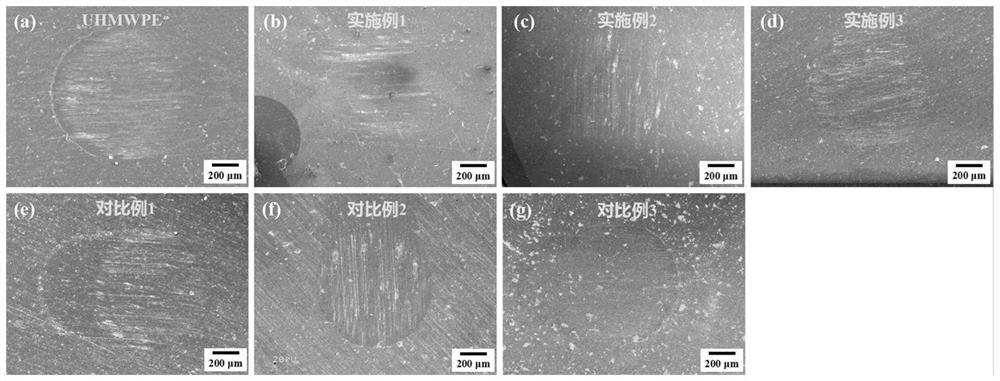

Attapulgite-titanium dioxide modified ultra-high molecular weight polyethylene composite material as well as preparation method and application thereof

ActiveCN112226264AHigh surface energyInhibit wearLubricant compositionPigment physical treatmentHigh surfaceTitanium oxide

The invention provides an attapulgite- titanium dioxide modified ultra-high molecular weight polyethylene composite material as well as a preparation method and application thereof, and belongs to thetechnical field of solid lubricating materials. According to the invention, attapulgite- titanium dioxide is used as a filler in ultrahigh molecular weight polyethylene, titanium dioxide particles have high surface energy, hard high-roughness particles can be formed after the titanium dioxide particles are loaded on attapulgite, and after attapulgite-titanium dioxide serving as filler is combinedwith ultrahigh molecular weight polyethylene, a better bearing effect can be achieved in the friction process, and abrasion of the material can be prevented; and meanwhile, the attapulgite-titanium dioxide is added, so that the heat resistance of an ultrahigh molecular weight polyethylene matrix can be improved, the composite material is not prone to deformation under the condition that frictionheat is concentrated, the deformation degree of the material is reduced to a certain extent, correspondingly, adhesive wear is also reduced to a certain extent, and the anti-friction and wear-resisting properties of the material are further improved.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Intelligent metal plate polishing device for automobile production

InactiveCN113352186AEasy to holdAvoid damageGrinding drivesGrinding feed controlInfrared thermometryPolishing

The invention relates to the technical field of metal plate polishing devices, and discloses an intelligent metal plate polishing device for automobile production. Through arrangement of a limiting spring and the like, to-be-polished workpieces of different sizes and different shapes are conveniently clamped, meanwhile, through arrangement of a pressure sensor and the like, intelligent clamping is achieved, and through arrangement of a scanning imager and the like, Intelligent polishing is achieved, and polishing errors are reduced; through the arrangement of an infrared thermometer and the like, the temperature of the polishing position is conveniently monitored in real time, the situation that the local temperature of a workpiece is too high, deformation is caused, and the polishing effect is affected is avoided; and on the other hand, intelligent polishing is achieved, and through the arrangement of a driving annunciator, a driving wire and the like, a central controller can indirectly control multiple electric sliding blocks to move conveniently, a polishing mechanism is indirectly driven to move at multiple positions through the arrangement of the multiple electric sliding blocks and a sliding rail, and therefore multi-direction and multi-angle polishing can be conveniently achieved for workpieces of different shapes and sizes, the purpose of self-adaptive clamping is achieved, and intelligent polishing is achieved.

Owner:DESIGN INST NO 9 MINISTRY OF MECHINE BUILDING

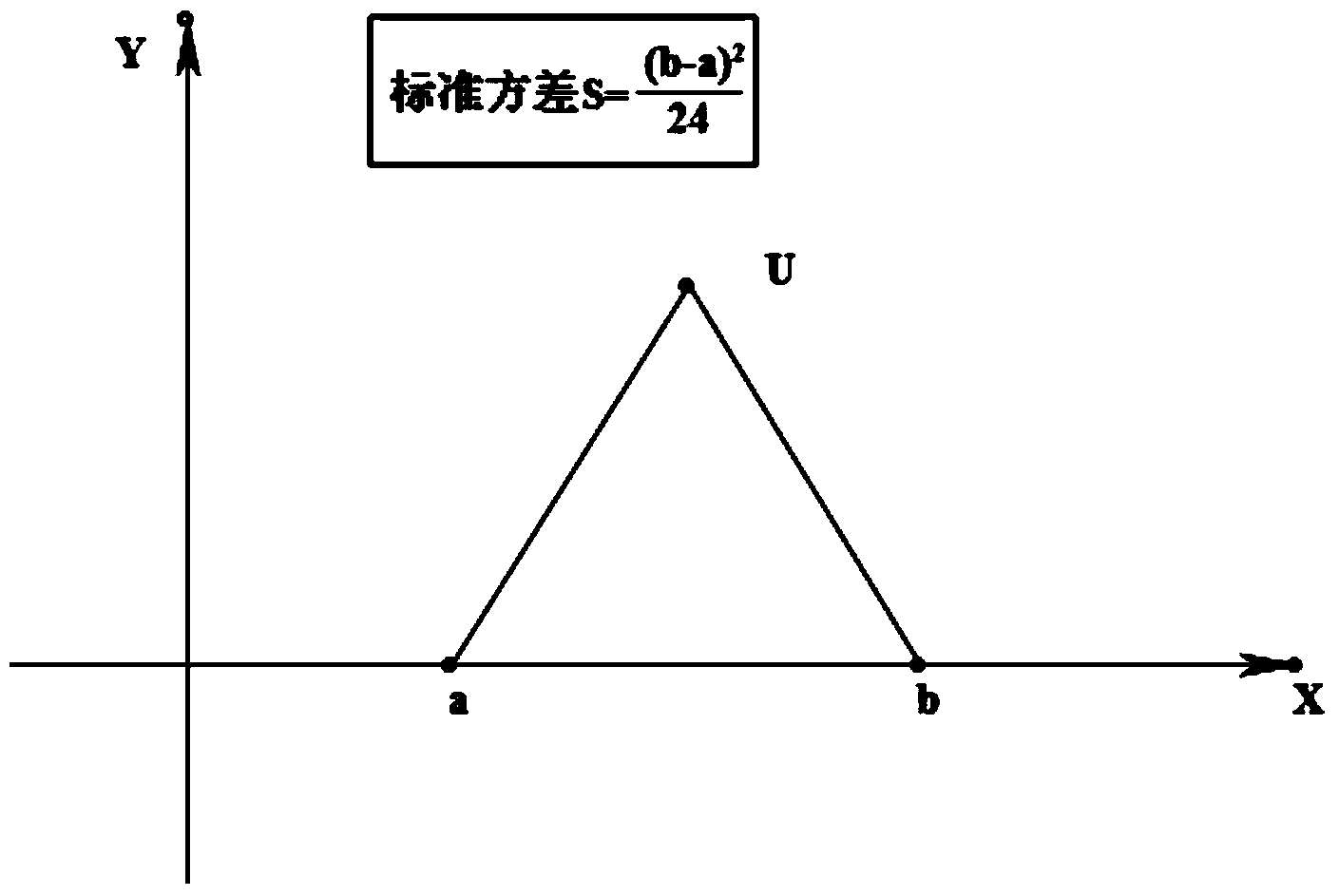

Non-deforming three-dimensional image parallax quick adjusting method

InactiveCN103841403AReduce the degree of deformationGood subjective effectSteroscopic systemsDepth of fieldStereopsis

The invention relates to a non-deforming three-dimensional image parallax quick adjusting method which is characterized by comprising the following steps that S01. a depth value to be adjusted is determined, namely a depth changing value DA; S02. a parallax adjusting coefficient k = f(DA) is computed; S03. according to the smallest field depth changing error threshold value SDA = f(v and d) which can be perceived by a human eye, the value range (k1 and k2) of the parallax adjusting coefficient k is computed, wherein v is the watching distance between a person and a screen, and d is the distance between a three-dimensional image and the screen; and S04. an original image is zoomed according to a fixed drawing coefficient k, the value range of k is limited in (k1 and k2), and the fact that deforming cannot be perceived is guaranteed. Compared with a traditional method, the deforming degree is lowered by more than 50%, three-dimensional vision subjectivity effect is better, and method efficiency for high-definition video is improved by 48%.

Owner:FUZHOU UNIVERSITY

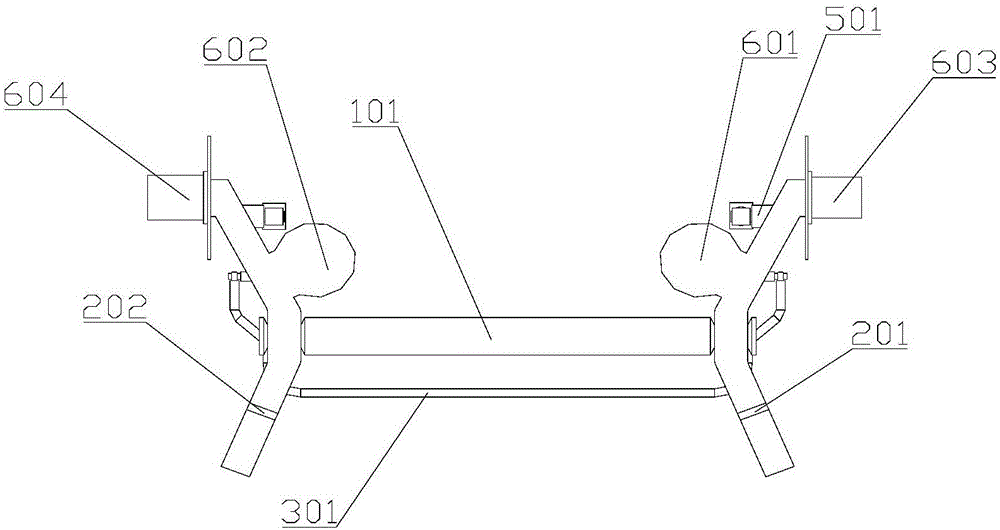

Semi-independent automobile rear suspension

InactiveCN105034743AIncrease toughnessReduce the degree of deformationInterconnection systemsPivoted suspension armsRoad surfaceAdaptive capacity

The invention provides a semi-independent automobile rear suspension and belongs to the technical field of vehicles. The semi-independent automobile rear suspension comprises a left dragging arm, a right dragging arm, a beam and movable connecting pieces. The two ends of the beam are movably connected with the left dragging arm and the right dragging arm through the movable connecting pieces respectively. Due to the fact that the left dragging arm and the right dragging arm are movably connected with the beam, the dragging arms on the two sides can move within a certain degree in a relatively-independent mode, in the driving process of an automobile, the deformation degree of the beam is reduced, the beam only bears the axial acting force of the beam, the overall suspension is more flexible, the adaptive capacity of the suspension to complex road surfaces is improved, and the overall comfort degree of the automobile with the semi-independent automobile rear suspension is greatly improved.

Owner:李海龙

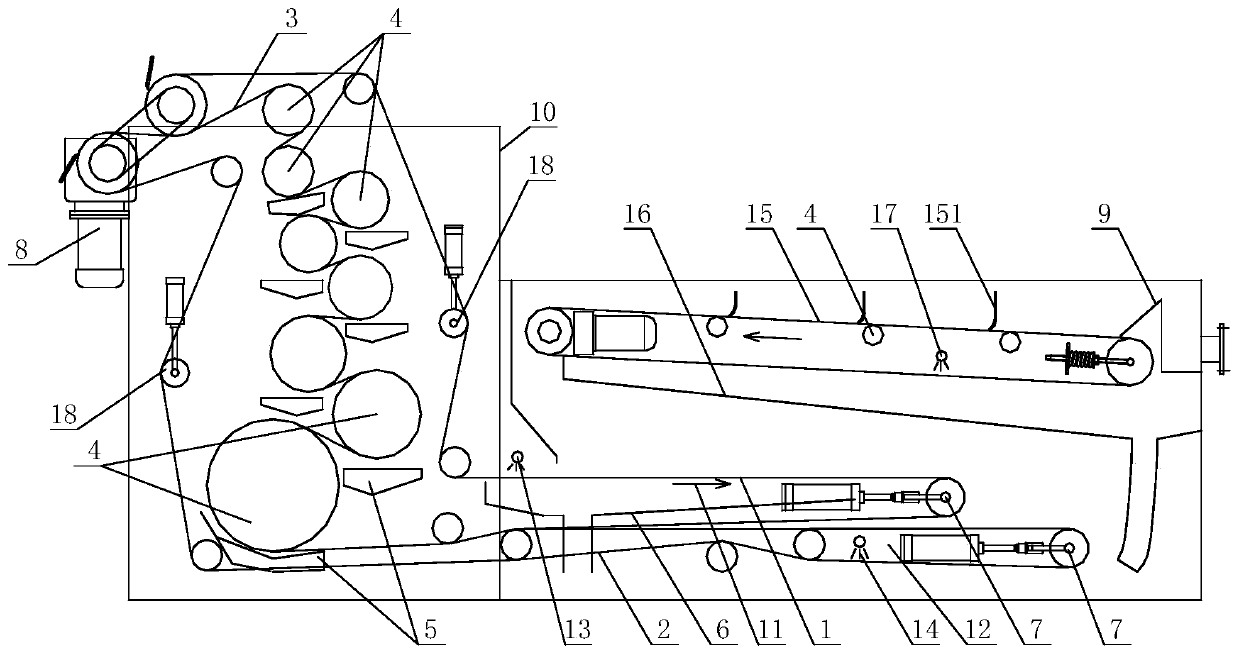

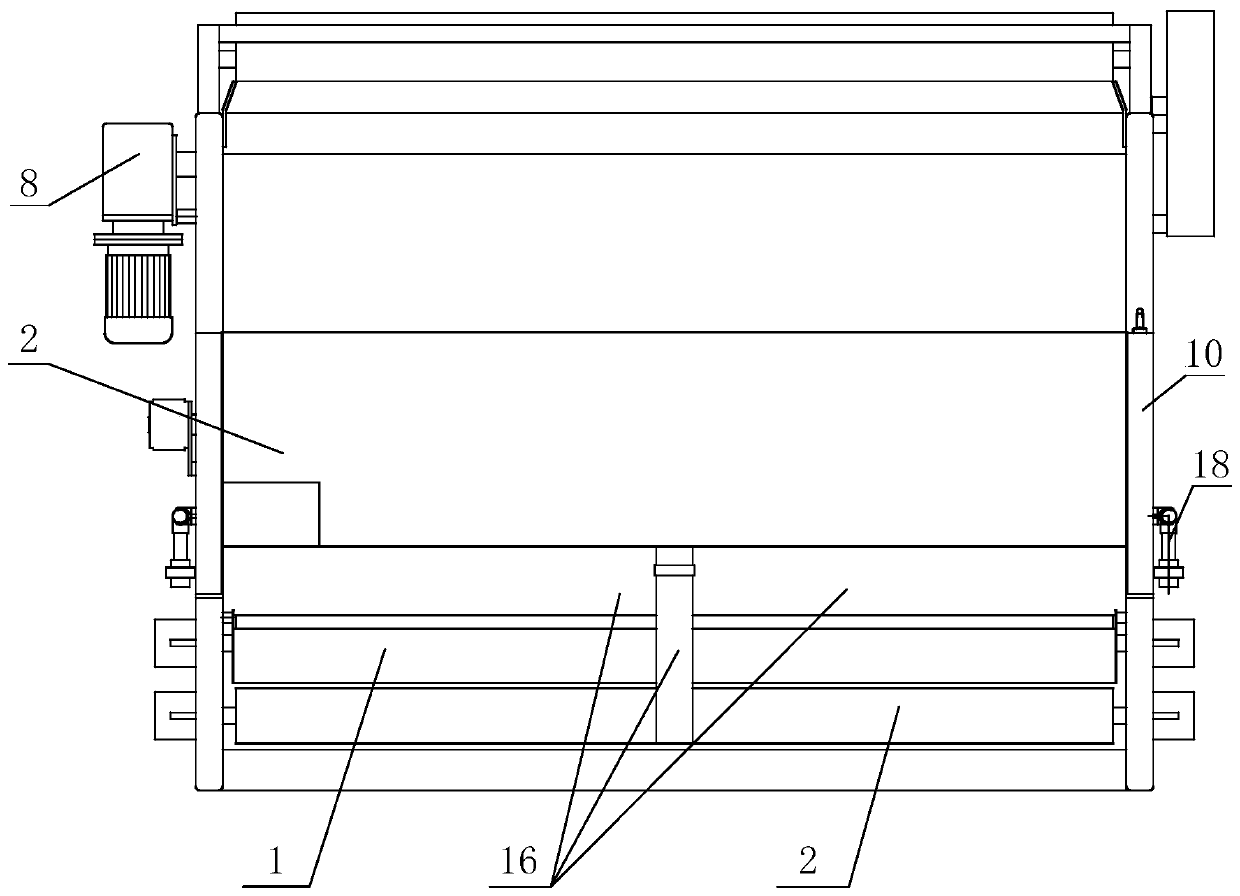

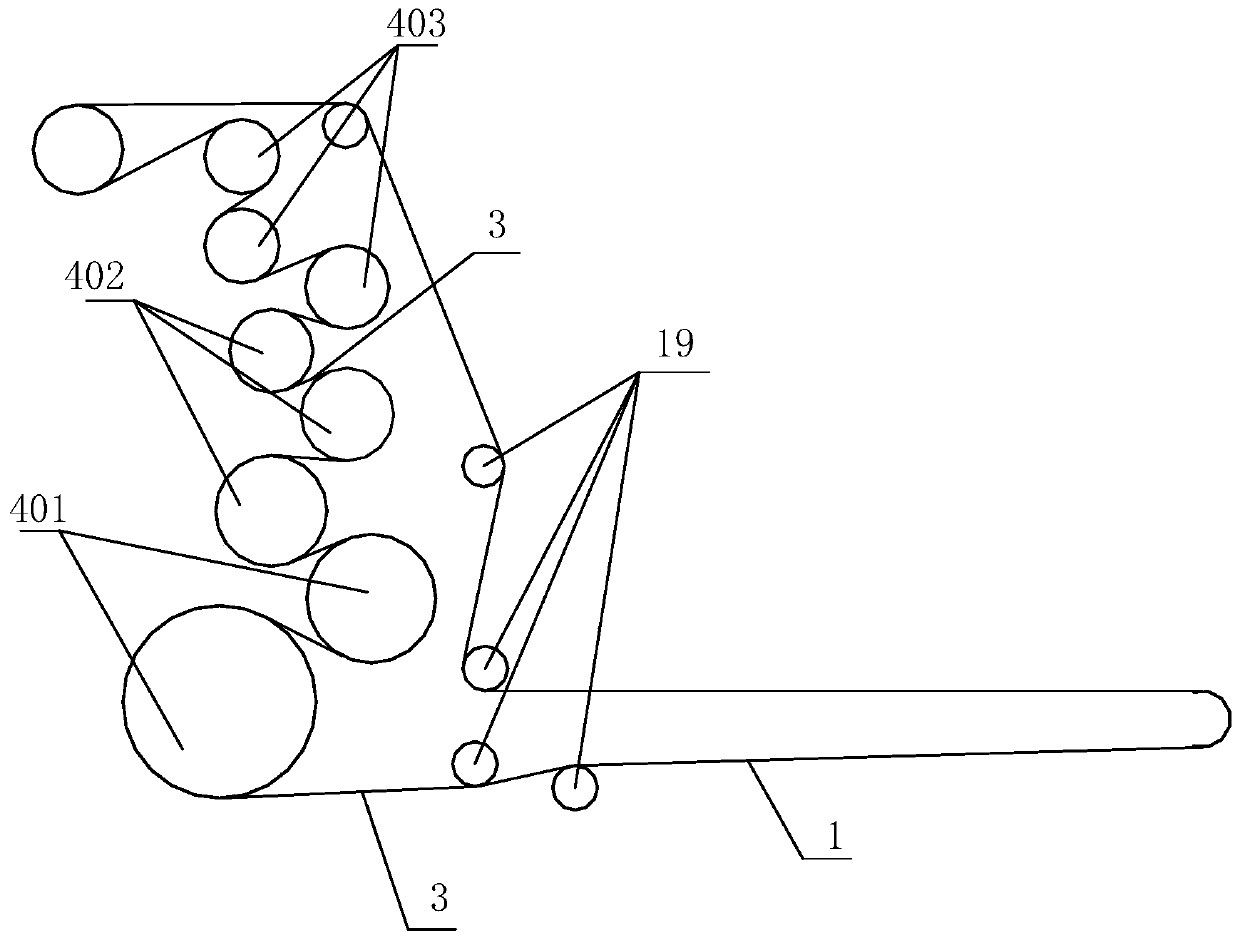

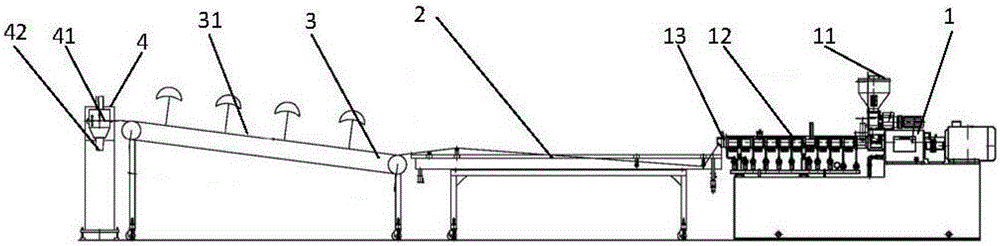

Manufacturing device of artificial turf hollow particles

The invention discloses a manufacturing device of artificial turf hollow particles. The manufacturing device comprises an extruding machine, a cooling device, a conveying device and a particle cutting machine; the extruding machine, the cooling device, the conveying device and the particle cutting machine are sequentially connected; the extruding machine comprises a feeding machine, a vacuum exhaust device and a die head; the vacuum exhaust device is connected with the feeding machine through an inserting pipe; the die head is mounted on the vacuum exhaust device; the die head comprises a shell, a runner and a heating part; the runner and the heating part are both mounted in the shell; the heating part is mounted on the side wall of the runner, the feeding end of the runner is communicated with a discharging opening of the vacuum exhaust device, and the discharging end of the runner is provided with a discharging nozzle; an embedding block is arranged in the discharging nozzle; according to the manufacturing device, improvement is carried out according to the shape of the hollow rubber particles needed on the artificial turf, the device can directly produce the hollow particles, the form of finished products is stable, and the quality is good.

Owner:GUANGZHOU AOSHENG ARTIFICIAL STRAW CO LTD

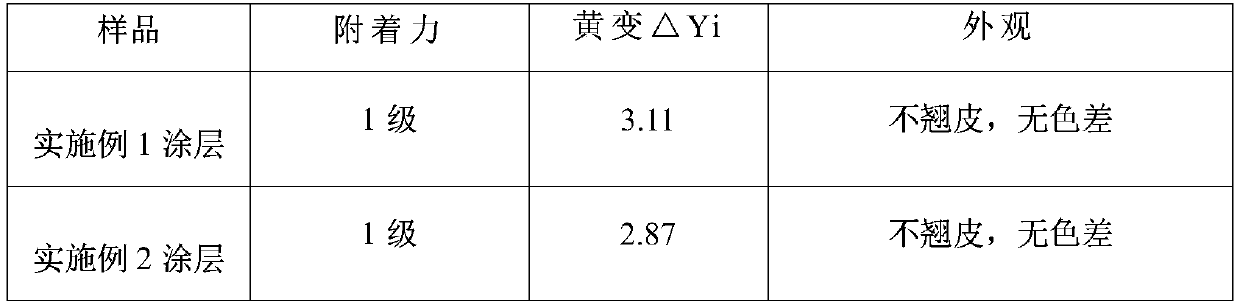

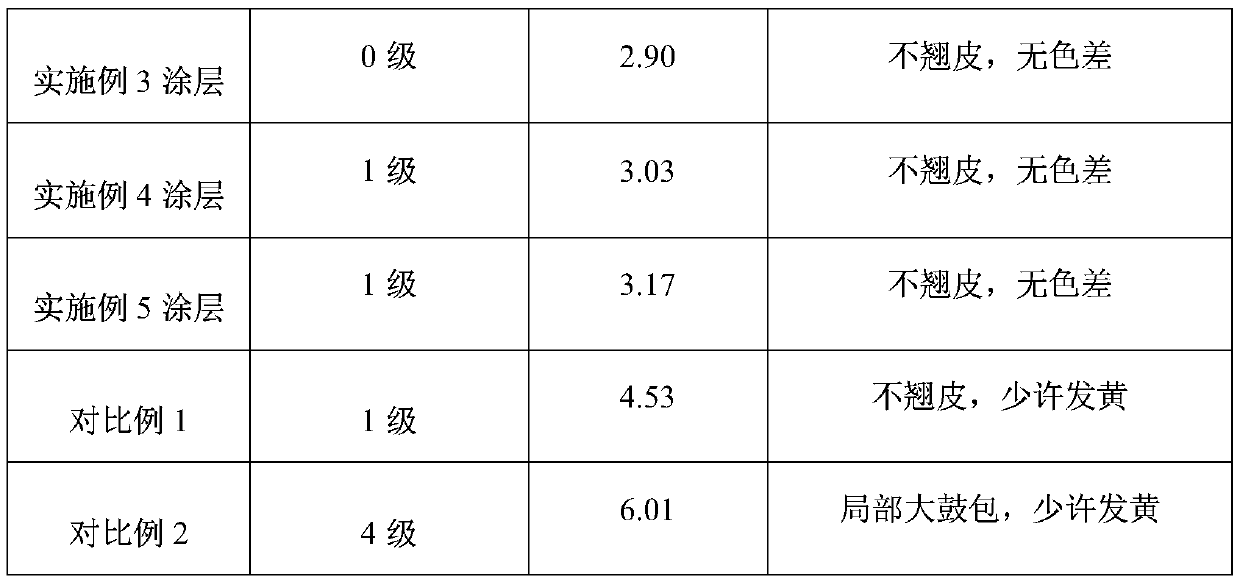

Photovoltaic backplane repair coating and its repair method and application

ActiveCN107779015BSmall shrinkageNo peeling phenomenonCoatingsSpecial surfacesFirming agentPhysical chemistry

The invention discloses a photovoltaic backing plate refinishing paint as well as a refinishing method and applications thereof. The refinishing paint comprises the following raw materials in parts byweight: 40-60 parts of fluorine resin, 10-25 parts of silicone prepolymer, 1-19 parts of epoxy resin, 15-31 parts of inorganic filler, 1-13 parts of auxiliaries, 5-30 parts of diluent, and 5-34 partsof isocyanate curing agent; the refinishing method of a photovoltaic backing plate coating comprises the following steps: (1) cleanly treating the flaws of a photovoltaic backing plate; and (2) filling the prepared photovoltaic backing plate refinishing paint into the flaws, and drying; the applications comprise that the photovoltaic backing plate refinishing paint is applied in refinishing of coatings of coated type, compound type, co-extrusion type and PET type photovoltaic backing plates; and the photovoltaic backing plate refinishing paint not only can meet the strong hydrophobicity situation, but also has the advantages of being low in stress, yellowing-resistant, good in glossiness and strong in adhesivity.

Owner:SUZHOU FIRST PV MATERIAL CO LTD

Steel bar positioning structure for building construction

InactiveCN112049441AReduce the degree of deformationImprove stabilityBuilding material handlingArchitectural engineeringRebar

The invention belongs to the field of building construction, and particularly discloses a steel bar positioning structure for building construction. The steel bar positioning structure comprises a positioning seat, a positioning formwork and a first positioning mechanism, the positioning seat is in a rectangular column shape, multiple first through holes and second through holes in a penetrating manner are formed in the end of the positioning seat, and first screw holes are formed in four corners of the end of the positioning seat. The multiple first through holes and the second through holesare distributed in the end face of the positioning seat in a rectangular array manner, the first through holes are located in the inner sides of the second through holes, and steel bars penetrate through the inner sides of the first through holes and the inner sides of the second through holes. The positioning formwork is arranged over the positioning seat, the four corners of the positioning formwork are connected and matched with the first screw holes through screws, a third through hole and multiple fourth through holes in a penetrating manner are formed in the positioning formwork, and themultiple fourth through holes are distributed along the four corners of the third through hole. According to the steel bar positioning structure, the steel bar positioning and supporting stability can be improved, the positioning strength is improved, meanwhile, a positioning assembly can reduce the deformation degree of the steel bars, and the overall stability of the device is improved.

Owner:浙江富成建设集团有限公司

Device for preventing deformation of rock wool color steel plate through pressure dispersion method

InactiveCN113334895AExtend the production cycleReduce production efficiencyLiquid surface applicatorsLamination ancillary operationsMining engineeringAdhesive glue

The invention relates to the field of color steel plates, in particular to a device for preventing deformation of a rock wool color steel plate through a pressure dispersion method. The technical problem to be solved by the invention is to provide a device for preventing deformation of a rock wool color steel plate through a pressure dispersion method. According to the technical scheme, the device for preventing the rock wool color steel plate from deforming through the pressure dispersion method comprises a conveying mechanism, a pressure dispersion mechanism, a glue cleaning mechanism, a fixing frame and the like, wherein the conveying mechanism is connected with the pressure dispersion mechanism, the conveying mechanism is connected with the fixing frame, the pressure dispersion mechanism is connected with the fixing frame, and the glue cleaning mechanism is connected with the fixing frame. According to the invention, the rock wool color steel plate can be adhered at a time, so that the production efficiency of the rock wool color steel plate is effectively improved; and in the production process, pressure is dispersed, so that deformation of the rock wool color steel plate is effectively prevented, and the effect that the quality of the rock wool color steel plate reaches the standard is achieved.

Owner:黄宗勇

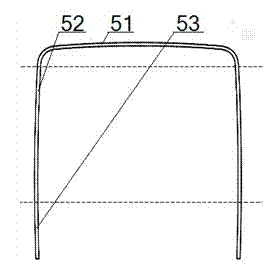

Forced cooling injection mold device

InactiveCN103407079AReduce contact areaReduce the degree of deformationPlastic injection moldingEngineering

The invention discloses a forced cooling injection mold device, which comprises a front baffle (5), a plurality of mold cavity boards (6) with cavities formed in inner sides, and a back baffle (7), wherein the plurality of mold cavity boards (6) are positioned between the front baffle (5) and the back baffle (7), a plurality of flow passages of which the upper parts and the lower parts are communicated are arranged in the front baffle (5), the mold cavity boards (6), and the back baffle (7) respectively; a injection molding hole (2) is formed in the front baffle (5); an exhaust hole is formed in the back baffle (7). The cavity parts of mold cavities are formed by the combination of a plurality of parts, so that the mold is allowed to be able to adapt to mold opening of the mold cavities with complex shapes, the enhance of the injection molding precision of plastic products with complex shapes is facilitated, and subsequent reprocessing is eliminated or reduced; the arranged flow passages facilitate the selection of an optimum cooling manner according to a specific material property for better adapting to requirements of cooling speed required to be maintained of the plastic injection molding of different plastics, and therefore, the improvement of the production efficiency of enterprises and the quality of products are facilitated.

Owner:成都万顺达模具零件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com