Patents

Literature

201results about How to "Reduce lattice defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modified Y-type molecular sieve and preparation method thereof

ActiveCN103073024AReduce yieldIncrease profitCatalytic crackingMolecular sieve catalystsMolecular sieveLattice defects

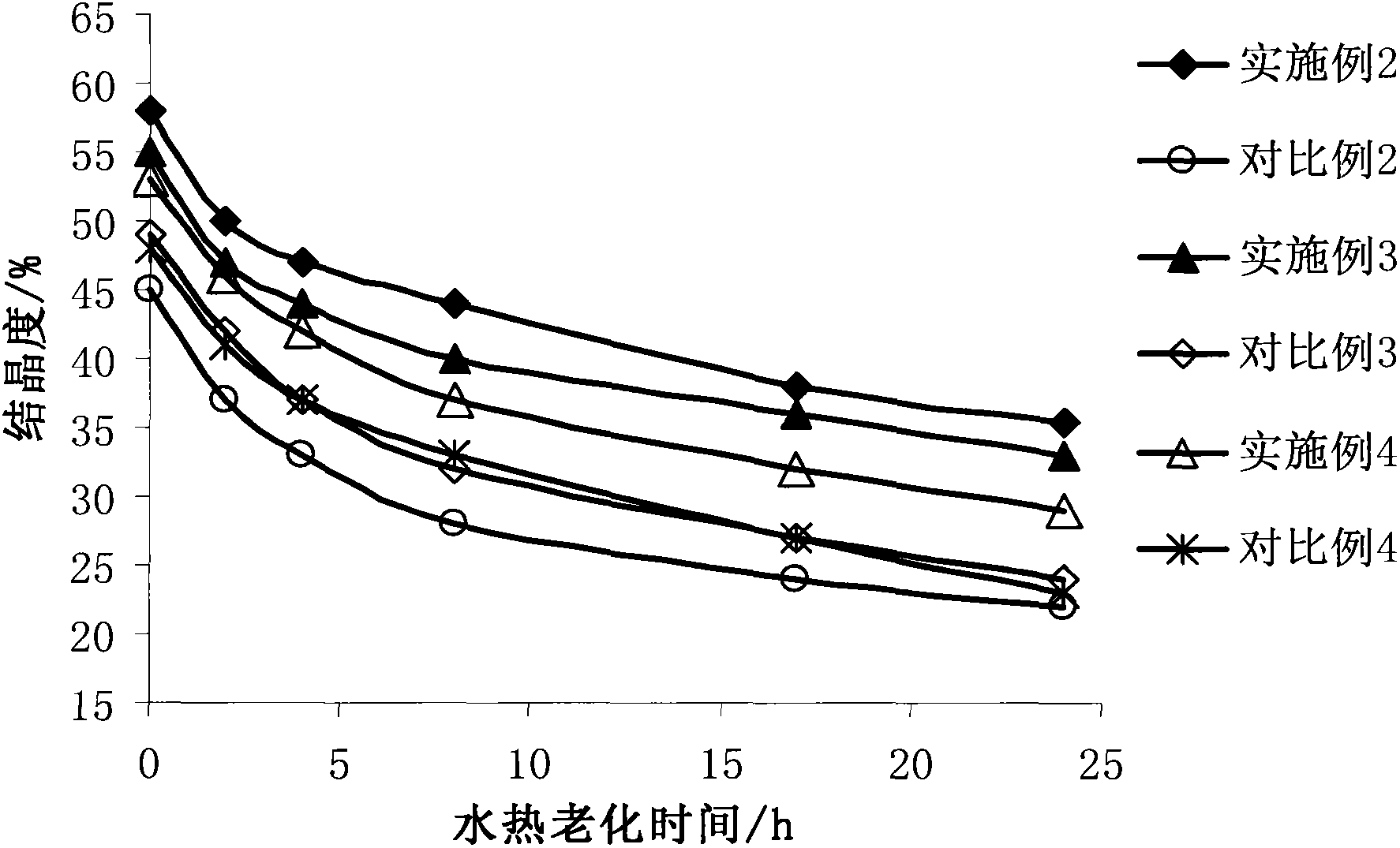

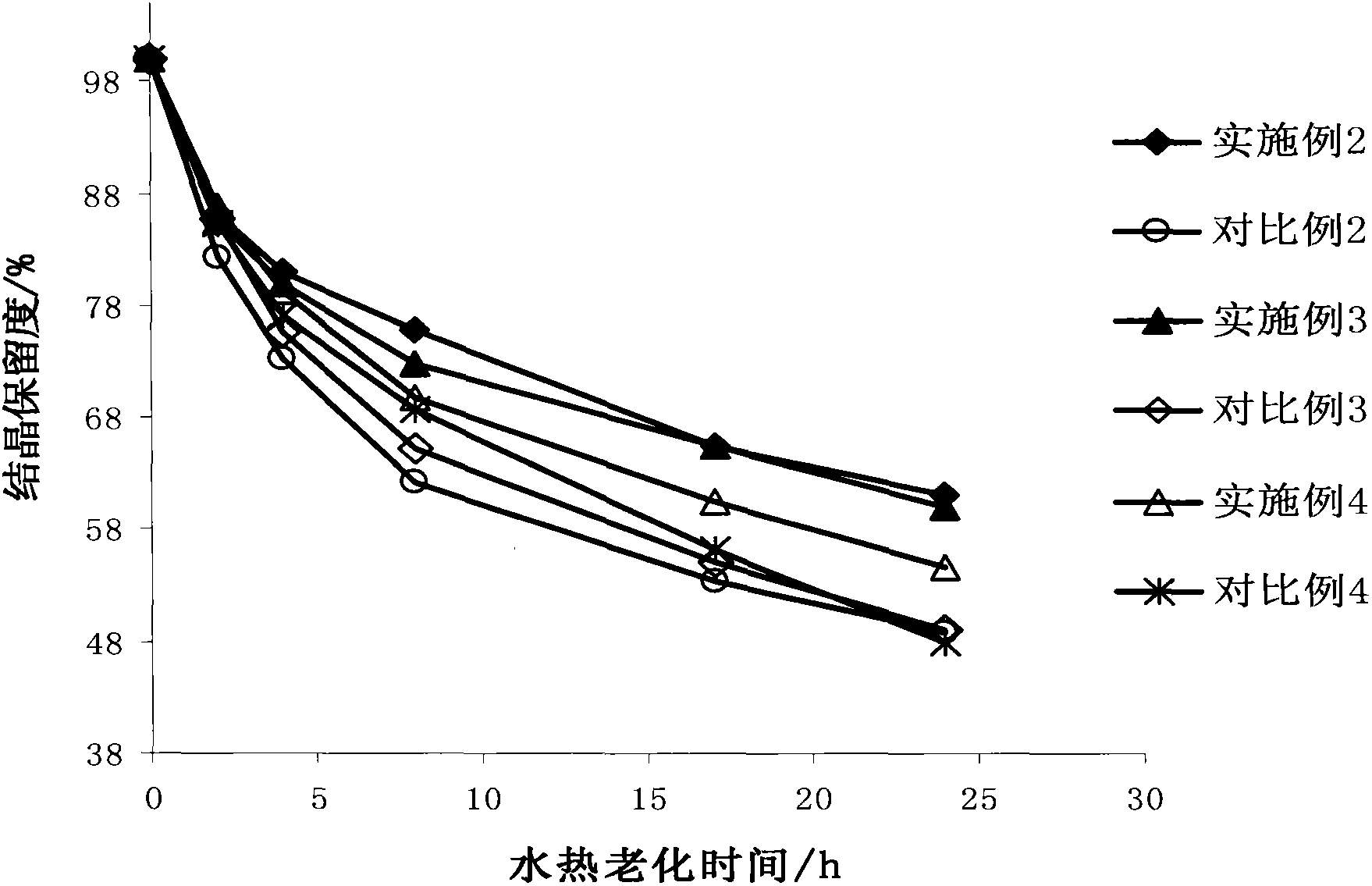

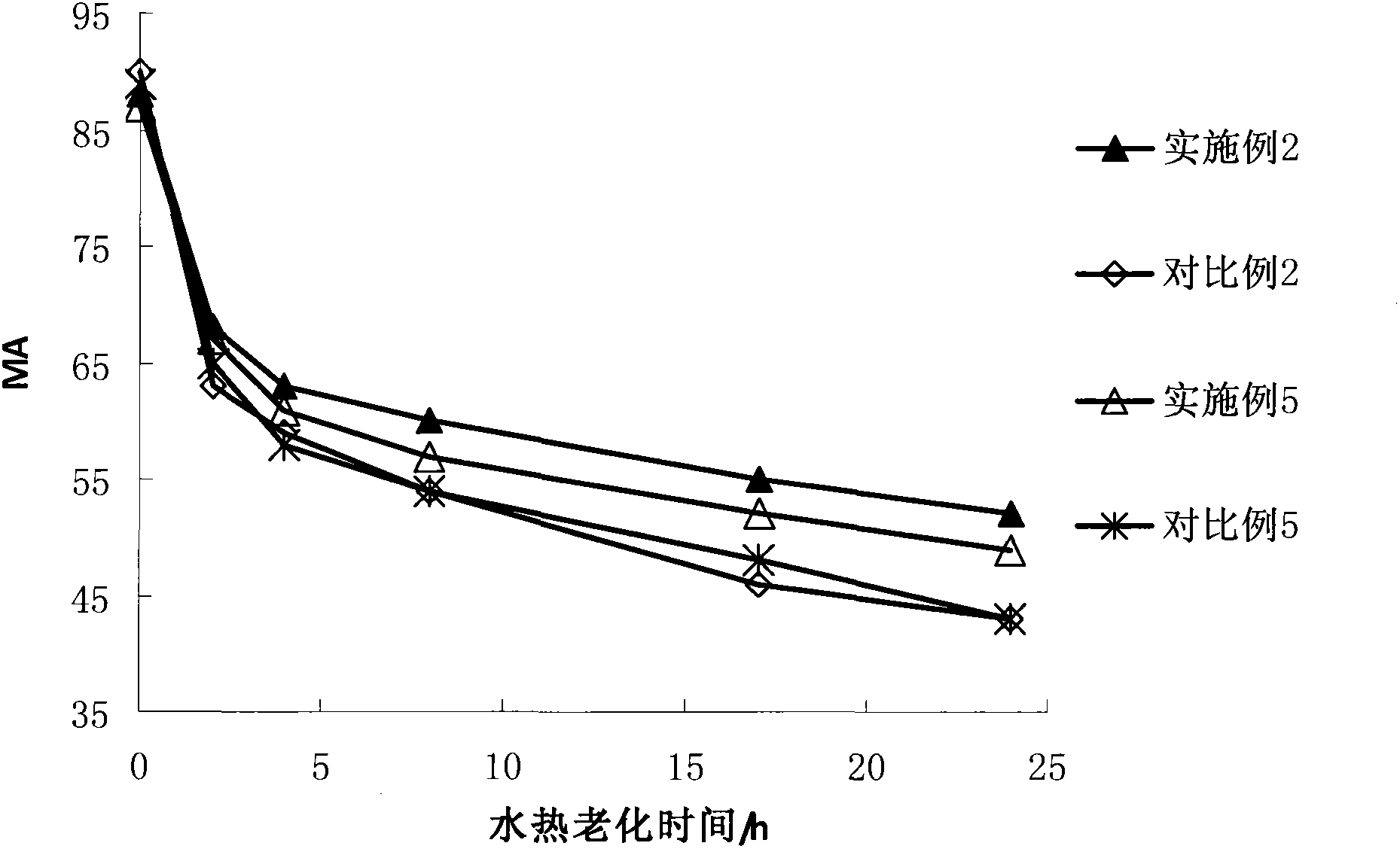

The invention discloses a modified Y-type molecular sieve which is characterized in that a cell constant is 2.420-2.440nm. According to weight percentages, the molecular sieve comprises 0.05-6% of P, 0.03-10% of RE2O3, and less than 22% of alumina. A specific hydroxyl nest concentration is smaller than 0.35mmol / g. In a formula, M200 DEG C, M500 DEG C and M800 DEG C t respectively represent weight loss percentages of the sample measured at 200 DEG C, 500 DEG C and 800 DEG C. C is sample crystallinity degree. The molecular sieve provided by the invention has low lattice defect, and can be used in a catalytic cracking catalyst as an active component. With the molecular sieve, long-period stable activity can be maintained, coke yield can be effectively controlled, and heavy oil utilization rate can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

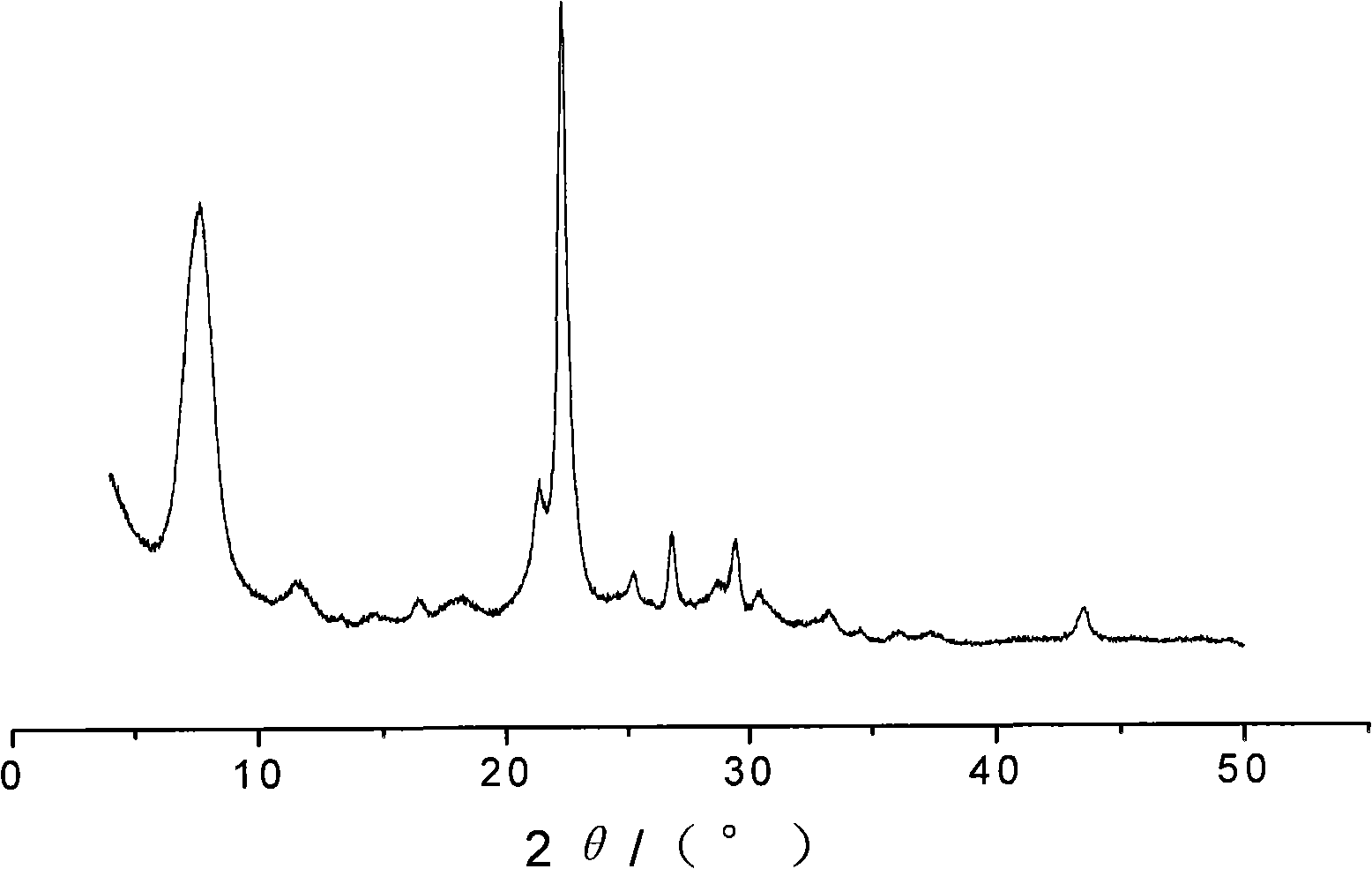

Synthetic method of nano aluminum-rich beta-zeolite

ActiveCN101353168AReduce moisture contentReduce lattice defectsCrystalline aluminosilicate zeolitesLattice defectsCrystallinity

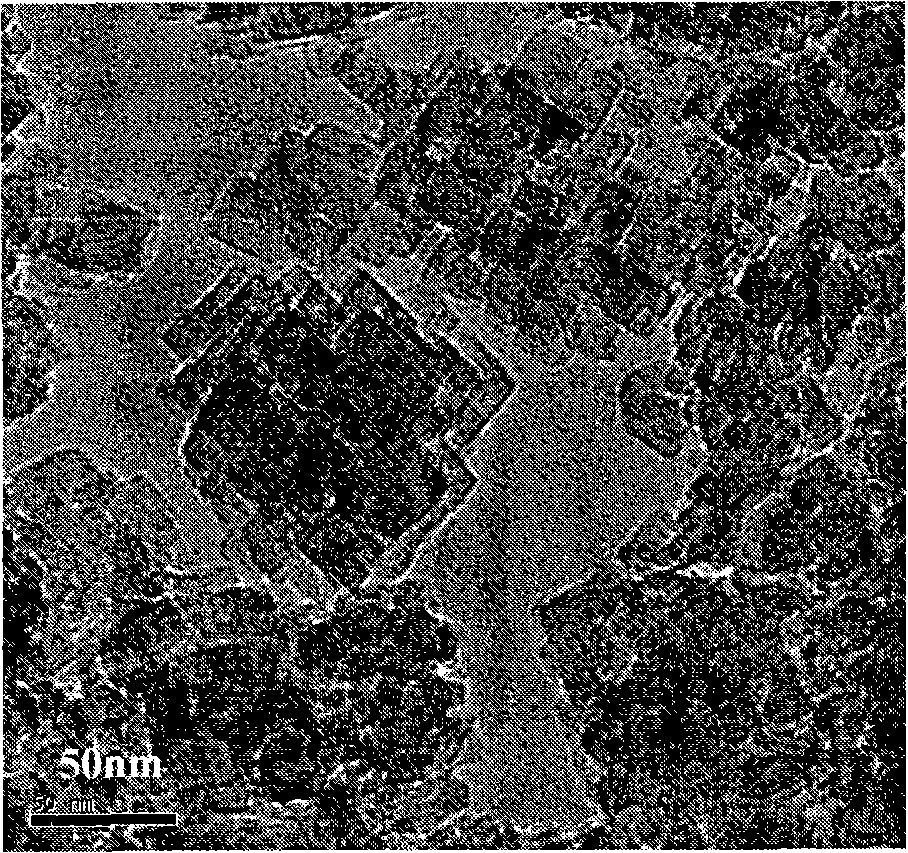

A method for synthesizing nano aluminum-rich beta-zeolite comprises the steps as follows: (1) an alumino silica gel which is formed by mixing an aluminum source and acid is evenly mixed with aluminum source particles, dried and crushed into alumino silica gel particles, wherein, the mol ratio of the aluminum source to the silicon source is 0.05-0.2; and (2) a template agent is added to the alumino silica gel particles obtained in the step (1) and evenly mixed to produce a reaction mixture which is crystallized at the temperature of 80-190 DEG C for 1-6 days, therefore a product is obtained through recovery. The mol ratios of the feeding ingredients of the reaction mixture are as follows: the mol ratio of the template agent to the silicon source equals 0.1-1.0, and that of water to the silicon source equals 2-12. The template agent is a mixture of a tetraethylammonium compound and a fluoride, or tetraethylammonium fluoride dihydrate. The method provided by the invention is characterized by high yield of a single kettle and low moisture of the synthesis system. The beta-zeolite synthesized by the method provided by the invention has high relative crystallinity, few lattice defects and good thermal stability, and the ratio between the silicon and aluminum of the synthesized beta-zeolite is 5-20, which is up to the nano crystal grain dimension.

Owner:CHINA PETROLEUM & CHEM CORP +1

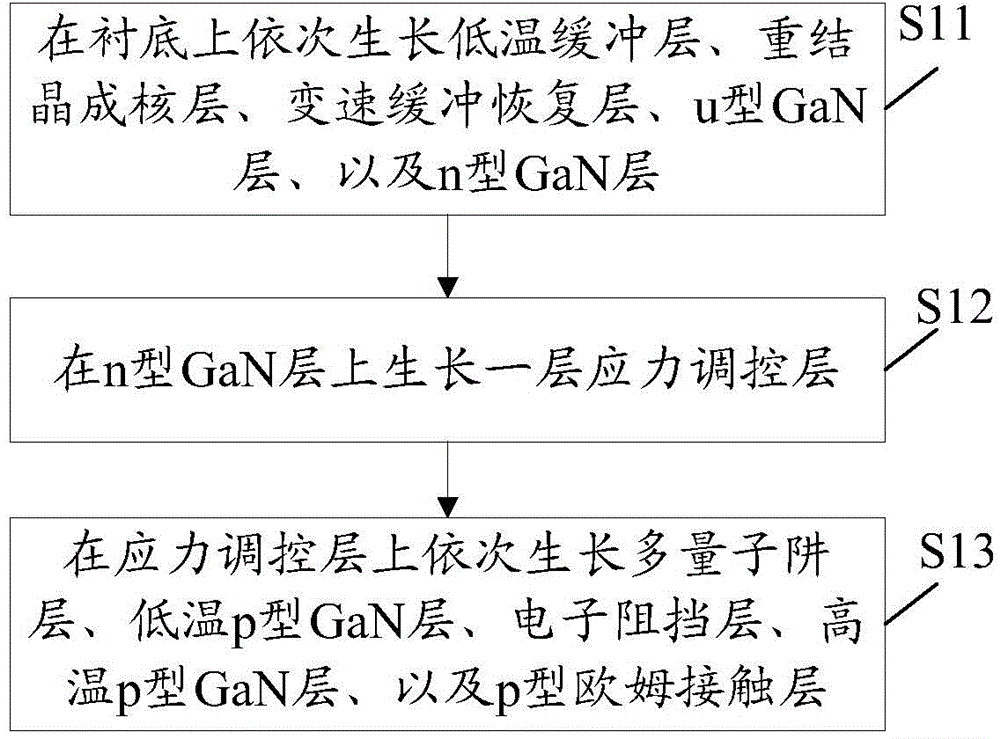

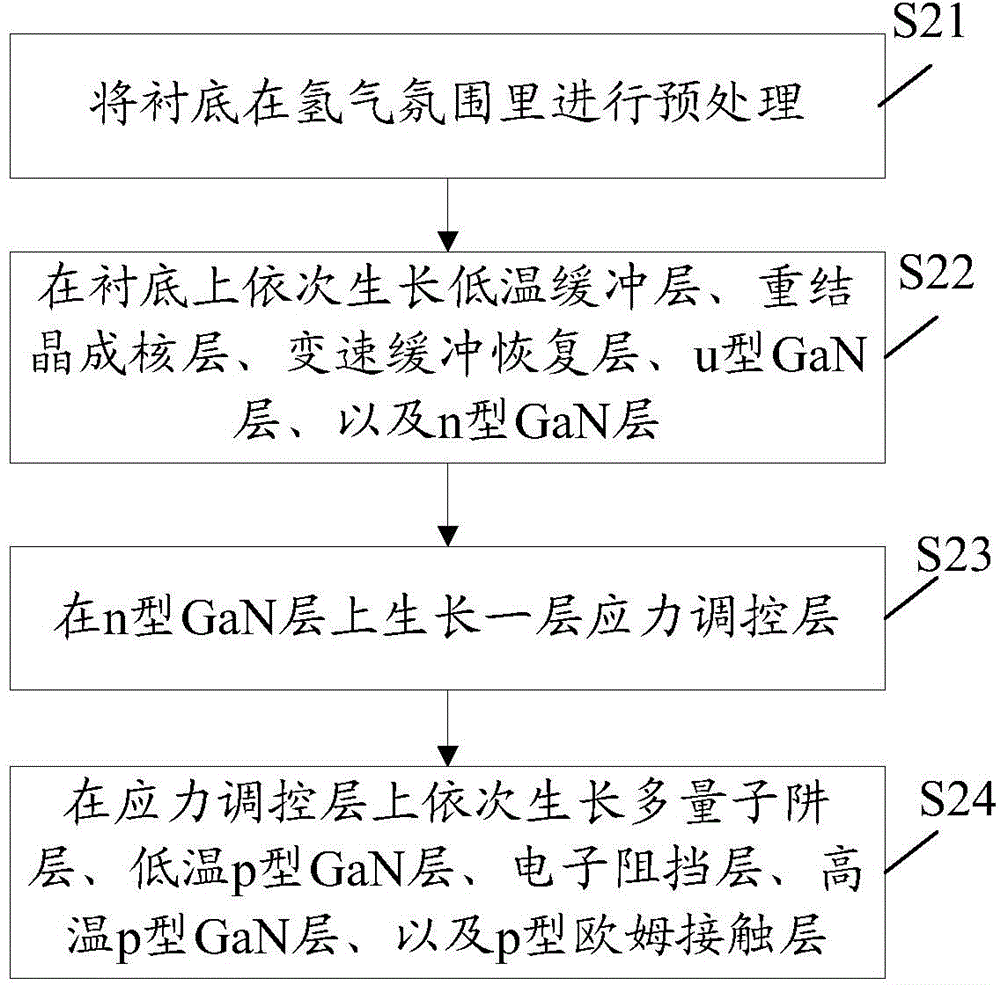

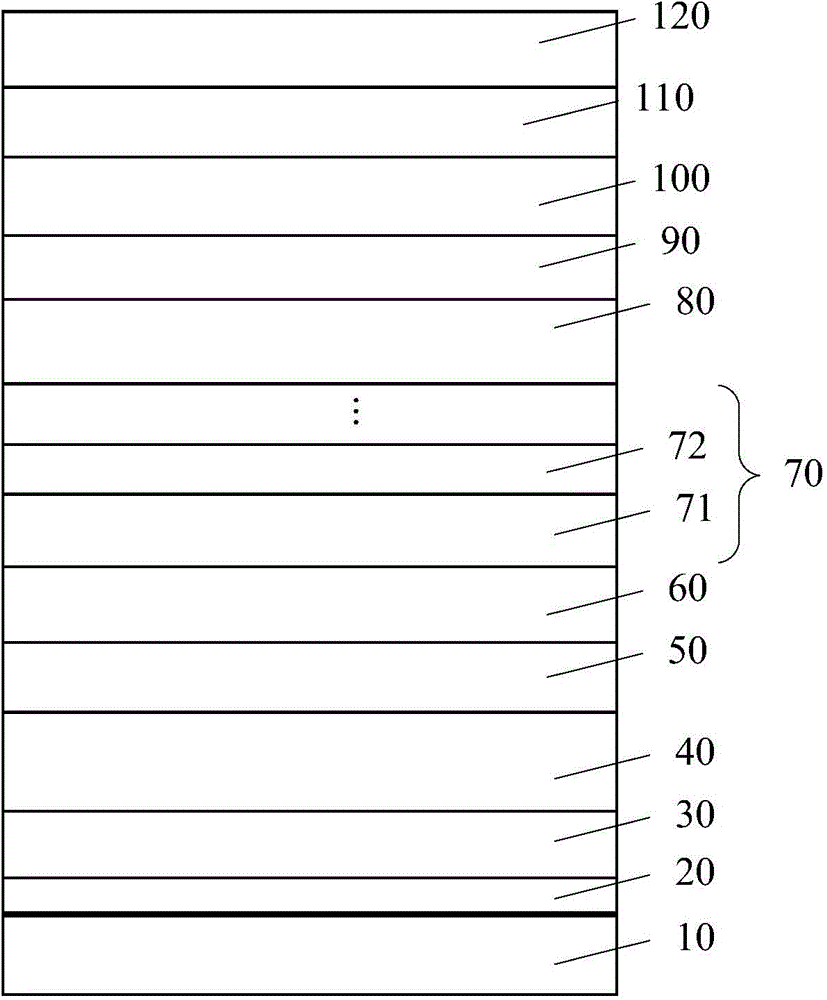

GaN-based light-emitting diode epitaxial wafer production method and produced epitaxial wafer

ActiveCN104810451AImprove growth qualityQuality improvementSemiconductor devicesHydrogenOhmic contact

The invention discloses a GaN-based light-emitting diode epitaxial wafer production method and a produced epitaxial wafer, and belongs to the field of semiconductor light-emitting diodes. The method includes growing a buffer layer, an n-type GaN layer, a stress regulation layer, a multiple quantum well layer, a p-type GaN layer and a p-type ohmic contact layer on a substrate sequentially. The stress regulation layer is of a multi-period structure. A growth method of each period of the multi-period structure includes growing a stress regulation InGaN sub layer at a first growth temperature, supplying hydrogen into a reaction chamber at a second growth temperature after the stress regulation InGaN sub layer finishes growing, and etching the surface of the stress regulation InGaN sub layer, wherein the second growth temperature is different from the first growth temperature. The GaN-based light-emitting diode epitaxial wafer production method and the produced epitaxial wafer have the advantages that through treatment of the stress regulation InGaN sub layer, a smooth contact surface is formed between the stress regulation InGaN sub layer and a stress regulation GaN sub layer, and accordingly, continuous extension of defects is prevented.

Owner:HC SEMITEK SUZHOU

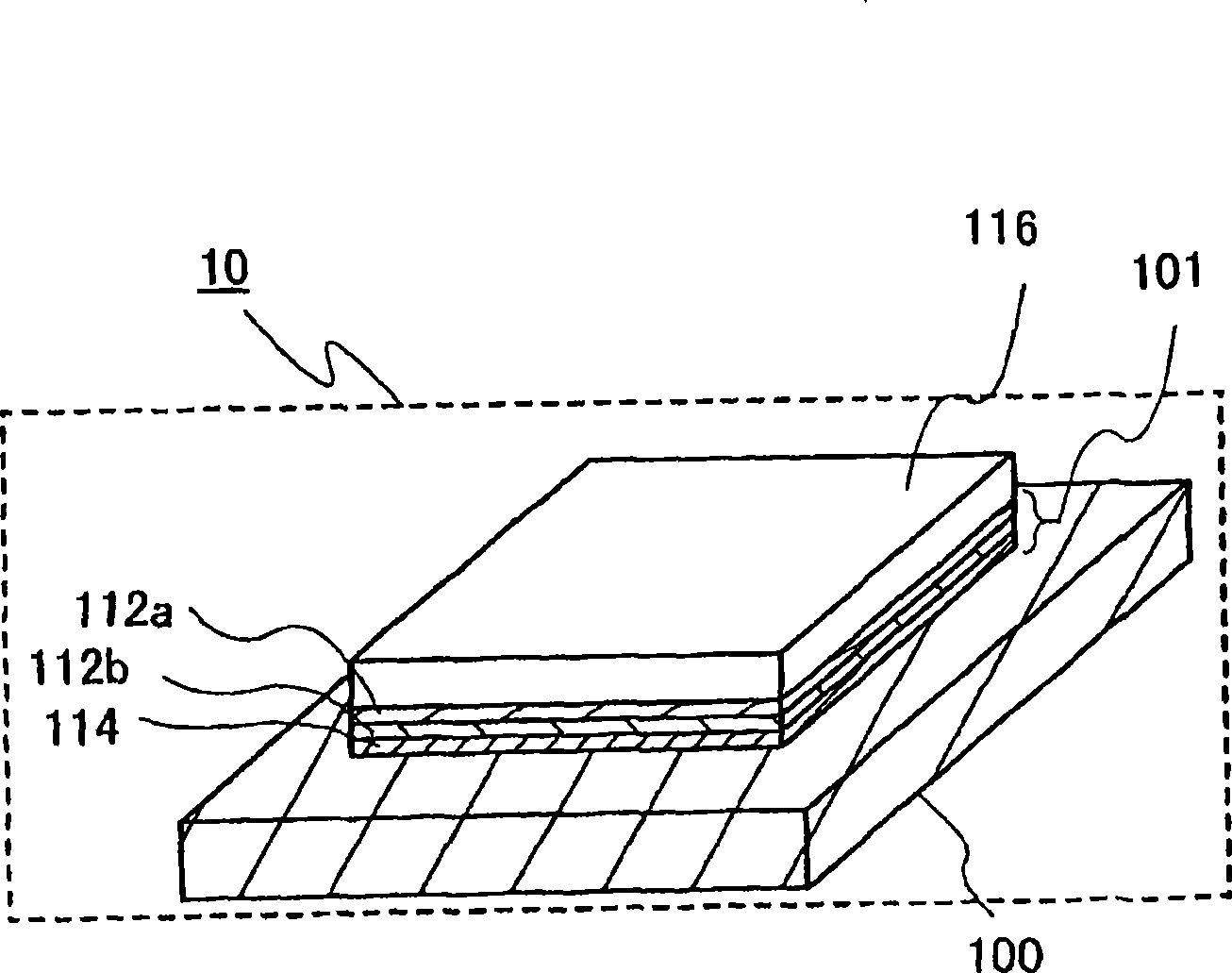

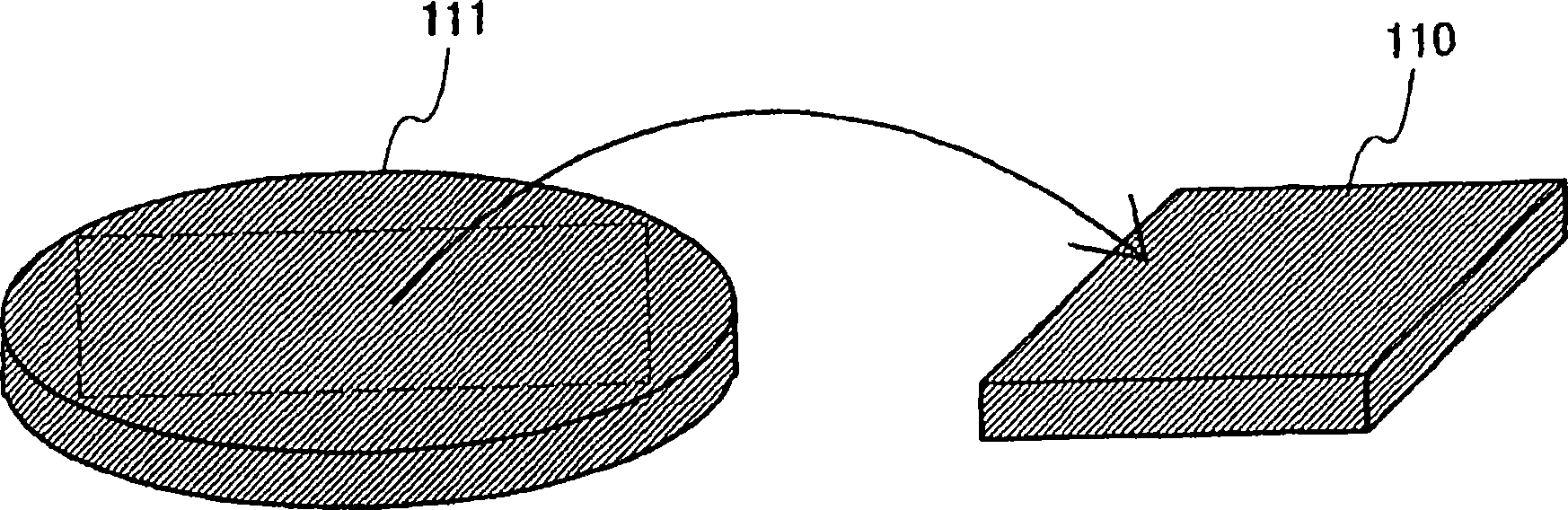

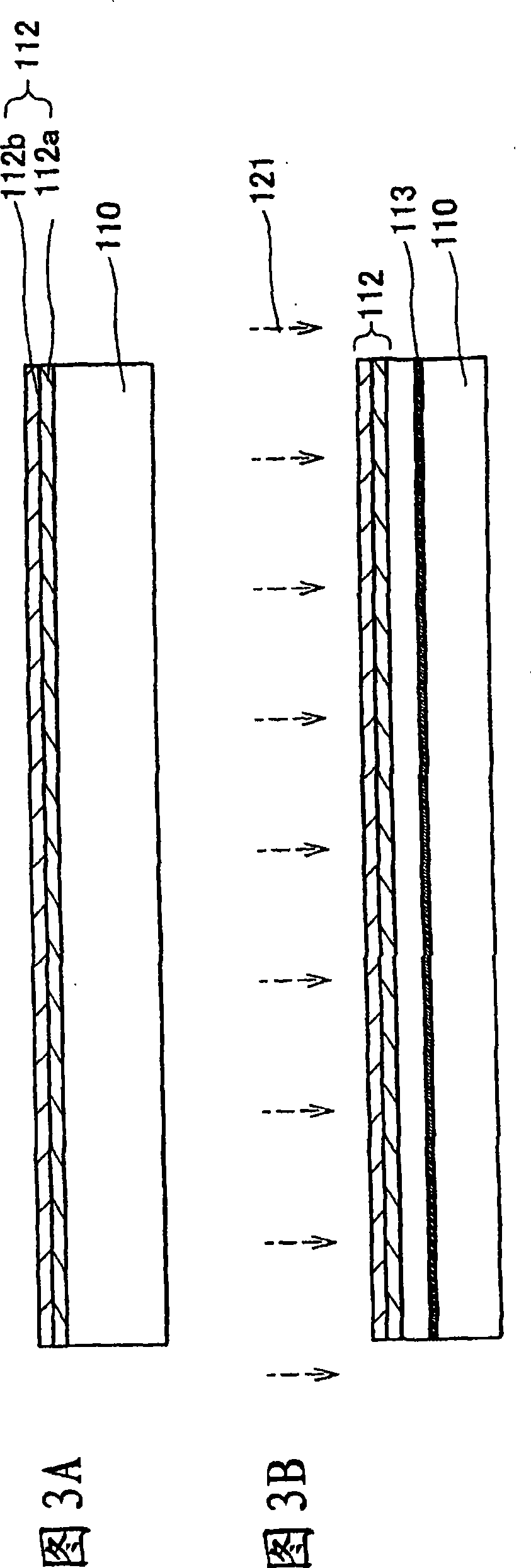

Method for manufacturing semiconductor substrate, semiconductor device and electronic device

InactiveCN101425449AImprove flatnessReduce lattice defectsTransistorSolid-state devicesHydrogenSingle crystal

Owner:SEMICON ENERGY LAB CO LTD

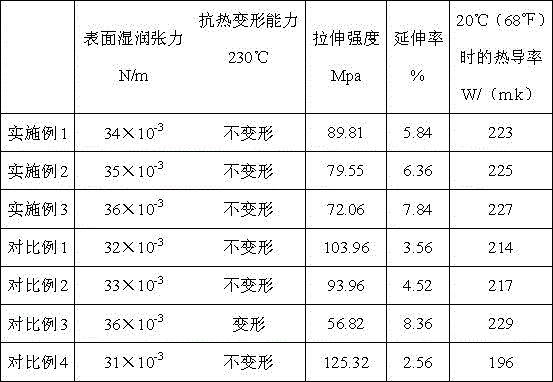

Polypropylene composite capable of resisting thermal oxidizing aging

InactiveCN102408630AImprove interface bonding performancePrevent free diffusionPolypropylene compositesPolymer science

The invention discloses a polypropylene composite capable of resisting thermal oxidizing aging, comprising the following components based on weight percentages: 40-82% of polypropylene resin, 2-10% of compatilizer, 10-40% of filler, 0.2-0.5% of nucleating agent, 2-10% of anti-oxidant synergistic agent, 0.2-1.0% of anti-oxidant and 0.2-1.0% of processing agent, wherein the polypropylene resin is a mixture of homopolymerized polypropylene and block copolymerization polypropylene; the compatilizer is graft polymer of polypropylene and unsaturated carboxylic acid or its anhydride. The advantages are as follows: the nucleating agent is a substance which makes the sphaerocrystal of the polypropylene more refine, the crystallization more homogenized and regularized, and increases the crystallinity; the anti-oxidant synergistic agent is one of or a mixture of fluoropolymer and polysiloxane. The composite has both mechanics performance and performance of resisting thermal oxidizing aging. In addition, the anti-oxidant synergistic agent has a very low surface tension and has a trend of migrating and assigning to the surface of the composite during the forming and use process. The configuration of the anti-oxidant synergistic agent has an effect of separating oxygen molecules, and can lower the ratio of the oxygen entering the base body through the surface of the composite such that the performance of resisting thermal oxidizing aging for the polypropylene is increased.

Owner:KINGFA SCI & TECH CO LTD +1

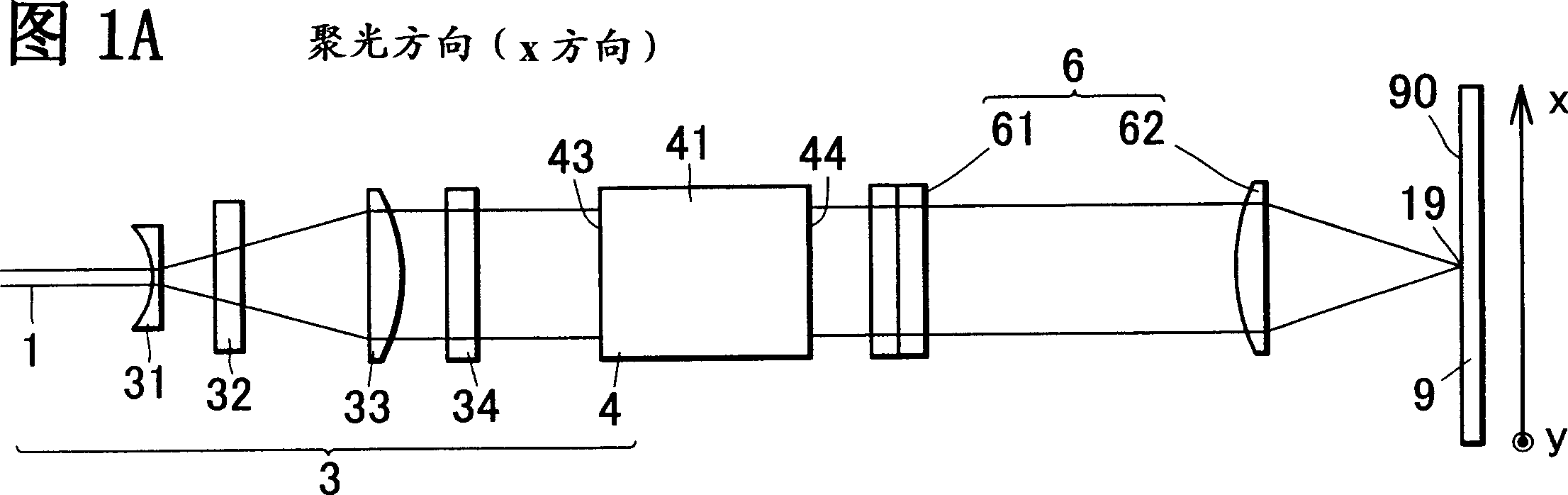

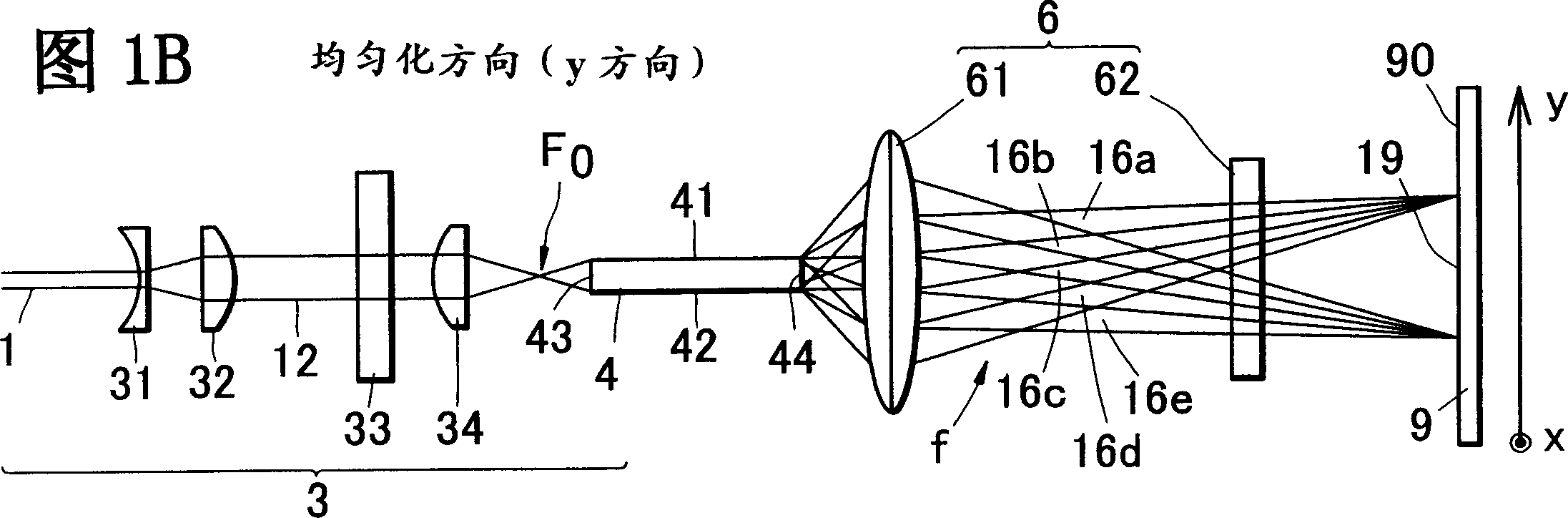

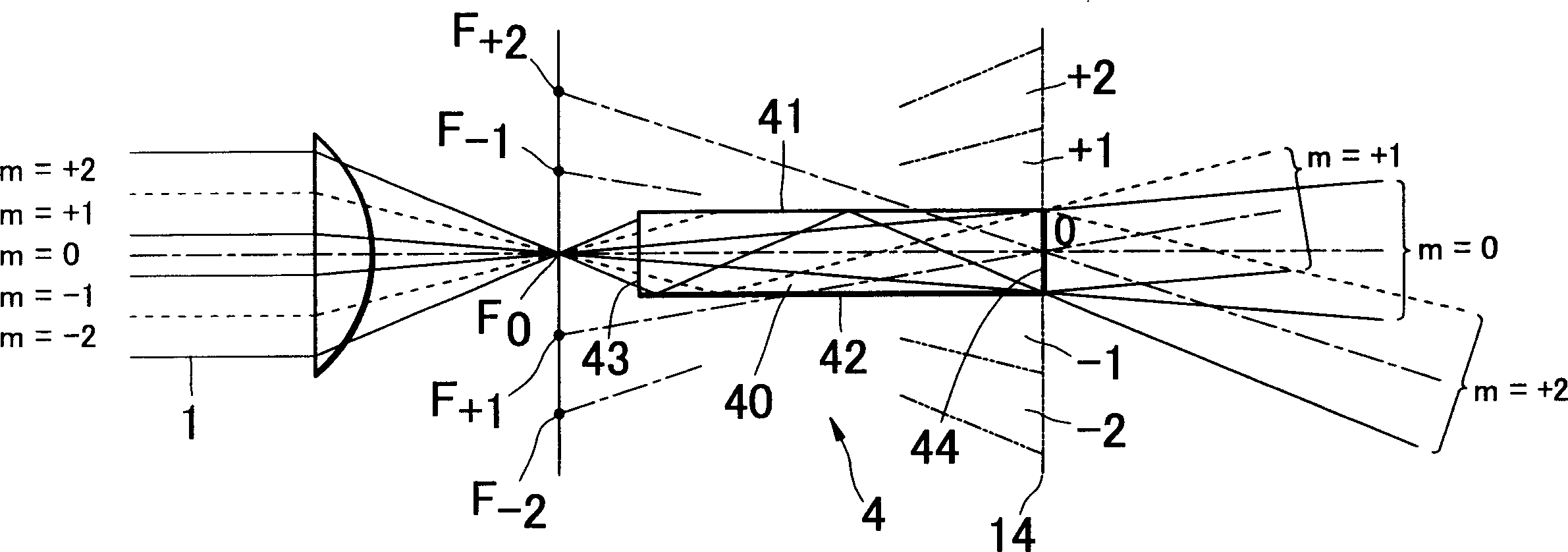

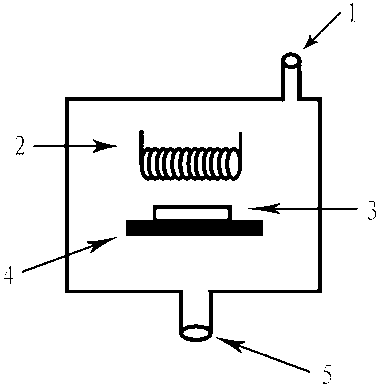

Optical system with laser beam uniform irradiation

InactiveCN1448753AUniform distribution of irradiation intensityUniform intensity distributionLaser detailsSemiconductor/solid-state device manufacturingOptoelectronicsLight source

An optical system with laser beam uniform irradiation, comprises: a wave-guide space-dividing a laser beam from a light source into divided beams; a superposition lens by which the divided beams are superposition-irradiated on an irradiation face; a delay plate by which beam intensity on the irradiation face is uniform. The wave-guide makes width of the divided beams more than 1 / 2 times large of a space interference distance on a laser beam section; the delay plate makes a delay of the adjacent divided beams longer than an interference distance of the time of the laser beam, and reduces interference on the irradiation face. An other optical system comprises: a laser beam dividing component for dividing the laser beam into divided beams; a superposition-irradiation component for superposition-irradiating the divided beams on the irradiation face; a homogenization component for homogenizing beam intensity on the irradiation face. The homogenization component includes an optical delay component which makes a delay of the adjacent divided beams longer than an interference distance of the time of the laser beam, a light rotation component which makes polarization directions of the adjacent divided beams actual orthogonal.

Owner:MITSUBISHI ELECTRIC CORP

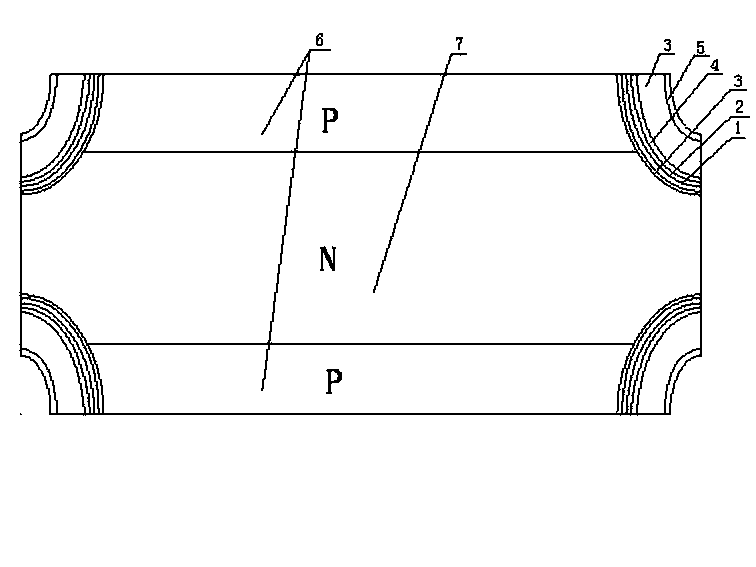

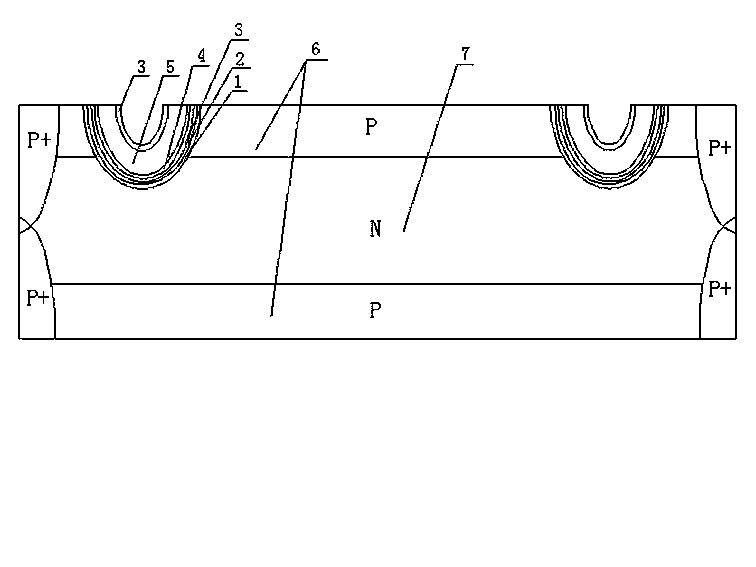

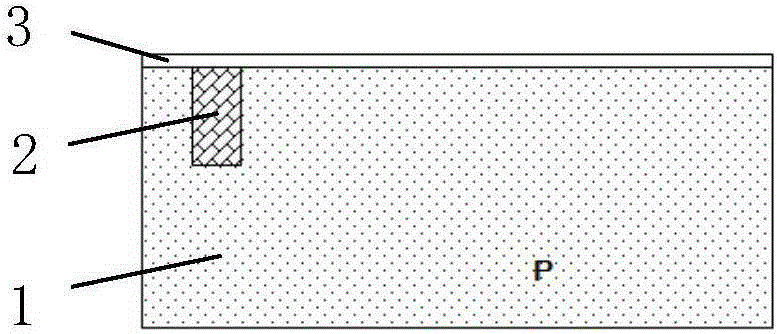

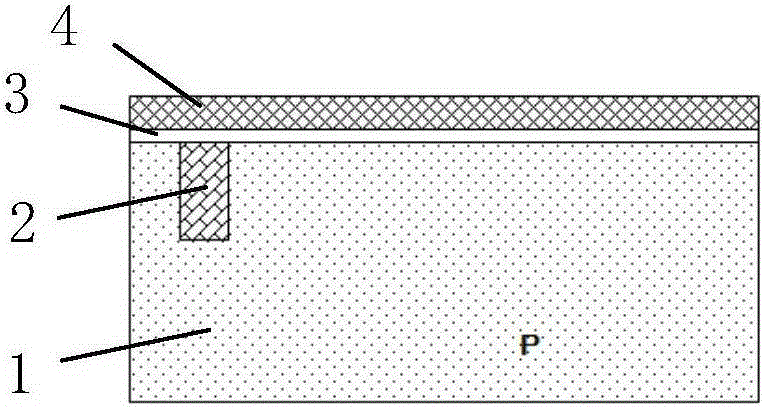

Multilayer composite membrane passivation structure of table top high-power semiconductor device and manufacturing technology of multilayer composite membrane passivation structure of table top high-power semiconductor device

ActiveCN103730430ARepair damageImprove breakdown voltagePolycrystalline material growthSemiconductor/solid-state device detailsManufacturing technologyPolycrystalline silicon

The invention discloses a multilayer composite membrane passivation structure of a table top high-power semiconductor device. The multilayer composite membrane passivation structure comprises P-type boron junction areas and an N-type phosphorus junction area, the upper end and the lower end of the N-type phosphorus junction area are provided with the P-type phosphorus areas respectively, and an alpha-polycrystalline silicon layer, a semi-insulating polycrystalline silicon thin membrane, a low-temperature heat oxidation layer, a high-temperature Si3N4 thin membrane, a negative charge glass passivation layer and a low-temperature heat oxidation layer are sequentially arranged on the surface of a PN junction of a table top of the table top high-power semiconductor device from inside to outside. A manufacturing technology of the multilayer composite membrane passivation structure of the table top high-power semiconductor device includes the following steps: a, depositing the alpha-polycrystalline silicon, b, depositing semi-insulating polycrystalline silicon, c, depositing the low-temperature heat oxidation layer, d, depositing Si3N4, e, conducting passivation on glass, and f, depositing the low-temperature heat oxidation layer in the outmost layer. The multilayer composite membrane passivation structure and the manufacturing technology have the advantages that the alpha-polycrystalline silicon layer is deposited, so that crystal lattice adaptation can be achieved, damage to crystal lattices of a silicon wafer in a groove can be repaired, leaked currents in the surfaces of junctions are reduced, and the stability and the reliability of the device at the high temperature are improved.

Owner:江苏吉莱微电子股份有限公司

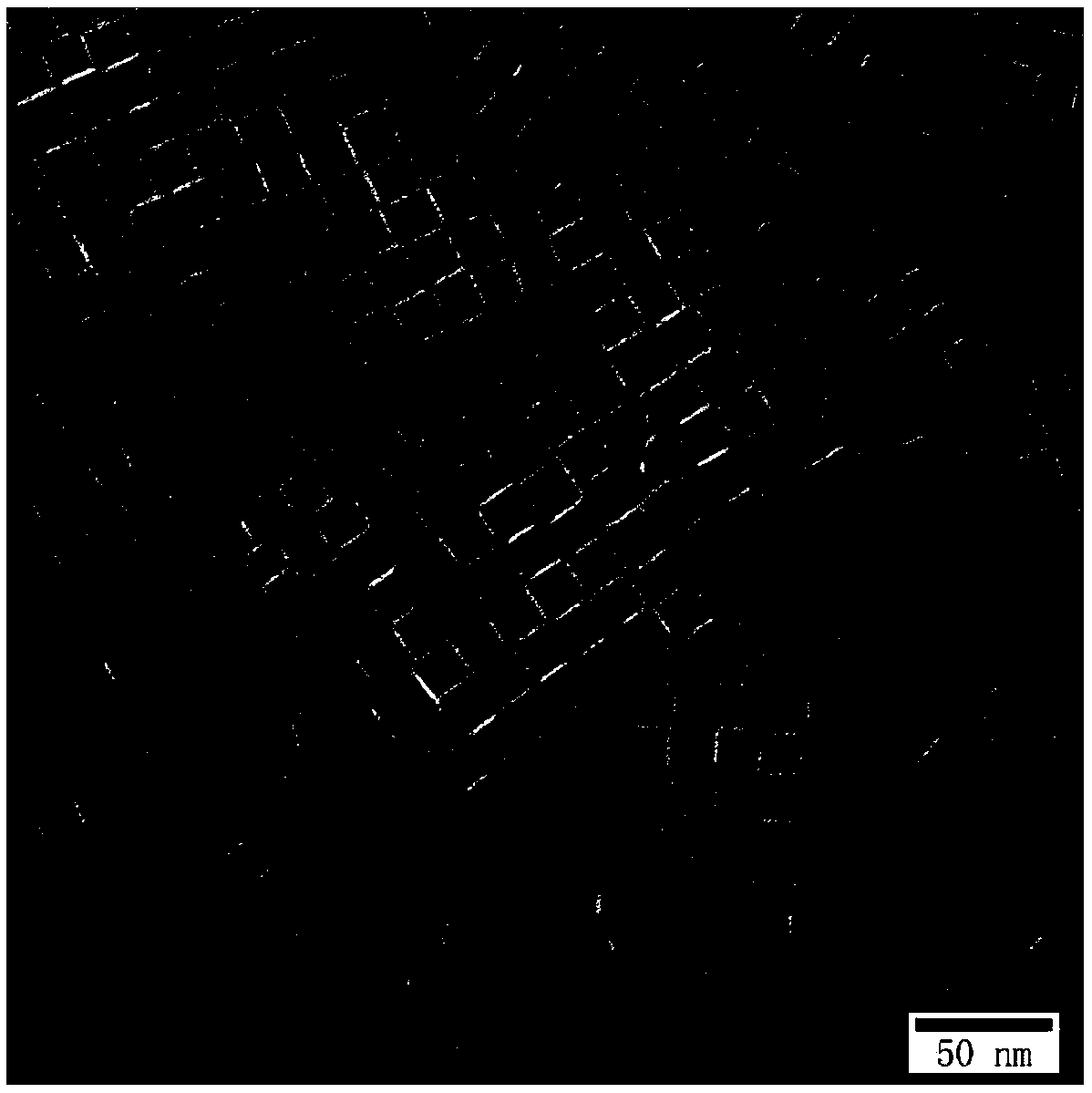

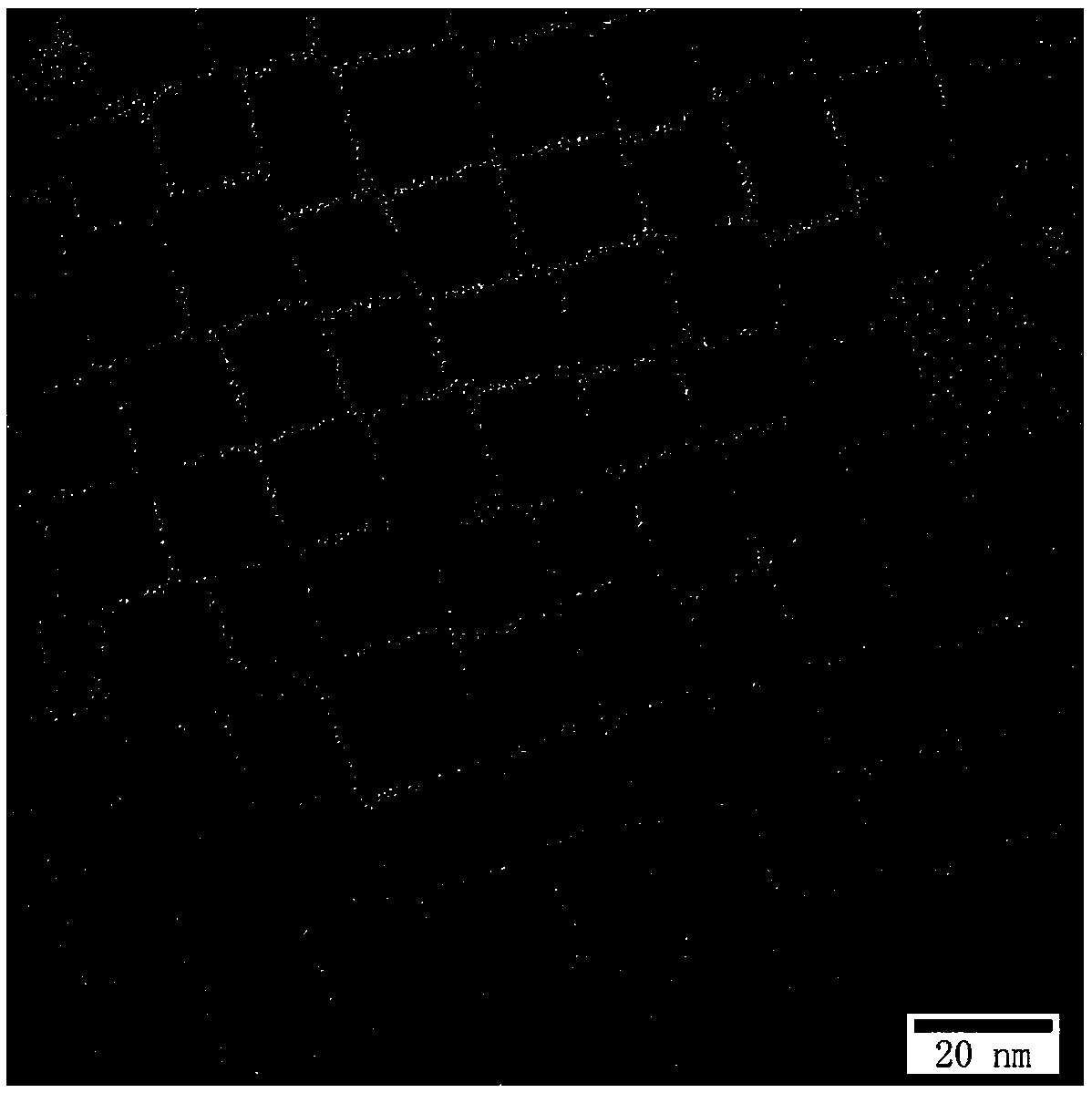

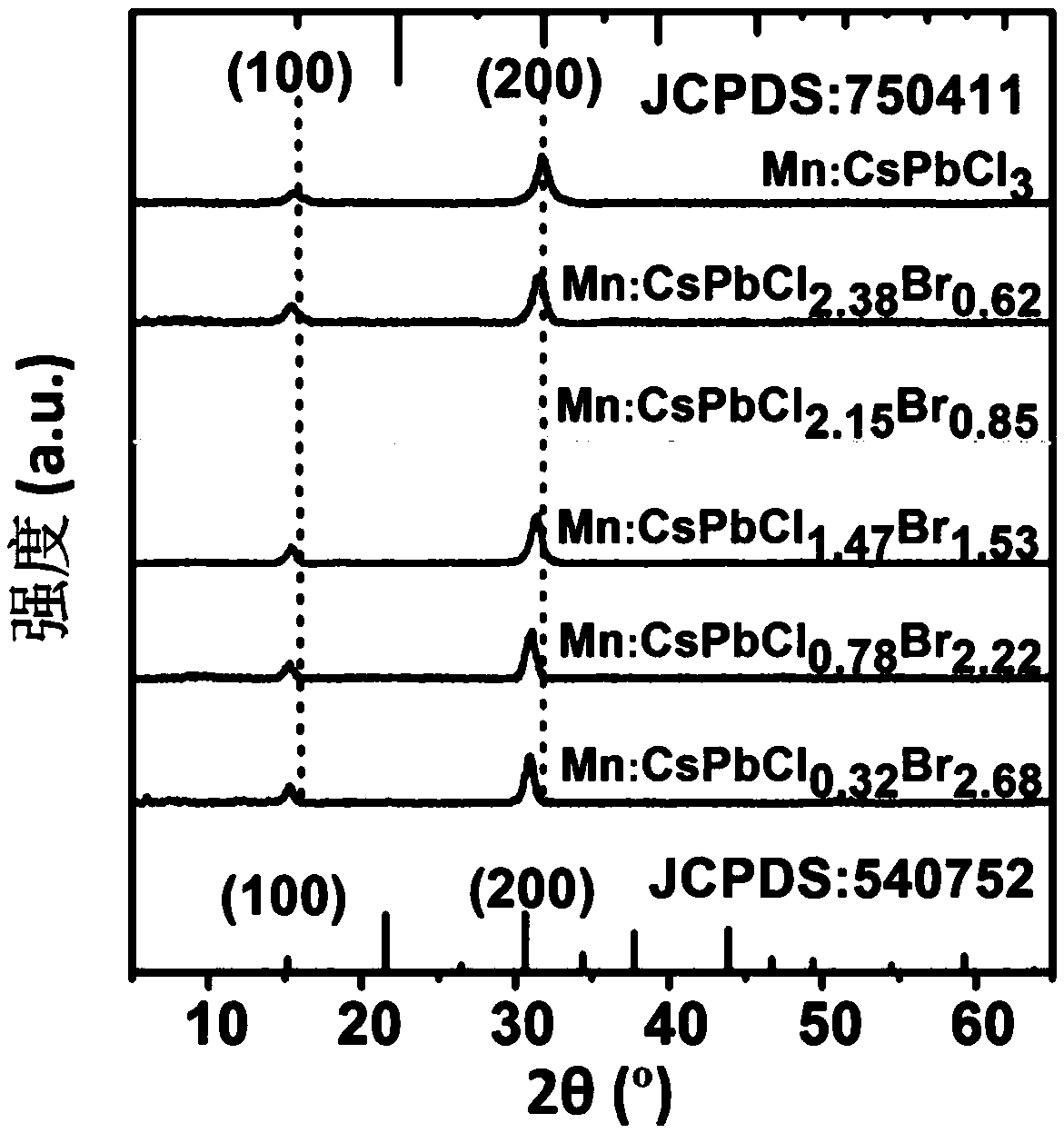

Method for preparing luminescent band gap tunable double-light emitting manganese doping perovskite nano-crystal

InactiveCN108865126ALuminous color continuous tuningHigh photoluminescence efficiencyNanoopticsLuminescent compositionsTrioctylphosphineIon exchange

The invention provides a method for preparing luminescent band gap tunable double-light emitting manganese-doping perovskite nano-crystal, and belongs to the technical field of material preparation. The method comprises: firstly mixing cesium carbonate, oleic acid, and octadecene, obtaining a cesium oleate precursor solution; mixing lead bromide, oleylamine, oleic acid and octadecene, obtaining alead bromide precursor solution; mixing lead chloride, manganese chloride, and octadecene, obtaining a first mixed solution; adding oleylamine, oleic acid, and tri-n-octylphosphine to the first mixedsolution, obtaining a second mixed solution; adding the cesium oleate precursor solution to the second mixed solution, to obtain Mn:CsPbCl3 nano-crystal solution; injecting the lead bromide precursorsolution to the Mn:CsPbCl3 nano-crystal solution, and stirring, preparing Mn:CsPbCl3-xBrx nano-crystals, wherein X is greater than 0 but less than 3. By adopting the method provided by the invention,the luminescent band gap of the manganese-doping perovskite nanocrystals and continuous tuning of the corresponding illuminating color are realized through anion exchange.

Owner:JILIN NORMAL UNIV

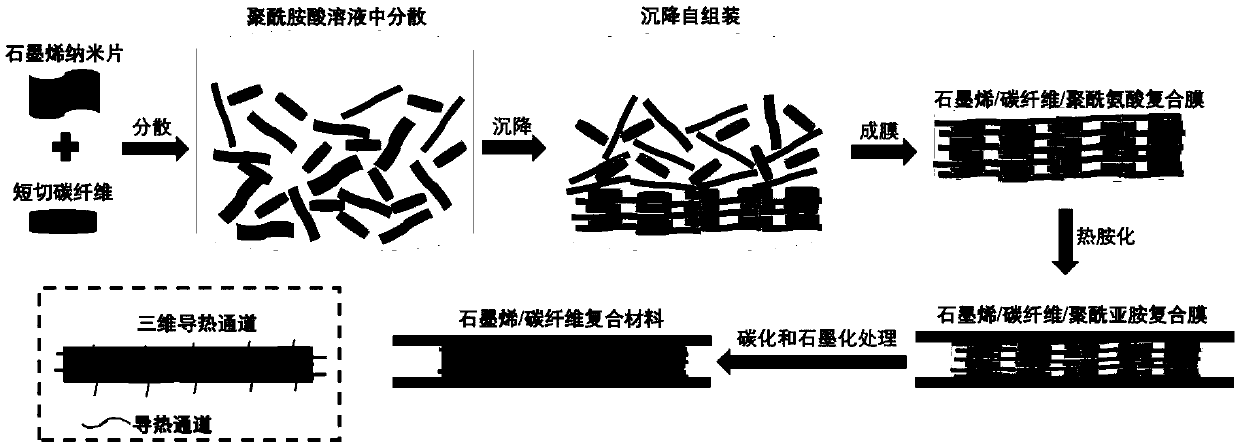

Preparation method of high-heat-conductive graphene/chopped carbon fiber composite material

The invention discloses a preparation method of a high-heat-conductive graphene / chopped carbon fiber composite material. By means of high heat-conductivity of graphene in in-plane direction and high heat-conductivity of carbon fibers in axial direction, the graphene layer and the chopped carbon fibers are subjected to deposition molding in a liquid phase, and by means of adhesion effect of polyimide, the carbon fibers and graphene are connected, and finally, through carbonization and graphitization, the polyimide is converted into graphene, thus manufacturing the whole-carbon high-heat-conductive composite material. A conventional graphene material has ultrahigh heat conductivity in horizontal plane due to the two-dimensional structure of graphene but is poor in heat conductivity since thegraphene is lack in heat conductive path in thickness direction; therefore, by means of the axial high heat-conductivity, the high heat-conductive paths are formed between the graphene layers, so that the heat-conductivity of the material in thickness direction is vertically improved, and the defect of poor heat conductivity in the thickness direction is overcome, thereby preparing the high-heat-conductive material.

Owner:TIANJIN UNIV

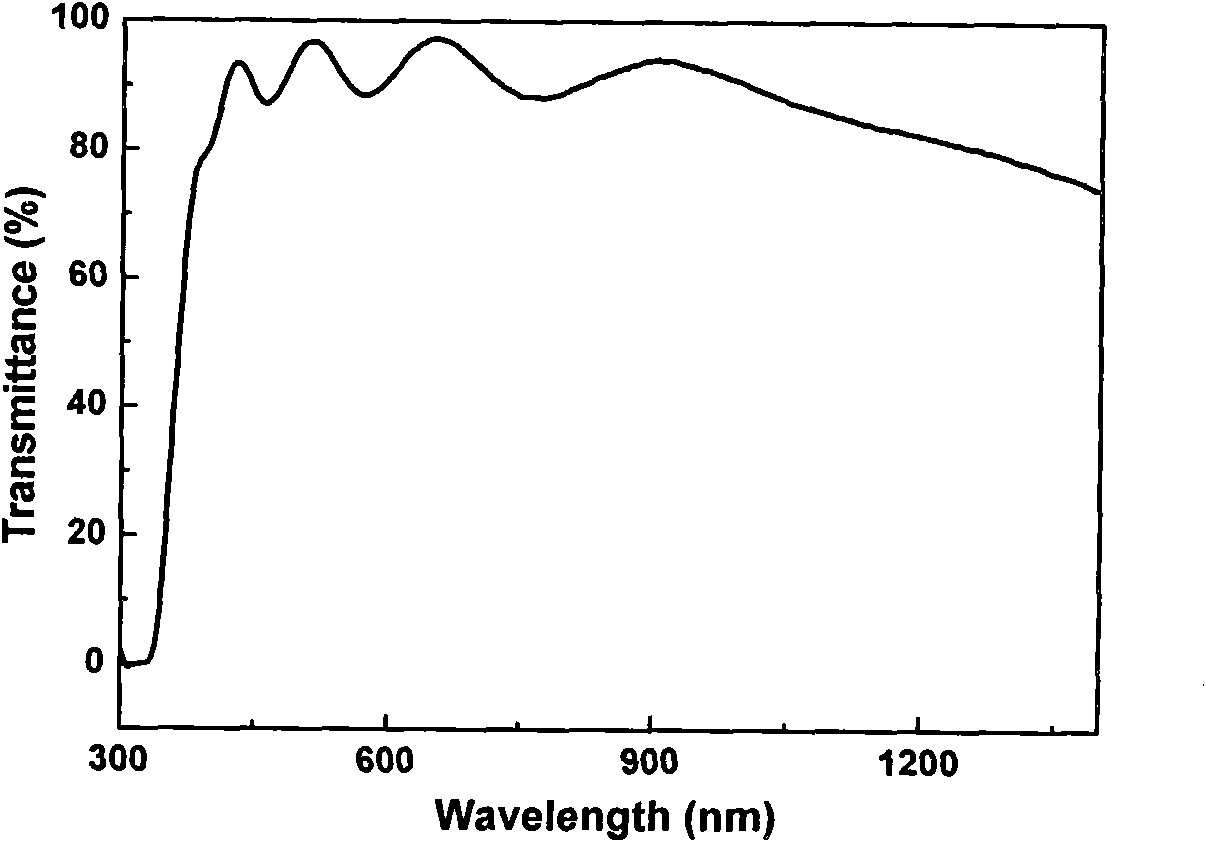

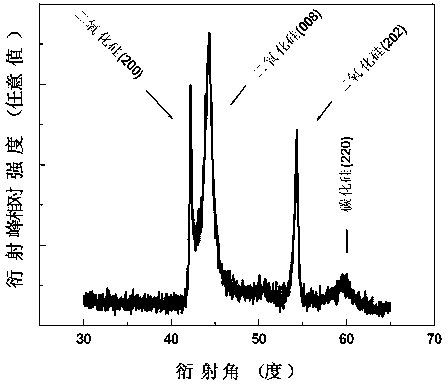

Cation-anion co-doping n-type zinc-oxide-base transparent conducting film and preparation method thereof

ActiveCN101660121APromote crystallizationHigh crystallinityVacuum evaporation coatingSputtering coatingTransparent conducting filmSolar cell

The invention provides a cation-anion co-doping n-type zinc-oxide-base transparent conducting film. The doped cation is a high-valency cation M<n+>, and n is 3, 4, 5 or 6; and the doped anion is a low-valency anion X<m->, and m is equal to 1. The preparation method adopts the High-vacuum Magnetron Sputtering technique and promotes the n-type transparent conductivity of the zinc-oxide film by utilizing high-valency cations and low-valency anions to prepare the high-performance cation-anion co-doping zinc-oxide polycrystal film. A compound containing low-valency anions can be used as a fluxing agent to promote the crystallization of the zinc-oxide-base polycrystal film and enhance the visible light transparency of the film and the electron conductivity. The high-performance zinc-oxide-base transparent conducting film has the advantages of simple preparation process, superior visible light transparency and conductivity, and low cost, and has wide application prospects in the fields of solar cells and photoconducting devices.

Owner:山东中科泰阳光电科技有限公司

Method for preparing anode material iron phosphate lithium of lithium ion battery

ActiveCN101118963AAvoid complicatedHigh crystallinityElectrode manufacturing processesChemical productsCrystallinity

The present invention relates to a method for producing LiFePO4 of positive pole of lithium ion battery. The invention is prominently characterized in that the method comprises three steps as follows: mixing the iron material, the lithium material and the phosphorus material uniformly to compound highly crystallized LiFePO4 in a high temperature first; adding a little diluted acid in the LiFePO4, after mixing and drying the processed LiFePO4 and conductive agent or pre-conductive agent, conducting ball mill for the mixture using a heavy ball; processing the mixture at a lower temperature and then the positive material LiFePO4 with excellent electrochemical performance can be gained. The gained LiFePO4 has favorable crystallinity and the electronic and the lithium ion conducting net is unique with excellent performance. The present invention uses cheap chemical product as raw material and the compounding art is simple thus is easy for producing on scale. The electrochemical character is favorable.

Owner:龚思源

Film-coating product

InactiveCN102555354ALow emissivityReduce surface resistanceGlass/slag layered productsInfraredNiobium

The invention discloses a film-coating product, in particular relates to film-coating glass capable of being performed with high-temperature thermal treatment. Materials for reflecting infrared film layers of the film-coating product is changed from traditional pure silver materials into alloy materials of silver and niobium, an Agl-aNba film layer deposited by the alloy materials of silver and niobium replaces a pure silver film layer to serve as a functional layer of the film-coating product, stability of films in high-temperature thermal treatment is improved, and simultaneously chemical stability of a silver layer is improved and mechanical performance of the silver layer is improved. The film-coating product has high visible light transmission rate, good mechanical resistance and chemical stability. The film-coating product is mainly used in automobile windshields.

Owner:FUYAO GLASS IND GROUP CO LTD +1

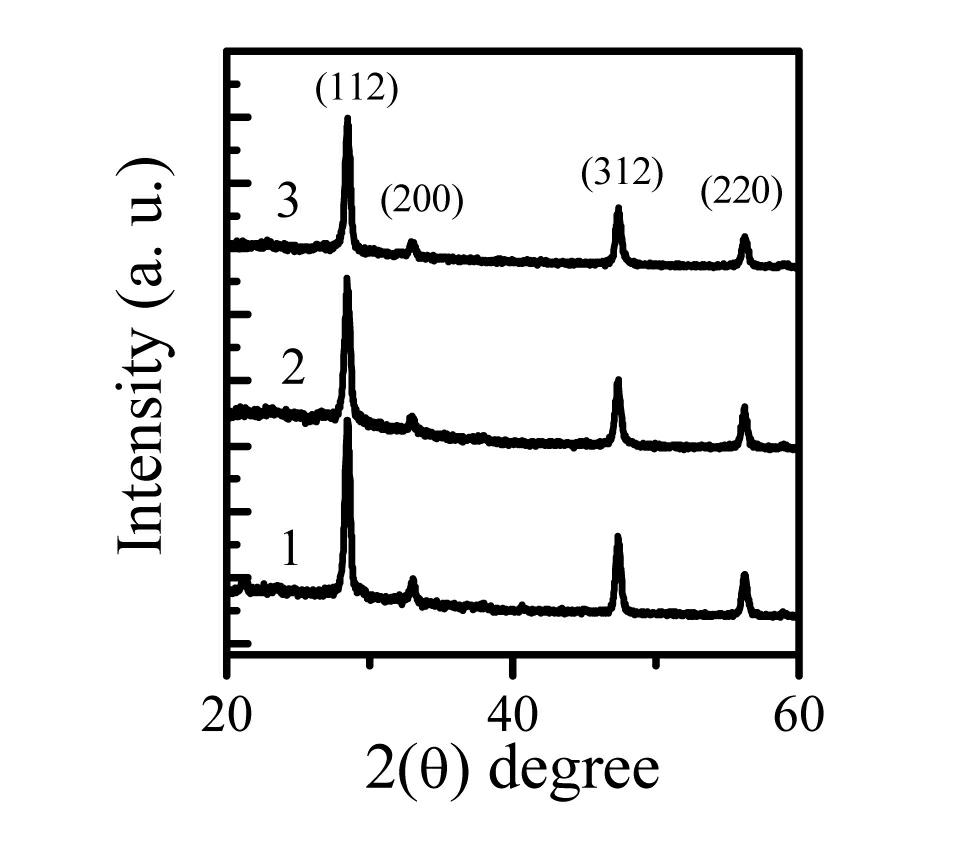

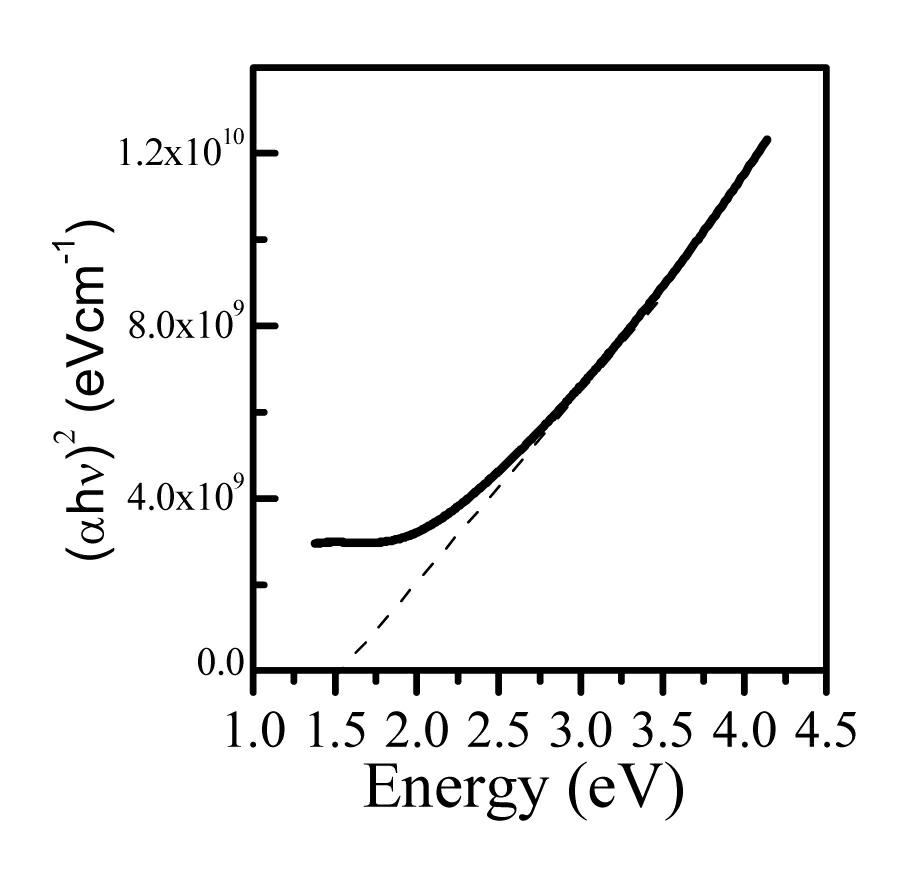

Band gap tunable copper zinc tin sulfur semiconductor film and preparation method thereof

InactiveCN102569443AImprove crystal qualityImprove compactnessFinal product manufactureVacuum evaporation coatingMetallurgyPhysical chemistry

The invention discloses a band gap tunable copper zinc tin sulfur semiconductor film and a preparation method thereof. The chemical formula of the semiconductor film is CuaZnbSncS4, wherein 1<= a<=3, 0.3<=b<= 2, 0.2<=c<=2. The preparation method comprises the steps of adding high purity metals of copper, zinc and tin to different tungsten boats and molybdenum boat, acquiring a lamellar metal film precursor through vacuum thermal evaporation, and vulcanizing the precursor in vacuum to obtain the band gap tunable copper zinc tin sulfur semiconductor film. Adjustments of components and optical properties are achieved and high-quality copper zinc tin sulfur semiconductor film is obtained by changes of evaporation order, mass ratio or mole ratio. The chemical formula of the semiconductor film has the advantages of being simple in device requirements, low in cost, environment friendly and pollution-free, suitable for industrial production and capable of being produced in a large scale and controlling band gaps.

Owner:WUYI UNIV

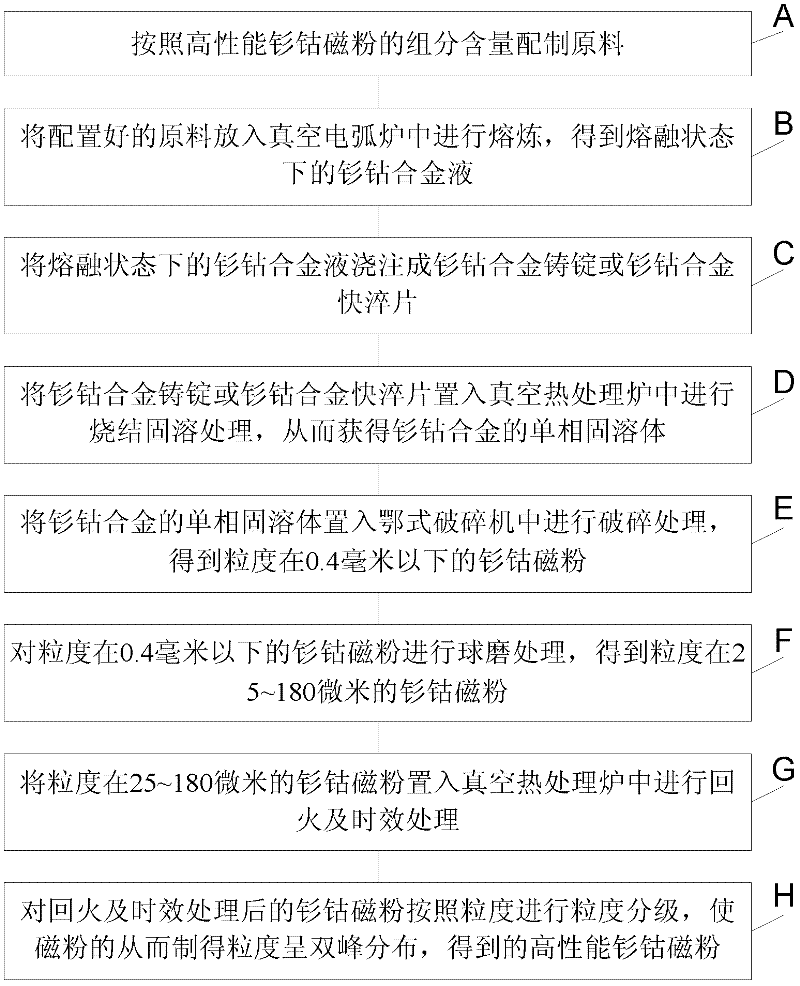

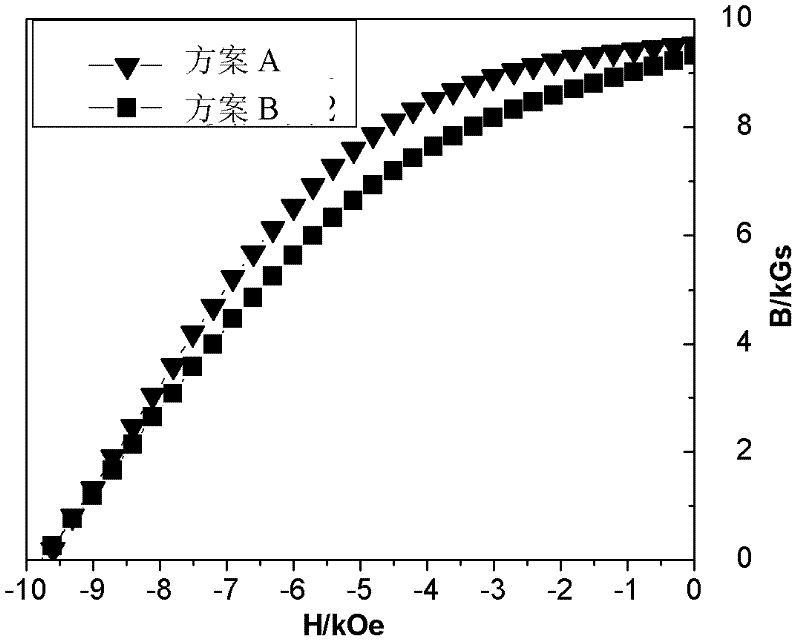

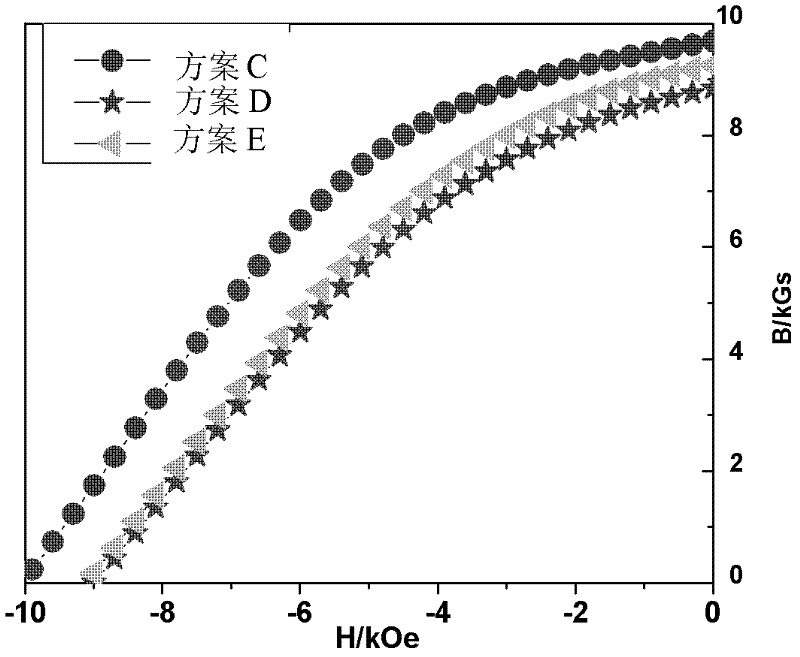

High-performance samarium-cobalt magnetic powder and preparation method thereof

ActiveCN102543340AImprove performanceImprove consistencyInorganic material magnetismMetallurgySamarium

The invention discloses high-performance samarium-cobalt magnetic powder and a preparation method thereof. The general formula is as follows: Sm.alpha.Co. 1-alpha-gamma-delta-psi-omega.Fe.gamma.M.delta.Q.psi.R.omega., and the balance of Co wherein M is at least one of Cu or Zr; Q is at least one of Er, Gd, Dy or Ho; R is at least one of V, Cr, Mn, Sr, Al or Cs; alpha is greater than 20 wt percent and less than 28 wt percent; gamma is greater than 14 wt percent and less than 25 wt percent; delta is greater than 0.5 wt percent and less than 15 wt percent; psi is greater than 0.1 wt percent and less than 5 wt percent; and omega is greater than 0.1 wt percent and is less than 5 wt percent. Due to the composition, the consistency of columnar crystals growth can be promoted, so that the performances of the samarium-cobalt magnetic powder are improved; and the preparation method comprises the following steps of: compounding, smelting, pouring, sintering, solutioning, crushing, aging, adjusting granularity, and the like, so that the magnetic powder with the granularity in bimodal distribution can be prepared, the filler content of the magnetic powder is favored to be improved, and performances of the prepared samarium-cobalt magnetic powder are improved.

Owner:BEIKUANG MAGNETS FUYANG CO LTD

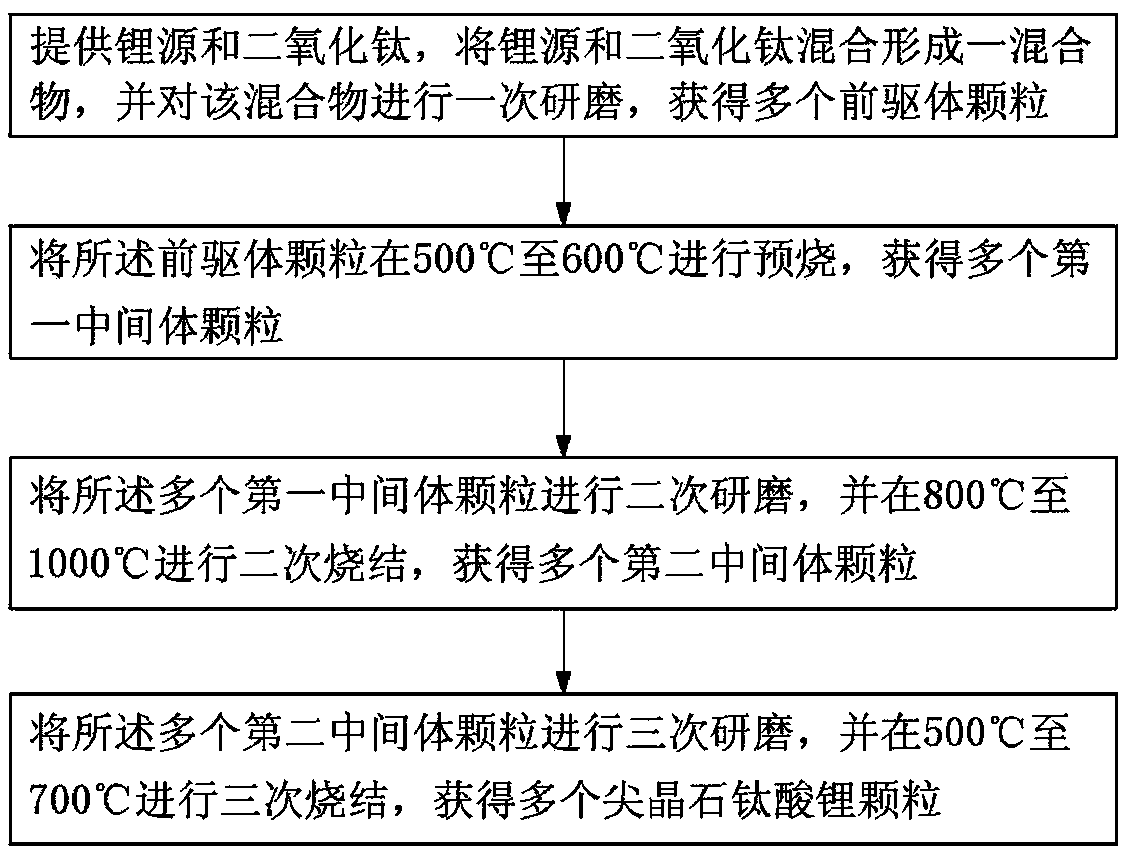

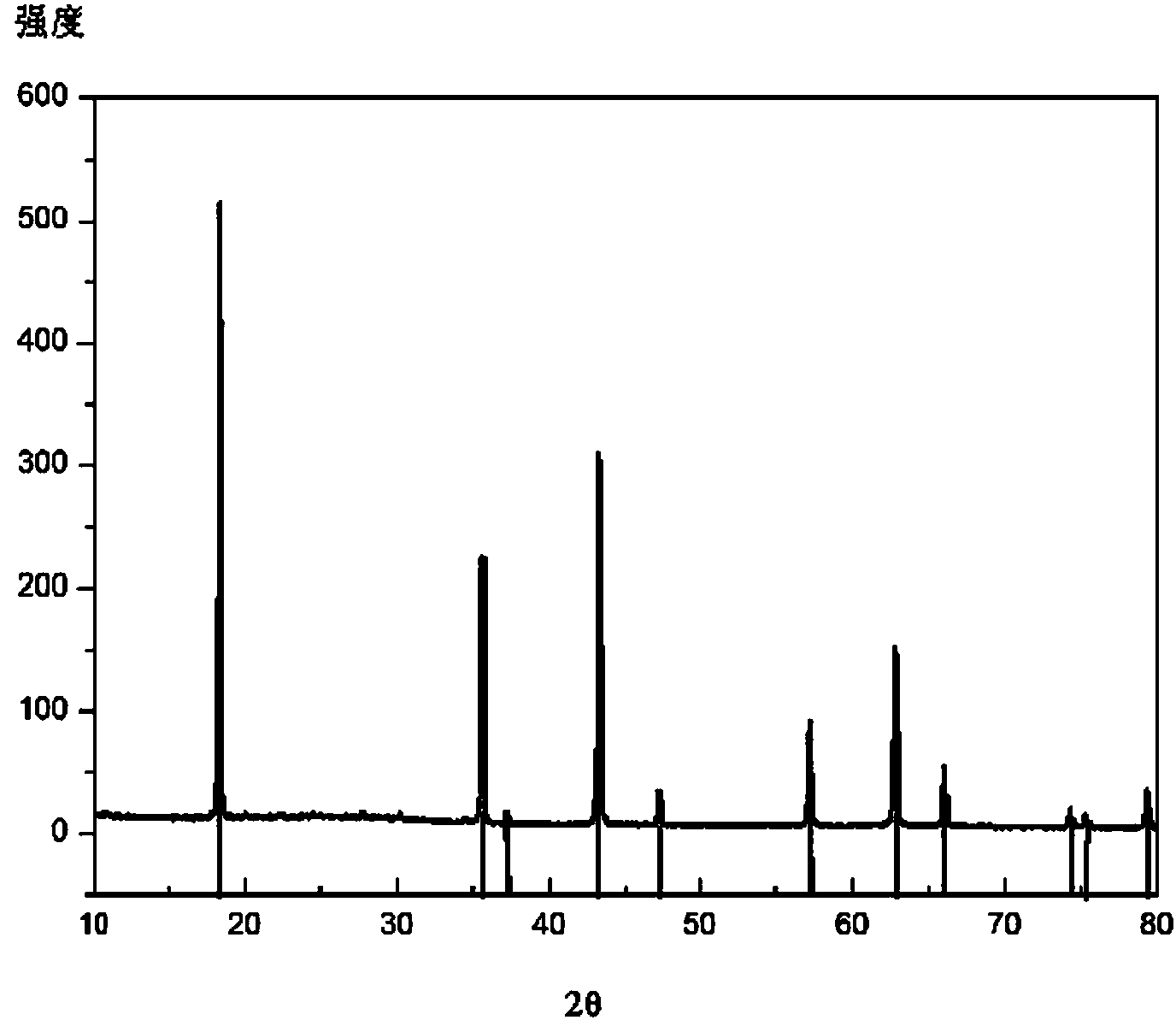

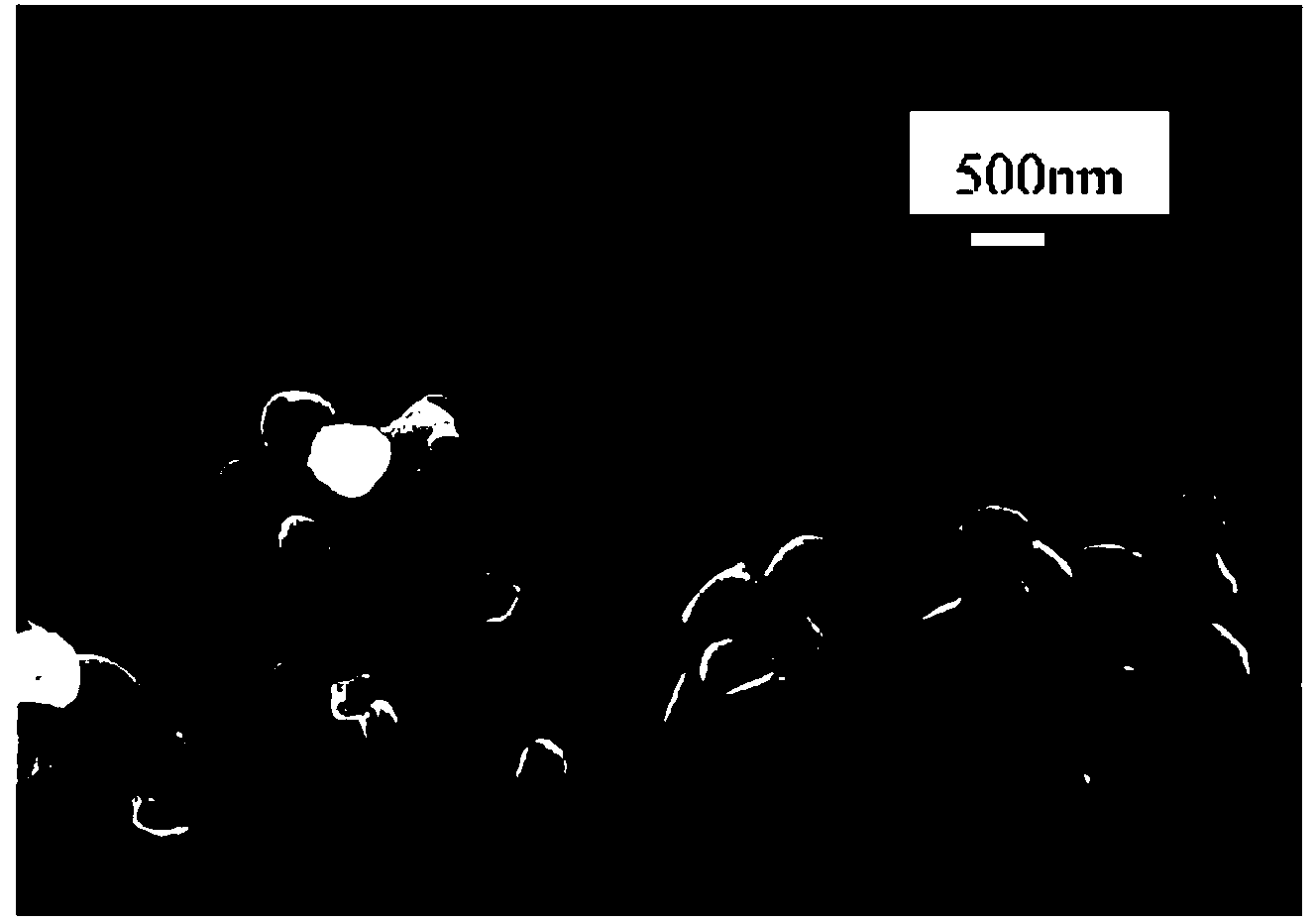

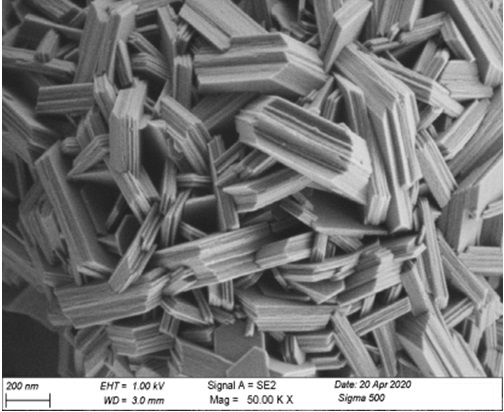

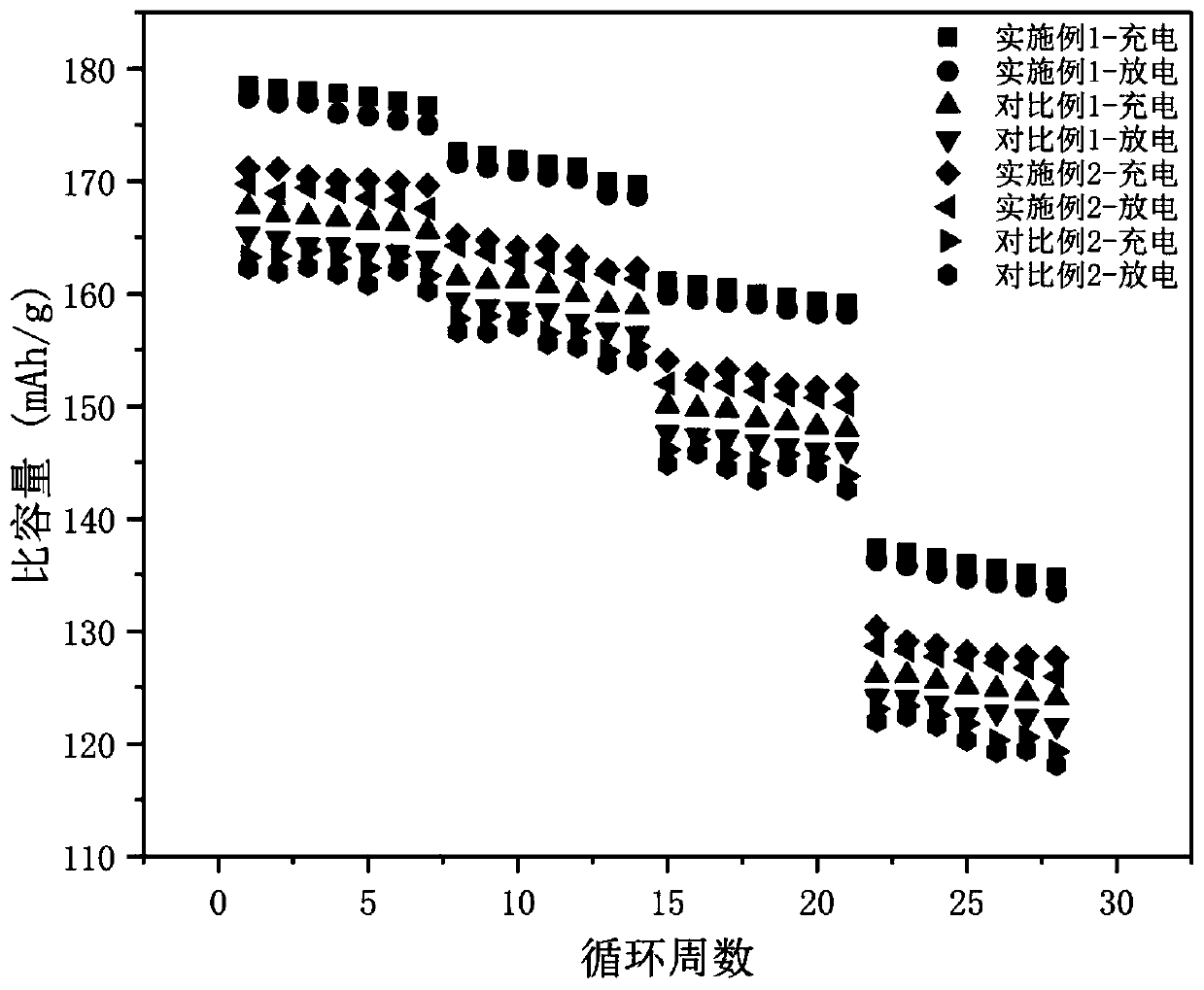

Preparation method of lithium ion battery electrode active material

ActiveCN103515589ASmall particle sizeParticle size becomes smaller and makes the distribution smallerAlkali titanatesCell electrodesSpinelTitanium oxide

The invention relates to a preparation method of a lithium ion battery electrode active material. The method comprises the steps that: lithium source and titanium oxide are provided, and are mixed into a mixture; the mixture is subjected to first grinding, such that a plurality of precursor particles are obtained; the precursor particles are pre-sintered under a temperature of 500-600 DEG C, such that a plurality of first intermediate particles are obtained; the plurality of first intermediate particles are subjected to second grinding, and are subjected to second sintering under a temperature of 800-1000 DEG C, such that a plurality of second intermediate particles are obtained; and the plurality of second intermediate particles are subjected to third grinding, and are subjected to third sintering under a temperature of 500-700 DEG C, such that spinel lithium titanate particles are obtained.

Owner:JIANGSU HUADONG INST OF LI ION BATTERY +1

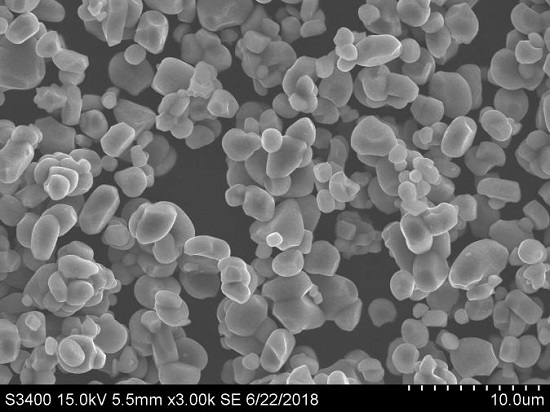

Single-crystal lithium nickel cobalt manganate precursor and preparation method thereof and single-crystal lithium nickel cobalt manganate

ActiveCN112226820AEasy to enter evenlyInto the uniformAfter-treatment apparatusPolycrystalline material growthManganateSingle crystal

The invention provides a single crystal lithium nickel cobalt manganate precursor and a preparation method thereof. The preparation method comprises the following steps: preparing a mixed salt solution, a precipitant solution and a complexing agent solution, and introducing a mixed gas of oxygen and non-oxygen in a volume ratio of 1:19-1:29 into a reaction kettle at a flow rate of 7-20 L / min; adding the mixed salt solution, a sodium hydroxide solution and an ammonia water solution at a flow rate of 60-120 ml / min for reaction; and keeping the pH value at 10.0-11.0, a temperature at 30-60 DEG Cand a stirring rotating speed at 100-500 rpm to obtain the single crystal lithium nickel cobalt manganate precursor, wherein the thickness of the primary particle sheet layer is 100-200 nm, the particle size D50 is 3.0-4.0 [mu]m, and the particle size distribution (D90-D10) / D50 is less than or equal to 0.8. According to the invention, the secondary particle size D50 of the precursor prepared by the method is 3.0-4.0 [mu]m, and the particle size distribution is not more than 0.8; and the single crystal lithium nickel cobalt manganese oxide particles prepared by the precursor are narrow in particle size distribution and good in high and low temperature performance.

Owner:HENAN KELONG NEW ENERGY CO LTD

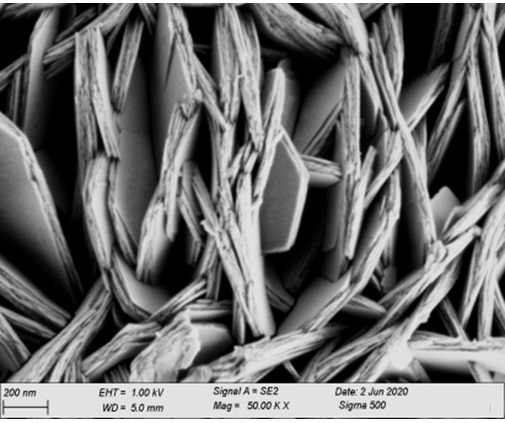

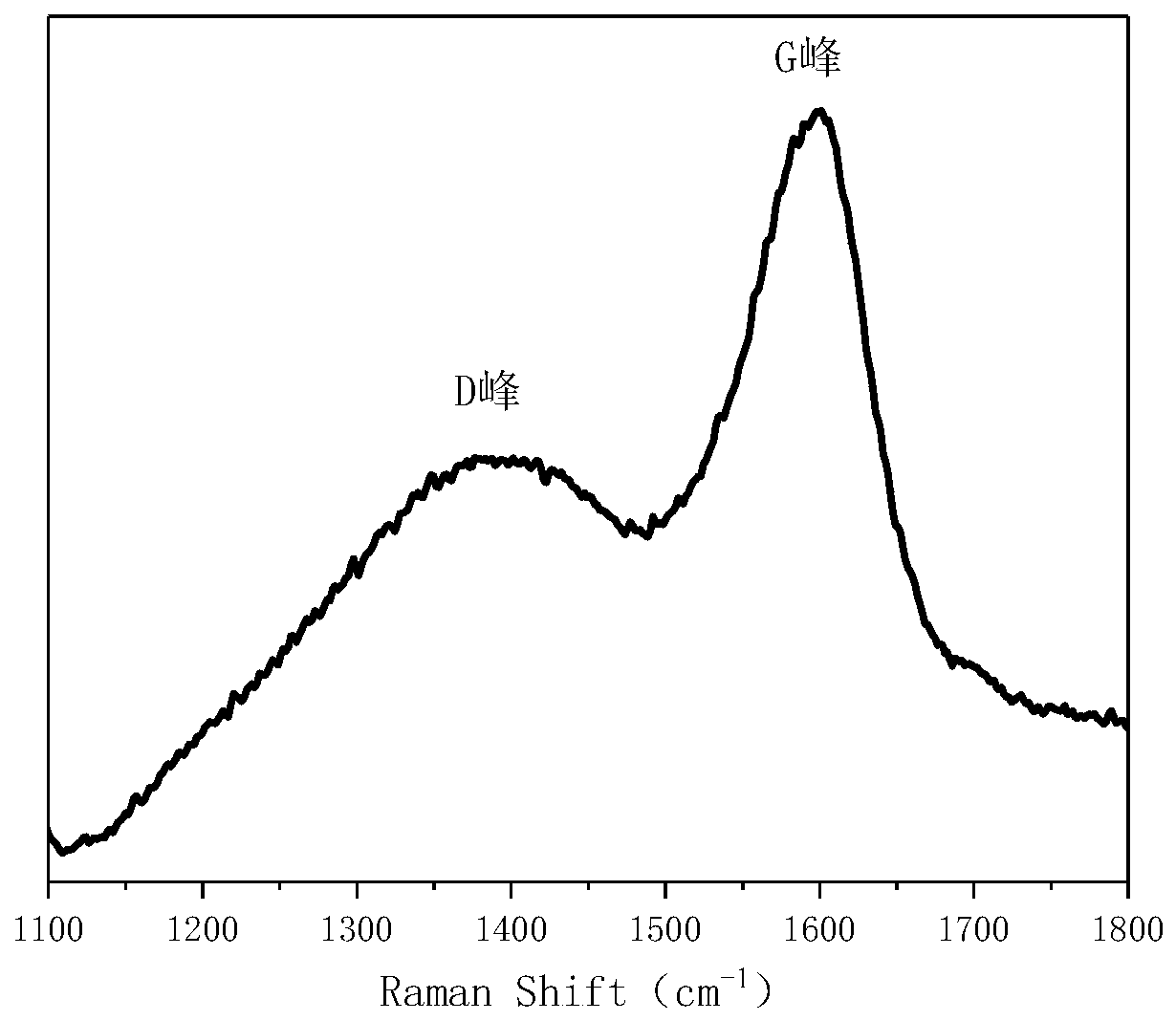

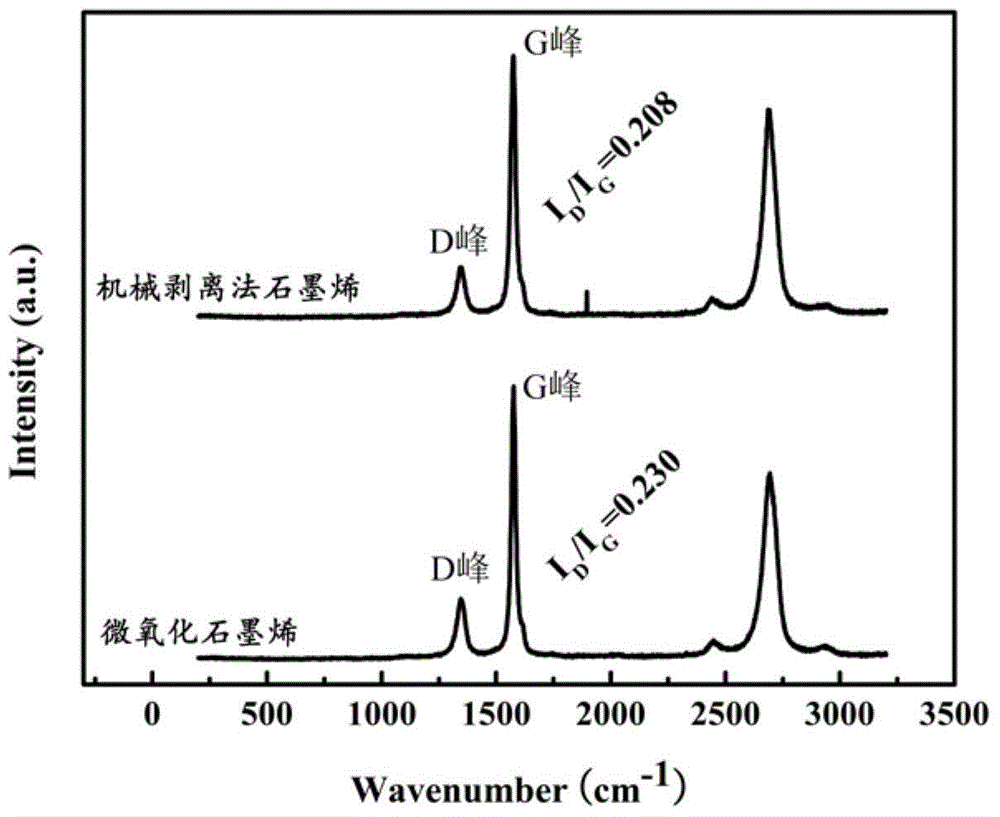

Carbon-coated solid electrolyte material as well as preparation method and application thereof

InactiveCN111403806AReduce lattice defectsHigh degree of graphitizationSolid electrolytesSecondary cellsCarbon layerSolid state electrolyte

The invention discloses a carbon-coated solid electrolyte material as well as a preparation method and application thereof. The carbon-coated solid electrolyte material comprises a solid electrolyte core and a carbon layer shell. The particle size of the solid electrolyte core is 10 nm to 100 [mu]m, and the carbon layer shell is particles with a particle size of 1nm to 1 [mu]m or a continuous filmwith a thickness of 1nm to 1 [mu]m. The particle size of the carbon-coated solid electrolyte material is 10nm to 100 [mu]m. The Raman spectrum of the carbon-coated solid electrolyte material has twocharacteristic peaks, namely a peak D and a peak G, wherein the peak D appears in the wavelength range of 1300cm<-1> to 1460cm<-1>, the peak G appears in the wavelength range of 1460cm<-1> to 1620cm<-1>, and the peak intensity ratio ID / IG of the peak D to the peak G is less than or equal to 1.0.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

High-thermal-conductivity silicon nitride ceramic substrate and preparation method thereof

ActiveCN112159236AReduce lattice oxygen contentReduce lattice defectsThermal conductivitySilicon nitride

The invention discloses a high-thermal-conductivity silicon nitride ceramic substrate and a preparation method thereof, and belongs to the technical field of ceramic substrate materials. The method comprises the following steps: carrying out primary ball milling and mixing on silicon nitride powder, a sintering aid, carbon black, triethyl phosphate and a solvent; adding a binder and a plasticizer,and carrying out secondary ball milling to obtain a slurry; carrying out vacuum defoaming treatment, and then carrying out tape casting to obtain a flaky biscuit; and performing high-temperature sintering after vacuum glue discharging to obtain the silicon nitride ceramic substrate. According to the invention, the carbon black is introduced based on the raw material ratio, and the sintering is carried out by two-step heating, so that the carbon black and the oxygen impurities of the silicon nitride are fully subjected to chemical reaction at a proper temperature and under a proper atmospherecondition, the lattice oxygen content of the silicon nitride ceramic is effectively reduced, and the thermal conductivity of the silicon nitride ceramic is improved. The silicon nitride ceramic substrate prepared by the invention has good performances of high thermal conductivity and high bending strength.

Owner:江苏贝色新材料有限公司

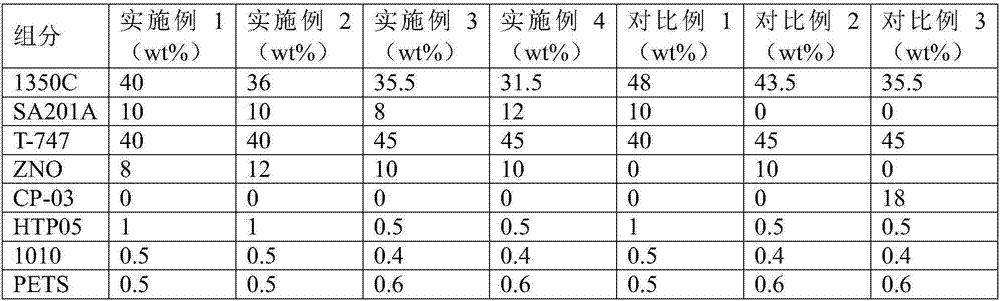

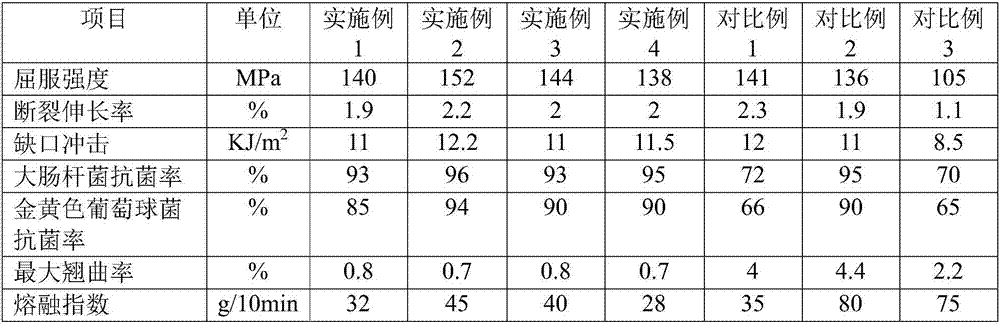

Antimicrobial low-warpage low-flash PPS composite material and preparation method thereof

The invention discloses an antimicrobial low-warpage low-flash PPS composite material and a preparation method thereof. The material is prepared from, by weight, 31.5-48% of PPS resin, 6-12% of PPE resin, 40-45% of glass fibers, 8-12% of antimicrobial agent, 0.5-1% of nucleating agent, 0.4-0.5% of antioxidant and 0.5-0.6% of lubricating agent. An engineering plastic, namely PPS, serves as a main body, the PPE resin, the glass fibers, the antimicrobial agent, the nucleating agent the antioxidant and the lubricating agent are added, the raw materials are mixed together and melted through a double-screw extruder, and then the antimicrobial low-warpage low-flash PPS composite material which is capable of meeting the antimicrobial requirements of household appliances is prepared. The material has the advantages of being antimicrobial, low in warpage and low in flash on the basis of ensuring the original excellent mechanical performance, heat resistance, fire resistance and electrical performance of PPS.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

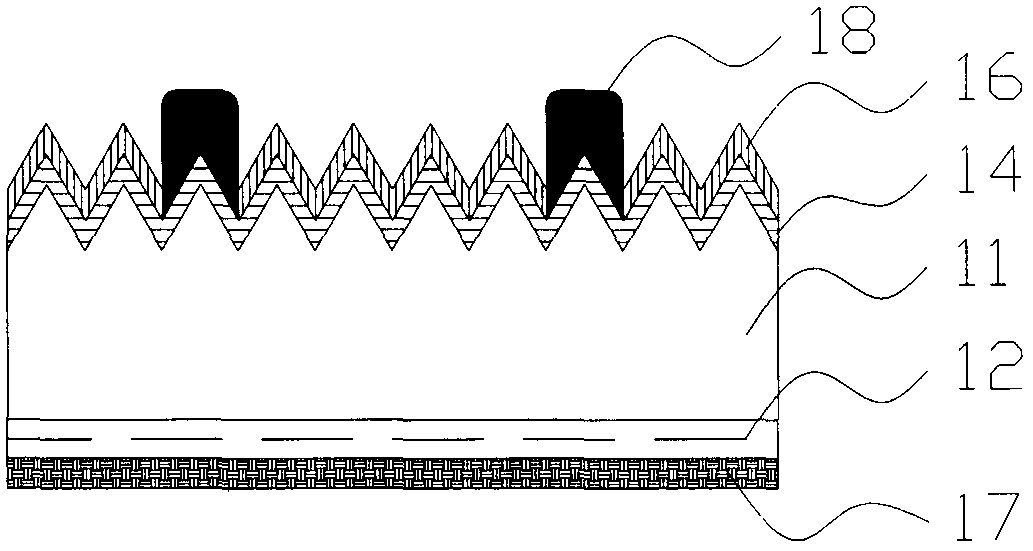

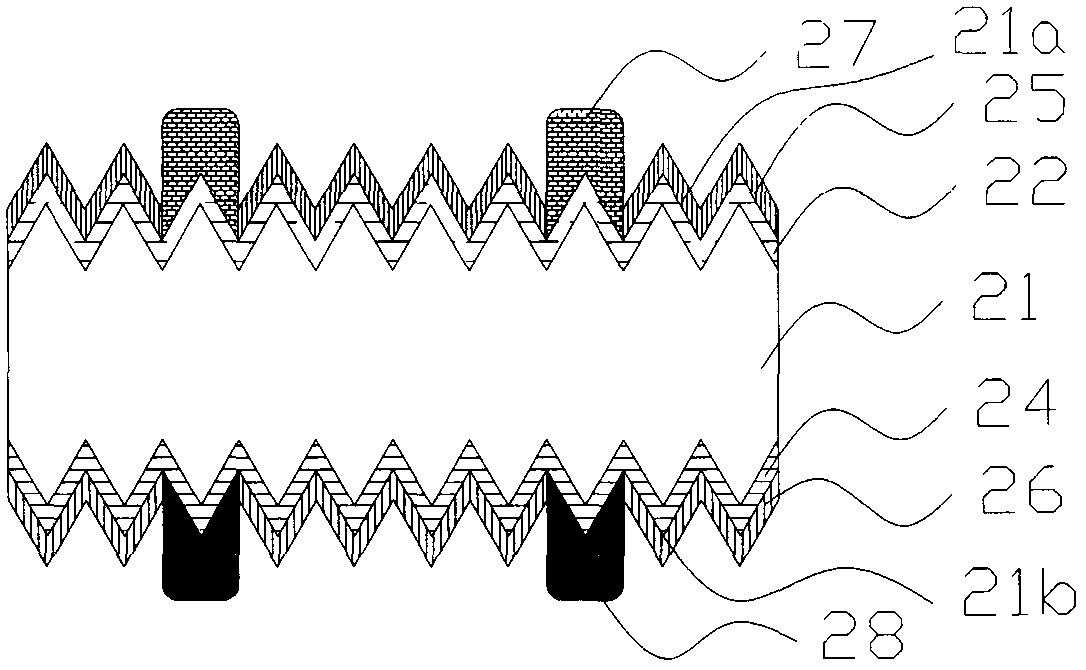

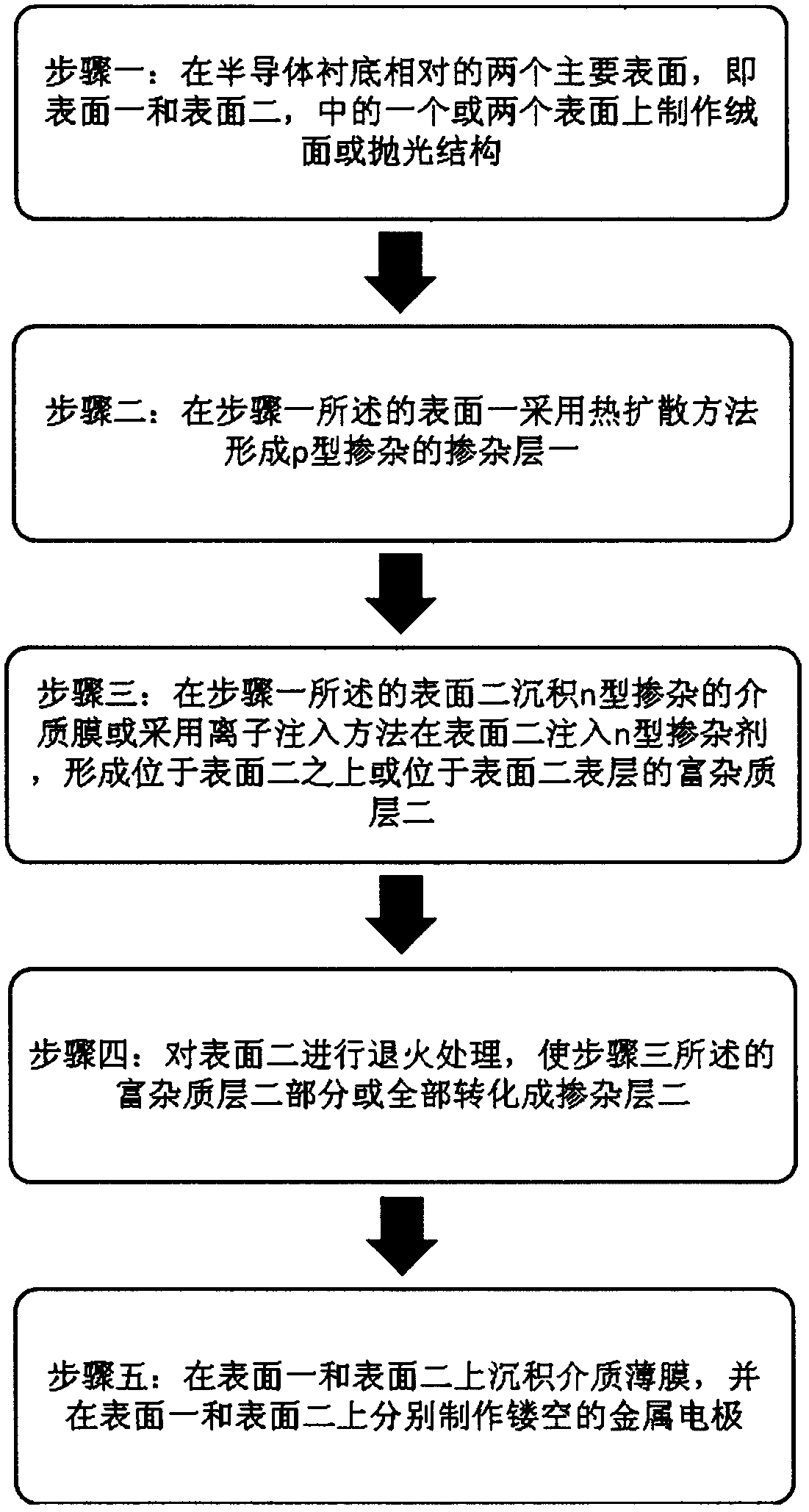

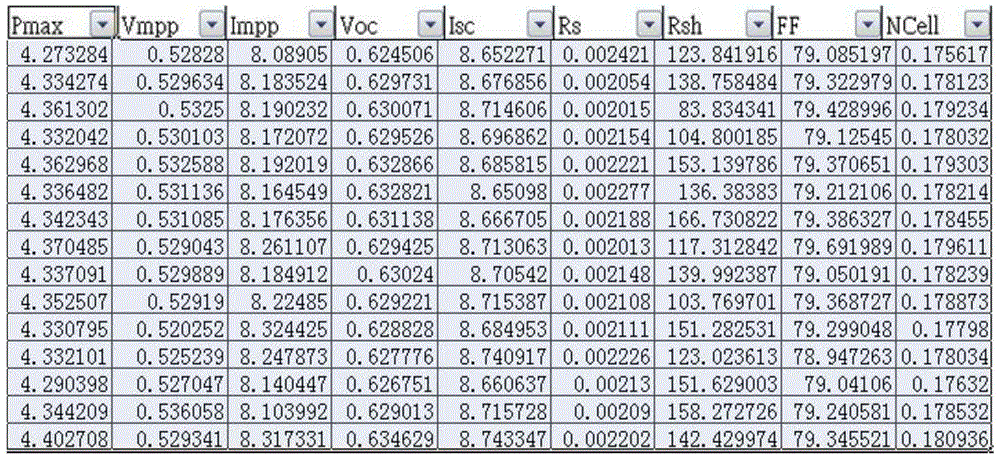

Method for manufacturing bifacial solar cell

InactiveCN103474506AReduce manufacturing costSimple processFinal product manufactureSemiconductor devicesDopantSolar cell

The invention belongs to the field of solar cells, and proposes a method for manufacturing a solar cell. Specifically, the method for manufacturing a solar cell comprises a step of manufacturing textured surface or polished structures on two main surfaces of a substrate; a step of forming a p-type doped doping layer One on a main surface One of the substrate through thermal diffusion; a step of depositing an n-type doped medium membrane on the main surface Two of the substrate or injecting n-type dopant in the main surface Two of the substrate by using an ion injection method; a step of performing annealing processing on the main surface Two of the substrate to form an n-type doped doping layer Two; and a step of depositing medium thin films and hollow-out metal electrodes on the two main surfaces of the substrate. The method is mainly used for manufacturing bifacial solar cells. Compared with methods in the prior art, the method solves technical problems that the manufacture of the bifacial solar cell requires that mutually isolated doping layers be formed on the two main surfaces of the semiconductor substrate in a simpler way, helps to reduce the manufacturing cost and meanwhile helps to improve device performance.

Owner:SUZHOU RUNYANG PHOTOVOLTAIC TECH

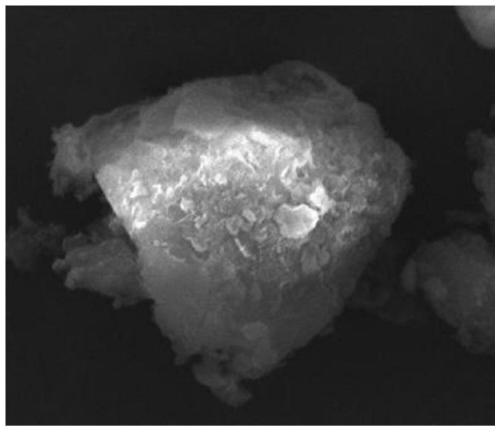

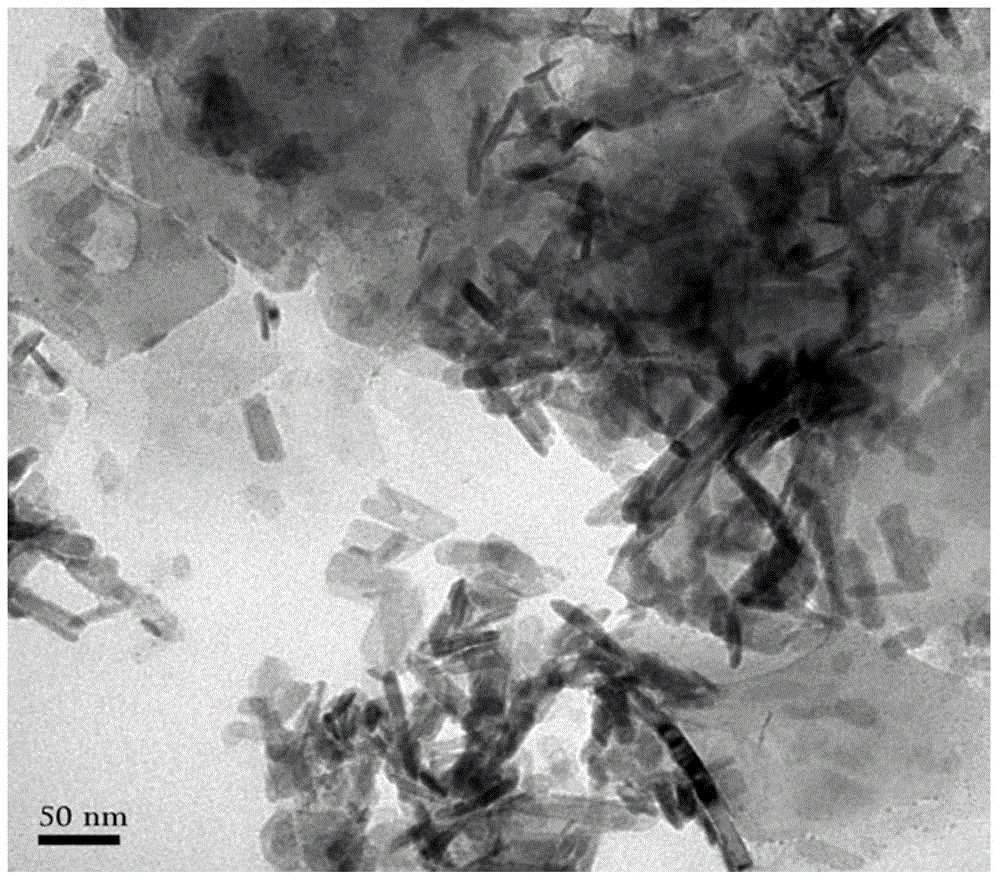

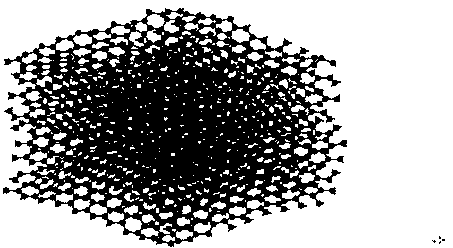

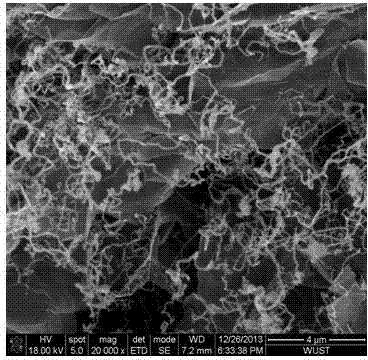

Micro-oxidized graphene and preparation method thereof

ActiveCN104386677AReduce the degree of oxidationReduce lattice defectsCvd grapheneFunctional composite

The invention belongs to the technical field of graphene materials and in particular relates to micro-oxidized graphene and a preparation method thereof. The micro-oxidized graphene contains a small amount of active groups, is low in degree of oxidation, and has the oxygen element content of 1-10wt% and the bulk density of 0.01-0.1g / ml. The micro-oxidized graphene contains a proper amount of chemical reaction active group points, and meanwhile, a relatively complete graphene lattice structure is remained so that the micro-oxidized graphene has excellent dispersibility, special reactivity and excellent physical properties. The invention provides an industrial micro-oxidized graphene preparation route which is efficient, stable, economical, controllable and environment-friendly and the defects of uncontrollable graphene activation, great operation risks, serious environmental pollution, serious equipment corrosion, high cost investment and the like of a traditional acid oxidation method can be overcome. The micro-oxidized graphene prepared by use of the preparation method has extremely wide prospect in the fields of functional composites, coatings, ink, photoelectric materials, biological medicine and the like.

Owner:XIAMEN KNANO GRAPHENE TECH CORP

1120 alloy aluminum foil of flexible sticky ceramic welding backing and production method thereof

The invention discloses 1120 alloy aluminum foil of a flexible sticky ceramic welding backing and a processing technology thereof. According to the 1120 alloy aluminum foil, copper, iron, silicon and aluminum are adopted as main raw materials, the copper, the iron and the silicon are proportioned according to the weight ratio being 2 to 1 to 0.5, and the aluminum foil is obtained through the technological steps of smelting, continuous casting-rolling, cold rolling, recoiling and trimming, intermediate annealing, foil rolling, aluminum foil surface roughening, aluminum foil surface cleaning, aluminum foil shearing and splitting and finished product annealing. The produced 1120 alloy aluminum foil of the flexible sticky ceramic welding backing is 0.05-0.07 mm thick and has excellent flexibility, adhesiveness, heat resistance and thermal conductivity. Aluminum foil tape produced through the aluminum foil is good in flexibility, the part, adhering to the bottom of base metal in the heat-affected zone surrounding a welding line, of the aluminum foil tape is high in adhesiveness and good in heat dissipation effect and does not get deformed and warped or fall off easily on the condition of welding arc heating effect, and the use requirement of keeping stable in the welding process of the ceramic welding backing can be met.

Owner:江阴新仁铝箔科技有限公司

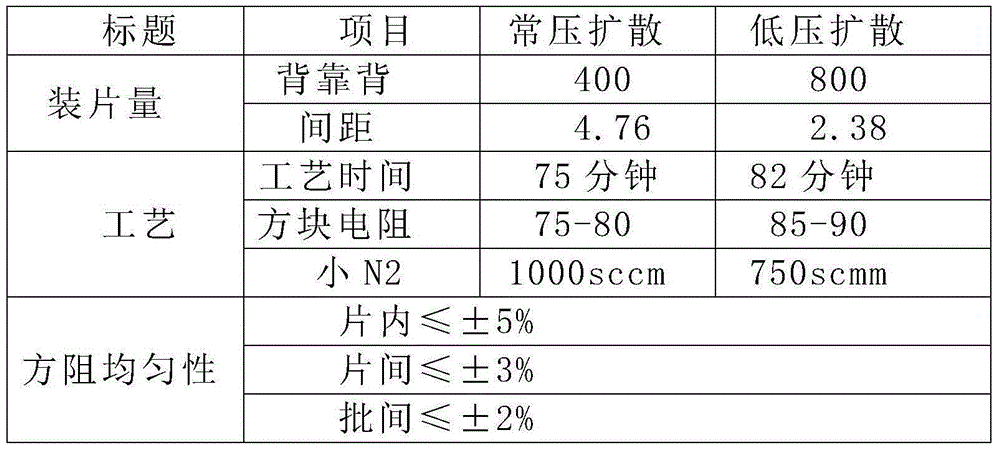

Low-pressure diffusion technique in solar cell silicon wafer production process

InactiveCN105070782AReduce lossGood process uniformityFinal product manufacturePhotovoltaic energy generationNitrogenOmega

The present invention provides a low-pressure diffusion technique in a solar cell silicon wafer production process, and belongs to the technical field of solar cell production. The technical problem that silicon wafer surface diffusion is not uniform in the conventional solar cell silicon wafer production process is solved. The low-pressure diffusion technique comprises a first step of vacuumizing, placing a silicon wafer into a reaction chamber of a diffusion furnace and vaccumizing the reaction chamber of the diffusion furnace to be of a 50 mbar-150 mbar vacuum state by using a vacuum pump; a second step of gas inflation, inflating a small amount of nitrogen and phosphorus oxychloride into the reaction chamber of the diffusion furnace; a third step of low-pressure diffusion, maintaining pressure inside the reaction chamber to be unchanged, low-pressure diffusion time being 700S-900S; and a fourth step of detection, detecting a low-pressure diffusion result to enable silicon wafer surface square resistance to be 80 omega-130 omega per square and uniformity being within +-3%. The technique provided by the present invention has the advantages of excellent diffusion uniformity, sharp reduction in losses of chemicals and special gases, long maintenance cycle, and the like.

Owner:PERLIGHT SOLAR

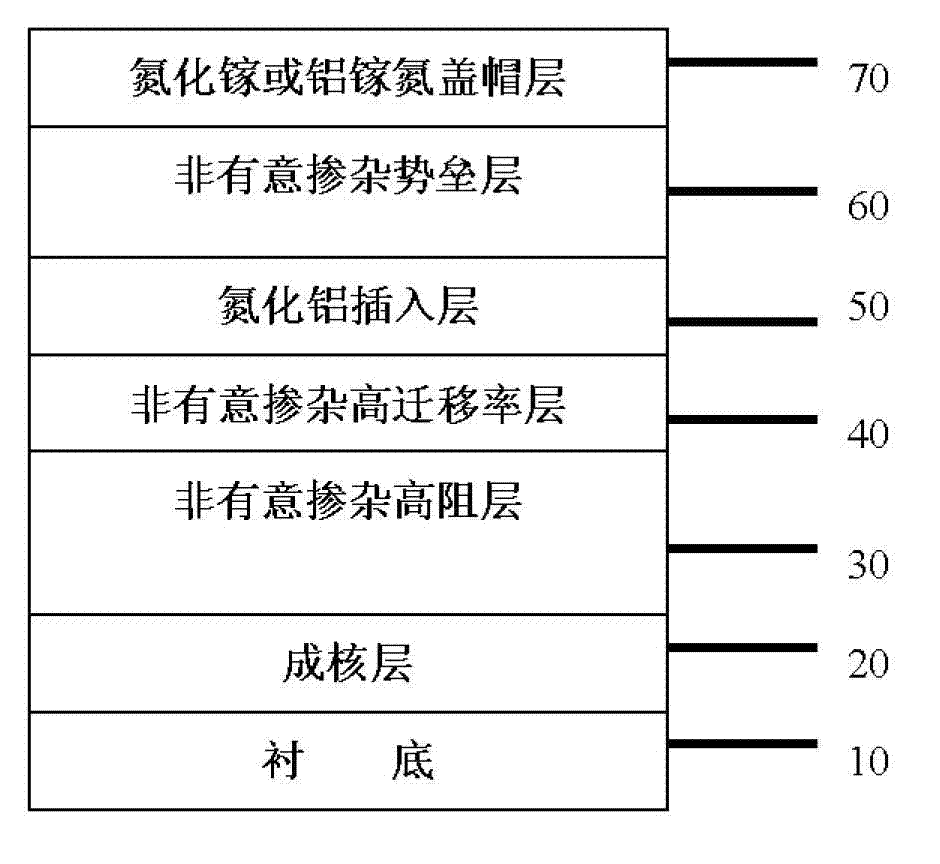

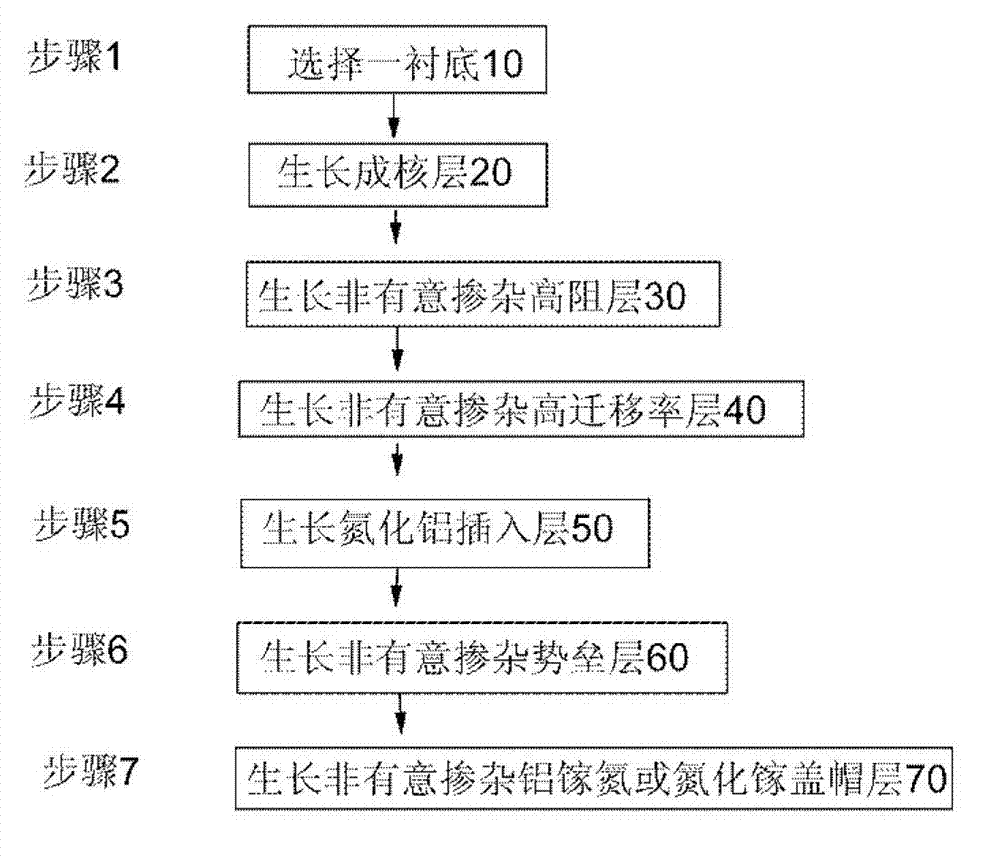

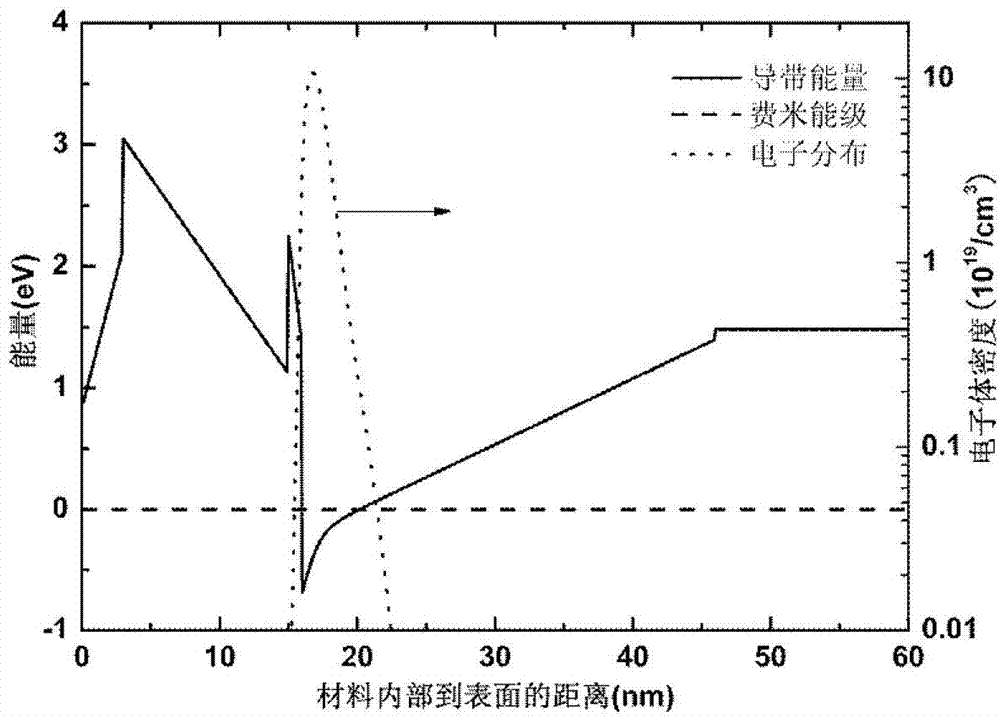

Double-heterojunction gallium nitride based HEMT (High Electron Mobility Transistor) taking aluminum-gallium-nitrogen as high-resistance layer and manufacturing method thereof

ActiveCN102931230AReduce leakageIncrease the restrictive effectSemiconductor/solid-state device manufacturingSemiconductor devicesHigh resistanceHeterojunction

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

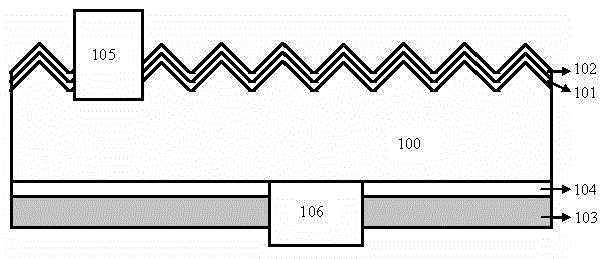

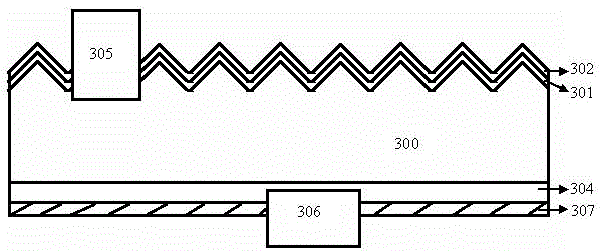

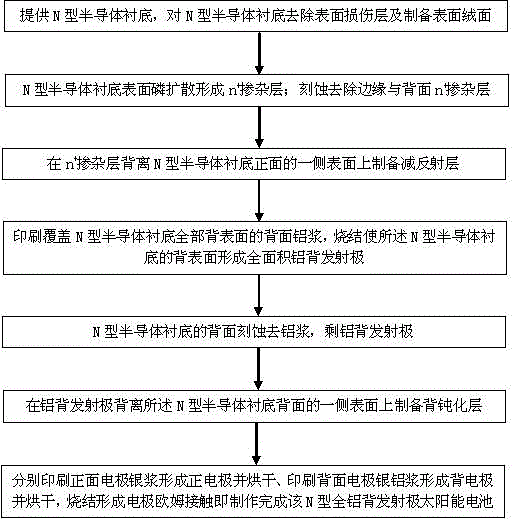

Manufacturing method of N type all-aluminum back emitter solar cell and solar cell prepared by the same

InactiveCN104868011AAvoid leakage currentImprove energy conversion efficiencyFinal product manufacturePhotovoltaic energy generationSilver pasteSilver electrode

The invention discloses a manufacturing method of an N type all-aluminum back emitter solar cell and a solar cell prepared by the same. The manufacturing method comprises: providing an N type semiconductor substrate, removing a surface damage layer, and preparing a surface pile face; carrying out phosphorus diffusion to form an n<+> doping layer and etching and removing the parts, formed at the edge and the back, of the n<+> doping layer; preparing an antireflection layer at the front side; printing a back aluminium paste and carrying out sintering to form a full-area aluminum back emitter; carrying out etching at the back and removing the aluminium paste and keeping the aluminum back emitter; preparing a back passivation layer at the back; printing a front electrode silver paste and carrying out drying, printing a back electrode silver-aluminium paste and carrying out drying, and carrying out sintering to form electrode ohmic contact. According to the invention, a problem of leak current existence at the boundary of the local back aluminium emitter and the back silver electrode can be solved; the solar cell quality is improved; and the conversion efficiency is improved by increasing the effective area of the PN node. With the back passivation layer, the open-circuit voltage and short-circuit current of the cell are increased. Moreover, the dual-face solar cell can be manufactured, so that the cell energy output is enhanced and the conversion efficiency is improved.

Owner:DK ELECTRONICS MATERIALS INC

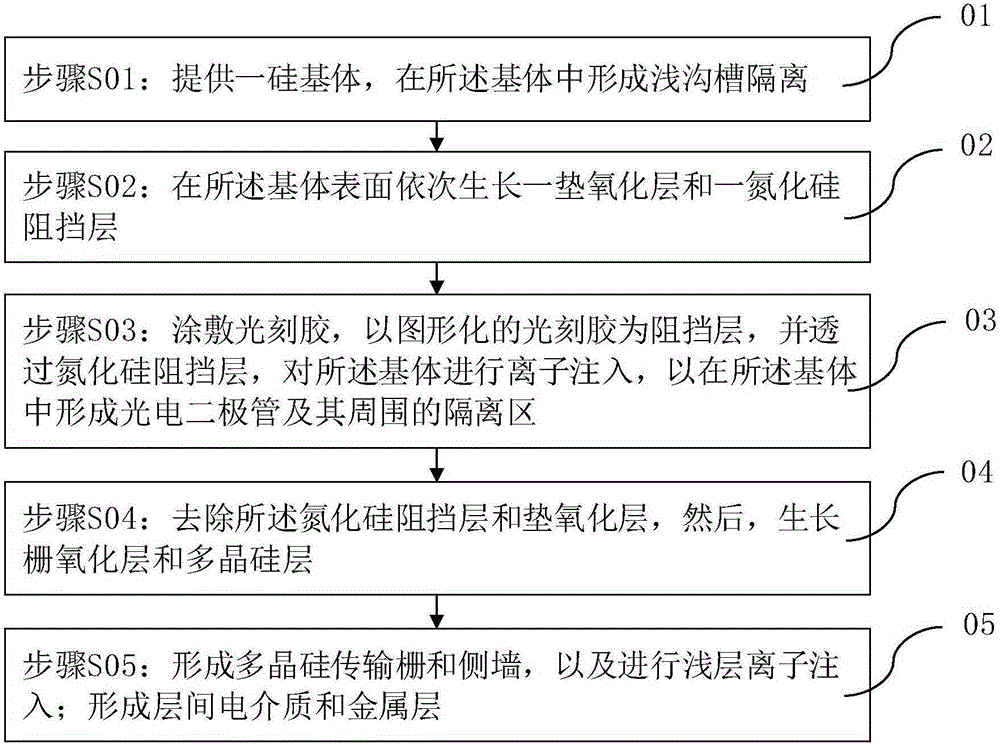

Integrated technology of reducing CMOS image sensor white pixels

ActiveCN105185747AReduce lattice defectsWhite pixel reductionSolid-state devicesSemiconductor/solid-state device manufacturingDielectricLattice defects

The present invention discloses an integrated technology of reducing CMOS image sensor white pixels. The integrated technology comprises the steps of forming the shallow trench isolation in a matrix; growing a pad oxide layer and a silicon nitride barrier layer orderly on the surface of the matrix; coating a photoresist, taking the graphical photoresist as the barrier layer, and penetrating the silicon nitride barrier layer to carry out the ion implantation on the matrix to form a photodiode and an isolation area around the photodiode in the matrix; removing the silicon nitride barrier layer and the pad oxide layer, and then growing a gate oxide layer and a polycrystalline silicon layer; forming a polycrystalline silicon transmission gate and a side wall, and carrying out the shallow-layer ion implantation; forming an interlayer dielectric and a metal layer. The silicon nitride barrier layer can block the ion implantation, especially can block the metal impurities introduced by the metal elements volatilized by the electronic shower during a high energy ion implantation process, at the same time, can reduce the crystal lattice defects caused by an arc effect when the ions are implanted in a shallow-layer area, thereby reducing the white pixels effectively.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Method for preparing beta-silicon carbide film

InactiveCN103346073AReduce lattice defectsQuality improvementSemiconductor/solid-state device manufacturingSemiconductor materialsHydrogen

The invention relates to the technical field of semiconductor materials, and discloses a method for preparing a beta-silicon carbide film. The method comprises the following steps: silane is used as a silicon source, hydrogen is used as a diluent gas and a carrier gas for the silicon source, graphite is used as a substrate and a carbon source, the beta-silicon carbide film is prepared on the graphite substrate through a hot filament chemical vapor deposition method, the prepared beta-silicon carbide film is subjected to follow-up annealing treatment in an inert gas, and a finished beta-silicon carbide film is obtained further through micromechanical cleavage. According to the novel method, the beta-silicon carbide film is prepared on the graphite substrate, namely the beta-silicon carbide film is prepared on the graphite substrate which has high electric conductivity and heat conductivity, lattice imperfection inside the film is reduced, the crystalline quality of the film is greatly improved, therefore, the heat dispersion performance of a silicon carbide-based electronic (photoelectronic) high-power device is improved, and the service life of the silicon carbide-based electronic (photoelectronic) high-power device is prolonged; the cleavage of a silicon carbide film material and the graphite substrate is easy to realize through the micromechanical cleavage and other methods, and the method for preparing the beta-silicon carbide film is simple, practicable and low in cost.

Owner:DALIAN UNIV OF TECH

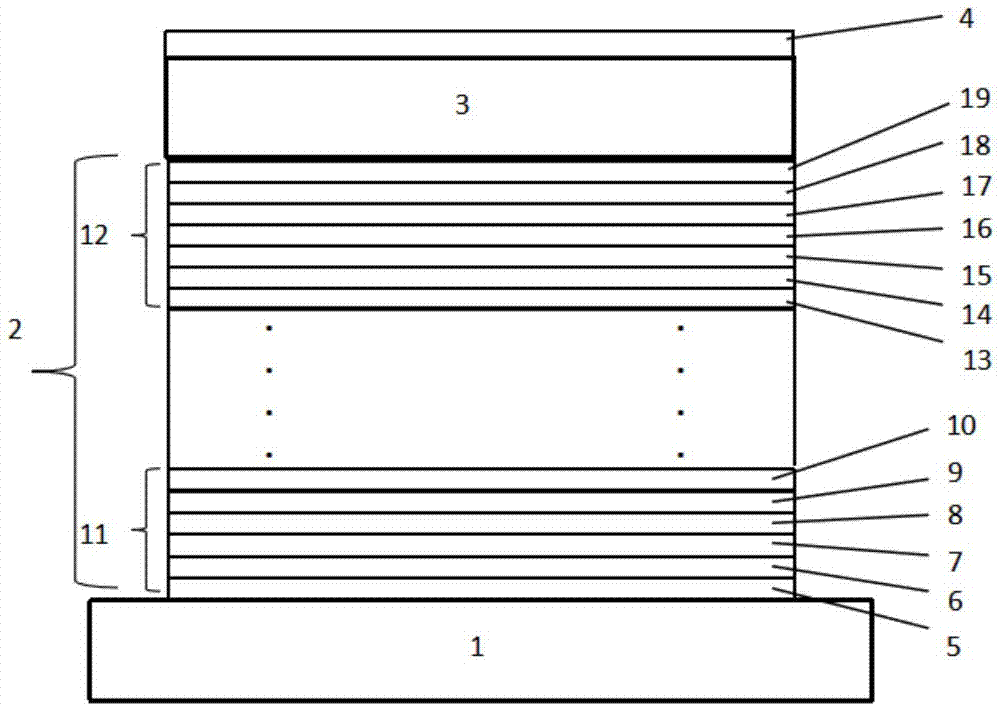

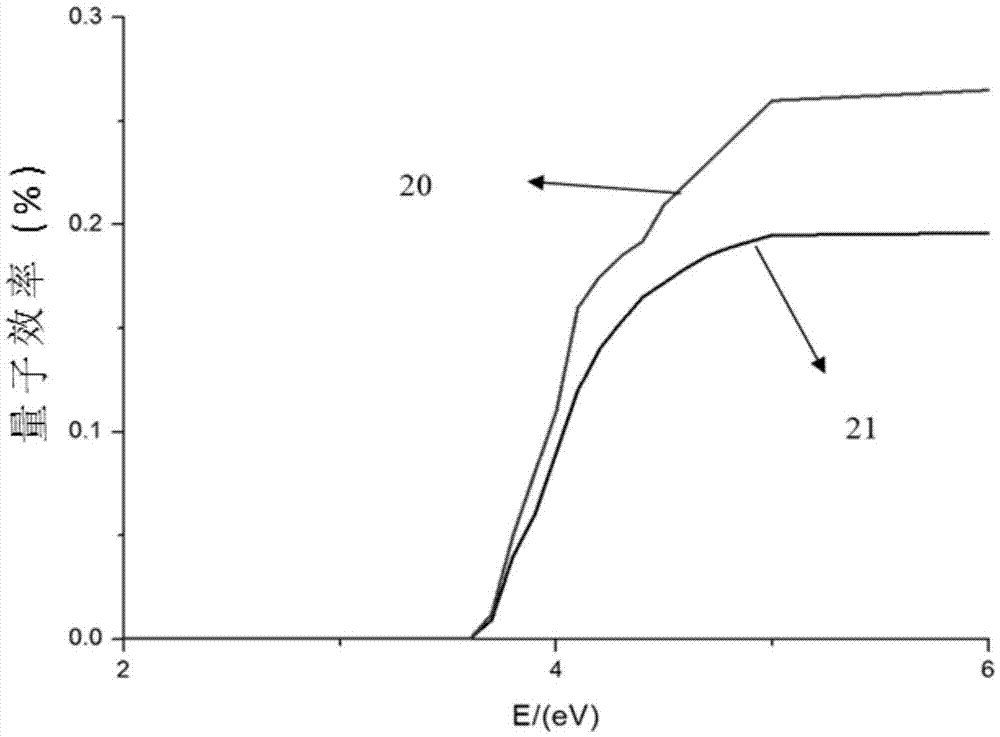

Superlattice graded buffer layer transmissive AlGaN ultraviolet cathode and preparation method therefor

InactiveCN105449066AImprove growth qualityReduce lattice defectsSemiconductor devicesPhysicsAbsorption rate

The invention discloses a superlattice graded buffer layer transmission-type AlGaN ultraviolet photoelectric cathode and a preparation method therefor. The photoelectric cathode consists of a substrate layer, a superlattice wedge graded p-type AlxGa1-xN buffer layer, a p-type AlyGa1-yN emission layer and a Cs or Cs / O activation layer from bottom to top, wherein the superlattice wedge graded p-type AlxGa1-xN buffer layer consists of 8-15 cyclically stacked graded layers and one transitional layer; the transitional layer is in contact with the emission layer; and the lowest graded layer is in contact with the substrate layer. According to the ultraviolet cathode and the preparation method, the growth quality of crystals is improved, the lattice defects in the buffer layer are reduced to a relatively large extent, the photon absorption rate of the emission layer is increased, and finally the photoelectric emission quantum efficiency of the photoelectric cathode is improved.

Owner:NANJING UNIV OF SCI & TECH

ZnO/SiC/Si heterojunction solar battery and preparation method thereof

InactiveCN101694853AImprove crystal qualityHigh degree of crystallinityFinal product manufactureVacuum evaporation coatingHeterojunctionGas phase

The invention discloses a ZnO / SiC / Si heterojunction solar battery and a preparation method thereof, wherein the solar battery comprises a substrate layer, a SiC layer arranged on the substrate layer and a ZnO layer arranged on the SiC layer, wherein the material of the substrate layer in the ZnO / SiC / Si heterojunction solar battery is Si piece. The thickness of the substrate layer is 3-4mm, the thickness of the SiC layer is 500-3000nm, and the thickness of the ZnO layer is 300-2000nm. The preparation method comprises utilizing a chemical vapor deposition method to firstly prepare the SiC layer on the substrate, and then preparing the ZnO layer, and the method for preparing ZnO is a chemical vapor deposition method or a reactive sputtering method. The solar battery improves the crystallization quality of heterogeneous epitaxial films, obviously improves photoelectric transformation efficiency, can improve more than 1 time than a solar battery which is directly made of ZnO / Si, and has extremely wide application prospect.

Owner:UNIV OF SCI & TECH OF CHINA

Carbon raw material for carbon composite refractory material and preparation method thereof

The invention relates to a carbon raw material for a carbon composite refractory material and a preparation method thereof. The technical scheme comprises the following steps: firstly uniformly filling the bottom of a graphite crucible with a monatomic silicon powder, uniformly coating the monatomic silicon powder with graphite, carrying out thermal insulation at 1000-1400 DEG C in the atmosphere of argon or nitrogen for 1-4 hours, and taking out a substance which covers the monatomic silicon powder so as to prepare the carbon raw material for the carbon composite refractory material, wherein graphite is one of expandable graphite and graphene, and mass ratio of graphite to the monatomic silicon powder is (0.01-0.9):1. By adjusting the mass ratio of graphite to the monatomic silicon powder, in-situ preparation of different numbers and sizes of silicon carbide whiskers is realized on the edge of graphite. The prepared carbon raw material for the carbon composite refractory material has excellent resistance to oxidation, good dispersibility and excellent mechanical properties, is used in a carbon composite refractory material, and can be used to raise overall performance of a carbon composite refractory material and especially enhance mechanical properties and oxidation resistance of the carbon composite refractory material.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com