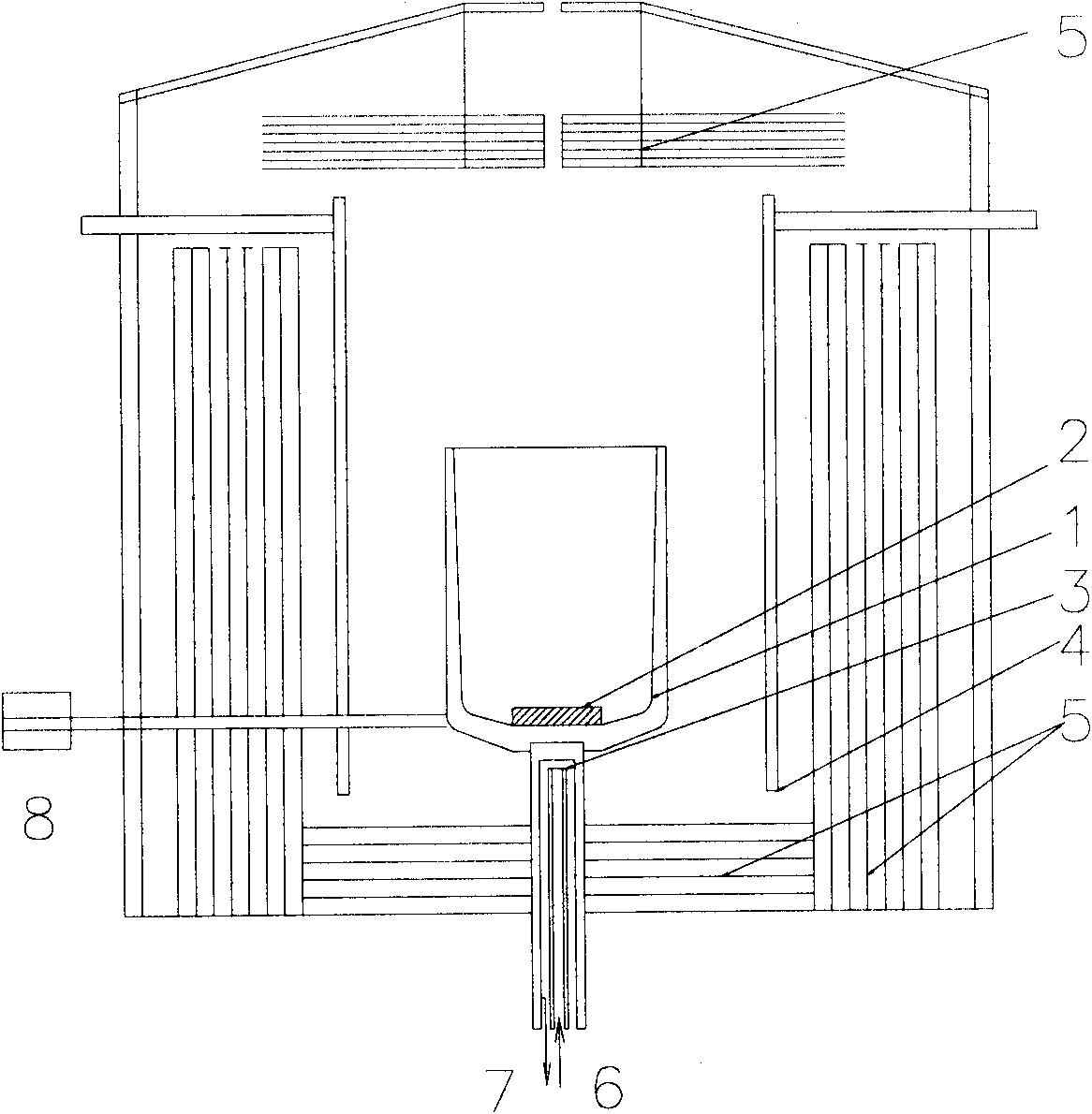

Crystal growth technology and crystal growth furnace

A crystal growth furnace and crystal growth technology, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems that the crystal size is difficult to exceed 4 inches, and the crystal size is small, so as to simplify the crystal growth process and reduce stress , high-quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The crystal growth process of the present invention includes the preparation step, the crystal seeding step, the shouldering step, the equal-diameter growth step, and the cooling and annealing steps carried out in sequence.

[0022] The above-mentioned steps of the present invention are as follows: preparation step: after checking the consistency of the thermal field in the crystal growth furnace, the raw material to be melted is packed into the tungsten crucible in the crystal growth furnace, then the crystal growth furnace is closed, and the crystal growth furnace is closed under an inert atmosphere. Use the heating element in the crystal growth furnace to heat the raw material to melt it, and keep the flow rate of the refrigerant gas leading to the bottom of the tungsten crucible constant during the heating and heating period; crystal seeding step: after the raw material is melted, keep the heating element The power of the tungsten crucible is kept constant for the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com