Patents

Literature

607 results about "Infrared thermometry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An infrared thermometer. An infrared thermometer is a thermometer which infers temperature from a portion of the thermal radiation sometimes called black-body radiation emitted by the object being measured.

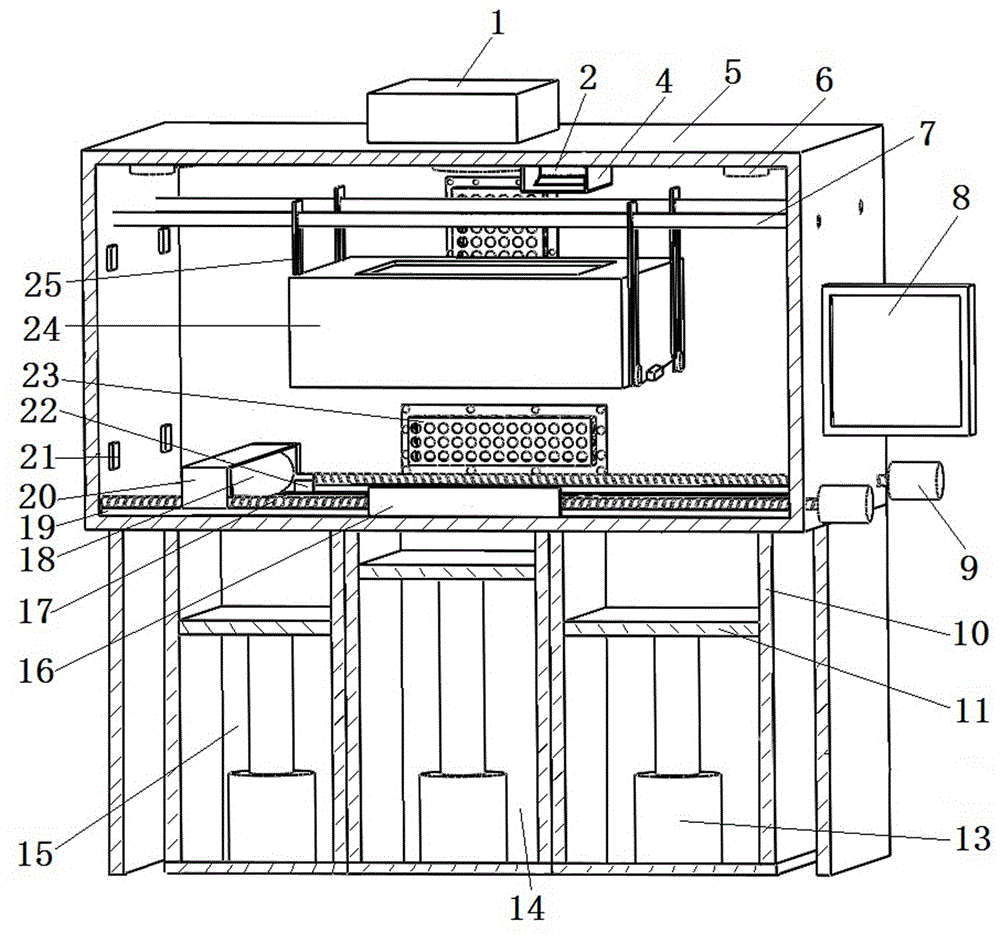

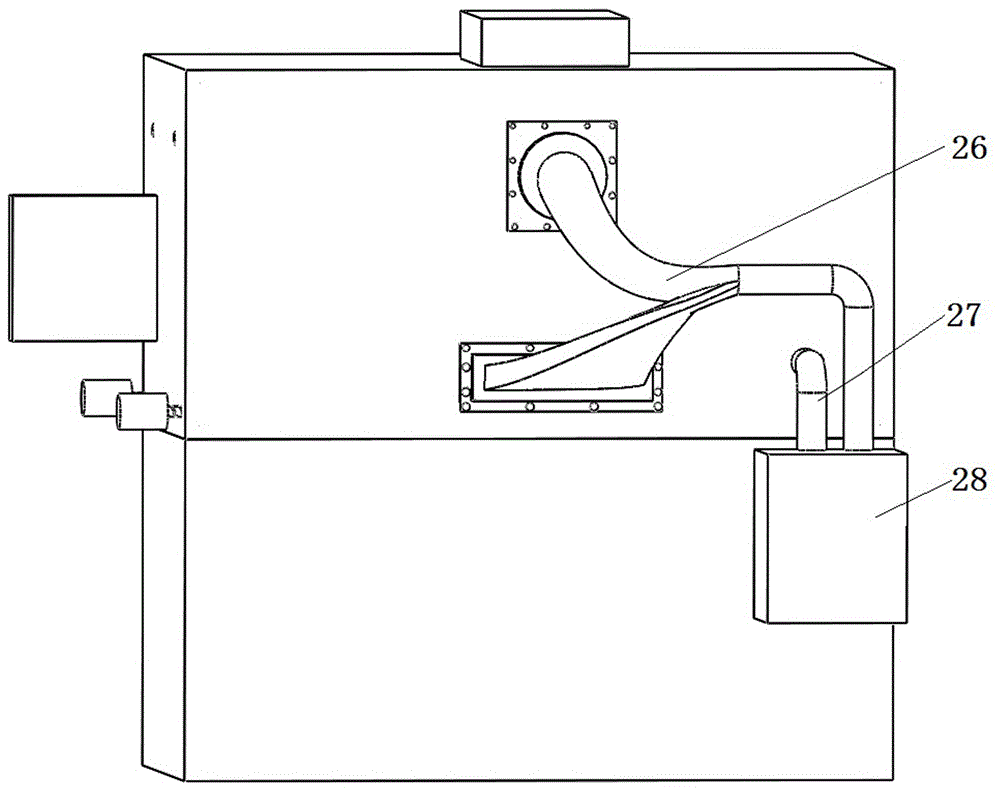

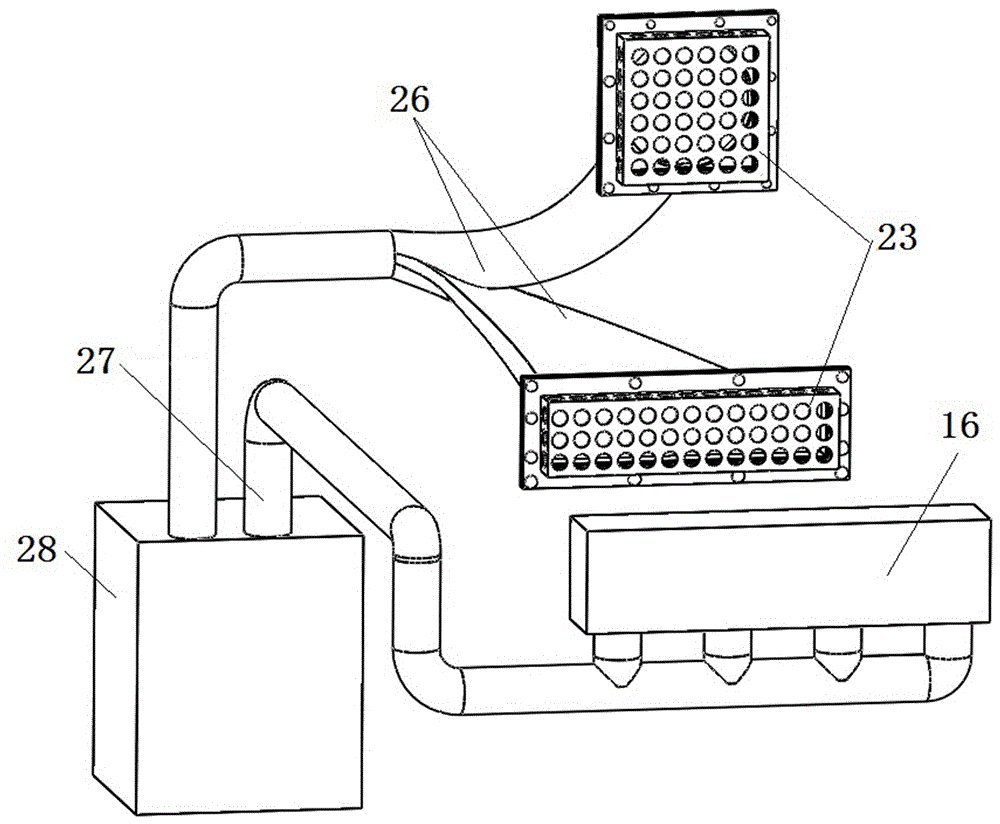

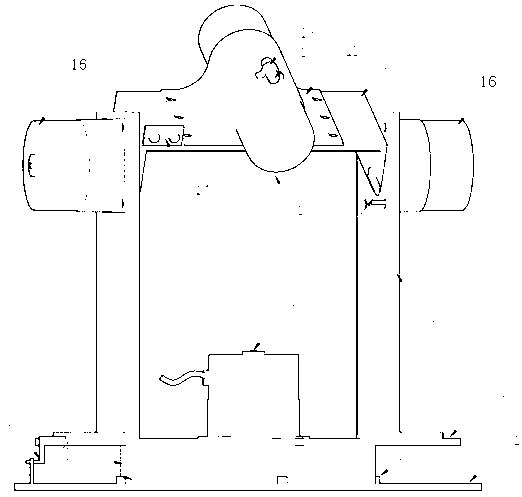

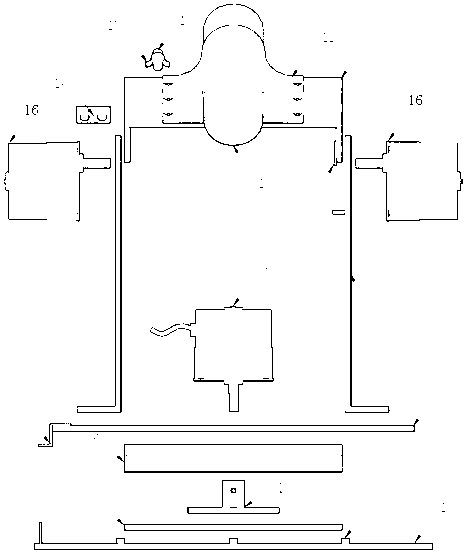

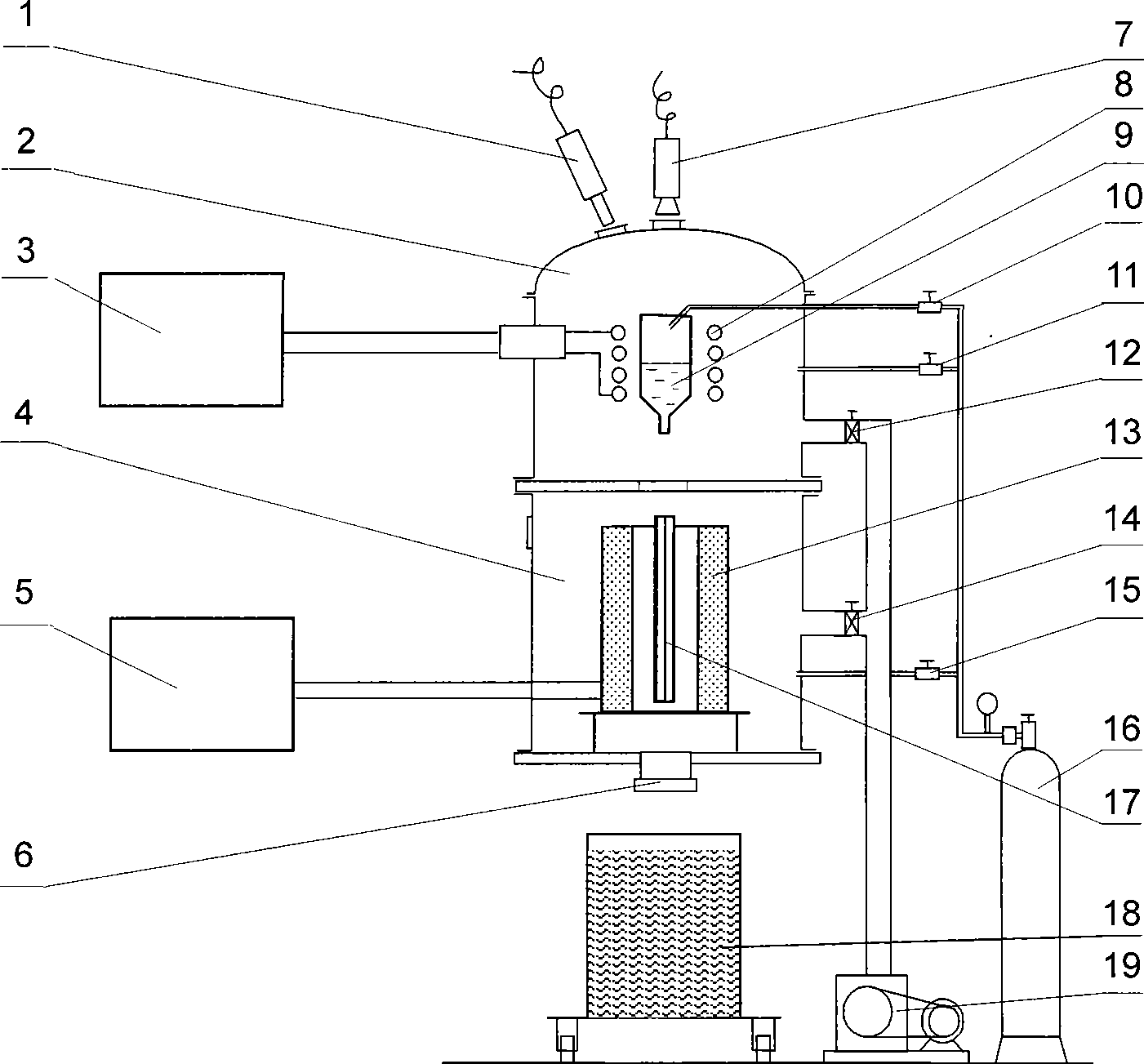

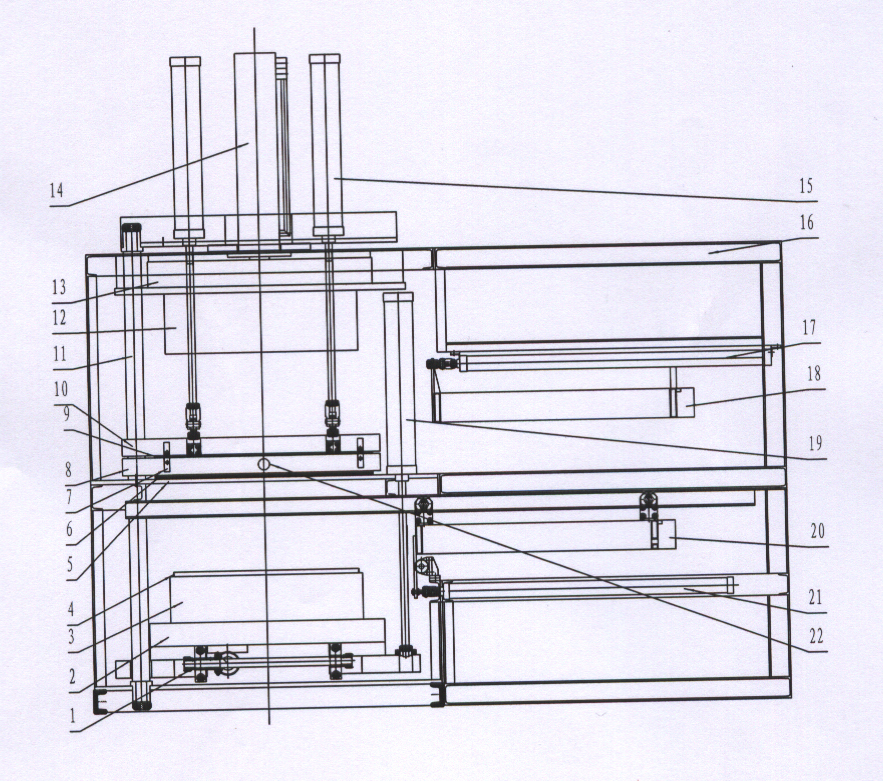

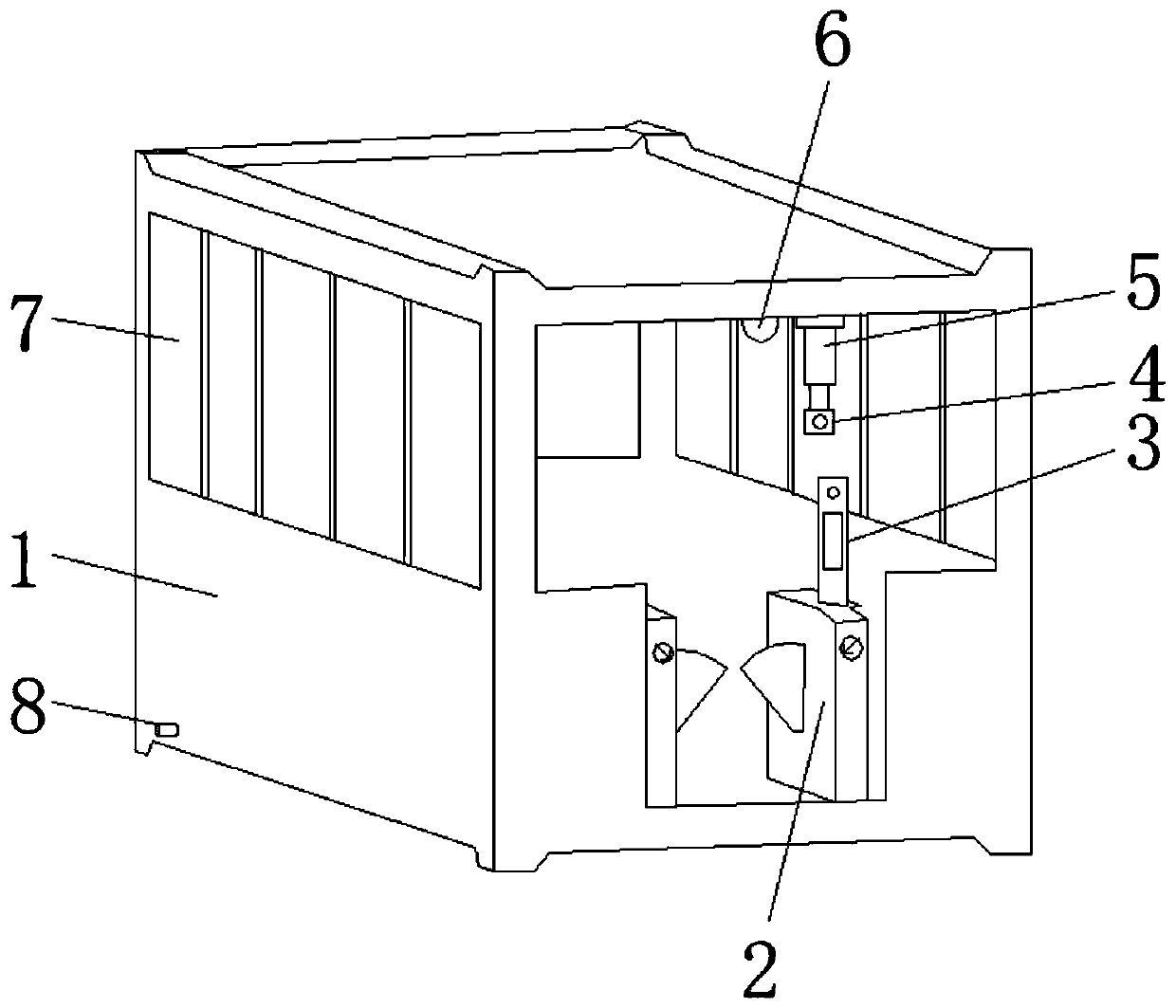

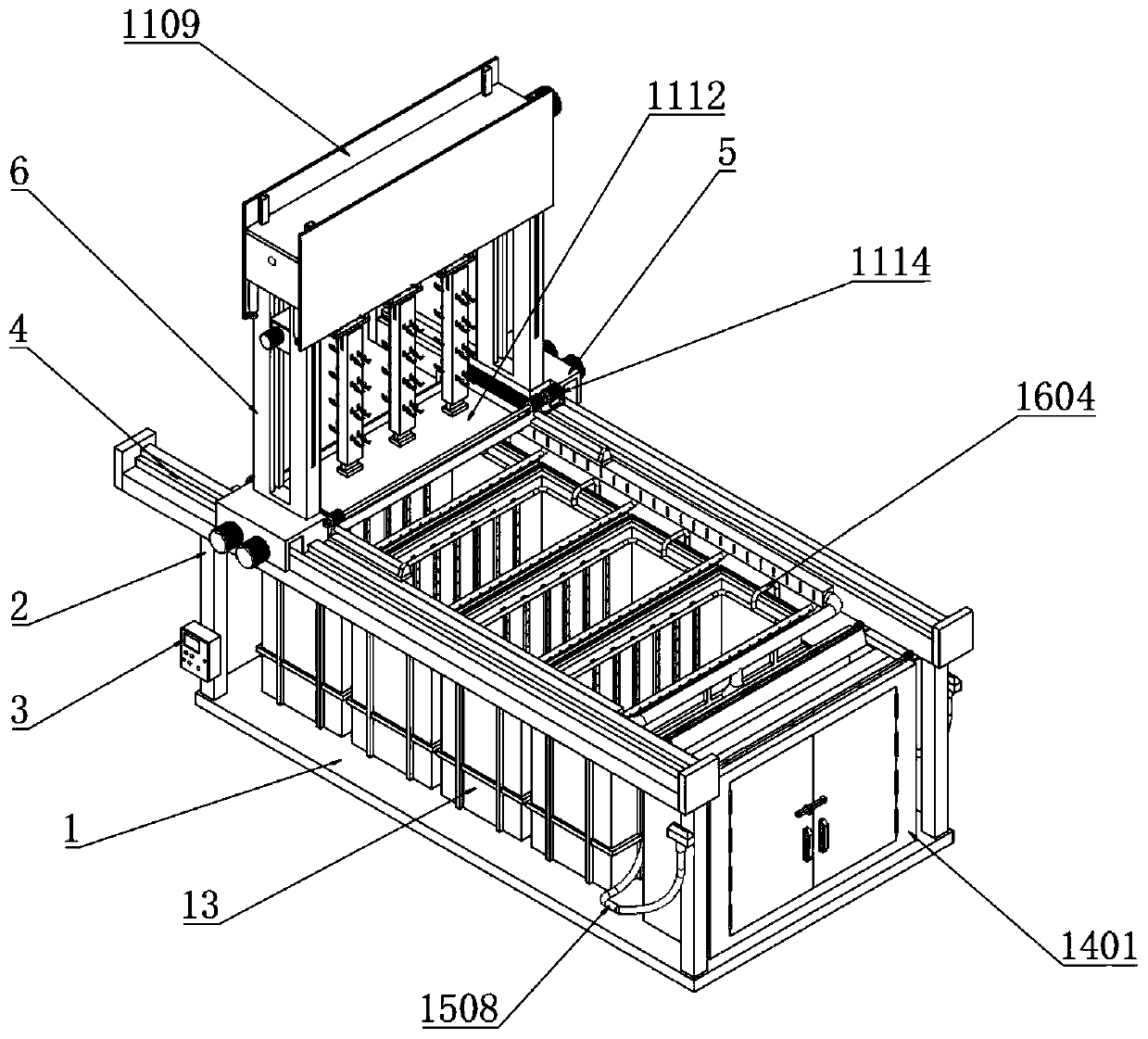

Powder material laser-sintering forming device

ActiveCN106041080APrevent oxidationImprove quality and efficiencyAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing technologyInfrared thermometry

The invention relates to a powder material laser-sintering forming device, belongs to the technical field of 3D printing additive manufacturing technologies and provides a powder material laser-sintering forming device which is simple to operate, high in powder spreading efficiency, good in powder spreading effect and wide in application range. The powder material laser-sintering forming device adopts the technical scheme that hydraulic oil cylinders are arranged in a material collecting cylinder, a forming cylinder and a powder supply cylinder; material pushing baffles are arranged on the hydraulic oil cylinders; powder spreading sliding rails are arranged in the middle of a forming cavity; a roller rack is mounted on the powder spreading sliding rails in a sliding way; a powder spreading roller is mounted on the roller rack; roller rack lead screws are arranged on the roller rack; preheating guide rails are arranged at the upper part of the forming cavity; a preheating housing is mounted on the preheating guide rails in a sliding way; preheating rods are arranged in the preheating housing; an infrared thermometer is arranged outside the preheating housing; a laser scanning system is arranged at the top of the forming cavity; and a gas intake and exhaust device is arranged on the side wall of the forming cavity. The powder material laser-sintering forming device is widely used for laser-sintering forming of powder material.

Owner:ZHONGBEI UNIV

Protective cover for infrared thermometer

A probe cover for an infrared (IR) thermometer having two distinct portions, one which is substantially rigid, and the other which is stretchable by at least two times to envelop the probe of the IR thermometer. The stretchable portion allows IR radiation to pass toward the optical window of the IR thermometer probe. The rigid portion of the probe cover is engaged with the probe during the installation process.

Owner:ADVANCED MONITORS

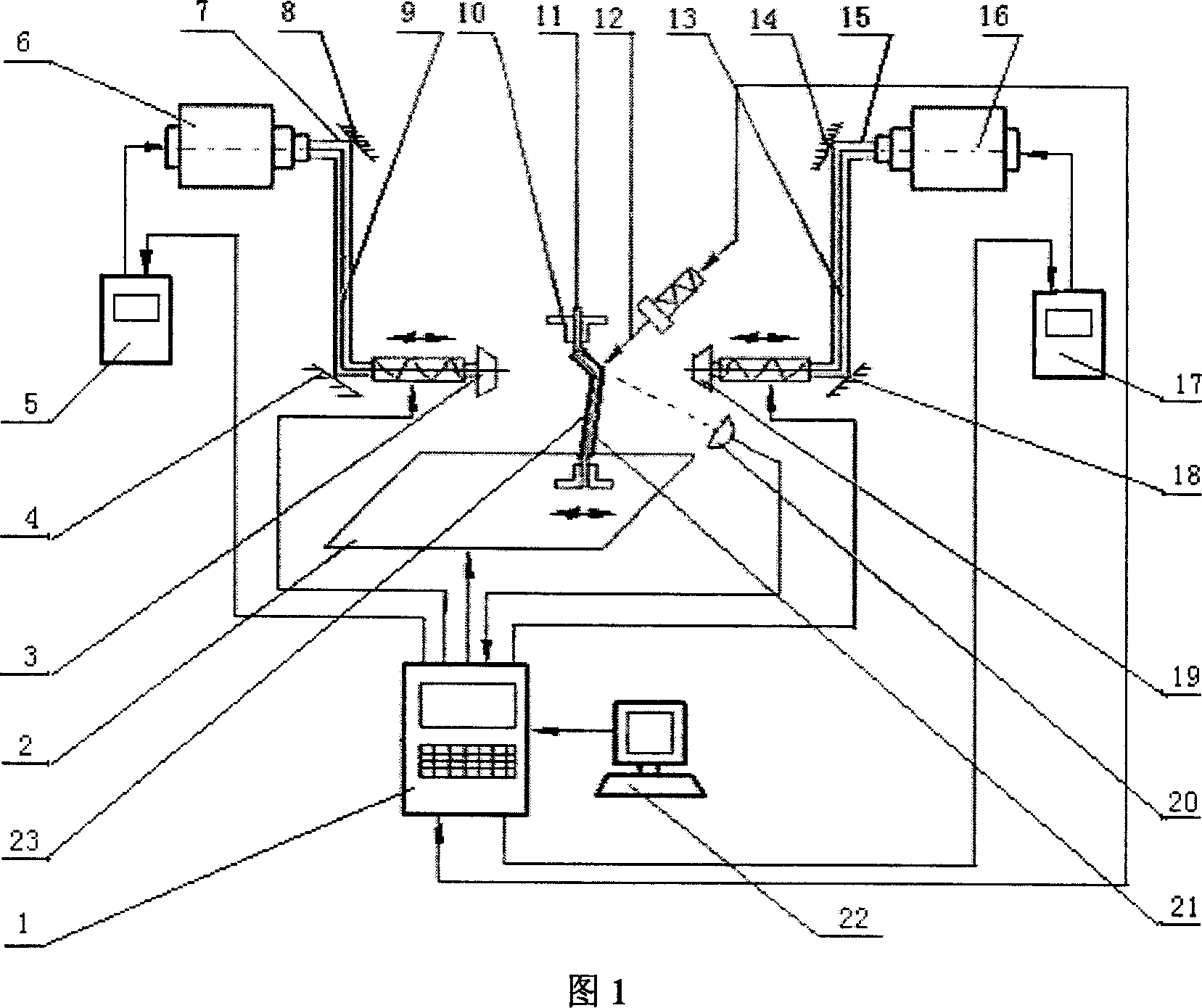

Plate forming process and apparatus

InactiveCN1931467APrecise Local FormingAccurate shapeShaping toolsComputer controlShock waveLaser processing

The plate forming process and apparatus belongs to the field of laser processing technology. The present invention has CO2 laser for pre-heating plate, infrared thermometer for measuring and controlling the plate heating temperature, neodymium glass laser for providing powerful short laser pulse to induce the generation of laser shock wave as the forming force source in processing plate and plate deformation measuring feedback device. The present invention is superior to laser thermal stress forming process, which has inferior formed surface quality, and laser shock forming process, which has small deformation amount, and can form plate directly in relatively great deformation amount, relatively high size precision and relatively high surface quality.

Owner:JIANGSU UNIV

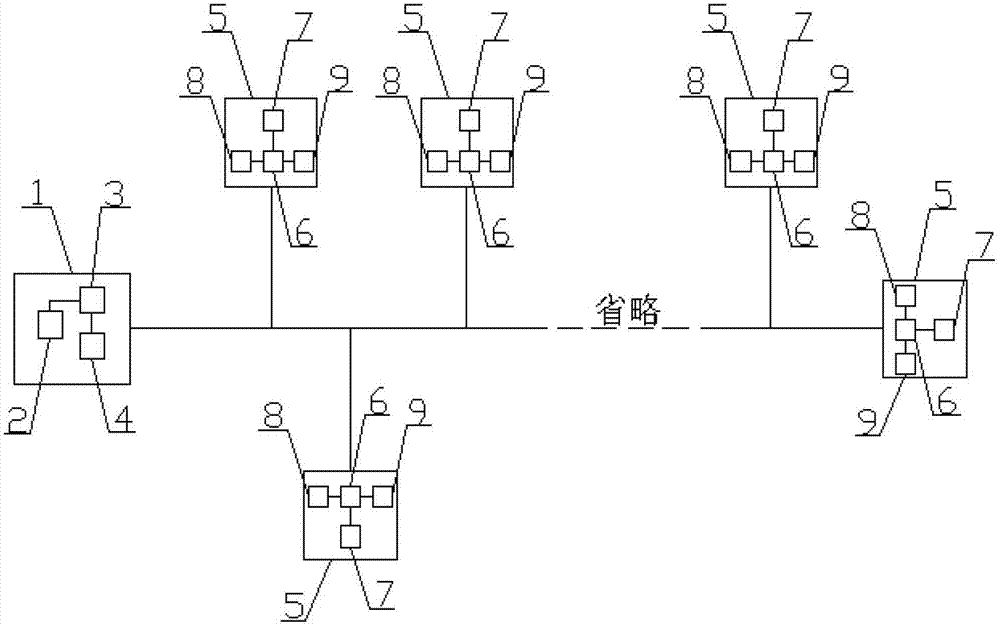

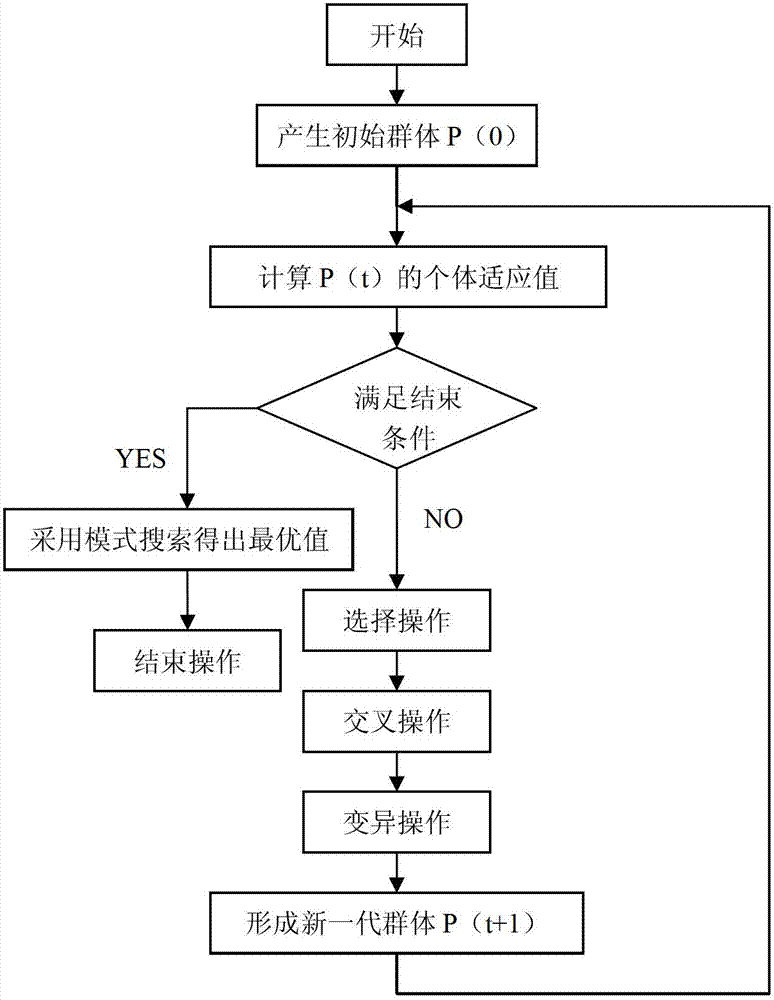

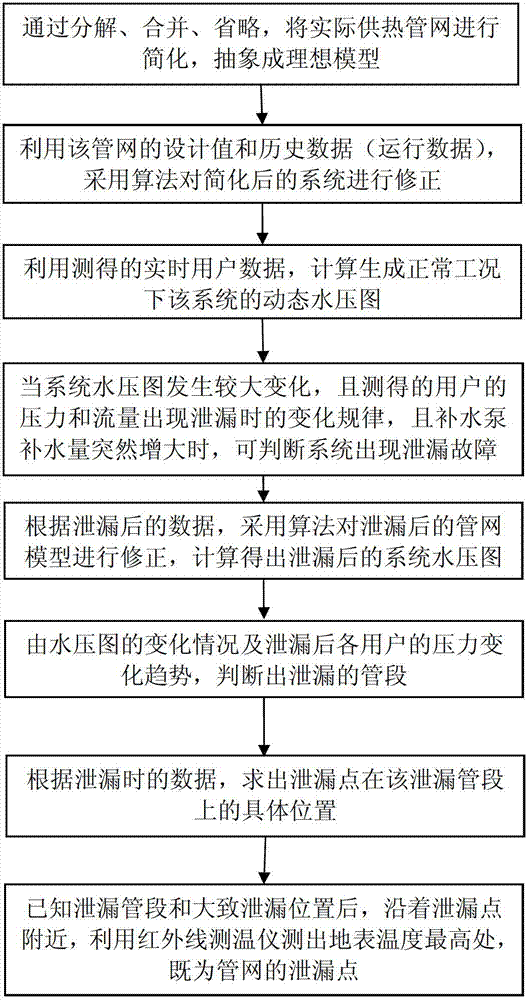

Heat supply pipe network leakage positioning system and heat supply pipe network leakage positioning method

InactiveCN102865459AAchieve positioningReal-time hydraulic conditionsPipeline systemsTraffic capacityInfrared thermometry

The invention belongs to the field of monitoring heat supply pipe network faults, and particularly relates to a heat supply pipe network leakage positioning system and a heat supply pipe network leakage positioning method. The system comprises a control center and a heat exchange station terminal, wherein the control center is composed of a computer, a multi-channel driving receiver and a piece of data transmission equipment; the heat exchange station terminal is composed of a piece of heat exchange station terminal data transmission equipment, a heat exchange station terminal microprocessor, a heat exchange station pressure sensor and a heat exchange station flow sensor; calculation programs of a heat supply pipe network are arranged inside a memory of the computer, so that data fed back by the heat exchange station terminal are stored and processed; once the heat supply pipe network has leakage, the pipe section at which the leakage point is located can be identified by obtaining the hydraulic power working condition of the system having the leakage by calculating the data of the change on the pressure and the flow at the entrance of a heat exchange station through the programs, wherein the data are fed back by monitoring points at the tail end of the heat exchange station; and furthermore the specific position of the leakage can be confirmed through the auxiliary monitoring of an infrared thermometer.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Infrared temperature measuring device based on ultrasound ranging temperature compensation

The invention relates to an infrared temperature measuring device based on the ultrasound ranging temperature compensation. Stepping motors in horizontal direction and vertical direction, an infrared temperature measuring unit, an ultrasound ranging module, a laser indicator and a positioning switch are arranged on a holder mechanical structure; the holder mechanical structure is connected with a calibrating module through the laser indicator and a control module; a calibrated parameter storing module, a control system and calibrating module, a system positioning interface circuit and the ultrasound ranging module are respectively connected with a central processing unit (CPU); the infrared temperature measuring unit sends the detected temperature value signal to the CPU, CPU sends the value signal to an upper computer through a wireless communication interface module. The infrared temperature measuring device can perform non-contact online temperature measurement on the to-be-tested points distributed at every position of the space; the infrared temperature measuring device is high in precision and quick in measuring speed; the structure design is reasonable, the infrared thermometer and the accurate positioning technology are combined, therefore, the online monitoring of multi-point temperature of the space is realized, and the cost is saved.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

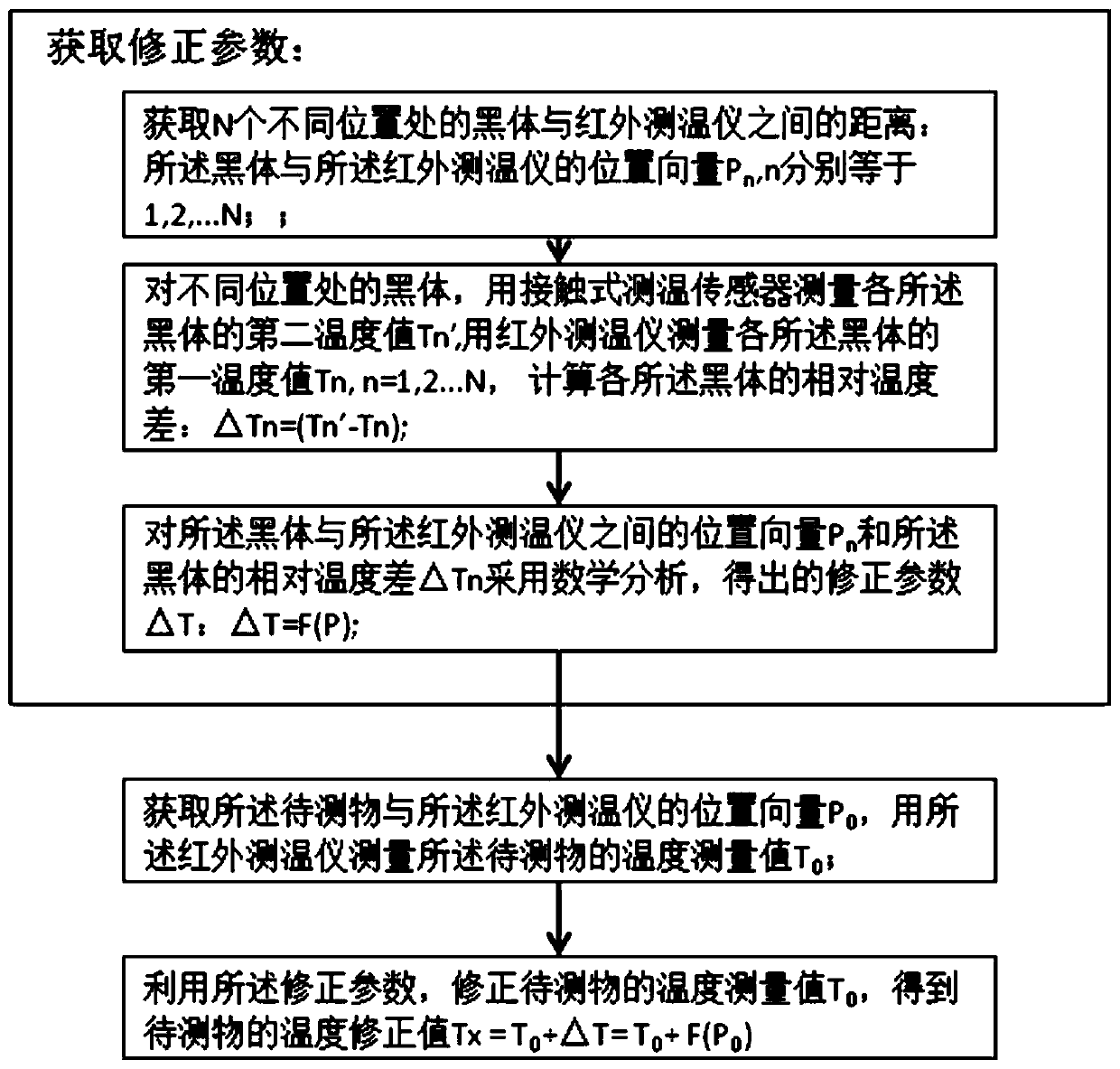

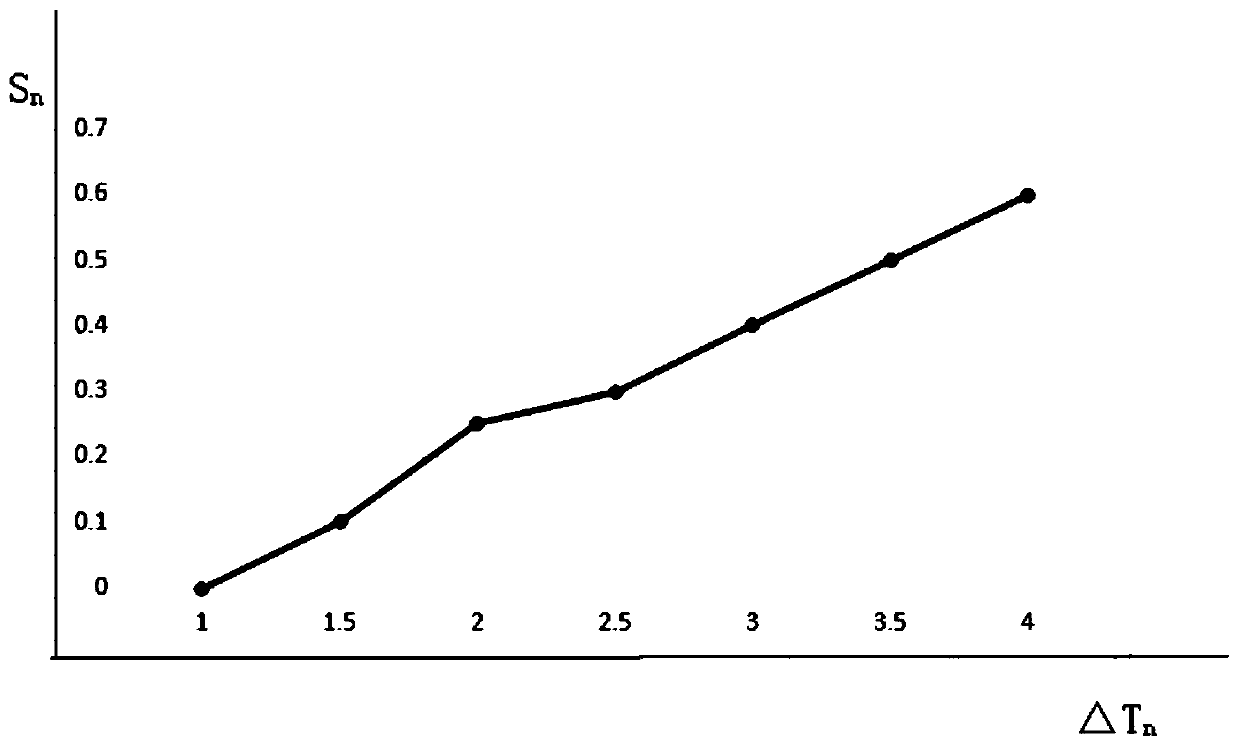

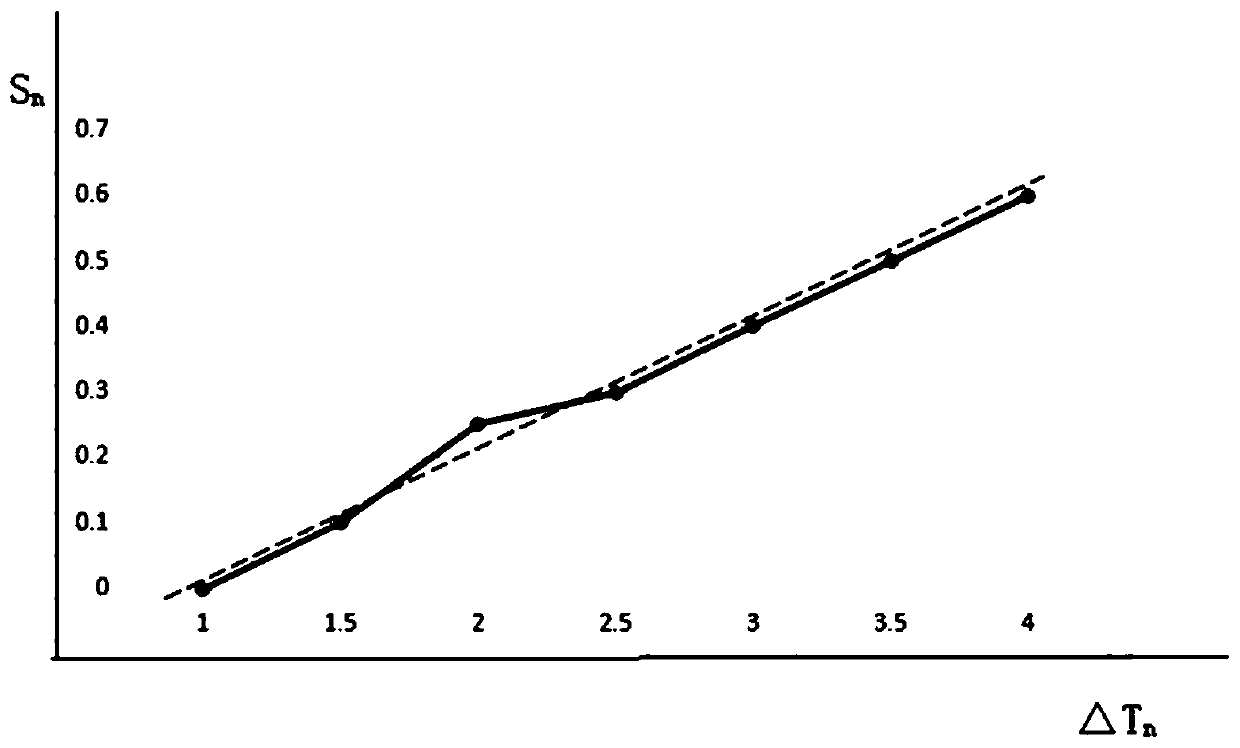

Temperature correction method for infrared temperature measurement, and infrared thermal imager

PendingCN111351583ATemperature correctionImprove correction accuracyRadiation pyrometryBlack bodyMaterials science

The invention discloses a temperature correction method for infrared temperature measurement, and an infrared thermal imager. The method completes the temperature correction through the following steps: obtaining the position vectors between N black bodies at different positions and an infrared thermometer, improving the correction precision through the black bodies at different positions, and providing a data source for the temperature correction; then, respectively measuring the temperatures of the black bodies by using a contact type temperature measuring sensor and the infrared thermometer, calculating the relative temperature differences of the black bodies, and based on the temperature differences and the spatial relationship between the black bodies and the infrared thermometer, incombination with preset parameters of the external environment such as temperature, humidity, wind speed, illumination conditions and the like, using a mathematical analysis technology to obtain correction parameters, and correcting the temperature measurement value of a measured object to complete temperature correction of the infrared thermometer. The high-precision constant-temperature controlof the black bodies is converted into real-time accurate monitoring of the temperature of the black bodies, so that the calibration cost is effectively controlled, and the temperature measurement accuracy is ensured.

Owner:广州尚衡信息科技有限公司

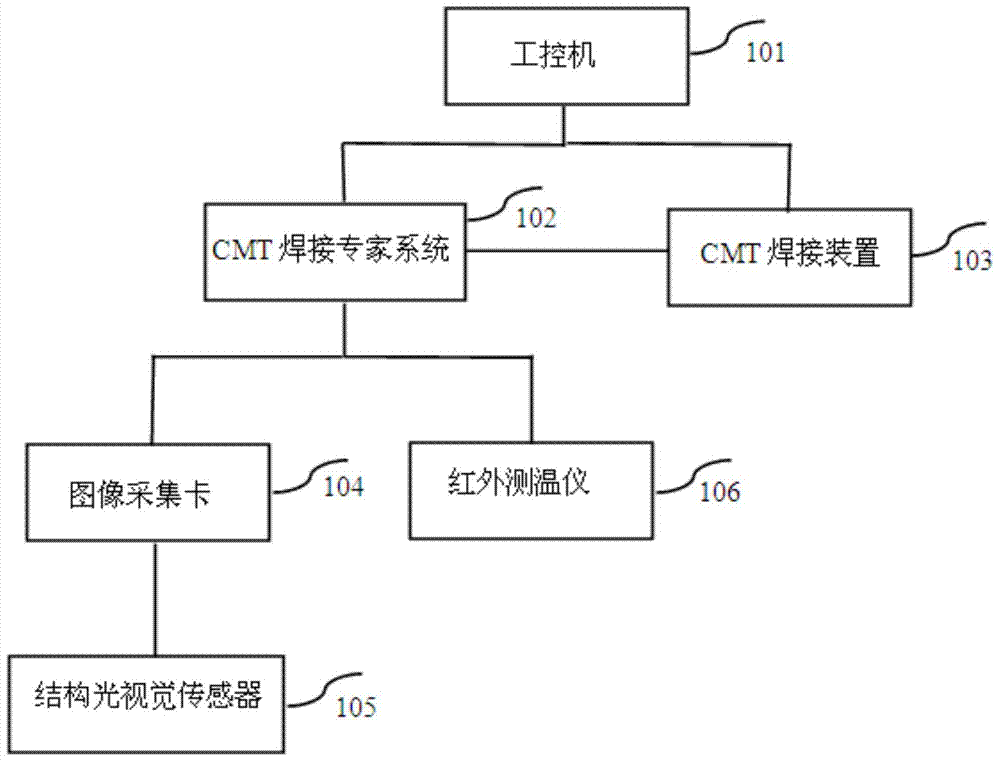

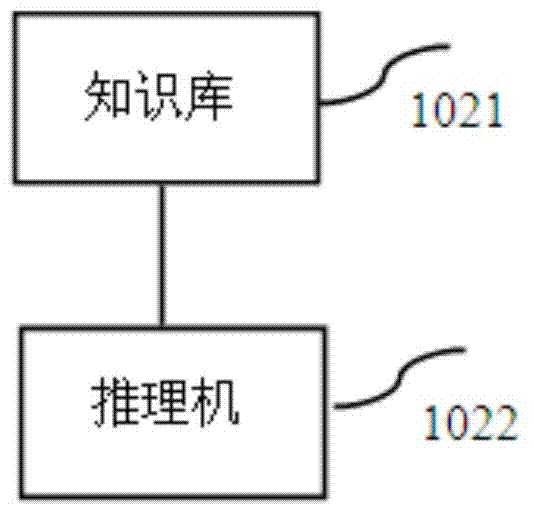

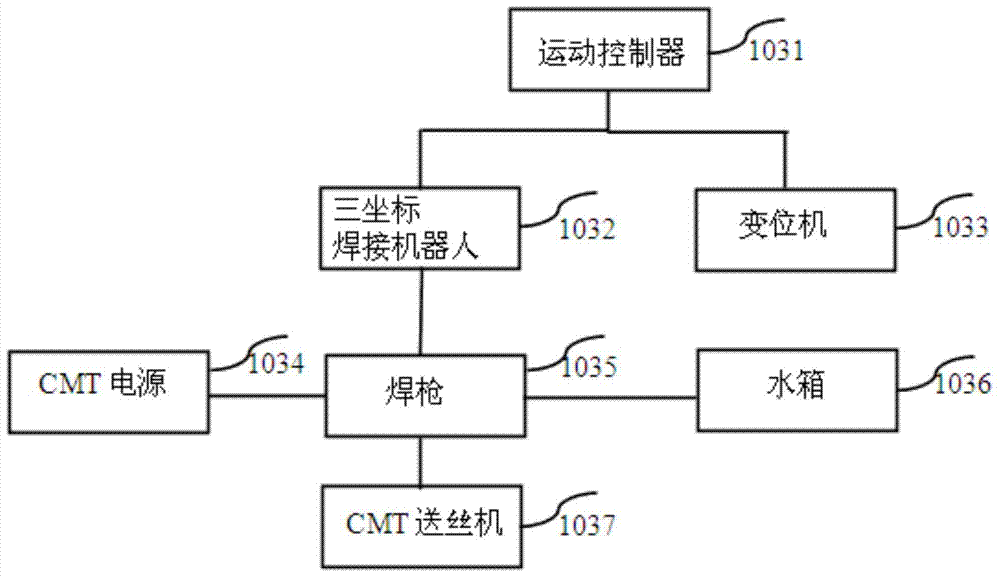

Metal welding rapid formation system and method based on CMT

InactiveCN104842042ARealize closed-loop controlGuaranteed accuracyArc welding apparatusClosed loopEngineering

The invention discloses a metal welding rapid formation system and method based on CMT. The metal welding rapid formation system comprises an industrial personal computer for generating the path code information of welding formation, a CMT welding expert system for conducting inference and obtaining conclusion according to the rules in a collecting data matching knowledge base and converting the conclusion into the feedback control signals for closed-loop control, a CMT welding device for piling up and forming the objective formation parts; a structured light visual sensor for conducting the surface topography measurement on the piled formed welding pass, an image capture card for processing the signals collected by the structured light visual sensor and an infrared thermometer for measuring the surface temperature of the piled welding pass. Through the measurement of the temperature and the surface topography of the welding formation welding passes, a welding formation expert system, a formation height and width feedback system and a temperature detection feedback system are established, the closed-loop control of the CMT metal welding rapid formation is realized, and the precision and the quality of formation is ensured.

Owner:XI AN JIAOTONG UNIV

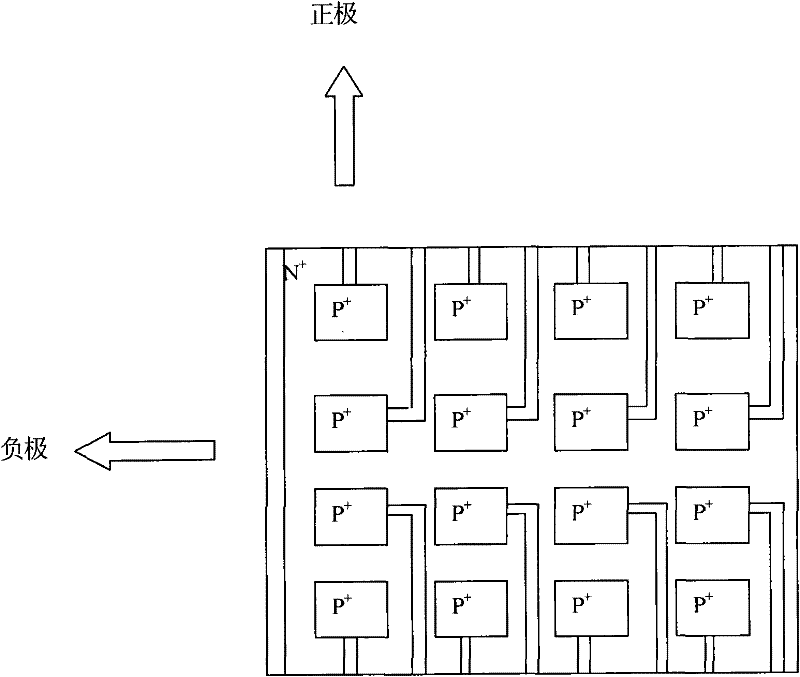

Novel centrifugal melt electrostatic spinning device

ActiveCN104088024ASolve the blockageBatch preparation in orderFilament/thread formingFiberCircular cone

The invention discloses a novel centrifugal melt electrostatic spinning device. The device mainly comprises a spinning component, a receiving component, an electromagnetic heating component, a high voltage generating component, a power-driven component and a rack. The spinning component comprises a liquid storage tank, an end cover, first circular cone frustum spray head assemblies and second circular cone frustum spray head assemblies. The receiving component comprises a plastic bottom plate made of nylon and an aluminum receiving plate which can slide on the plastic bottom plate through bolt adjusting, wherein a groove is formed in the plastic bottom plate. The electromagnetic heating component comprises an electromagnetic coil, an electromagnetic control box, an infrared thermometer and supporting rods. The electromagnetic coil is located at the lower end of the liquid storage tank. The high voltage generating component comprises a high voltage generator, wherein a positive electrode of the high voltage generation is connected with the static receiving plate of the receiving component. The power-driven component comprises a motor and a shaft, the shaft is driven by the motor to rotate so as to drive the liquid storage tank to rotate. The rack is grounded and supports the whole spinning system. Centrifugal force is introduced into a traditional melt electrostatic spinning device, by the utilization of dual functions of electrostatic force and centrifugal force, fibers are stretched and refined, and finally nanometer fibers are manufactured in order in batch.

Owner:BEIJING UNIV OF CHEM TECH

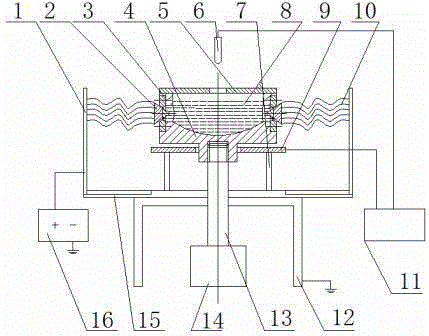

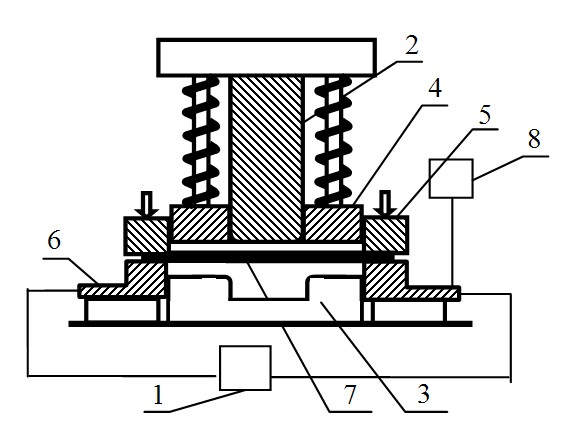

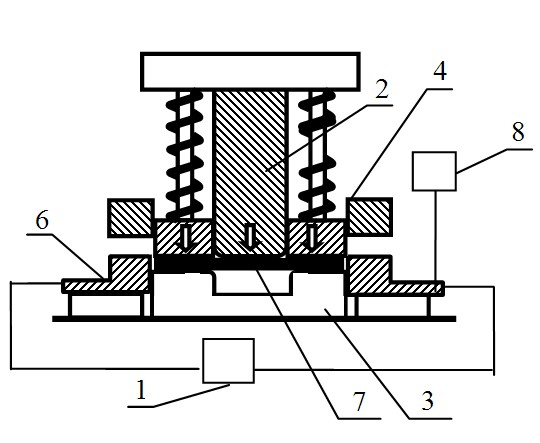

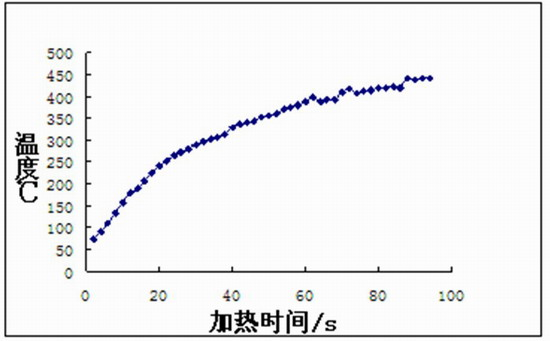

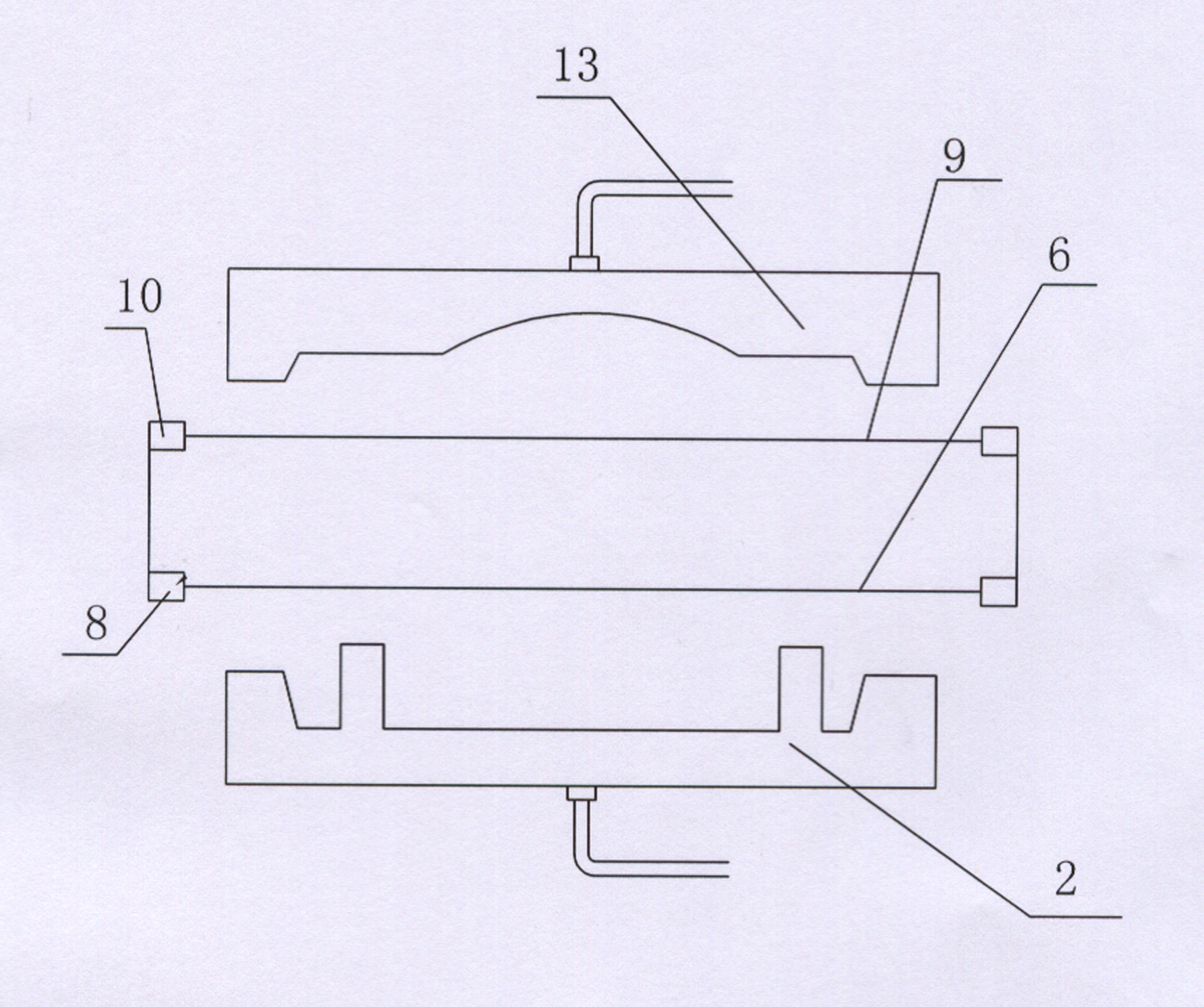

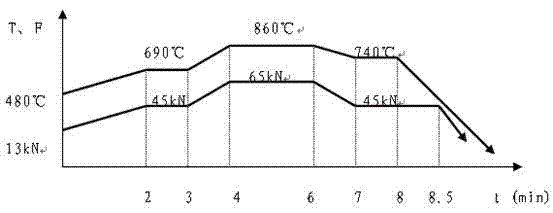

Method fur forming aluminum base composite material thin wall part by current self-resistance heating

The invention relates to a method for forming an aluminum base composite material thin wall part by current self-resistance heating, which belongs to the field of heat processing. The invention aims to solve the problems of poor forming quality of a thin wall part just by heating a blank as well as low heat utilization ratio and great energy consumption by heating the blank together with a die when the stretching formation is carried out on a particle-reinforced aluminum base composite material. The method comprises the following steps of: 1. placing a forming device on a press machine; 2. pressurizing an upper electrode clamping plate, clamping the blank to be formed, switching on a power supply and heating the blank to be formed; 3. measuring temperature in real time by using an infrared thermometer and adjusting an output current parameter of a power supply in real time so that the heating speed of the blank to be formed reaches 5-20 DEG C / s; 4. when the blank to be formed reaches 350-450 DEG C, removing the pressure on the upper electrode clamping plate and pressurizing an edge press ring by the press machine so that the edge press ring compresses the blank to be formed on a lower die; and 5. pressing an upper die for descending and pressing the blank to be formed for forming.

Owner:HARBIN INST OF TECH

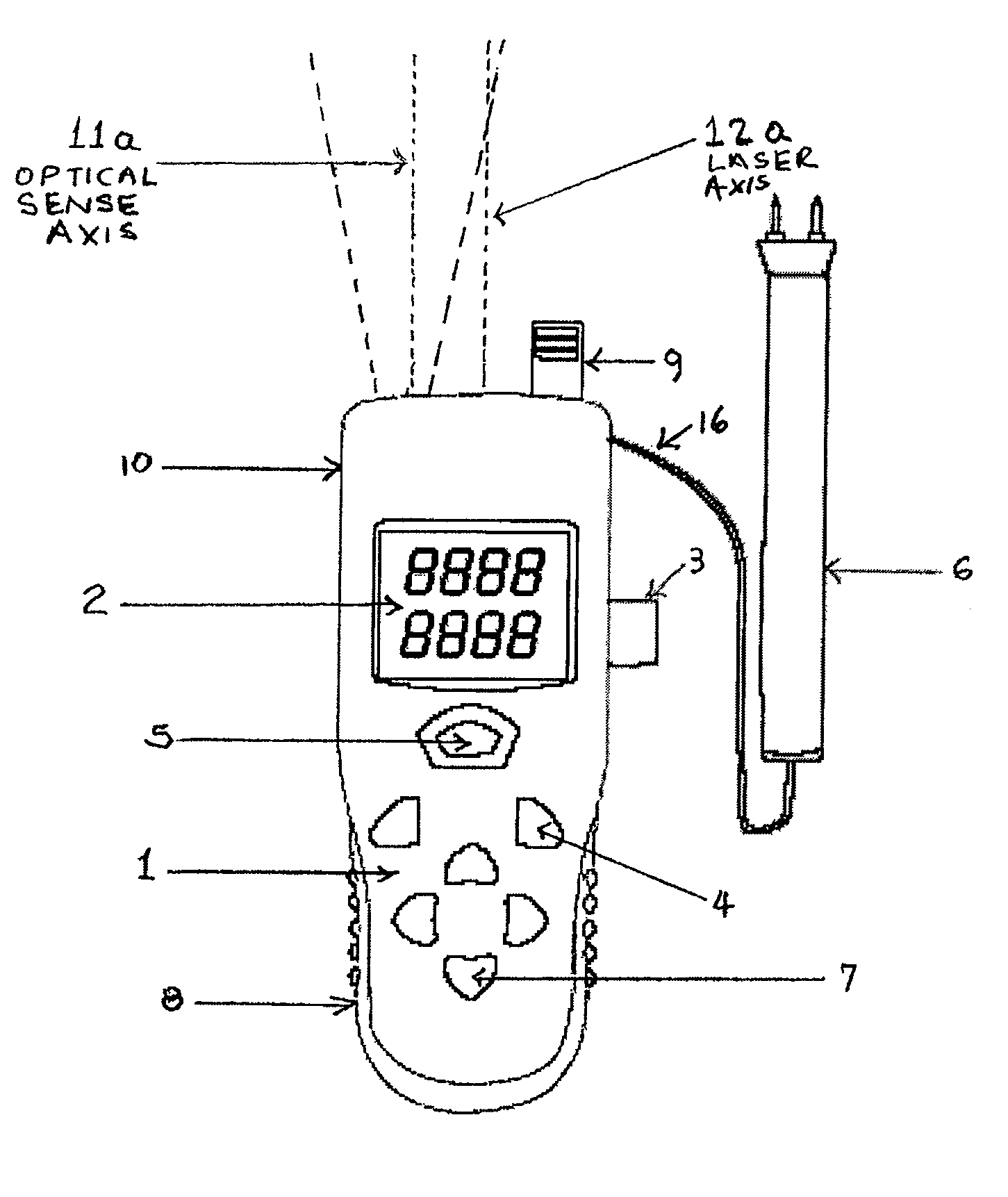

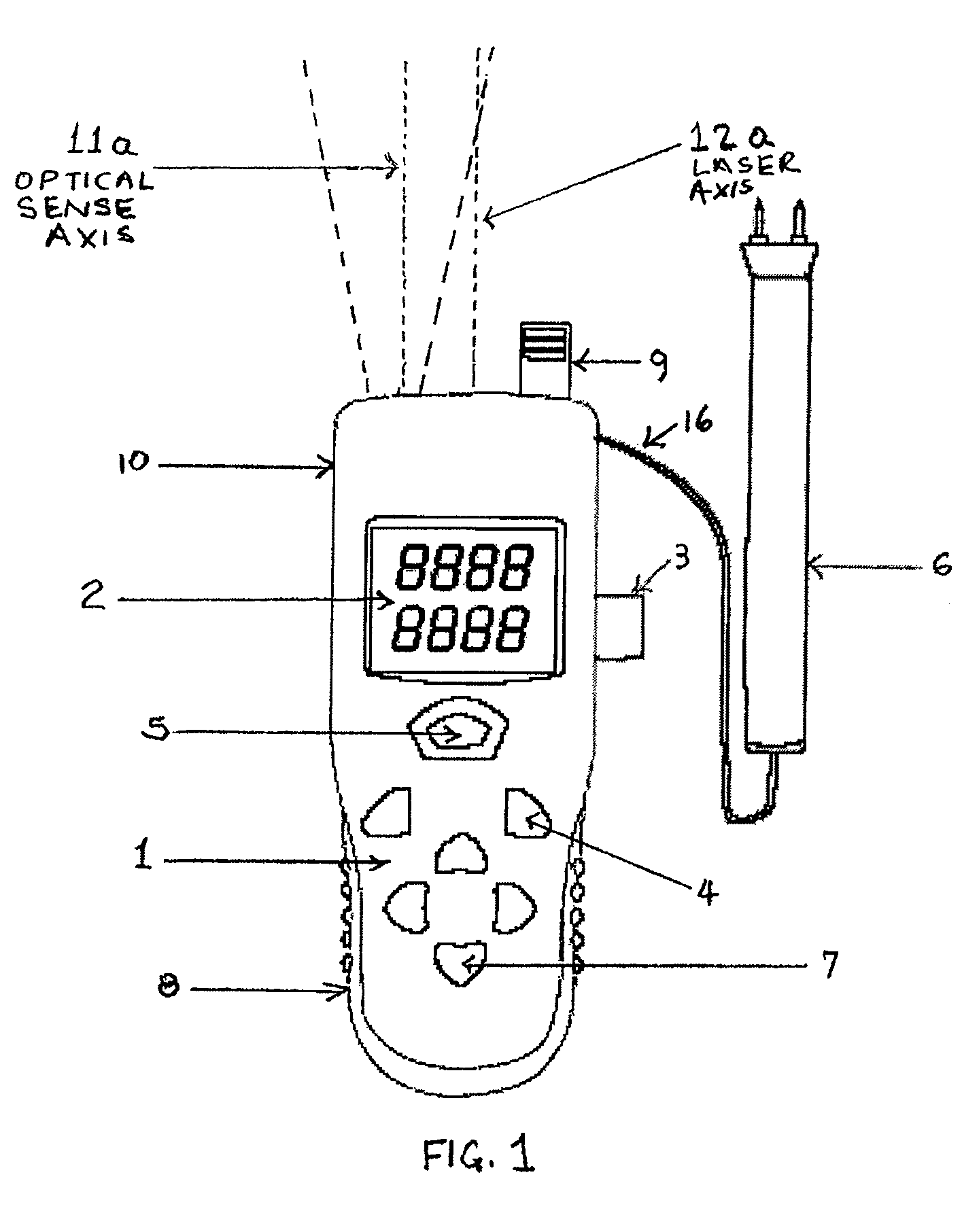

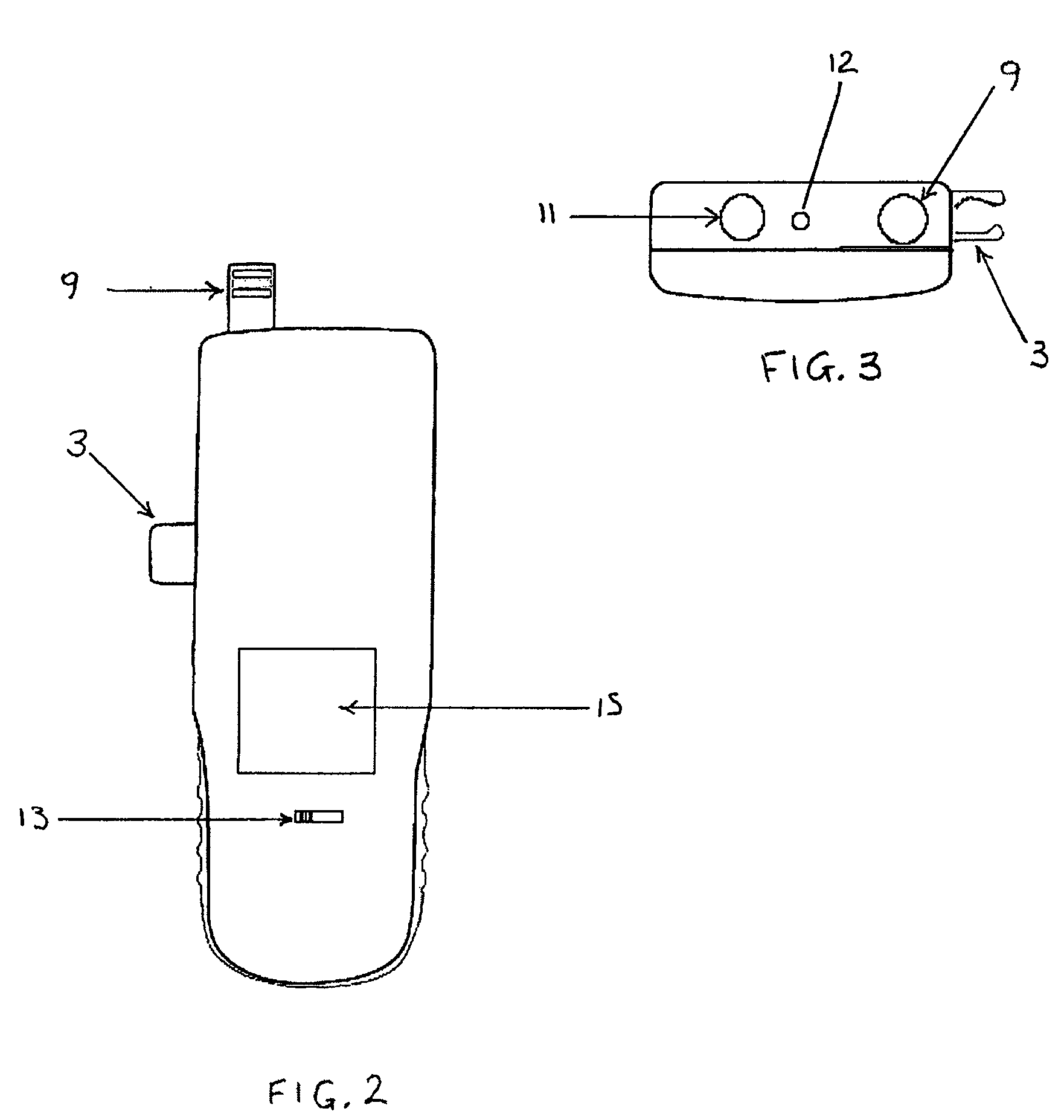

Moisture meter with non-contact infrared thermometer

ActiveUS8727608B2Easy to useImprove portabilityThermometer detailsRadiation pyrometryDisplay deviceEngineering

A moisture meter with non-contact temperature measurement capability having a housing, a moisture-detecting device coupled to or contained at least partially in the housing, and having an output related to measured moisture parameters, a non-contact, optically-based temperature sensing device coupled to the housing, having an output related to sensed temperature, an output display contained in the housing, for displaying measurements to a user, and circuitry contained in the housing for processing both the moisture-detecting device output and the non-contact temperature sensing device output, and transmitting the processed outputs to the output display. The moisture-detecting device can be either one or both of a contact-type moisture-detecting device such as a pad on the rear side of the housing, and a pin-type moisture-detecting device in a hand-held probe, and electrically coupled to the circuitry in the housing through a cord.

Owner:TELEDYNE FLIR LLC

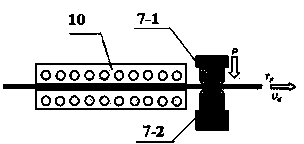

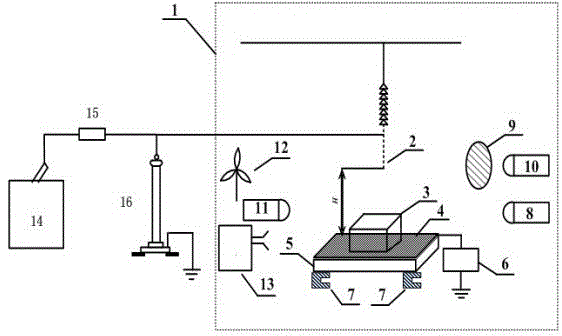

Equipment for preparing multifunctional amorphous composite material

ActiveCN101418386AIdeal interface structurePrecise temperature controlTemperature controlInfrared thermometry

The invention relates to a technique for impregnating and solidifying melt, in particular to equipment for preparing a multifunctional non-crystal composite material, and solves the problems of lower macroscopic plasticity of massive non-crystal alloys, limited application range and the like. The equipment is provided with a vacuum chamber consisting of an upper vacuum cavity and a lower vacuum cavity, and the middle of the equipment can be separated by a blind plate and can be also mutually communicated. An inductive heating coil is arranged in the upper vacuum cavity; a melting pot is arranged in the inductive coil; and the outside of the upper vacuum cavity is provided with a camera and an infrared thermometer. A precise temperature control heating furnace is arranged in the lower vacuum cavity; the bottom of the lower vacuum cavity is provided with a quick detachable flange sealing port; and the underside of the outside the lower vacuum cavity is provided with a cooling system. The equipment is mainly used for preparing the non-crystal composite material, can precisely control melting and impregnating temperature of the alloy, and is favorable for obtaining an ideal interface structure and improving performance of the non-crystal composite material. The equipment has multiple functions, and can be also used for melting alloy, preparing pure non-crystal samples, carrying out vacuum heat treatment, and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

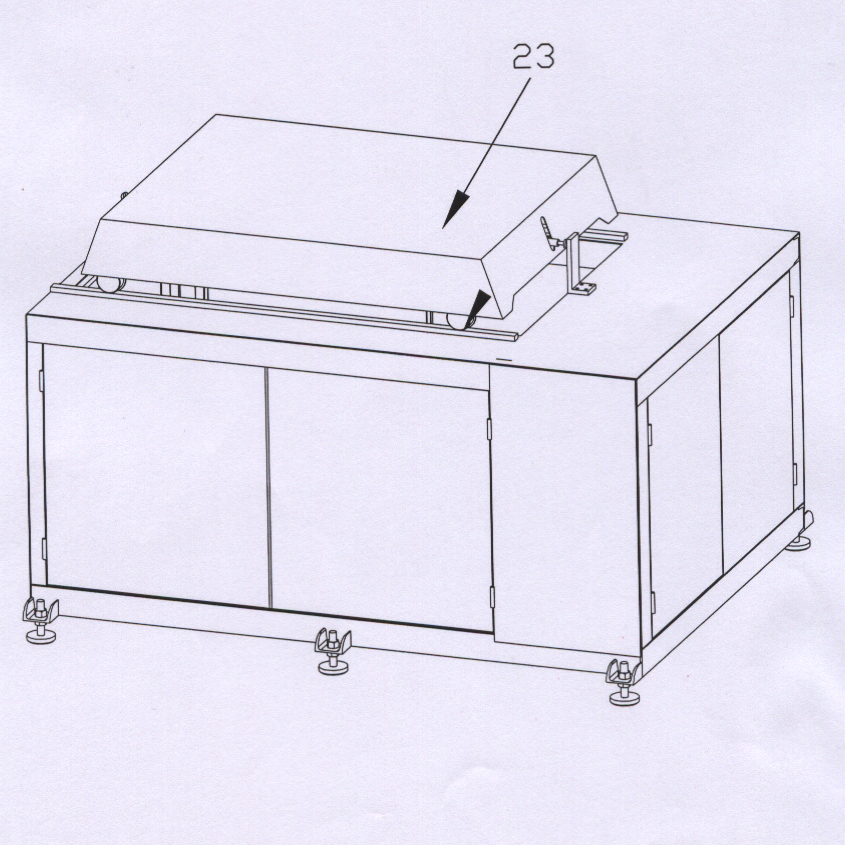

One-step molding device for double-layer thick plastic sheet and molding process thereof

The invention relates to a one-step molding device for a double-layer thick plastic sheet and a molding process thereof. The device and the mold can realize carrying out the blow molding process, the plastic sucking molding process and the hot seal molding process on the double-layer thick plastic sheet, and comprise an automatic feeding device, a upper and a lower molds, a vacuum system, a compressed air system, an upper and a lower heating furnaces, a plastic sheet clamping device, a plastic sucking product trimming device, a movement control system, a temperature control system and the like. The molding process comprises the following steps: (1) the automatic feeding device sends two plastic sheets to the molding area of the device, and the two plastic sheets are tightly pressed by an upper and a lower material pressing frames; (2) the upper and lower heating furnaces are moved to the molding area to simultaneously heat the two sheets, and an automatic infrared thermometer goes into operation; (3) the heating furnaces are automatically reset when the temperature of the infrared thermometer reaches to the molding temperature, compressed air is blown in between the two plastic sheets, simultaneously the upper and the lower molds start to move in the opposite directions to tightly press the two plastic sheets (realizing the thermal bonding of bonding parts of the two plastic sheets and the trimming of trimming positions), and two mold vacuum-pumping systems are turned on to realize the plastic sucking molding of the product; and (4) the upper mold and the lower mold are reset, and plastic sucking products are taken away. The device can realize the one-step blow plastic sucking molding of the double-layer thick plastic sheet as well as the plastic sucking molding of the single-layer thick plastic sheet, and has the advantages of compact structure, convenient operation, high molding efficiency, large molding area, small occupied area and energy saving.

Owner:潘震州

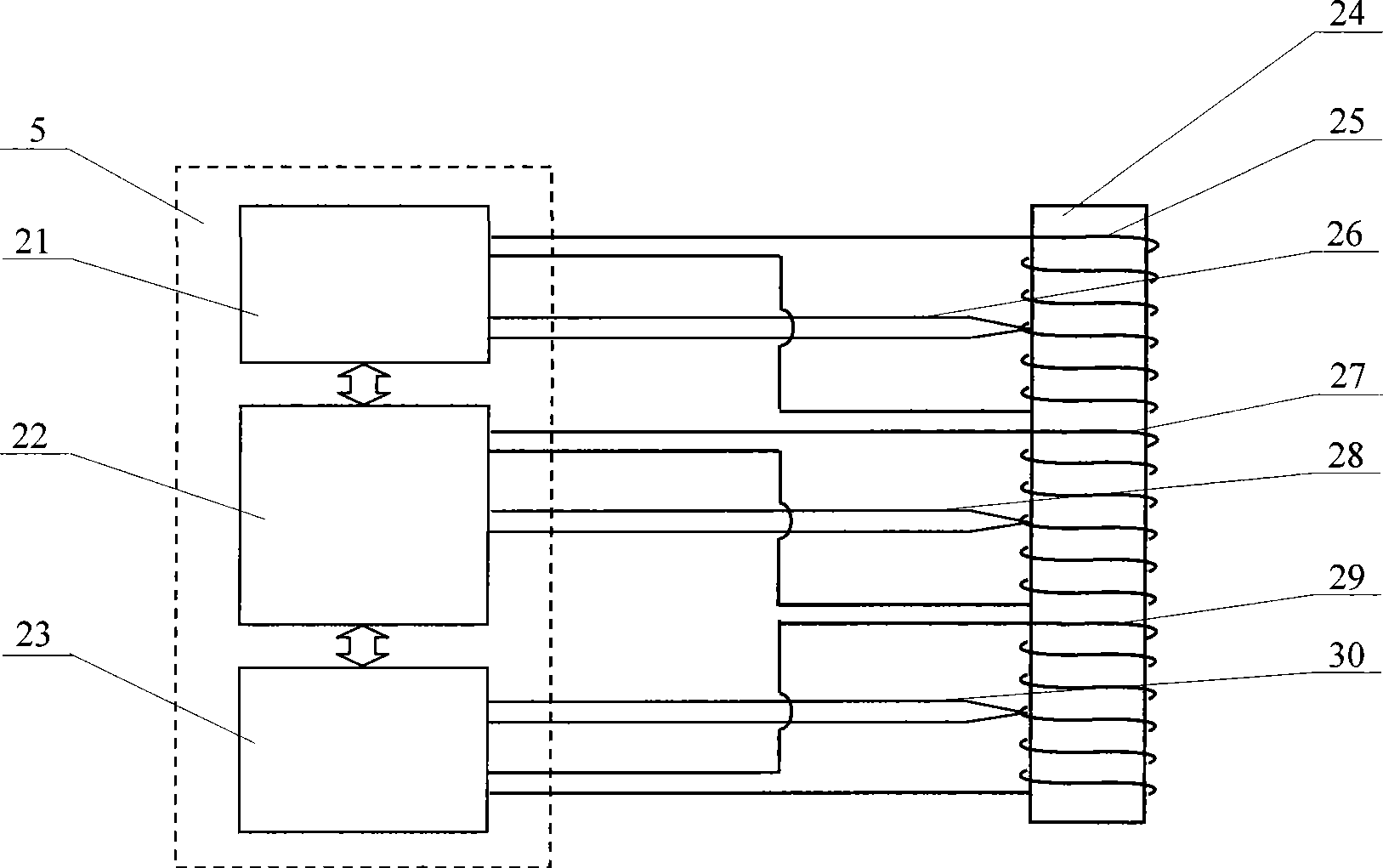

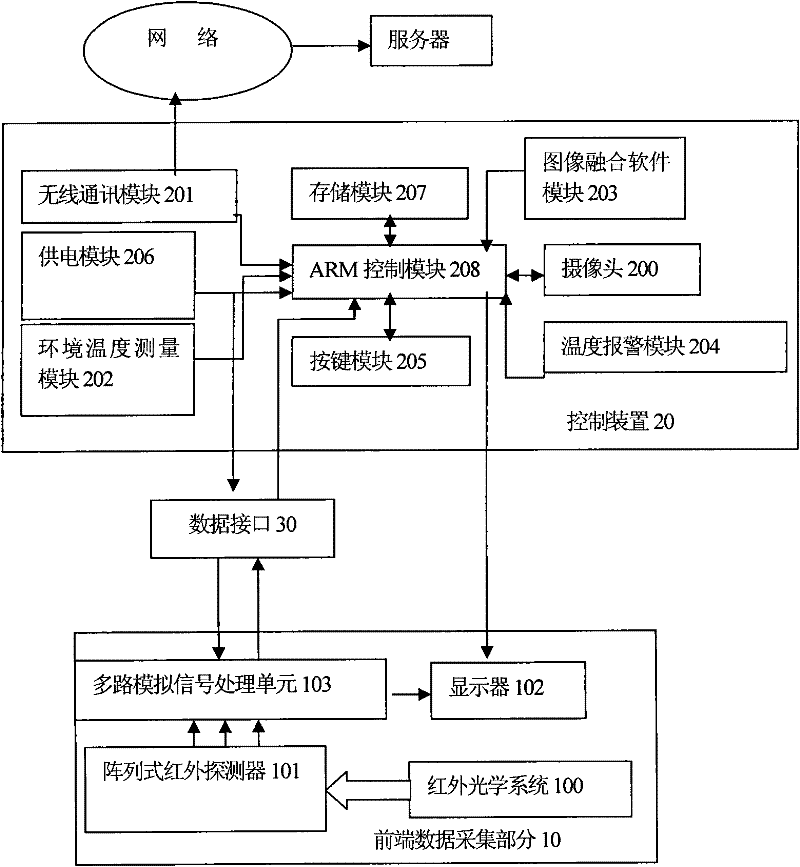

Array infrared thermometer

InactiveCN102162752AHigh precisionImprove temperature measurement accuracyTransmission systemsPyrometry using electric radation detectorsData acquisitionData interface

The invention provides an array infrared thermometer belonging to the field of non-contact infrared thermometry and image processing. The thermometer comprises a front data acquiring part, a control device and a data interface connected between the front data acquiring part and the control device, wherein the front data acquiring part comprises an infrared optical system, an array infrared detector and the like; and the control device comprises a camera, a wireless communication module, an ambient temperature measurement module, an image fusion software module, a temperature alarm module, a button module, a power supply module, a memory module and the like. The array infrared thermometer can measure the temperature distribution condition on the surface of an object in real time, simultaneously ensure infrared temperature distribution of the object to correspond to the measured object, display the real-time variation condition of the temperature of the measured object and directly measure the actual temperature of the measured object through real-time calibration, thus greatly improving the analysis effect of monitoring the infrared temperature on the surface of the object.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Gas sensor, analyzer and method for measuring oxygen concentration of a respiratory gas

A gas sensor is disclosed herein. The gas sensor includes an emitter for emitting radiation to a body at least partly coated with a luminophore emitting luminescent radiation indicative of an oxygen concentration when in contact with a respiratory gas. The gas sensor also includes a filter for transmitting the luminescent radiation emitted by the luminophore and an oxygen detector for receiving the luminescent radiation transmitted by the filter. The gas sensor also includes an infrared thermometry unit for receiving a thermal radiation from the luminophore. A gas analyzer and a method for measuring oxygen concentration of a respiratory gas are also provided.

Owner:GENERAL ELECTRIC CO

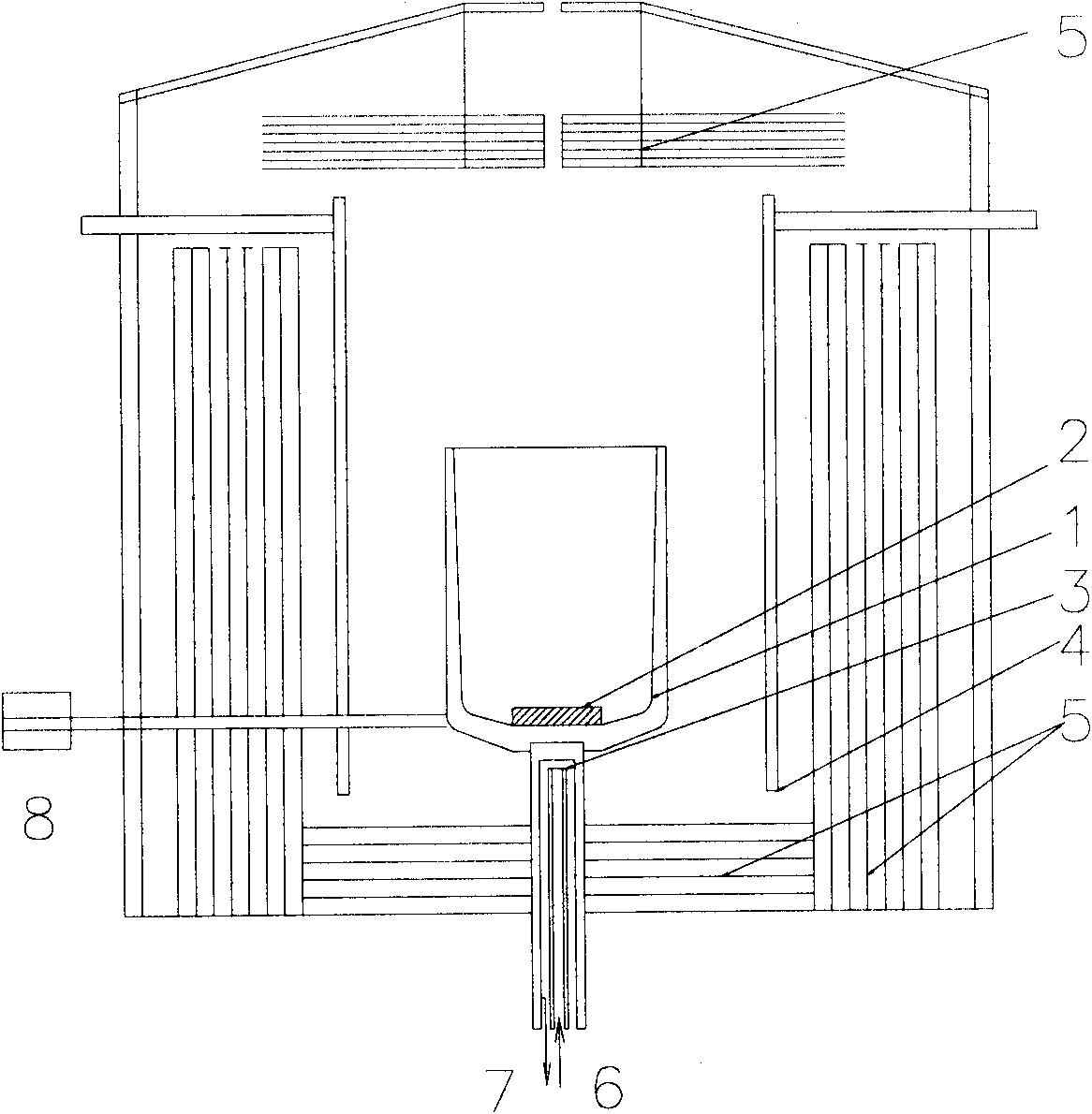

Crystal growth technology and crystal growth furnace

InactiveCN102732944ALow experience requirementSimple growth processPolycrystalline material growthFrom frozen solutionsInfrared thermometryHeat conducting

The invention provides a crystal growth technology. The crystal growth technology comprises the following steps of a preparation process, a seeding process, a shoulder-expanding process, a constant-diameter growth process, and a cooling and annealing process. The shoulder-expanding process comprises that after the seeding process, a flow of a refrigerant fed to the bottom of a tungsten crucible is increased without a change of heating element power so that a diameter of a crystal is increased. The constant diameter growth process comprises that when a flow of the refrigerant reaches to a preset value, the heating element power is maintained for a second preset time; and through monitoring of a cooling rate of the bottom of the tungsten crucible, constant diameter growth of crystals is controlled. Through an infrared thermometer, a flow of a refrigerant and the power of a heating element are controlled and a change of a temperature of the bottom of the tungsten crucible is monitored. The invention also provides a crystal growth furnace. The crystal growth furnace comprises the heating element woven from a wolfram wire mesh, the tungsten crucible surrounded by the heating element, a heat-conducting support for supporting the bottom of the tungsten crucible, and the infrared thermometer used for controlling the power of the heating element and a flow of refrigerant gas and connected to the bottom of the tungsten crucible. The crystal growth technology and the crystal growth furnace reduce requirements on technologist's experiences. The crystal growth technology simplifies the existing crystal growth technology and is convenient for industrialization.

Owner:江苏同人电子有限公司

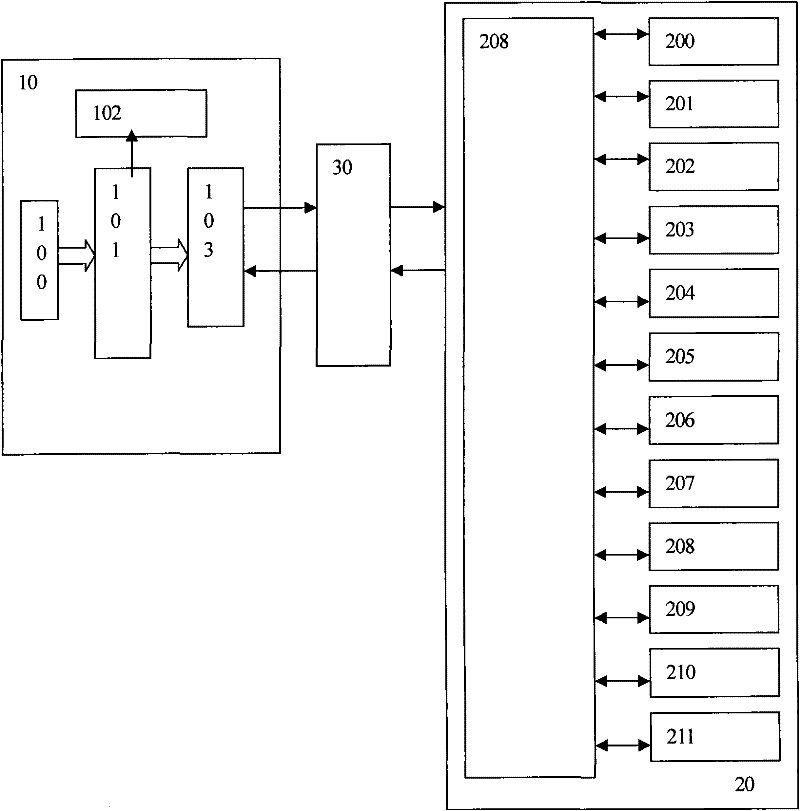

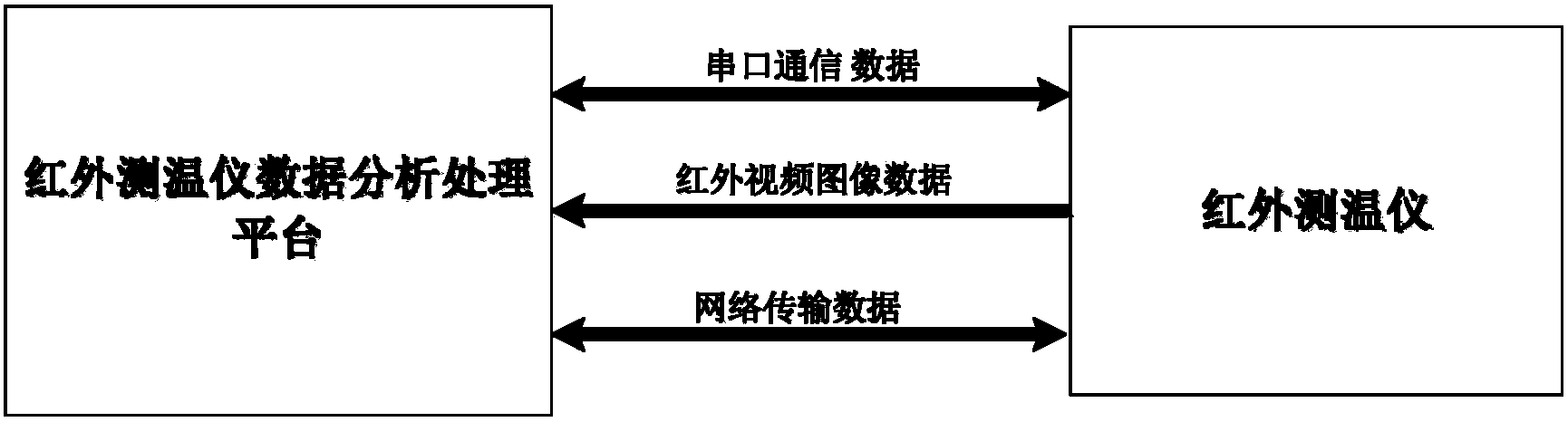

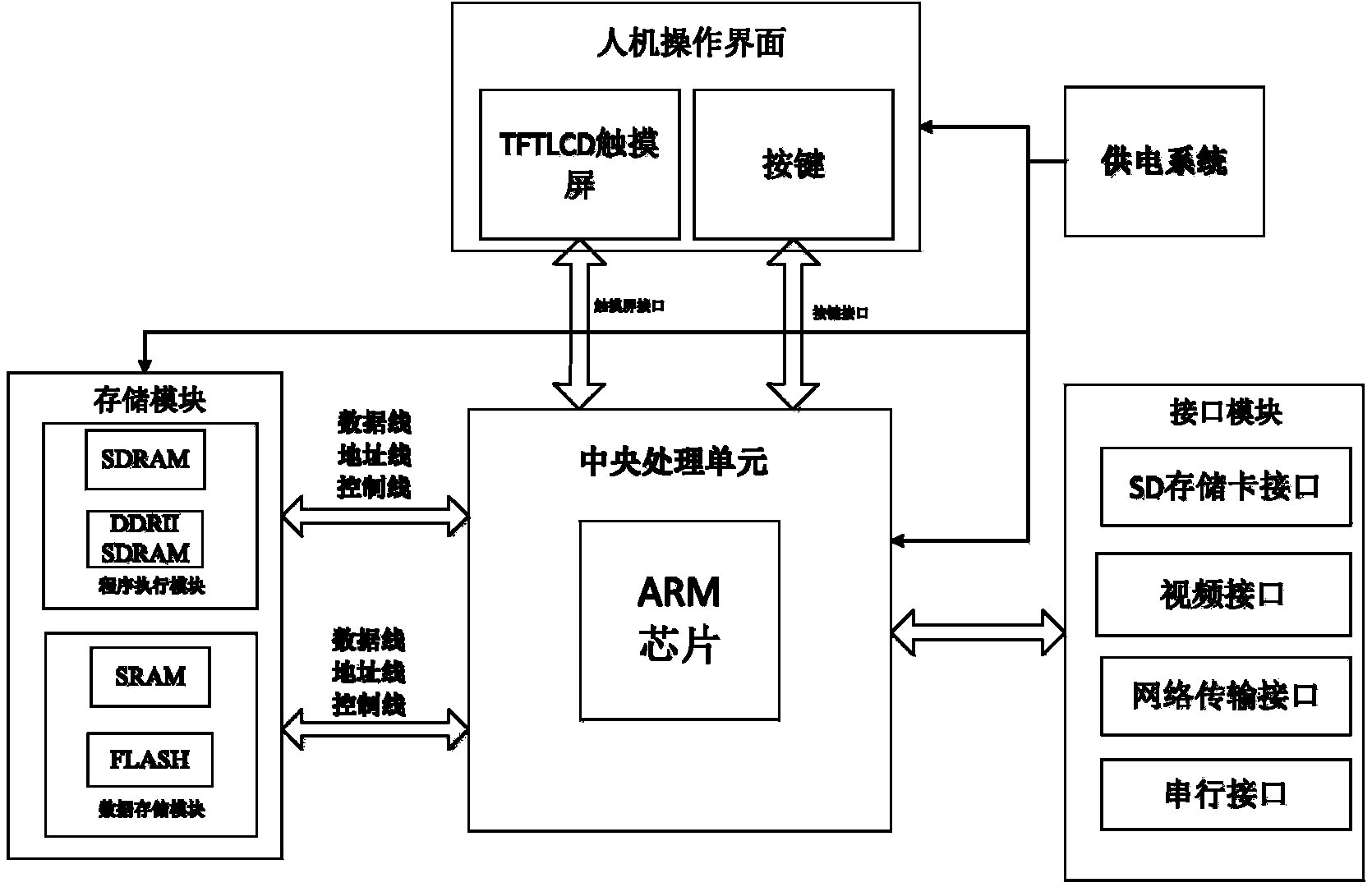

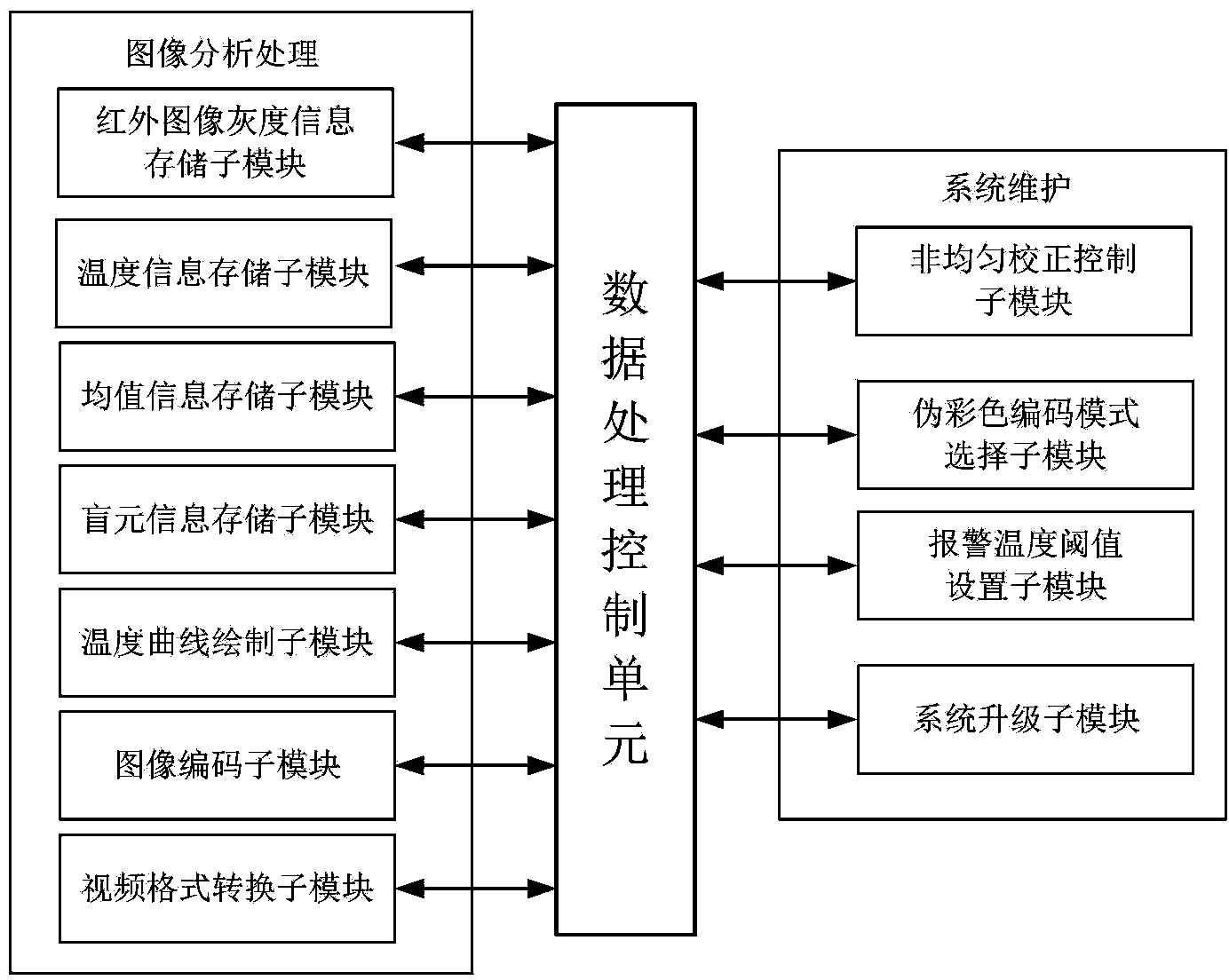

Infrared thermometer data analysis processing platform and method

InactiveCN104251737AReduce power consumptionStrong battery lifeRadiation pyrometryControl signalSystem maintenance

The invention discloses an infrared thermometer data analysis processing platform comprising a central processing unit, a storage module, a human-machine operating interface and an interface module; the storage module, the human-machine operating interface and the interface module are connected with the central processing unit; a TFT LCD (thin-film transistor liquid crystal display) touch screen of the human-machine operating interface or keys are used to transmit control signals to an ARM (advanced RISC machines) chip of the central processing unit; the ARM chip is controlled to receive infrared video data of an infrared thermometer through a video interface, receive network transmission data of the infrared thermometer through a network transmission interface or receive video data or infrared image data in an SD (secure digital) storage card through an SD storage card interface; the ARM chip of the central processing unit analytically processes the infrared video data or infrared image data received and transmits analytic results to the TFT LCD touch screen for displaying; a serial interface transmits serial control command packets to the infrared thermometer and systematically maintain the infrared thermometer. The infrared thermometer data analysis processing platform allows efficient and accurate analysis of infrared temperature measurement images and allows systematic maintenance for the infrared thermometer.

Owner:NANJING UNIV OF SCI & TECH

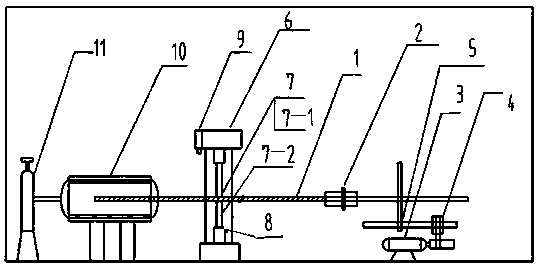

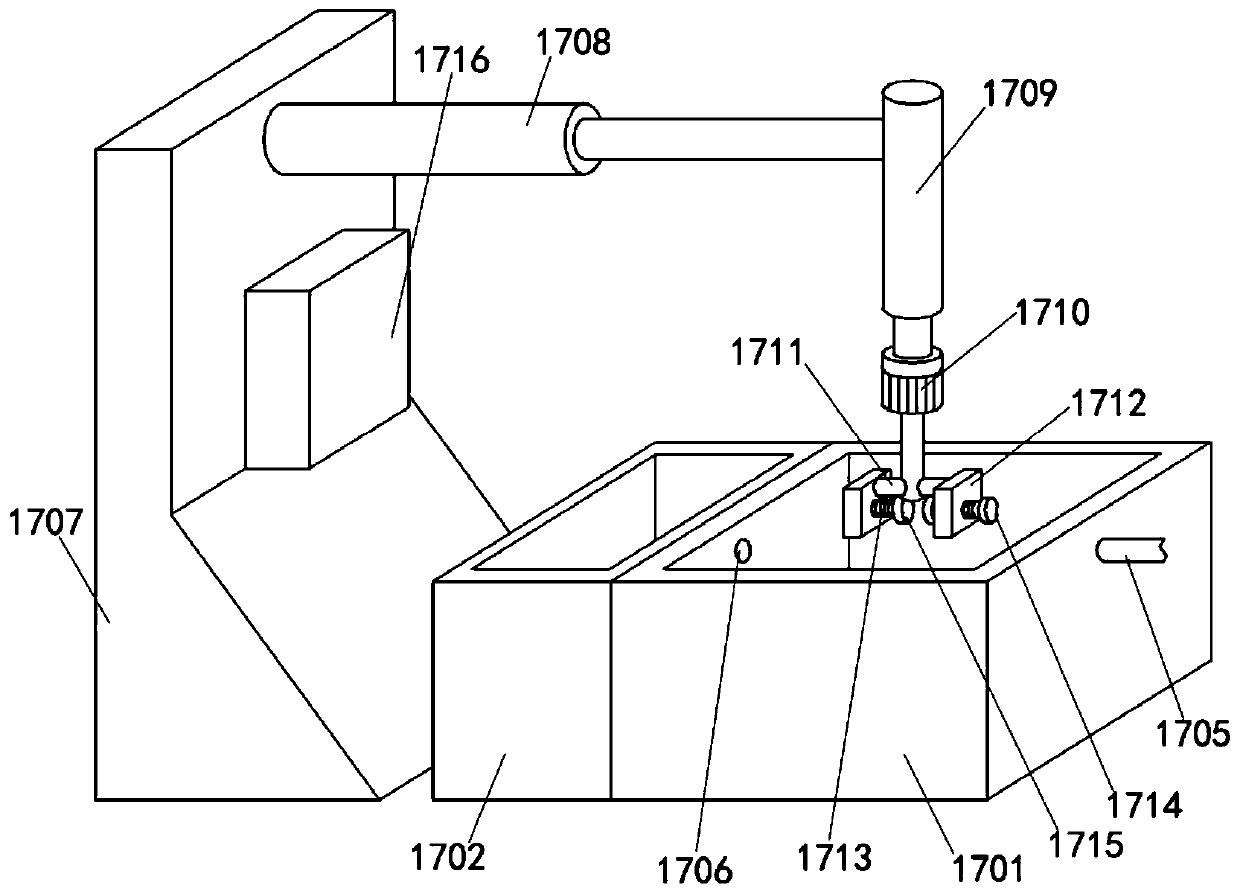

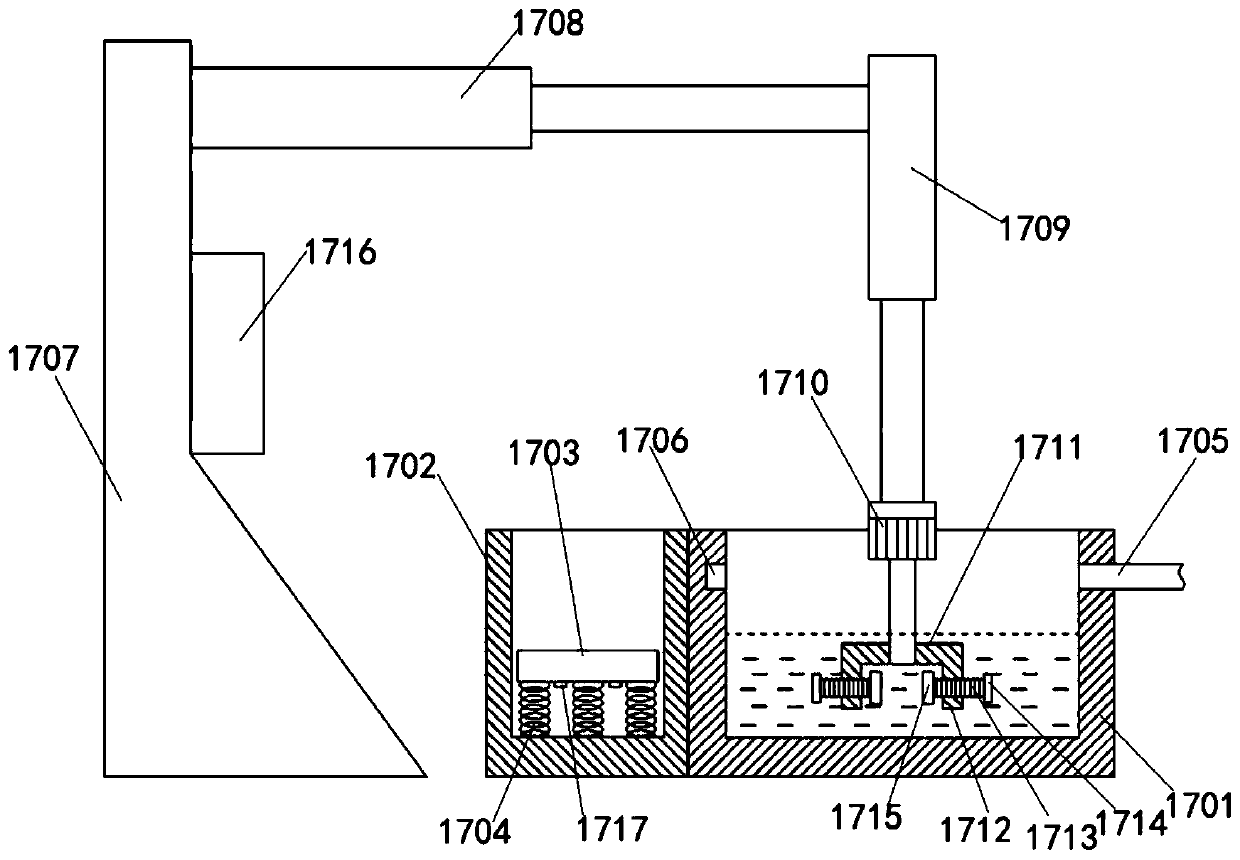

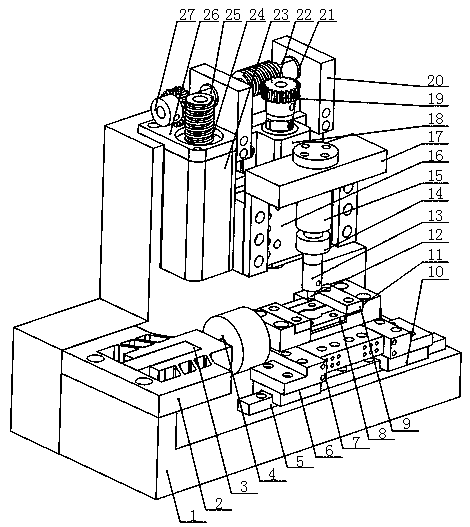

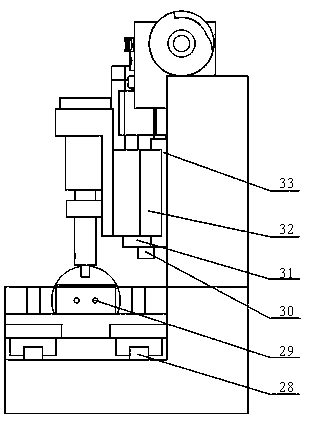

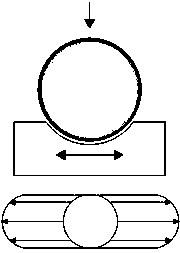

Device for testing thermal friction coefficient of sheet material in hot stamping forming process

InactiveCN103630491ATest accurateSimple structureUsing mechanical meansMaterial analysisHot stampingFrictional coefficient

A device for testing thermal friction coefficient of a sheet material in a hot stamping forming process is used for testing the friction coefficient of a high strength steel sheet at a high temperature. The device comprises an argon bottle connected with a heating furnace through a pipeline, an infrared thermometer, a pressure head, a hydraulic mechanism, a sensor, a drawing device and the like, wherein in the heating furnace with protective atmosphere, a tested sheet material sample is heated; after a corresponding temperature is reached, the tested sheet material sample is discharged from a furnace mouth under the drawing of the drawing device and penetrates through the middle part of the pressure head; a pressure is exerted by the pressure head, and the sensor records a pressure value of the pressure head and a drawing force value; and according to a Coulomb friction formula, the friction coefficient is calculated by a computer processing system. The device is simple in structure, and can accurately test the friction coefficient value of a high-strength steel sheet at high temperature, so as to provide a significant parameter for design and numerical simulation of a hot forming process.

Owner:马鸣图

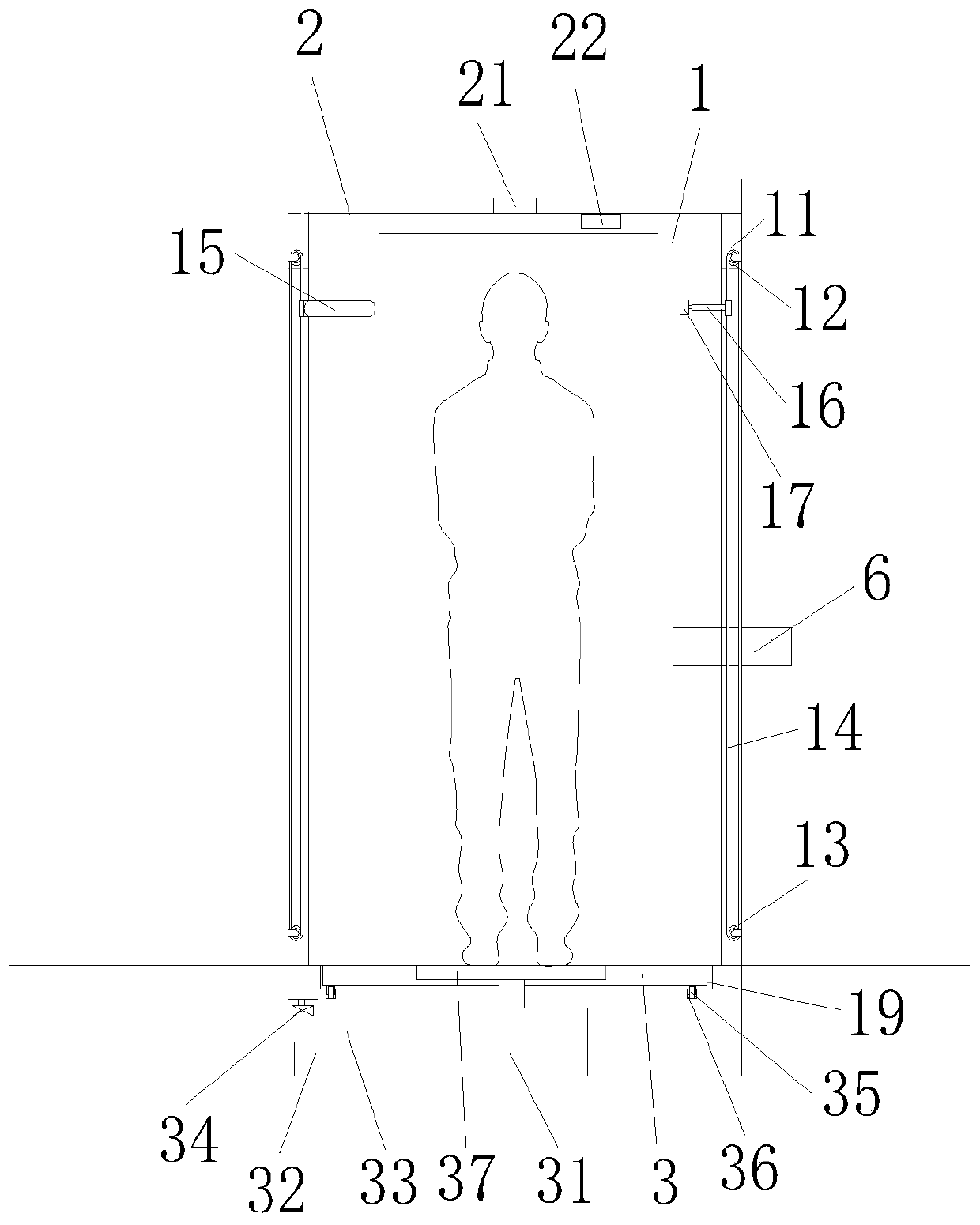

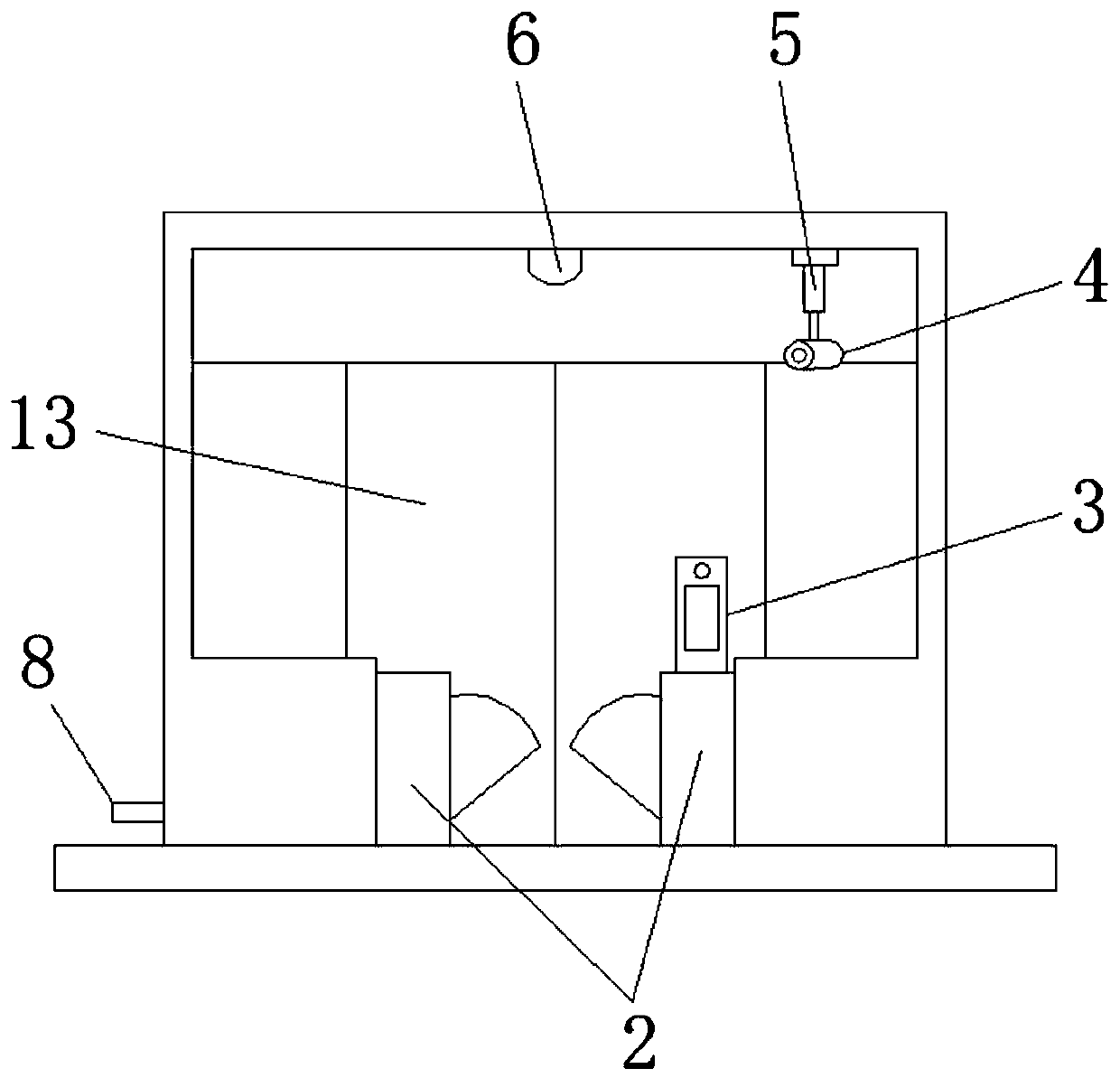

Anti-epidemic disinfection device and use method thereof

PendingCN111249504AGuaranteed distanceAvoid accidental injuryRadiation pyrometryBody temperature measurementHuman bodyInfrared thermometry

The invention provides an anti-epidemic disinfection device and a use method thereof. The device includes a disinfection room for disinfection, a partition plate is arranged at the inner upper end ofthe disinfection room, and an ultrasonic detector for detecting the height of a human body is arranged on the upper surface of the partition plate; first motors are oppositely arranged at the left andright ends of the inner peripheral side wall of the disinfection room, and the first motors are located at the upper end of the inner peripheral side wall of the disinfection room; and a first guidewheel is arranged at the tail end of the output shaft of each first motor, second guide wheels are arranged at the lower ends of the left and right sides of the inner peripheral side wall of the disinfection room, each first guide wheel is connected with one corresponding second guide wheel through one belt, an arc-shaped spray nozzle sleeves the belt located at the left end, a telescopic rod sleeves the belt located at the right end, and the tail end of the telescopic rod is provided with an infrared thermometer for detecting the body temperature of the human body. The device is simple in structure and convenient to operate, can effectively disinfect the whole body of the human body, and is provided with an independent disinfection space, thereby effectively preventing the spread of epidemic.

Owner:福建旭辰信息科技有限公司

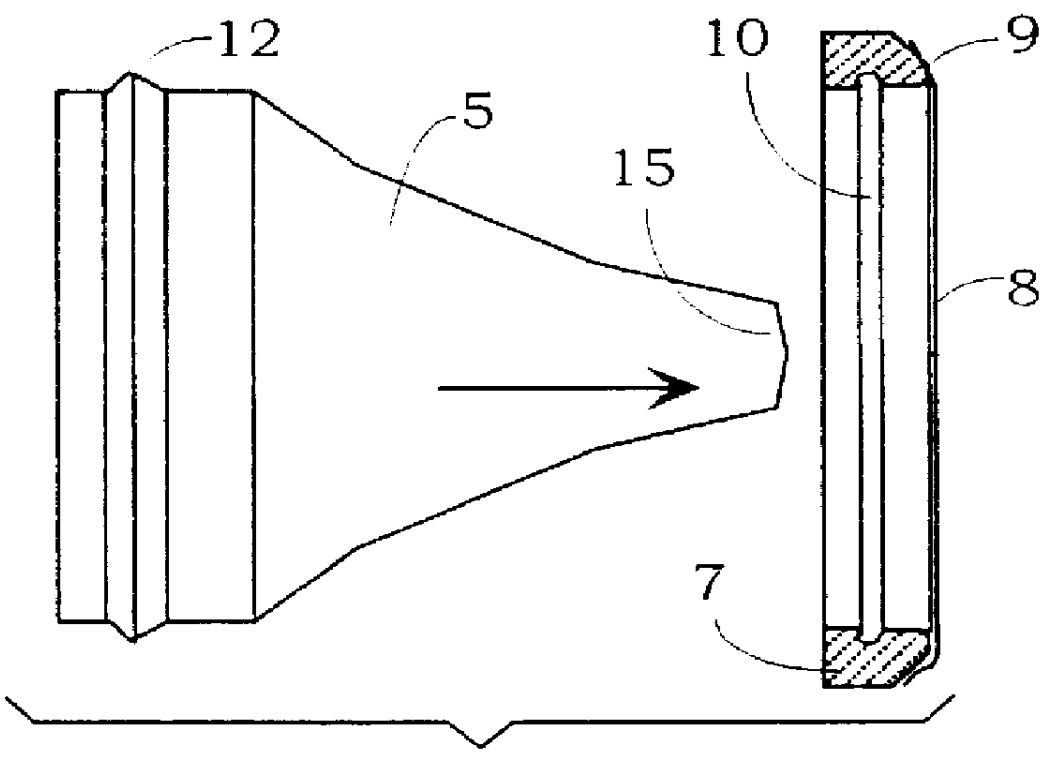

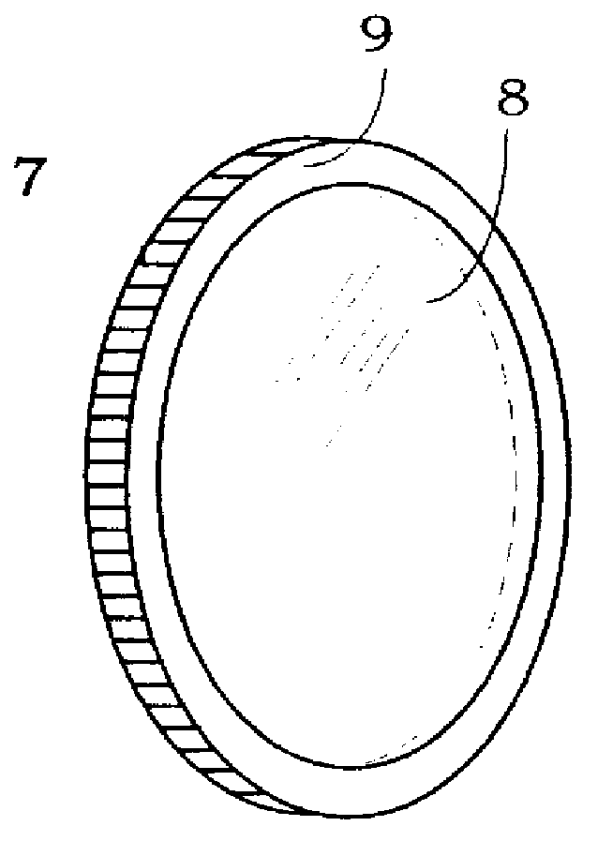

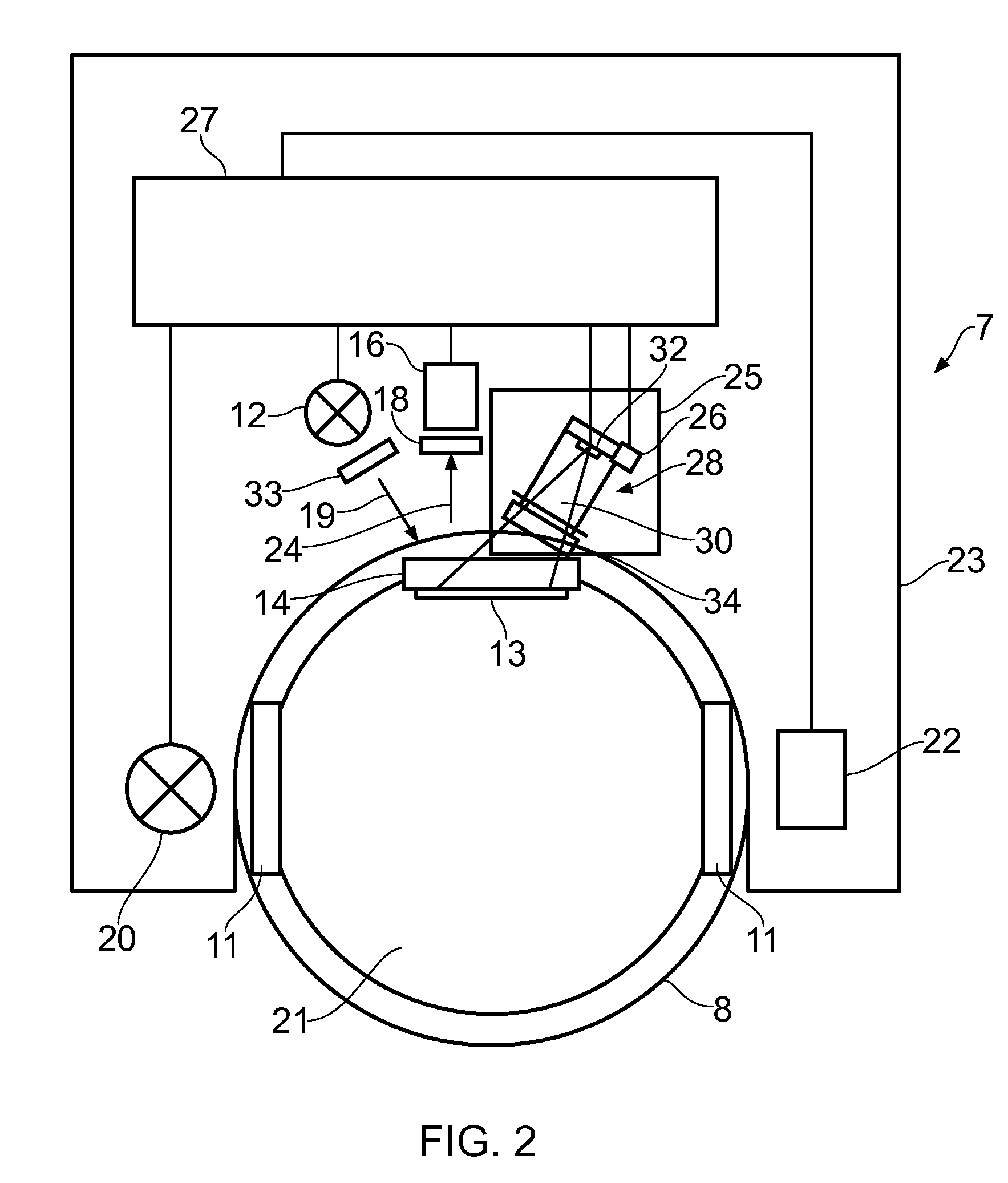

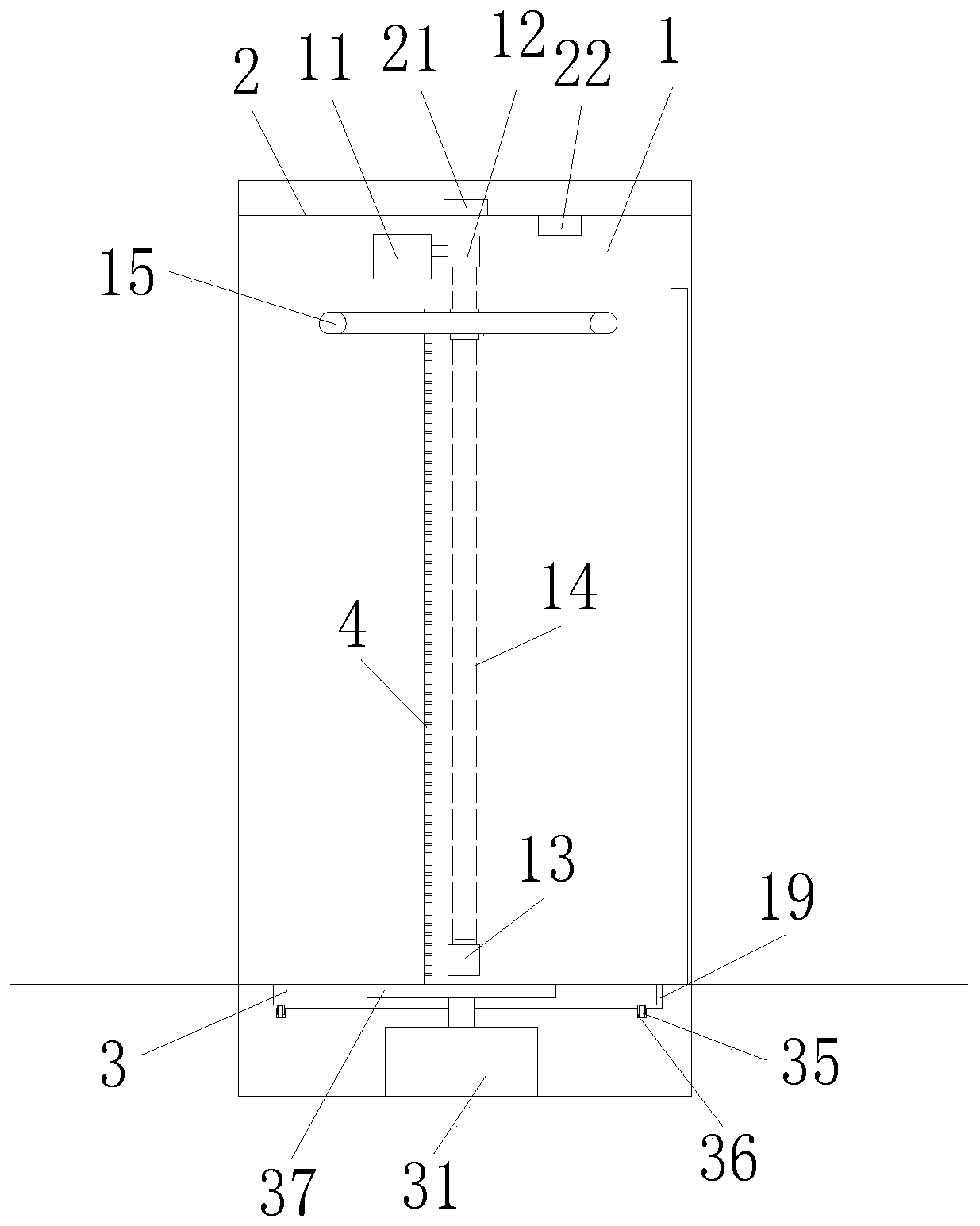

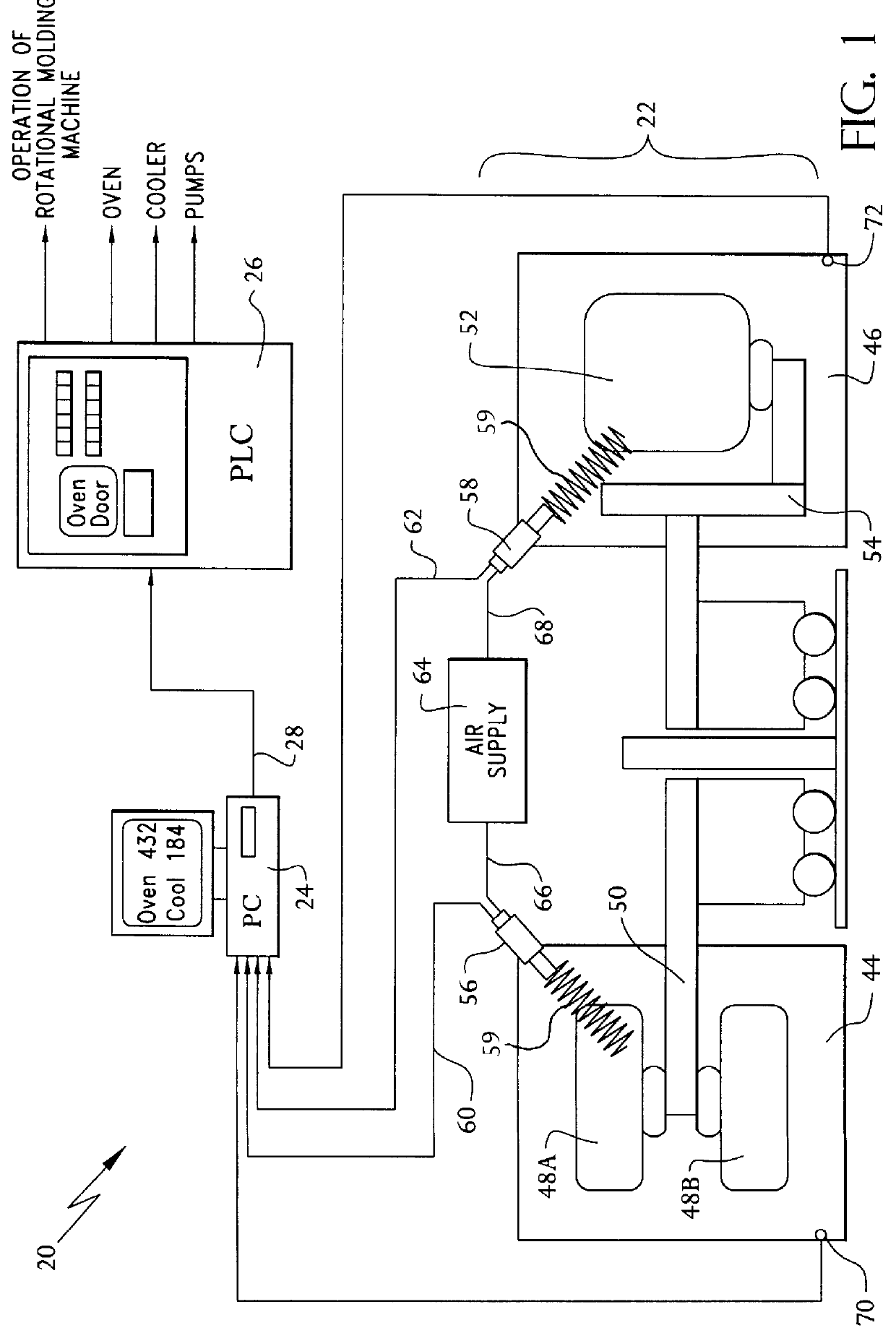

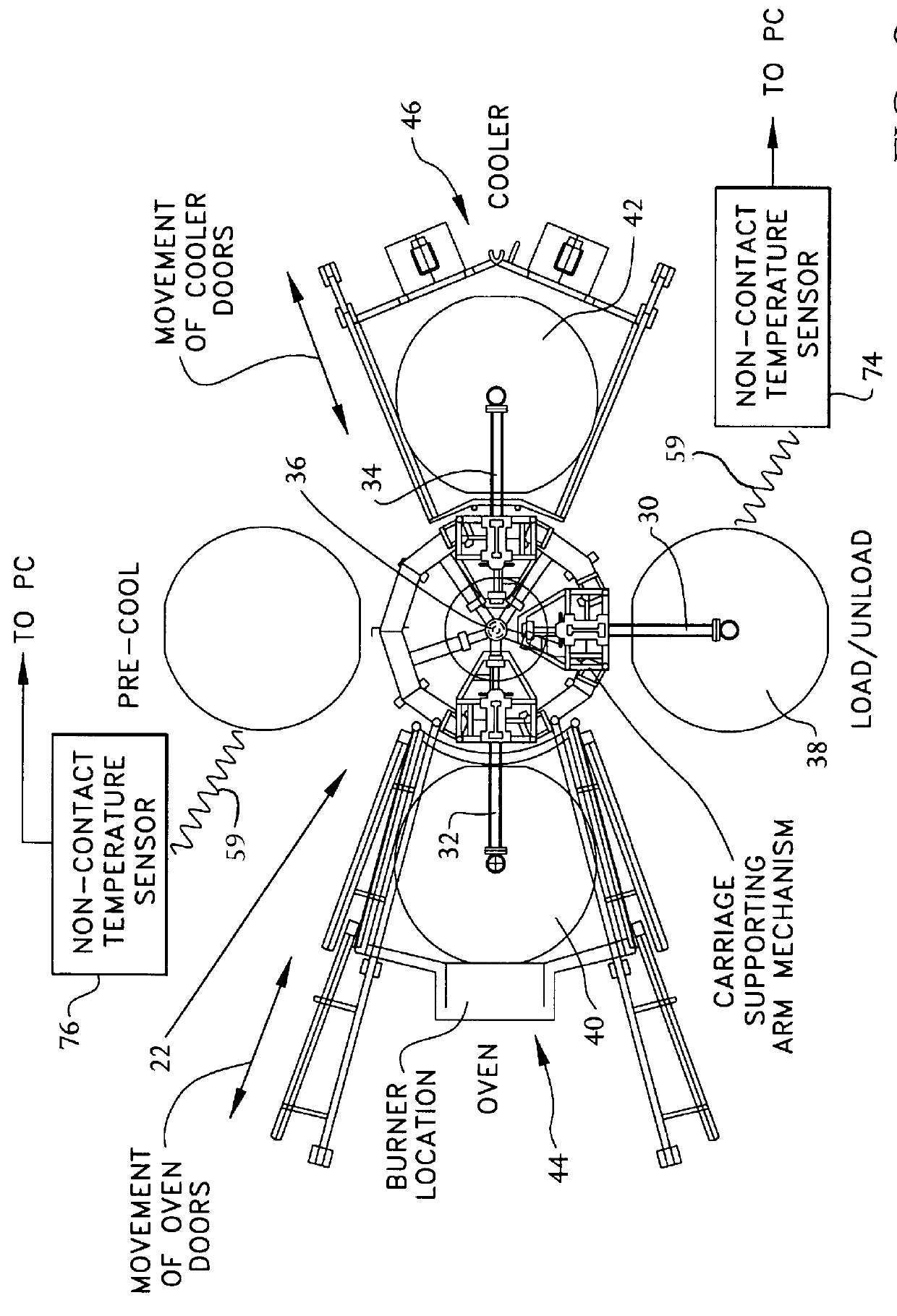

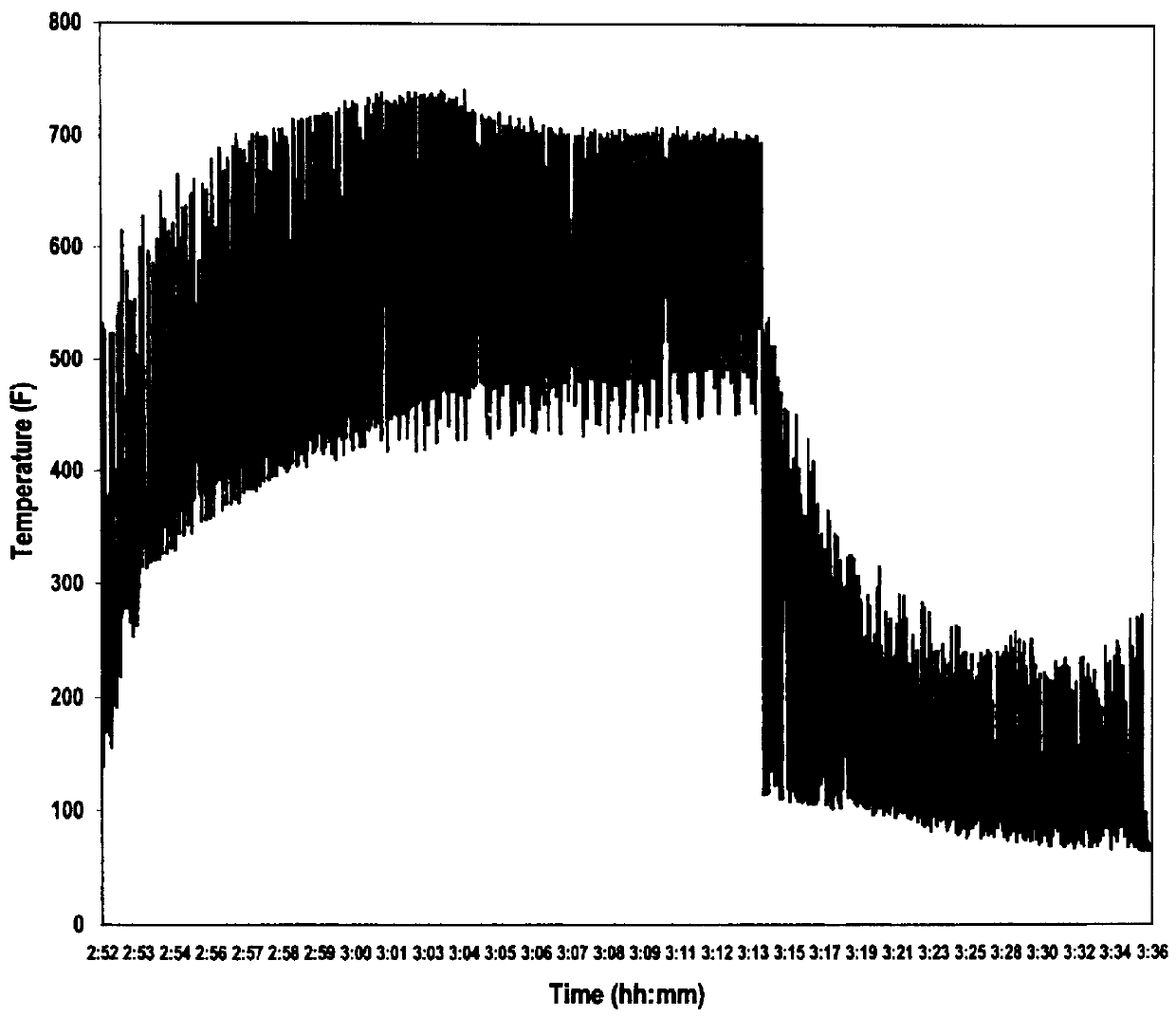

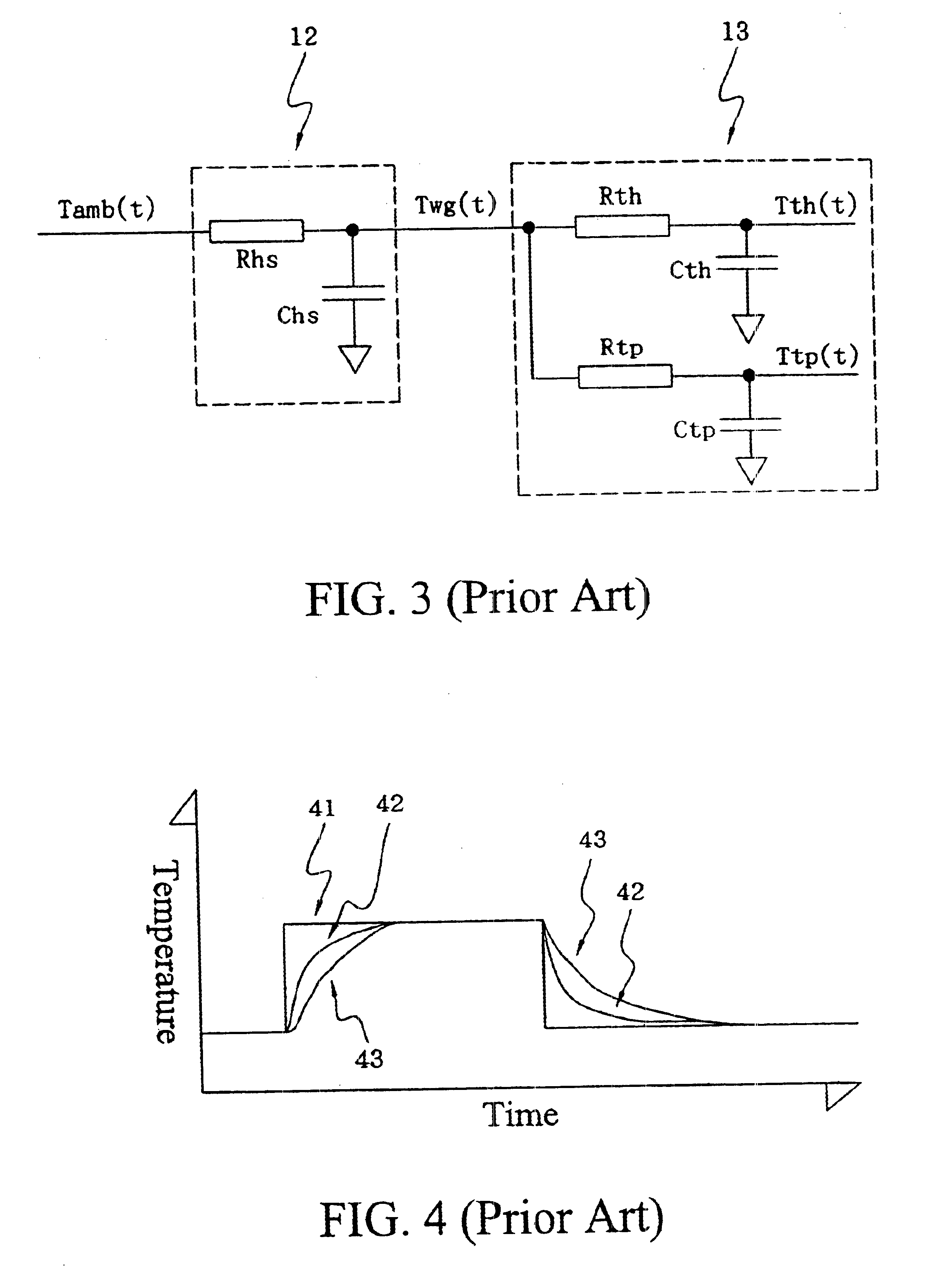

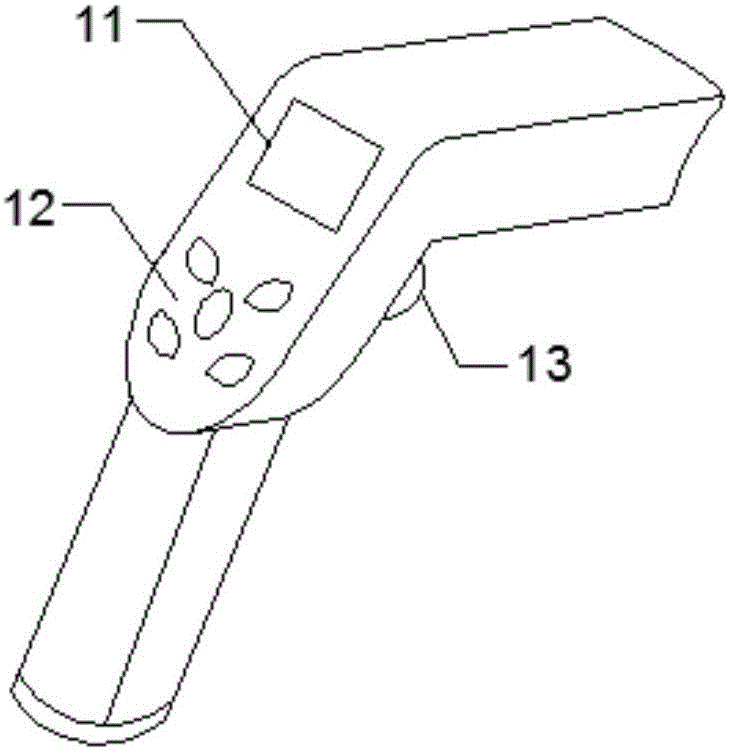

Rotational molding apparatus and method using infrared thermometry

InactiveUS6036897AContinuous measurementConfectionerySweetmeatsInfrared thermometryInfrared temperature measurement

A rotational molding apparatus that utilizes stationary temperature sensors, e.g., infra-red thermometry (IRT) sensors, for continuously monitoring the temperature of the molds during rotation.

Owner:FERRY IND

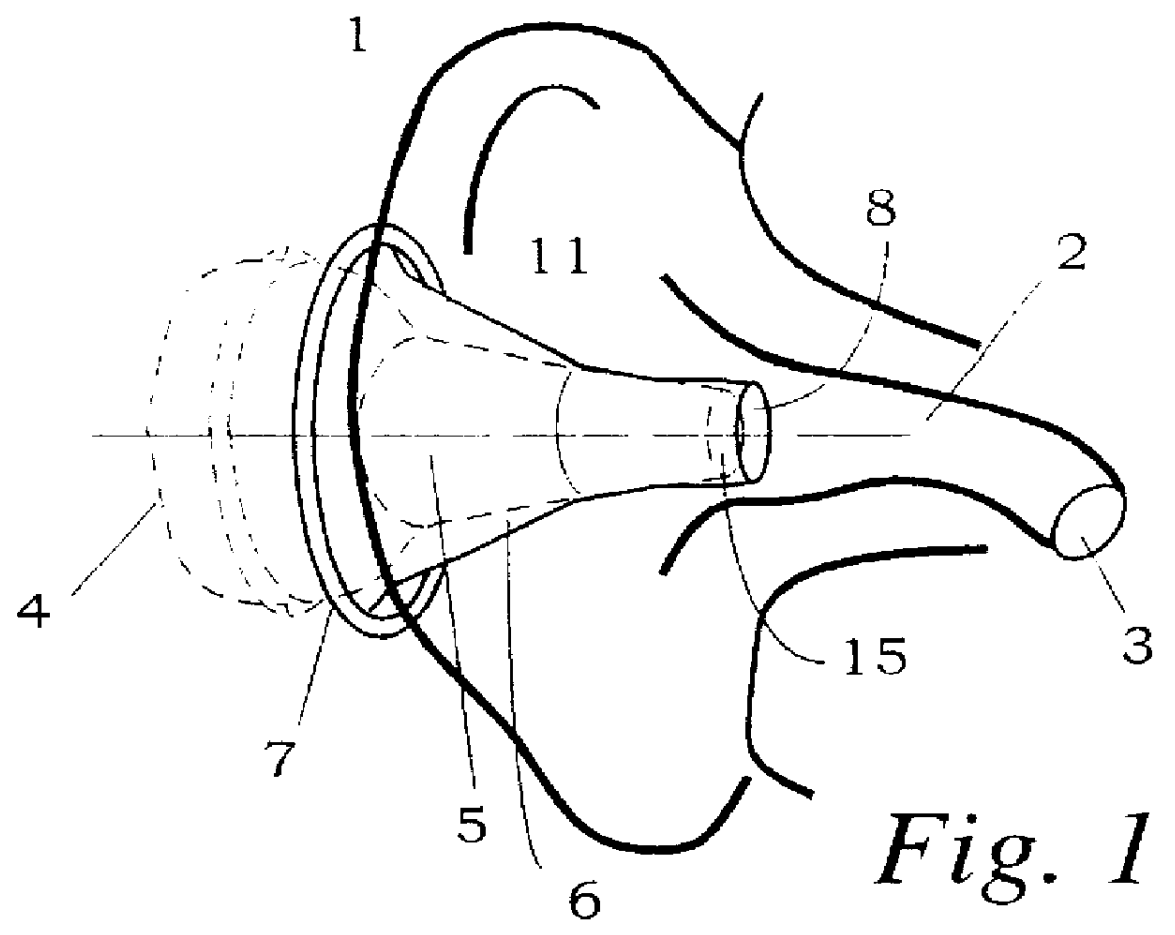

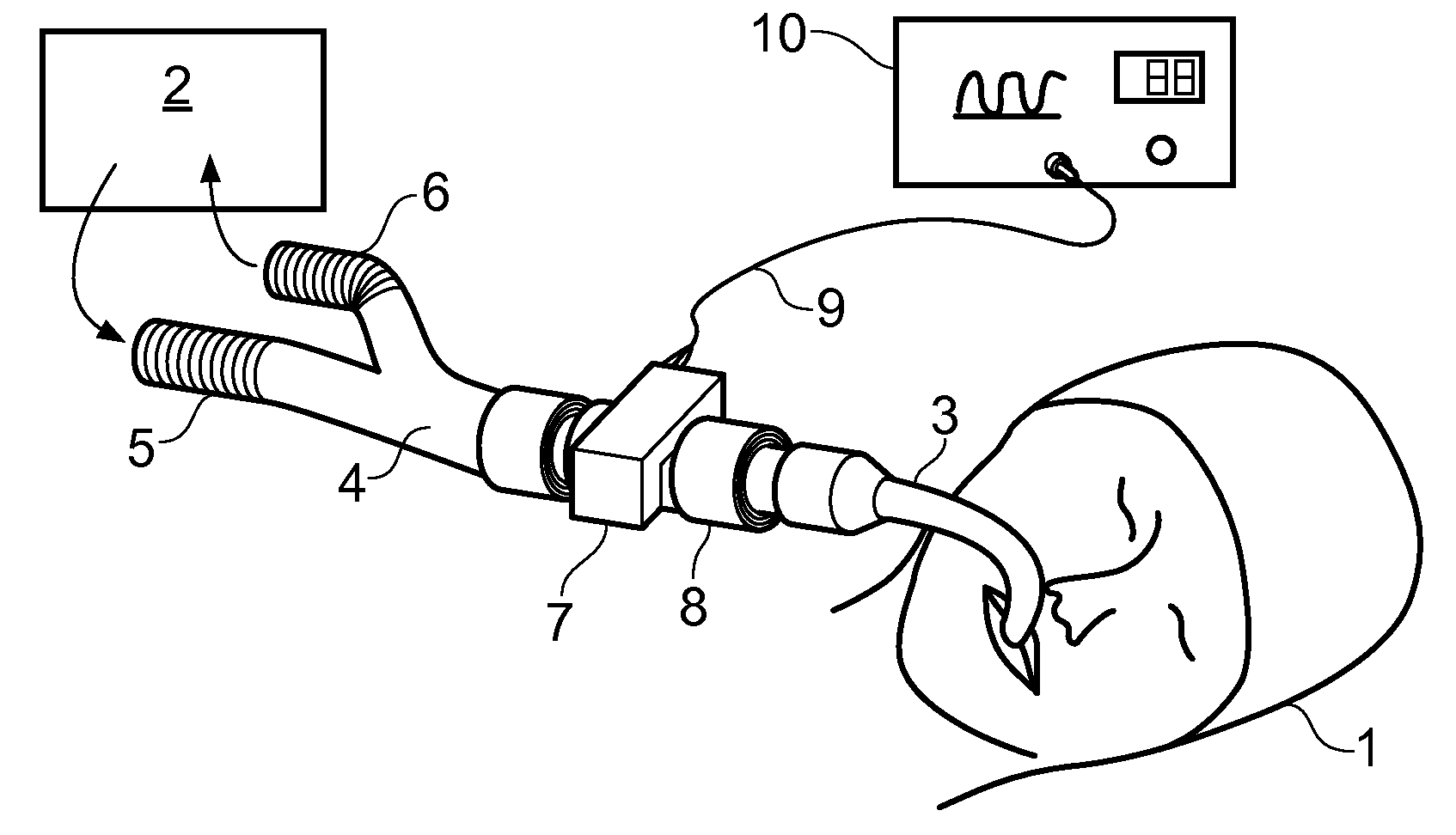

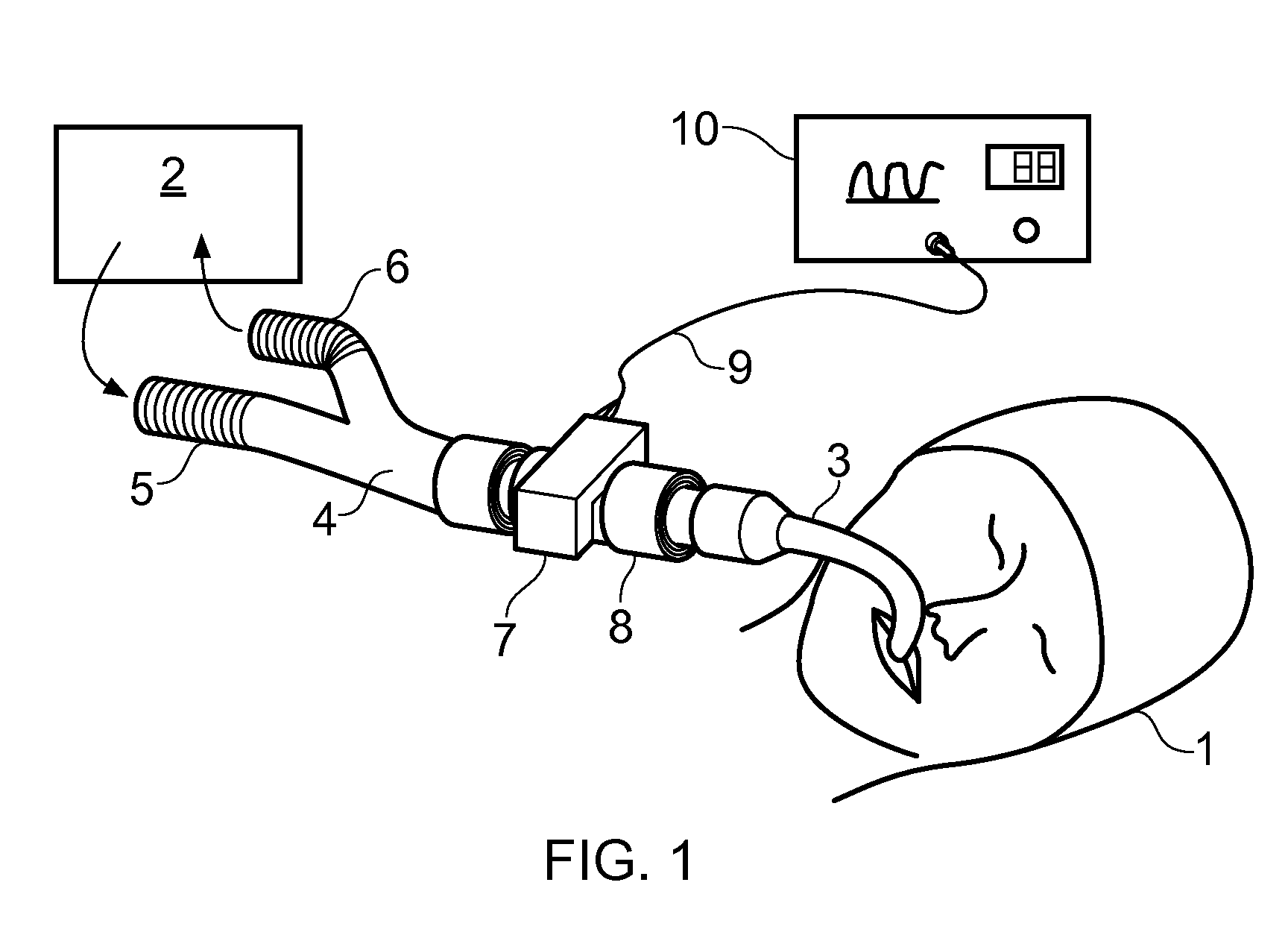

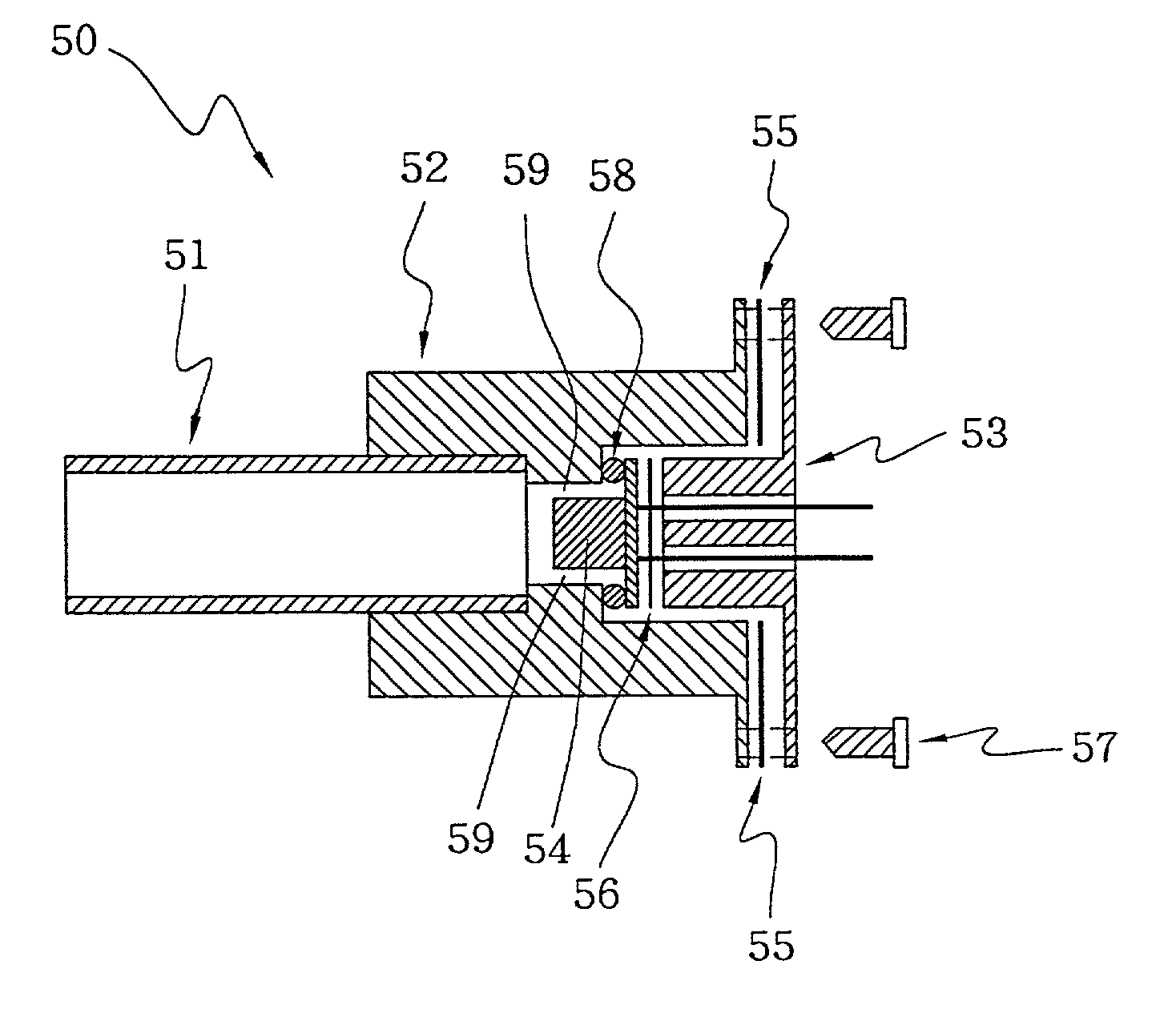

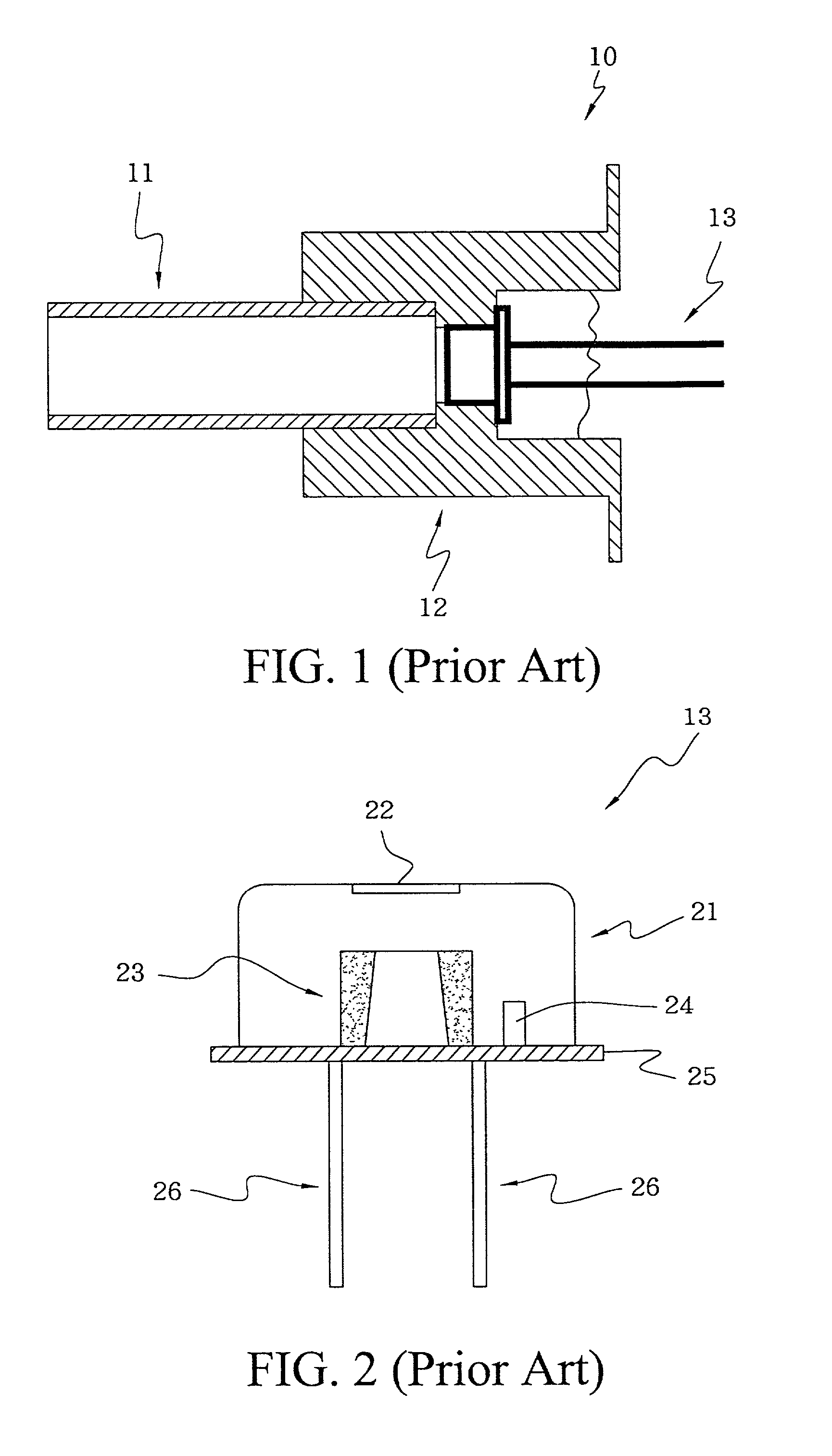

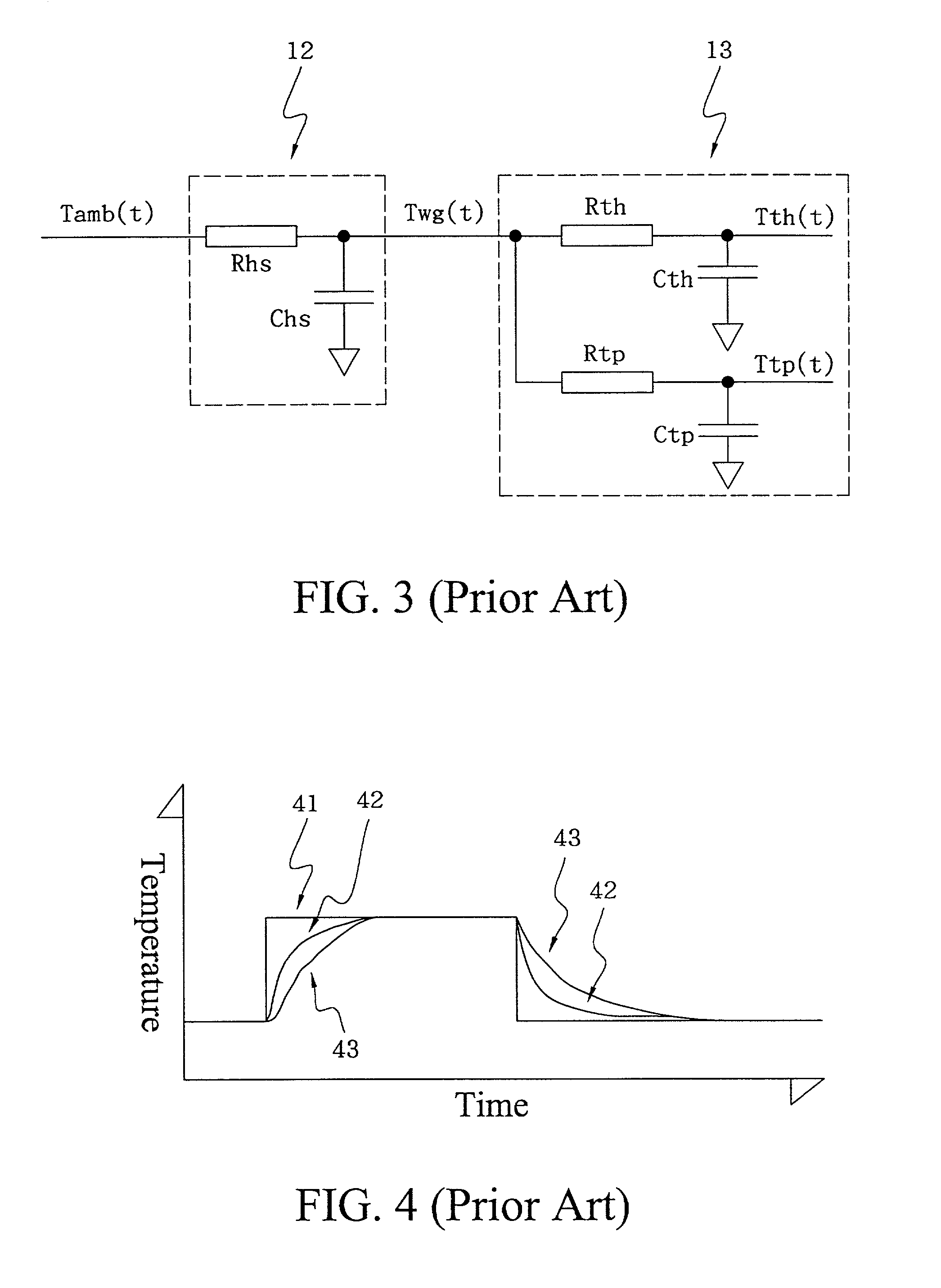

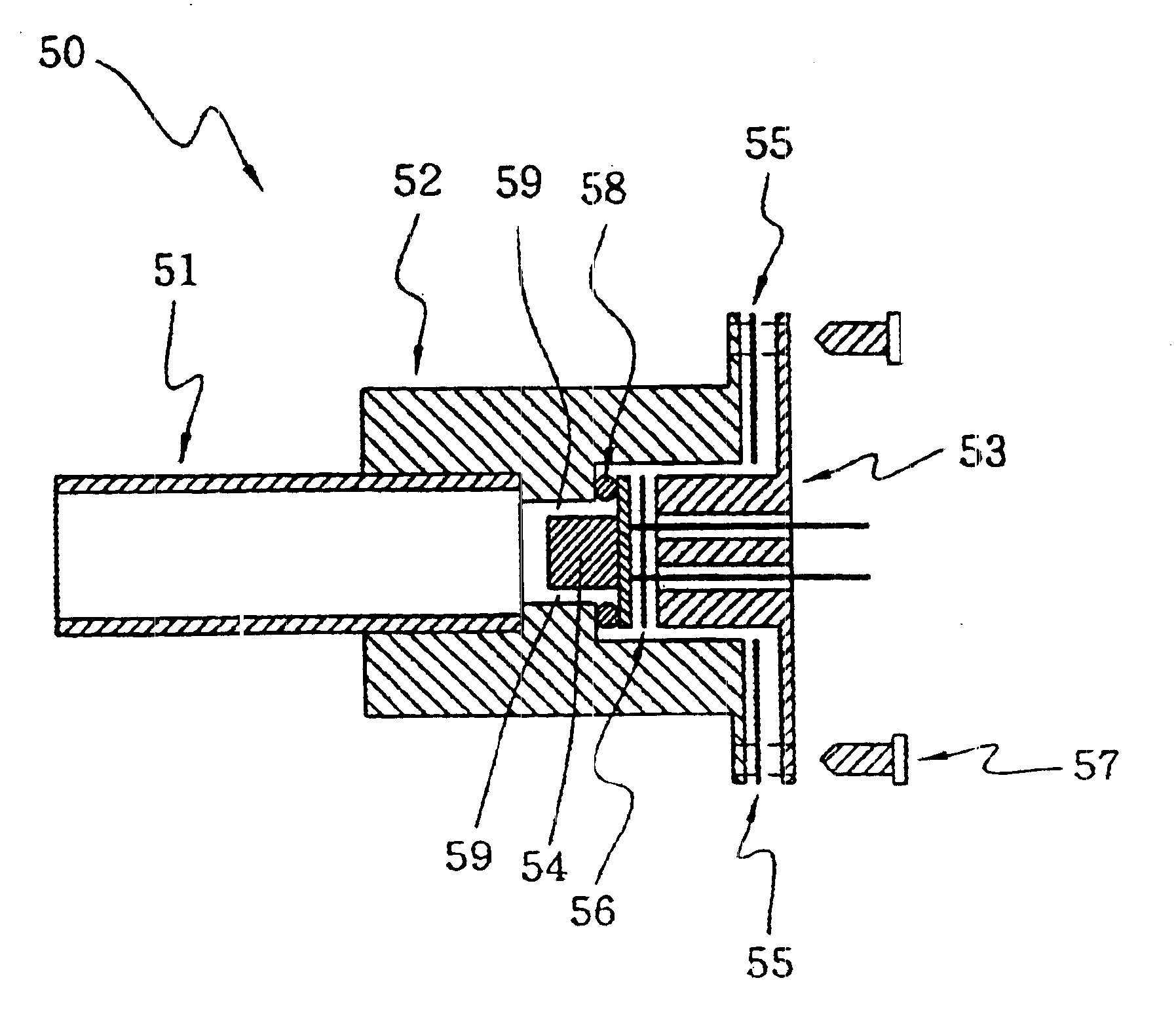

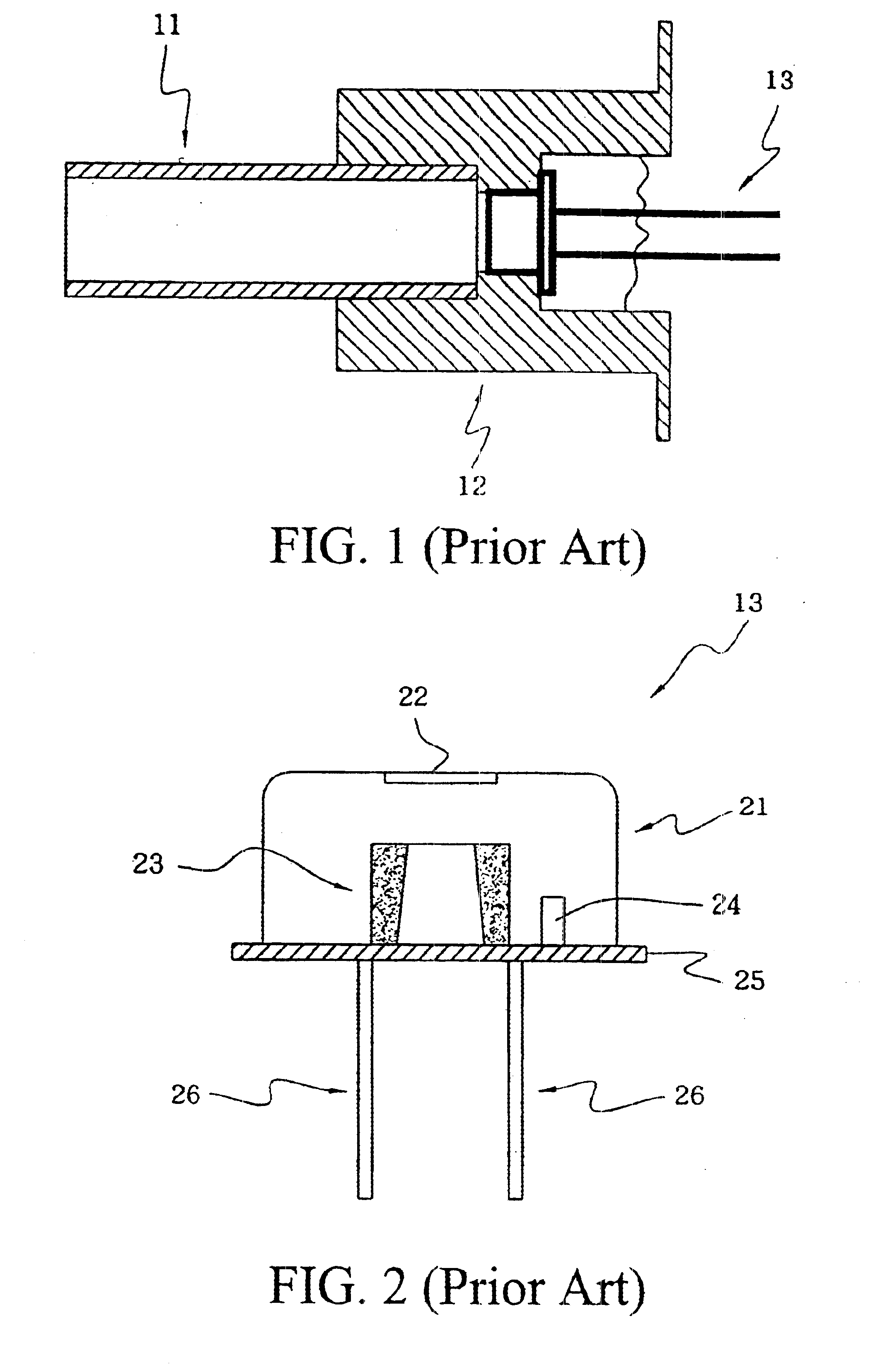

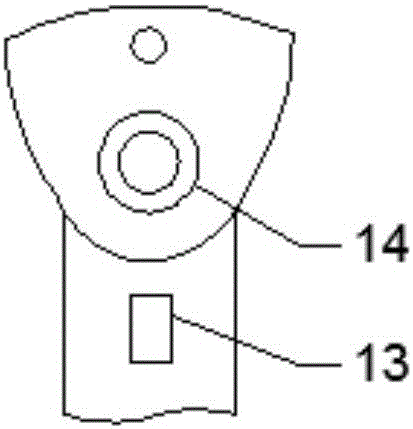

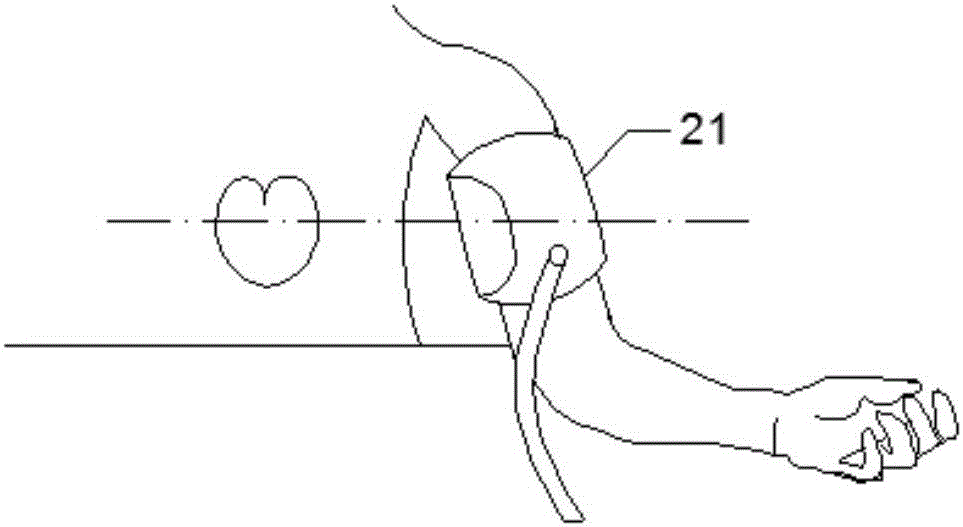

Probe for use in an infrared thermometer

InactiveUS20030016729A1Diagnostic recording/measuringSensorsElectrical resistance and conductanceThermopile

The present invention discloses a probe assembly for used in an infrared ear thermometer. Given that the exchanged thermal radiation and the infrared detector's temperature are known, the subject temperature can be calculated according to Stefan-Boltzman's law. To make the Stefan-Boltzman's law applicable in a dynamic environment where temperature may vary greatly, the contact temperature sensor (thermistor) must acuurately and fast track the temperature of the infrared detector (thermopile sensor). By using the heat transfer theorem, the disclosed assembly makes the thermistor accurately track the cold junction temperature of the thermopile chip without being in an isothermal condition. Not only minimizes the measurement error in a dynamic environment, the design of the disclosed probe assembly also makes a samll and compact infrared thermometer possible.

Owner:ORIENTAL SYST TECH

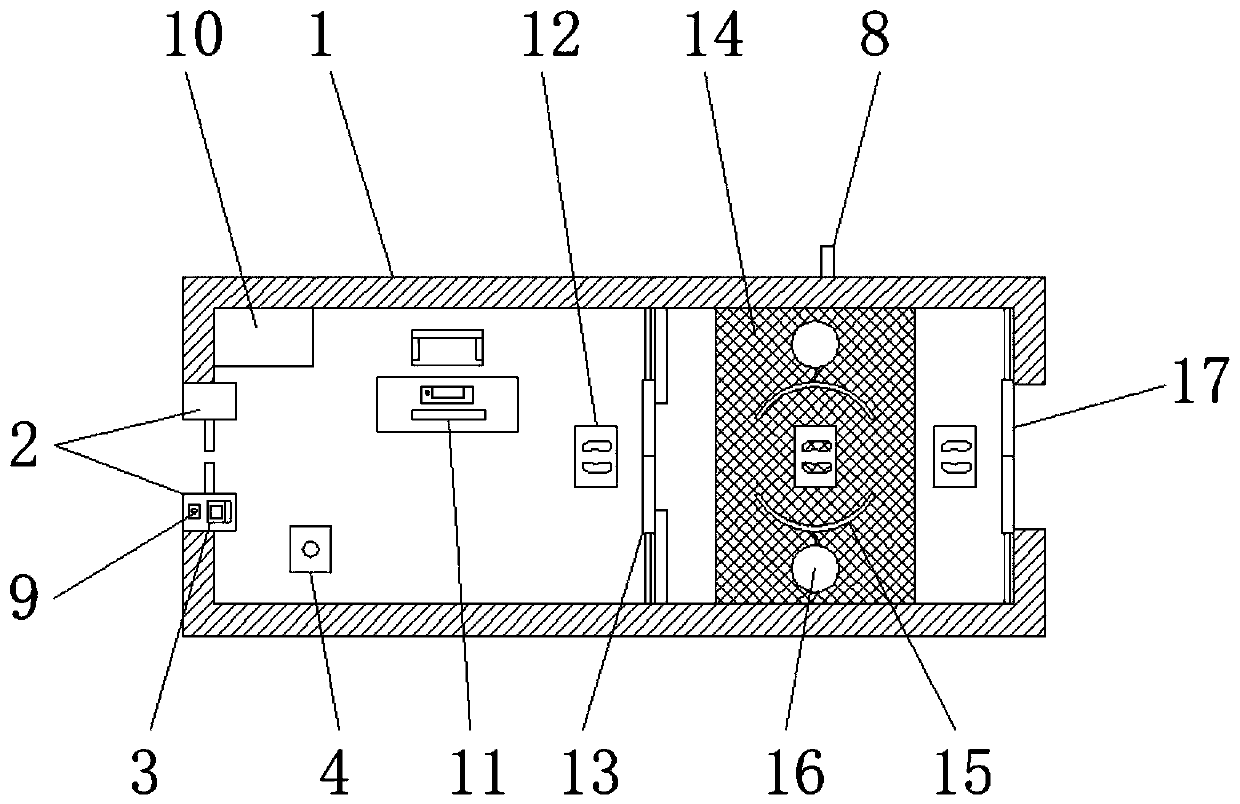

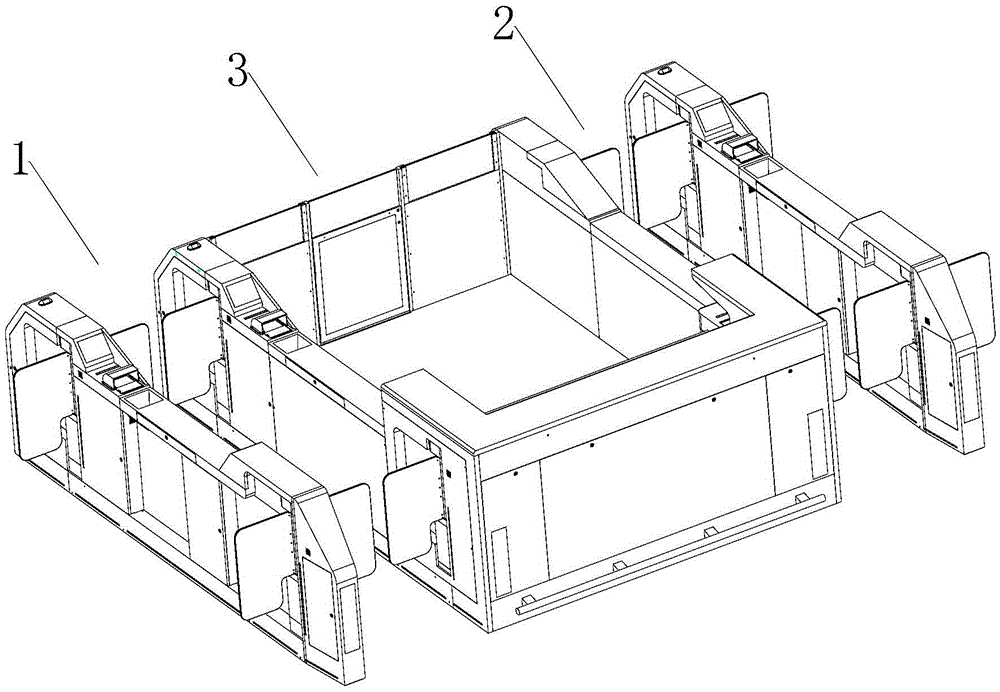

Assembled rapid intelligent temperature measurement and purification monitoring system based on project work resumption and epidemic prevention and control and monitoring method thereof

PendingCN111157122AEasy to use and efficientEasy to collectBody temperature measurementCharacter and pattern recognitionMedicineInfrared thermometry

The invention discloses an assembled rapid intelligent temperature measurement and purification monitoring system based on project work resumption and epidemic prevention and control and a monitoringmethod thereof, and belongs to the field of epidemic prevention and control. The monitoring system comprises an equipment body, wherein an inlet of the equipment body is provided with a recognition gate and a face recognition panel, and the recognition gate is provided with a recognition area; a temperature measurement area and a disinfection area are sequentially arranged in the equipment body, an infrared thermometer is arranged in the temperature measurement area, a first sealing door and a second sealing door are respectively arranged at an inlet and an outlet of the disinfection area, pedal switches are respectively arranged in front of the first sealing door and the second sealing door, and a spray disinfection unit is arranged in the disinfection area. The system overcomes the defects of low epidemic situation detection efficiency and easy infection in the prior art, not only can improve the detection efficiency, but also is conducive to avoiding cross infection, and can be better suitable for large-scale and severe epidemic situation prevention and control environments.

Owner:CHINA MCC17 GRP

Probe for use in an infrared thermometer

The present invention discloses a probe assembly for used in an infrared ear thermometer. Given that the exchanged thermal radiation and the infrared detector's temperature are known, the subject temperature can be calculated according to Stefan-Boltzman's law. To make the Stefan-Boltzman's law applicable in a dynamic environment where temperature may vary greatly, the contact temperature sensor (thermistor) must acuurately and fast track the temperature of the infrared detector (thermopile sensor). By using the heat transfer theorem, the disclosed assembly makes the thermistor accurately track the cold junction temperature of the thermopile chip without being in an isothermal condition. Not only minimizes the measurement error in a dynamic environment, the design of the disclosed probe assembly also makes a samll and compact infrared thermometer possible.

Owner:ORIENTAL SYST TECH

Mobile health data collection and integrated management system employing internet + and application method thereof

InactiveCN106845146AEasy to analyzeEasy to moveHealth-index calculationMedical automated diagnosisTablet computerThe Internet

The invention discloses a mobile health data collection and integrated management system employing the internet + and an application method thereof. The mobile health data collection and integrated management system comprises an ID card reader, a tablet computer, an oximeter, an infrared thermometer, electrocardiogram equipment, a urine analyzer, a multifunctional glucometer, a sphygmomanometer and a portable printer; a mobile health data collection and integrated management system APP is arranged in the tablet computer and comprises health follow-up project question and answer to automatically draw a conclusion; the ID card reader, the oximeter, the tablet computer, the infrared thermometer, the electrocardiogram equipment, the urine analyzer, the multifunctional glucometer, the sphygmomanometer and the portable printer are connected with a wireless bluetooth of the tablet computer separately. According to the mobile health data collection and integrated management system employing the internet +, various small portable instruments are matched with a wireless bluetooth technology and connected with the tablet computer, comprehensive data collection can be carried out on the physical condition of a testee, and analyzing, tracking and recording of comprehensive situations of chronic diseases are facilitated.

Owner:TAHOCO ELECTRONICS TECH FUJIAN

Electroplating production line system with rapid pre-cleaning and drying functions

InactiveCN111424304AScientific and reasonable structureEasy to useCellsTanksProduction lineInfrared thermometry

The invention discloses an electroplating production line system with rapid pre-cleaning and drying functions. The electroplating production line system with the rapid pre-cleaning and drying functions comprises a pre-cleaning and drying device and an electroplating device, wherein a workpiece cleaned and dried by the pre-cleaning and drying device is hung on a hook of the electroplating device byan operator to be subjected to electroplating. The pre-cleaning and drying device comprises a cleaning tank filled with cleaning liquid, one side wall of the cleaning tank communicates with a hot airpipe, and an infrared thermometer is inlaid and fixed to the other opposite side wall of the cleaning tank. The pre-cleaning and drying device also comprises a support fixedly connected to the ground, the side wall of the support is fixedly connected with a pneumatic cylinder, an output rod of the pneumatic cylinder is fixedly connected with a shell of a high-level electric telescopic rod, the output rod of the high-level electric telescopic rod is fixedly connected with the upper end of a cleaning motor, the two sides of an output shaft of the cleaning motor are fixedly connected with mounting plates through connecting rods, a threaded rod is screwed through each mounting plate, the outer end of each threaded rod is fixedly connected with a convex edge, and a clamping plate is fixedly connected to the inner end of each threaded rod.

Owner:刘理仁

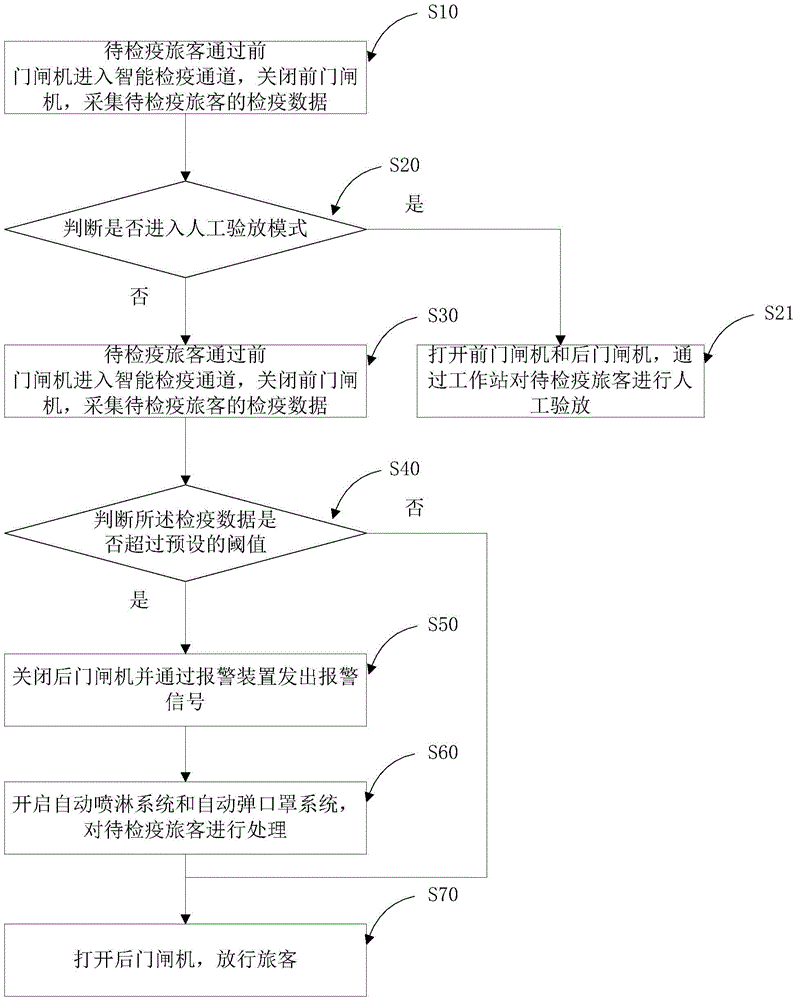

Intelligent quarantine inspection platform and quarantine method

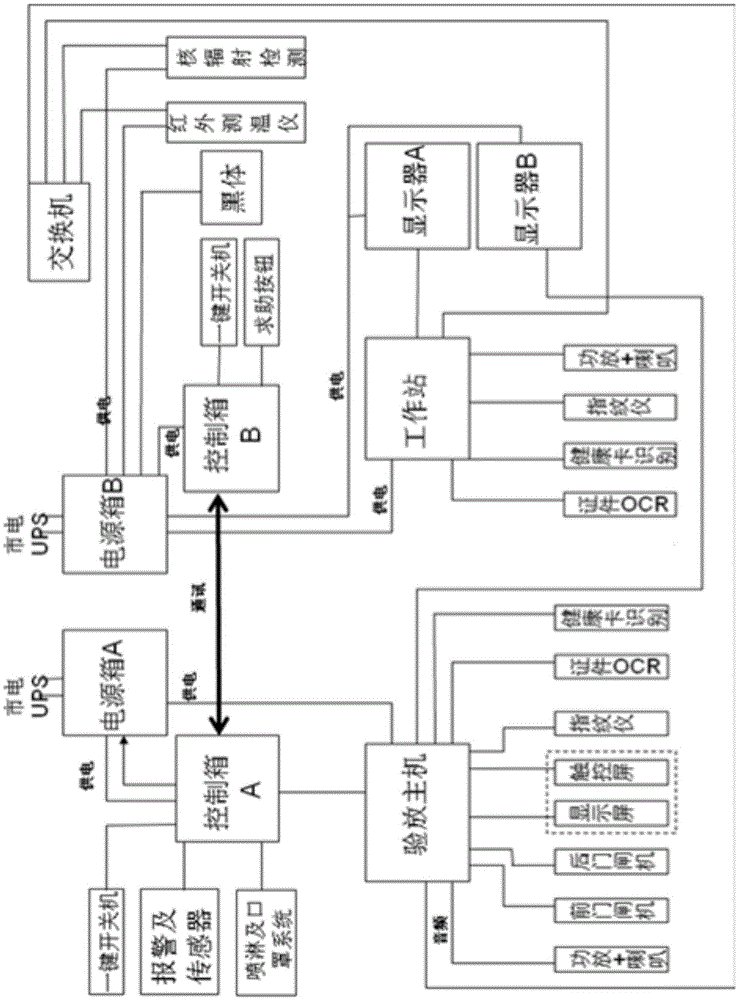

ActiveCN105527870AImprove inspection and release speedReduce exposureDiagnostic recording/measuringSensorsInfrared thermometryRespirator

The invention relates to the technical field of quarantine and especially relates to an intelligent quarantine inspection platform and a quarantine method. The intelligent quarantine inspection platform comprises a switch, a checking and releasing host computer, a control cabinet A, a control cabinet B, a spray and mouth mask system, and a work station. The switch is connected to the checking and releasing host computer and the work station. The switch is also connected to an infrared thermometer and transmits data acquired by the infrared thermometer to the checking and releasing host computer and the work station. The control cabinet A is connected to the checking and releasing host computer, and the spray and mouth mask system. The spray and mouth mask system comprises an automatic spraying system and an automatic mouth mask ejecting system. By use of the device and the method provided by the invention, an intelligent switch of self quarantine and manual quarantine is realized, the checking and releasing rate of quarantine passages is increased, the detection accuracy is guaranteed, contacts between work staff and passengers are reduced, and safety is increased.

Owner:SHENZHEN MAXVISION TECH

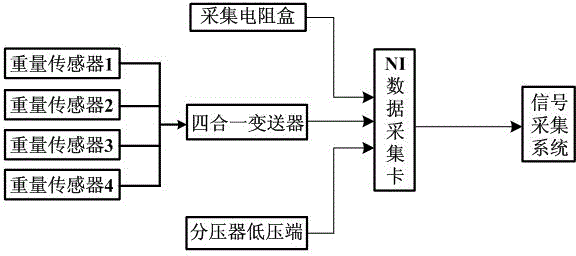

Gap discharge characteristic test platform influenced by multiple factors under simulated mountain fire condition

The invention discloses a gap discharge characteristic test platform influenced by multiple factors under the simulated mountain fire condition. The test platform is used for simulating the practical environment of a transmission line corridor so as to obtain the breakdown characteristics of a gap under different combustion conditions, and quantitative research is further carried out on a tripping mechanism of a power transmission line under the mountain fire condition. The test platform comprises a test power source, a water resistor, a voltage divider and a sealed laboratory. A first electrode, a second electrode, a heat insulation plate, a resistor box, a weight sensor, a DV camera, a high-speed camera, an infrared thermometer, a fan, a particular generator and a signal collecting system are arranged in the sealed laboratory. By means of the gap discharge characteristic test platform influenced by the multiple factors under the simulated mountain fire condition, contrast tests of the gap under different combustion conditions can be carried out conveniently, the problem that the test factors of an existing test platform are single is solved well, and the quantitative research of the breakdown characteristics of the gap under the mountain fire condition is possible. The test platform is easy to operate, high in adaptability and capable of meeting the design requirement.

Owner:WUHAN UNIV

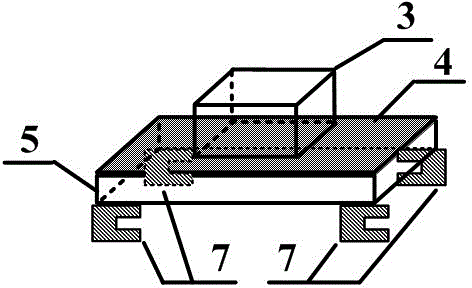

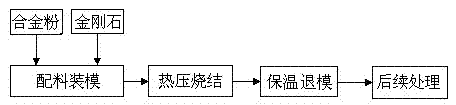

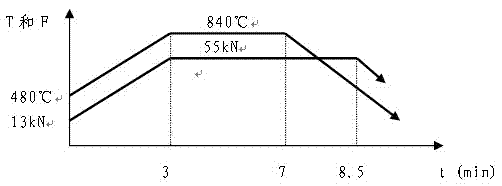

Preparation method of diamond bits and sintering device thereof

InactiveCN103084574AMeet the process requirementsIncrease productivityDrill bitsNumerical controlOperating frequency

The invention discloses a preparation method and a sintering device of diamond bits. The preparation method comprises batching and filling die, hot pressed sintering, heat preservation and receding die, and sequential processing procedures, wherein the hot pressed sintering procedure uses changeable medium frequency sintering, two-way vibration pressure and two-track temperature and pressure curve control. The sintering device is composed of a hot press, a medium frequency power supply and a control system, the control system detects sintering temperature in real time through an infrared thermometer, and adjusts electric current and working efficiency of the medium frequency power supply through a controller, and meanwhile detects hydro-cylinder pressure in real time through a pressure sensor, and the control system is made to operate according to setting temperature and pressure curve of the system. The preparation method and the sintering device of the diamond bits has the advantages of being simple in process, high in degree of automation by using full numerical control, small in graphite dies for sintering, and energy-saving and cost-reducing. By using the preparation method and the sintering device of the diamond bits to manufacture impregnated diamond bits, average manufacturing time of bits is shortened by 40%, power consumption is reduced by 36%, and service life is prolonged by more than 40%.

Owner:HUBEI CHANGJIANG JINGGONG MATERIALS TECH

Piezoelectric driving type low-temperature in-situ high-frequency reciprocating fretting friction and wear test platform

PendingCN109060575APrecise and stable transmissionReasonable structure layoutInvestigating abrasion/wear resistanceFrettingX-ray

The invention relates to a piezoelectric driving type low-temperature in-situ high-frequency reciprocating fretting friction and wear test platform and belongs to the field of precision in-situ testing. A test pressure loading unit is powered by a precision servo motor. A two-stage worm gear reduction mechanism is cooperated with a screw nut pair so as to perform precise pressure loading. A high-frequency reciprocating unit is arranged on the lower side, an advanced piezoelectric ceramic drive technology is adopted, and an independently designed flexible hinge is cooperated to output high-frequency fretting displacement; a low-temperature precision clamping unit is accurately clamped by upper and lower fixtures and is low-temperature loaded by a liquid nitrogen pipe in the lower fixture; adata acquisition unit comprises a tension sensor, a pressure sensor, and a dual-colorimetric infrared thermometer. The piezoelectric driving type low-temperature in-situ high-frequency reciprocatingfretting friction and wear test platform in the invention has the advantages of reliable principle, compact size, compact structure and high frequency, and has good compatibility with a microscopic imaging system with an open space structure such as a mainstream optical microscope, a Raman spectrometer and an X-ray diffractometer.

Owner:JILIN UNIV

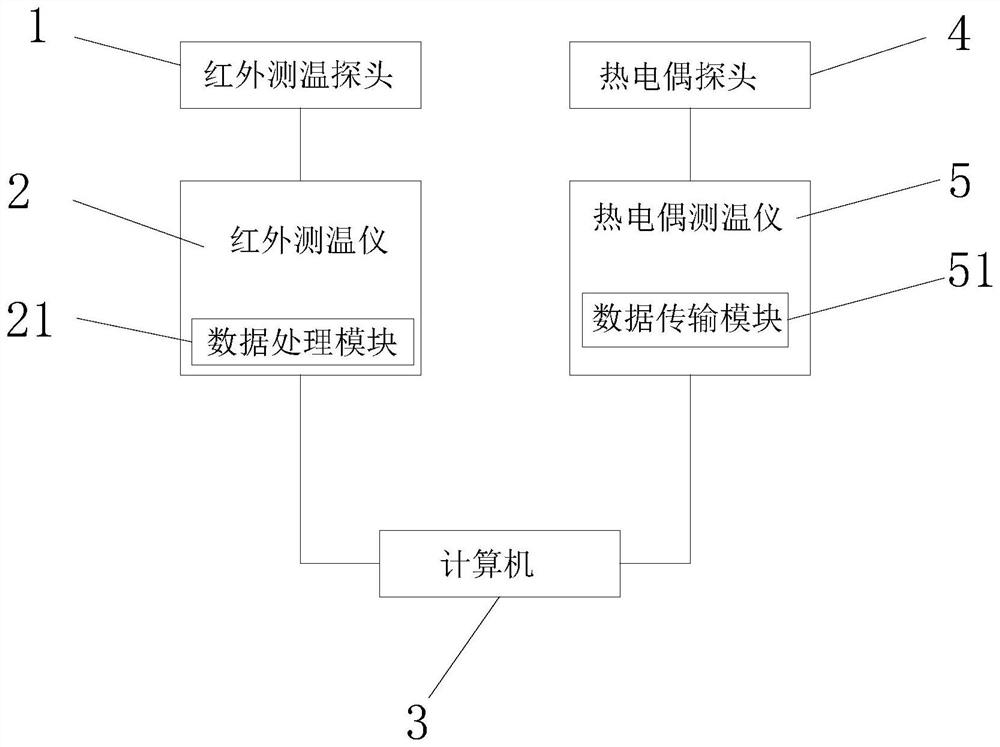

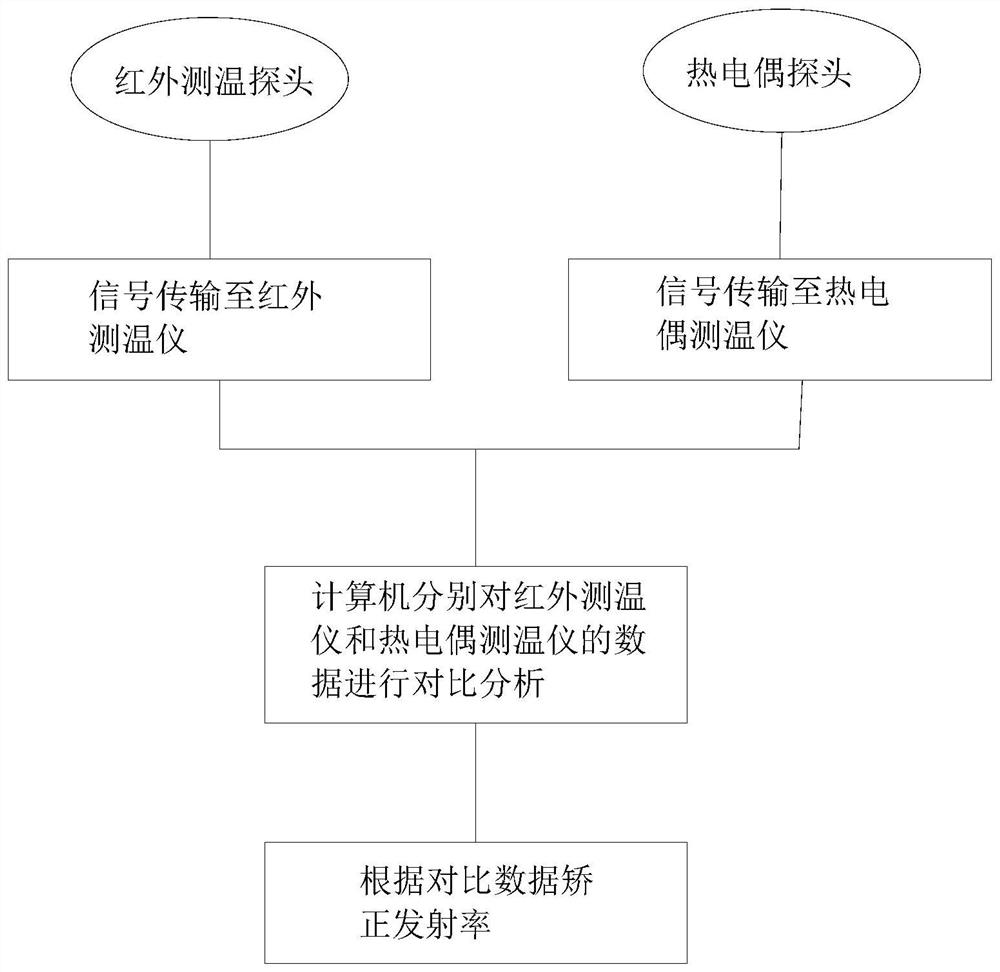

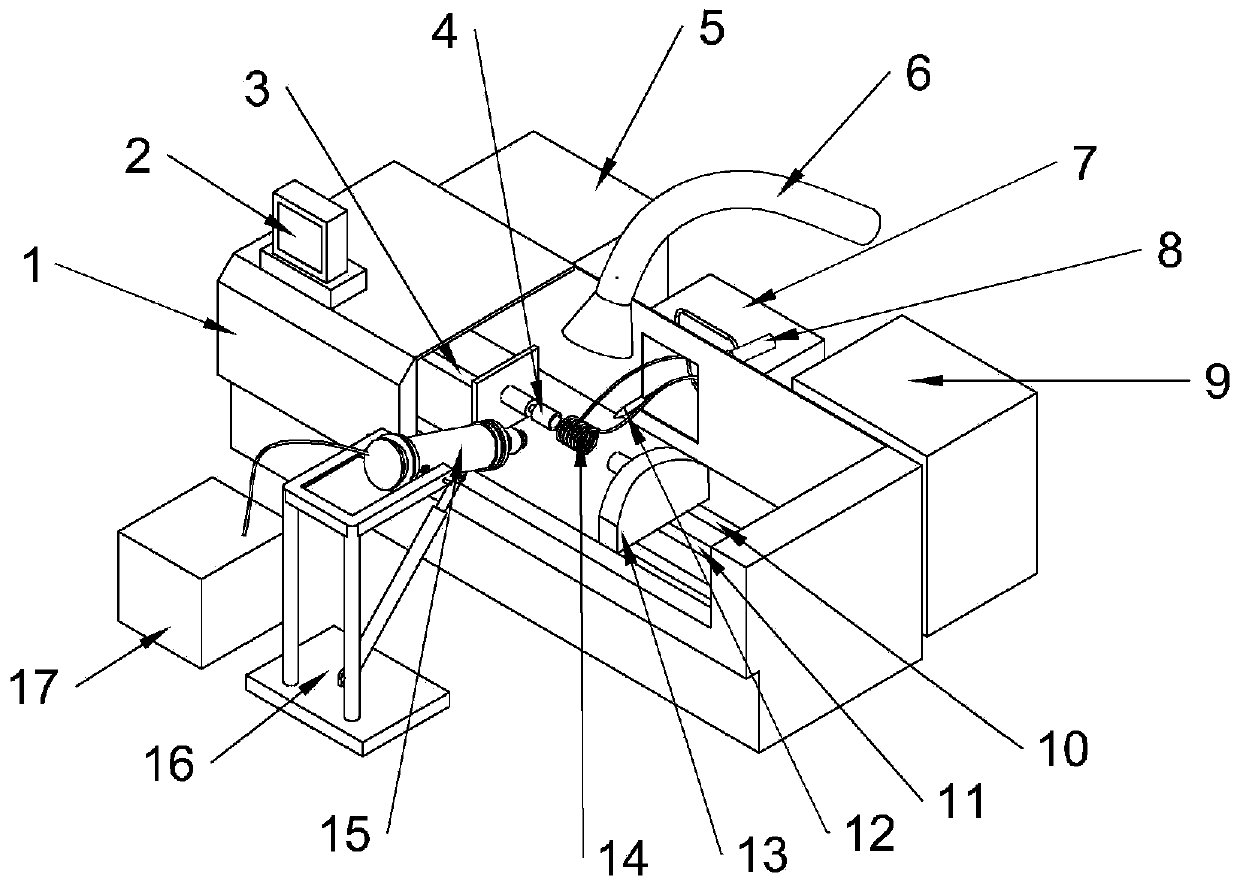

Emissivity calibration method for infrared temperature measurement system

InactiveCN111912526AAccurate measurementHigh precisionRadiation pyrometryEmissivityInfrared thermometry

The invention discloses an emissivity calibration method for an infrared temperature measurement system, and belongs to the technical field of infrared temperature measurement. According to the present invention, a computer is included, a thermocouple thermodetector is arranged at the input end of the computer, the thermocouple thermodetector comprises a data transmission module, and the input endof the computer is connected with the data transmission module through a wire. By arranging the thermocouple thermometer, the temperature of an object to be measured is accurately measured, the measurement precision is ensured, the measurement range is enlarged, and the use convenience is ensured; the data of the thermocouple thermometer can be compared with the temperature data of the infrared thermometer, so that the emissivity adjustment precision of the infrared thermometer is improved, and the temperature measurement reliability is improved; the calibration convenience is guaranteed, work efficiency is improved, use quality is guaranteed, accuracy and reliability of measurement results are guaranteed, synchronous correction can be conducted in the continuous work process, and measurement errors are prevented.

Owner:广东红鼎技术股份有限公司

Device for high-frequency induction cladding with assistance with ultrasonic vibration and working method for device

PendingCN109811339AReduced crack susceptibilityImprove densification performanceMetallic material coating processesIncreasing energy efficiencyEngineeringUltrasonic generator

The invention relates to a device for high-frequency induction cladding with assistance with ultrasonic vibration and a working method for the device and particularly aims at surface treatment and reinforcement of a workpiece. The device comprises a horizontal machine tool, a PLC, a slide carriage tank, a triangular chuck, a power supply controller, a smoke removal system, an induction power supply, an infrared thermometer, an industrial water cooling circulation system, a guide rail, a ball screw, a nozzle, an ejector pin, an induction coil, an amplitude-change pole, a bracket and an ultrasonic generator. In the process of starting the induction coil for heating, and the PLC is used for controlling a motor to enable the workpiece to rotate at a certain speed (a specific speed value is obtained according to the fluidity of a molten pool in a state with assistance of ultrasonic vibration and the diameter of the workpiece), and unevenness in thickness of upper and lower cladding layers of the workpiece caused by the fact that the molten metal flows downwards due to gravity in the cladding process can be avoided. A gas protection device needs to be started before induction heating, sothat the workpiece is in an argon environment before being heated, injection of argon is stopped after the workpiece is thoroughly cooled, and the cladding layers and cladding layer influence regionscan be well prevented from being oxidized. By adding ultrasonic assistance equipment in the high-frequency induction cladding process, the quality of a bonding layer is improved to the maximum, generation of bubbles and cracks is reduced, the residual stress is eliminated, the comprehensive properties of the cladding layers are improved, the service life of the workpiece is prolonged, the production efficiency is improved, and the cost is lowered.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com