Hydraulic pressing, flushing and pumping integrated hole sealing device and method

A hole sealing device and hydraulic fracturing technology, which is applied in earthwork drilling, sealing/isolation, wellbore/well parts, etc., can solve the problems of complex hole sealing technology, long sealing time, cumbersome process, etc., and achieve easy Promote application, save sealing materials, and improve economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

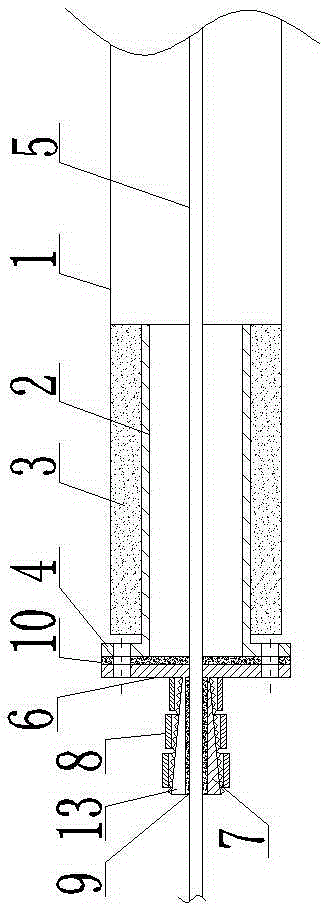

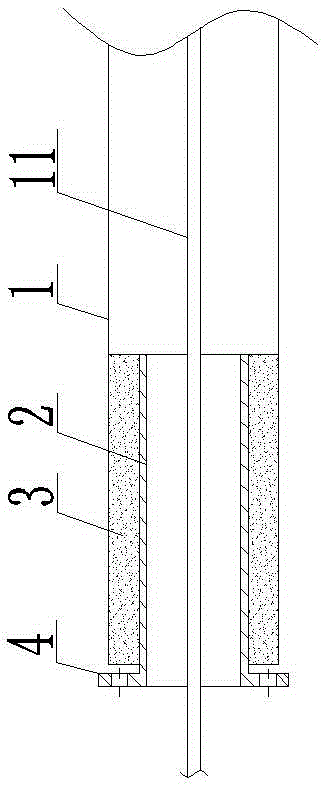

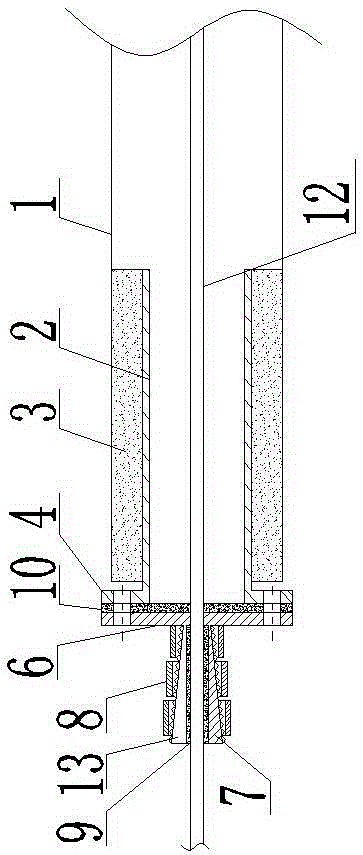

[0030] Such as Figure 1-Figure 3 As shown, a hydraulic pressure, punching and pumping integrated hole sealing device of the present invention includes a casing 2 with a length of 8 m, and the outer end of the casing 2 is provided with an inner flange 4 concentric with the casing 2. The bolts of the flange 4 are connected with an outer flange 6, and the center of the outer flange 6 is provided with a round hole, and the outer surface of the outer flange 6 is welded with a conical ferrule 7 with the same center line, and the outer contour of the axial section of the ferrule 7 The line is trapezoidal, the angle between the busbar of the ferrule 7 and the center line of the outer flange 6 is 3°, the ferrule 7 is provided with a through groove 13 along the axial direction, and the ferrule 7 is connected with three nuts 8 by external threads, and the ferrule 7 A through hole is opened inside along the axial direction, and the inner diameter of the through hole is equal to that of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com