Extruded polymer foam with filler particles and method

a polymer foam and filler technology, applied in the field of foamed polymer materials, can solve the problems of limited use of filler materials, damage to the foam, and inability to produce polymer foams, etc., and achieve the effect of inhibiting the reaction of mixed components within the screw and high quality dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

With reference to FIG. 5, an extrusion system 102 which is also suitable for practicing the invention is illustrated. Extrusion system 102 includes a single or twin screw extruder 104 and an associated reservoir system 106. The extruder 104 includes a series of barrels C1-C12 and an extruder head 120. The reservoir system 106 includes a plurality of reservoirs 150-156 from which the foam components are supplied.

The reservoirs 150-156 feed the foam component materials to the barrels C1-C12 and head 120 of the extruder 104 via a network of feed lines and valves as illustrated.

In manufacturing foam using the extrusion system of FIG. 5, filler material is preferably provided to the extruder 104 at barrels C1 and C4 from reservoirs 150 and 152. Isocyanate solution is mixed and fed to barrels C2 and C6 of the extruder 104 from reservoirs 151 and 153. The isocyanate solution may be optionally mixed with a dispersing agent and / or surfactant. Surfactant may be mixed at reservoirs 151 and 153...

examples

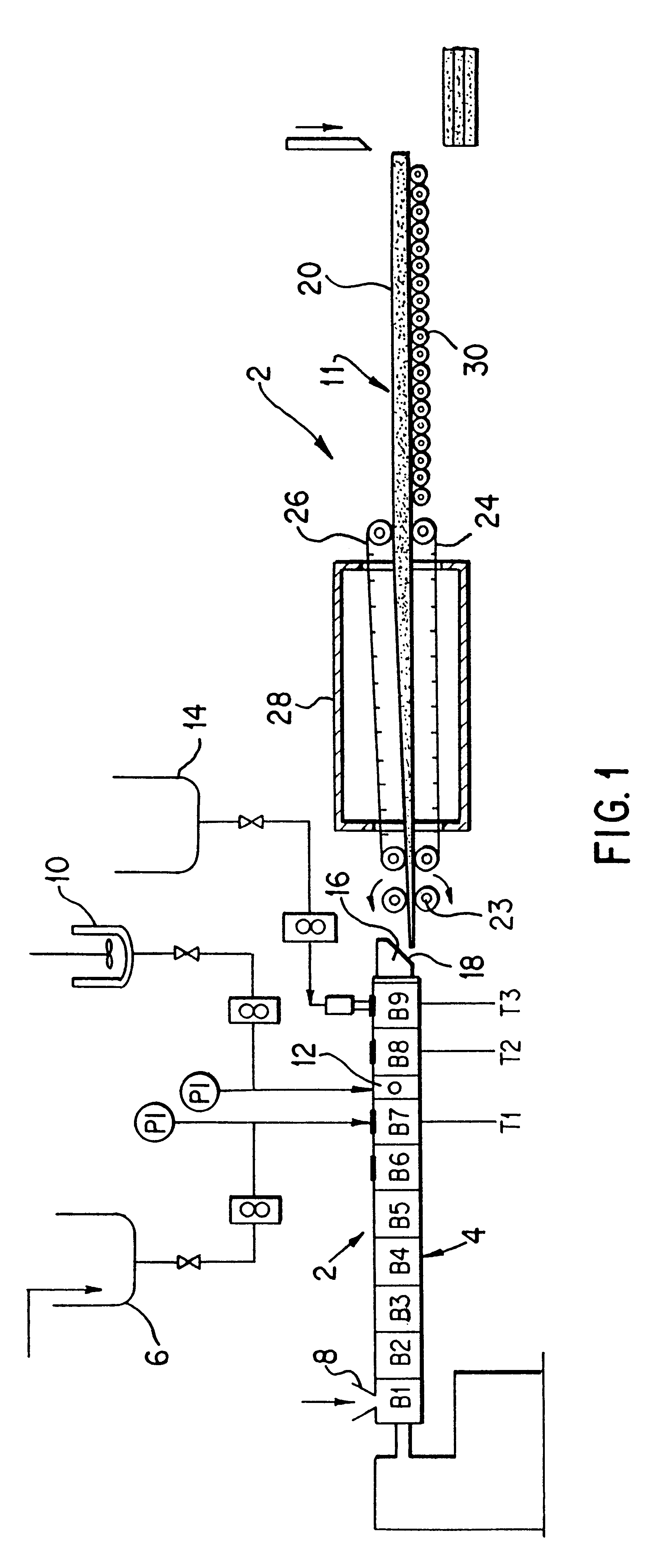

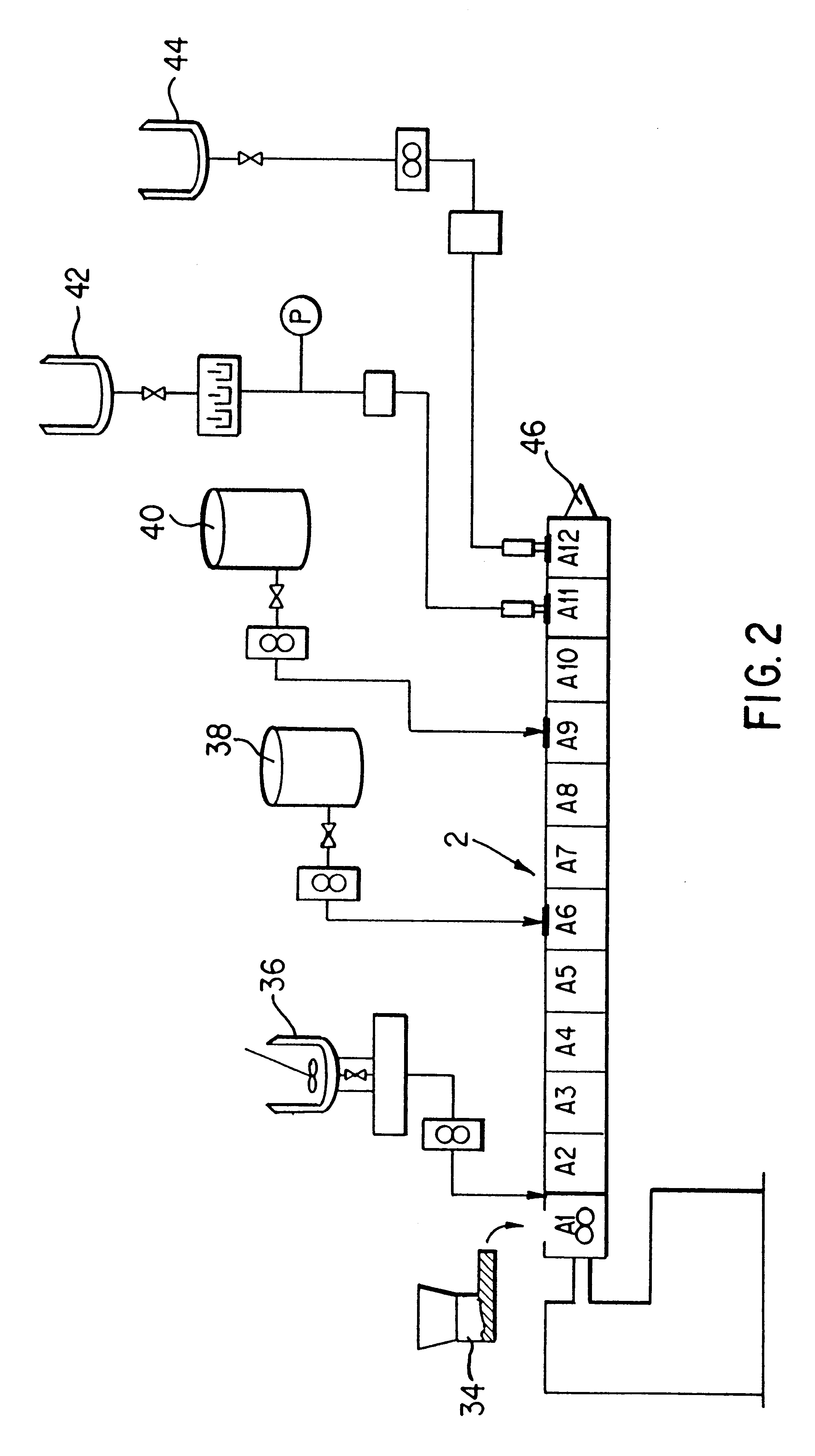

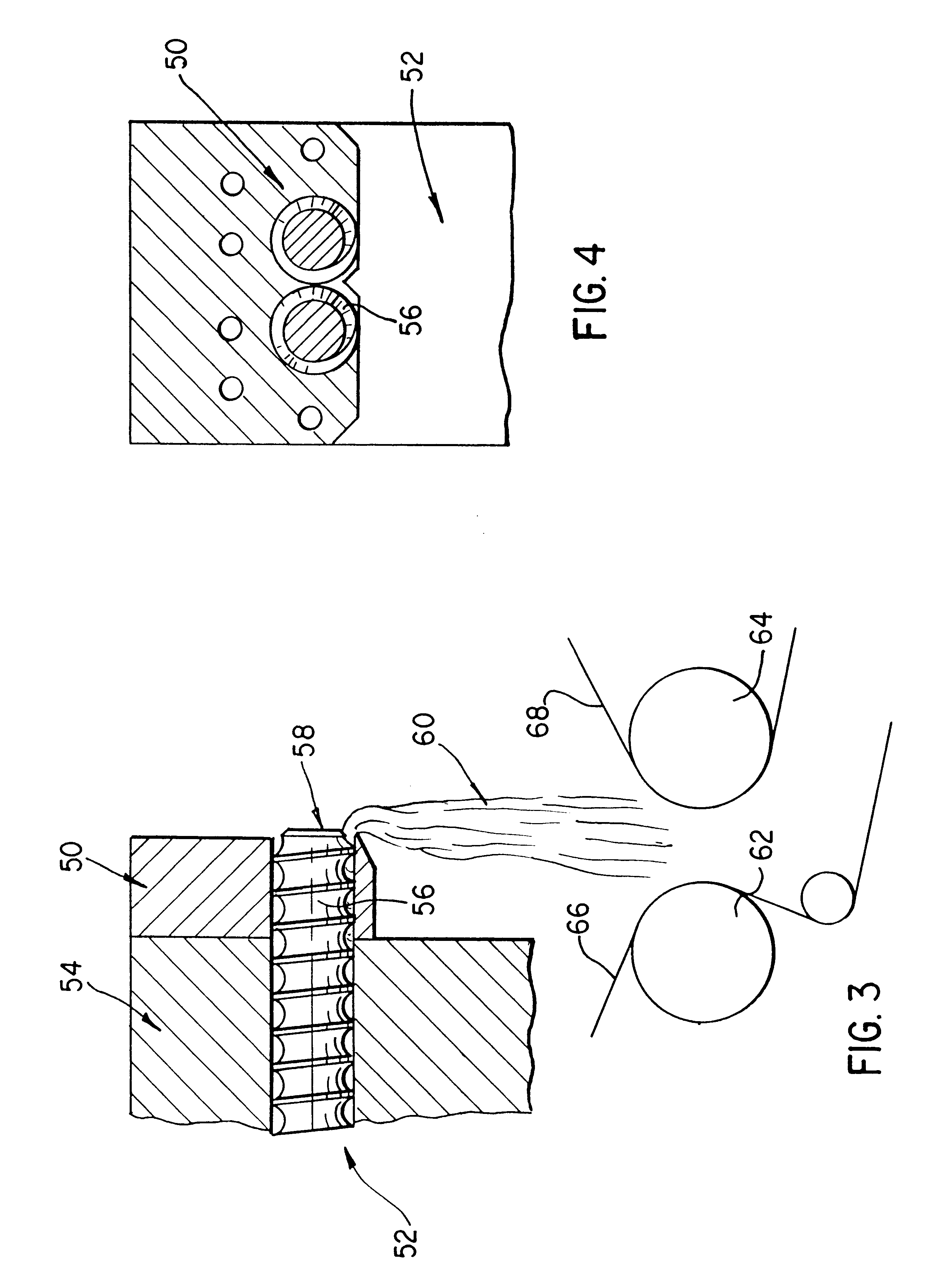

The following Examples 1-48 were made in accordance with the process described in conjunction with FIGS. 1-4. Examples 49-60 were made using the alternate embodiment of the process as described in conjunction with FIGS. 5-6.

examples 1 to 33

Carbon Black Dispersion Made in the Extruder Screw

Table 1 shows the composition used for each formulation and Table 2 shows the composition of each polyol premix, used as indicated in Table 1. Pelron P-344 dispersant and Cabot Black Pearls 280 carbon black were used in all the examples. The catalyst was a 3:1 blend, by weight, of potassium octoate and DMP-30. A catalyst blend of 3:1 to 6:1 may be used. The ratio of the catalyst blend is dependent upon how close the catalyst is added to the extruder outlet. The average equivalent weight of BASF 226 prepolymer (polymer / isocyanate mix) and ICI high viscosity isocyanate is about 152.

TABLE 1 Parts by % Formulation Component Weight % Index Trimer I Premix I 40.6 11.8 2.74 12.4 2852E Polyol 59.4 17.2 MR-200 Isocyanate 192.0 55.7 Catalyst 7.5 2.2 HCFC - 14 lb 45.0 13.1 II Premix II 40.6 11.2 2.93 12.8 Carbon Black (C / B) 17.4 4.8 2852E Polyol 59.4 16.4 MR-200 Isocyanate 192.0 53.0 Catalyst 7.5 2.1 HCFC - 14 lb 45.0 12.4 III Premix III 63.5 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com