Patents

Literature

705results about How to "Improve growth quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non polarity A side nitride film growing on the silicon(102) substrate and its making method and use

InactiveCN101009347AEasy to separateIncrease overlapLaser detailsFinal product manufactureSolar batteryLight-emitting diode

The invention relates to a nonpolar A side nitride film that comprises a silicon (102) underlay, metal layer which grows upon the silicon underlay sequentially, InGaAlN initial growth layer and the first InGaAlN buffer layer, it characterized in that: said silicon underlay is Si underlay which adopts the (102) side or offset angle. The nonpolar a side nitride film which grows on the silicon underlay can be used in LBD, laser, solar battery. The component extension configuration is adopted according to different component, for example the LBD and laser, and using the mature silicon craft further to produce relative diprosopia electrode component or peeling off component. The advantages of the invention are: the invention can increase the growth quality of nonpolar GaN base material, and decrease the cost; the craft of current component can be simplified greatly, the cost can be decreased, and increase the elimination efficiency and lightening efficiency greatly.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

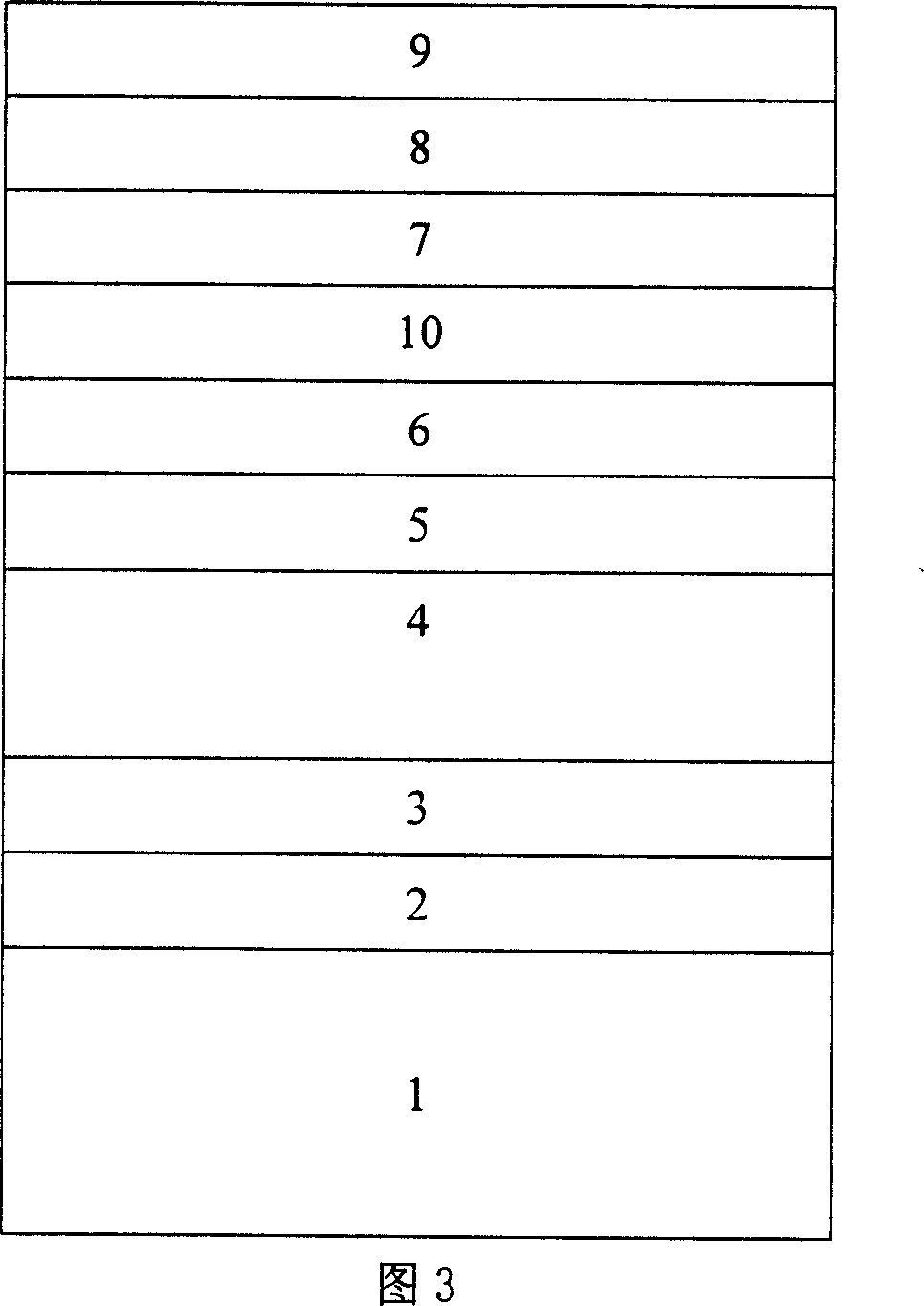

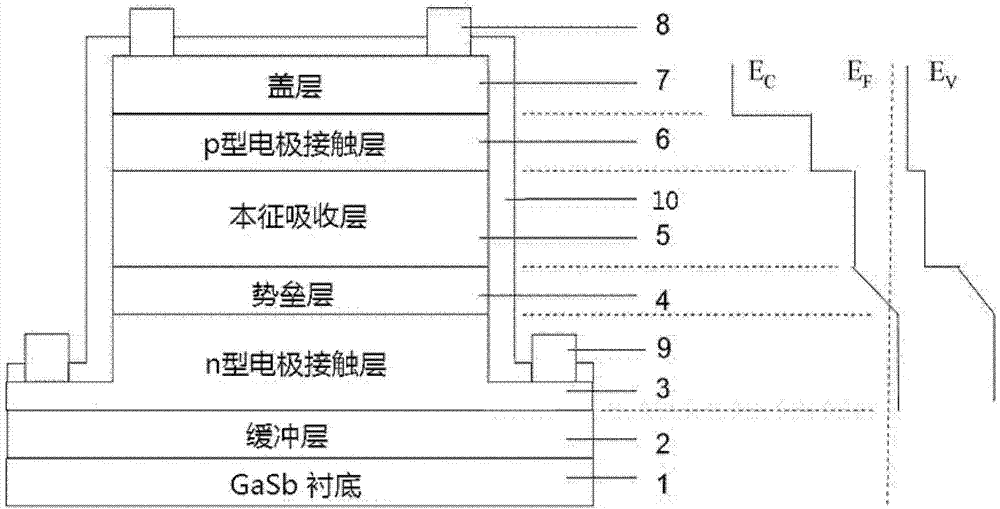

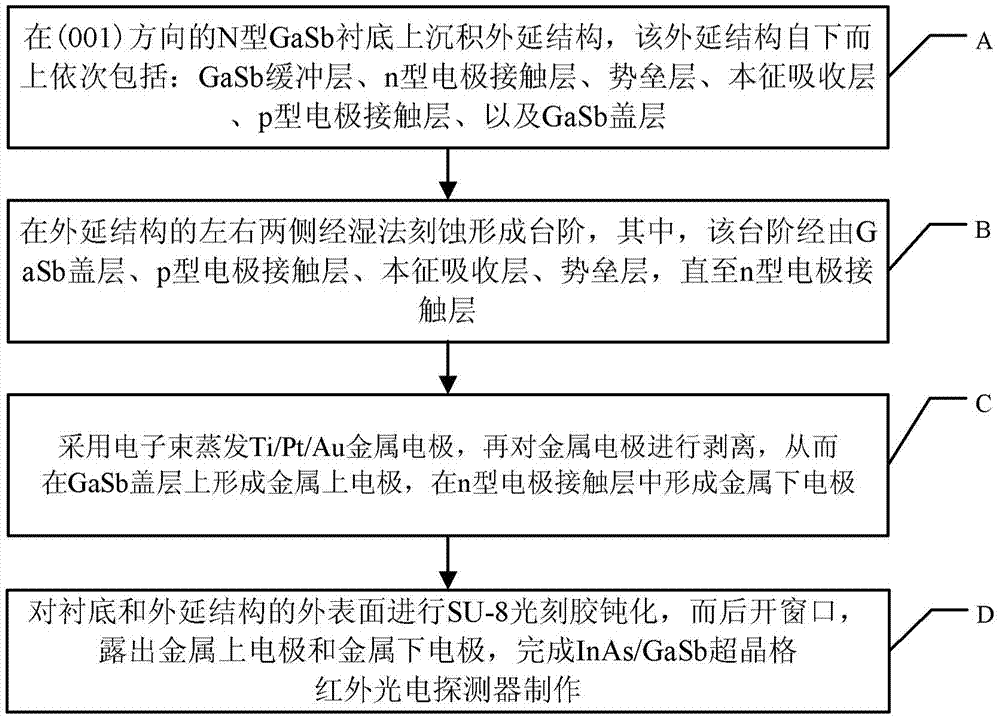

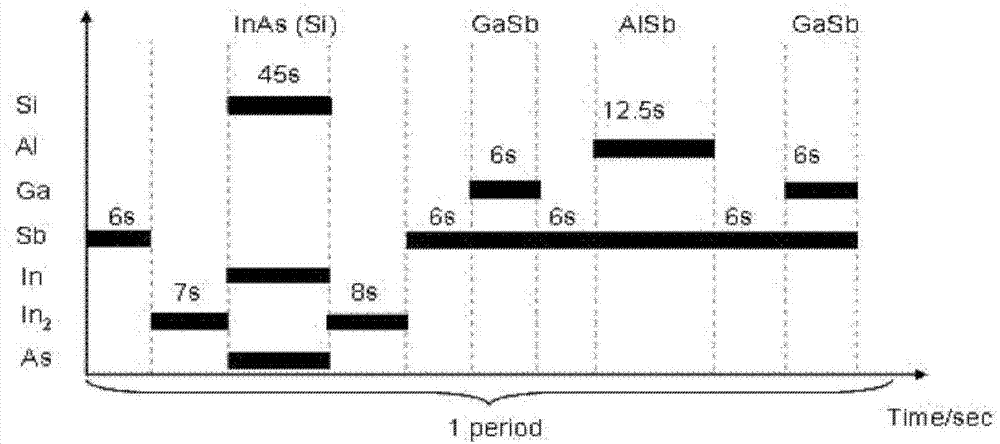

InAs/GaSb superlattice infrared photoelectric detector and manufacturing method thereof

ActiveCN103887360AImprove performanceSuppression-recombination dark currentFinal product manufactureSemiconductor devicesPhotovoltaic detectorsElectrode Contact

The invention provides an InAs / GaSb superlattice infrared photoelectric detector and a manufacturing method thereof. The InAs / GaSb superlattice infrared photoelectric detector comprises a substrate, an epitaxy structure deposited on the substrate, an upper metal electrode formed above steps, a lower metal electrode formed under the steps and a passivation layer, wherein the epitaxy structure comprises an n-type doping buffer layer, an n-type electrode contact layer, a barrier layer, an intrinsic absorption layer, a p-type electrode contact layer and a cover layer, the steps are formed on two sides of the epitaxy structure through etching, the intrinsic absorption layer is composed of a plurality of periodical InAs / InSb / GaSb / InSb superlattice structures. In the InAs / GaSb superlattice infrared photoelectric detector, InSb is respectively inserted into two interfaces of each superlattice period of the intrinsic absorption layer to form strained superlattices, the stress between the superlattices and the substrate is effectively balanced, the material growing quality is improved, and accordingly the photoelectric performance of the detector is improved.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Chinese herbal medicine pesticide

InactiveCN104082358AImprove growth qualityNo pollution in the processPlant growth regulatorsBiocidePesticideStemona

The invention relates to a Chinese herbal medicine pesticide. The Chinese herbal medicine pesticide is prepared from the following raw materials in parts by weight: 1-10 parts of garlic, 4-10 parts of scrophularia ningpoensis, 1-9 parts of kusnezoff monkshood root, 5-9 parts of rhizoma arisaematis, 1-6 parts of sophora flavescens, 3-6 parts of agrimonia pilosa ledeb, 2-7 parts of sanguisorba officinalis, 1-5 parts of ferula, 1-9 parts of stemona, 1-10 parts of polygonum cuspidatum, 3-6 parts of szechwan chinaberry fruit, 2-5 parts of cyrtomium rhizome, 1-6 parts of pepper and 3-9 parts of herba houttuyniae. The pesticide has no residue on crops, and is efficient, low in toxicity and free from pollution on the environment; the pesticide has the effects of high efficiency, quick control on plant diseases and insect pests, disease prevention and disease treatment, and further is capable of promoting the growth of plants and improving the growth quality of crops.

Owner:匡铁铃

Method for preparing earthworm cultivation substratum

InactiveCN102812931AEnhance immune functionImprove digestion and absorption rateAnimal husbandryBiotechnologyEdible mushroom

The invention discloses a method for preparing earthworm cultivation substratum. By mixing livestock dung and edible fungus residue without foreign matters to carry out anaerobic fermentation, the method obtains the substratum for cultivating and reproducing earthworms, the livestock dung is pig dung or cow dung or the mixture of pig dung and cow dung, and the edible fungus residue is residue which is left over in the growth of cultured saprophytic lignicolous fungi or coprophilous fungi. Since the method utilizes the livestock dung and the edible fungus residue as the cultivation substratum to raise the earthworms, the method not only solves the problem of dung accumulation and waste and prevents environment pollution, but also increases the cultivation scale and growth quality of the earthworms by adding the edible fungus residue, thus effectively increasing the output of the earthworms.

Owner:NANJING AGRICULTURAL UNIVERSITY

Oil camellia bud seedling stock-grafting propagation method in winter and spring

ActiveCN103081699AImprove survival rateImprove growth qualityHorticultureComing outCamellia oleifera

The invention discloses an oil camellia bud seedling stock-grafting propagation method in winter and spring. The oil camellia bud seedling stock-grafting propagation method in winter and spring comprises processes such as stock cultivation, seedling growing bed preparation, seedling growing container preparation, grafting, grafted seedling planting, and seedling management. By heating a germination bed in winter and spring and utilizing the lifting-type seedling growing bed for growing seedlings, oil camellia bud seedling stock-grafting and grafted seedling cultivation are achieved in winter and spring, cultivation in an enclosed high-temperature and high-moisture environment is guaranteed for the initial stage of the oil camellia bud seedling stock-grafting, the survival rate reaches to 98.56%, average height in the same year reaches to 28.34 cm, and the ground diameter is 3.56 mm. Therefore, the survival rate of the grafted seedlings is increased, the grafted seedlings are capable of coming out of a nursery in the same year, the seedling cultivation circle is shortened, the using rate of cutting wood is increased, and the survival rate and seedling growing quality of oil camellia large-scale grafting are effectively improved.

Owner:GUANGXI FORESTRY RES INST

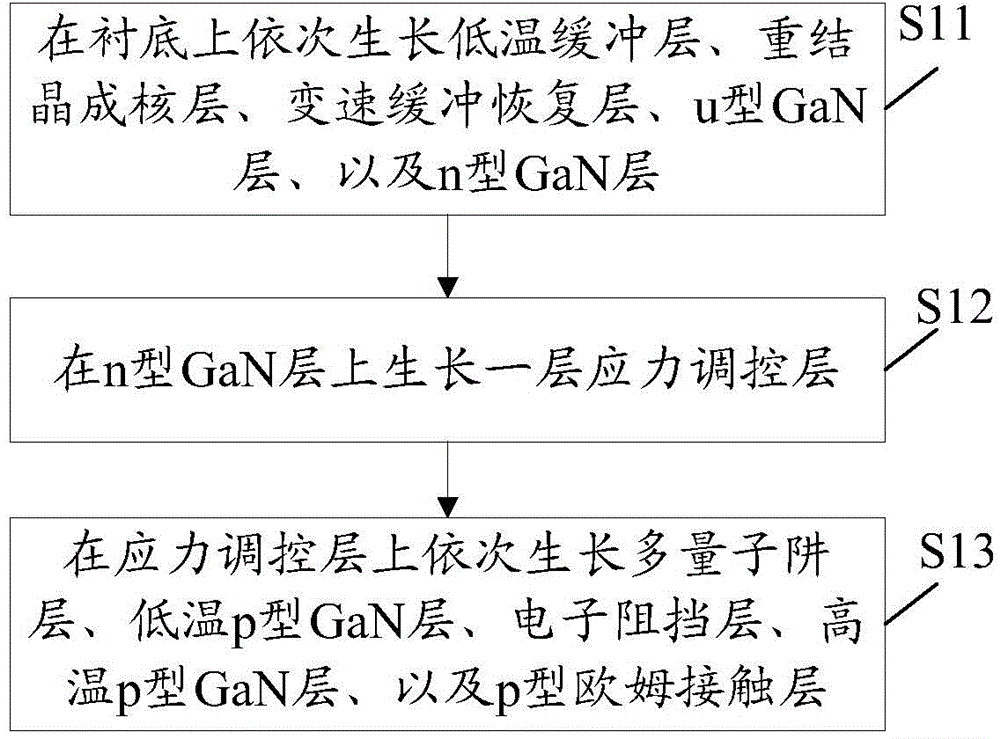

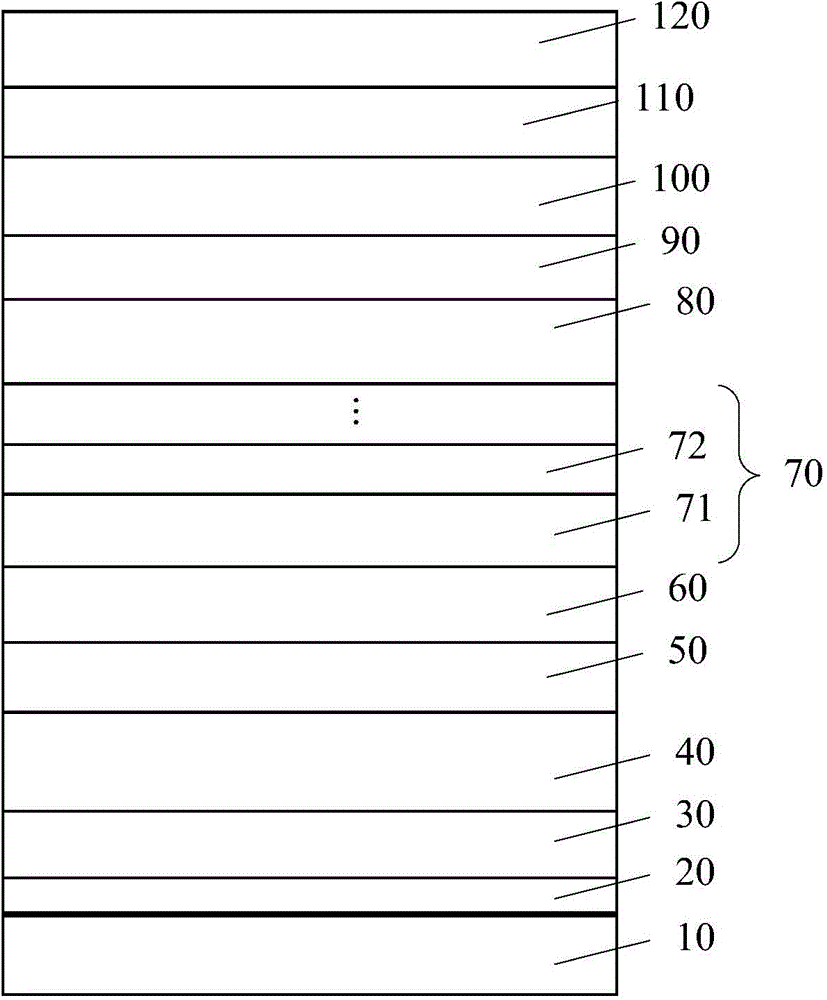

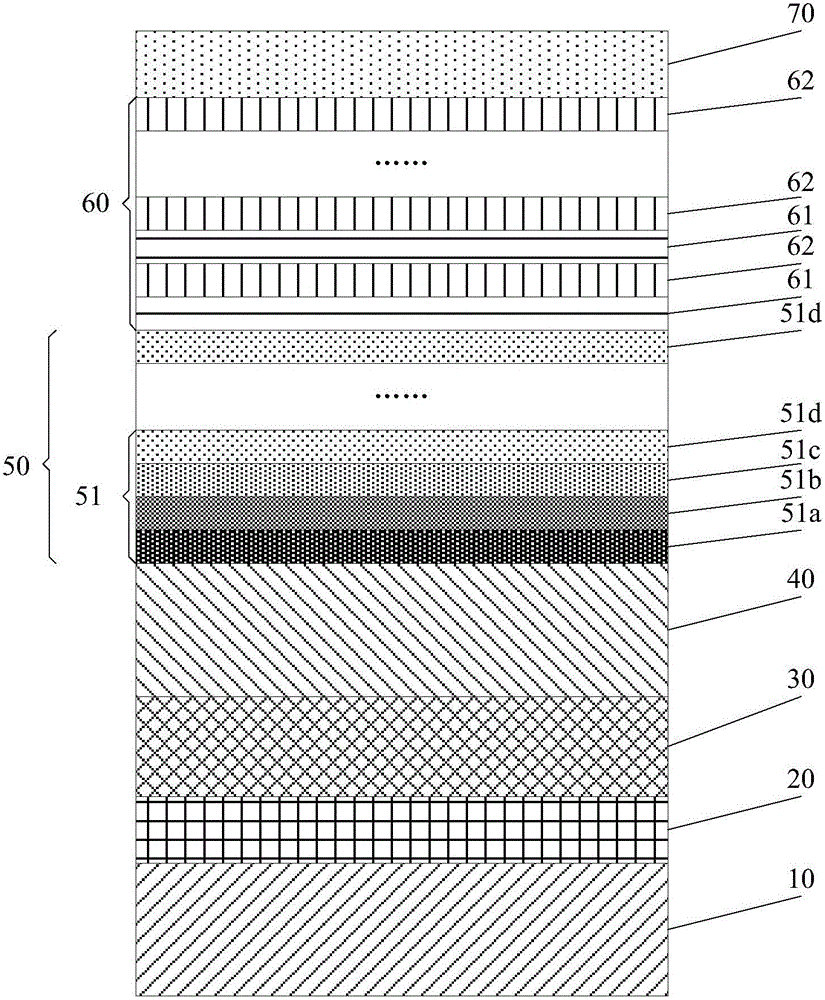

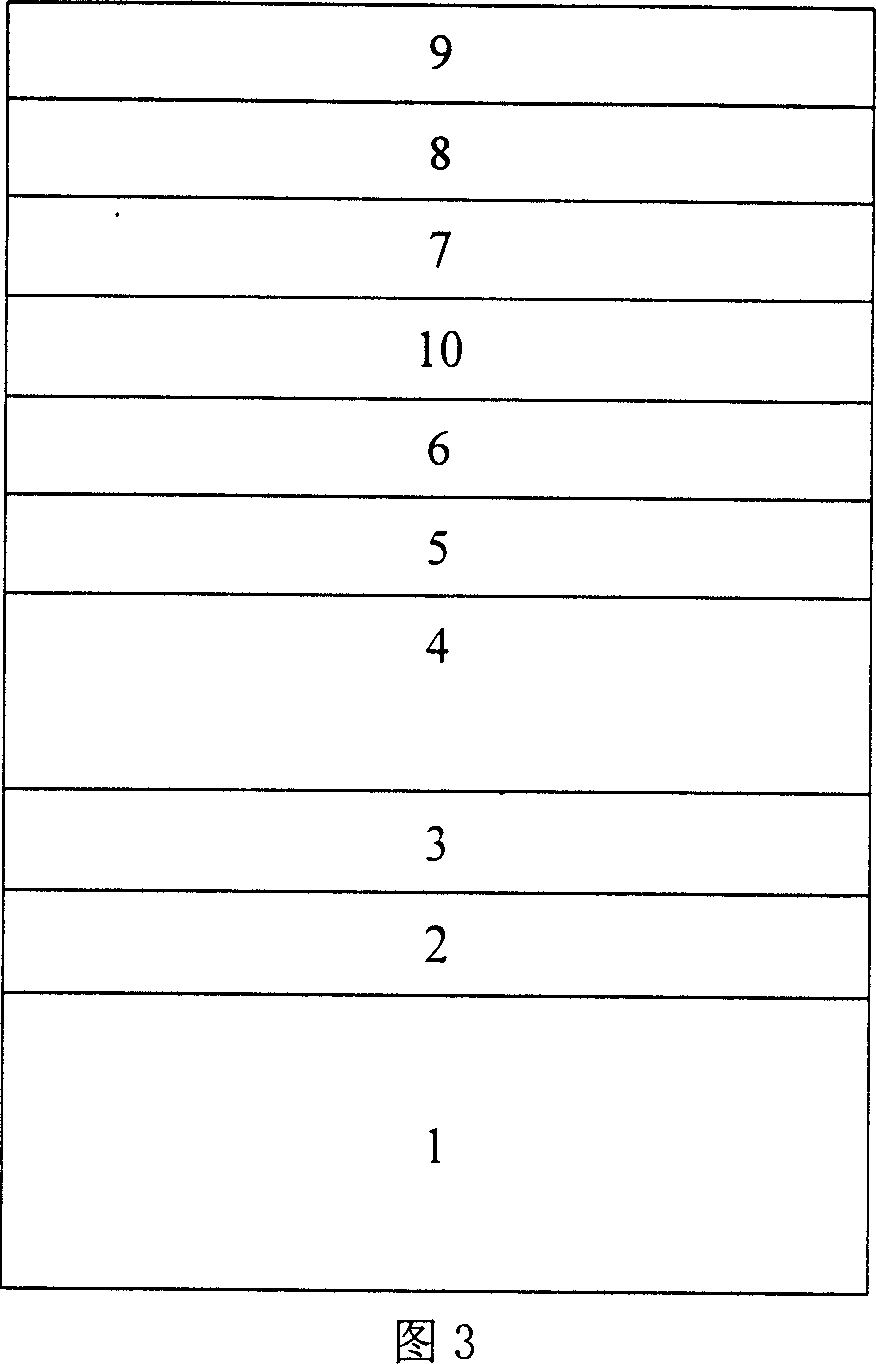

GaN-based light-emitting diode epitaxial wafer production method and produced epitaxial wafer

ActiveCN104810451AImprove growth qualityQuality improvementSemiconductor devicesHydrogenOhmic contact

The invention discloses a GaN-based light-emitting diode epitaxial wafer production method and a produced epitaxial wafer, and belongs to the field of semiconductor light-emitting diodes. The method includes growing a buffer layer, an n-type GaN layer, a stress regulation layer, a multiple quantum well layer, a p-type GaN layer and a p-type ohmic contact layer on a substrate sequentially. The stress regulation layer is of a multi-period structure. A growth method of each period of the multi-period structure includes growing a stress regulation InGaN sub layer at a first growth temperature, supplying hydrogen into a reaction chamber at a second growth temperature after the stress regulation InGaN sub layer finishes growing, and etching the surface of the stress regulation InGaN sub layer, wherein the second growth temperature is different from the first growth temperature. The GaN-based light-emitting diode epitaxial wafer production method and the produced epitaxial wafer have the advantages that through treatment of the stress regulation InGaN sub layer, a smooth contact surface is formed between the stress regulation InGaN sub layer and a stress regulation GaN sub layer, and accordingly, continuous extension of defects is prevented.

Owner:HC SEMITEK SUZHOU

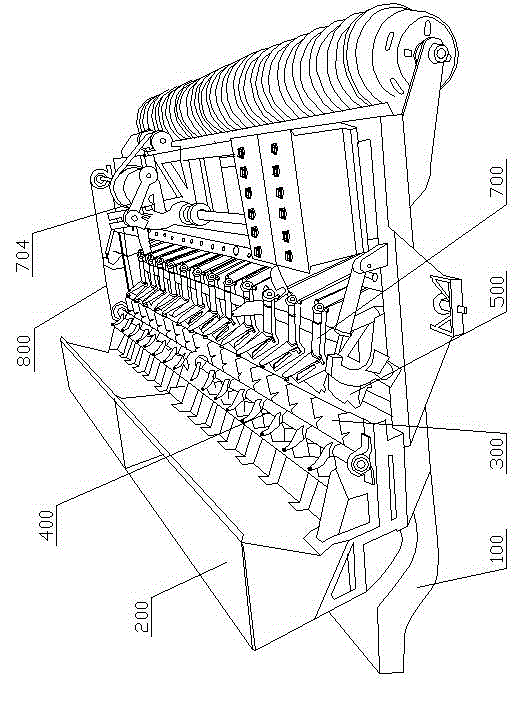

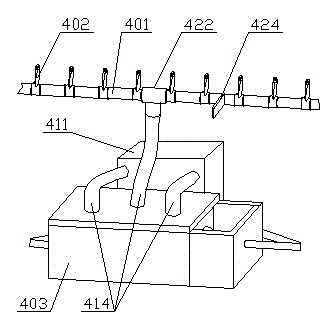

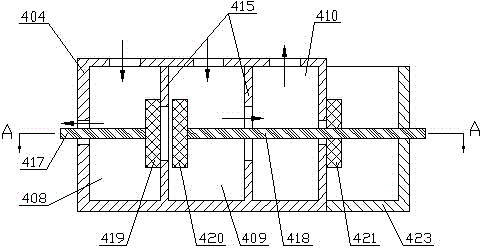

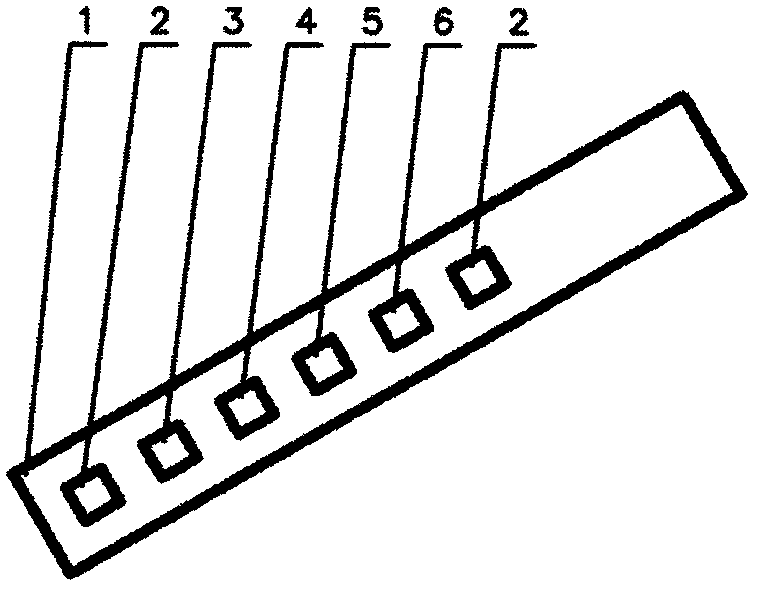

Garlic sowing method and garlic sower

InactiveCN104396387AEasy to operateImprove accuracySeed depositing seeder partsSingle grain seedersSeederAllium sativum

The invention provides a garlic sowing method and a garlic sower, and belongs to the technical field of garlic sowing. The garlic sowing method is convenient in operation and solves the problems in the prior art that a single garlic clove is difficult to get, the sowing precision of garlic clove with upward bulbils is low, garlic cloves are difficult for keeping upright in soil and difficult for continuous sowing. The garlic sower is provided aiming at the sowing method. A single-clove fetching device is utilized for finishing fetching of a single garlic clove and enables the single-clove fetching accuracy to be 98%; an automatic identification and direction-adjusting device is utilized for detecting the garlic clove and adjusting the direction, so that the possibility of the garlic clove with the upward bulbils dropping into a continuous sowing mechanism is guaranteed to reach 98%, so that the garlic sower is efficient and accurate, and also full preparation is made for the garlic clove with upward bulbils to drop into soil from the continuous sowing mechanism; and finally the continuous sowing mechanism is vertically inserted into soil and is withdrawn from soil in an inclined way, so that the upright degree of the garlic clove in soil is guaranteed, and finally the purposes of improving the garlic output and quality are finally realized.

Owner:梁开星

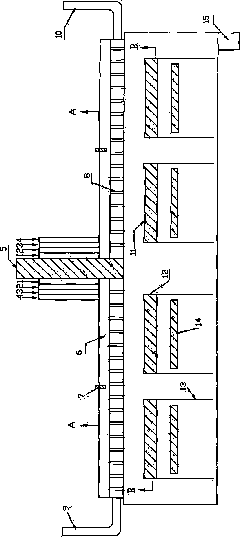

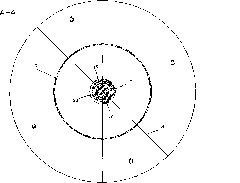

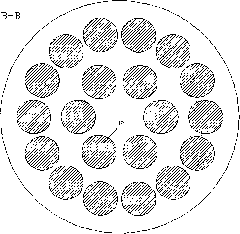

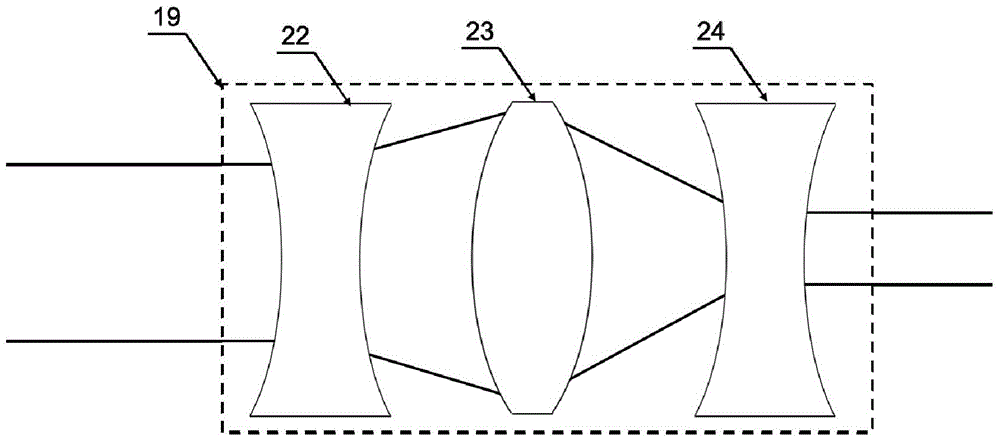

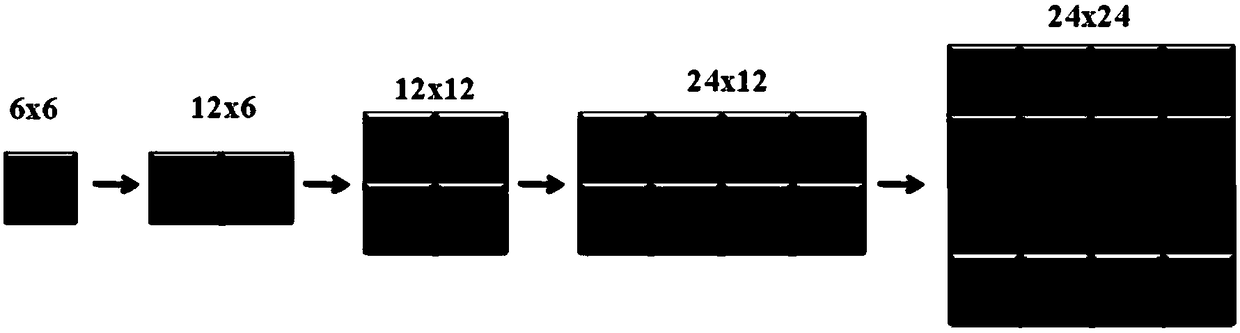

Vertical shower type MOCVD reactor

InactiveCN101824606AEliminate spoilersImprove growth qualityChemical vapor deposition coatingEngineeringParasitic reaction

The invention discloses a vertical shower type metal organic chemical vapor deposition (MOCVD) reactor, which comprises a reaction chamber, a shower head on the top of the reaction chamber, cooling water inlet and outlet of the shower head, substrate holders at the bottom of the reaction chamber, a heater and a gas outlet, wherein a gas inlet for inputting the reaction gas is formed in the shower head; the vertical shower type MOCVD reactor is characterized in that more than three independent regions are formed in the cavity of the shower head at intervals; each independent region is provided with an independent gas inlet; a rotating shaft is penetrated through the axial centre of the shower head; the shower head is in linkage with the rotating shaft; and the plurality of substrate holders are relatively isolated and annularly arranged at the bottom of the reaction chamber. Due to the application of the technical scheme of the invention, the reaction gases are isolated and showered in sequence so as to effectively eliminate the gaseous-phase parasitic reaction; and meanwhile the tail gas after the reaction can quickly flow off through the gap of each substrate holder to be discharged from the reactor; therefore, the turbulence effect of the accumulated tail gas on the reaction gas is effectively eliminated to improve the growth quality of an epitaxial wafer and make the realization of infinitely increasing the wafer loading capacity possible.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

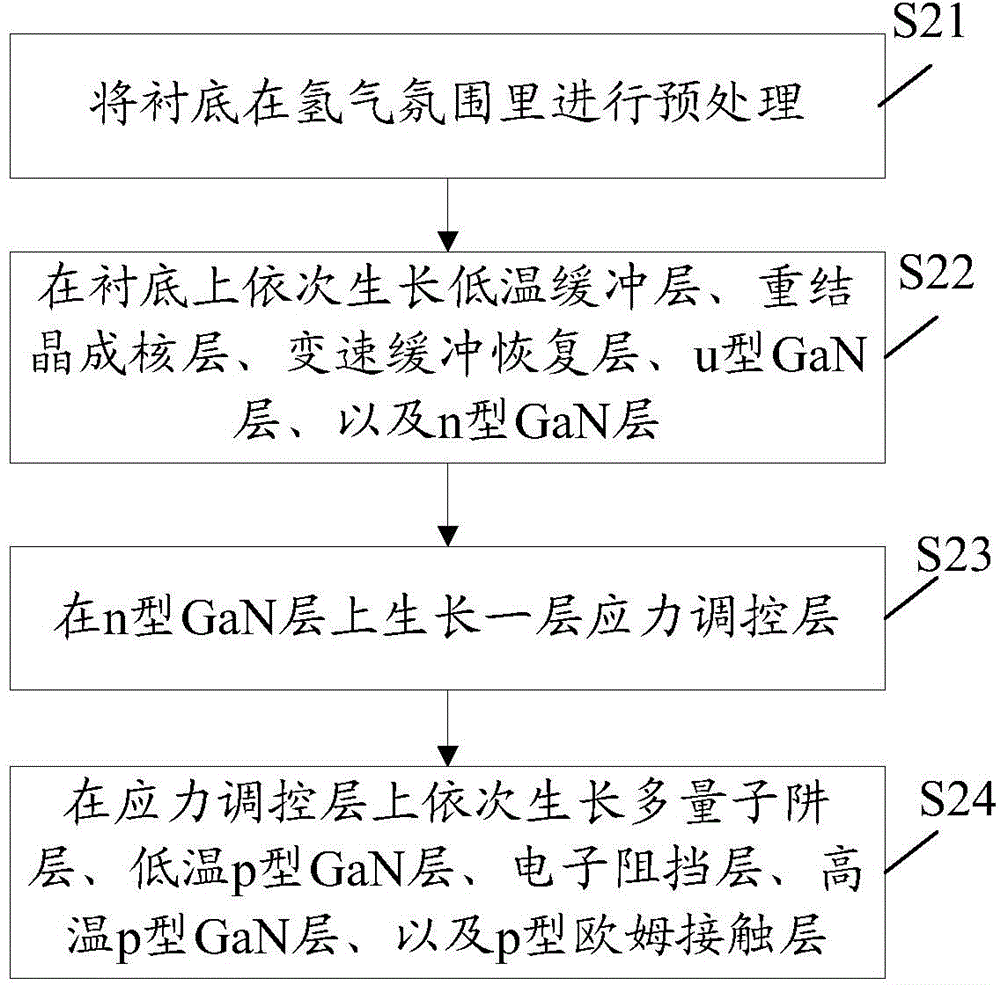

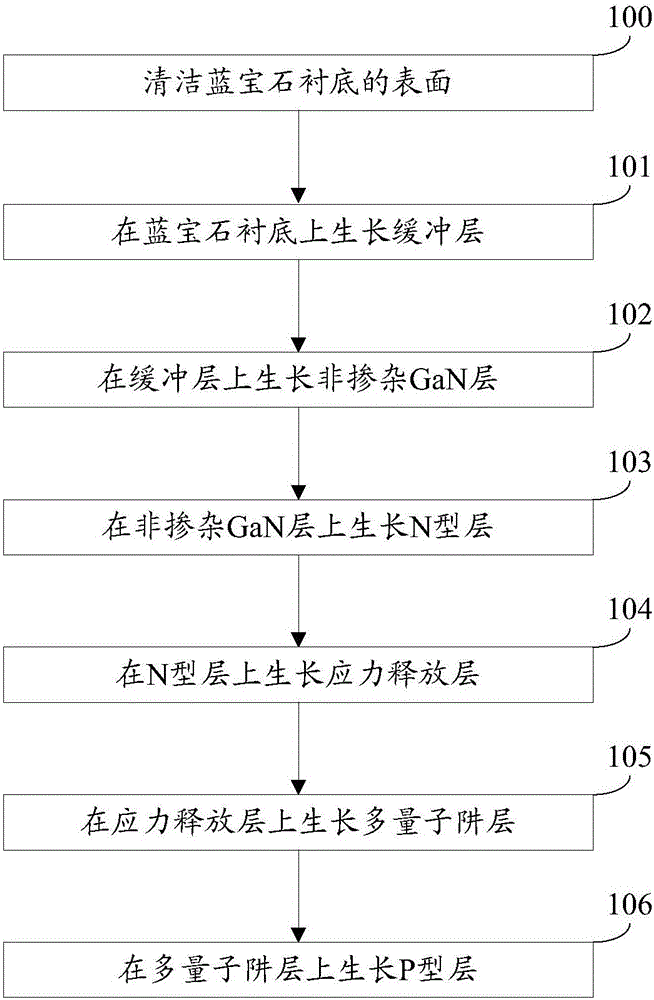

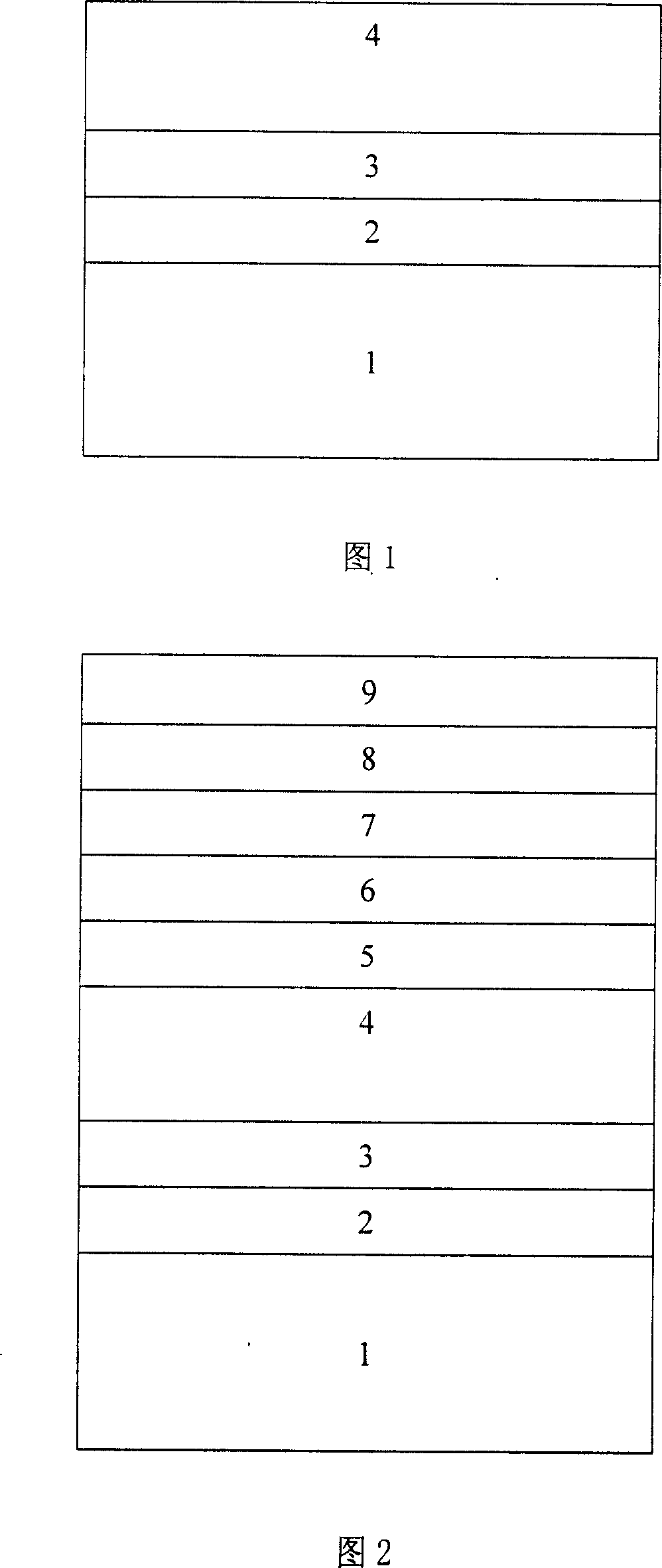

Preparation method for epitaxial wafer of GaN-based light emitting diode

ActiveCN106057988AImprove growth qualityImprove photoelectric performanceSemiconductor devicesLattice mismatchMultiple stress

The invention discloses a preparation method for an epitaxial wafer of a GaN-based light emitting diode, and belongs to the technical field of a semiconductor. The preparation method comprises the steps of laminating a buffer layer, a non-doped GaN layer, an N type layer, a stress release layer, a multi-quantum well layer and a P type layer on a sapphire substrate in sequence, wherein the stress release layer comprises multiple stress release sub-layers, the stress release sub-layers comprise a first sub-layer, a second sub-layer, a third sub-layer and a fourth sub-layer which are laminated in sequence, the first sub-layer is an AIGaN layer, the third sub-layer is an InGaN layer, the second and fourth sub-layers are GaN layers, and the growth temperature of the first sub-layer is higher than that of the third sub-layer. According to the method, a periodic structure is employed in the stress release layer, the relatively low growth temperature is employed in the InGaN layer, thereby facilitating good growth of lattices, the stress generated between the sapphire substrate and the GaN layers due to lattice mismatch can be released, the growth quality of the multi-quantum well layer is improved, and the photoelectric property of the LED is improved.

Owner:HC SEMITEK SUZHOU

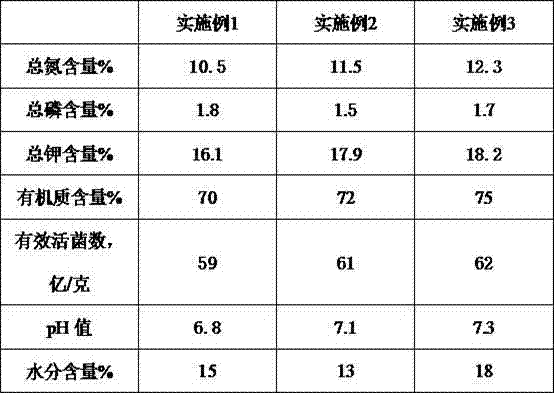

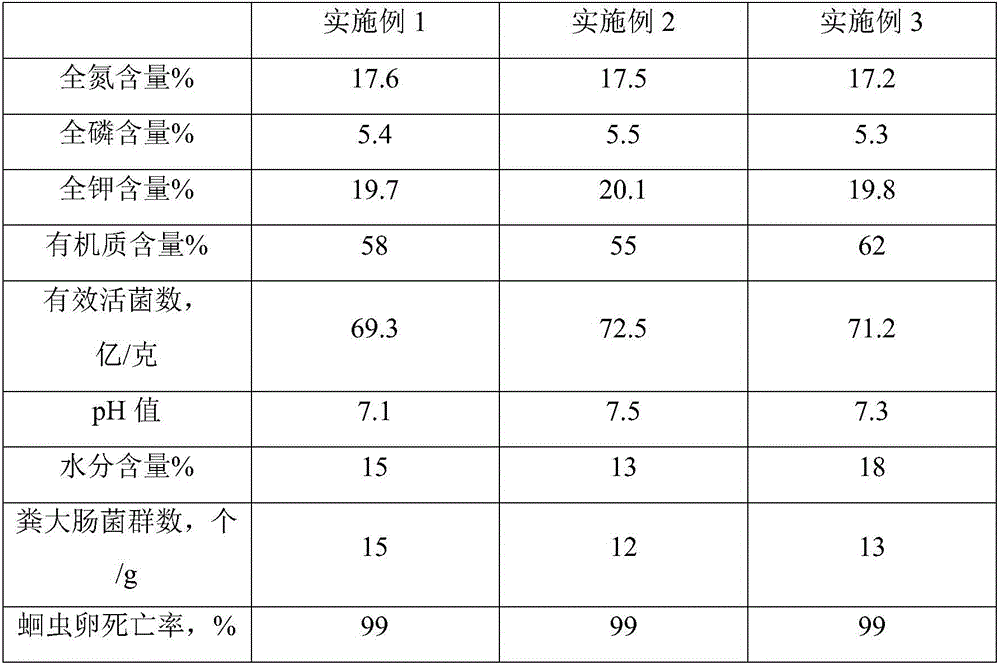

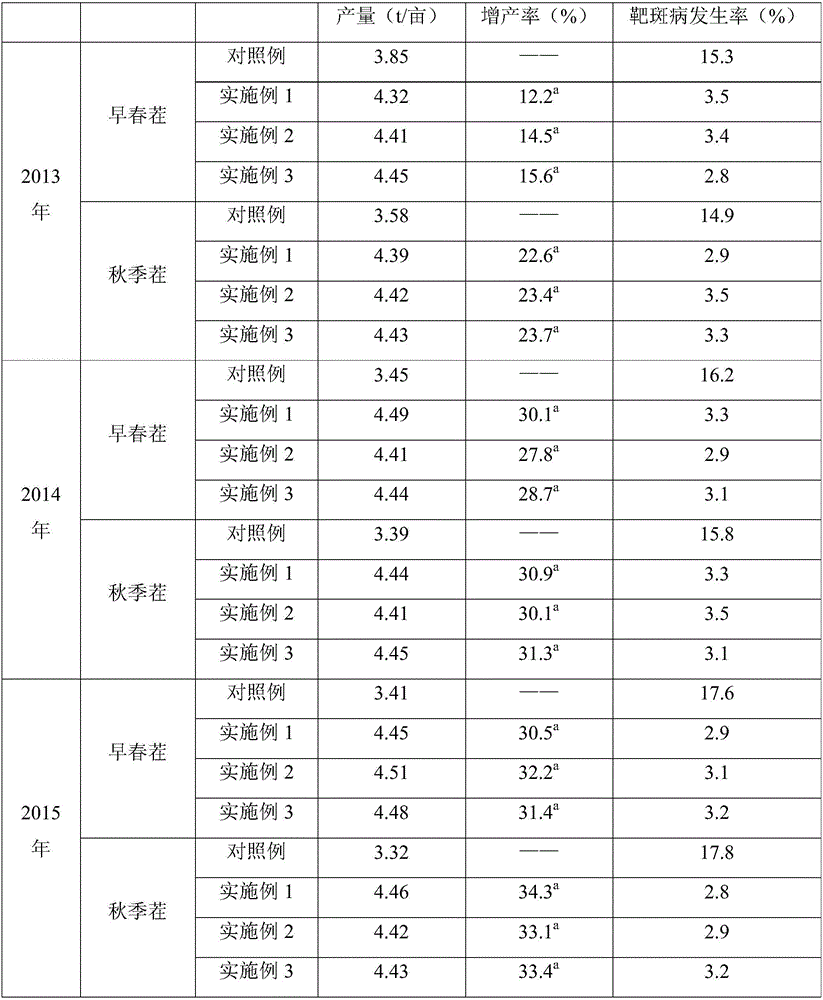

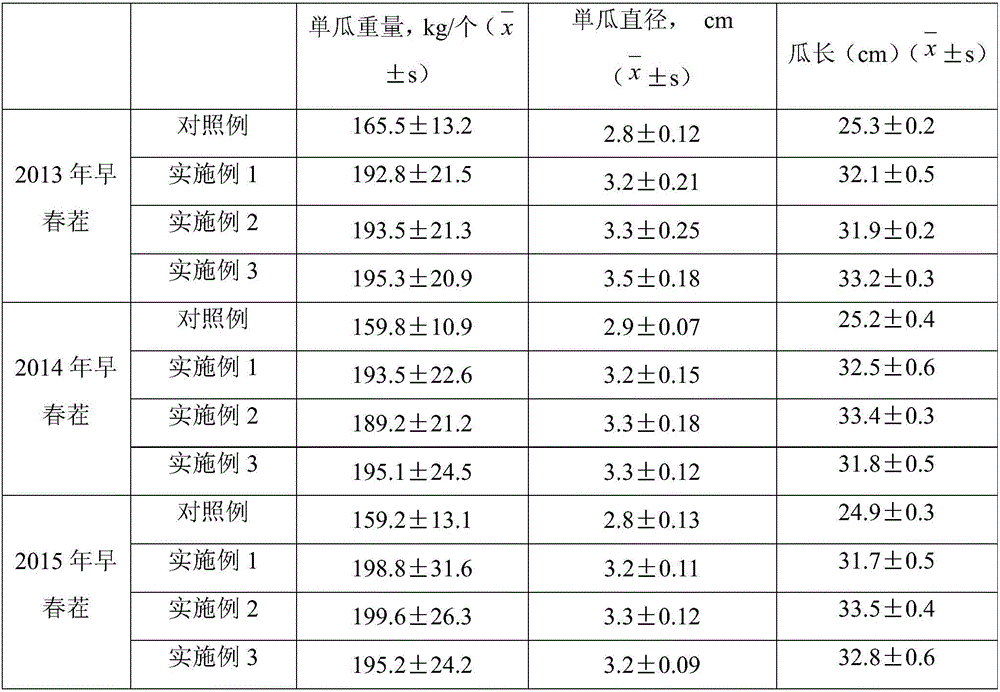

Special organic fertilizer for watermelons and preparation method of special organic fertilizer

The invention discloses a special organic fertilizer for watermelons and a preparation method of the special organic fertilizer, and belongs to the technical field of fertilizers. The special organic fertilizer is prepared from the following raw materials in parts by weight: 30-40 parts of chicken manure, 20-35 parts of decomposed plant straw, 10-15 parts of wheat bran, 10-15 parts of peanut oil residue, 5-10 parts of oil sludge, 5-10 parts of humic acid, 2-5 parts of urea, 10-20 parts of trace elements, 5-10 parts of a complex microbial agent and 5-10 parts a functional microbial agent. The special organic fertilizer can provide abundant nutritive elements for the watermelons according to the growth characteristics of watermelons in various periods, and the special organic fertilizer can increase the yield, improve the quality and character and promote the good growth of watermelons. By using the special organic fertilizer, the use amount of unreasonable fertilizers can be reduced.

Owner:DANGSHAN CHUNYUAN FERTILIZER CO LTD

Pig feed additive

The invention discloses a pig feed additive which belongs to the field of feed and relates to a feed additive. The pig feed additive comprises the following components in parts by weight: 10-25 parts of yeast extract, 10-18 parts of high-temperature resistance lactic acid bacteria, 5-10 parts of soybean peptide, 8-18 parts of ganoderma fruiting body, 5-15 parts of bran, 10-22 parts of cordyceps mycelia, 1-3 parts of fructose-oligosaccharide, 1-4 parts of raffinose, 1-3 parts of cellulase, 1-2 parts of protease, 1-3 parts of mixed amino acids and 0.5-2 parts of amino acid chelated copper. After being compounded, the pig feed additive has the advantages of having very good anti-diarrhea effect, effectively enhancing the immunity of piglets, reducing the application amount of antibiotic products and improving the growth quality of the piglets; and through application of the pig feed additive, the phenomena that the piglets have long hair in a nursing stage, and the growth and development of the pigments are hindered after the nursing stage are avoided.

Owner:南通华多种猪繁育有限公司

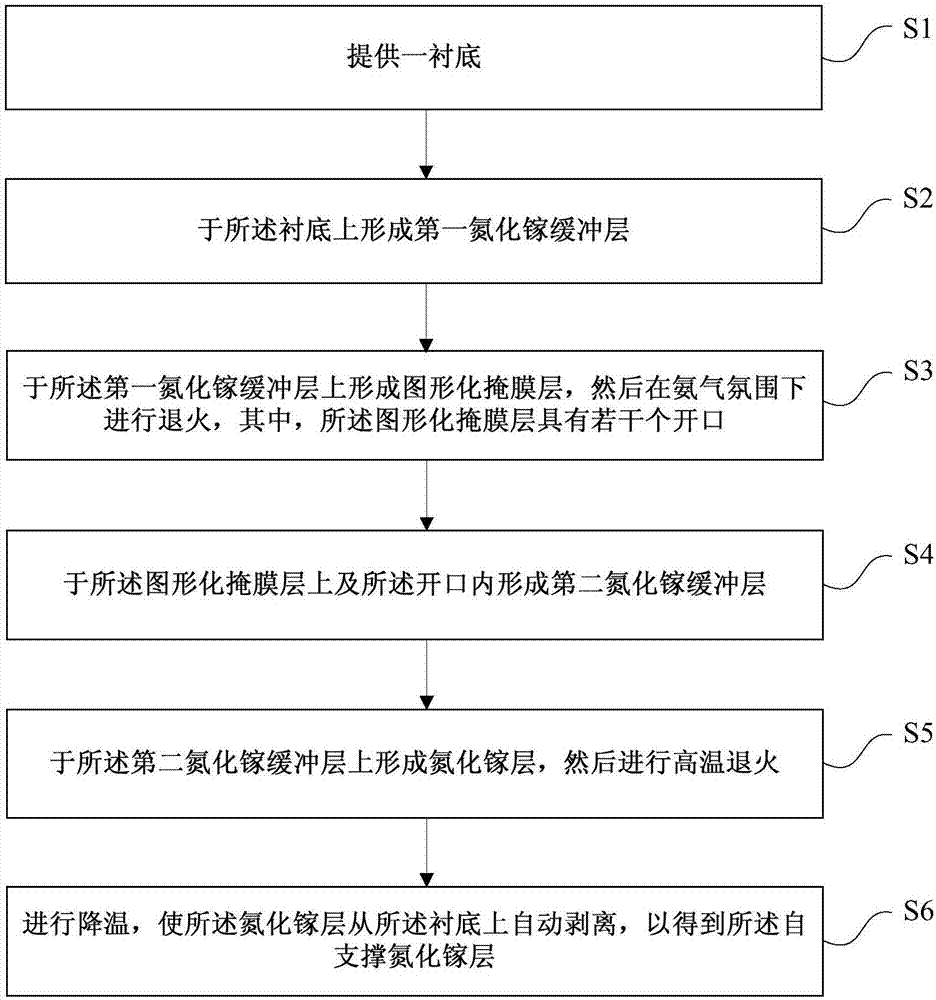

Self-supporting gallium nitride layer, preparation method therefor, and annealing method

ActiveCN107275187AImprove yieldImprove growth qualitySemiconductor/solid-state device manufacturingGallium nitrideMaterials science

The invention provides a self-supporting gallium nitride layer, a preparation method therefor, and an annealing method. The preparation method at least comprises the following steps: providing a substrate; forming a first gallium nitride buffering layer on the substrate; forming a patterned mask layer on the first gallium nitride buffering layer, and carrying out the annealing under the atmosphere of ammonia gas, wherein the patterned mask layer is provided with a plurality of openings; forming second gallium nitride buffering layers on the patterned mask layer and in the openings; forming gallium nitride layers on the second gallium nitride buffering layers, and carrying out the high-temperature annealing; carrying out the cooling, enabling the gallium nitride layers to be automatically peeled off from the substrate, so as to obtain the self-supporting gallium nitride layer. According to the invention, the preparation method is lower in requirements for the preparation technology, and can achieve the quick automatic peeling of the gallium nitride layers. Moreover, the thermal stress generated in a peeling process cannot affect the gallium nitride layers, so the self-supporting gallium nitride layer with the high finished product rate can be obtained.

Owner:镓特半导体科技(上海)有限公司

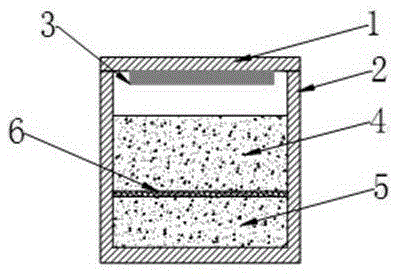

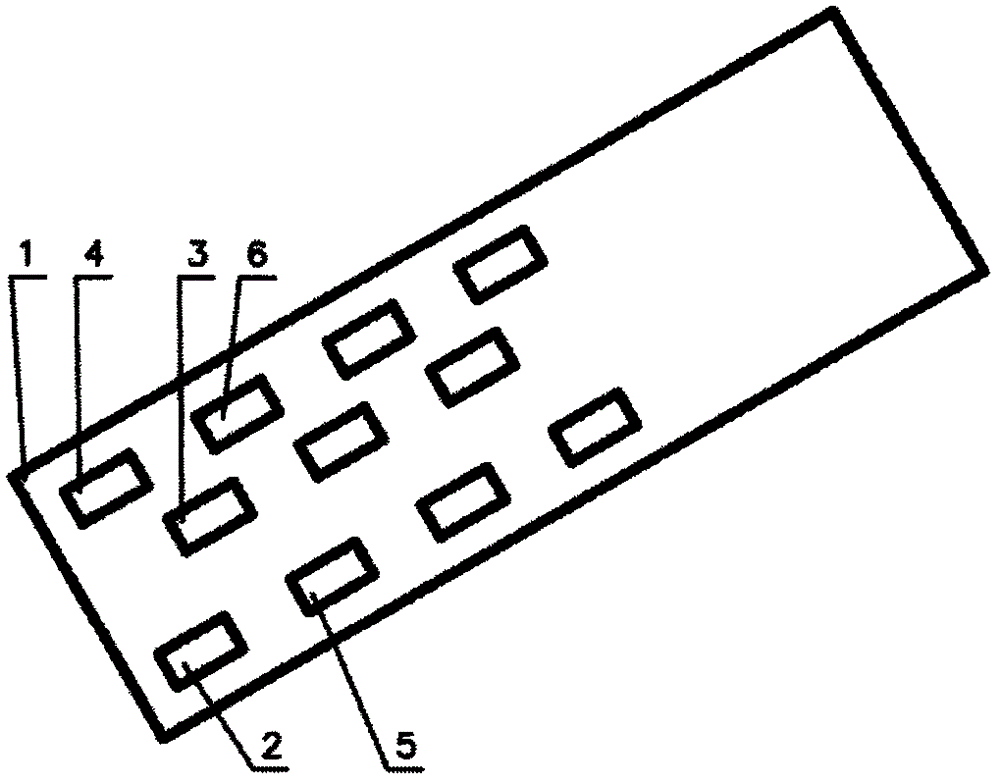

Sustained release device for growing of SiC single crystals with PVT (physical vapor transport) method

InactiveCN105671637ADoes not change the temperature field distributionImprove growth qualityPolycrystalline material growthFrom condensed vaporsCrucibleCrystal growth

The invention discloses a slow-release device for growing silicon carbide single crystal by PVT method. The device comprises a crucible, a crucible cover is fastened on the crucible, a seed crystal is fixed on the inner side of the crucible cover, and silicon carbide powder is installed in the crucible The crucible is provided with a partition, which separates the silicon carbide powder source into upper and lower layers, and the partition is provided with several holes connecting the upper and lower layers of the silicon carbide powder source. The invention divides the straight-through crucible inner cavity into upper and lower layers, reduces the gas transmission rate from the wall to the seed crystal, effectively solves the problem of Si loss, and at the same time does not change the temperature field distribution in the crucible, and improves the crystal growth quality. Increase the utilization rate of raw materials, reduce the cost of raw materials, and bring benefits to the enterprise.

Owner:BEIJING CENTURY GOLDRAY SEMICON CO LTD

Non polarity A side nitride film growing on the silicon substrate and its making method and use

InactiveCN101009346AEasy to separateIncrease overlapLaser detailsFinal product manufactureSolar batteryLight-emitting diode

The invention relates to a nonpolar (1120)A side nitride film that comprises a silicon underlay, metal layer which grows upon the silicon underlay sequentially, InGaAlN initial growth layer and the first InGaAlN buffer layer, it characterized in that: said silicon underlay is Si underlay which adopts the (100) side, (110) side or offset angle. The nonpolar a side nitride film which grows on the silicon underlay can be used in LBD, laser, solar battery. The component extension configuration is adopted according to different component, for example the LBD and laser, and using the mature silicon craft further to produce relative diprosopia electrode component or peeling off component. Comparing with current technique, the advantages of the invention are: the invention can increase the growth quality of nonpolar GaN base material, and decrease the cost; the craft of current component can be simplified greatly, the cost can be decreased, and increase the elimination efficiency and lightening efficiency greatly.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Method for improving nutritive saline-alkali land soil

InactiveCN101816250ASimple structureImprove flatnessHorticultureSoil-working methodsEcological environmentAlkali soil

The invention discloses a method for improving nutritive saline-alkali land soil, and relates to the field of saline-alkali treatment. The method comprises the following steps of: 1, ploughing the soil; 2, applying stalks in a deep layer; and 3, covering sand on a surface layer. The method has the following advantages that: 1, the crop stalks are degraded to provide a great number of organic matters, improve soil structure and provide nutrient needed by plants; 2, the sand covers on the surface layer, and facilitates the flatness of the ground; 3, the stalks turned under the soil, together with the covered sand, can cut off capillaries of the soil, reduce water loss and inhibit salt return of the saline-alkali land soil; and 4, the method has low cost, can comprehensively improve the saline-alkali land soil in a large area, improve the growth quality of the plants in the saline-alkali land and protect and improve ecological environment, and has wide application prospect.

Owner:WUHAN BOTANICAL GARDEN CHINESE ACAD OF SCI

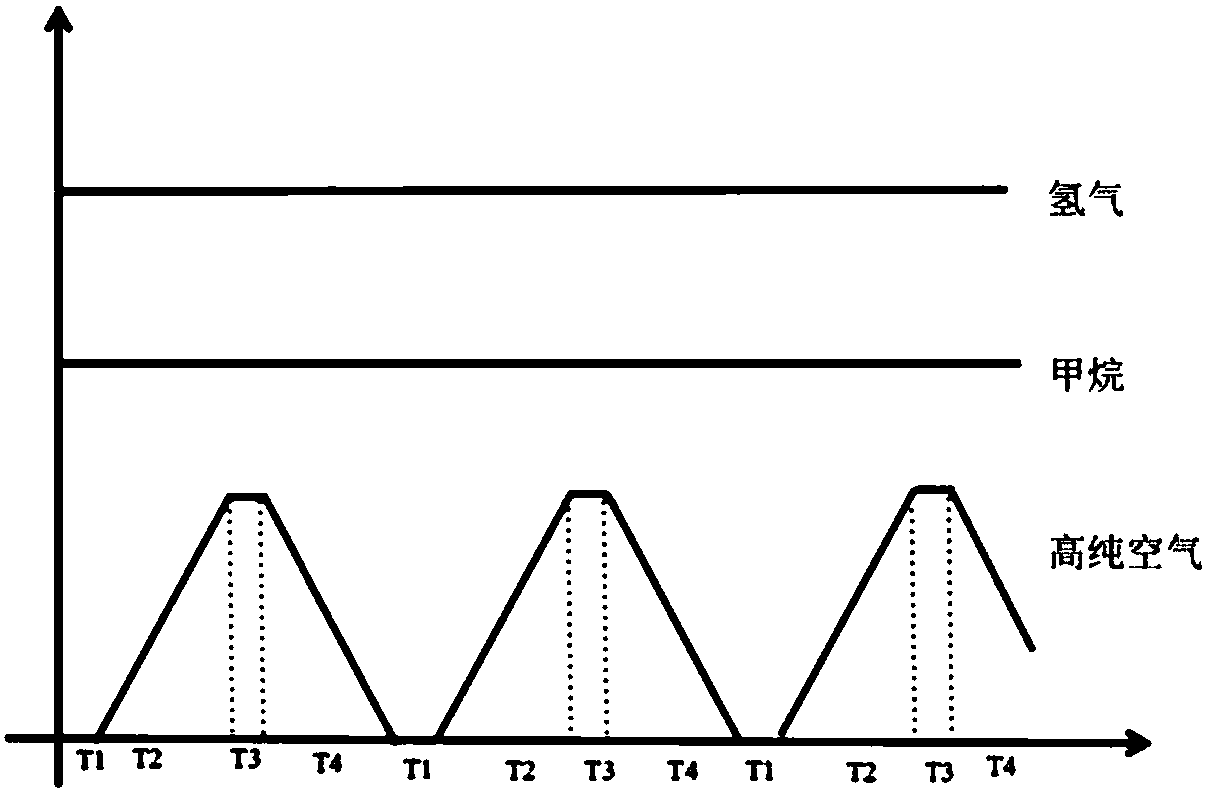

Gradient monocrystalline diamond and preparation method thereof

ActiveCN107740184AFast growthHigh hardnessPolycrystalline material growthFrom chemically reactive gasesHydrogenNitrogen

The invention relates to the field of growth of monocrystalline diamonds through a microwave plasma chemical vapor deposition method and in particular relates to a gradient monocrystalline diamond anda preparation method thereof. Microwave plasma chemical vapor deposition equipment is adopted and high-purity air is introduced in a hydrogen and methane mixed gas source according to a continuous gradient concentration, so as to realize alternating deposition of a high-quality monocrystalline diamond layer without nitrogen and a nitrogen-containing diamond layer; then the gradient monocrystalline diamond with high quality, high strength and good toughness is prepared.

Owner:湖北碳六科技有限公司

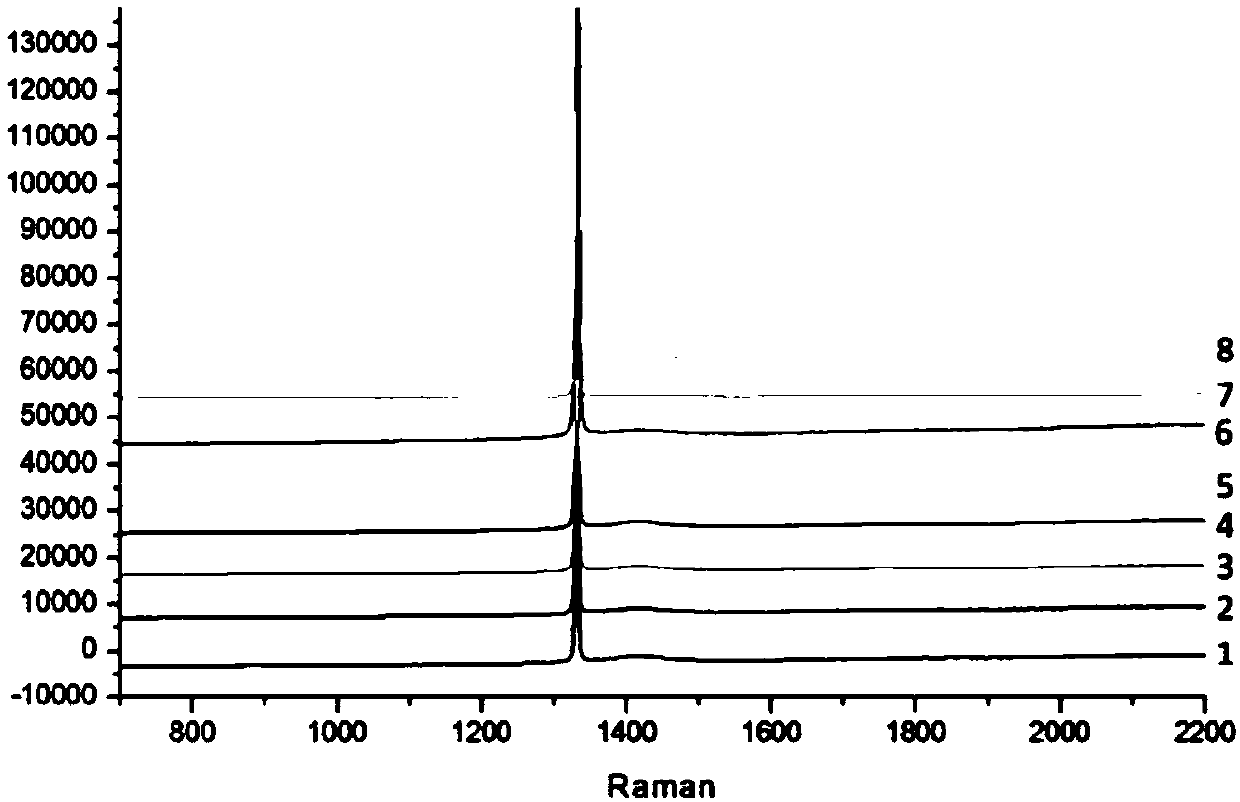

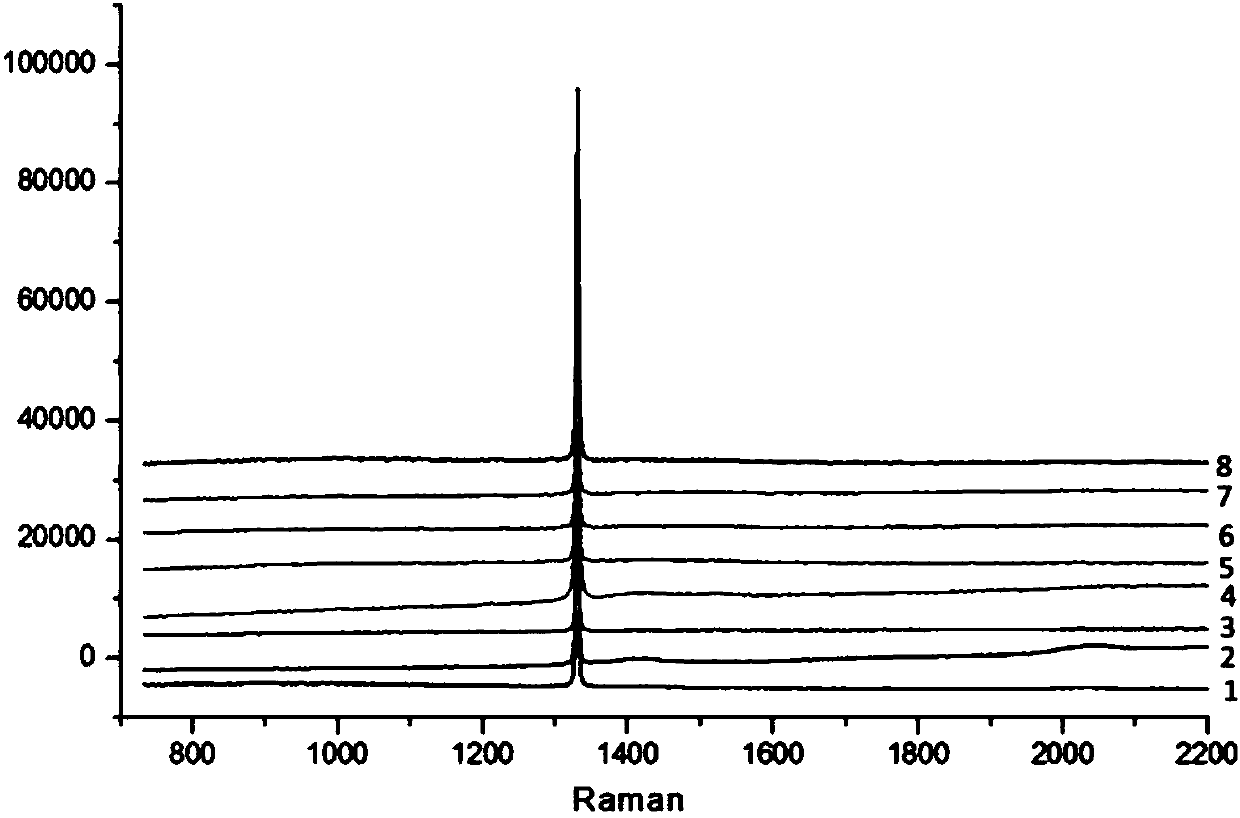

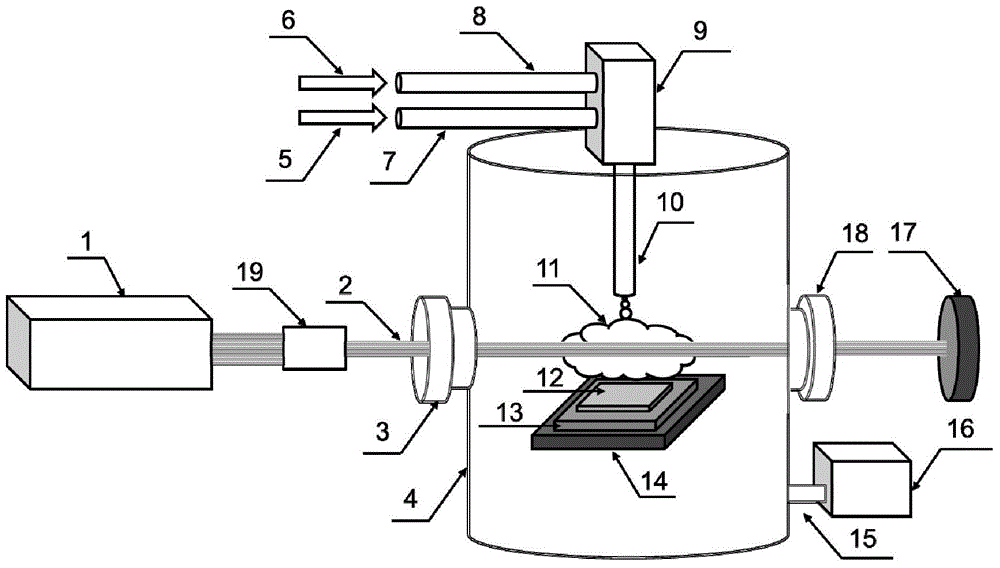

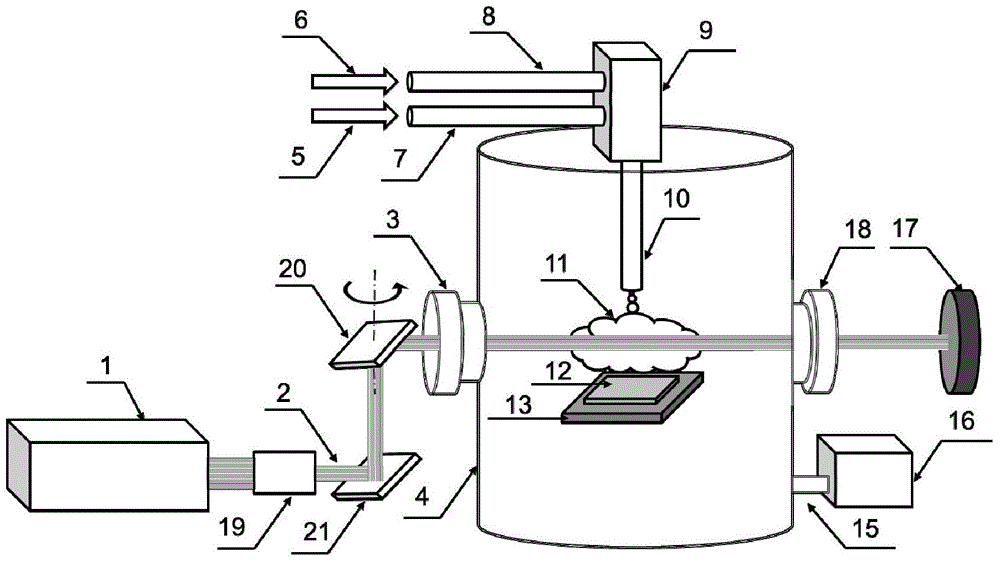

Method and device for growth ofnitride materials at low temperature through laser assistance

ActiveCN104532211AEasily brokenIncrease growth rateChemical vapor deposition coatingChemical reactionResonance

The invention discloses a method and device for growth of nitride materials at low temperature through laser assistance. The method comprises the steps that precursor steam of a non-nitrogen element and active nitrogen precursor gas are conveyed to a substrate material at the temperature ranging from 250 DEG C to 800 DEG C in a reaction chamber; a laser beam with the wavelength equal to the length of active nitrogen molecular bond resonance waves is utilized for acting on active nitrogen gas to enable laser energy to be directly coupled to active nitrogen gas molecules; and breakage of NH keys is accelerated, sufficient active nitrogen is provided, the non-nitrogen element chemically react with the active nitrogen, the III group of nitrogen film coating materials are deposited, and sustained action is carried out until a sediment covers a whole substrate and reaches the needed thickness. The device comprises a vacuum reaction cavity, a gas pre-mixing cavity, a wavelength tunable laser device and a moving mechanism. On the basis of improvement in the active nitrogen utilization rate and reduction of the environmental pollution, large-area, rapid and high-quality growth of the nitrogen film coating materials under the low-temperature environment can be achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

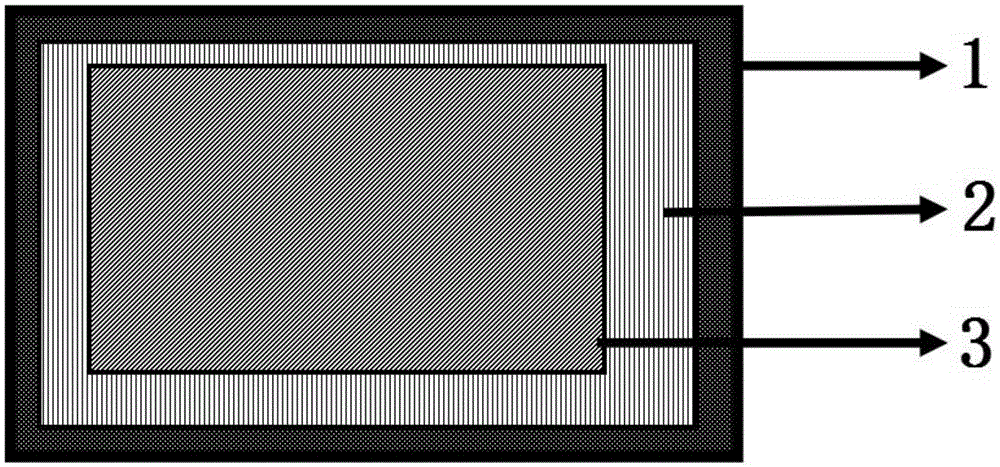

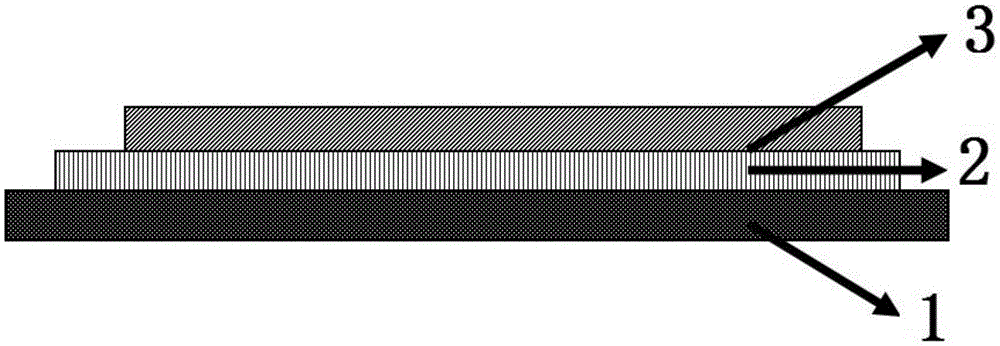

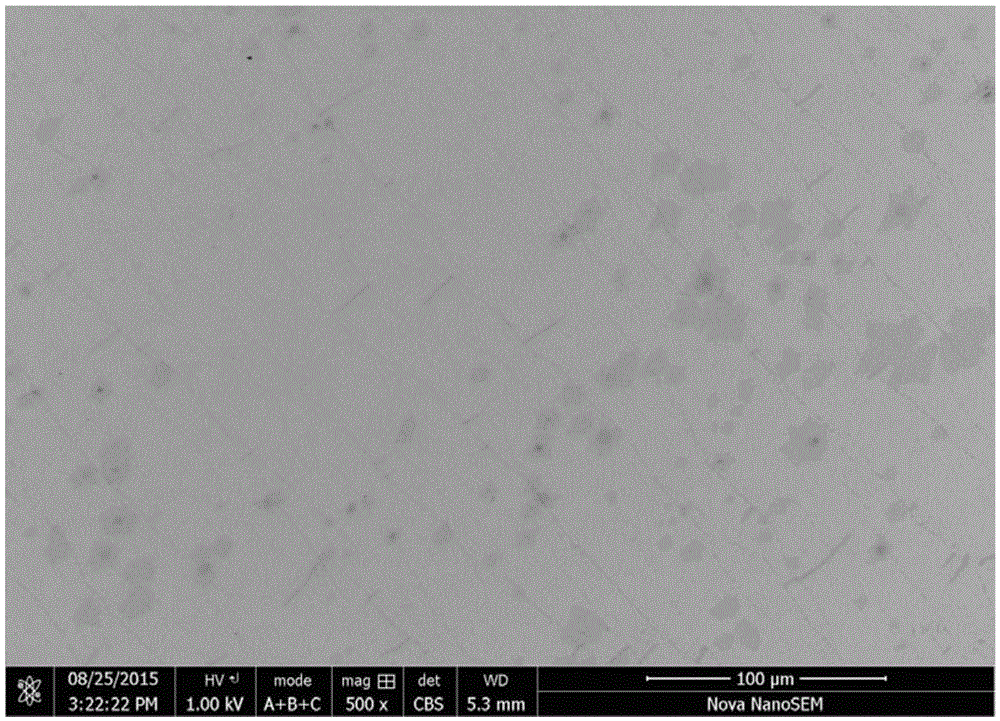

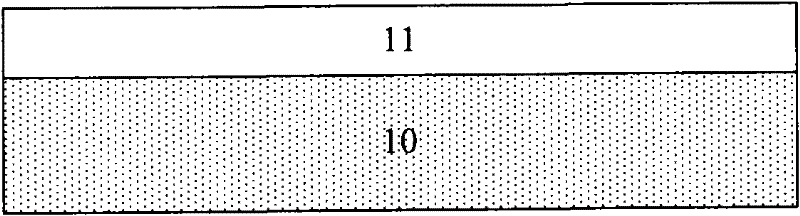

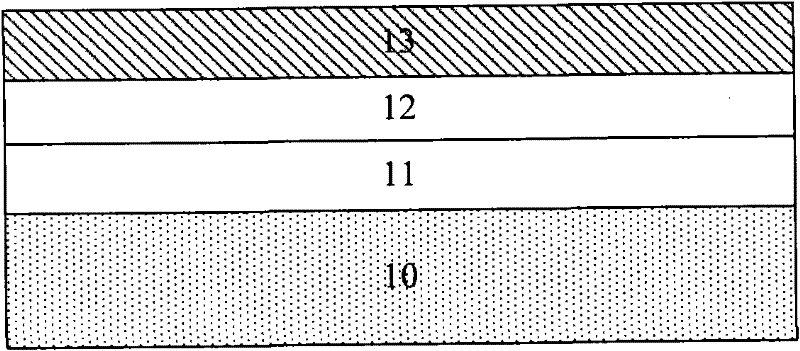

Large-scale production method for chemical vapor deposition (CVD) graphene film

ActiveCN105603384AAvoid stickingDoes not affect depositionChemical vapor deposition coatingCatalytic pyrolysisCopper foil

The invention discloses a large-scale production method for a chemical vapor deposition (CVD) graphene film. By the adoption of a CVD technology, first, heat treatment is performed on metal substrates under a vacuum state, inert gas and carbon source gas are injected, the carbon source gas is subjected to catalytic pyrolysis on the surfaces of the metal substrates at high temperature, then graphene grows, large-scale growth is achieved by the adoption of the mode that the multiple layers of metal substrates are overlaid, and every two adjacent layers of metal substrates are separated through a separation layer. Through arranging the separation layers, adhesion between the metal substrates is prevented, in addition, deposition of high-quality graphene on each layer of copper coil is not affected, the multiple layers of metal substrates used for graphene growth can be installed on one basal plate, in this way, the capacity which is a hundred times that of a traditional CVD method is achieved through the same reaction furnace, and large-scale production is achieved.

Owner:WUXI GRAPHENE FILM +1

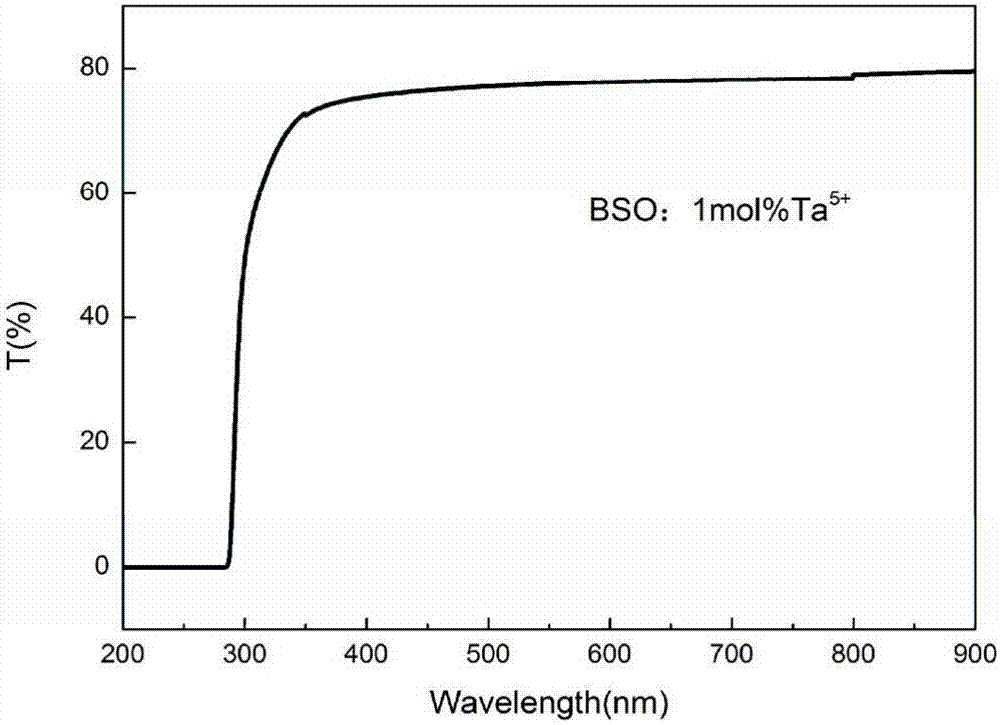

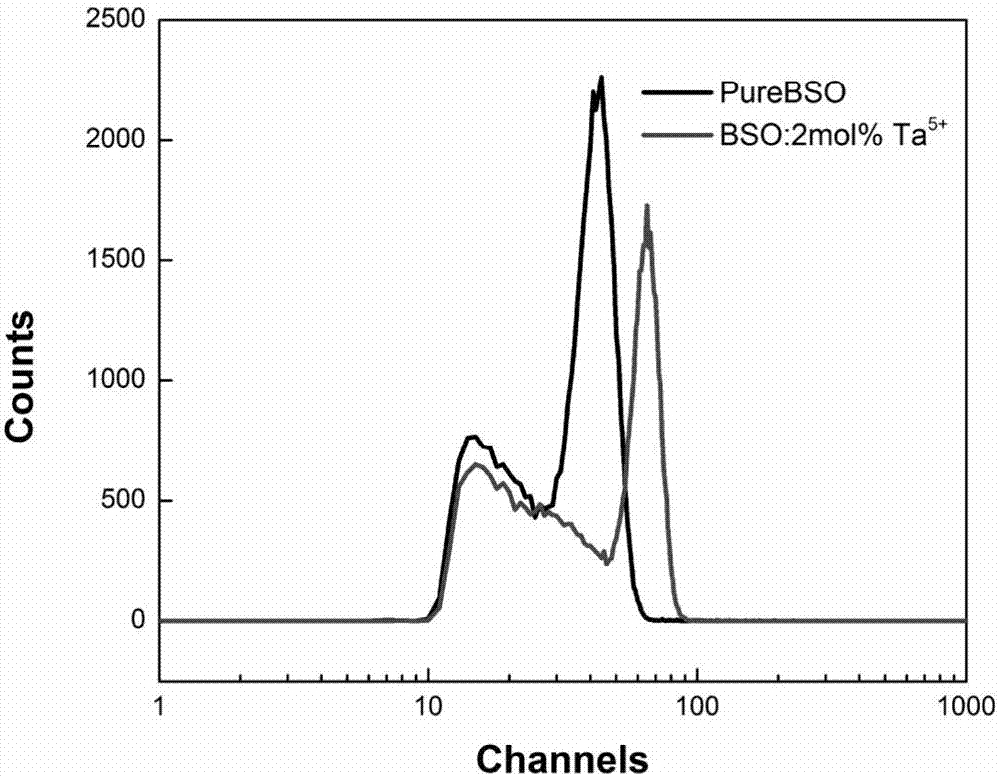

High-light-output bismuth silicate scintillation crystal and preparation method thereof

ActiveCN106948006APrevent volatilizationReduce segregationPolycrystalline material growthFrom frozen solutionsCrucibleScintillation crystals

The invention provides a high-light-output bismuth silicate scintillation crystal. A bismuth silicate crystal is doped with Ta<5+> in the doping form of Ta2O5, doping quantity being 0.2-4 mol% / mol. The invention also provides a preparation method of the high-light-output bismuth silicate scintillation crystal. The preparation method includes the steps of: a) synthesizing a doped bismuth silicate polycrystal powder material through a solid phase sintering method, and compressing the doped bismuth silicate polycrystal powder material into compact cylindrical material bulks; b) fixing a seed crystal on a seed crystal position on the bottom of a crucible, and placing the polycrystal material bulks in the crucible and sealing the crucible, placing the crucible in a crystal growing furnace, and controlling temperature to be 1050-1200 DEG C, wherein the growth speed of the crystal is 0.2-0.6 mm / h. Because of doping of the Ta<5+>, light output of the BSO crystal is greatly increased. The preparation method achieves high-light-output and high-quality growth of the bismuth silicate monocrystal, is simple in technical equipment, can grow a plurality of crystal rods simultaneously, and greatly improves the growth efficiency and application of the bismuth silicate scintillation crystal.

Owner:SHANGHAI INST OF TECH

Method for cultivating chili pepper seedlings

InactiveCN104041314AAids in healthy germinationImprove growth qualityFertilising methodsSeed immunisationSeedlingSeed treatment

The invention discloses a method for cultivating chili pepper seedlings. The method for cultivating the chili pepper seedlings comprises the following steps of seed treatment, seedbed treatment, seedling cultivation, sowing, seedbed management and seedling management. According to the method for cultivating the chili pepper seedlings, healthy sprouting of the chili pepper seedlings is facilitated, it is guaranteed that the seedlings are not damaged by insects and diseases, the growing quality is improved, the production yield is improved, and earnings are increased.

Owner:苏州市美人半岛齐力生态农产品专业合作社

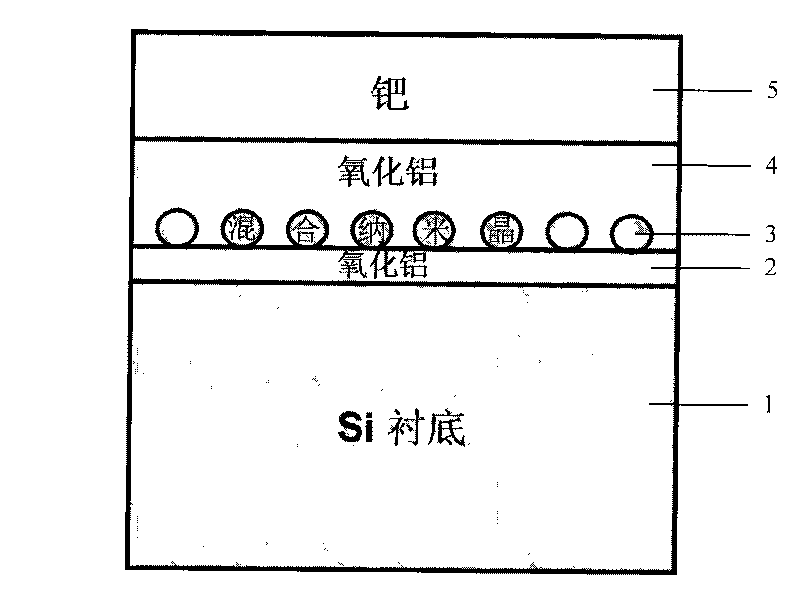

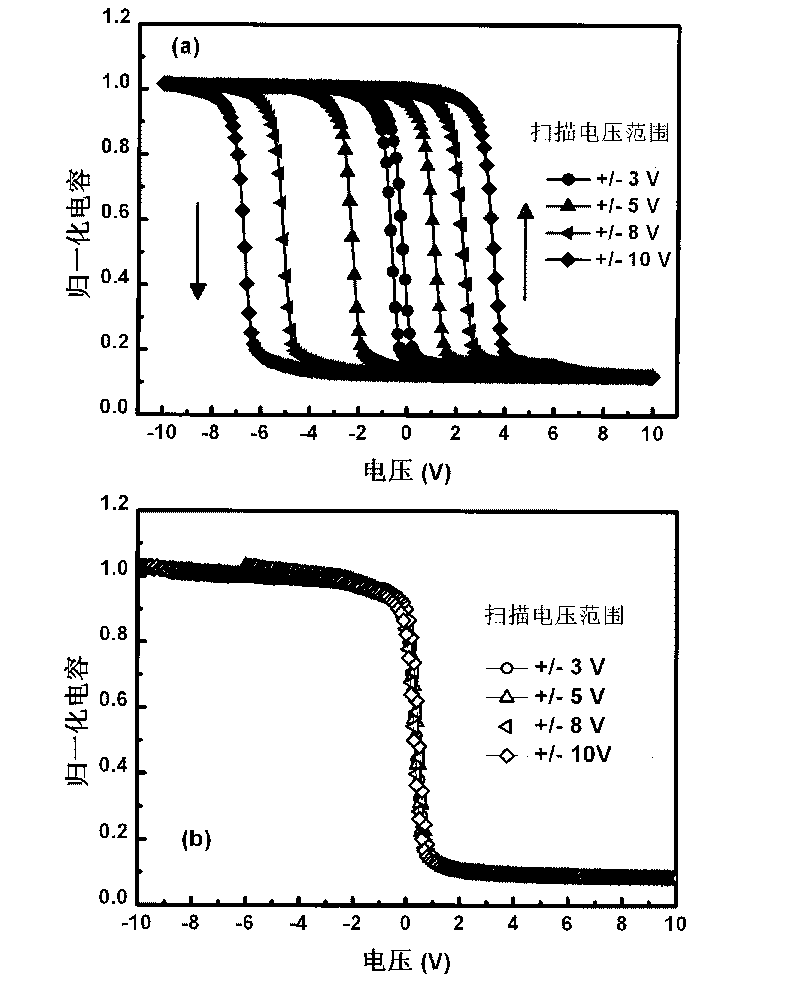

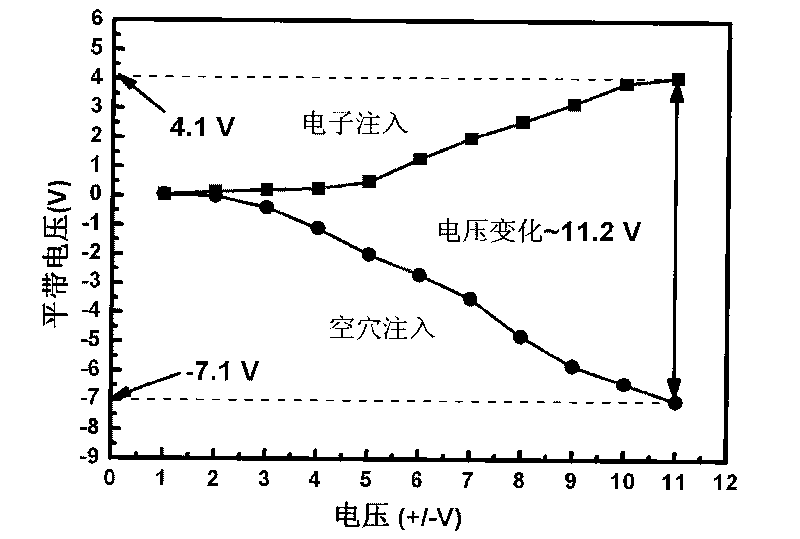

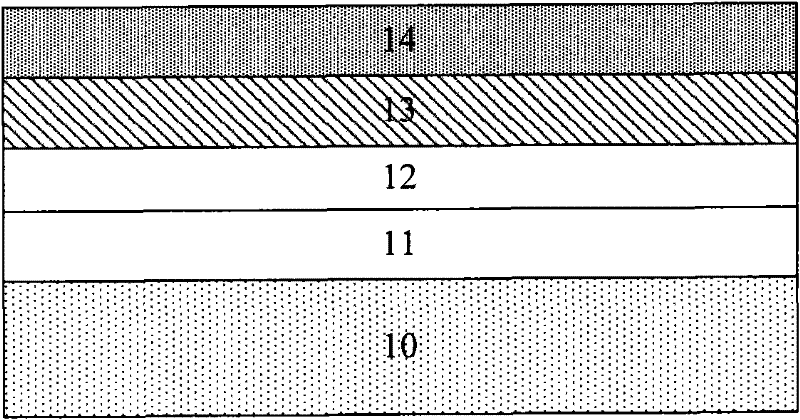

Capacitor structure of mixed nano-crystal memory and preparation method thereof

InactiveCN101692463AHigh densityControl thicknessSemiconductor/solid-state device manufacturingSemiconductor devicesCapacitanceCharge retention

The invention belongs to the technical field of manufacturing semiconductor integrated circuits, and particularly relates to a capacitor of a nano-crystal memory and a preparation method thereof. The capacitor uses P-type monocrystalline silicon as a substrate, and an Al2O3 tunneling layer, a ruthenium and ruthenium oxide mixed nano-crystal, an Al2O3 blocking layer and a palladium electrode layer are arranged on the substrate in turn, wherein the Al2O3 layer is prepared by adopting an atomic layer deposition method; the mixed nano-crystal is formed by depositing a ruthenium layer through magnetron sputtering first and then performing rapid thermal annealing in a mixed gas atmosphere of nitrogen gas and a trace amount of oxygen gas; and the palladium electrode layer is formed by adopting a lift-off method. The capacitor structure of the memory has the excellent characteristics of good programming and erasing properties, long charge retention time and the like, and has a good application prospect on a flash memory.

Owner:FUDAN UNIV

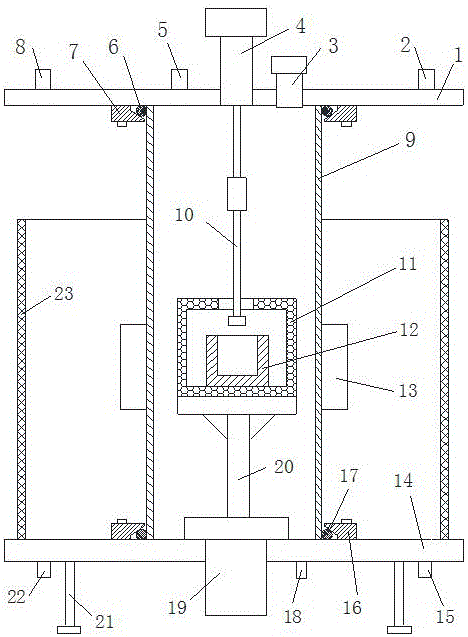

Crystal pulling furnace with replaceable furnace cavity

ActiveCN106435712AImprove growth efficiencyImprove growth qualityBy pulling from meltCrucibleEngineering

The invention discloses a crystal pulling furnace with a replaceable furnace cavity. The crystal pulling furnace comprises the furnace cavity, a rotating pulling weighing unit, a heat-preservation heat field and a crucible. The heat-preservation heat field is arranged in the furnace cavity, the crucible is put into the heat-preservation heat field, the rotating pulling weighing unit is arranged on the furnace cavity, and a seed rod is arranged in the furnace cavity and connected with the a rotating pulling weighing unit; the furnace cavity comprises an upper flange disc, a lower flange disc and a cavity body, the cavity body is arranged between the upper flange disc and the lower flange disc, a heating device is arranged inside the cavity body or arranged on the periphery, and sealing devices are arranged between the cavity and the upper flange disc and the lower flange disc. A lifting device is arranged in the furnace cavity and fixed on the lower flange disc, and the heat-preservation heat field and the crucible are arranged on the lifting device. The crystal pulling furnace can be adjusted and replaced and can be suitable for growth of more size crystals, and is simple in structure, convenient to assemble and maintain and low in energy dissipation. In addition, the crucible can be located in the best temperature filed through lifting device, and the crystal growing efficiency and quality are improved.

Owner:济南金曼顿自动化技术有限公司

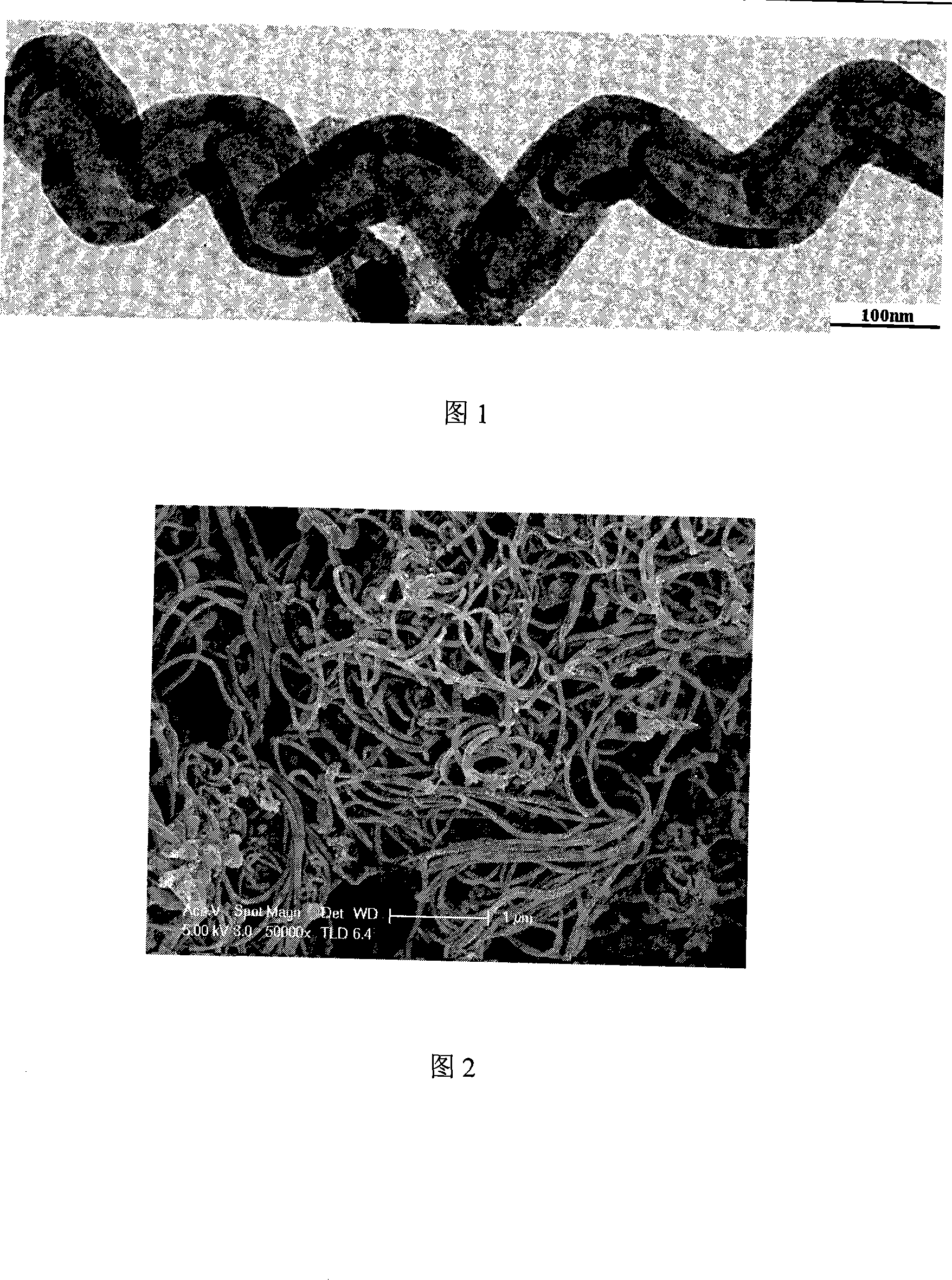

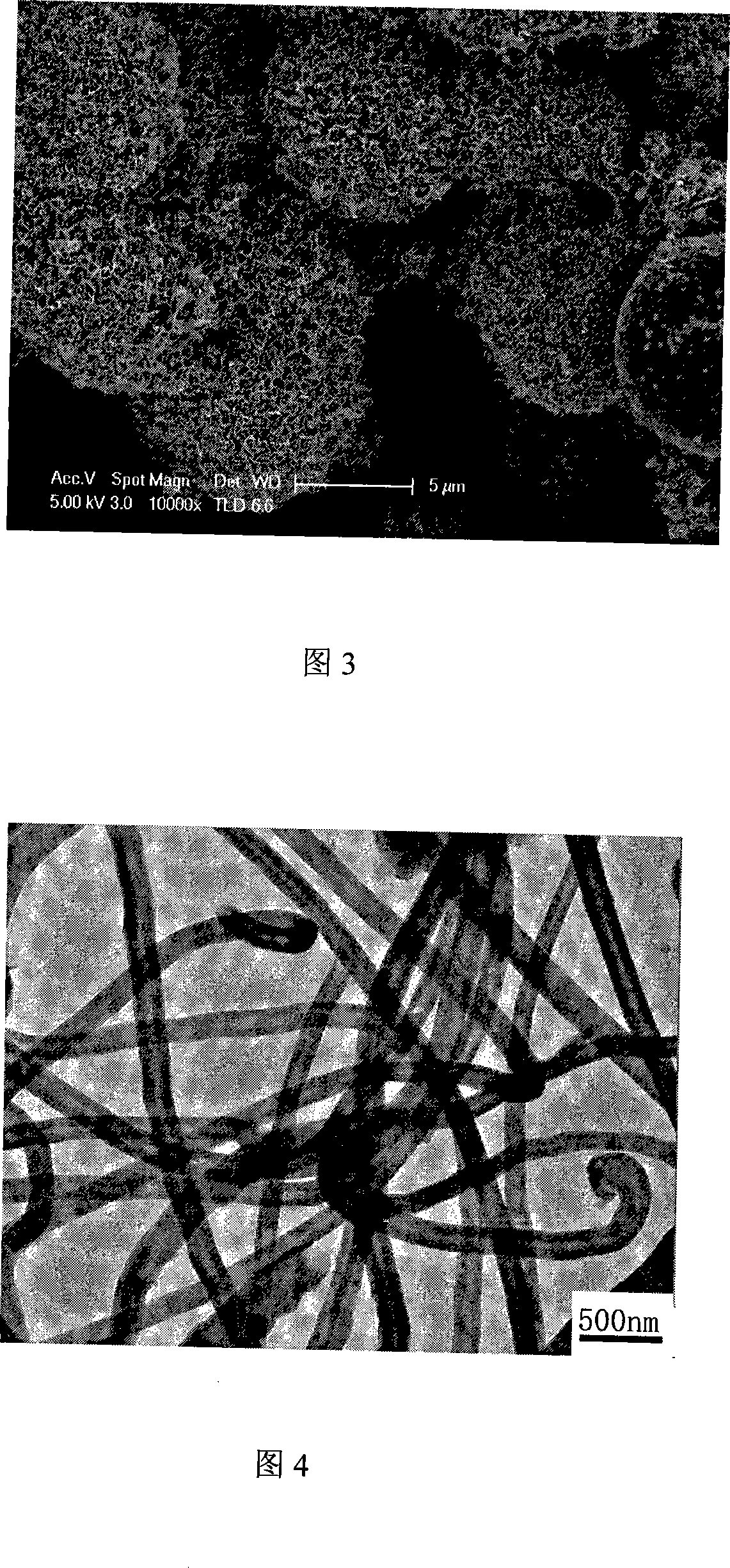

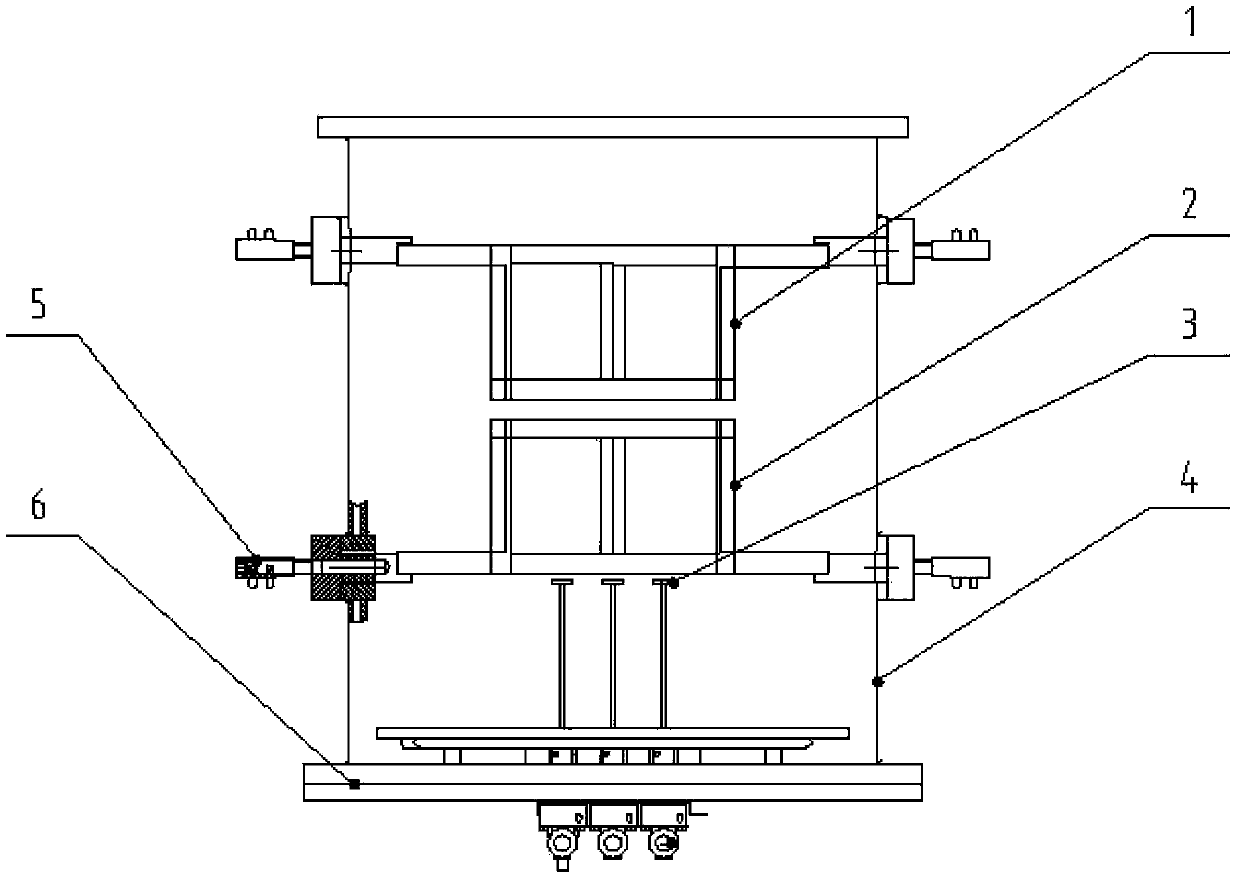

Method of preparing multi-wall carbon nano-tube by using polymer as raw material

InactiveCN101239713AQuick breakdownIncrease growth rateNanostructure manufacturePolymer scienceCarbon nanotube

The present invention provides a method of multi-walled carbon nantubes using polymer as raw material, belonging to inorganic function material synthesizing technology field, in particular: polyethylene or polypropylene, PEMA or polypropylene and catalyst are placed in the sealing container according to a certain proportion, calculated by weight percentage, polyethylene or polypropylene : PEMA or polypropylene : catalyst is 1:0.25-0.5:0.05-0.005; baking 10-25 hour under the temperature 600-850 Celsius, cooling to room temperature, removing reactant, acid washing to remove catalyst, the product is obtained by drying. The invention has a simple operation, high productive rate, lower cost, and is a green method for acquiring carbon nantubes, the multi-walled carbon nantubes have wide application, used as hydrogen storage material, high strength composite field, catalyst carrier etc.

Owner:JIANGSU UNIV

Sapphire crystal growth furnace having three heaters

ActiveCN103469295AImprove growth qualityImprove yieldPolycrystalline material growthBy pulling from meltEngineeringCrystal growth

The present invention relates to the field of crystal growth furnaces, wherein a purpose of the present invention is to provide a sapphire crystal growth furnace having three heaters. The sapphire crystal growth furnace comprises three mesh heaters woven by using tungsten wires, wherein the three mesh heaters respectively are the upper portion heater, the middle portion heater and the lower portion heater, the upper portion heater and the middle portion heaters are respectively arranged on electrodes on the upper portion and the middle portion of the furnace cylinder of the sapphire crystal growth furnace, and the lower portion heater is arranged on an electrode on the furnace bottom plate of the sapphire crystal growth furnace. According to the present invention, based on different requirements on the thermal field temperature gradient at different crystal growth stages, powers of the three heaters are matched, such that the seeding process and the crystal growth process achieve the optimized temperature environment; and significant effects are provided crystal growth quality increase, production cycle shortening, yield increase, and energy consumption reduction.

Owner:ZHEJIANG JINGSHENG MECHANICAL & ELECTRICAL

Method for manufacturing memory cell including resistor

InactiveCN102270738APrecise and controllable componentsImprove uniformityElectrical apparatusDigital storageMemory cellMaterials science

The present application discloses a manufacturing method of a memory cell including a resistor, comprising the following steps: a) forming a bottom electrode layer on an insulating substrate; b) forming a resistive material layer on the bottom electrode layer by MOCVD; c) forming a resistive material layer on the bottom electrode layer; forming a top electrode layer on the resistive material; and d) patterning the top electrode layer and the resistive material layer to form separated memory cells. The MOCVD method can be used to manufacture a resistive material layer with precise controllable thickness and composition and good uniformity, so that a memory cell of an RRAM with an MOM structure and excellent interface characteristics can be obtained.

Owner:PEKING UNIV

Chemical granulation processing method for quartz surface

A method for chemically and roughly treating a quartz surface overcomes the defects of the prior art in which the treatment to the quartz surface easily leads to damage and influences the size accuracy of the quartz product. The method is as below: at a normal temperature and a normal pressure, immersing a quartz product into a container filled with a treating fluid so as to undergo reaction after the surface of the quartz product is polished, taking out the quartz product after two-hour reaction, and immersing the quartz product into the treating fluid again so as to repeat the preceding reaction till the roughness Ra of the surface of the quartz product is equal to 1.5 micrometers to 4.5 micrometers after attachments on the surface of the quartz product is eliminated with deionized water. The treatment process has reasonable design, involves simple devices and is easy to be operated, and the obtained quartz product has uniform surface roughness which is free from the influence of the shape. During the participation in the CVD reaction, the crazing and the shedding of a deposited film on the quartz surface is effectively reduced so as to reduce the possibility of pollution to the reaction cavity, to remarkably improve the finished product rate and the production efficiency, and then further to prolong the service life of the quartz product, save time, reduce consumption and reduce production cost.

Owner:SHENYANG HANKE SEMICON MATERIALS

Atractylodes macrocephala cultivation technology

InactiveCN103053290AImprove the effect of prevention and controlImprove growth qualityHorticultureTechnical managementPest control

The invention discloses an atractylodes macrocephala cultivation technology. Through technical management of field choosing, field preparation, seedling cultivation, transplantation, field management, pest control, seed reservation and the like, pest control effect of atractylodes macrocephala is enhanced, the atractylodes macrocephala is good in grow quality and high in yield, and economical benefits are improved.

Owner:李洪运

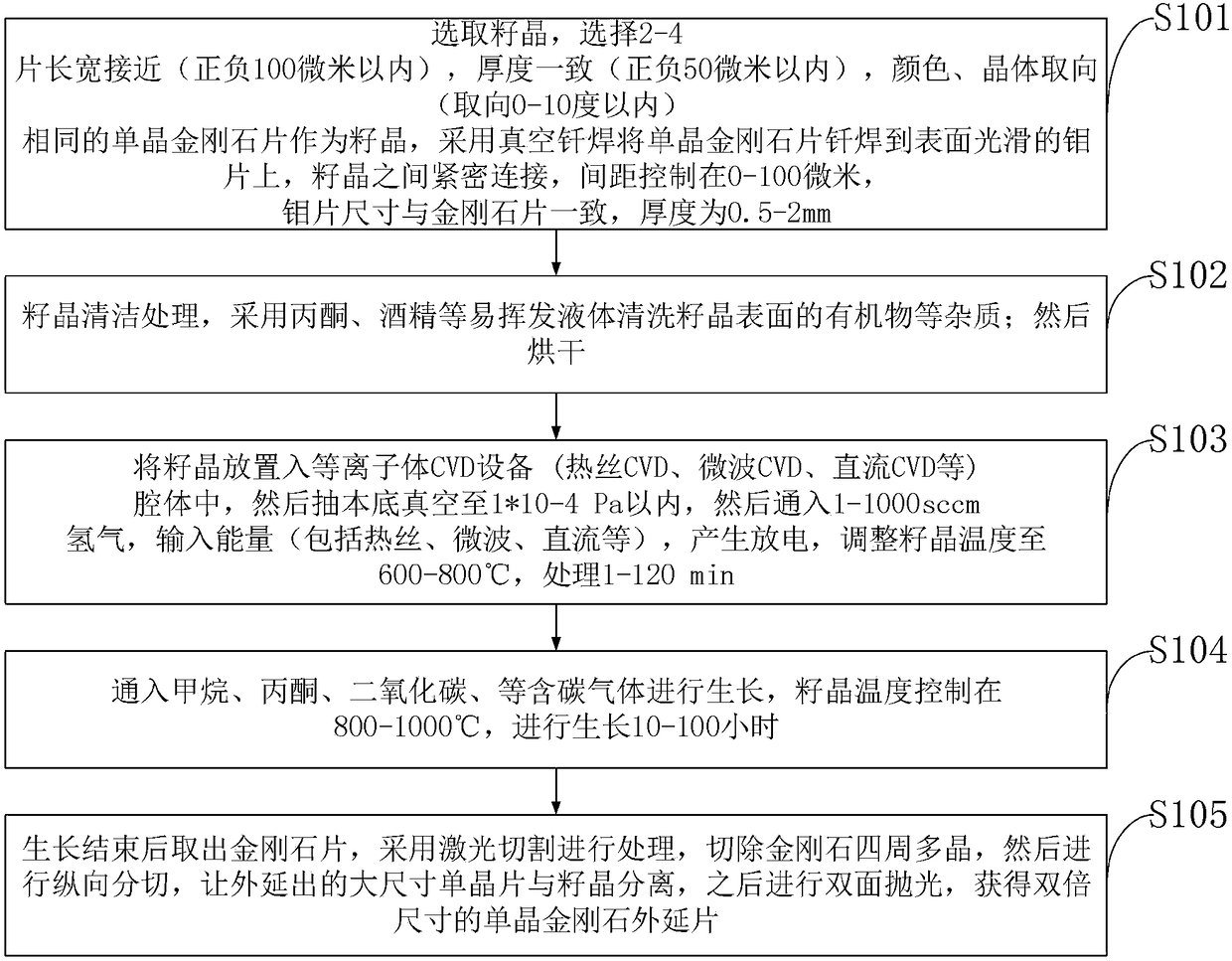

Method and system for splicing and growing single-crystal diamond

InactiveCN108103570ASolve the bottleneckSolve bottlenecksPolycrystalline material growthFrom chemically reactive gasesBottle neckChemistry

The invention belongs to the technical field of diamond preparation and discloses a method and a system for splicing and growing single-crystal diamonds. The method comprises the following steps: putting a seed crystal into a plasma CVD equipment cavity, sucking off ultimate pressure, introducing hydrogen, inputting energy, generating power discharge, and adjusting the temperature of the seed crystal; introducing a methane (or carbon-containing gases such as acetone and carbon dioxide) gas, growing the seed crystal for 1-100 hours at 800-1000 DEG C, and the like. According to the method, single-crystal diamonds are grown by using a CVD method through spicing growth, the purpose that the single-crystal diamonds is grown in a large scale is achieved, synthesis sizes directly depend on sizesof the seed crystals since conventional growth of single-crystal diamonds can be only longitudinally amplified on original seed crystals, two single-crystal diamond flakes of a same size and approximate thicknesses are fixed and spliced and grown simultaneously, then a large-size single-crystal diamond is grown, and bottle neck problems are solved.

Owner:湖北碳六科技有限公司

LED plant-growth lamp with continuous spectrum

InactiveCN105240748AMeet the needs of absorptionSuit one's needsPoint-like light sourceElectric circuit arrangementsGrowth plantGreen-light

The invention discloses an LED plant-growth lamp with a continuous spectrum. The LED plant-growth lamp comprises an LED light source lamp bead group (namely a light source), a light source base board, a radiator and a driving power source matched with the light source, wherein the LED light source lamp bead group consists of warm white light LEDs and red light LEDs. The correlated color temperature of the warm white light LEDs is below 4000K, and each warm white light LED is formed by applying fluorescent powder on a blue light chip of which the wave length of emitted light is 420-490nm; the fluorescent powder is a mixture of YAG fluorescent powder which emits yellow light at peak and fluorescent powder which emits green light at peak wavelength; the green-light fluorescent powder accounts for 5%-30% of the total weight of the fluorescent powder; the wave length of the red light LEDs is within the range of 620-680nm. The LED plant-growth lamp disclosed by the invention has the technical effects that the wave length of light is within the range of 430-680nm, and the lamp has the continuous spectrum so that the requirements of plants for light with other wave lengths can be met; the light supplementing effect is good; the growth quality of plants is high. The LED plant-growth lamp saves energy and is low in production cost.

Owner:郭敏 +1

Special biological organic fertilizer for cucumbers and preparation method of the special biological organic fertilizer

InactiveCN106747933ASmooth releaseAbundant supplyBiocideBio-organic fraction processingPlant diseaseNutrient

The invention discloses special biological organic fertilizer for cucumbers and a preparation method of the special biological organic fertilizer, which belong to the technical field of organic fertilizers. The fertilizer is prepared from cattle and sheep excrement, corn straws, peanut seedlings, hazelnut meal, humic acid, brown sugar, EM fungicide, rhizoma coptidis, honeysuckle flower, Houttuynia cordata, radix isatidis, urea, trace elements, attapulgite, sepiolite powder, soil conditioner and a composite microorganism agent according to a given weight proportion. The fertilizer has rich nutrients, satisfies the nutrient demand for the growth of the cucumbers at different periods, can effectively improve the physical and chemical properties of the soil, can improve the water and fertility retention capacity of the soil, can prevent various physical and chemical diseases of plants, and can effectively improve and the yield and quality of the cucumbers.

Owner:LINYI ACADEMY OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com