Method fur forming aluminum base composite material thin wall part by current self-resistance heating

An aluminum-based composite material, heat forming technology, applied in the field of thermal processing, can solve the problems of waste of energy, poor forming quality of thin-walled parts, low heat utilization rate, etc., to improve energy utilization rate, facilitate plastic deformation, and temperature distribution uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

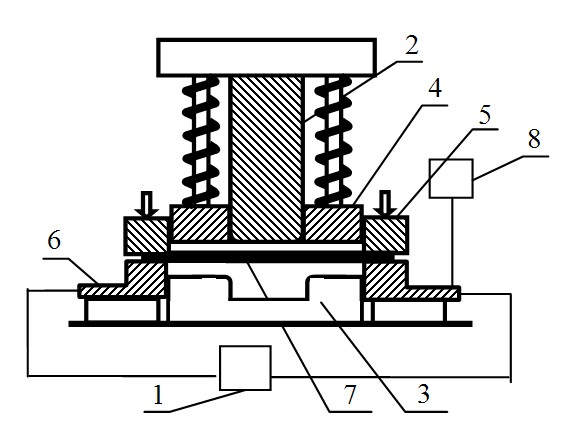

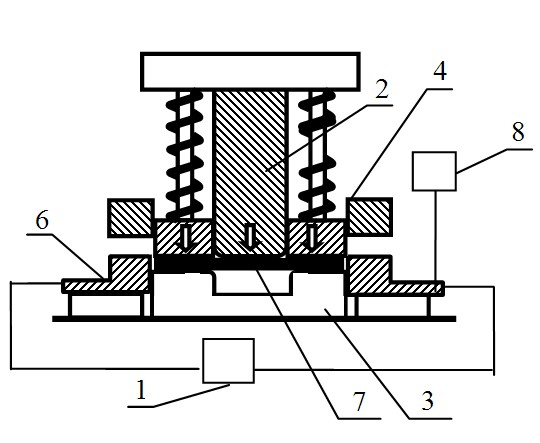

[0015] Specific implementation mode one: the following combination Figure 1 to Figure 4 Describe this embodiment, the molding device used in the method of this embodiment includes a power supply 1, a mold, an upper electrode splint 5, a lower electrode splint 6 and an infrared thermometer 8,

[0016] The mold includes an upper mold 2 and a lower mold 3, a blank holder 4 is arranged on the mold, and a pair of upper electrode splints 5 and lower electrode splints 6 corresponding to the upper and lower positions are arranged outside the blank holder 4, and the upper electrode splint 5 and the lower electrode splint The two electrodes clamped by 6 are respectively connected to both ends of the power supply 1, and the upper electrode splint 5 and the lower electrode splint 6 are kept insulated from the mold.

[0017] The current self-resistance heating method for forming thin-walled aluminum matrix composite parts comprises the following steps:

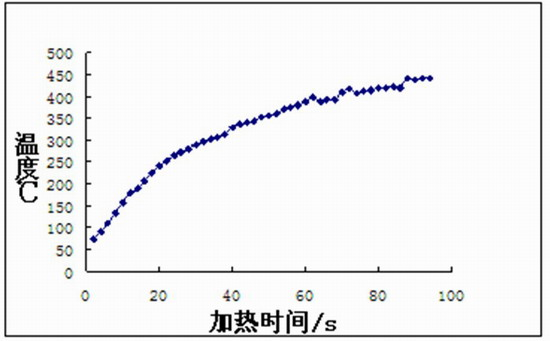

[0018] Step 1, placing the formin...

specific Embodiment approach 2

[0028] Embodiment 2: The difference between this embodiment and Embodiment 1 is that a high-temperature-resistant mica sheet, ceramic or asbestos rubber plate is fixed between the upper electrode splint 5 and the lower electrode splint 6 and the mold to achieve insulation. Others are the same as in the embodiment. One is the same.

specific Embodiment approach 3

[0029] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the current parameters output by the power supply 1 described in step 3 are: the voltage is 6V-8V, the current is 5000A-10000A, and the others are the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com