Patents

Literature

889 results about "Combustibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

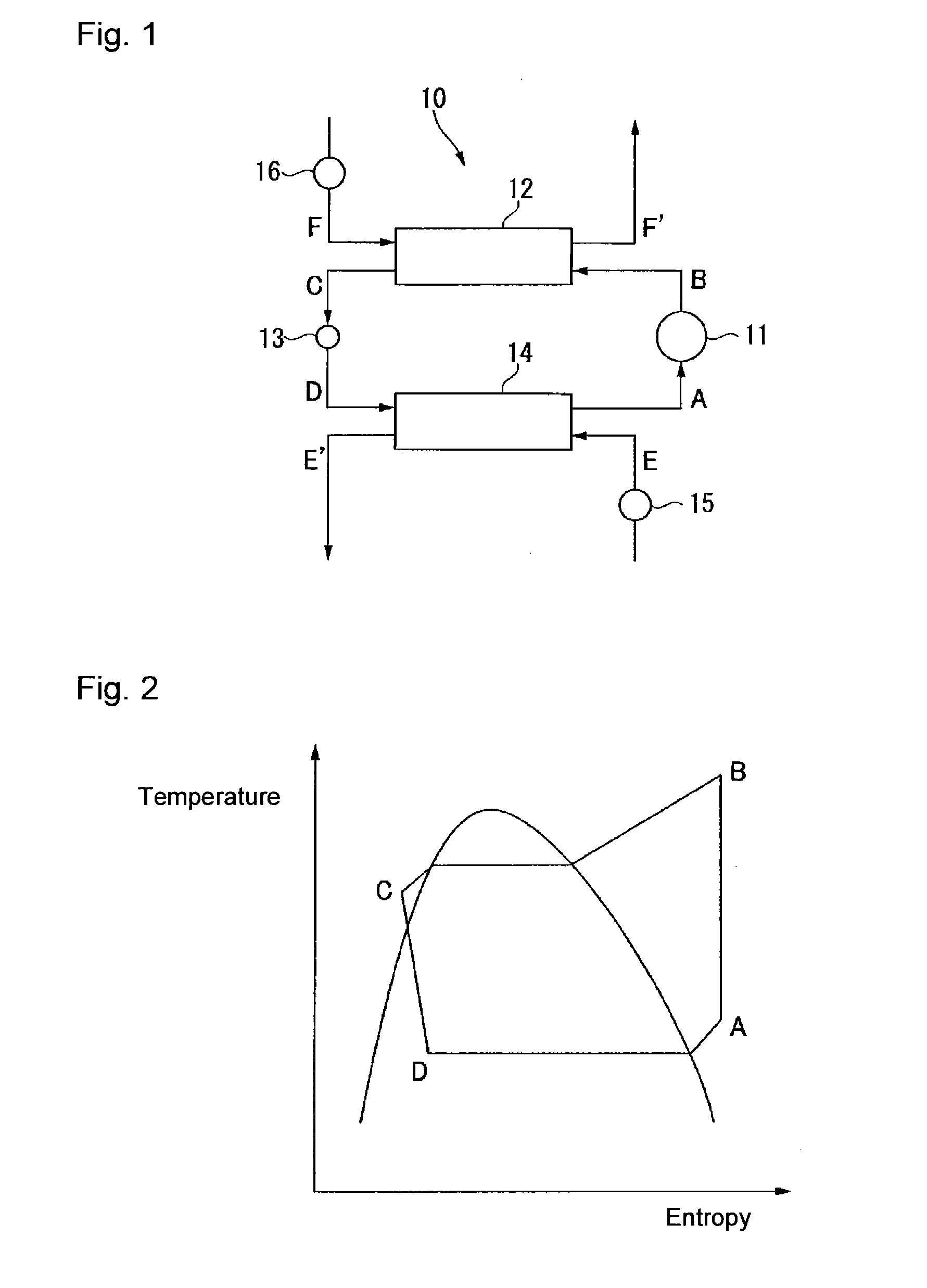

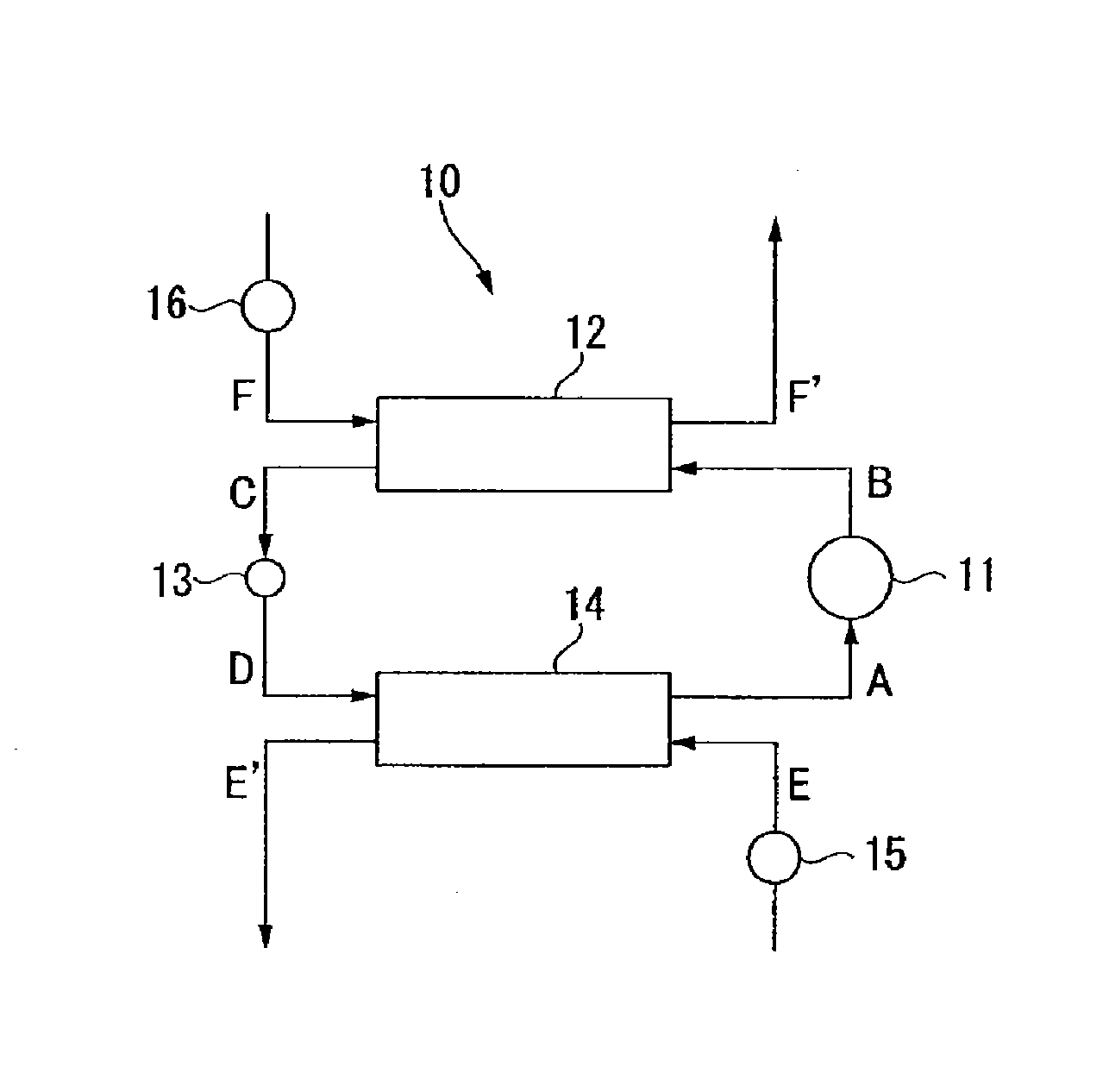

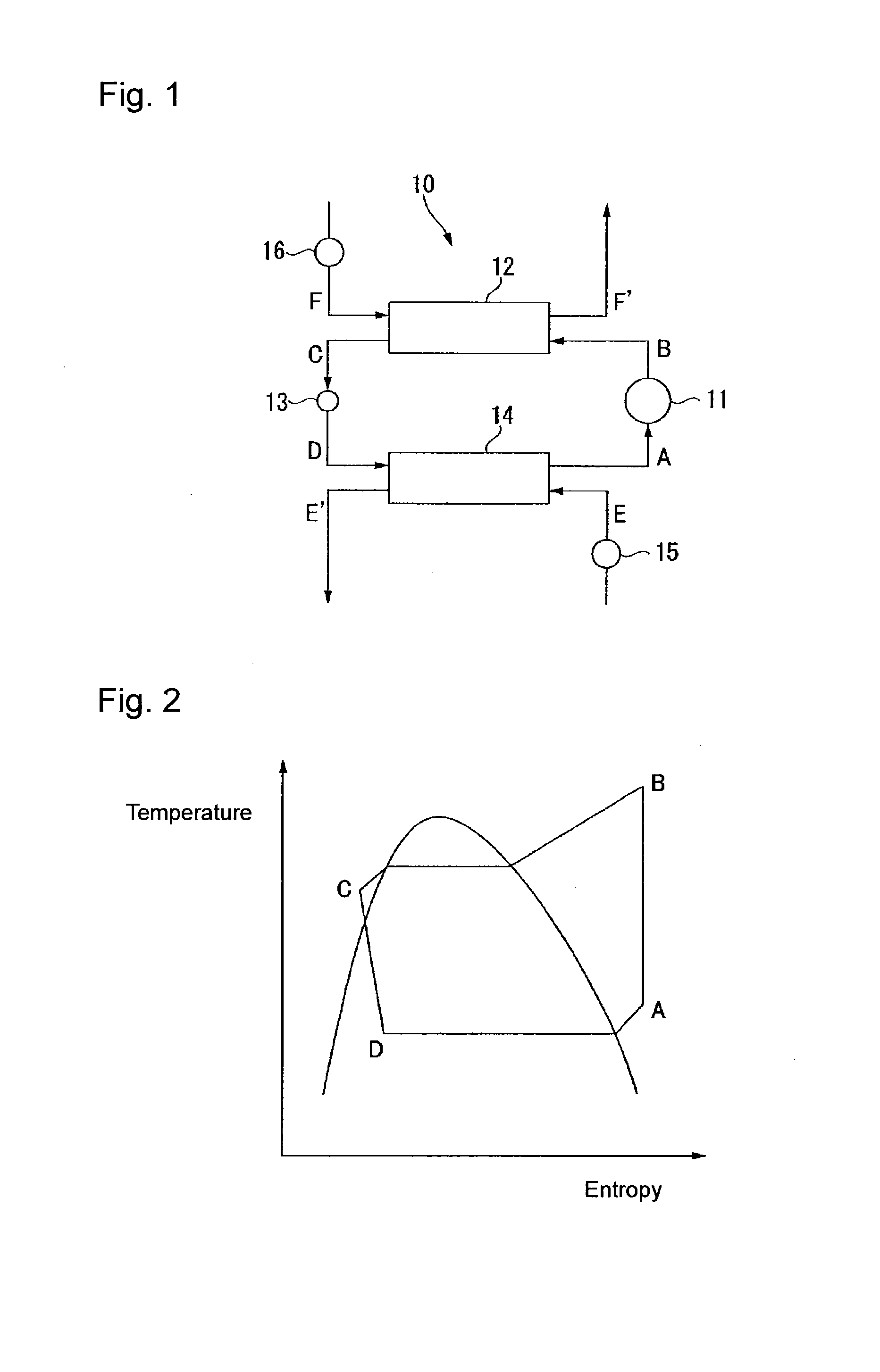

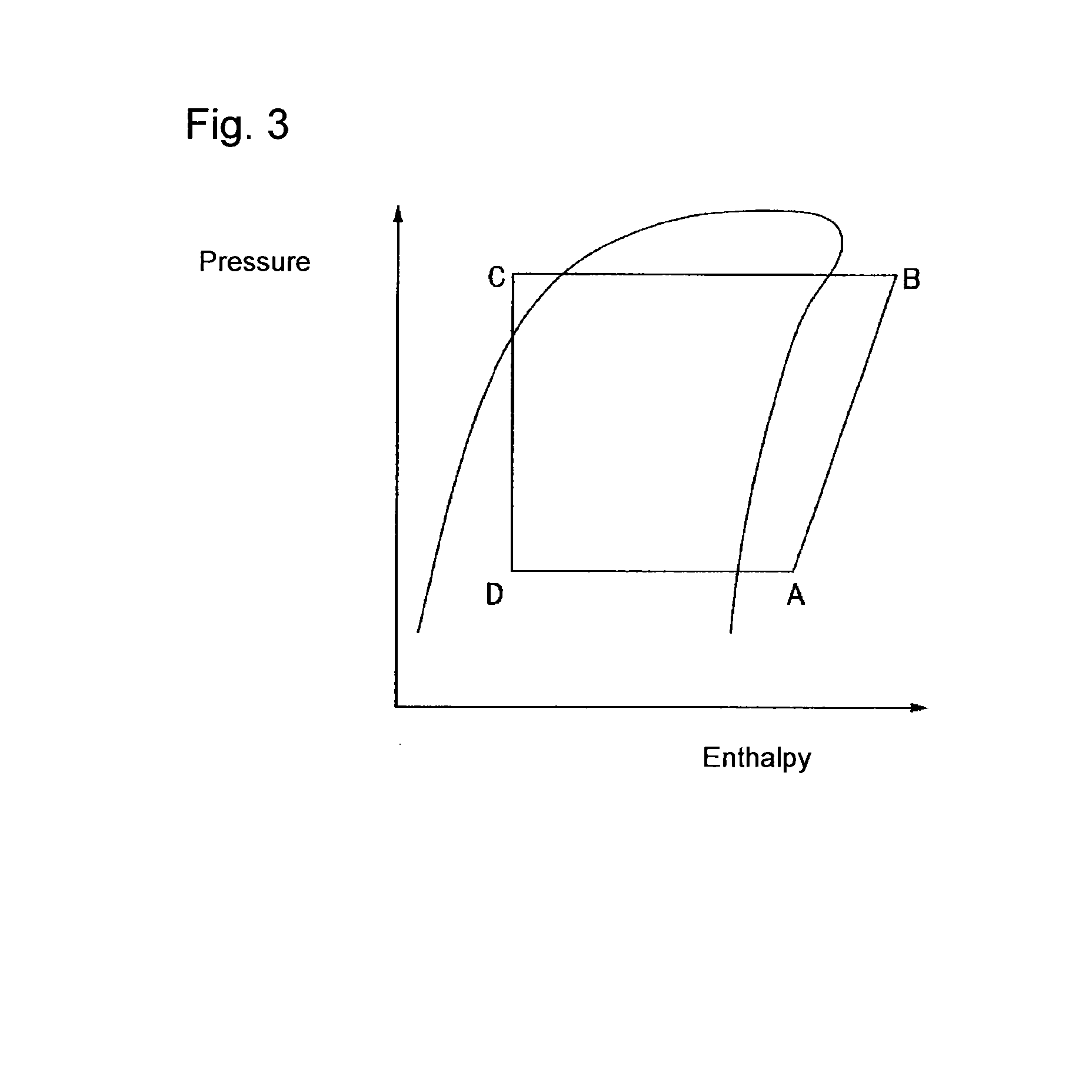

Working medium and heat cycle system

ActiveUS20140070132A1Promote decompositionLess influenceOrganic chemistryCompression machinesTransport systemOzone layer

To provide a working medium for heat cycle, of which combustibility is suppressed, which has less influence over the ozone layer, which has less influence over global warming and which provides a heat cycle system excellent in the cycle performance (capacity), and a heat cycle system, of which the safety is secured, and which is excellent in the cycle performance (capacity).A working medium for heat cycle comprising 1,1,2-trifluoroethylene is employed for a heat cycle system (such as a Rankine cycle system, a heat pump cycle system, a refrigerating cycle system 10 or a heat transport system).

Owner:ASAHI GLASS CO LTD

Catalyzer for catalyzing combustion and its preparing method

InactiveCN1415410AReduced activityAvoid overwritingCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsOrganic acidActive component

A catalyst for the catalytic combustion of combustible waste gas is prepared by dipping the Pt as active component on the coated layer of cellular ceramics as carrier. The said coated layer contains Al2O3 (20-80 wt.%), TiO2 (10-40 wt.%), CeO2 (5-30 wt.%) and ZrO2 (5-20 wt.%). Its advantages are high utilization rate of Pt, and high distribution uniformity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polymer powder with phosphonate-based flame retardant, process for its production, and moldings produced from this polymer power

ActiveUS20050027047A1UL® classificationMaintain mechanical propertiesAdditive manufacturing apparatus3D object support structuresPolymer sciencePolyamide

The present invention relates to a polymer powder composed of polyamide or of copolyamides, which also comprises flame retardant, in particular phosphonates, to a layer-by-layer process which selectively melts regions or selectively binds them, and also to moldings produced from this polymer powder. Compared with conventional products, the moldings constructed using the powder of the invention exhibit marked advantages in flammability and combustibility and drop behavior, particularly with respect to UL® (Underwriters Laboratories) classification. Furthermore, moldings produced from polymer powder of the invention have adequately good mechanical properties when compared with moldings based on polymer powders without flame retardant, in particular in terms of modulus of elasticity and tensile strain at break. In addition, these moldings also have a density close to that of injection moldings.

Owner:EVONIK OPERATIONS GMBH

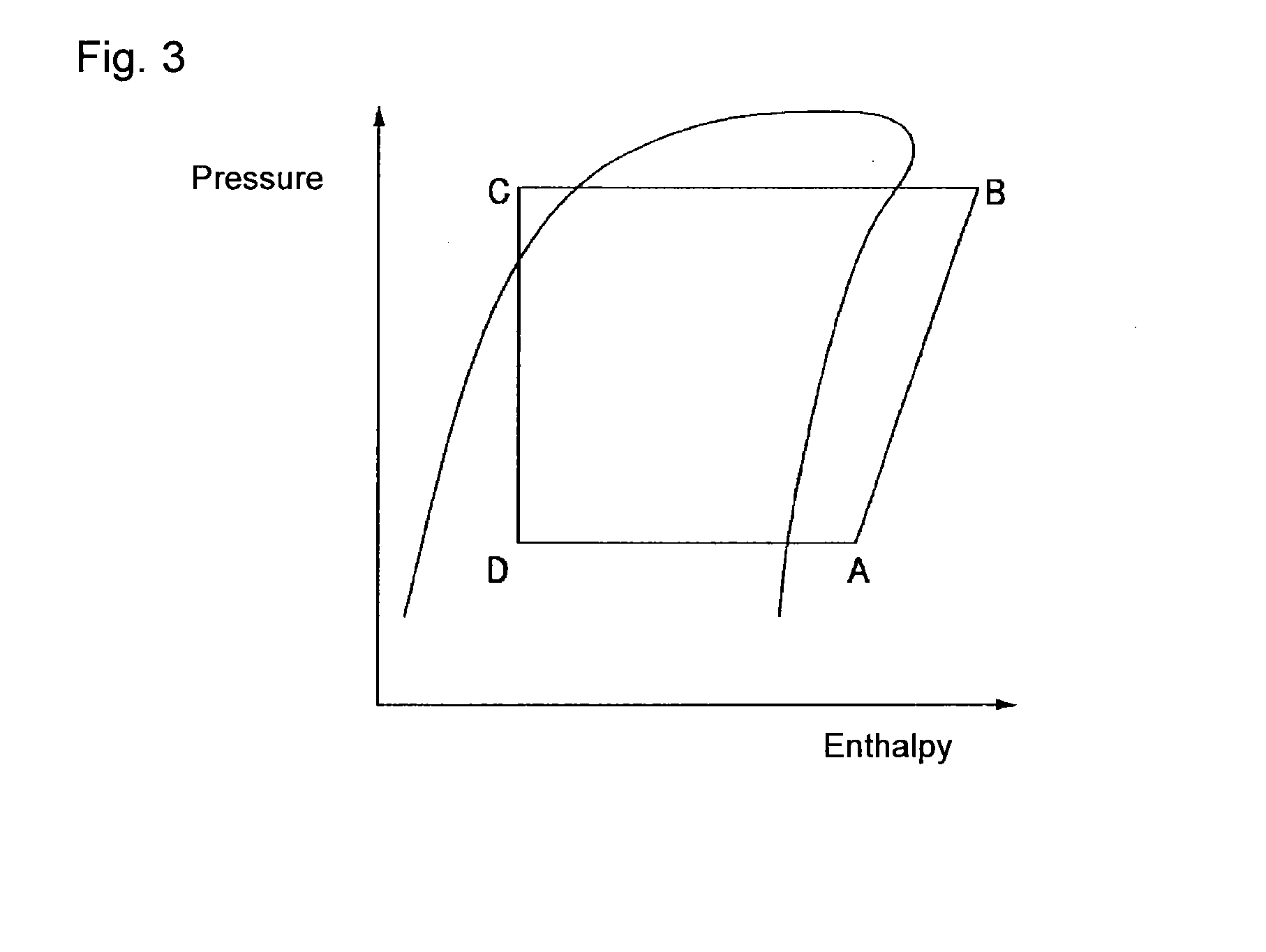

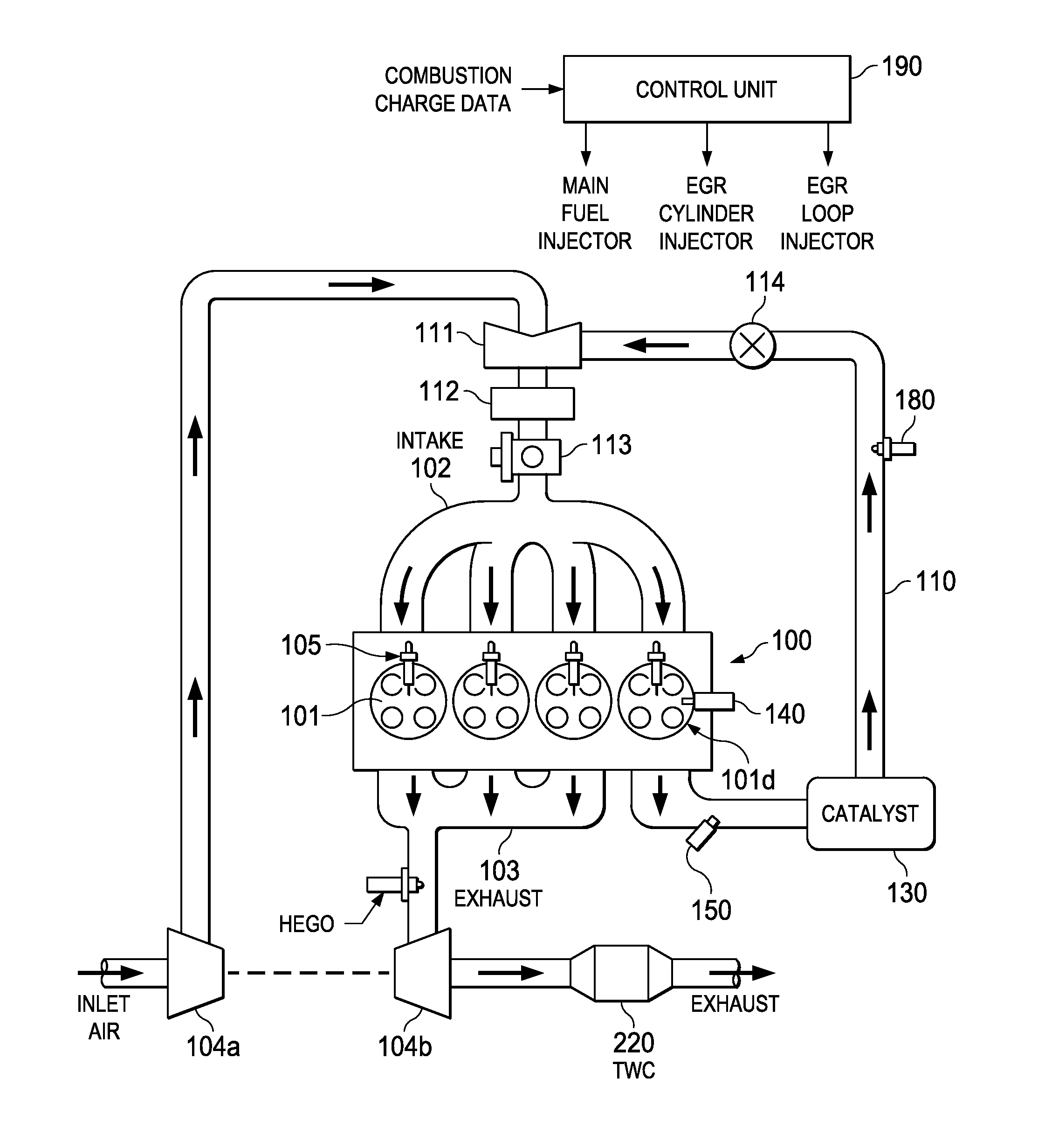

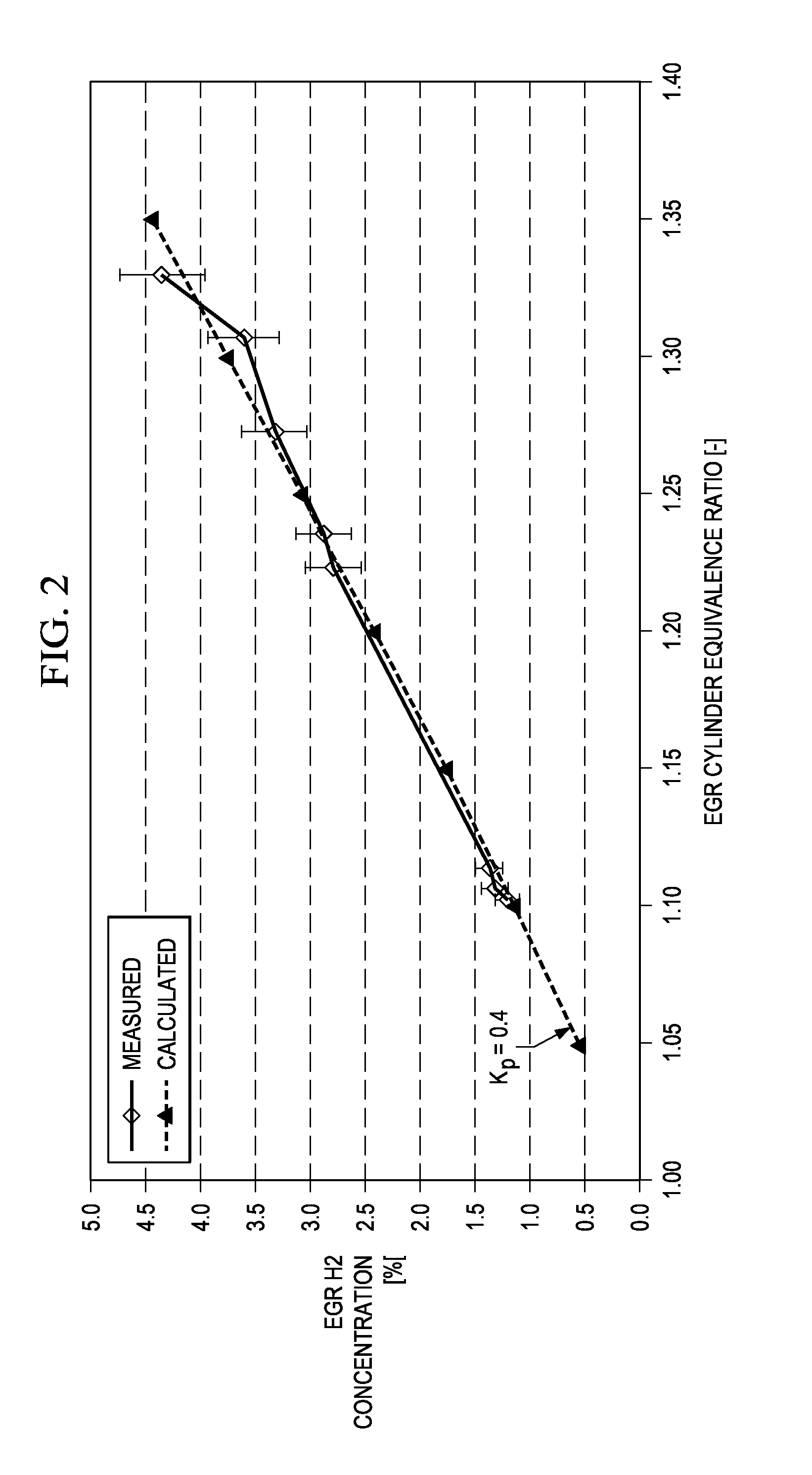

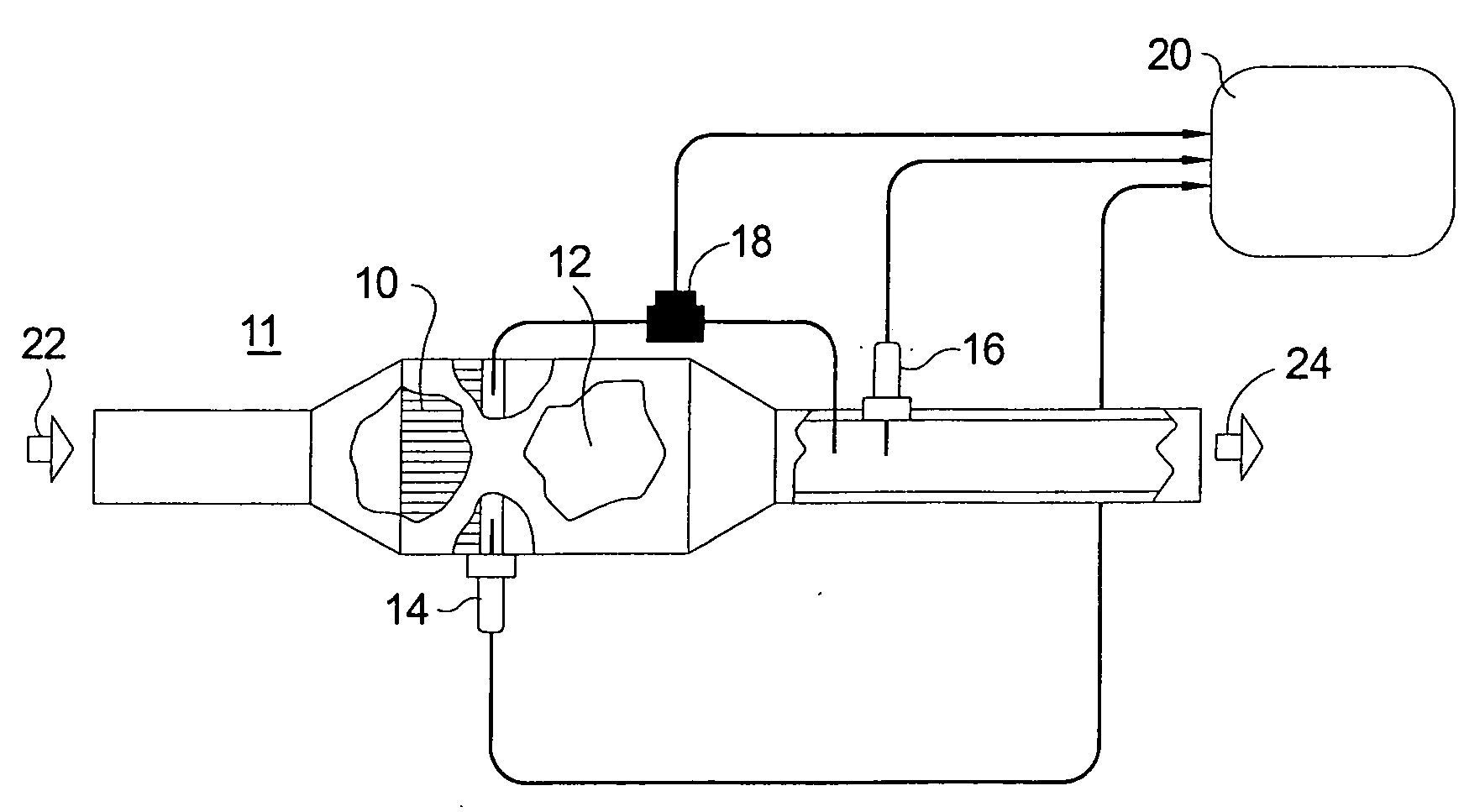

Ignition and Knock Tolerance in Internal Combustion Engine by Controlling EGR Composition

ActiveUS20140196702A1Improve efficiencyElectrical controlNon-fuel substance addition to fuelHydrogenExhaust gas recirculation

A method for improving ignition of a spark ignited internal combustion engine by controlling the composition of recirculated exhaust gas. It is assumed that the engine has a spark ignition system and an exhaust gas recirculation (EGR) loop such that at least one of the combustion cylinders is an EGR cylinder that generates an EGR stream carried by the EGR loop. Thus, the combustion charge is a mixture of air, fuel and recirculated exhaust. A first step is receiving combustibility data representing the current ignitability of the charge. It is then determined whether the energy of the ignition system is sufficient to ignite the charge. If not, the amount of hydrogen in the EGR stream is increased, which increases the ignitability of the charge.

Owner:SOUTHWEST RES INST

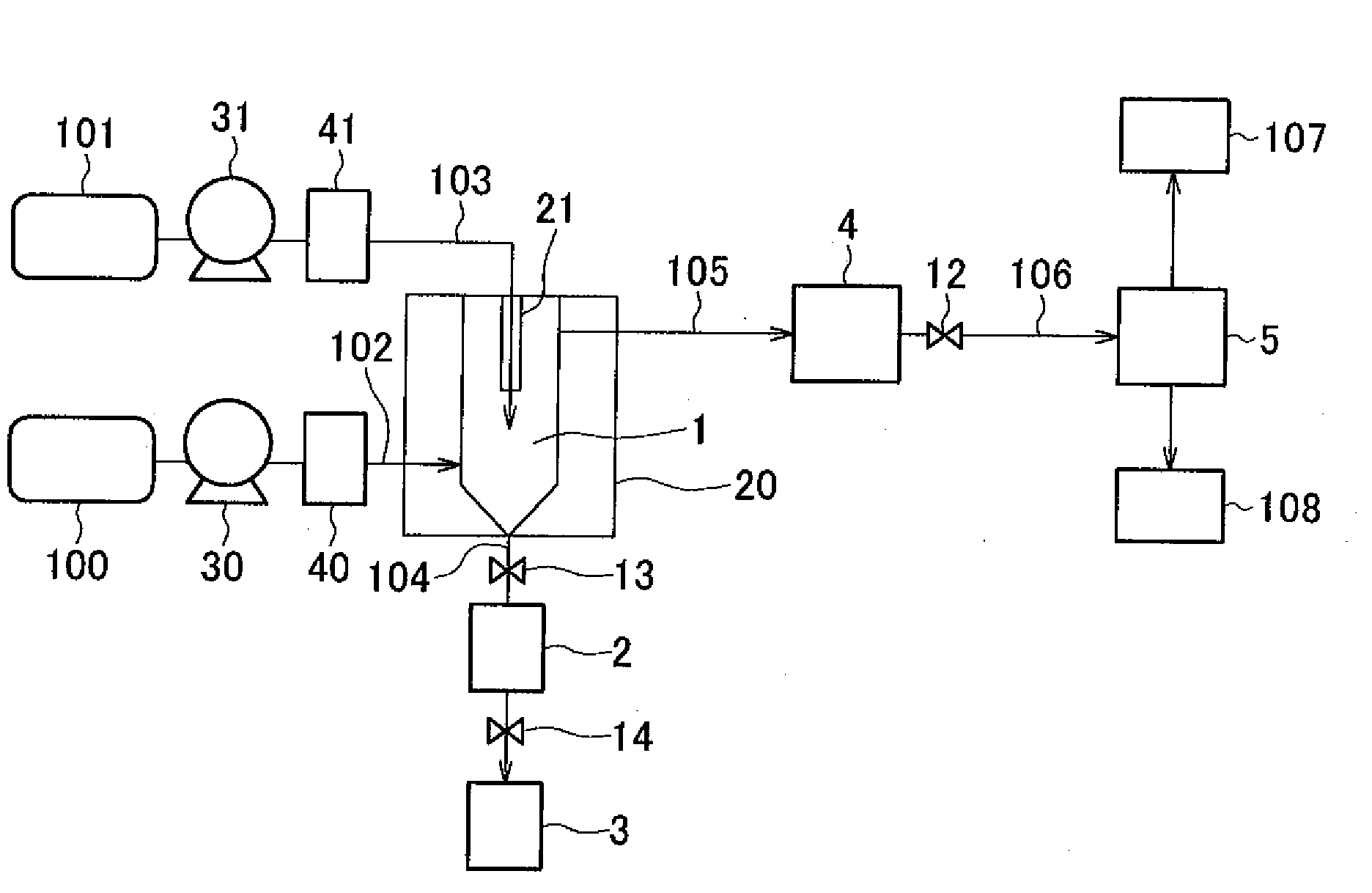

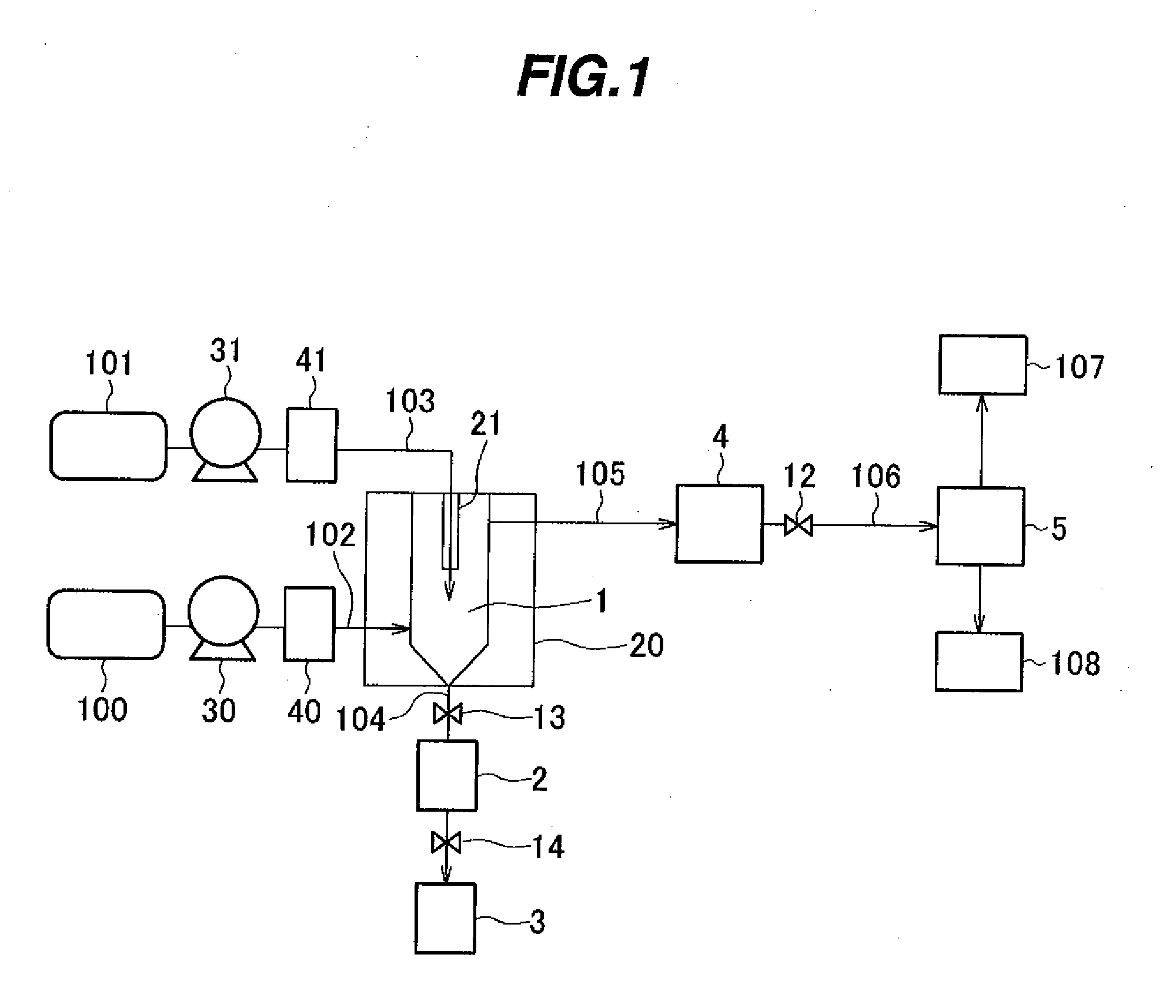

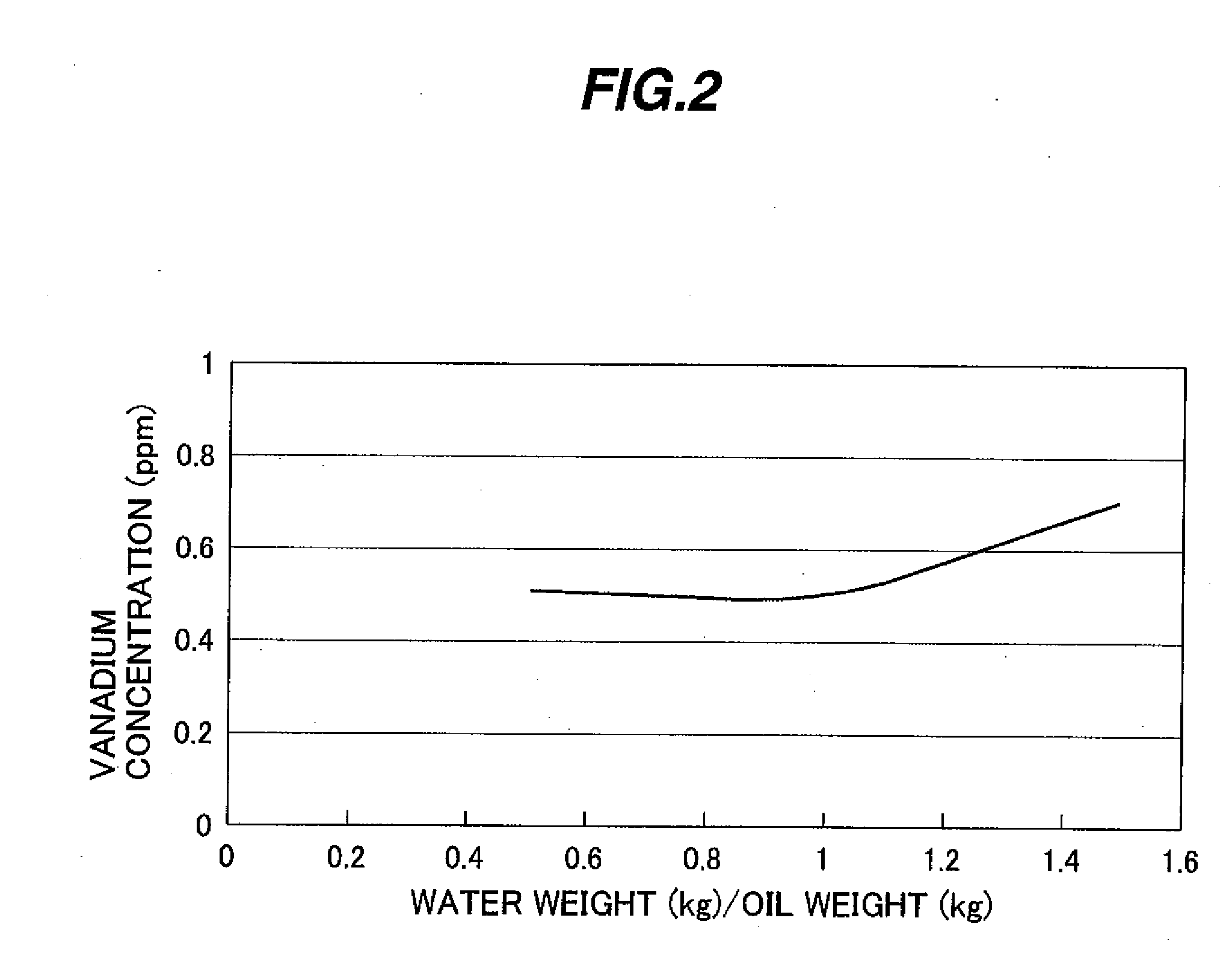

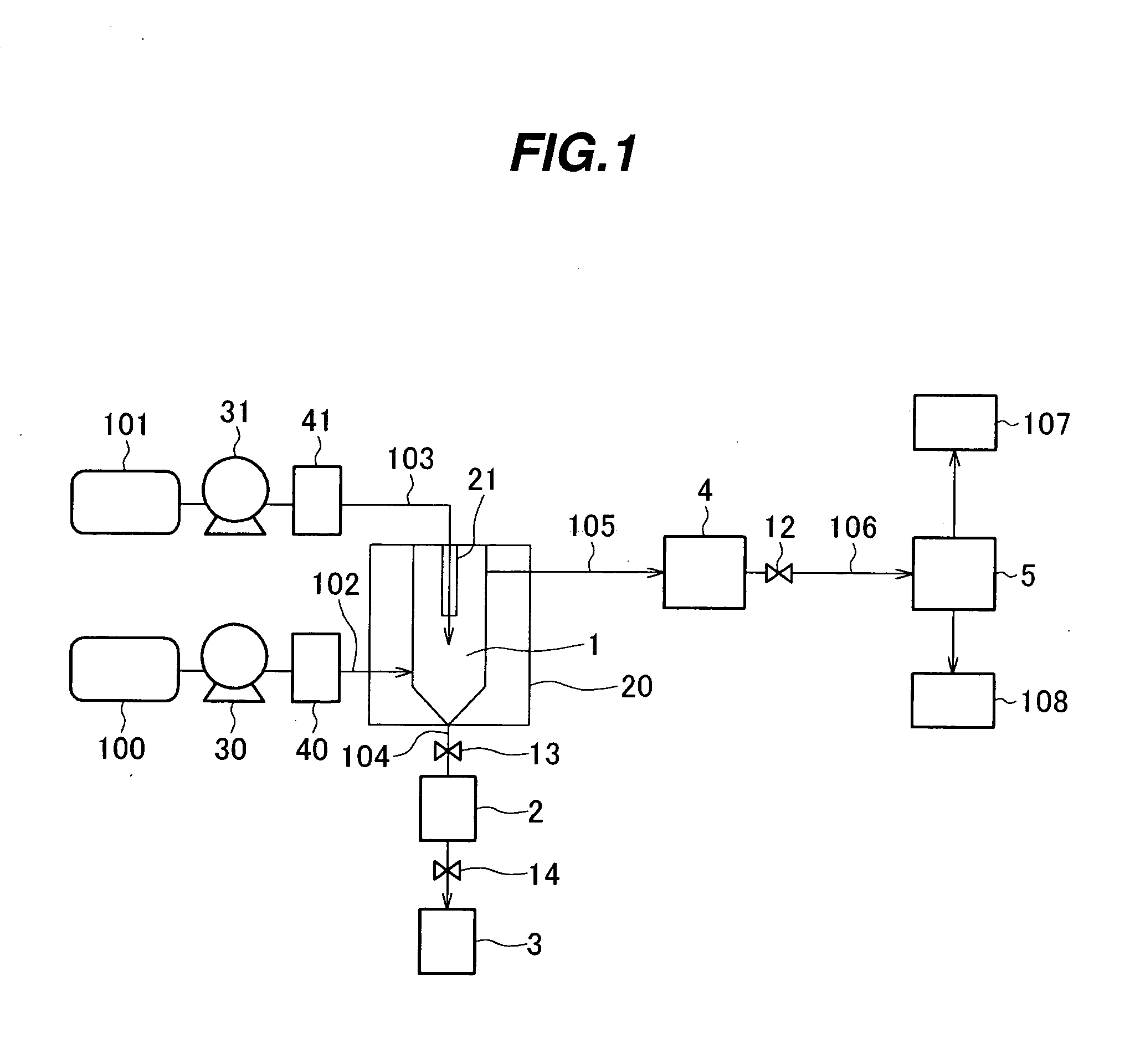

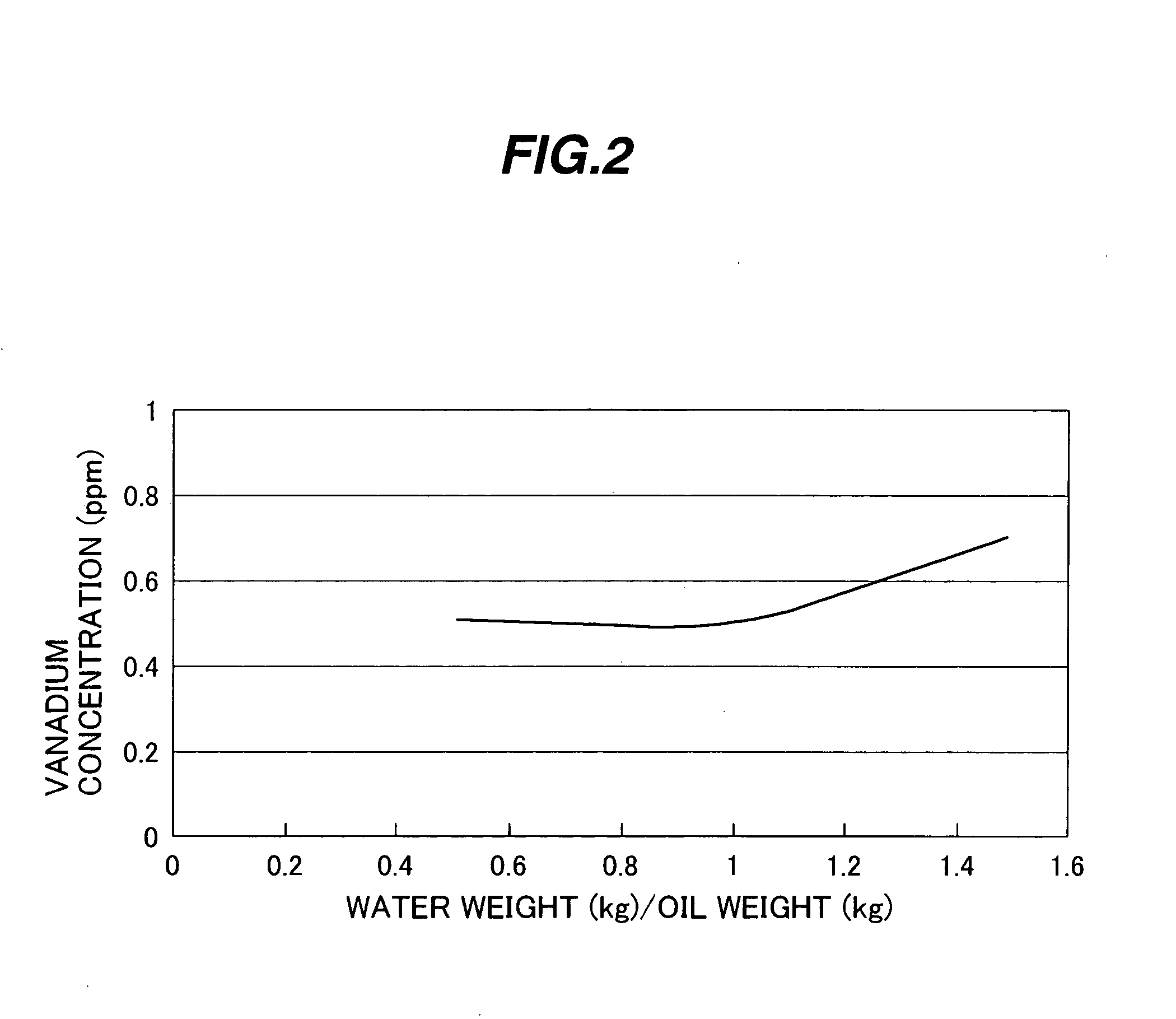

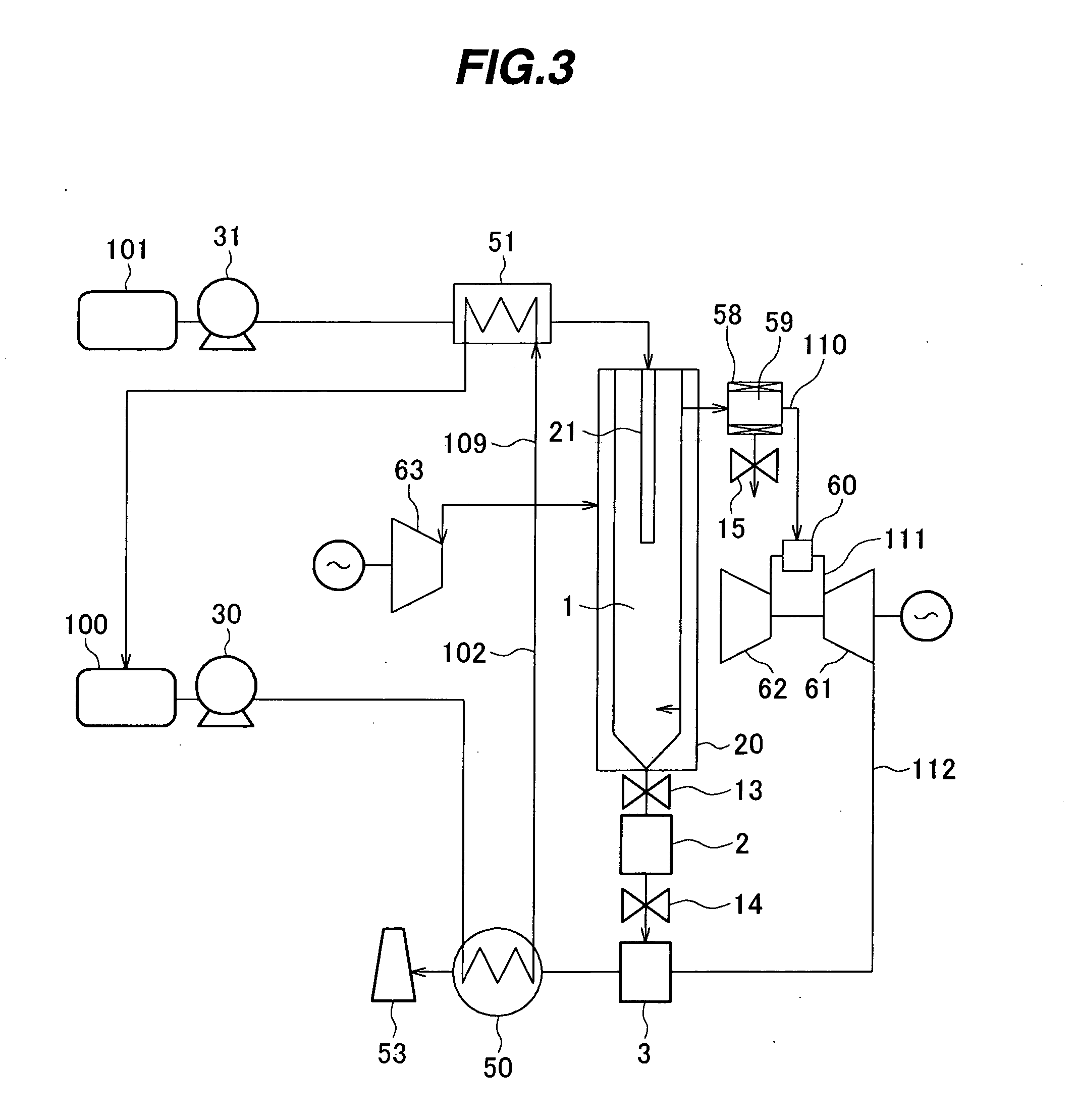

Heavy oil treating method and heavy oil treating system

InactiveUS20090032436A1Eliminate needMolecular sieve catalystsRefining with oxygen compoundsLighter fuelHigh pressure water

The invention is intended to produce high-pressure light fuel gas with good combustibility by contacting and reacting high-temperature, high-pressure water and heavy oil with each other in a contact-reaction unit to extract light oil components from the heavy oil and to remove metals. The high-temperature, high-pressure water and the heavy oil are introduced to the contact-reaction unit for contact and reaction with each other therein. Heavy oil components not dissolved in the high-temperature, high-pressure water are separated by precipitation from hydrocarbon gases and light oil components which are dissolved in the high-temperature, high-pressure water. The separated heavy oil components are burnt or incinerated without any further modification.

Owner:TAKAHASHI HIROKAZU +6

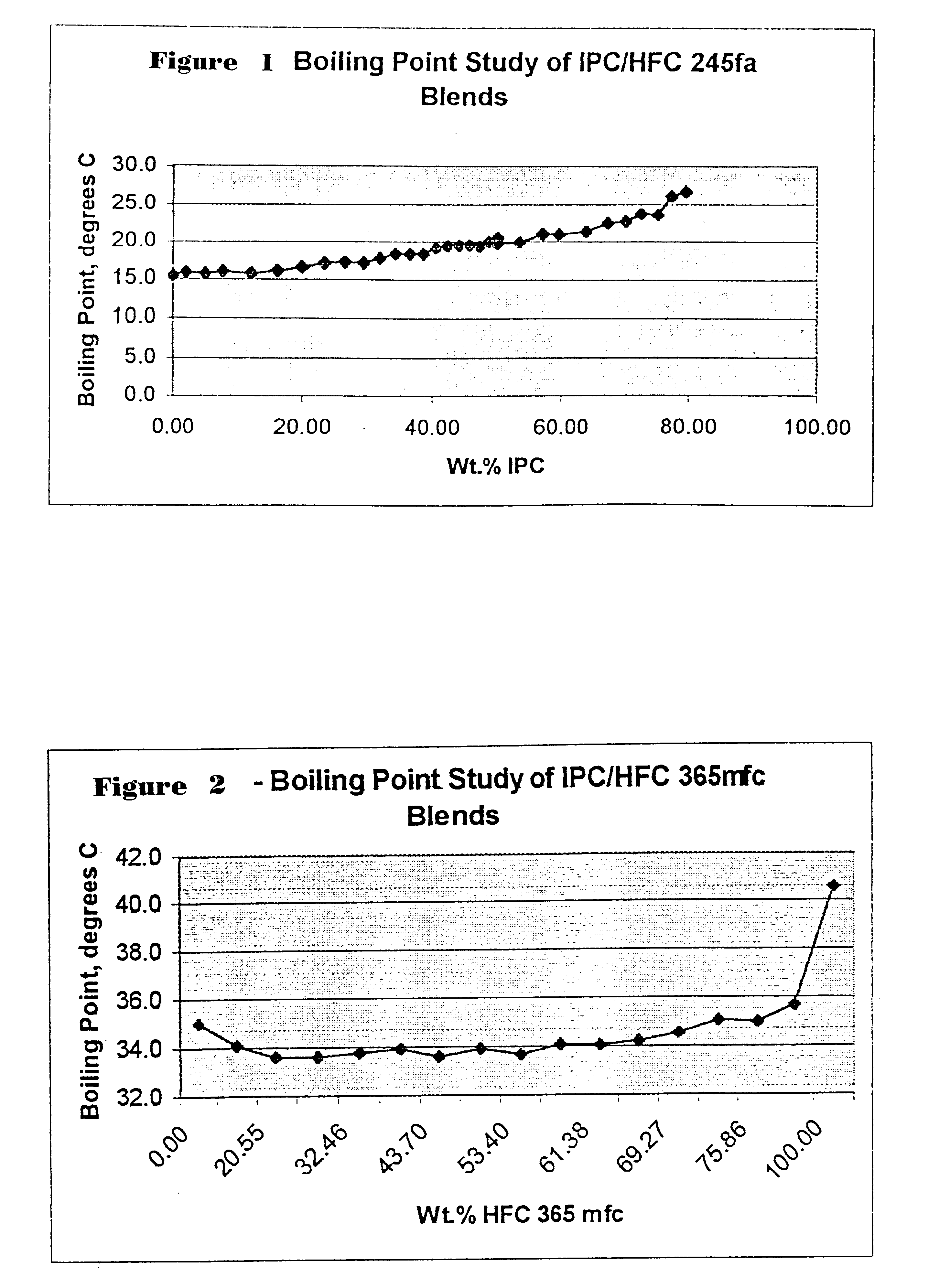

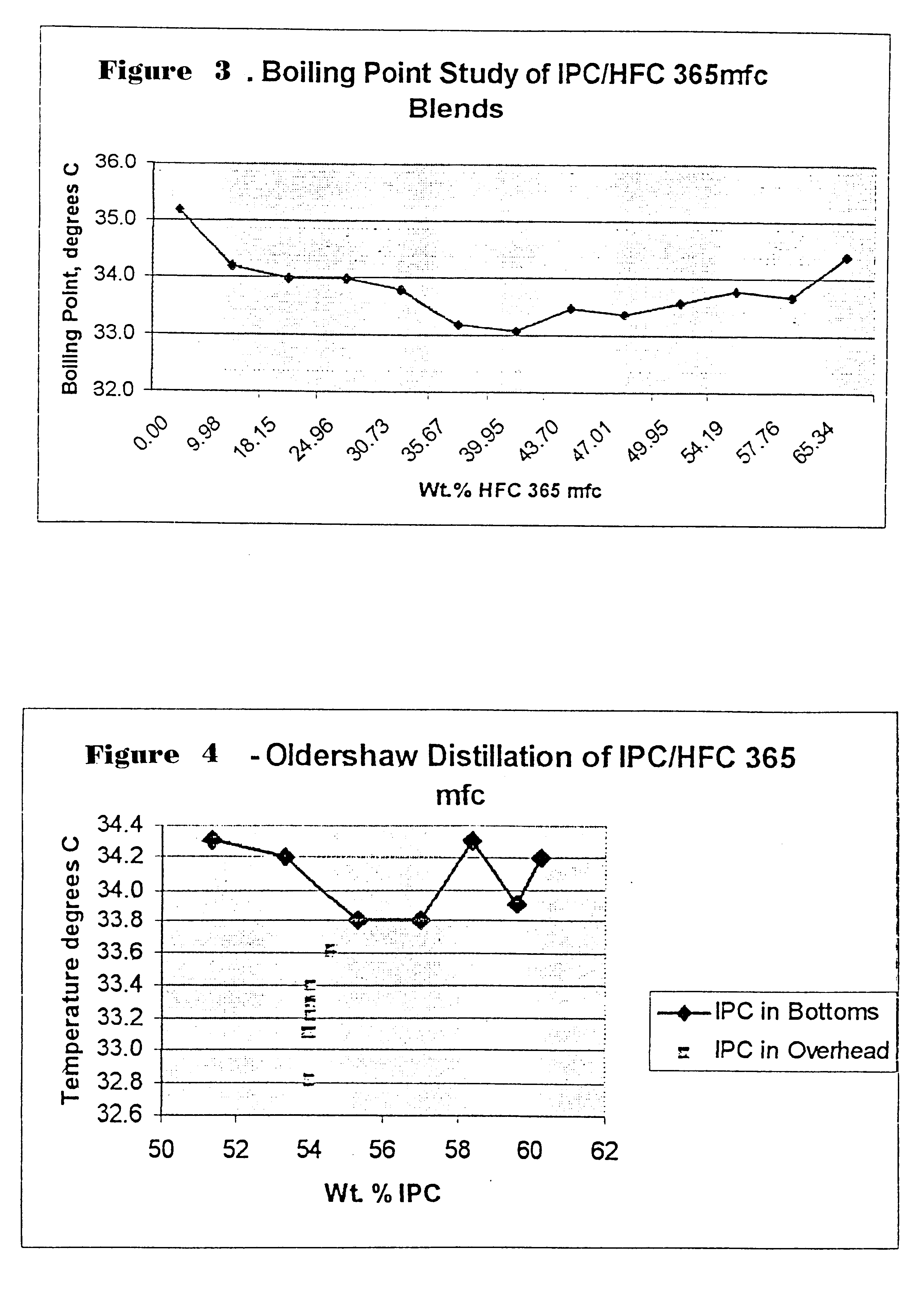

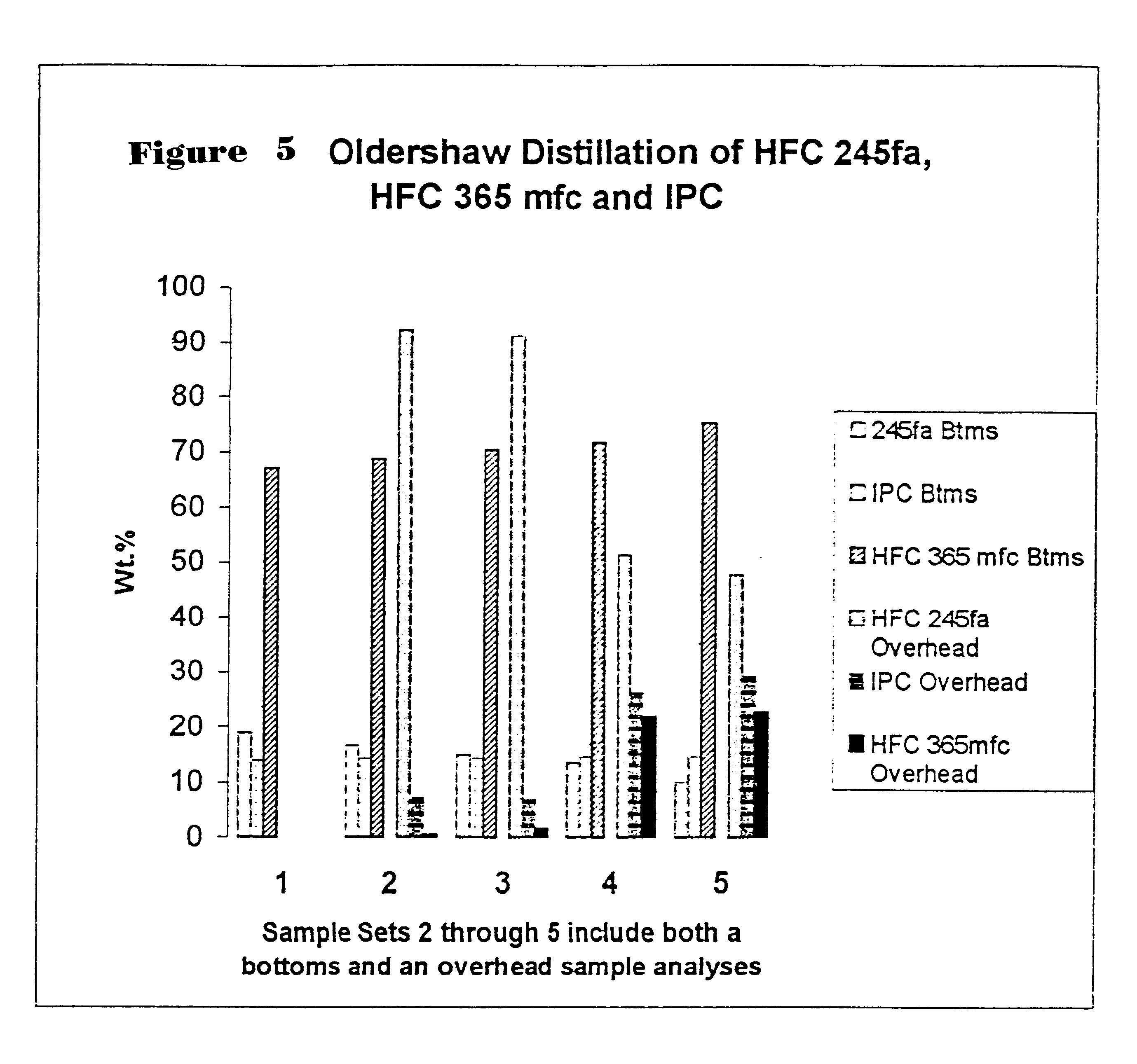

Isopropyl chloride with hydrofluorocarbon or hydrofluoroether as foam blowing agents

InactiveUS6646020B2Combustibility is reduced and eliminatedReduce flammabilityHeat-exchange elementsLiquid soapsPolyisocyanurateHydrofluoroether

A composition useful as a blowing agent having no flash point or reduced combustibility comprising 2-chloropropane and a gas selected from the group consisting of a fluorohydrocarbon, perfluorocarbons, fluoroethers, hydrofluoropolyethers and mixtures thereof is disclosed. A polyisocyanurate foam or a polyurethane modified polyisocyanurate foam having a mainly closed cell structure and also a method for preparing this foam, the latter comprising closed cells wherein a foam blowing agent consisting of a mixture of 2-chloropropane and one or more HFC compounds including pentafluoropropane, pentafluorobutane, heptafluoropropane, hexafluoropropane or pentafluoroethane are disclosed. Pentanes can be added if desired. Azeotropic mixtures in which 2-chloropropane is an ingredient are disclosed.

Owner:OCCIDENTAL CHEM CORP

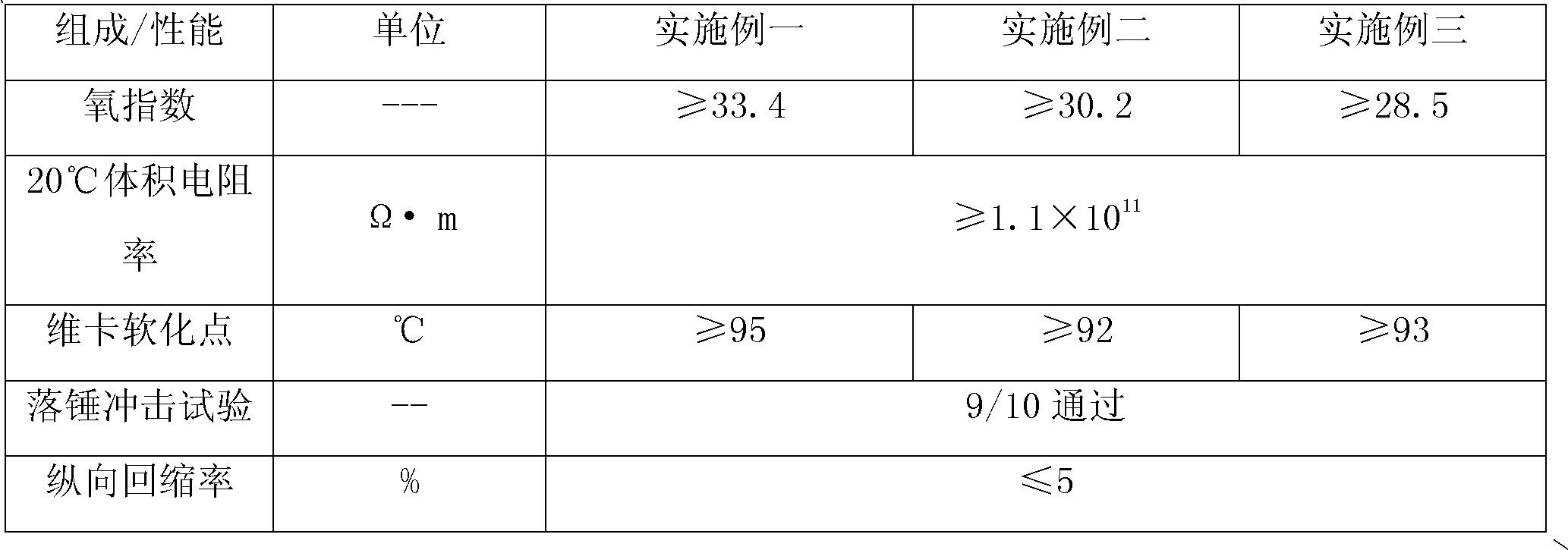

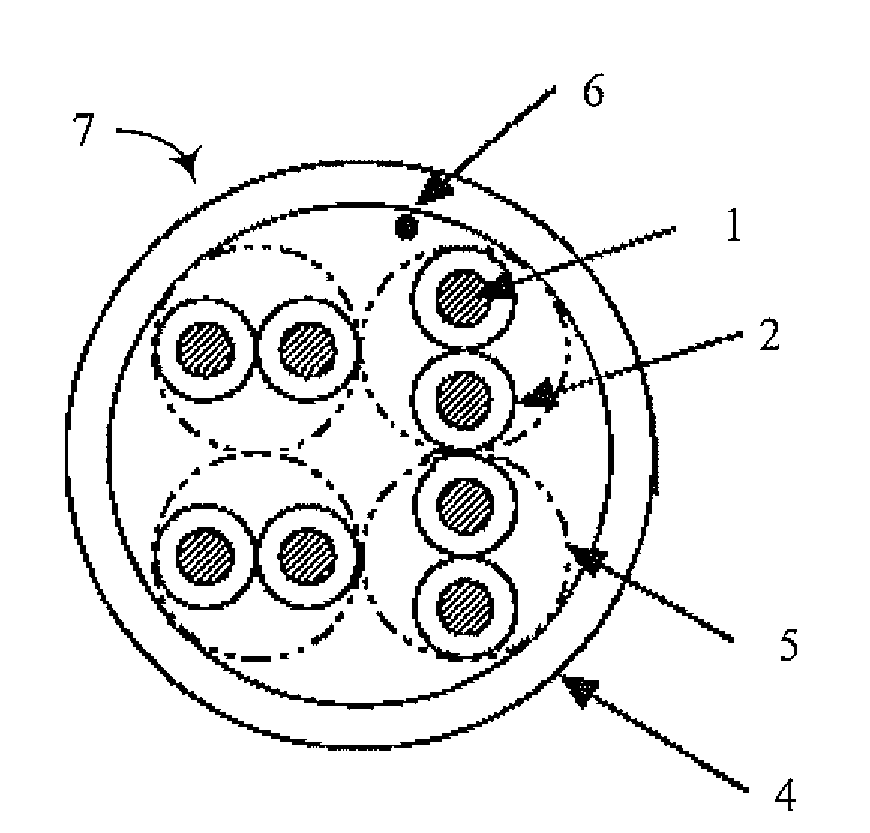

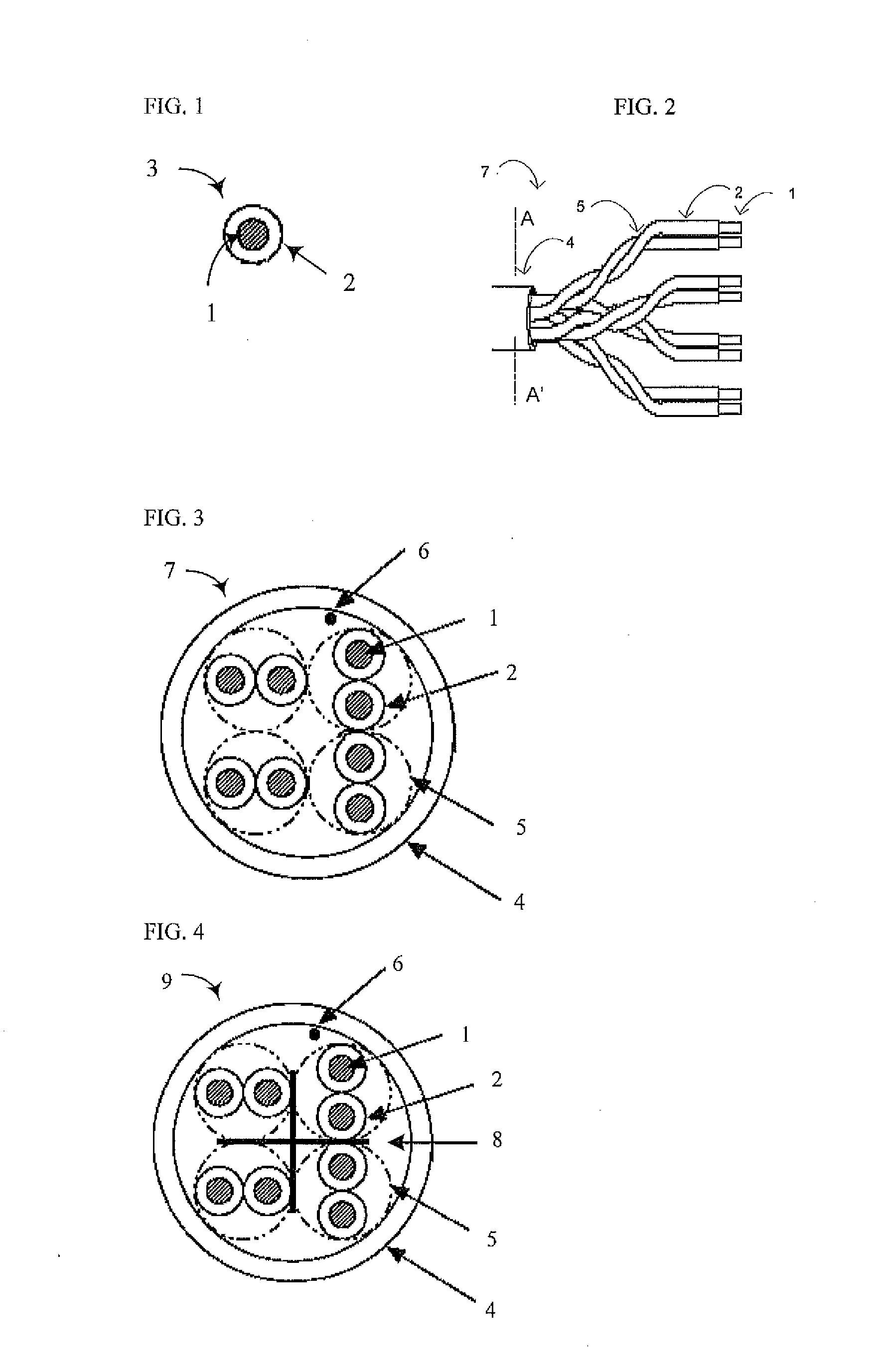

Fire-retardant insulating polyvinyl chloride material and electrical sleeve

InactiveCN102093652AImprove flame retardant performanceImprove insulation performanceInsulating bodiesLow voltagePolyvinyl chloride

The invention discloses a fire-retardant insulating polyvinyl chloride material and an electrical sleeve made from the material. The fire-retardant insulating polyvinyl chloride material comprises the following raw materials in part by weight: 100 to 150 parts of polyvinyl chloride, 0.2 to 5 parts of heat stabilizer, 5 to 20 parts of compatibilizer, 20 to 60 parts of fire retardant master batch, 0.3 to 1 part of lubricant, 1 to 3 parts of titanium white powder, 10 to 20 parts of impact modifier, 2 to 4 parts of processing aid and 5 to 20 parts of calcium carbonate. The fire-retardant insulating polyvinyl chloride material provided by the invention has excellent flame retardant property and insulating property; the oxygen index can be over 33.4; the test is up to V-0 level according to the measurement standard of GB / T2048-2008 plastic combustibility; and the resistivity can be up to 1.1*1,011 Omega.m. Therefore, the material can meet the requirement on insulation and fire retardance of a low-voltage wire cable.

Owner:KANGTAI PLASTIC SCI & TECH GRP

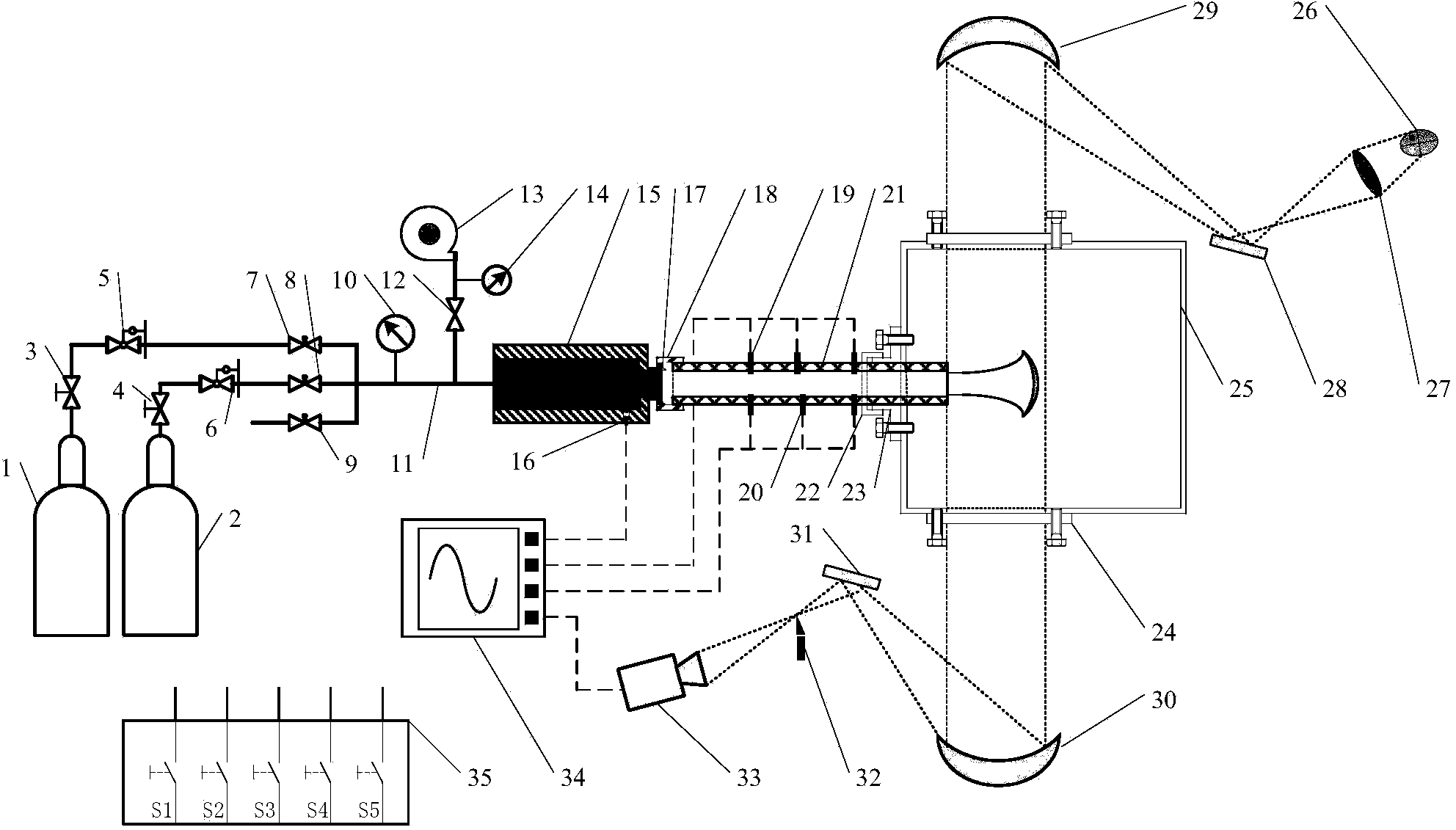

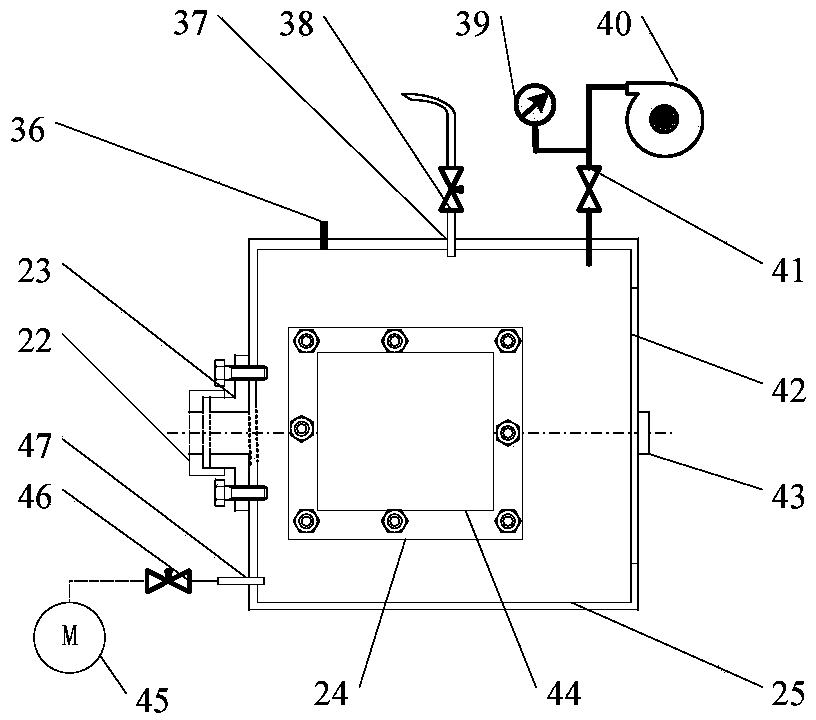

Test device for high-pressure combustible gas leakage spontaneous combustion and shock wave induction ignition

InactiveCN103454396APerfect spontaneous ignition mechanismEnable Visualization ResearchFuel testingSpontaneous combustionShock wave

The invention discloses a test device for high-pressure combustible gas leakage spontaneous combustion and shock wave induction ignition. The whole test device comprises a test gas bottle, a nitrogen gas bottle, a high-pressure ventilating pipeline, a pressure stabilization valve, an electromagnetic valve, a pressure gauge, a vacuum pump, a high-pressure storage tank, a pressure transducer, an ICP (inductively coupled plasma) pressure sensor, a photoelectric diode, a rupture disk clamp (in which a rupture disk is arranged), downstream pipelines, a schlieren, a high-speed camera, a protection box, an air compressor and the like. The device can be used for (1) researching the influence of factors, such as different leakage pressures, shapes, lengths and diameters of different downstream pipelines, the gas initial temperature, a breakage shape of the rupture disk and obstacles outside an orifice, on the spontaneous combustion ignition, and further completing a spontaneous combustion ignition mechanism; (2) researching a shock wave induction ignition process and disclosing a shock wave induction ignition mechanism and influence factors thereof; (3) realizing the visible research on spontaneous combustion ignition and shock wave induction processes.

Owner:UNIV OF SCI & TECH OF CHINA

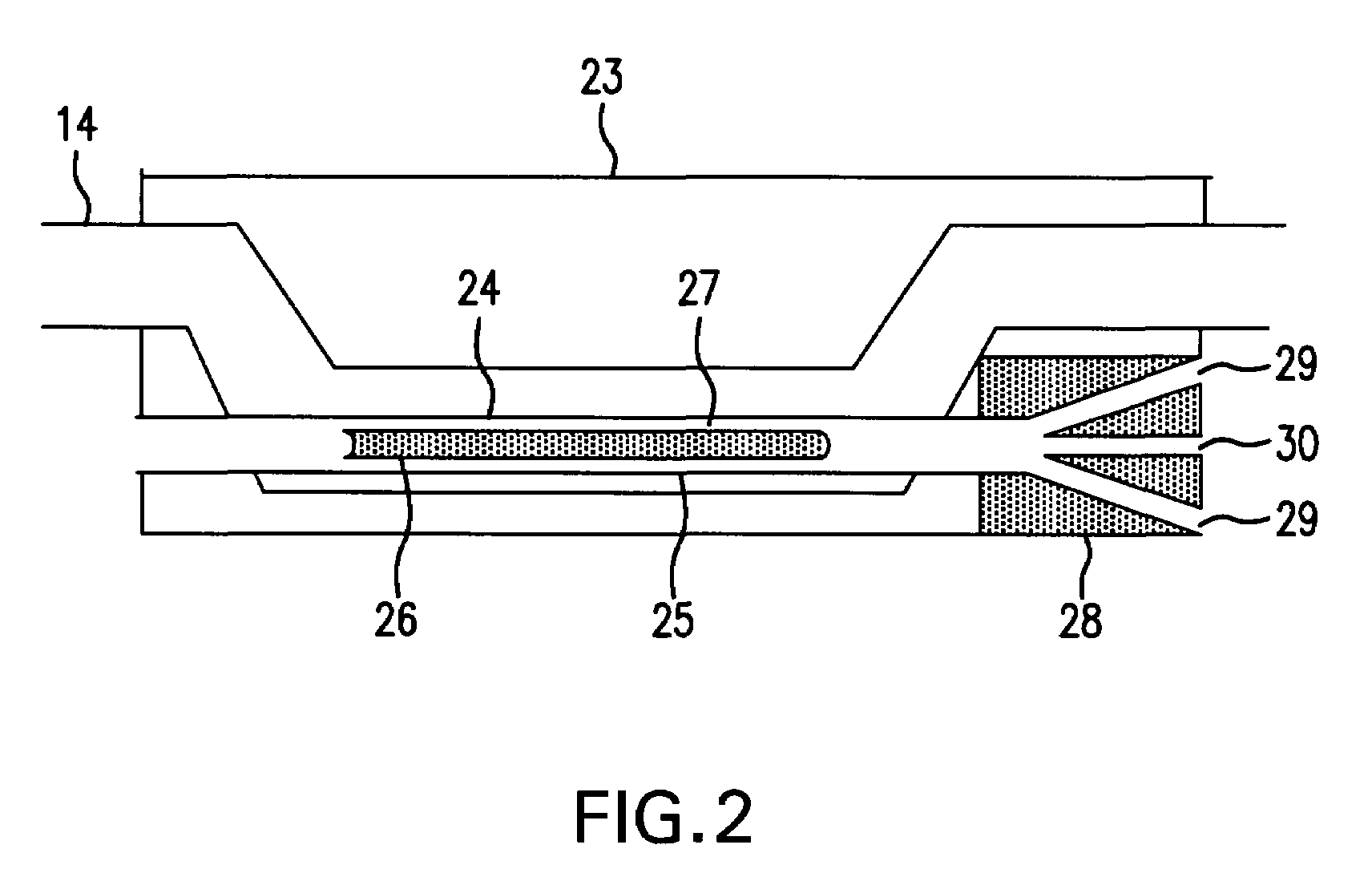

Working medium and heat cycle system

ActiveUS20140077122A1Improve cycle performanceHigh proportion of halogenCompressorOrganic chemistryTransport systemOzone layer

To provide a working medium for heat cycle, of which combustibility is suppressed, which has less influence over the ozone layer, which has less influence over global warming and which provides a heat cycle system excellent in the cycle performance (efficiency and capacity), and a heat cycle system, of which the safety is secured, and which is excellent in the cycle performance (efficiency and capacity).A working medium for heat cycle comprising 1-chloro-2,3,3,3-tetrafluoropropene is employed for a heat cycle system (such as a Rankine cycle system, a heat pump cycle system, a refrigerating cycle system 10 or a heat transport system).

Owner:ASAHI GLASS CO LTD

Polymer powder with phosphonate-based flame retardant, process for its production, and moldings produced from this polymer powder

ActiveUS7317044B2Easy to classifyMaintain mechanical propertiesAdditive manufacturing apparatus3D object support structuresPolymer sciencePolyamide

Owner:EVONIK OPERATIONS GMBH

Perfluoropolymer Composition

InactiveUS20090069480A1Low flameEmission reductionFibre treatmentAnti-corrosive paintsAlkaline earth metalFluoropolymer

The invention concerns a composition comprising:at least one melt-processible per(halo)fluoropolymer (polymer A);from 0.01 to 5% by weight of polymer A of at least one smoke-suppressant agent (S) having a decomposition temperature of at least 350° C., selected from the group consisting of molybdenum derivatives, borates of an alkaline-earth metal or of a group 12 transition metal, and mixtures thereof;optionally, at least one oxide of a metal different from molybdenum.The composition of the invention excels simultaneously in providing excellent insulating properties on meal wires or optical fibers, outstanding processing parameters for high speed cable manufacture and high performance ratings on flammability, smoke generation and fuel load. Advantageously, cables comprising said composition comply with 25 / 50 / 8 requirements according to NFPA-255 and -259 for limited combustible materials.

Owner:SOLVAY SOLEXIS

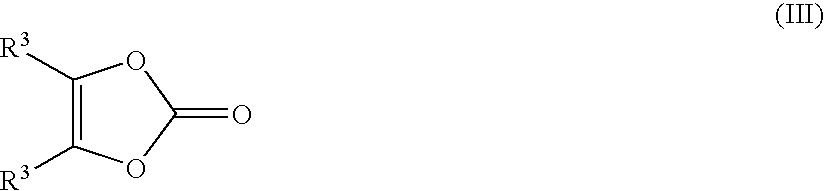

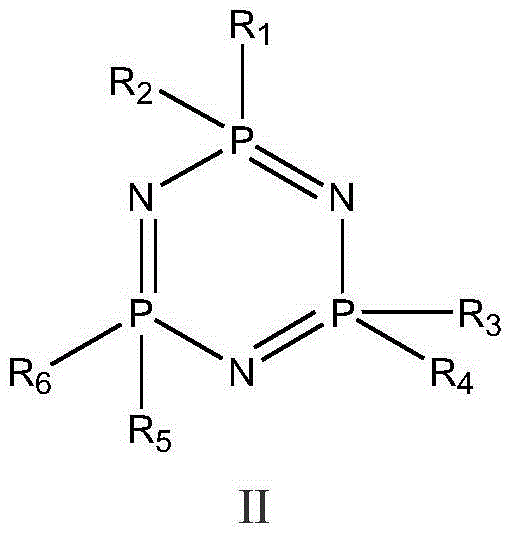

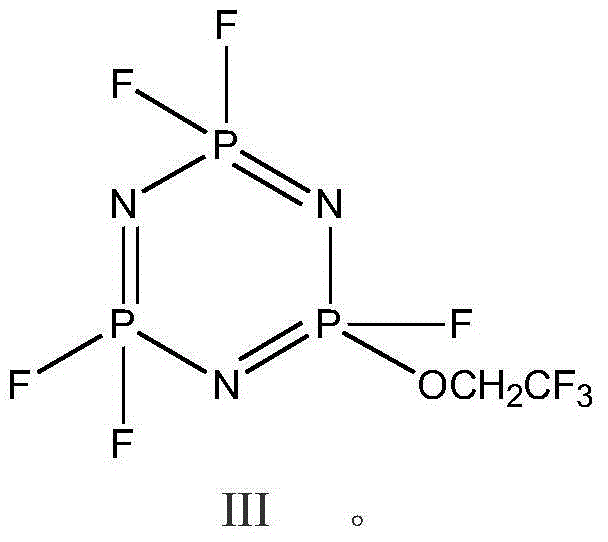

Non-Aqueous Electrolyte and Non-Aqueous Electrolyte Battery Comprising the Same

InactiveUS20080153005A1Improve battery performanceNon-combustibility of the non-aqueous electrolyte can be highly improvedOrganic electrolyte cellsSolid electrolyte cellsHalogenAlkoxy group

This invention relates to a non-aqueous electrolyte exhibiting a non-combustibility even under a condition having a higher oxygen concentration, and more particularly to a non-aqueous electrolyte characterized by comprising a non-aqueous solvent containing a cyclic phosphazene compound represented by the following general formula (I):(NPR12)n (I)[wherein R1s are independently a halogen element or a monovalent substituent; and n is 3-4] and a fluorophosphate compound represented by the following general formula (II):[wherein R2s are independently a halogen element, an alkoxy group or an aryloxy group, and at least one of the two R2s is the alkoxy group or the aryloxy group], and a support salt.

Owner:BRIDGESTONE CORP

Heavy oil treating method and heavy oil treating system

The invention is intended to produce high-pressure light fuel gas with good combustibility by contacting and reacting high-temperature, high-pressure water and heavy oil with each other in a contact-reaction unit to extract light oil components from the heavy oil and to remove metals. The high-temperature, high-pressure water and the heavy oil are introduced to the contact-reaction unit for contact and reaction with each other therein. Heavy oil components not dissolved in the high-temperature, high-pressure water are separated by precipitation from hydrocarbon gases and light oil components which are dissolved in the high-temperature, high-pressure water. The separated heavy oil components are burnt or incinerated without any further modification.

Owner:GASOLINEEUM ENERGY CENT FOUND +1

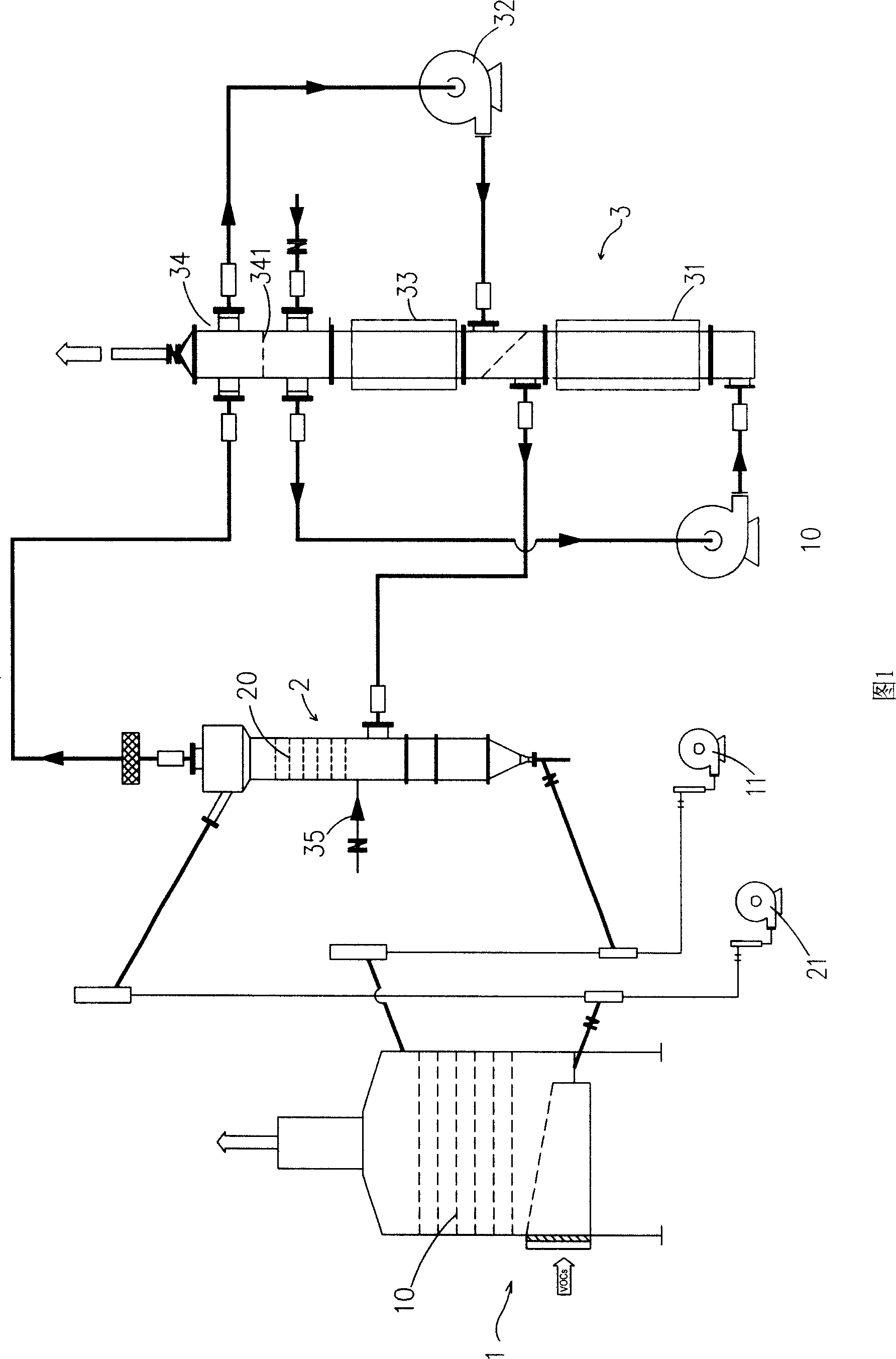

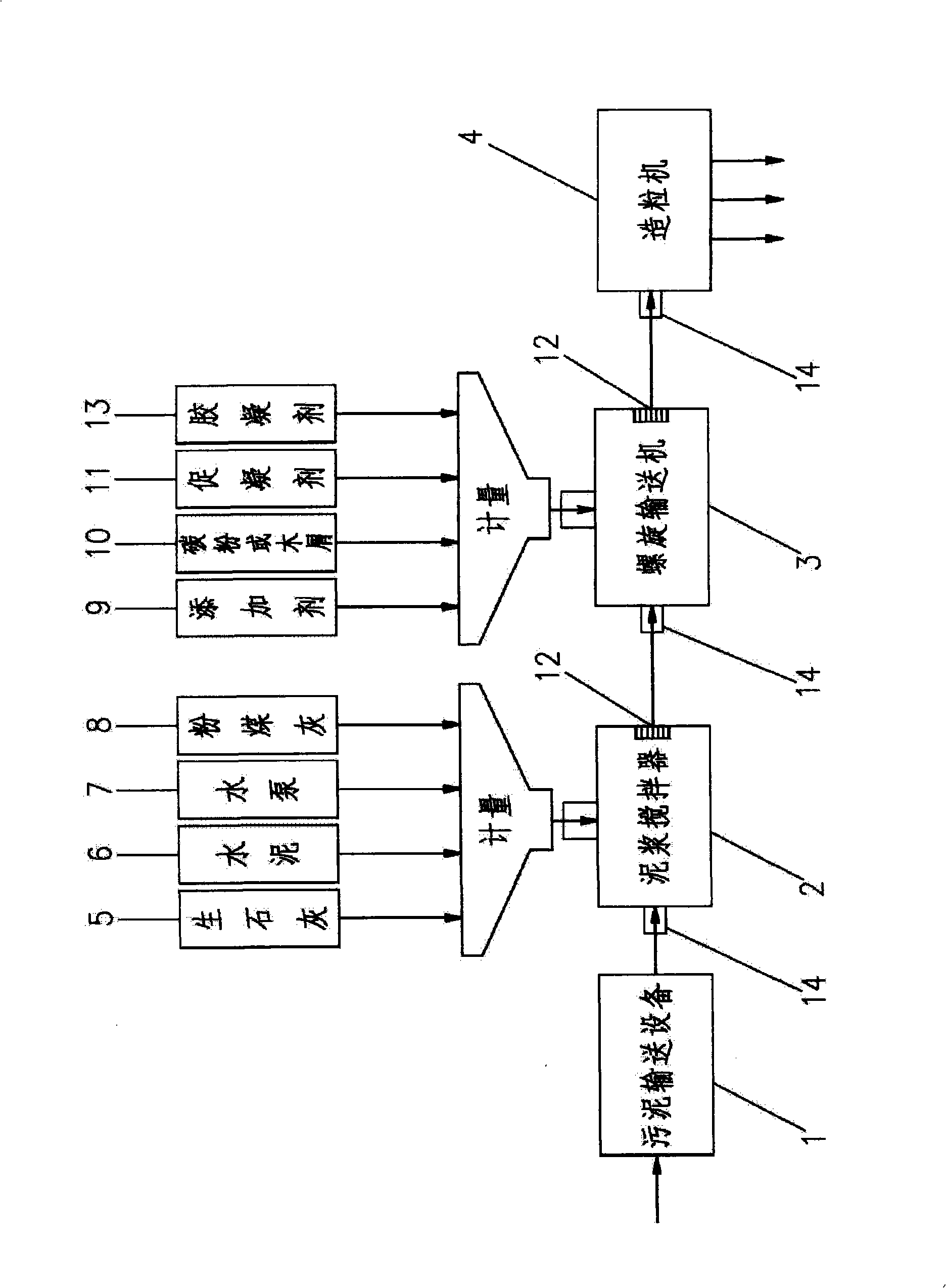

Absorption processing system of volatile organic compounds

InactiveCN101199913AImprove processing efficiencyReduce operating costsDispersed particle separationEnvironmental resistanceHigh concentration

The invention provides a novel adsorption treatment system for volatile-organic-compound waste gas, mainly for solving the problem that the traditional active-carbon flow-type adsorption device along with a condensation recovery device may cause secondary pollution of the waste solution and big energy consumption. The invention is characterized in that volatile organic compound (VOC) is adsorbed in a fluidized way by granule-shaped active carbon and then sent to fluidized desorption bed for desorption by adopting the hot gas produced by a heat exchanger and a positive pressure windmill; the desorbed VOC of high concentration uses back-drafting windmill for entering a VOC oxidation heater; the VOC is urged to relieve the heat after being pyrolyzed in high temperature; then the heat is recovery and provides for the devices mentioned above. As the active carbon used for adsorption and desorption in the system of the invention is completely separated, with the nitrogen fire-extinguishing mechanism arranged and the heat source can be produced by the combustibility of the waste gas discharged during the production instead of using gas or heavy oil, the cost is reduced and the processing efficiency of the discharge standard for the environmental protection is quite high, so that the industrial competitive advantage can be improved greatly.

Owner:蔡铭升

Fiberglass reinforced fire retardant engineering plastics and preparation method

The invention discloses glass fiber reinforced flame retardant engineering plastic and a preparation method thereof. Besides glass fiber, 30-70 parts of polycaprolactam, 8-30 parts of acrylonitrile-butadiene-styrol copolymer, 3-6 parts of compatilizer, 12-16 parts of flame retardant, 0.3-0.5 parts of antioxidant and 0.3-0.8 parts of lubricant are put in a high-mixing machine to blend for 2-5 minutes, then the blending material is put in a double screw extruder; meanwhile, 18-35 parts of glass fiber are put in the rear half section of the double screw extruder to mix together to be granulated and molded; wherein, the processing temperature is 180-245 DEG C and the screw speed is 240-560 revolutions per minute. The prepared glass fiber reinforced flame retardant engineering plastic is characterized by high size stability, large mechanical strength, excellent heat resistance, etc. The combustibility can reach UL94 V-0(1.6mm) level, thus expanding the application in electronics.

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

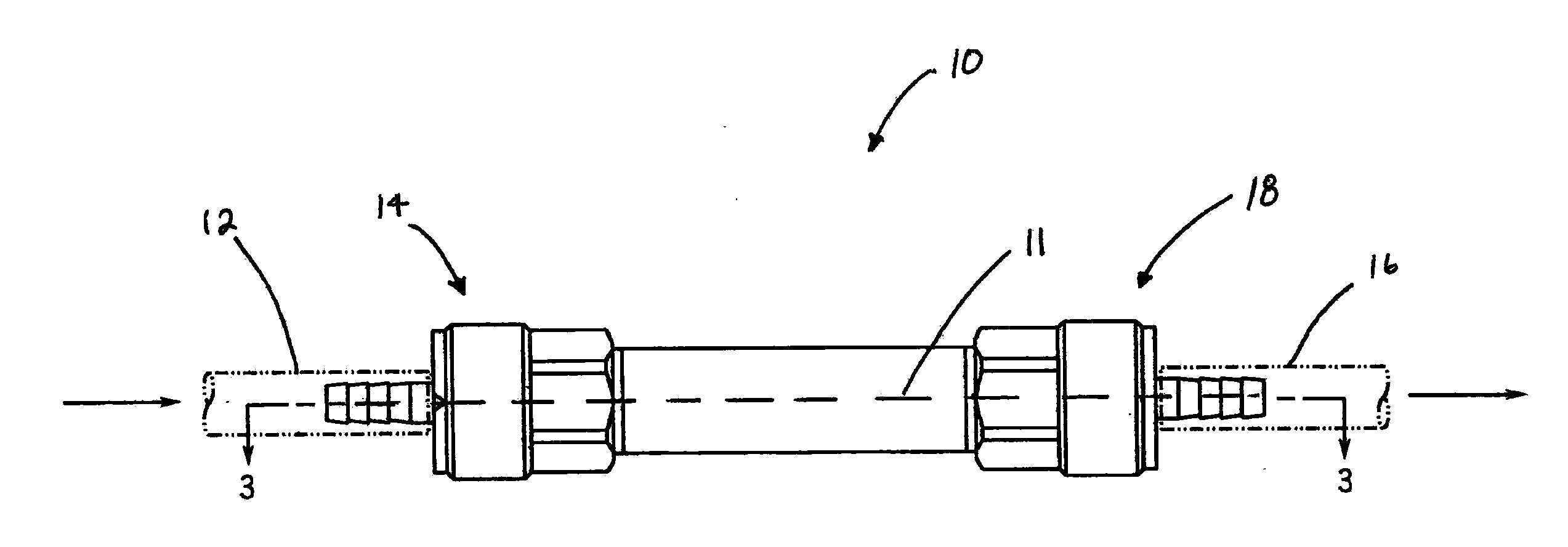

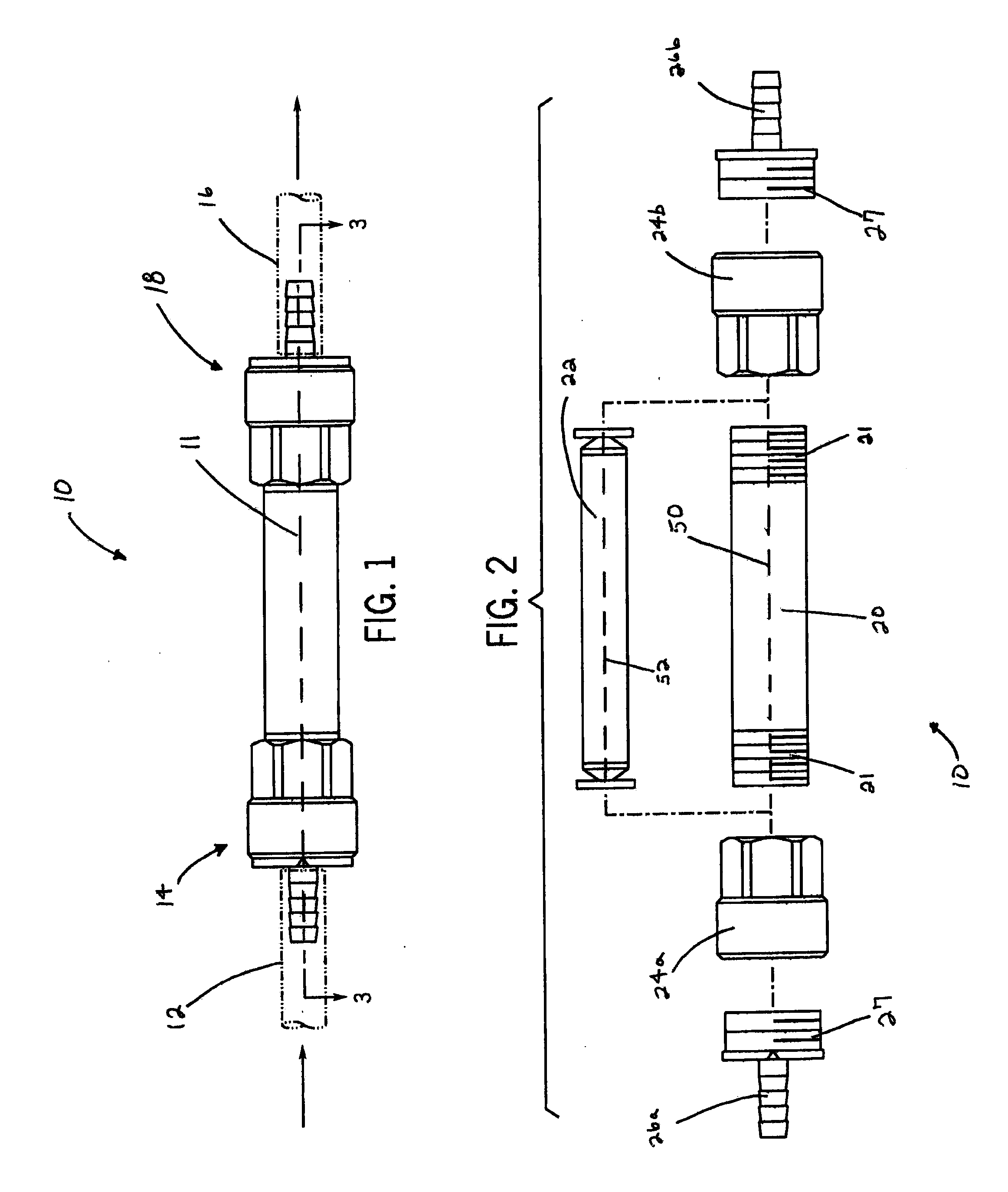

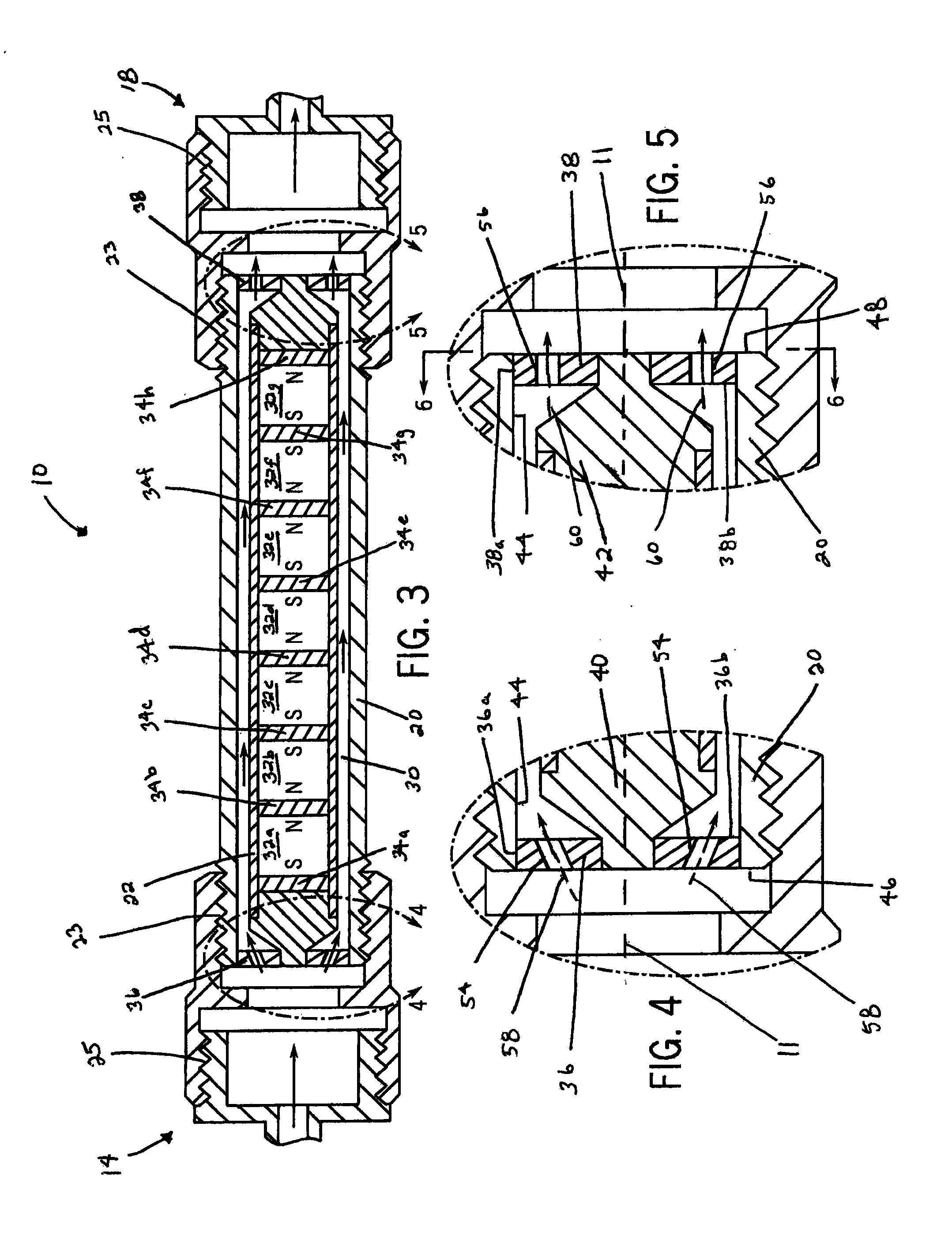

In-line fuel conditioner

ActiveUS20120067802A1Improve flammabilityEmission reductionElectrostatic separationWater/sewage treatment by magnetic/electric fieldsNuclear engineeringLiquid fuel

A fuel conditioner is provided for improving fuel combustibility and reducing emissions into the environment. The fuel conditioner may be placed in-line in a fuel delivery system for internal combustion engines and may include the following components: a first housing defining a sealed chamber, a fuel inlet in fluid communication with the sealed chamber, a second housing disposed within the sealed chamber, a magnet disposed in the second housing, a fuel outlet in fluid communication with the sealed chamber, and a flow path in the sealed chamber for flow of the liquid fuel between the fuel inlet and the fuel outlet. Along its flow path, the liquid fuel is split apart and passes through magnetic fields due to one or more magnets inside the second housing to condition the fuel to improve fuel combustibility and reduce toxic emissions.

Owner:IRVIN WALLACE TAYLOR

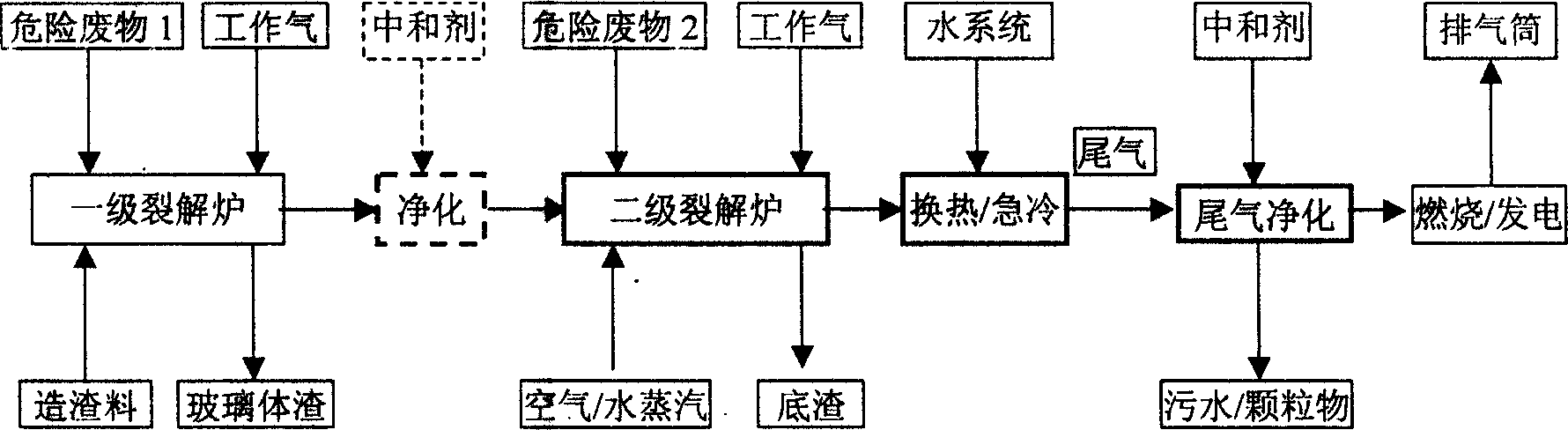

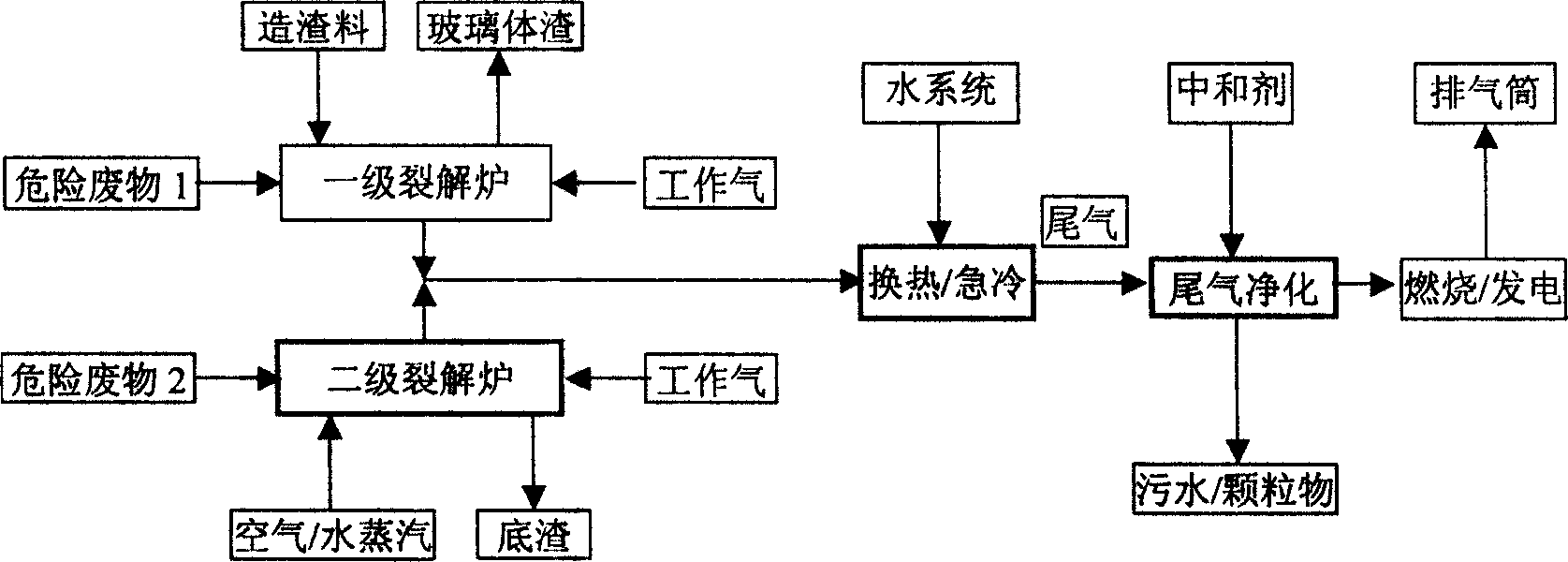

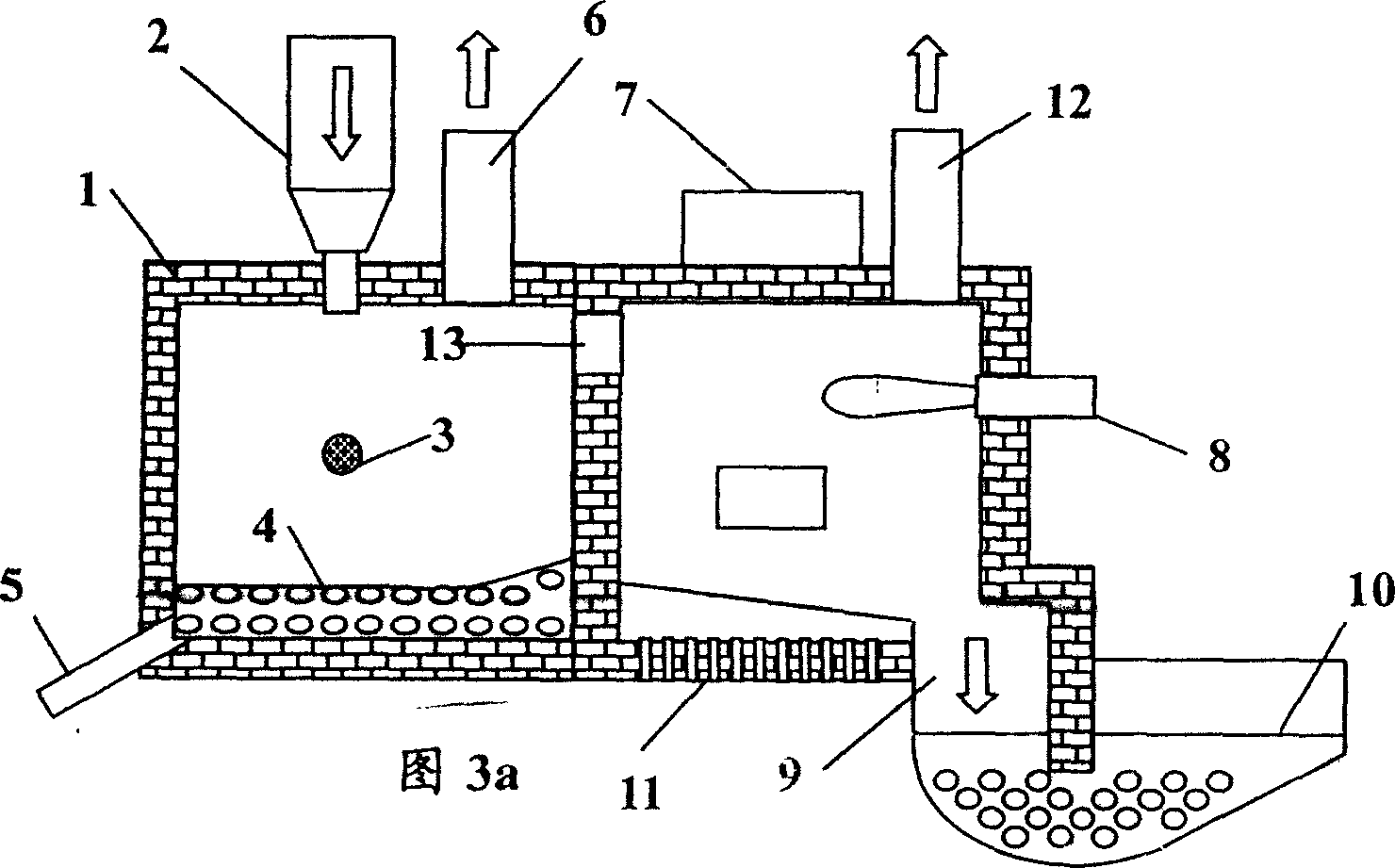

Plasma multi-stage cracking technology and apparatus capable of processing multiple organic wastes simultaneously

ActiveCN1621743AIncrease supplyReduce consumptionIncinerator apparatusCombined combustion mitigationElectricityCombustor

The present invention relates to one kind of multistage plasma cracking method and apparatus for treating several kinds of organic waste simultaneously. There are the first stage of plasma cracking furnace adopting reductive gas and producing inflammable tail gas capable of providing the next stage with auxiliary energy source; and the second stage of cracking furnace adopting oxidizing gas to save electric power consumption. In parallel configuration, the first cracking furnace and the second cracking furnace may share one tail gas unit. In serial configuration, the tail gas from the first stage may be used as the auxiliary fuel in the second stage, and the inflammable gas the second stage exhausts may be burned in the combustor or used in generator to produce electricity. The two-stage cracking furnace has at least one gas inlet for raising the cracking temperature and saving energy source, and may be designed integrally.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Micro-pore foaming glass pumice stone and preparation method thereof

ActiveCN103073184AGreen planting soil improvementLight weightGlass shaping apparatusPumice dustOptoelectronics

The invention relates to a micro-pore foaming glass pumice stone, which is characterized by being prepared by carrying out high-temperature heating and foaming, and cooling on a foaming mixture of components according to weight percentage of 85-95 of waste glass grains, 1-10 of marble powder and 1-10 of quick lime. The diameter of a micro-pore of the micro-pore foaming glass pumice stone is 0.23-5mm. The invention further relates to a preparation method of the micro-pore foaming glass pumice stone. The micro-pore foaming glass pumice stone is obtained by regenerating and utilizing waste glass and is a novel material; and the micro-pore foaming glass pumice stone has the advantages of no pollution, light weight, water permeability, water-retaining property, ventilation, fire resistance (non-combustibility and fireproof property), heat insulation property and long-period effectiveness.

Owner:江苏晶瑞特环保新材料有限公司

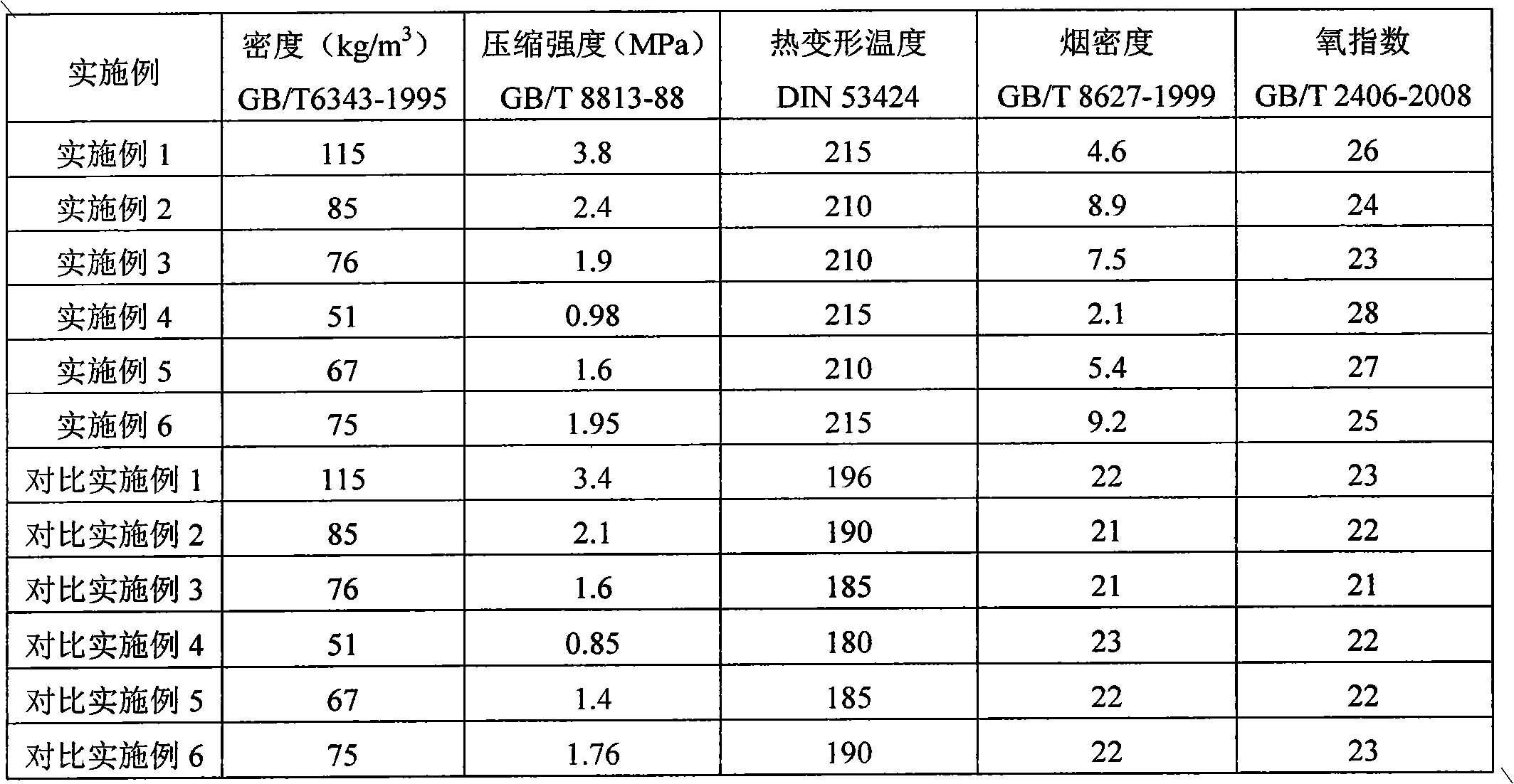

Whisker modified polymethacrylimide foamed plastic and preparation method thereof

InactiveCN102051012AImprove mechanical propertiesHigh heat distortion temperaturePolymer scienceFoaming agent

The invention relates to whisker modified polymethacrylimide foamed plastic, which is prepared from the following raw materials in part by weight: 30 to 70 parts of acrylic acid or methacrylic acid, 30 to 70 parts of acrylonitrile or methacrylonitrile, 0.1 to 20 parts of whisker material, 0.1 to 5 parts of thixotropic agent, 0.1 to 6 parts of nucleating agent, 0.05 to 2 parts of initiator, 0.1 to 15 parts of foaming agent, 0.01 to 2 parts of cross-linking agent and 0.01 to 0.7 part of retarding agent. The invention also relates to a preparation method of the foamed plastic, which comprises the following steps of: (1) mixing the raw materials; (2) performing polymerization reaction on the materials obtained in the step (1); (3) heating a plate prepared in the step (2), and preheating and foaming; and (4) heating the foamed plate prepared in the step (3). The combustibility and smoke density of the foamed plastic are reduced, and the foamed plastic is a plastic material with high performance.

Owner:湖南兆恒材料科技有限公司

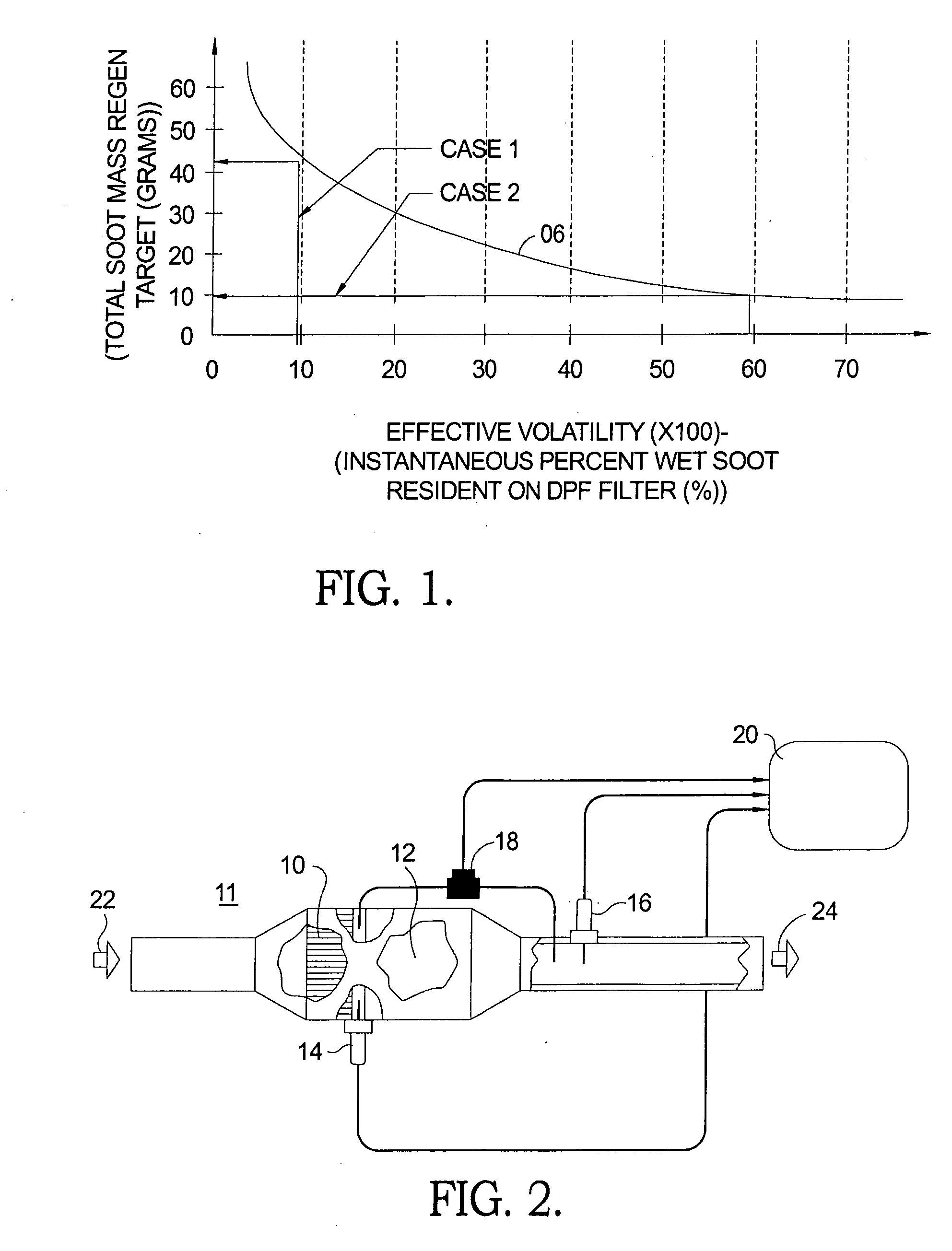

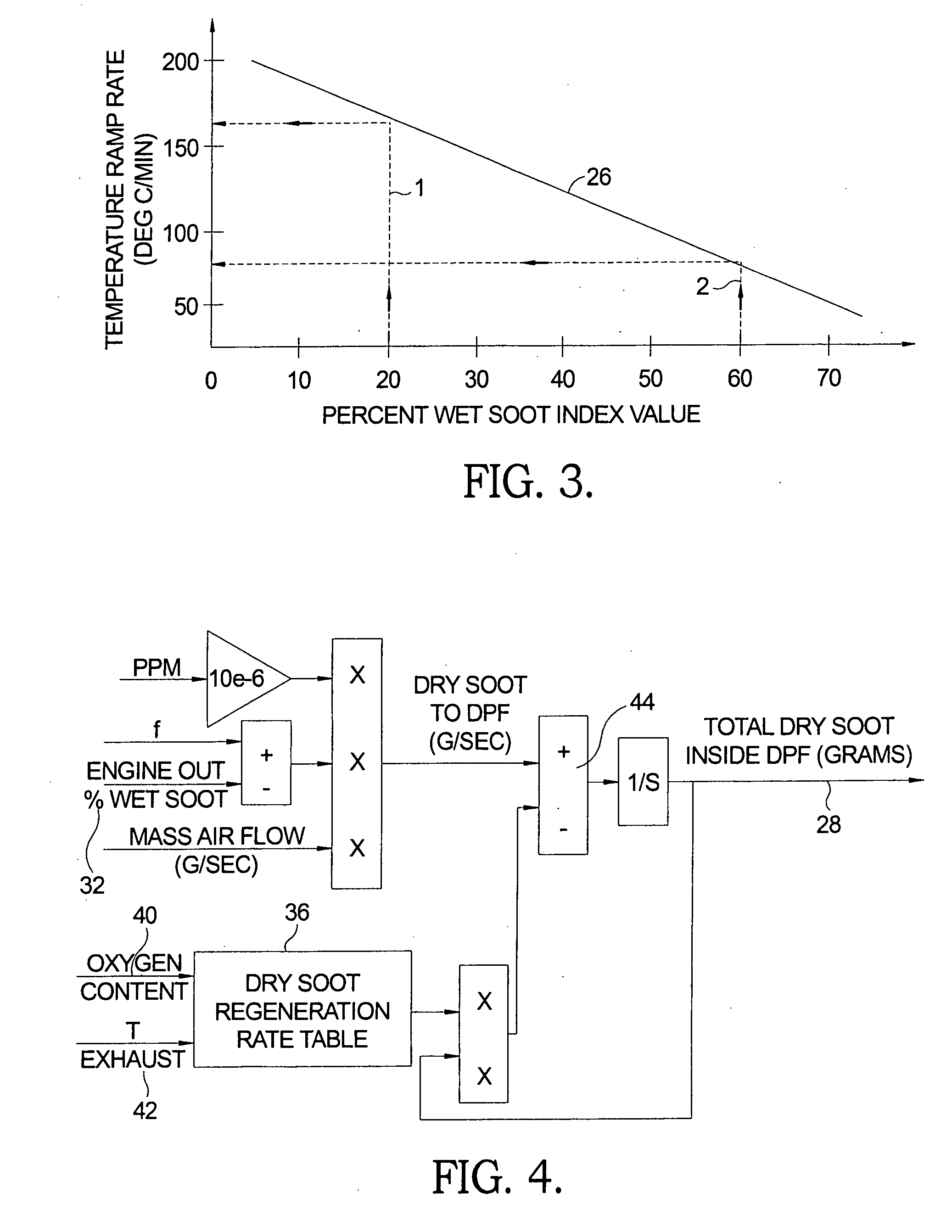

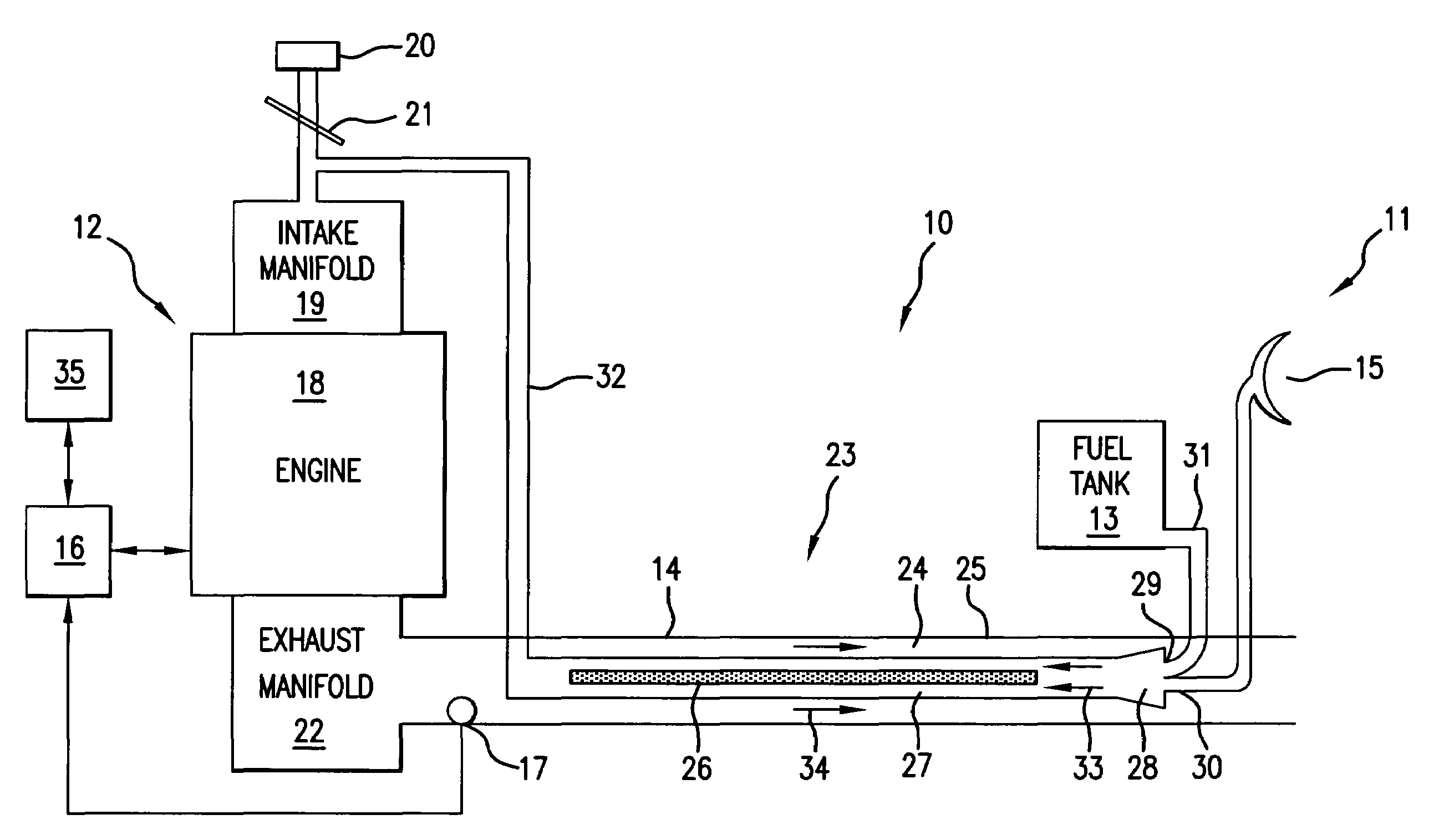

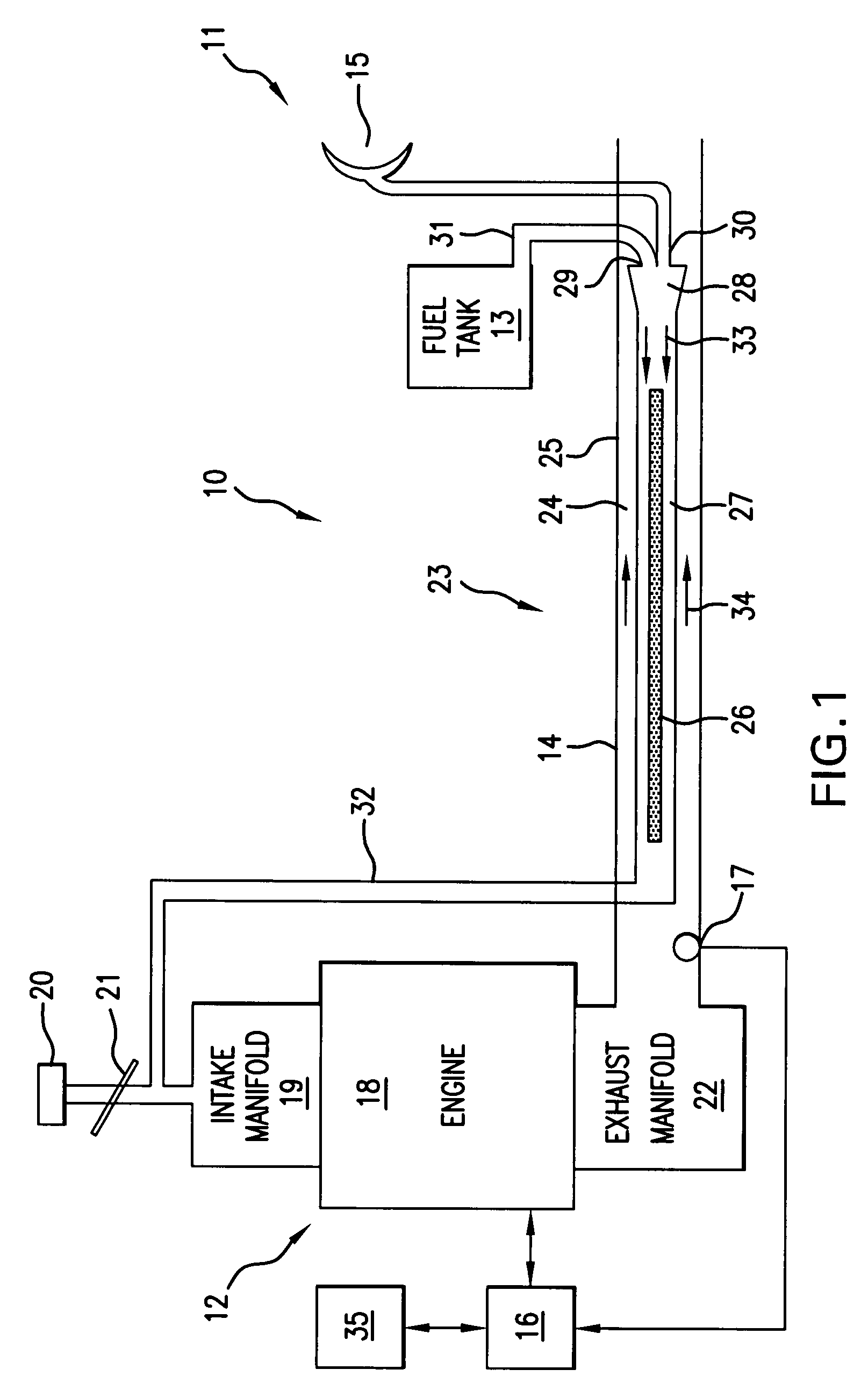

Method for controlling catalyst and filter temperatures in regeneration of a catalytic diesel particulate filter

InactiveUS20090188243A1Analogue computers for vehiclesInternal combustion piston enginesTemperature controlEngineering

A system for managing regeneration of a CDPF in a diesel engine. The system determines volatility of the accumulated soot by a weighting / indexing method to select a regeneration control strategy that protects the CDPF from thermal damage. The system determines the mass of wet soot and dry soot accumulated over the previous driving cycle and selects a management strategy to control the rate of temperature increase and the thermal gradient imposed upon the filter. The wet soot percent is an index for setting the regeneration temperature control profile for an allowable total accumulated soot mass as a function of the accumulated wet soot. The method also scales the soot mass regeneration threshold value based upon wet soot accumulation and accumulation rate and provides an indicator of combustibility of the soot accumulation. The method provides a temperature ramp rate, total regeneration time, and exhaust oxygen level required to control regeneration.

Owner:DELPHI TECH INC

Pre-ignition fuel treatment system

InactiveUS7487764B2Improve responseHighly combustibleInternal combustion piston enginesThermal treatment of fuelNuclear engineeringFuel treatment

A method and apparatus for reforming a hydrocarbon fuel which increases the efficiency with which said fuel's energy content may be extracted resulting in improved combustibility and reduction of by-products produced. The hydrocarbon fuel is cracked and ionized in a reactor vessel by means of a feedback loop of electro-chemical interactions with a reactor rod comprised of materials which are both magnetic and catalytic.

Owner:LEE DENNIS

Trifluoroiodomethane-containing mixed refrigerant

InactiveCN101824305AReduce flammabilityWon't breakHeat-exchange elementsRefrigerationTrifluoroiodomethane

The invention relates to a trifluoroiodomethane-containing mixed refrigerant. The trifluoroiodomethane-containing mixed refrigerant is prepared by mixing component 1, a component 2 and a component 3, wherein the component 1 is trifluoroiodomethane with the combustion and explosion inhibiting effect; the component 2 comprises 1,1,1,2-tetrafluoroethane, 1,1,2,2-tetrafluoroethane or mixture of the 1,1,1,2-tetrafluoroethane and 1,1,2,2-tetrafluoroethane; the component 3 comprises propane, propylene or mixture of the propane and propylene; in the mixed refrigerant, the content of the component 1 is between 1 and 10 weight percent; the content of the component 2 is between 20 and 40 weight percent; the content of the component 3 is between 50 and 75 weight percent; the ODP value of the mixed refrigerant is zero; the GWP value is far less than that of a routine HFCs work substance; and the trifluoroiodomethane-containing mixed refrigerant has good lube intersolubility, can directly substitute an R22 working substance without making large alteration on a refrigeration system; and as the mixed refrigerant has the combustion inhibiting component, the combustibility of the refrigerant is greatly reduced or even the refrigerant is completely incombustible so that the safety of the refrigeration system is greatly improved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

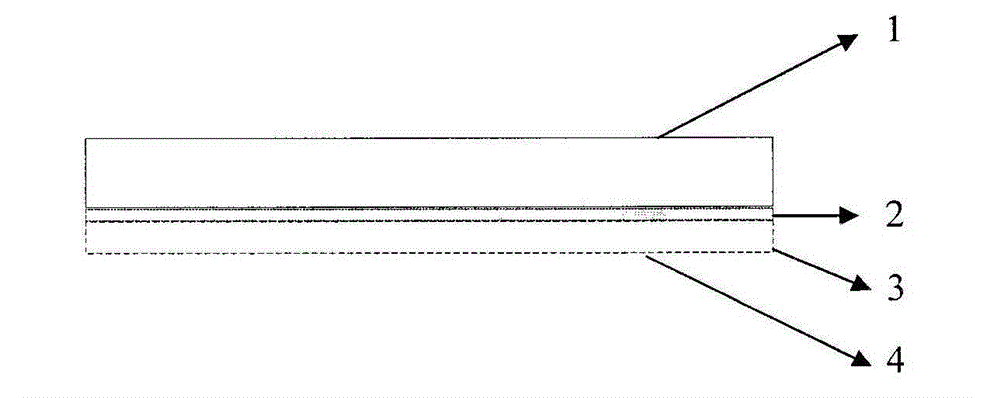

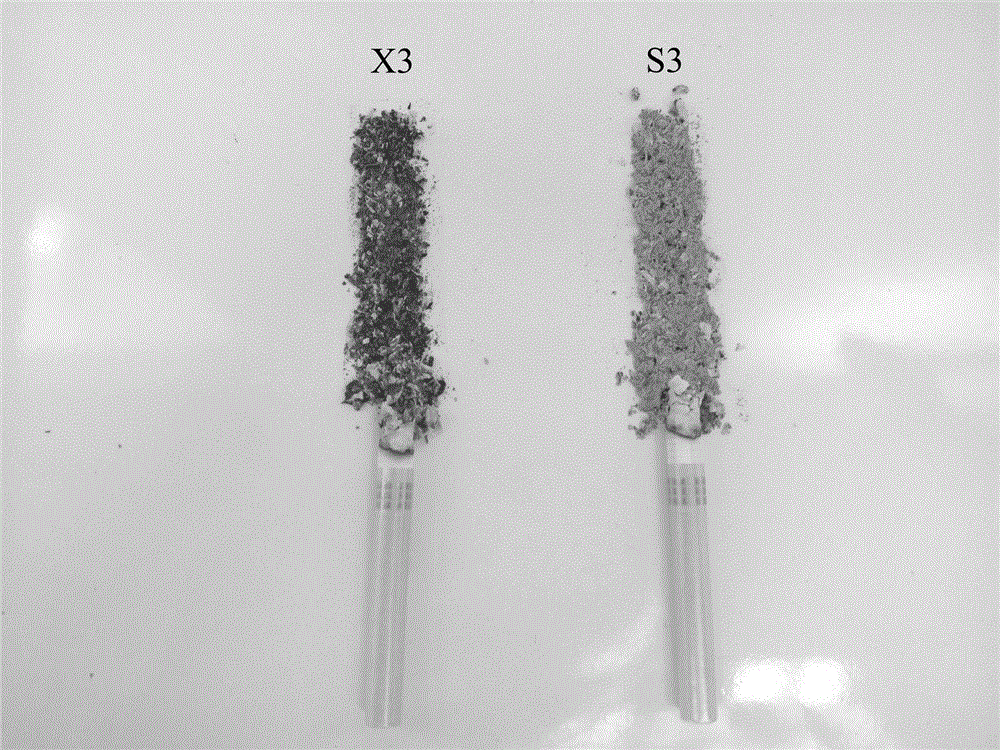

Compounded cigarette paper with aluminum foil layer and application method thereof

The invention relates to compounded cigarette paper with an aluminum foil layer. The compounded cigarette paper with the aluminum foil layer is characterized by being formed through compounding combustible wood-pulp fiber paper and aluminum foil, and through holes are uniformly distributed in the aluminum foil; the combustible wood-pulp fiber paper is prepared from the following raw materials in percentage by weight: 55-70% of wood pulp fibers, 15-30% of filler calcium carbonate, 0.5-5% of combustion improver and 1-5% of paper making additives; and the fiber paper has relatively high porosity, the gas permeability of 50-200CU, the fixed quantity of 30-200g / m<2> and the thickness of 0.02-2mm. When the compounded cigarette paper disclosed by the invention is used for producing a novel tobacco product cigarette through rolling, the aluminum foil layer is in direct contact with cut tobaccos, and during combustion-smoking, the aluminum foil is heated through combusting the combustible wood-pulp fiber paper at an outer layer of the aluminum foil and then the cut tobaccos are heated. The invention has the biggest characteristic that a kind of cigarette paper suitable for producing novel, low-temperature and non-combustion tobacco products is provided, and the aluminum foil is heated by a heat source generated through combusting the cigarette paper of an outer layer of a cigarette and then the cut tobaccos are heated.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

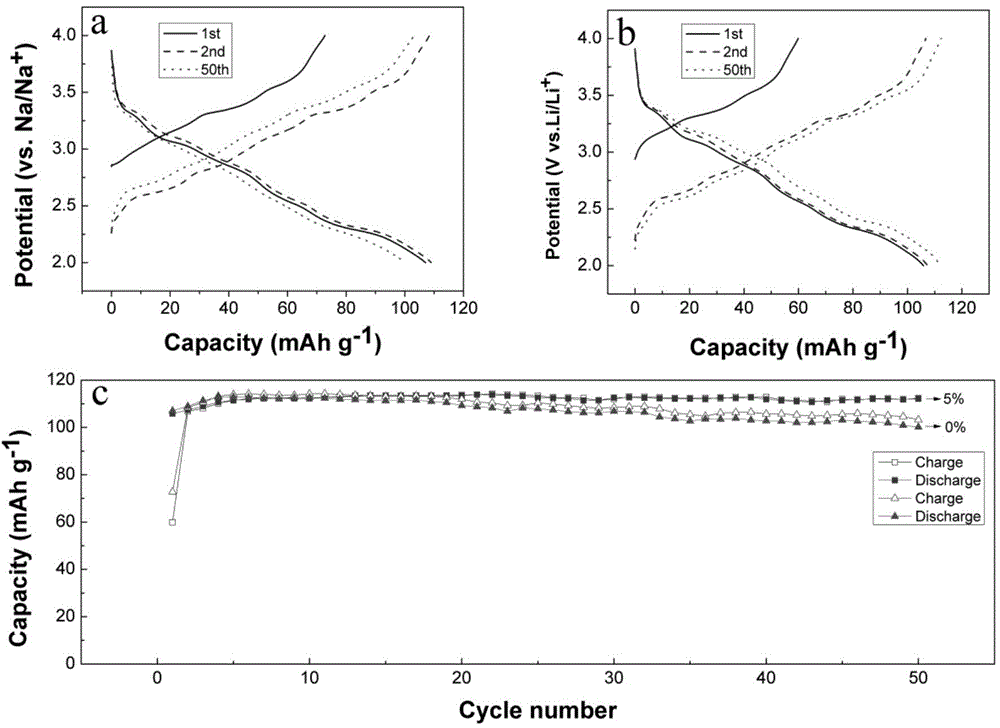

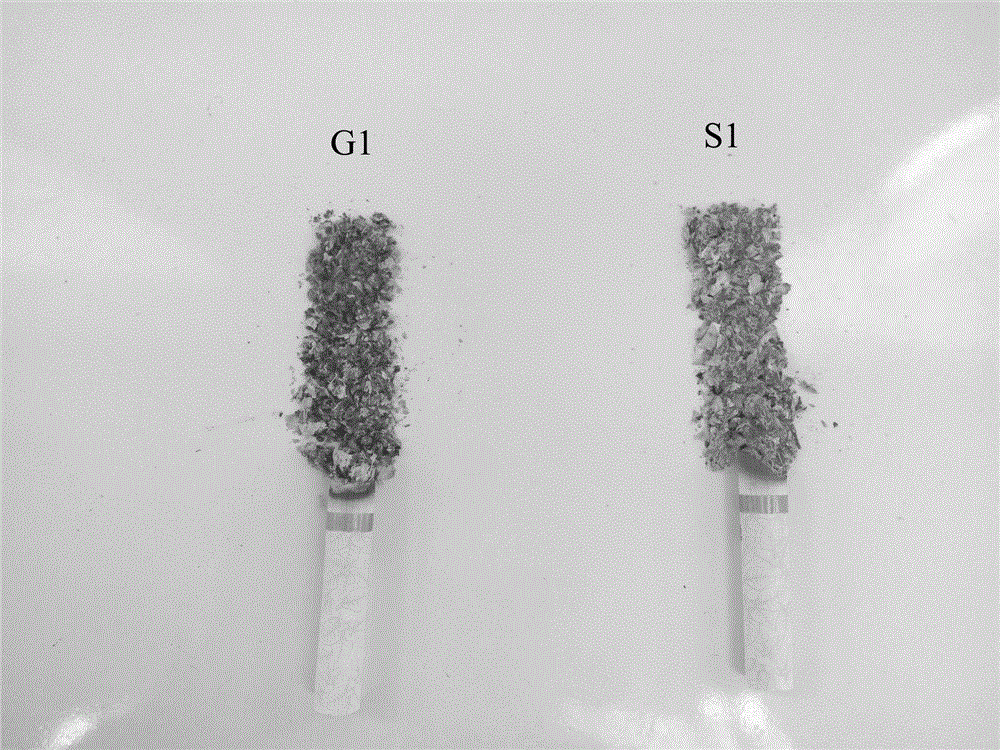

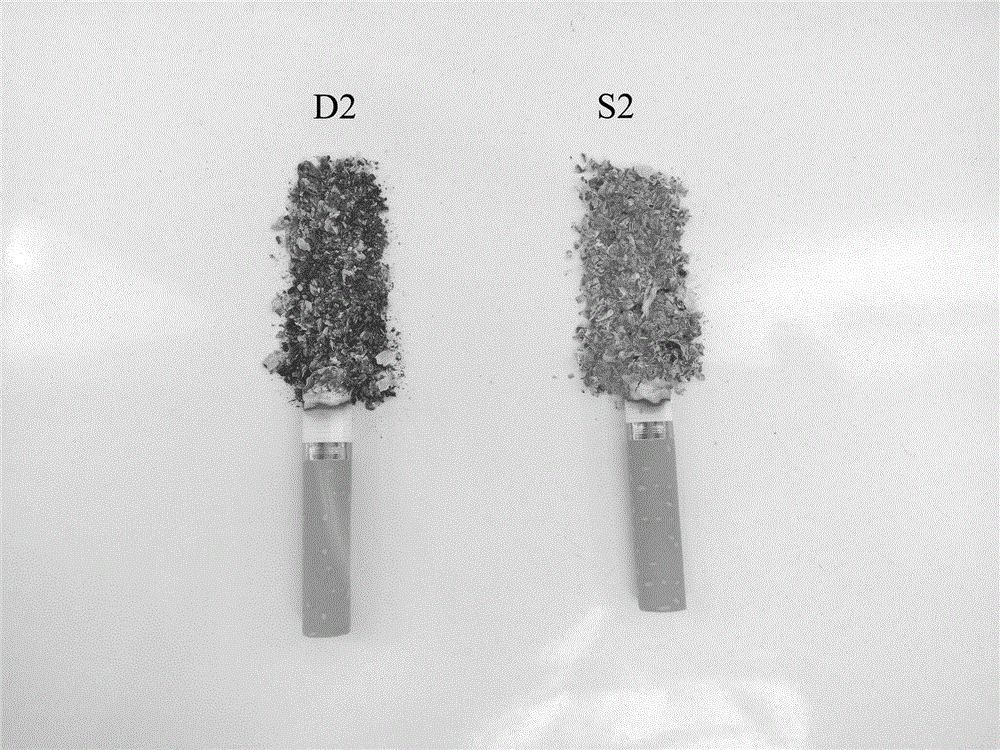

Flame retardant sodium-ion battery electrolytic solution and application thereof

ActiveCN104900879AImprove flame retardant performanceLittle impact on electrochemical performanceCell electrodesSecondary cellsOrganic solventCarbonate ester

The invention relates to a flame retardant sodium-ion battery electrolytic solution and application thereof. The electrolytic solution comprises the following ingredients with the concentration: 0.001-2mol / L sodium salt, carbonate esters and / or ether organic solvents, 0.1-50% of a flame retardant additive and 0-0.5mol / L other functional additives. The flame retardant sodium-ion battery electrolytic solution is applied into a sodium primary battery, a sodium secondary battery and a sodium ion battery. A sulfuryl fluoride base group-containing compound has good flame retardance, has little influence on the electrochemical performance and can be used as a novel electrolytic solution flame retardant additive; the flame retardant additive is added into the electrolytic solution, so that the combustibility of the electrolytic solution can be reduced. A phosphonitrile base group-containing compound has good flame retardance, has little influence on the electrochemical performance, and can be used as a novel electrolytic solution flame retardant additive; the flame retardant additive is added into the electrolytic solution, so that the combustibility of the electrolytic solution can be reduced. After the electrolytic solution is applied to the sodium battery, the combustion possibility of the electrolytic solution is zero.

Owner:SHANDONG ZESHI NEW MATERIALS TECH CO LTD

Method for improving cigarette soot whiteness

ActiveCN105725255AIncrease moisture contentUniform sizeTobacco preparationTobacco treatmentRolling paperPotassium

The invention provides a method for improving cigarette soot whiteness. Tobacco raw materials include mature tobacco with the potassium-chlorine ratio large than 4, and papermaking process reconstituted tobacco at least accounting for 5% of the tobacco raw materials. Finished product tobacco is obtained by conducting vacuum moisture regaining, loose moisture regaining, screening and casing, shredding, the leaf and tobacco temperature increase procedure before drying, the leaf and tobacco drying procedure, leaf and tobacco winnowing and perfuming. A collimator of the appropriate specification is selected to conduct cigarette rolling on finished product cut tobacco, and it is ensured that the density change rate of finished product tobacco distribution at the ends and in the middles of the cigarettes is smaller than 11.5%. By controlling the cigarette production process, finished product cut tobacco can have the appropriate moisture content, an appropriate filling value and appropriate elasticity, and the problem that the tobacco combustibility is poor is solved; by selecting cigarette rolling paper matched with cut tobacco and controlling relatively-low-weight cigarettes, combustion of smoked cut tobacco of cigarettes is more complete, the cigarette soot whiteness is obviously improved, and the tar release amount and the CO release amount are decreased.

Owner:CHINA TOBACCO HENAN IND

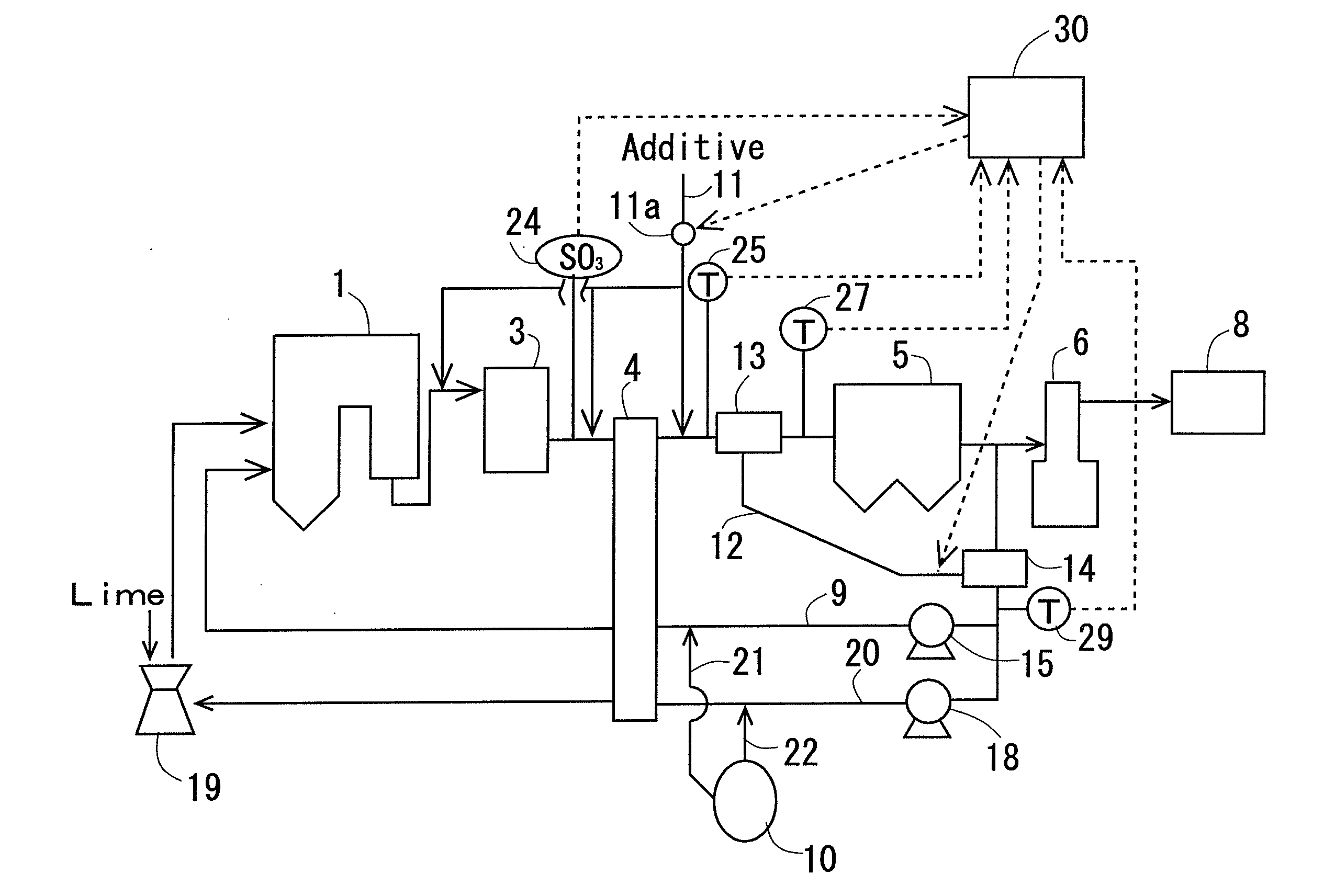

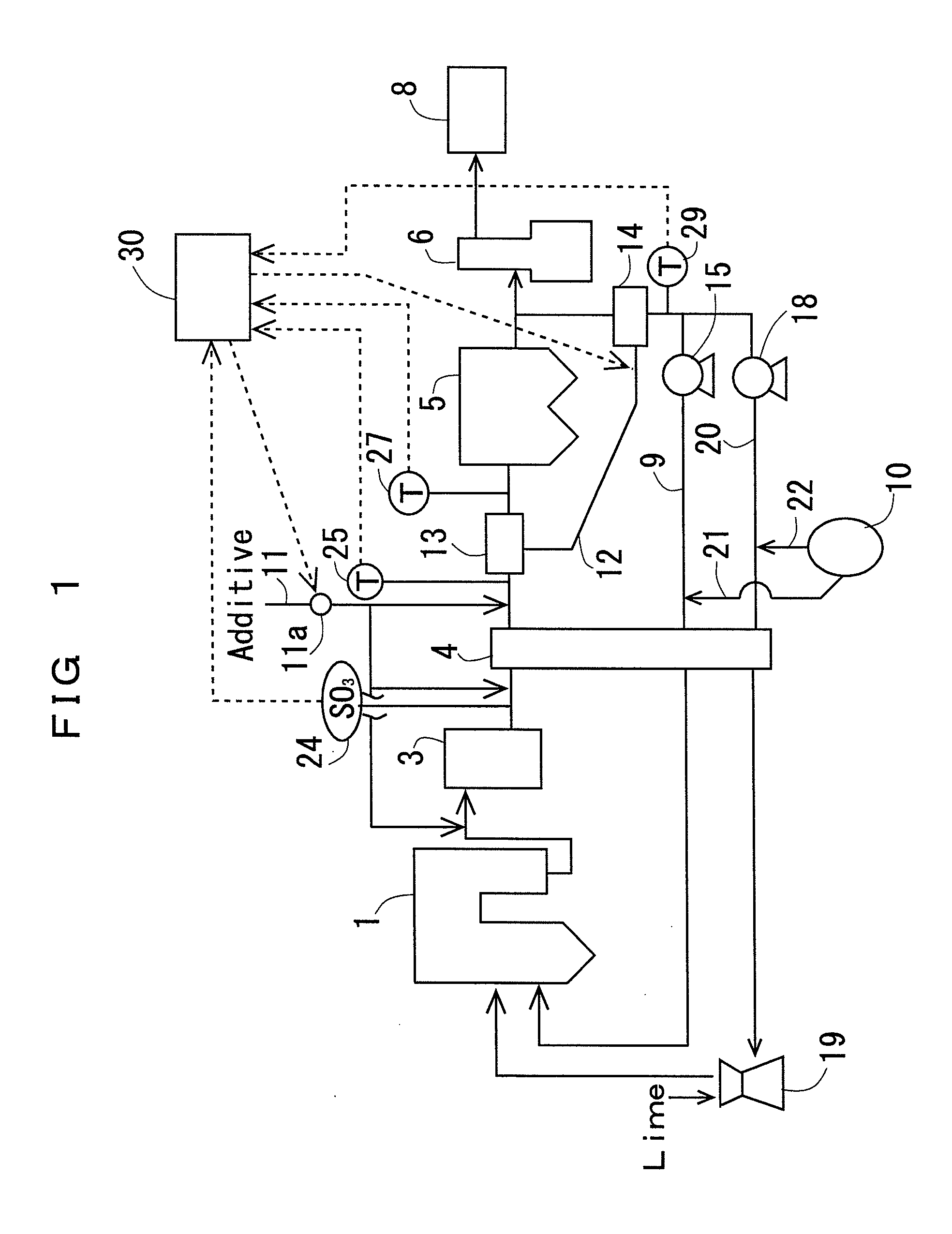

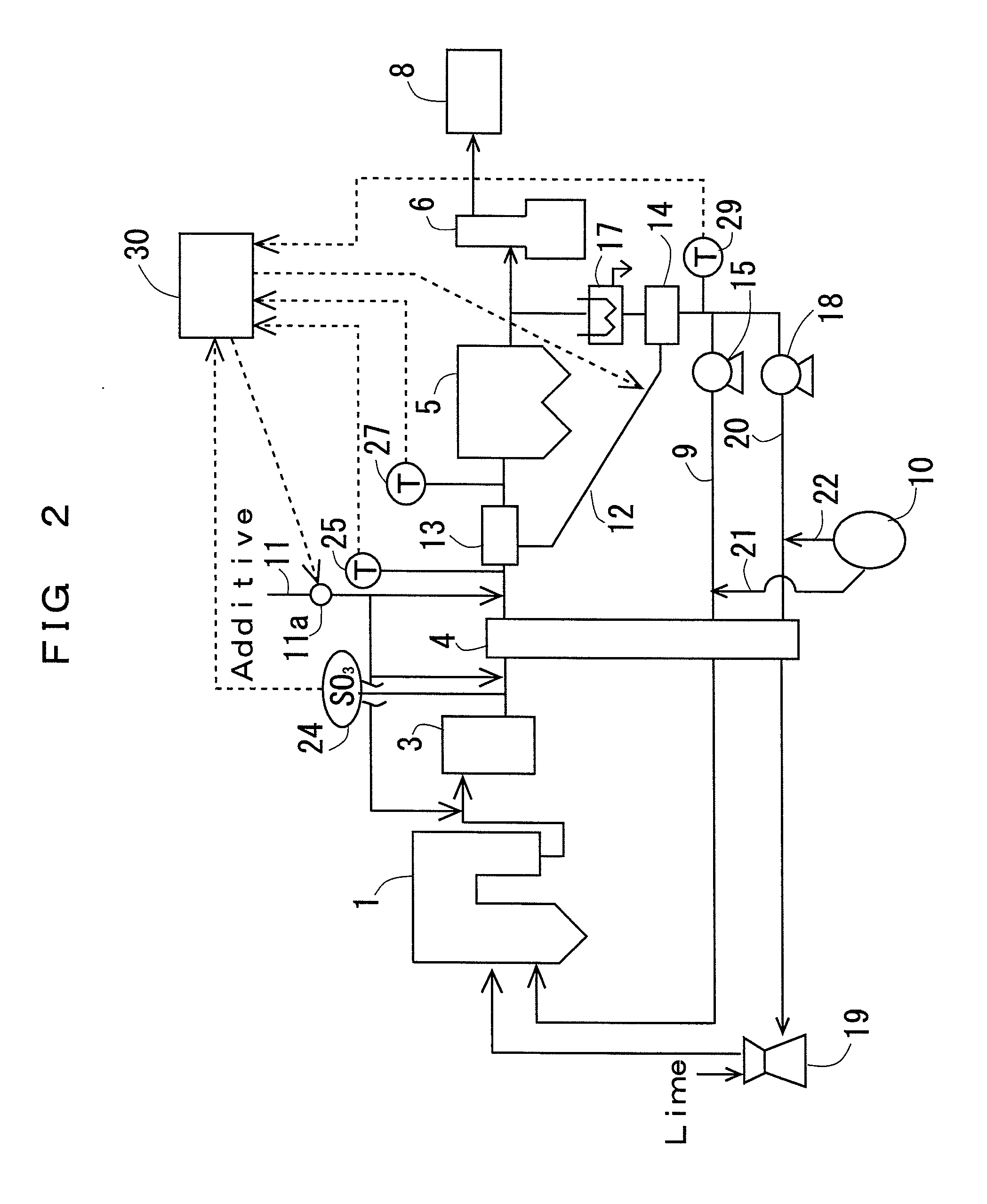

Exhaust gas treatment device for an oxygen combustion system

InactiveUS20120272626A1Efficient removalAvoid corrosionCombination devicesGas treatmentAir preheaterCombustion chamber

In an exhaust gas treatment device provided with: an exhaust gas treatment unit in which an oxygen combustion boiler 1 using coal as fuel, a denitration device 3, an air preheater 4, a dust-collection device 5, a desulfurization device 6, and a carbon dioxide recovery device 8 are sequentially arranged from the upstream side to the downstream side of an exhaust gas duct; and an exhaust gas circulation unit which branches off from the exhaust gas duct at an outlet of the dust-collection device 5 or an outlet of the desulfurization device 6 and through which the exhaust gas is preheated by the air preheater 4 and returned to the oxygen combustion boiler 1, a heat-recovery heat exchanger 13 that adjusts a gas temperature at an inlet of the dust-collection device 5 to be not greater than an acid dew point of SO3 and not lower than a water dew point is provided between the air preheater 4 and the dust-collection device 5, a reheating heat exchanger 13 that adjusts a gas temperature to be not lower than the acid dew point of SO3 is provided in the vicinity of a branch of the exhaust gas circulation unit, adjusting the gas temperature at the inlet of the dust-collection device 4 to be not greater than the acid dew point of SO3 makes it possible to prevent corrosion of pipes in the exhaust gas circulation unit and to avoid a decrease in fluidity or combustibility of the pulverized coal in the pipes in the mill.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

Method for realizing live cleaning of secondary equipment

ActiveCN102580937AMeet cleaning requirementsImprove insulation performanceInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsNon toxicityEngineering

The invention relates to a method for cleaning, dedusting and descaling secondary equipment, in particular to a method for realizing live cleaning of secondary equipment. During live operation of the secondary equipment, live cleaning agents are used for flushing or spray-washing the secondary equipment through a cleaning device, and a recovery device is used for recovering dirt. On the premise that the secondary equipment is not powered off and does not stop running, various dirt such as dust, greasy dirt, moisture, salt, metal dust, carbon stains and the like on the surface and in a deep layer of the equipment can be safely and efficiently cleaned, high safety of high insulation, non-toxicity, non-combustibility, corrosion resistance and the like is achieved, and the gap of safely cleaning the secondary equipment in live operation in the prior art is filled. The method makes a great breakthrough, and has fine application prospect in the field of secondary equipment maintenance.

Owner:广州华盈电气科技有限公司

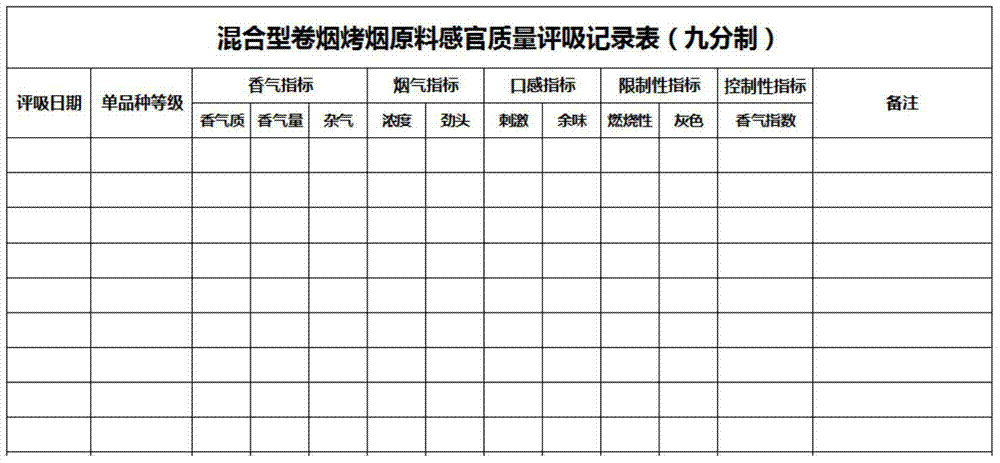

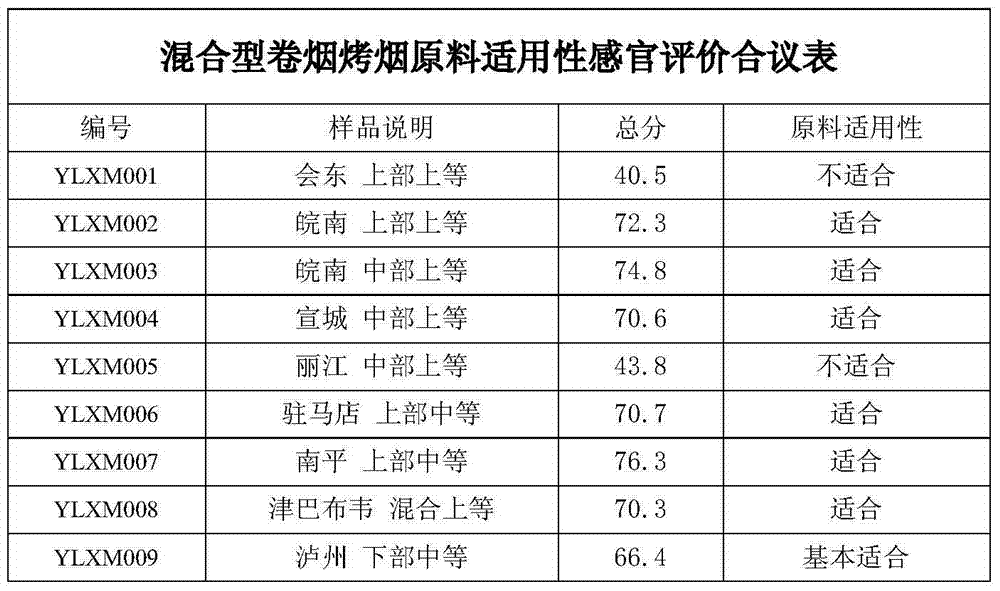

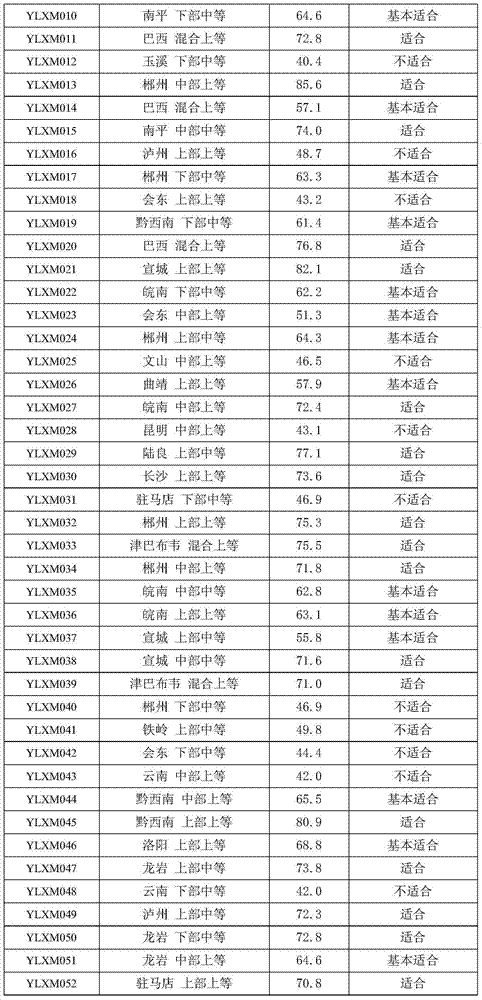

Flue-cured tobacco raw material sensory quality evaluation method applicable to mixed type cigarettes

The invention discloses a flue-cured tobacco raw material sensory quality evaluation method applicable to mixed type cigarettes. The sensory quality evaluation method comprises ten evaluation indexes including aroma, aroma amount, miscellaneous gas, smoke concentration, strength, irritation, aftertaste, combustibility, gray and a controlling index, wherein the controlling index is a comprehensive index of tobacco raw materials applicable to the mixed type cigarettes. According to the sensory quality evaluation method, sensory evaluation of the quality of the flue-cured tobacco raw materials is quantified for the first time to judge the applicability in a mixed type cigarette leaf group formula; each index is graded according to nine points; aiming at the emphasis of the flue-cured tobacco raw material needed by the mixed type cigarettes, the weight of the final score of each index sub-item is different, the statistical total score is converted by a centesimal system and the weights of all the indexes are contained in the final score. The method is easy to operate, is simple and clear and can directly judge the applicability of the flue-cured tobacco raw materials.

Owner:CHINA TOBACCO ANHUI IND CO LTD

Mud granulizing method, mud granule produced thereby and application thereof

InactiveCN101514072AImprove processing efficiencyEasy to storeSludge treatmentSolid waste disposalFilling materialsSludge

The invention discloses a mud granulizing method, mud granules produced by the method and application of the mud granules. The method comprises the following steps: mixing mud and quicklime evenly, granulizing with a granulator to form mud granules, adding moderate amount of cement to enhance the strength of the mud granules which can be used as building filters, and adding moderate amount of carbon powder or sawdust to improve the combustibility of the mud granules which can be used as fuel. The mud granulizing method of the invention can be directly combined with the sewage disposal process, and mud is taken as raw material to produce mud granules with multiple uses to ensure that the mud produced by mud disposal can be recycled, thus resolving the mud disposal problem of the sewage disposal industry. The method can realize continuous and automatic work, avoid manual work directing at mud, and improve work environment.

Owner:BEIJING SIFANGRUGANG CONCRETE PROD +1

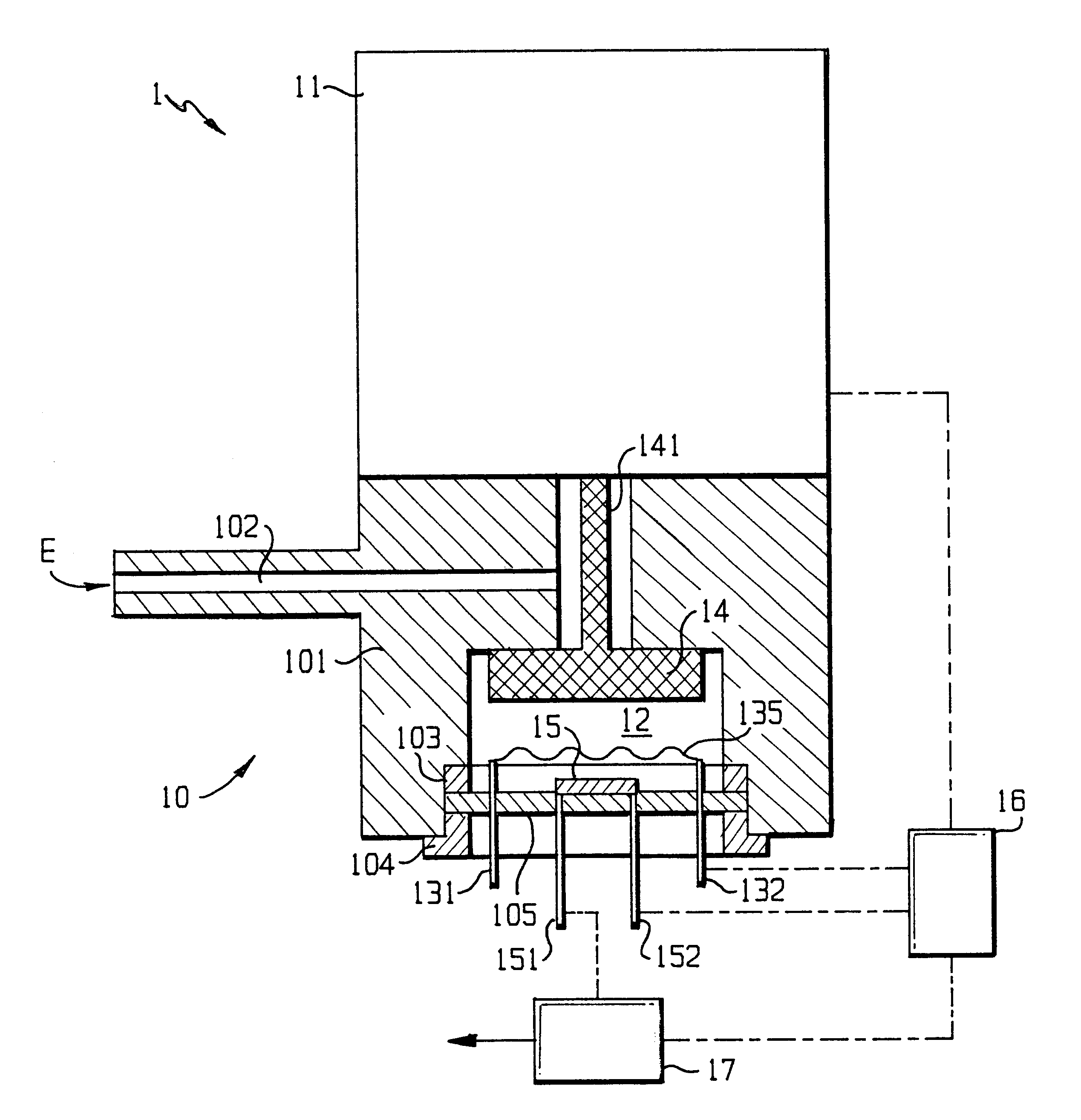

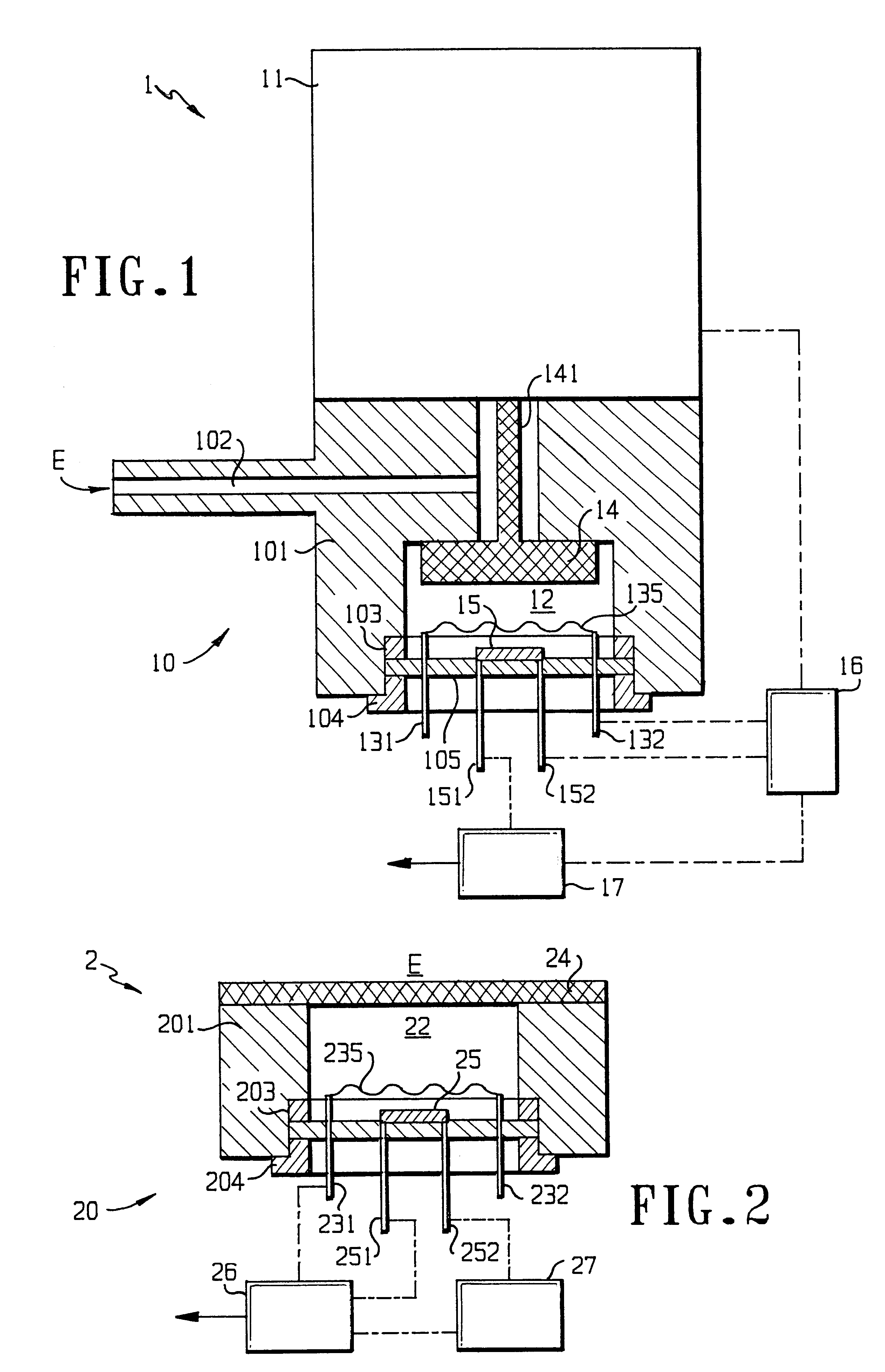

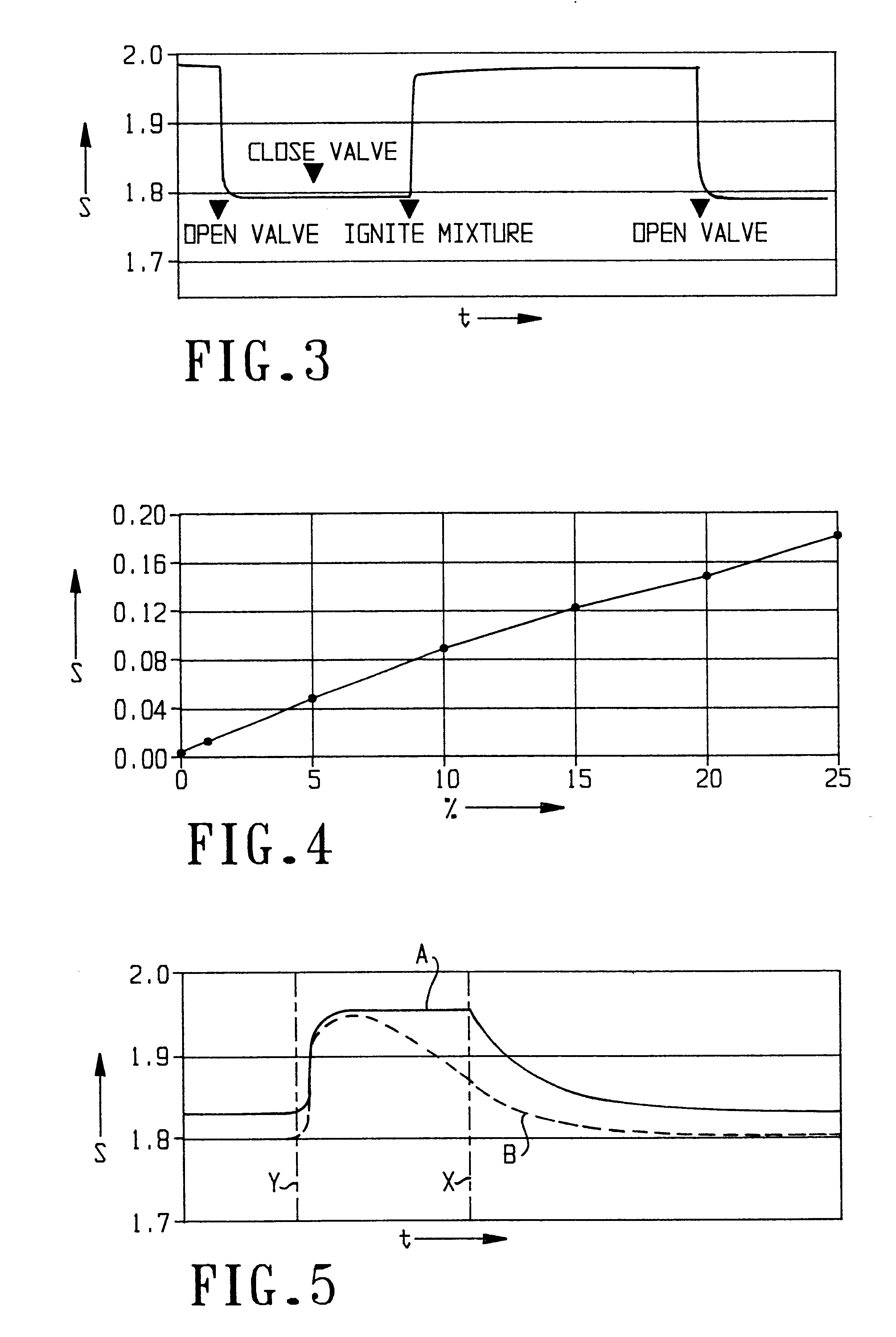

Combustibility monitor and monitoring method

InactiveUS6623976B1Reliable and significant dataQuantity minimizationDetection of fluid at leakage pointMaterial heat developmentHydrogenOperation mode

An apparatus (1) for determining the concentration of a critical first component, such as hydrogen, of an atmosphere or environment (E), wherein the first component is capable of forming a combustible mixture with a second component, such as oxygen; the apparatus comprises: (A) a sampling unit (10) including: (A1) a small measuring chamber (12) operatively connected with an ignition means (135) capable of being operated so as to initiate in said chamber a combustion of said critical first component by reaction with said second component, and (A2) at least one sensor (15) operatively connected with said measuring chamber for generating a signal formed by essentially proportionate contributions from all significant components contained in said measuring chamber; (B) at least one flame arrestor (14) intervening between said measuring chamber (12) and aid environment (E) of interest; and (C) a control unit (16) capable of imposing a mode of operation in at least two distinct phases wherein, during a first phase, said environment of interest is allowed to accumulate in said measuring chamber; and wherein, during a second phase, said ignition means is operated for initiating said combustion in said chamber; and (D) a means (17) for evaluating at least one signal generated by said at least one sensor before operation of said ignition means, and at least one signal generated by said at least one sensor after operation of said ignition means so as to generate a signal (S) which is indicative of said concentration of said critical first component in said environment of interest.

Owner:ORBISPHERE LAB NEUCHATEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com