GaN-based light-emitting diode epitaxial wafer production method and produced epitaxial wafer

A technology of light-emitting diodes and epitaxial wafers, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of large stress in multi-quantum well layers, reduce luminous efficiency, and lattice mismatch, so as to reduce the polarization electric field and improve the growth rate. quality, slow down the effect of continuing to extend

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

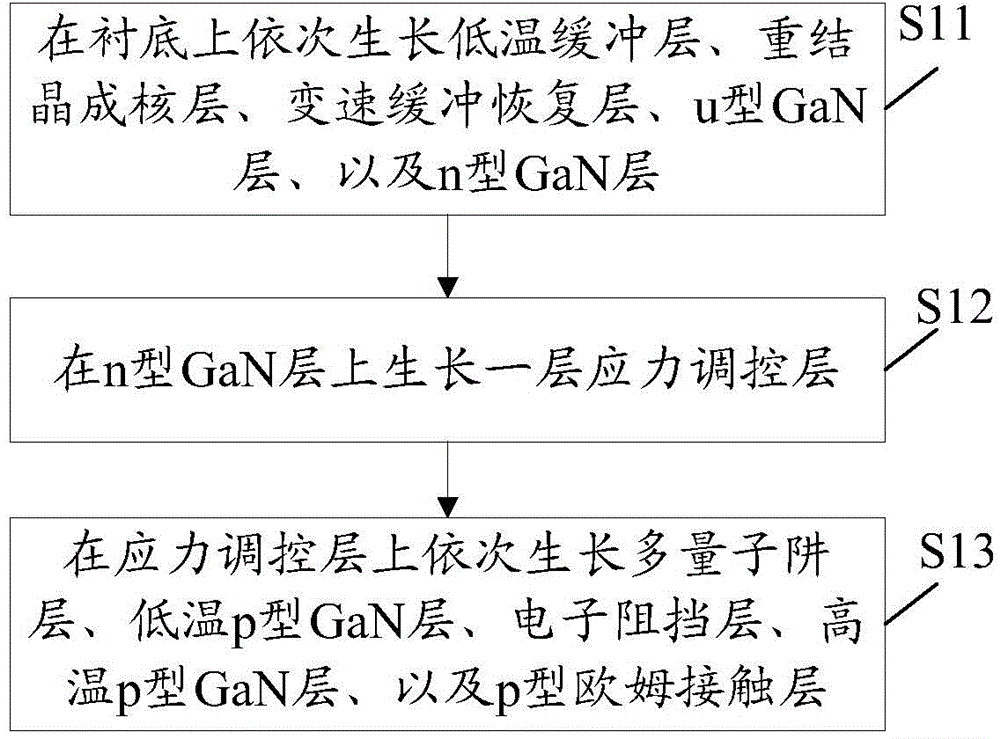

[0031] An embodiment of the present invention provides a method for preparing GaN-based light-emitting diode epitaxial wafers, which is suitable for preparing GaN-based light-emitting diode epitaxial wafers that emit blue-green light. See figure 1 , the method includes:

[0032] Step S11 , growing a low temperature buffer layer, a recrystallization nucleation layer, a variable speed buffer recovery layer, a u-type GaN layer, and an n-type GaN layer sequentially on the substrate.

[0033] In this embodiment, a sapphire substrate is used.

[0034] Step S12, growing a stress control layer on the n-type GaN layer.

[0035] Specifically, the stress regulating layer is a multi-period structure, and each period of growing the multi-period structure includes:

[0036] growing a stress-regulating InGaN sublayer at a first growth temperature;

[0037] After the growth of the stress-regulated InGaN sub-layer is completed, hydrogen gas is introduced into the reaction chamber at a secon...

Embodiment 2

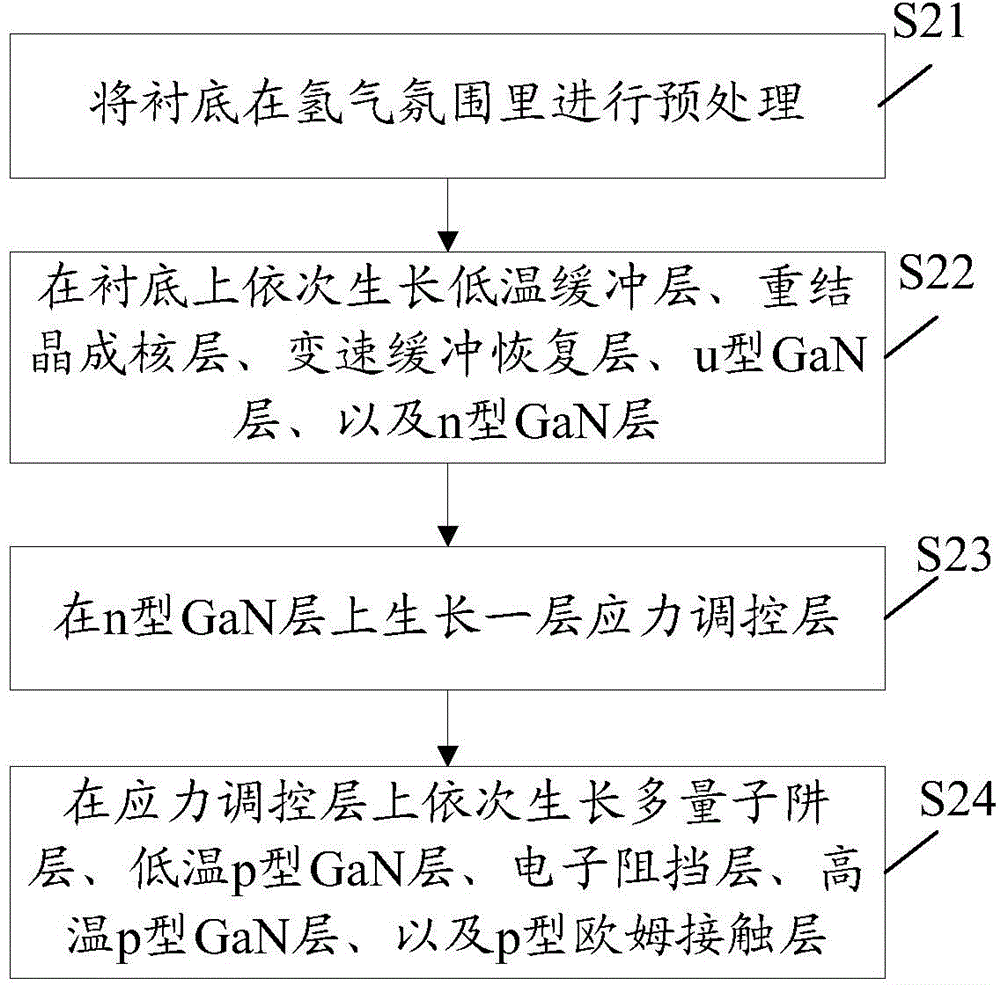

[0046] An embodiment of the present invention provides a method for preparing GaN-based light-emitting diode epitaxial wafers, which is suitable for preparing GaN-based light-emitting diode epitaxial wafers that emit blue-green light. See figure 2 , the method includes:

[0047] In step S21, the substrate is pretreated in a hydrogen atmosphere.

[0048] Specifically, the sapphire substrate is annealed in a hydrogen atmosphere for 1-10 minutes, the surface of the substrate is cleaned, and the temperature of the reaction chamber is raised to 1000-1200° C. to preheat the substrate.

[0049] Step S22 , growing a low temperature buffer layer, a recrystallization nucleation layer, a variable speed buffer recovery layer, a u-type GaN layer, and an n-type GaN layer on the substrate in sequence.

[0050] In this embodiment, a sapphire substrate is used.

[0051] Step S23 , growing a stress regulation layer on the n-type GaN layer.

[0052] Specifically, the stress regulating layer ...

Embodiment 3

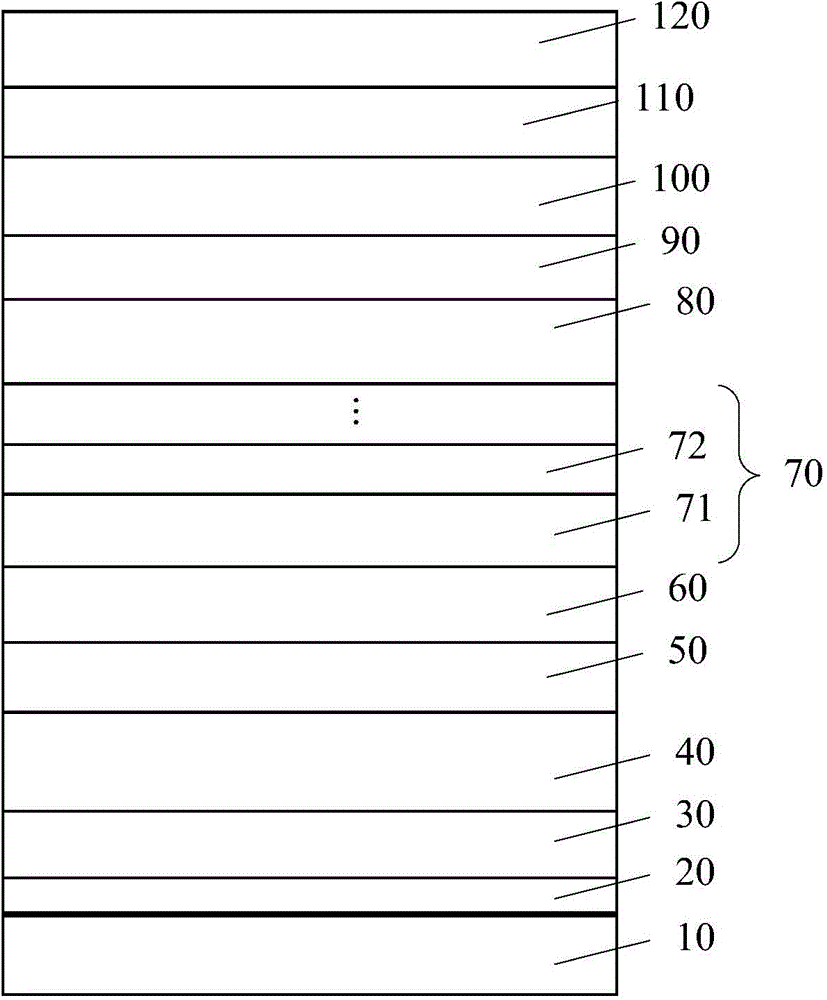

[0086] An embodiment of the present invention provides a GaN-based light-emitting diode epitaxial wafer, which can be prepared by the method described in Embodiment 1 or Embodiment 2, see image 3 , the epitaxial wafer includes: a substrate 10 and a low-temperature buffer layer 20 sequentially covered on the substrate 10, a recrystallization nucleation layer 30, a variable speed buffer recovery layer 40, a u-type GaN layer 50, an n-type GaN layer 60, a multi-quantum Well layer 80 , low temperature p-type GaN layer 90 , electron blocking layer 100 , high temperature p-type GaN layer 110 , and p-type ohmic contact layer 120 .

[0087] The epitaxial wafer also includes: a stress regulation layer 70 disposed between the n-type GaN layer 60 and the multi-quantum well layer 80, the stress regulation layer 70 is a multi-period structure, and each period of the multi-period structure includes: The stress-regulating InGaN sublayer 71 grown at the growth temperature and subjected to etc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com