Patents

Literature

120results about How to "Simple growth process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A method for direct growth of graphene on various substrates

ActiveCN102260858ASimple growth processAchieve growthChemical vapor deposition coatingNoble gasAtmospheric pressure

The invention discloses a method for directly growing graphine on various substrates. The method comprises the following steps: A) putting a substrate material in a plasma enhanced chemical vapor deposition (PECVD) cavity, vacuuming, heating the substrate to 400-600 DEG C, introducing hydrocarbon gases and other noble gases, and controlling the pressure of the gases to be at most 1Torr; and B) switching on a plasma power supply so that the hydrocarbon is ionized and cracked to active groups, and reacting on the substrate surface of 400-600 DEG C, thereby achieving the direct growth of the graphine. By the method in the invention, the problem that high-quality graphine is directly grown on the surface of a non-specific substrate is solved; and the method in the invention has an important sense at the aspects of exploring a large-area direct growth technology of graphine, understanding a growth mechanism of graphine, researching a fundamental physical problem of graphine, exploring practical applications of graphine films and broadening application ranges of graphine.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

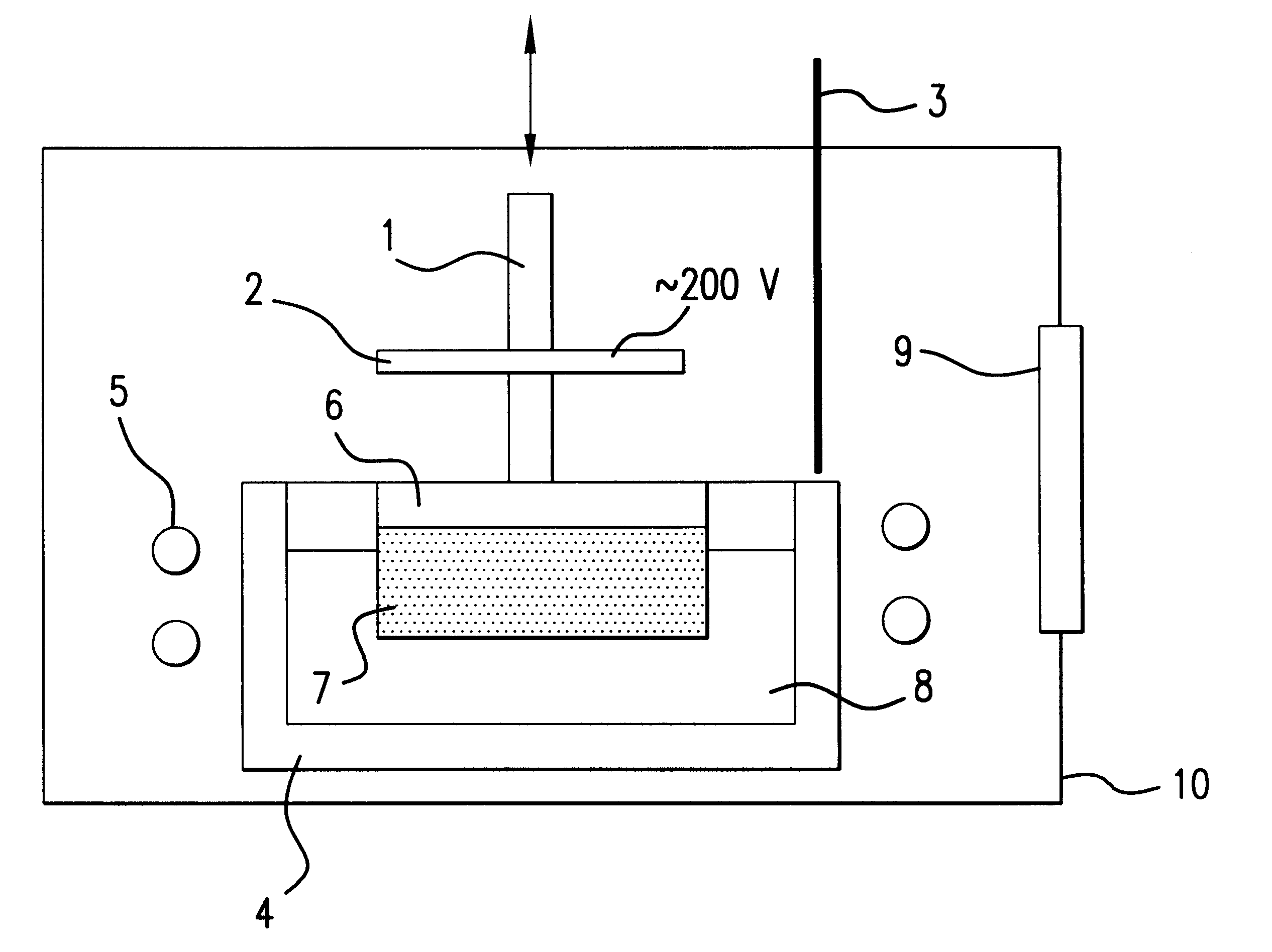

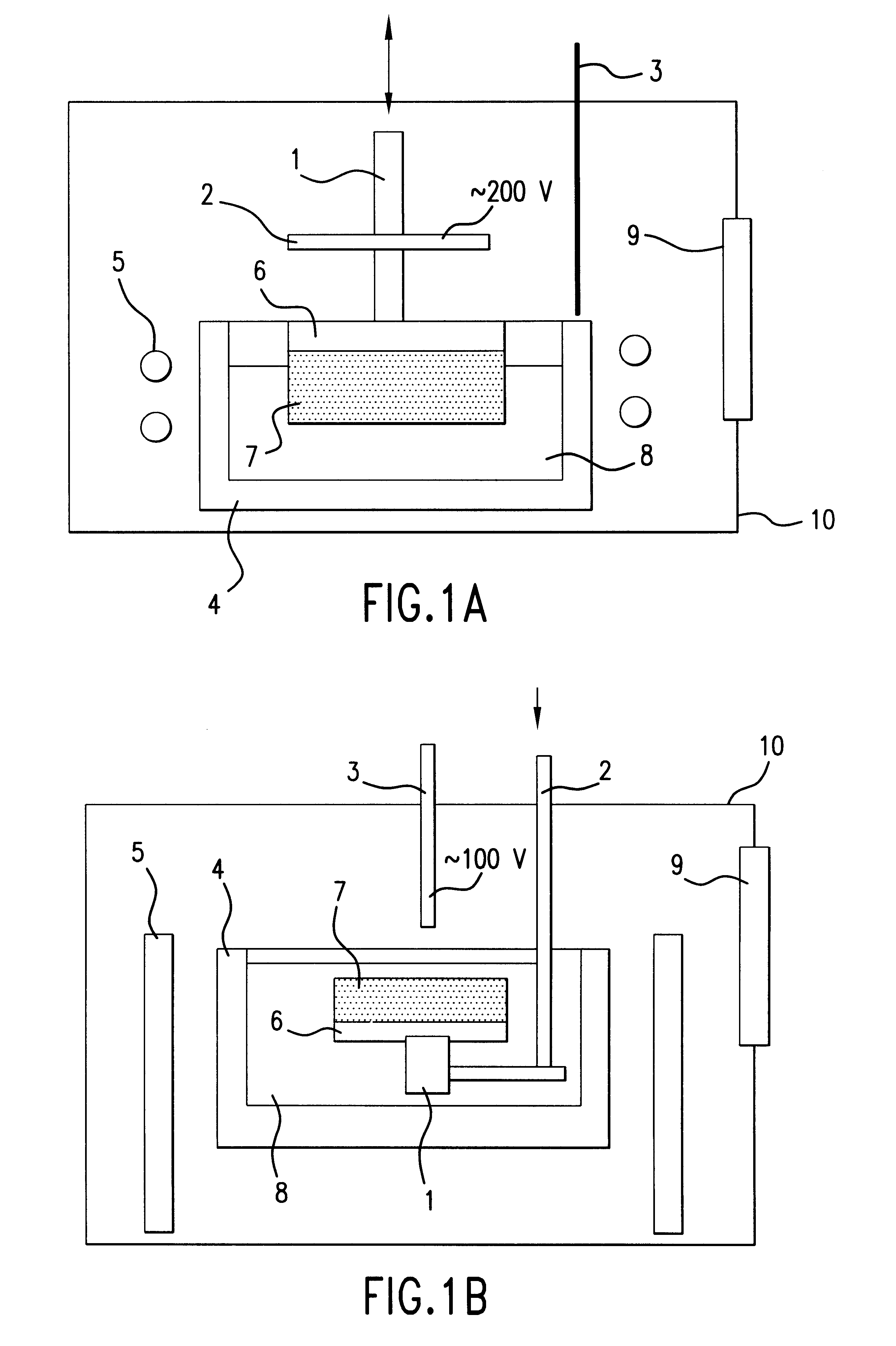

Method of manufacturing GaN ingots

InactiveUS6562124B1Low costSimple growth processSemiconductor/solid-state device manufacturingBy pulling from meltSemiconductor materialsIngot

A novel method for growing semiconductor material including GaN is disclosed. The method involves placing a first substance into a growth reactor, supplying a second gaseous substance into the grouth reactor, and applying electrical field to the second gaseous substance to produce the cry stalline compound material.

Owner:OSTENDO TECH INC

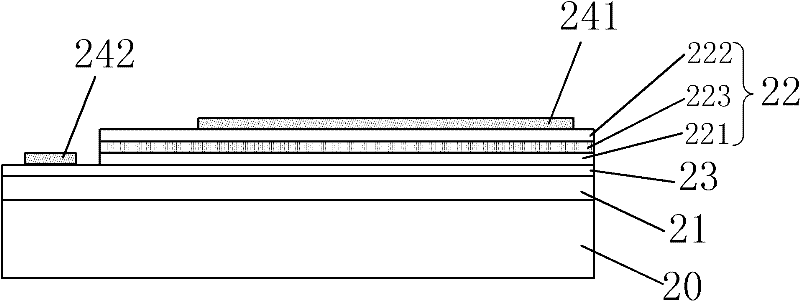

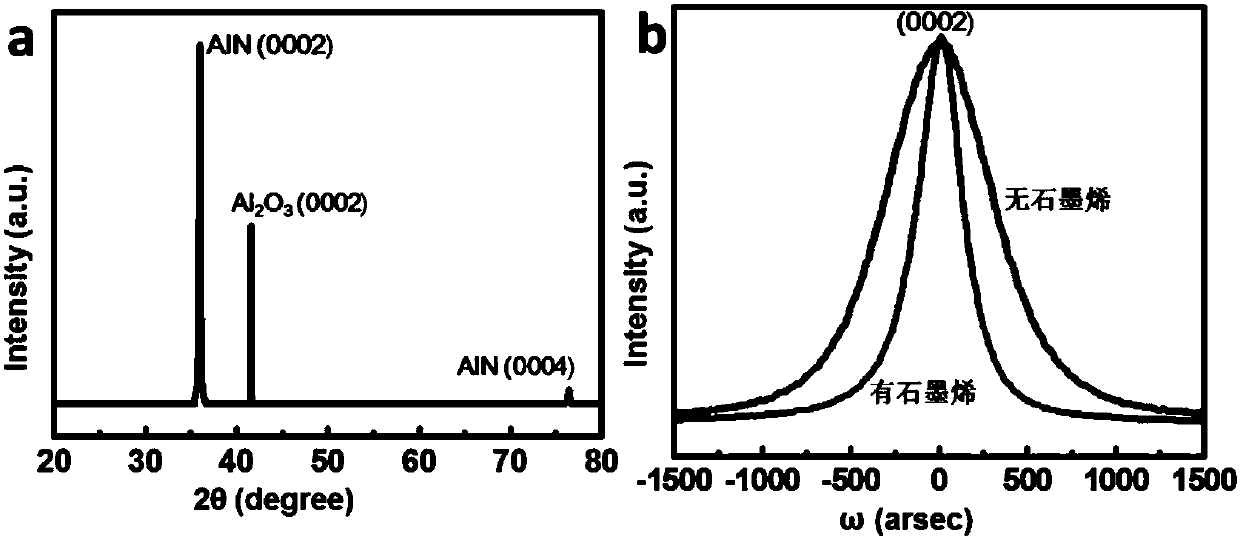

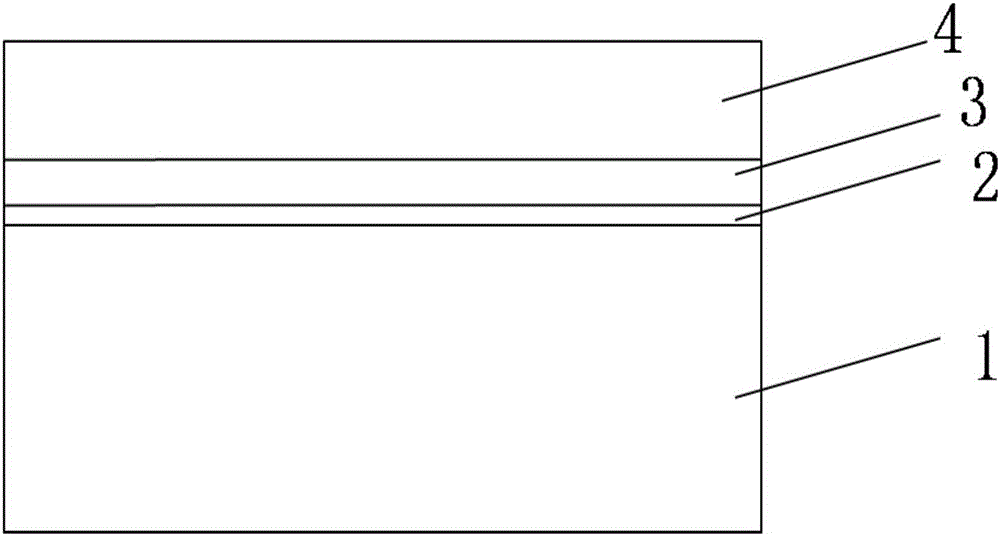

III-nitride substrate growing method, substrate and LED (light emitting diode)

InactiveCN102201503AWill not introduceSimple growth processSemiconductor devicesCvd grapheneLight-emitting diode

A III-nitride substrate growing method comprises the following steps: providing a copper support substrate; forming a graphene layer on the surface of the support substrate; and forming a III-nitride semiconductor layer on the surface of the graphene layer, wherein the highest growing temperature of the III-nitride semiconductor layer is lower than the melting point of copper. In the method, since graphene and III-nitride are sequentially grown on the conductive metallic copper substrate with high melting point, growth process is simple and impurities cannot be introduced in the production process.

Owner:SUZHOU NANOWIN SCI & TECH +1

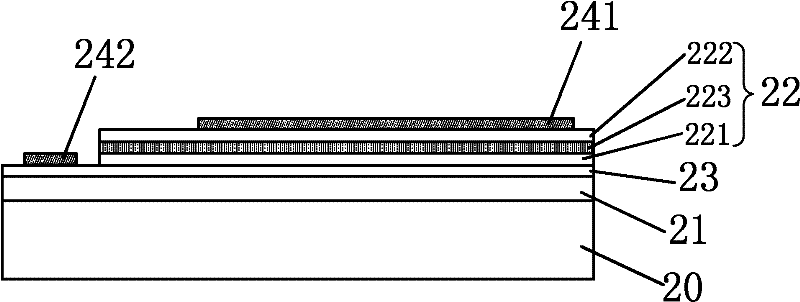

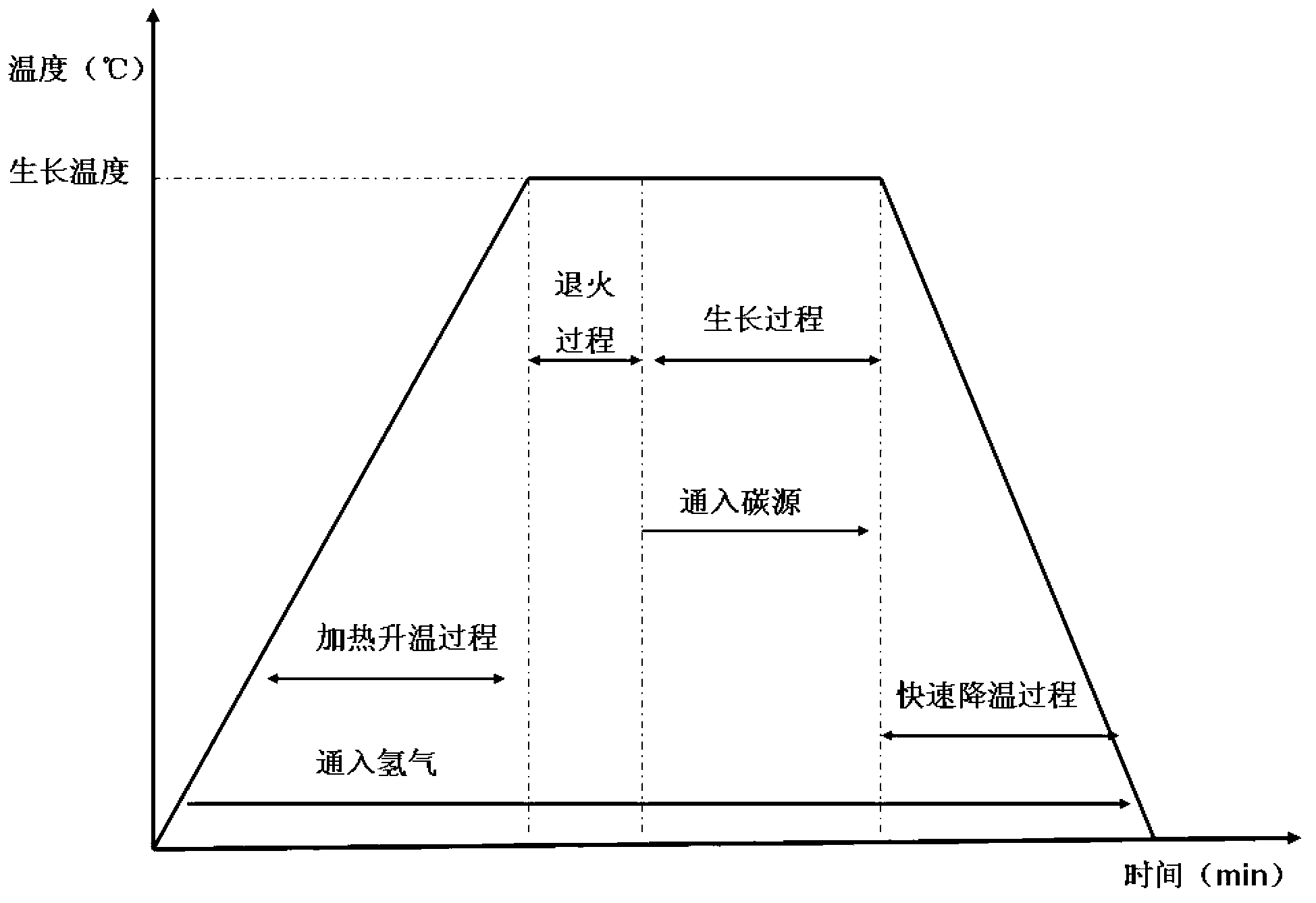

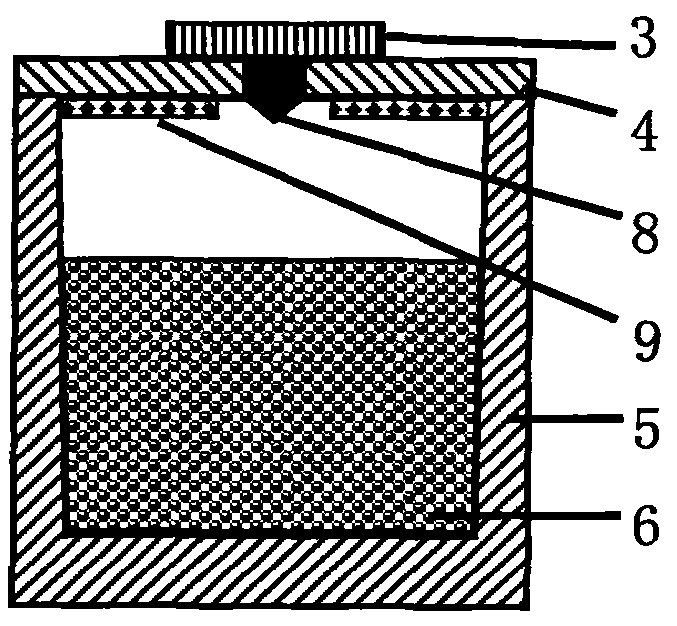

Low-temperature direct preparation method of graphene under double-temperature-zone control, and double-temperature-zone tube furnace

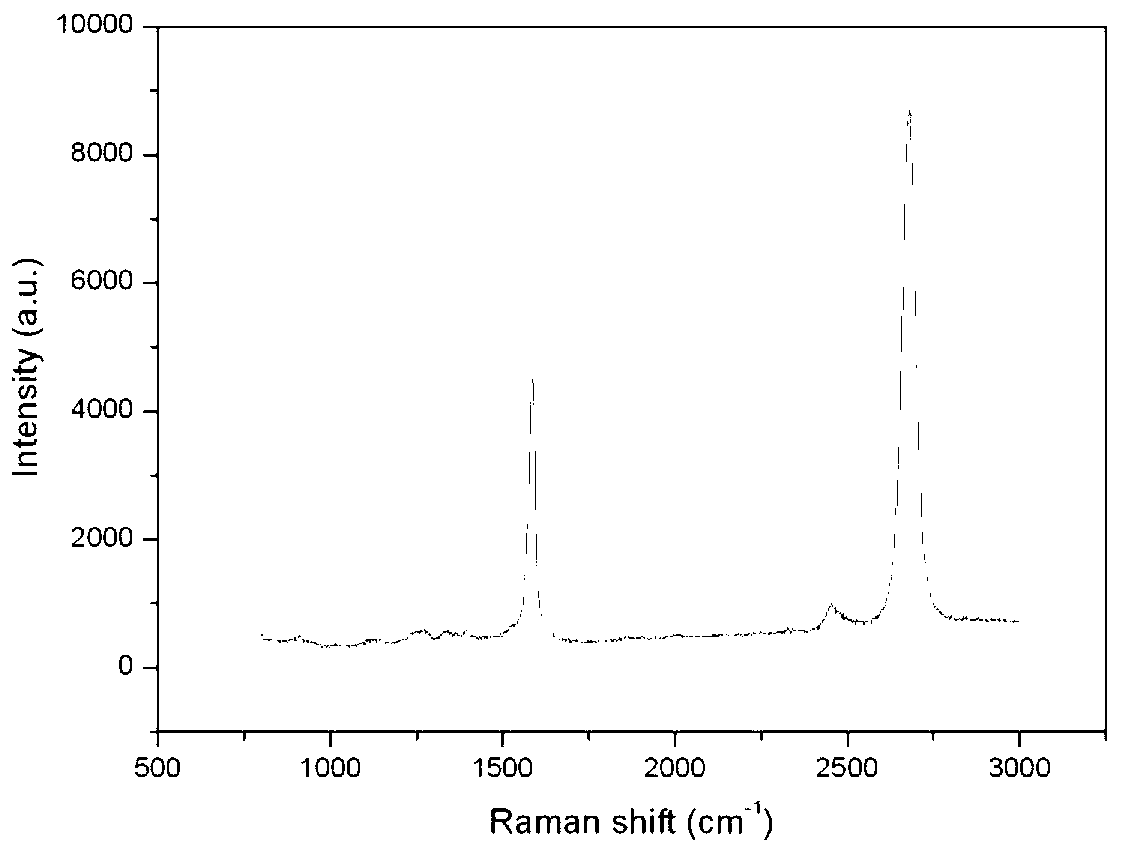

InactiveCN102849733APrecise control of growth temperatureSimple growth processGrapheneHydrogenDefective graphene

The invention discloses a low-temperature direct preparation method of graphene under double-temperature-zone control, and a double-temperature-zone tube furnace. The method comprises the steps of dividing a vacuum reaction furnace into a high-temperature zone and a low-temperature zone, putting transition metal into the high-temperature zone, directly putting substrate material into the low-temperature zone, vacuumizing, injecting hydrogen gas into the vacuum reaction furnace, heating the low-temperature zone to 100-1,000 DEG C, heating the high-temperature zone to 1,000-1,100 DEG C, introducing carbon source into the vacuum reaction furnace, cracking the carbon source in the high-temperature zone, and performing chemical vapor deposition (CVD) for 5-180 min in the low-temperature zone while keeping constant hydrogen gas flow, to obtain graphene directly deposited on the substrate. The preparation method has the advantages of simple growth process, no need of catalysis, low growth temperature of 100-1,000 DEG C, no restriction on substrate material, and large-area growth of graphene. The grown graphene has low defect peak, high crystal quality, excellent light transmittance and electrical conductivity.

Owner:SHANDONG NORMAL UNIV

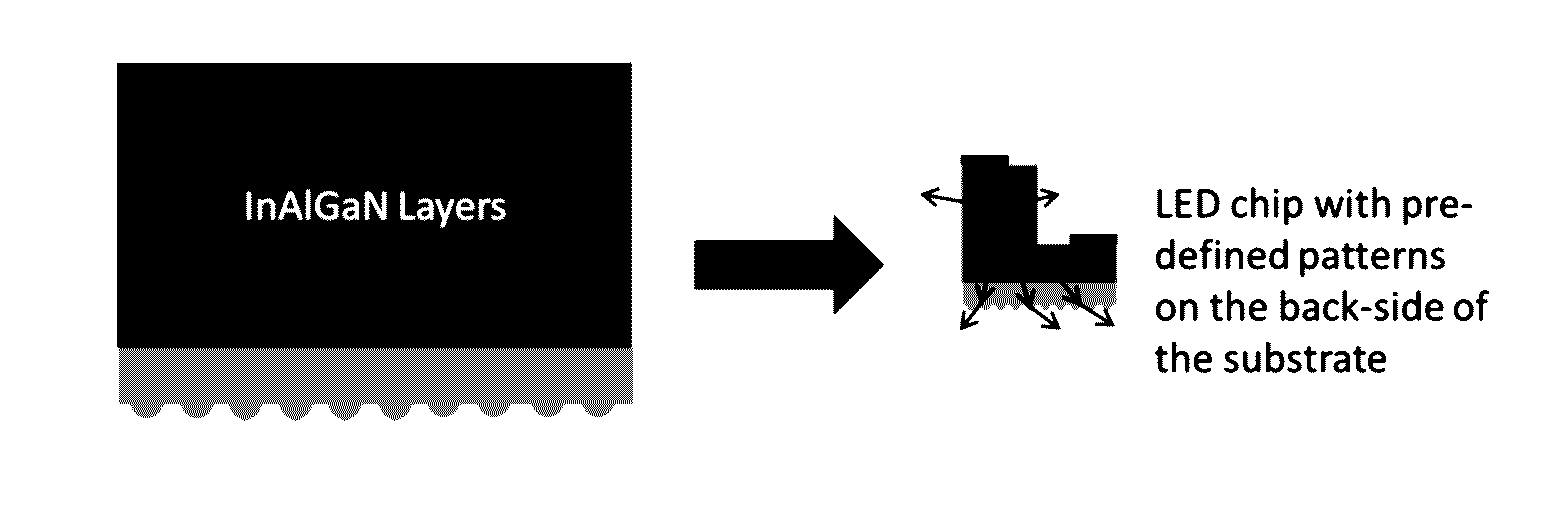

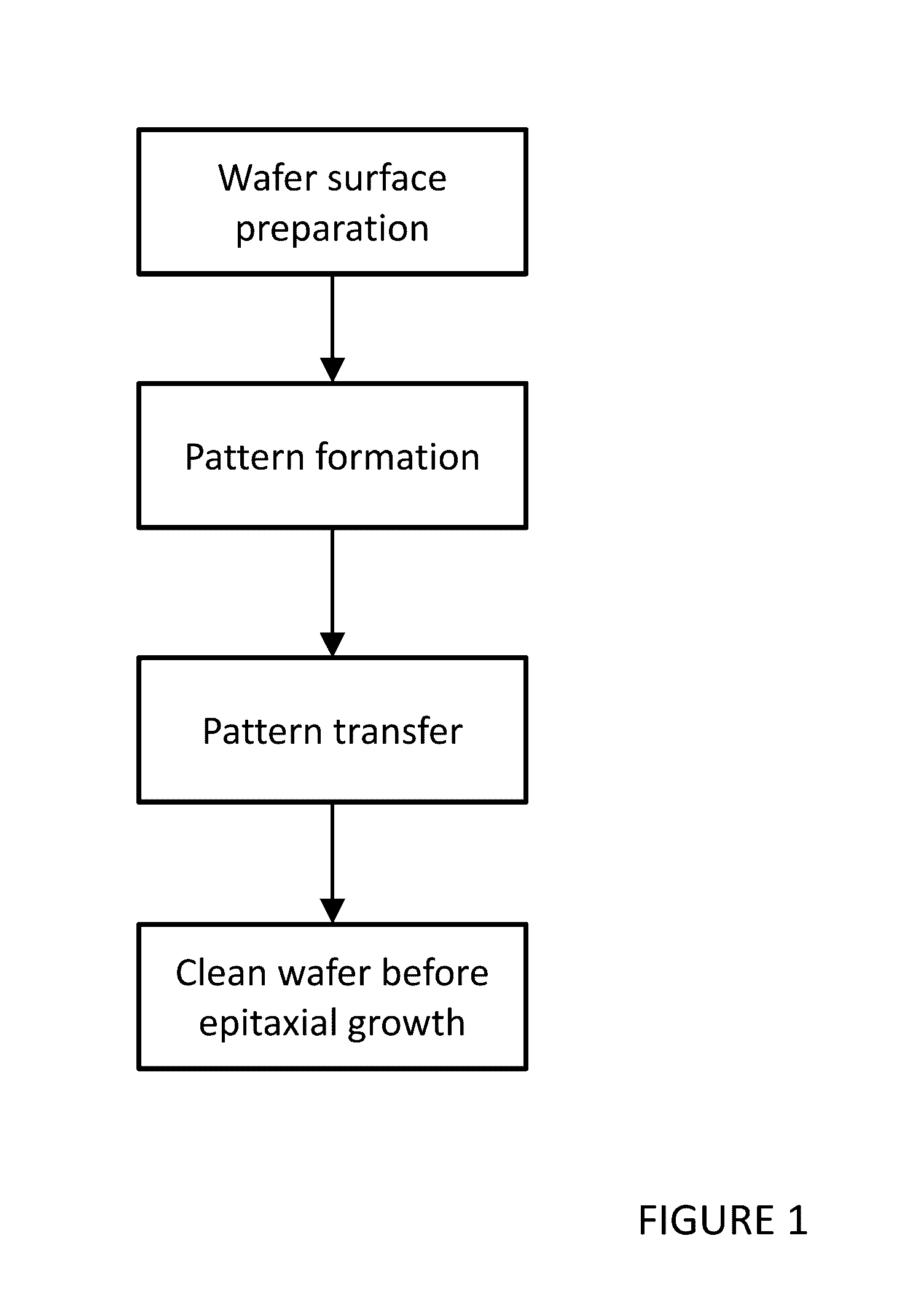

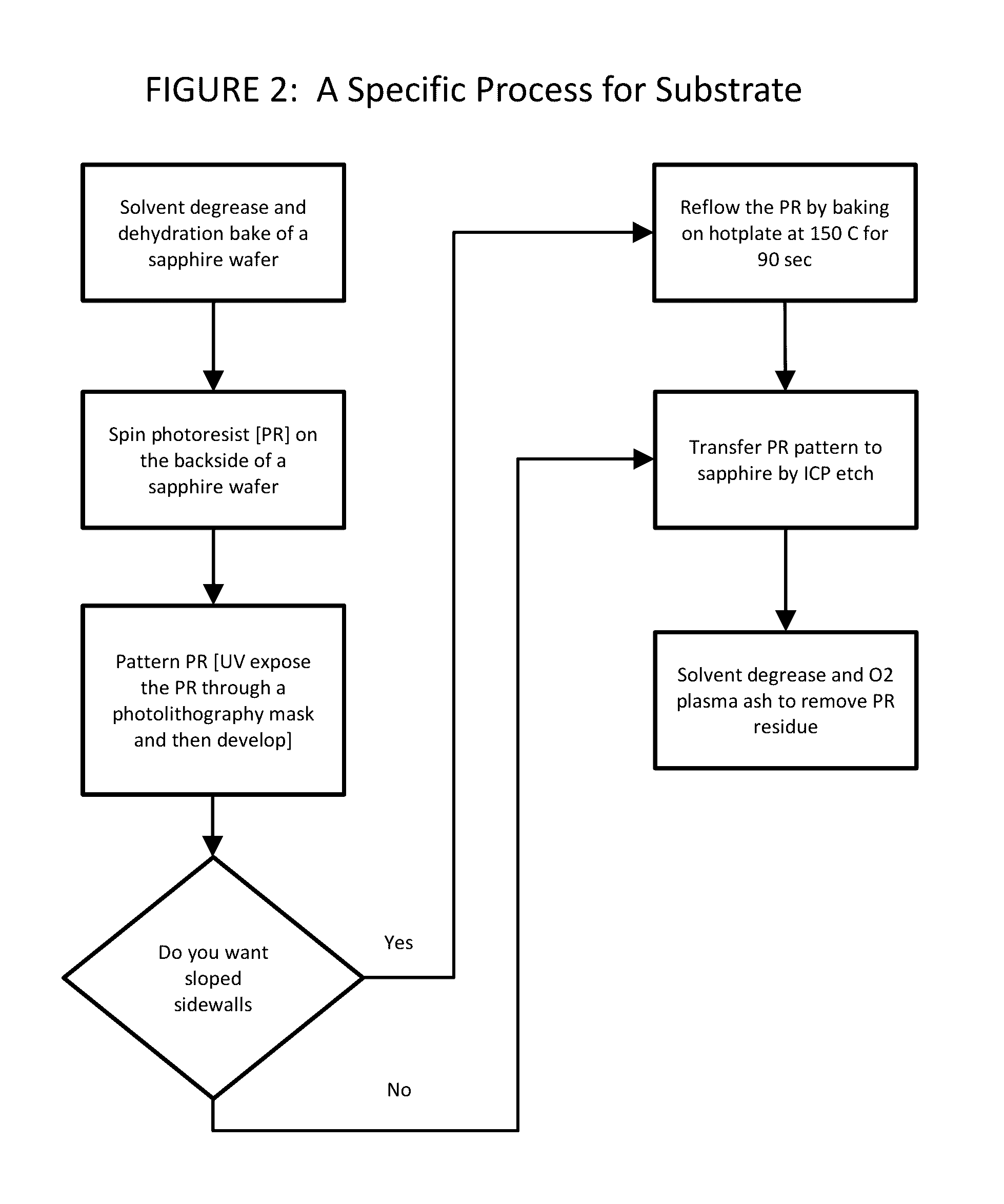

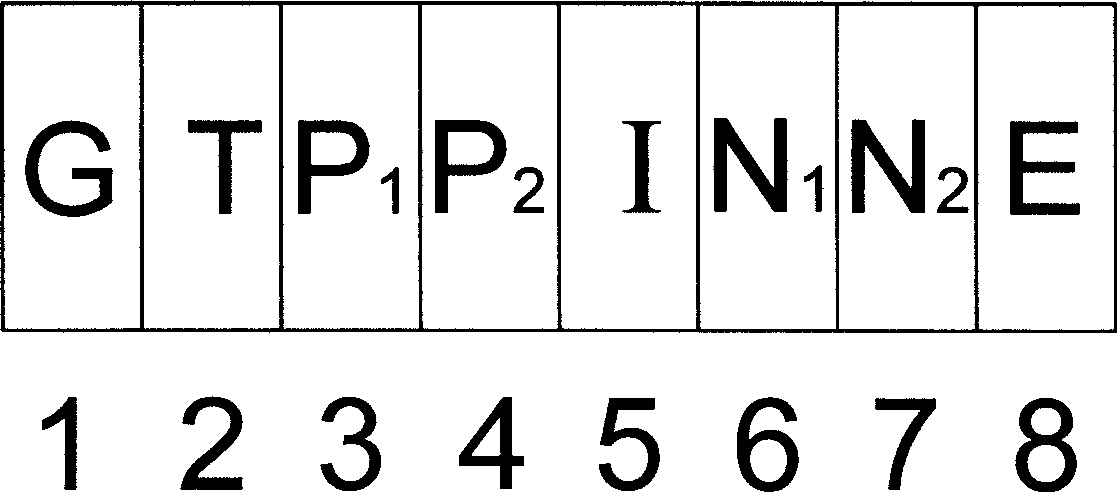

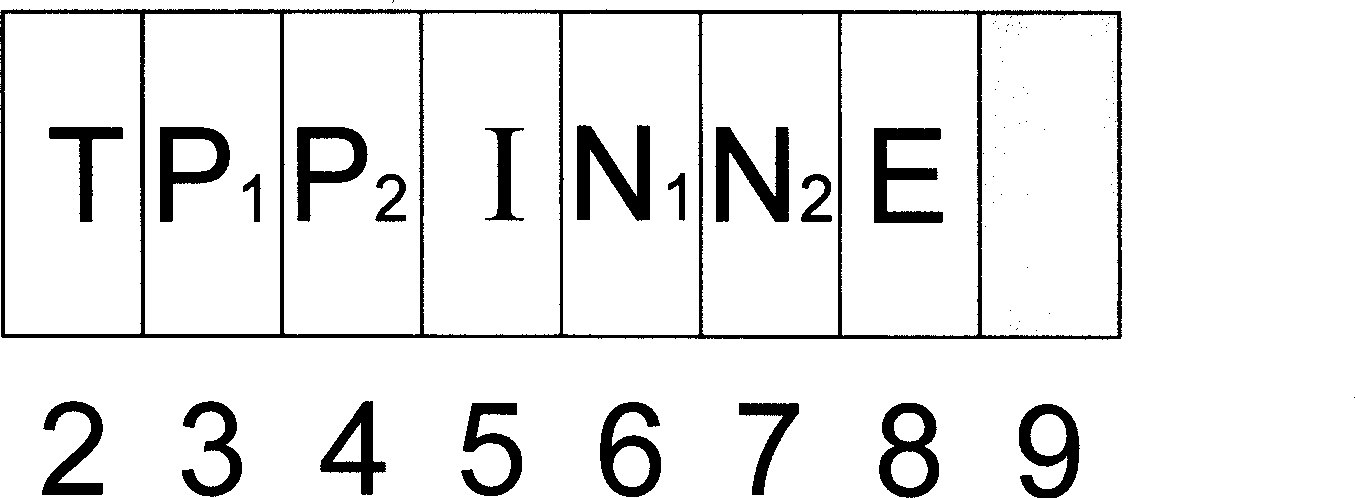

Backside transparent substrate roughening for UV light emitting diode

InactiveUS9461198B2Simple growth processEasy to operateSemiconductor/solid-state device manufacturingSemiconductor devicesPost-growthPatterned substrate

Owner:RAYVIO

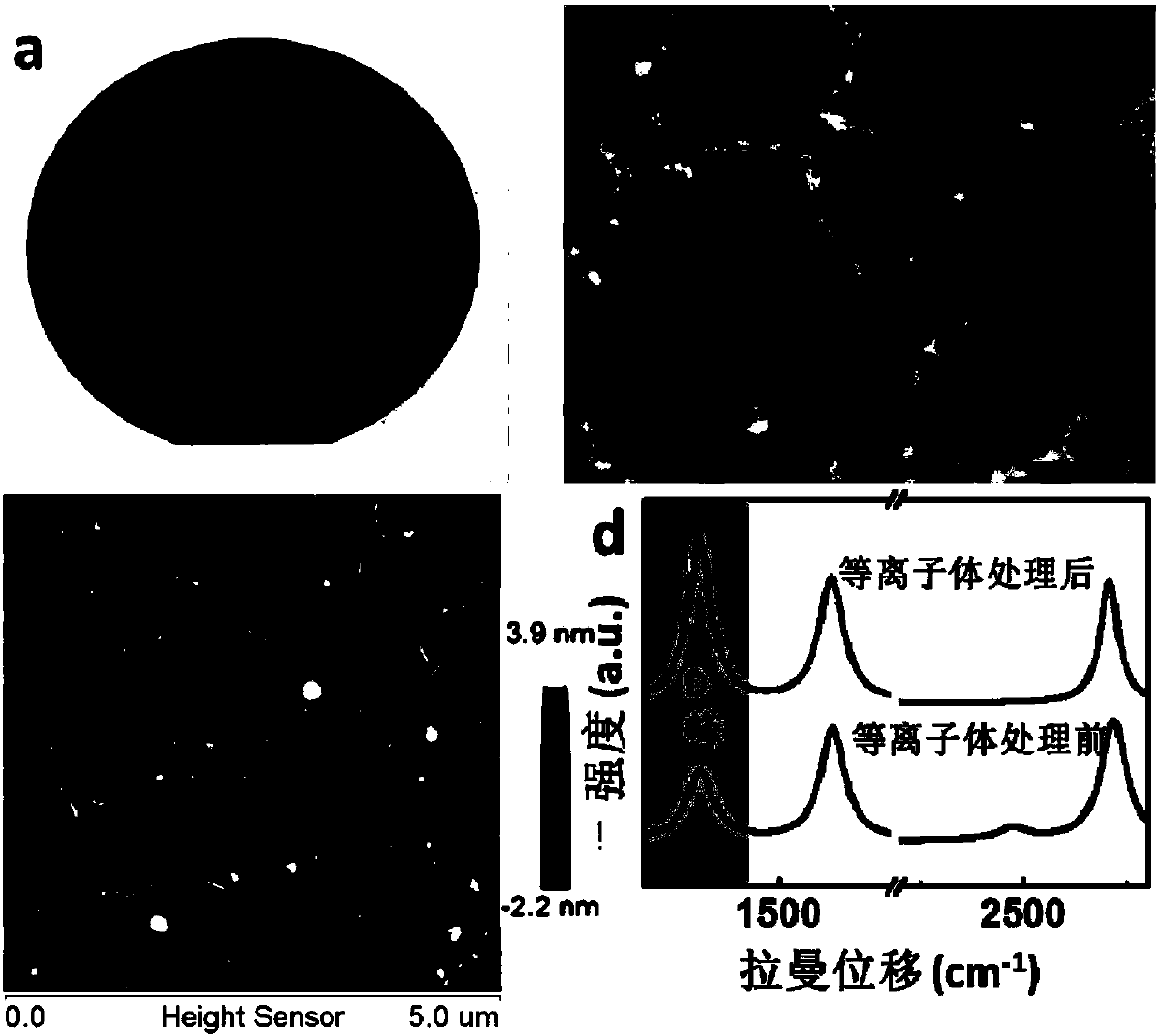

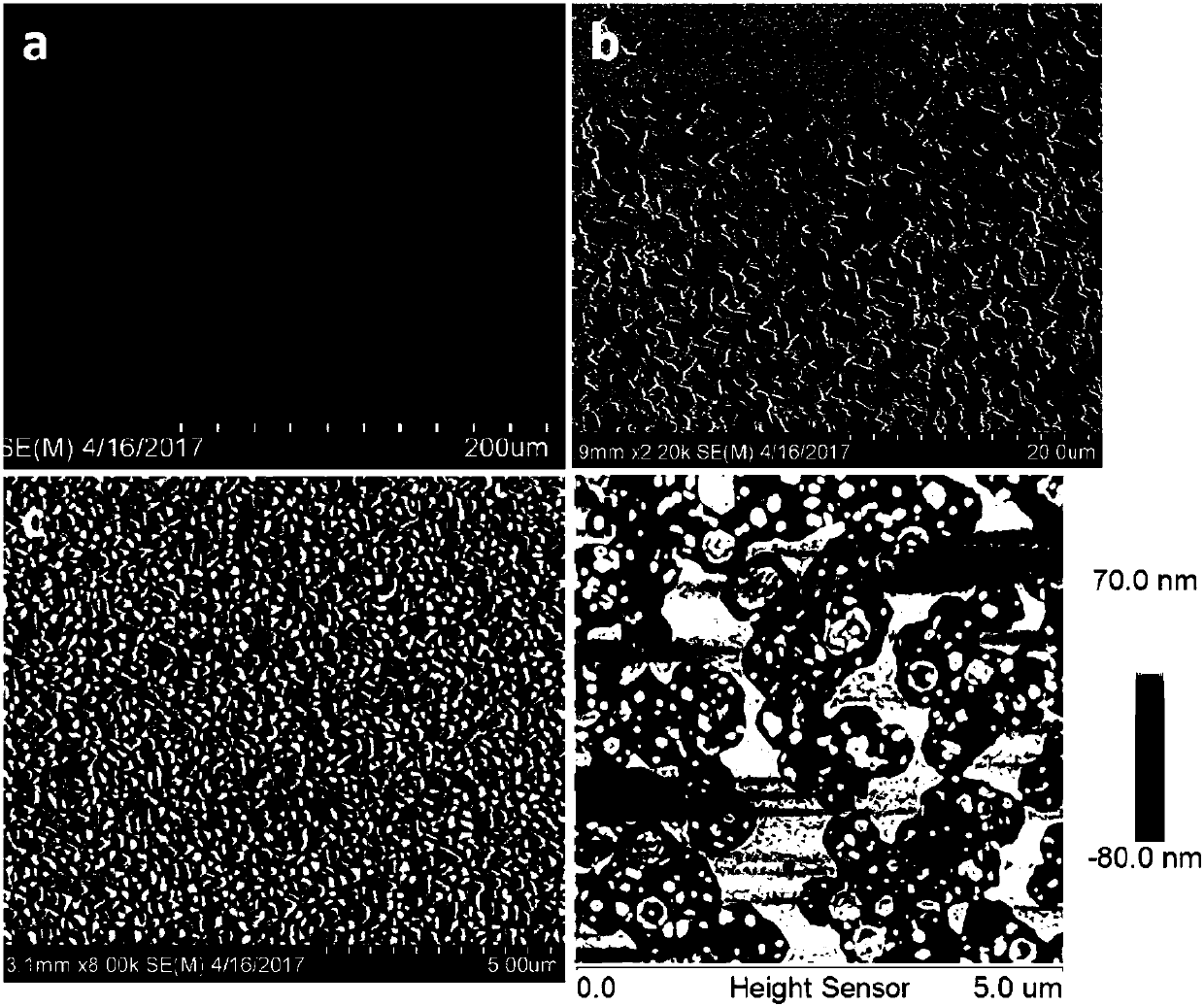

Graphene sapphire substrate suitable for epitaxial growth of III-nitride

InactiveCN107689323AImprove qualityEfficient preparationSemiconductor/solid-state device manufacturingSemiconductor devicesNitrogen plasmaGas phase

The invention discloses a graphene sapphire substrate suitable for epitaxial growth of III-nitride. A preparation method of the substrate comprises the following steps of performing graphene chemicalvapor deposition on the sapphire substrate; performing plasma treatment on a system after the chemical vapor deposition, wherein the plasma treatment process specifically comprises oxygen plasma treatment, nitrogen plasma treatment or argon plasma treatment. The preparation method has the advantages that an III-nitride thin film can be quickly and efficiently prepared, and the preparation cost ofthe III-nitride thin film is greatly reduced; the obtained III-nitride can be further processed into LED (light emitting diode) devices, and the problem of overheat in a use process can be solved forthe prepared LED chip because of very good heat conductivity of the graphene.

Owner:PEKING UNIV

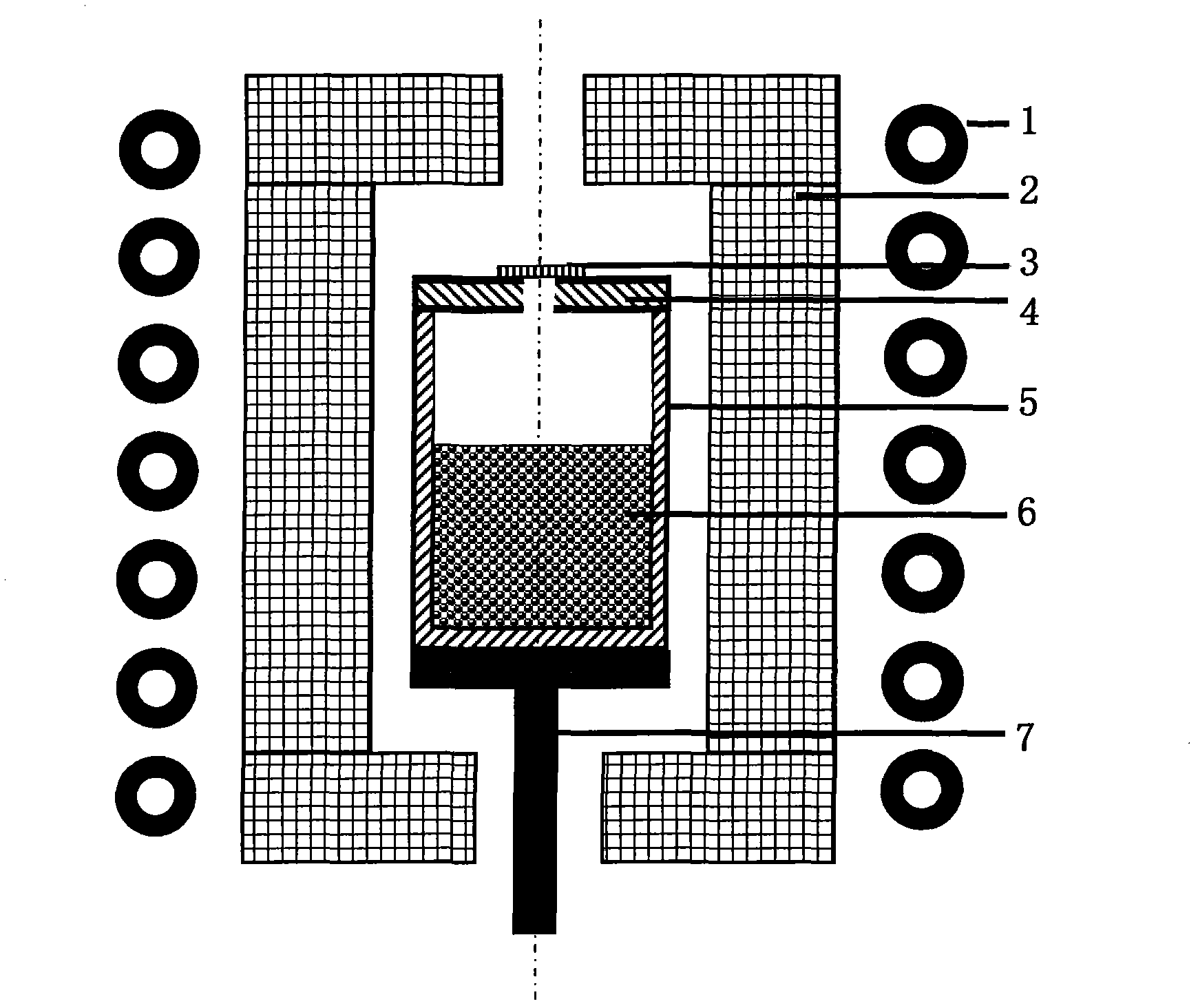

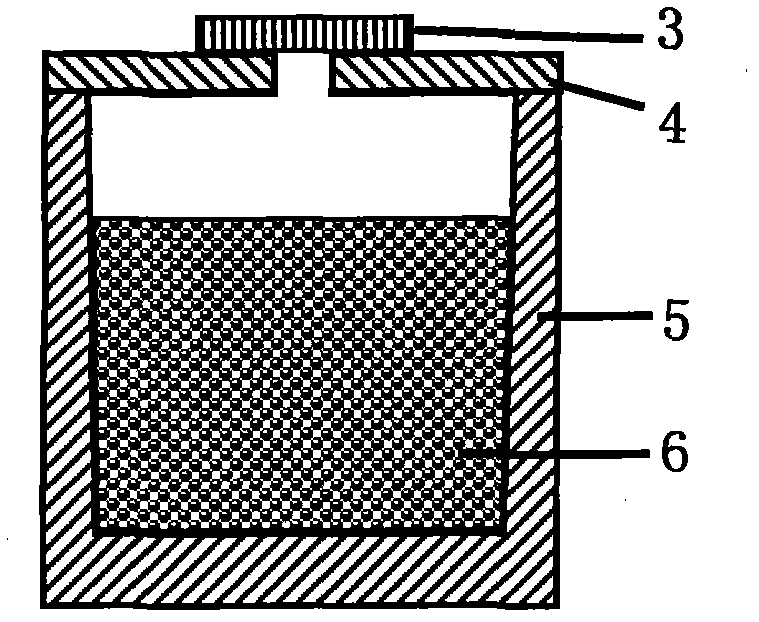

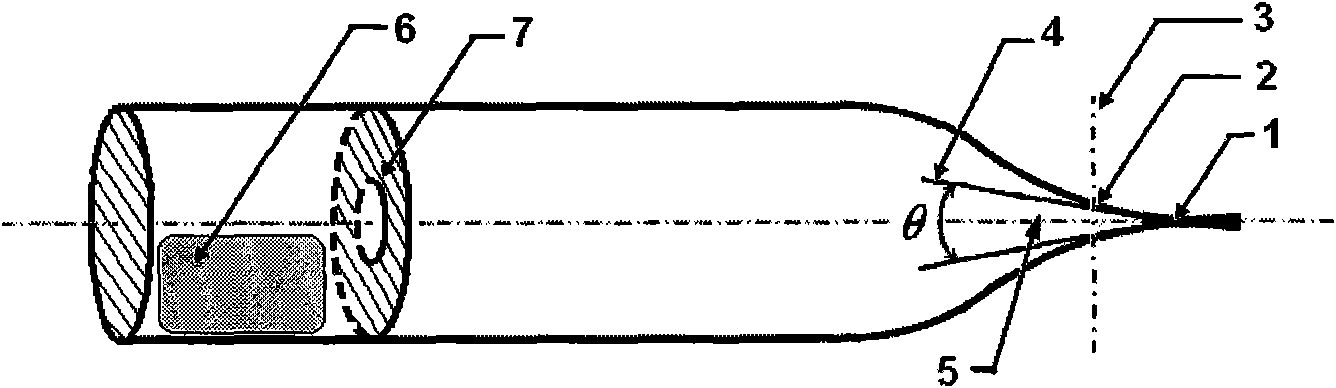

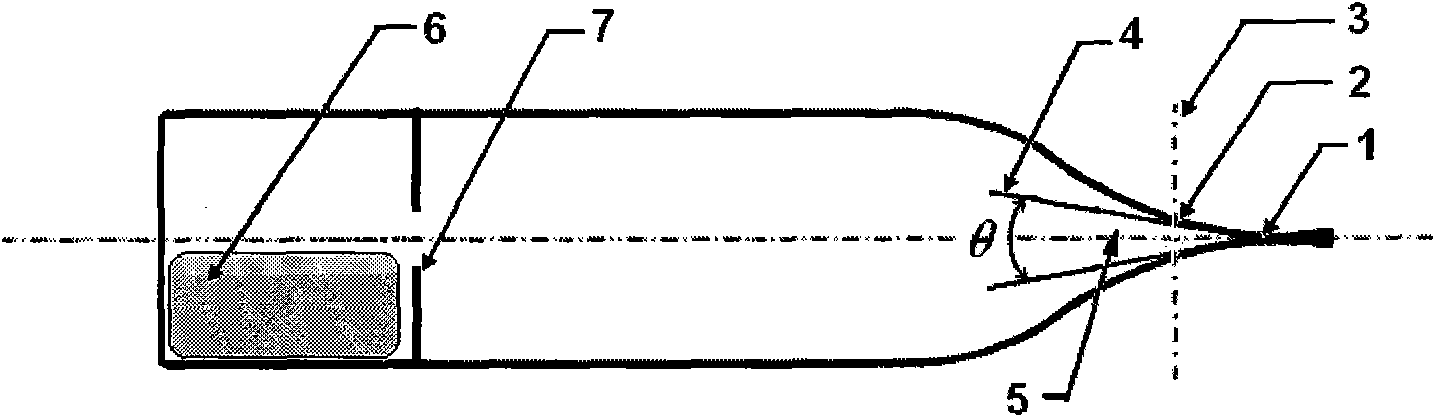

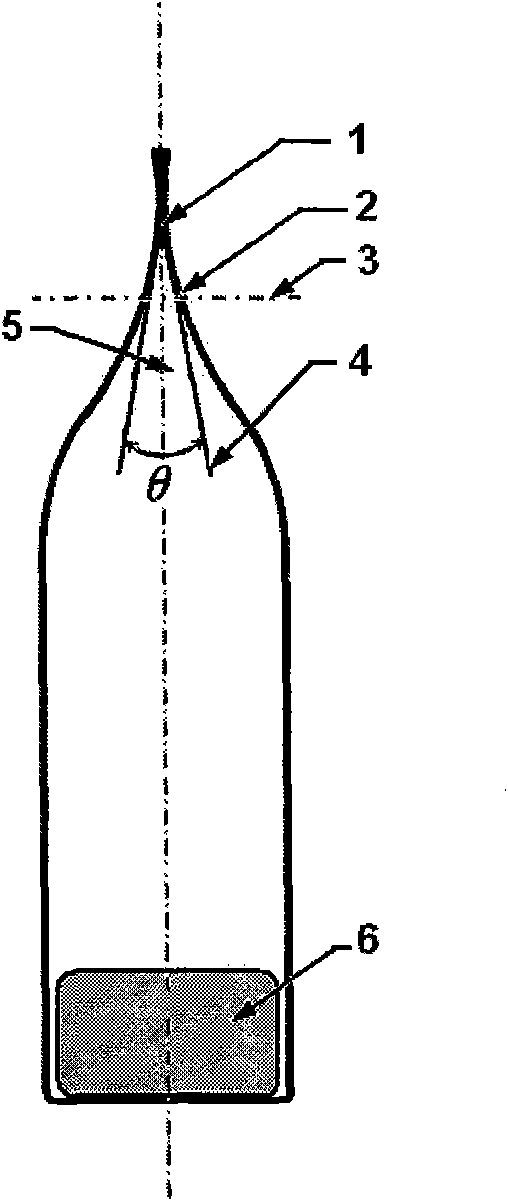

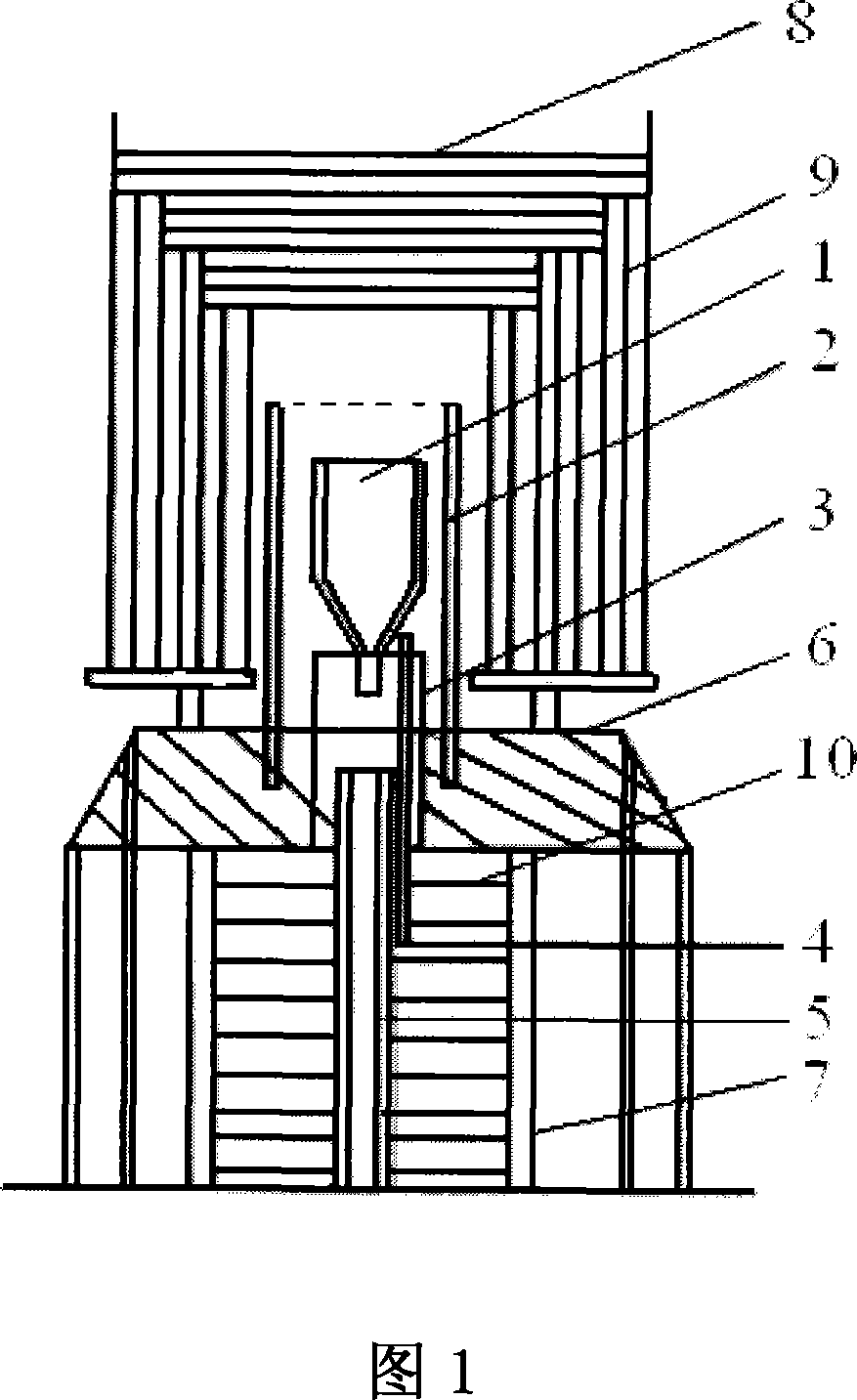

Device and process for preparing aluminum nitride crystals by adopting spontaneous crystal seed method

InactiveCN103103611ASimple growth processStrong operabilityPolycrystalline material growthFrom frozen solutionsCrucibleSingle crystal

The invention belongs to the field of crystal preparation, and in particular relates to a device for preparing aluminum nitride crystals and a corresponding process. The invention provides the device and the process for preparing aluminum nitride crystals by adopting a spontaneous crystal seed method. The device comprises an inductive heating coil, an insulating layer, a crucible device and a crucible lifting device. The crucible device consists of a crucible body, a crucible cover and a cover sheet. A hole which is 1-2mm in diameter is formed in the crucible cover, the cover sheet is located above the crucible cover and completely shields the hole, and the area of the cover sheet is between those of the hole and the crucible cover. The preparation process comprises the two steps of: (1) obtaining aluminum nitride single crystals through spontaneous crystallization at the hole to be used as the crystal seeds due to limit of anisotropic crystalline characteristic of aluminum nitride and geometric dimension of the hole at lower temperature; and (2) obtaining large-dimensional aluminum nitride crystals by weakening the anisotropic crystalline characteristic of aluminum nitride at high temperature and meanwhile slowly adjusting the position of the crucible by lifting through the lifting device.

Owner:SHENZHEN UNIV

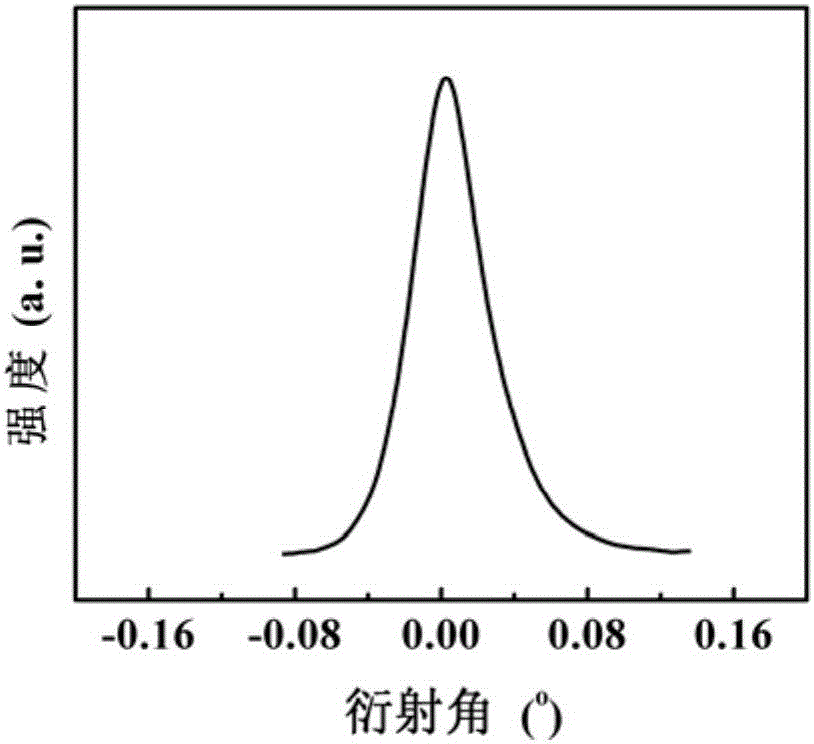

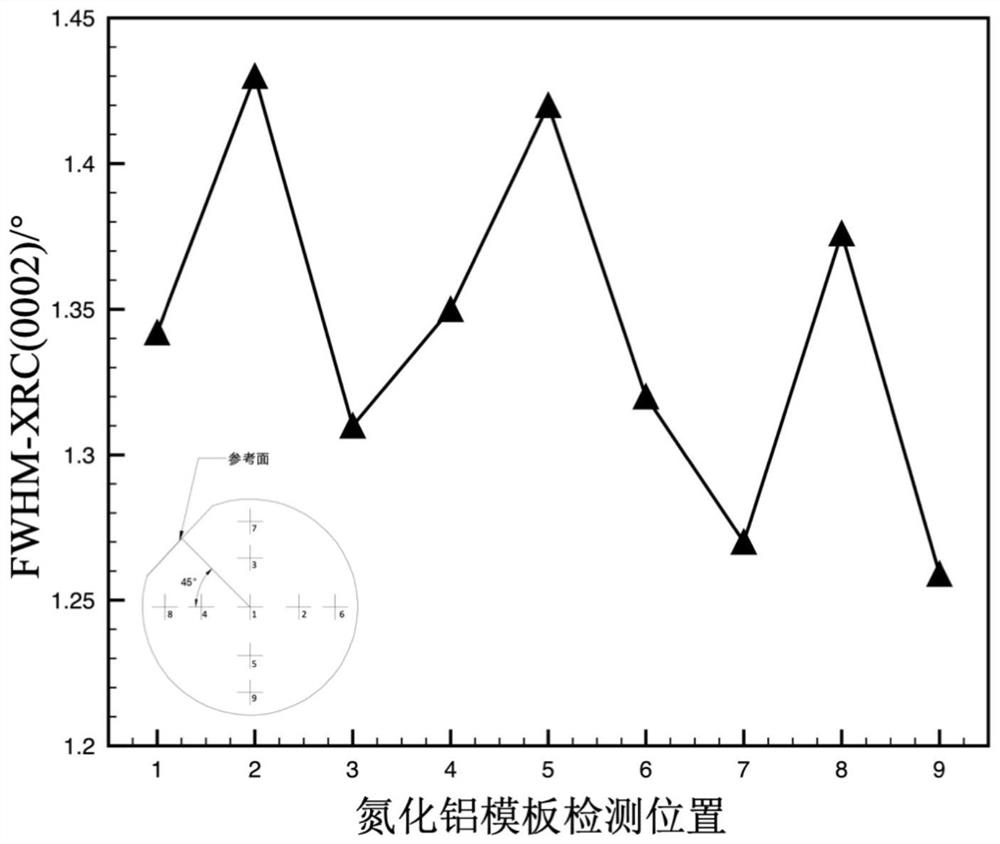

High-quality AlN thin film epitaxially grown on Si substrate, and preparation method of high-quality AlN thin film

ActiveCN106128937ASpend less timeImprove mobilitySemiconductor/solid-state device manufacturingCrack freeSurface acoustic wave

The invention discloses a high-quality AlN thin film epitaxially grown on a Si substrate, and a preparation method of the high-quality AlN thin film. The preparation method specifically comprises the following steps of 1) choosing the Si substrate; 2) pre-paving an Al layer in an epitaxial manner; 3) enabling an AlN core-forming layer to be grown; and 4) enabling the AlN thin film to be grown, wherein in the growth process of the AlN thin film, trimethyl gallium is introduced at a speed of 0.2-0.5mL / min to be used as a surfactant. By adoption of the preparation method, the relatively thick and crack-free AlN thin film with a thickness which is greater than 1[mu]m can be manufactured; inter-island union and two-dimensional growth of the AlN thin film are realized; compared with a multi-step multi-layered or high-temperature AlN thin film growth technology, the time consumption for preparing the thin film by the method provided by the invention can be shortened; the growth process is unique, simple and feasible; the large-scale production can be realized conveniently; and the thin film can be widely applied to the fields of a photovoltaic thin film for an LED, an ultraviolet and deep ultraviolet device, a surface acoustic wave device and the like.

Owner:广州市艾佛光通科技有限公司

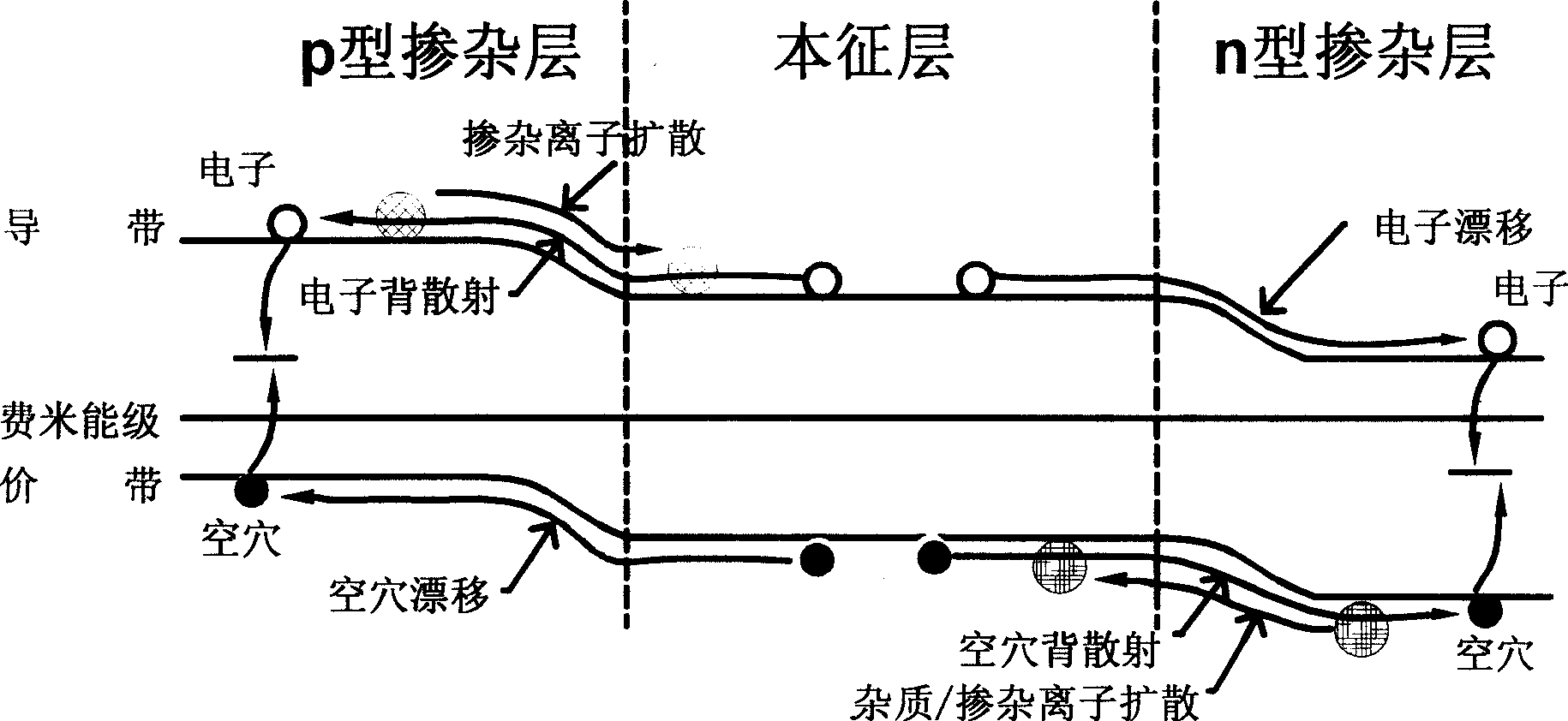

Double-layer doping-layer silicon-based film solar cell

InactiveCN101373799AIncrease the open circuit voltageImprove stabilityPhotovoltaic energy generationSemiconductor devicesDopantParticle interaction

The invention relates to a double doped layer silicon-based film solar cell. In a p type doped layer and an n type doped layer, the optical band gap of the layer closely adjacent to an intrinsic layer is larger than that of the layer far away from the intrinsic layer, but the difference value of the band gaps is not larger than 0.45 eV. The difference of the optical band gaps of the double doped layer structure is realized by arranging different materials according to the matching principle, or by changing the growth technology parameter of the identical material to control the optical band gaps. According to the invention, the inhibition to the particle interaction at the interface between the doped layers and the intrinsic layer and the control to the dopant particles and the accumulation and the distribution of defects can be realized simultaneously, excessive defects in the intrinsic layer can be reduced, simultaneously, the initial photoelectric conversion efficiency and the irradiation stability of the solar cell can be improved, the production cost for the silicon-based film solar cells can be further reduced, therefore, the structure can be applied to any silicon-based single-junction solar cell, laminated solar cell and multi-junction solar cell with p-i-n structure and n-i-p structure.

Owner:SOUTH WEST INST OF TECHN PHYSICS

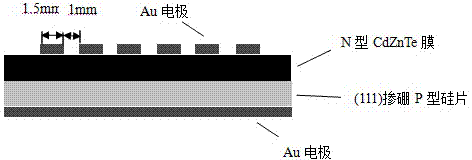

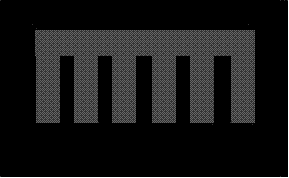

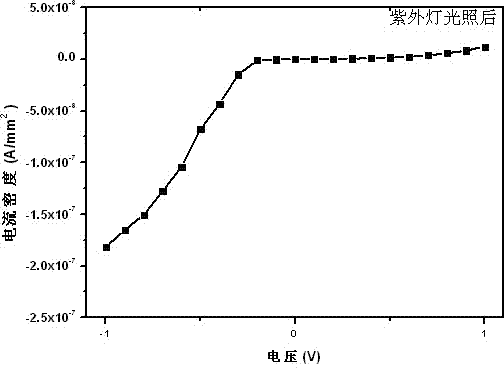

Preparation method of silica-based CdZnTe film ultraviolet light detector

InactiveCN103500776ASimple growth processLow costFinal product manufactureSemiconductor devicesHeterojunctionUltraviolet lights

The invention relates to a preparation method of a silica-based CdZnTe thin film ultraviolet light detector, which belongs to the technical field of ultraviolet light detector light-sensitive material and device manufacturing process. A near-space sublimation method is adopted, an N-type CdZnTe thin film is prepared on a P-type Si substrate, an ultraviolet light detector with a CdZnTe thin film / Si heterogeneous structure is formed, and a new method is provided for manufacturing the ultraviolet light detector with high performance. The invention relates to the silicon substrate-based heterojunction CdZnTe thin film ultraviolet light detector, which is characterized in that a CdZnTe thin film sample with high smoothness, uniform particle size and high quality is prepared on a Si chip by adopting the near-space sublimation method, and the prepared heterojunction detector has high sensitivity.

Owner:SHANGHAI UNIV

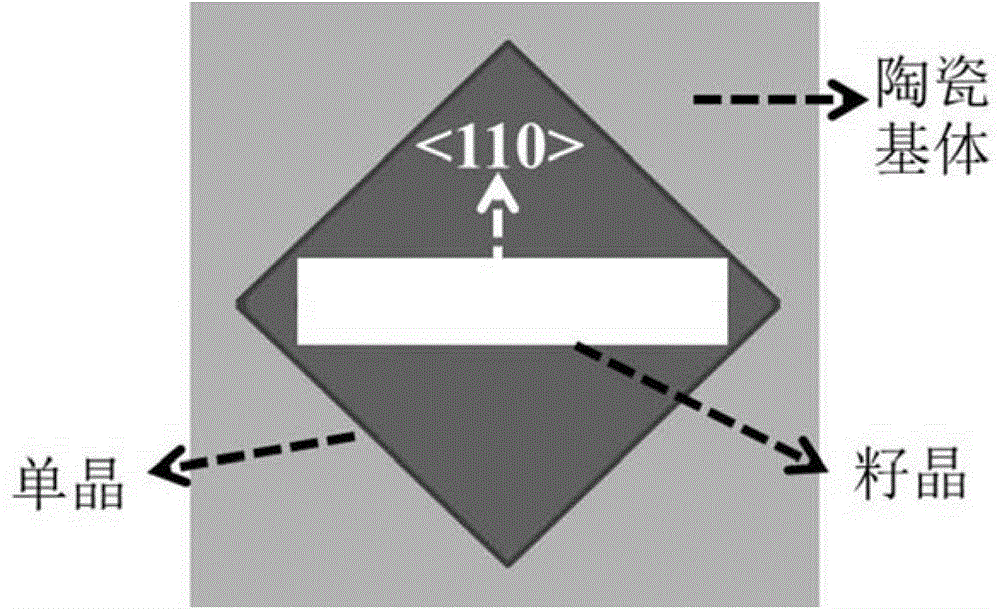

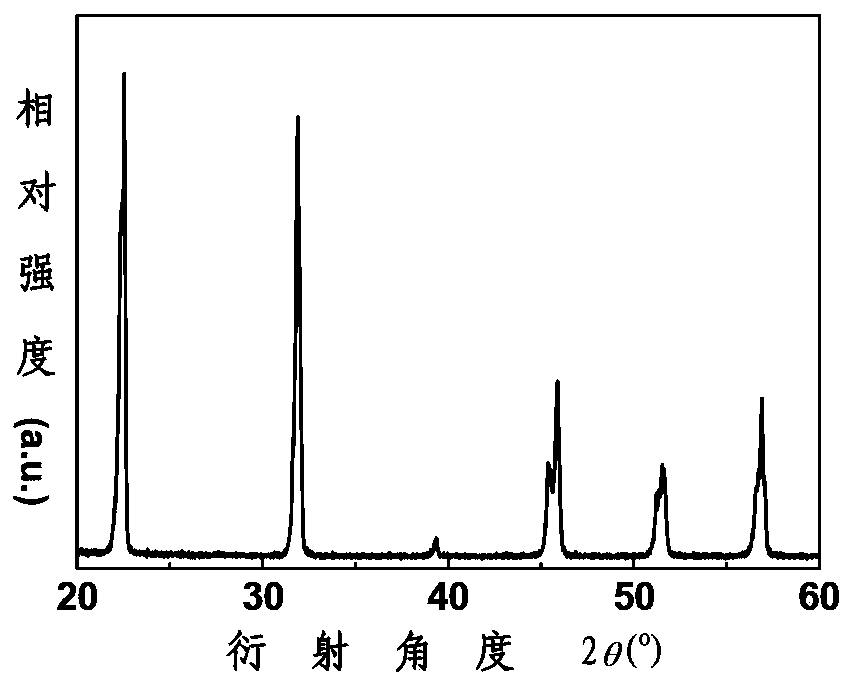

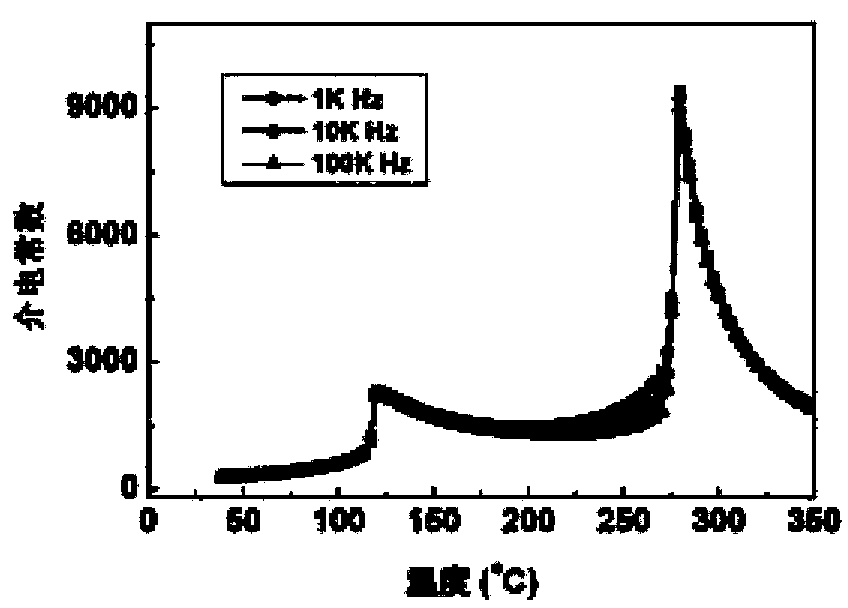

Potassium sodium niobate based single crystal and preparation method thereof

InactiveCN104357910ASimple growth processLow costPolycrystalline material growthFrom solid stateCeramic sinteringCombustion

The invention relates to a potassium sodium niobate based single crystal and a preparation method thereof. The potassium sodium niobate based single crystal has a chemical formula of (K0.45Na0.55)[1-x]Li[x]NbO3, wherein x is not less than 0 and not more than 0.1, and the size of the potassium sodium niobate based single crystal is more than 10 mm. In combination with single crystal preparation and ceramic sintering processes, a small amount of combustion-supporting agent is introduced and single crystal seeds are adopted for induction, so that a ceramic matrix is converted into single crystals at the temperature lower than the melting point of the ceramic matrix, and the potassium sodium niobate based lead-free piezoelectric single crystal with the size of more than 10 mm is successfully prepared.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Zinc selenide single crystal growing method and zinc selenide single crystal growing container

InactiveCN101665983ALess impuritiesGuaranteed mononuclear growthPolycrystalline material growthSingle crystal growth detailsPhase reactionAmpoule

The invention discloses a zinc selenide single crystal growing method and a zinc selenide single crystal growing container. The method uses zinc and selenium as raw materials and iodine as a vapour phase reaction promoter, and further completes the growth of a zinc selenide single crystal in an ampoule. The method sequentially comprises the following steps: comprehensively cleaning the ampoule, feeding the materials into the ampoule and evacuating the ampoule, sealing the ampoule, cleaning a growing area of the sealed ampoule with hot water, growing crystals, cooling the crystals, and the like. The ampoule has the basic structure that: a raw material area is easy to mix Zn and Se elementary substances; and the growing area consists of a conical body formed by the tangency of two sections of arcs on the cross section of a middle axis of the ampoule. The technical scheme adopted by the invention can grow zinc selenide single crystals of a diameter of 12 to 20mm, and also can be applied to the preparation of other II-VI group compound semiconductor crystals. The grown zinc selenide single crystals have the characteristics of integral structure, good uniformity, small stress, low cost,and simple process.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Plane indium and gallium infrared focusing plane detector and its making method

InactiveCN101170142AGood lookingStop the spreadFinal product manufactureSemiconductor devicesDiffusionIndium

The invention discloses a flat type InGaAs infrared focal plane device, which includes a flat type PN junction formed by Zn diffusion on an epitaxial wafer. The invention is characterized in that: a thickened Cr / Au ring electrode is positioned around the upper part of the Zn diffusion area and the limitation on a photosensor element is realized by the Au layer reflection of incident lights. The shape of the thickened electrode is decided by a photoetching graph, so the effective photosensor element area can be controlled precisely. The preparation method of the device is characterized in that: before heat treatment, generate SiO2 passive film to prevent Zn from out diffusion in the heat treatment course, improve PN junction thermal stability, and realize device surface passivation and light antireflection by controlling the thickness of SiO2 film. p electrode adopts single Au layer, which simplifies p electrode growth process and is important to process stability and device evenness. The Au and the InP have better adhesiveness. And the thermal annealing course under the protection of SiO2 layer can realize good ohmic contact with Au / Zn / Au.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Process for growing cerium-doped LYSO scintillating crystals by using molybdenum crucible

ActiveCN104294365AImprove qualitySolve process problemsPolycrystalline material growthFrom frozen solutionsCrucibleCerium

The invention discloses a process for growing cerium-doped LYSO scintillating crystals by using a molybdenum crucible, which belongs to the technical field of scintillating crystal preparation. The process for growing scintillating crystals comprises the following steps: (a) putting a solid-phase reaction material into the molybdenum crucible; (b) putting the crucible into a vacuum furnace, and vacuumizing the vacuum furnace until the pressure of the inside of the furnace is less than or equal to 10 Pa; (c) filling flowing weak reductive protective gas in the furnace; (d) heating the inside of the furnace, and carrying out at least primary air exchange in the process of heating, wherein the air exchange includes vacuumizing the inside of the furnace until the pressure is less than or equal to 10 Pa, and then filling flowing weak reductive protective gas in the furnace again; and (e) further heating the inside of the furnace until the solid-phase reaction material is melted, and carrying out crystal growth. The process for growing LYSO scintillating crystals overcomes technical problems; and by using the process, the molybdenum crucible both can resist oxidation and erosion of molten LYSO raw materials, then high-quality LYSO scintillating crystals grow, and therefore, the production cost is greatly reduced, and the process is relatively simple and easy to control.

Owner:成都东骏激光股份有限公司

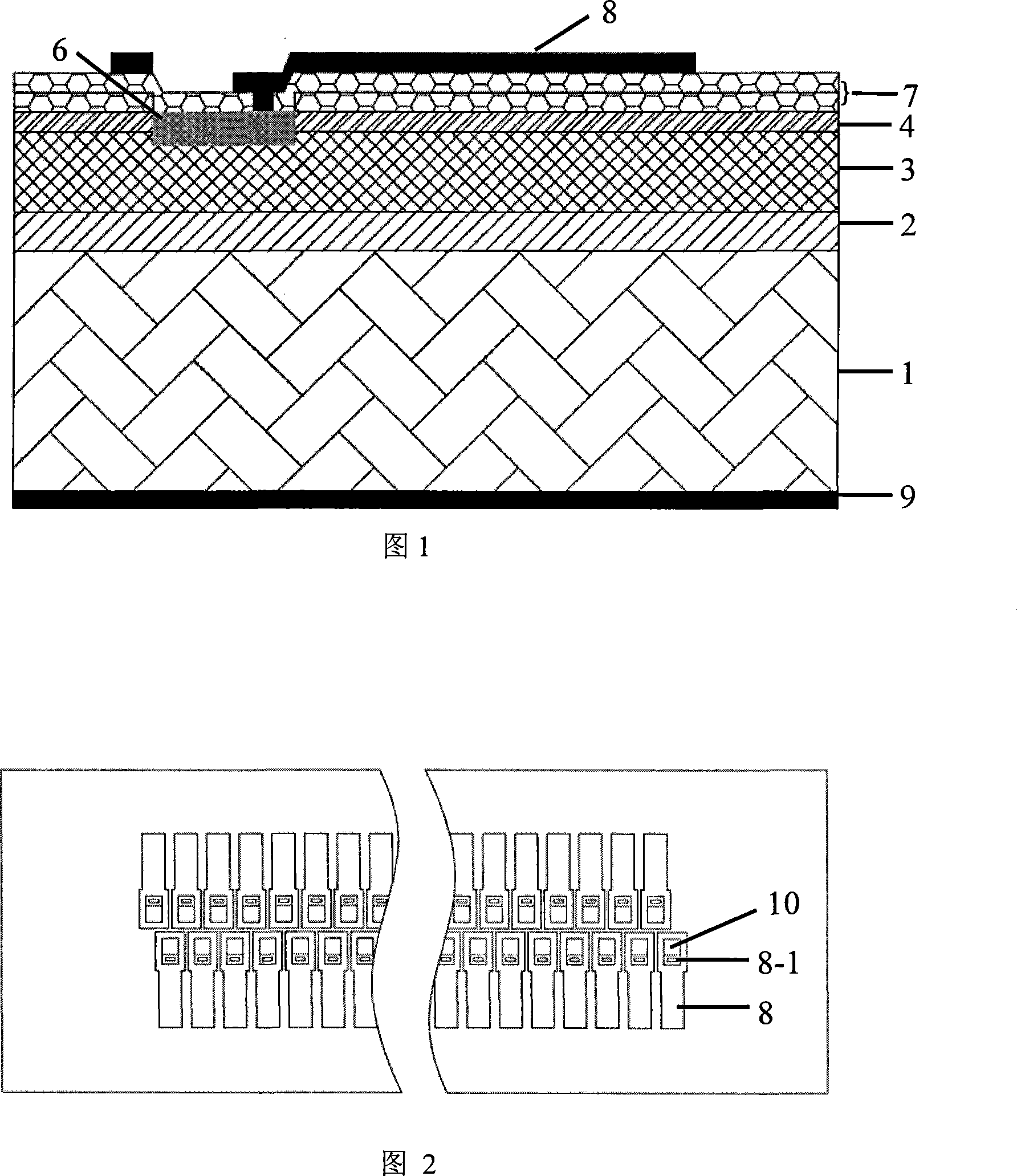

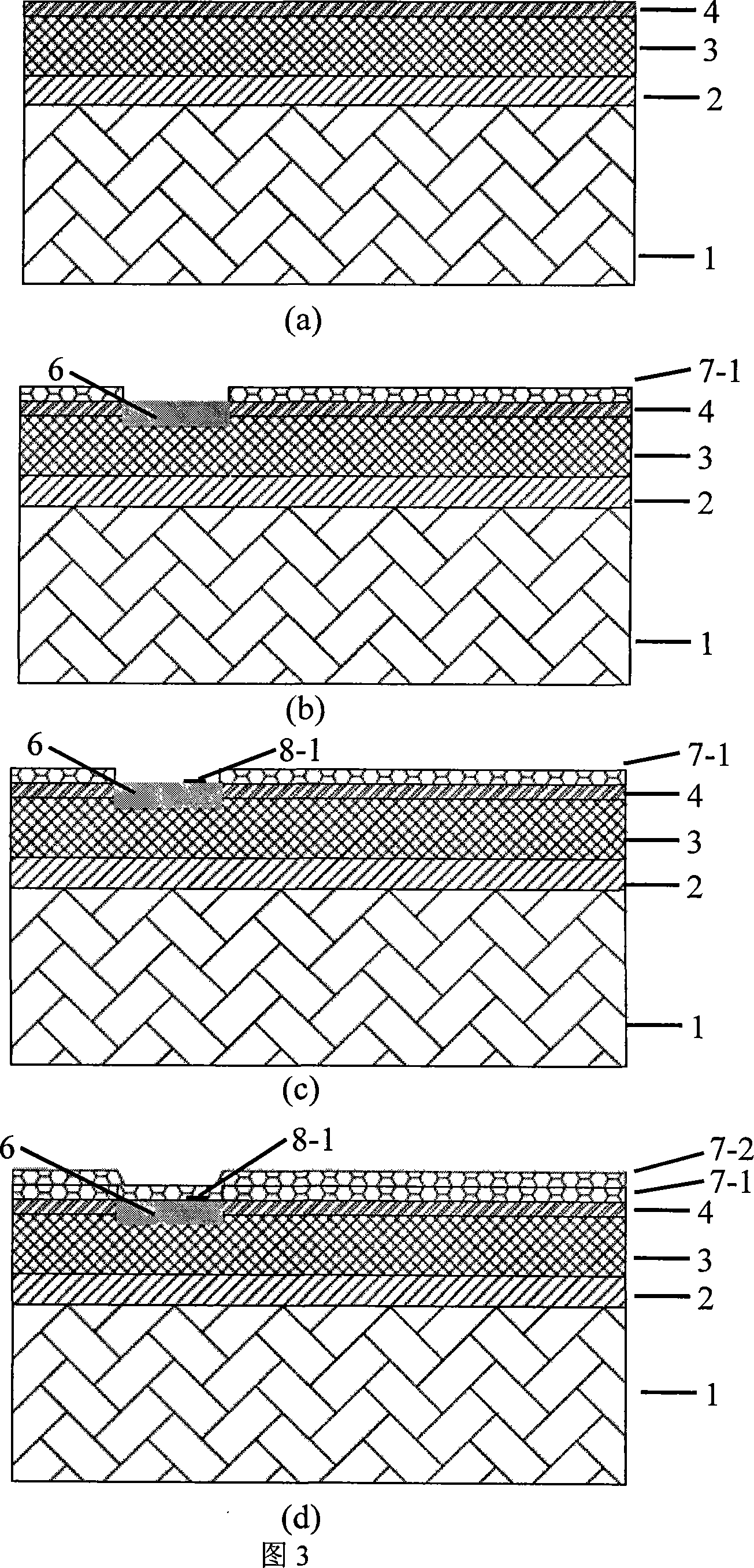

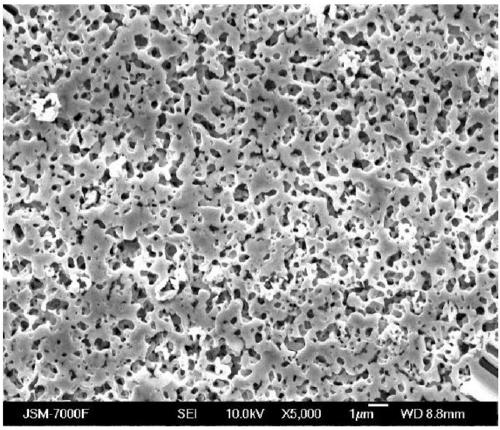

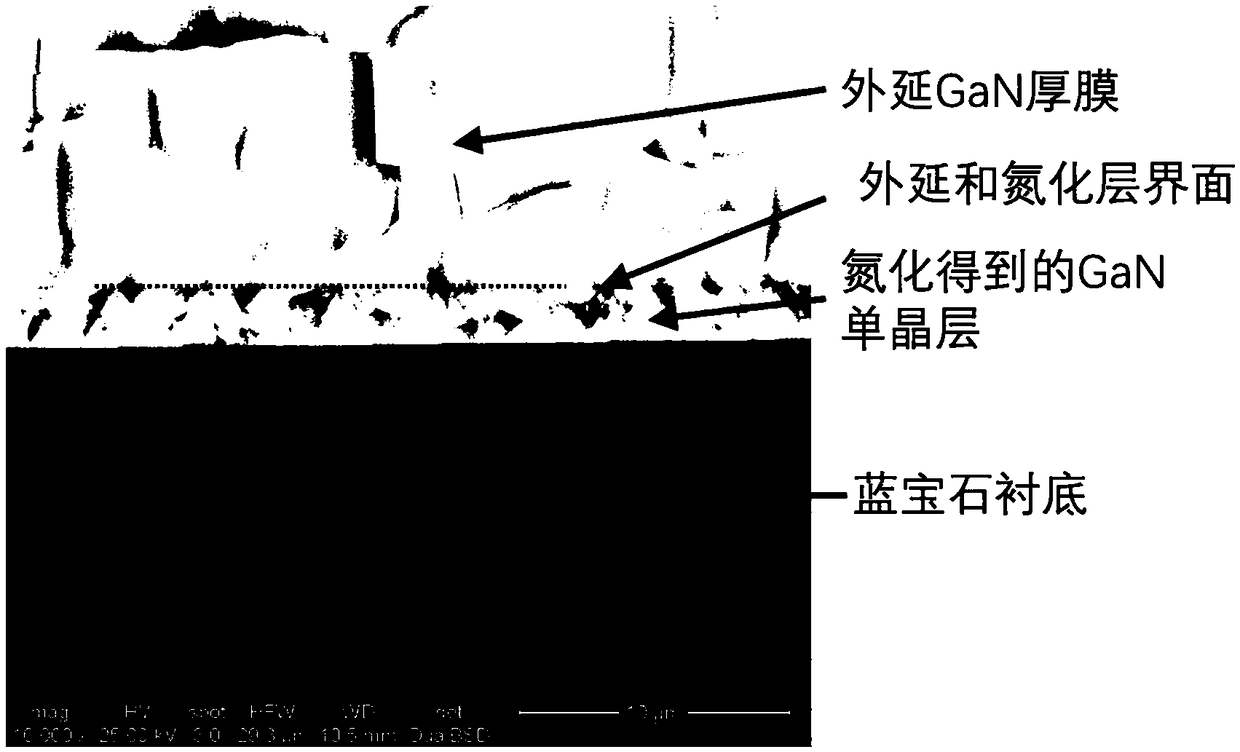

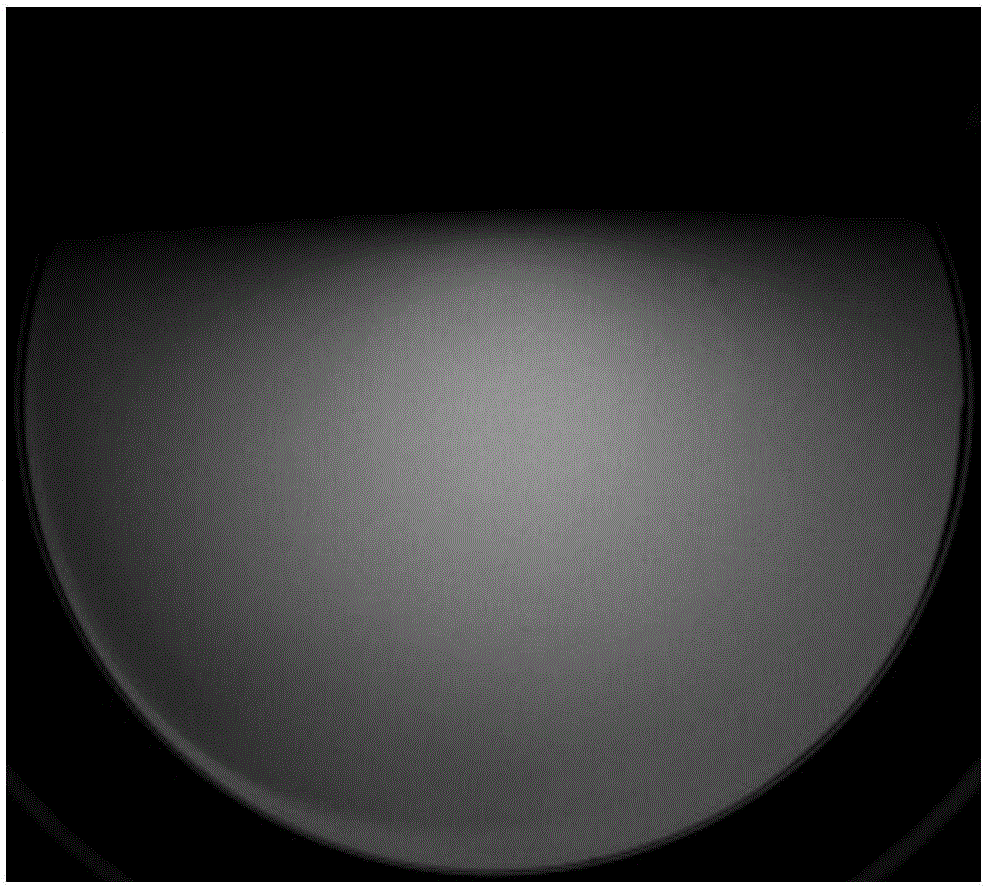

Self-separation method for preparing self-supporting GaN substrate

InactiveCN109023516AIncrease stressSustained DiffusionPolycrystalline material growthFrom chemically reactive gasesRoom temperatureGallium nitride

The invention discloses a self-separation method for preparing a self-supporting GaN substrate, which includes steps of: 1) on a sapphire substrate, growing a uniformly-distributed Ga2O3 film, whereinthickness range of the film is 0.1-1 [mu]m; 2) in an ammonia atmosphere, performing complete nitridation to the film, thus forming a porous GaN film in latticed distribution; 3) on the porous GaN film, performing halide vapor phase epitaxy growth of a GaN thick film, thus forming a low stress and high quality GaN thick film; 4) after the epitaxy is completed, cooling the material to room temperature, so that the epitaxy GaN thick film is automatically separated from the sapphire substrate, thus obtaining the self-supporting GaN substrate.

Owner:NANJING UNIV

Method for preparing molybdenum sulfide two-dimensional material by adopting MOCVD equipment

ActiveCN110655111AThickness is easy to controlControl nucleation densityChemical vapor deposition coatingMolybdenum sulfidesPhysical chemistrySulfidation

The invention discloses a method for preparing a molybdenum sulfide two-dimensional material by adopting MOCVD (Metal Organic Chemical Vapor Deposition) equipment, and the method is used for growing the MoS2 two-dimensional material on a Sapphire substrate in multiple steps, and comprises the following steps of: adopting Sapphire as the substrate; conveying the Sapphire substrate into an MOCVD (Metal Organic Chemical Vapor Deposition) equipment; introduced N2 gas into a MOCVD cavity; raising the temperature to a constant-temperature growth temperature, wherein the initial pressure in the cavity is 90Torr; introducing H2S as a sulfur gas source; introducing MO (CO) 6 as a molybdenum gas source for nucleation; reducing the pressure intensity in the cavity step by step, and promoting nucleation crystal grains to transversely grow so as to obtain the MoS2 two-dimensional material growing on the Saphire substrate. The preparation method provided by the invention has the advantages of simplegrowth process, controllable material thickness, high quality and the like. Through the preparation method provided by the invention, the MoS2 two-dimensional material which is adjustable in forbidden band width and can be used for flexible chip application is grown.

Owner:ZHEJIANG UNIV

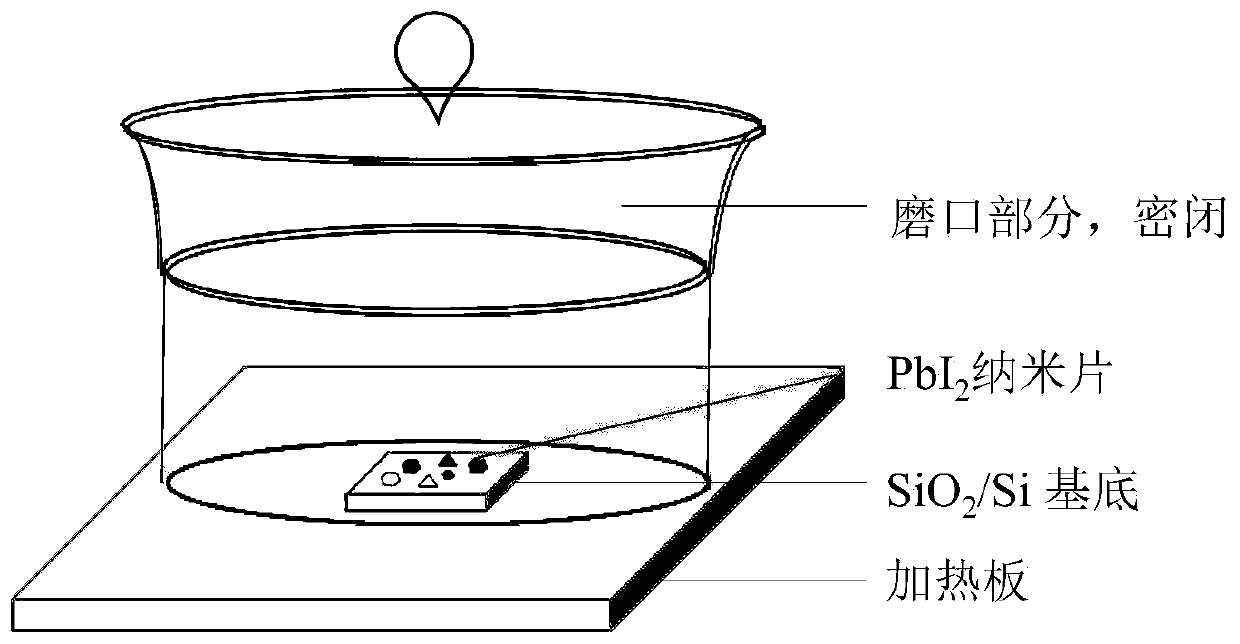

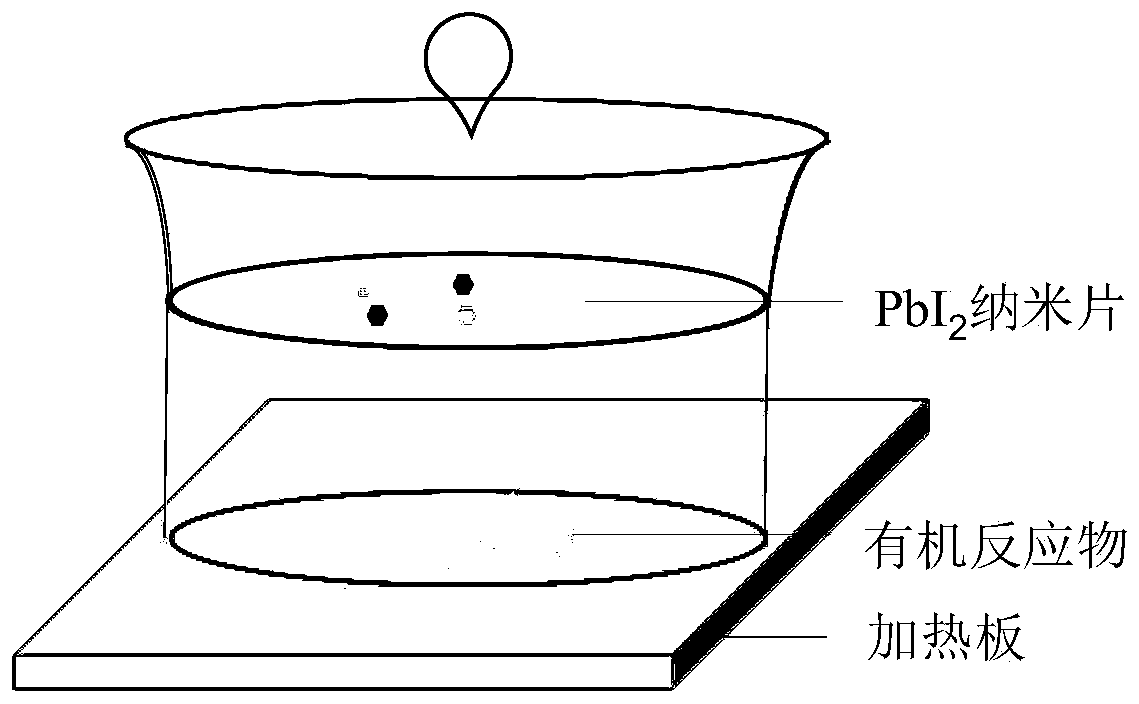

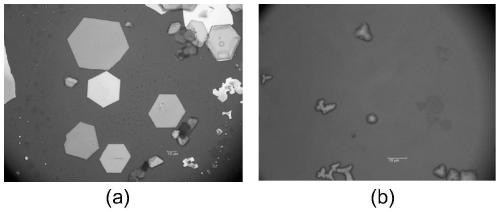

Preparation method of highly stable lead-based organic-inorganic hybrid perovskite nano sheet

ActiveCN110194718AAvoid problems such as high equipment requirements and high energy consumptionImprove production efficiencyMaterial nanotechnologyOrganic compound preparationHigh humidityGas phase

The invention provides a preparation method of a lead-based organic-inorganic hybrid perovskite nanosheet, the lead-based organic-inorganic hybrid perovskite nanosheet is prepared by a two-step method, and comprises the following steps: 1, dripping supersaturated lead halide aqueous solution onto a substrate to prepare a lead halide substrate; and 2, heating an organic precursor to a gas phase state for fully contacting and reacting with the lead halide substrate to obtain a lead-based organic-inorganic hybrid perovskite nano sheet. In the gas phase method, hydrophobically modified piperazineis added to the organic precursor for treating lead halide. The wetting angle of the perovskite nanosheet increases obviously, which indicates that the water resistance of the perovskite nanosheet isimproved. Aging tests prove that perovskite can keep stable for a long time under high temperature and high humidity environment, and the perovskite can be prepared into a solar cell with good photoelectric efficiency. The lead-based organic-inorganic hybrid perovskite nanosheet provided by the preparation method has excellent comprehensive performance, can simultaneously have good photoelectric efficiency and stability, and has good market promotion prospects.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

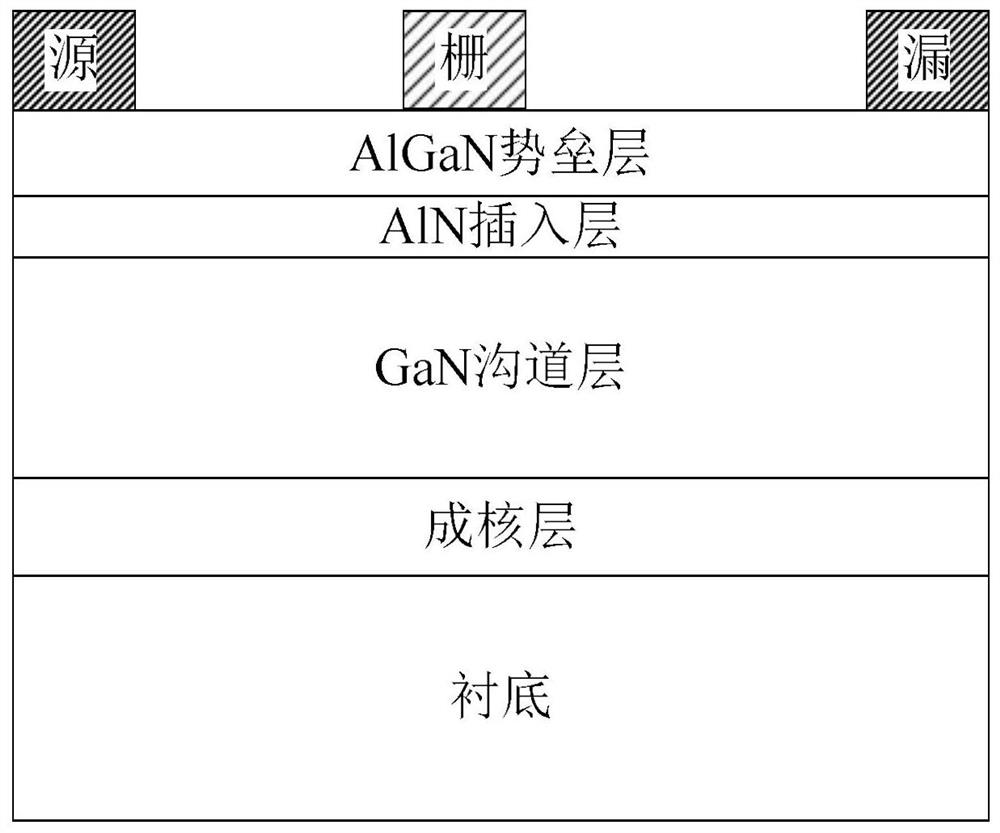

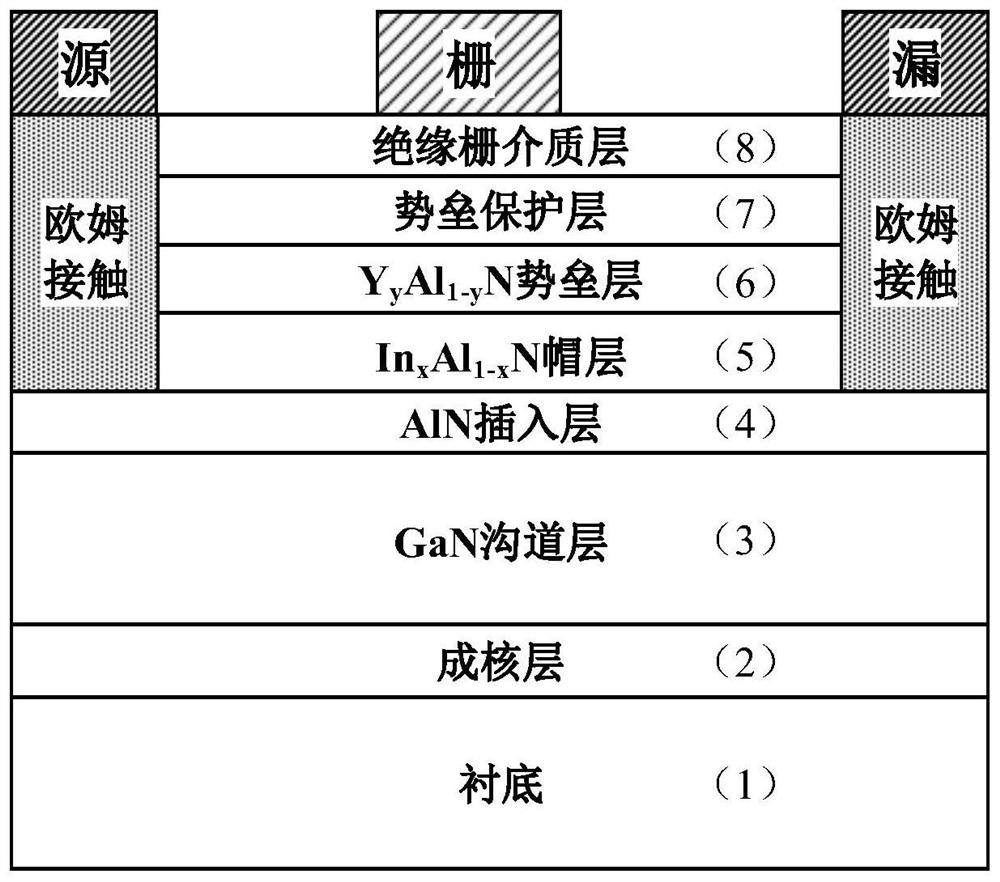

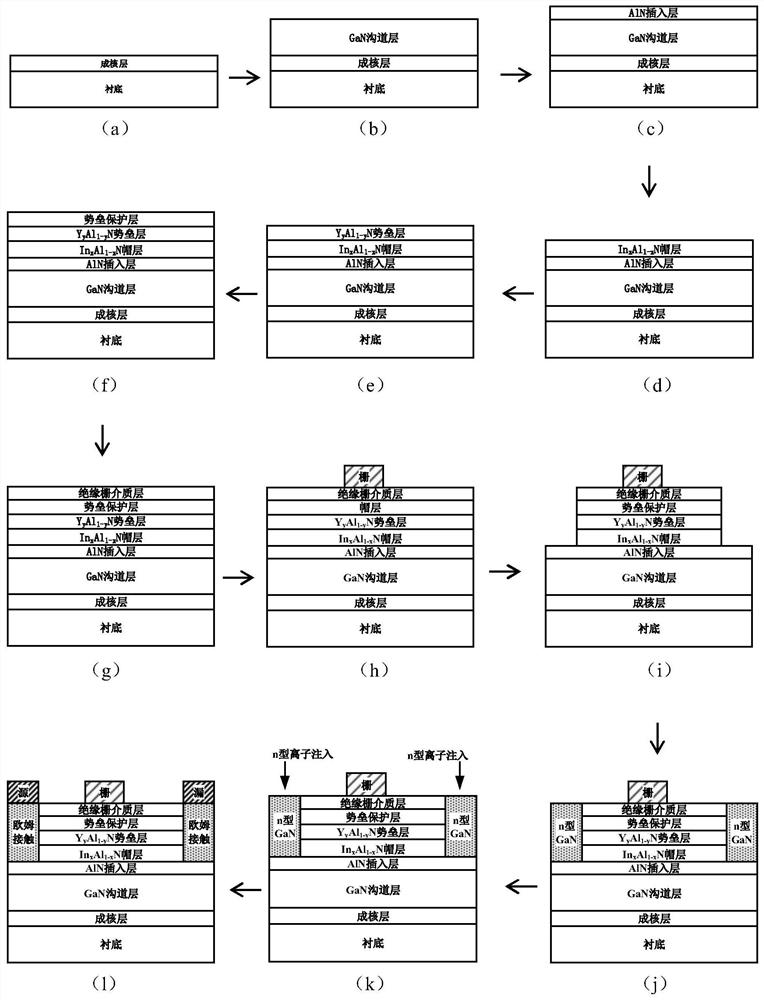

YAlN/GaN high-electron-mobility transistor and manufacturing method thereof

ActiveCN112736131AEffective protectionImprove breakdown voltageSemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricOhmic contact

The invention relates to a YAlN / GaN high-electron-mobility transistor and a manufacturing method thereof, and mainly solves the problems of low working frequency and high material dislocation density of an existing nitride microwave power device. The transistor comprises a substrate, a nucleating layer, a GaN channel layer, an AlN insertion layer and a YAlN barrier layer from bottom to top, wherein an InAlN cap layer is arranged between the insertion layer and the barrier layer; a barrier protection layer and an insulated gate dielectric layer are sequentially arranged at the upper part of the barrier layer, and ohmic contact regions for manufacturing a source electrode and a drain electrode are arranged on two sides from the InAlN cap layer to the insulated gate dielectric layer. A nucleating layer, a GaN channel layer, an AlN insertion layer and an InAlN cap layer in the structure are grown by adopting MOCVD; and the YAlN barrier layer and the barrier protection layer are grown by adopting MBE. The material is high in polarization intensity, high in device working frequency, high in reliability, simple in manufacturing process and high in consistency, and can be used for a high-frequency microwave power amplifier and a microwave millimeter wave integrated circuit.

Owner:XIDIAN UNIV

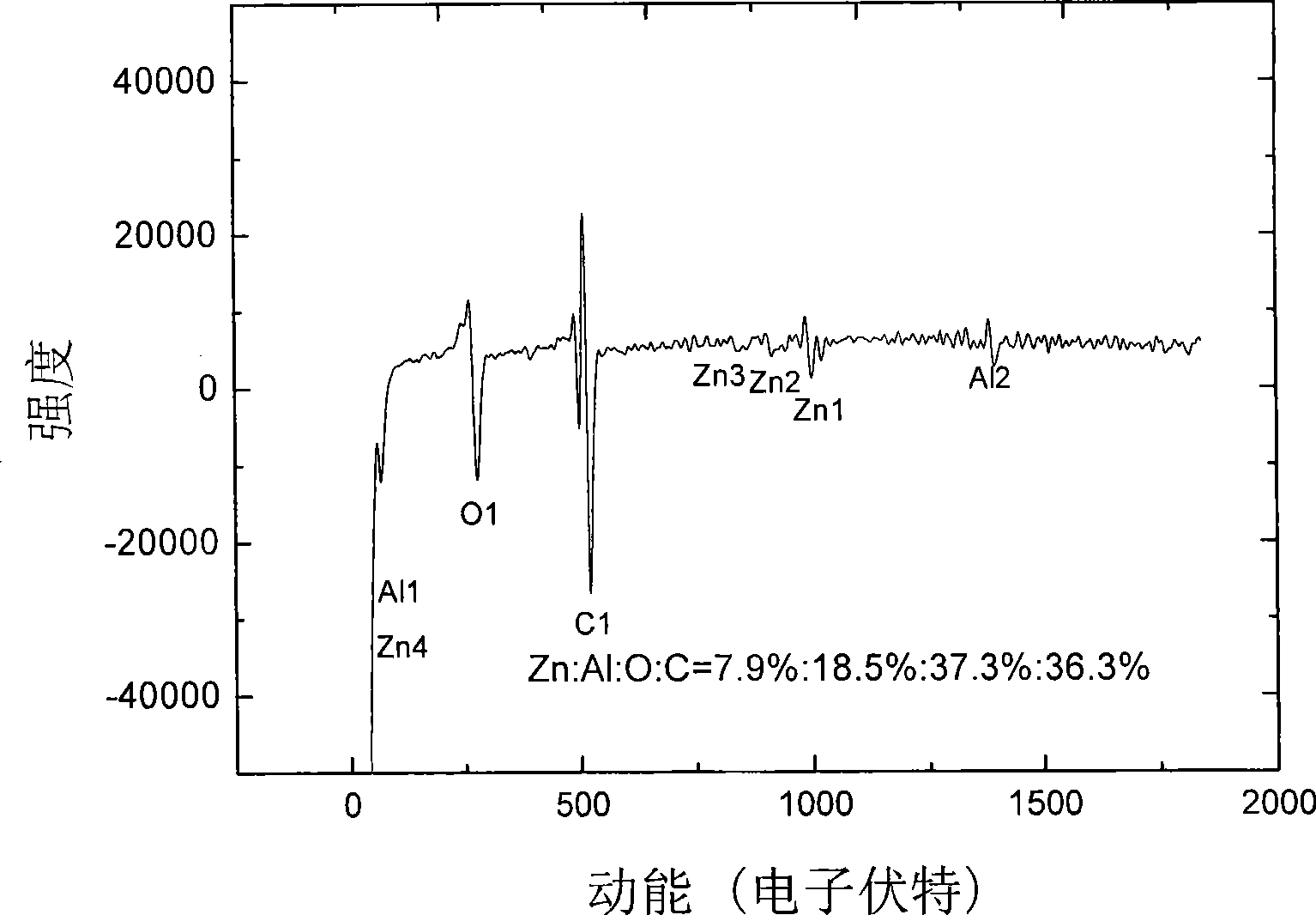

Method for growth of large size high quality zinc oxide single crystal thick film on sapphire

InactiveCN101469448AImprove growth qualitySmall sizePolycrystalline material growthFinal product manufactureEtchingPolyvinyl alcohol

The invention discloses a method for growing a zinc oxide single-crystal thick film with large size and high quality on a sapphire substrate, which comprises the steps of: 1) using zinc acetate, polyvinyl alcohol and deionized water to be prepared into a colloid solution; 2) soaking the sapphire substrate with clean surface in the deionized water for certain time; 3) using a photoresist spinner to evenly spread a layer of zinc acetate-polyvinyl alcohol colloid solution on a C plane of the sapphire substrate; 4) performing high-temperature annealing on the colloid solution after the colloid solution is dried; 5) using a wet method to etch the substrate annealed by the step 3, using the deionized water to rinse after the etching is finished, and spin-drying; and 6) using metal-source chemical vapor phase epitaxial growth technology (MVPE) to grow the zinc oxide single-crystal thick film on the spin-dried sapphire substrate. The method has the characteristics of simple process and equipment, low cost, high repeatability and so on.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

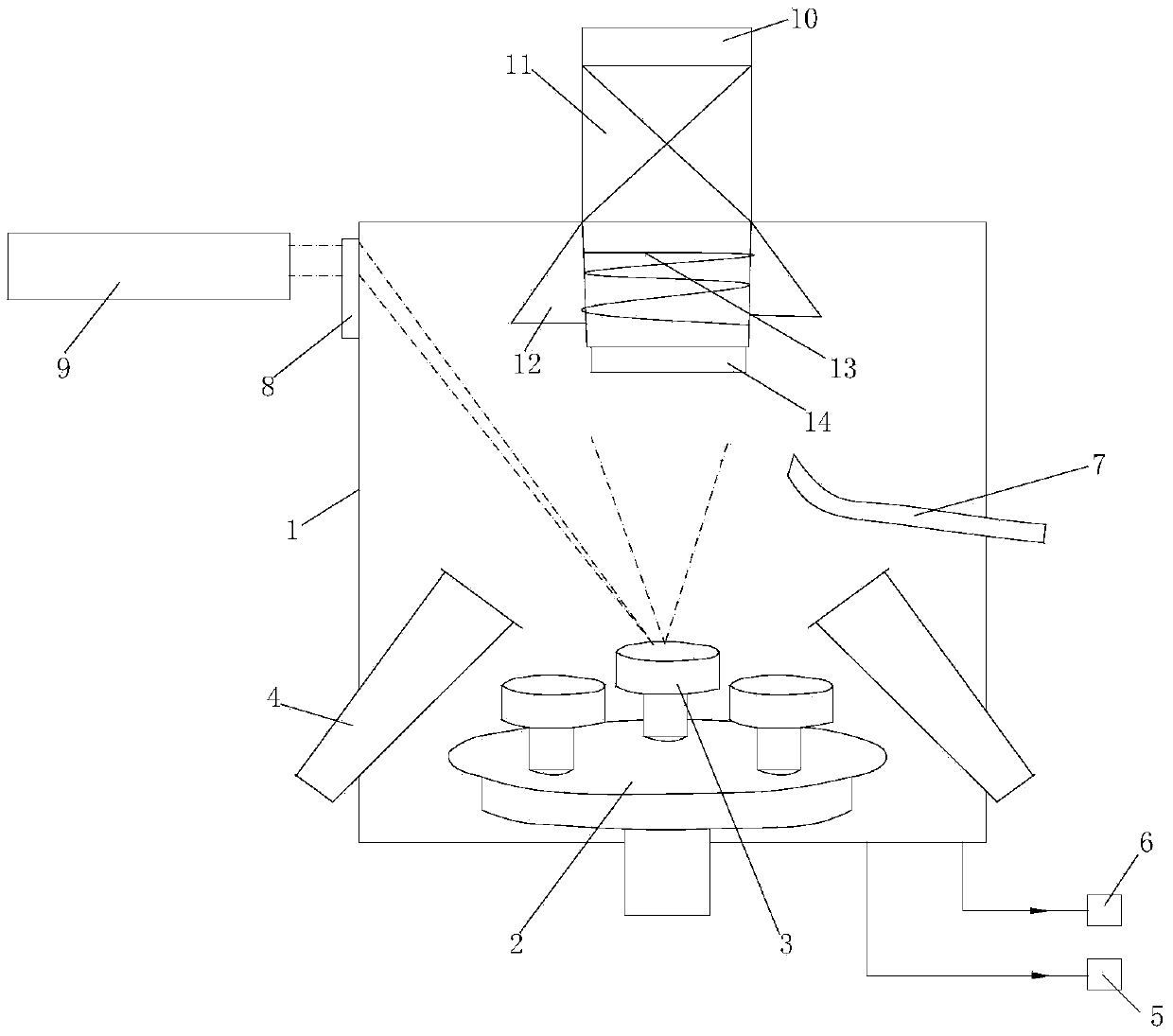

Pulsed laser deposition and molecular beam epitaxy combined coating device and application thereof

ActiveCN103996605AImprove performanceFunctionalVacuum evaporation coatingSputtering coatingState of artHigh energy

The invention discloses a pulsed laser deposition and molecular beam epitaxy combined coating device and application thereof. A target material tray capable of conducting revolution and rotation is added to the middle area of an MBE evaporation source, and a target material required by PLD coating is placed; a high-performance solid laser device is added, and meanwhile a quartz window is added to an appropriate position of a cavity of an MBE growth chamber and high-energy lasers with the wave length of 150 nm to 355 nm are introduced for evaporation of the target material. The coating device is a PLD and MBE combined body and has the functions and advantages of a PLD and an MBE at the same time; the coating device can be used as the PLD or the MBE individually and can also be used as the combination of the PLD and the MBE; the coating device can be used for epitaxial growth of a thin film and manufacturing of thin film devices, especially for solar cells, LEDs and LDs of a quantum well structure. Compared with the prior art, the coating device has the advantages of being simple in growth process, low in manufacturing cost and wide in application range.

Owner:广州市艾佛光通科技有限公司

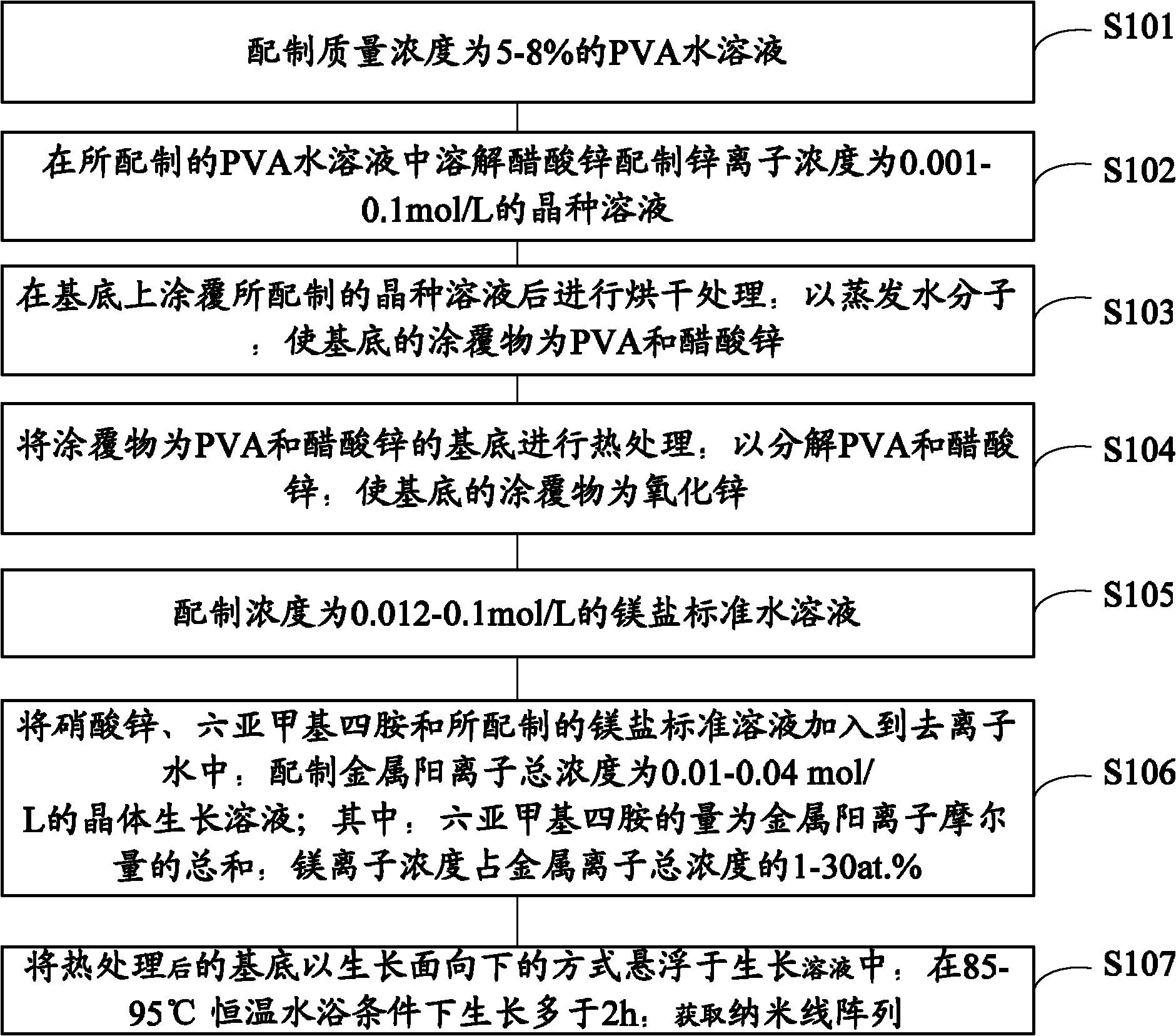

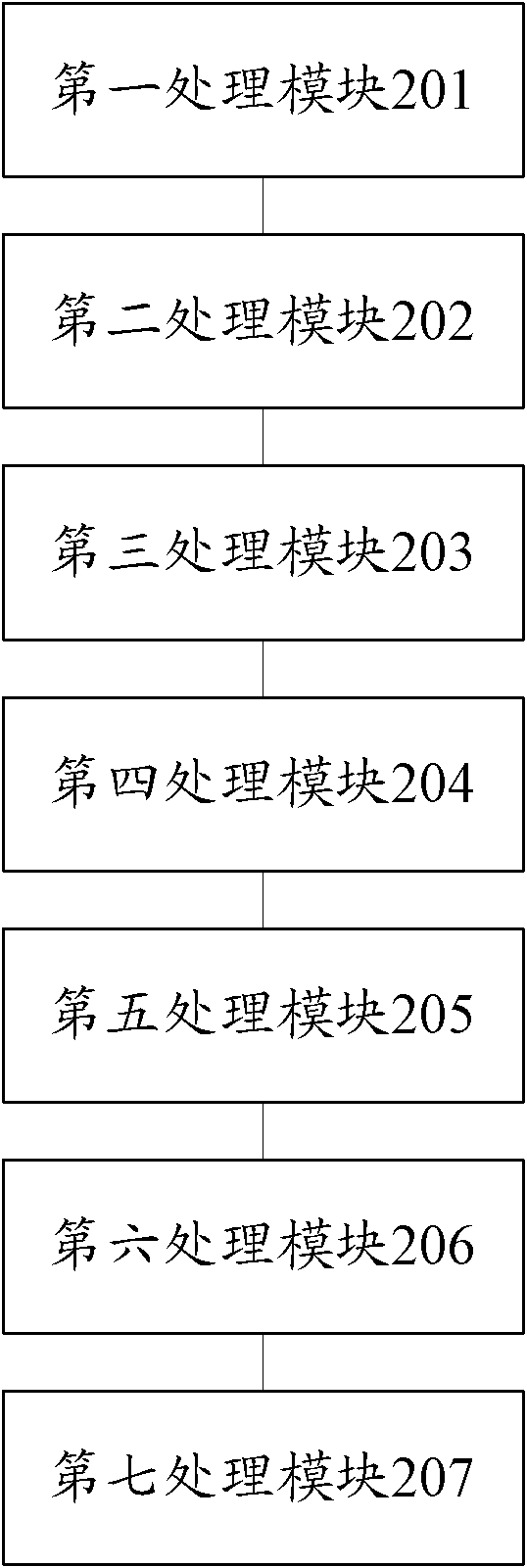

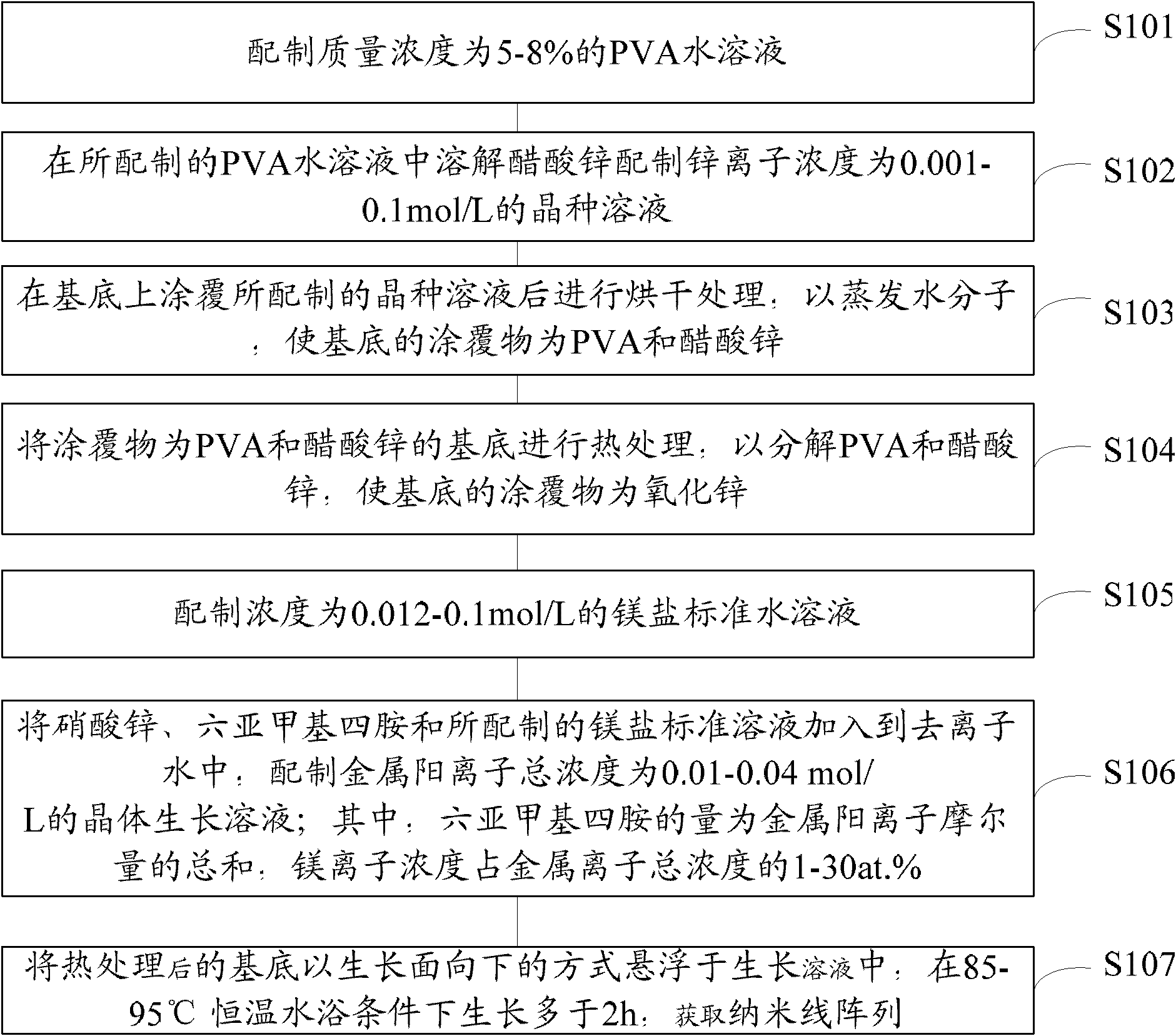

Method and device for preparing Mg-doped ZnO nanowire array

InactiveCN102115912ALow costSimple growth processPolycrystalline material growthFrom normal temperature solutionsWater bathsMagnesium salt

The invention provides a method and a device for preparing an Mg-doped ZnO nanowire array. The method comprises the following steps of: dissolving zinc acetate in 5 to 8 mass percent aqueous solution of polyvinyl alcohol (PVA) to prepare crystal seed solution with the zinc ion concentration of 0.001 to 0.1mol / L; coating the crystal seed solution on a substrate and drying to ensure that the coating material of the substrate is the PVA and the zinc acetate; performing heat treatment to ensure that the coating material of the substrate is zinc oxide; preparing 0.012 to 0.1mol / L standard aqueous solution of magnesium salt; adding the standard aqueous solution, zinc nitrate and hexamethylenetetramine into deionized water to prepare growth solution with the total metal cation concentration of 0.01 to 0.04mol / L; and suspending the substrate subjected to heat treatment in the growth solution, and growing in an 85 to 95 DEG C constant-temperature water bath for more than 2 hours to obtain the nanowire array. Therefore, the Mg-doped ZnO nanowire array can be grown at a low temperature, the cost of the used raw materials is low, and the production process is simple and has high repeatability.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

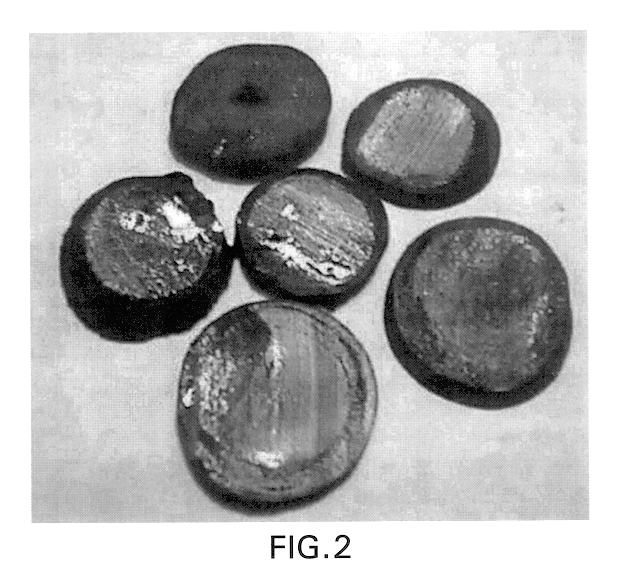

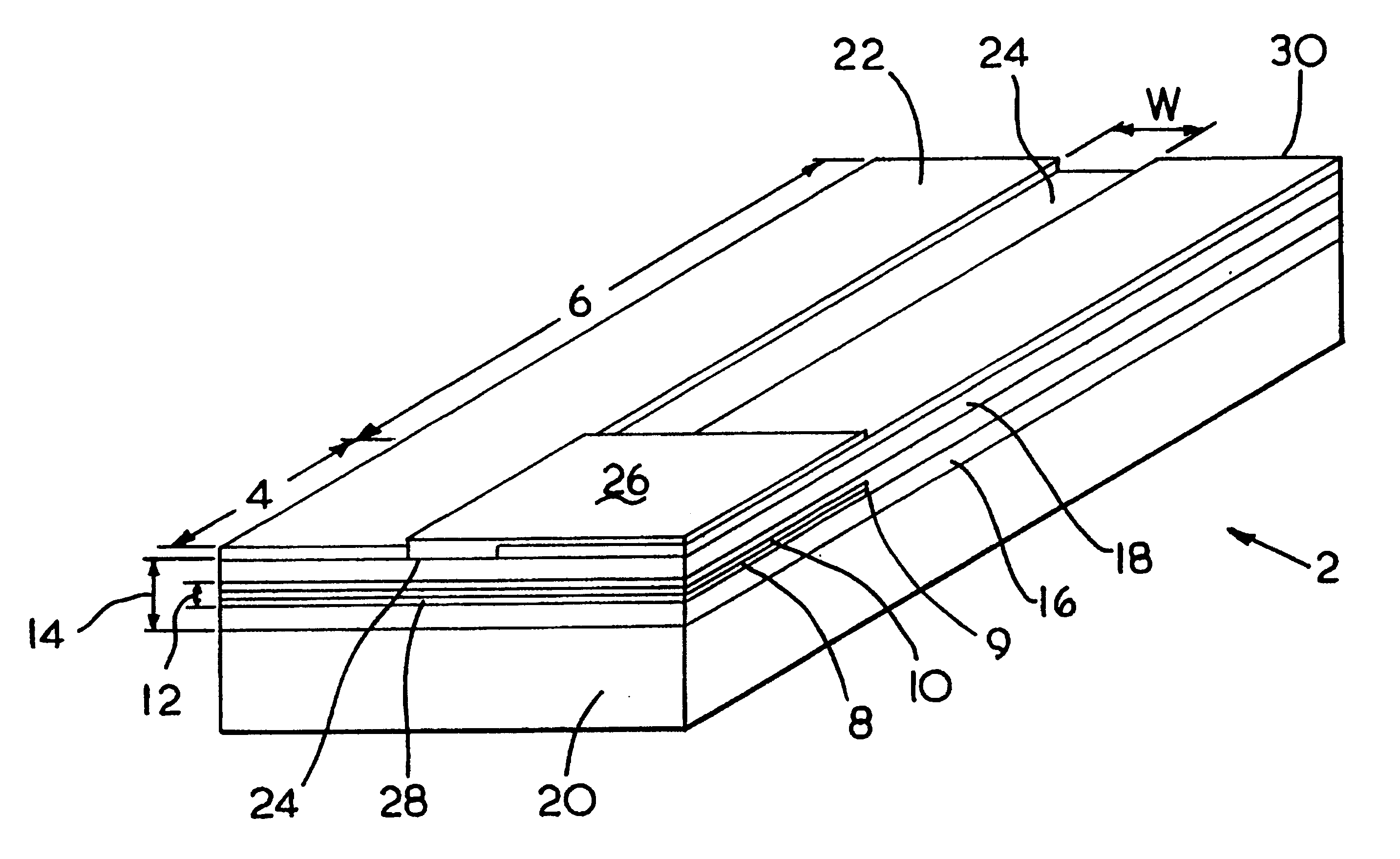

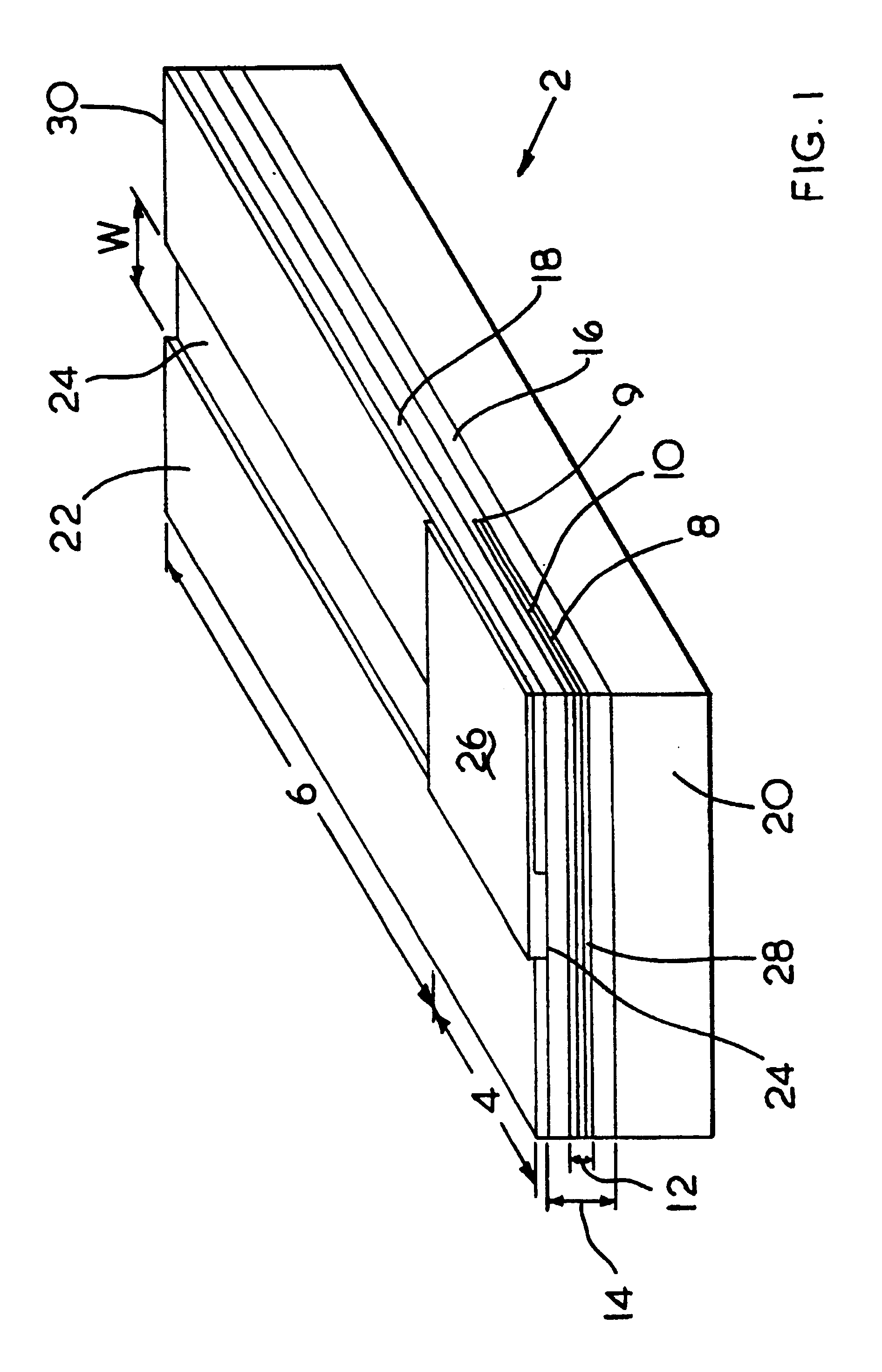

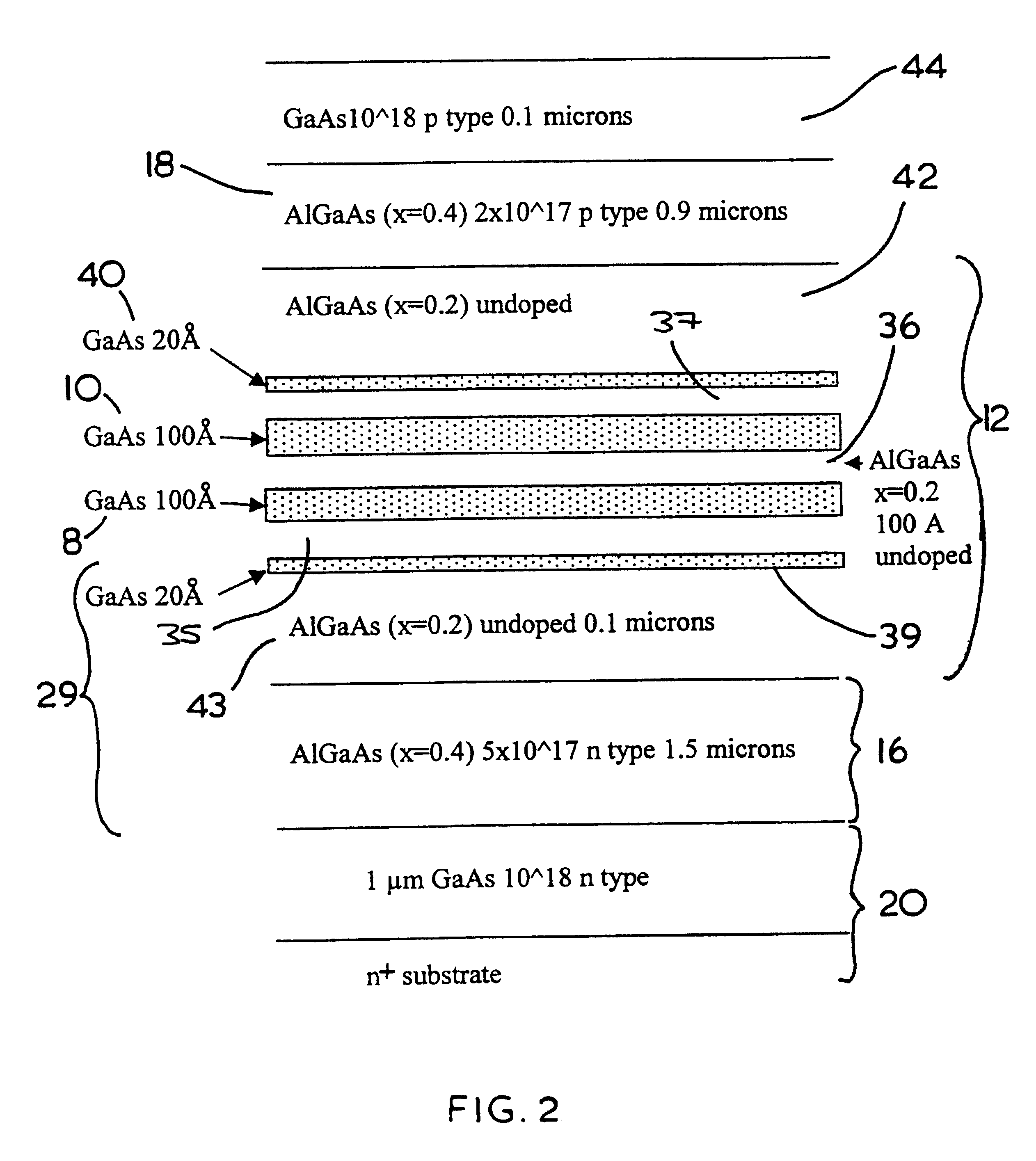

Electro-optic semiconductor devices and method for making the same

InactiveUS6630693B1Simple growth processInexpensive wayLaser detailsSolid-state devicesSemiconductor waveguidesWaveguide

An electro-optic semiconductor device comprising a semiconductor waveguide with a core region within which is located at least one active area wherein the core of the waveguide outside of the one or more active areas are not contaminated by diffuse active area material and the one or more active area(s) and the waveguide are monolithic and are grown in an additive growth process. Also provided is a method of making an electro-optic semiconductor device, comprising the steps of; growing a first part of a core layer of a semiconductor waveguide, selectively growing an active layer over a partial area of the first part of the core layer, and growing a second part of the core layer of the semiconductor waveguide over the first part and the active layer, characterised in that the method comprises an additive growth process.

Owner:HANGER SOLUTIONS LLC +1

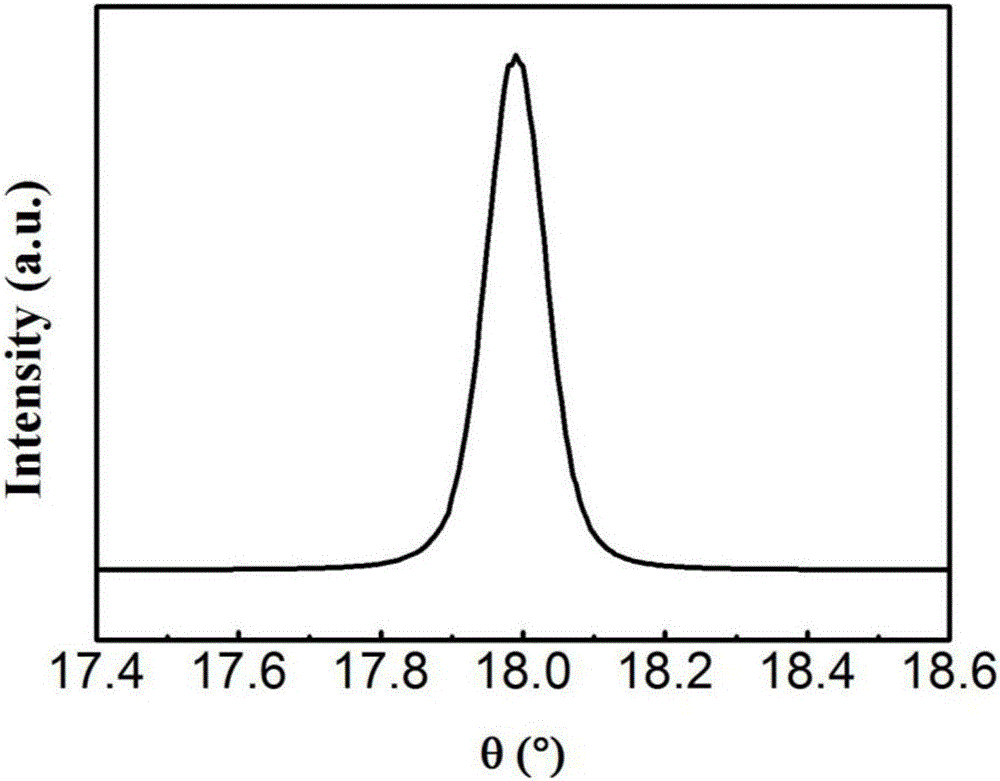

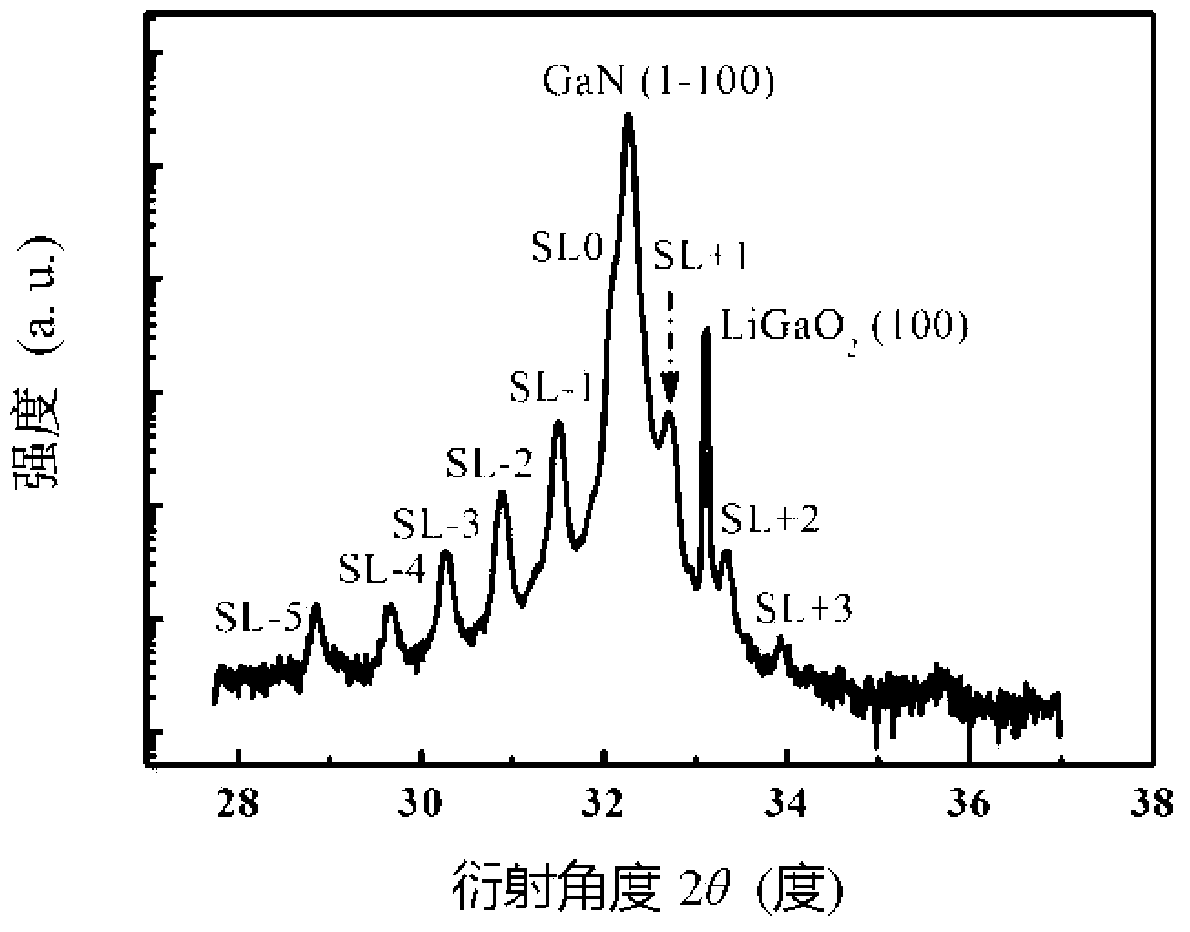

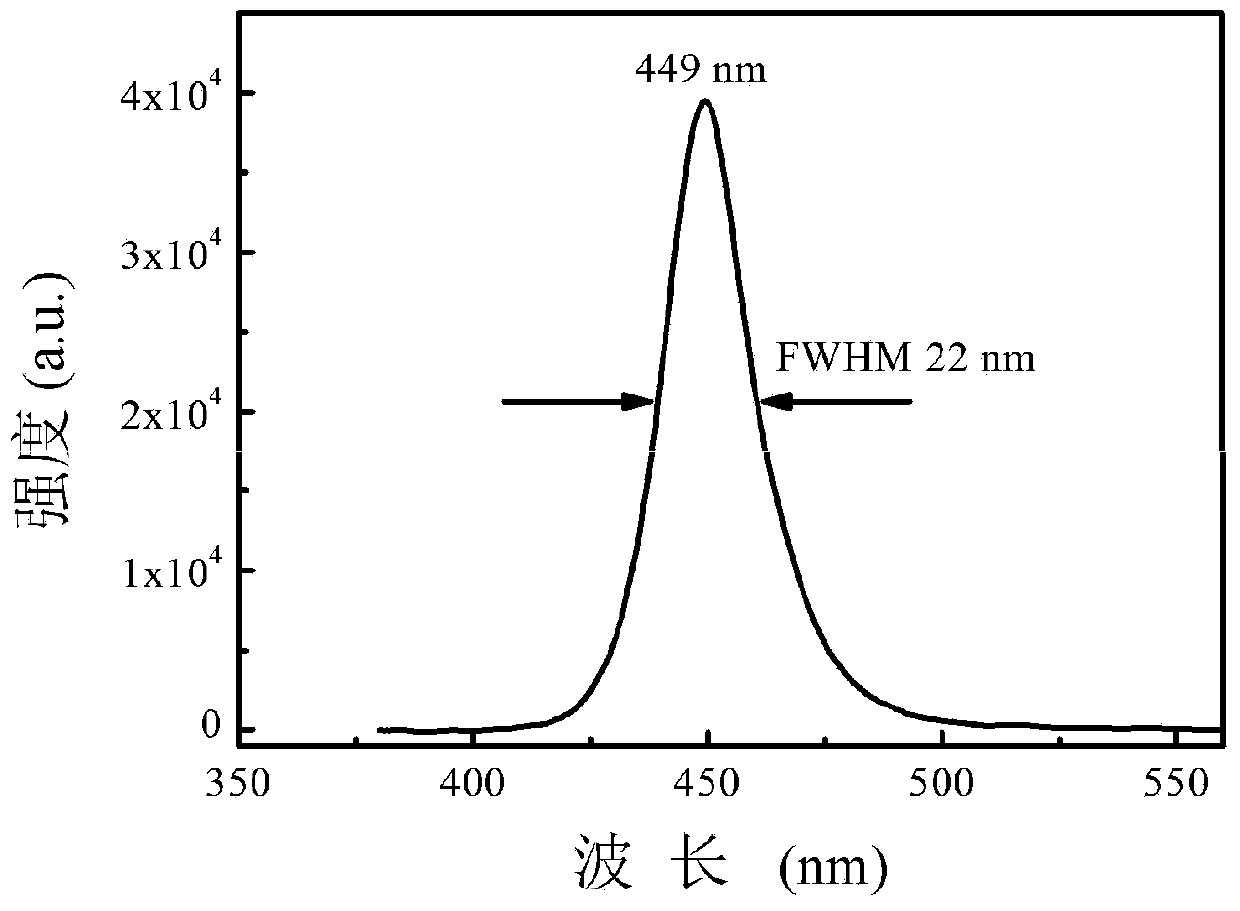

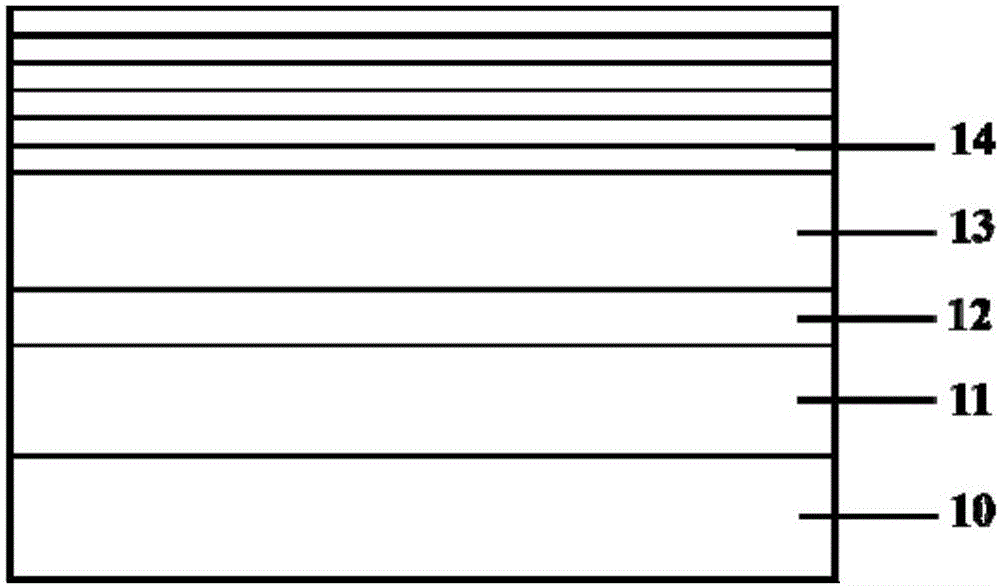

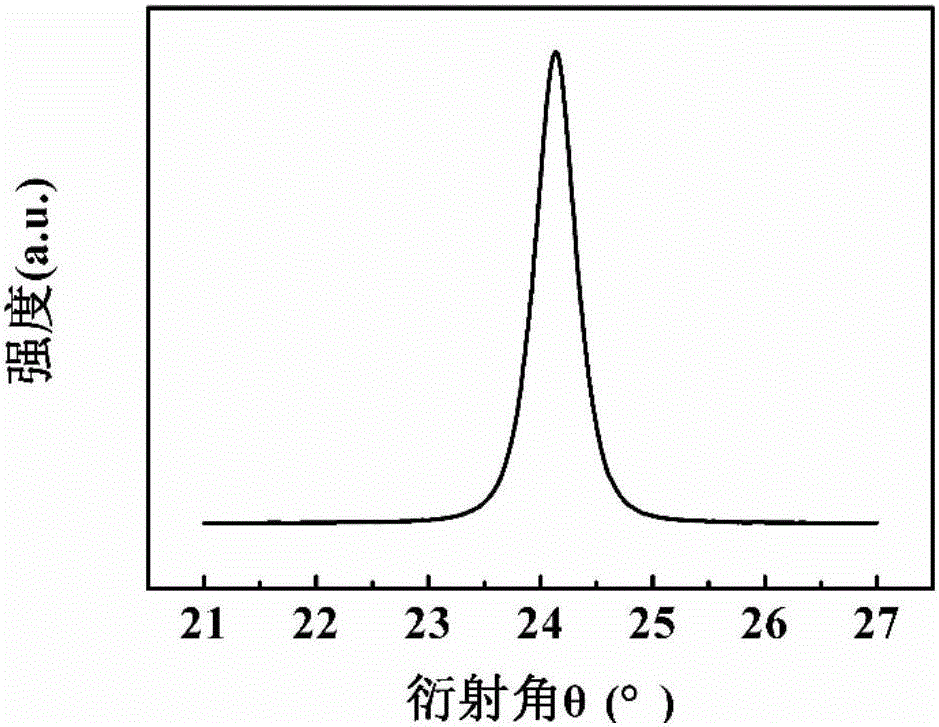

InGaN/GaN quantum well grown on ScMgAlO4 substrate and preparation method of InGaN/GaN quantum well

The invention discloses an InGaN / GaN multi-quantum well grown on a ScMgAlO4 substrate. The InGaN / GaN multi-quantum well comprises a first GaN buffer layer, an amorphous AlN insertion layer, a second GaN buffer layer and an InGaN / GaN quantum well which are sequentially grown on the ScMgAlO4 substrate. The invention also discloses a preparation method of the InGaN / GaN multi-quantum well grown on the ScMgAlO4 substrate. The InGaN / GaN multi-quantum well has the advantages of simple growth process and low preparation cost, and moreover, the prepared InGaN / GaN multi-quantum well is low in defect density, good in crystal quality and excellent in luminous performance.

Owner:SOUTH CHINA UNIV OF TECH

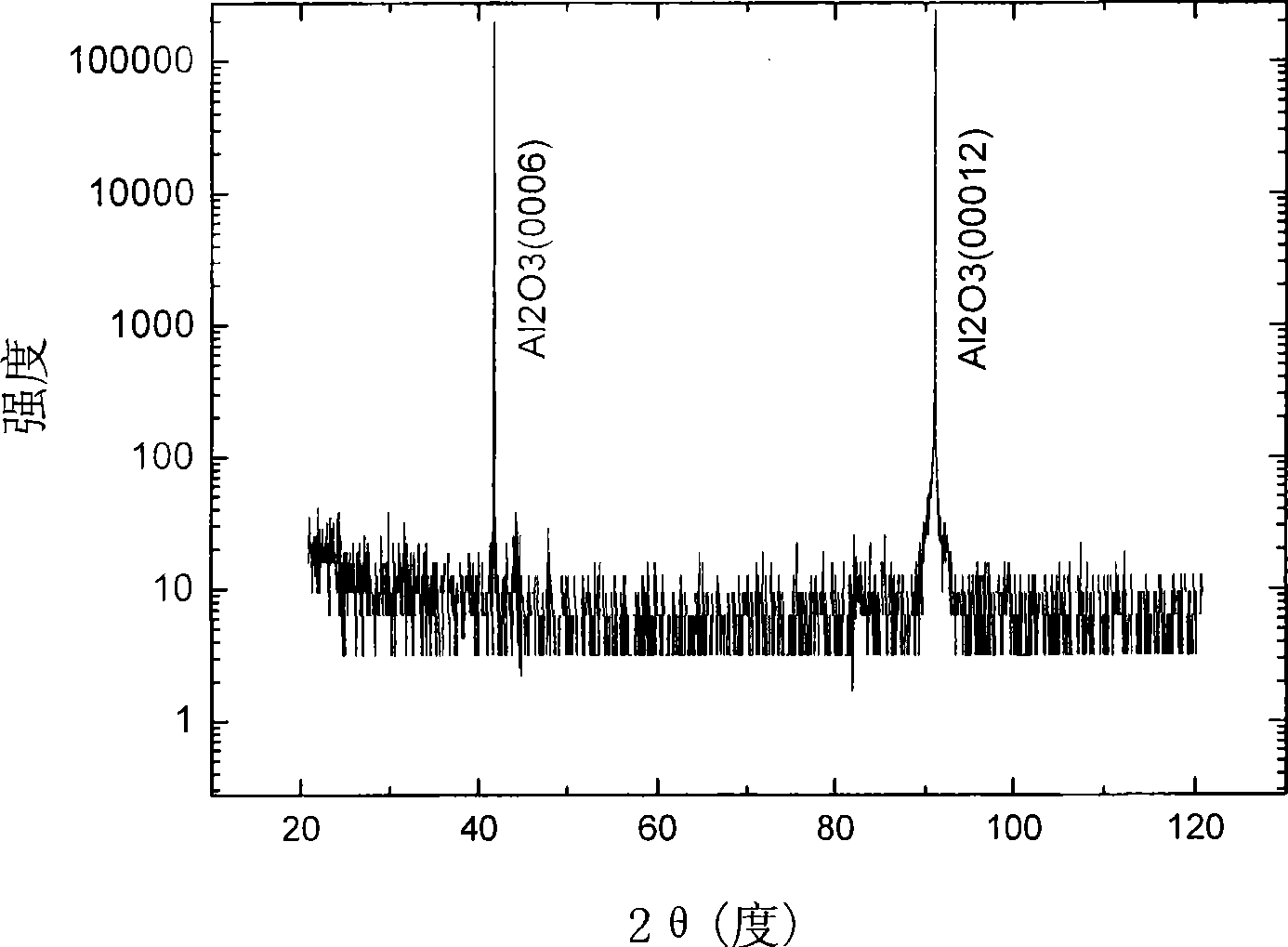

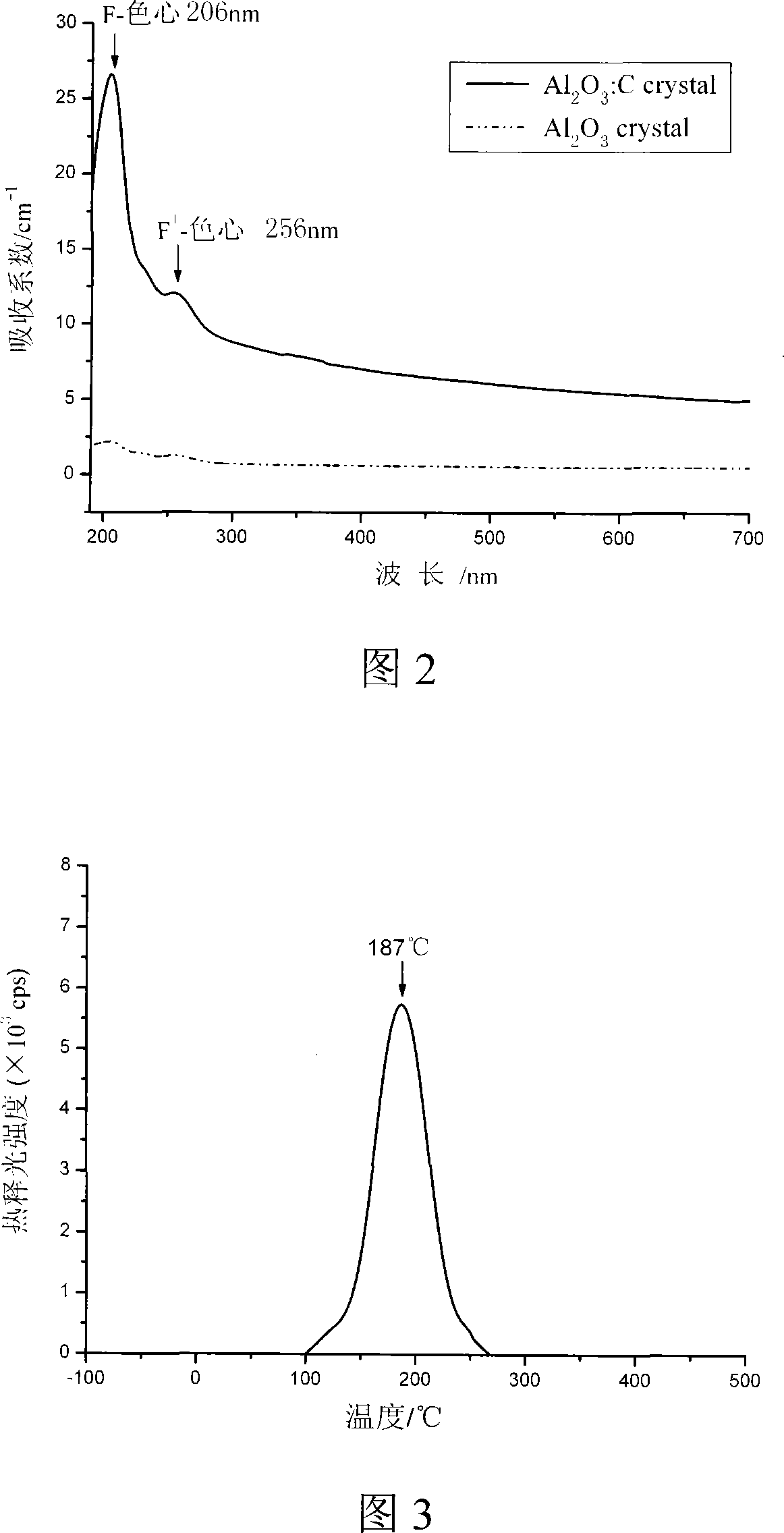

Growing method for carbon-doped sapphire crystal

InactiveCN101230484ASimple growth processIncrease productivityPolycrystalline material growthFrom frozen solutionsThermoluminescenceCrucible

The invention relates to a method of growing a carbon-mixed sapphire crystal, is characterized in that the method of targeted gradient temperature is adopted to grow the Alpha-Al2O3: C crystal. The process flow is as follows: firstly, a certain qualitative amount of Alpha-Al2O3 is weighed and then graphite of 100 to 5,000 ppm is added in and stirred to mix well; secondly, oriented sapphire seed crystals are placed in the seed crystal tank of the molybdenum crucible in the temperature gradient furnace and the well-mixed powder lot is put into the crucible evenly and then the crucible is covered; and thirdly, the crucible is placed in the furnace. The furnace is vacuumized to be 5 by 10<-3>Pa, persistently overheated to be 2,080 DEG Cand kept constant for 0.5 to 1 hour and then the temperature is reduced to the room temperature at a velocity of 3 to 5 DEG C per hour and then the furnace mantle is unclosed to take out the crystal. The Alpha-Al2O3: C crystal directly grown in the invention has excellent thermoluminescence capability and high crystal quality, which can be used for manufacturing highly-sensitive thermoluminescent detectors.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

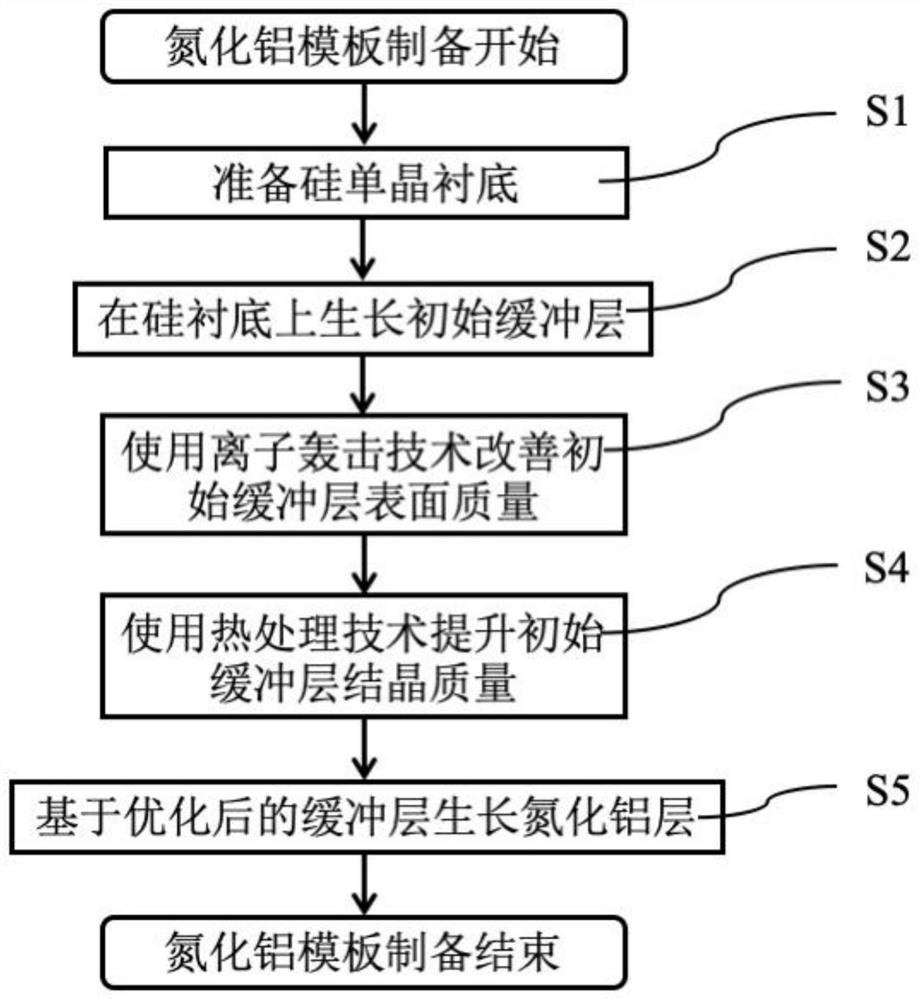

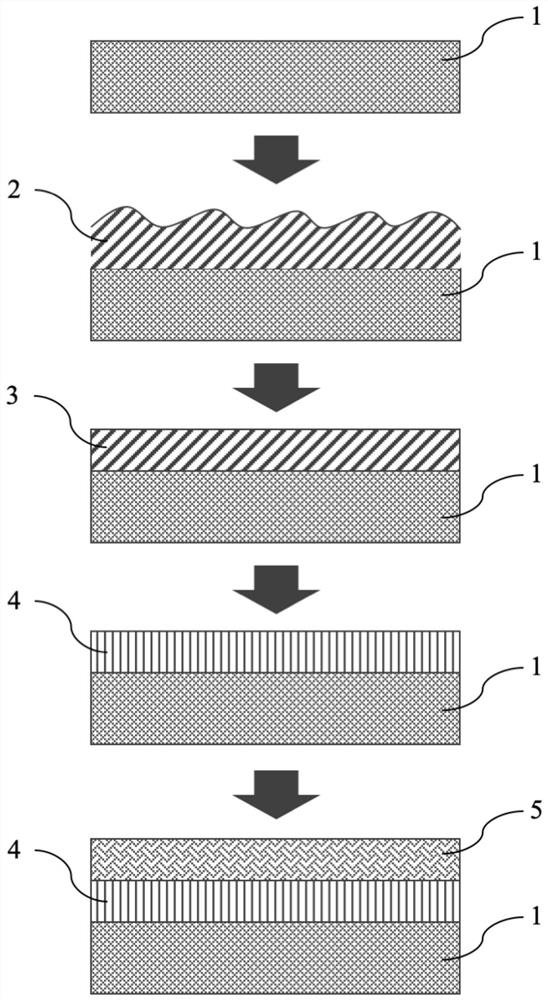

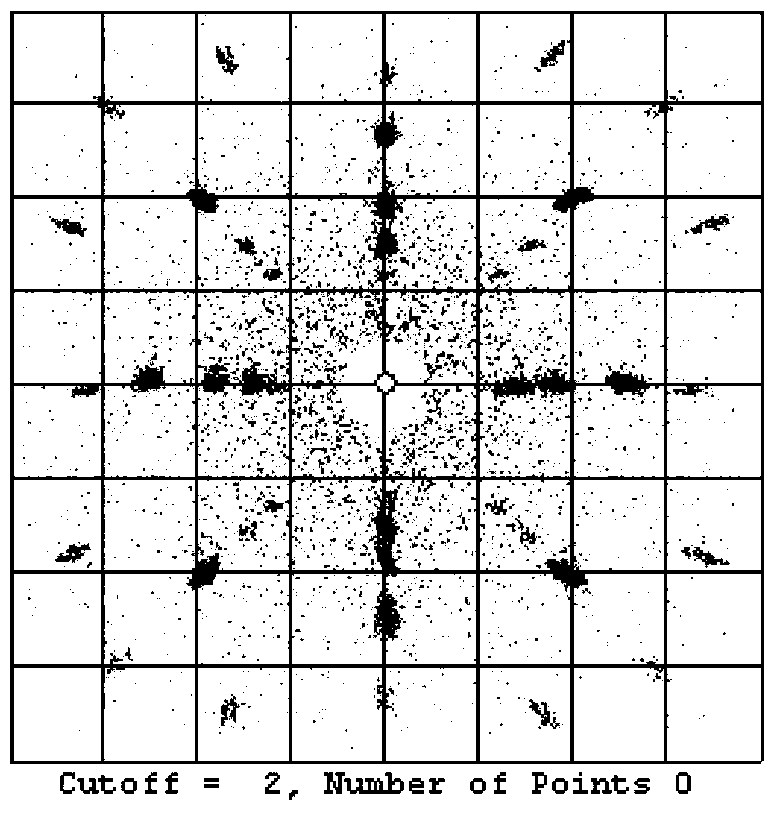

Method for preparing high-quality silicon-based aluminum nitride template

ActiveCN111809154AImprove crystal qualityReduce mismatchVacuum evaporation coatingSputtering coatingIon bombardmentFilm base

The invention discloses a method for preparing a high-quality silicon-based aluminum nitride template, and aims to solve the problem that the quality of an epitaxial aluminum nitride layer is influenced by poor surface quality and crystallization quality of a silicon-based buffer layer. The method for preparing the high-quality silicon-based aluminum nitride template comprises the following specific steps of: 1) preparing a silicon single crystal substrate; 2) growing an initial buffer layer based on the silicon single crystal substrate; 3) reducing the surface roughness of the initial bufferlayer through ion bombardment; 4) performing heat treatment on the buffer layer subjected to ion bombardment; and 5) growing an aluminum nitride film based on the buffer layer subjected to heat treatment. According to the method, a large number of tests are carried out based on the process, and the detection result shows that the crystallization quality, roughness and other properties of the aluminum nitride layer are greatly improved, the template quality uniformity is high, and the method can be used for preparation of large-batch high-quality silicon-based aluminum nitride templates and application of downstream devices.

Owner:ULTRATREND TECH INC

Preparation method of tantalump-doped potassium-sodium niobate lead-free piezoelectric single crystal with high electromechanical coupling property

InactiveCN103436963ASimple growth processLow costPiezoelectric/electrostrictive device manufacture/assemblyPolycrystalline material growthSingle crystal growthElectricity

The invention discloses a preparation method of tantalump-doped potassium-sodium niobate lead-free piezoelectric single crystal with a high electromechanical coupling property, relates to a preparation method of potassium-sodium niobate base lead-free piezoelectric single crystal, and aims to solve the problems that the conventional potassium-sodium niobate base lead-free piezoelectric single crystal is hard to grow, small in size and low in electromechanical coupling coefficient. The chemical formula of the tantalump-doped potassium-sodium niobate lead-free piezoelectric single crystal with the high electromechanical coupling property is (K1-xNax)(Nb1-yTay)O3, wherein x is greater than 0.4 and less than 0.7, and y is greater than 0.20 and less than 0.35. The preparation method particularly comprises the following steps: step one, pre-sintering so as to synthesize a polycrystal powder raw material; step two, putting the polycrystal powder raw material into a single crystal pull furnace so as to carry out single crystal growth; step three, cooling and annealing by using a multi-step cooling method. The preparation method has the advantages that firstly, the growth process is simple and low in cost, secondly, the prepared tantalump-doped potassium-sodium niobate single crystal is large in size and good in quality, and thirdly, the high electromechanical coupling property is achieved. By utilizing the preparation method, a piezoelectric material with the high electromechanical coupling property is prepared.

Owner:HARBIN INST OF TECH

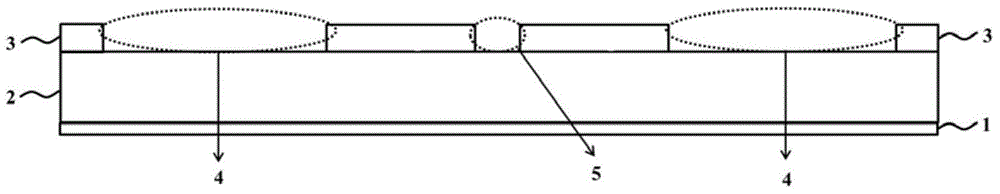

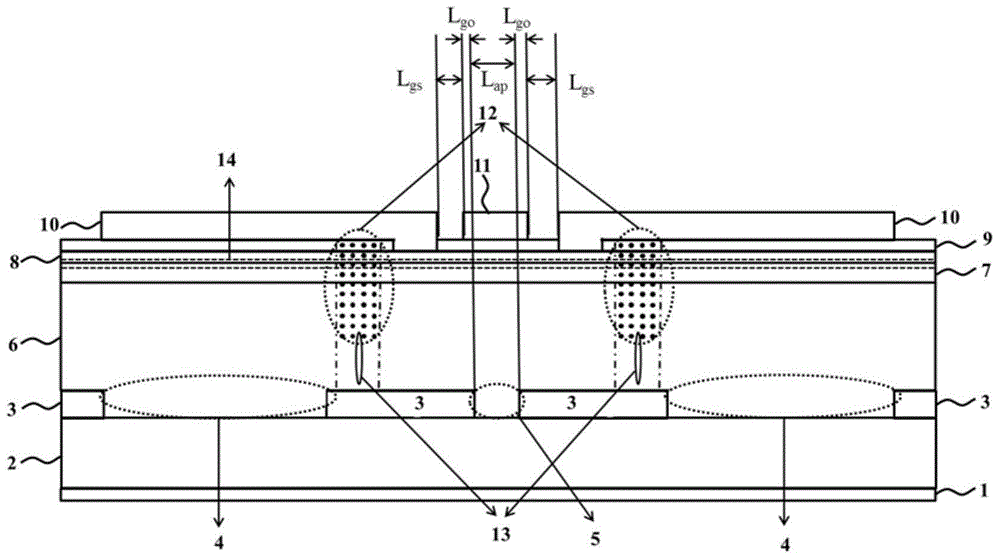

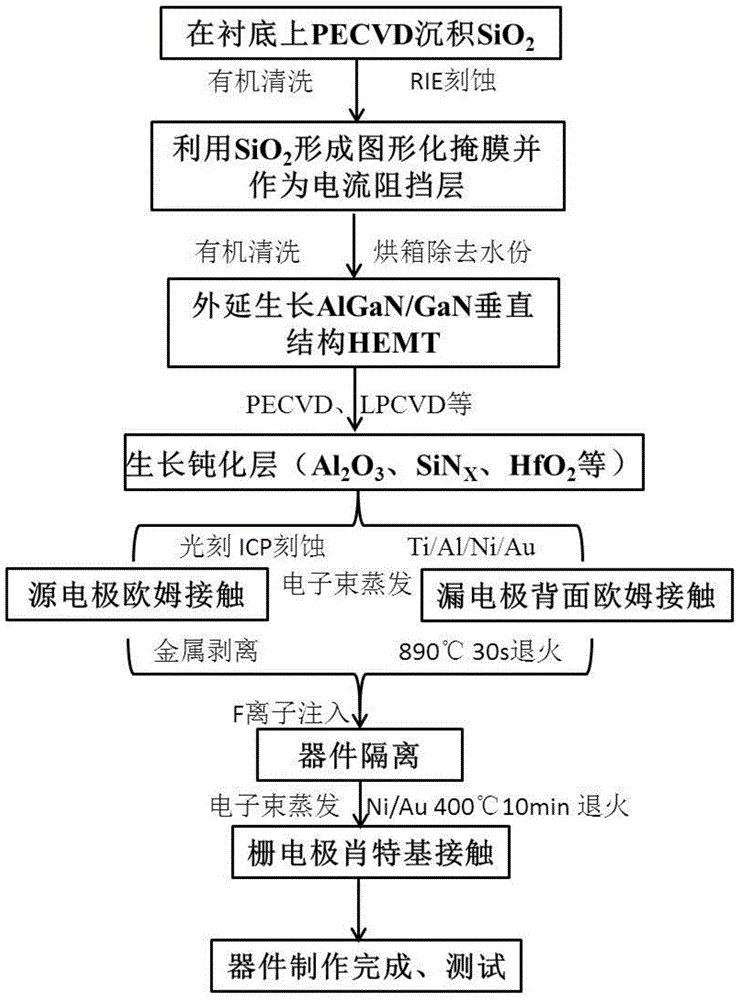

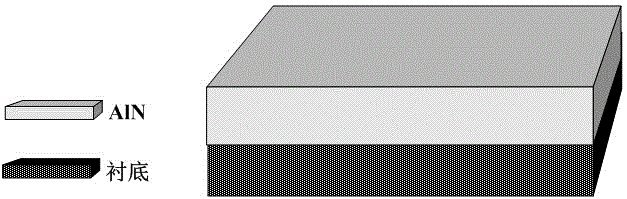

Lateral epitaxial technique based longitudinal structure AlGaN/GaN HEMT device and manufacture method thereof

ActiveCN104659089ARaise the barrier heightImprove crystal qualitySemiconductor/solid-state device manufacturingSemiconductor devicesElectricitySelf-diffusion

The invention discloses a lateral epitaxial technique based longitudinal structure AlGaN / GaN HEMT device and a manufacture method thereof. The device comprises a substrate, a current blocking layer and an epitaxial layer, wherein the current blocking layer is formed on the substrate; the epitaxial layer laterally epitaxially grows on the current blocking layer; a current conducting through hole is formed in the current blocking layer. According to the invention, the current blocking layer acts as an insulation layer, so that the problems that the two-dimensional electron gas concentration, self-diffusion, high electricity leakage and the like are caused by ion implantation damage due to Mg doping, barrier height improvement by Mg ion implantation and formation of a similar insulation layer by Al ion implantation in a traditional technology can be solved; meanwhile, the defects of high cost, long time consumption, technology complexity and the like due to secondary epitaxial growth are also prevented; in addition, a clearance region formed by incomplete healing is isolated via F ion implantation, so that the clearance region is not involved in the device structure, and the problems of electric leakage and the like caused by the clearance region are relieved effectively.

Owner:SUZHOU NENGWU ELECTRONICS TECH

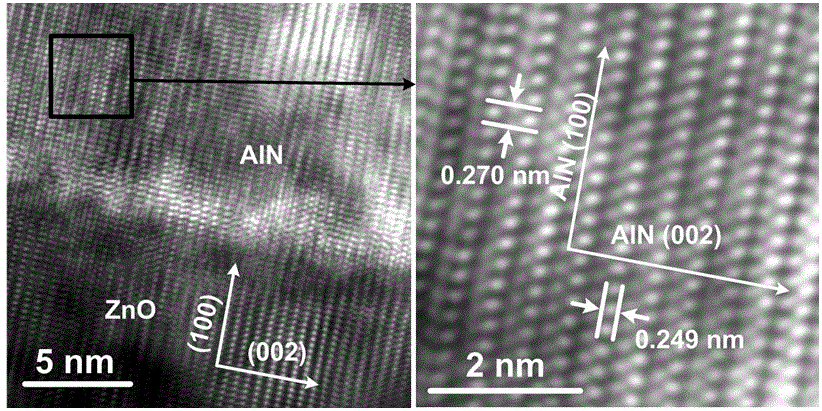

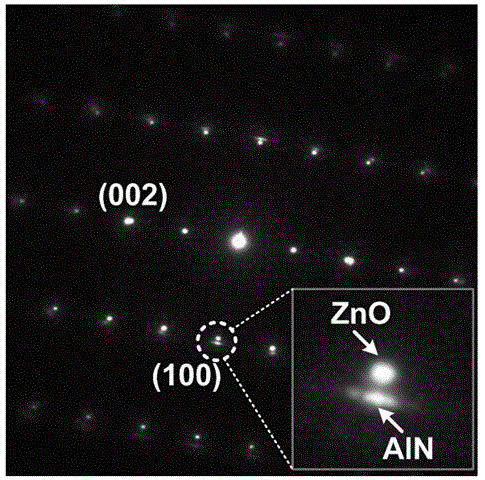

Preparation method of aluminum nitride monocrystalline film

InactiveCN106504980APrecise and controllable thicknessLow growth temperatureSemiconductor/solid-state device manufacturingField emission deviceUltraviolet lights

The invention belongs to the technical field of semiconductor film materials, and particularly discloses a preparation method of an aluminum nitride (AlN) monocrystalline film. The method comprises the steps of utilizing a ZnO monocrystalline substrate or other heterogeneous materials as a substrate, growing an AlN film by using an atomic layer deposition coating (ALD) method, putting the cleaned substrate into a reaction chamber and setting the temperature of the reaction chamber to be 250-500 DEG C; utilizing trimethylaluminum (TMA), an ammonia gas (NH3) and the like as reaction precursors and alternately introducing the reaction precursors for growing the AlN film; and finally forming the AlN monocrystalline film in a nonpolar direction (100) through epitaxial growth. According to the preparation method of the aluminum nitride monocrystalline film, epitaxial growth of the AlN material is achieved under a low temperature condition; the growth temperature and the requirements on the vacuum degree are greatly reduced; the process is simple; the growth cost of AlN monocrystalline is reduced; and the preparation method is compatible with an existing semiconductor growth technology. The preparation method of the aluminum nitride monocrystalline film has a wide application prospect in the aspects of an AlN-based deep ultraviolet light-emitting device, a piezoelectric device, a surface, buffer layers of a bulk acoustic wave device, a field emission device and an III-IV nitride device and the like.

Owner:FUDAN UNIV

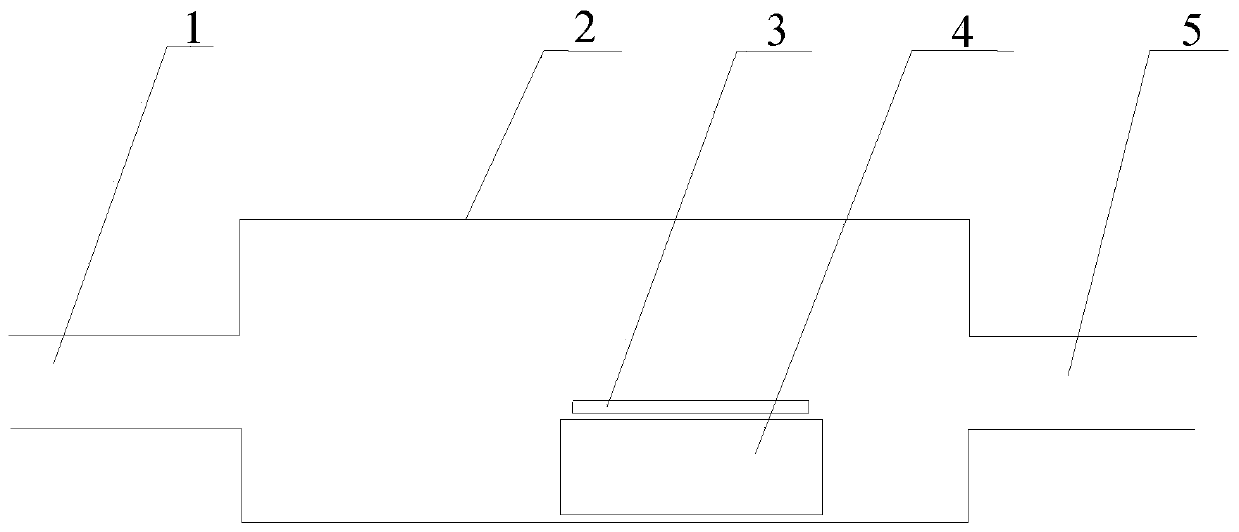

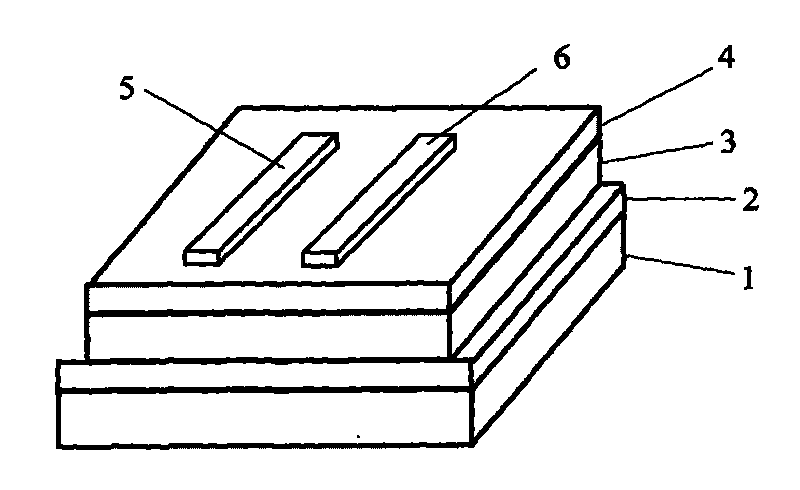

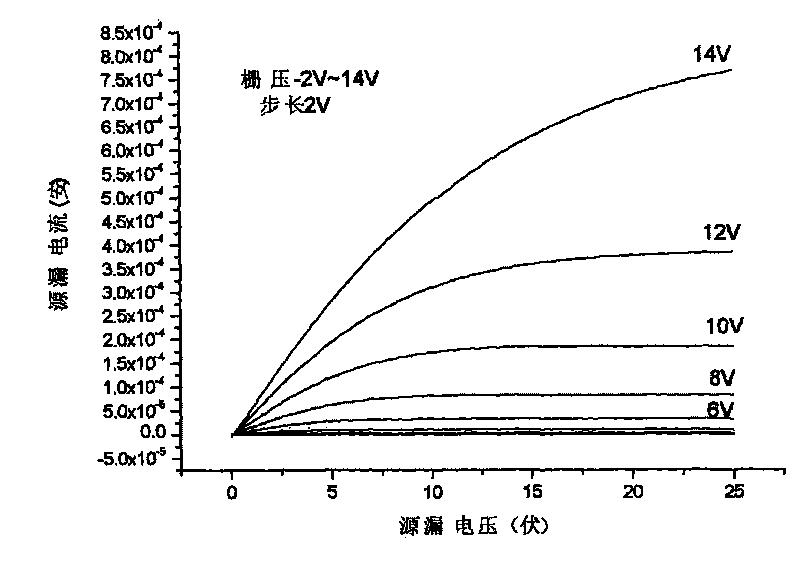

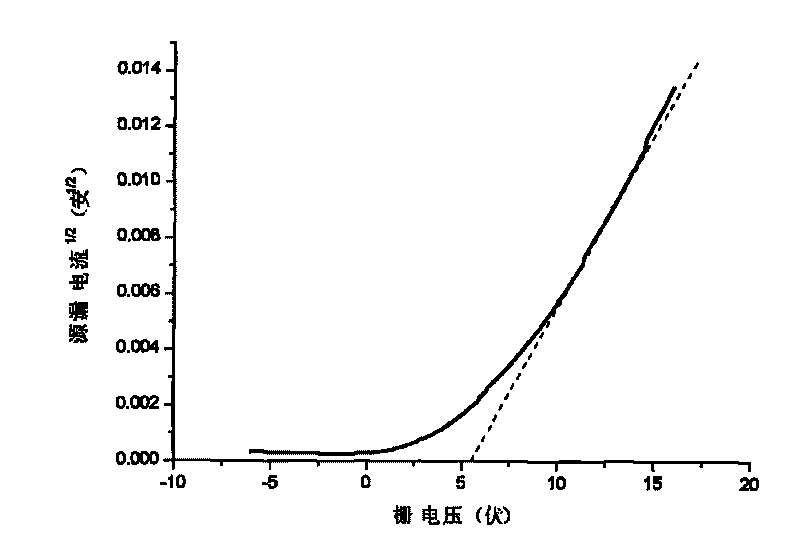

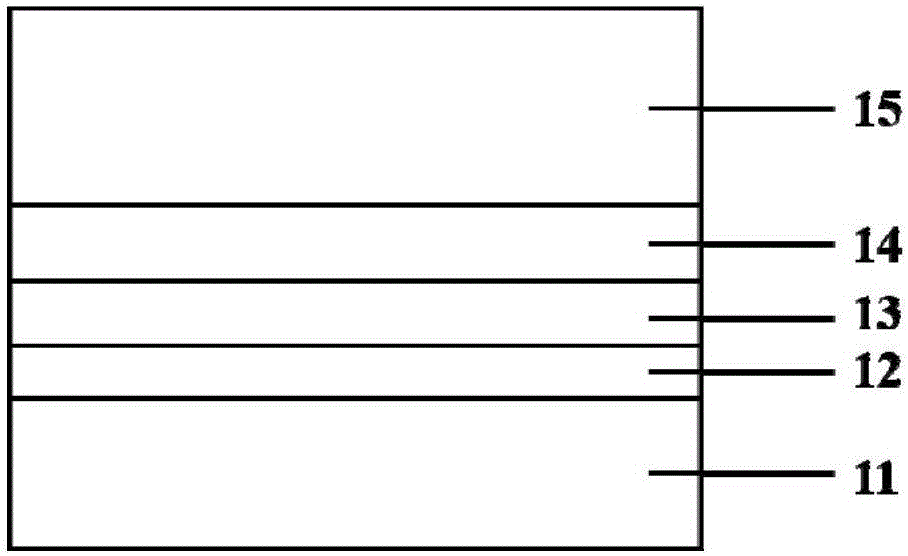

Method for preparing ZnO (zinc oxide)-based thin film transistor by using metal organic chemical vapor deposition

InactiveCN101740397ALow priceGood chemical stabilitySemiconductor/solid-state device manufacturingSemiconductor materialsGas phase

The invention belongs to the field of microelectronic technology, particularly relates to a method for preparing a zinc oxide (ZnO)-based thin film transistor (TFT) by using organic chemical vapor deposition (MOCVD). The ZnO-based thin film transistor consists of a lining, a grid, an insulating layer, a ZnO based active channel layer, a source electrode and a drain electrode, wherein the insulating layer and the ZnO based active channel layer both adopt the MOCVD technology to finish the growth of materials, and compared with other extension technologies, the MOCVD technology has the advantage that a prepared semiconductor material has higher quality. The growth of material in all layers is finished in one step in MOCVD growth equipment, thereby the material growth process is greatly simplified, and the thickness of each layer of semiconductor material can be accurately controlled. The invention provides the process method for growing the ZnO-based TFT by adopting the MOCVD growth equipment suitable for industrial production, solves the key problems that the prepared ZnO-based TFT has low quality by using other methods, and the like, and prepares the ZnO-based TFT with higher quality.

Owner:JILIN UNIV

GaN film growing on magnesium aluminate scandium substrate as well as preparation method and application of GaN film

InactiveCN106158592AEasy to manufactureMature production processLaser detailsFinal product manufactureNucleationScandium

The invention discloses a GaN film growing on a magnesium aluminate scandium substrate. The GaN film comprises a GaN buffer layer, a GaN nucleation layer, a GaN amorphous layer and a GaN film which sequentially grow on an ScMgAlO4 substrate, wherein a (0001) surface, which deviates from a (11-20) surface by 0.5-1 degrees, of the ScMgAlO4 substrate is an extension surface. The invention fuehrer discloses a preparation method and application of the GaN film. Compared with the prior art, the preparation method has the advantages that the growing process is simple, and the preparation cost is low; and meanwhile, by utilizing an amorphous layer technique, the GaN film prepared by virtue of the preparation method has the characteristics of good crystalline quality, low defect density and the like.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com