A method for the synergistic and controllable preparation of organic semiconductor nanowires

An organic semiconductor and synergistic technology, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, nanotechnology for materials and surface science, etc., can solve the difficult to achieve controllable preparation of organic single crystal nanowires with a diameter of 100nm, etc. problem, to achieve the effect of high-quality uniform dispersion, high fluorescence quantum yield, and tailorable fluorescence quantum yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 6.97 mg of methoxydimethylaminoamine styryl phenyl ketone to 4 mL of dichloromethane and sonicate for 3 min to obtain a stock solution of methoxydimethylaminoamine styryl phenyl ketone dichloromethane. Take 1 mL of the stock solution and add it to 1 mL of ethanol, shake well, and then drop it on the substrate (such as silicon wafer, glass wafer or quartz wafer). After the organic solvent is evaporated to dryness, organic nanowires with a strong deep red color are obtained. By powder X-ray diffraction (XRD, Figure 4 ), scanning electron microscopy (SEM, Figure 5 ), transmission electron microscopy (TEM), and selected electron diffraction (SAED) ( Figure 6 ) test means to characterize the organic eutectic micro-crystals.

Embodiment 2

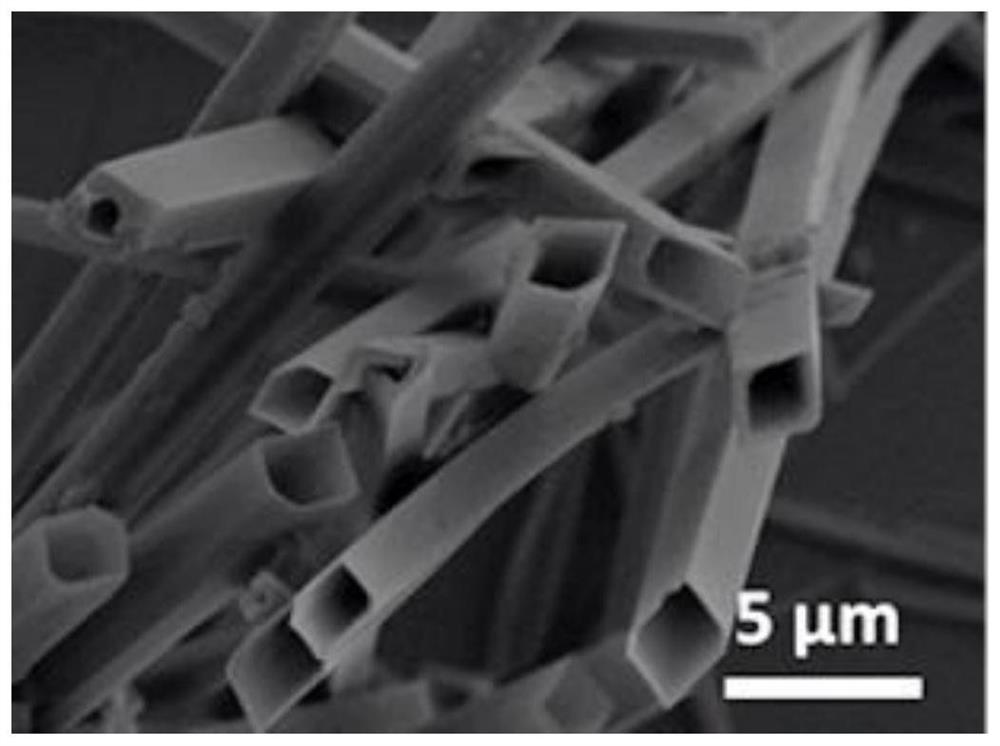

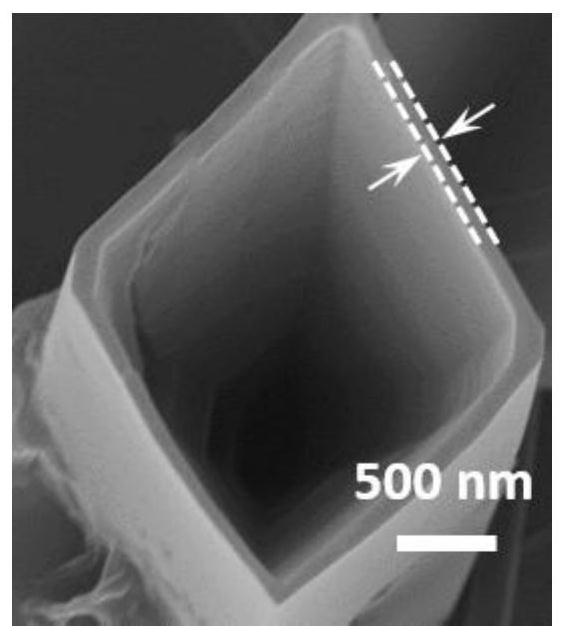

[0030] Add 6.35 mg of dimethylaniline styryl phenyl ketone to 4 mL of dichloromethane and sonicate for 3 min to obtain a stock solution of dimethyl aniline styryl phenyl ketone in dichloromethane. Take 1 mL of the stock solution and add it to 5 mL of ethanol, shake well, and then drop it on the substrate. After the organic solvent evaporates to dryness, high-quality organic nanowires with uniform morphology are obtained. scanning electron microscope (SEM, Figure 7 ) test means to characterize organic micro-crystals.

Embodiment 3

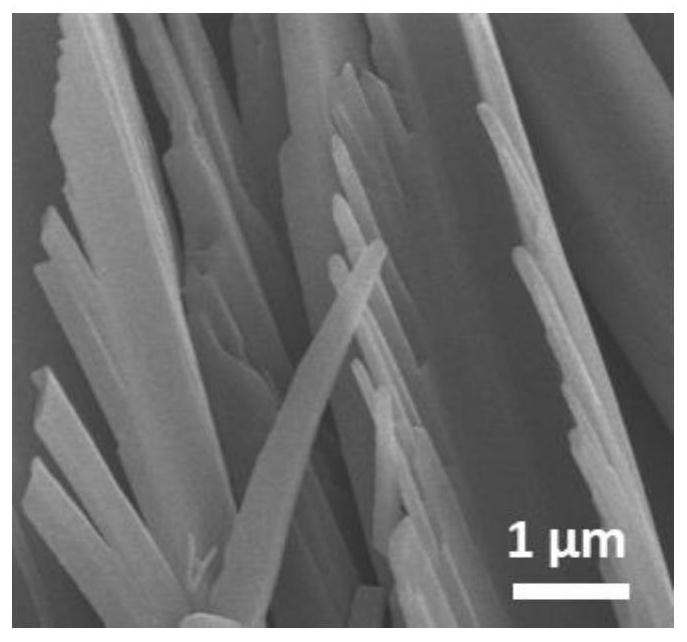

[0032] Add 6.94 mg of methoxydimethylaminoamine naphthalene vinyl phenyl ketone to 4 mL of dichloromethane and sonicate for 3 min to obtain a stock solution of methoxy dimethylaminoamine naphthyl vinyl phenyl ketone dichloromethane. Take 1 mL of the stock solution and add it to 10 mL of ethanol, shake well, and then drop it on the substrate. After the organic solvent evaporates to dryness, high-quality organic nanowires with uniform morphology are obtained. scanning electron microscope (SEM, Figure 8 ) test means to characterize organic micro-crystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com