Patents

Literature

169results about How to "Prevent shrinkage deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

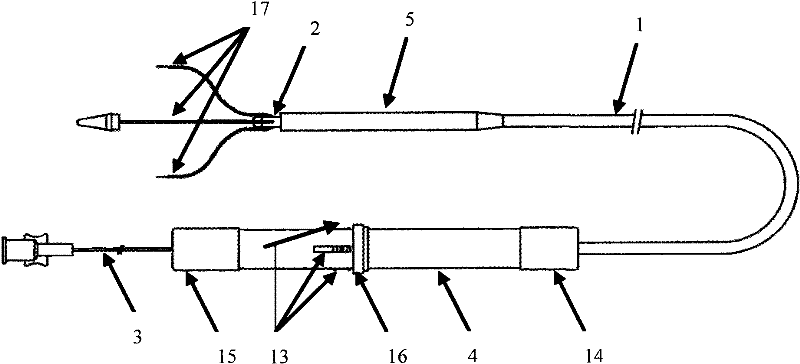

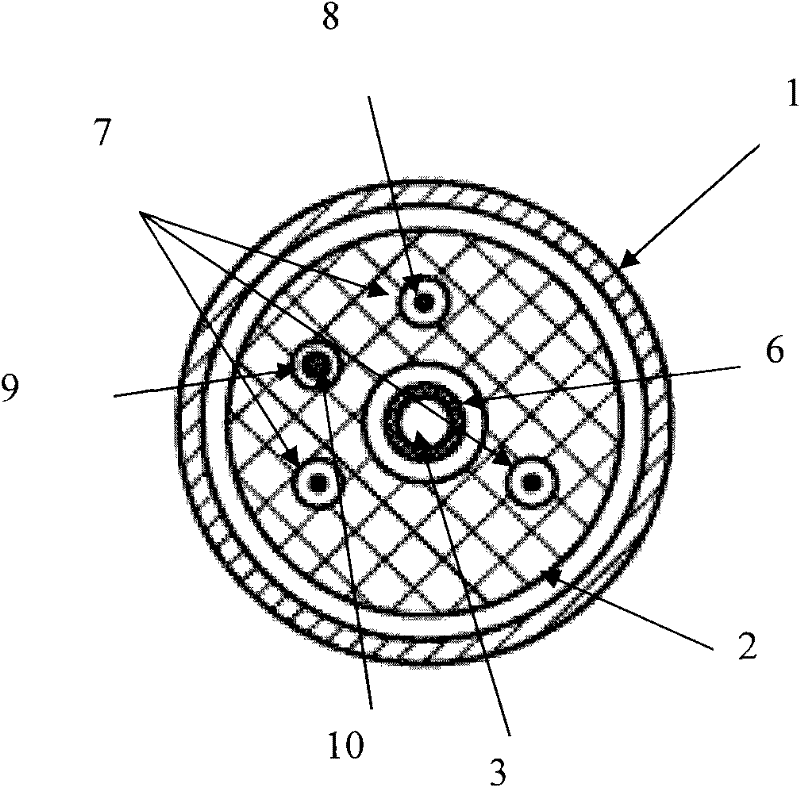

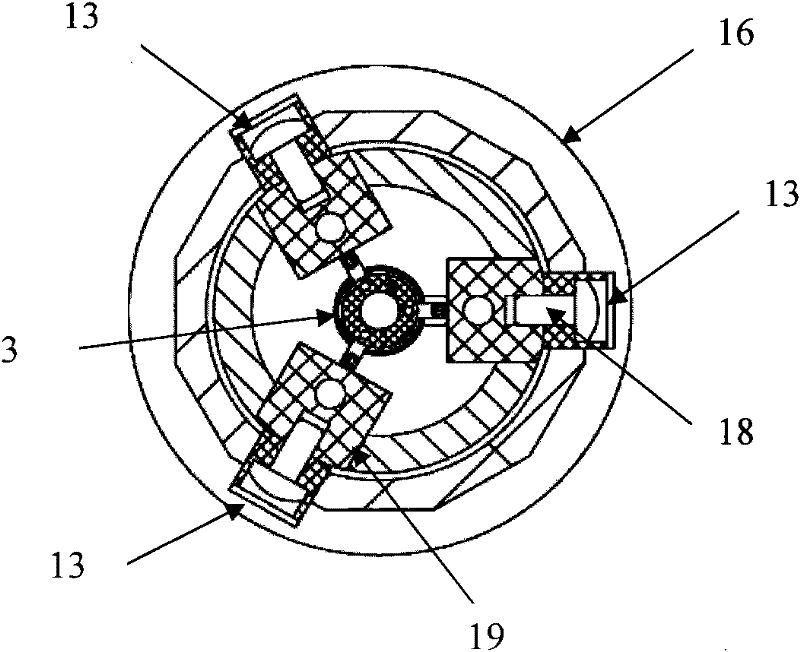

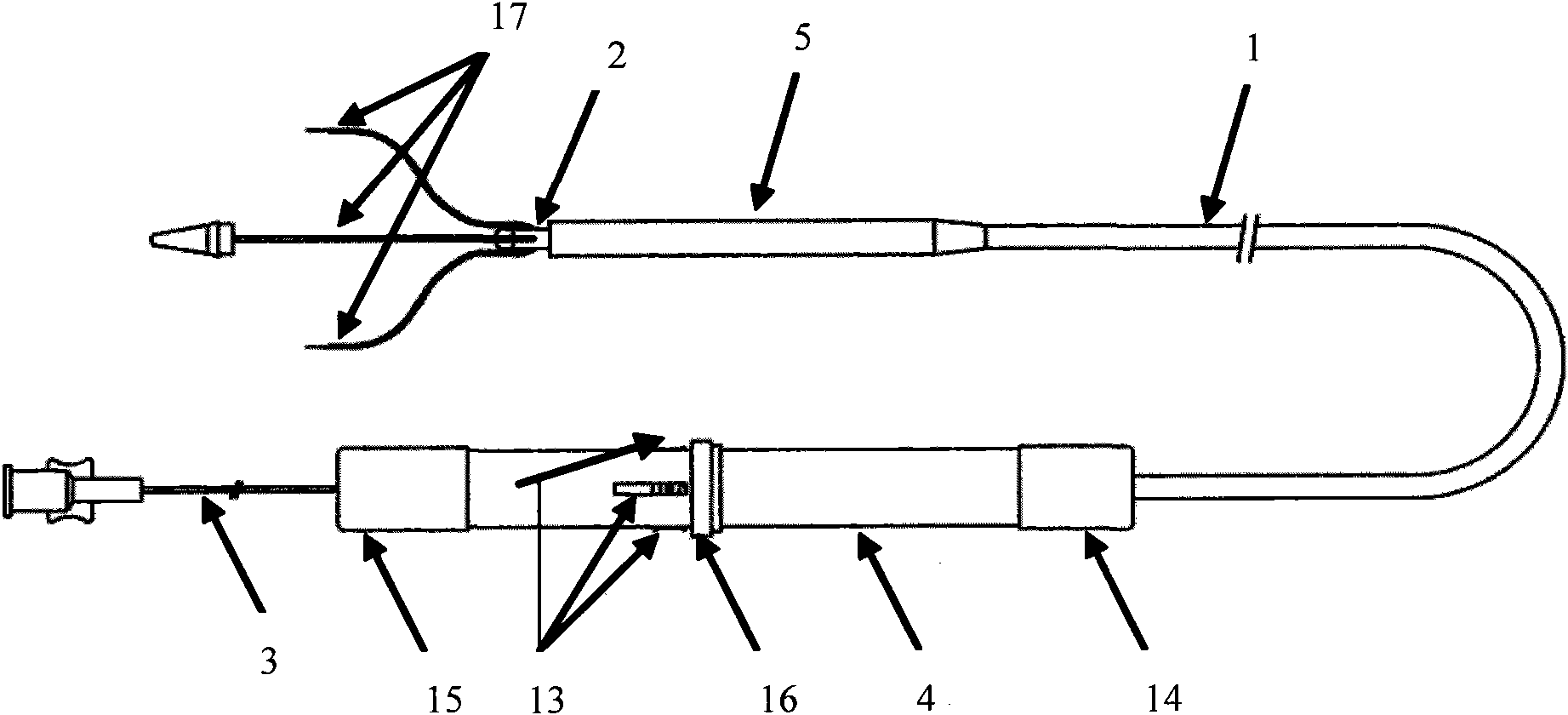

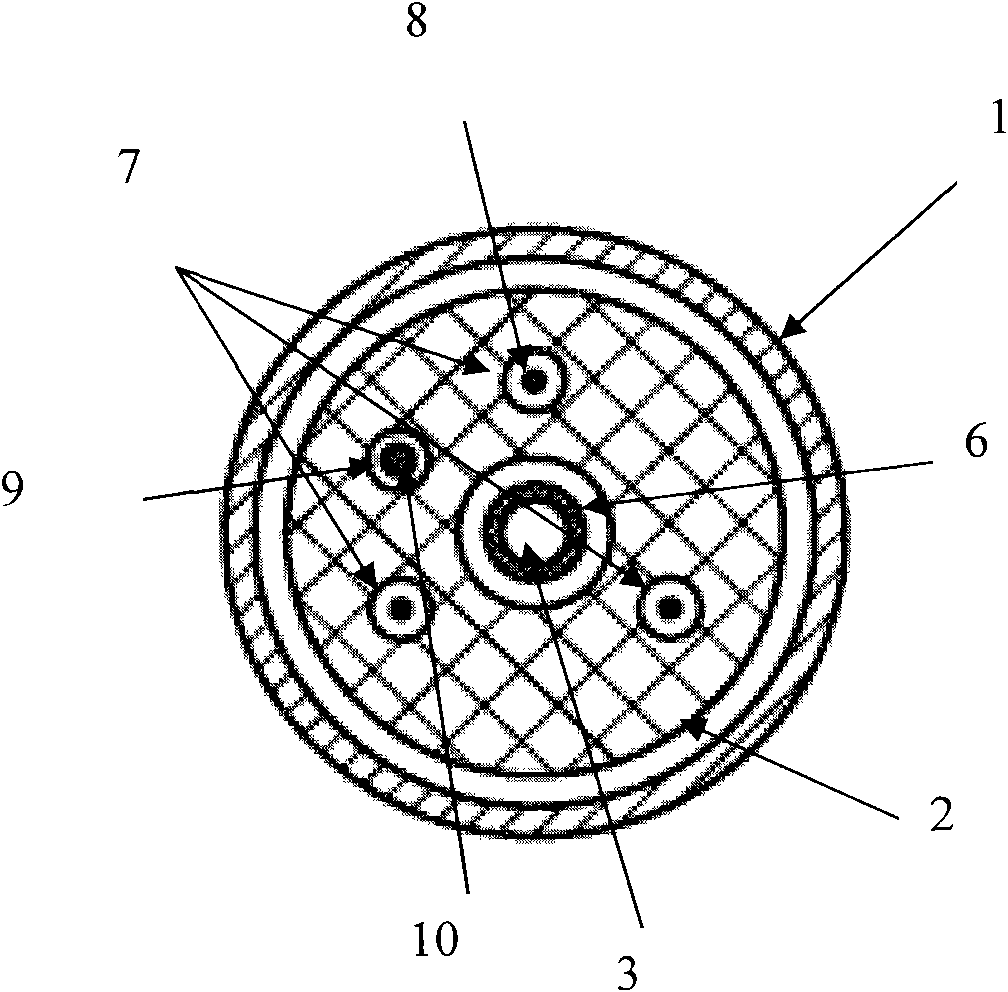

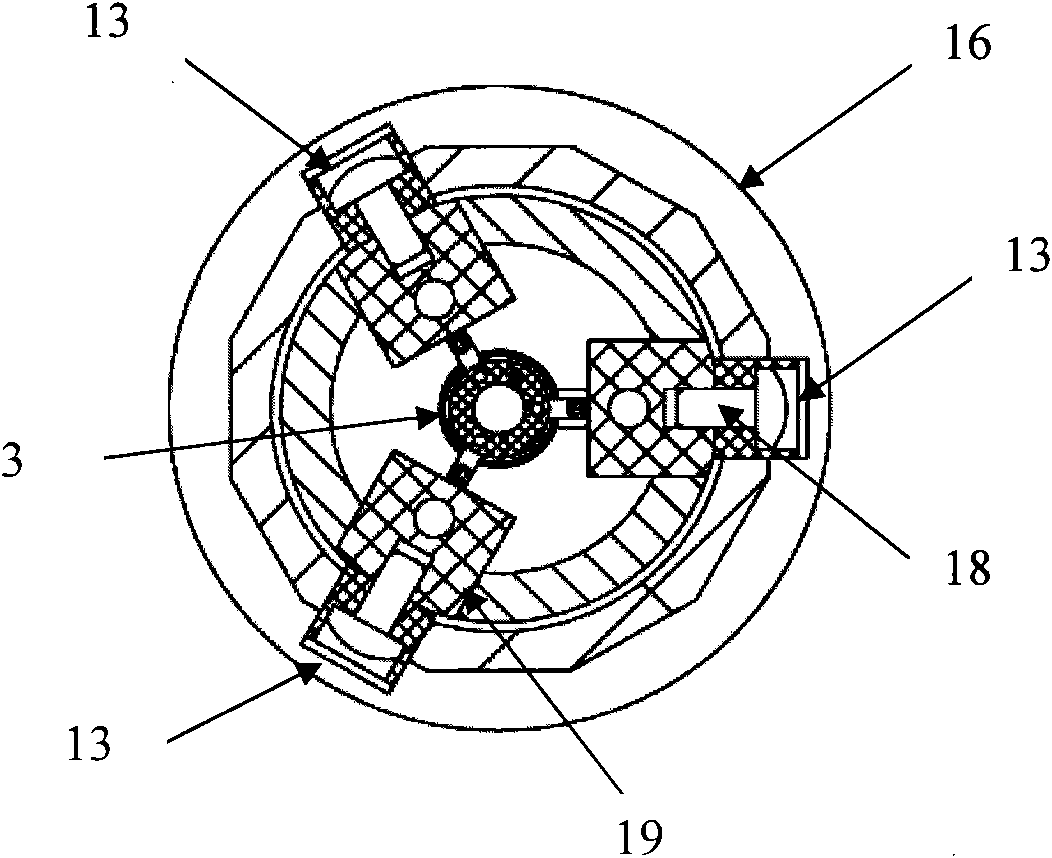

A heart valve delivery system and its delivery device

The embodiment of the invention discloses a delivery device, which comprises an outer delivery tube, a push rod, an inner tube, a functional handle and a plurality of connecting tubes, wherein one end of each connecting tube is connected with the push rod; the tube cavities of the connecting tubes are communicated with a metal wire passage in the push rod; the other ends of the connecting tubes are provided with connecting grooves; and the connecting grooves are communicated with the tube cavities of the connecting tubes. The connecting grooves are used for connecting the connecting port of a heart valve and the connecting tubes, and metal wires pass through the connecting port and are kept in the tube cavities of the connecting tubes, so that the metal wires are connected with the heart valve. The heart valve is fixed through the metal wires and the connecting grooves; when the heart valve is released, the metal wires must be extracted from the connecting grooves to finish release of the heart valve; therefore, before the heart valve is totally separated from the delivery device, the delivery device can be connected with the heart valve and can reclaim and reset the heart valve. The invention also discloses a heart valve delivery system.

Owner:SHANGHAI MICROPORT CARDIOFLOW MEDTECH CO LTD

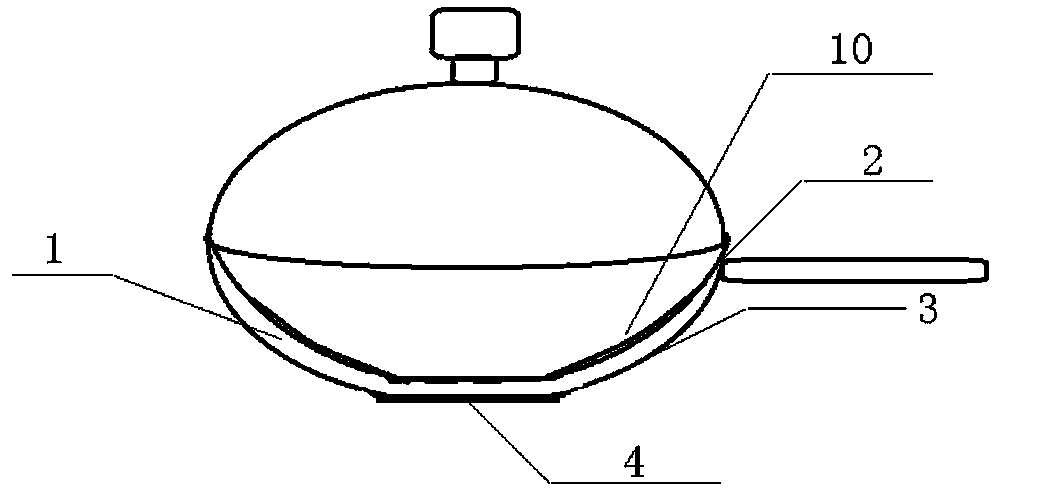

Novel composite cooker and manufacturing method thereof

The invention provides a novel composite cooker which comprises a cooker body with the thickness of 1.5 mm-5.0 mm. The thickness of the cooker wall is successively and progressively decreased by the 2 mm-3 mm space from the upper portion of the plane of a cooker bottom to the edge of the cooker wall. The cooker body comprises an inner layer cooker body and an outer layer cooker body, the inner layer cooker body is made of one of iron, iron-base alloy, stainless steel, titanium and titanium alloy, the outer layer cooker body is made of aluminum alloy or pure aluminum or AZ31B magnesium alloy or magnesium alloy, and a magnetic conduction energy storage layer is pressed on the outer surface of the outer layer cooker body. The materials of the inner surface of the cooker is healthful and sanitary, the heat conduction performance of the outer surface of the cooker is good, the outer surface is light in material, the magnetic conduction energy storage layer is arranged on the outer portion of the cooker bottom, the heat collection effect of the cooker bottom is increased, cooking energy consumption is reduced, and the application range of the cooker is expanded. The invention further provides a manufacturing method of the novel composite cooker. The method is easy to operate, saves materials, reduces cost, and is convenient to implement and beneficial to industrialization of the novel composite cooker.

Owner:WUYI RUIPU KITCHENWARE CO LTD

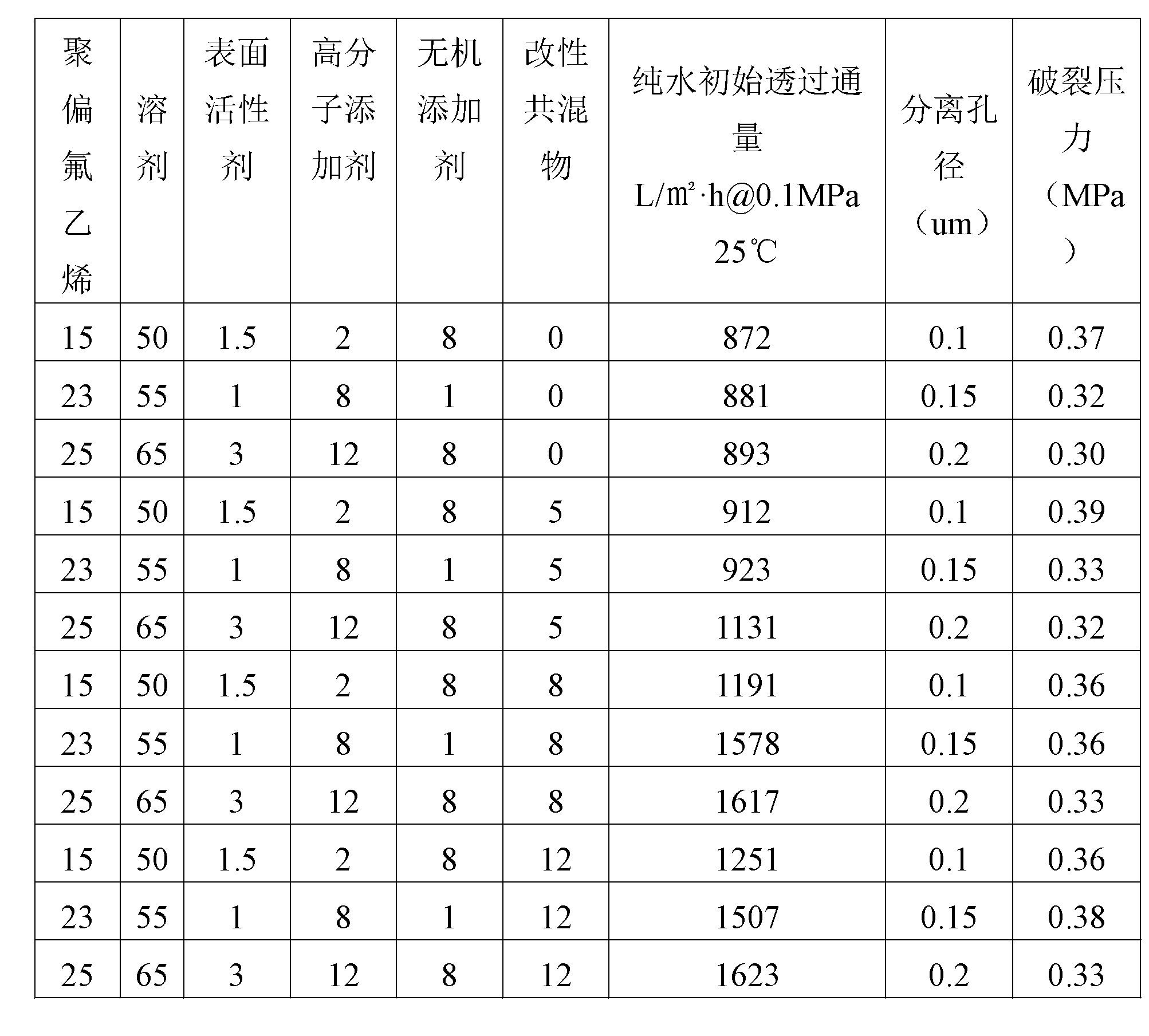

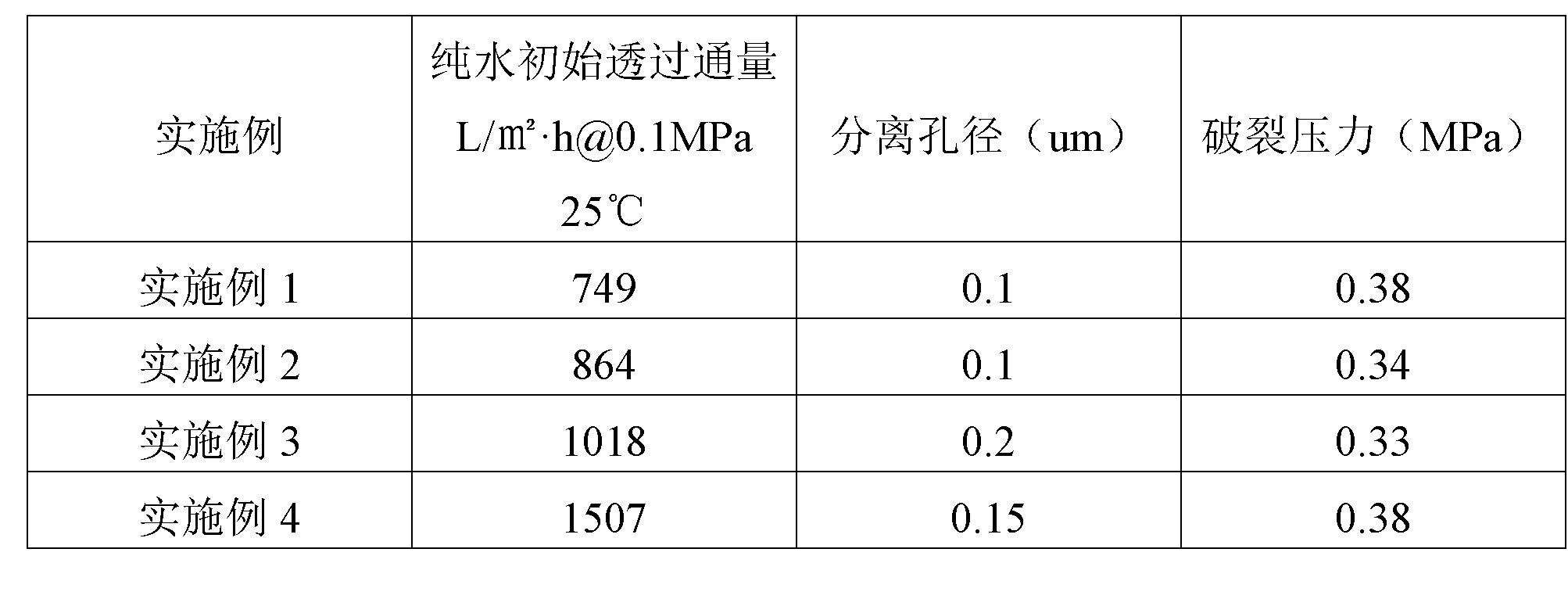

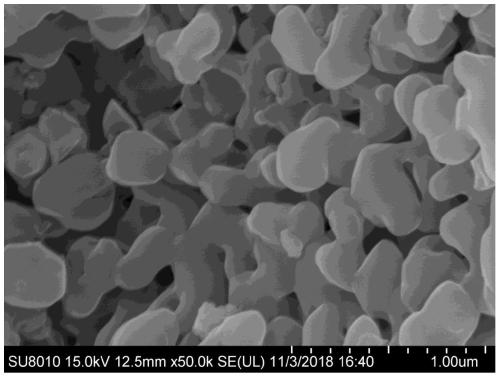

Polyvinylidene-fluoride hollow fibre membrane and preparation method thereof

InactiveCN102836645AEasy extractionPrevent shrinkage deformationSemi-permeable membranesHollow filament manufactureFiberHollow fibre membrane

The invention discloses a polyvinylidene-fluoride hollow fibre membrane and a preparation method thereof. Calculated according to parts by weight, the polyvinylidene-fluoride hollow fibre membrane is mainly prepared by the following components: 15 to 25 parts of polyvinylidene fluoride, 50 to 80 parts of solvent, 1 to 3 parts of surfactant, 2 to 12 parts of polymeric additive, 1 to 8 parts of inorganic additive and 1 to 12 parts of modified blend. By utilizing the simultaneous action of two modes of organic blending and inorganic adding according to the polyvinylidene-fluoride hollow fibre membrane and the preparation method thereof, the hydrophilcity of the polyvinylidene-fluoride hollow fibre membrane is obviously improved, and the pollution resistance can be obviously reinforced; and the pure water flux of the polyvinylidene-fluoride hollow fibre membrane is further enhanced by selecting and regulating the raw materials and the mixture ratio of the modified blend and the inorganic additive so as to obtain the permanently hydrophilic modified polyvinylidene-fluoride hollow fibre membrane.

Owner:CHINA HUADIAN ENG

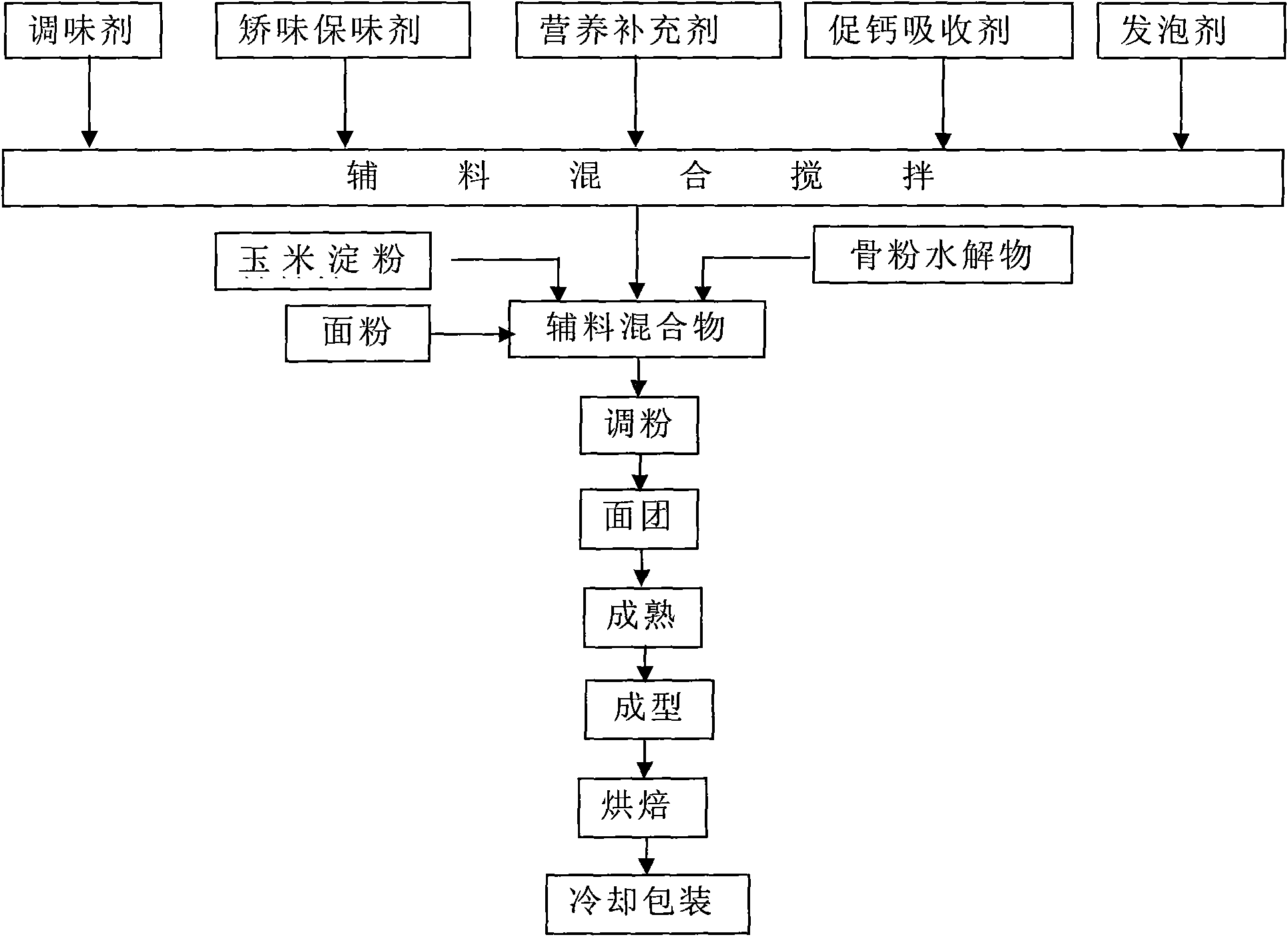

Nutritional biscuit with high bone calcium and making method thereof

InactiveCN101606545AIt has the effect of correcting and preserving flavorImprove and improve organizational structureDough treatmentBakery productsFlavorFoaming agent

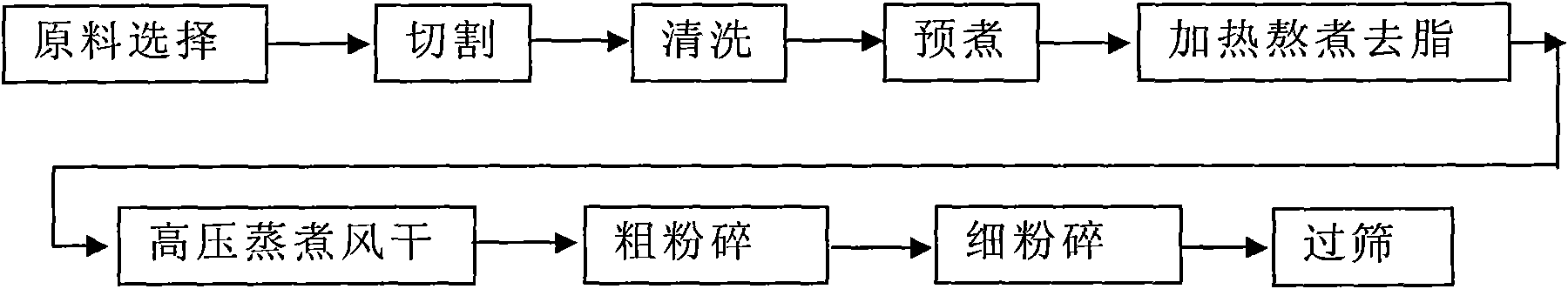

The invention relates to a nutritional biscuit with high bone calcium and a making method thereof, belonging to a processing and making technique of foods required by the life of human beings. The nutritional biscuit is formed by preparing and processing the following raw materials according to a certain proportion formula and a certain production technology and comprises the following raw materials according to the formula and the mixture ratio: 950g of flour, 50g of corn starch, 350g to 450g of cattle bone powder hydrolyzing substance, 240g to 260g of flavoring agent, 140g to 160g of flavoring taste-retaining agent, 280g to 300g of nutritional extender, 80g to 100g of calcium absorption promoter, 6g to 8g of foaming agent and 1ml of butter essence. The product contains high effective calcium and abundant nutrition, the color of the surface of the biscuit is bright, and the biscuit has a deep red brown color, has the special flavor of bone, is soft, savory and crisp and has no peculiar odor. The processing procedure of the invention is shown as the attached drawing of the abstract.

Owner:GUIZHOU UNIV

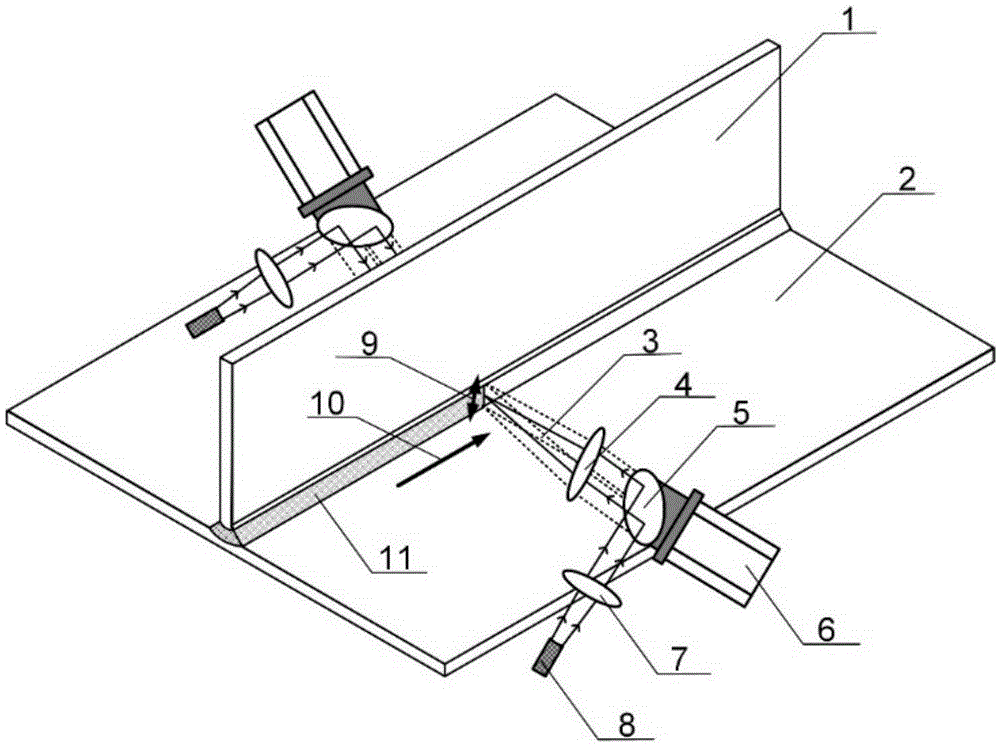

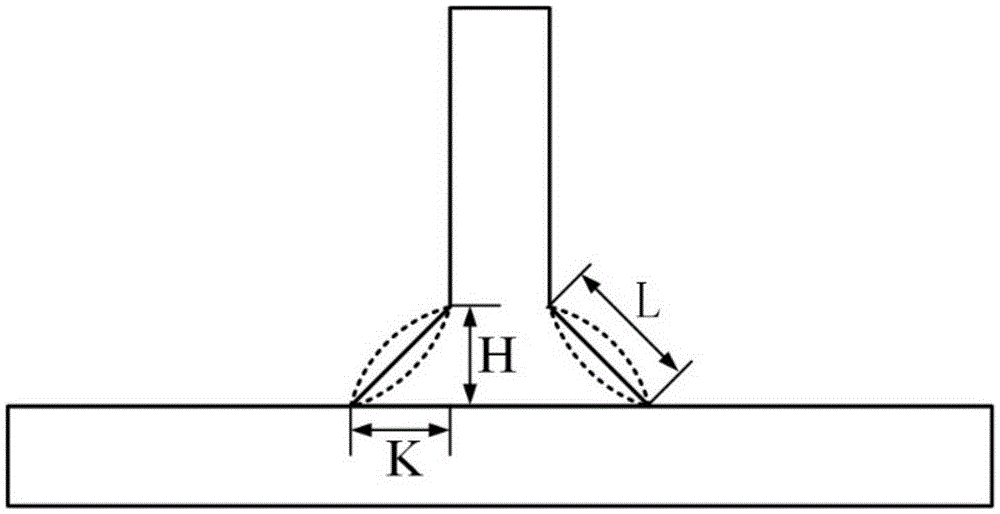

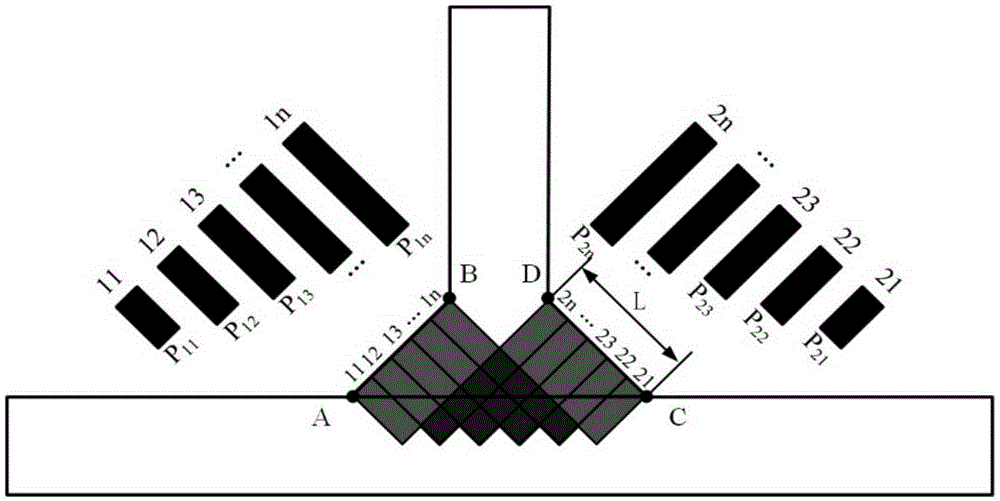

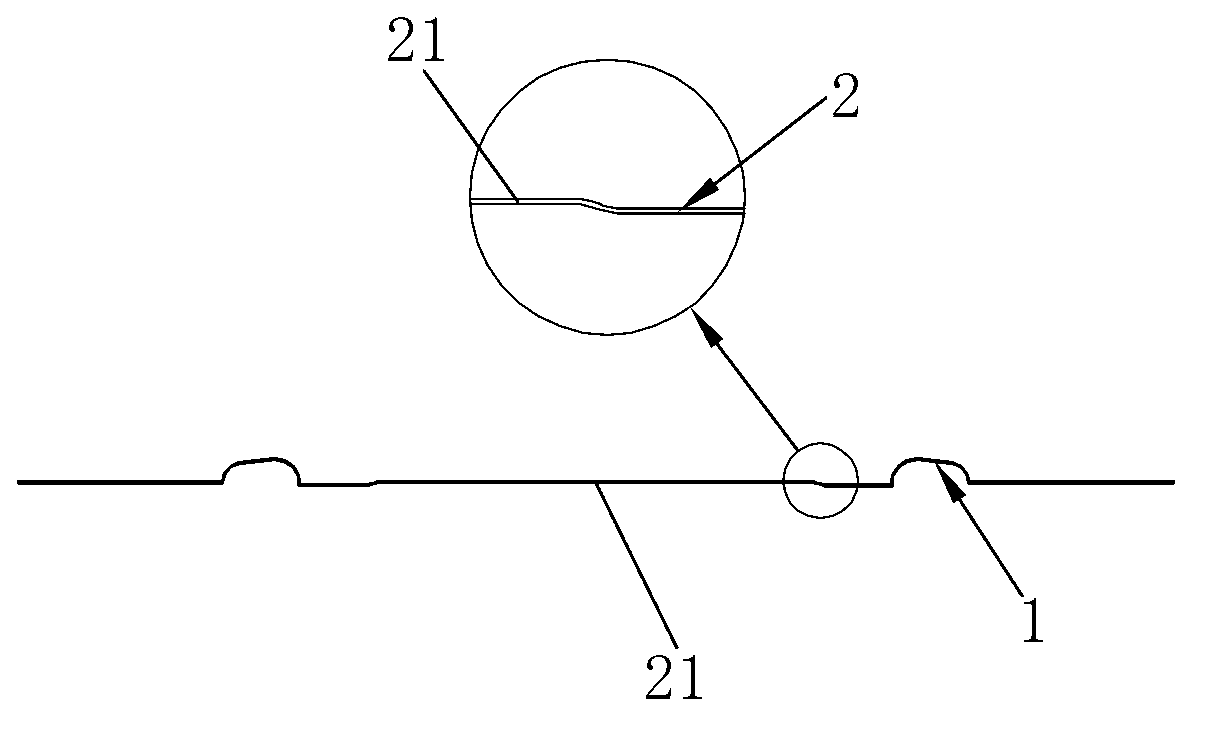

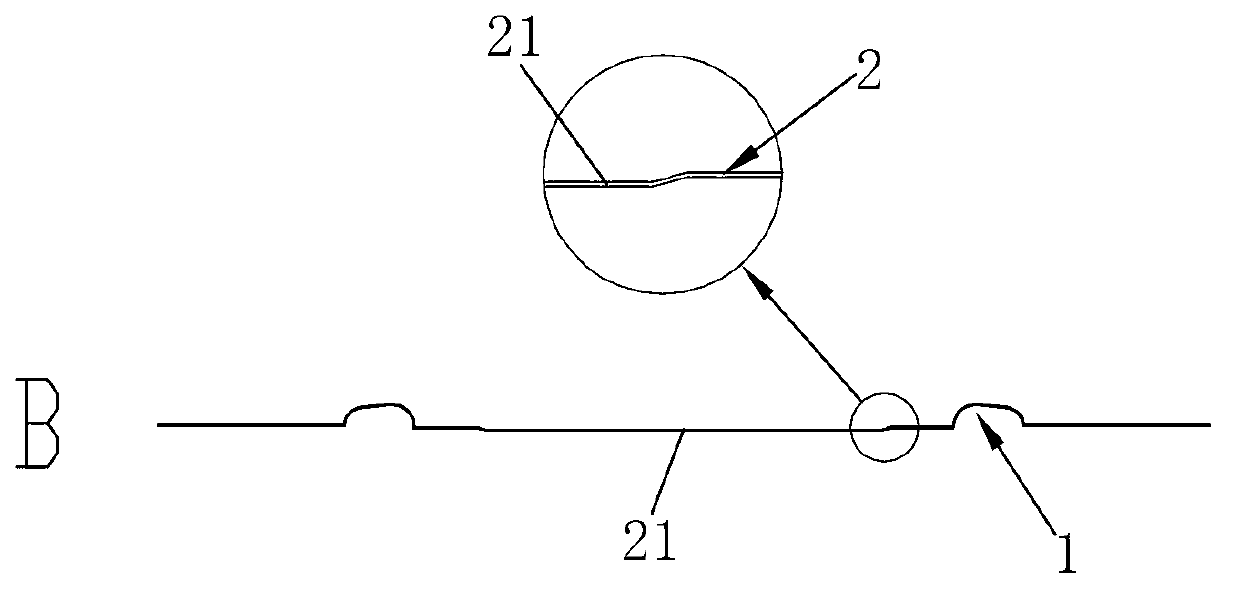

Bilateral laser scanning and welding method of T-shaped connector

InactiveCN105382411AEasy to weld throughEasy to installLaser beam welding apparatusThick plateLaser scanning

The invention provides a bilateral laser scanning and welding method of a T-shaped connector, belongs to the technical field of laser machining, particularly relates to a laser welding method of the T-shaped connector and aims to solve the problems that in the thick plate welding process, it is difficult to conduct wire filling, and molten drop transition is not stable. The bilateral laser scanning and welding method includes the steps that 1, the size K / H of a welding pin is determined; 2, a purlin vertical plate is machined; 3, mounting and positioning are conducted; 4, bilateral laser scanning and welding are conducted. By means of the method, high-frequency swing in different scanning width ranges is achieved through laser beams of a laser scanning system, the size of laser power required at different positions in the ranges can be accurately adjusted, approximate continuous adjustment of the size of the laser beam power is achieved, energy of laser beams can be reasonably distributed and utilized, adaptability of laser to T-shaped connectors of different sizes is improved, and the application field of the laser welding technology is broadened.

Owner:HARBIN INST OF TECH

Nutritious sweet potato biscuit and its production process

InactiveCN1973677AStronger bond strengthAdd flavorDough treatmentDigestive systemNutritive valuesFiber

The present invention is nutritious sweet potato biscuit and its production process. Sweet potato powder in 50-100 weight portions, sugar powder in 30-50 weight portions, palm oil in 20-40 weight portions, flour in 50-150 weight portions, starch in 10-15 weight portions, maltose in 2-4 weight portions, ammonium bicarbonate in 2-4 weight portions and water in 4-12 weight portions are mixed through stirring to form dough; the dough is pressed to form; and the formed biscuit blank is low temperature roasted to produce the nutritious sweet potato biscuit. The nutritious sweet potato biscuit has the features of high nutritious value, high fiber content and easy digestion.

Owner:SHANDONG ZHENGHANG FOODSTUFF

Color protection and combined drying method of apple chips

InactiveCN101991070AKeep the original color and tasteLess nutrient lossFood preparationSulfurEngineering

The invention relates to a color protection and a combined drying method of apple chips, which comprises the following steps of: peeling, denucleating and slicing apples; immediately placing the sliced apples into sulfur-free color protection liquid; cleaning the apple slices after being subject to the color protection fixing by clean water; paving and placing the apple slices into a disc to be sent into a hot air drying box for being dried; carrying out vacuum low-temperature drying after the hot air drying is completed; and encapsulating the dried and checked apple chips to complete the production of the apple chips. The invention belongs to the combined drying process of the apple chips, which prepares the sulfur-free color protection liquid of the apple chips according to the browning prevention mechanism of the apple chips and the characteristics of the water losing process of the apple slices, and combines the hot air drying with the vacuum low-temperature drying technology. The sulfur-free color protection liquid of the invention effectively prevents the browning of the apple slices and the shrinkage strain in the drying process, greatly reserves the original color and original taste of the apples, and realizes the sulfur-free color protection. The invention combines the hot air drying and the vacuum low-temperature drying, reduces the drying energy consumption and improves the drying efficiency, the produced apple chips have low nutrient loss, and the invention has the advantages of health and environment protection.

Owner:SHAANXI UNIV OF SCI & TECH

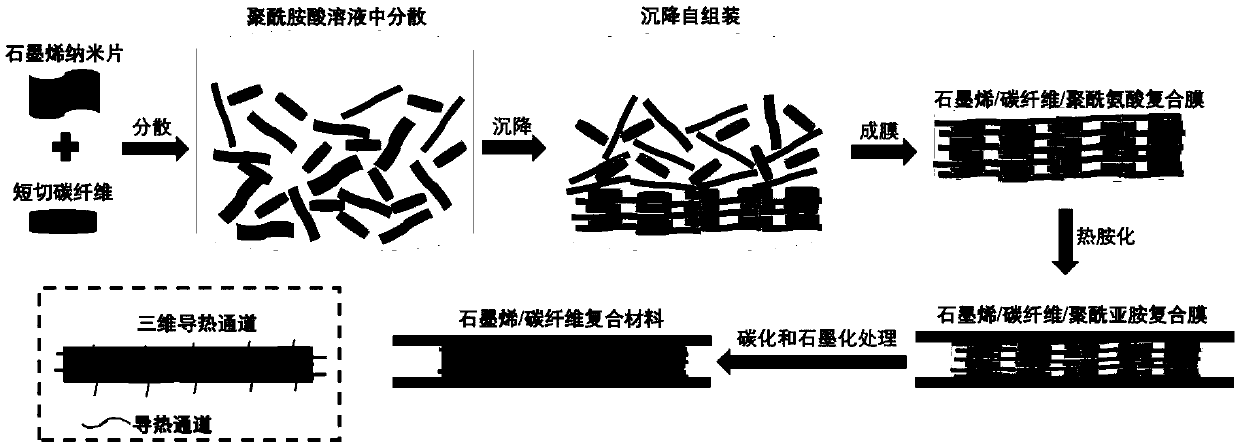

Preparation method of high-heat-conductive graphene/chopped carbon fiber composite material

The invention discloses a preparation method of a high-heat-conductive graphene / chopped carbon fiber composite material. By means of high heat-conductivity of graphene in in-plane direction and high heat-conductivity of carbon fibers in axial direction, the graphene layer and the chopped carbon fibers are subjected to deposition molding in a liquid phase, and by means of adhesion effect of polyimide, the carbon fibers and graphene are connected, and finally, through carbonization and graphitization, the polyimide is converted into graphene, thus manufacturing the whole-carbon high-heat-conductive composite material. A conventional graphene material has ultrahigh heat conductivity in horizontal plane due to the two-dimensional structure of graphene but is poor in heat conductivity since thegraphene is lack in heat conductive path in thickness direction; therefore, by means of the axial high heat-conductivity, the high heat-conductive paths are formed between the graphene layers, so that the heat-conductivity of the material in thickness direction is vertically improved, and the defect of poor heat conductivity in the thickness direction is overcome, thereby preparing the high-heat-conductive material.

Owner:TIANJIN UNIV

Nutritious plumule biscuit and its production process

InactiveCN1973634AHigh nutritional valuePromote peristalsisDough treatmentBakery productsFermentationChemistry

The nutritious plumule biscuit and its production process belong to the field of food producing technology. The nutritious plumule biscuit is produced with wheat plumule powder, flour, starch, sugar powder, ammonium bicarbonate, water, palm oil and compound enzyme preparation, and through mixing the materials, fermentation and roasting. The present invention replaces enzyme preparation for food level sodium metabisulfite, and adopts low temperature roasting, laminating and short fermentation time. The nutritious plumule biscuit has less damping, less breaking and long shelf life.

Owner:SHANDONG ZHENGHANG FOODSTUFF

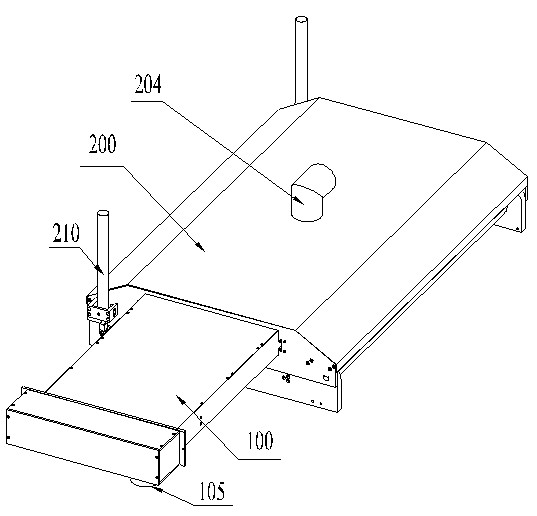

Printer

InactiveCN102632700APrevent shrinkage deformationAvoid crackingPrinting press partsSolvent moleculeGas phase

The invention discloses a printer, comprising a printer body and a radiating drier, wherein the radiating drier comprises a box body device in which the material to be dried can be put and a radiating device which is internally embedded into the box body device and used for garneting radiation, and the radiating device is internally provided with a launcher capable of generating electromagnetic wave. When the electromagnetic wave generated by the launcher is irradiated on the material to be dried, the solvent molecules in the material to be dried repeatedly steer and move under the repeated alternating magnetization of an electric field and a magnetic field, so that the high-speed vibration is formed, the kinetic energy is increased, and the heat energy is sequentially increased; finally, the solvent molecules are heated to leave from the surface of the material to be dried to enter gas phase, so that the effect of material drying can be achieved; and the protective gas is charged in the process of drying, so that the material to be dried can not be oxidized, burnt, exploded and the like when the material is dried.

Owner:GUANGDONG NEW UVI PRINTING EQUIP & TECH CO LTD

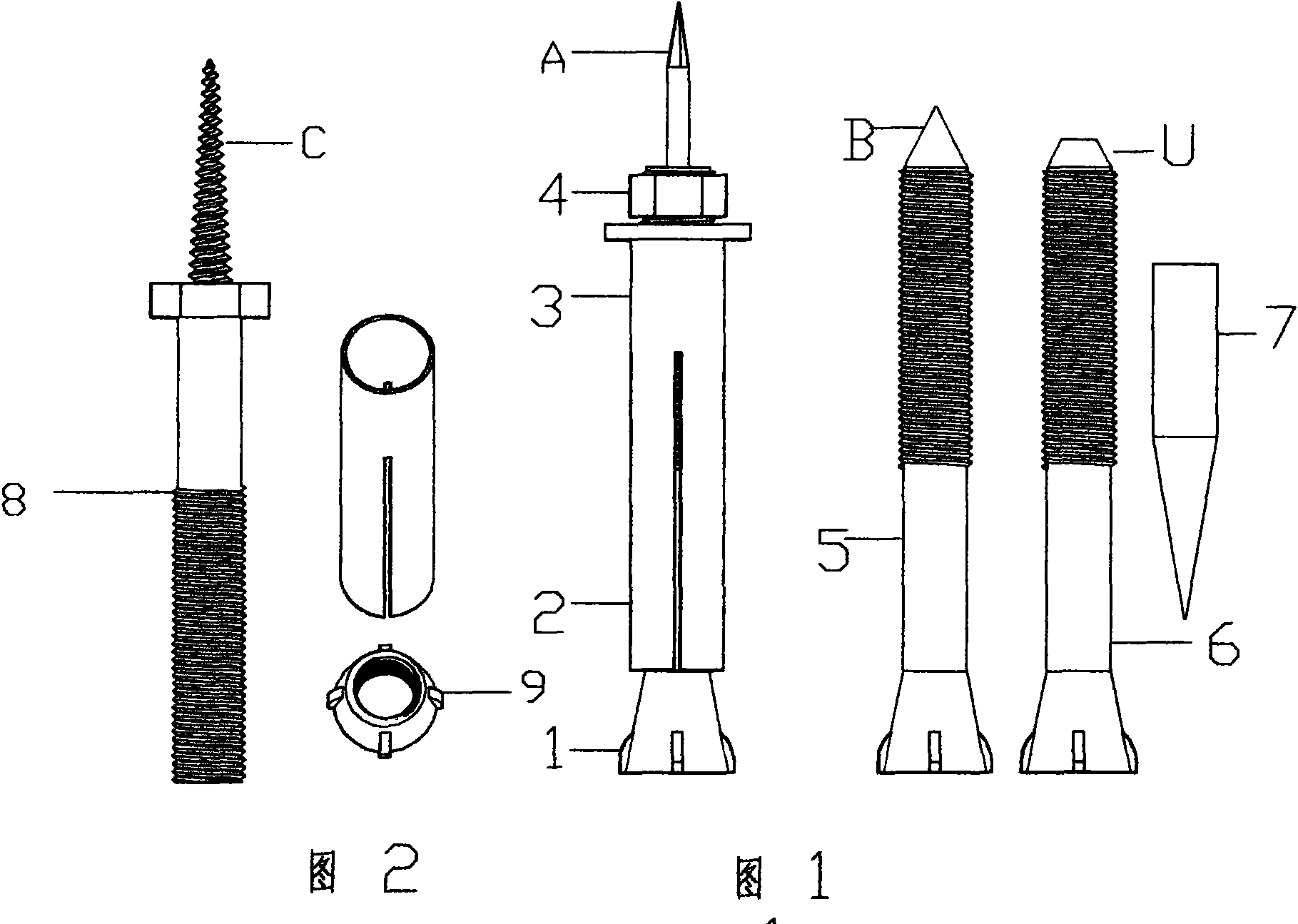

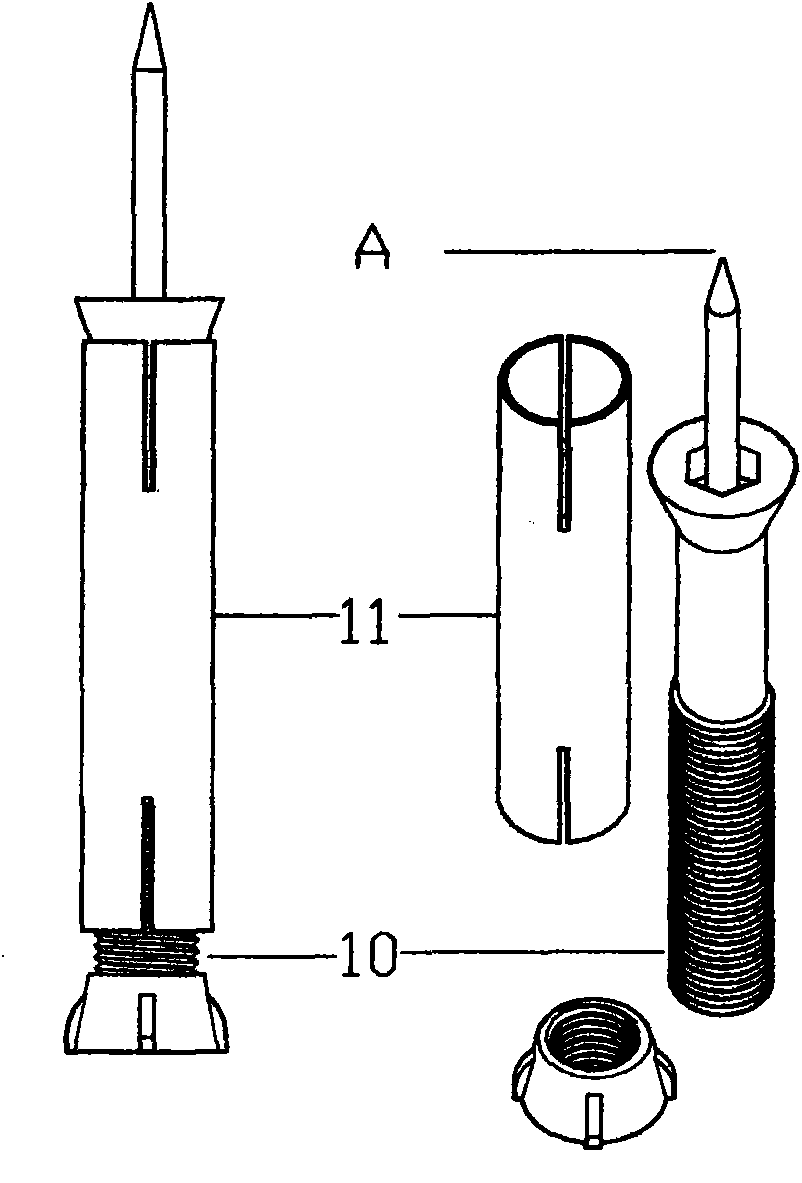

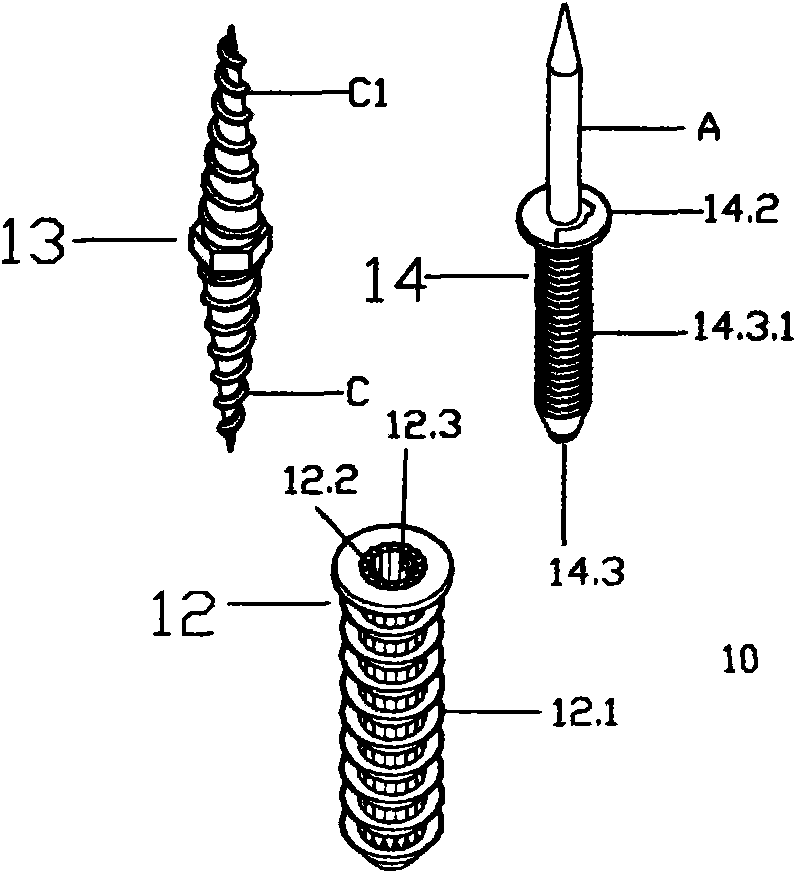

Method for installing door/window cover, matched tool, fitting and door/window cover

The invention provides a method for installing a door / window cover, a matched tool, a fitting and the door / window cover. The invention is characterized in that the method adopts an expansion bolt with a nail or a screw nail, a dowel and a connecting piece component, and comprises the steps of arranging a support bar and a glue groove on the door / window cover and a wall, tightly blocking by a wedge, injecting foaming glue and the like; and the invention provides the door / window frame cover with a support bracket, a perpendicularity disc, a chamfer clamp, an expansion bolt with a nail or a screw nail, a dowel, a support bar, a glue groove, a wedge, a connecting piece, a hasp with a connecting piece, a glue groove and a support bar. The invention has the advantages of being firm in installation, improving the work efficiency, saving the glue, improving moisture-proof, sound-proof and heat-preserving effects, and prolonging the service life of the door / window cover.

Owner:徐一鸣

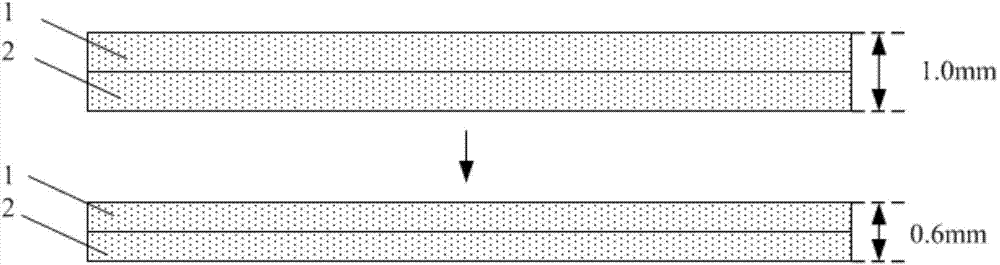

Display panel, manufacturing method thereof and display device

InactiveCN104849900AControl Thinning ThicknessIncreasing the thicknessLamination ancillary operationsLayered product treatmentDisplay deviceEngineering

The invention belongs to the technical field of display, and particularly relates to a display panel, a manufacturing method thereof and a display device. The display panel comprises a first substrate and is divided into a display area and a non-display area, and the non-display area of the first substrate comprises an IC attaching area. The manufacturing method includes the step of thinning. The manufacturing method is characterized in that the step of thinning includes: 1), forming a barrier layer insoluble in thinning liquid in an area, corresponding to the IC attaching area, of the first surface of the first substrate of the display panel; 2), adopting the thinning liquid to thin the display panel to enable thickness of the IC attaching area of the first substrate to be larger than that of the display area; 3), removing the barrier layer. Zones, different in thickness, of the display panel are formed through local thinning, suitability of attaching of a driving IC is realized while strength of the display panel is guaranteed, and thinning of the display panel is realized; thickness of the display area of the display panel is guaranteed, so that light leakage and bad COG Mura effect are avoided.

Owner:BOE TECH GRP CO LTD +1

Production process of high-strength wear-resisting shaped activated carbon

The invention discloses a production process of high-strength wear-resisting shaped activated carbon. The production process comprises the following steps of: uniformly mixing carbon powder, a bonding agent and a nucleating agent and feeding into an extruder to be extruded and palletized; subsequently feeding the prepared grains into a carbonizing and activating furnace to be carbonized and activated; raising the temperature of the furnace to be at 500-550 DEG C and subsequently adding a composite activating agent; further continuously raising the temperature to be at 650-750 DEG C and keeping the temperature constantly; further raising the temperature to be at 950-1,000 DEG C and keeping the temperature constantly; after the carbonization and activation is accomplished, cooling the hearth to be at about 500 DEG C and stopping introducing the composite activating agent; and introducing nitrogen, cooling in air to be less than 100 DEG C and discharging so as to obtain a finished product. The production process of the activated carbon, disclosed by the invention, has the characteristics that the process is short, the energy consumption is low, and the prepared product is large in specific surface area, high in strength and less in ash content; and the prepared granular carbon of expected shapes, such as a sphere shape or a cylinder shape, can be applied to special fields of liquid gas storage devices, toxic gas protection and the like.

Owner:BEIJING ZHONGSHIHONG INSTALLATION ENG

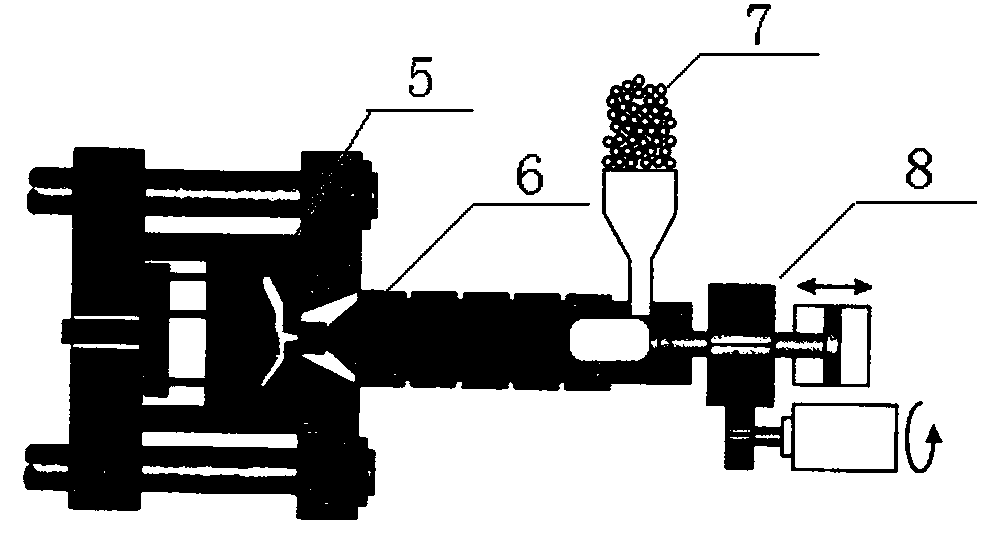

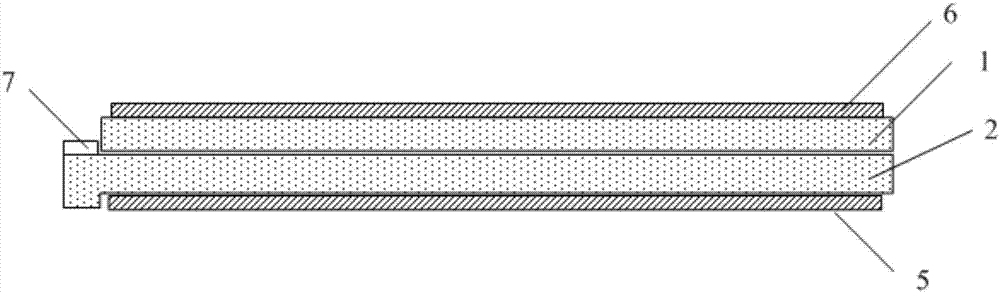

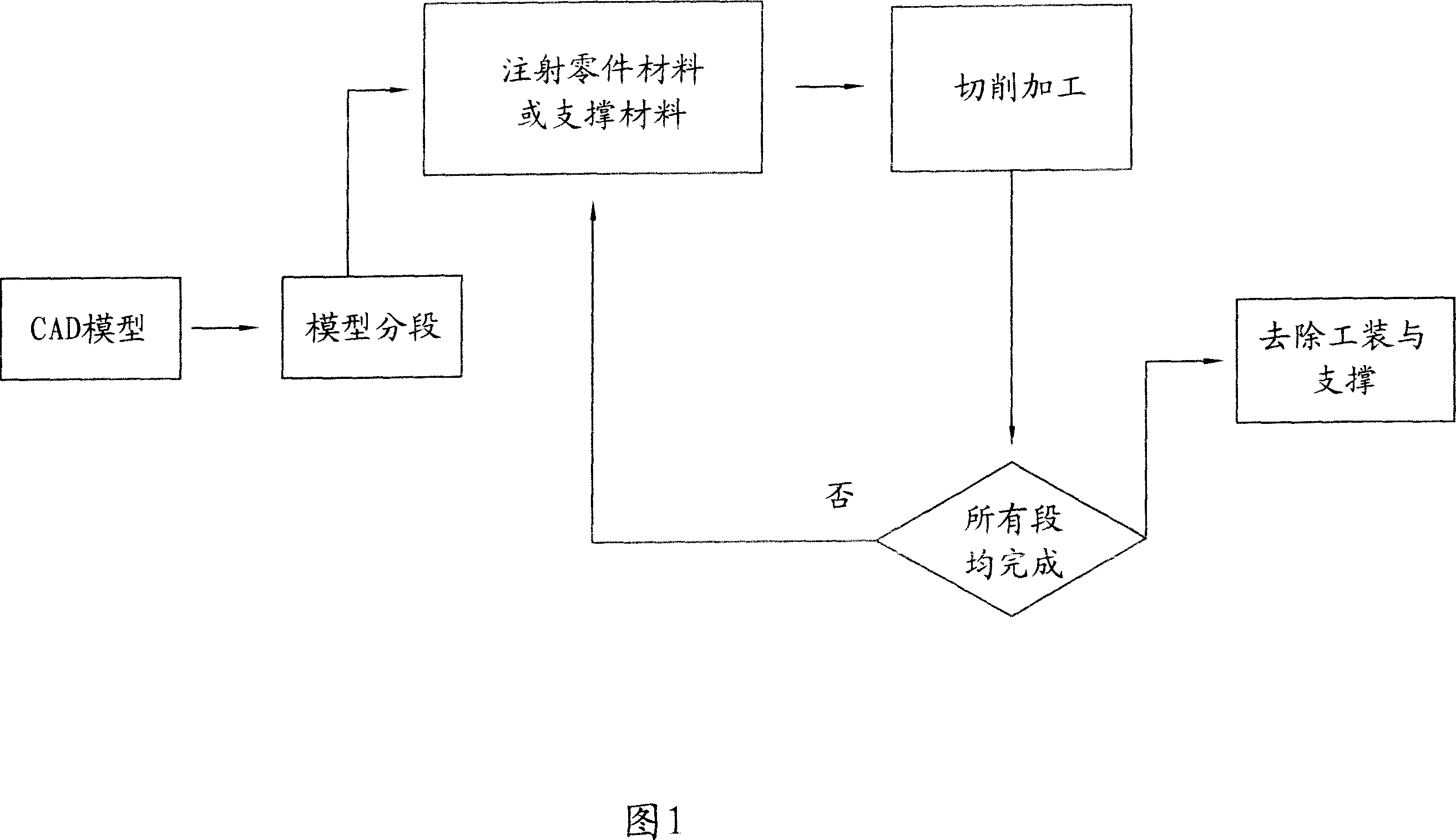

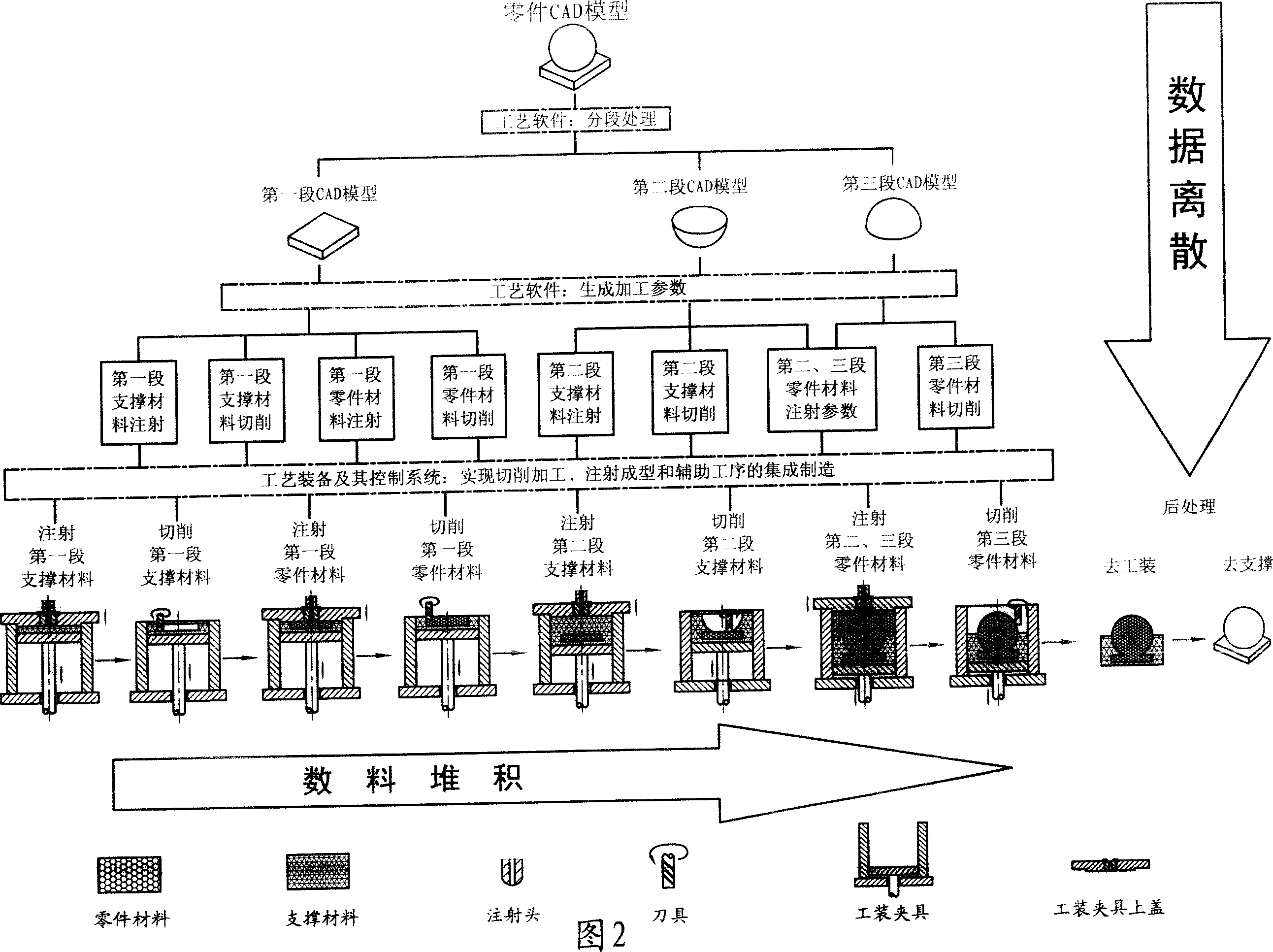

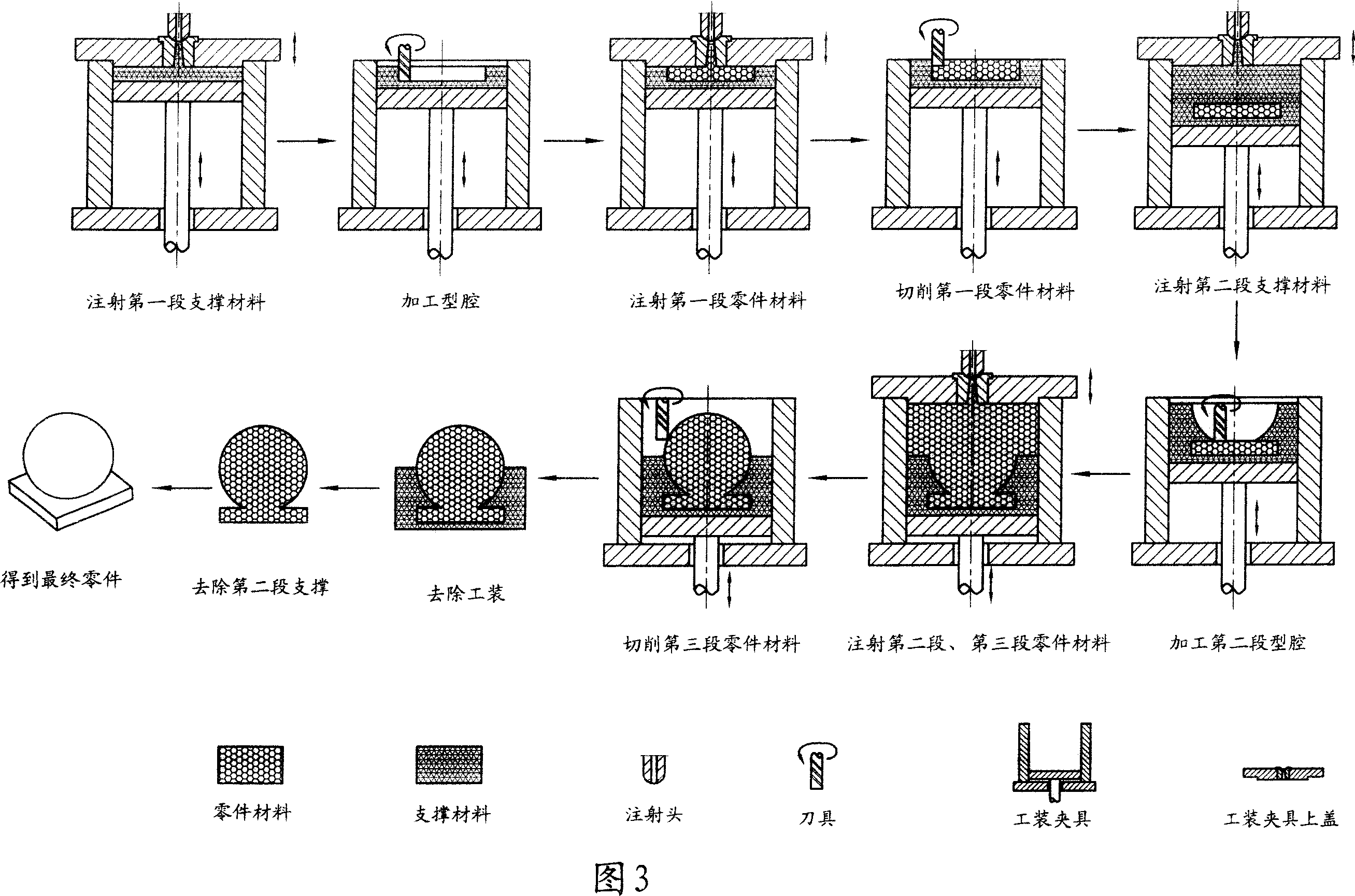

Stage injection/carving composite fast shaping technology

InactiveCN100999123AIncrease flexibilityImprove densification performanceProgramme controlComputer controlMaterial removalEngineering

The present invention discloses a sectional injection / carving combined quick forming process, it is a integrated combined forming process including material accumulation, material removal and material injection forming. Said invention provides the working principle of said sectional injection / carving combined quick forming process and its concrete operation steps. Said invention can be used for making any complex component, and making said component have high accuracy and surface quality.

Owner:HUAQIAO UNIVERSITY

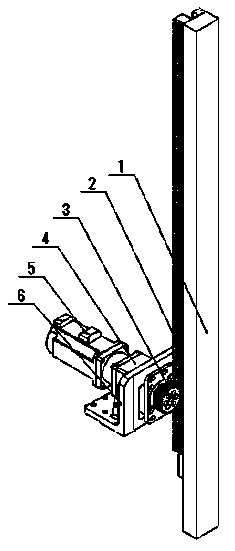

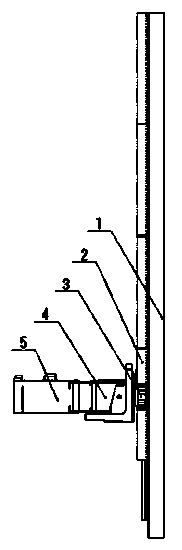

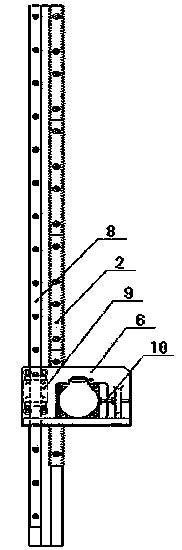

Plastic gear rack transmission device for mechanical arm

InactiveCN103522278ALow costSolve bulkyProgramme-controlled manipulatorReciprocating motionEngineering

A plastic gear rack transmission device for a mechanical arm is used for the reciprocating motion of a mechanical arm slide arm of a knockout machine. A motor is fixed to a speed reducer, a drive gear is in shaft connection with the speed reducer, the speed reducer is arranged on a speed reducer fixing plate, the speed reducer fixing plate is connected with a unit support, a guide rail is arranged on the left side face of the slide arm, sliding blocks are arranged on the unit support, the sliding blocks are fixedly locked with the guide rail, a plastic gear rack moulded in an injection mode is assembled parallel to the guide rail on the left side face of the slide arm, the plastic gear rack is of a two-side symmetric structure, the drive gear is meshed with the plastic gear rack, and the unit support is provided with an adjusting screw. The motor rotates to drive the drive gear to rotate, the drive gear rotates to drive the plastic gear rack to move, and each unit of the mechanical arm is made to carry out reciprocating motion under the matching action of a power device and a guide mechanism. Cost is greatly lowered, meanwhile, the defects that the mechanical arm of an existing knockout machine is heavy and high in transmission noise are overcome, and the plastic gear rack transmission device is simple in structure and production process, convenient to mount and maintain, light and low in transmission noise.

Owner:STAR SEIKI XIANGYANG

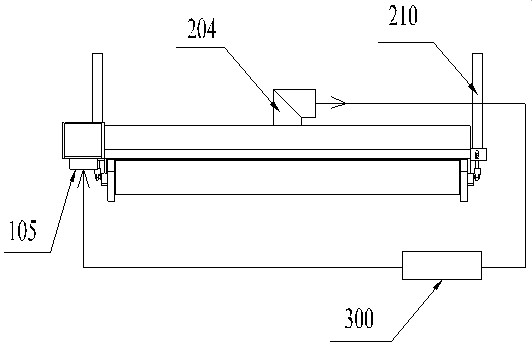

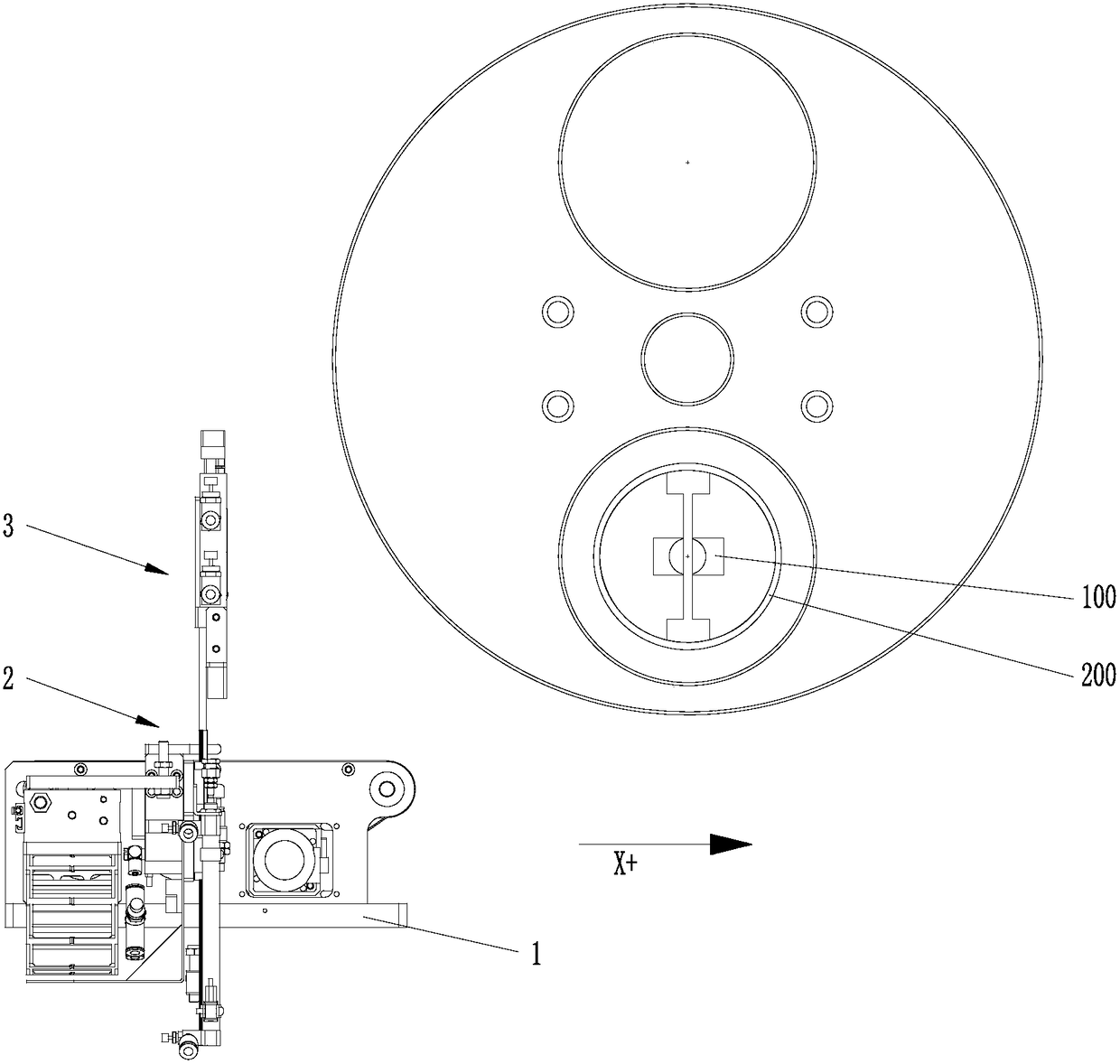

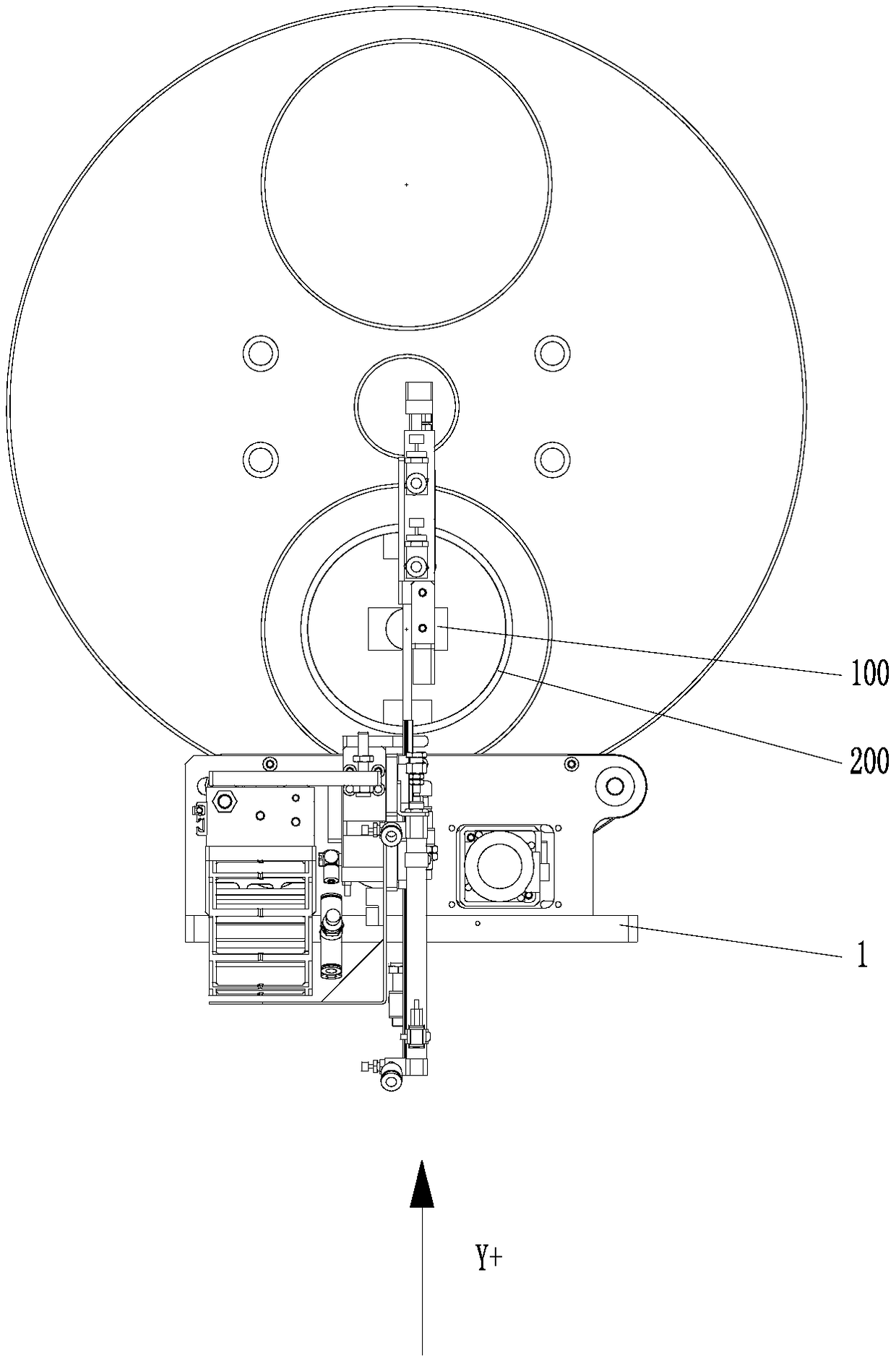

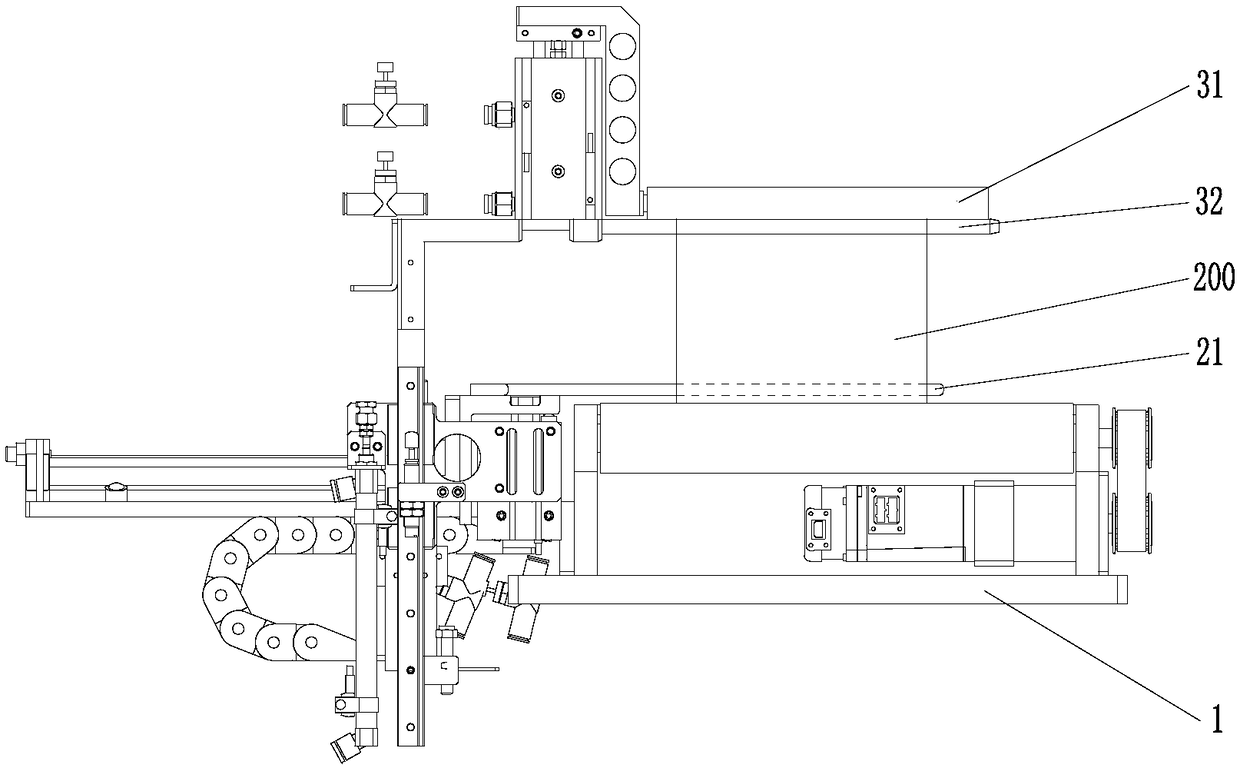

Device and method for discharging and forming cells

PendingCN108428923APrecise positioning controlPrevent shrinkage deformationAssembling battery machinesFinal product manufactureLocking mechanismPole piece

The invention discloses a device and a method for discharging and forming cells. A bare cell is wound on a winding needle. The device for discharging and forming the cells comprises a discharge movable platform and a locking mechanism. The locking mechanism is used for positioning the bare cell and comprises a lower positioning mechanism and an upper positioning mechanism, the lower positioning mechanism is used for positioning the lower portion of the inside of the bare cell, the upper positioning mechanism is used for positioning the upper portion, which is opposite to the lower portion, ofthe bare cell, and the upper positioning mechanism and the lower positioning mechanism are movably arranged on the discharge movable platform. The device and the method for discharging and forming thecells have the advantages that the device is simple in structure, the cells can be accurately positioned and controlled when automatically discharged, contraction deformation of the cells towards internal spaces of the cells can be prevented, accordingly, the purpose of controlling pole pieces to prevent displacement can be achieved, and the quality of the cells can be improved.

Owner:苏州迈展自动化科技有限公司

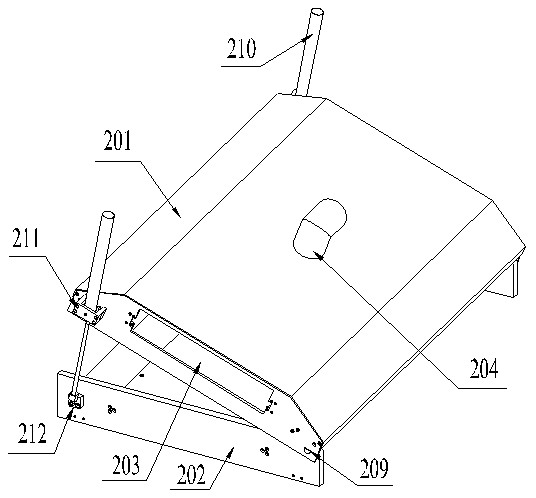

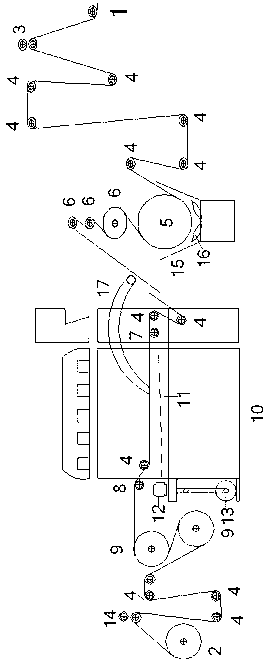

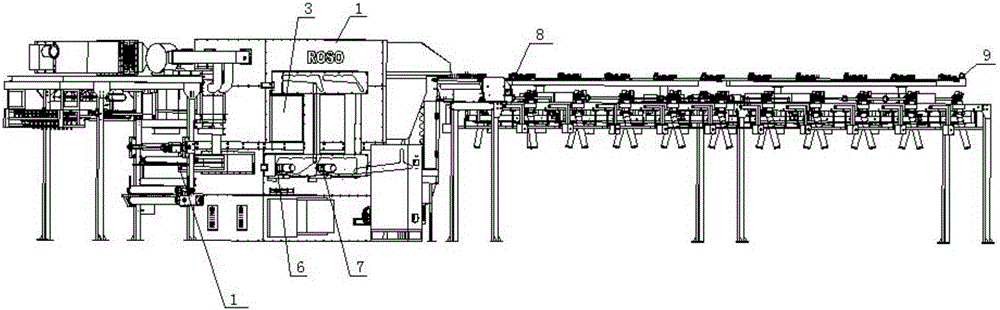

Production method of chemical fiber window screening and setting machine needed by same

InactiveCN103284577AReduce production process costsSimple processLiquid/gas/vapor removalTextile treatment machine arrangementsFiberPolyester

The invention relates to the production technology of a window screening, in particular to a production method of a chemical fiber window screening and a setting machine needed by the production method of the chemical fiber window screening. The production method of the chemical fiber window screening comprises the following steps that FDY polyester silk is used as base materials to be woven into screen cloth, and the FDY polyester silk is glued and colored and directly enters into a baking oven, and the FDY polyester silk is sized in a high-temperature amplitude-preserved mode in the baking oven and then the window screening is manufactured. The window screening is low in manufacturing technique cost, simple in technology, easy to operate, of a bi-directional structure of product mesh, directly coated and colored, solid and durable and colorful. According to the setting machine, screen cloth is under the action of traction wheels and tension rollers to enter into a material groove to be soaked, glued and colored and directly enter the baking oven, and high temperature setting is conducted on the screen cloth. The setting machine needed by the production method of the chemical fiber window screening is simple in operation and free of procedures of barrel throwing and dehydration, saves energy, and is pollution-free.

Owner:山东菏泽瑞莱博网业有限公司

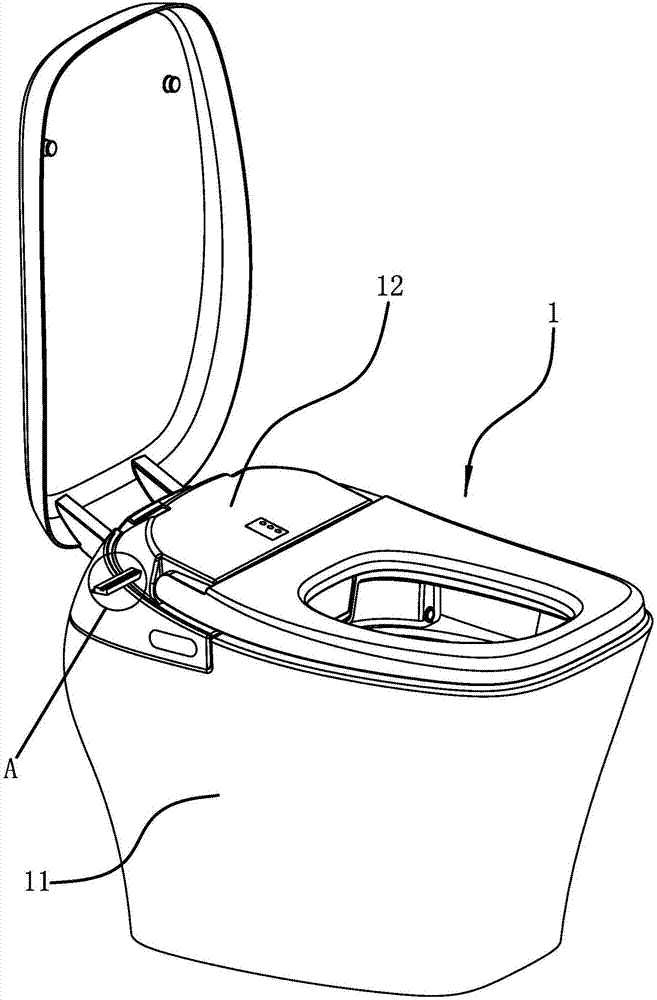

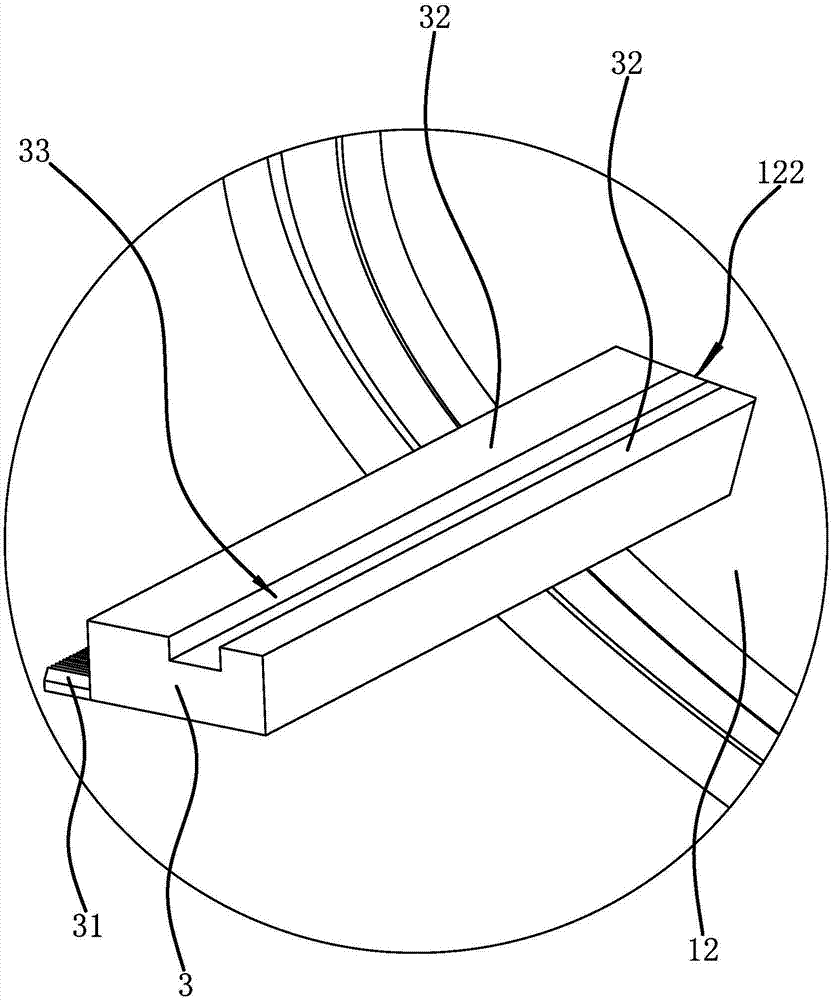

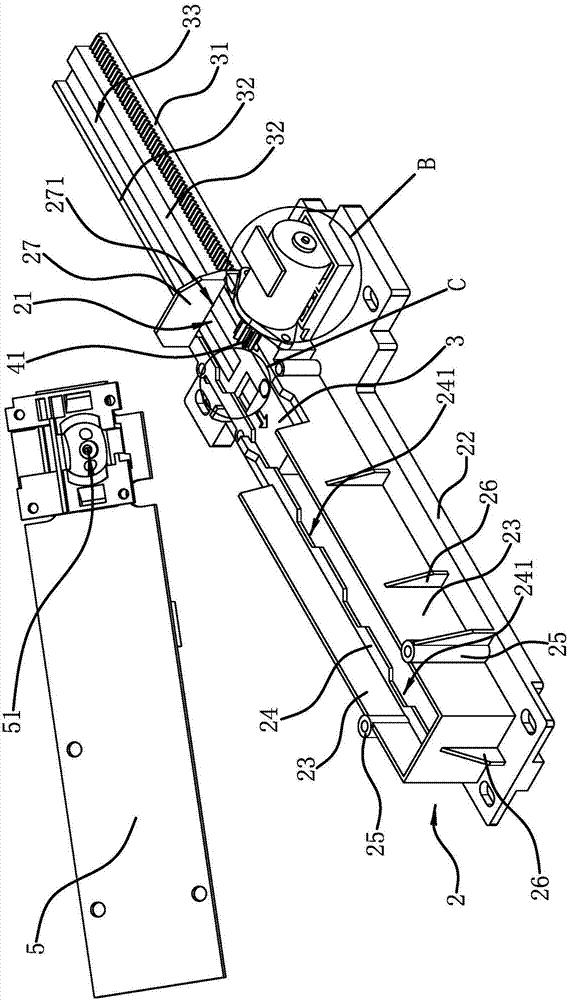

Urine detection device for intelligent closestool and use method of urine detection device

InactiveCN107237380AEasy to moveImprove detection accuracyLavatory sanitoryMaterial analysisPaper basedComputer science

The invention provides a urine detection device for an intelligent closestool and a use method of the urine detection device, and belongs to the technical field of intelligent closestools. By means of the urine detection device, the problems that an existing urine detection device for the intelligent closestool is poor in precision and inconvenient to use are solved. The urine detection device for the intelligent closestool comprises a shell, a urine analysis probe is arranged on the shell, a test paper base is connected with the inside of the shell in a sliding mode, two guide protruding edges are arranged on the test paper base, guide outward edges are arranged on the inner wall of the shell, and the guide outward edges are matched with the guide protruding edges in a sliding and guiding mode. A guide base is arranged on the outer side of the shell, and a limiting structure used for limiting the end of test paper into a test paper groove is arranged in the shell. The use method of the urine detection device for the intelligent closestool comprises the steps of Bluetooth connection, starting up, detection and analysis, result generation and the like. By means of the urine detection device for the intelligent closestool, the detection precision can be improved, and the use method of the urine detection device for the intelligent closestool is simple and convenient in operation.

Owner:ZHEJIANG WANJIE SMART BATHROOM

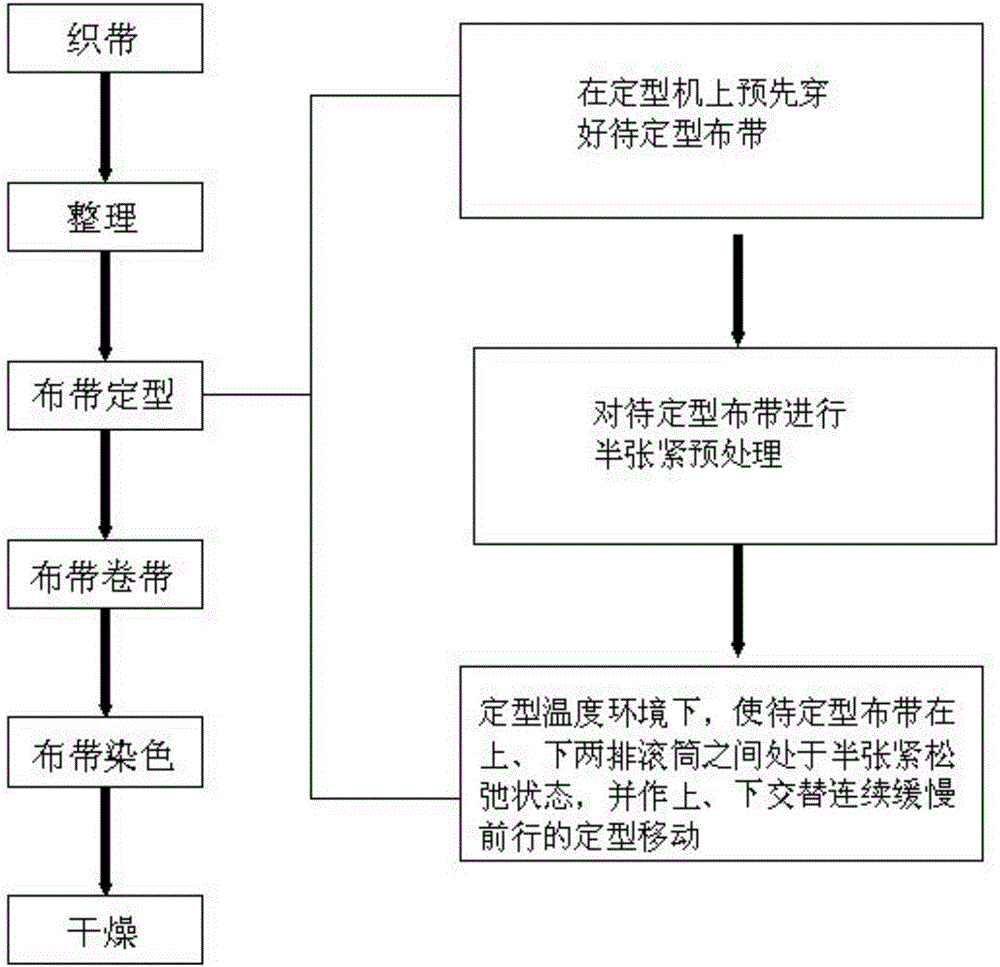

Production technology of zipper cloth tape

InactiveCN105220388AAvoid color differencesTraining step improvementsHeating/cooling textile fabricsElectric machineryEngineering

The invention discloses a production technology of a zipper cloth tape. The production technology comprises a cloth tape setting process, wherein the cloth tape setting process comprises the following steps: penetrating a to-be-set cloth tape on a setting machine in advance, carrying out semi-tensioning pretreatment on the to-be-set cloth tape, starting the setting machine, continuously feeding the to-be-set cloth tape into a setting chamber of the setting machine in a semi-tensioning state by using a tension constant control device driven by a first motor; enabling the to-be-set cloth tape to be in a semi-tensioning relaxed state between upper and lower rows of rollers in the setting chamber, and carrying out up-and-down alternately continuous and slow forward setting movement to a tape outlet direction of the setting chamber, so as to obtain the set cloth tape with the shrinking percentage of 1%-7%; and controlling the rotating speeds of the motors, and enabling the set cloth tape to reach the required shrinking percentage. According to the production technology, the cloth tape is shrunk in set in advance, so that the shrinkage amount is reduced in subsequent dyeing process, and further cloth tape indentation is prevented; the color difference of a zipper among the upper layer, the middle layer and the lower layer in the dyeing process is avoided; and the cloth tape dyeing uniformity is improved.

Owner:CHENGDU ROCK SOLID AUTOMATION TECH

Eryngii mushroom microwave vacuum drying method

The invention belongs to the technical field of agricultural product deep processing, in particular to an eryngii mushroom microwave vacuum drying method. According to the method, eryngii mushrooms are used as raw materials and are subjected to sulfur-free color protection treatment after the cleaning and the block cutting shaping, and then, the microwave vacuum drying is carried out until the water content is 10 to 12 percent (wet basis). The color of products is bright and white, the form is full, the rehydration performance is good, and the nutrition ingredient remaining rate is high. The operation of a preparation method is simple, health and environment protection are realized, the production period is short, the operation cost is low, the energy utilization rate is high, and the quality and the market competitiveness of the eryngii mushroom dry products are favorably improved.

Owner:FUJIAN AGRI & FORESTRY UNIV

Treatment method of wickerwork raw material wickers

ActiveCN107186846AAntioxidantThermally stableWood treatment detailsReed/straw treatmentAlkaline waterFiber

The invention relates to the technical field of wickerwork artware and discloses a treatment method of wickerwork raw material wickers. The method comprises the following steps that (1) newly-cut wickers are dewatered through natural drying, the high temper of the wickers is improved, heating treatment is conducted in alkaline water, thus peeling is facilitated, the glossiness of the wickers can be improved, and cold treatment is conducted after peeling; (2) the wickers subjected to cooling treatment are immediately steeped through a steeping solution A, the steeping solution can be rapidly adsorbed by fibers with negative charges under the effect of positive charges in the aqueous solution, a thin film is formed on the surface of each fiber, binding force among the fibers is reinforced, and shrinkage deformation of the fibers is prevented; and (3) the wickers are heated and baked in a drying oven after being steeped by the steeping solution A and then put into a steeping solution B for steeping, the steeping solution B has oxidation resistance and heat stability, connection points among the fibers are protected, and heating deformation of the fibers is prevented.

Owner:阜南县猛发工艺品有限公司

Andalusite and sillimanite saggar and preparation method thereof

InactiveCN108218445AHigh purityPrevent shrinkage deformationCharge supportsBreaking strengthPolymer science

The invention relates to an andalusite and sillimanite saggar and a preparation method thereof. The andalusite and sillimanite saggar is prepared from andalusite granules, sillimanite granules, zirconium oxide micro-powder, andalusite active micro-powder, aluminum oxide micro-powder aggregates and ball clay as main raw materials according to different weight percent through the steps of mixing, forming, drying and final high-temperature calcination. The andalusite and sillimanite saggar product overcomes the defects of short service life, poor stability, low breaking strength and the like in the prior art. The saggar prepared by the preparation method provided by the invention has the advantages of high breaking strength at high temperature, good thermal shock resistance, long service lifeand the like.

Owner:万燕杰

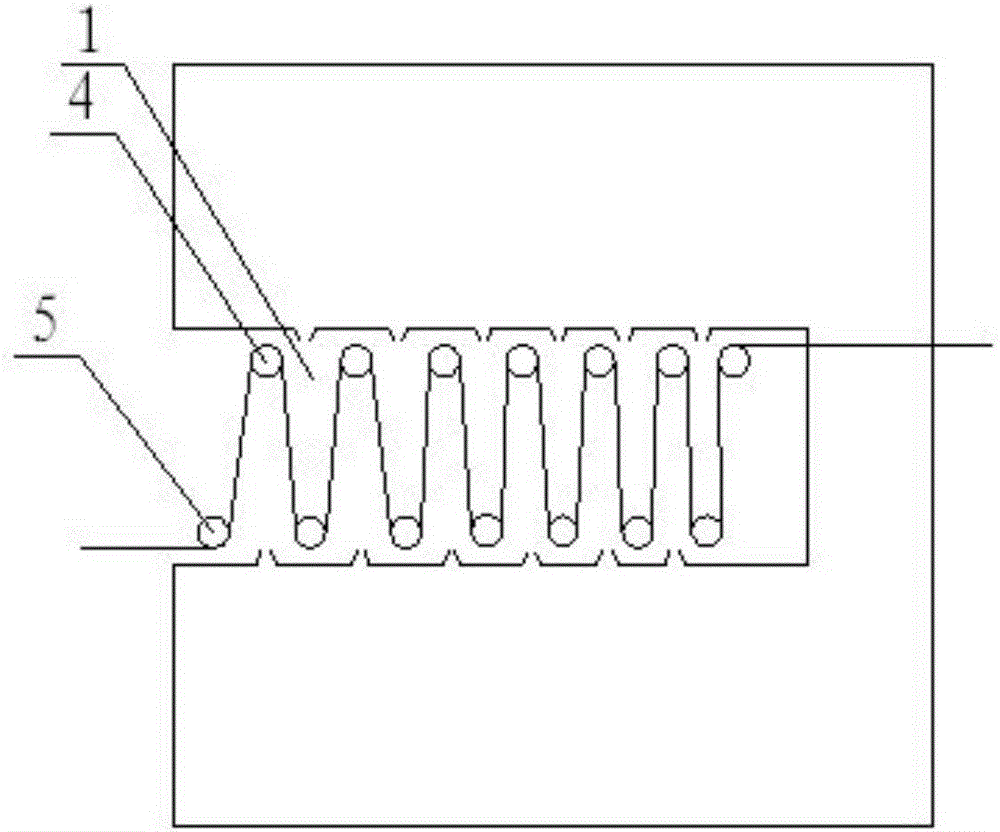

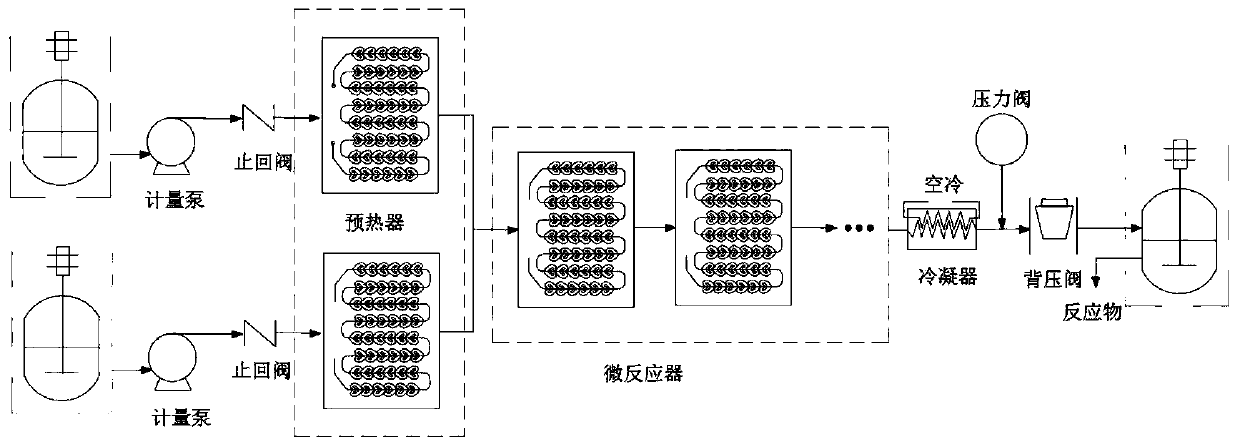

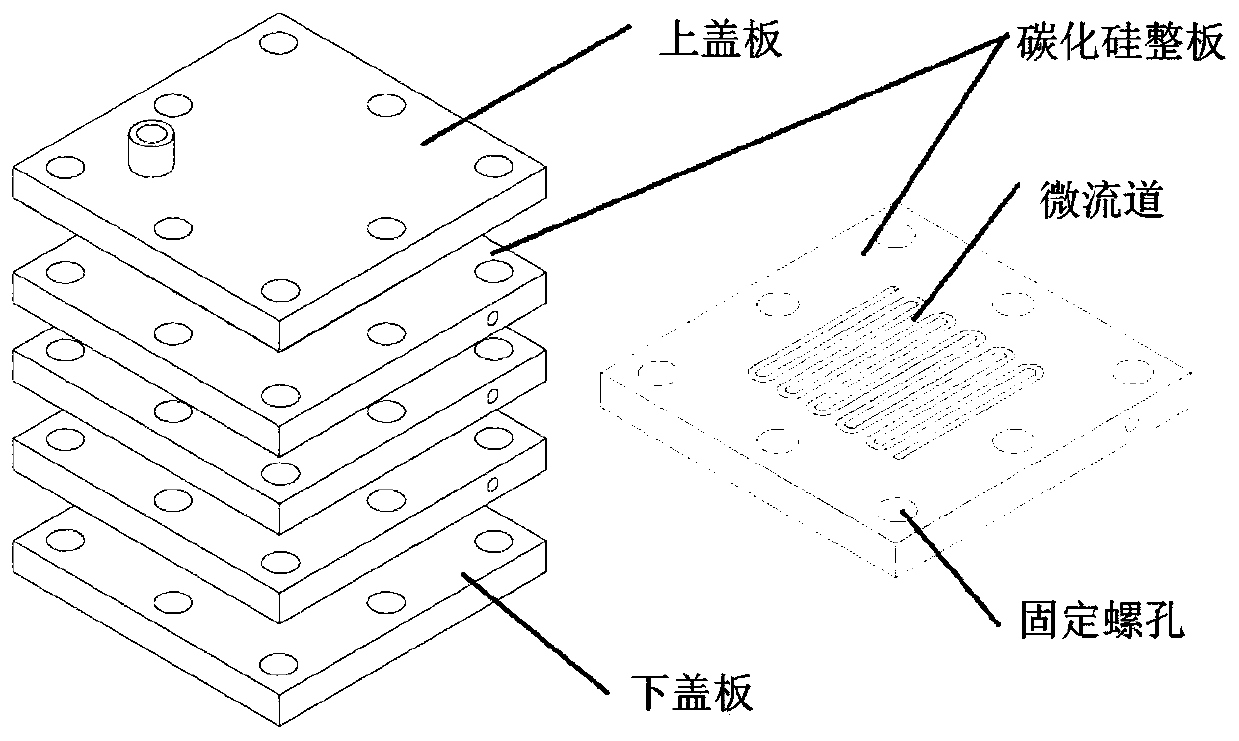

Production method of silicon carbide micro-reactor based on gel molding

ActiveCN110407582AHigh strengthHigh microstructural homogeneity requirementsChemical/physical/physico-chemical microreactorsGel basedPolyvinyl alcohol

The invention discloses a production method of a silicon carbide micro-reactor based on gel molding. The method comprises: (1) preparing a concentrated silicon carbide suspension; (2) preparing a polyvinyl alcohol and water-soluble phenolic resin mixed glue; (3) adding the mixed glue to the concentrated silicon carbide suspension, and performing mixing to obtain a slurry; (4) pouring the slurry into a mold, freezing the slurry to obtain a physical gel, unfreezing the physique gel, naturally drying the unfrozen gel, placing and drying the naturally dried gel in an oven, and carrying out cold isostatic pressing, low temperature sintering and phenolic resin curing; (5) shaping the surface of the obtained blank; (6) dumping the blank; (7) embedding the blank in silicon powder in a sintering furnace, and performing reactive sintering; and (8) finishing the assembled surface after the sintering, and carrying out high temperature bonding on two silicon carbide plates to produce the silicon carbide micro-reactor. In the invention, the polyvinyl alcohol physical gel is cured, so all components are uniformly distributed; and the residual carbon rate reaches 60-70% after the introducing of the introduced phenolic resin, and the sintered phenolic resin reacts with a silicon liquid to generate carbon carbide, so the content of free silicon in the silicon carbide is reduced, and the denseness is good.

Owner:QUZHOU UNIV

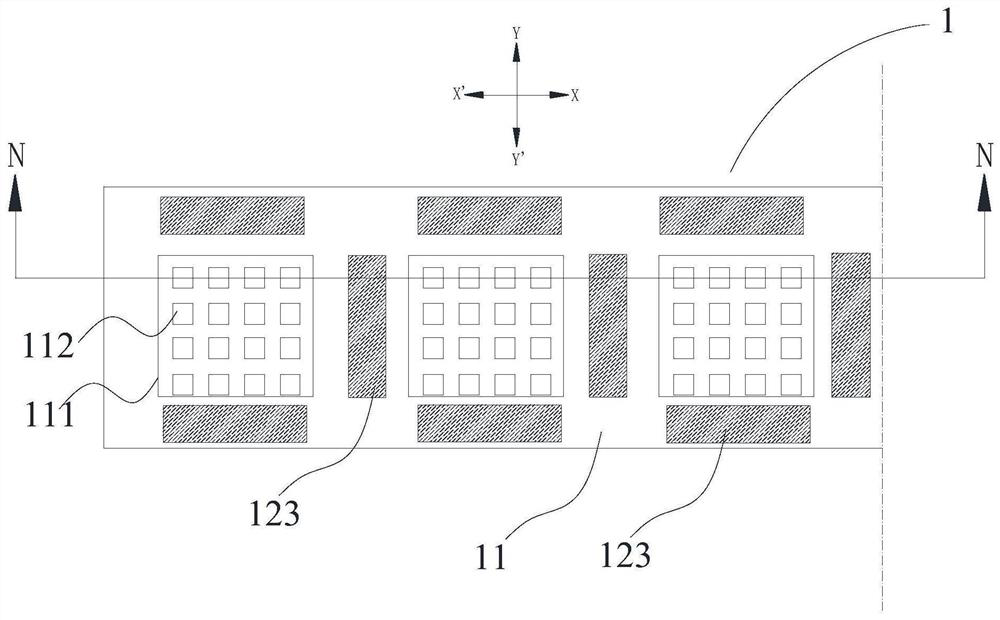

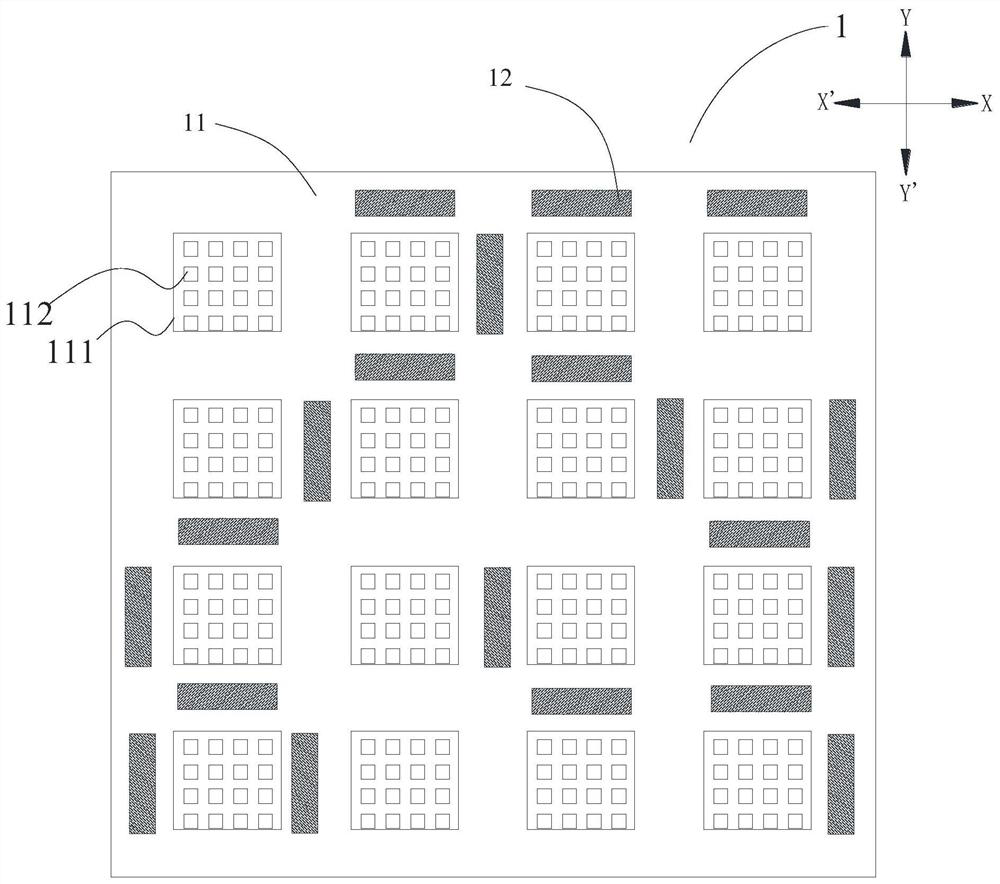

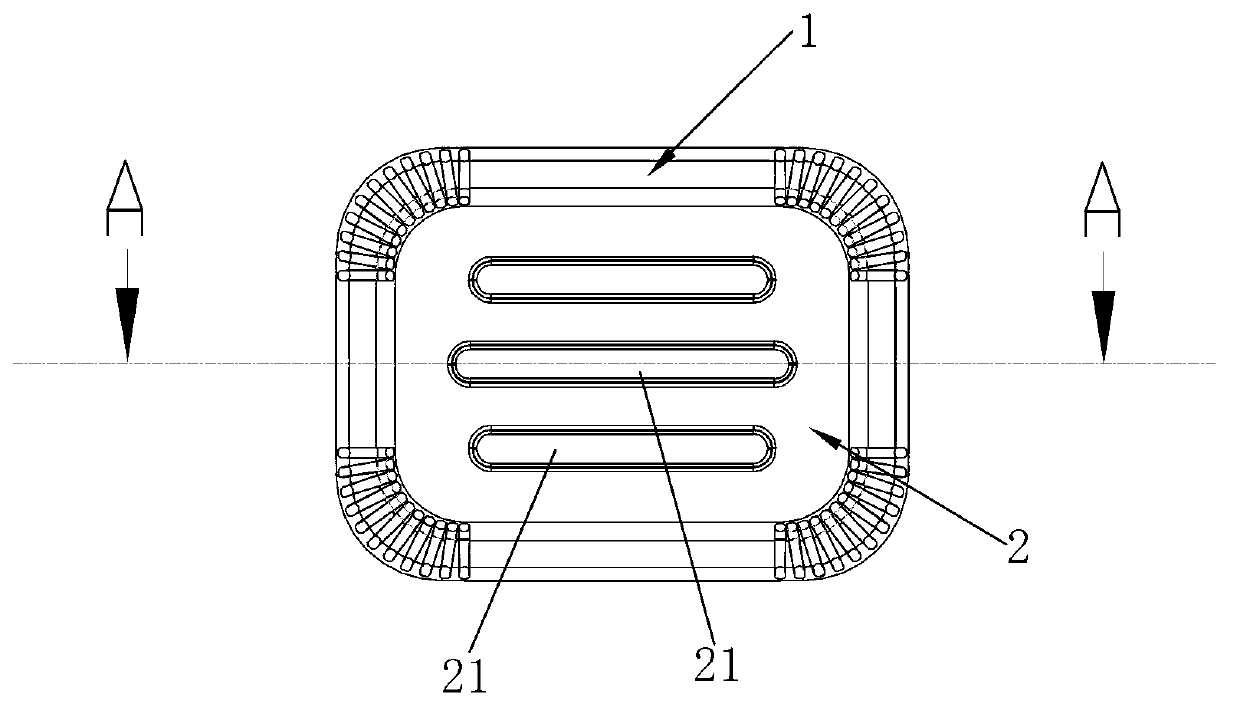

Mask and evaporation device

PendingCN111850466APrevent shrinkage deformationReduce wrinklesVacuum evaporation coatingSputtering coatingEngineeringMechanical engineering

The embodiment of the invention provides a mask and an evaporation device. The mask comprises a mask body and tensile expansion parts, wherein the mask body comprise a pattern evaporation area, and aplurality of evaporation openings are formed in the pattern evaporation area; and the tensile expansion parts are distributed on the peripheral side of the pattern evaporation area, a deformation direction of the tensile expansion parts is opposite to a deformation direction of the mask body in the direction perpendicular to a tensile stress direction, and interaction force exists between the tensile expansion parts and the mask body. According to the mask, by arranging the tensile expansion parts, wrinkles are prevented from being formed in a net stretching process, the relative position precision when the mask is attached to a display substrate is improved, local Mura and obvious stripes are prevented from occurring when a display panel is lightened after evaporation, and the display effect is improved.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

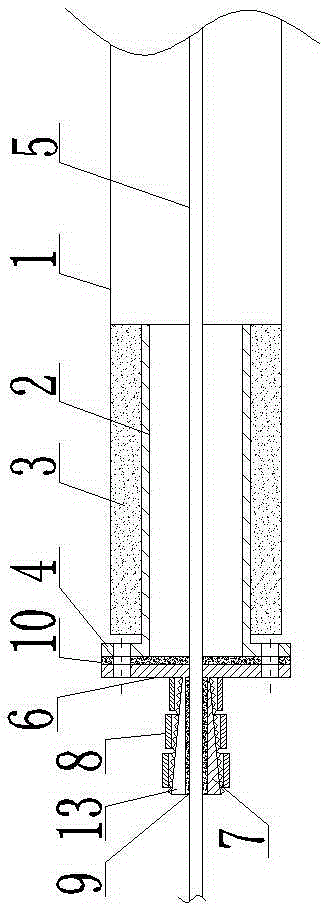

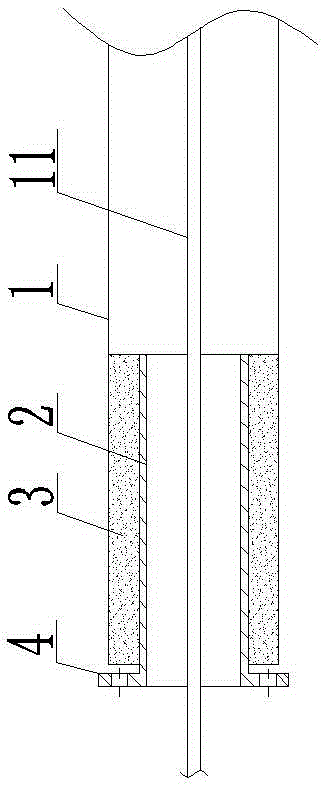

Heart valve delivery system and delivery device

ActiveCN102258402BEasy loadingEvaluate performanceHeart valvesDelivery systemElectrical and Electronics engineering

The embodiment of the invention discloses a delivery device, which comprises an outer delivery tube, a push rod, an inner tube, a functional handle and a plurality of connecting tubes, wherein one end of each connecting tube is connected with the push rod; the tube cavities of the connecting tubes are communicated with a metal wire passage in the push rod; the other ends of the connecting tubes are provided with connecting grooves; and the connecting grooves are communicated with the tube cavities of the connecting tubes. The connecting grooves are used for connecting the connecting port of a heart valve and the connecting tubes, and metal wires pass through the connecting port and are kept in the tube cavities of the connecting tubes, so that the metal wires are connected with the heart valve. The heart valve is fixed through the metal wires and the connecting grooves; when the heart valve is released, the metal wires must be extracted from the connecting grooves to finish release of the heart valve; therefore, before the heart valve is totally separated from the delivery device, the delivery device can be connected with the heart valve and can reclaim and reset the heart valve. The invention also discloses a heart valve delivery system.

Owner:SHANGHAI MICROPORT CARDIOFLOW MEDTECH CO LTD

Preparation method of vacuum freeze dried fruit and vegetable fruit granules through probiotic fermentation

PendingCN109463673ARich and full flavorOvercoming cold chain transportationFood freezingFruit and vegetables preservationNutrition functionFreeze dry

The invention provides a preparation method of vacuum freeze dried fruit and vegetable fruit granules through probiotic fermentation. Fruit granules are stuffed and hardened, then the hardened fruit granules and fermenting mediums are fermented, probiotics are inoculated for fermentation, and a vacuum freeze drying technique is combined, so that the vacuum freeze dried fruit and vegetable fruit granules through probiotic fermentation are produced. Fermented fruits and vegetables have complete nutrition functions, during fermentation of fruits and vegetables, probiotics can produce vitamins including B1, B2 and B6, as well as vitamin K and the like, in addition, lactic acid produced by the probiotics in the fermentation course also benefits absorption of calcium, ferrum and potassium by human bodies, and the fruits and the vegetables contain nutrient components and nutrient value richer than those of general fruits and vegetables. The fermented fruit and vegetable fruit granules prepared by the method provide original nutrients of the fruits and the vegetables for human bodies, and the nutrient value of the fruits and the vegetables can also be maximized. The fermented fruit and vegetable fruit granules are freeze-dried, the original thermal sensitivity components of products can be sufficiently guaranteed, color, scent, shape and activity of probiotics of the fruits and the vegetables can also be guaranteed, the quality guarantee period can be prolonged, and the fermented fruit and vegetable fruit granules are convenient to eat, transport and stored for a long term.

Owner:清谷田园食品有限公司

Ceramic firing kiln furniture and preparation method

The invention relates to ceramic firing kiln furniture and a preparation method. Andalusite granules, magnesium aluminate gel, micro calcium-stable zirconia powder, active micro andalusite powder, alumina micro powder agglomerates, Yixing clay and 0.1-0.15% of binding agent are mixed in different weight percentages, formed and dried, and finally, the ceramic firing kiln furniture is prepared through high-temperature calcination. The zirconium-containing andalusite toughening sagger product overcomes the existing defects that the service life is short, the stability is poor and the breaking strength is low. The sagger prepared by using the method has the advantages that the high-temperature breaking strength is high, the thermal shock resistance is high and the servicer life is long.

Owner:万燕杰

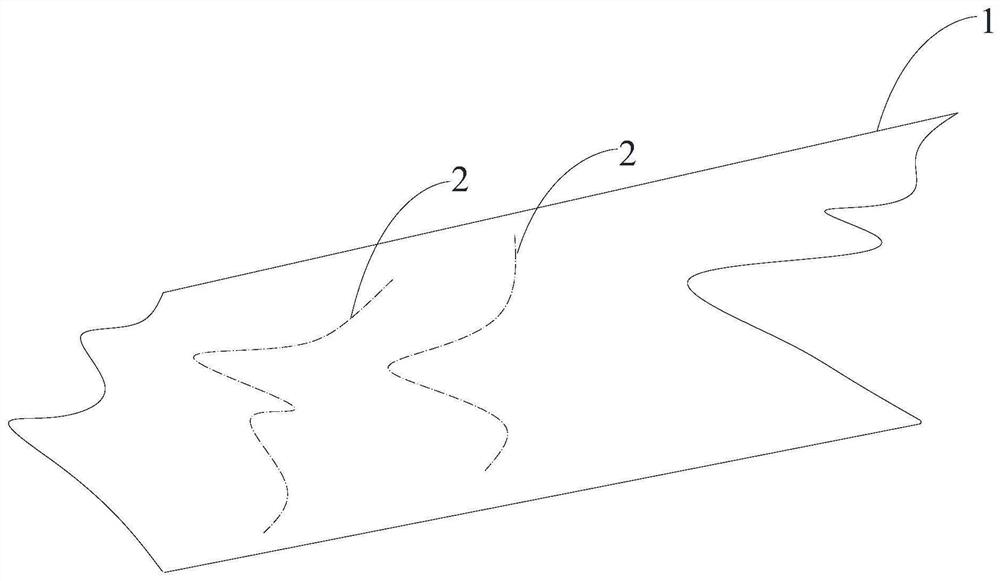

Loudspeaker diaphragm

ActiveCN103347233APrevent shrinkage deformationReduce distortionPlane diaphragmsLoudspeakerEngineering

The invention discloses a loudspeaker diaphragm. The loudspeaker diaphragm comprises a diaphragm body part and a rigid composite layer at the center position of the diaphragm body part. The diaphragm body part comprises a center part and a bending ring part, wherein the center part is located at the center position and of a plane shape, the bending ring part is located at the border position, and a protrusion or a concave reinforced groove is formed in the position, combined with the composite layer, of center part. The thickness, located at the reinforced groove, of the diaphragm body part is consistent with the thickness of the plane part of the center part. The reinforced groove part and the plane part of the center part are on the same plane after the composite layer and the center part are combined. By the adoption of the structure, the diaphragm can be prevented from shrinking and deforming, flatness of the diaphragm is improved, so that the distorting phenomenon of products is reduced, and acoustic performance of the products is improved.

Owner:GEER INTELLIGENT TECH CO LTD

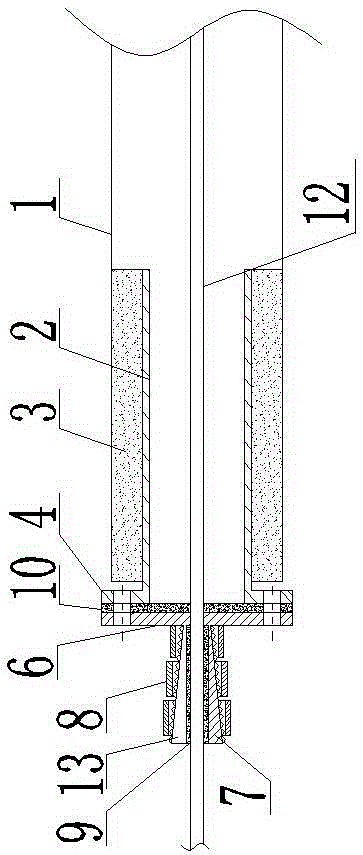

Hydraulic pressing, flushing and pumping integrated hole sealing device and method

The invention provides a hydraulic pressing, flushing and pumping integrated hole sealing device and method. The method comprises the following steps: tripping in a casing in one end of a drilling hole opening; injecting blocking cement plugs in the casing and drilling hole annular space; arranging an inner flange which is integrated with the casing on a portion, out of a drilling hole, of the casing; forming a round hole in the middle of an outer flange; welding a conical hollow ferrule on the periphery of the round hole; enabling a hydrofracture tube to penetrate in the ferrule and the round hole so as to enter the drilling hole; connecting the inner flange and the outer flange by a bolt; implementing hydrofracture after the ferrule and the hydrofracture tube are sealed; hermetically connecting an extraction pipeline and the ferrule when gas is extracted; and carrying out networking extraction after the inner flange is connected with the outer flange via the bolt. The hydraulic pressing, flushing and pumping integrated hole sealing device is simple in structure, convenient to mount and dismount, high in hole sealing speed and good in effect, and can be repeatedly used in a plurality of working procedures such as hydrofracture, punching and gas extraction, and the problems that during staged fracturing in the prior art, fracturing in each stage needs temporary hole sealing, and working procedures are complicated are solved.

Owner:HENAN POLYTECHNIC UNIV

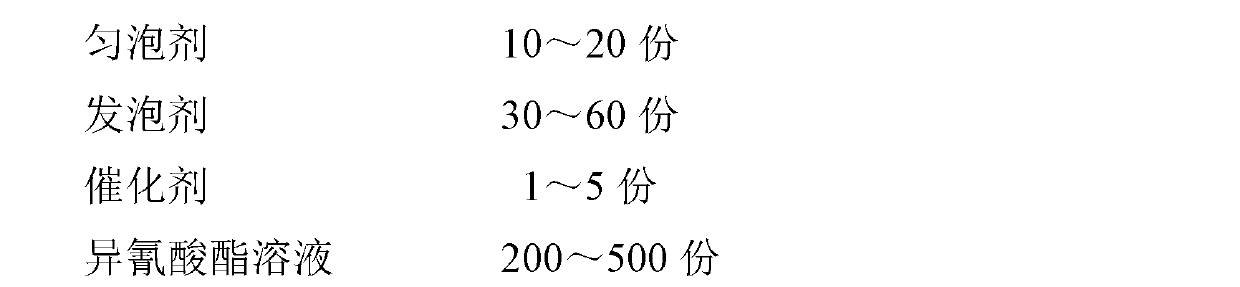

Polyisocyanurate foam plastic for ultralow-temperature insulation and preparation method thereof

ActiveCN103012730ABoth high and low temperature mechanical propertiesReduced risk of high temperature shrinkage and low temperature fractureIsocyanateDecomposition

The invention relates to a polyisocyanurate foam plastic for ultralow-temperature insulation and a preparation method thereof, belonging to the technical field of plastics. The preparation method comprises the following steps: 1) uniformly mixing and stirring polyalcohol with foam stabilizer, foaming agent and catalyst to obtain a mixture; 2) adding an isocyanate solution into the mixture obtained in the step 1), stirring for 8-12 seconds, filling into a mold within 30 seconds, and carrying out foaming reaction at normal temperature for 2-3 minutes to obtain a foamed product; and 3) heating the foamed product obtained in the step 1) in a 50-80 DEG C drying oven for 1-3 hours to obtain the polyisocyanurate foam plastic. The invention polyisocyanurate foam plastic provided by the invention has favorable temperature resistance (the foam decomposition temperature is higher than 200 DEG C), and has the advantages of high material modulus and high strength in the aspects of mechanical properties; and the invention lowers the elongation at break on the premise of enhancing the temperature resistance, and is especially obviously apparent in a low-temperature environment.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com