Grain scraper

A grain picking machine and grain picking technology, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problem that the moving parts are easy to be entangled, and achieve the effects of high comprehensive performance, noise reduction, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

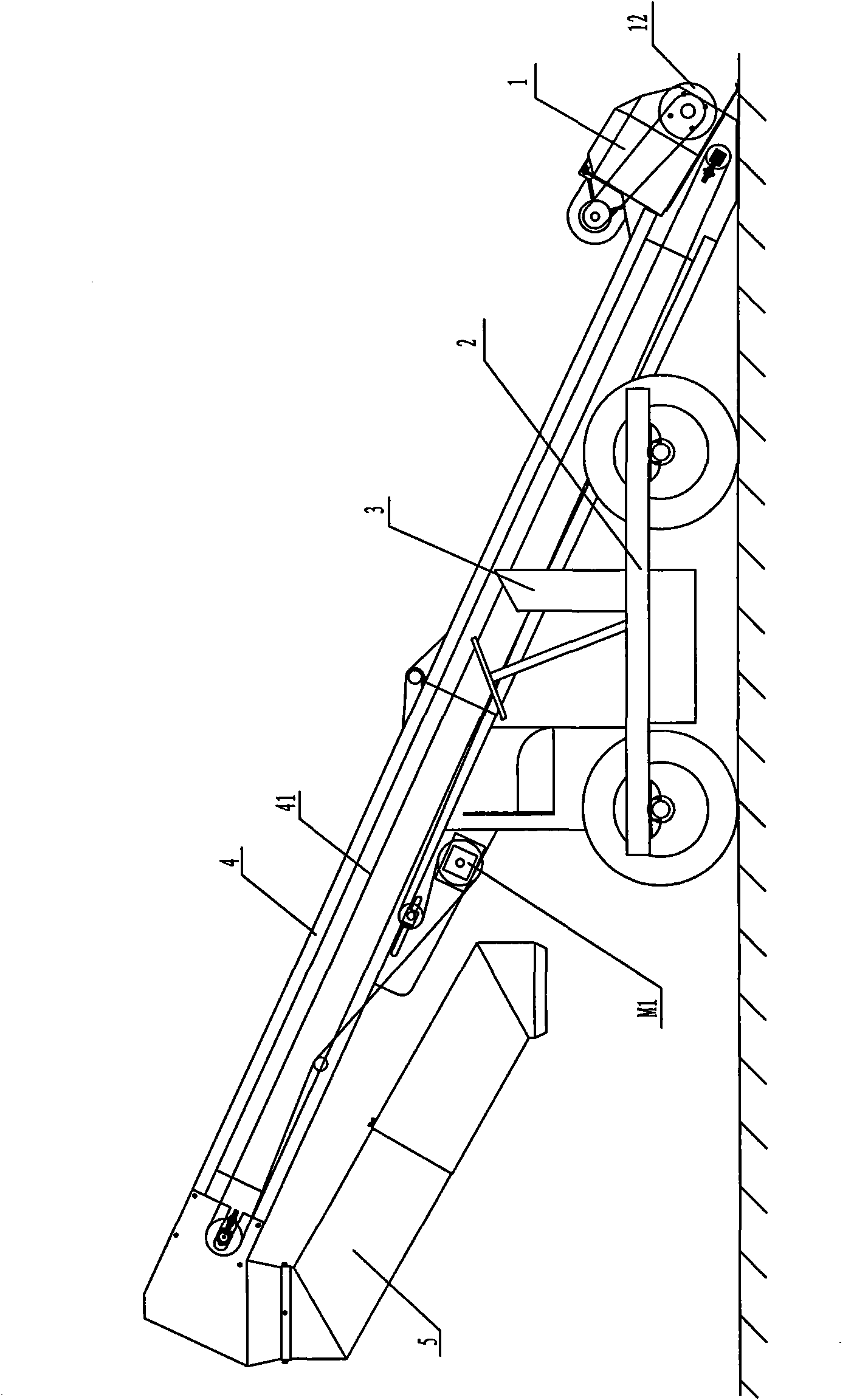

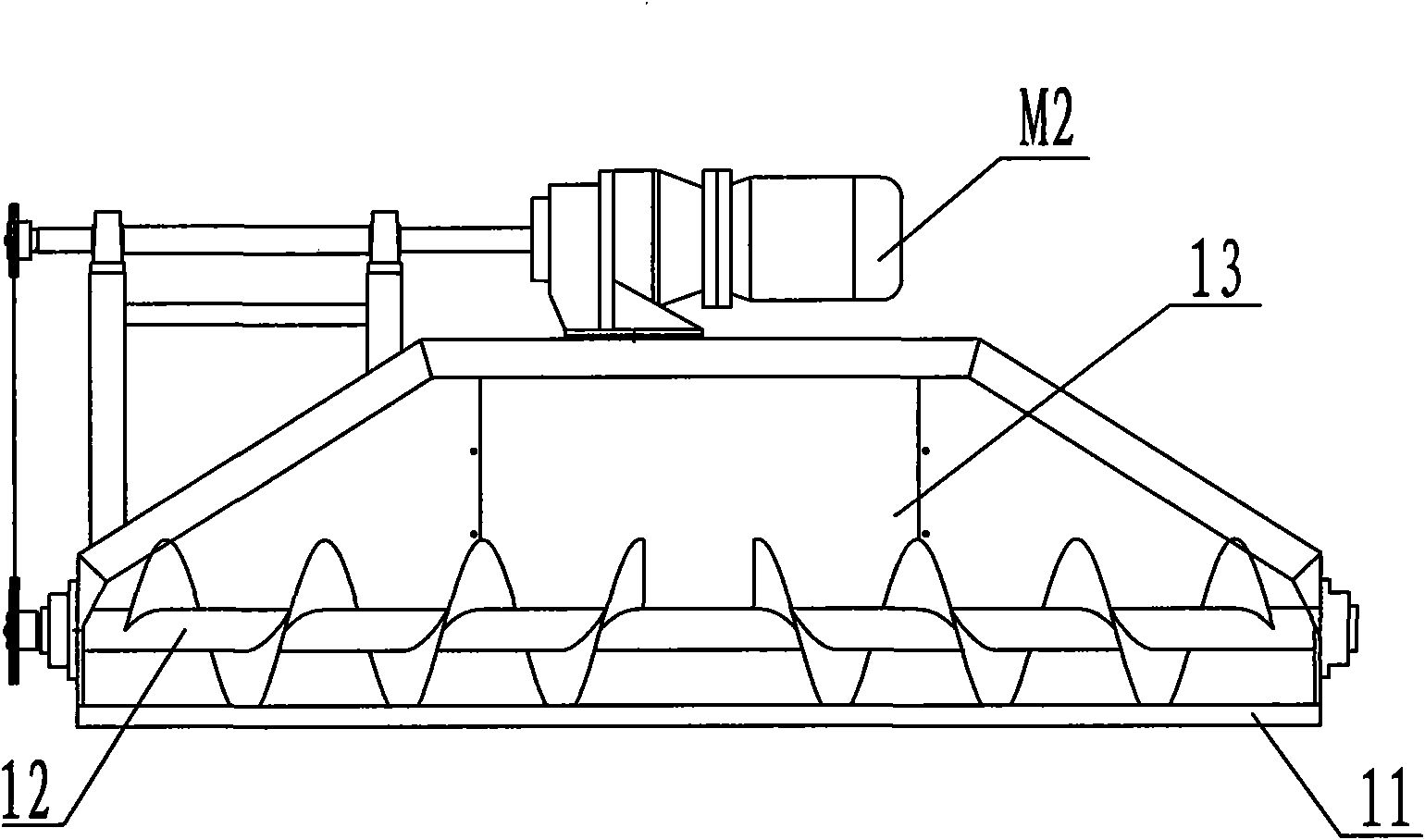

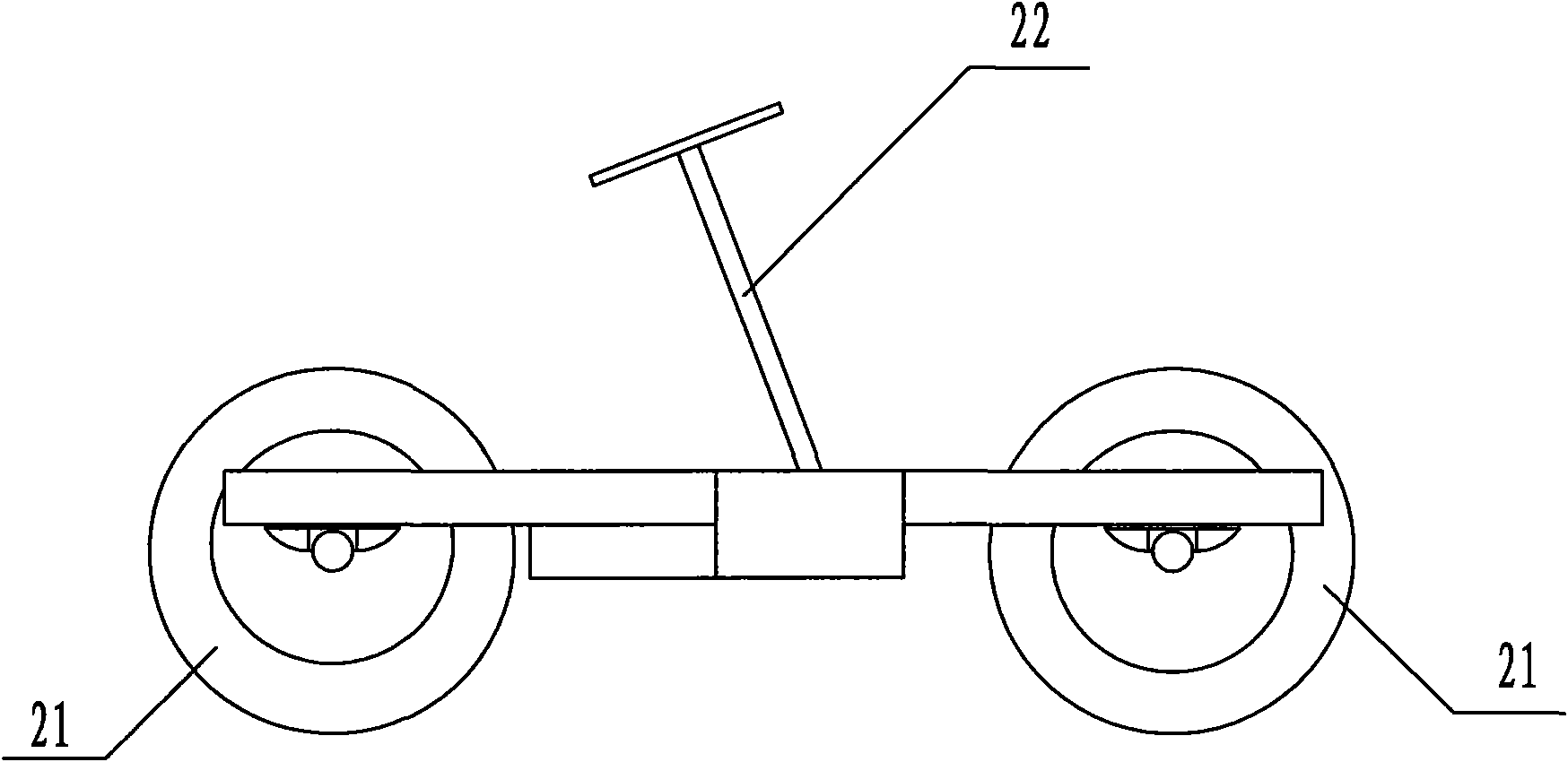

[0019] figure 1 It is the structural representation of the grain grilling machine of the present invention. As shown in the figure, the grain picking machine of the present invention includes a walking device 2, a grain picking device 1, a conveying device 4, a grain outlet 5, and a control device 3, and the conveying device 4 is fixed on the walking device 2 with an inclination of 30°; the conveying device 4 includes The motor M1, the belt 41 and the cylindrical closed groove, the belt 41 is installed in the closed groove and driven by the motor M1; the lower end of the conveying device 4 is docked with the grain picking device 1 so that the screw shaft 12 is parallel to the belt 41 and perpendicular to the direction of motion of the belt 41 , the conveying device 4 is hingedly connected with the grain-picking device 1, and a switch is arranged between the two. Docking with the grain outlet 5 enables the grain to flow smoothly from the conveying device 4 through the grain ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com