Patents

Literature

274results about How to "Meet cleaning requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glass curtain wall cleaning machine

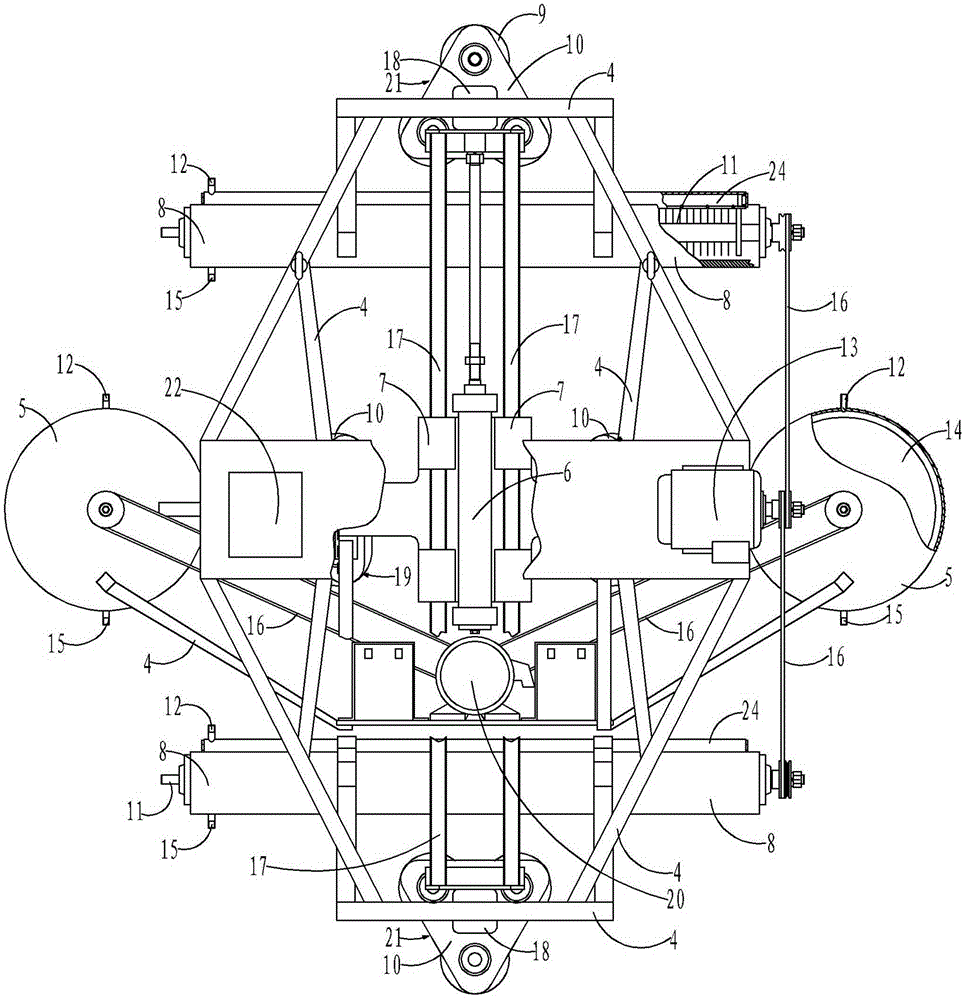

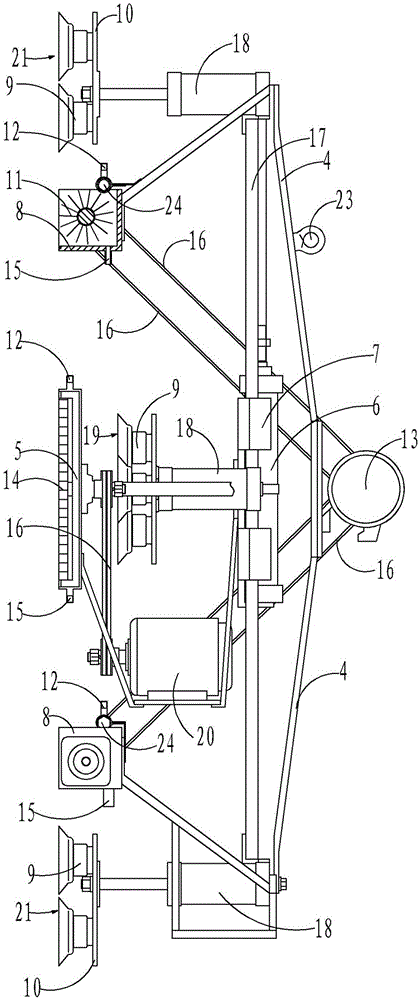

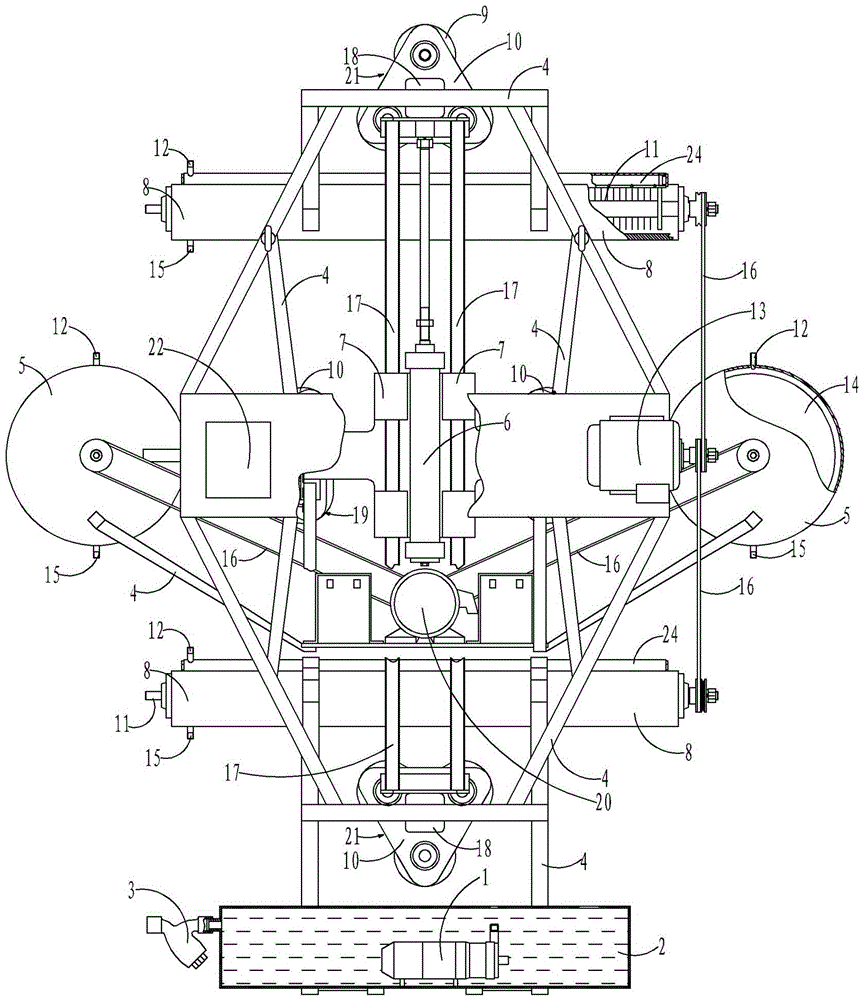

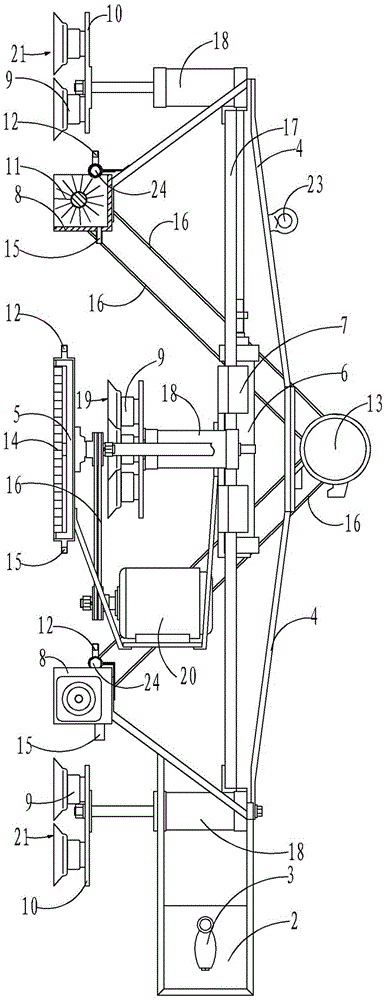

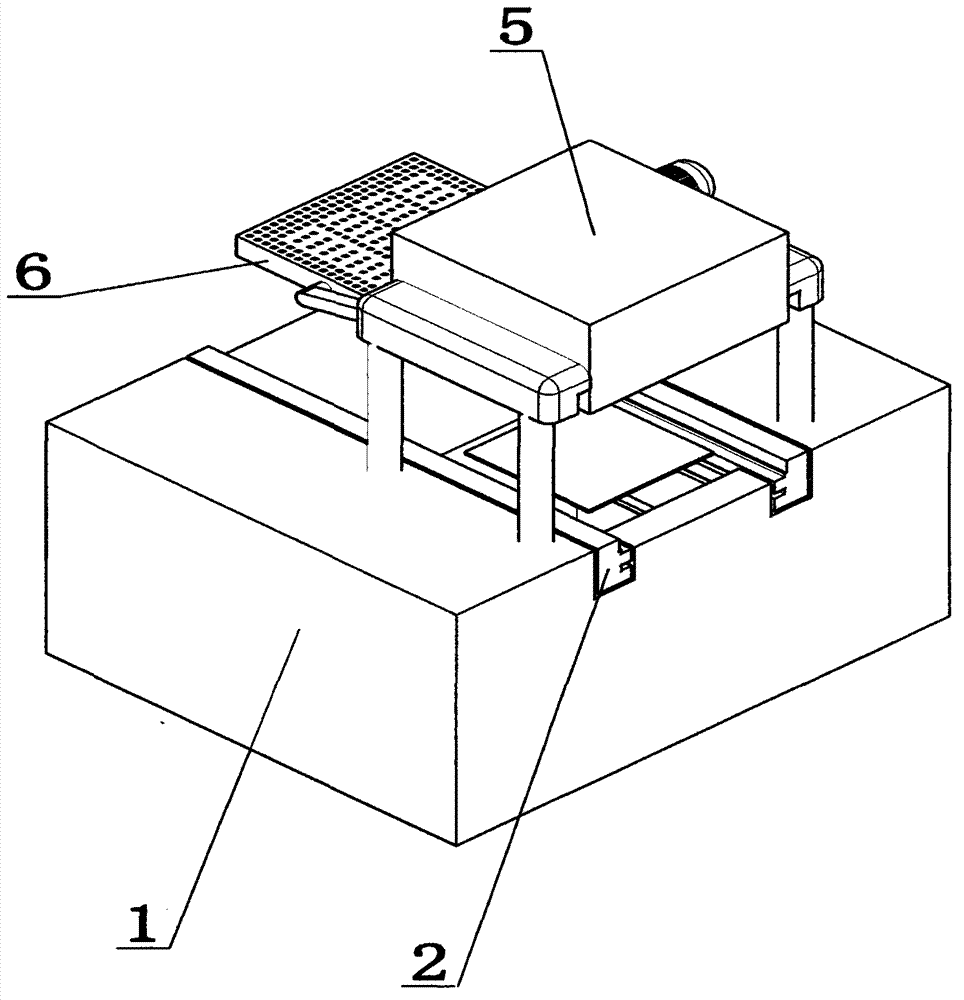

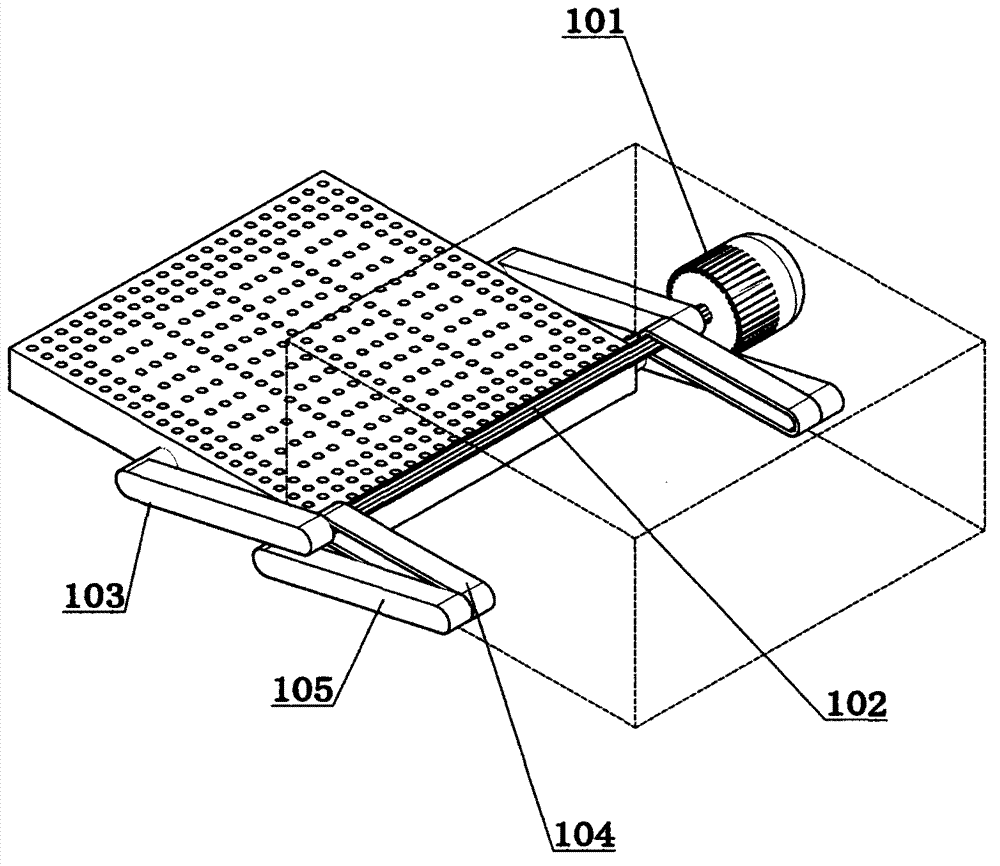

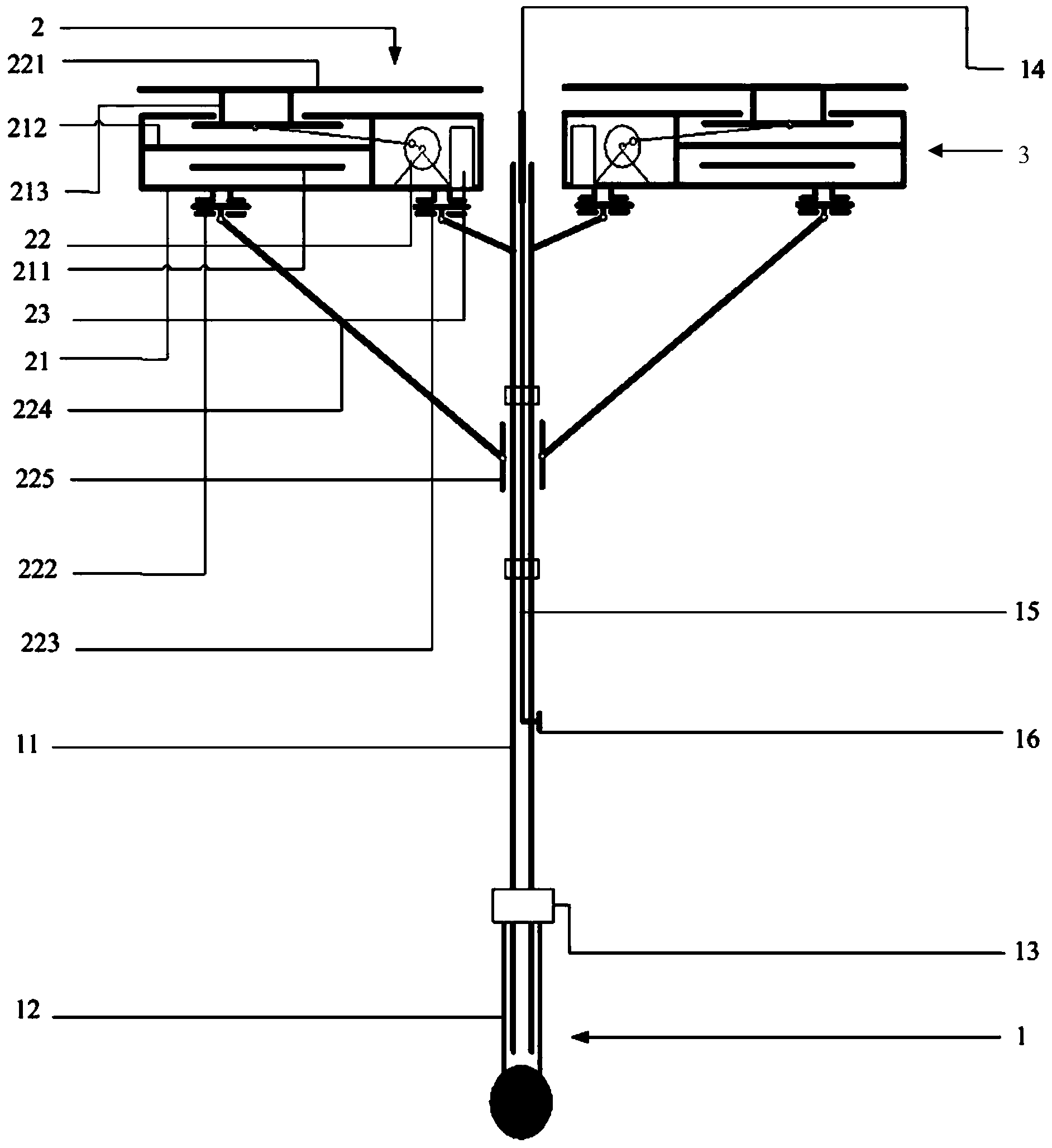

The invention relates to a glass curtain wall cleaning machine. The glass curtain wall cleaning machine comprises a walking mechanism, a cleaning mechanism and a water circulating mechanism which are fixed on a bracket, wherein the walking mechanism comprises a translation cylinder, a slide block, a slide rail, a lifting cylinder, first sucking disk sets and second sucking disk sets; two groups of first sucking disk sets are symmetrically arranged on the left and right sides of the bracket; two groups of second sucking disk sets are symmetrically arranged on the upper and lower sides of the bracket; the slide block is connected with the slide rail in a sliding way; a piston rod of the translation cylinder is fixedly connected with the bracket; the translation cylinder is fixedly connected with the slide block. By adopting the glass curtain wall cleaning machine, unmanned cleaning of the exterior walls of tall buildings is realized, the cleaning speed and cleaning efficiency are high, and automatic walking and barrier crossing functions of the cleaning machine are realized; moreover, the walking speed can be adjusted in a stepless way, and the cleaning force can be adjusted in order to meet the cleaning requirements of different exterior walls.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

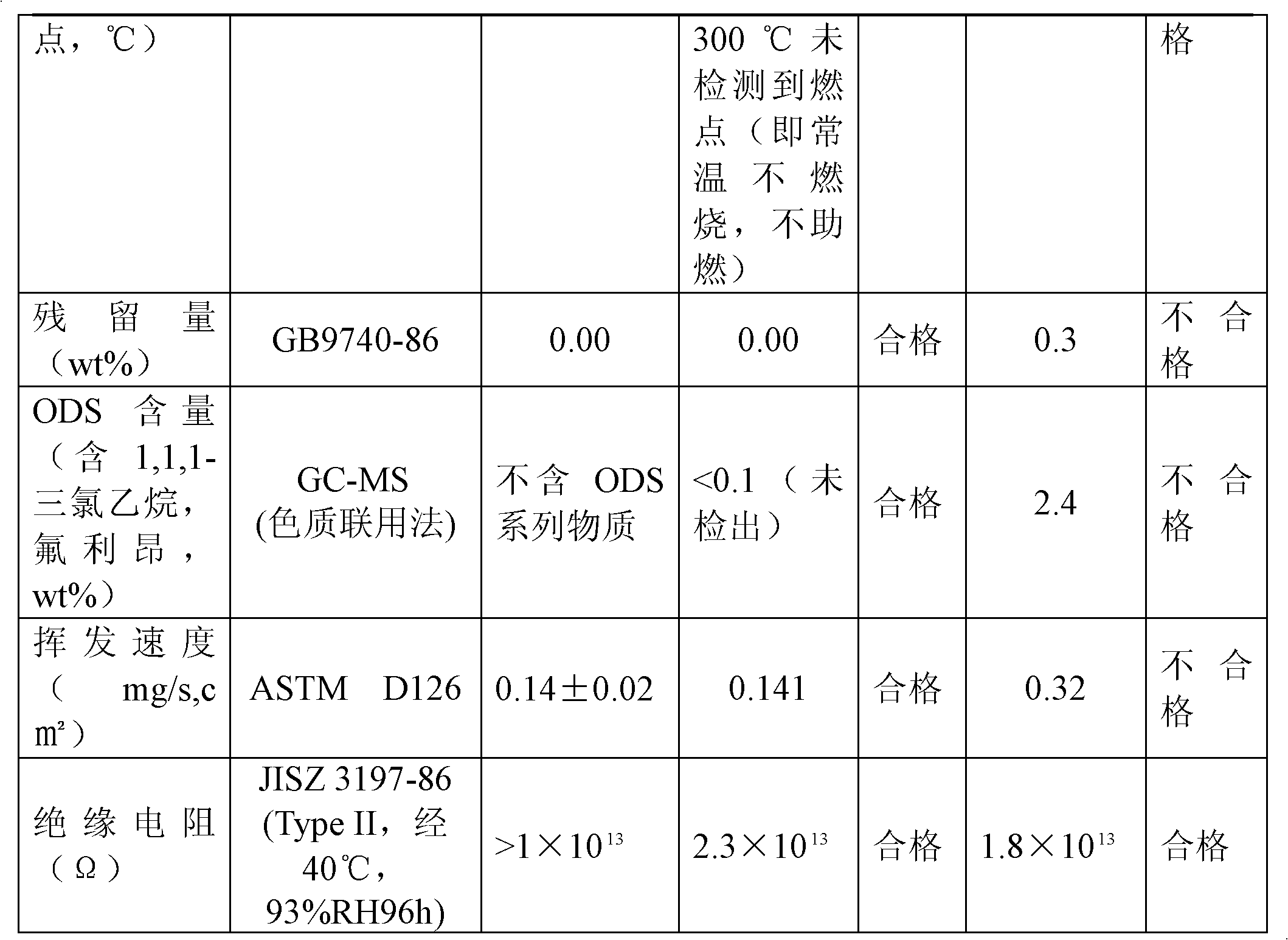

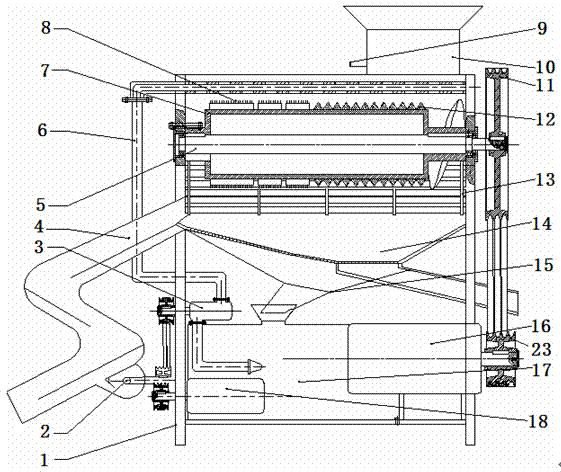

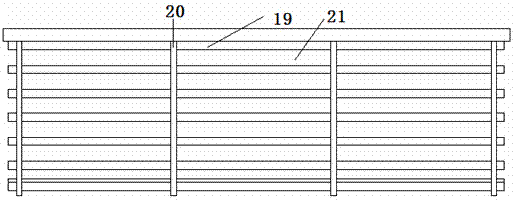

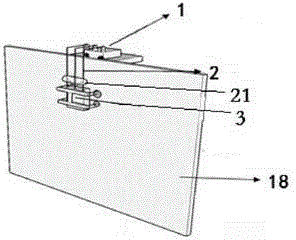

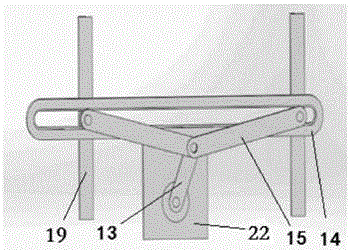

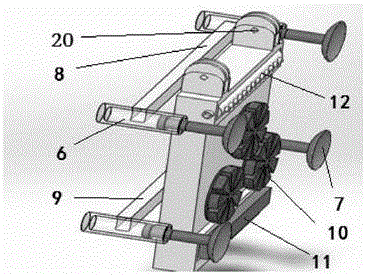

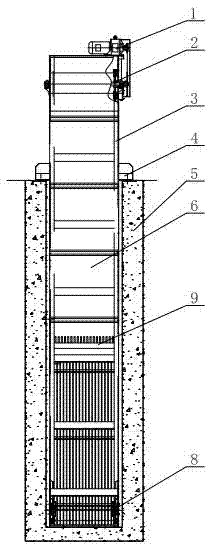

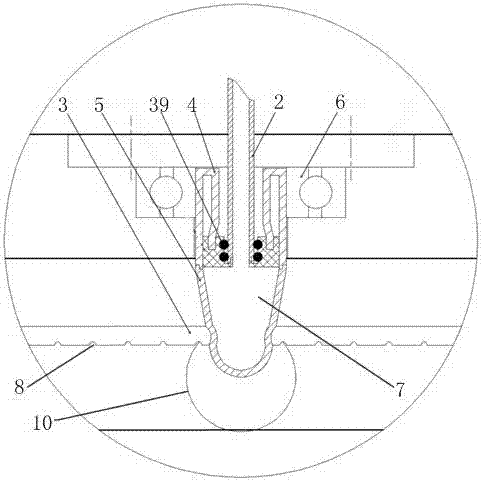

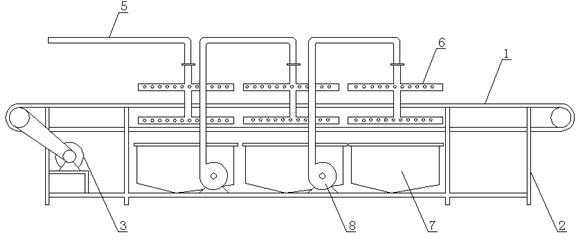

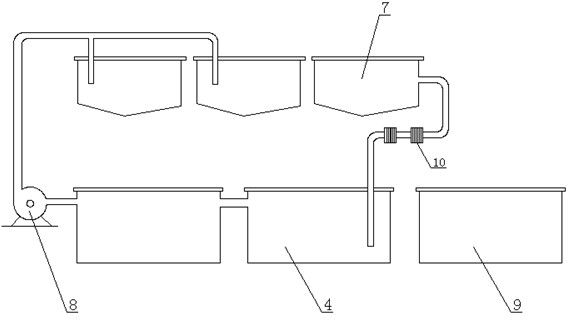

Sucking disk type high-rise building outer wall cleaning machine

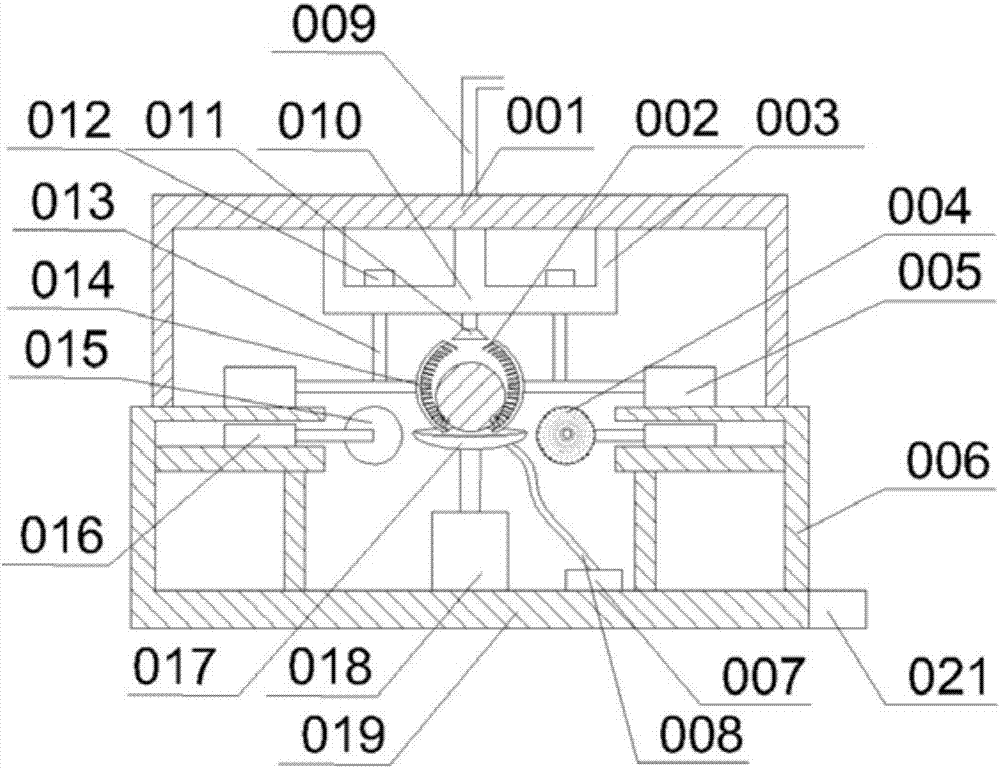

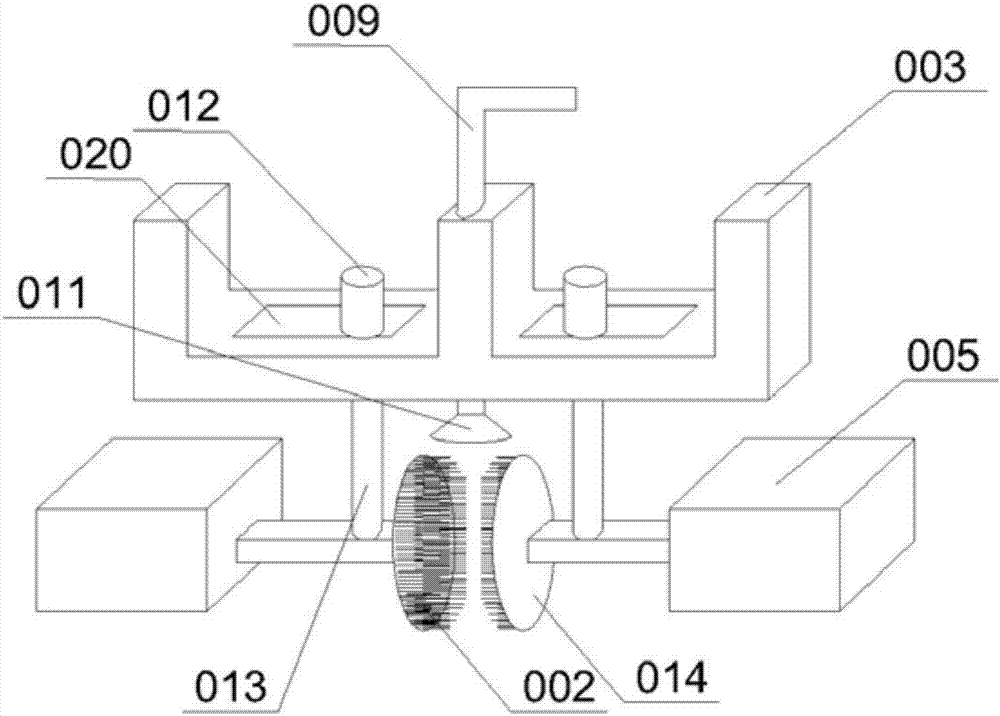

InactiveCN104382536AEffective attachmentWill not harmCarpet cleanersFloor cleanersEngineeringWater circulation

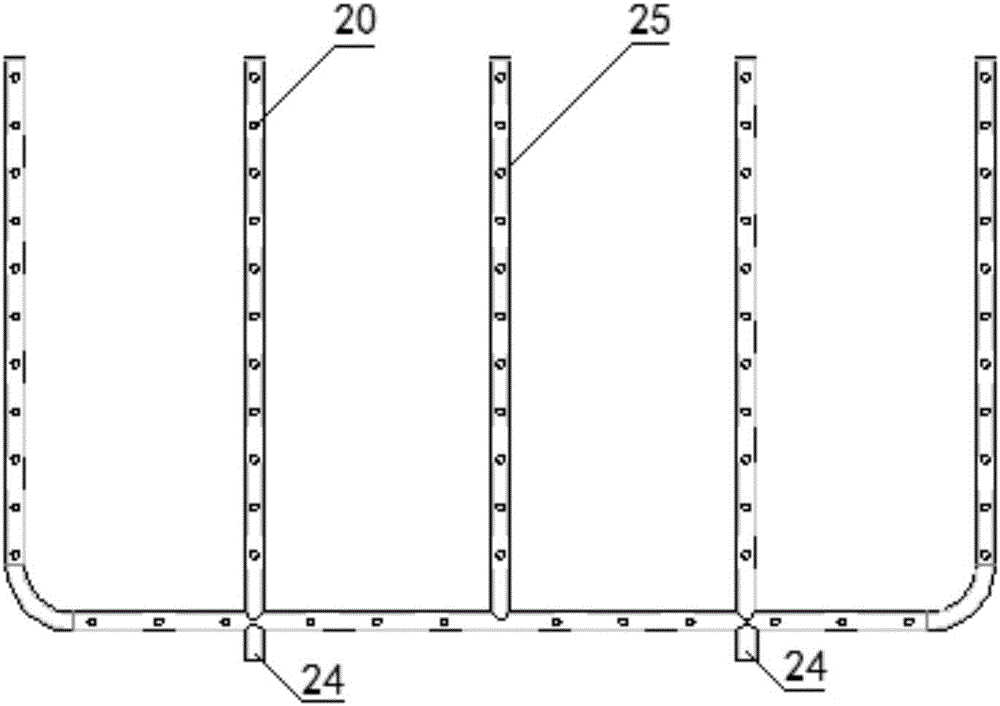

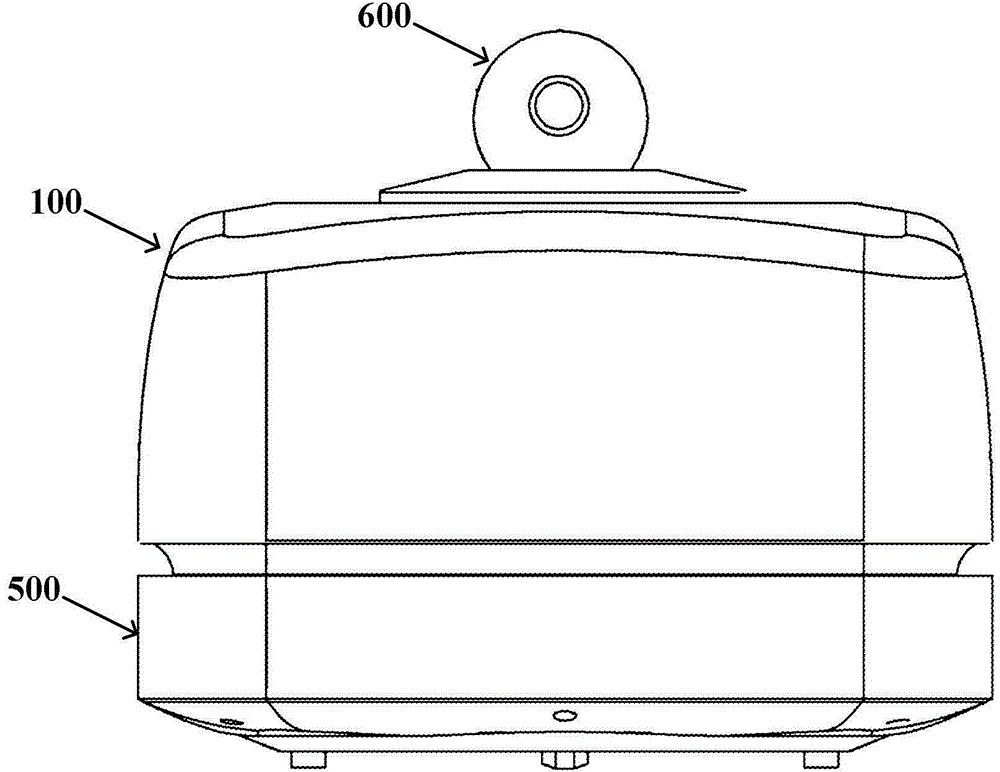

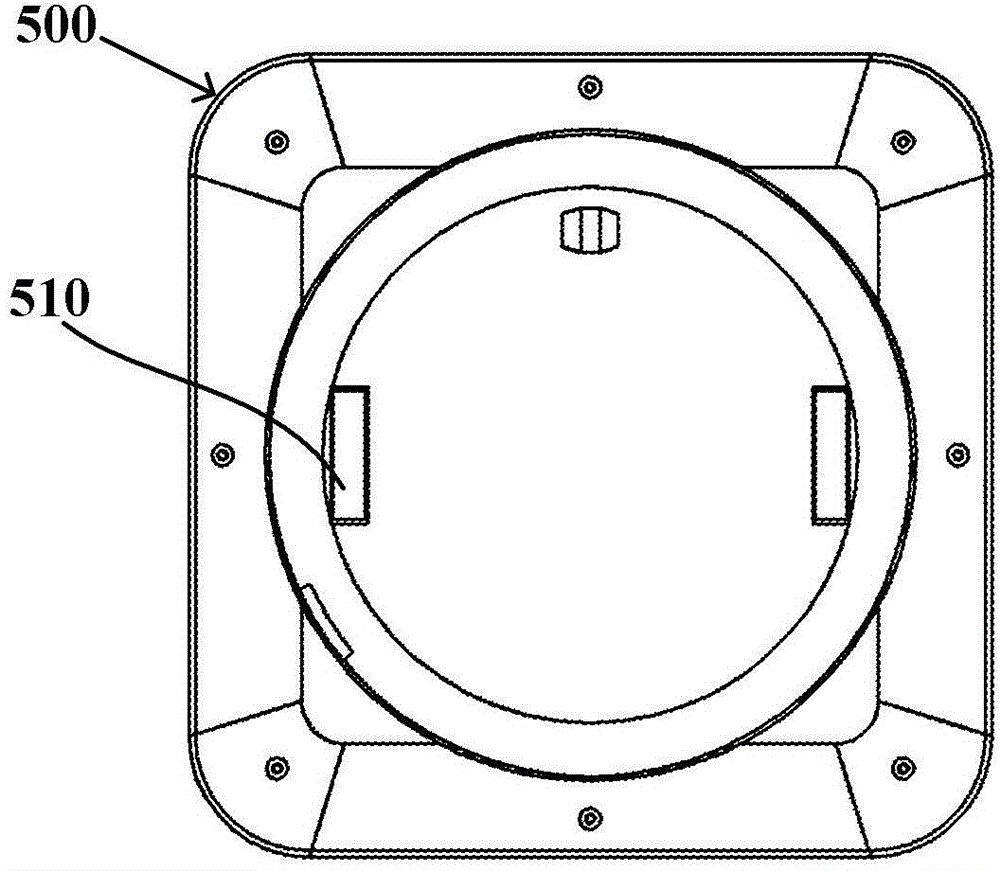

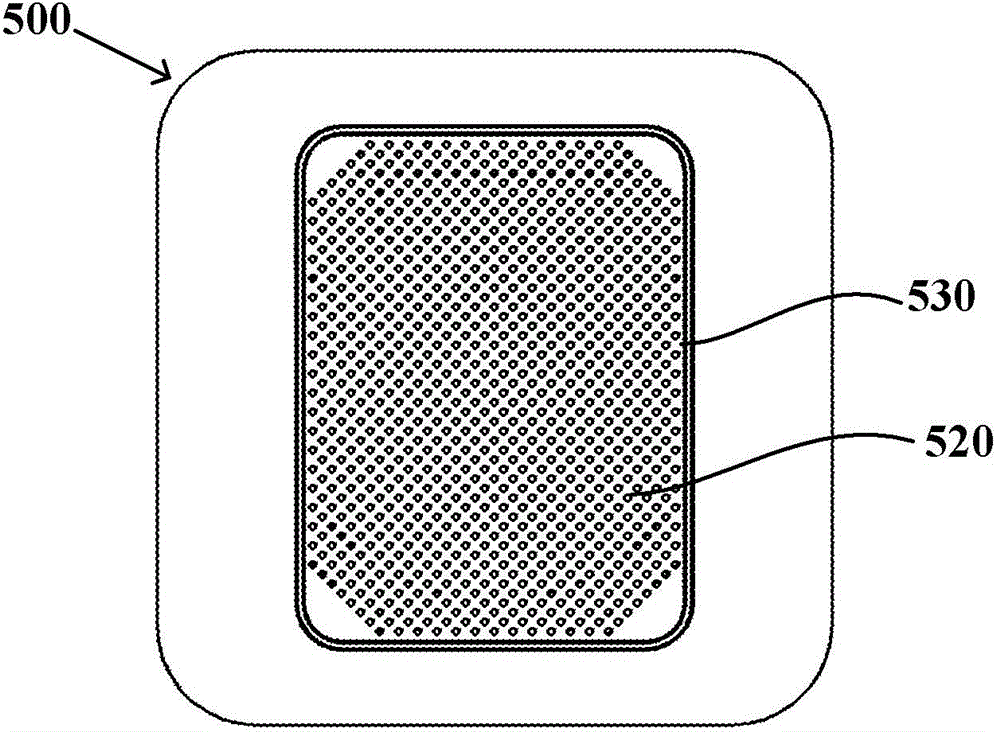

The invention relates to a sucking disk type high-rise building outer wall cleaning machine. The sucking disk type high-rise building outer wall cleaning machine comprises a walking mechanism fixed on a bracket, a cleaning mechanism and a water circulation mechanism, wherein the walking mechanism comprises a translation cylinder, a sliding block, a sliding rail, a lifting cylinder, two first sucking disk groups and two second sucking disk groups, the two first sucking disk groups are symmetrically arranged on left and right sides of the bracket, the two second sucking disk groups are symmetrically arranged on upper and lower sides of the bracket, the sliding block is connected with the sliding rail in a sliding mode, a piston rod of the translation cylinder is fixedly connected with the bracket, and a cylinder body of the translation cylinder is fixedly connected with the sliding block. The sucking disk type high-rise building outer wall cleaning machine is fast in cleaning speed, high in cleaning efficiency, steplessly adjustable in walking speed, and capable of achieving unmanned cleaning, automatic walking, as well as an obstacle crossing function, and adjusting cleaning capability to meet the cleaning requirements of different outer walls.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

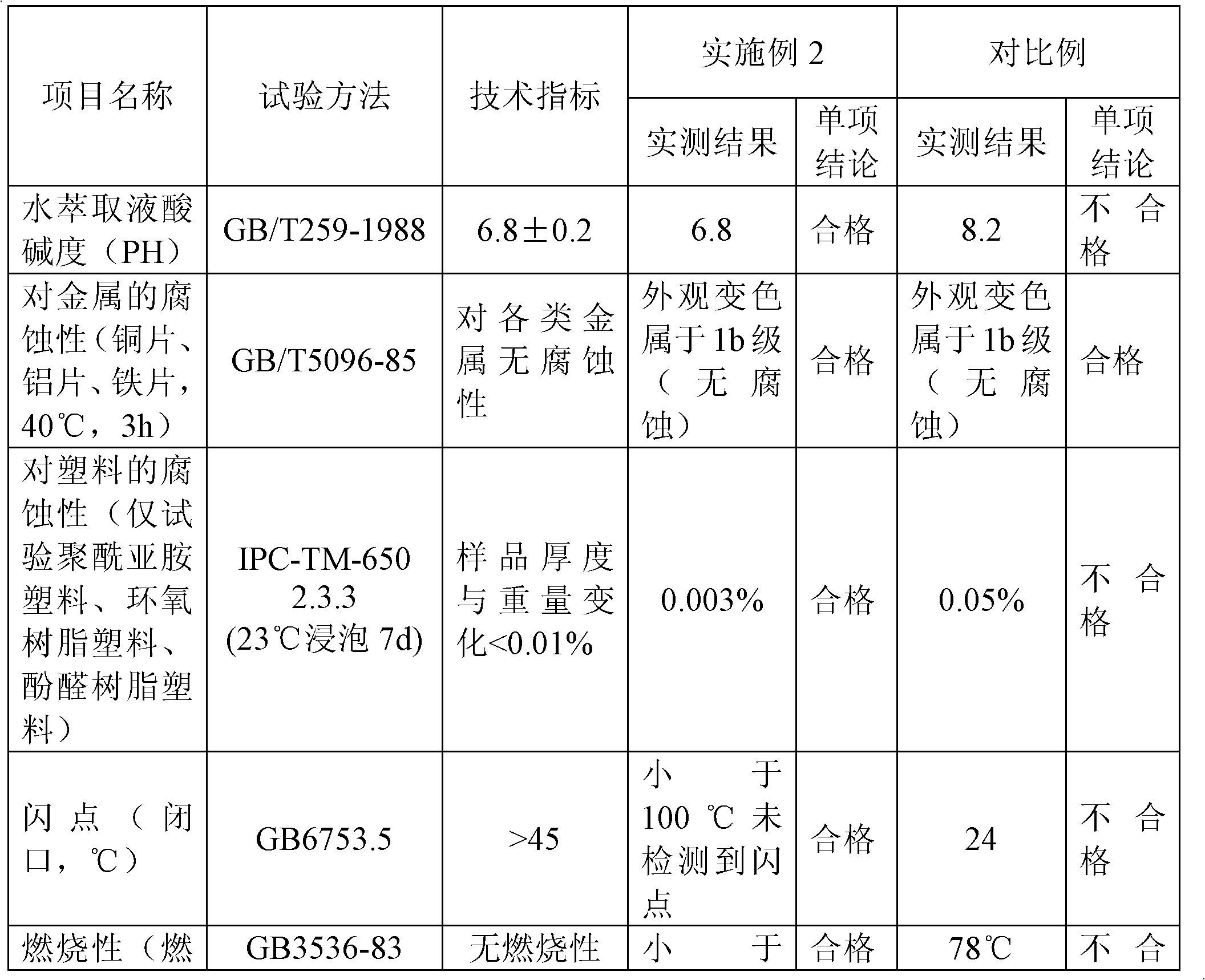

Method for realizing live cleaning of secondary equipment

ActiveCN102580937AMeet cleaning requirementsImprove insulation performanceInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsNon toxicityEngineering

The invention relates to a method for cleaning, dedusting and descaling secondary equipment, in particular to a method for realizing live cleaning of secondary equipment. During live operation of the secondary equipment, live cleaning agents are used for flushing or spray-washing the secondary equipment through a cleaning device, and a recovery device is used for recovering dirt. On the premise that the secondary equipment is not powered off and does not stop running, various dirt such as dust, greasy dirt, moisture, salt, metal dust, carbon stains and the like on the surface and in a deep layer of the equipment can be safely and efficiently cleaned, high safety of high insulation, non-toxicity, non-combustibility, corrosion resistance and the like is achieved, and the gap of safely cleaning the secondary equipment in live operation in the prior art is filled. The method makes a great breakthrough, and has fine application prospect in the field of secondary equipment maintenance.

Owner:广州华盈电气科技有限公司

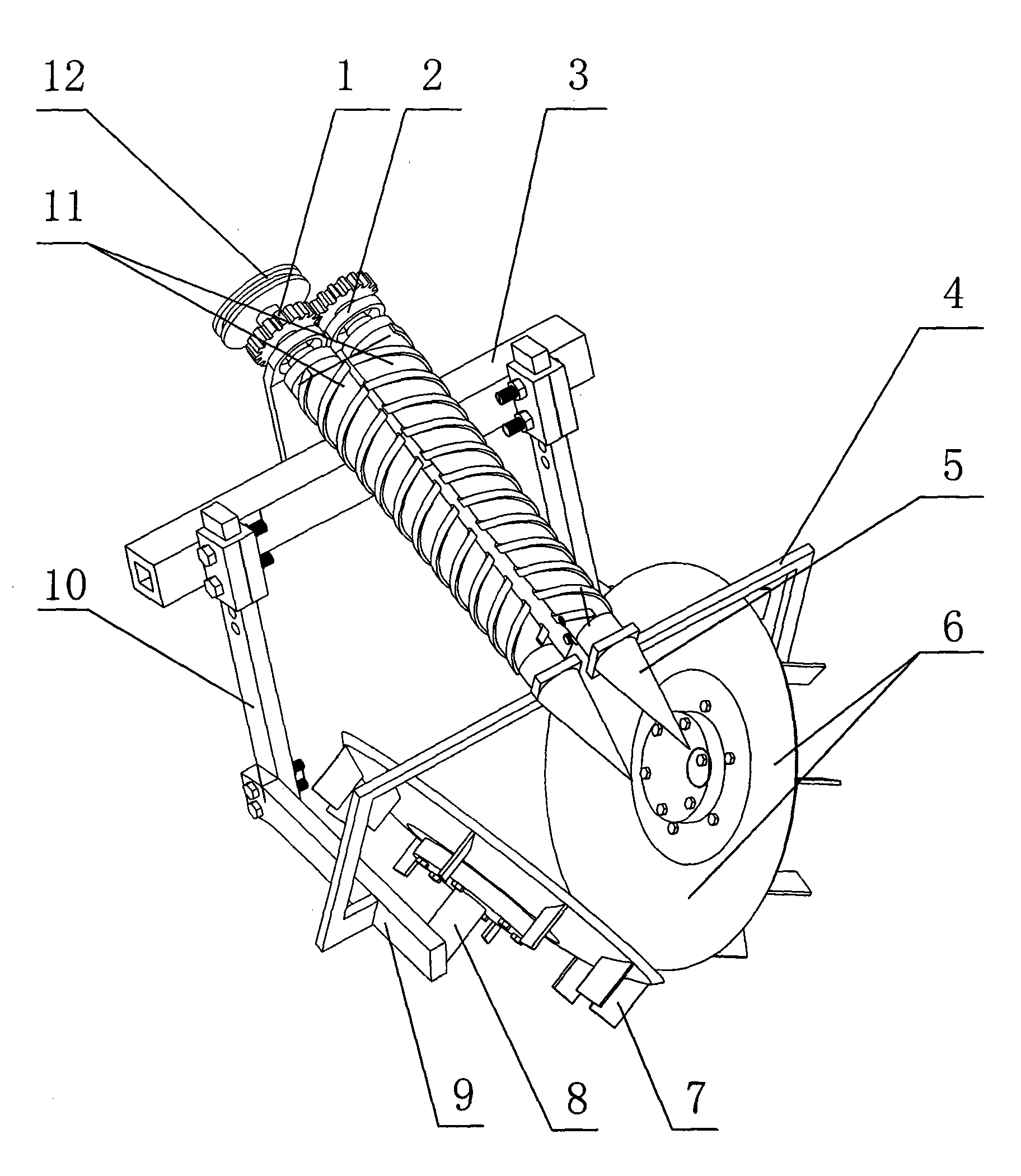

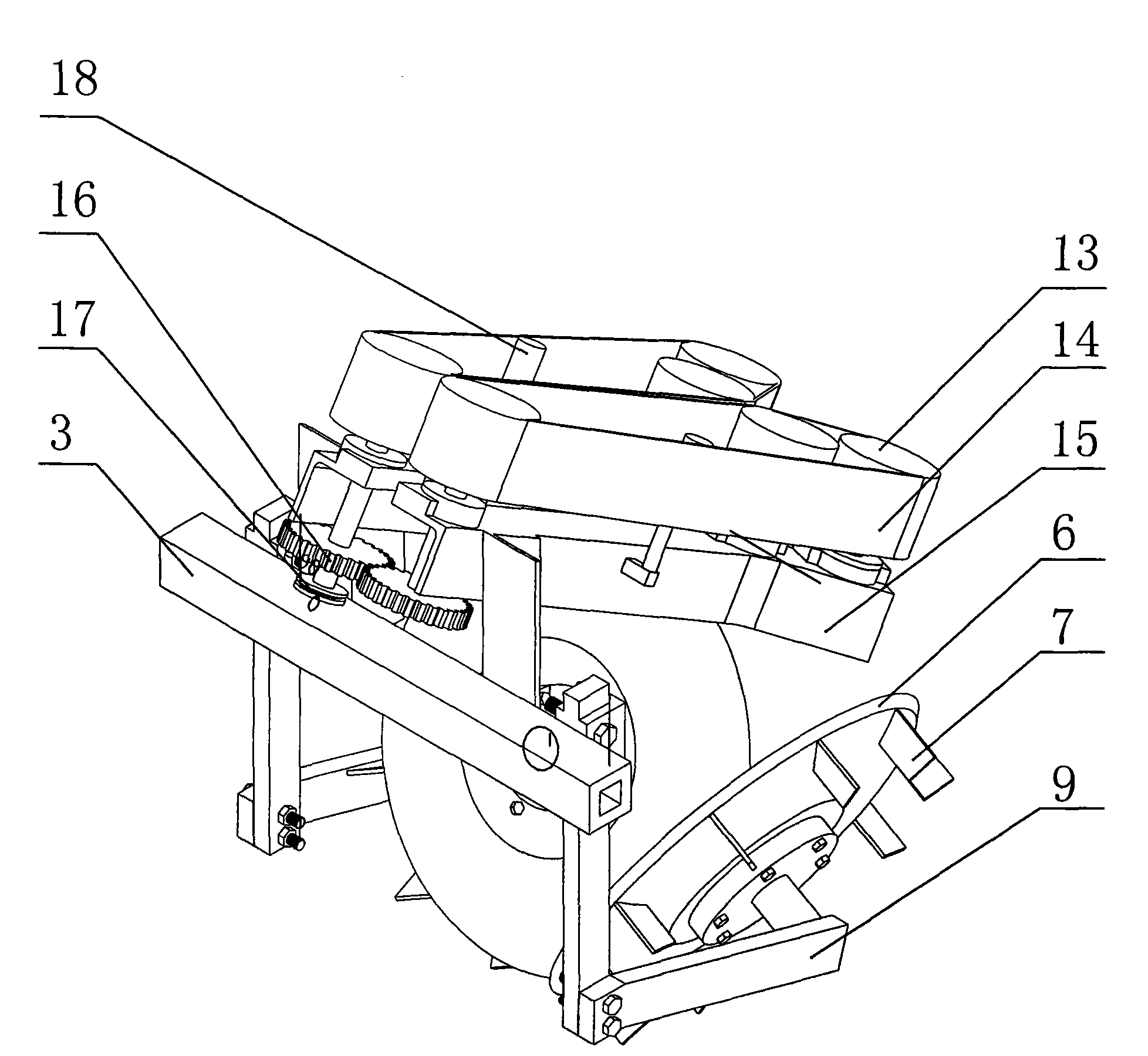

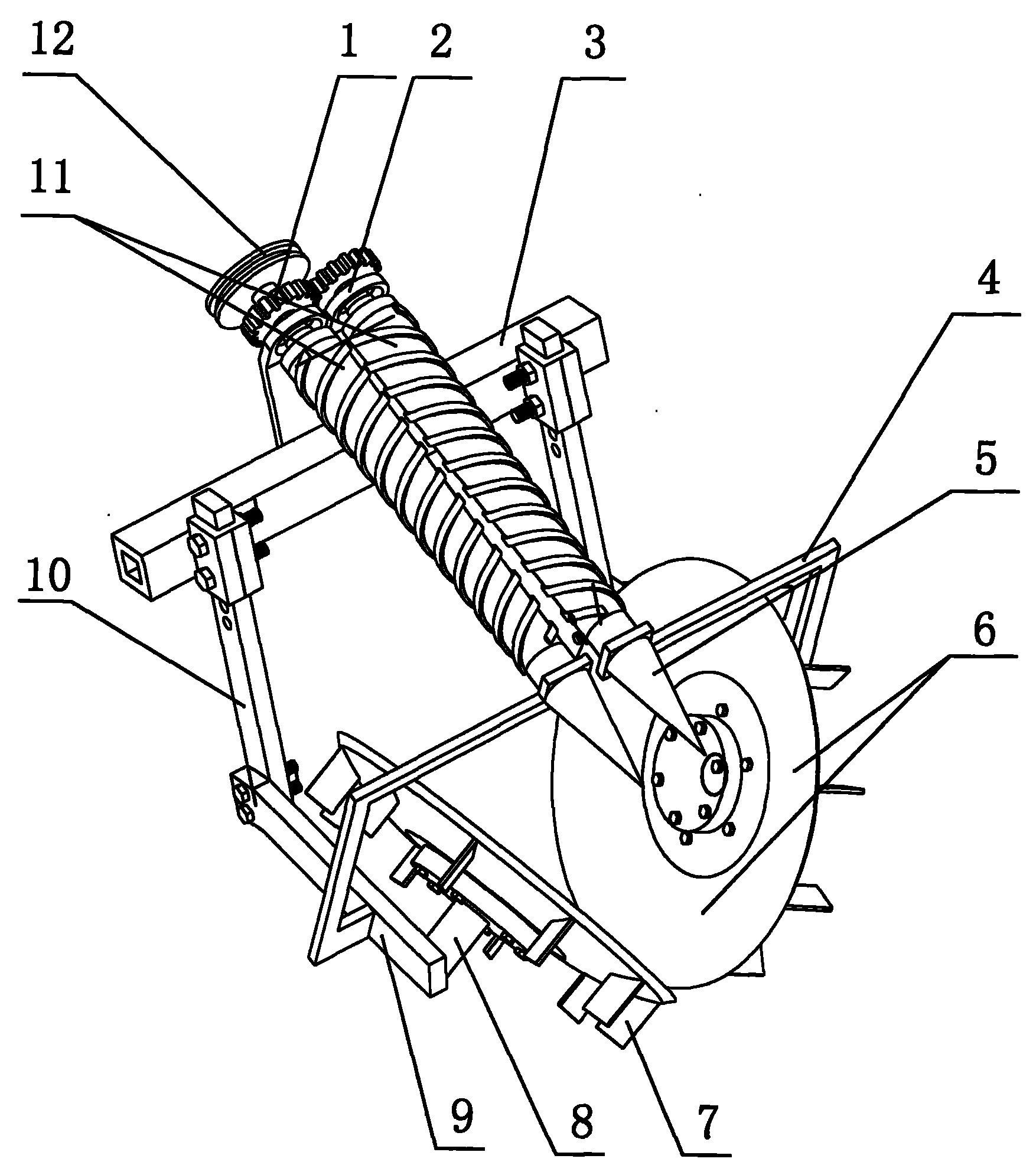

Peeling-cleaning all-in-one machine for green walnuts

InactiveCN104256858ARealize mechanized productionShorten the timeClimate change adaptationHuskingWalnut NutWater storage

The invention relates to a peeling-cleaning all-in-one machine for green walnuts, and belongs to the technical field of processing mechanical equipment for agriculture products. The peeling-cleaning all-in-one machine for green walnuts disclosed by the invention comprises a peeling device, an impurity removal and cleaning device, and a drying device, wherein the peeling device comprises a rack, a central main shaft, a peeling rotary drum, a charge port, a concave-plate sieve and a first motor; the impurity removal and cleaning device comprises a water pump, an S-shaped discharge tube, a water tube, a residue collection device, a water collection bucket, a water storage box and a second motor; the drying device comprises a hot-air device and the S-shaped discharge tube. The peeling-cleaning all-in-one machine for green walnuts disclosed by the invention is capable of meeting peeling and cleaning requirements on green walnuts, and ensuring the quality of peeling, thorough in peeling, complete in cleaning, high in automation degree, capable of realizing the cyclic utilization of water resources and primary drying for walnuts, low in cost, stable in running, and wide in market prospect.

Owner:KUNMING UNIV OF SCI & TECH

Building outer facade washing robot system and using method thereof

ActiveCN104983369ASolve cleaning problemsSafe and automated cleaning workCarpet cleanersFloor cleanersRobotic systemsEngineering

The invention discloses a building outer facade washing robot system and a using method thereof. The building outer facade washing robot system comprises a safety servo trolley, and a cleaning machine body is connected to the lower portion of the safety servo trolley through a safety cable; a movement track is arranged on the cleaning machine body, robot feet are connected to the movement track through sliding blocks, transverse rods are connected to the lower portions of the sliding blocks, telescopic devices are connected to the transverse rods, and sucking cups are connected to the bottoms of the telescopic devices; and the robot feet comprise the front foot and the back foot. By means of the building outer facade washing robot system and the using method, safe and efficient automation cleaning work on the outer surface of a building can be done, and therefore the aim of cleaning the outer surface of the high-rise building is achieved. By means of the system, on the premise that the cleaning requirement is met, the working efficiency is improved, the work danger coefficient is reduced, and the using rate of the labor force is improved while the development tendency of the contemporary science and technology is met.

Owner:FUJIAN UNIV OF TECH

Comprehensive cleaning device for sports ball equipment of different sizes

InactiveCN107469308APrevent slippingMeet cleaning requirementsBall sportsTransverse axisSports equipment

The invention discloses a comprehensive cleaning device for sports ball equipment of different sizes, and relates to the field of sports equipment. The comprehensive cleaning device comprises a bearing table, a supporting frame, a bearing support arranged at the upper portion of the supporting frame, and annular clamping plates symmetrically arranged in the middle of the bearing table. A balancing plate is arranged at the lower end of the bearing support and fixed to the top wall of the bearing support through a plurality of supporting connecting rods. Clamping groove sliding openings are symmetrically formed in the surface of the balancing plate in the direction of the transverse axis. Two connecting rods are symmetrically arranged in the clamping groove sliding openings. The bottom ends of the two connecting rods are connected with two first electric push rods. The ends of the two first electric push rods are connected with the annular clamping plates respectively. The lower ends of the two first electric push rods are provided with two second electric push rods respectively. The ends of the two second electric push rods are each connected with an annular cleaning brush plate. The comprehensive cleaning device is simple in structure, meets the requirement of cleaning balls with different diameters, more comprehensively cleans the surfaces of the ball equipment, is better in cleaning effect and reduces the environment pollution.

Owner:弘毅天承知识产权股份有限公司

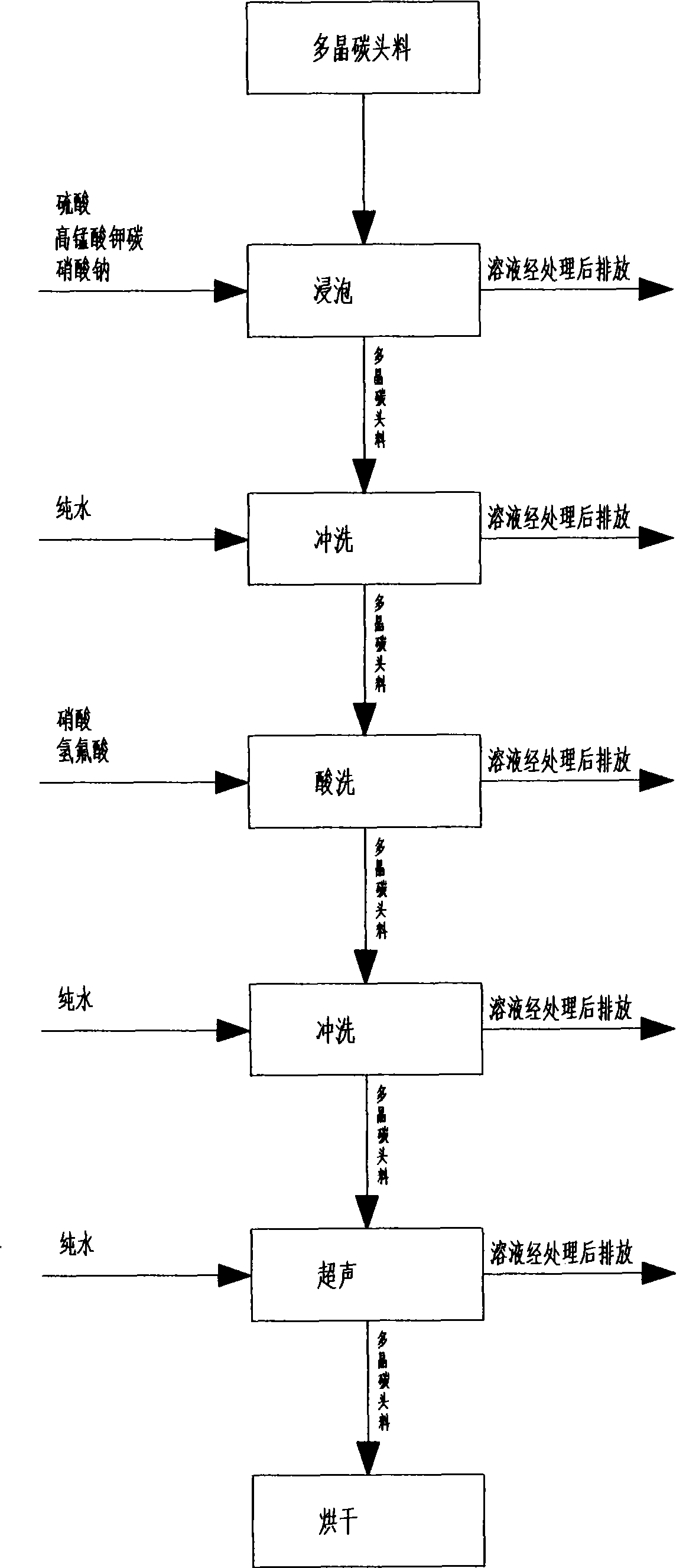

Method for cleaning polycrystal carbon head material

InactiveCN101481824AReduce lossMeet cleaning requirementsPolycrystalline material growthAfter-treatment detailsChemical solutionSodium nitrate

The invention discloses a cleaning method of primary polycrystalline carbon materials. The cleaning method mainly comprises the following steps: soaking the primary polycrystalline carbon materials in mixed solution of sulfuric acid, potassium permanganate and sodium nitrate, washing the primary polycrystalline carbon materials with clear water after fetching the primary polycrystalline carbon materials, placing the primary polycrystalline carbon materials into mixed solution of nitric acid and hydrofluoric acid for cleaning, fetching the primary polycrystalline carbon materials and washing with purified water, performing purified water supersonic treatment on the primary polycrystalline carbon materials and fetching the primary polycrystalline carbon materials for drying. The method abandons the traditional machining methods for removing graphite impurities from the primary polycrystalline carbon materials, and employs a chemical cleaning method. Compared with the traditional methods, the cleaning method using chemical solution for cleaning the primary polycrystalline carbon materials can remove the graphite impurities from the primary polycrystalline carbon materials, fully satisfies the cleaning requirements of the solar silicon industry, has less primary polycrystalline carbon material loss and increases the raw material availability. Cleaning waste acid and washing fluid do not pollute the environment after emission treatment.

Owner:嘉兴嘉晶电子有限公司

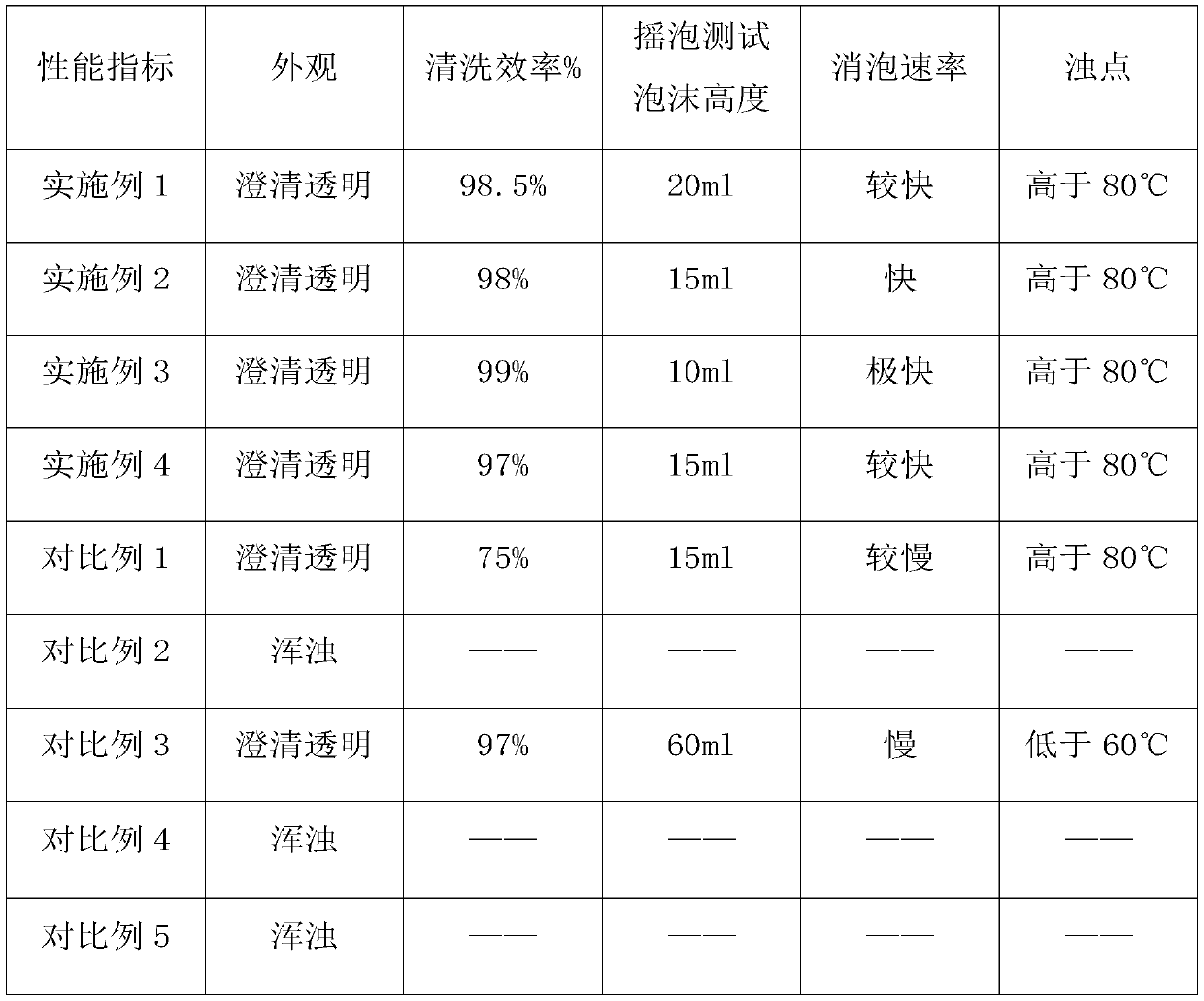

Cleaning agent for silicon materials and method for cleaning silicon materials

InactiveCN102010797AGood biodegradabilityMeet cleaning requirementsInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsIonTriethanolamine

The invention discloses formulas of a cleaning agent SEH-1, a cleaning agent SHE-2 and a cleaning agent SHE-3, wherein the cleaning agent SEH-1 comprises the following components in parts by weight: 5-25 parts of fatty alcohol polyoxyethylene ether, 3-15 parts of alkyl phenyl polyoxyethylene ether, 2-8 parts of alkylolamide, 0.5-7 parts of ethylene glycol alkyl ether, 0.1-5 parts of chelating agent, 5-10 parts of chloracid, 0.5-5 parts of H2O2 (hydrogen peroxide) and the balance of deionized water, and the total number of parts is 100; the cleaning agent SHE-2 comprises the following components in parts by weight: 4-15 parts of coconut oil alkyl amide phosphate, 3-15 parts of triethanolamine oleic soap, 1-5 parts of triethanolamine, 0.1-5 parts of aminotriacetic acid, 1-5 parts of potassium hydroxide and the balance of the deionized water, and the total number of parts is 100; and the cleaning agent SHE-3 comprises the following components in parts by weight: 5-10 parts of acetic acid, 0.5-10 parts of citric acid, 0.1-5 parts of sorbitol and the balance of the deionized water, and the total number of parts is 100. The invention further discloses a method for cleaning silicon materials by utilizing the three cleaning agents. The method is completely in line with the cleaning requirement for production of solar grade single crystal silicon and does not pollute the environment.

Owner:LONGI GREEN ENERGY TECH CO LTD

Online chip cleaning and drying equipment

ActiveCN102820242ASimple structureIngenious designDrying using combination processesSemiconductor/solid-state device manufacturingEngineeringElectrical and Electronics engineering

The invention discloses online chip cleaning and drying equipment which comprises an automatic feeding mechanism, a spray type cleaning device, vacuum drying equipment and a positioning table. The vacuum drying equipment comprises a frame; a pair of drying conveying belts which are connected with a cleaning machine, support the two sides of a chip and horizontally move are arranged in the middle of the frame; a push plate which controls and supports the chip to move up and down through mechanical power is arranged on the frame below the part between the drying conveying belts; a first vacuum chamber provided with a vacuum sucker and an infrared heating tube is arranged right over the push plate; a second vacuum chamber which is movably connected with the first vacuum chamber through a connecting rod mechanism and provided with a sealing structure matched with the lower end of the first vacuum chamber is arranged on one side of the first vacuum chamber; and a vacuum adsorption hole corresponding to the chip is formed on one side of the second vacuum chamber corresponding to the first vacuum chamber and provided with the sealing structure. The equipment is simple in structure and skillful in design, automatically picks up chips, performs spray type cleaning and vacuum drying on the chip, dries the chip through thermal power in the vacuum environment, and prevents the chips from being damaged.

Owner:铜陵太阳岛农业科技有限公司

Multifunctional household cleaning tool

InactiveCN103961020AMeet cleaning requirementsEasy to cleanCarpet cleanersFloor cleanersReciprocating motionEngineering

The invention discloses a multifunctional household cleaning tool which comprises a handheld rod assembly and two cleaning assemblies. The handheld rod assembly comprises a main long rod, a telescopic rod, a telescopic rod adjusting circle, an inner cleaning brush, a sliding rod and a sliding adjusting disc, and the length of the handheld rod assembly can be changed. One end of the sliding rod is connected with the inner cleaning brush, the other end of the sliding rod is connected with the sliding adjusting disc, the sliding rod is arranged in the main long rod, and the sliding rod can do reciprocating motion relative to the main long rod. Each cleaning assembly comprises a cleaning shell, an inner supporting frame in the cleaning shell, an inner sliding rod, a transmission supporting seat, a cleaning movable cover, two angle rotary pairs, a telescopic rod and a sliding adjusting circle, the cleaning movable covers, the angle rotary pairs, the telescopic rods and the sliding adjusting circles are arranged outside the cleaning shells, and the cleaning movable covers can achieve left and right horizontal movement under the action of the inner sliding rods. The cleaning shells can swing in two directions under the action of the angle rotary pairs. The multifunctional household cleaning tool can achieve cleaning work of different angles, lengths and directions.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Multifunctional plate-cleaning roller machine

InactiveCN106111574AMeet cleaning requirementsImprove cleaning qualityCleaning using toolsCleaning using gasesPulp and paper industrySilica gel

The invention discloses a multifunctional optical plate-cleaning roller machine which is provided with a plate conveyor belt. A detection lamp case, a dust collection assembly and dust-binding assemblies are arranged along the plate conveyor belt sequentially. The dust collection assembly is provided with one or more dust collection devices. Each dust collection device is provided with a shell, wherein brushes are arranged on the lower portion of the shell; an air knife is arranged in the middle of the shell; and a dust collection port is formed in the top of the shell. Each dust-binding assembly comprises an installing plate, wherein a soft sticking silica gel wheel, dust-binding paper and a plurality of static electric bars are installed on the installing plate; and the static electric bars are arranged on the two sides of the soft sticking silica gel wheel correspondingly. According to the multifunctional optical plate-cleaning roller machine, the functions of dust removing, dust collection and static electricity removing are integrated, the cleaning quality is high, the cleaning efficiency is increased by over 30% compared with a conventional cleaning roller machine, and cleaning requirements of optical plates can be met.

Owner:REGENCY OPTICS ELECTRON CORP

Polycrystalline silicon carbon head material separation corrosion solution and separation method

The invention discloses polycrystalline silicon carbon head material separation corrosion solution and a separation method, and relates to separation corrosion solution for a polycrystalline silicon carbon head material and a separation method, a separation method for treating a carbon head material produced by a vapor deposition method and preparation of the separation corrosion solution. The separation corrosion solution is characterized by comprising the following components in part by weight: 55 to 97 parts of high-purity sulfuric acid solution, 2 to 30 parts of potassium permanganate and 1 to 15 parts of sodium salt. The separation method is characterized by comprising the following steps of: 1, mixing and stirring 55 to 97 weight parts of high-purity sulfuric acid solution, 2 to 30 weight parts of potassium permanganate and 1 to 15 weight parts of sodium salt to form mixed solution; 2, soaking the carbon head material into the mixed solution for 1.5 to 16 hours; 3, taking out and cleaning the carbon head material, and cleaning the surface of the carbon head material by using cleaning solution containing nitric acid and hydrofluoric acid in a weight ratio of 5:1 for 1 to 3 minutes; and 4, cleaning the treated material by using pure water and ultrasonic wave, and drying the material.

Owner:ASIA SILICON QINGHAI

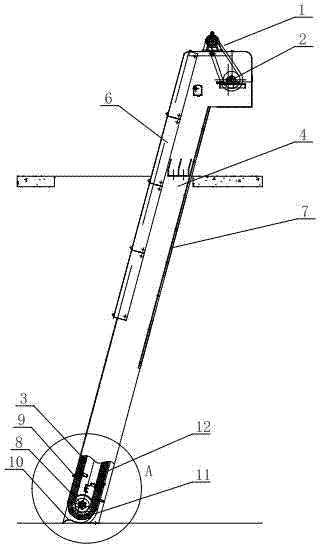

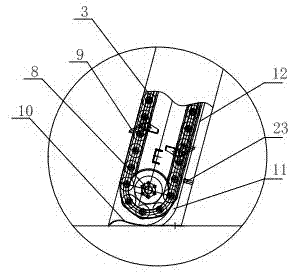

Anti-fishing type grating trash cleaning machine

ActiveCN102351256AEffective interceptionImprove cleaning efficiencyWater cleaningWater/sewage treatmentGratingSlag

The invention discloses an anti-fishing type grating trash cleaning machine. The machine is characterized in that: the machine is arranged in a ditch through arranging a frame at a certain inclined angle, a variable speed drive system which is arranged on the upper part of the frame drives a driving chain wheel to rotate, a drag chain is arranged on the left side and the right side of the frame, rake teeth which are arranged between the left and right drag chain form a revolution crawler belt and can revolute between the driving chain wheel and a bottom support wheel; a back gating which comprises a bottom arc-shaped grid bar and a support member is fixed on the back of the revolution crawler belt; and when revolution is carried out, the rake teeth are inserted into grids of the back gating to clean the back gating. The machine, which allows the back gating to be arranged on the back of the revolution crawler belt, makes a small amount of banded or shredded dirt which is remained on the rake teeth and is difficult to remove when the turning slag cleaning is carried out not be rushed into rear clean water, not enter back clean water and be effectively intercepted by the back gating, so the trash cleaning efficiency is substantially improved, and slag is thoroughly intercepted; and the water crossing area is substantially increased, so trash cleaning requirements of low water level ditches or dry periods can be satisfied.

Owner:JIANGSU ZHAOSHENG ENVIRONMENTAL PROTECTION TECH CO LTD

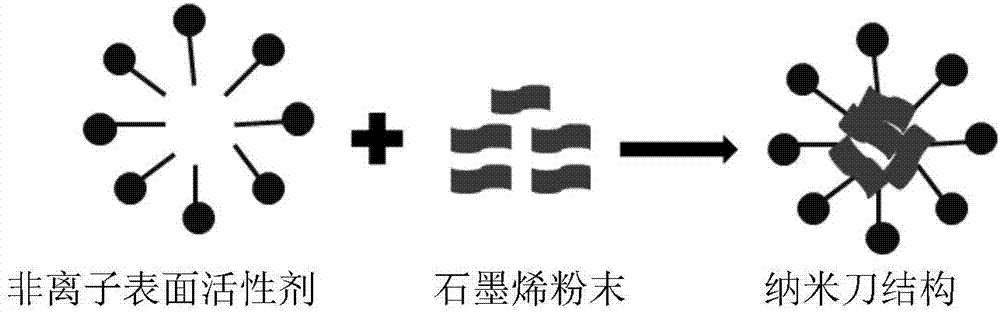

Graphene anti-bacterial compound solution and preparation method thereof

InactiveCN107057880ANon-cytotoxicWith greenInorganic/elemental detergent compounding agentsAntibacterial agentsGrapheneAnti bacterial

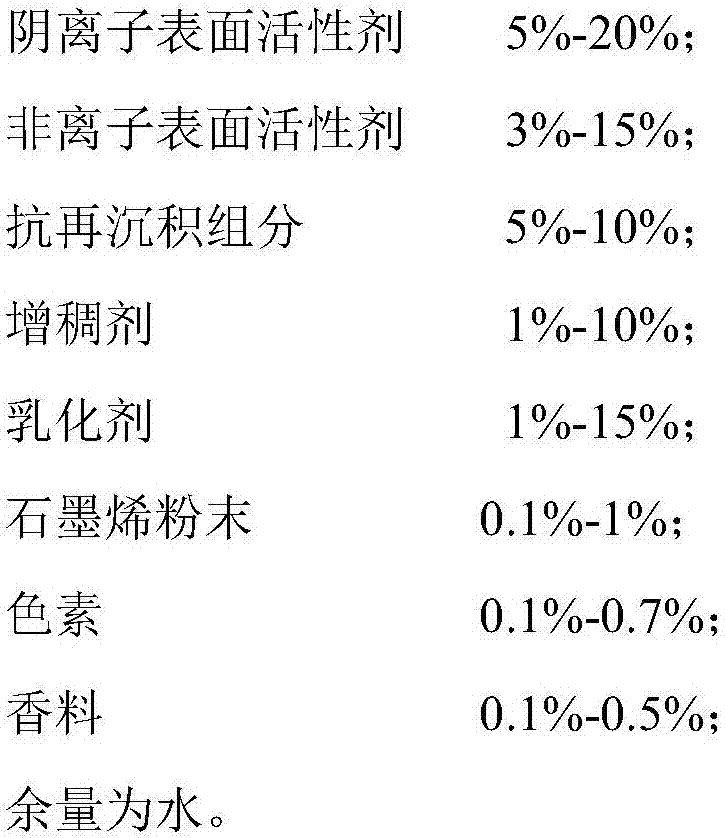

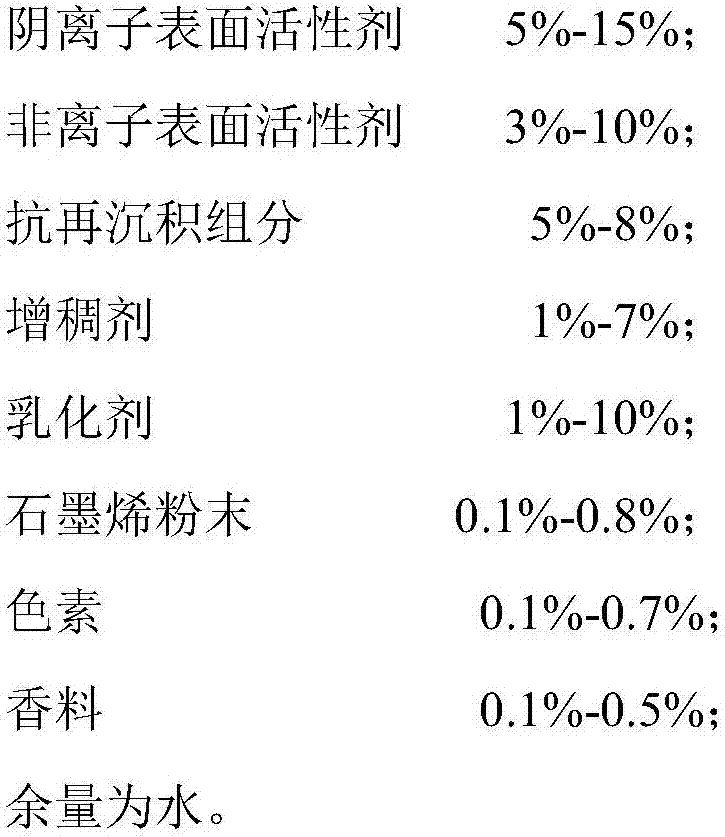

The invention relates to a graphene anti-bacterial compound solution and a preparation method thereof. The graphene anti-bacterial compound solution is prepared from the following components in percentage by weight: 5 to 20 percent of an anionic surfactant, 3 to 15 percent of a non-ionic surfactant, 5 to 10 percent of an anti-redeposition component, 1 to 10 percent of a thickening agent, 1 to 15 percent of an emulsifying agent, 0.1 to 1 percent of graphene powder, 0.1 to 0.7 percent of pigment, 0.1 to 0.5 percent of perfume and the balance of water. According to the graphene anti-bacterial compound solution disclosed by the invention, graphene is grafted with a surfactant through a nano-microcapsule technology, so that functional graphene is embedded in the surfactant, and cell structures of bacteria and mites are destroyed by a nano knife formed by utilizing graphene nano-microcapsules. In the graphene anti-bacterial compound solution disclosed by the invention, the graphene and the surfactant have a synergistic effect, and anti-bacterial and anti-mite functions are realized; compared with an anti-bacterial agent and an anti-mite agent existing in the market, the graphene antibacterial compound solution has the advantages that the graphene antibacterial compound solution is green, environmentally friendly and nontoxic.

Owner:NANTONG QIANGSHENG GRAPHENE TECH CO LTD

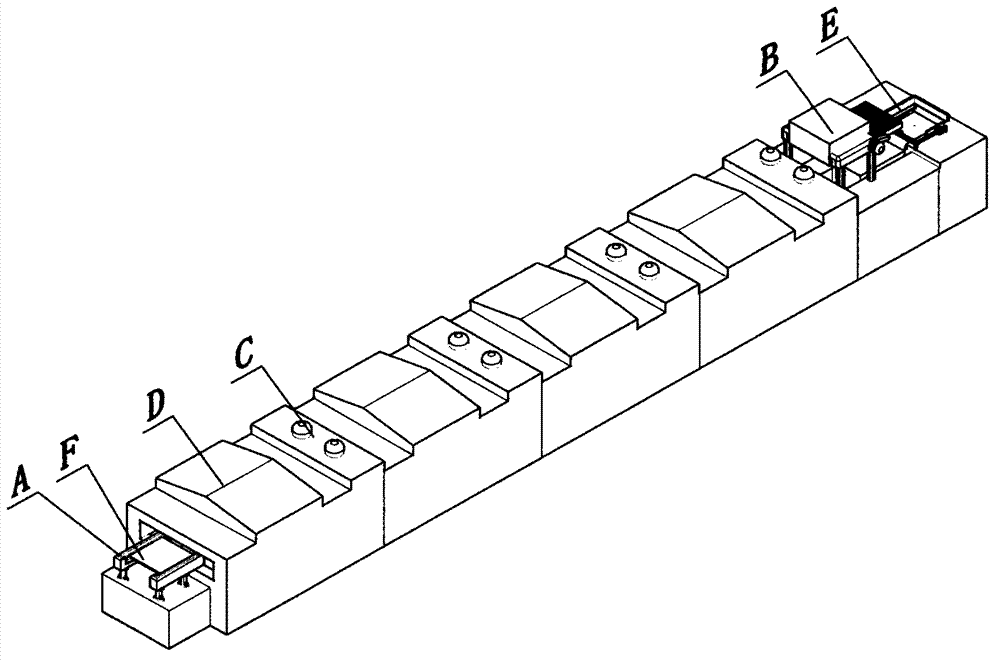

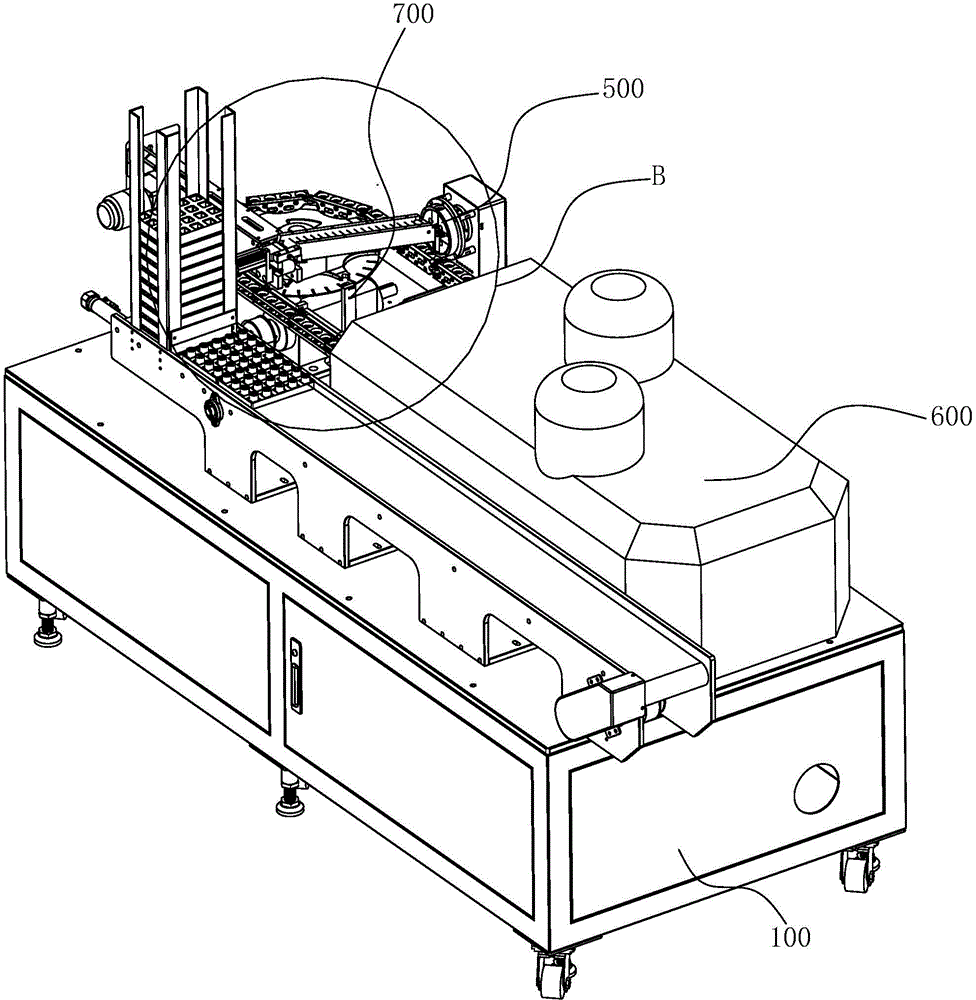

Battery cleaning equipment

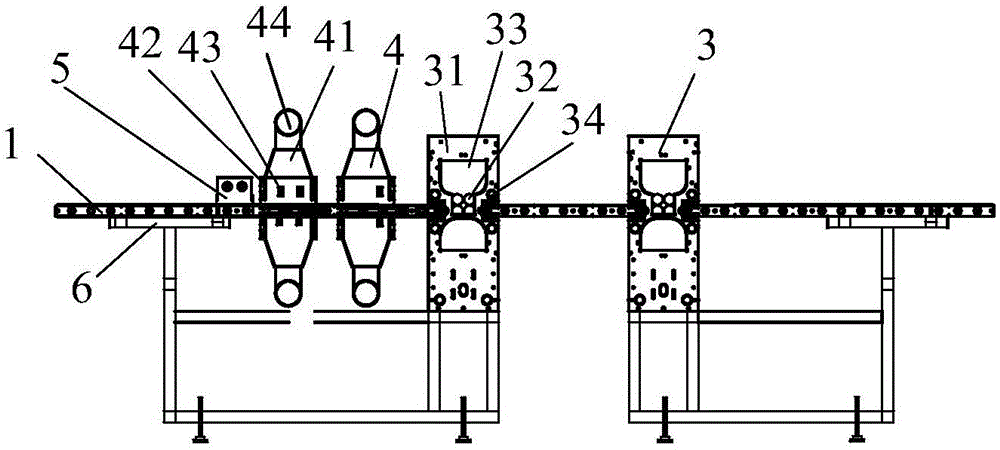

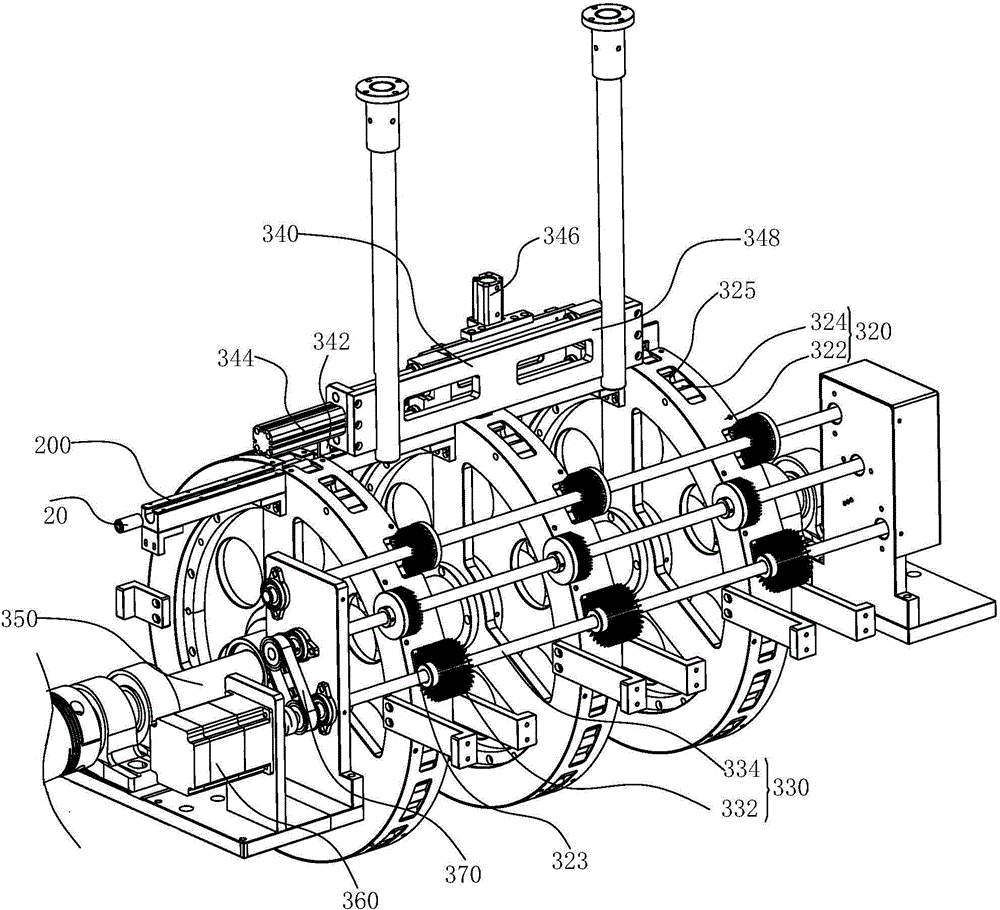

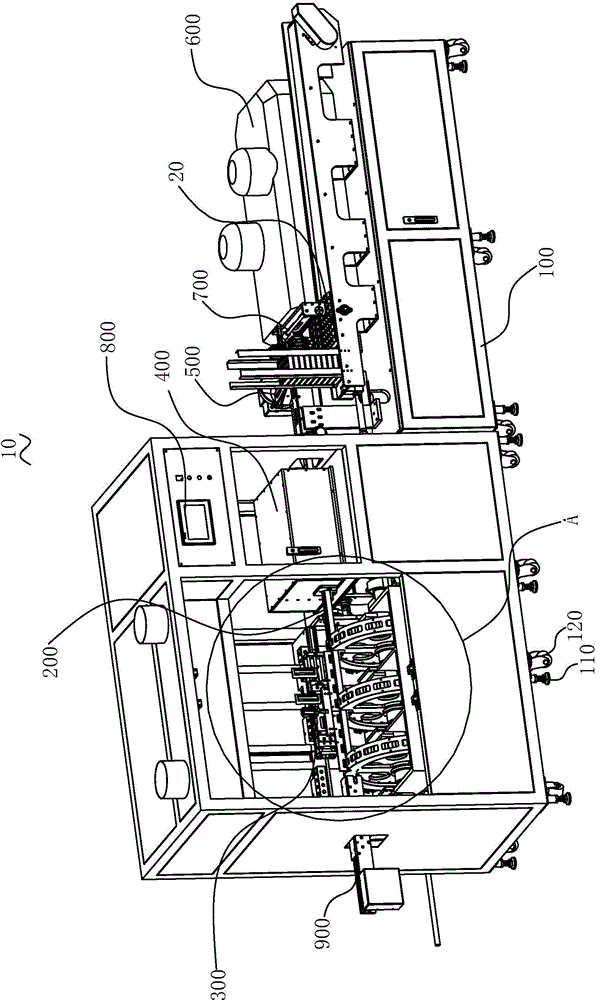

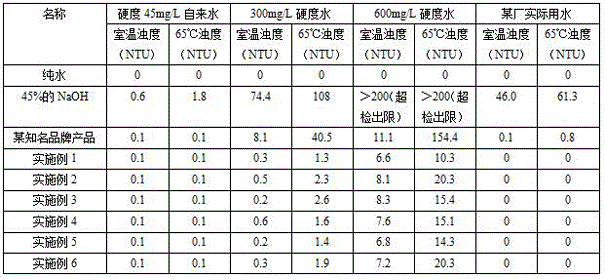

ActiveCN104438232AImprove the level of automated productionMeet cleaning requirementsCleaning using toolsCleaning using liquidsElectrical batteryEngineering

Battery cleaning equipment is used for sequentially cleaning, dewatering, turning over and drying a battery and loading the battery on a plate and comprises a base, a conveying passage, a cleaning device, a dewatering box, a turning-over device, a drying box and a plate loading device. Through the coordinative cooperation of all the mechanical parts, the battery sequentially passes through the cleaning device, the dewatering box, the turning-over device, the drying box and the plate loading device on the conveying passage. Due to the structural design of the cleaning device, the cleaning requirement for the battery is met, and the cleaning cleanliness of the battery is improved. Due to the structural design of the turning-over device, the battery is turned over into the vertical state from the lying state to get ready for the follow-up battery loading work. According to the battery cleaning equipment, the production efficiency is improved, the production cost is reduced, the harm to human health is reduced, and the mechanical automation production level is improved.

Owner:EVE ENERGY CO LTD

Dewaxing cleaning agent for sapphire substrate

InactiveCN104178367AEasy to cleanImprove cleaning efficiencyInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsWater basedWater quality

The invention relates to a preparation method of a dewaxing cleaning agent for a sapphire substrate, and is characterized in that the dewaxing cleaning agent for the sapphire substrate contains a starch glycoside surfactant, other surfactants, a cosolvent, a metal complex, a suspending agent, a water quality softener or a hard water resistant agent, a corrosion inhibitor and pure water; the dewaxing cleaning agent for the sapphire substrate is characterized by containing 5-15 wt% of the starch glycoside surfactant, 5-20 wt% of the other surfactants, 3-5 wt% of the cosolvent, 3-5 wt% of the metal complex, 0.01-1 wt% of the water quality softener or the hard water resistant agent, 0.5-1 wt% of the suspending agent, 10-20 wt% of a sapphire substrate corrosive agent and a proper amount of pure water; the dewaxing cleaning agent for the sapphire substrate is a water-based environmentally-friendly cleaning agent, and the cleaning agent can be degraded by self within 15 days after cleaning; and the cleaning requirement can be reached just with cleaning for one time, the production efficiency is improved, and with addition of the corrosion inhibitor, the cleaning agent is ensured not to cause severe corrosion to the sapphire surface in the cleaning process.

Owner:天津西美半导体材料有限公司

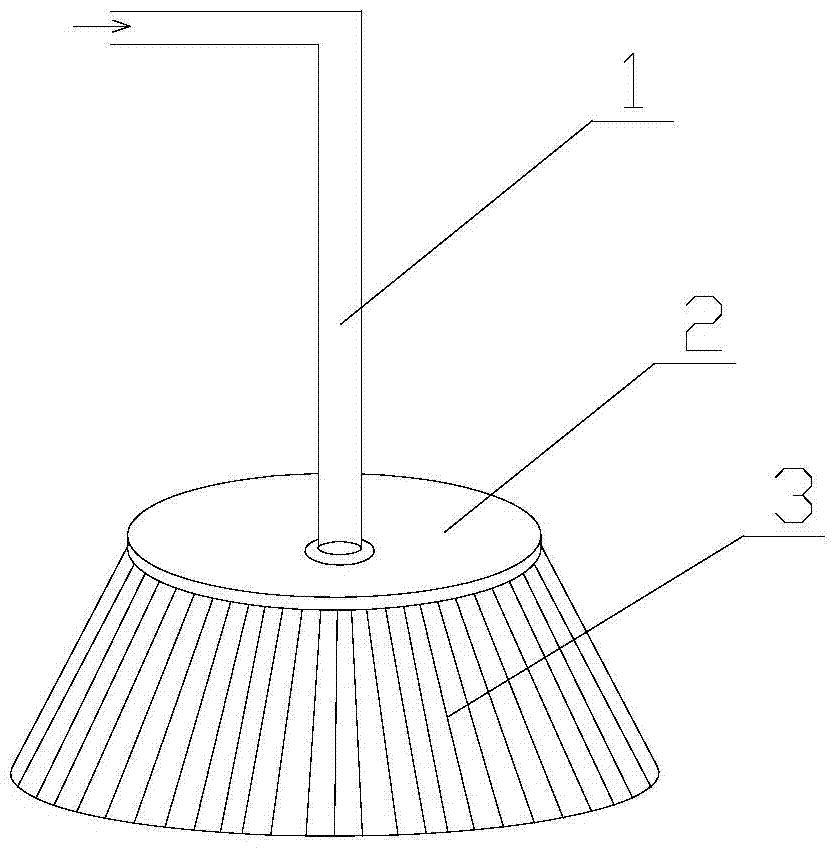

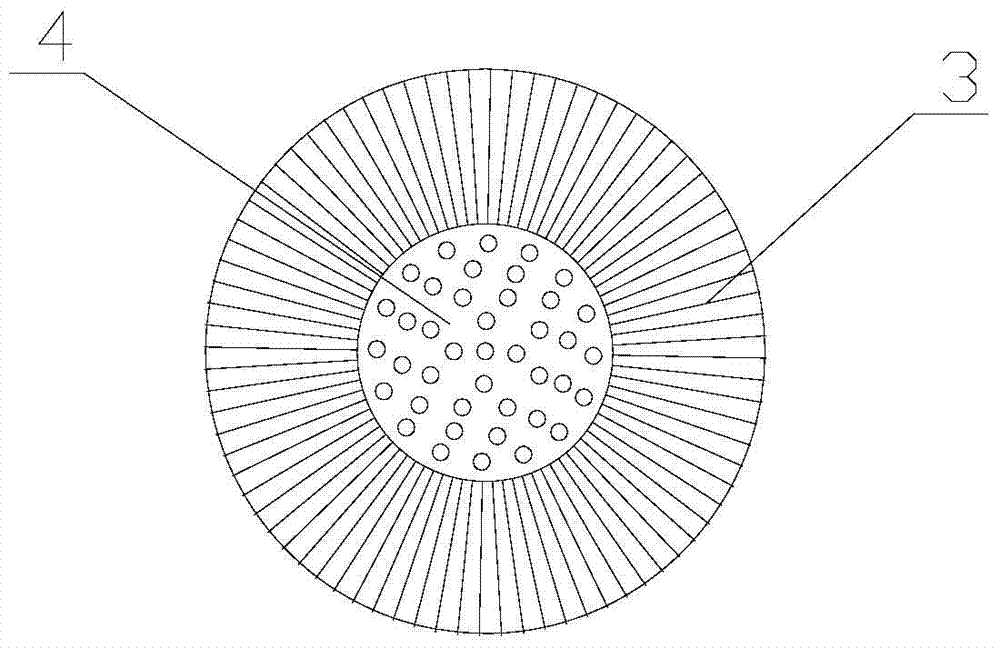

Multifunctional garbage cleaning trolley sweeping brush

The invention relates to the technical field of cleaning equipment, in particular to a sweeping brush for a garbage cleaning trolley with a sprayer. The sweeping brush comprises a brush rod of a hollow structure and a brush head component arranged below the brush rod. The brush head component comprises a circular disc and brush bristles distributed in an annular shape. A showerhead is arranged below the circular disc and is communicated with the brush rod. The other end of the brush rod is connected with a water inlet. According to the multifunctional garbage cleaning trolley sweeping brush, a nozzle is arranged on the common brush bristles, after connecting with a garbage trolley water storing box, the effect of integration of the functions of sweeping and watering can be achieved, in addition, the brush bristles are of a detachable structure, washing is convenient, meanwhile, the brush bristles can be replaced, economy and environment protection are achieved, various cleaning requirements are met, design is simple, and using effect is good.

Owner:印金福

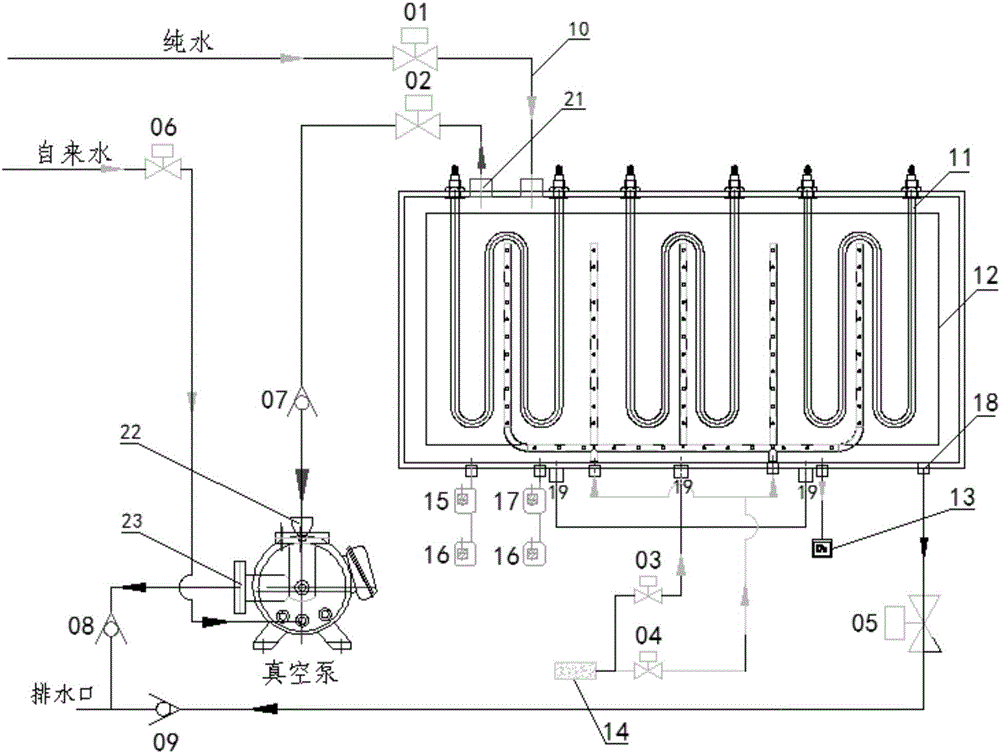

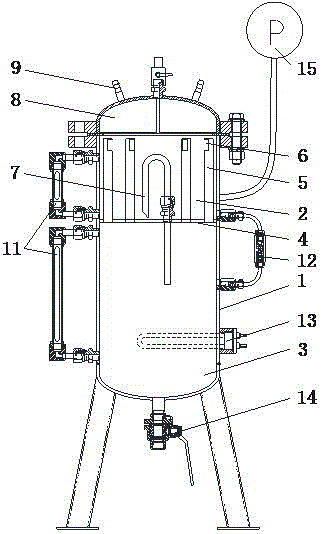

Multistage variable-pressure pulse washing system and washing method thereof

InactiveCN106269661AImprove cleaning efficiencyGuaranteed cleaning qualityDiagnosticsSurgeryVacuum pumpingBoiling point

The invention provides a multistage variable-pressure pulse washing system and a washing method thereof. The washing system mainly comprises a water charging system, a heating device, a washing cabin, a pressure detection device, a drainage system, a gas breaking system, a water level detection system and a vacuum pump circulation system. The washing method comprises the steps of putting an object to be washed into the washing cabin, closing a cabin door, and supplementing cleaning fluid; when the cleaning fluid reaches a set liquid level, starting to heat to be 45 DEG C to 55 DEG C; when the temperature reaches set temperature, starting a vacuum pump to pump out gas in the washing cabin; reducing the boiling point of the cleaning fluid in a tank along with the continuous reduction of the vacuum degree in the tank, starting to shaking and boiling the liquid in the tank when the liquid in the tank reaches the boiling point, after maintaining the state for a while, switching on a liquid breaking valve or a gas breaking valve for 1s to 30s, and quickly recovering the pressure in the washing tank; repeating the steps of vacuum pumping and switching on the liquid breaking valve or the gas breaking valve for washing; after the washing is finished, taking the washed object out. According to the multistage variable-pressure pulse washing system and the washing method thereof provided by the invention, the manpower is saved, the simplicity and the convenience in operation are realized, and the washing effect is good.

Owner:深圳市美雅洁技术股份有限公司

High concentration alkaline cleaner used for food industrial device and having scale inhibition dispersion function

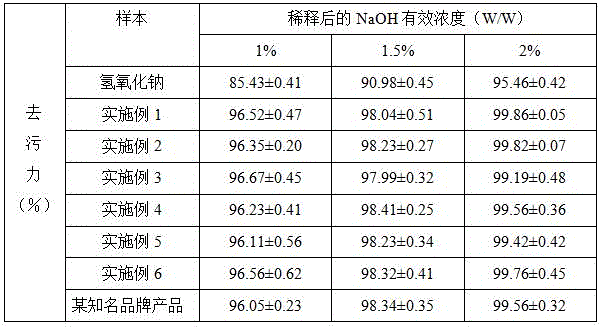

InactiveCN105462714AExtend your lifeAvoid formingDetergent mixture composition preparationOrganic non-surface-active detergent compositionsFood industryHigh concentration

The invention discloses a high concentration alkaline cleaner used for a food industrial device and having a scale inhibition dispersion function. The high concentration alkaline cleaner comprises, by mass percentage, 45-55% of sodium hydroxide, 0.3-2% of chelating agent, 0.2-2% of dispersant and the balance water. According to the formula, the alkaline cleaner has excellent decontamination capability, meets the cleaning requirements at various temperatures, is good in compatibility to water of different hardness, good in high and low temperature stability and low in cost, and has wide market prospect.

Owner:GUANGDONG HUANKAI MICROBIAL SCI & TECH

Low foaming surfactant for cleaning and method for preparing same

InactiveCN1880423AThe preparation method is scientific and reasonableAdd lessSurface-active detergent compositionsSURFACTANT BLENDRaw material

The invention discloses a low-foam surface activist for cleaning, which is characterized by the following: two or three random proportions of span type, tween type, OP type and AEO type are mixed together to produce activating material; the span typed raw material contains span20, span40, span60 and span80;the tween typed raw material contains tween20, tween40, tween60 and tween80;the OP typed raw material contains OP-4, OP-9 and OP-10; The AEO typed raw material contains AEO-7, AEO-9, AEO-10, AEO-15 and AEO-20. The invention is easy to dissolve in the water, which cleans blood and oil stain by over 90 percent.

Owner:SHINVA MEDICAL INSTR CO LTD

Bridge road surface washing device

The invention discloses a bridge road surface washing device. The device comprises a base and a machine body arranged above the base, the bottom inside the base is provided with a third driving machine, the top of the third driving machine is connected to a rotary rod, the top of the rotary rod penetrates through the wall body of the base and is fixedly connected to the bottom of the machine body, a bearing is arranged between the machine body and the base, the machine body is internally provided with a first accommodation cavity, the machine body at the top of the first accommodation cavity is internally provided with a second accommodation cavity, the inner top wall of the second accommodation cavity is provided with a slide groove, the outer wall of the machine body at the right side of the first accommodation cavity is internally provided with a blocking groove, a through groove is formed between the blocking groove and the first accommodation cavity, the first accommodation cavity is internally provided with a rotary shaft which is arranged to extend up and down, the top of the rotary shaft penetrates through the wall body inside the machine body, extends into the second accommodation cavity and is in rotary and cooperative connection with the second accommodation cavity, a rotor drum is fixedly arranged on the rotary shaft in the first accommodation cavity, and clapboards are symmetrically arranged at the upper and lower two sides of the rotor drum. The bridge road surface washing device is simple in structure and convenient to operate, reduces the labor amount of workers, and improves the cleaning efficiency.

Owner:张家港和智珅知识产权有限公司

Energy-accumulation type ultrasonic cleaning device applied to spinneret plate in spinning industry

InactiveCN103143529AMeet cleaning requirementsImprove cleaning efficiencyCleaning using liquidsEngineeringLoudspeaker

The invention discloses an energy-accumulation type ultrasonic cleaning device applied to a spinneret plate in the spinning industry. The device comprises a cleaning water tank and energy-accumulation type ultrasonic cleaning device parts, wherein the energy-accumulation type ultrasonic cleaning device parts can make reciprocating motion axially along the cleaning water tank, and are arranged above the cleaning water tank; the cleaning water tank is internally provided with a plurality of ultrasonic vibration boxes corresponding to the energy-accumulation type ultrasonic cleaning device parts; and the ultrasonic vibration boxes are arranged on motion trails of the energy-accumulation type ultrasonic cleaning device parts. The energy-accumulation type ultrasonic cleaning device adopts a mode of high frequency and low frequency combination, upper-lower switching and positioning cleaning, tiny holes and guide holes are cleaned completely once, and no turnover plate is used, so that the cleaning efficiency can be improved greatly; low-frequency high-power energy-accumulation type ultrasonic positioning is used for cleaning the tiny holes with smaller hole diameters at the upper part; conventional ultrasonic is used for cleaning the guide holes at the lower part; the distributed ultrasonic vibration boxes consisting of loudspeaker vibrators connected with basic matrixes in parallel are adopted; the ultrasonic cleaning mode of upper-lower combination is very good in effect; and cleaning requirements of various spinneret plates can be met.

Owner:无锡南方声学工程有限公司

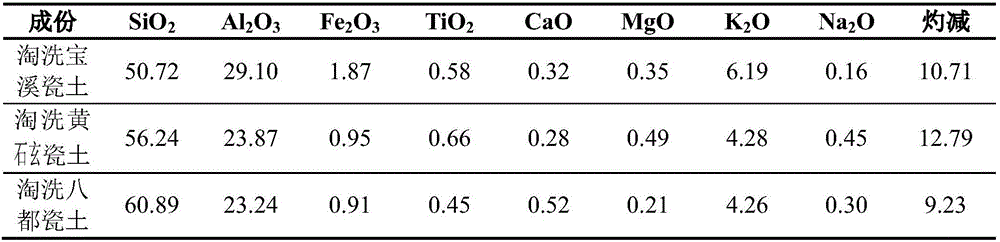

High-plasticity reinforced longquan celadon ware and preparing method thereof

The invention provides a high-plasticity reinforced longquan celadon ware and a preparing method thereof. A blank of the high-plasticity reinforced longquan celadon ware is prepared from, by weight, 35-55% of elutriated Baoxi porcelain clay, 13-27% of elutriated Huang Shixuan porcelain clay, 25-45% of elutriated Badu porcelain clay, 10-15% of Al2O3 micro powder and 1-2% of zirconium oxide micro powder. The reinforced longquan celadon ware has high strength and high thermal stability when sintered in a reducing atmosphere at the high temperature of 1280-1300 DEG C, the breaking strength of the reinforced longquan celadon ware can reach 90-130 MPa, the reinforced longquan celadon ware does not crack in 240-20 DEG C cold and hot water exchange on the thermal stability, the breaking and bending strength is improved by 100-120% compared with that of existing common longquan celadon ware, the thermal stability is improved by 50%, the product can be prevented from being damaged by small knocks in daily use, and the produced daily celadon product can meet the cleanness requirement of mechanical equipment. The components of the blank have high strength, have very high plasticity at the same time, can adapt to various forming methods such as manual forming, rolling forming, slip casting forming and the like in the ceramic industry field, and are high in applicability.

Owner:LONGQUAN JINHONG PORCELAIN +1

Ground cleaner and control method thereof

InactiveCN106175603AImprove cleanlinessFlexible and reliable controlFloor sweeping machinesEngineeringAirflow

The invention provides a ground cleaner and a control method thereof. The ground cleaner comprises a walking sweeping module, a fan module, an image shooting module and a control device, wherein the walking sweeping module is configured to be driven by an internal driving device to move on the ground in a to-be-swept area so as to execute cleaning; the fan module is detachably arranged above the walking sweeping module to produce airflow for sucking dust on the ground into the walking sweeping module; the image shooting module is arranged above the fan module and used for shooting images of the surrounding environment of the walking sweeping module; the control device is configured for acquiring the images and adjusting moving states of the walking sweeping module through the driving device according to the images, and the walking sweeping module is enabled to change the moving direction and / or the moving speed. With the adoption of the scheme, on one hand, all parts can be flexibly assembled, the structure is simple, and the assembling is convenient; on the other hand, the ground cleaner is flexible and convenient to control and is convenient to use.

Owner:QINGDAO HAIGAO DESIGN MFG CO LTD

Cleanser and preparation method thereof

InactiveCN109705996AGood synergyEasy to cleanInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsCleansers skinSulfate

The invention provides a cleanser; according to 100 parts, the cleanser is prepared from: 10 to 20 parts of inorganic alkali, 5 to 15 parts of a chelating agent, 5 to 15 parts of a composite surfactant, 0.5 to 2 parts of a dispersant, 0.5 to 3 parts of a solubilizer, 3 to 10 parts of a solvent, and the balance being pure water. The composite surfactant includes one or more of propylene glycol block polyether, TMN-10, isooctyl sulfate, RhodaNop-880 and pine oil, and alkyldiphenyloxide disulfonate. The cleanser has excellent cleaning effect, and has strong removal effect on abrasive powder, oildirt and composite-type dirt, is non-foam or low-foam and satisfies the cleaning requirement of a plate-type cleaning machine. The cleanser can reach more than 80 DEG C in cloud point and can work athigh temperature. The invention also provides a preparation method of the cleanser, which is simple and has great economic benefit.

Owner:LENS TECH CHANGSHA

Processing method of coating film crushed materials of solar silicon cell

InactiveCN102151669AAlleviate material shortageImprove availabilityCleaning using liquidsSilicon cellSodium hydroxide

The invention relates to a processing method of coating film crushed materials of a solar silicon cell. The processing method sequentially comprises the following steps of: a, placing the coating film crushed materials into a hydrofluoric acid solution for soaking; b, placing into a hydrochloric acid solution for the soaking; c, placing into a mixed solution of nitric acid, hydrochloric acid and hydrofluoric acid for soaking; d, placing into a sodium hydroxide solution for soaking; e, placing into an ultrasonic cleaning tank for cleaning; and f, dewatering after ultrasonic cleaning and then placing into a drying oven for drying. Compared with the traditional processing method, the processing method has the remarkable effects of completely meeting the cleaning requirements of a solar silicon industry on the quality and ensuring the quality, thereby realizing the reuse of waste materials and enhancing the availability of raw materials; and after cleaning is completed, waste acids and bleaching liquor are treated and then drained without polluting environment.

Owner:KAIFENG WANSHENGXIN MATERIALS

Round disc type plant straw uprooting device

InactiveCN102027838AReduce disturbanceReduce power consumptionHarvestersGatherer machinesProduction rateAgricultural engineering

Owner:HENAN AGRICULTURAL UNIVERSITY

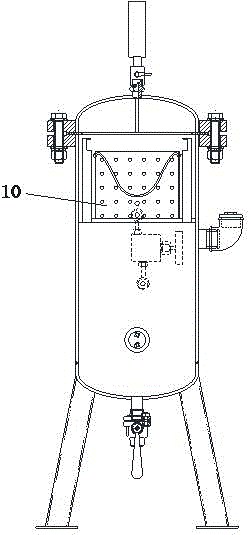

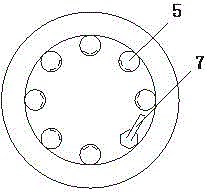

Rock core oil washing instrument

InactiveCN106483002AImprove oil washing efficiencyProtect environmentPreparing sample for investigationBall valveEngineering

Owner:南通市中京机械有限公司

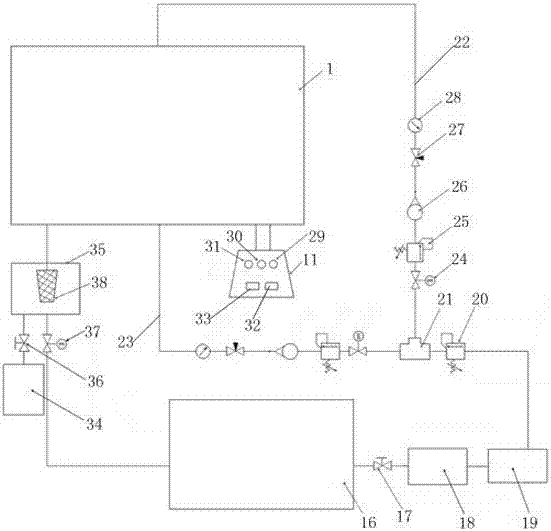

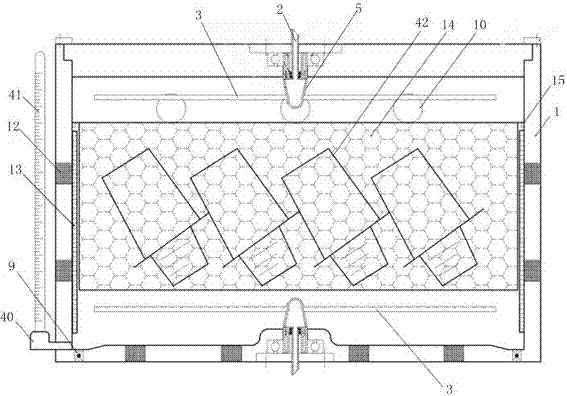

Machine part washing unit

PendingCN107051953AEasy to operateEasy to cleanCleaning using liquidsMachine partsMechanical components

The invention discloses a machine part washing unit. The machine part washing unit comprises a liquid pressurization system, a flow control system, an ultrasonic system and a washing box (1); an upper plate and a lower plate of the washing box (1) are provided with an upper spraying system and a lower spraying system correspondingly; the ultrasonic system comprises an ultrasonic controller (11), an ultrasonic oscillator (12) and a field railing heating device (13); and the liquid pressurization system is composed of a liquid storage box (16), a total flow valve (17), a water suction pump (18), a booster pump (19), a total overflow valve (20) and a t-branch pipe (21) which are sequentially connected. The machine part washing unit has the beneficial effects that the structure is compact, the washing effect is good, the automatic degree is high, and the washing efficiency is high.

Owner:PLA NO 5719 FACTORY

Water-saving type ginger cleaning device

InactiveCN102657367AReduce cleaning costsMeet cleaning requirementsClimate change adaptationFood treatmentWater savingSediment

The invention discloses a water-saving type ginger cleaning device which comprises a ginger delivery system and a circulating spraying and cleaning system, wherein the ginger delivery system comprises a ginger delivery net band and a driving device thereof, wherein the ginger delivery net band is installed on a support; the circulating spraying and cleaning system comprises a sediment pool, a water supplying pipe, at least two spraying pipe sets and at least two water collecting pools; the spraying pipe sets are opposite to the ginger delivery net band and are ranked along the delivery direction of the ginger delivery net band; the water collecting pools are positioned below the ginger delivery net band and are in one-to-one correspondence to the spraying pipe sets; at the delivery direction of the ginger delivery net band, the previous water collecting pool is communicated with the following spraying pipe set through a water pump; the foremost spraying pipe set is communicated with the water supplying pipe; the last water collecting pool is communicated with the sediment pool; and the sediment pool is communicated with the foremost water collecting pool through the water pump. According to the invention, the ginger can be cleaned only with less supplied water, the aim of water conservation is achieved; and meanwhile, the water-saving type ginger cleaning device provided by the invention is high in automation degree and great in treatment quantity, and can clean the ginger continuously and automatically on a large scale.

Owner:CHONGQING TECH & BUSINESS UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com