Manufacturing method of drawing die face on handle of outboard door panel of automobile and outboard door panel of automobile

A manufacturing method and technology of panel handles, which are applied to door leaves and other directions, can solve problems such as easy deformation, and achieve the effects of improved stress distribution and increased rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

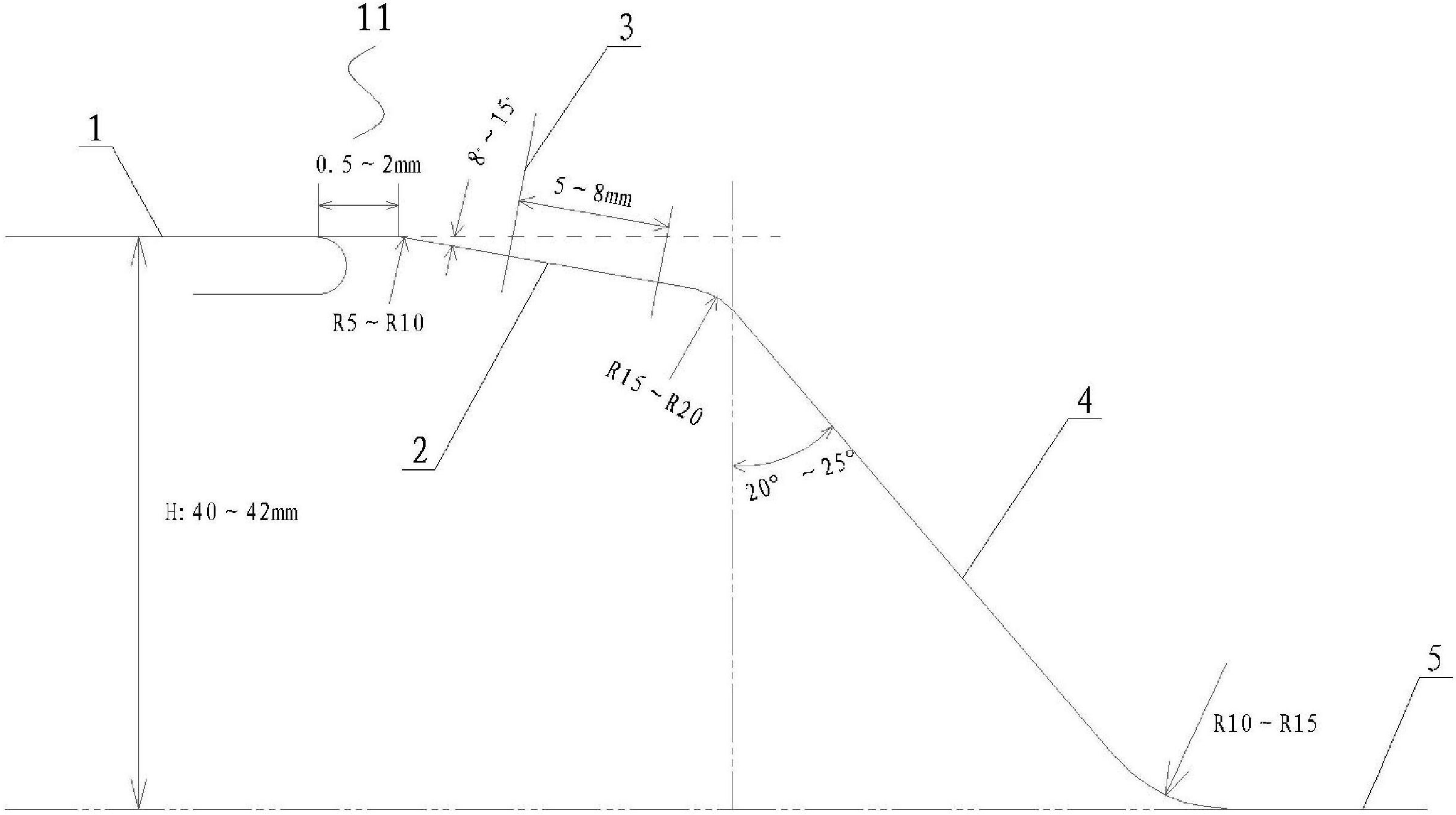

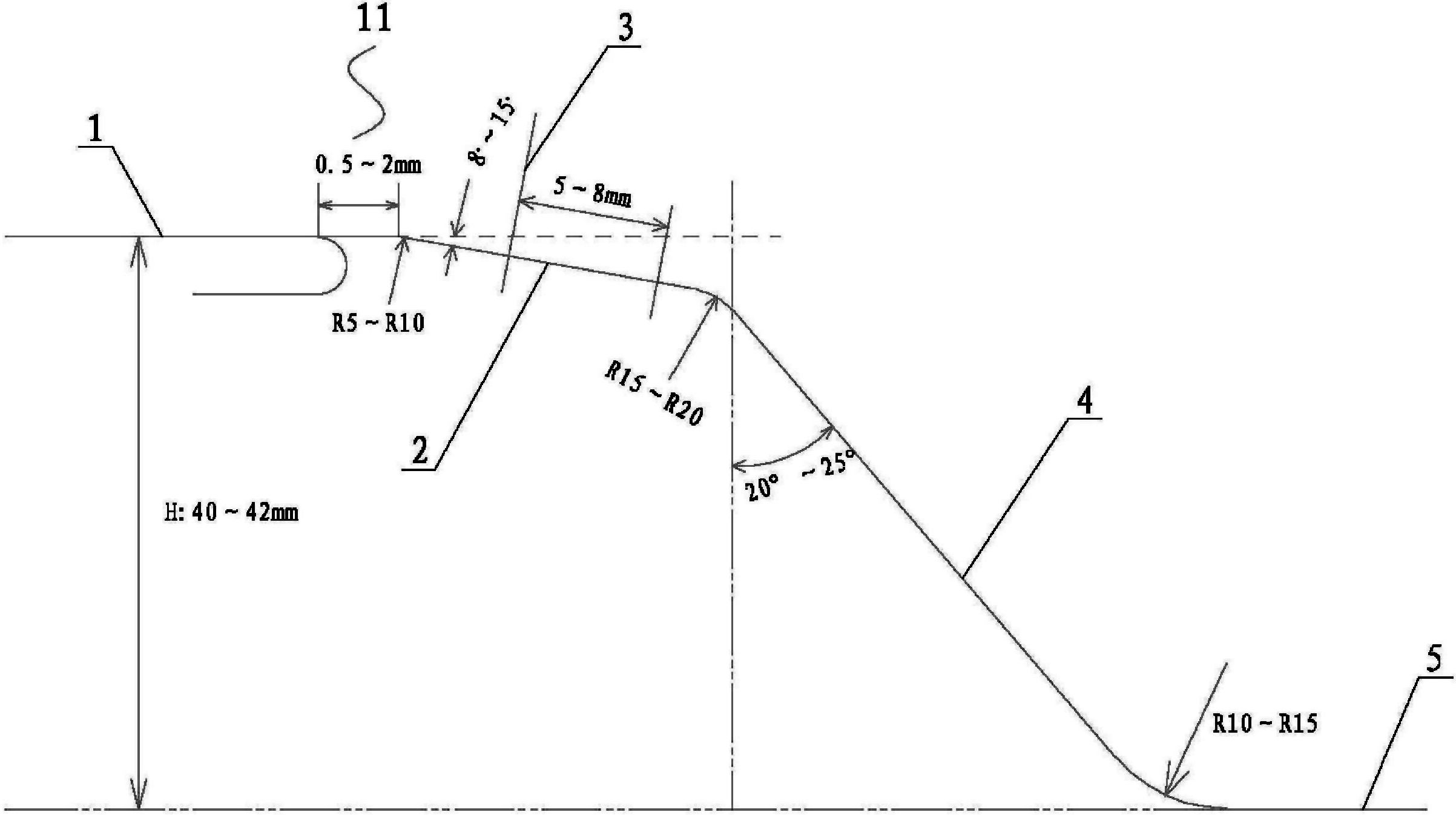

[0028] This embodiment provides a method for manufacturing the drawing die surface at the handle of the outer panel of an automobile door, see figure 1 , The manufacturing method includes:

[0029] When making the drawing die surface at the handle of the car door outer panel, the boundary of the door outer panel handle area A surface 1 is extended along its own curvature to form a boundary extension 11, the length of the boundary extension 11 is preferably 0.5 mm ~2.0mm, more preferably 1mm; the boundary extension section 11 intersects the straight section 2 that forms an angle of 10° with the A surface 1. The straight section 2 continues to extend to form a drawn wall 4, which is 25 with the punching direction °Included angle; the drawn wall 4 intersects the blanking surface 5 after extension. As another embodiment, the boundary extension section 11 can be selected to intersect the straight line section 2 with any included angle in the range of 8°~15° with the A surface 1 as re...

Embodiment 2

[0035] This embodiment provides an outer panel of an automobile door, which has a drawing die surface at the handle manufactured by the method of the first embodiment.

[0036] The sequence numbers of the foregoing embodiments of the present invention are only for description, and do not represent the superiority of the embodiments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Vertical distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com