Method and device for preparing Mg-doped ZnO nanowire array

A nanowire array and seed crystal technology, which is applied in the field of preparation of ZnO nanowire arrays, can solve the problems of complex procedures, high cost, and limited application, and achieve the effects of good repeatability, low cost, and simple growth process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

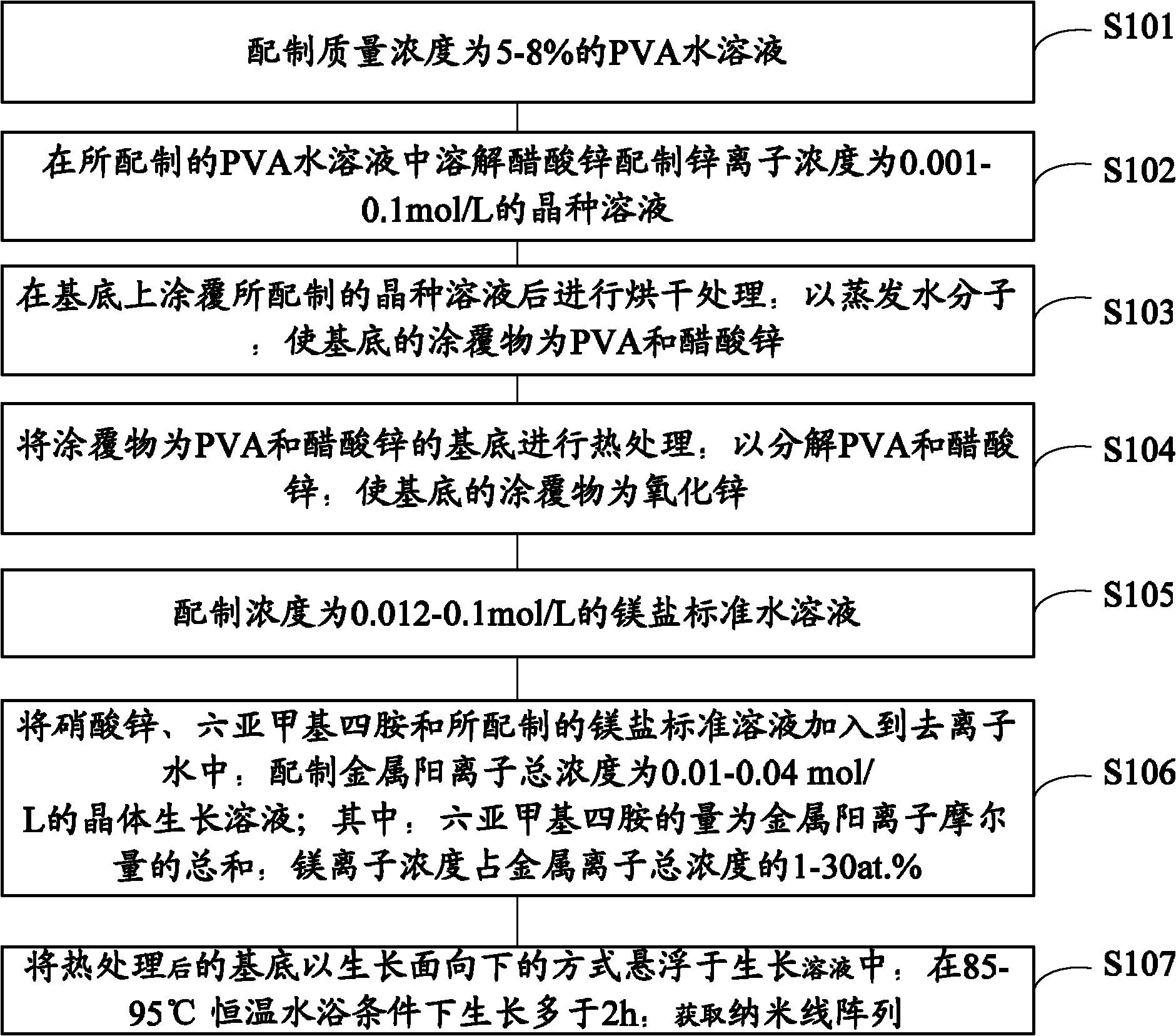

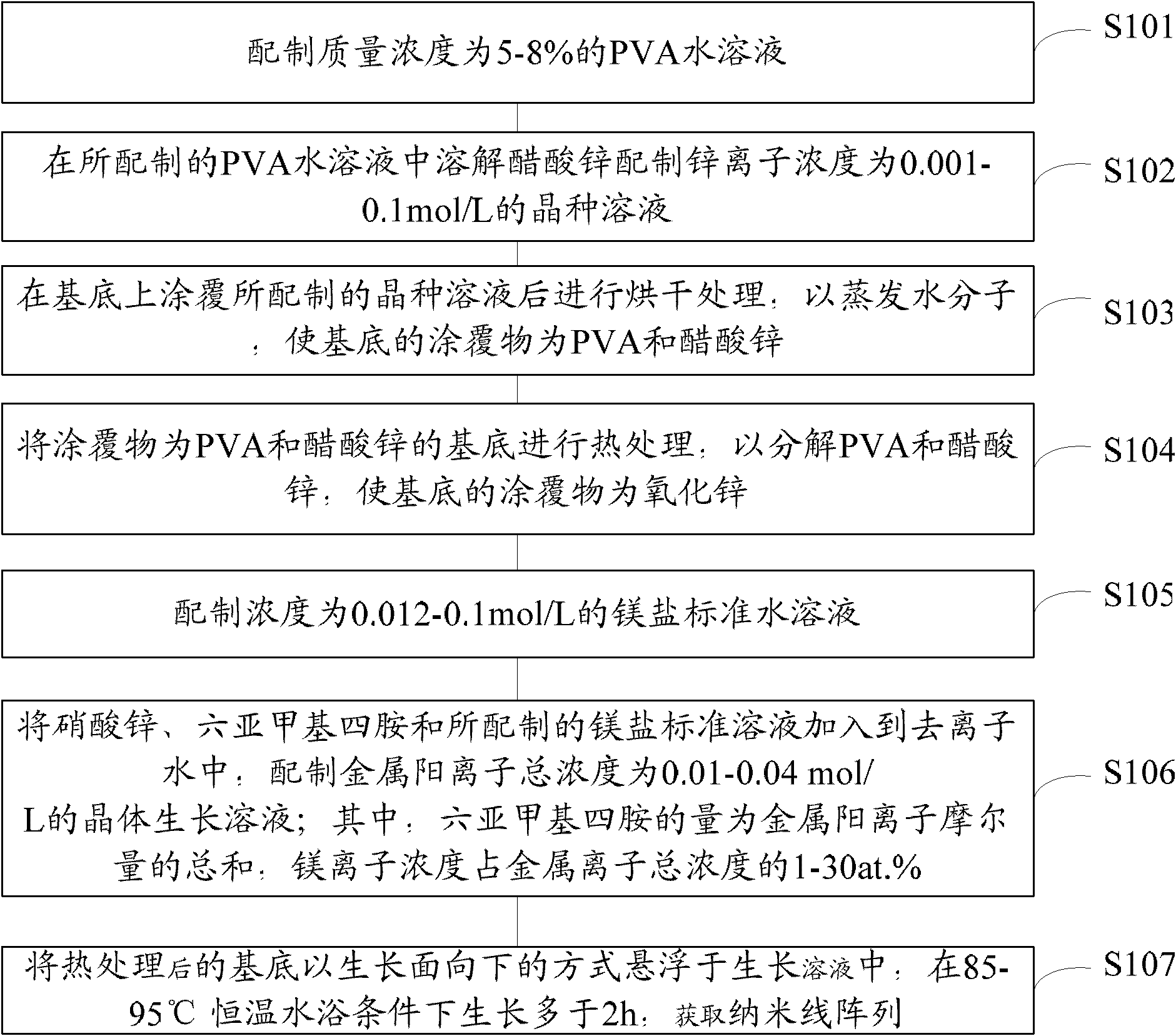

[0042] refer to figure 1 , shows a flow chart of a method for preparing a Mg-doped ZnO nanowire array of the present invention, the method specifically comprising:

[0043] Step S101, preparing a PVA aqueous solution with a mass concentration of 5-8%;

[0044] Preferably, the average degree of polymerization of the PVA is 1750±50.

[0045] Step S102, dissolving zinc acetate in the prepared PVA aqueous solution to prepare a seed solution with a zinc ion concentration of 0.001-0.1mol / L;

[0046] A certain amount of PVA (polyvinyl alcohol, Chinese name: polyvinyl alcohol) is dissolved in deionized water to prepare a PVA aqueous solution with a mass concentration of 5-8%, and a certain amount of zinc acetate is added to the PVA aqueous solution to make it The zinc ion concentration is 0.001-0.1mol / L, so as to obtain the seed crystal solution with the zinc ion concentration of 0.001-0.1mol / L.

[0047] Step S103, coating the prepared seed crystal solution on the substrate and the...

example 1

[0064] 1) Weigh 6.003g of PVA and 100mL of deionized water, stir continuously to make it swell, and then fully dissolve it in a water bath at 70°C. After the solution is cooled to room temperature, take 50ml of its supernatant for use.

[0065] 2) Weigh 0.053g of zinc acetate and dissolve it in the prepared PVA solution to prepare a 0.005mol / L seed crystal solution.

[0066] 3) Uniformly coat a layer of seed liquid on the Si substrate by dipping-pulling method, put it into an oven, and dry it at 120° C. for 15 minutes. After this process was repeated 6 times, it was put into a high-temperature furnace at 550°C, sintered for 1.5h and taken out.

[0067] 4) Weigh 1.785g Zn(NO 3 ) 2 ·6H 2 O and 0.841 g of hexamethylenetetramine were stirred and dissolved in 150 ml of deionized water to prepare a growth solution.

[0068] 5) Suspend the Si substrate with the seed crystal in the growth solution with the growth side down, seal the beaker with plastic wrap (the purpose is to prev...

example 2

[0071] 1) Weigh 6.004g of PVA and 100mL of deionized water, stir continuously to make it swell, and then fully dissolve it in a water bath at 70°C. After the solution is cooled to room temperature, take 50ml of its supernatant for use.

[0072] 2) Weigh 0.054g of zinc acetate and dissolve it in the prepared PVA solution to prepare a 0.005mol / L seed solution; prepare a 0.060mol / L magnesium acetate standard solution in a 200ml volumetric flask (actually called magnesium acetate is 2.573 g) Standby.

[0073] 3) Uniformly coat a layer of seed liquid on the Si substrate by pulling and dipping, put it in an oven, and dry it at 120° C. for 15 minutes. After this process was repeated 6 times, it was put into a high-temperature furnace at 550°C, sintered for 1.5h and taken out.

[0074] 4) Measure 10ml of zinc acetate standard solution in a clean beaker, then add 140ml of deionized water. Weigh 1.606g Zn(NO 3 ) 2 ·6H 2 O and 0.841g hexamethylenetetramine were stirred and dissolved...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com