Polyisocyanurate foam plastic for ultralow-temperature insulation and preparation method thereof

A technology of polyisocyanurate and foam plastics, applied in the field of plastics, can solve problems such as brittle fracture, achieve the effect of improving temperature resistance, high strength, and reducing the risk of high temperature shrinkage and low temperature fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

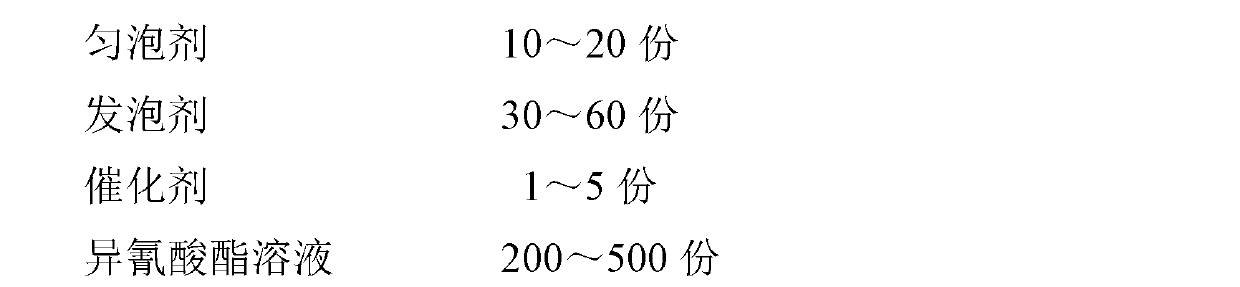

[0031] 1) Mix 100g of polyol mixture (30g of glycerol-propylene oxide polyether; 30g of trimethylolpropane-propylene oxide polyether; 40g of trimethylolpropane polyester) with 10g of LK221 foam stabilizer and 50g of HCFC-141b The foaming agent and 5g of TMR-4 catalyst were mixed and stirred evenly.

[0032] 2) Add 300g of isocyanate solution PM-2010 to the mixture obtained in step 1, stir for 10s, pour the obtained mixture into a 200×200×100mm square steel mold within 30s for foaming reaction, the foaming reaction is 3min at room temperature.

[0033] 3) Heat the product obtained in step 2) in an oven at 60°C for 2 hours. After completion, polyisocyanurate foam with ultra-low temperature insulation performance can be obtained, and its density is 60kg / m 3 .

[0034] The thermal conductivity of the obtained foamed plastics was tested. According to GJB328 "Test Method for Low Temperature Steady State Thermal Conductivity of Thermal Insulation Materials", at the liquid oxygen t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com