Patents

Literature

88results about How to "Realize automatic walking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glass curtain wall cleaning machine

The invention relates to a glass curtain wall cleaning machine. The glass curtain wall cleaning machine comprises a walking mechanism, a cleaning mechanism and a water circulating mechanism which are fixed on a bracket, wherein the walking mechanism comprises a translation cylinder, a slide block, a slide rail, a lifting cylinder, first sucking disk sets and second sucking disk sets; two groups of first sucking disk sets are symmetrically arranged on the left and right sides of the bracket; two groups of second sucking disk sets are symmetrically arranged on the upper and lower sides of the bracket; the slide block is connected with the slide rail in a sliding way; a piston rod of the translation cylinder is fixedly connected with the bracket; the translation cylinder is fixedly connected with the slide block. By adopting the glass curtain wall cleaning machine, unmanned cleaning of the exterior walls of tall buildings is realized, the cleaning speed and cleaning efficiency are high, and automatic walking and barrier crossing functions of the cleaning machine are realized; moreover, the walking speed can be adjusted in a stepless way, and the cleaning force can be adjusted in order to meet the cleaning requirements of different exterior walls.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

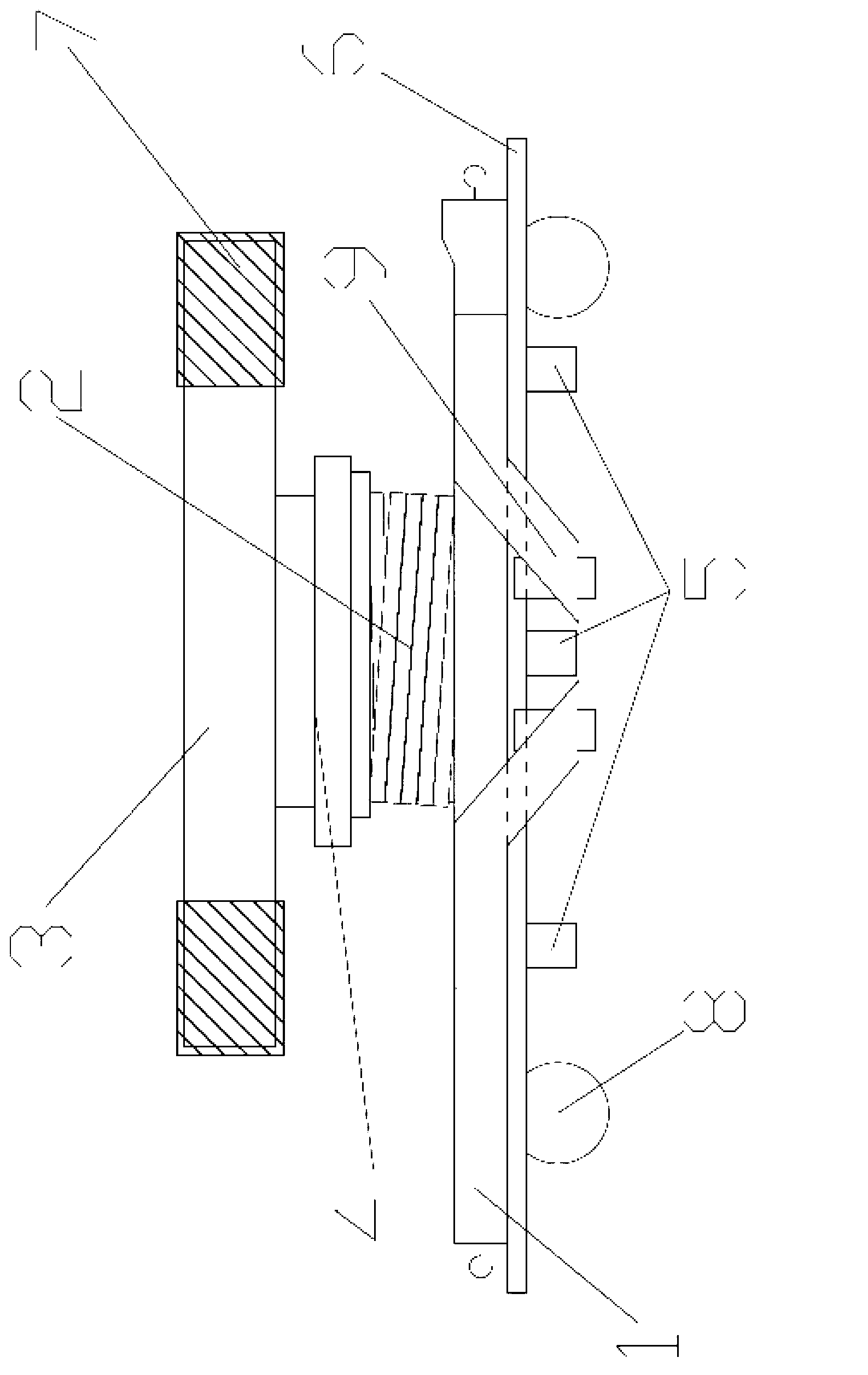

Sucking disk type high-rise building outer wall cleaning machine

InactiveCN104382536AEffective attachmentWill not harmCarpet cleanersFloor cleanersEngineeringWater circulation

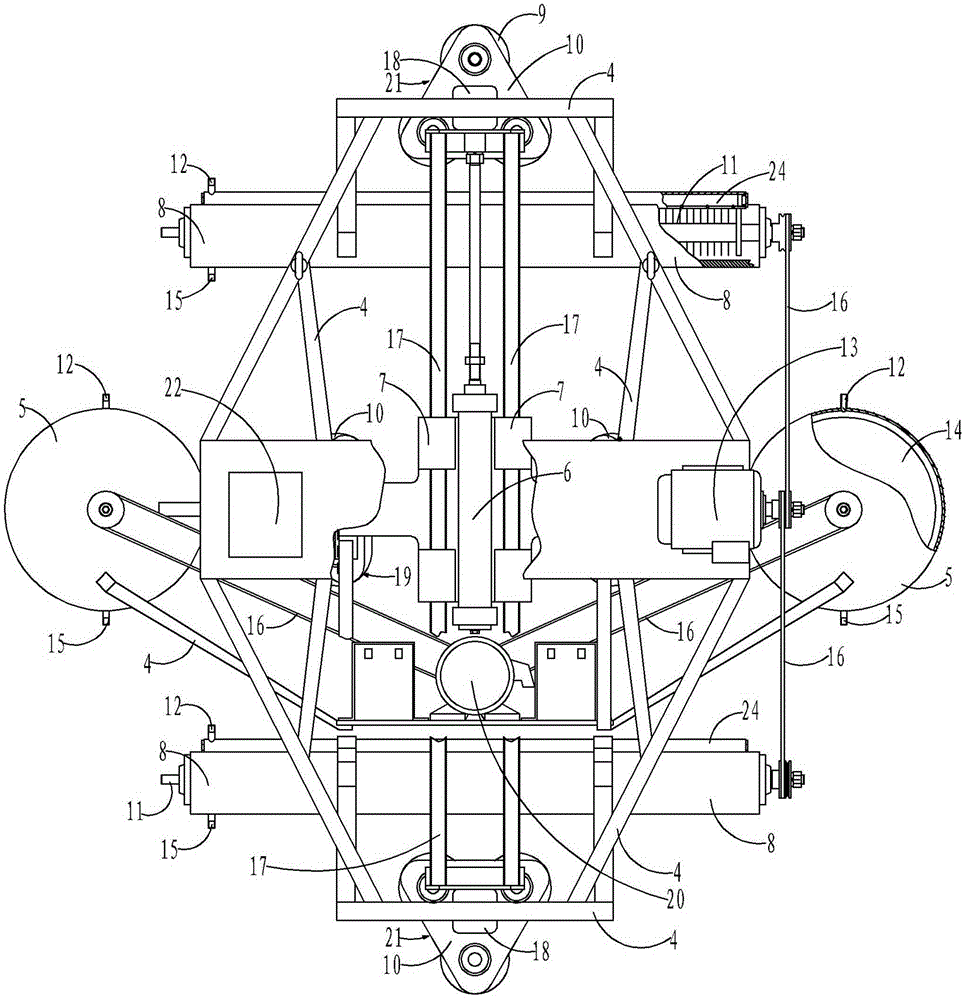

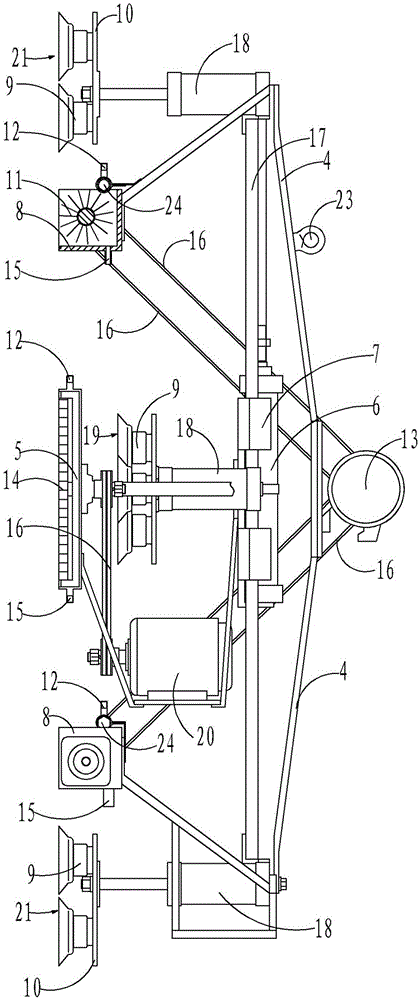

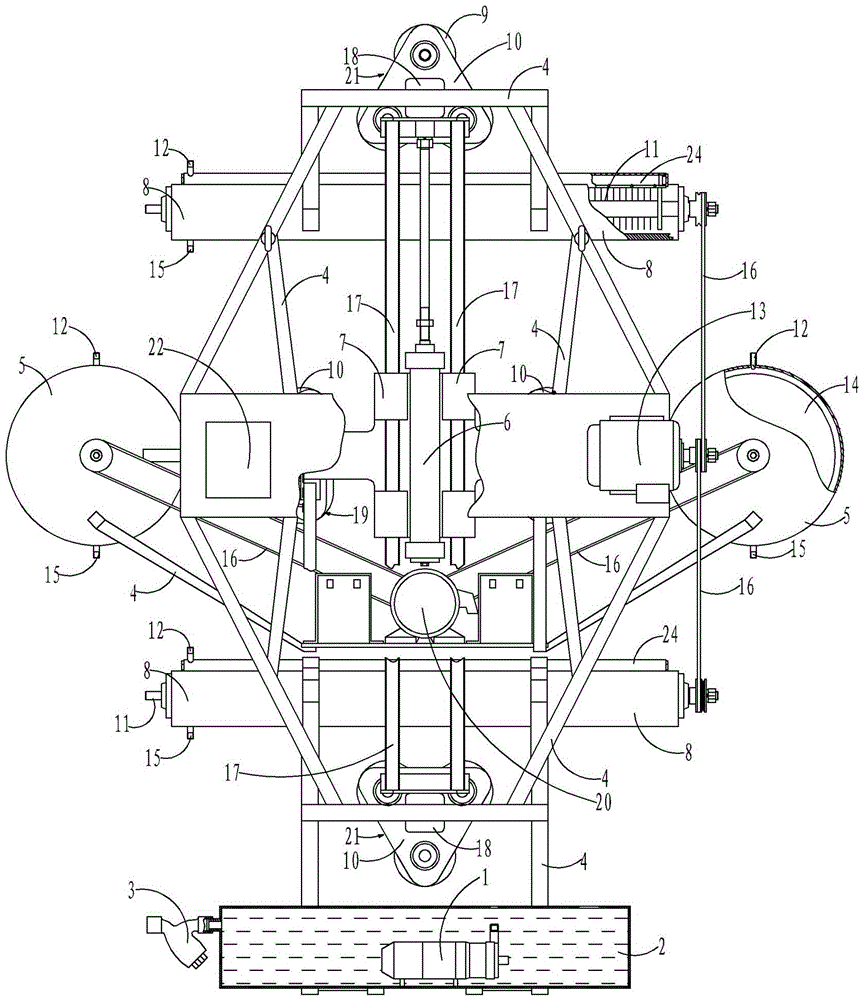

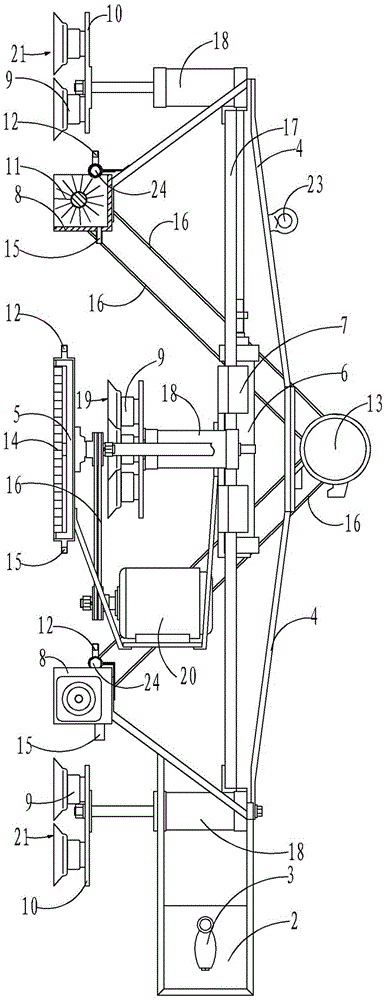

The invention relates to a sucking disk type high-rise building outer wall cleaning machine. The sucking disk type high-rise building outer wall cleaning machine comprises a walking mechanism fixed on a bracket, a cleaning mechanism and a water circulation mechanism, wherein the walking mechanism comprises a translation cylinder, a sliding block, a sliding rail, a lifting cylinder, two first sucking disk groups and two second sucking disk groups, the two first sucking disk groups are symmetrically arranged on left and right sides of the bracket, the two second sucking disk groups are symmetrically arranged on upper and lower sides of the bracket, the sliding block is connected with the sliding rail in a sliding mode, a piston rod of the translation cylinder is fixedly connected with the bracket, and a cylinder body of the translation cylinder is fixedly connected with the sliding block. The sucking disk type high-rise building outer wall cleaning machine is fast in cleaning speed, high in cleaning efficiency, steplessly adjustable in walking speed, and capable of achieving unmanned cleaning, automatic walking, as well as an obstacle crossing function, and adjusting cleaning capability to meet the cleaning requirements of different outer walls.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

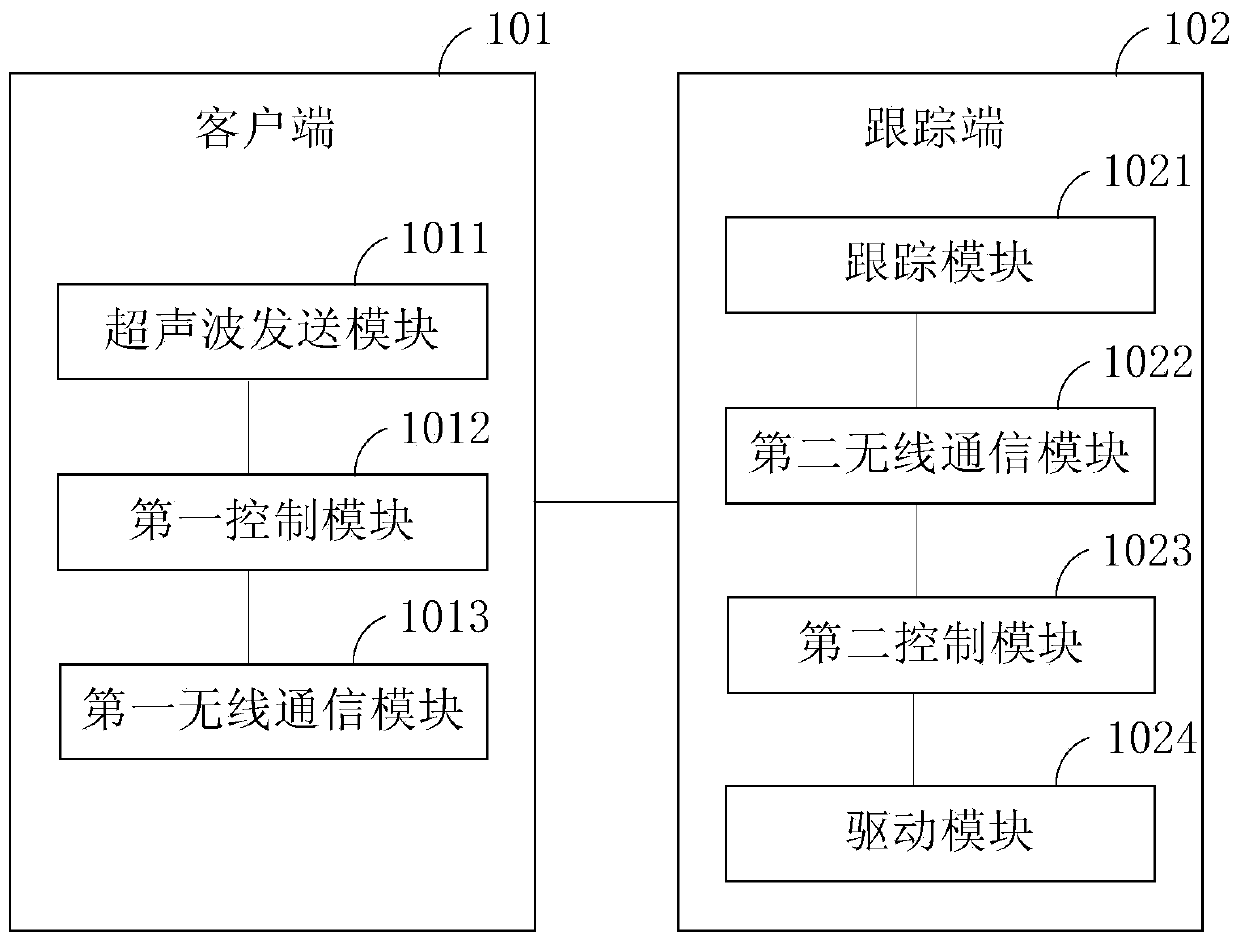

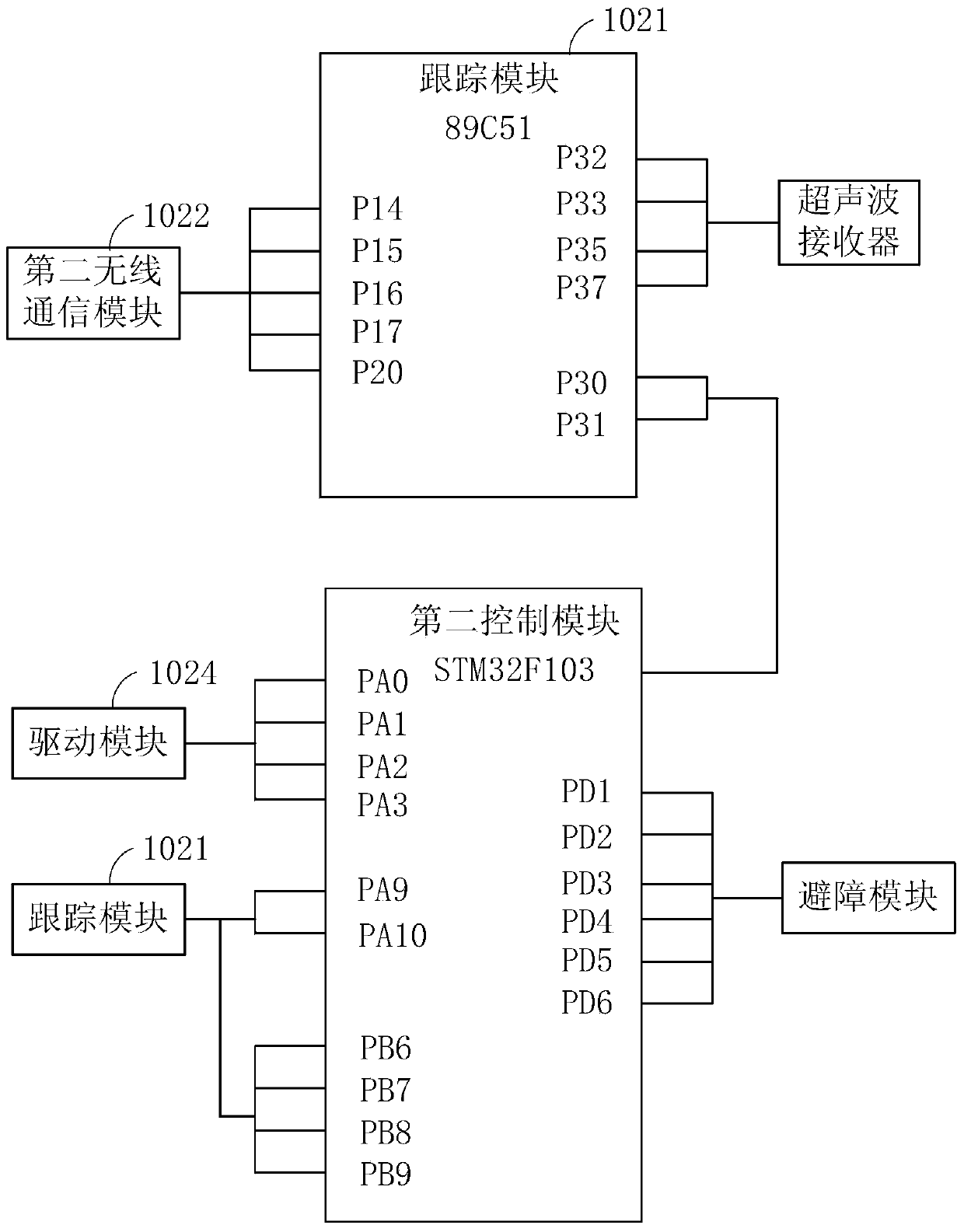

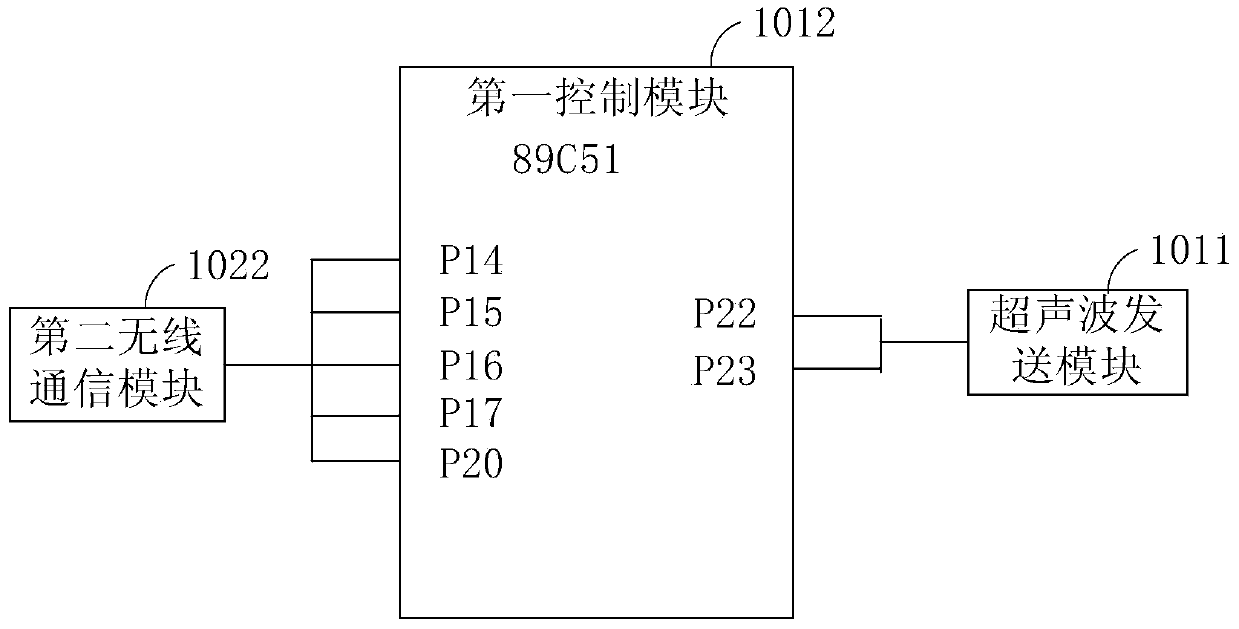

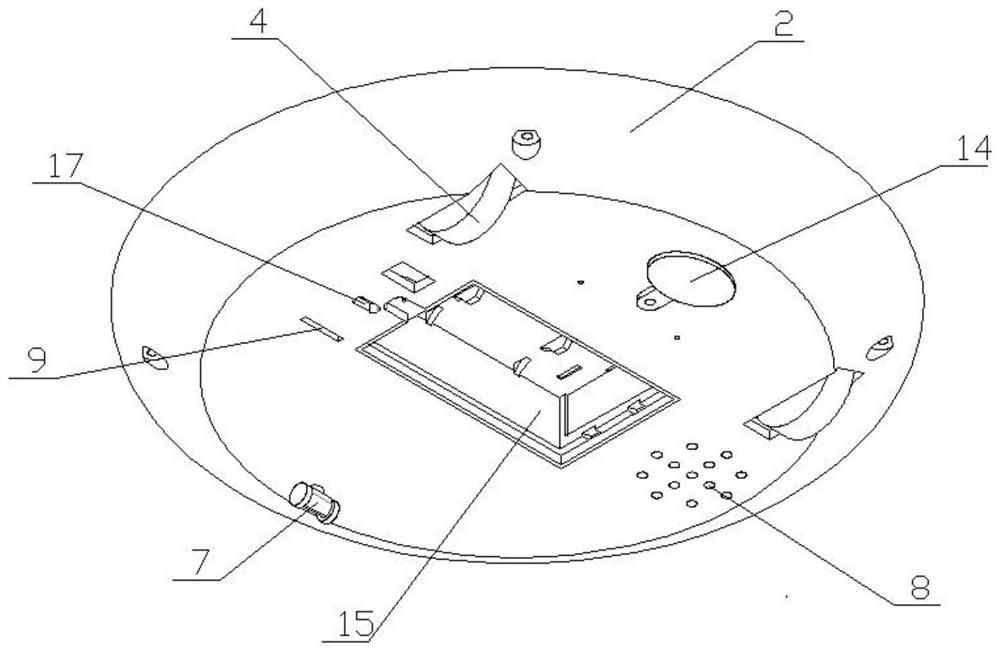

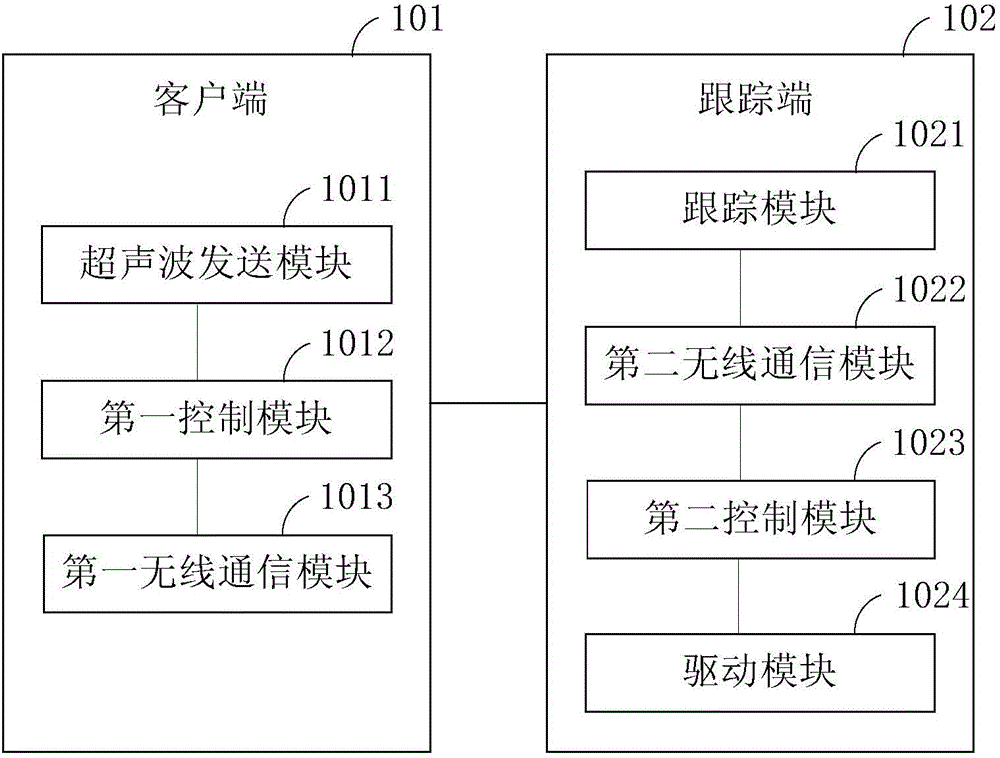

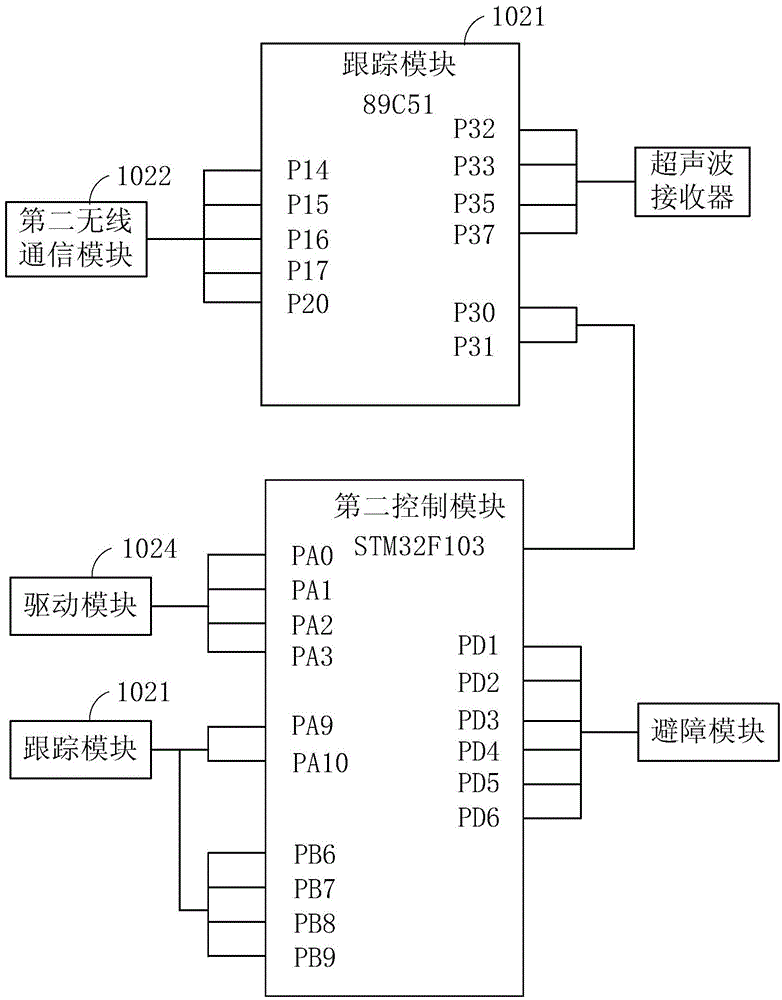

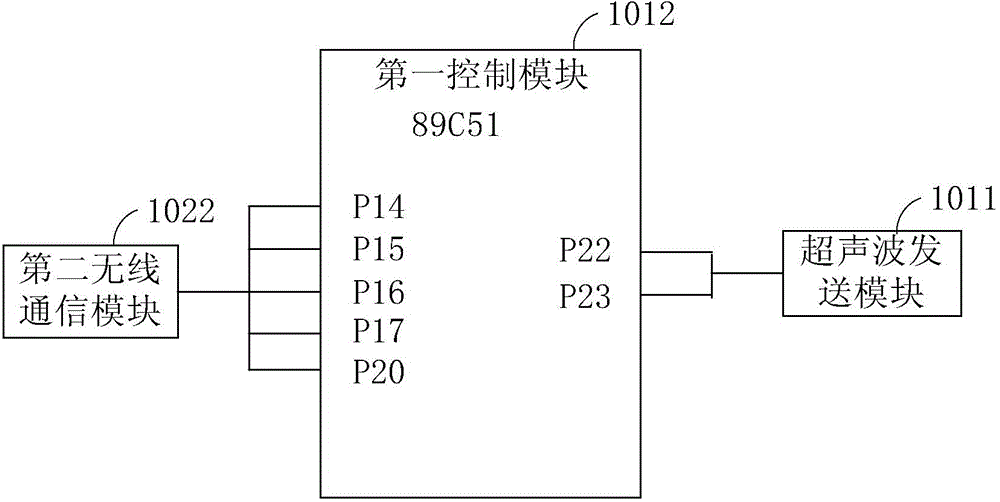

Automatic tracking robot control device and automatic tracking robot

InactiveCN104260092AImplement trackingAchieve positioningProgramme-controlled manipulatorTime informationAutomatic train control

The invention provides an automatic tracking robot control device and an automatic tracking robot. The device comprises a client side and a tracking side. The tracking side comprises a tracking module, a second wireless communication module, a second control module and a driving module, wherein the tracking module comprises an ultrasonic wave receiver which is arranged on the robot through a steering engine, and the tracking module is used for receiving an ultrasonic wave signal sent by an ultrasonic wave sending module, generating rotating angle information of the steering engine and sending the ultrasonic wave signal and the rotating angle information to the second control module. The second control module is used for obtaining positioning information between the client side and the tracking side according to the ultrasonic wave signal, the rotating angle information and time information, generating walking instruction information according to the position information, and sending the walking instruction information to the driving module. According to the automatic tracking robot control device, the problems that an existing automatic tracking control device is inaccurate in direction determining and signals are prone to being lost are solved.

Owner:DALIAN UNIV OF TECH

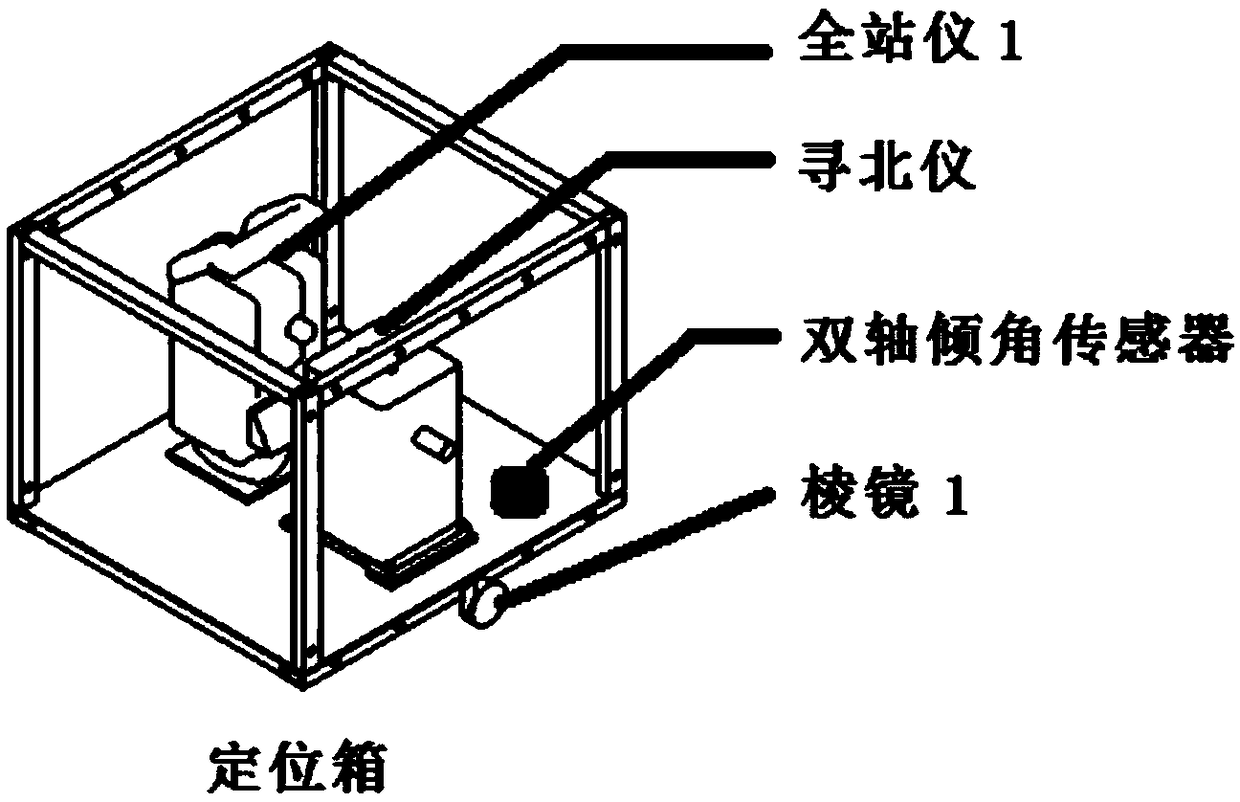

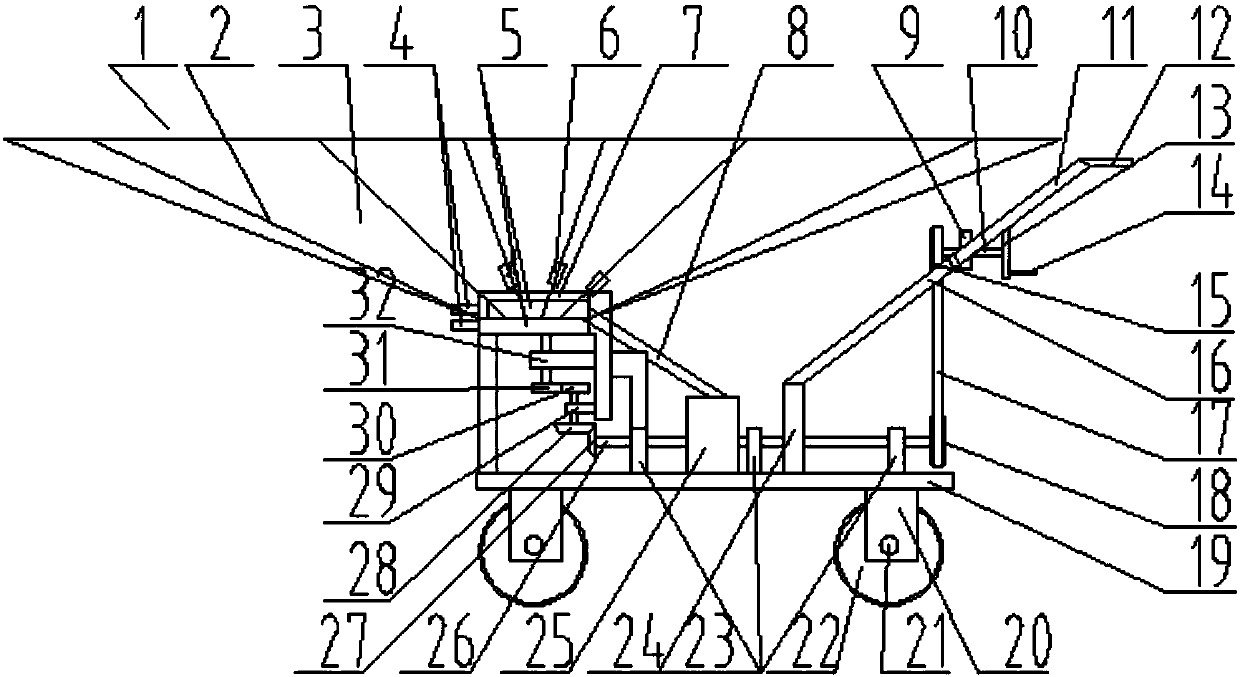

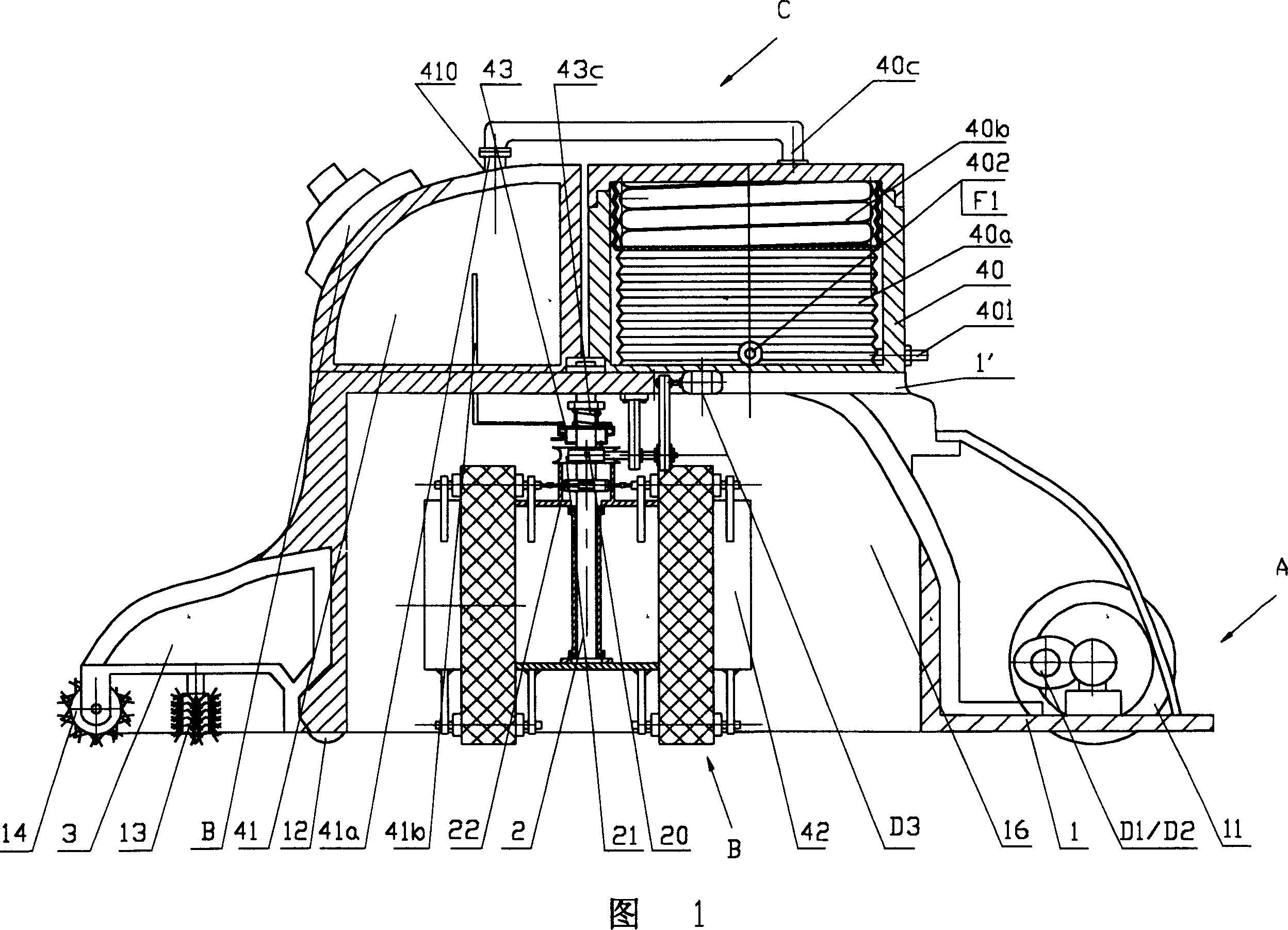

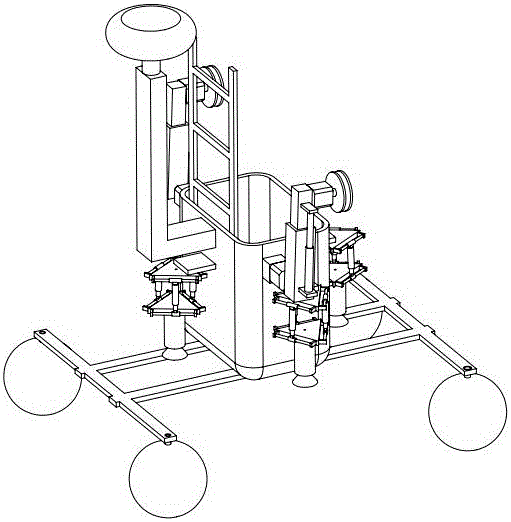

Roadheader, system and method

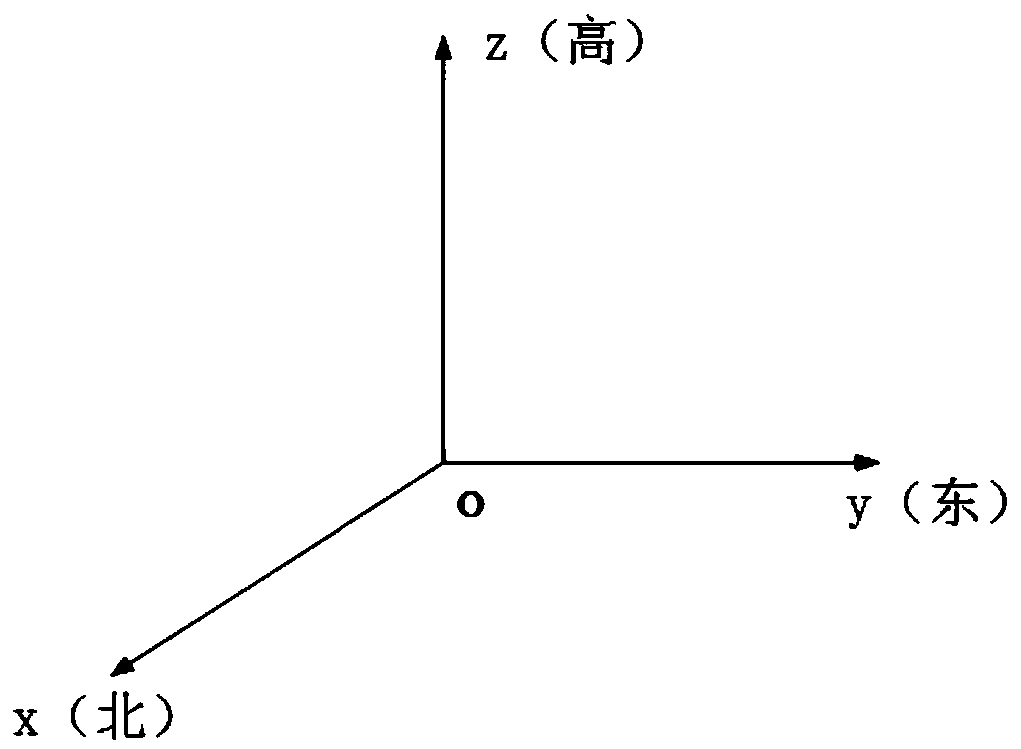

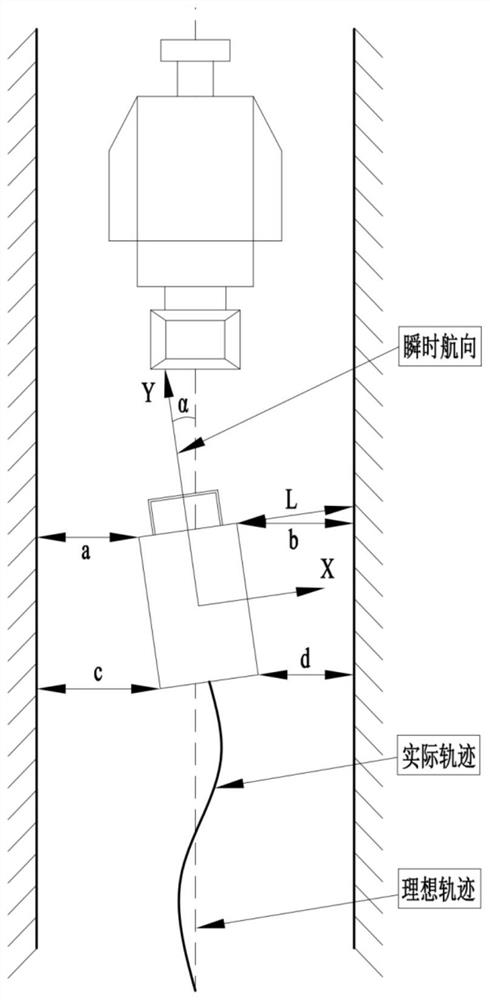

ActiveCN109356608AAchieve positioningSolve the fast-moving puzzleMining devicesTesting machinesAutomatic controlRemote control

The invention provides a roadheader, a system and a method. According to the roadheader, the system and the method, three-dimensional space coordinates of the roadheader can be tracked and measured inreal time to realize the millimeter levelpositioning accuracy of the set distance within the visual range, remote control operation and automatic control over the roadheader are facilitated, and themovement path and the speed of a cutting head as well as the direction, position and posture of a roadheader body can be automatically adjusted according to the position change of the roadheader and the rock wall hardness change of a heading working face roadway.

Owner:山东新矿信息技术有限公司

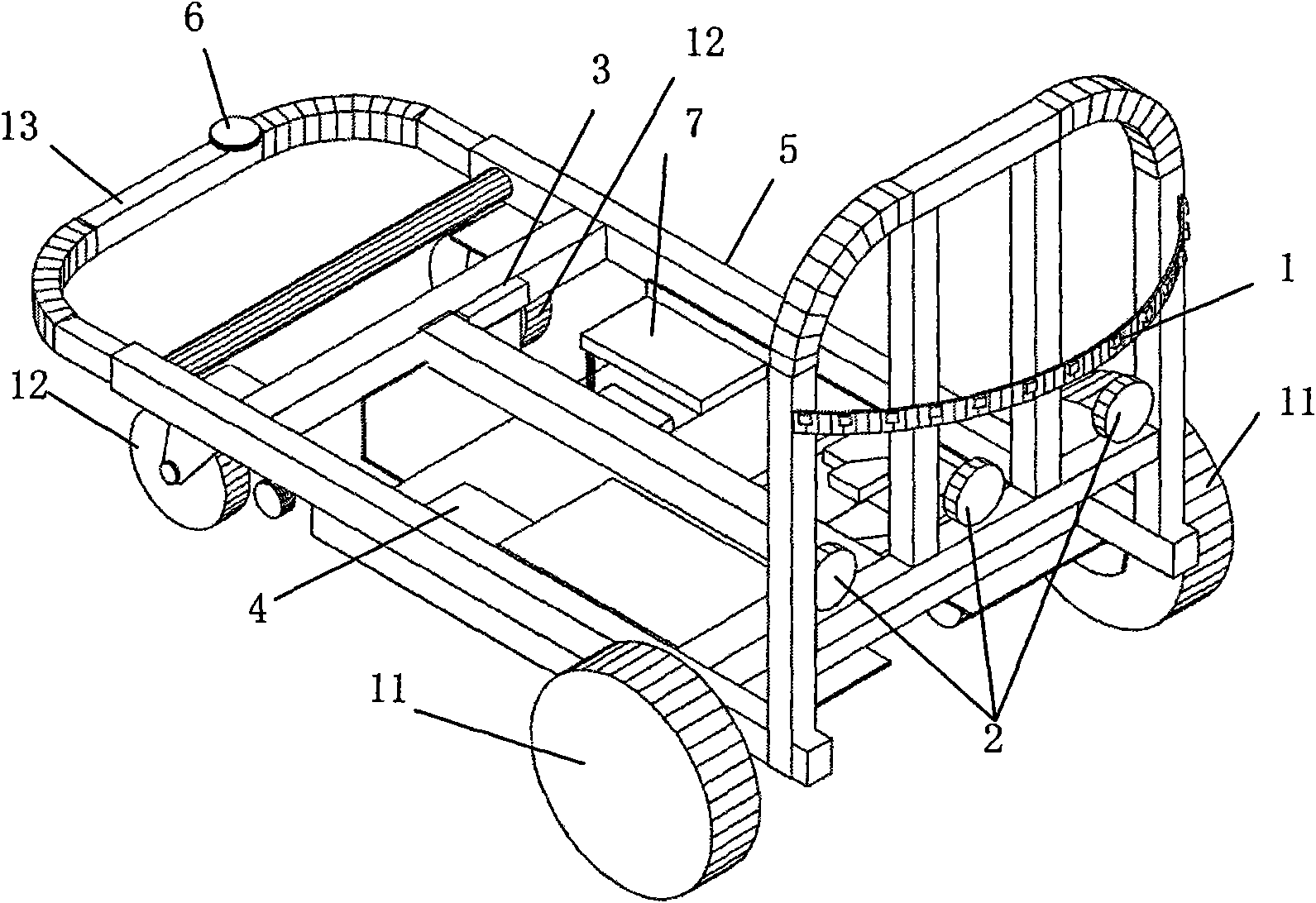

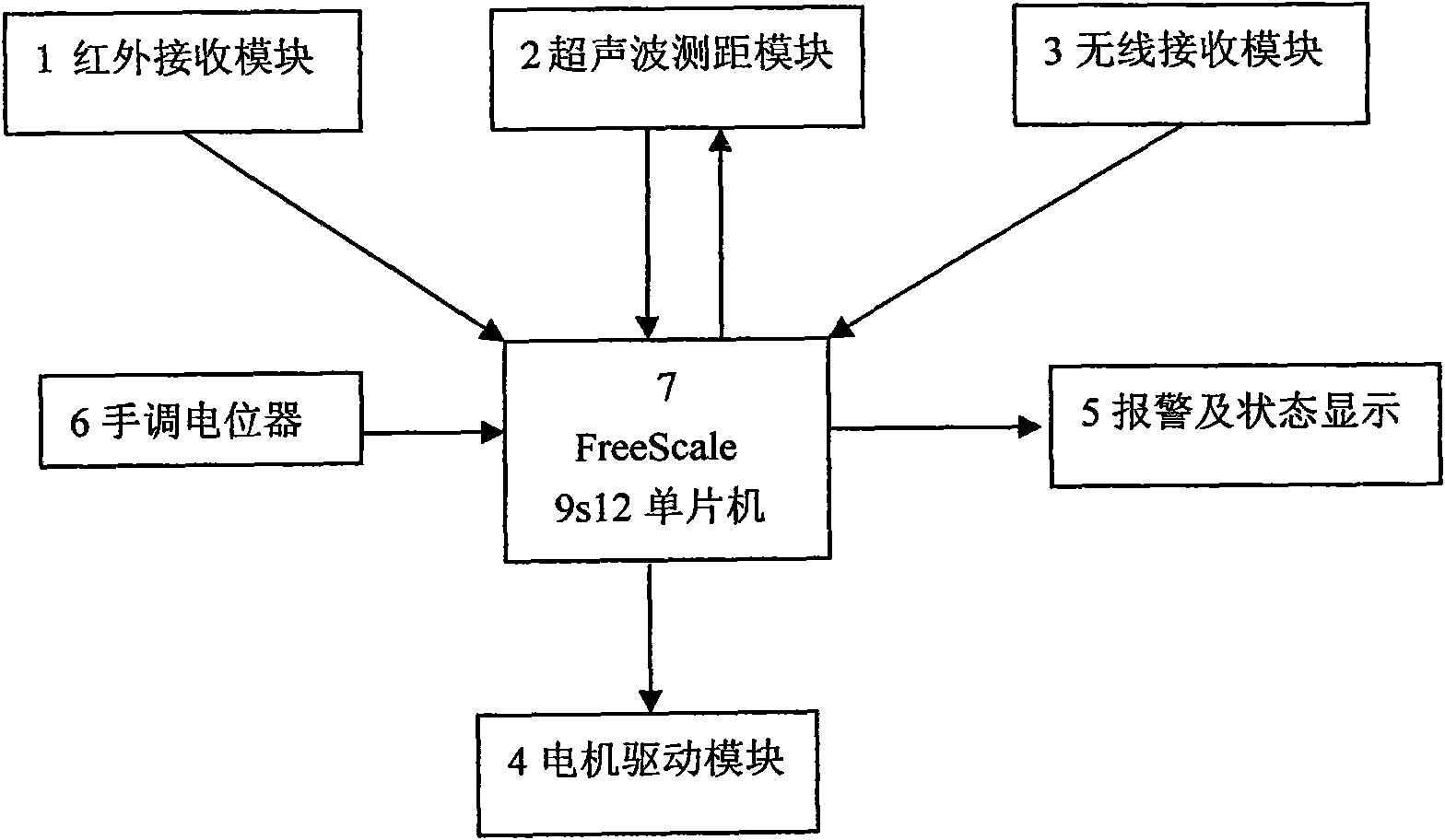

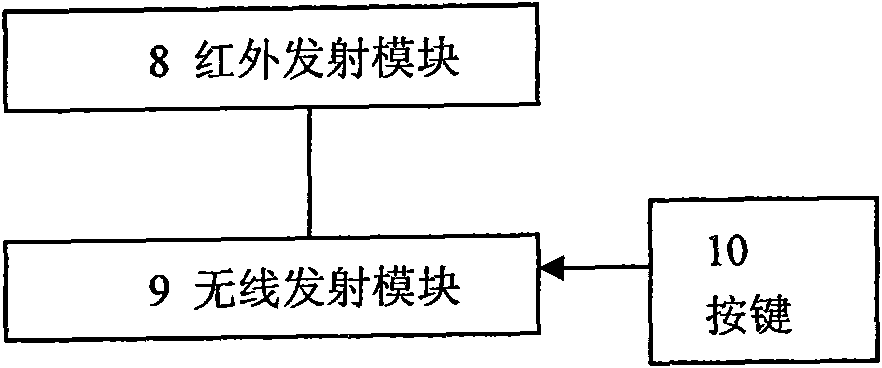

Intelligent tracking assisting luggage rack

InactiveCN101612950AEasy to useAchieving autonomous trackingProgramme controlComputer controlIntelligent lightingMicrocontroller

The invention provides an intelligent tracking assisting luggage rack which comprises a luggage rack body and a hand-held device; the luggage rack body is provided with an infrared receiving module, an ultrasonic ranging module, a wireless receiving module, a motor rive module, an alarm and state display module, a manual adjustment potentiometer, a singlechip and a walking mechanism, wherein the hand-held device is provided with an infrared transmitting module, a wireless transmitting module and keys. The invention realizes the intelligent tracking and the automatic walking of the luggage rack through automatically controlling the singlechip and transmitting and receiving infrared signals, can recognize special personnel and realize the automatic tracking under the tracking mode and can be applied to crowd or environment complex conditions under the assisting mode.

Owner:SHANDONG UNIV

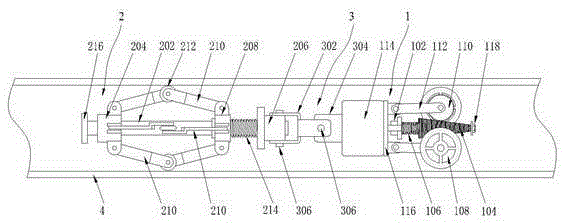

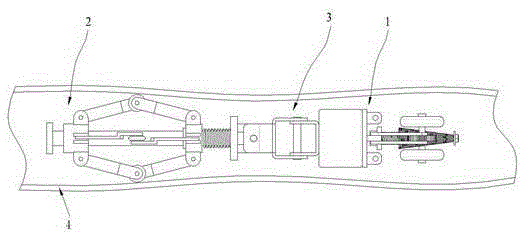

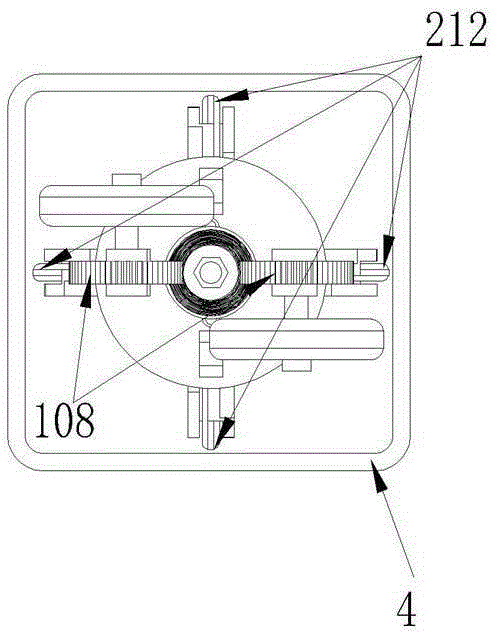

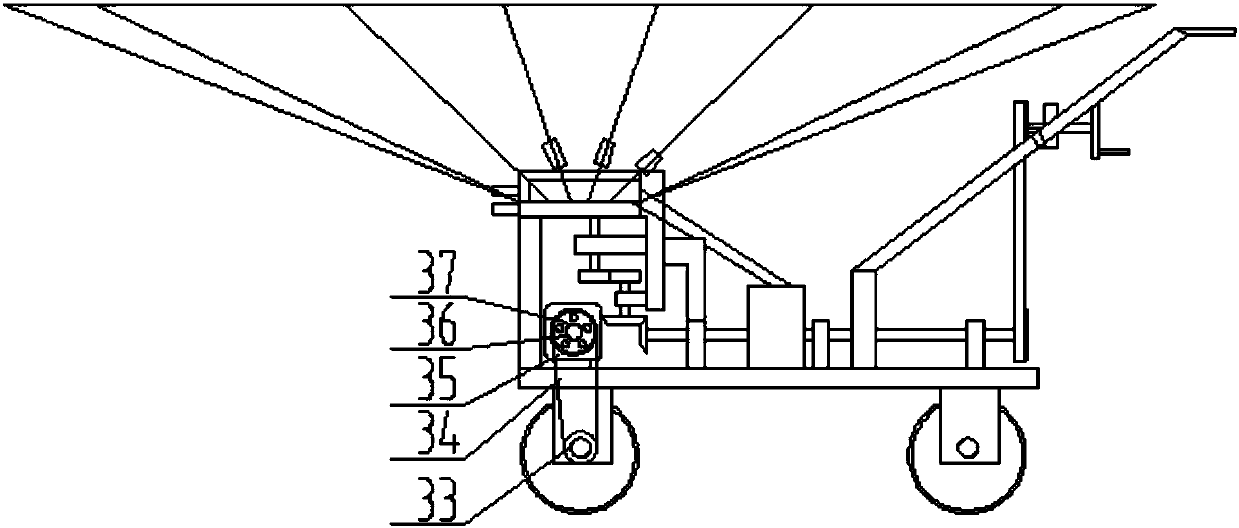

In-pipe walking robot

The invention discloses an in-pipe walking robot. The in-pipe walking robot comprises a running mechanism, a connecting rod assembly and a universal connecting mechanism connected with the running mechanism and the connecting rod assembly. The running mechanism comprises a transmission mechanism, a first pressure spring, two road wheels and two rocker connecting rods. The connecting rod assembly comprises a center rod, a front locking block, a rear locking block, a sliding block, at least two pairs of connecting rod slices, at least two pulleys and a second pressure spring. According to the in-pipe walking robot, the synergistic effect of worm gears, a worm and the first pressure spring is adopted, the close fit of the worm gears and the worm is retained, and the road wheels are made to roll on the inner wall of a pipe in a tightly attached mode. When the worm is in a shape of a taper or a circular truncated cone, the running mechanism can automatically adjust the interval of the worm gears in pipes with different diameters, so that the road wheels are ensured to make contact with the inner wall of the pipe all the time and the adhesive force is retained; due to the second pressure spring, the symmetrical pulleys are always pushed by the sliding block to make contact with the inner wall of the pipe, so that a flange plate is ensured to be positioned on the central axis of the pipe all the time, and an operating mechanism externally connected with the flange plate can run with the flange plate steadily.

Owner:S Z VICTOR AUTOMATION TECH

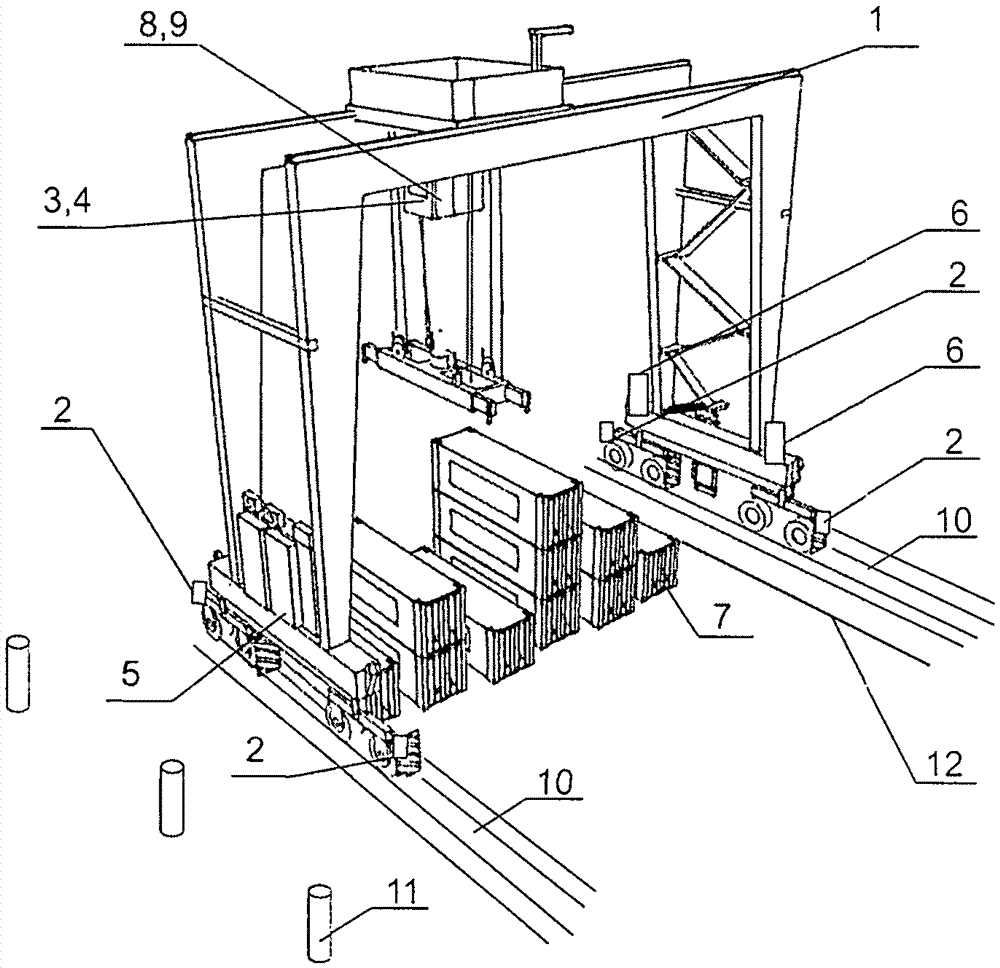

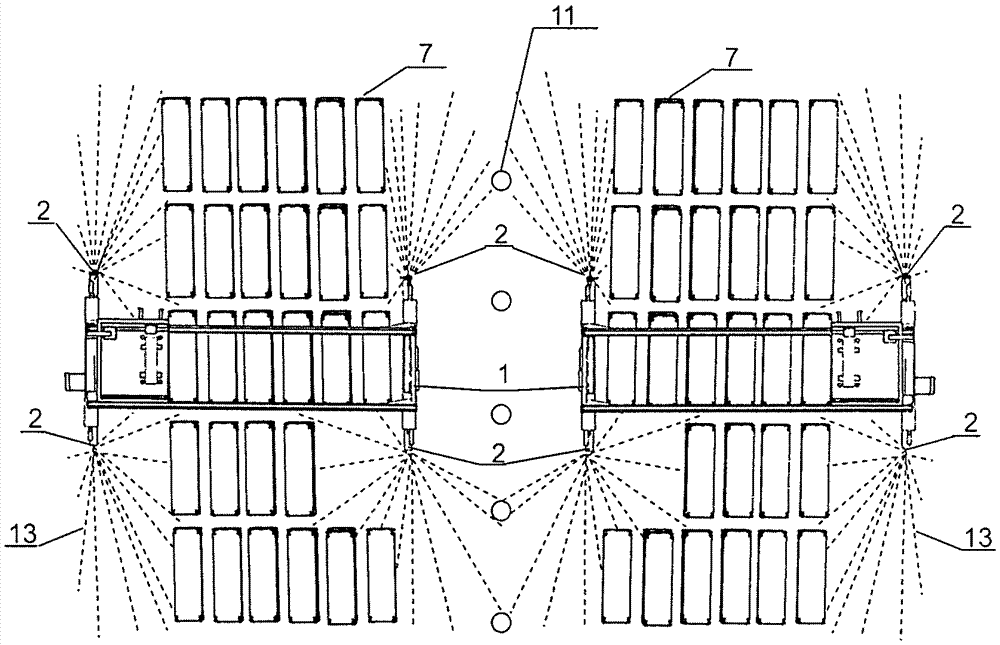

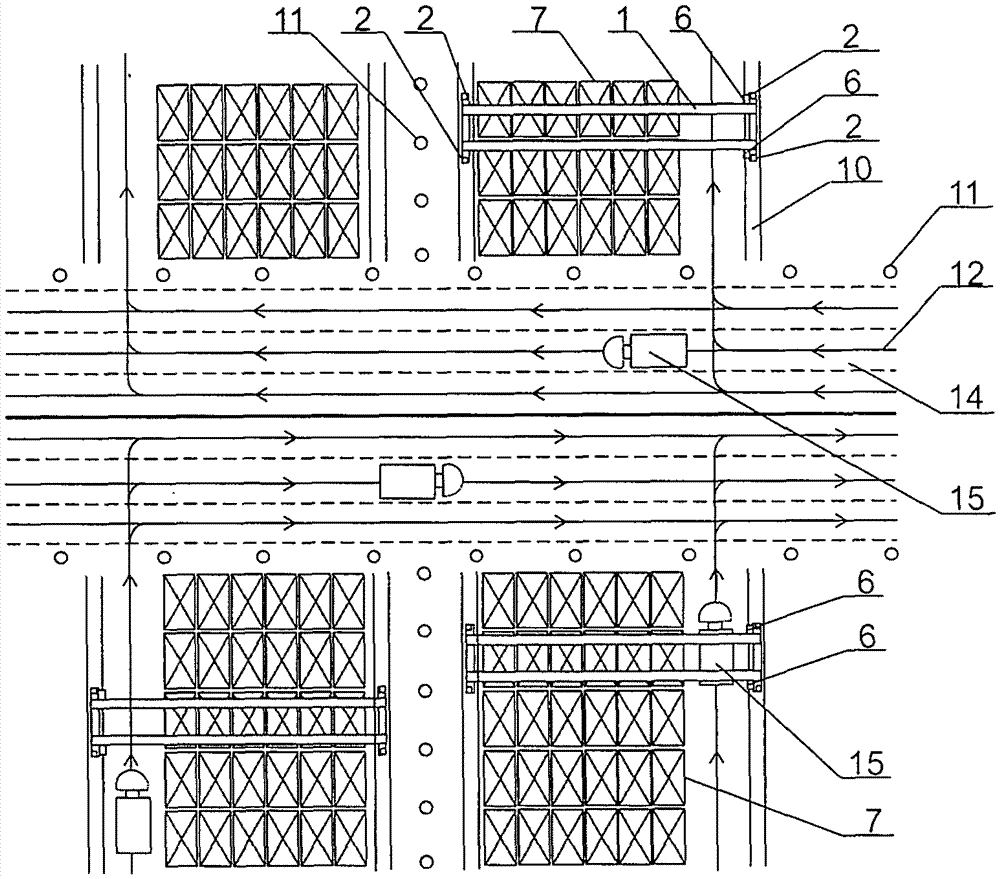

Container wharf flow equipment automatic walking method

InactiveCN106946049ARealize automatic walking correctionRealize automatic walkingStorage devicesImaging processingSimulation

The invention provides a container wharf flow equipment automatic walking method. Laser scanners are installed on four door leg tire front wheel brackets of a tire crane correspondingly, vertical columns are installed between the back surfaces of two tire crane lanes by a certain distance or the length of a container at intervals and are located in a straight line, the positions of the vertical columns are detected through the tire crane laser scanners, and automatic walking of the tire crane is achieved. Meanwhile, vertical columns are installed on the two sides of a road lane by a certain distance and are located in a straight line; vertical columns are installed on the inner sides of two door legs, close to the lane, of the tire crane correspondingly; and vertical columns are installed on the inner side and the outer side of each door leg of a bridge crane correspondingly. An ordinary container lorry is improved into an automatic navigation vehicle, the vertical columns higher than the top surface of the container, a camera and the laser scanners are installed on the navigation vehicle, walking datum line paint is at the center of the ground lane, the navigation vehicle shoots the walking datum line through the camera so as to conduct image processing and alignment, the positions of the vertical columns are detected through the scanners, and automatic walking of the navigation vehicle is achieved.

Owner:SHANGHAI HAILEI LASER TECH

Automatic urinal cleaning robot

PendingCN108049474AEvenly distributedEasy to cleanUrinalsLavatory sanitoryEngineeringDistance measurement

An automatic urinal cleaning robot comprises a photoelectric sensor, a lower lifting plate, a lead screw, a lifting motor, an upper lifting plate, curved guide rails, slider motors, sliders, a fixed plate, a plate-shaped sprayer, a guide pipe, a circular rolling brush, a circular rolling brush fixed block and the like. The robot is characterized in that the curved guide rails are mounted in grooves in four corners of the upper lifting plate, the sliders are matched with the curved guide rails, horizontal distance measurement sensors are arranged on the front side surfaces of the sliders, the sliders are connected with the slider motors, the circular rolling brush and the plate-shaped sprayer are positioned on the fixed plate, a plate-shaped sprayer support is hinged onto the fixed plate, two ends of the circular rolling brush fixed block are mounted on the plate-shaped sprayer support, the middle and lower portion of the plate-shaped sprayer support is connected with the upper end of abuffer spring, the circular rolling brush and the plate-shaped sprayer are mounted on the circular rolling brush fixed block, the plate-shaped sprayer is connected with a conveying pump through the guide pipe, a horizontal cylinder is fixed on a horizontal supporting plate of the fixed plate, a vertical motor is mounted on a vertical motor seat, and a spherical brush is mounted on a spindle of the vertical motor.

Owner:邵丽丹

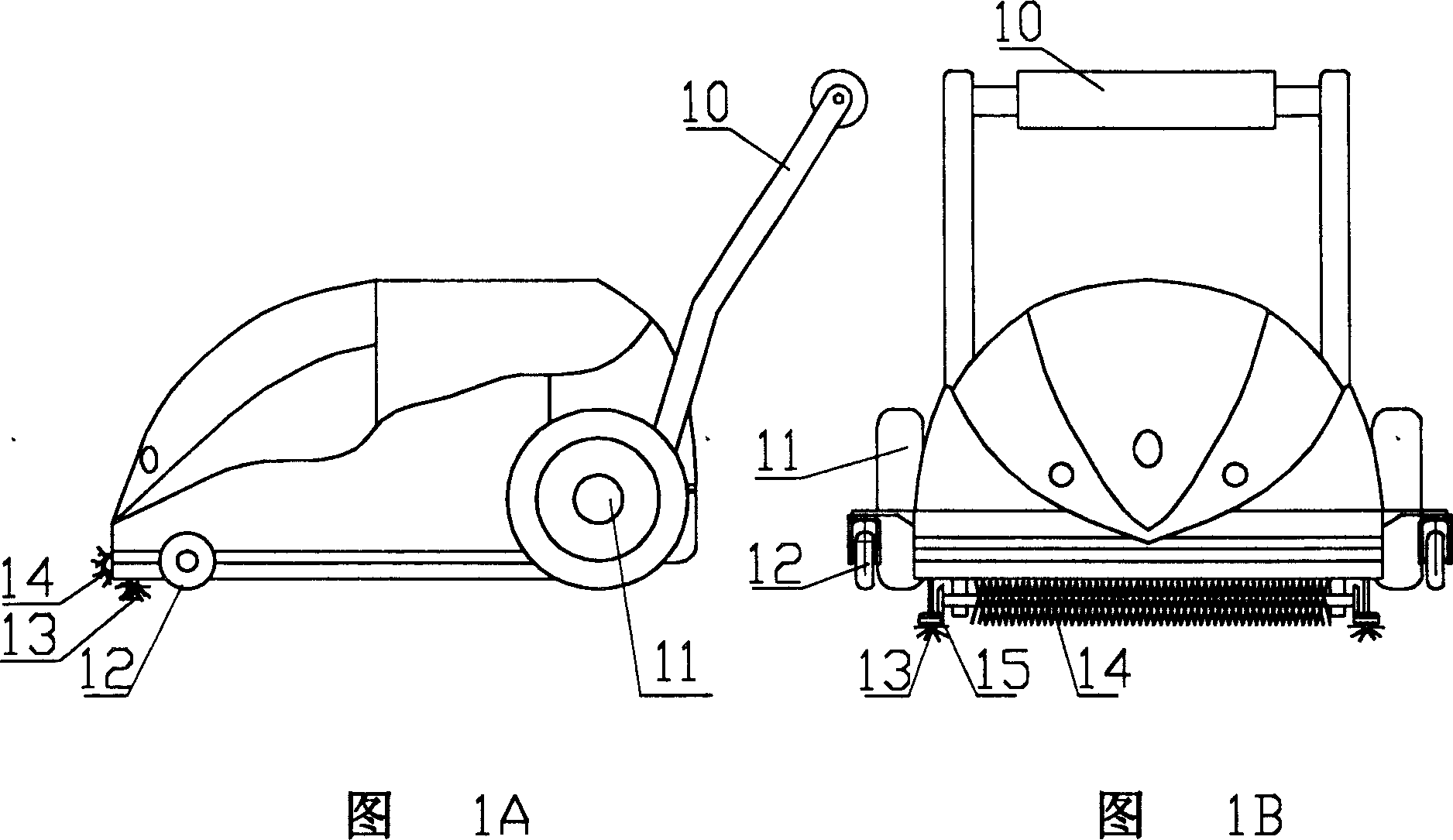

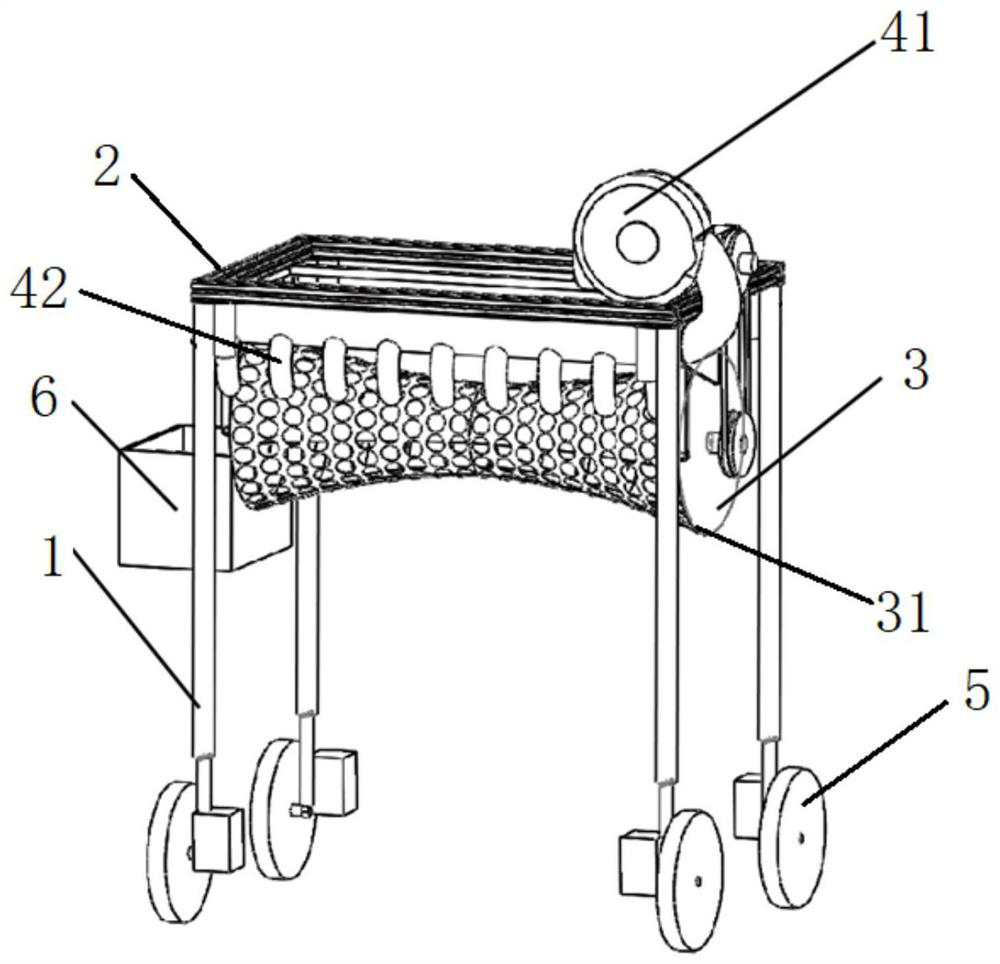

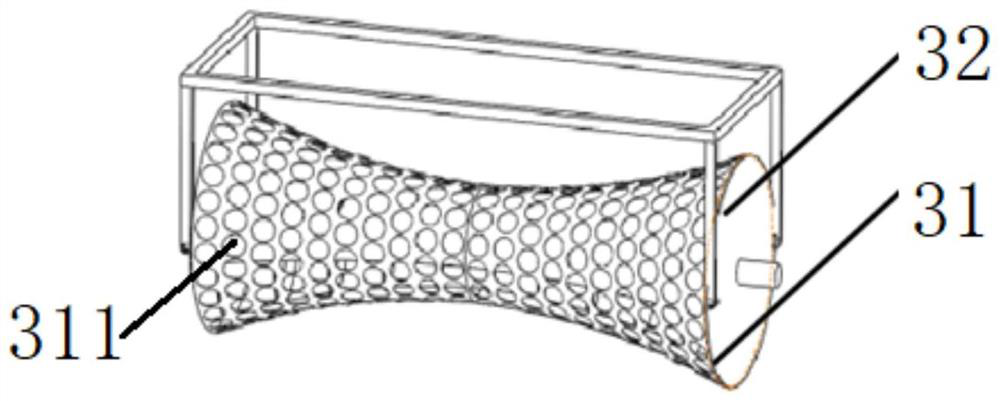

Mulberry picker

PendingCN107750641AReasonable structureEasy to manufacturePicking devicesRenewable energy machinesMotor speedGear wheel

The invention provides a mulberry picker, belonging to the field of agricultural machinery. The mulberry picker comprises a collecting device, a rack, a power and transmission device and a traveling device. By clockwise and anticlockwise rotation of a rotary rocking bar, a transmission system can be used for controlling meshing between a gear and an arc-shaped gear rack, a collecting umbrella is opened and closed to wrap a mulberry tree to form a wrapping and encircling surface with an area of 4-5 square meters below the mulberry tree, by shaking the mulberry tree, mulberries can fall in the collecting umbrella, the collecting umbrella is used for collecting the mulberries, and the mulberries fall in a hopper through a collecting pipeline. A motor can also be used for driving a main shaftto rotate to open or close the collecting umbrella, and a motor can be used for driving the traveling device to lead a machine to advance in the field. The mulberry picker has a reasonable structure,and is easy to manufacture, when the motor is used as power in the using process, the motor speed can be adjusted to control the traveling speed of the device, in addition, the work efficiency of thedevice is dozens of times greater than artificial picking, the manufacture cost is relatively low, so that the mulberry picker is suitable for wide-range popularization.

Owner:SICHUAN ACAD OF AGRI SCI SERICULTURE INST

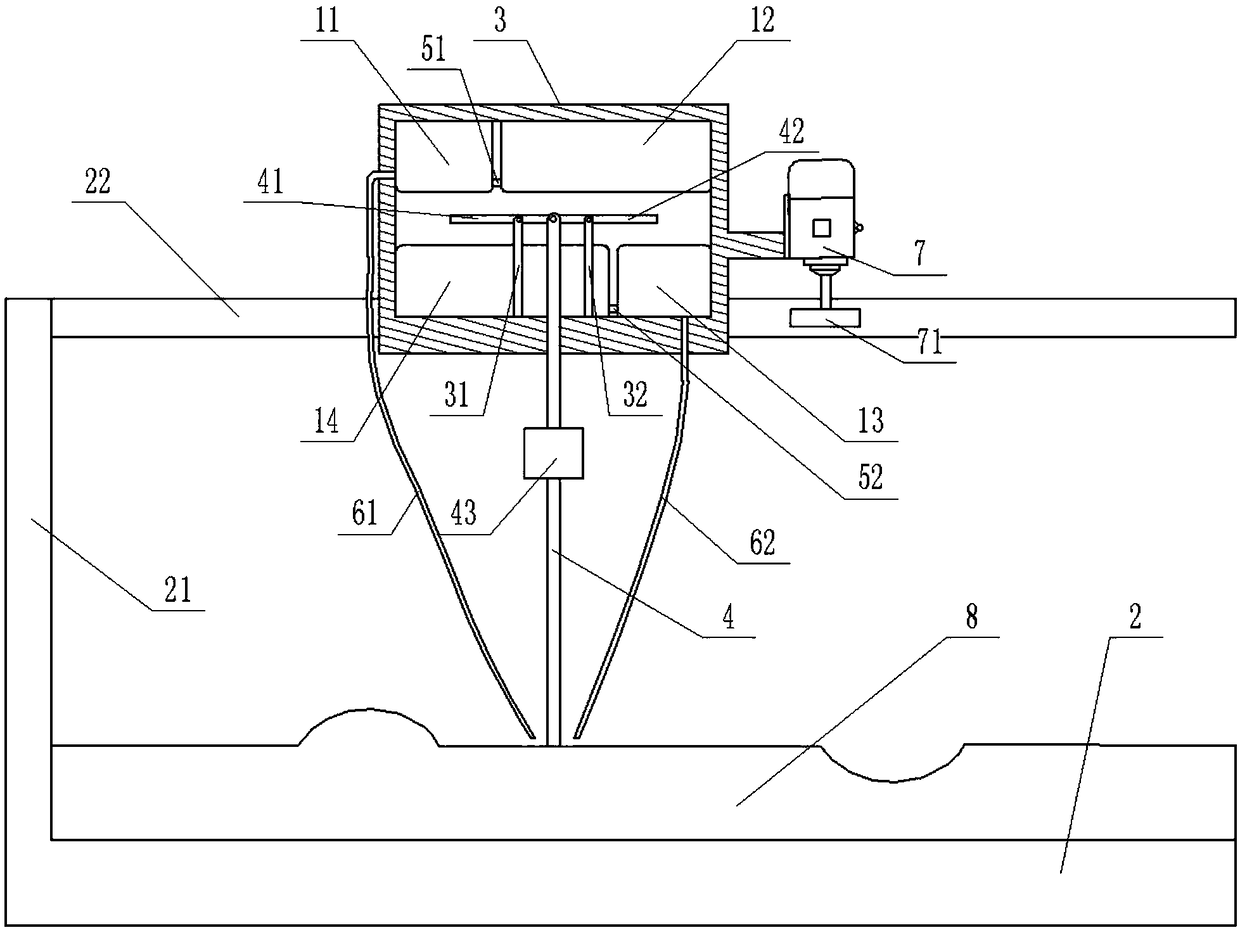

Water using wipe floor cleaning machine

InactiveCN1919134AGuaranteed cleaning qualityRealize automatic walkingCarpet cleanersFloor cleanersWater useDrive wheel

The invention discloses a water rag grazing cleaning machine, which comprises the following parts: walking, cleaning and water systems, wherein the walking part contains rack with back driving wheel and front guide wheel, fixing shaft with rotatable cleaning part, rotary disc rack, rag wiping and brushing device, wherein the rotary disc rack is encased on the fixing shaft, the rotary disc driving motor is set on the rack, which contains deceleration driving device from rotary disc rack, the rag can wipe device on the rotary disc rack, which contains brushing wheel, water squeezing pressure wheel and water sprayer, the water system supplies clear water and effluent reserving groove and cleaning groove, which provides clear water and gathers effluent in the effluent groove.

Owner:郑明珠

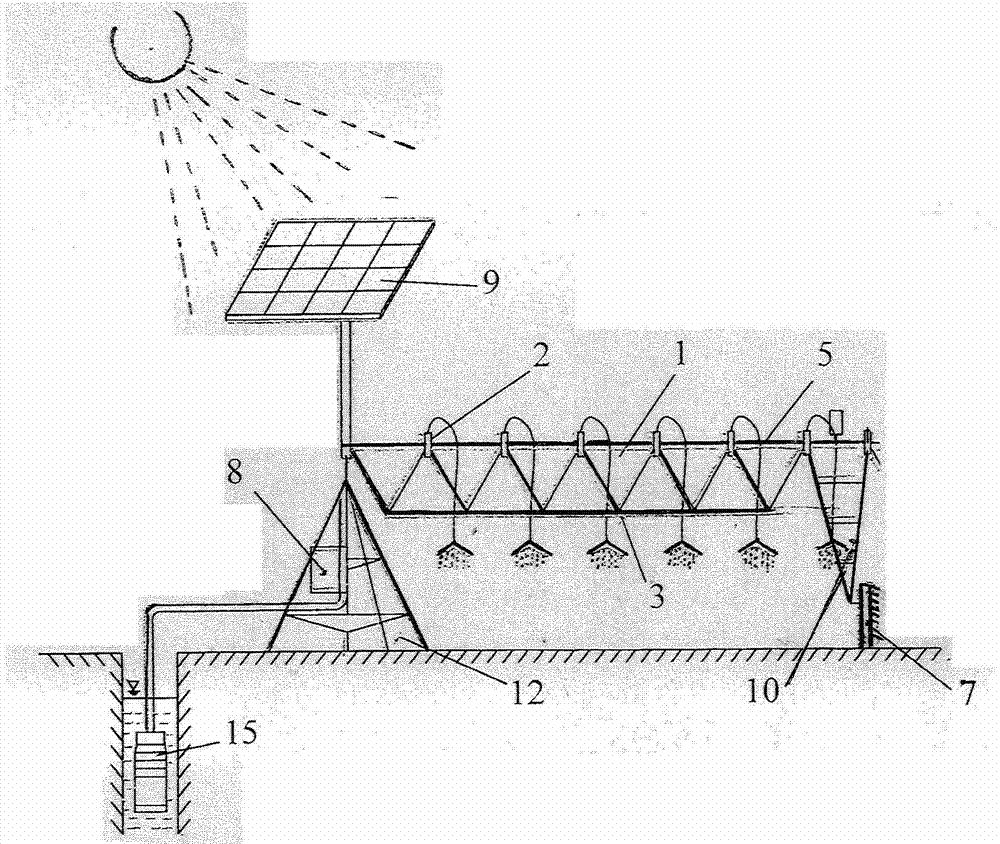

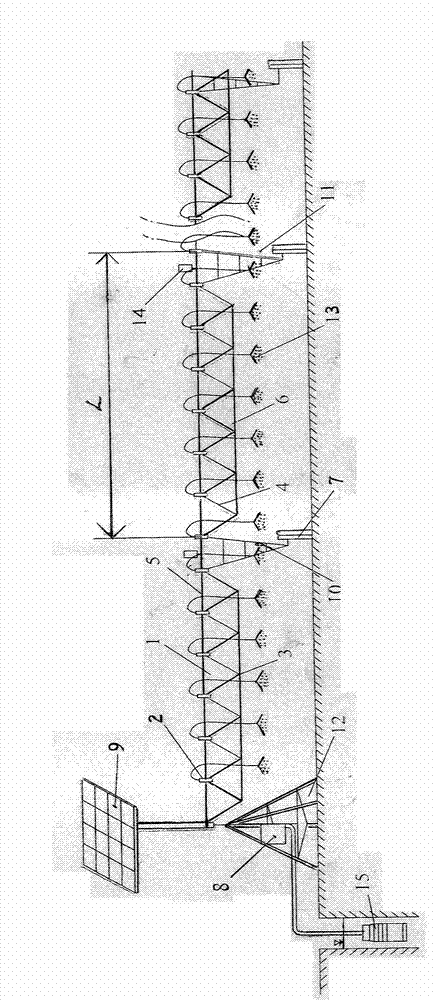

Center pivot light sprinkler irrigation system driven by solar energy

ActiveCN103039321ARealize automatic walkingSave energyClimate change adaptationWatering devicesElectric machineryMechanical equipment

A center pivot light sprinkler irrigation system driven by solar energy belongs to the field of agriculture mechanical equipments. The center pivot light sprinkler irrigation system driven by solar energy includes a center supporting base, tower vehicles, a tail end cantilever, an electronic control synchronizing system and a plurality of trusses, wherein the center supporting base can rotate around the center pivot light sprinkler irrigation system, the tower vehicle is arranged on a rotating arm and a plurality of trusses are provided with sprinkler heads and have a flexible connection between each other so as to adapt to sloping field walking operations. The trusses which are provided with a span of dozens of meters and a connection between each other are supported on a plurality of tower vehicles and have a configuration of the opening and closing of the electronic control synchronizing system and motors and walking wheels arranged on the driving tower vehicle. A piece of large solar panel which connects with a power supply device which is capable of being charged is arranged on the upper portion of a center pivot base. The power supply device which is capable of being charged is arranged on the center pivot base. The other end of the power supply device which is capable of being charged is connected with a well pump of water supply and is connected with the sprinkler heads arranged on branch points of the trusses by a main water conveying pipe. The sprinkler irrigation device is capable of walking automatically relying on solar energy, saves energy, has a light structure, is environment friendly, is moved conveniently and is low in cost.

Owner:CHINA IRRIGATION & DRAINAGE DEV CENT +3

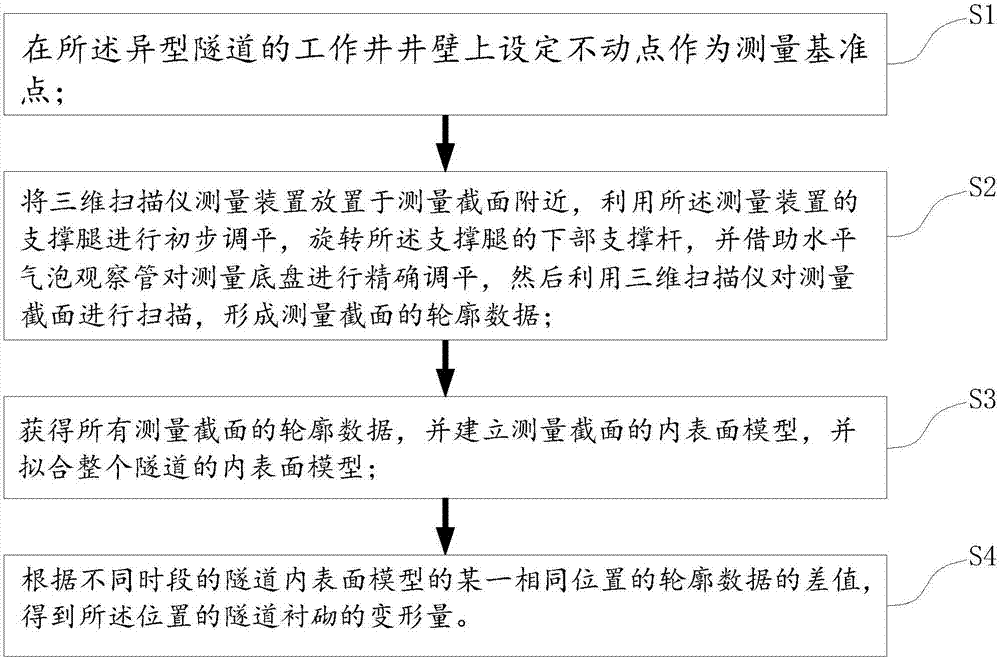

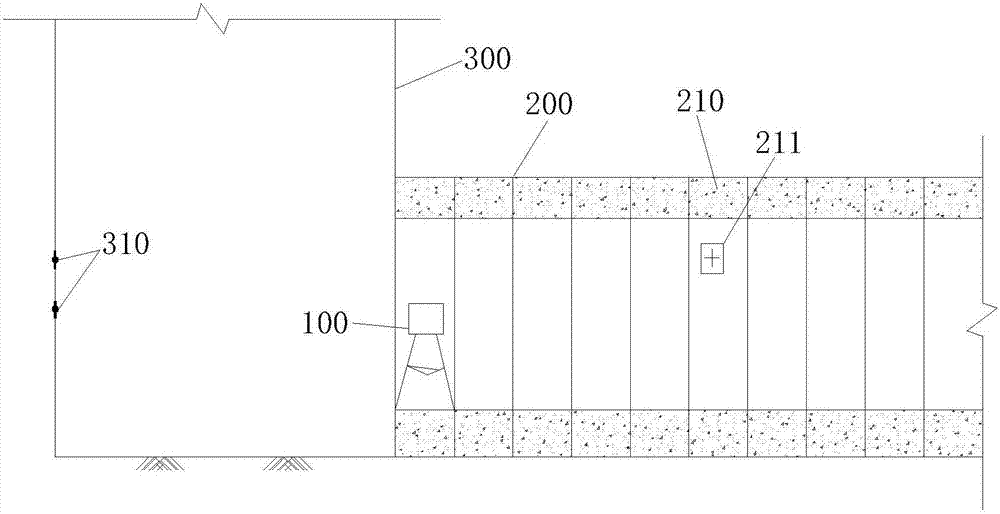

Special tunnel lining deformation monitoring method

PendingCN107091616AHigh measurement accuracyFast measurementUsing optical meansScannerData acquisition

The invention relates to a special tunnel lining deformation monitoring method, which belongs to the technical field of tunnel construction safety monitoring. According to the monitoring method, a three-dimensional scanner is used to carry out contour data acquisition on a measurement section of the tunnel lining, an inner surface model of the tunnel lining is built, the inner surface model of the whole tunnel lining is fit, and according to the contour data difference at the same position of the tunnel inner surface model during different time periods, the deformation of the tunnel lining at the position is obtained. The special tunnel lining deformation monitoring method provided by the invention has the advantages that the measurement precision is higher; the measurement speed is quicker; and as the later data processing is completed by computer software, the working efficiency can be greatly improved.

Owner:SHANGHAI CONSTRUCTION GROUP

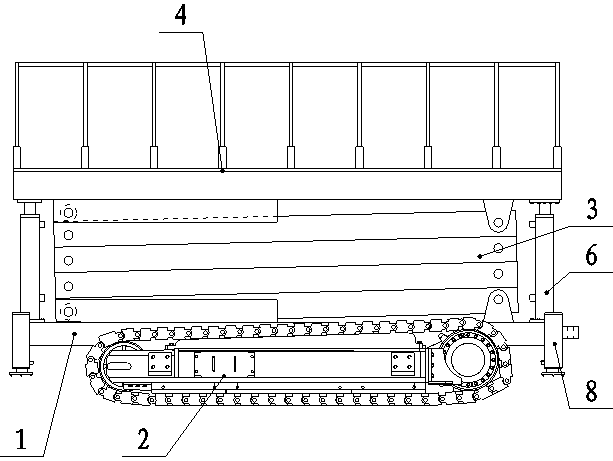

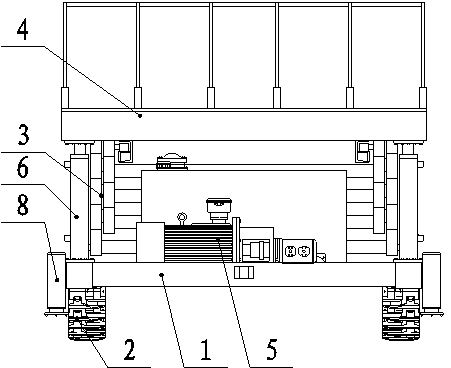

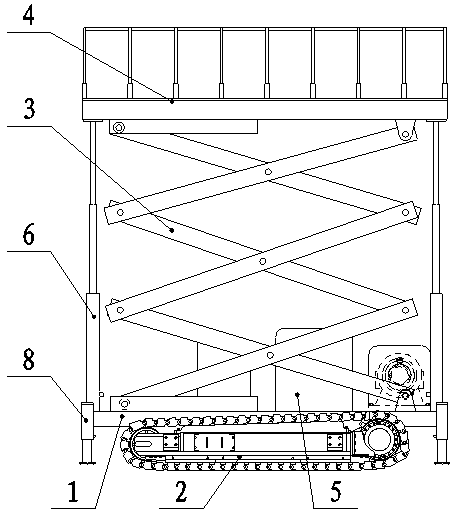

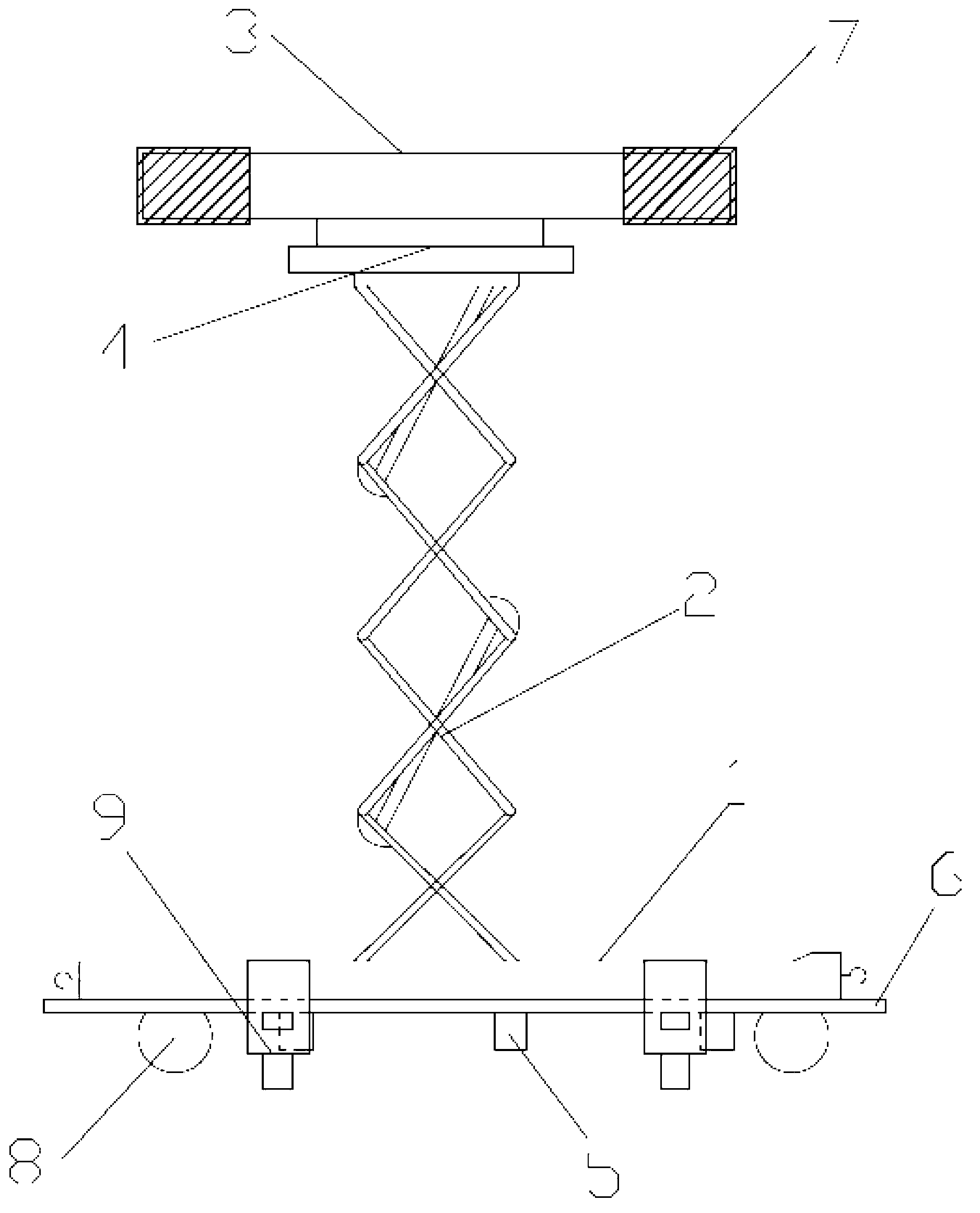

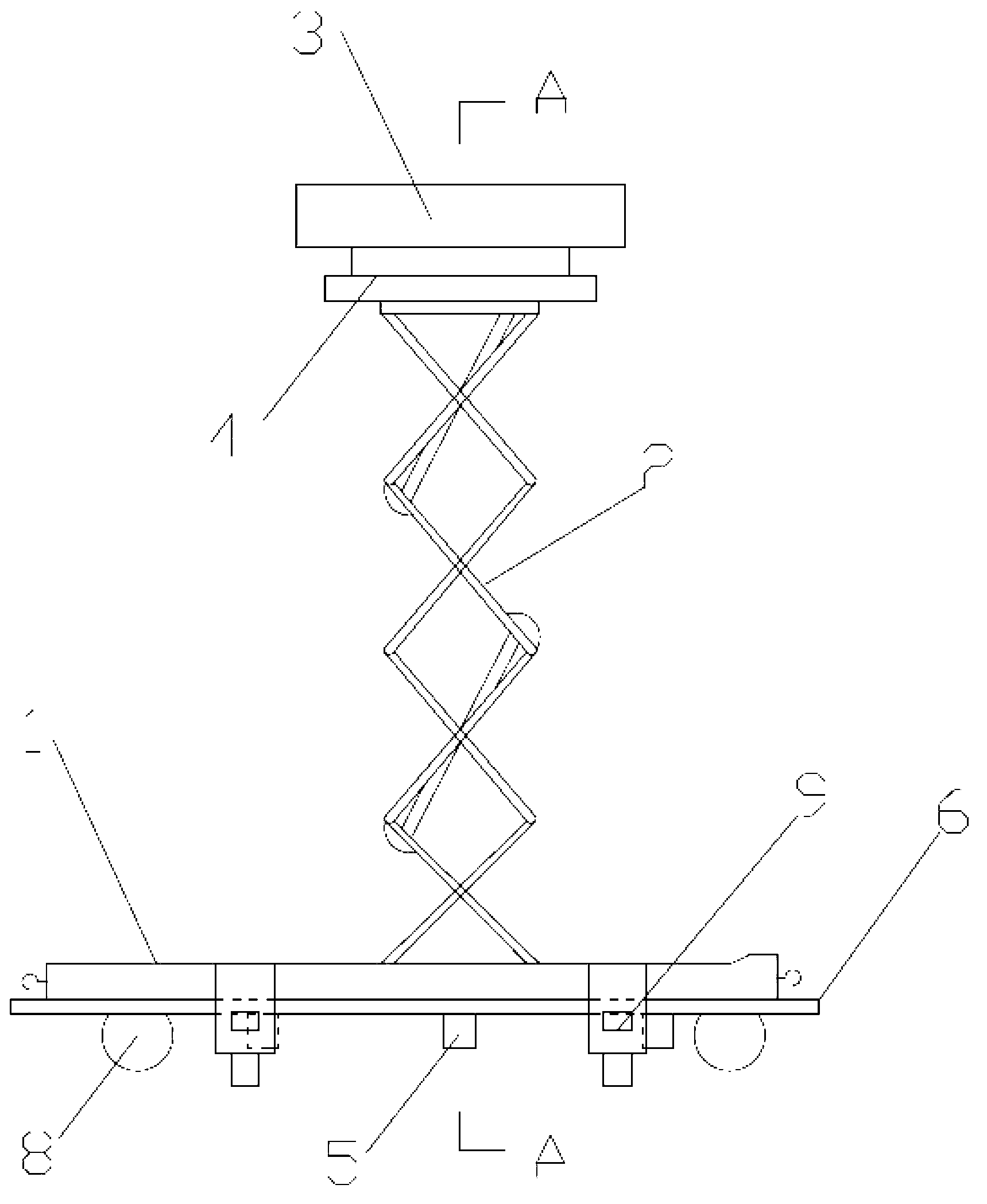

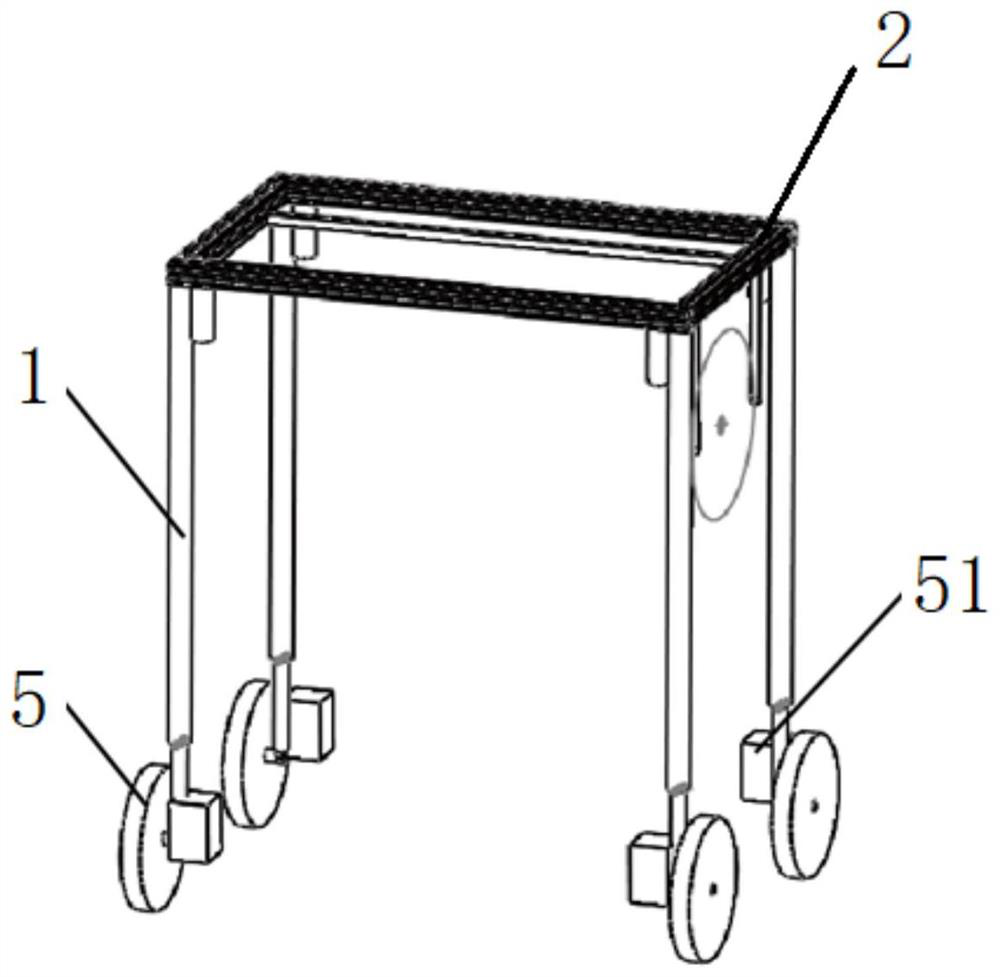

Mining lifting machine

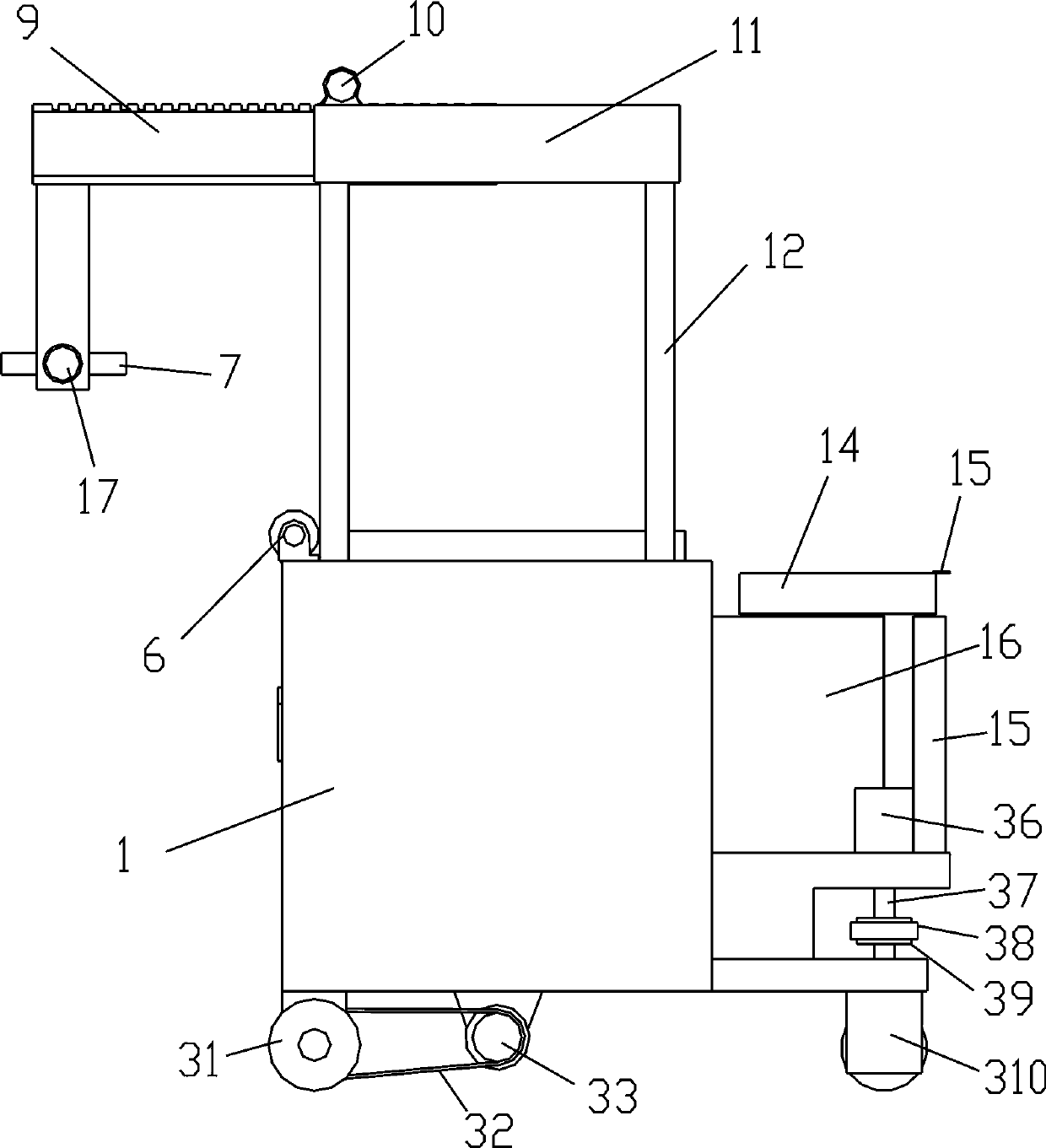

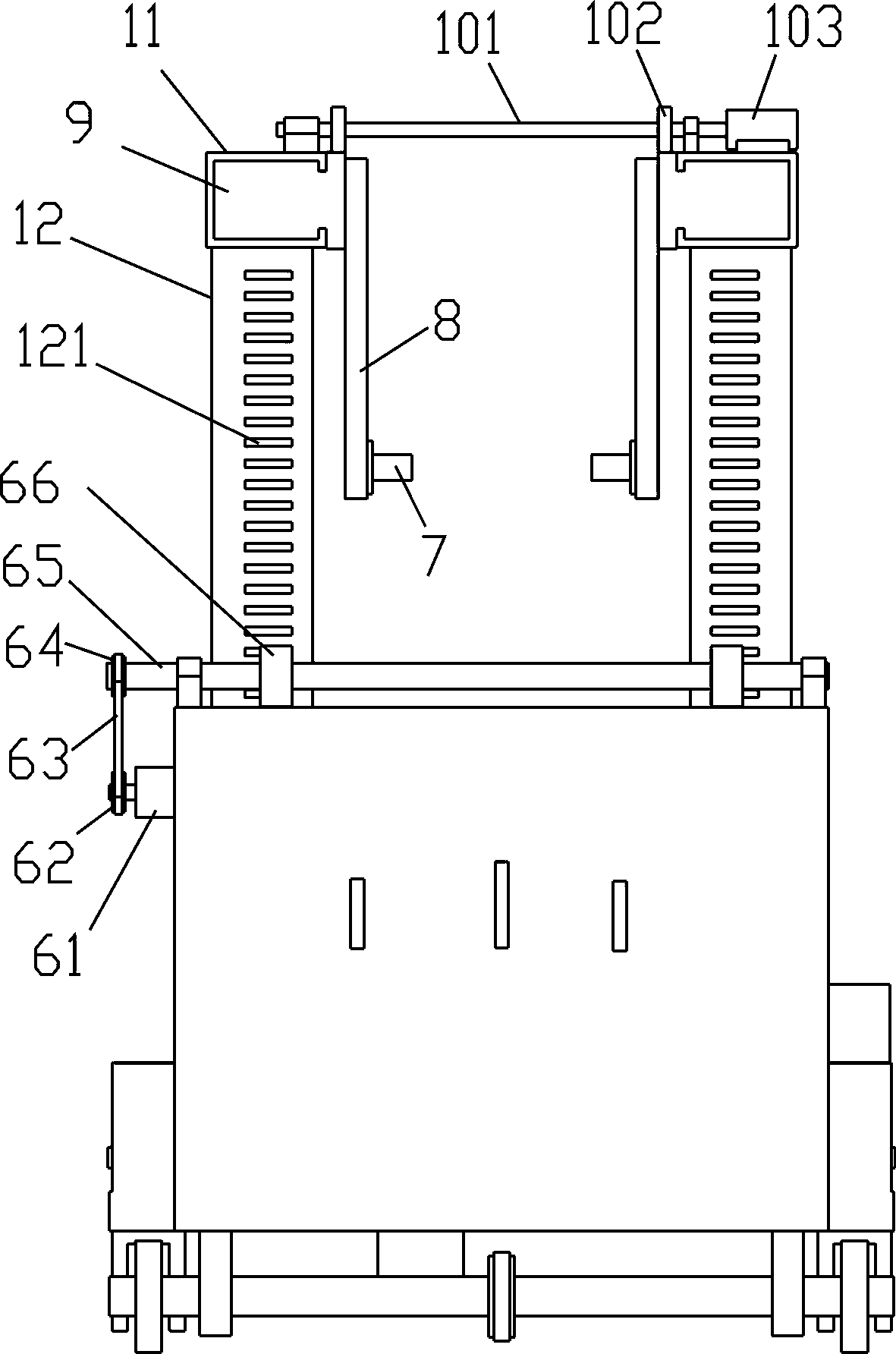

InactiveCN103991830ARealize lifting operationSimple structureLifting devicesAssistive device/technologyEngineering

The invention belongs to the technical field of auxiliary devices for high-position installation, and relates to a mining lifting machine to achieve the technical purpose of providing the mining lifting machine favorable for high position installation. The mining lifting machine is simple in structure and safe and convenient to use. According to the technical scheme, the mining lifting machine comprises a machine frame, a walking part, elevators, a platform, a pump station and telescopic oil cylinders. The lower portion of the machine frame is provided with the walking part, the machine frame is connected with the platform through the two elevators, the elevators are of structures that a plurality of connecting rods are hinged into retractable connected rhombus frameworks, the ends of the two connecting rods at the lower ends of the elevators are hinged to the machine frame, the ends of the two connecting rods at the upper ends of the elevators are hinged to the bottom face of the platform, the part, between the two elevators, of the machine frame is provided with the pump station, and the four end corners of the machine frame are connected with the four corresponding end corners of the platform through the telescopic oil cylinders with the power supplied by the pump station. The mining lifting machine is mainly used for helping workers to carry out the high-position operation in a roadway.

Owner:SHANXI DONGHUA MACHINERY

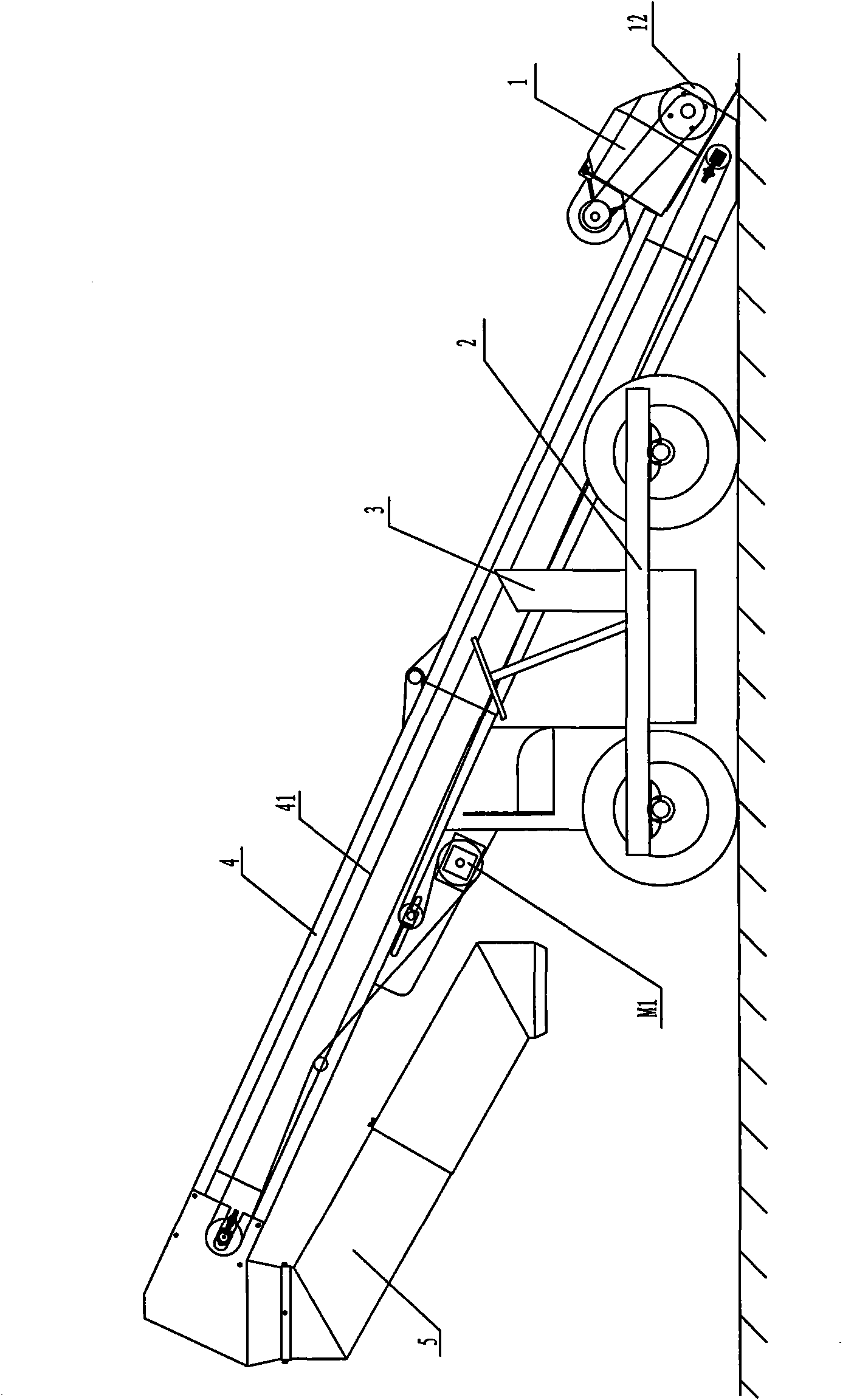

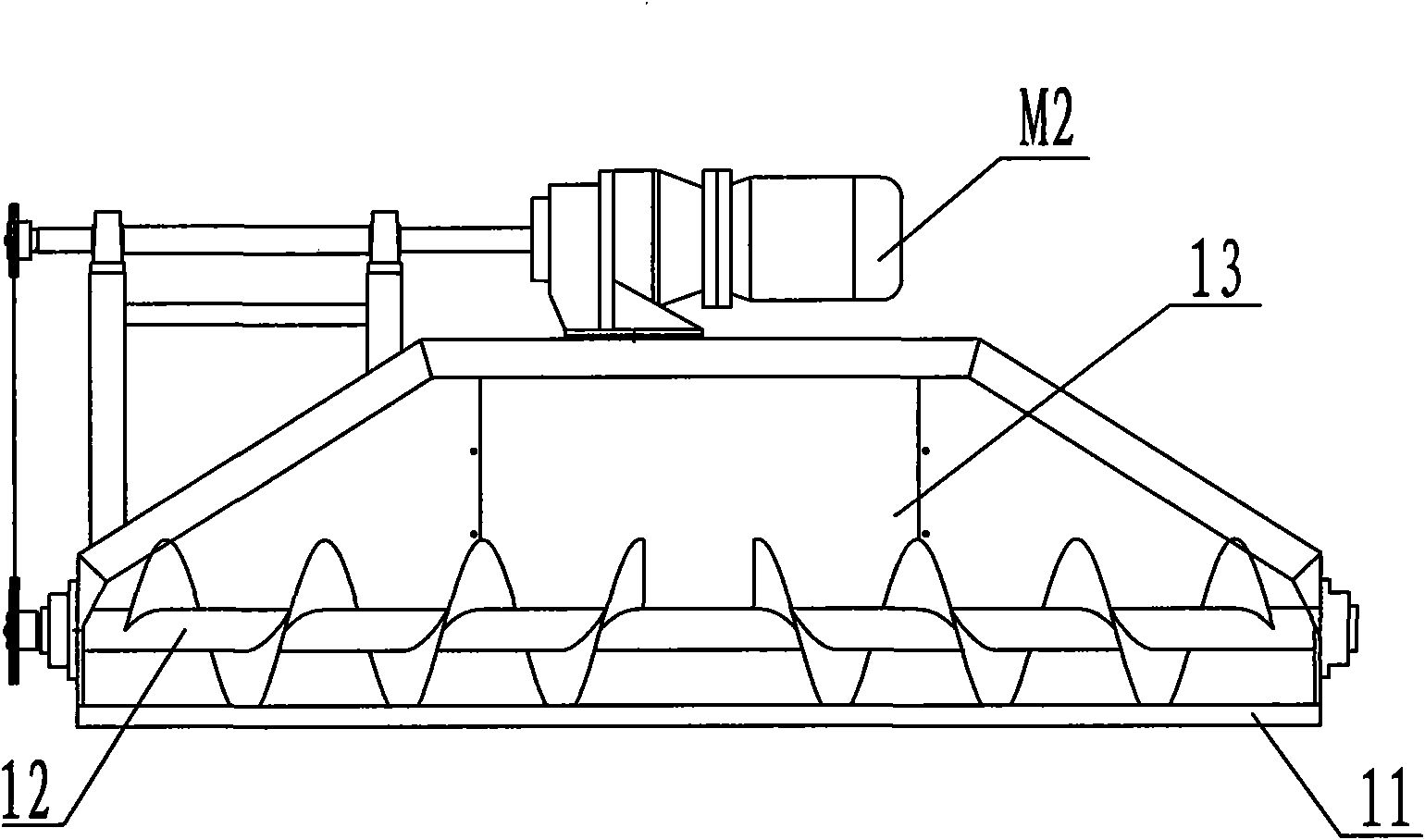

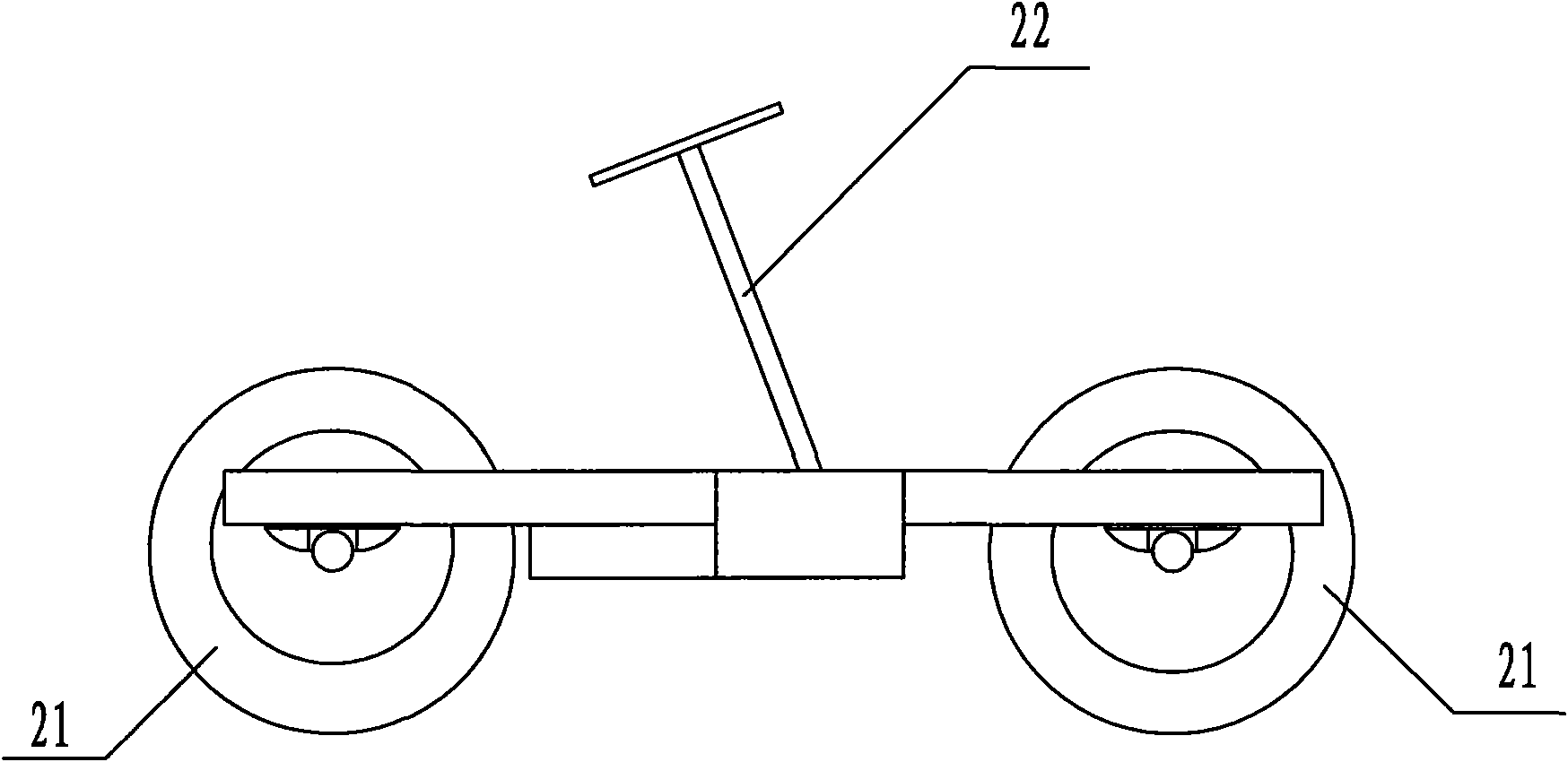

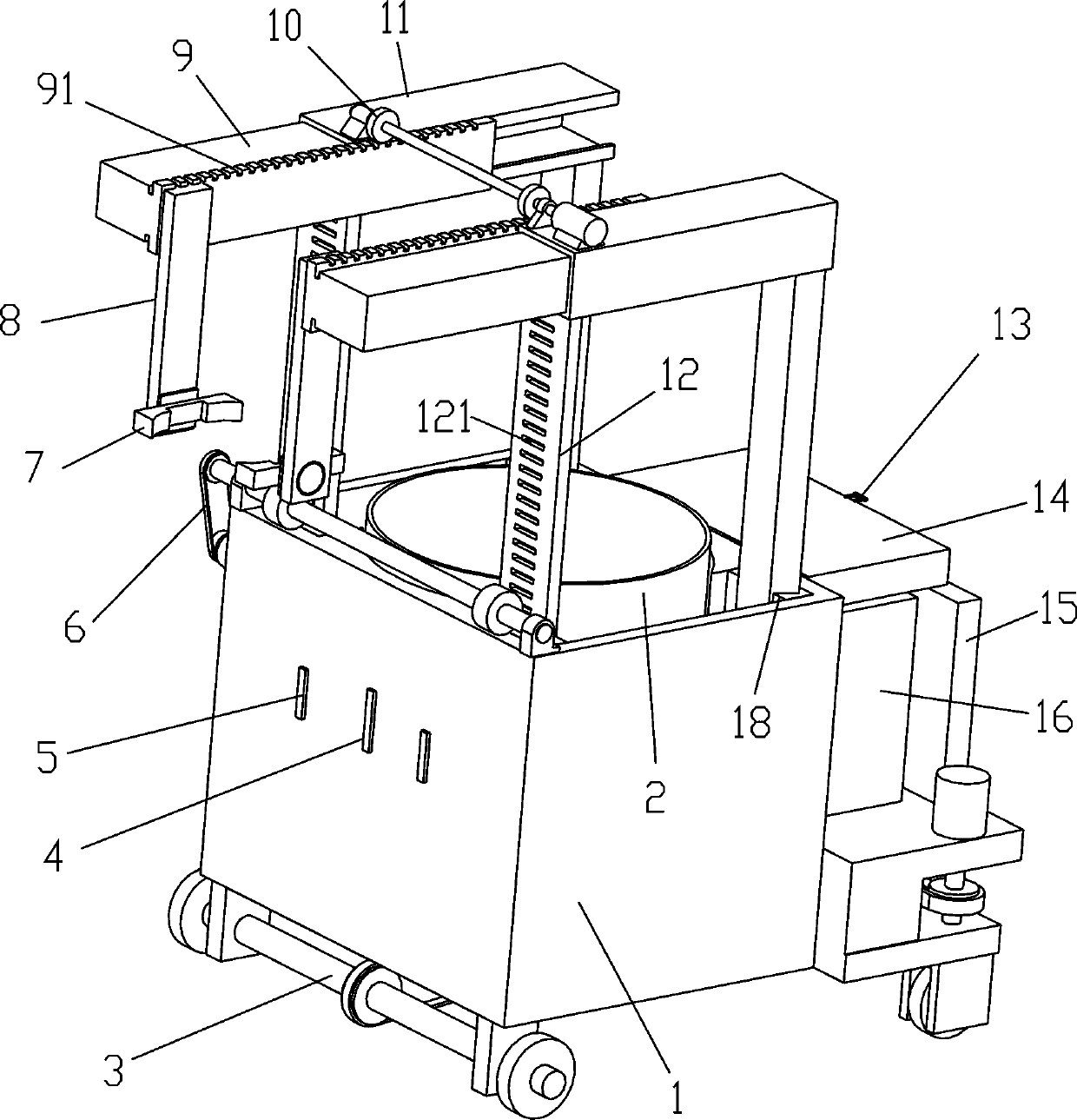

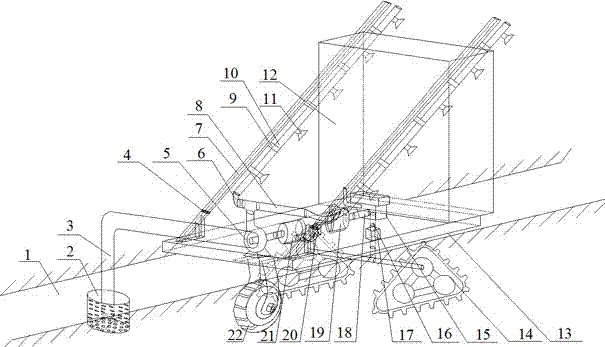

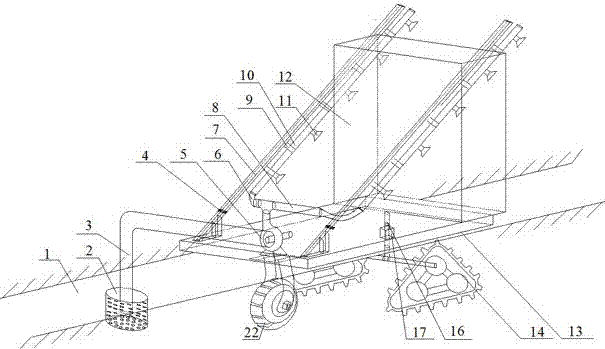

Grain scraper

InactiveCN101554960ARealize automatic walkingSolve slippery technical problemsLoading/unloadingState of artEngineering

The invention relates to the field of grain scrapers, in particular to automatic production equipment used for grain ex-warehousing and loading. The automatic production equipment comprises a traveling gear, a grain scraping device, a delivery mechanism, a grain outlet and a control device. The grain scraper adopts a screw shaft for grain scraping, thereby solving the technical problem that moving parts are easily wound; the grain scraper can automatically stop when encountering barriers, thereby improving safety of the operation; the traveling gear is of vehicle structure, thereby realizing automatic traveling of the grain scraper; front-tooth tires are adopted, thereby solving the technical problem that the grain scraper easily slips when moving on a smooth ground or a ground with grains; the delivery mechanism is made into a shape of a seal groove, thereby reducing dust and noise pollution; the grain outlet can rotate, thereby facilitating mating of the grain scraper and equipments like vehicles, barns and the like. With high comprehensive performance, experiments show that the grain scraper can scrape 120t of grains per hour during actual use, with efficiency far higher than that of the grain scrapers in the prior art.

Owner:樊自芳

Line patrol robot

InactiveCN113022869AWon't pullAffect sagAircraft componentsClosed circuit television systemsStructural engineeringMechanical engineering

The invention provides a line patrol robot which comprises a box body, a top plate is fixedly connected with the top of the box body, top boxes are fixedly connected with the two sides of the top of the top plate, electric telescopic rods are fixedly connected with the bottoms of the inner walls of the top boxes, the output ends of the electric telescopic rods penetrate through the top boxes and extend to the tops of the top boxes, the end, extending to the top of the corresponding top box, of the output end of each electric telescopic rod is fixedly connected with a fixed box. The invention relates to the technical field of circuit inspection. According to the power transmission line inspection equipment, the top of the box body is fixedly connected with the top plate, automatic walking can be achieved, hanging of different split conductors is facilitated, meanwhile, when encountering an obstacle, the whole equipment can be driven to move through a flying device, and the quality of power transmission line inspection work is guaranteed; the equipment can be remotely controlled and can be widely applied to inspection work of power transmission lines.

Owner:ZHENGZHOU UNIV OF IND TECH

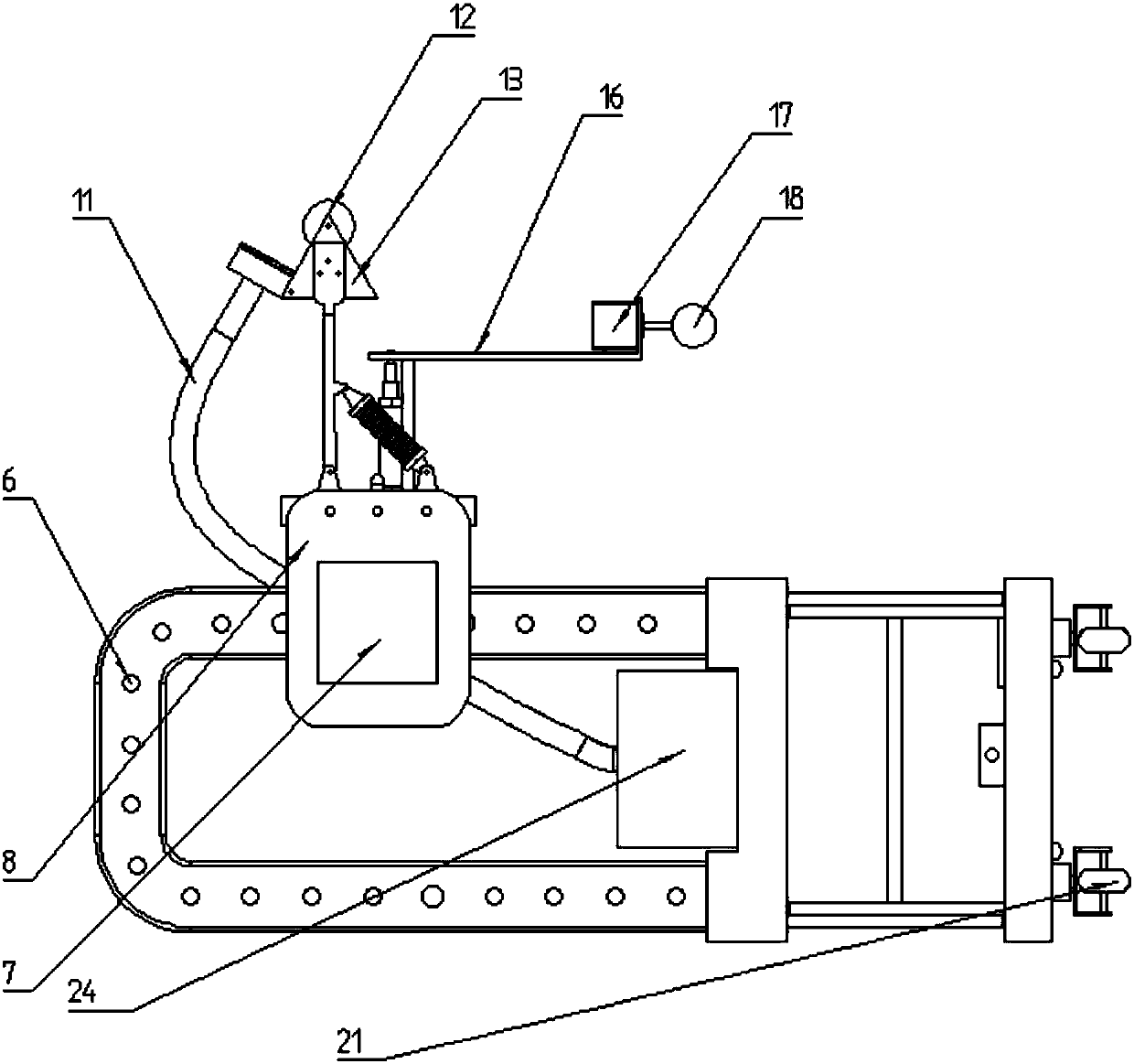

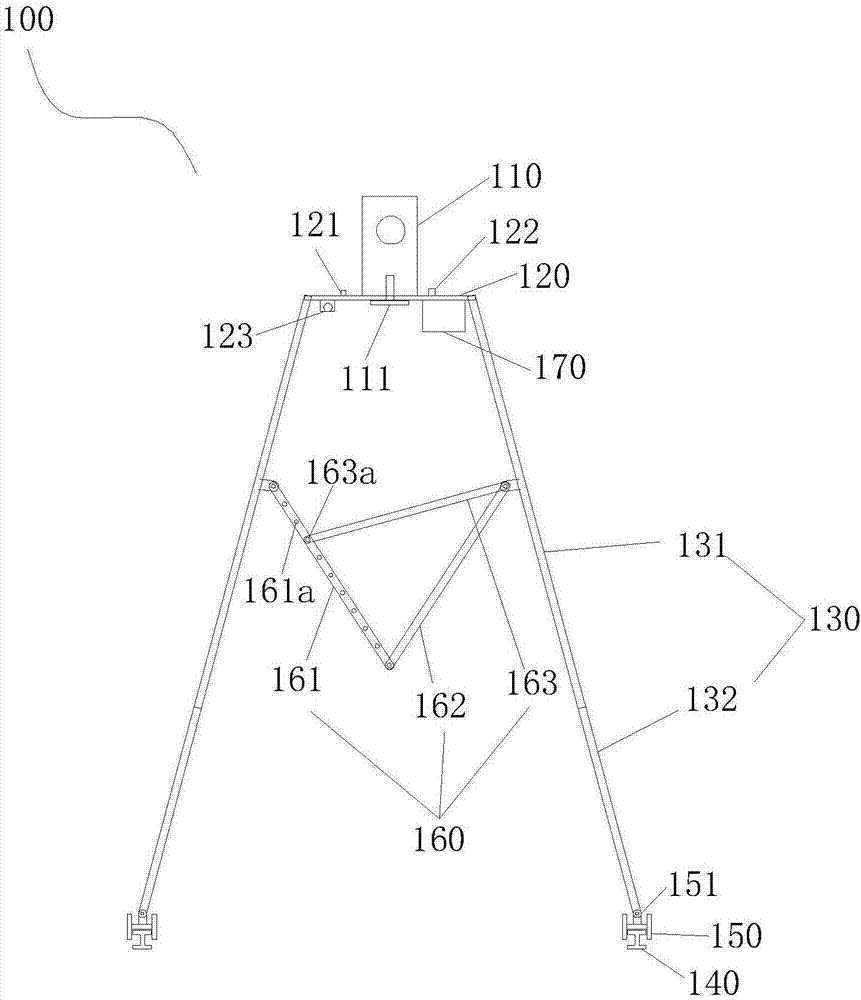

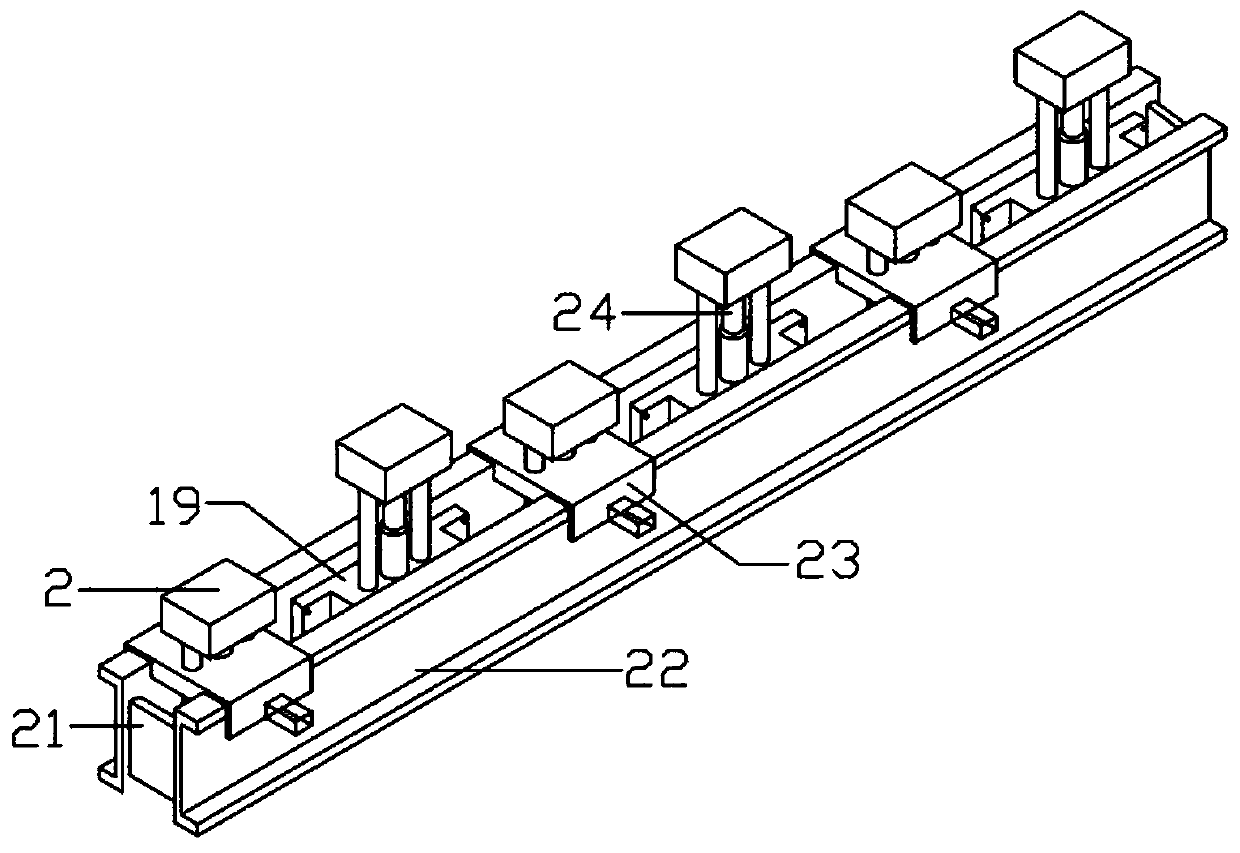

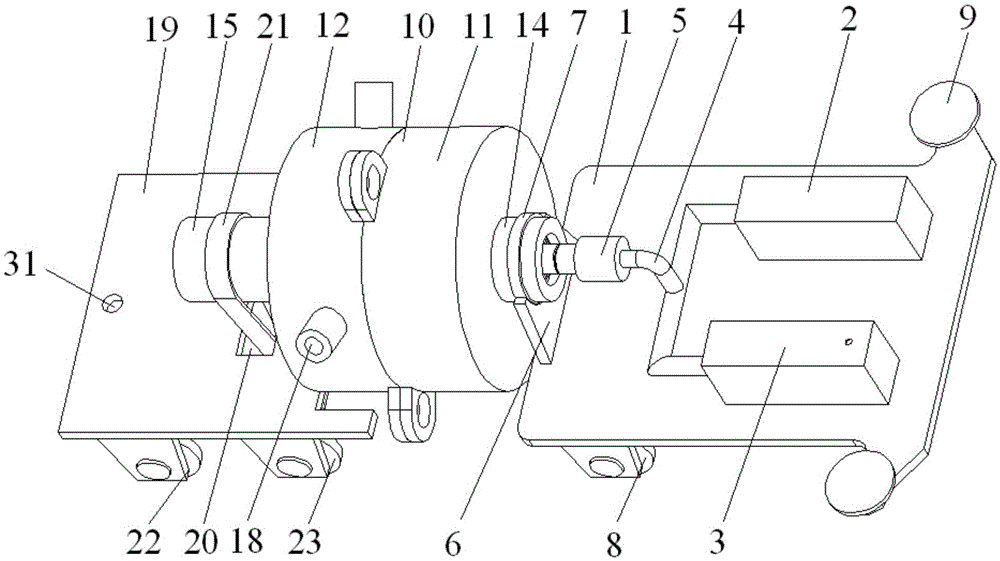

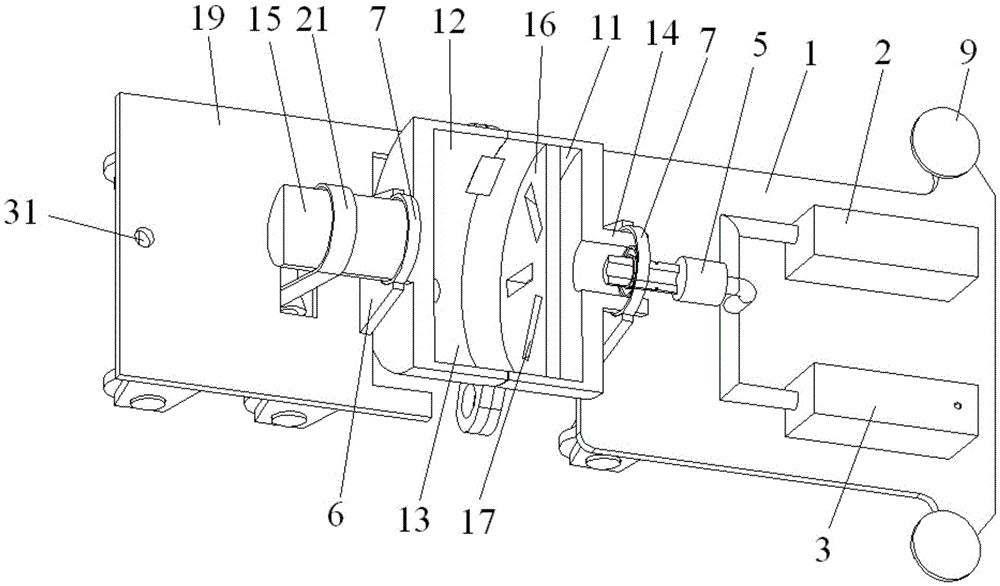

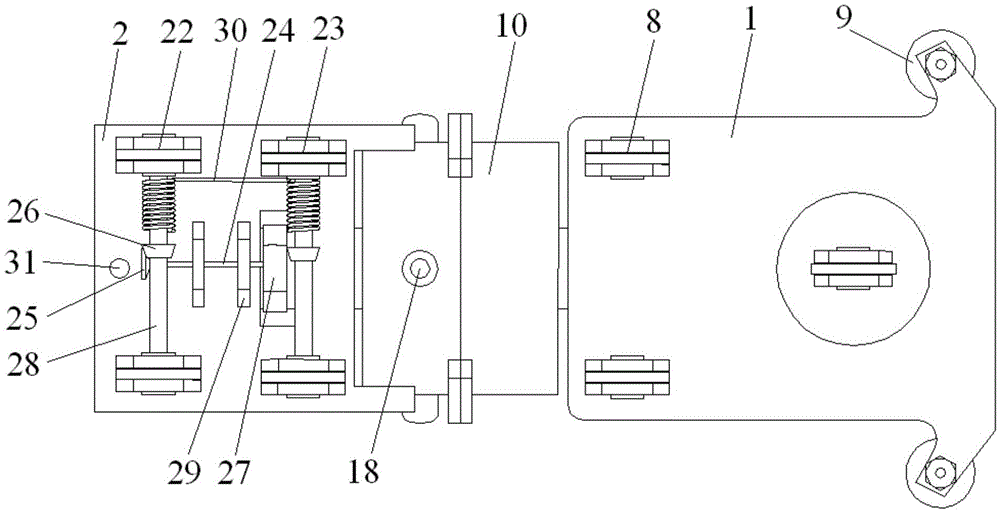

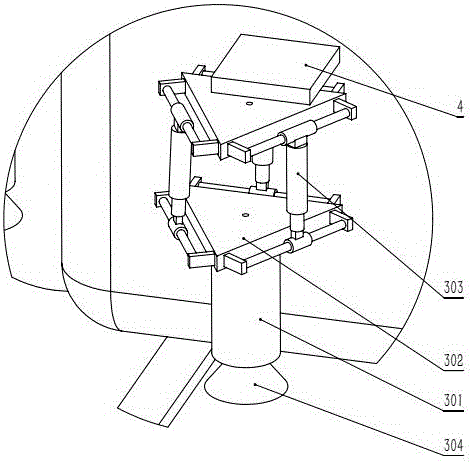

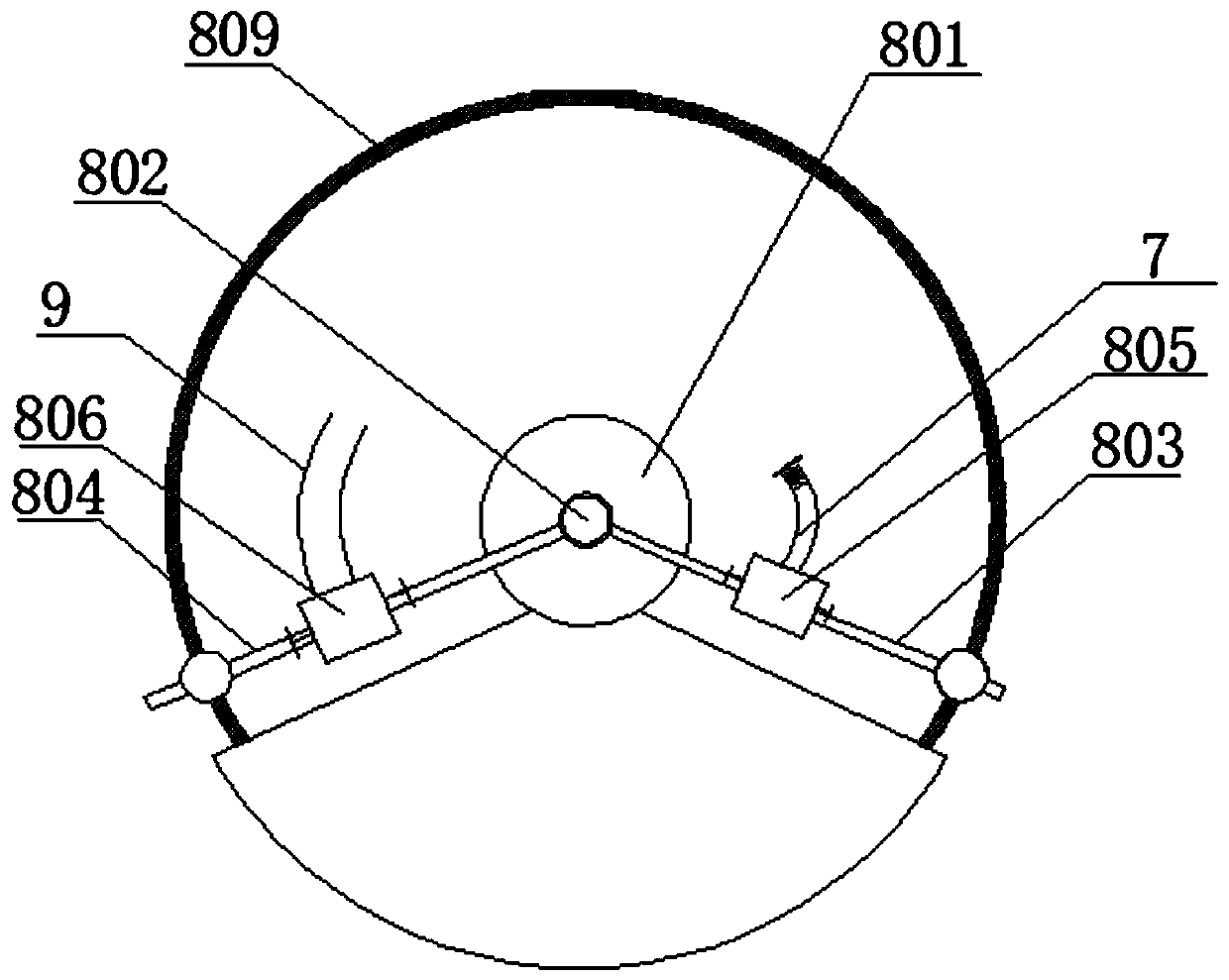

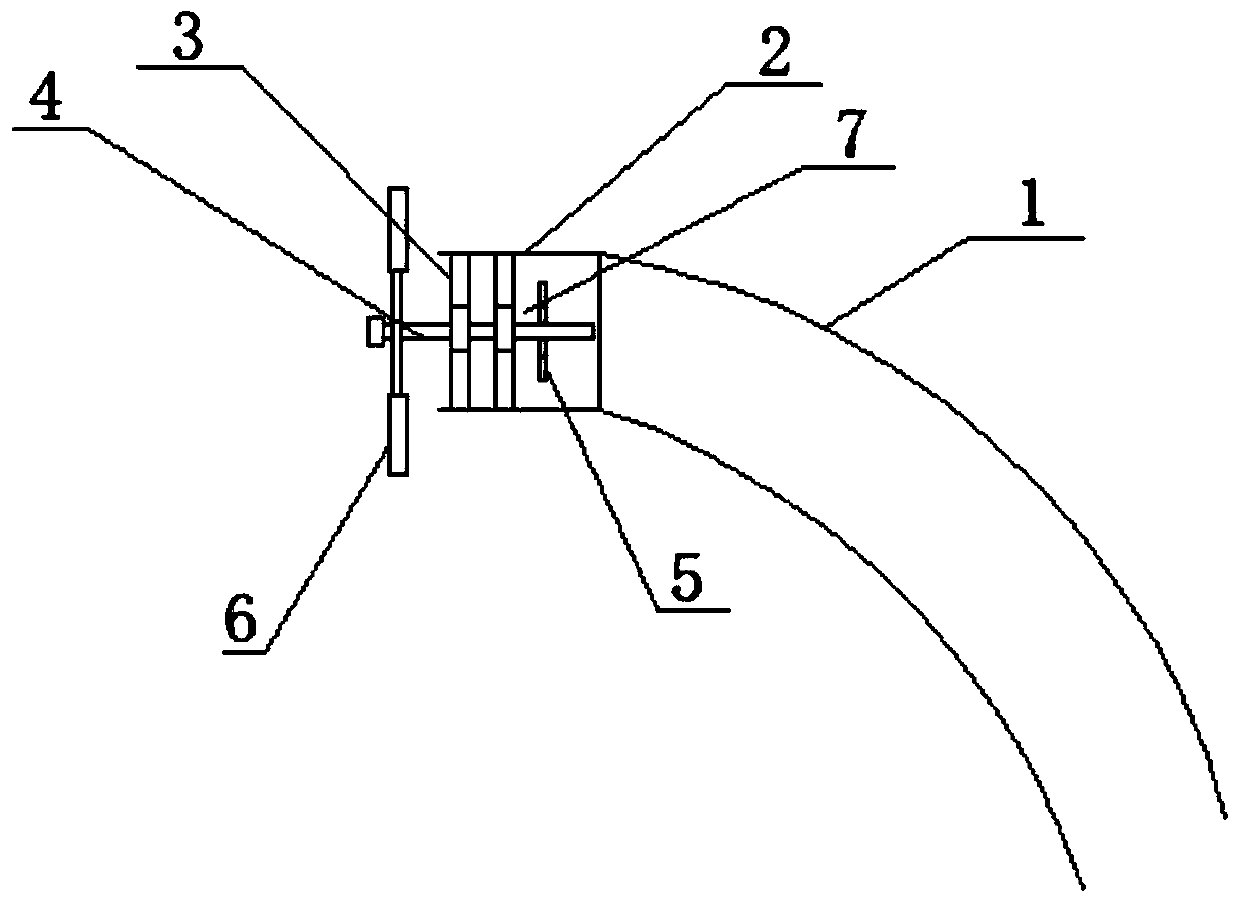

Suspension self-shifting type full-circumference rotary mounting machine and application method

ActiveCN111365041ARealize automatic walkingImprove installation efficiencyUnderground chambersTunnel liningStructural engineeringMechanical engineering

The invention discloses a suspension self-shifting type full-circumference rotary mounting machine and an application method. According to the technical scheme, the suspension self-shifting type full-circumference rotary mounting machine comprises a self-shifting type stepping beam device, a vertical telescopic mechanism, a rotating mounting mechanism and a mounting arm, the mounting arm is fixedto the front end of the rotating mounting mechanism, the rotating mounting mechanism is fixed under the self-shifting type stepping beam device through the vertical telescopic mechanism, and can moveforward and backward with the self-shifting type stepping beam device; the rotating mounting mechanism comprises a load-bearing platform, the load-bearing platform is connected with the self-shiftingtype stepping beam device through the vertical telescopic mechanism; a rotating telescopic mechanism is arranged at one end of the load-bearing platform, and the rotating telescopic mechanism can drive the mounting arm to rotate and expand horizontally; and the mounting arm comprises an electromagnetic sucker capable of moving in the vertical direction, and the electromagnetic sucker is capable ofabsorbing arc plates to be installed after being electrified. According to the suspension self-shifting type full-circumference rotary mounting machine and the application method, the arc plates canbe installed at any position of 360 degrees full circumference, and the installation efficiency is high.

Owner:SHANDONG JIANZHU UNIV

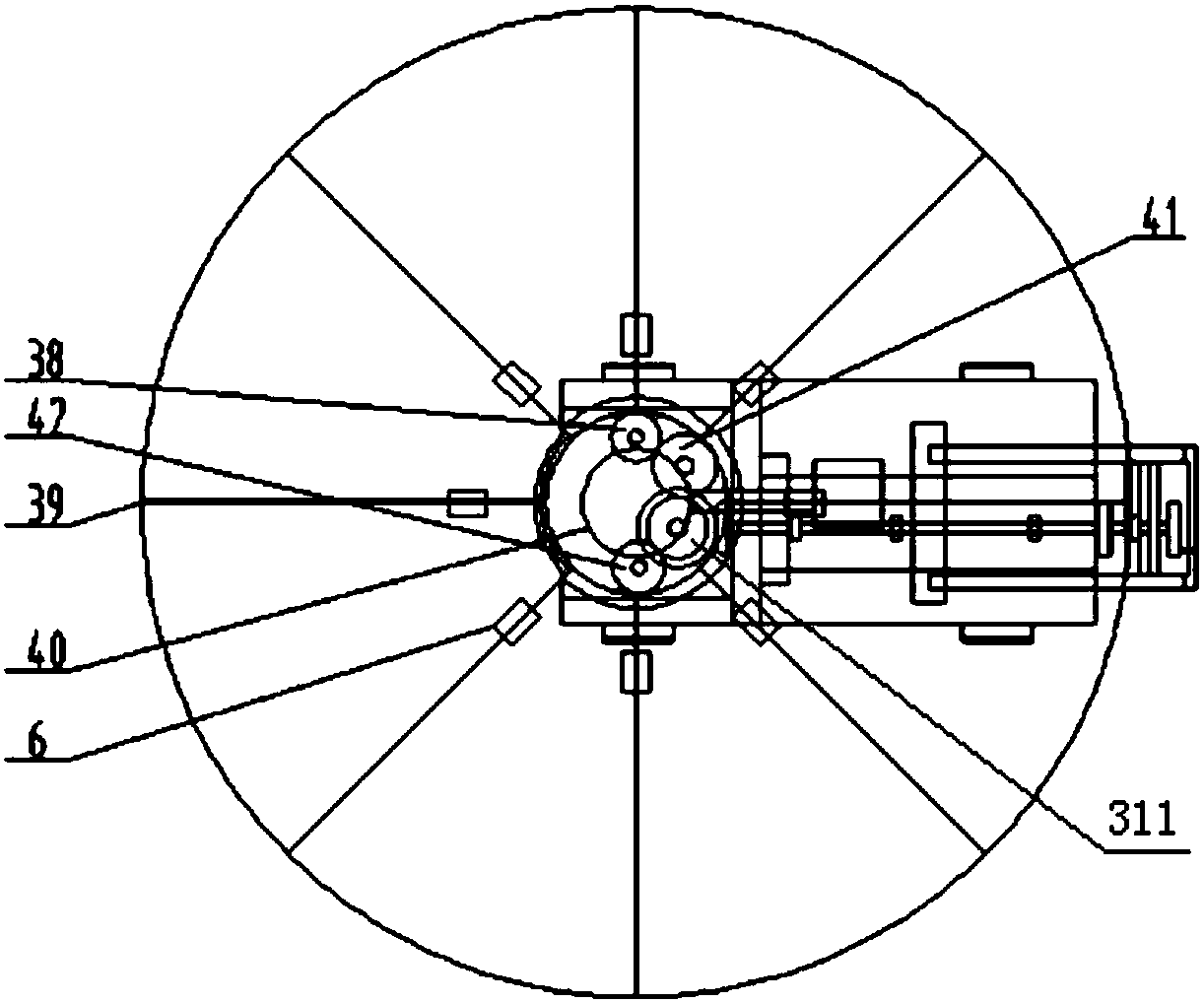

Passive self-walking pipeline inner wall spray-coating car and application method thereof

ActiveCN105618308ASpray evenlyAvoid safety hazards such as agingSpraying apparatusHydraulic motorDrive shaft

The invention discloses a passive self-walking pipeline inner wall spray-coating car and an application method thereof. The spray-coating car comprises a hydraulic motor, a first chassis and a second chassis, wherein the first chassis and the second chassis are arranged at the two sides of the hydraulic motor; an energy accumulator and an unloading machine are arranged on the first chassis and are connected to the hydraulic motor; a rotary disc is arranged inside the hydraulic motor; a spray-coating pipe is arranged at the sidewall of the hydraulic motor; a second wheel group and a third wheel group are arranged at the bottom of the second chassis; a driving shaft is arranged between the second wheel group and the third wheel group; a first bevel gear is arranged at one end of the driving shaft and is meshed with a second bevel gear of the second wheel group; a belt wheel is arranged at the other end of the driving shaft and is meshed with one end of a belt; the other end of the belt is connected with the hydraulic motor; a high-pressure paint can be input to the hydraulic motor by virtue of the energy accumulator; the high-pressure paint flows through the rotary disc inside the hydraulic motor and is sprayed out via the spray-coating pipe so as to realize spray-coating of a pipeline; meanwhile, torque is generated to drive the hydraulic motor to rotate in order to drive the spray-coating car to automatically walk inside the pipeline; therefore, uniform spray coating can be realized, no electric power is needed for driving, and the spray-coating car is safe and labor-saving.

Owner:LIAONING TECHNICAL UNIVERSITY

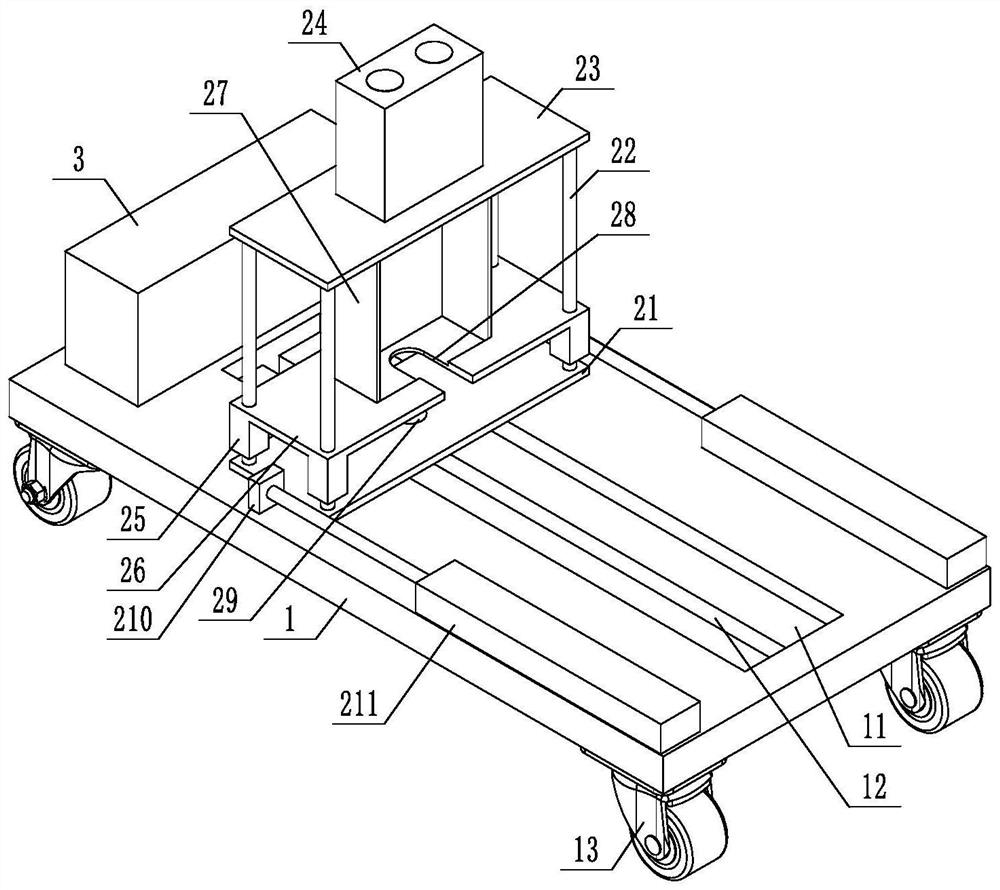

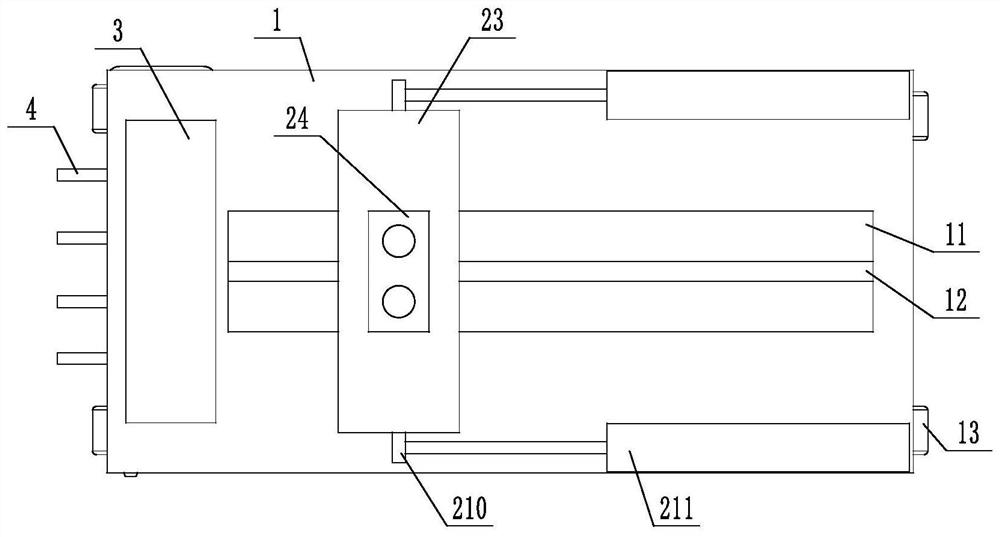

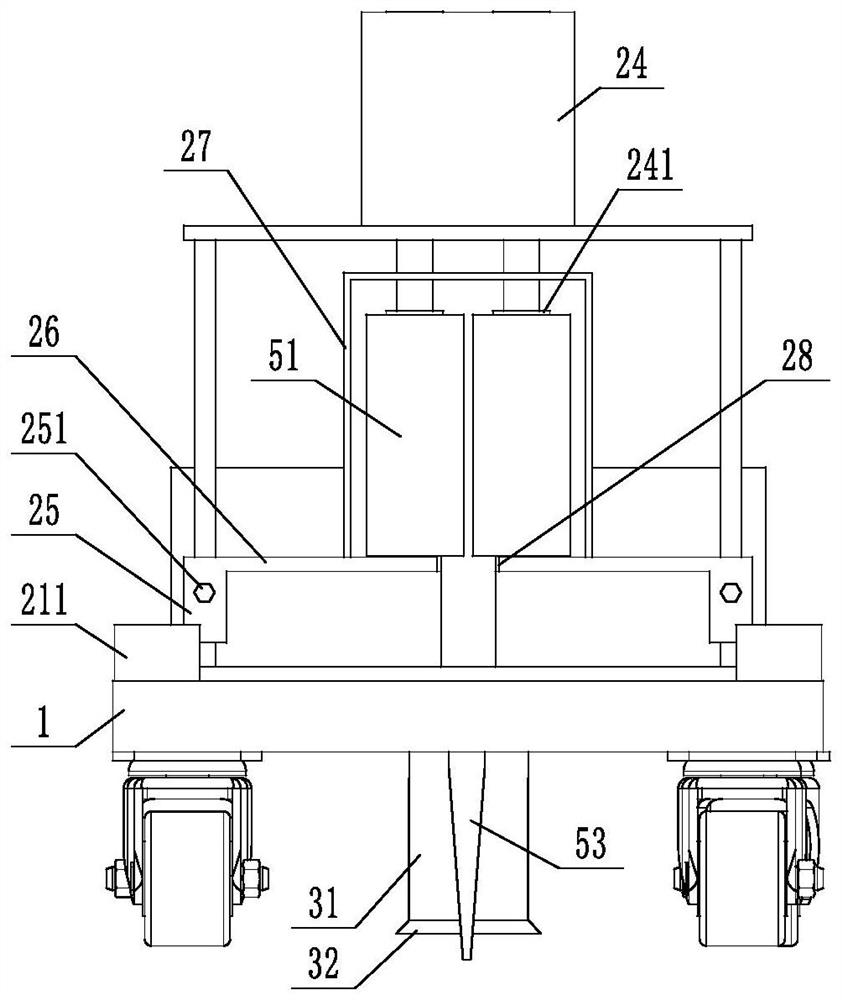

Long-span working-at-height rapid construction special cage

The invention discloses a long-span working-at-height rapid construction special cage which comprises a base plate, a lifting device and an operation platform, wherein the operation platform is arranged on the base plate through the lifting device in a lifting mode. The long-span working-at-height rapid construction special cage further comprises a horizontal rotation table which is used for driving the operation platform to rotate horizontally and at least three groups of liftable hydraulic supporting devices, the horizontal rotation table is arranged between the operation platform and the lifting device, and the liftable hydraulic supporting devices are slidingly arranged under the base plate. The long-span working-at-height rapid construction special cage has less impact on traffic and good site adaptability, and can bypass obstacles and construct on uneven roads such as green belts smoothly and rapidly.

Owner:SHANGHAI ROAD & BRIDGE (GRP) CO LTD

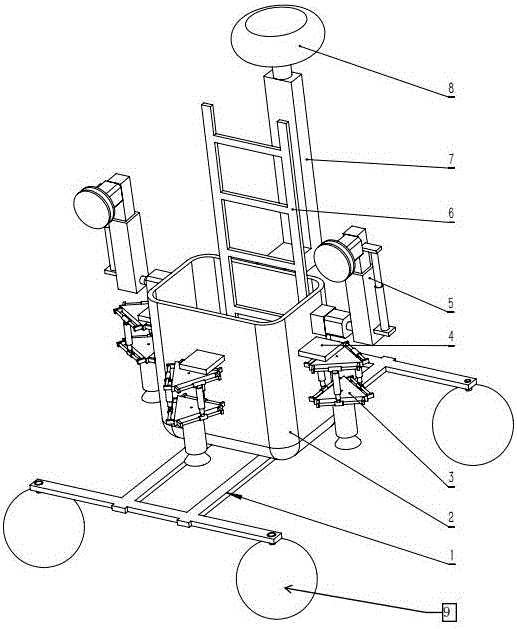

Safe power distribution implementation tool

ActiveCN106410670ARealize automatic walkingAvoid direct fallApparatus for overhead lines/cablesPower unitEngineering

The invention discloses a safe power distribution implementation tool which comprises a base, a suspension basket, four propelling units, a fixed plate, two walk driving power units, a ladder, a standing column, a parachute, and four rubber airbags. The base is formed by four steel pipes welded together, including two longitudinal steel pipes and two horizontal steel pipes wherein the two horizontal steel pipes are welded at the front parts and the back parts of the two longitudinal steel pipes. The left ends and the right ends of the two horizontal steel pipes are provided with four rubber airbags. Through the two walk driving power units, the robot is able to walk and to adjust the distance from the suspension basket to a high voltage line. The parachute and the propelling rockets are capable of preventing the people and the robot from direct falls when the power line breaks. Simple in structure, the tool of the invention can be used conveniently as well.

Owner:冯碧英

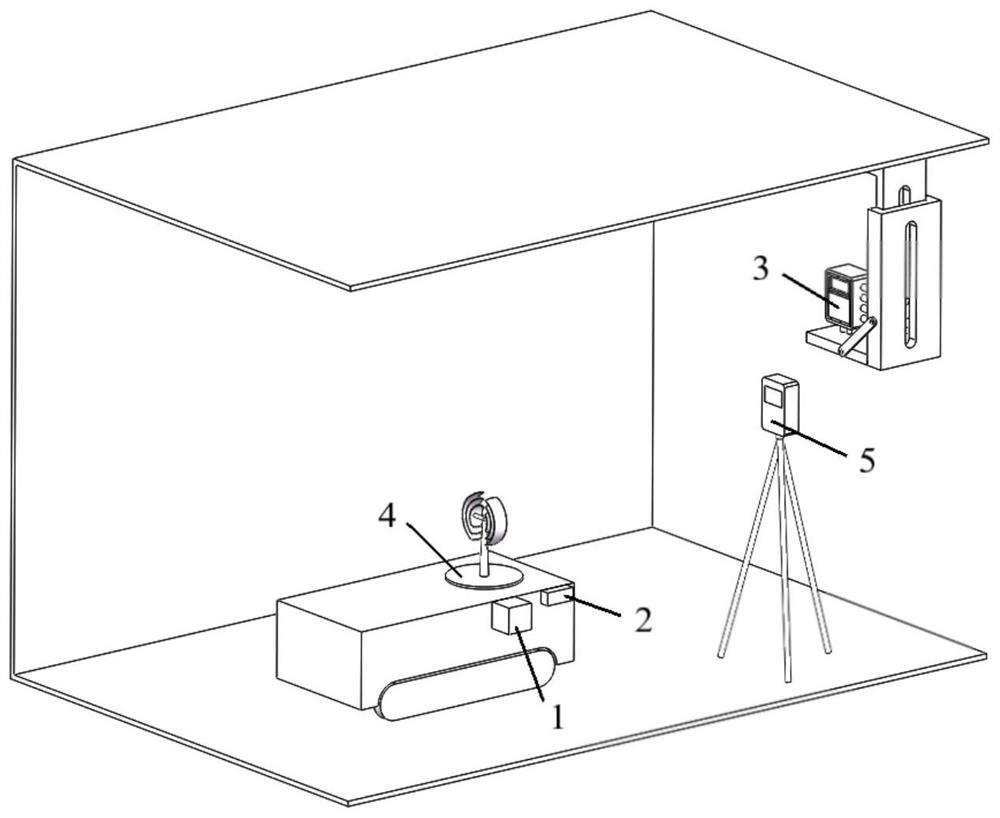

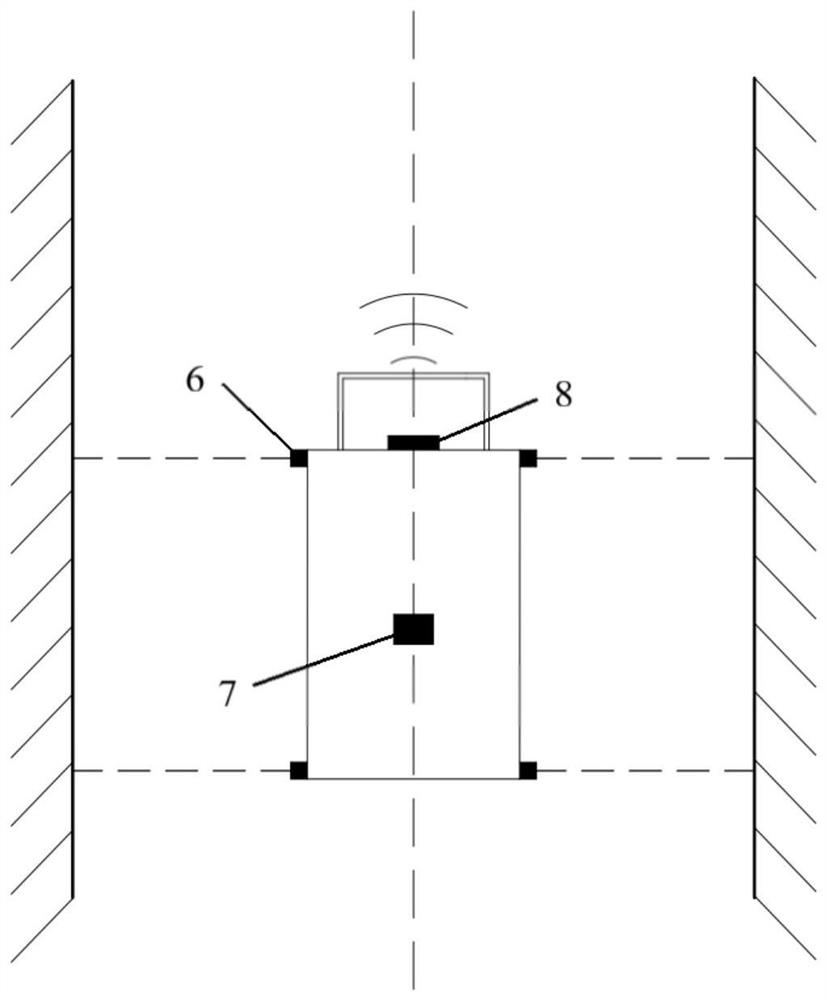

Tunneling self-moving tail positioning and navigation system and operation method

PendingCN114577207AImprove positioning and navigation accuracyAchieve positioningNavigational calculation instrumentsNavigation by speed/acceleration measurementsComputer visionEngineering

The invention discloses a tunneling self-moving tail positioning and navigation system and an operation method. The system comprises an absolute position positioning and navigation part, a relative pose positioning part and a motion control part, the absolute position positioning navigation part detects the absolute position and advancing navigation information of the self-moving tail in real time, the relative pose positioning part detects whether the self-moving tail deflects or not in real time, and the motion control part conducts deviation adjusting control on the self-moving tail. And automatic walking and automatic following of the self-moving tail can be realized.

Owner:CHINA UNIV OF MINING & TECH

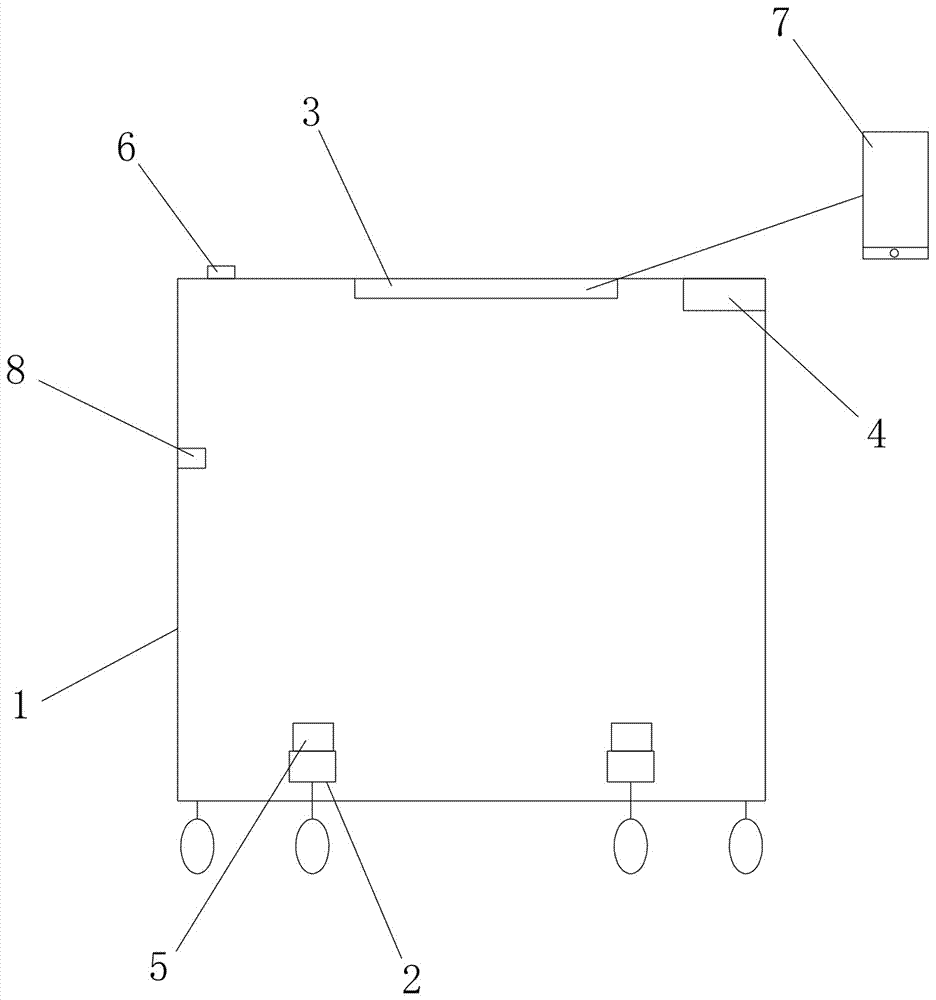

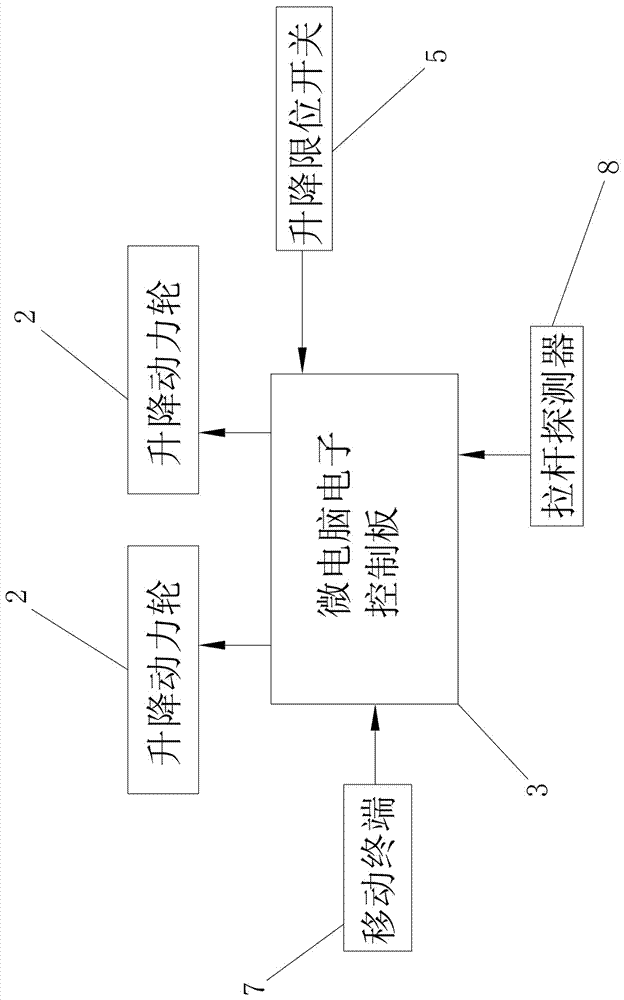

Method for realizing automatic following of pull rod luggage by remote control of mobile phone

InactiveCN107307539ASimple structureRealize automatic walkingPursesLuggageMicrocomputerRemote control

The invention discloses a method for realizing automatic following of a pull rod luggage by remote control of a mobile phone. The pull rod luggage comprises a pull rod luggage body, wherein lifting power rollers are arranged at the bottom of the pull rod luggage body; a microcomputer electronic control board is arranged on the pull rod luggage body; the lifting power rollers are connected with the microcomputer electronic control board; a battery is arranged on the pull rod luggage body and is connected with the microcomputer electronic control board; the microcomputer electronic control board is connected with a switch arranged on the pull rod luggage body; the microcomputer electronic control board is connected with a mobile terminal by Bluetooth. The method disclosed by the invention is simple in structure and is worthy of being popularized and applied; the lifting power rollers can lift according to the requirements and realize automatic walking.

Owner:厦门杰富绅科技有限公司

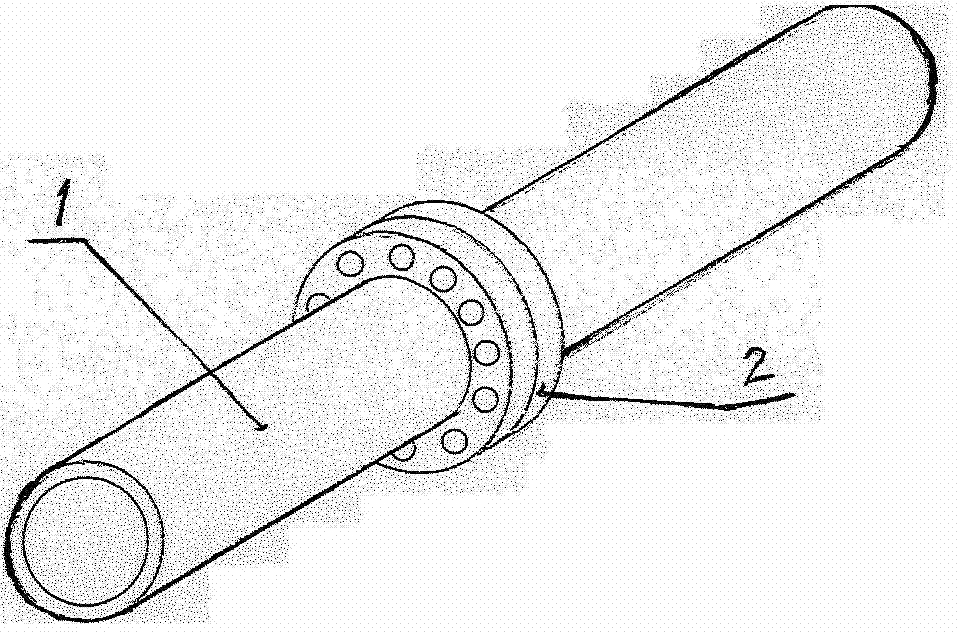

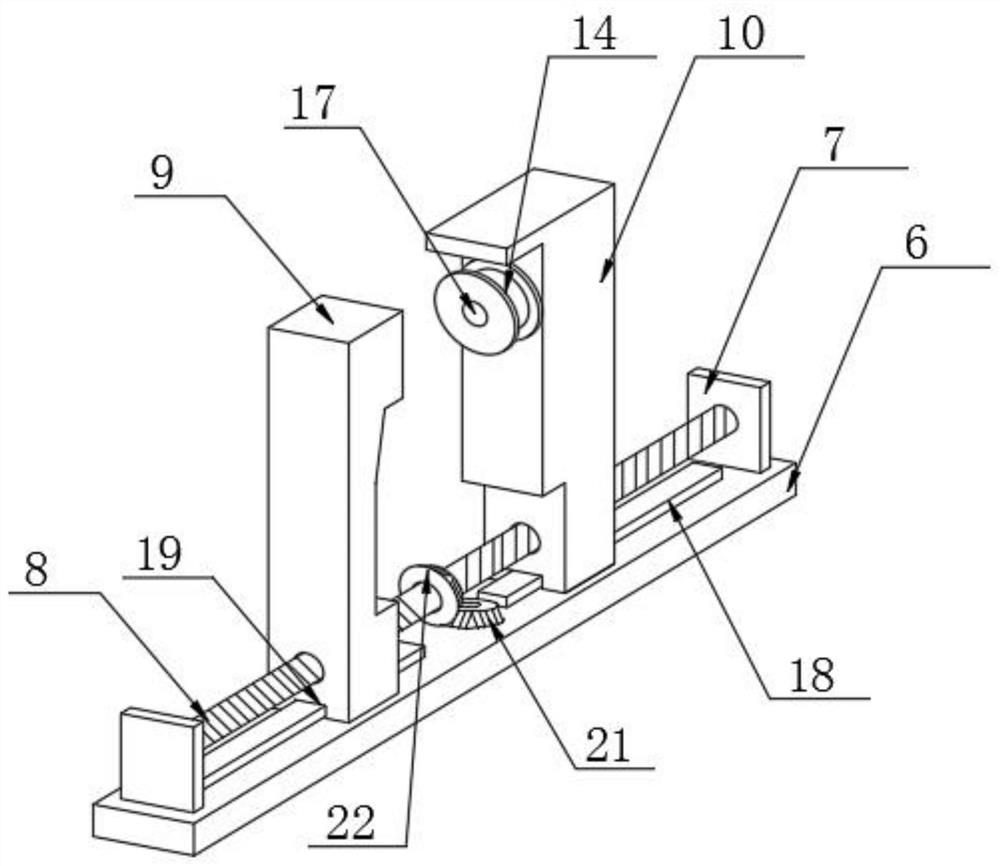

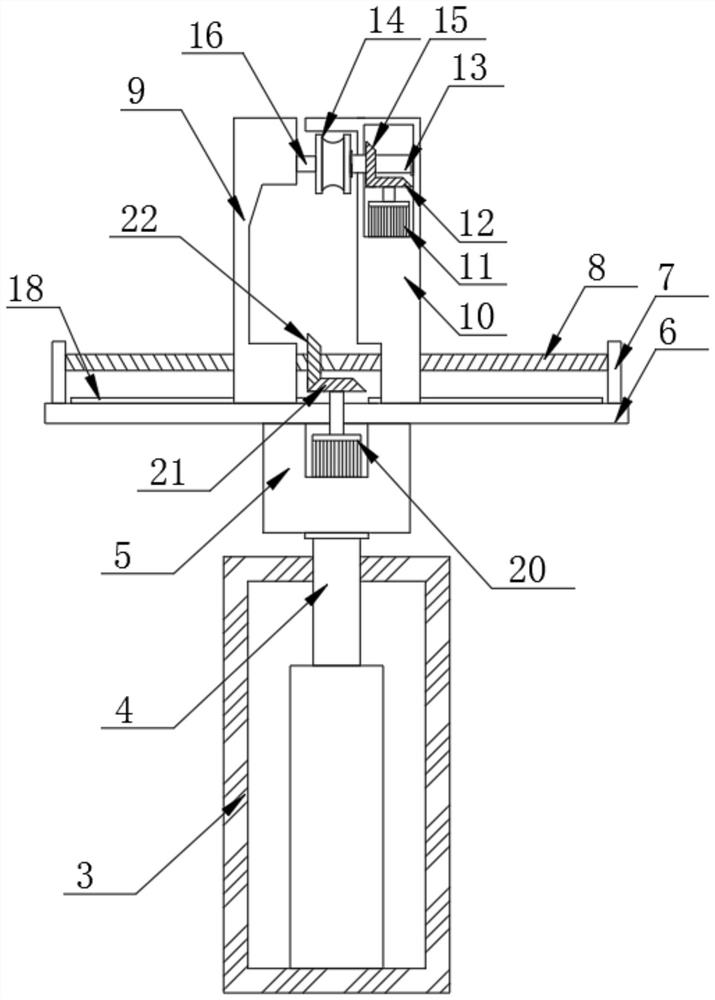

Pneumatic polishing mechanism and pneumatic device for automatically polishing and removing chips of inner wall of workpiece to be processed

ActiveCN111318927APlay a supporting roleGuaranteed stabilityGrinding wheel securing apparatusPolishing machinesStraight tubePolishing

The invention discloses a pneumatic polishing mechanism and a pneumatic device for automatically polishing and removing device chips of the inner wall of a workpiece. The pneumatic polishing mechanismincludes the following parts of a gas guide pipe, a straight pipe section, a supporting bearing and a central shaft. The pneumatic device for automatically polishing and removing device chips of theinner wall of the workpiece includes the pneumatic polishing mechanism, a stroke control mechanism, and the workpiece to be processed, the pneumatic polishing mechanism and the workpiece to be processed are installed on the stroke control mechanism at interval, and the end of the pneumatic polishing mechanism corresponds to the workpiece to be processed. The technical problems that the inner wallof the workpiece to be processed is difficult to polish and the powder is not easy to remove in the prior art are solved.

Owner:YANGZHOU PIPE FITTING FACTORY

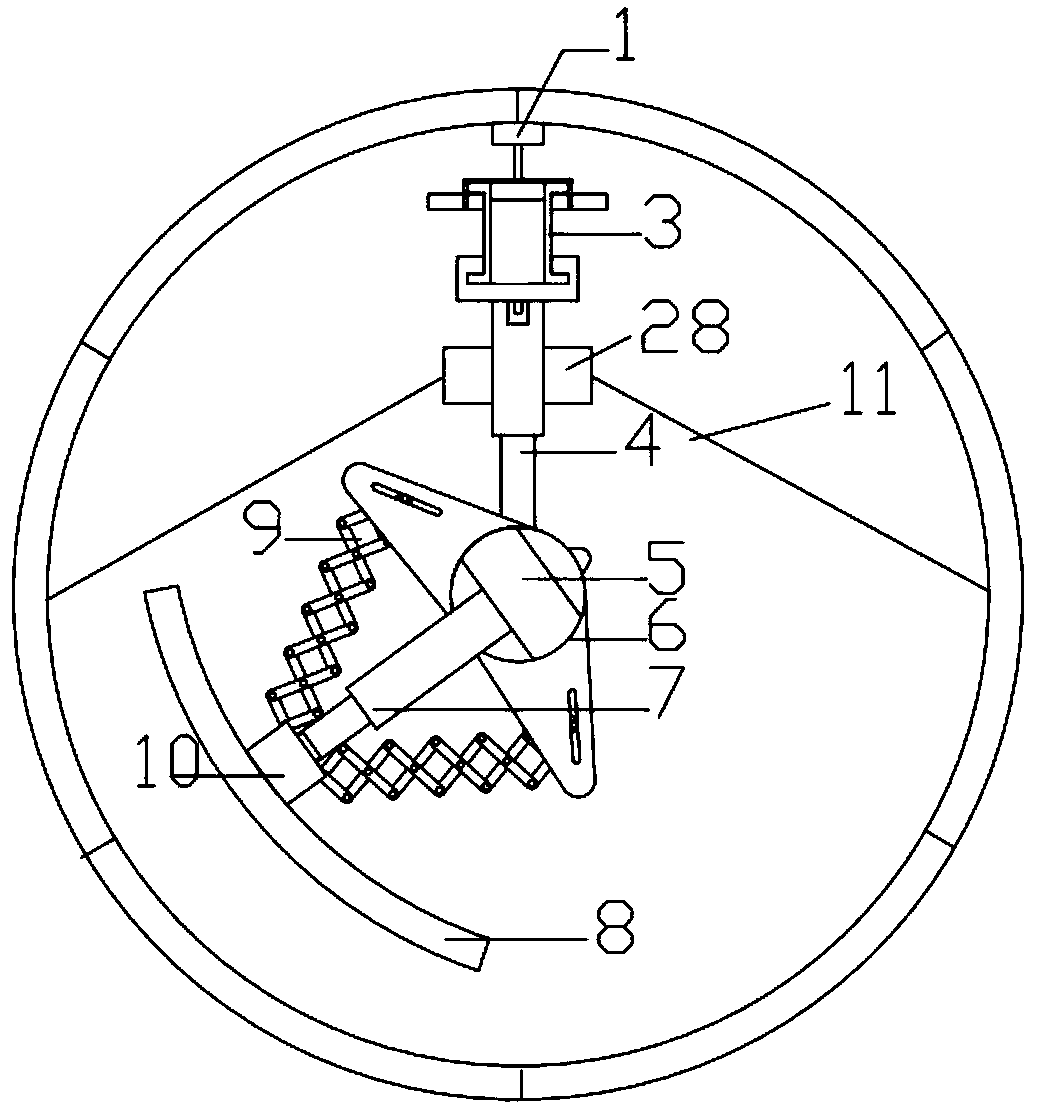

Mechanism for detecting flatness of injection molding part

The invention relates to the technical field of detection equipment, in particular to a mechanism for detecting the flatness of an injection molding part. The mechanism comprises a machining table, asupport and a detection mechanism, wherein a guide rail is arranged on the support; the detection mechanism comprises a sliding seat and a detection rod, the sliding seat is slidably connected to theguide rail, a cavity is formed in the sliding seat, and a vertical sliding hole is formed in the bottom of the sliding seat; the middle of the detection rod is slidably connected in the sliding hole of the sliding seat, a first connecting rod, a second connecting rod, a first swinging rod and a second swinging rod are arranged in the cavity of the sliding seat, the first connecting rod and the second connecting rod are both fixed on the inner wall of the sliding seat, the first connecting rod and the second connecting rod are located on the two sides of the detection rod respectively, the middle of the first swinging rod is hinged to the first connecting rod, the middle of the second swinging rod is hinged to the second connecting rod, the end portion of the first swinging rod is hinged tothe upper portion of the detection rod, and the end portion of the second swinging rod is hinged to the upper portion of the detection rod. The invention aims to provide the mechanism for detecting the flatness of the injection molding part, and the mechanism can be used for distinguishing the degree of the pits and the degree of the protrusions and marking the pits and the protrusions.

Owner:重庆雷钜电子科技有限公司

Garbage collection robot

PendingCN109940630ARealize automatic collectionRealize automatic walkingManipulatorRefuse collectionWaste collection

The invention discloses a garbage collection robot. By means of the arrangement of a first sliding rod, a second sliding rod, a corresponding first drive mechanism and a corresponding second drive mechanism, a mechanical arm is driven by cooperation of the first drive mechanism and the second drive mechanism, garbage in a garbage can at a fixed point is poured into a box body of the robot, and automatic collection of the garbage is achieved; and a moving mechanism is arranged below an outer shell, that is, a first rolling wheel, a fourth motor, a first transmission wheel, a second transmissionchain, a second transmission wheel and a rotating shaft are arranged at the front end of the outer shell to form a transmission structure, the robot is controlled to move, the rear end of the outer shell is provided with a second rolling wheel, two third transmission wheels at the upper end of a connecting shaft and the second transmission chain connected to the two third transmission wheels so that a transmission mechanism can be formed to control the robot to turn, automatic walking of the robot is achieved, the garbage in the garbage can is automatically removed, the labor intensity of workers is reduced, and the environmental cleanliness is maintained.

Owner:佛山市高明区高级技工学校

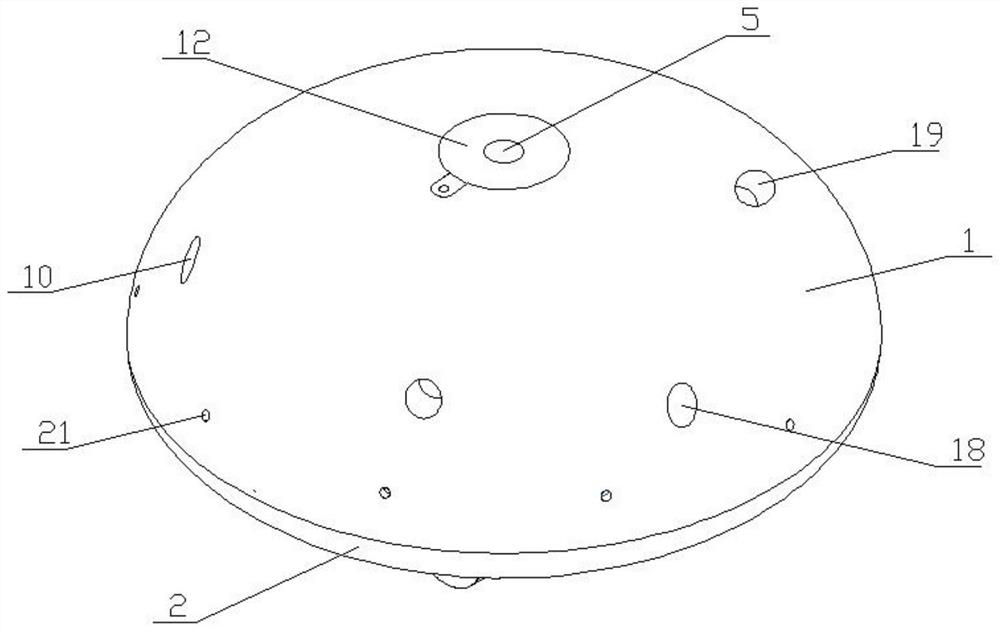

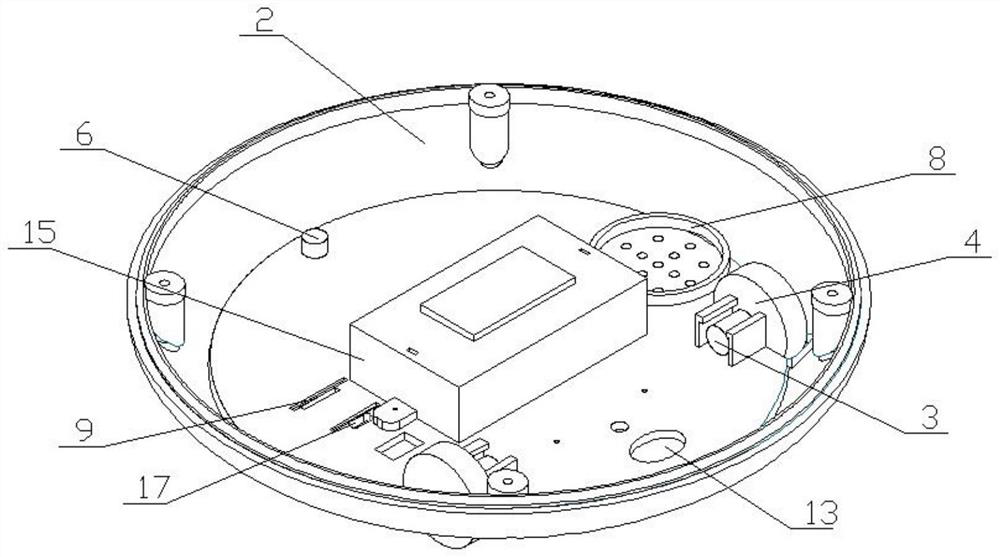

Pet entertainment robot and control method thereof

PendingCN114711163AAdd remote voice intercomFunction increaseOther apparatusTaming and training devicesLight irradiationLight spot

The invention discloses a pet entertainment robot and a control method thereof, and relates to the technical field of pet robots, the pet entertainment robot comprises a robot, an active driving mechanism module, an animal infrared detection module, a steering detection module, a central operation module, a sound playing control module, a light display module, a dog food feeding module and a power management module; in the first operation mode, the loudspeaker plays calling sound of an owner or music interested by the pet to attract the pet, the infrared sensor is triggered when the pet approaches the robot, the active driving mechanism module and the steering detection module drive the robot to move and steer to automatically avoid the pet, and pet food is released to attract the pet to participate in movement; according to the second operation mode, the strong light irradiation lamp irradiates towards the side face, the flickering function of the LED lamps on the periphery can be selected through a switch, the pet is attracted to run along with light spots along with rotation of the robot and light rotation, the ribbon on the teasing rod floats to guide the pet to grab and run, the purposes of pet entertainment and exercise training are achieved, the pet is automatically slid, and a feeder is liberated.

Owner:湖南康虹电子商务有限公司

A kind of automatic tracking robot control device and automatic tracking robot

InactiveCN104260092BImplement trackingAchieve positioningProgramme-controlled manipulatorTime informationAutomatic train control

The invention provides an automatic tracking robot control device and an automatic tracking robot. The device comprises a client side and a tracking side. The tracking side comprises a tracking module, a second wireless communication module, a second control module and a driving module, wherein the tracking module comprises an ultrasonic wave receiver which is arranged on the robot through a steering engine, and the tracking module is used for receiving an ultrasonic wave signal sent by an ultrasonic wave sending module, generating rotating angle information of the steering engine and sending the ultrasonic wave signal and the rotating angle information to the second control module. The second control module is used for obtaining positioning information between the client side and the tracking side according to the ultrasonic wave signal, the rotating angle information and time information, generating walking instruction information according to the position information, and sending the walking instruction information to the driving module. According to the automatic tracking robot control device, the problems that an existing automatic tracking control device is inaccurate in direction determining and signals are prone to being lost are solved.

Owner:DALIAN UNIV OF TECH

Ceramic tile seam beautifying device

ActiveCN111962837AReduce manual involvementReduce labor costsBuilding constructionsCeramic tilesManufacturing engineering

The invention discloses a ceramic tile seam beautifying device, and relates to the field of automation. The ceramic tile seam beautifying device includes a bottom plate; a supporting plate is slidablyfitted on the bottom plate; a first electric cylinder is connected onto the supporting plate; four guide posts are arranged on the supporting plate; the top ends of the four guide posts are providedwith an upper top plate; a support frame is slidably matched with the guide posts; a seam sealant is placed in the support frame; a second electric cylinder is installed on the upper top plate; a telescopic rod of the second electric cylinder abuts against the top of the seam sealant; the front end of the bottom plate is provided with a plurality of infrared receiving pair tubes; the front end ofthe bottom plate is provided with a vacuum cleaner; the front end of the bottom plate is provided with a pointing trowel assembly; and the back side of the bottom plate is provided with a seam pressing mechanism. The device adopts the pointing trowel assembly to clean up debris in seams, adopts the vacuum cleaner to remove the debris, adopts the electric cylinders to achieve seam filling with theseam sealant, and adopts a seam pressing ball to realize post-seam pressing of the seam sealant, manual participation in the process of the whole device is little, the labor cost is reduced, and the work efficiency is improved.

Owner:SHANDONG LABOR VOCATIONAL & TECHN COLLEGE

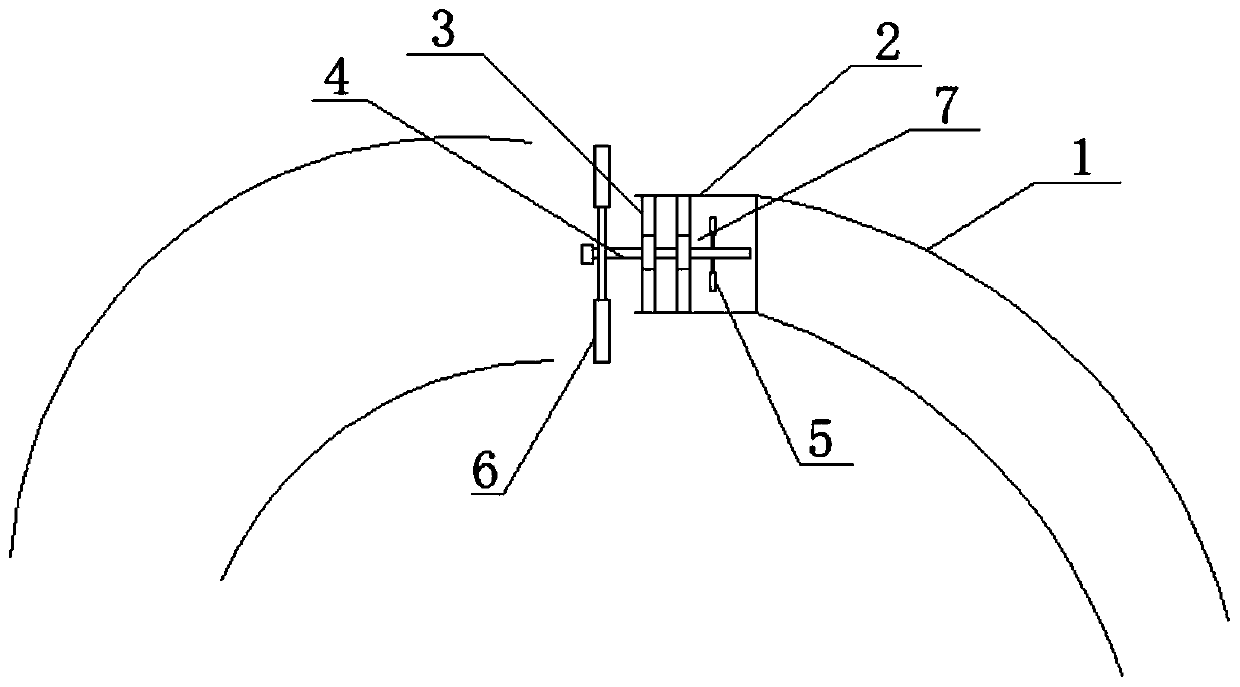

A tea garden bud tea picking robot and picking method

ActiveCN111406512BImprove qualityTo achieve the purpose of picking only young shootsSievingScreeningAgricultural engineeringMechanical engineering

Owner:HANGZHOU DIANZI UNIV

Mini type dual-folding channel feeding mobile spray irrigation machine

PendingCN107223541ASimple structureCompact structureWatering devicesCultivating equipmentsWater channelEngineering

The invention relates to a mini type dual-folding channel feeding mobile spray irrigation machine, which comprises a flat panel; a self-suction pump and two brackets are installed on the flat panel; a water inlet of the self-suction pump is connected with a water channel through a water inlet pipe, and a water outlet of the self-suction pump is connected with a main water outlet pipe; both ends of the main water outlet pipe are connected with branch water outlet pipes, and every branch water outlet pipe is fixed on the bracket; several low pressure nozzles are installed on every branch water outlet pipe. The a mini type dual-folding channel feeding mobile spray irrigation machine realizes the automation of the spray irrigation machine, thus the spray irrigation machine can automatically walk in the field; meanwhile, the spray irrigation machine structure is simplified and easy to operate; for applying the dual-folding structure, the placing space of the spray irrigation machine is saved while the high efficiency of irrigation of multiple fields is realized; therefore, the spray irrigation efficiency is greatly improved.

Owner:JIANGSU UNIV

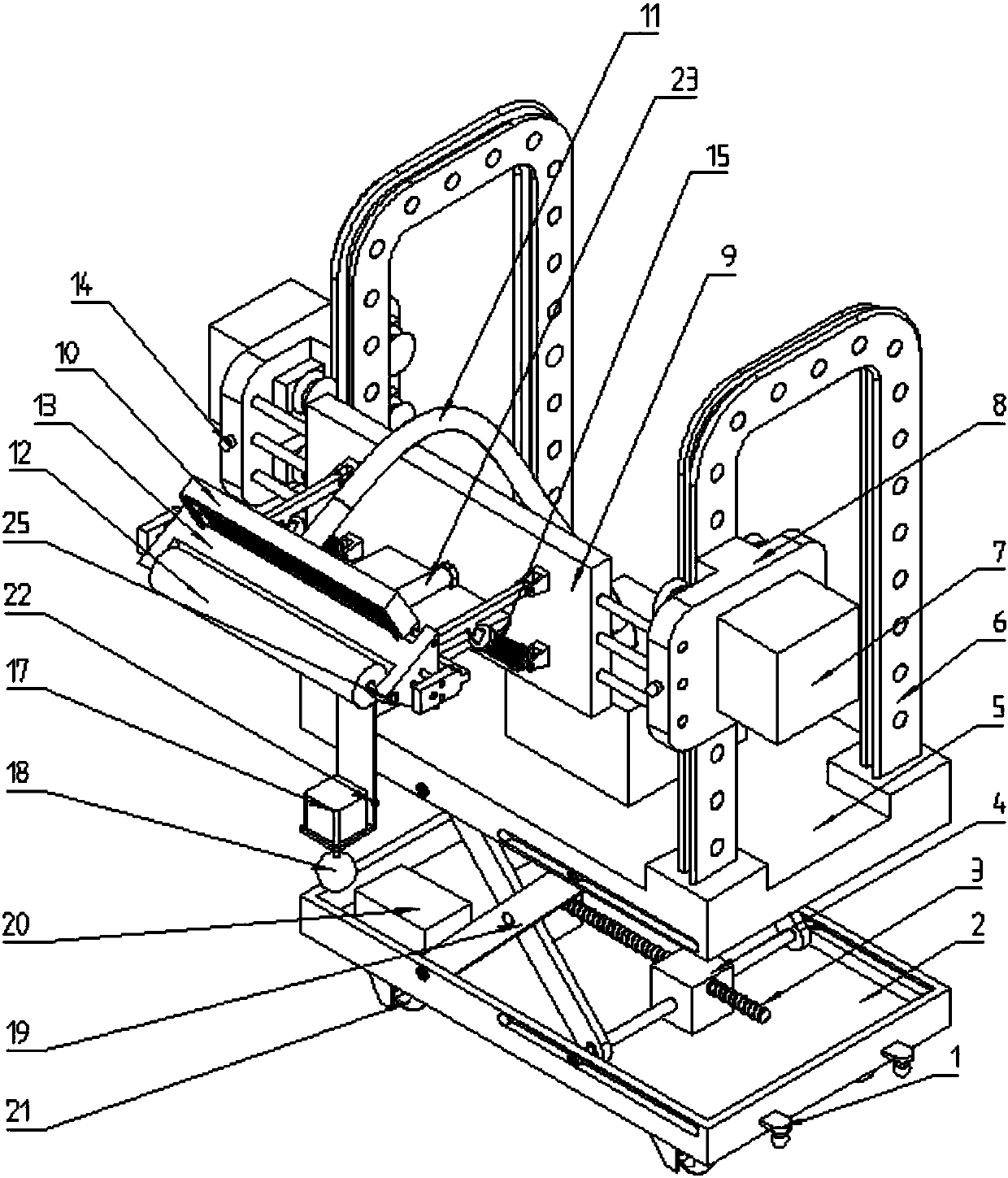

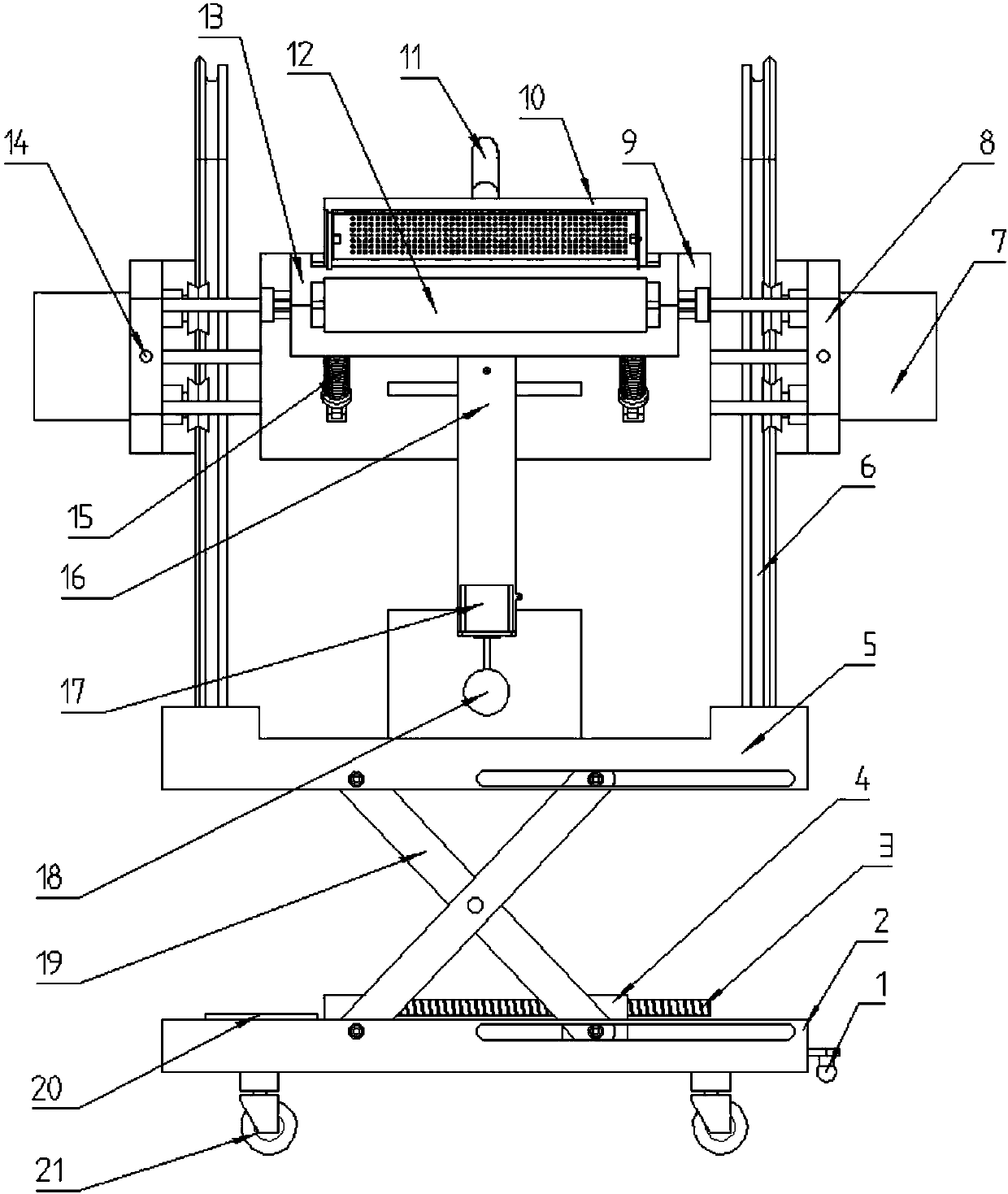

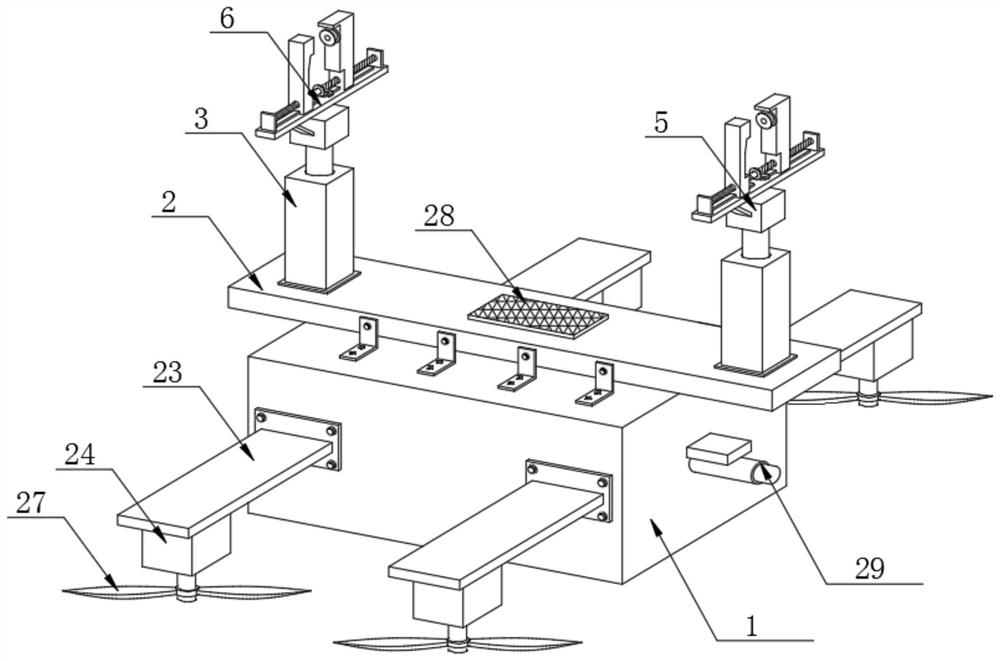

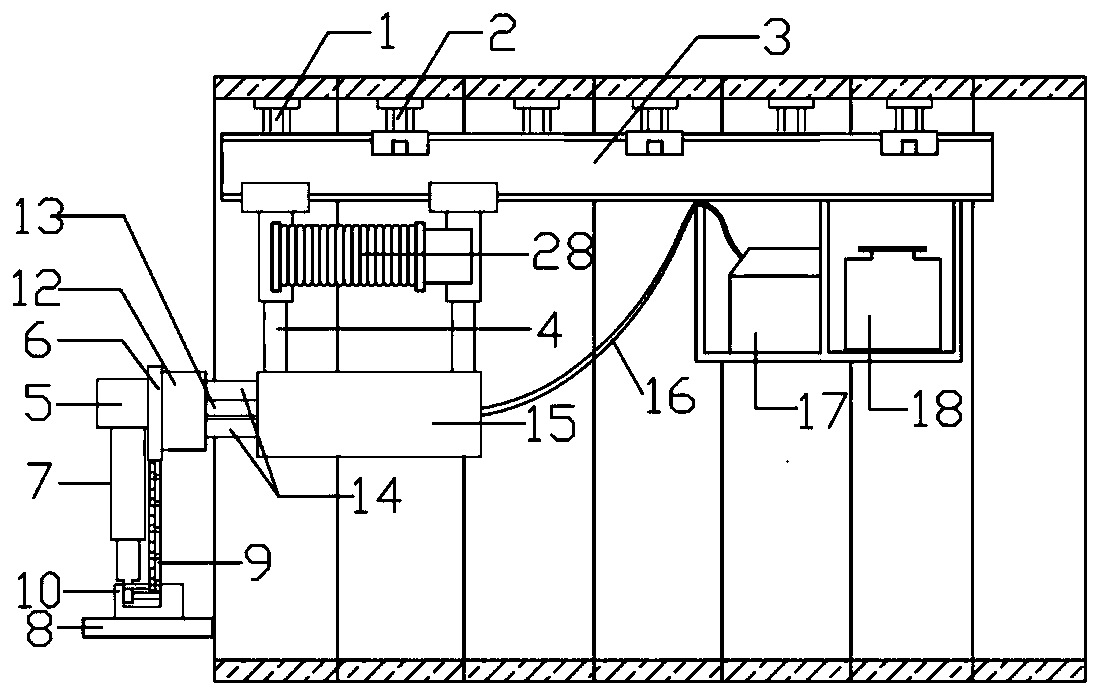

Force-taking power testing platform of paver spiral distributor and using method thereof

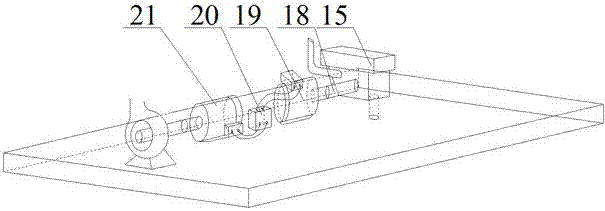

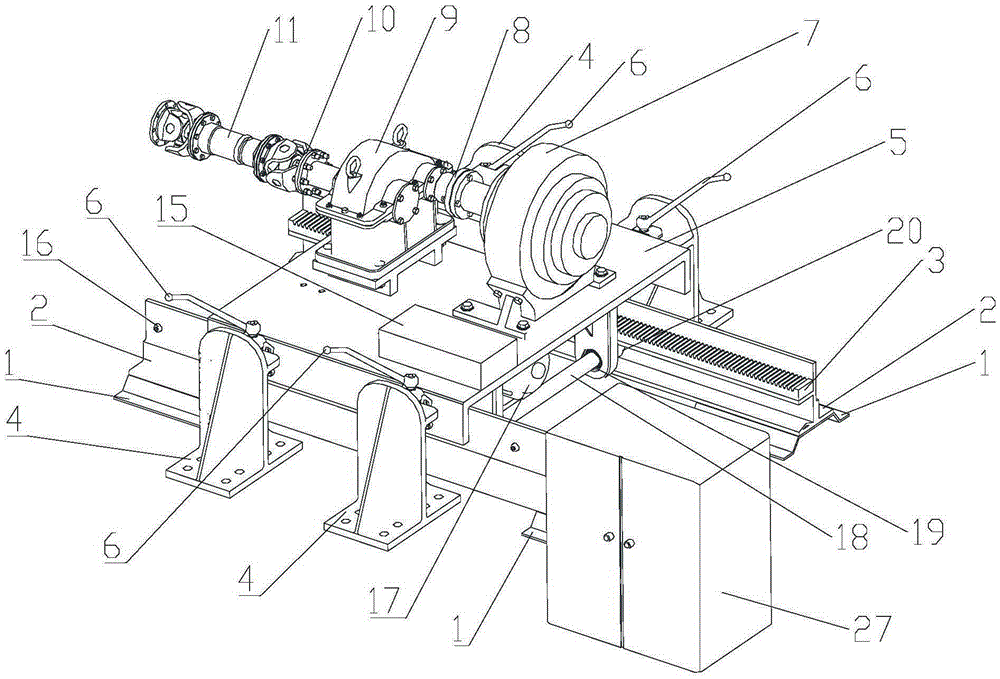

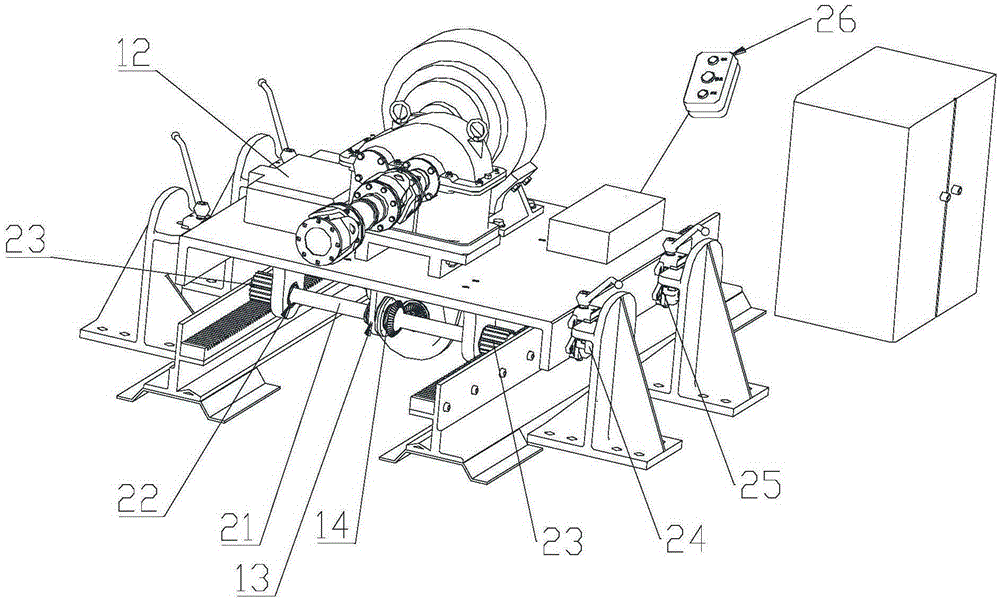

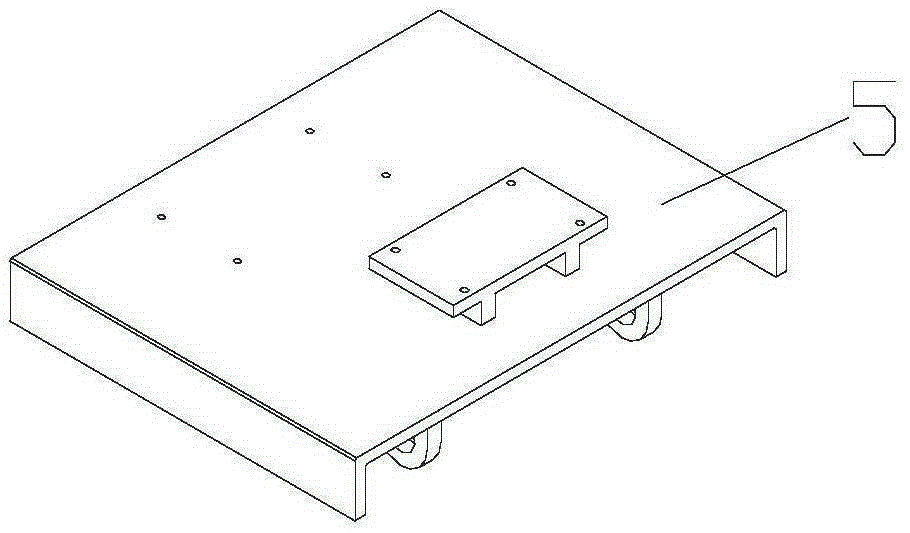

InactiveCN105277358AConvenient dynamometerEasy test loadingMachine part testingApparatus for force/torque/work measurementHand heldEngineering

The invention discloses a force-taking power testing platform of a paver spiral distributor and a using method thereof, wherein the platform comprises left and right guide rail bases, left and right guide rails, left and right racks, a mobile platform left-and-right positioning mechanism, a mobile platform, a mobile platform locking mechanism, a magnet powder brake, a speed reducer, a telescopic universal coupling device, a tool box for mobile platform testing, an orthogonal bevel gear set connected to a traction front shaft and a motor, a motor controller box, a three-phase asynchronous traction motor with a gearbox, a back shaft, a back shaft bearing component, a rear wheel with a V-shaped groove, a front shaft, a front shaft bearing component, gears mounted on the front shaft in cooperation with the racks, a forward position limiting switch, a withdraw position limiting switch, a handheld type platform movement controller and a power distribution box and the like. The platform is used for power testing and test loading of various types of paver spiral distributors so as to realize automatic walking of the apparatus and the platform is suitable for the tests of more machine types; and the test efficiency is improved and the security and the reliability of the test are also ensured.

Owner:CHANGAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com