Patents

Literature

491 results about "Polyisocyanurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyisocyanurate, also referred to as PIR, polyiso, or ISO, is a thermoset plastic typically produced as a foam and used as rigid thermal insulation. The starting materials are similar to those used in polyurethane (PUR) except that the proportion of methylene diphenyl diisocyanate (MDI) is higher and a polyester-derived polyol is used in the reaction instead of a polyether polyol. The resulting chemical structure is significantly different, with the isocyanate groups on the MDI trimerising to form isocyanurate groups which the polyols link together, giving a complex polymeric structure.

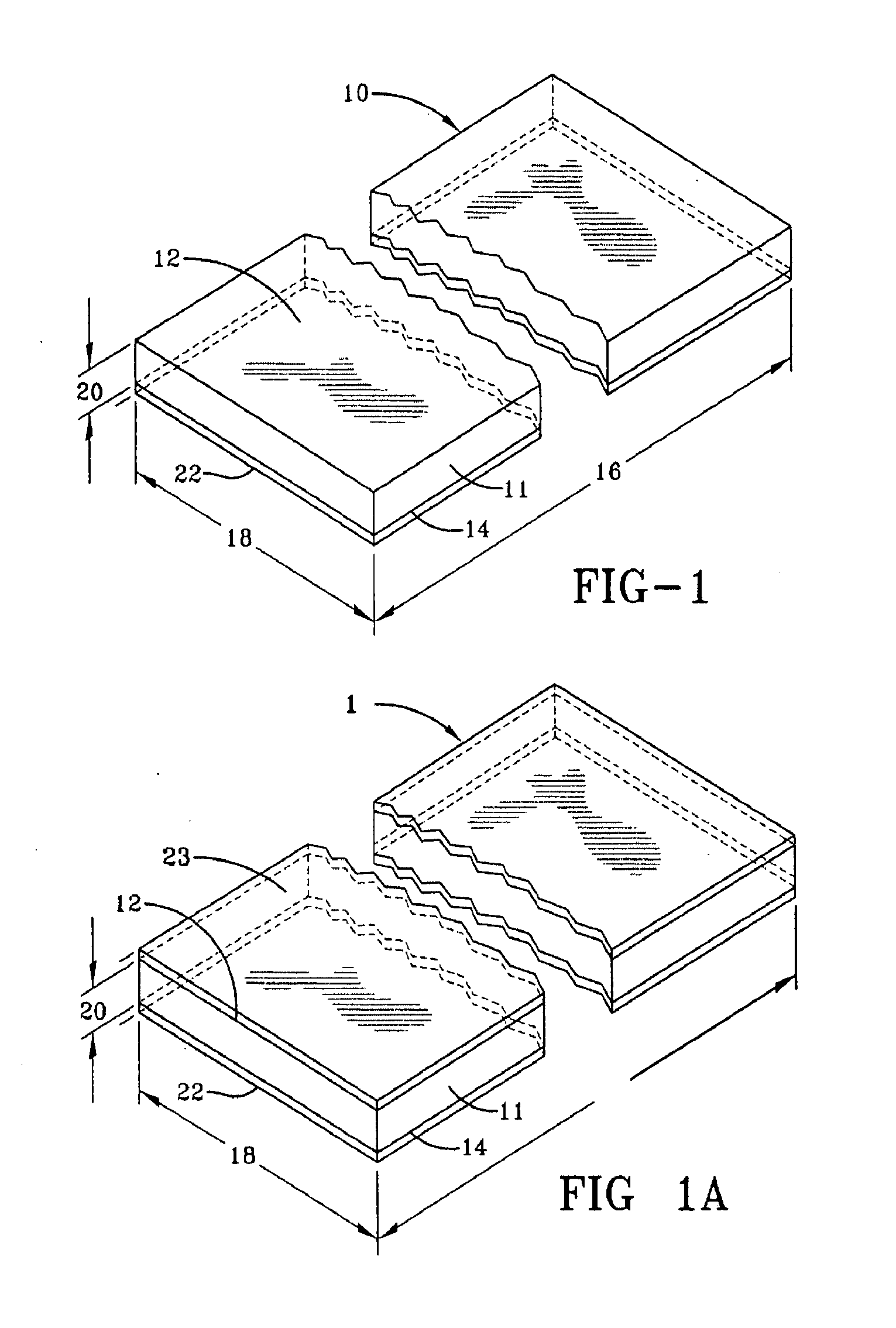

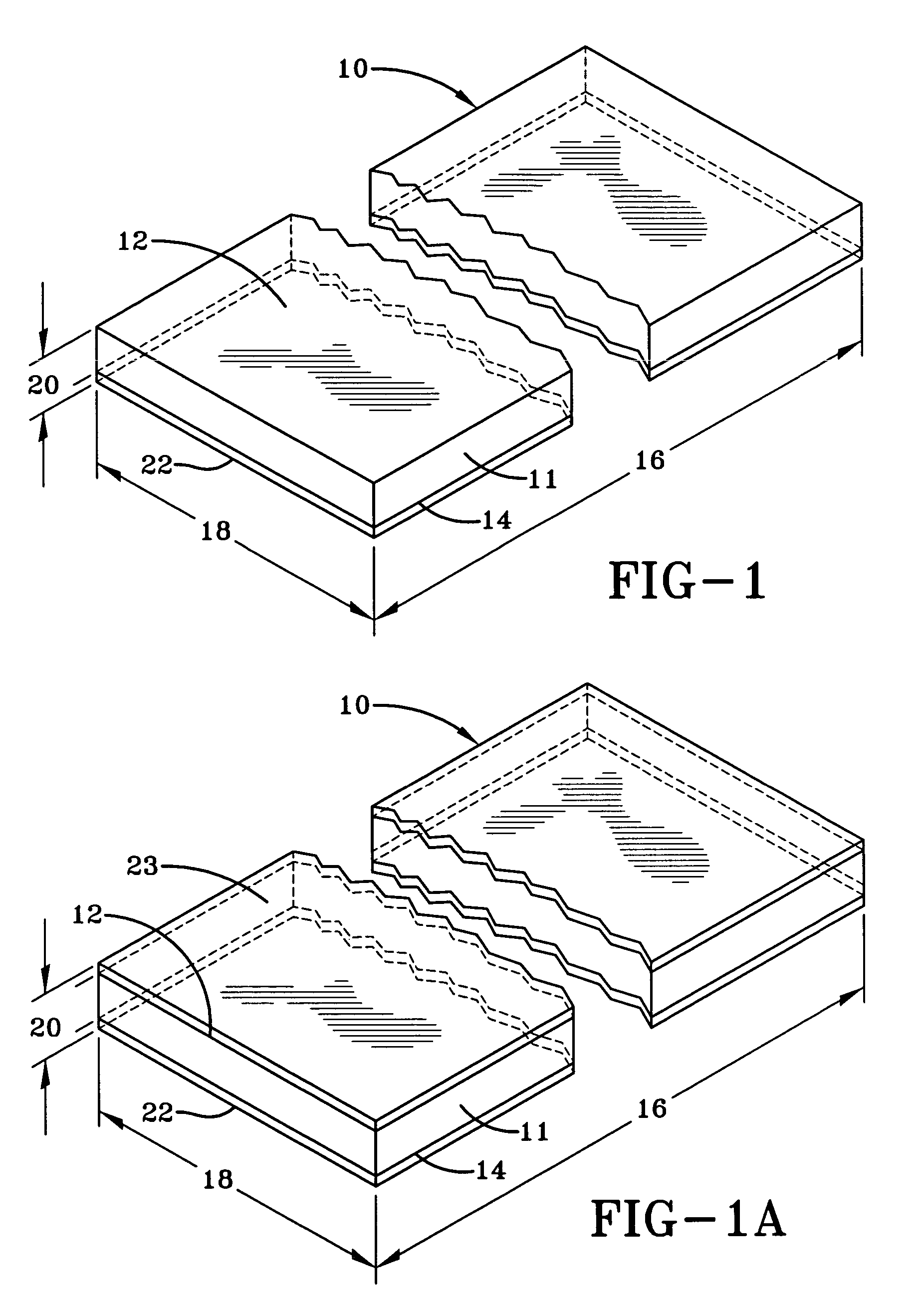

Composite roofing members having improved dimensional stability and related methods

InactiveUS6044604AGood baseRoof covering using slabs/sheetsConstruction materialGlass fiberPolymer science

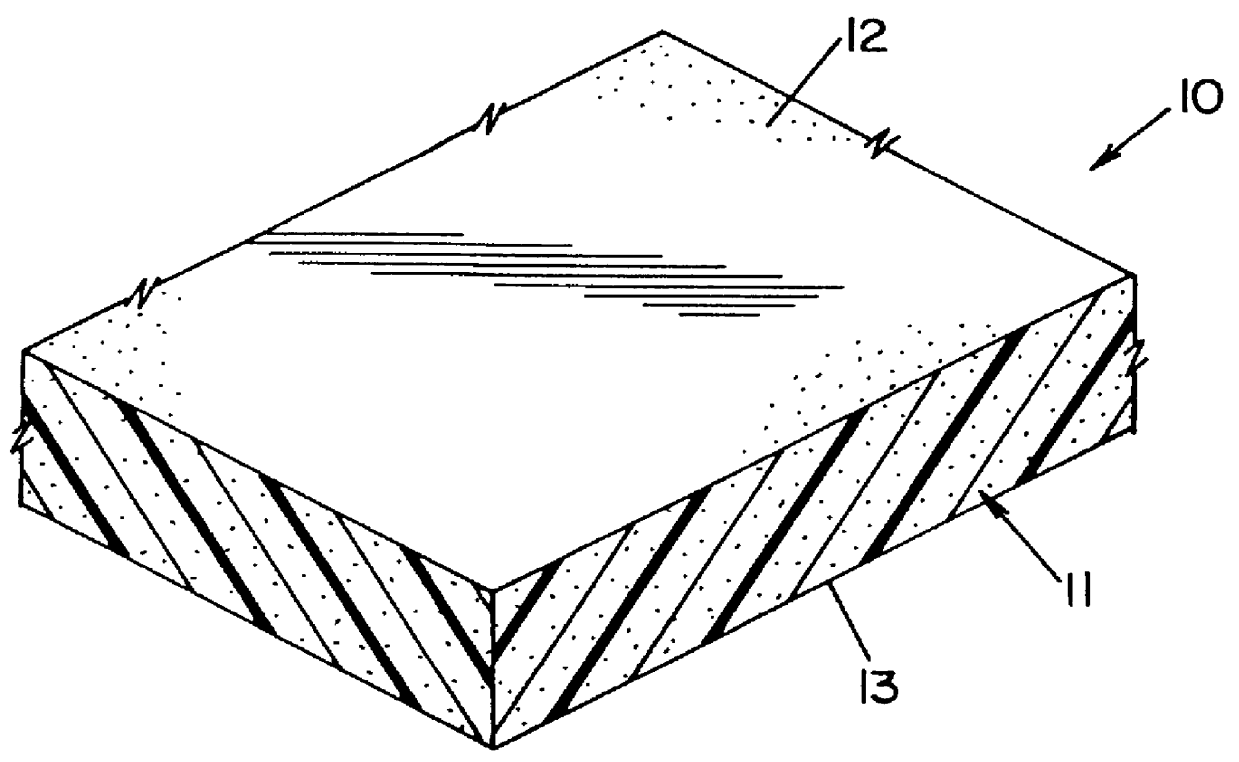

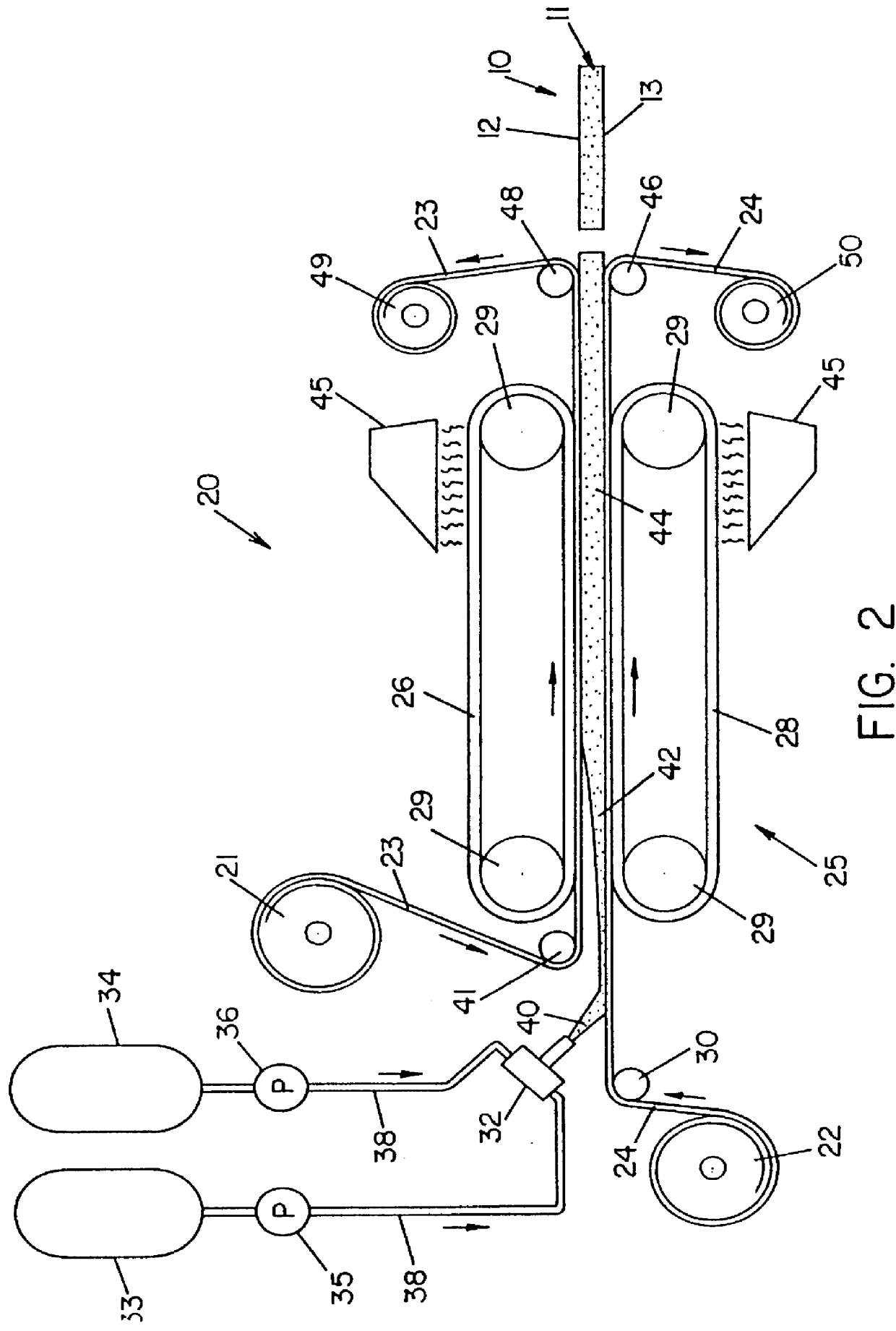

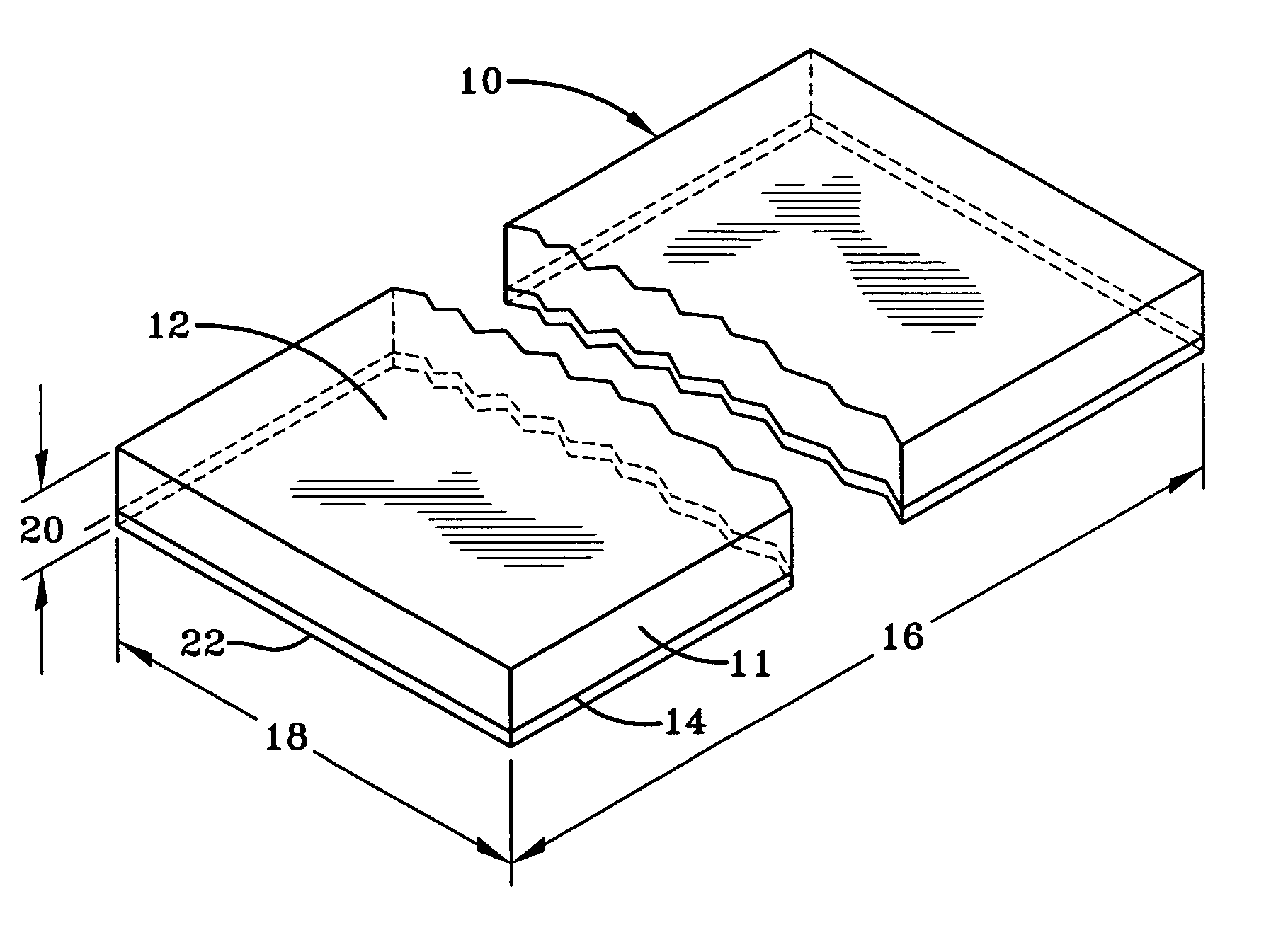

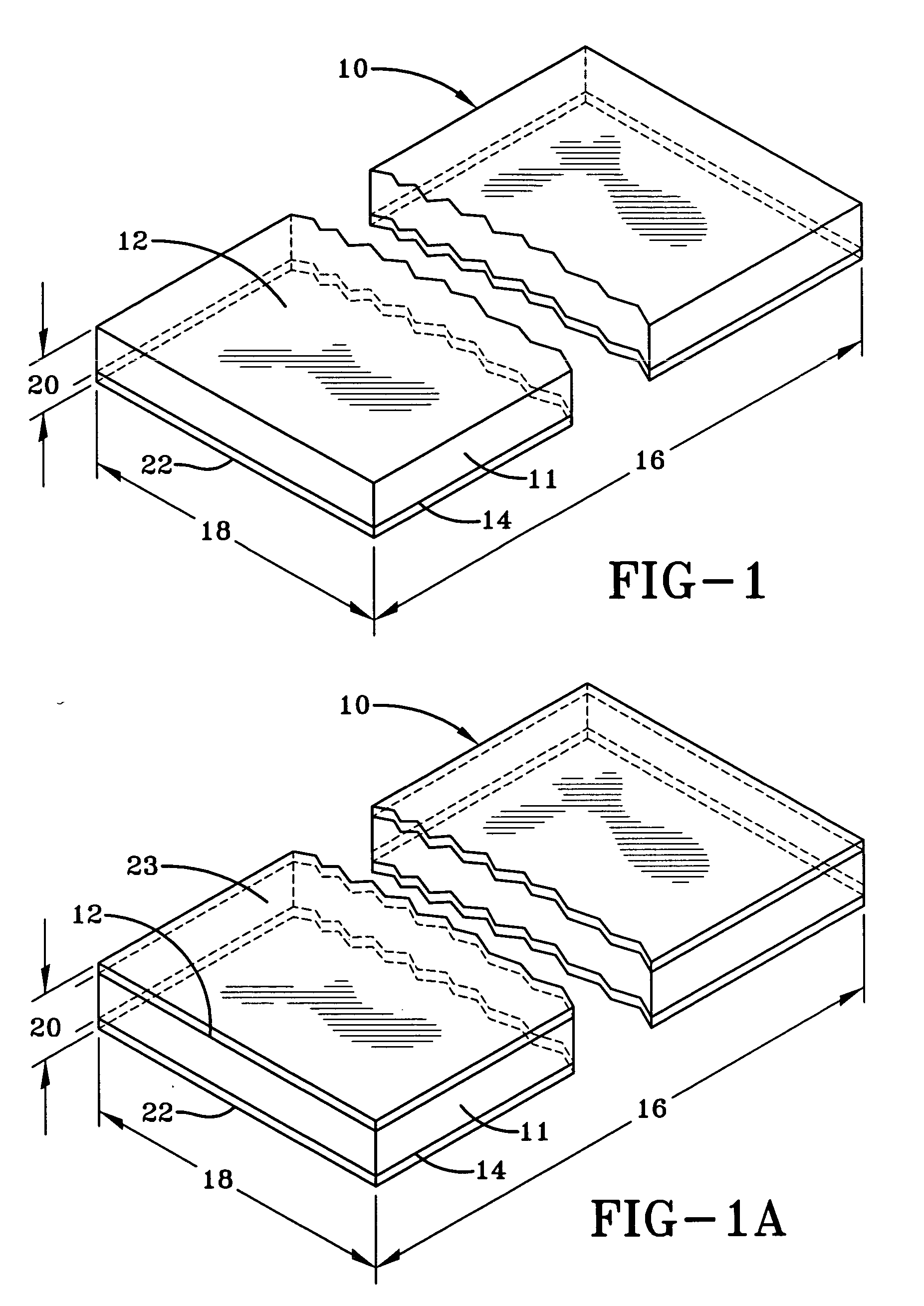

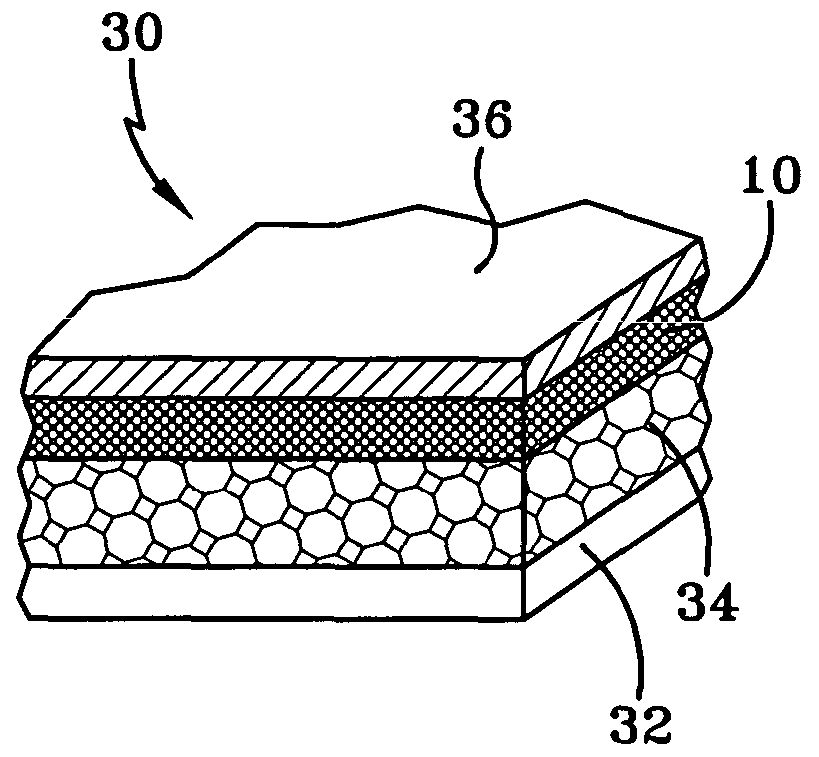

A composite recovery board (10) containing a foam core (11) of polyisocyanurate, polyurethane materials or mixtures thereof; a facer (15), applied to one major surface (13) of the foam core, where the facer includes polymer materials, reinforced polymer materials, cellulosic materials, paper, aluminum foil or trilaminates thereof, wherein the reinforced polymer material and the cellulosic material are reinforced with glass strands, glass fibers, or mixtures thereof; and, gypsum board (14), applied to the opposite major surface (12) of the foam core. A method of reroofing a roof by applying composite recovery boards of the present invention to a roof deck; and, applying a weather protective layer over the recovery boards. A continuous method of making a composite recovery board by feeding gypsum board (14) into a laminator assembly (21); depositing a foamable polymer liquid (36) onto the gypsum board; feeding a facer material (15) into the laminator assembly above the foamable polymer liquid; allowing the polymer liquid to rise between the gypsum board and facer material forming polymer foam of a pre-determined thickness; curing the polymer foam under heat (44) to create the composite board; and cutting the composite board to desired lengths.

Owner:FIRESTONE BUILDING PRODS

Expandable microspheres for foam insulation and methods

InactiveUS20050079352A1Use in some applicationHigh of encapsulationLiquid surface applicatorsGlass/slag layered productsPolymer scienceFoaming agent

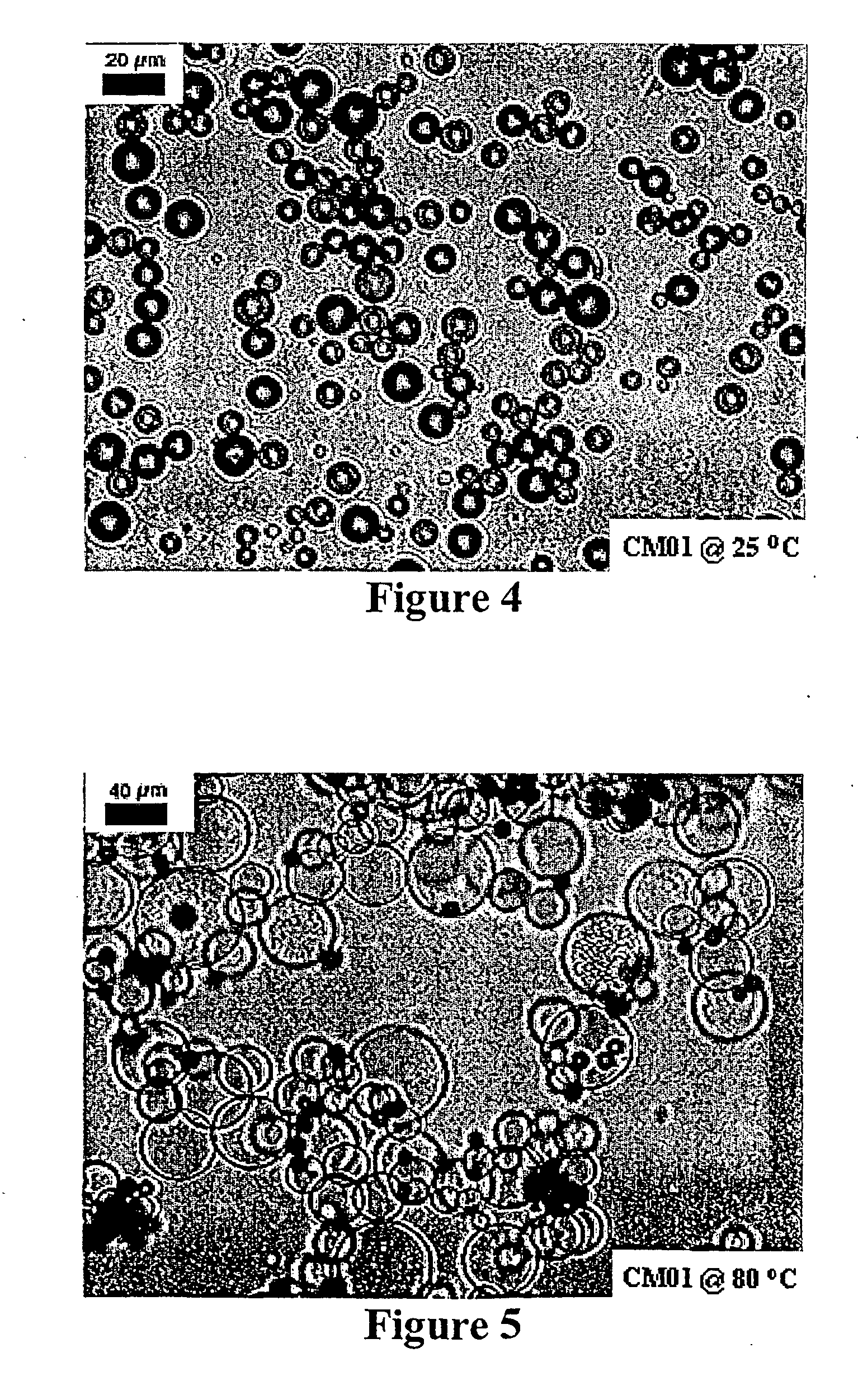

Hollow thermoexpandable particles or microspheres are provided that contain hydrocarbon blowing agents and have a shell polymer that can be softened at the onset of the expansion temperature and solidified at a higher temperature (thermoset) in an expanded state. Preferably, the microspheres have a shell of thermally expandable and thermally crosslinkable polymer and a hollow interior that contains a hydrocarbon liquid that boils at a temperature below the heat activated crosslinking temperature of the polymer shell. The crosslinking of the shell polymer during or after expansion, which is heat activated at an elevated temperature, can solidify the shell polymer and, then, maintain the expanded volume of the microspheres. The thermoexpandable thermoset polymer particles are useful in insulation, packaging, for making foam materials such as polyurethane or polyisocyanurate rigid foams. The invented thermoset microspheres can substantially improve the close cell percentage and compressive strength of the foam materials and make the foam manufacturing less hazardous.

Owner:IP RIGHTS +1

Roofing members without auxiliary facers and related methods

InactiveUS6117375ADimensionally stableGood baseConstruction materialLamination ancillary operationsPolyisocyanurateEngineering

An insulation board (10) insulation board comprising a foam core (11) selected from the group consisting of polyisocyanurate and polyurethane materials and mixtures thereof; the board being devoid of facers. A method of covering roofs comprises applying insulation boards to a roof deck, the insulation boards comprising a foam core selected from the group consisting of polyisocyanurate and polyurethane materials and mixtures thereof, the boards being devoid of facers; and, applying a weather protective layer over the insulation boards. A continuous method of making a facerless insulation board comprising the steps of feeding a first sheet (24) of temporary facer material into a laminator (25); depositing a foamable polymer liquid (40) onto the first sheet; feeding a second sheet (23) of temporary facer material into the laminator above the foamable polymer liquid; allowing the polymer liquid to rise between the first and second sheets forming polymer foam (44) of a pre-determined thickness; curing the polymer foam under heat (45) to create the insulation board; removing the first and second sheets from the board prior to final curing and cooling; and cutting the board to desired lengths.

Owner:FIRESTONE BUILDING PRODS

Stabilization of polyurethane foam polyol premixes containing halogenated olefin blowing agents

ActiveUS20090099272A1Reduced responseQuality improvementPreparation by halogen halide additionOrganic acidFoaming agent

The invention provides polyurethane and polyisocyanurate foams and methods for the preparation thereof More particularly, the invention relates to open-celled, polyurethane and polyisocyanurate foams and methods for their preparation. The foams are characterized by a fine uniform cell structure and little or no foam collapse. The foams are produced with a polyol premix composition which comprises a combination of a hydrohaloolefin blowing agent, a polyol, a silicone surfactant, and a catalyst which is an adduct of an amine and an organic acid.

Owner:HONEYWELL INT INC

Amine catalysts for polyurethane foams

The invention provides polyurethane and polyisocyanurate foams and methods for the preparation thereof More particularly, the invention relates to open-celled, polyurethane and polyisocyanurate foams and methods for their preparation. The foams are characterized by a fine uniform cell structure and little or no foam collapse. The foams are produced with a polyol premix composition which comprises a combination of a hydrohaloolefin blowing agent, a polyol, a silicone surfactant, and a sterically hindered amine catalyst.

Owner:HONEYWELL INT INC

Low-Odor Catalyst for Isocyanate-Derived Foams and Elastomers

InactiveUS20070282026A1Other chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsElastomerPolyisocyanurate

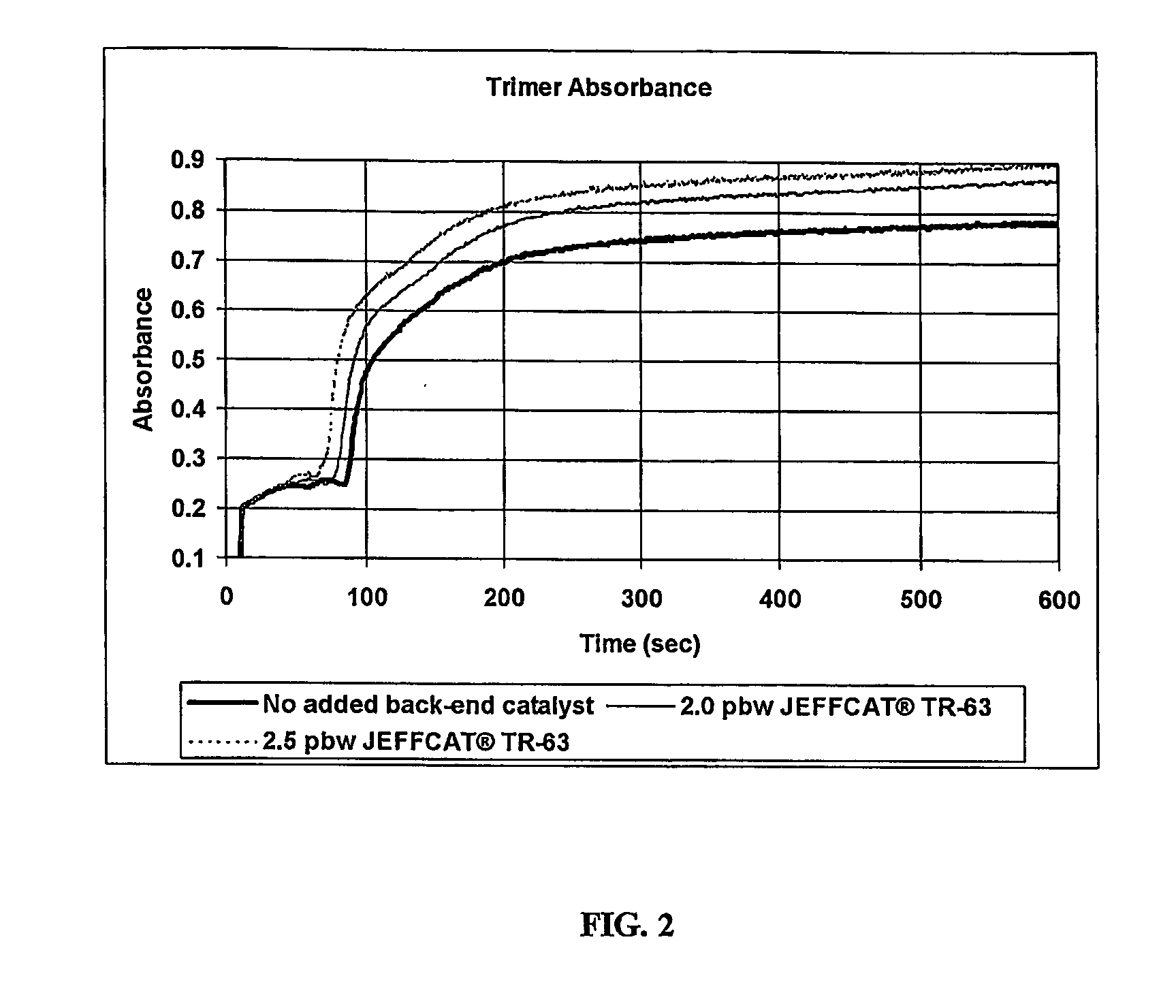

Provided herein are catalysts useful in providing foam products which are produced using an organic poly isocyanate as a starting material. A catalyst according to the present invention includes the tris-(hydroxyethyl)methyl ammonium cation, and optionally potassium cation, in combination with a variety of possible counter anions present to maintain charge balance and for compatibility. A catalyst according to the invention is preferably used in conjunction with one or more conventional tertiary amine catalysts in a foam producing process. The foams may be polyurethane foams, polyisocyanurate foams, flexible foams, or elastomeric foams.

Owner:HUNTSMAN PETROCHEMICAL LLC

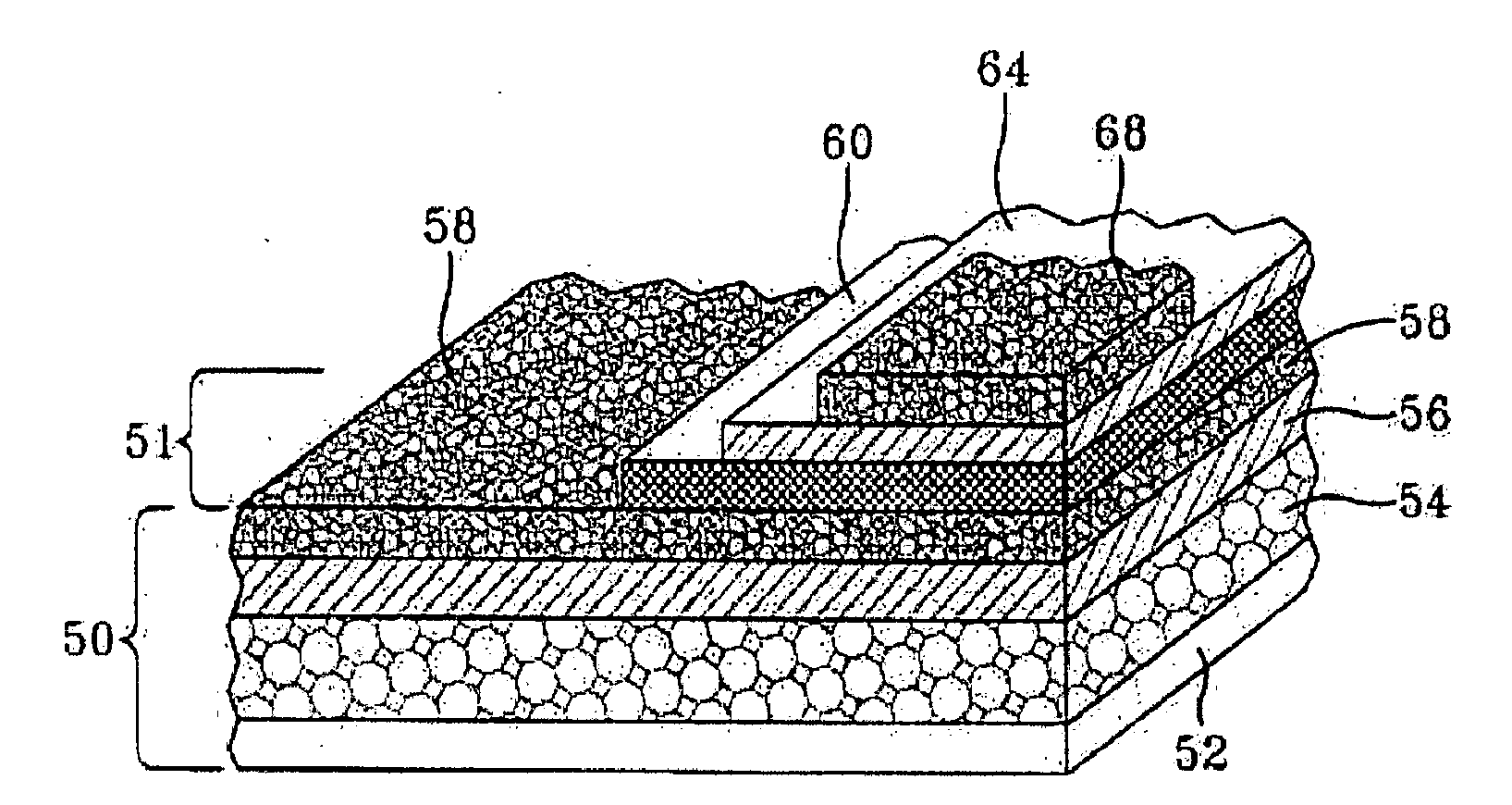

High density polyurethane and polyisocyanurate construction boards and composite boards

A covered low-slope or flat roof comprising (a) a roof deck, (b) an optional insulation board including a polyurethane or polyisocyanurate cellular structure having a density that is less than 2.5 pounds per cubic foot, (c) a coverboard including a polyurethane or polyisocyanurate cellular structure having a density greater than about 2.5 pounds per cubic foot, and (d) a membrane.

Owner:HOLCIM

Filled polymer composite and synthetic building material compositions

ActiveUS20050163969A1Improve mechanical propertiesLow costSolid waste managementLayered productsPolyesterFiber

The invention relates to composite compositions having a matrix of polymer networks and dispersed phases of particulate or fibrous materials. The polymer matrix contains a polyurethane network formed by the reaction of a poly- or di-isocyanate and one or more saturated polyether or polyester polyols, and an optional polyisocyanurate network formed by the reaction of optionally added water and isocyanate. The matrix is filled with a particulate phase, which can be selected from one or more of a variety of components, such as fly ash particles, axially oriented fibers, fabrics, chopped random fibers, mineral fibers, ground waste glass, granite dust, or other solid waste materials. The addition of water can also serve to provide a blowing agent to the reaction mixture, resulting in a foamed structure, if such is desired.

Owner:BORAL IP HLDG

Process for the manufacturing of an improved core for decorative laminates and a decorative laminate obtained by the process

InactiveUS6841023B2Improve brittlenessImprove the overall coefficientOrganic chemistryLamination ancillary operationsPolyesterFiber

A process for the manufacturing of a core forming a carrying structure for decorative laminates. The core comprises particles of cured, and optionally foamed, rigid, polyurethane, polyisocyanurate and / or phenolic resin. The particles are bonded to each other in a pressing procedure with a bonding agent comprising an adhesive such as a polymerizing monomer.i) The particles are achieved by grinding cured, and optionally foamed, rigid, polyurethane, polyisocyanurate and / or phenolic resin so that it passes through a 2 mm screen, preferably a 1 mm screen,ii) 100 parts per weight of particles is mixed with 1-100 parts per weight of fiber, the fiber additive having an average length in the range 1-15 mm.iii) The particle-fiber mixture is allowed to absorb a selected amount of water, the amount of water being in the range 1-15% by weight, The water is either added at any stage before the adding of bonding agent, and / or being used as a solvent in the bonding agent, and that,iv) 85 parts per weight of the particle mixture is mixed with 2-15 parts per weight of a bonding agent, the bonding agent selected from the group consisting of,a) A mixture of polyols, such as polyester or polyether, crude methylene diphenyl diisocyanate and possibly a small amount of blowing agent in a ratio forming a polymeric resin with a density in the range 600-1400 kg / m3.b) A formaldehyde based resin such as phenol-formaldehyde resin, urea-formaldehyde resin, melamine-urea-formaldehyde resin, melamine-urea-phenol-formaldehyde resin or phenol-resorcinol-formaldehyde resin, orc) Polyvinyl acetate resin.v)The mixture is applied between the belts of the continuos belt press or the press plates of a static press, optionally with at least one intermediate carrier web, the belts or press plates allowing a mainly uniform and specified material thickness to form. A slightly porous and preconditioned core with a selected water content in the range 0.8-12% is hereby achieved. The invention also relates to a decorative laminate achieved through the process.

Owner:PERGO

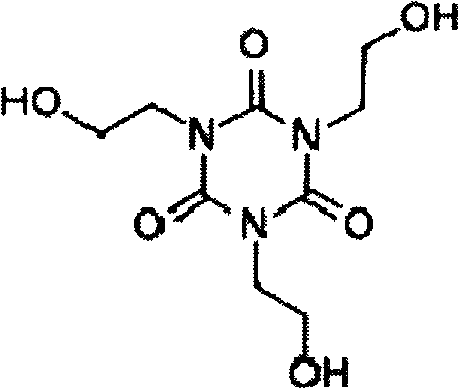

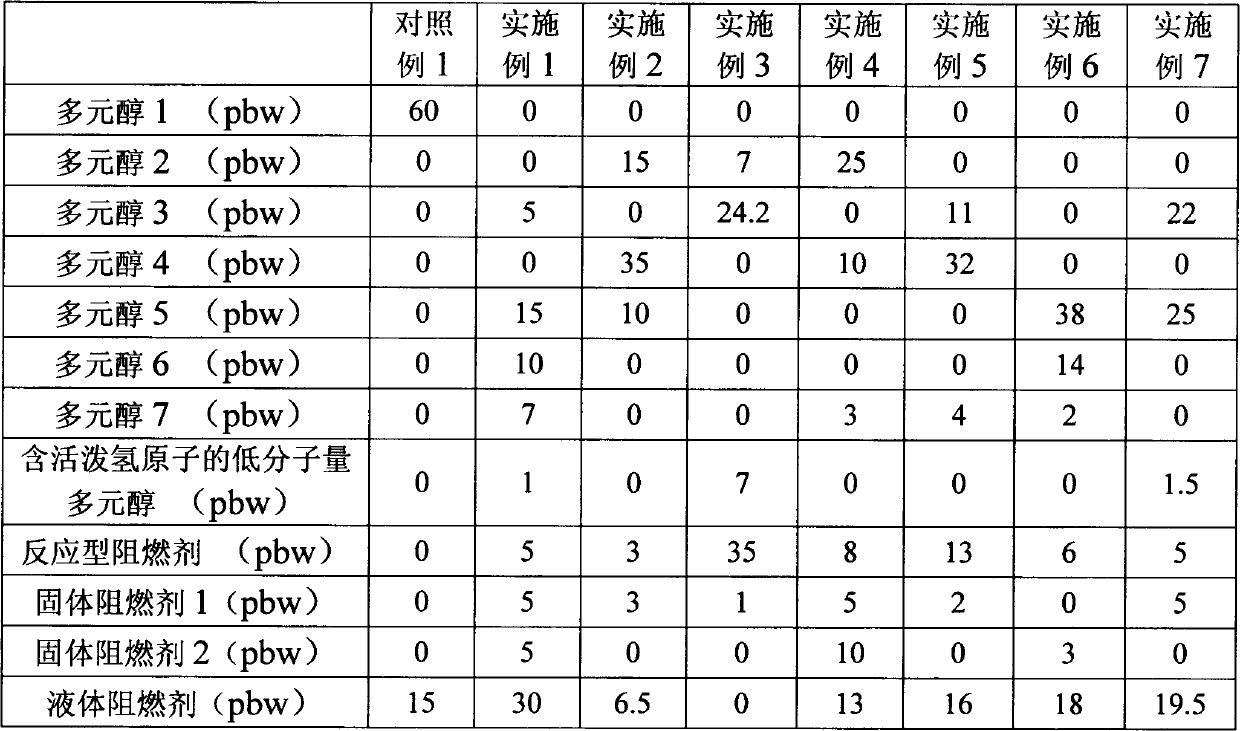

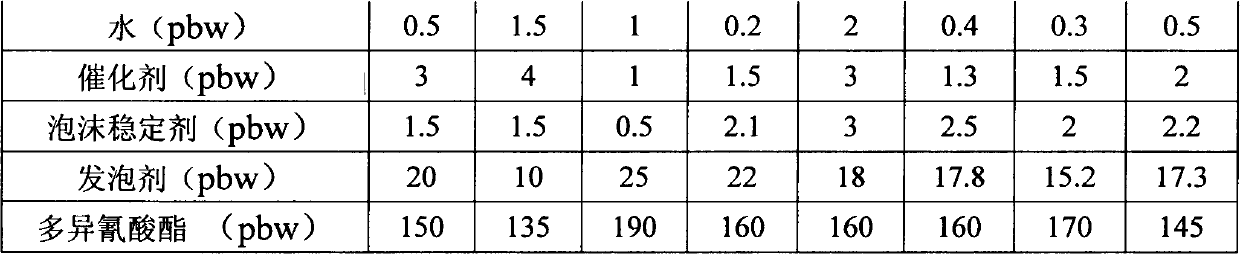

Composition for preparing highly fire-resistant polyisocyanurate foam

The invention discloses a composition for preparing highly fire-resistant polyisocyanurate foam. Based on the total quantity of the composition, the composition comprises the following components in percentage by weight: 30-60 percent of polyester polyol and / or polylol containing tri-(2-ethoxyl) isocyanurate units, 0-7 percent of polyether polyol, 0-7 percent of low molecular weight polylol or polyamine containing active hydrogen atoms, 3-35 percent of reactive flame retardant, 1-15 percent of solid flame retardant, 0-30 percent of liquid organic flame retardant, 0.2-2 percent of water, 1-4 percent of catalyst, 0.5-3 percent of foam stabilizer and 10-25 percent of physical foaming agent. Compared with a conventional PIR (Polyisocyanurate) composition, the composition system has the advantages of stability in material foaming rise, good cohesiveness of foam with plane materials, and the like. Compared with conventional polyurethane foam and PIR foam, foam prepared from the composition system has the advantages of excellent flame resistance and good compressive strength and dimensional stability.

Owner:WANHUA CHEM NINGBO RONGWEI POLYURETHANE

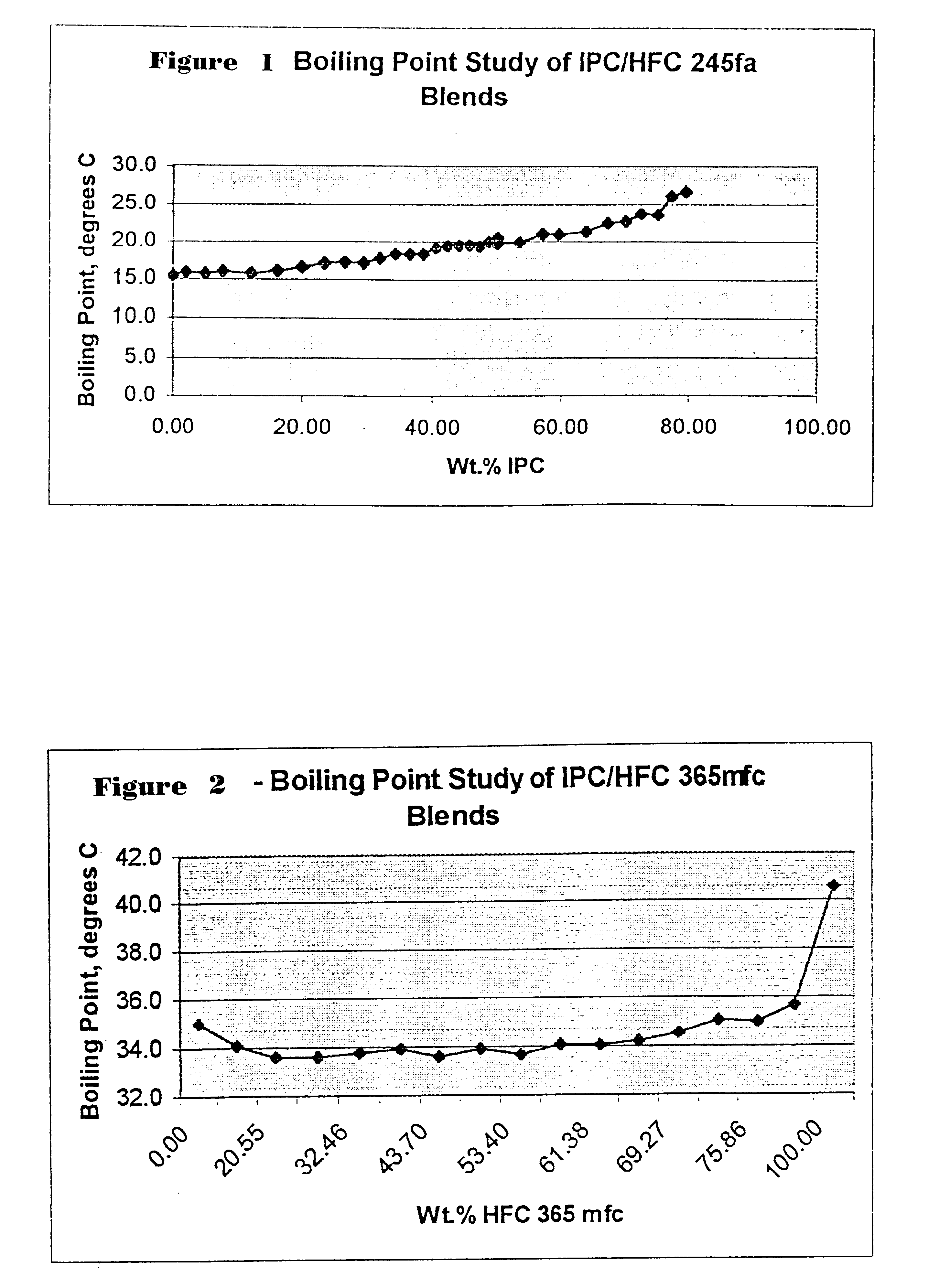

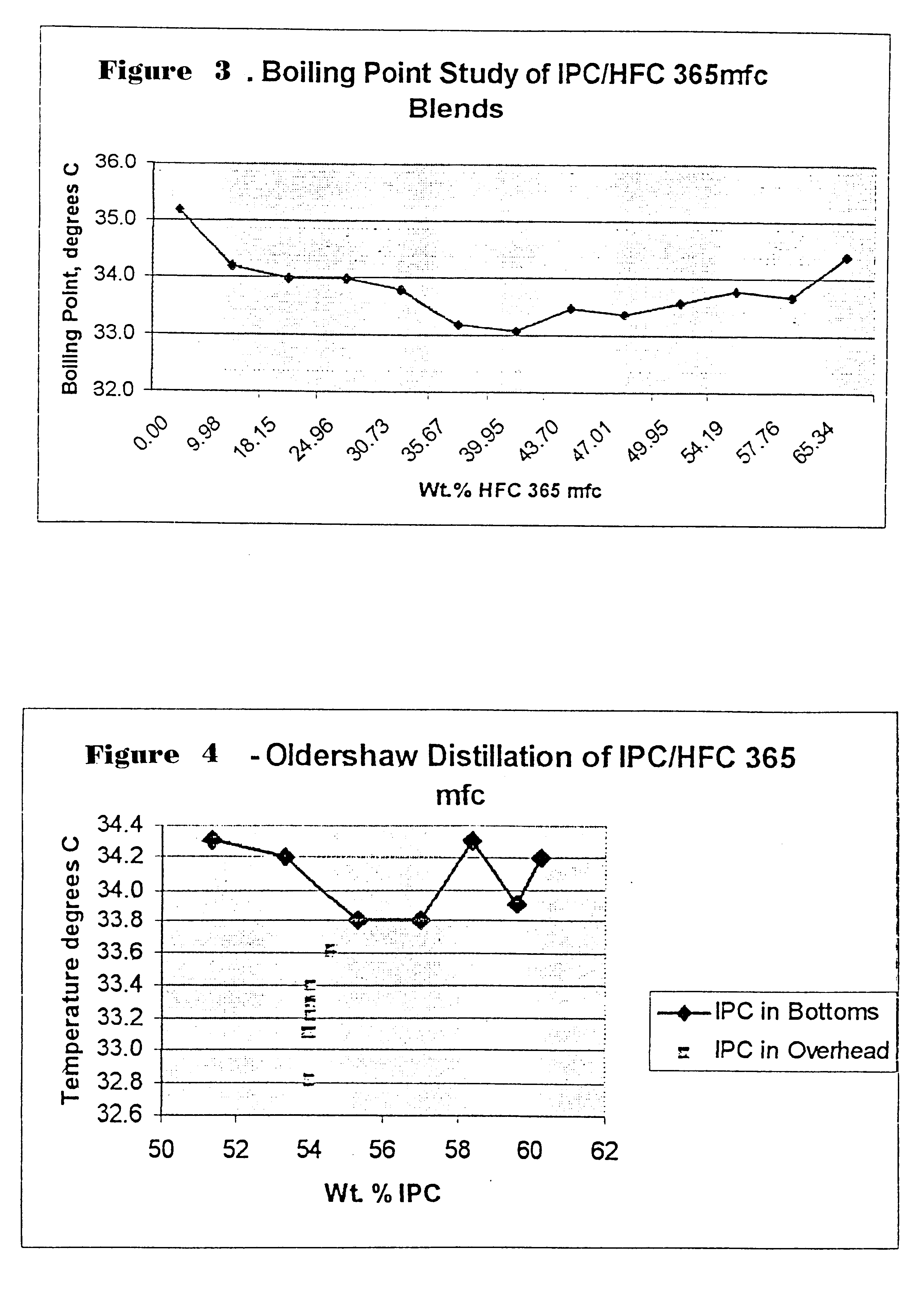

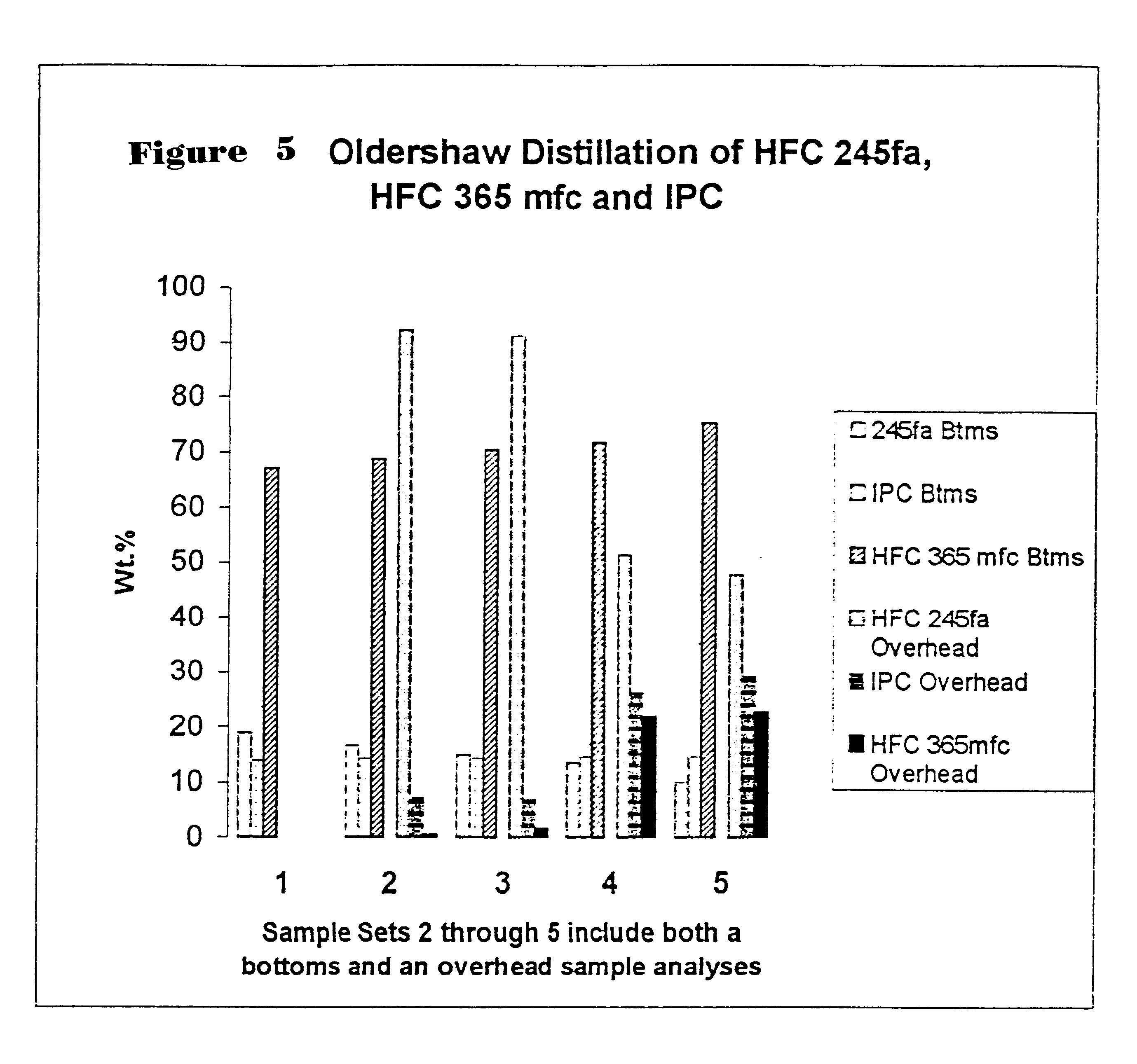

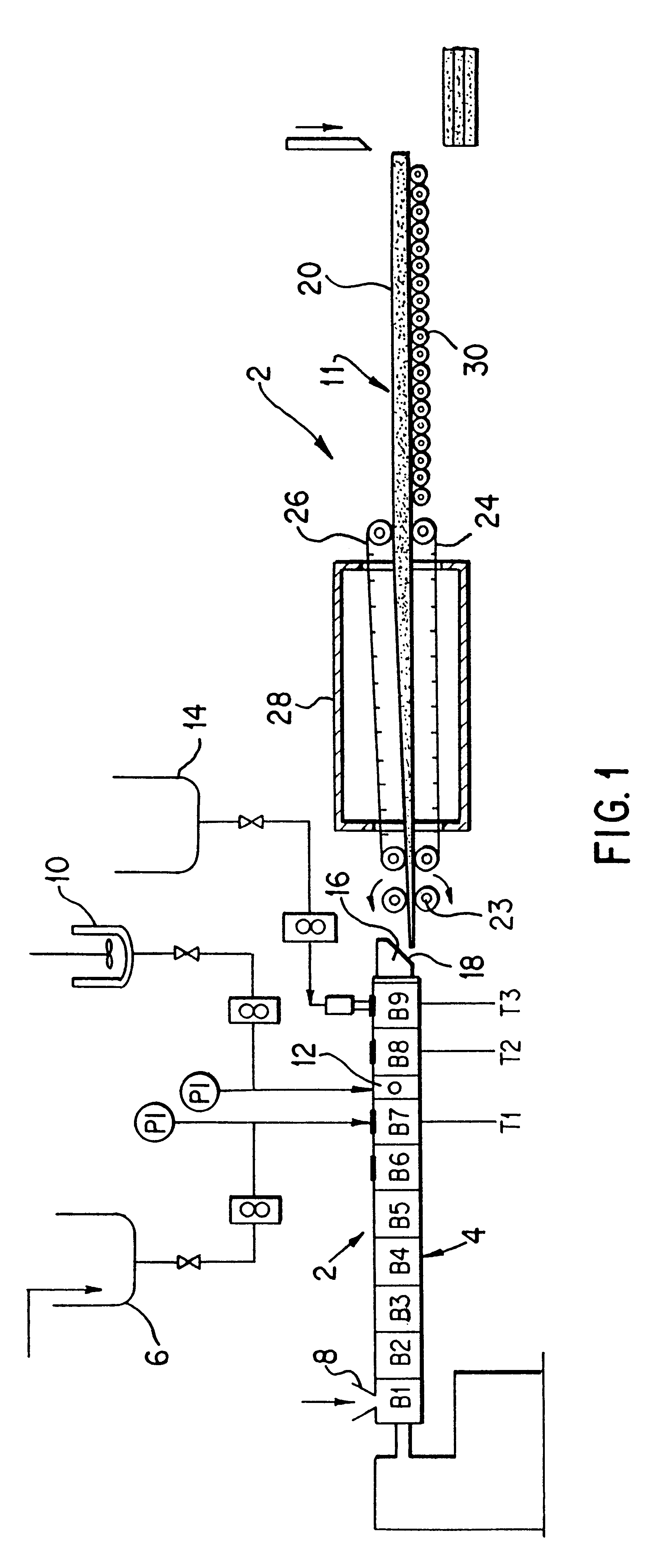

Isopropyl chloride with hydrofluorocarbon or hydrofluoroether as foam blowing agents

InactiveUS6646020B2Combustibility is reduced and eliminatedReduce flammabilityHeat-exchange elementsLiquid soapsPolyisocyanurateHydrofluoroether

A composition useful as a blowing agent having no flash point or reduced combustibility comprising 2-chloropropane and a gas selected from the group consisting of a fluorohydrocarbon, perfluorocarbons, fluoroethers, hydrofluoropolyethers and mixtures thereof is disclosed. A polyisocyanurate foam or a polyurethane modified polyisocyanurate foam having a mainly closed cell structure and also a method for preparing this foam, the latter comprising closed cells wherein a foam blowing agent consisting of a mixture of 2-chloropropane and one or more HFC compounds including pentafluoropropane, pentafluorobutane, heptafluoropropane, hexafluoropropane or pentafluoroethane are disclosed. Pentanes can be added if desired. Azeotropic mixtures in which 2-chloropropane is an ingredient are disclosed.

Owner:OCCIDENTAL CHEM CORP

Dual components foaming system and products in use for fireproof plugging

This invention discloses a bi-component foaming system and its product used for fireproof plugging of buildings. The bi-component foaming system is a fireproof plugging material, and is prepared by mixing components A and B at a ratio of (1-4):2, and reacting. Compoent A is composed of polyester polyol, polyether polyol, catalyst, foaming agent, foaming stabilizer and composite flame retardant. Component B is composed of polyisocyanates. The basic component of the bi-component foaming system and its product is flame retardant bi-component polyurethane foam plastic. The flame retardancy technique in this invention is much different from traditional flame retardancy technique using polyurethane foam plastic as the fireproof plugging material. Firstly, hollow microbeads are added during the preparation of polyurethane foam plastic, which can improve flame retardant effect, reduce the material viscosity, improve processability, and reduce the heat conductivity of polyurethane foam plastic. Thus polyurethane foam plastic with good heat insulation effect can be obtained. Secondly, polyisocyanurate is used to modify polyurethane foam plastic, which can improve the flame retardancy of polyurethane foam plastic. Thirdly, the synergistic flame retardant effect of polyisocyanurate, ammonium polyphosphate and expandable graphite can largely improve the flame retardancy of polyurethane foam plastic, and can largely reduce the addition amount of flame retardant with the same flame retardant effect.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Non-silicone surfactants for polyurethane or polyisocyanurate foam containing halogenated olefins as blowing agents

The invention provides polyurethane and polyisocyanurate foams and methods for the preparation thereof. More particularly, the invention relates to open-celled, polyurethane and polyisocyanurate foams and methods for their preparation. The foams are characterized by a fine uniform cell structure and little or no foam collapse. The foams are produced with a polyol premix composition which comprises a combination of a hydrohaloolefin blowing agent, a polyol, a surfactant component which comprises a non-silicone surfactant and is substantially absent of a silicone surfactant, and a tertiary amine catalyst.

Owner:HONEYWELL INT INC

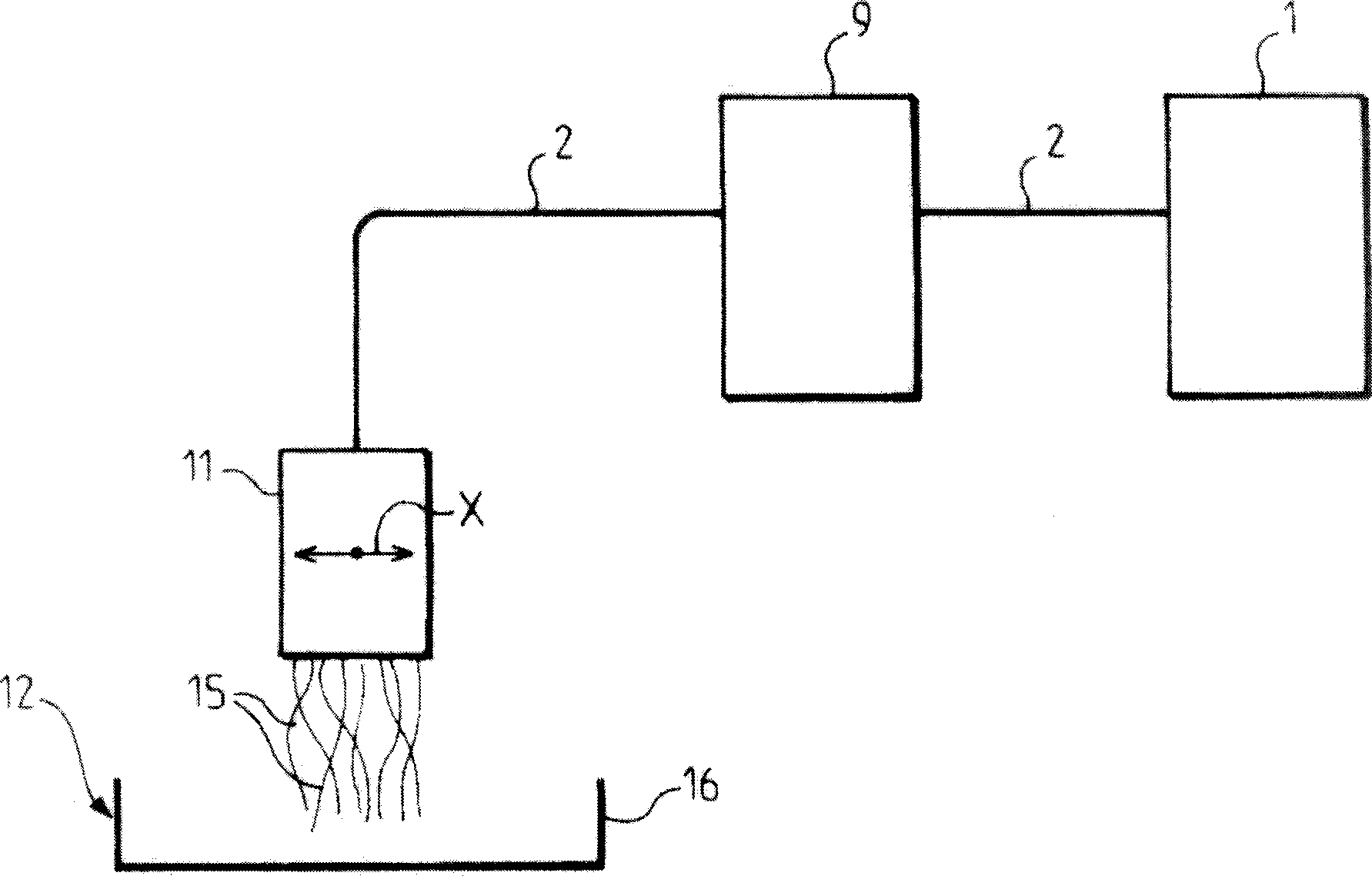

Method for preparing aliphatic polyisocyanurate by using microreactor

The invention discloses a method for preparing aliphatic polyisocyanurate by using a microreactor, which comprises the following steps: adding isocyanurate and a catalyst compound system formed by quaternary ammonium salt and inert alcohol solvent to enable the isocyanurate to generate a polymerization reaction; then feeding a formed material flow into a dynamic reactor for continuously carrying out a polymerization reaction; and enabling reaction solution obtained by the reaction to pass through a second-stage evaporator to obtain a polyisocyanurate product. The method can well control the reactivity of the catalyst, so that a trimerization reaction of the isocyanurate is finished under a mild condition to obtain a tripolymer product with excessively-high quality.

Owner:WANHUA CHEM GRP CO LTD +1

Extruded polymer foam with filler particles and method

InactiveUSRE37095E1High quality dispersionAvoid reactionFlat articlesCalcium silicatePolyisocyanurate

A thermosetting foam, preferably polyisocyanurate or polyurethane foam, is prepared in an extruder which permits the incorporation of high levels of filler particles. The method includes introducing polyol, isocyanate and filler particles to an extruder screw for mixing. In conjunction with extruding, a catalyst is added. The catalyst may be added either in a last extruder barrel or with the extruder head. Foam with filler particle content in excess of 12% made be readily made. Filler particles, such as aluminum trihydrate, perlite, carbon black, diatomaceous earth, polyiso powders, ammonium phosphate, fly ash, barium sulfate, calcium silicate, and calcium carbonate, may be used. The process described is preferably used for making foam boards or bunstock.

Owner:IP RIGHTS

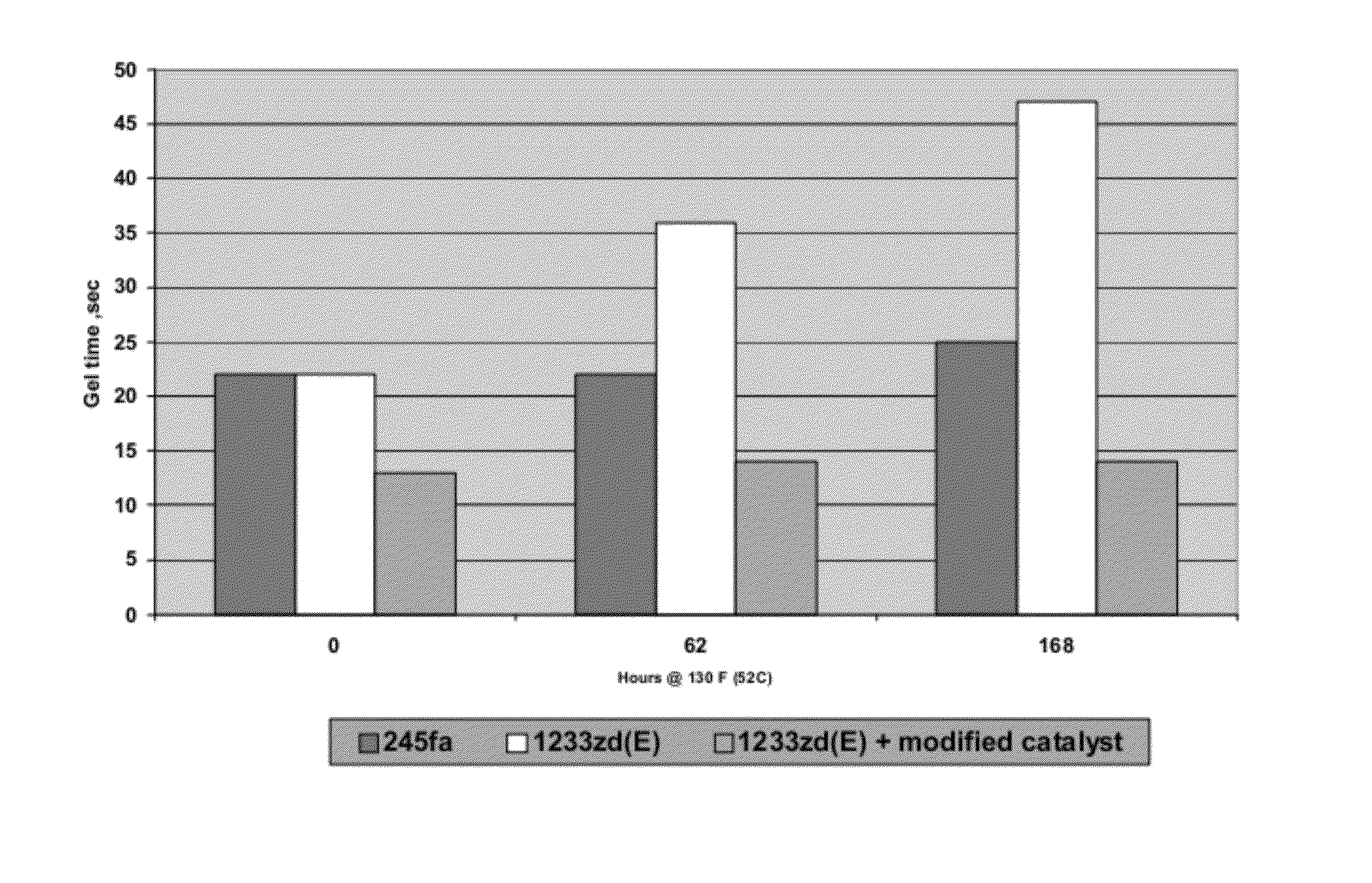

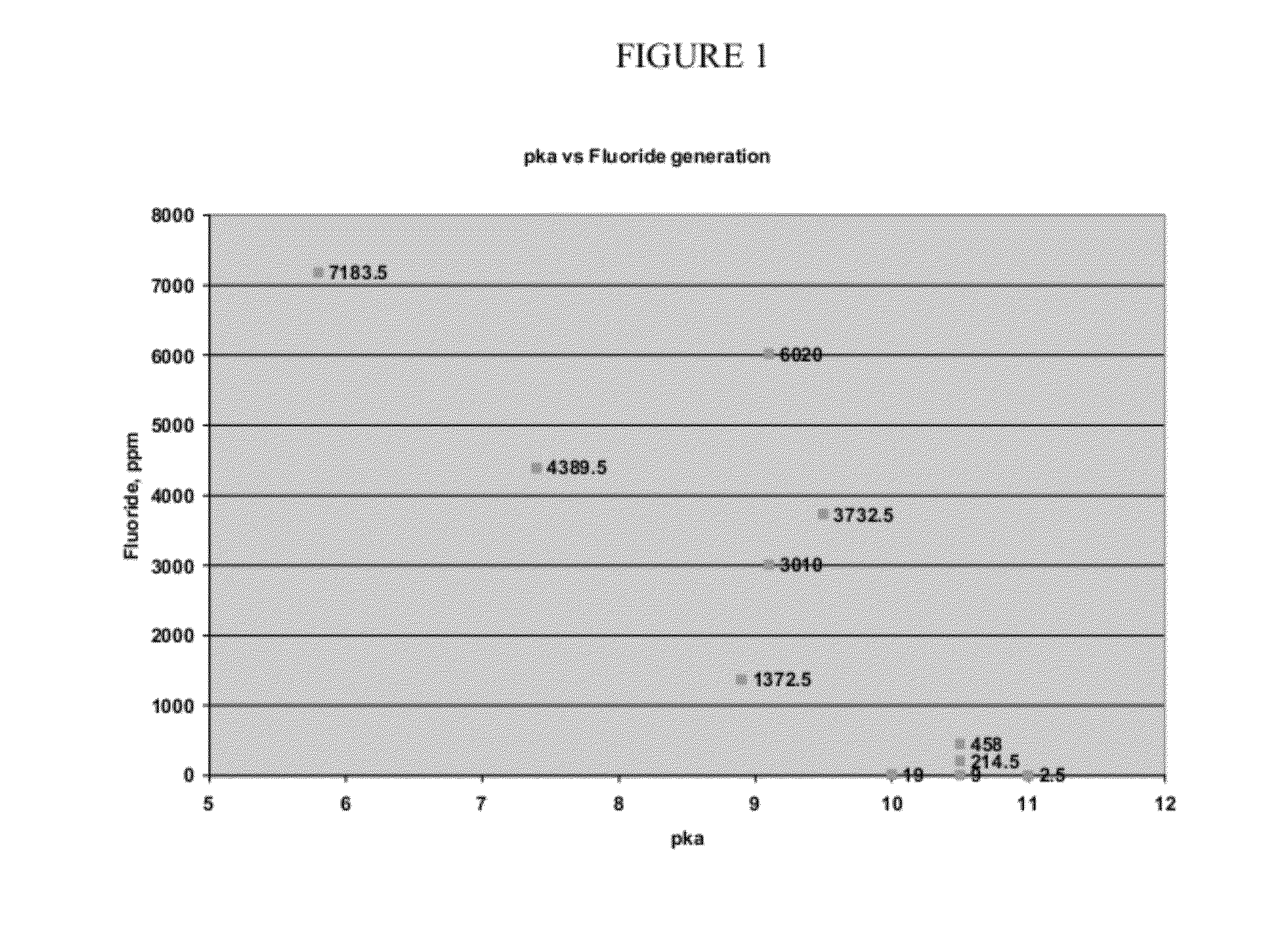

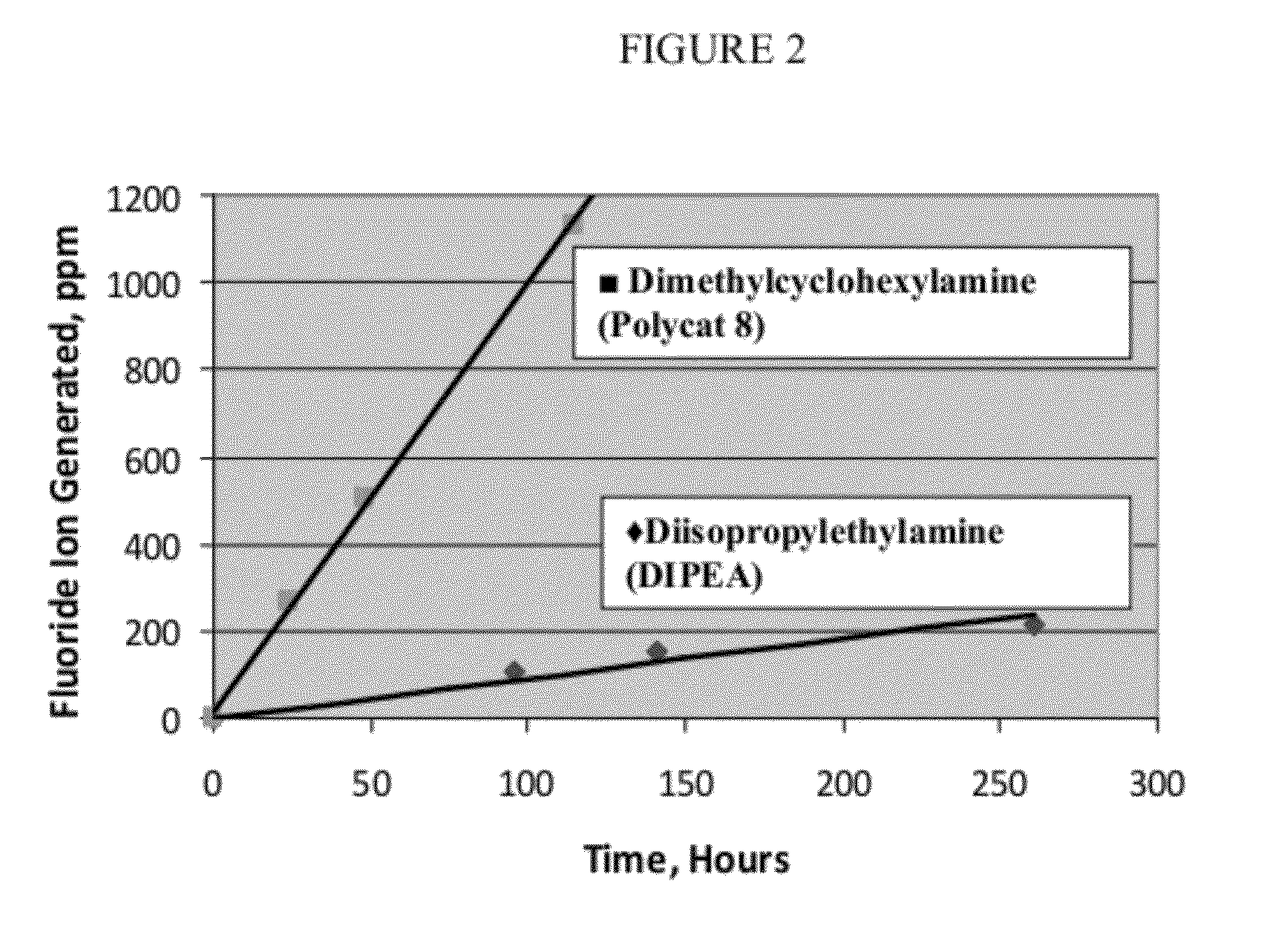

Catalysts For Polyurethane Foam Polyol Premixes Containing Halogenated Olefin Blowing Agents

InactiveUS20110152392A1Extended shelf lifeQuality improvementOrganic-compounds/hydrides/coordination-complexes catalystsFoaming agentPolyisocyanurate

The invention provides polyurethane and polyisocyanurate foams and methods for the preparation thereof. More particularly, the invention relates to closed-celled, polyurethane and polyisocyanurate foams and methods for their preparation. The foams are characterized by a fine uniform cell structure and little or no foam collapse. The foams are produced with a polyol premix composition which comprises a combination of a hydrohaloolefin blowing agent, a polyol, a silicone surfactant, and a non-amine catalyst used alone or in combination with an amine catalyst.

Owner:HONEYWELL INT INC

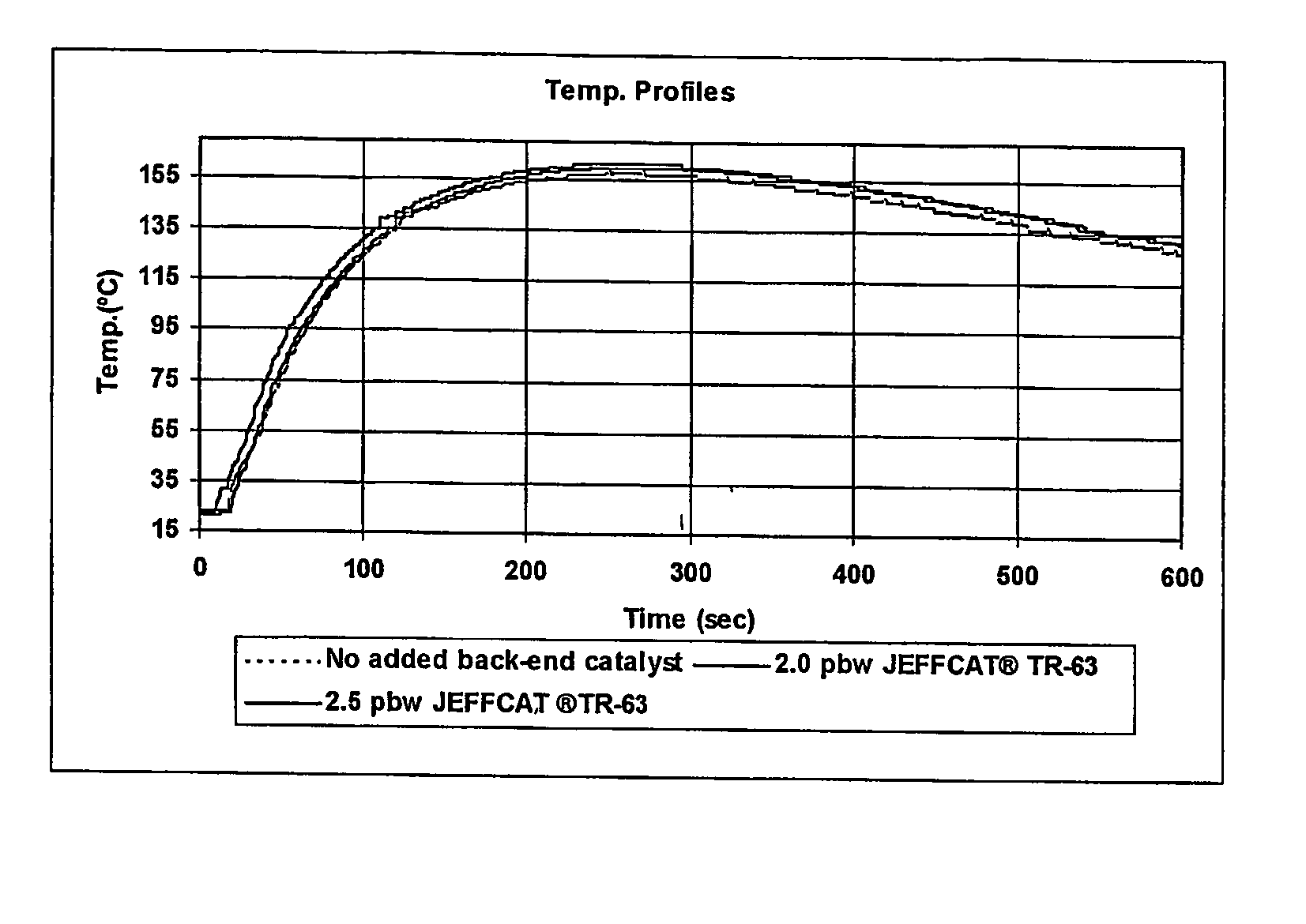

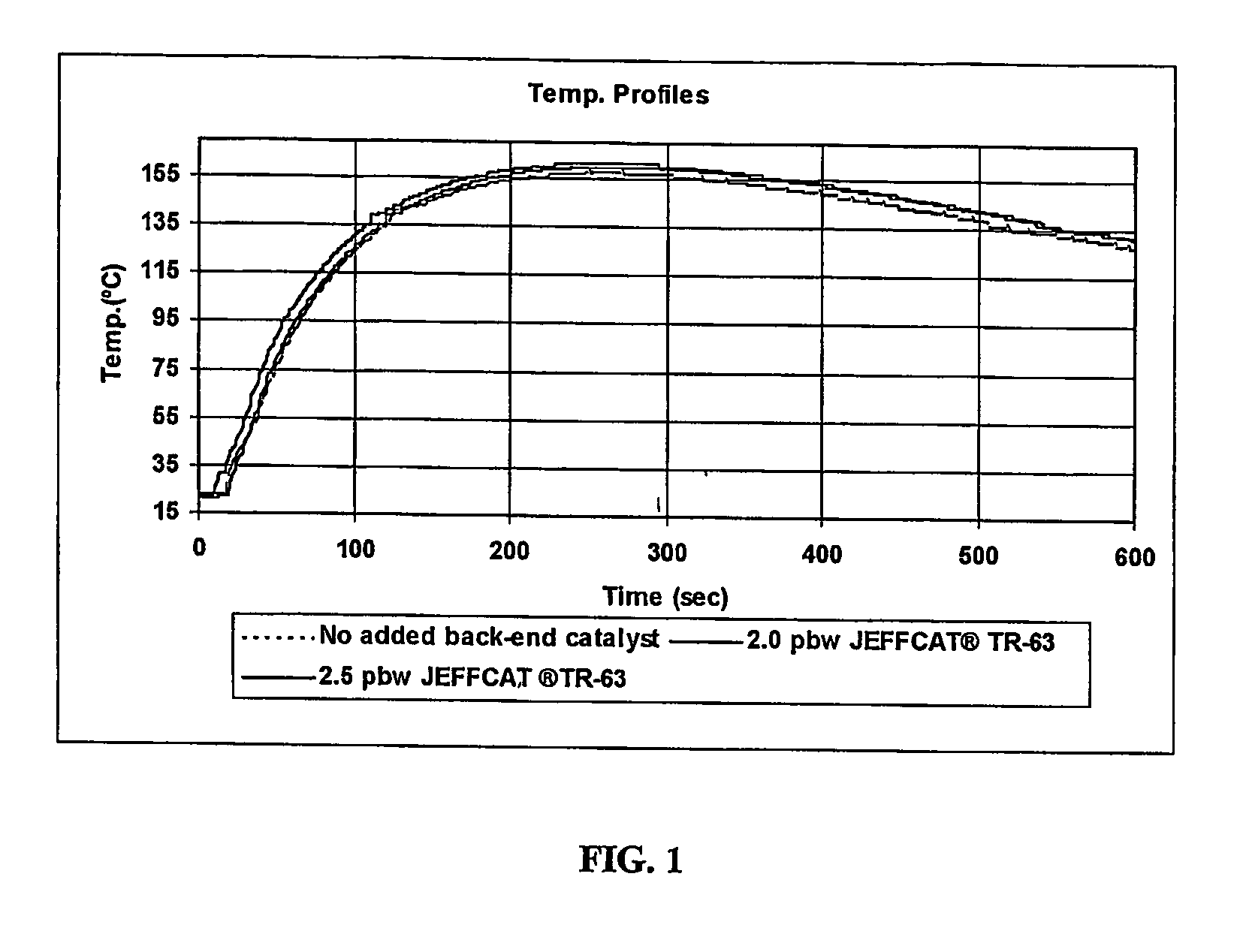

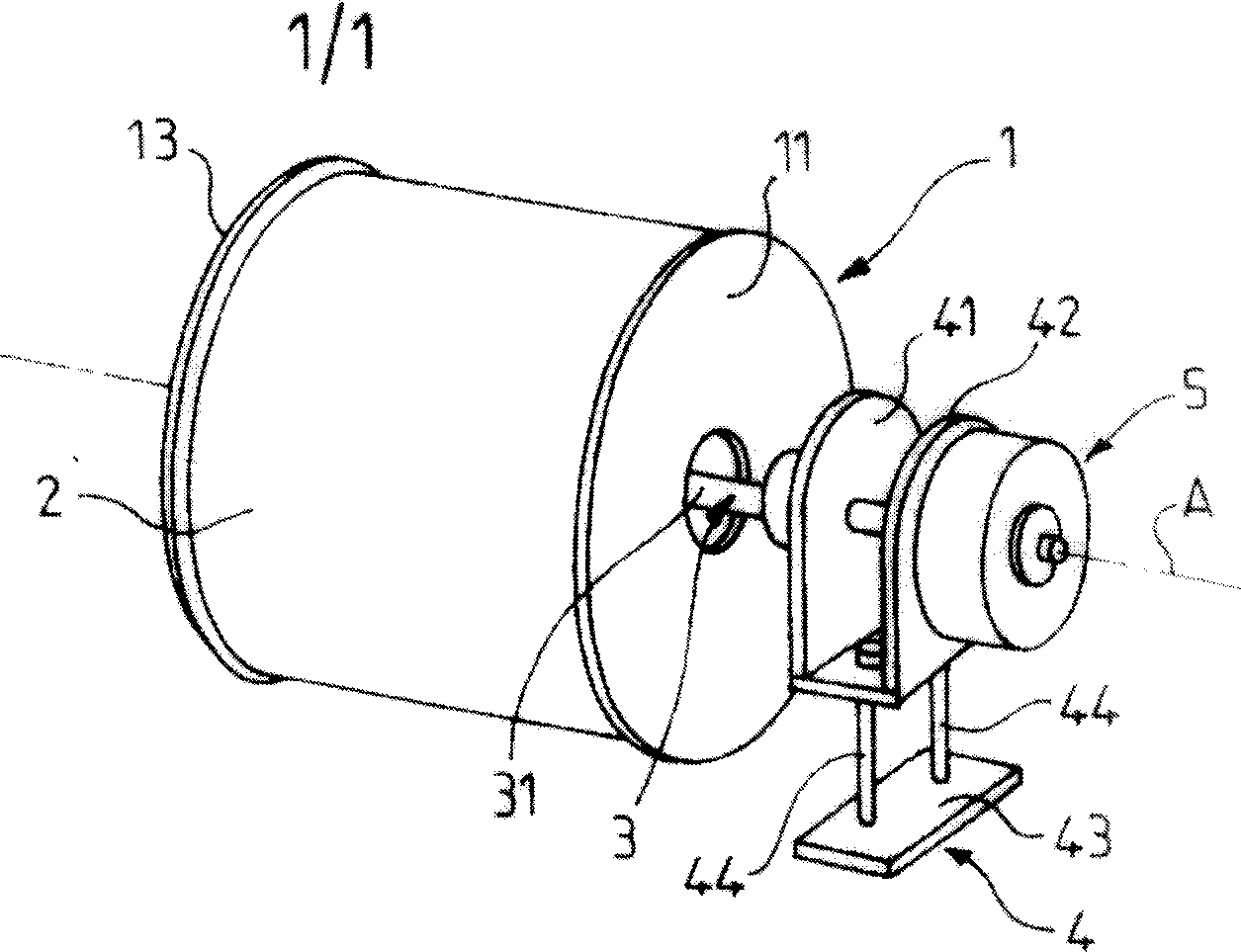

Process for manufacturing rigid polyisocyanurate foam products

InactiveUS6355701B1Layered product treatmentSynthetic resin layered productsProduction linePolyisocyanurate

Owner:JOHNS MANVILLE INT INC

Polyurethane Foam Premixes Containing Halogenated Olefin Blowing Agents And Foams Made From Same

The invention provides polyurethane and polyisocyanurate foams and methods for the preparation thereof. More particularly, the invention relates to closed-celled, polyurethane and polyisocyanurate foams and methods for their preparation. The foams are characterized by a fine uniform cell structure and little or no foam collapse. The foams are produced with a polyol premix composition which comprises a combination of a hydrohaloolefin blowing agent, a polyol, a silicone surfactant, and a non-amine catalyst used alone or in combination with an amine catalyst.

Owner:HONEYWELL INT INC

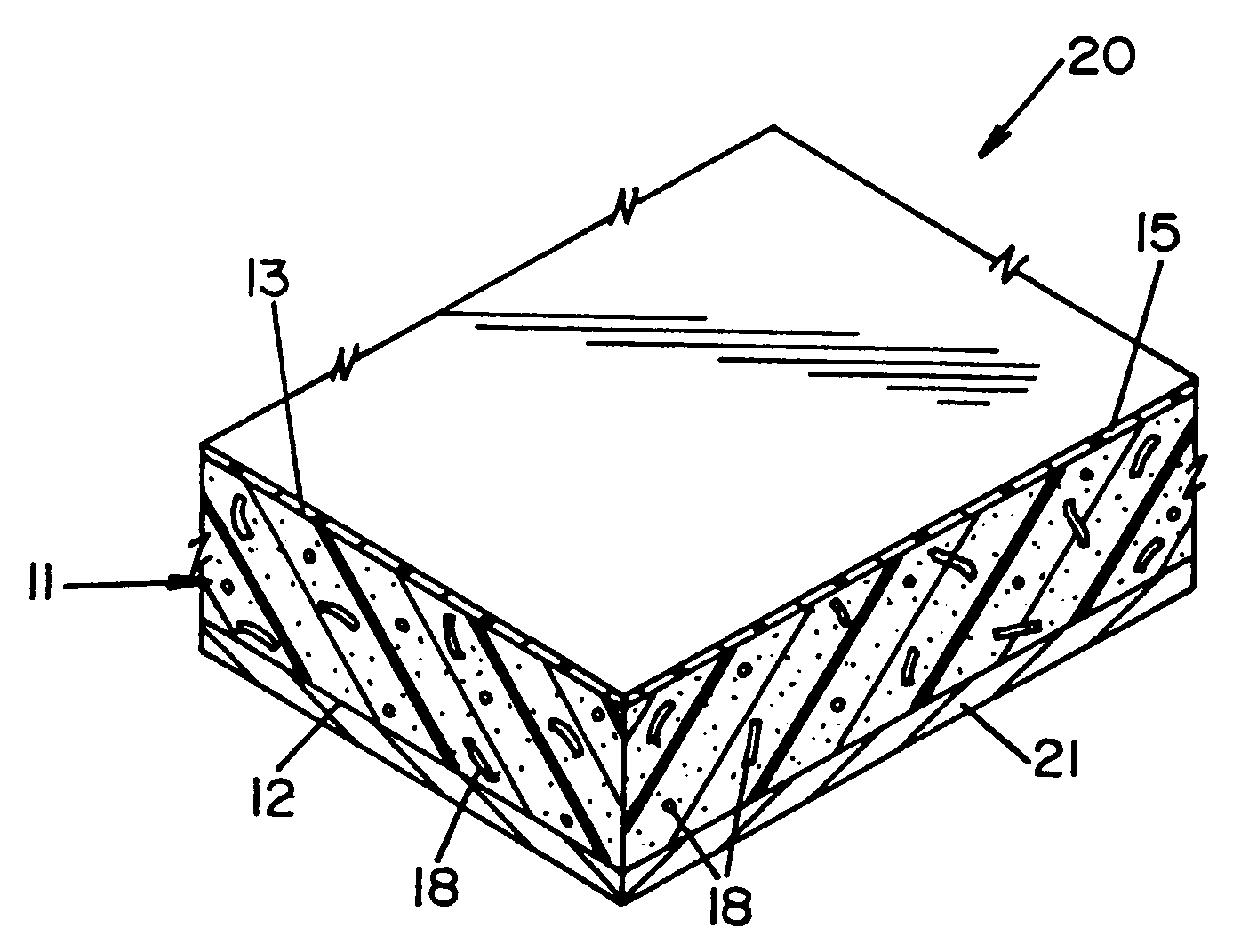

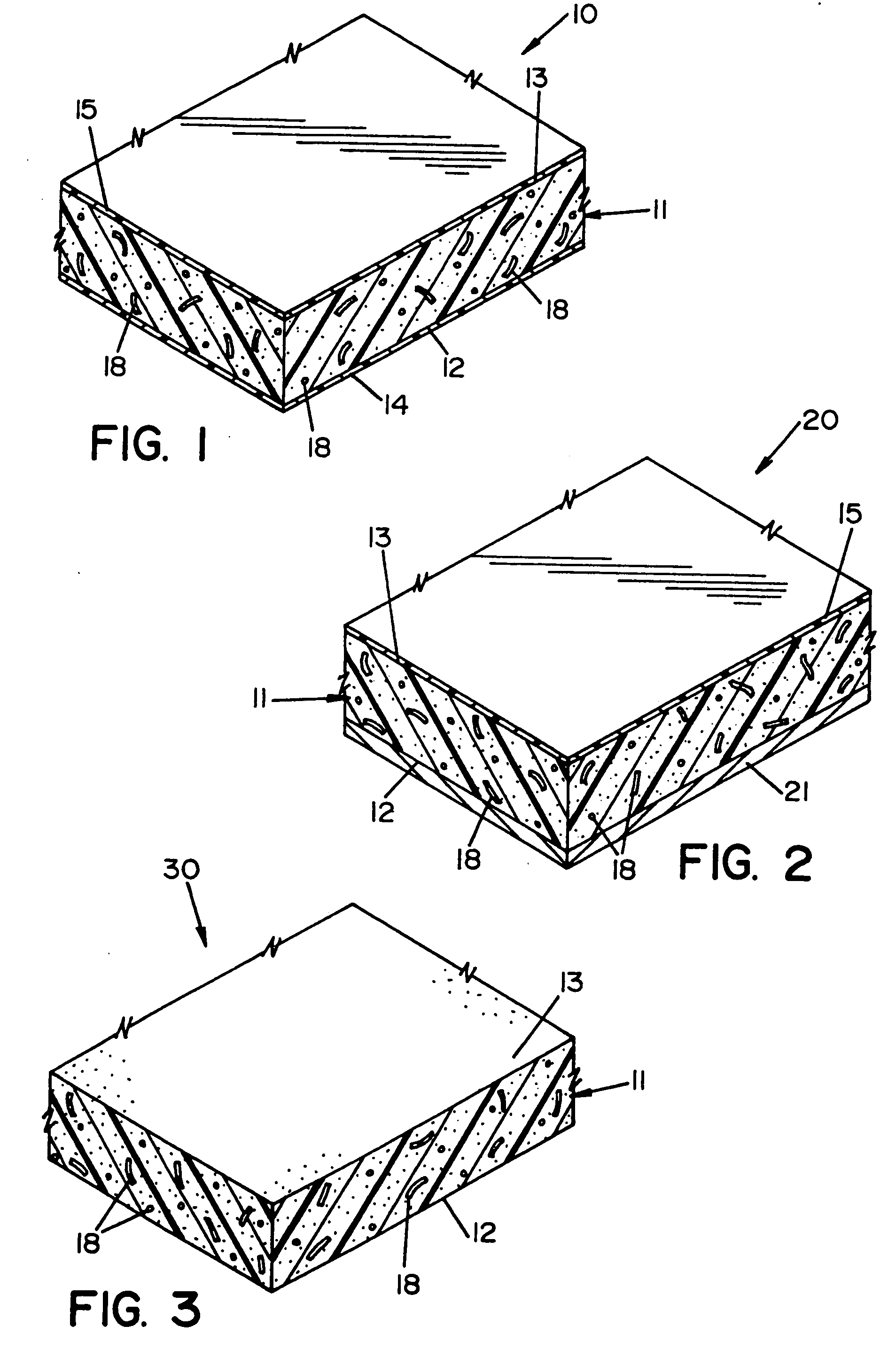

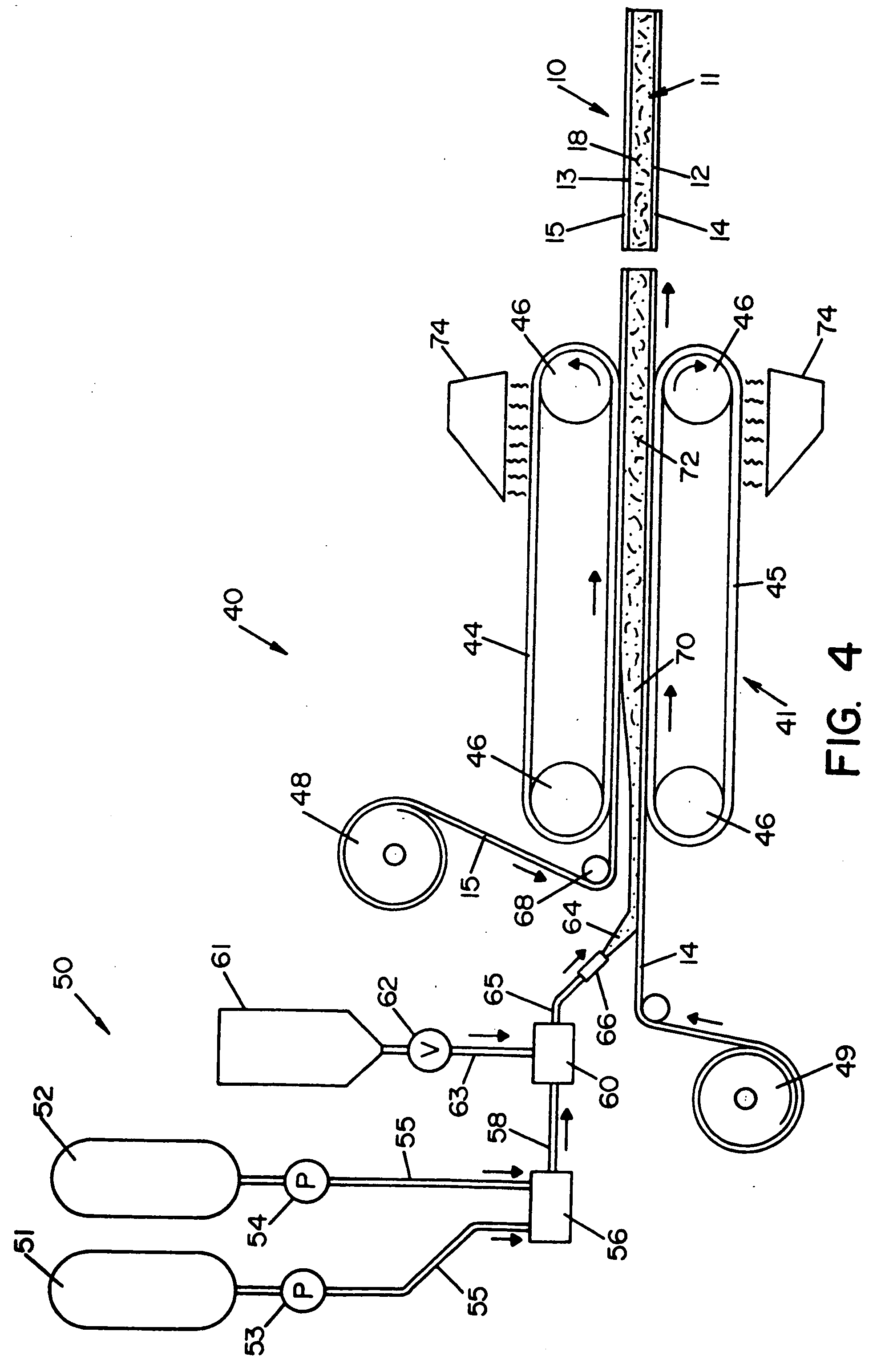

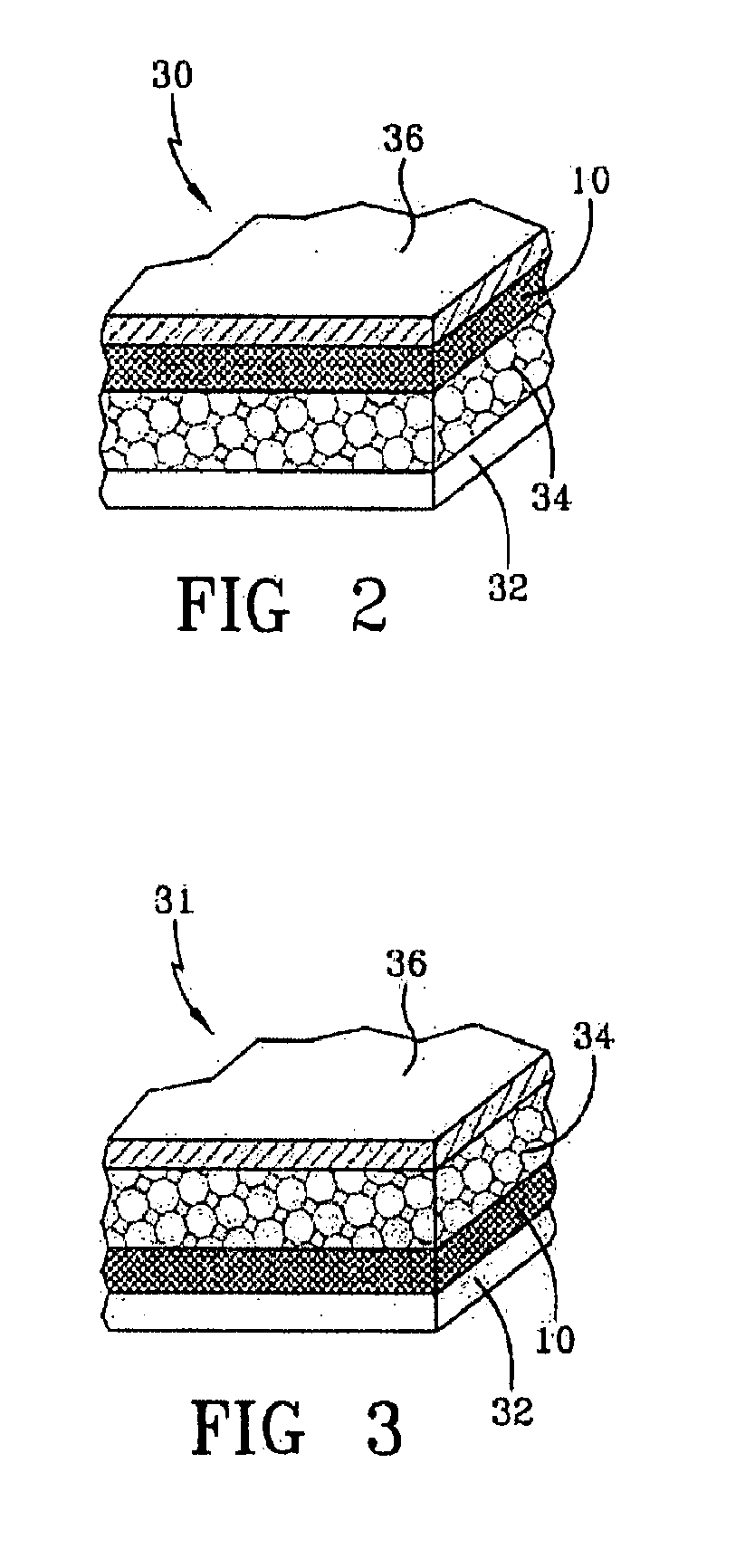

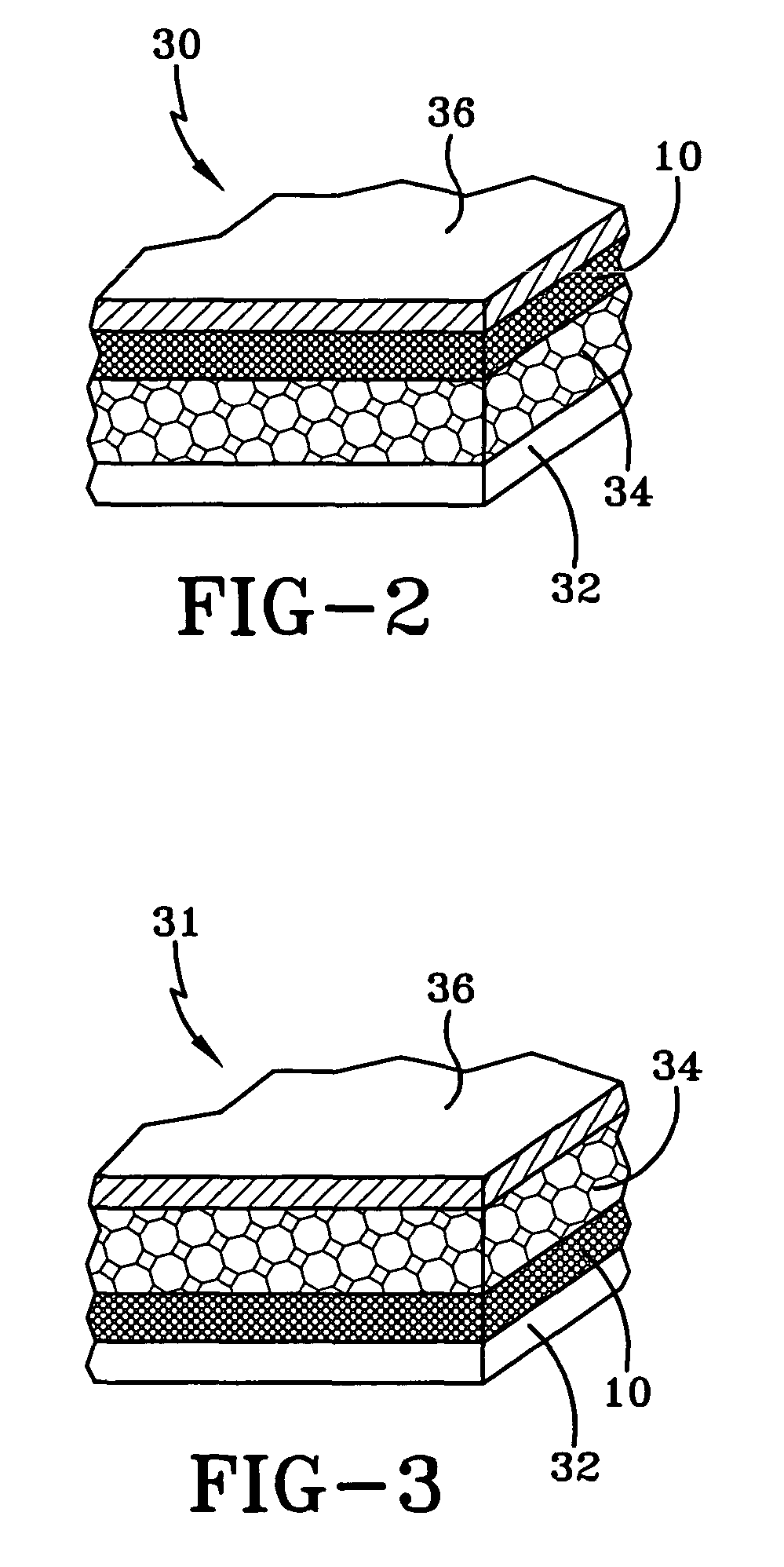

Tough and durable insulation boards produced in-part with scrap rubber materials and related methods

InactiveUS20060127664A1Need existsInsensitive to moisture in re-roofingBuild-up roofsSynthetic resin layered productsGlass fiberFiber

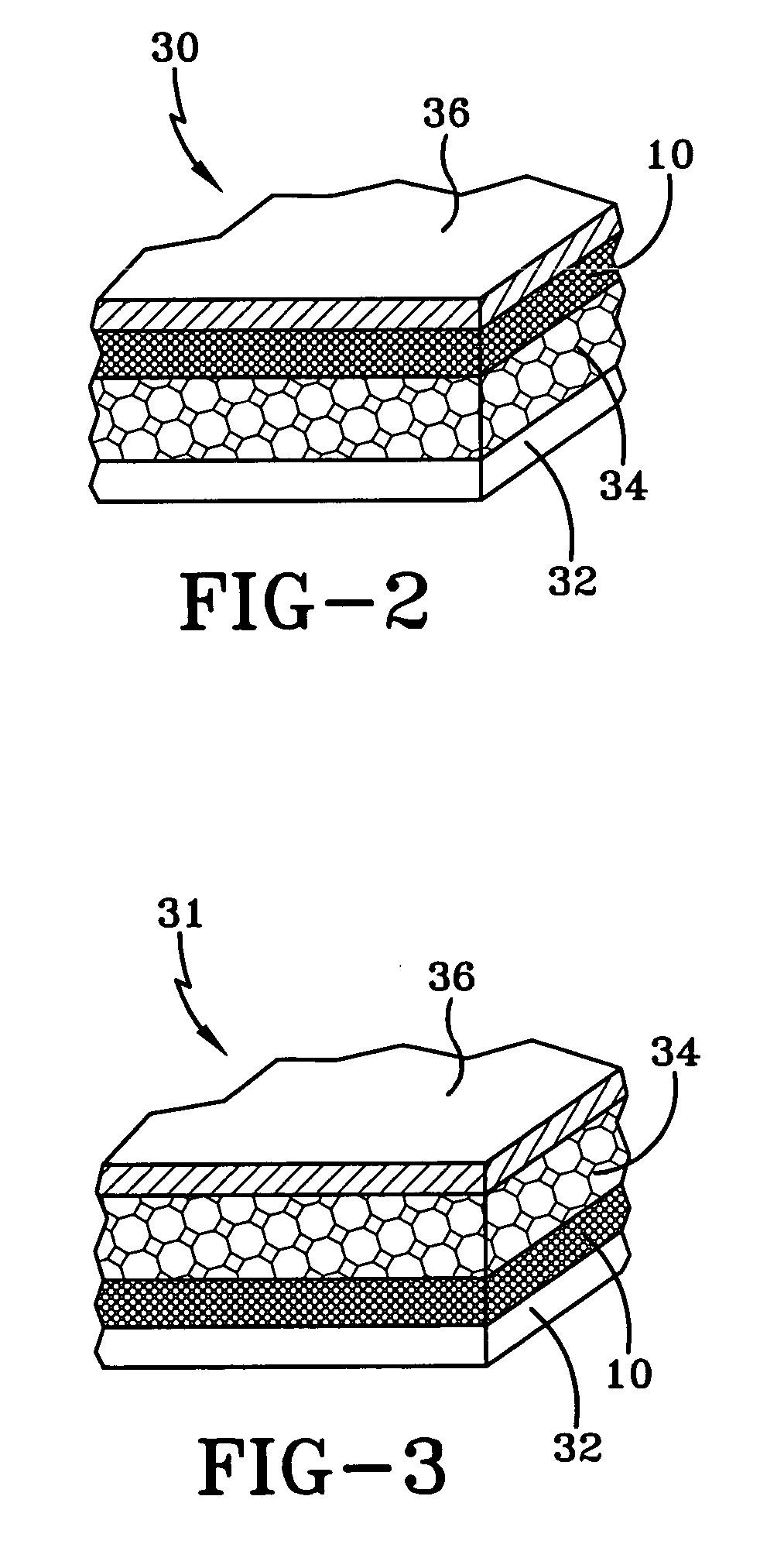

A composite recovery board (10, 20, 30) comprises a foam core (11) having lower (12) and upper (13) surfaces, wherein the foam core is selected from the group consisting of polyisocyanurate and polyurethane materials and mixtures thereof, and a filler within said foam core selected from the group consisting of rubber-tire vents, EPDM scrap material, plastic chips, polyurethane scrap, polyisocyanurate scrap, scrap rubber from recycled tires, wood chips, fiberglass strands and mixtures thereof. A method of re-roofing a roof comprising applying composite boards (10, 20, 30) of the present invention to a roof deck and applying a weather protective layer over the composite boards. A continuous method of making composite recovery boards (10) of the present invention comprises is also provided.

Owner:BFS DIVERSIFIED PRODS

Foams And Foamable Compositions Containing Halogenated Olefin Blowing Agents

ActiveUS20110039964A1Diminishing long-term stabilityImprove decomposition rateDecompositionPolyisocyanurate

The invention provides foam forming methods that comprise: (a) preparing a foamable system comprising at least one hydrohaloolefin; and (b) ensuring either (i) the substantial absence of long-term decomposition-inducing contact between said hydrofluoroolefin and an amine-containing catalyst; (ii) that an effective amount of surfactant is available in the system under conditions which prevent long term exposure of the surfactant to a long-term decomposition reaction environment; or (iii) a combination of (i) and (ii). Related methods, foamable systems and foams are also disclosed. Preferred embodiments provide polyurethane and polyisocyanurate foams and methods for the preparation thereof, including closed-celled, polyurethane and polyisocyanurate foams and methods for their preparation. The preferred foams are characterized by a fine uniform cell structure and little or no foam collapse. The foams are preferably produced with a polyol premix composition which comprises a combination of a hydrohaloolefin blowing agent, a polyol, a silicone surfactant, a catalyst and is further characterized by being substantially free of added water.

Owner:HONEYWELL INT INC

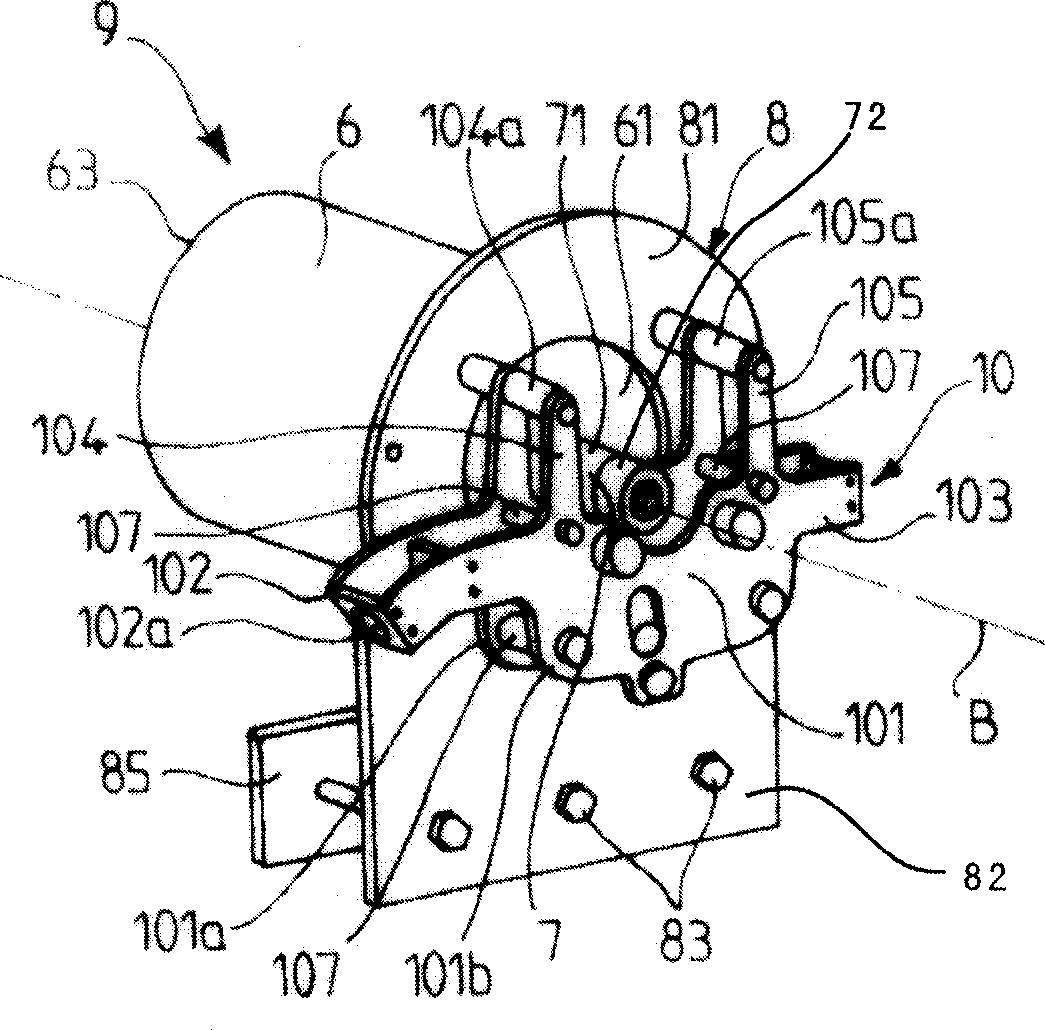

Glassfiber-reinforced polyurethane-polyisocyanurate foam

ActiveCN1834130ASatisfactory thermal insulation propertiesSurprising mechanical propertiesPressure vesselsFor bulk goodsGlass fiberPolymer science

Polyurethane polyisocyanurate foam reinforced by glass fibers, obtained by: reacting an isocyanate component and a polyol component comprising first, second and third polyols, in the presence of a catalyst, a physical and / or chemical blowing agent, an emulsifier and optionally a flame retarding agent to obtain a composition; impregnating, the composition in a glass fiber stacking; and expanding and solidifying the composition to form a reinforced foam block containing the glass fiber stacking. Said reinforced foam block has an average density of 115-135 kg / m3>, and an isocyanate index of 100-180.

Owner:GAZTRANSPORT & TECHNIGAZ

Foam-forming compositions containing mixtures of 2-chloro-3,3,3-trifluoropropene and at least one hydrofluoroolefin and their uses in the preparation of polyisocyanate-based foams

Foam-forming compositions are disclosed which contain a mixture of 2-chloro-3,3,3-trifluoropropene and at least one hydrofluoroolefin. Also disclosed is a closed-cell polyurethane or polyisocyanurate polymer foam prepared from reaction of an effective amount of the foam-forming composition with a suitable polyisocyanate. Also disclosed is a process for producing a closed-cell polyurethane or polyisocyanurate polymer foam by reacting an effective amount of the foam-forming composition with a suitable polyisocyanate.

Owner:EI DU PONT DE NEMOURS & CO

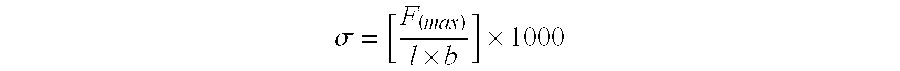

Two-component polyisocyanurate adhesive and insulation panels prepared therefrom

A layered insulation panel including a rigid polyisocyanurate foam layer and, adhered to at least one surface thereof, a facing material. The two materials are adhered by a two-component polyisocyanurate adhesive, and both the polyisocyanurate adhesive and the polyisocyanurate foam layer undergo polymerization concurrently and in place. The result is that the tensile bond strength between the polyisocyanurate foam layer and the facing surface is improved, due to interaction between the polymerization occurring at the surface of the foam layer and the polymerization of the polyisocyanurate adhesive.

Owner:DOW GLOBAL TECH LLC

Polyurethane or polyisocyanurate foam composition

Polyurethane or polyisocyanurate foam composition wherein at least 10 percent of the blowing gas volume is carbon dioxide formed from the reaction of polyisocyanate and water or organic acid and including a dipolar aprotic solvent in an amount from 1 percent by weight to 10 percent by weight based on the total weight of the foam forming mixture.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Process for production of isocyanate, isocyanate produced by the process, and use of the isocyanate

ActiveCN101203488AGood pipettingImprove productivityIsocyanic acid derivatives preparationOrganic compound preparationProduction ratePolyisocyanurate

The present invention provides a method for producing isocyanate, which is preferably used in the field of optical materials and is widely used as a raw material for polyurethane-based materials and polyisocyanurate-based materials, including a process capable of improving the productivity of hydrochloride . The manufacturing method of chain aliphatic isocyanate or cycloaliphatic isocyanate of the present invention comprises making chain aliphatic amine or cycloaliphatic amine and hydrogen chloride reaction, obtains chain aliphatic amine hydrochloride or cycloaliphatic amine A method for producing a chain aliphatic or cyclic aliphatic isocyanate according to a hydrochloride step, wherein the step is carried out at a pressure higher than atmospheric pressure by 0.01 MPa or more.

Owner:MITSUI CHEM INC

High density polyurethane and polyisocyanurate construction boards and composite boards

A construction board comprising a cellular body including at least one planar surface, where the cellular body includes a polyurethane or polyisocyanurate cellular structure, where the cellular structure has a density greater than about 2.5 pounds per cubic foot, an ISO index of at least 270, and where the cellular body includes at least 5.0% by weight flame retardant based on the weight of the cellular body.

Owner:HOLCIM

H-grade low-temp. beading polyurethane paint wire-covering paint

InactiveCN1394926AEasy to control smoothnessReduce dosagePolyurea/polyurethane coatingsPolyisocyanurateAdipic acid

The present invention relates to a H-grade low-temp. direct-welding enamelled wire enamel, said enamel liquor mainly includes three portions of hydroxyl component, closed type isocyanate component and solvent. The hydroxyl component is formed from raw materials of dihydric alcohol terephthate or amidoimide dihydric alcohol, new pentanediol or 2-methyl-1,3-propanedio, glycerine, 1,1,1-trihydroxymethyl propane, tri(alpha-hydroxyethyl) isocyanate, adipic acid and phthalic anhydride. The acid value of polyester polybasic alcohol is less than 2, hydroxy value is 70-250, number-average molecular weight is 2000-7000 and molecualr weight distribution index is 2-3. The isocyanate component is made up by using general raw material TDI and MDI through the processes of cyclic self-polymerization or addition with small quantity of tribasic alcohol and closing with dimethyl phenol.

Owner:NANJING UNIV

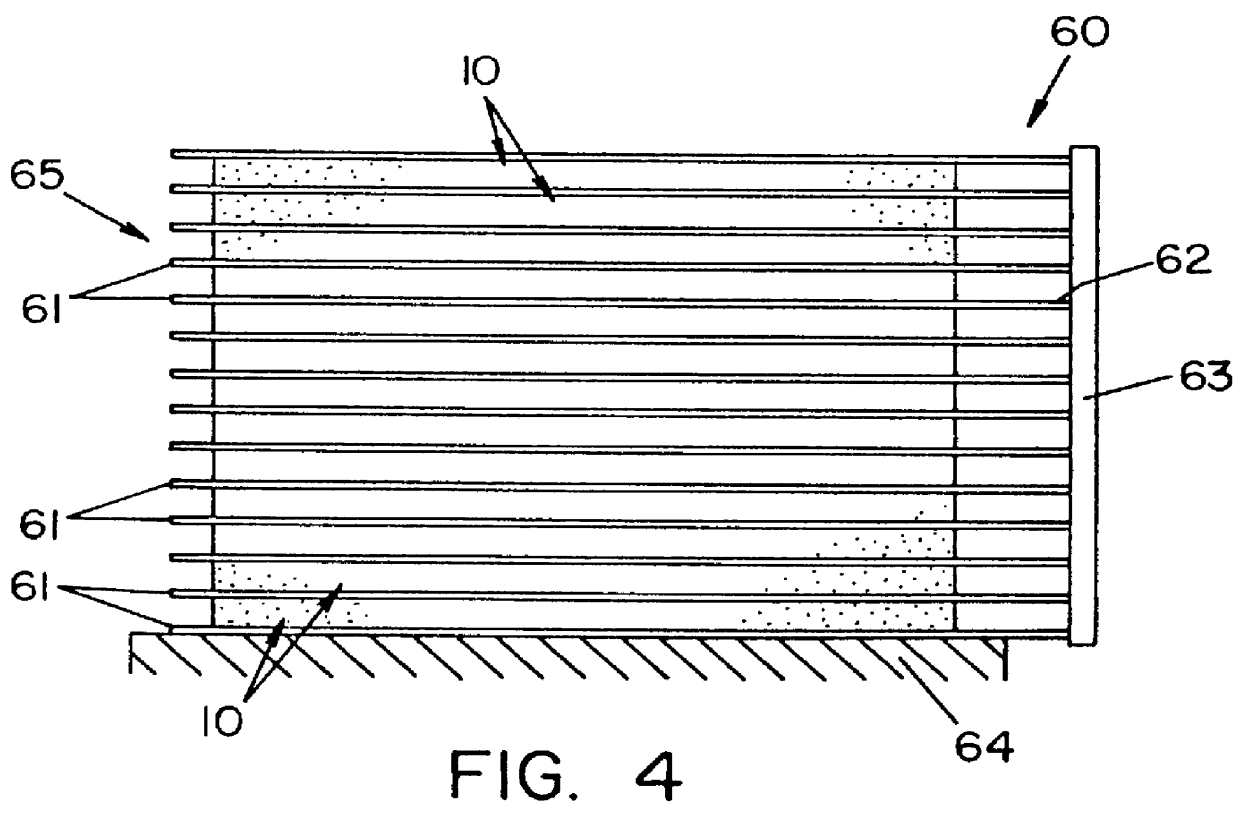

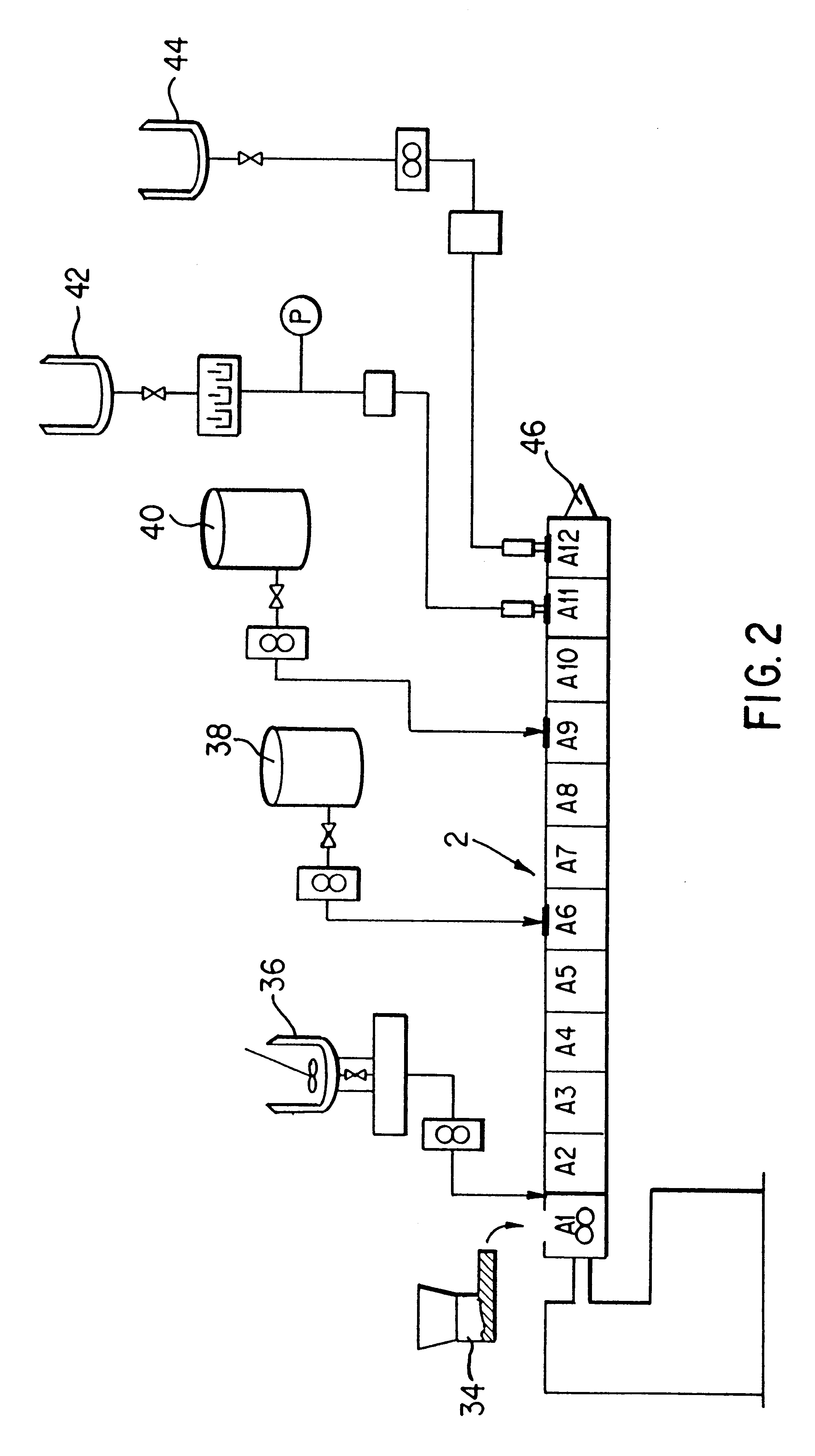

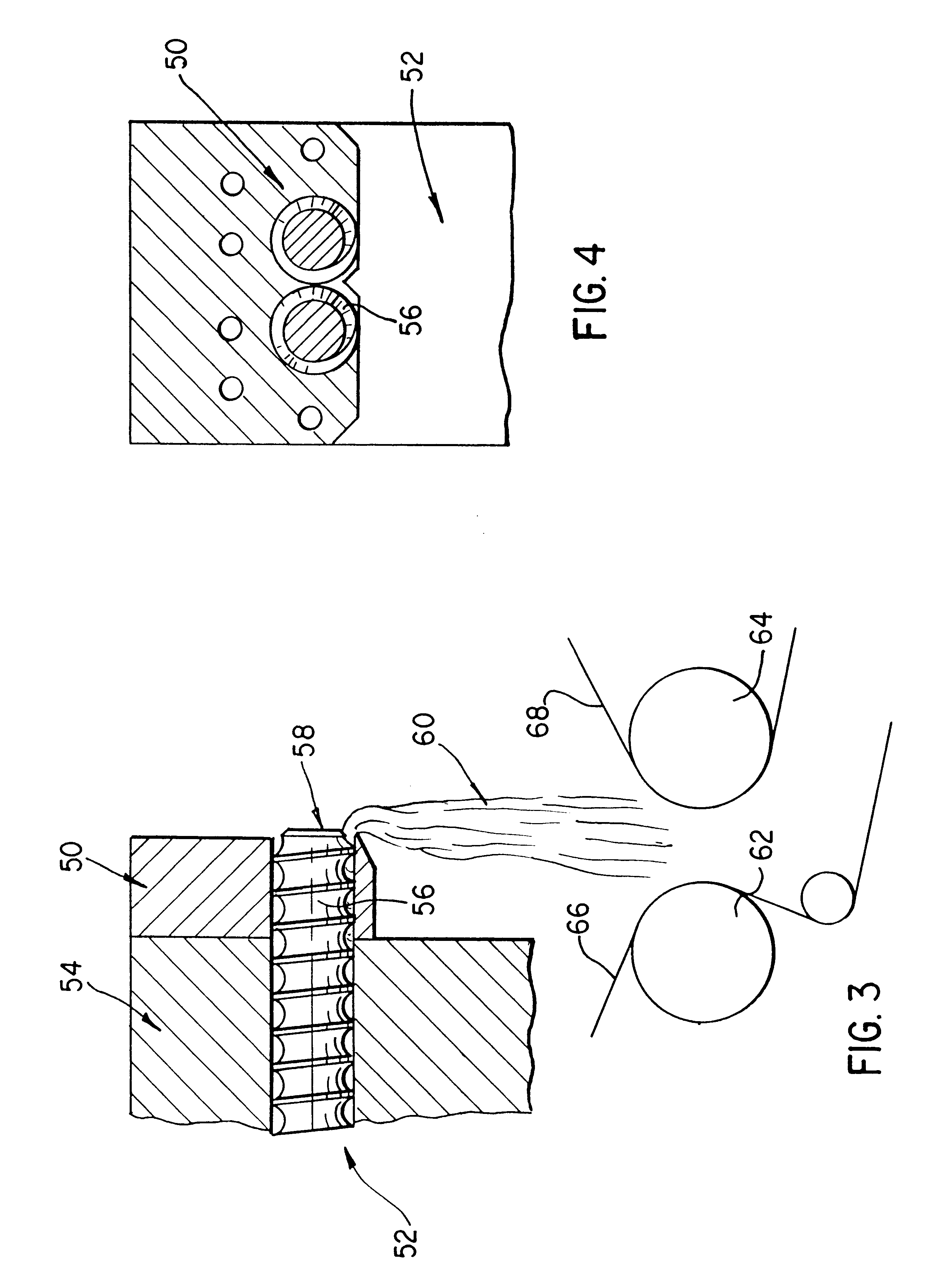

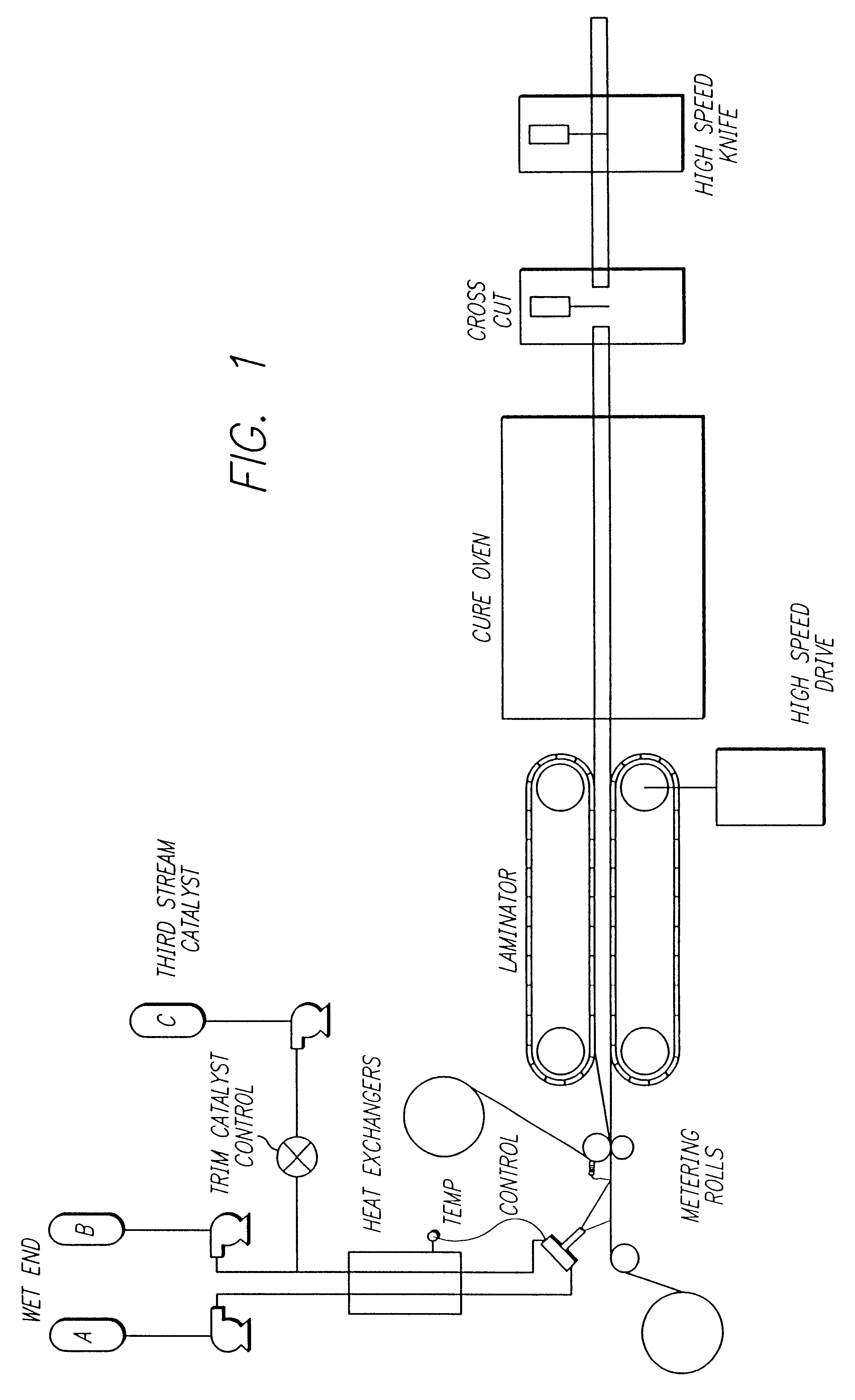

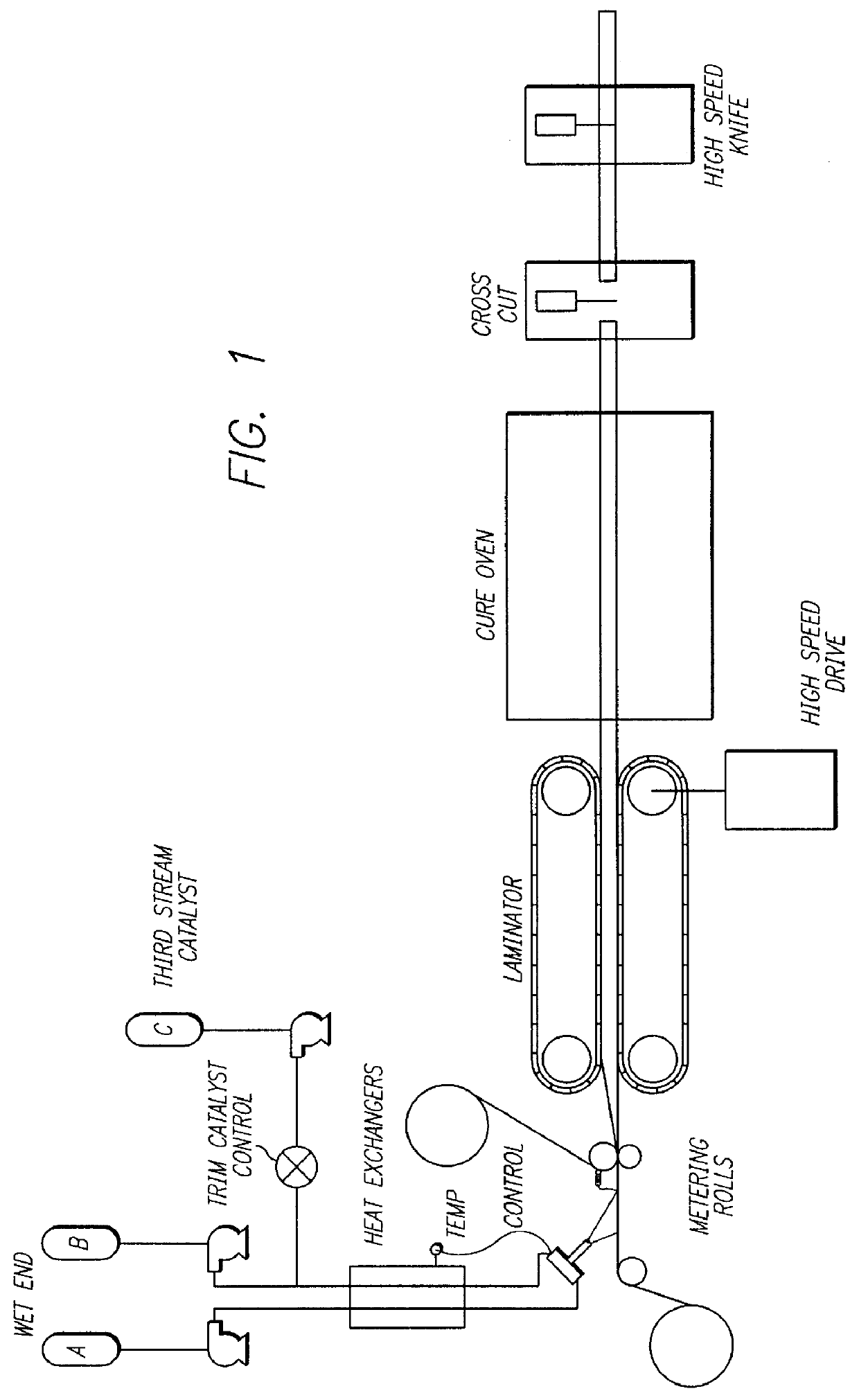

Process for manufacturing rigid polyisocyanurate foam products

A process for manufacturing an insulation board comprising a rigid polyisocyanurate foam core having two major surfaces and a facing material on at least one of the major surfaces, comprising (a) conveying a facing material along a production line for attachment to one major surface of the core; (b) applying a foam-forming mixture of polyisocyanurate to the facing material such that the mixture is applied along the entire width of the facing material; (c) optionally conveying a second facing material along the production line for attachment to the other major surface of the core; (d) conveying the facing material with applied foam-forming mixture into a laminator which comprises a gap for foam expansion and allowing the mixture to foam and expand to fill the gap within the laminator; and (e) curing the foam. The process provides excellent boardstock thickness control, minimal wasted densification at the foam / facer interface, greater compressive strength and high line speed.

Owner:JOHNS MANVILLE INT INC

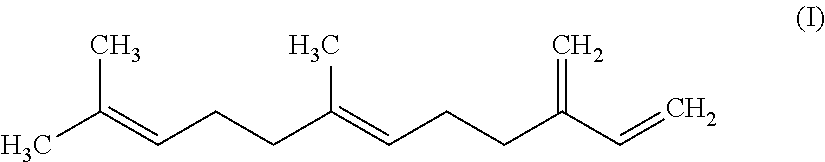

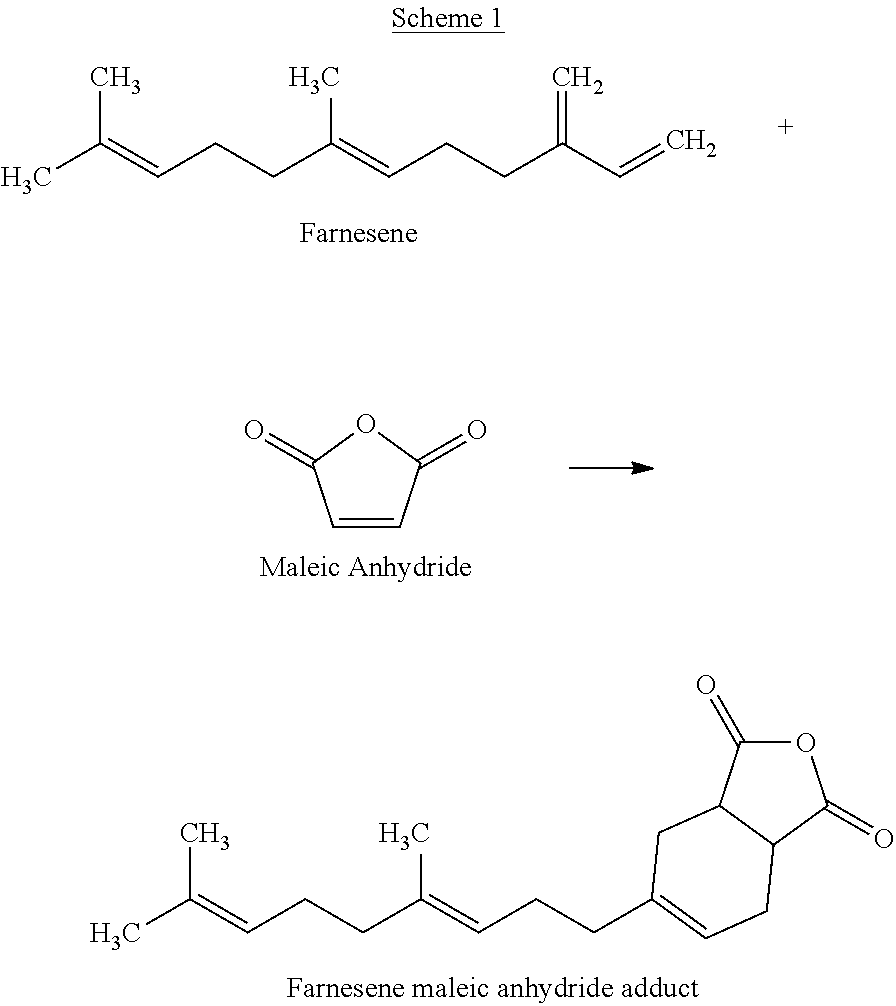

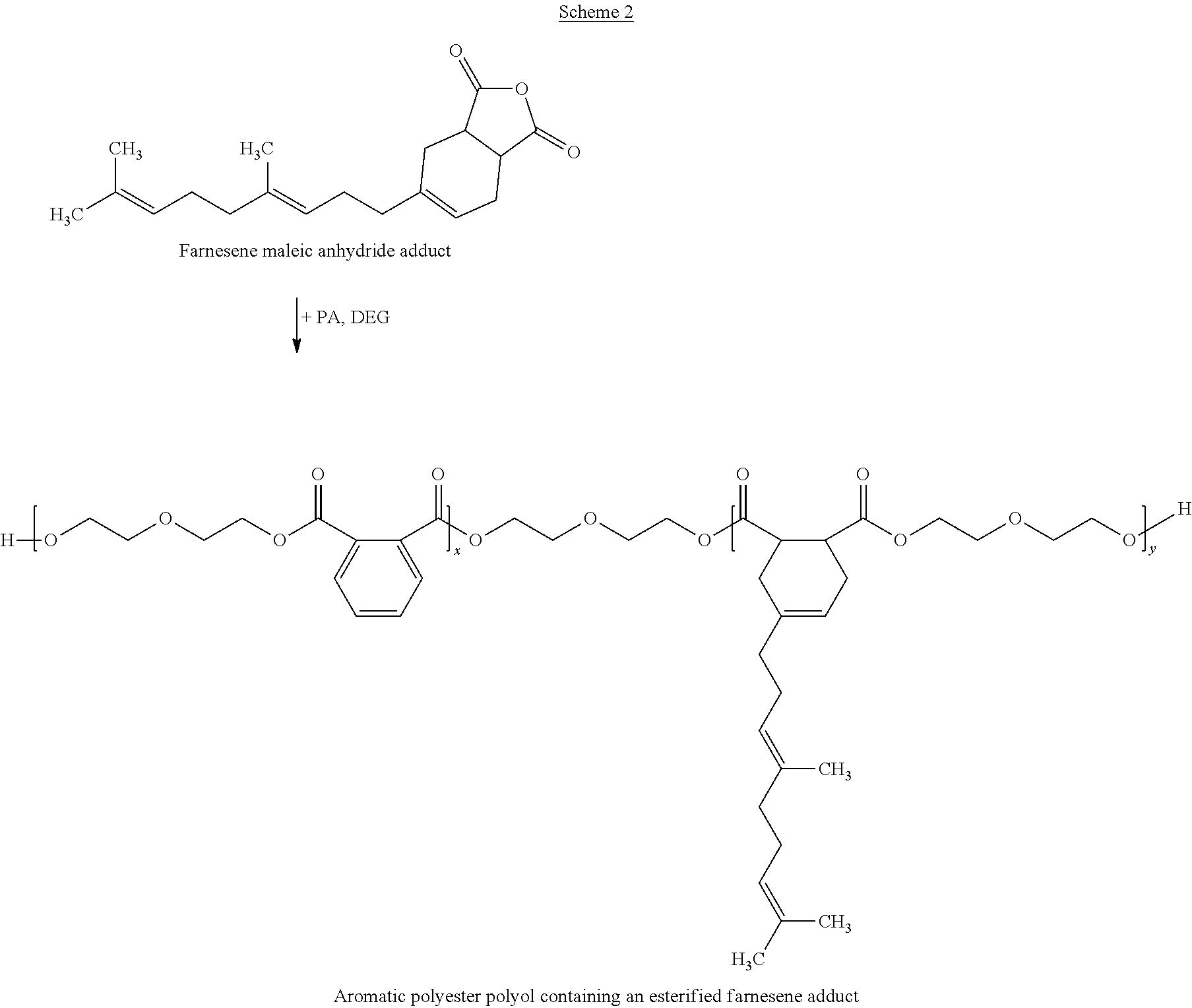

Polyester Polyols Containing Diels-Alder or Ene Adducts

Polyester polyols containing adducts formed from Diels-Alder and Ene reactions are disclosed. Processes for making the polyester polyols and uses of the polyester polyols as polyurethane coatings, adhesives, sealants, elastomers, and foams are also disclosed. In some embodiments, the polyester polyols contain biorenewable adducts based on maleic anhydride and farnesene and have particular application in making rigid and flexible polyurethane or polyisocyanurate foams.

Owner:STEPAN COMPANY

High density polyurethane and polyisocyanurate construction boards and composite boards

A covered low-slope or flat roof comprising (a) a roof deck, (b) an optional insulation board including a polyurethane or polyisocyanurate cellular structure having a density that is less than 2.5 pounds per cubic foot, (c) a coverboard including a polyurethane or polyisocyanurate cellular structure having a density greater than about 2.5 pounds per cubic foot, and (d) a membrane.

Owner:HOLCIM TECHNOLOGY LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com