Patents

Literature

1621results about How to "Reduce manual involvement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

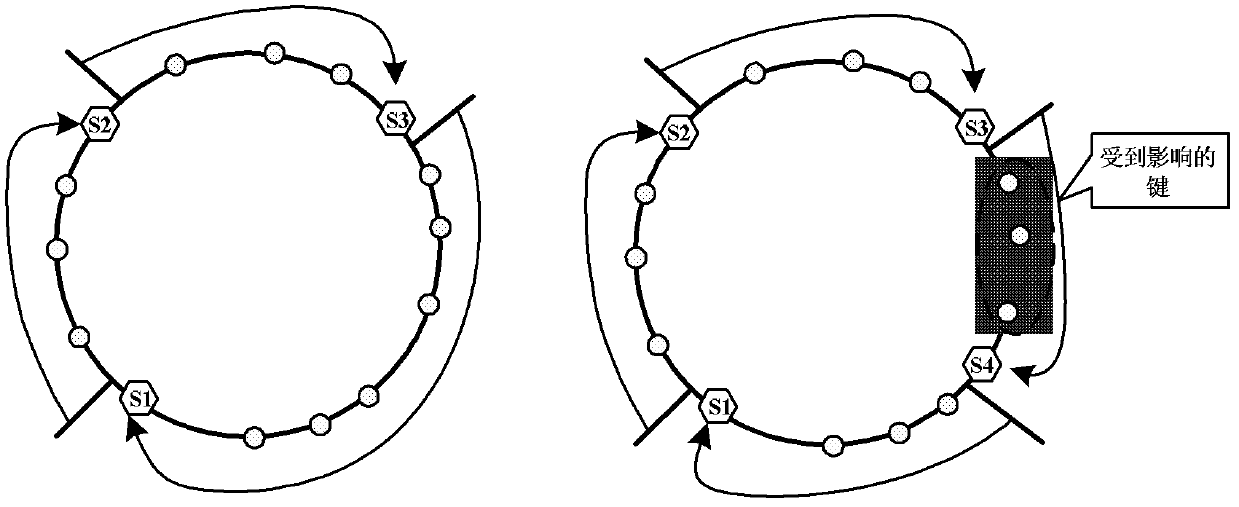

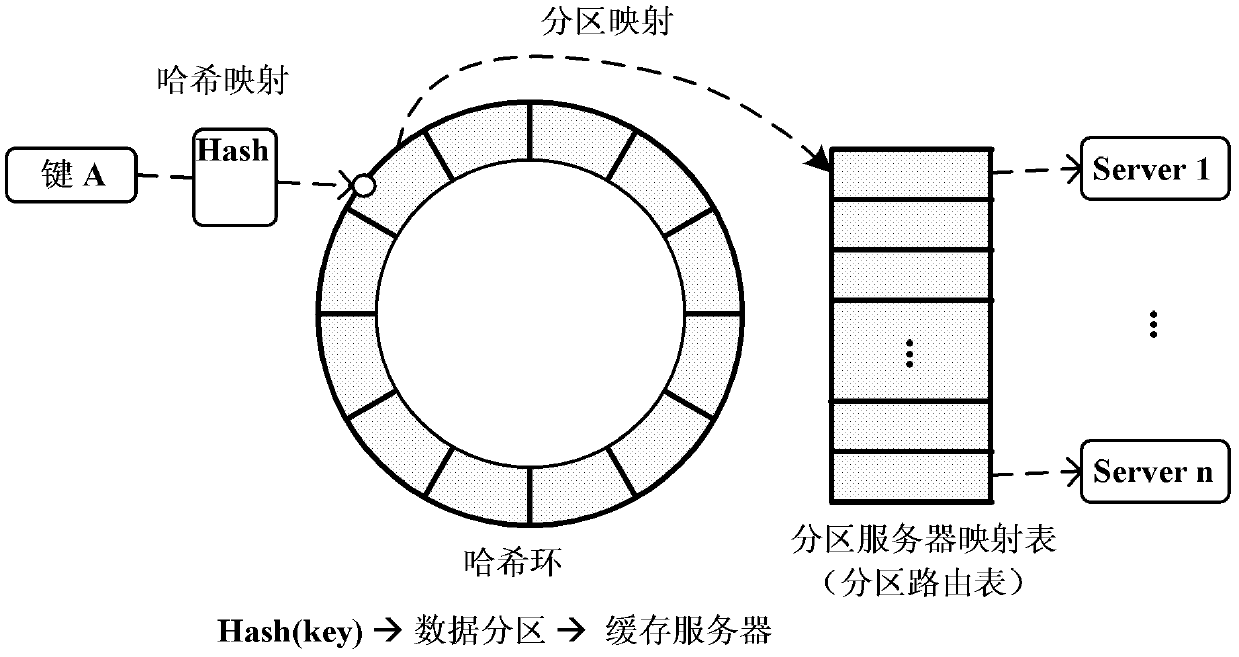

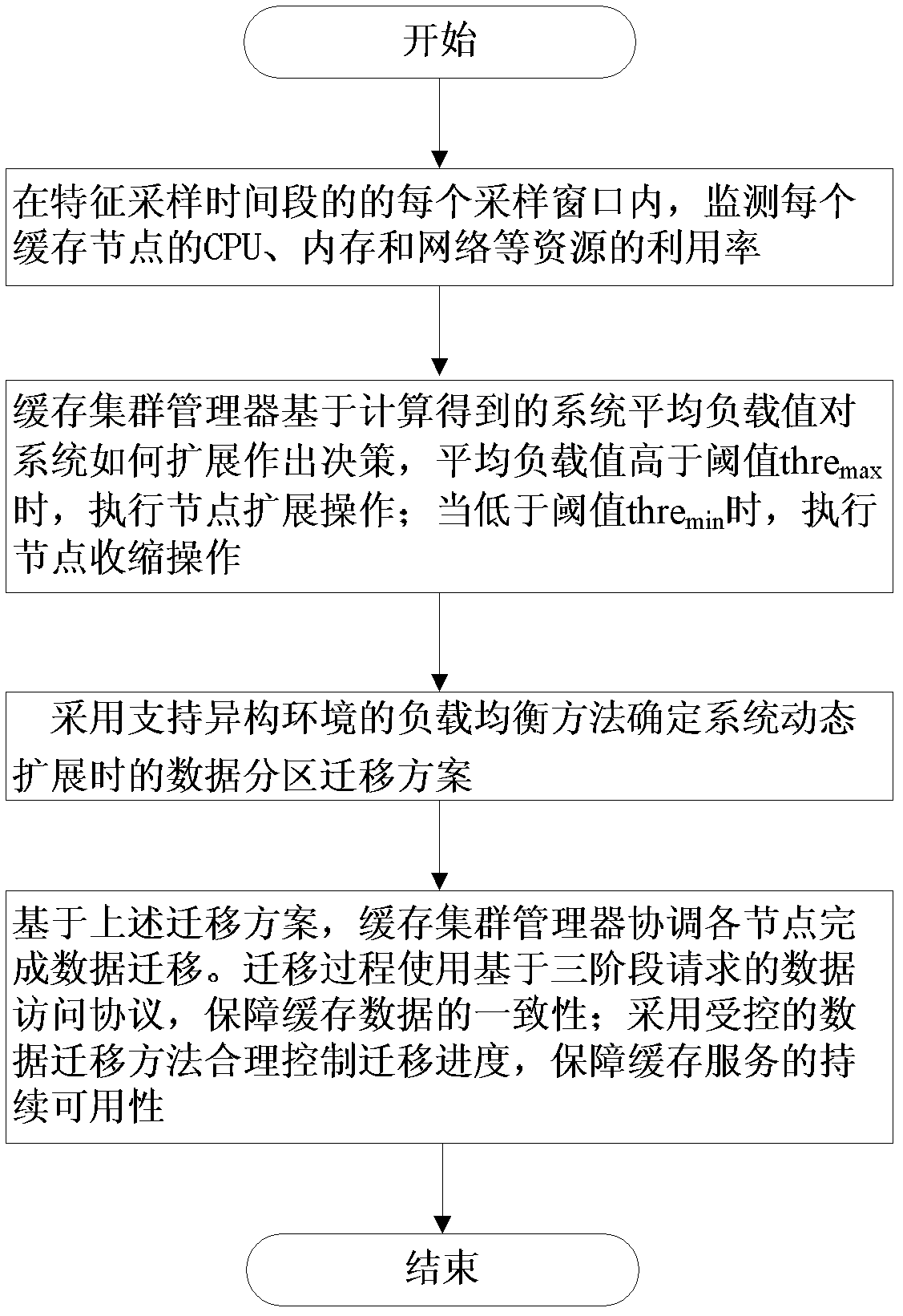

Distributed type dynamic cache expanding method and system supporting load balancing

InactiveCN102244685AReduce overheadImprove performanceData switching networksTraffic capacityCache server

The invention discloses a distributed type dynamic cache expanding method and system supporting load balancing, which belong to the technical field of software. The method comprises steps of: 1) monitoring respective resource utilization rate at regular intervals by each cache server; 2) calculating respective weighing load value Li according to the current monitored resource utilization rate, and sending the weighting load value Li to a cache clustering manager by each cache server; 3) calculating current average load value of a distributed cache system by the cache clustering manager according to the weighting load value Li, and executing expansion operation when the current average load value is higher than a threshold thremax; and executing shrink operation when the current average load value is lower than a set threshold thremin. The system comprises the cache servers, a cache client side and the cache clustering manager, wherein the cache servers are connected with the cache client side and the cache clustering manager through the network. The invention ensures the uniform distribution of the network flow among the cache nodes, optimizes the utilization rate of system resources, and solves the problems of ensuring data consistency and continuous availability of services.

Owner:济南君安泰投资集团有限公司

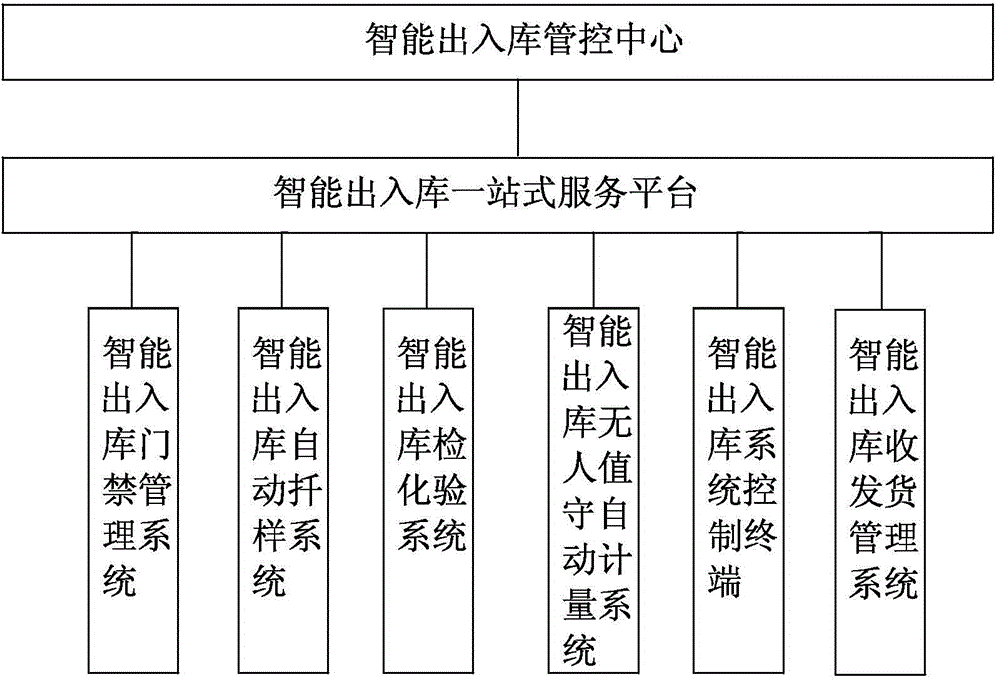

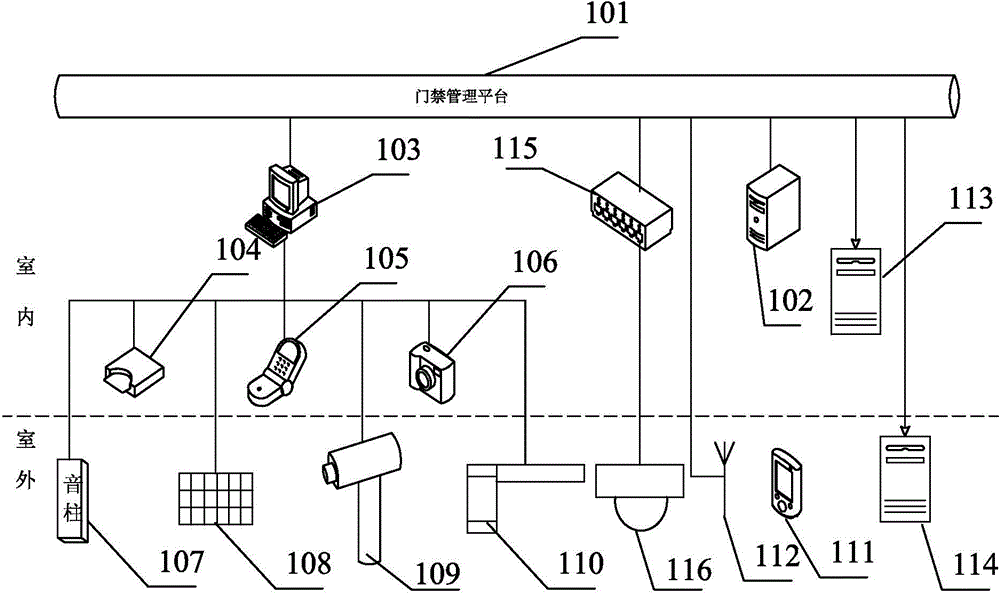

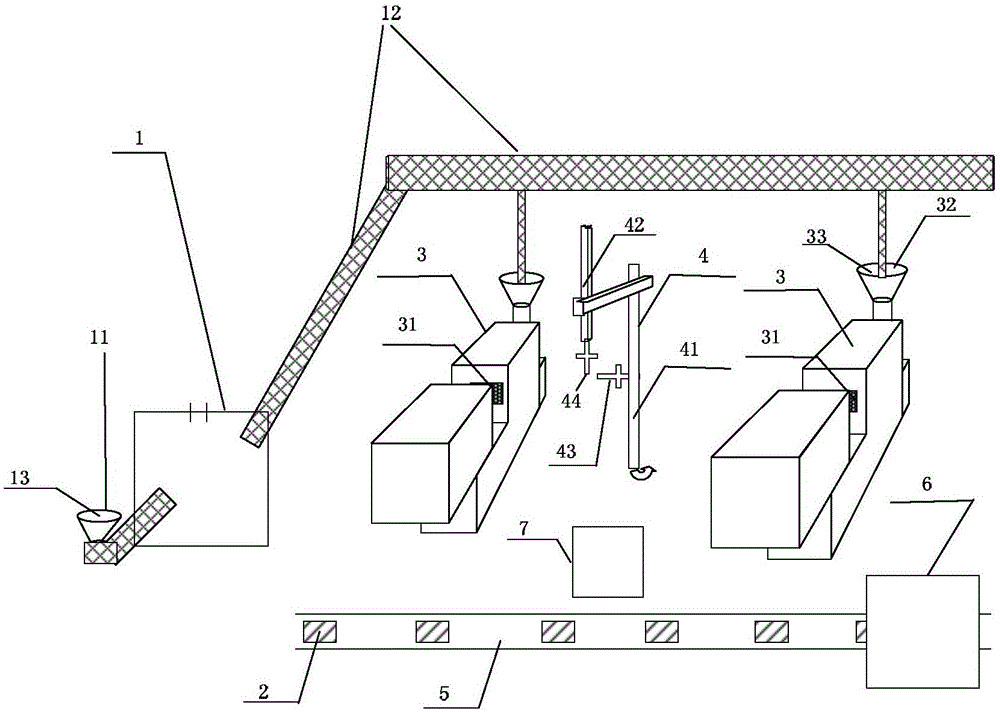

Intelligent depot output-input system of digital grain depot

ActiveCN103559605ASimplify business processesRealize paperless managementIndividual entry/exit registersLogisticsIntelligent managementComputer science

The invention discloses an intelligent depot output-input system of a digital grain depot. The intelligent depot output-input system of the digital gain depot comprises an intelligent depot output-input access control system, an intelligent depot output-input automatic sampling system, an intelligent depot output-input examination assay system, an intelligent depot output-input unattended operation automatic metering system, an intelligent depot output-input system control terminal, an intelligent depot output-input goods receiving-sending management system, an intelligent depot output-input system one-stop service platform and an intelligent depot output-input system control center. The intelligent depot output-input access control system, the intelligent depot output-input automatic sampling system, the intelligent depot output-input examination assay system, the intelligent depot output-input unattended operation automatic metering system, the intelligent depot output-input system control terminal, the intelligent depot output-input goods receiving-sending management system and the intelligent depot output-input system control center are connected with the intelligent depot output-input system one-stop service platform. According to the intelligent depot output-input system of the digital grain depot, a computer, the RFID internet of things technology, the communication technology and the information technology are converged together, networking, automation and intelligent management of the depot output and input are achieved, and labor participation is reduced.

Owner:JINAN JINZHONG ELECTRONICS SCALE +1

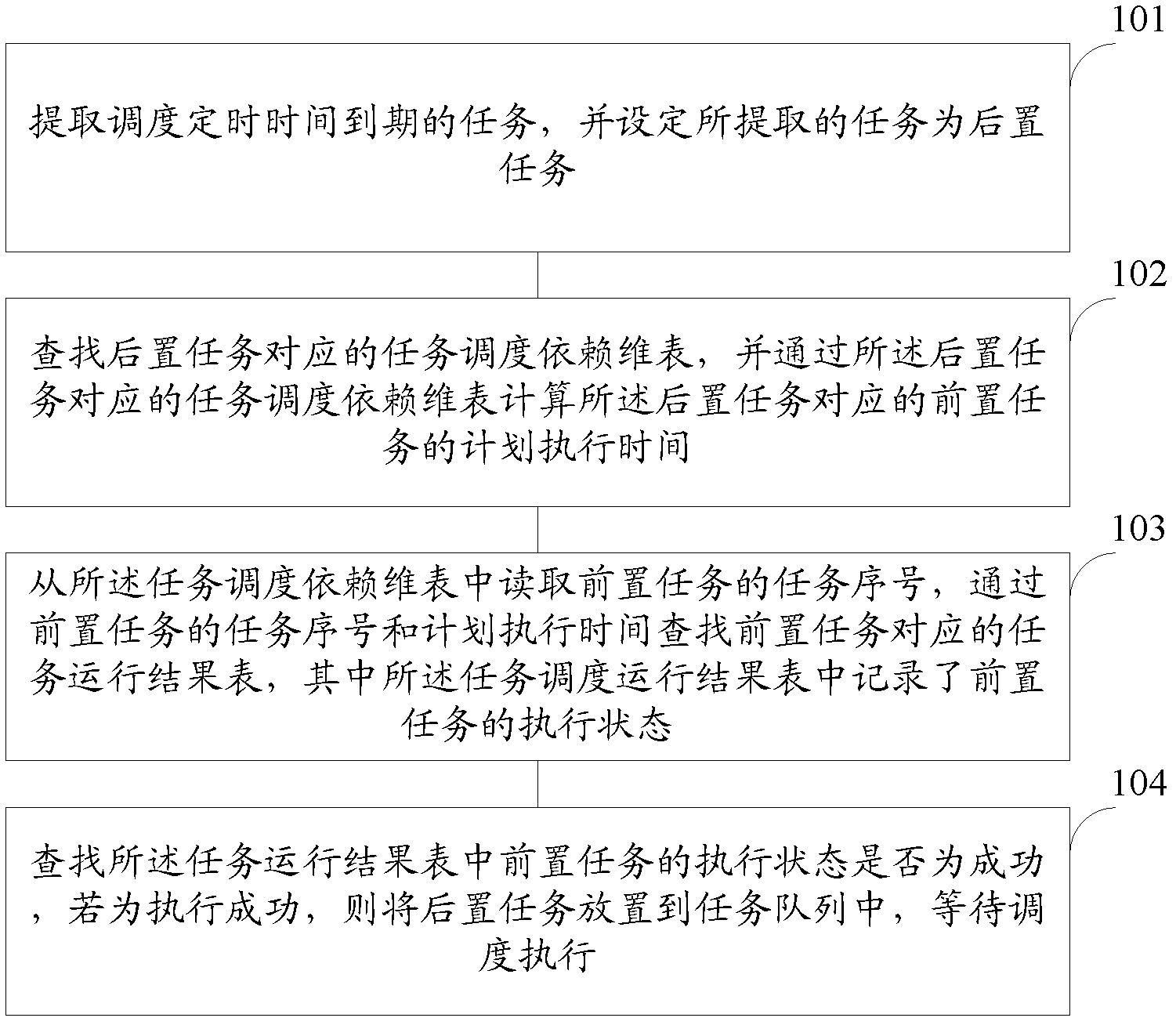

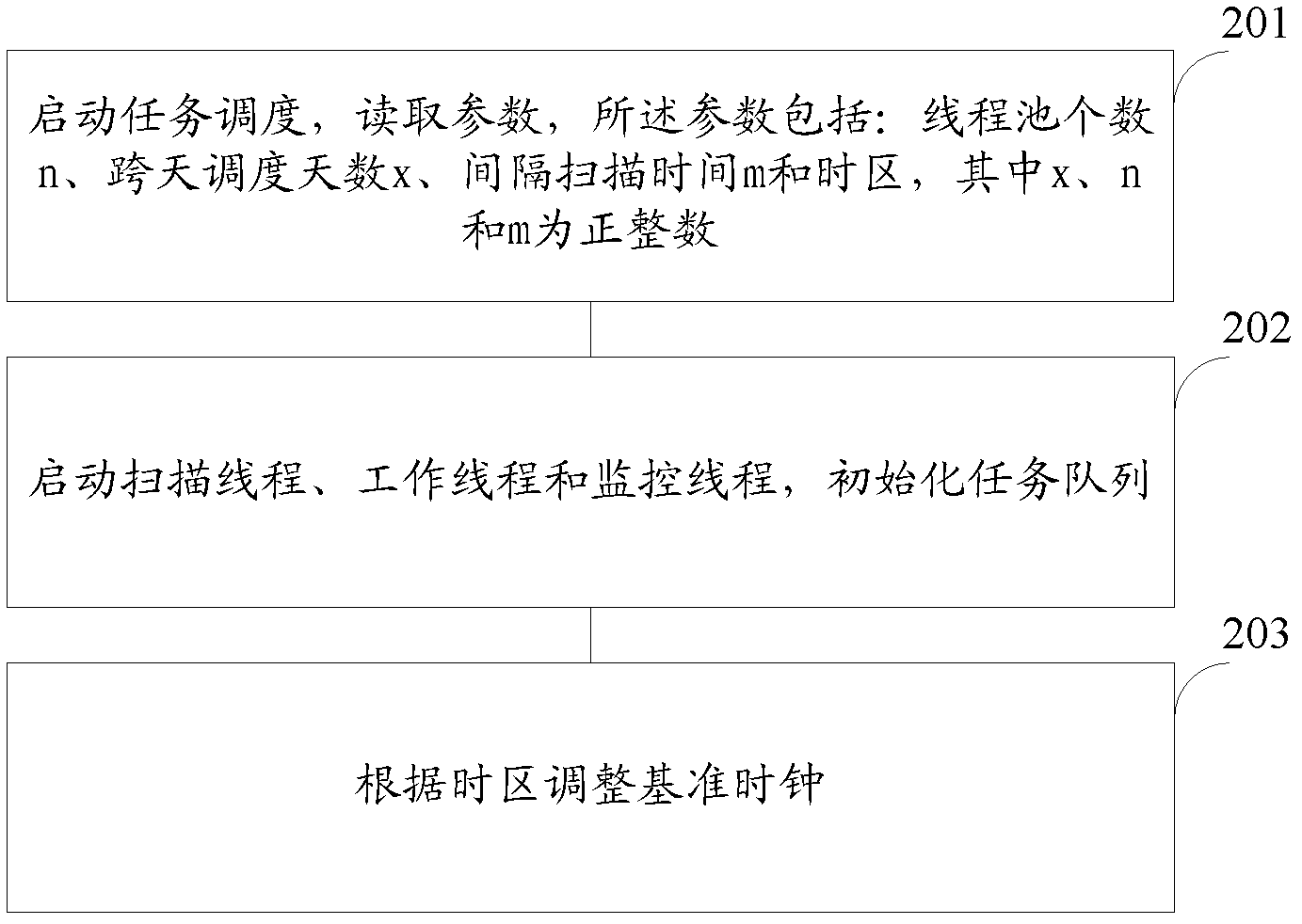

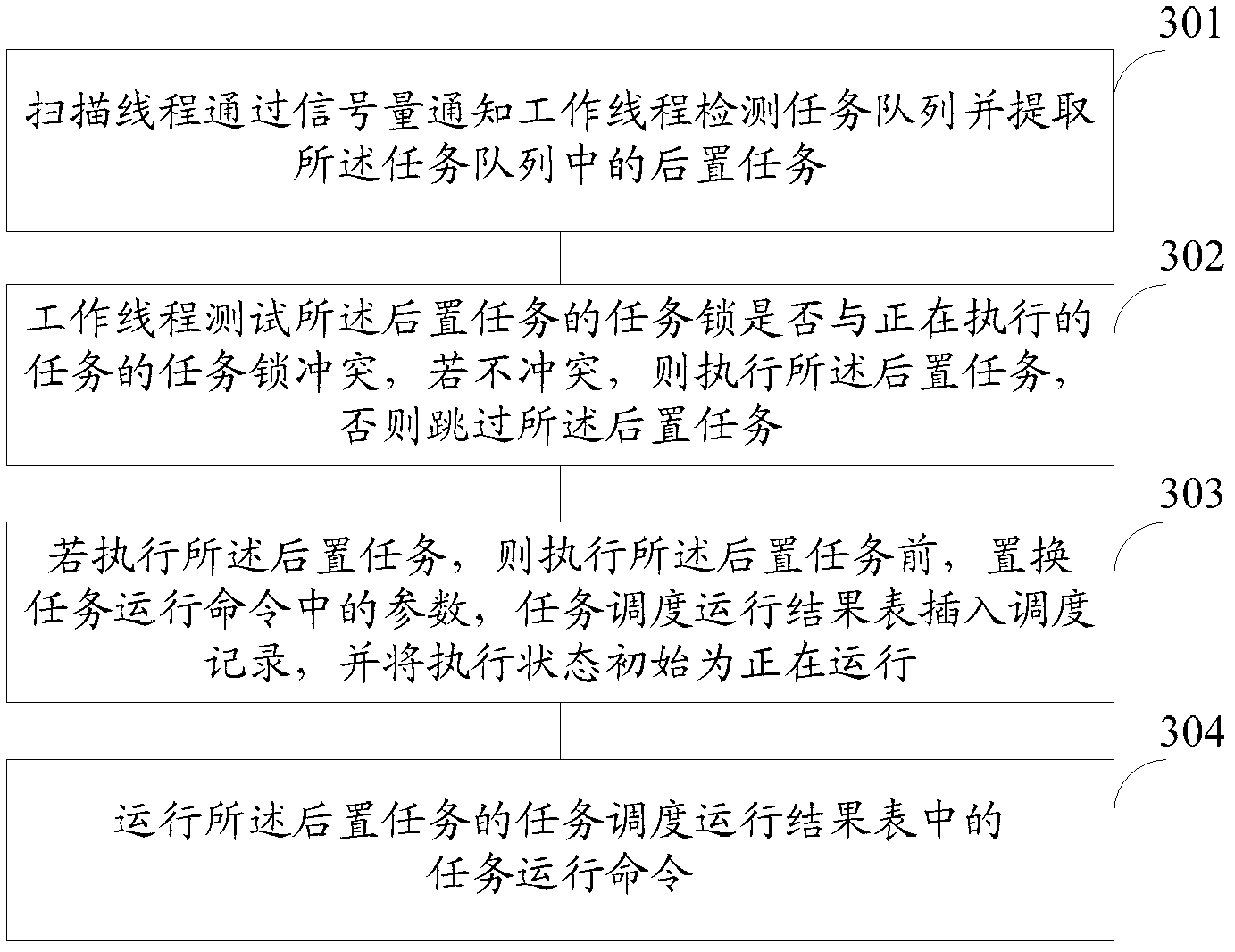

Task scheduling method and system

ActiveCN102981904APerfect task scheduling systemImprove scheduling efficiencyProgram initiation/switchingProgram planningResult list

The invention provides a task scheduling method and a system and aims at solving the problem of limitation of a system in task scheduling. The task scheduling method includes the following steps. Firstly, a task which is mature based on a set time are selected and designated as a postposed task. Plan performing time of a preposed task is calculated through a task scheduling reliance dimension table of the postposed task and a task sequence number of the preposed task is read from the task scheduling reliance dimension table. A performing state of the preposed task in a task scheduling operation result list is found out according to the task sequence number and the plan performing time of the preposed task. If performing is successful, the postposed task is lined up in a task queue and waits for scheduling performing. Under all circumstances, as long as a postposed task is confirmed, a preposed task can be found out and the postposed task can be performed as the preposed task is successfully performed so that the task scheduling system is modified. Scheduling time is shortened, scheduling efficiency is improved and fault rate is reduced.

Owner:ALIBABA GRP HLDG LTD

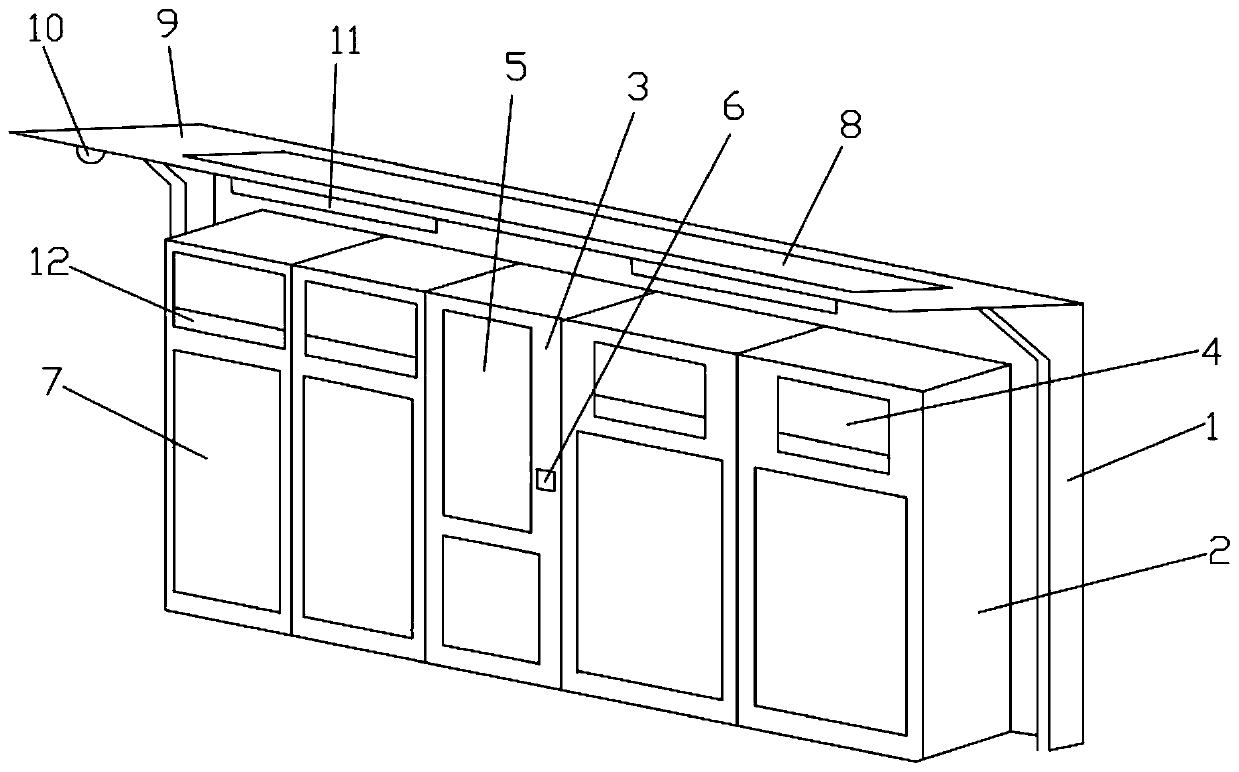

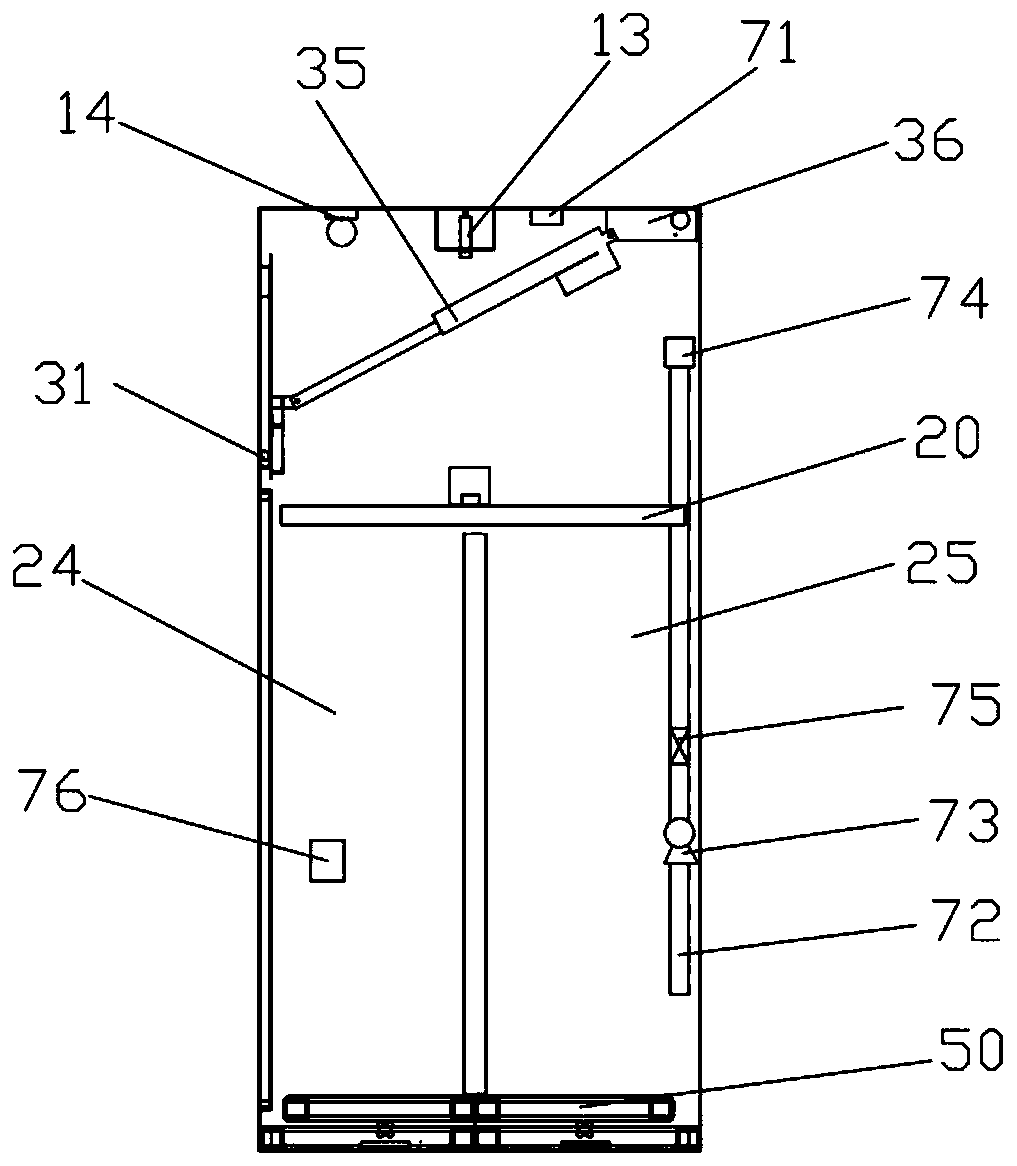

Garbage bin capable of achieving intelligent classified recovering and classification management method

PendingCN110371534ARaise recycling awarenessAct as an incentiveDiscounts/incentivesRefuse receptaclesEngineering

The invention relates to the technical field of classified garbage bins, in particular to a garbage bin capable of achieving intelligent classified recovering and a classification management method. Classified garbage bin bodies are included, each the classified garbage bin body is provided with a garbage input door, a detecting device, a garbage putting device and a controller, wherein the controller sends an opening signal to the garbage input door of the corresponding classified garbage bin body for garbage putting after receiving a garbage putting type signal selected by a garbage puttingperson and sending a signal for detecting the garbage class to the detecting device, after detecting is completed, the controller sends a signal for controlling opening and closing of the garbage putting device to the garbage putting device according to a detection result, and simultaneously a closing or delay closing signal is sent to the garbage input door. By means of the garbage bin and the classification management method, whether the put garbage class is right or not can be automatically identified, the putting person is reminded to put the garbage again as for mixing garbage or garbagewith classification errors, reward points are used for increasing the active recycling awareness of people to the garbage, and mastering of the garbage classification knowledge by people is promoted.

Owner:青岛方天科技股份有限公司

Cleaning robot, control method thereof and ground treatment system

PendingCN111345746AReduce manual involvementAvoid secondary pollutionAutomatic obstacle detectionTravelling automatic controlControl engineeringProcess engineering

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

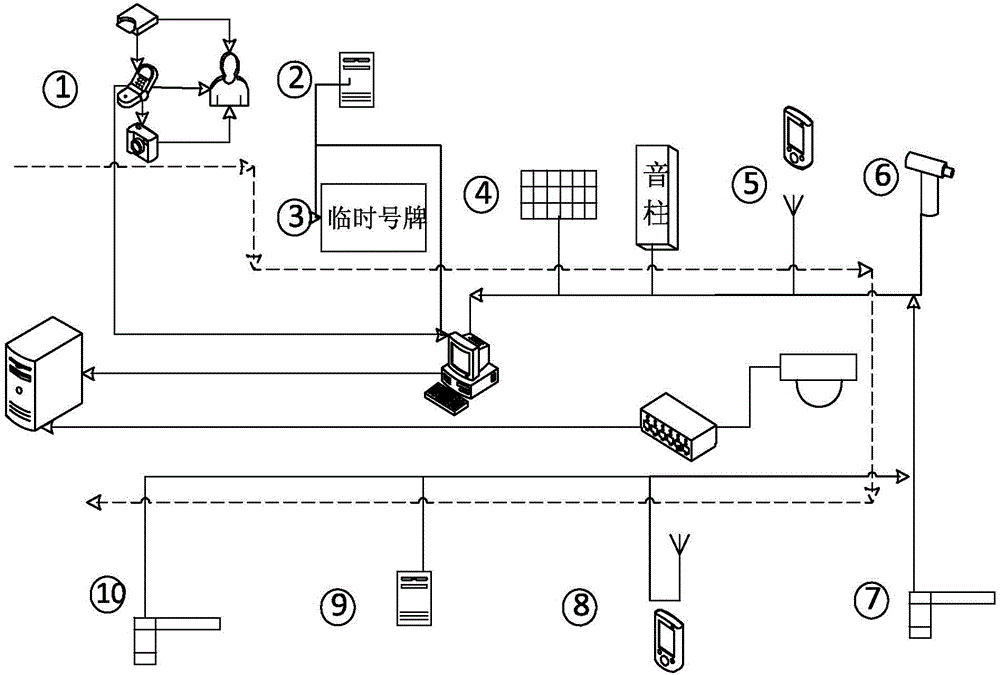

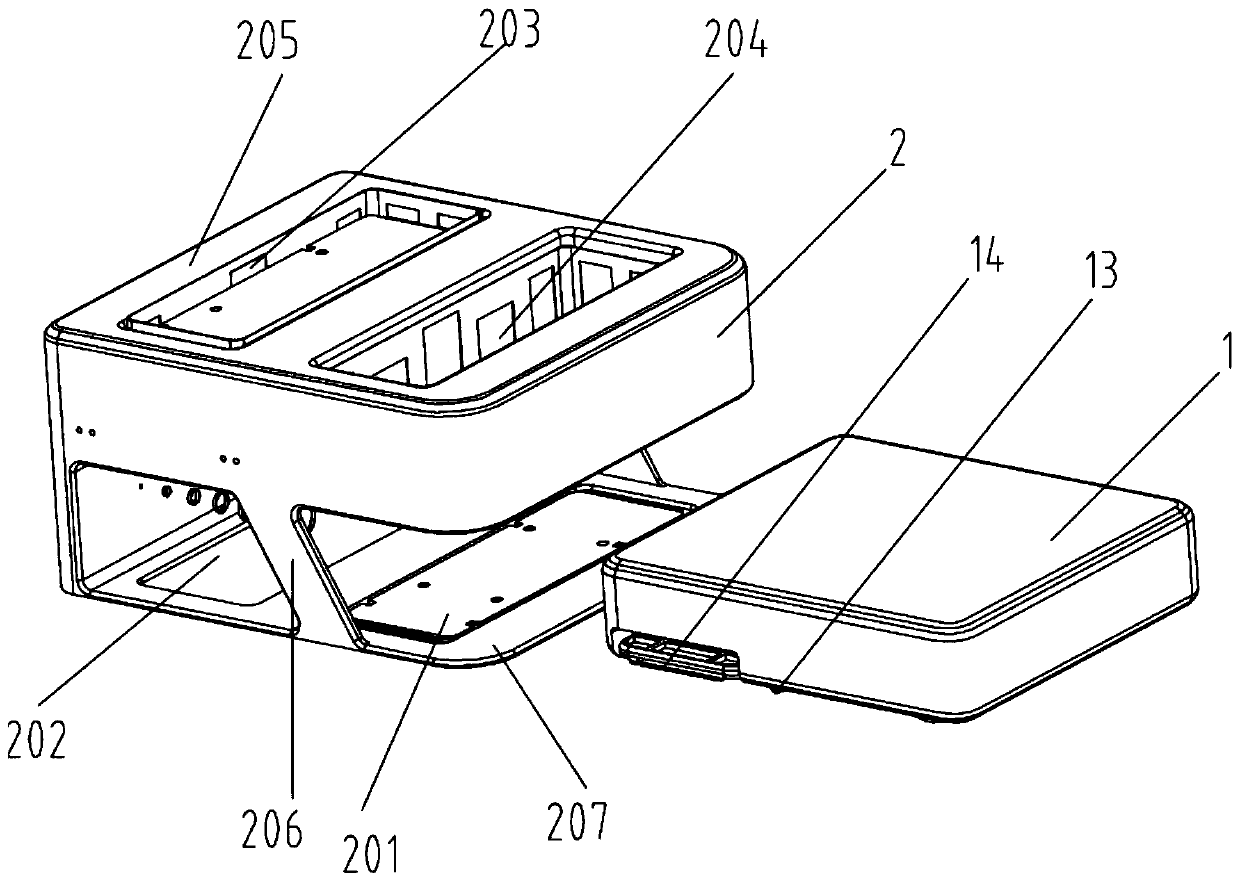

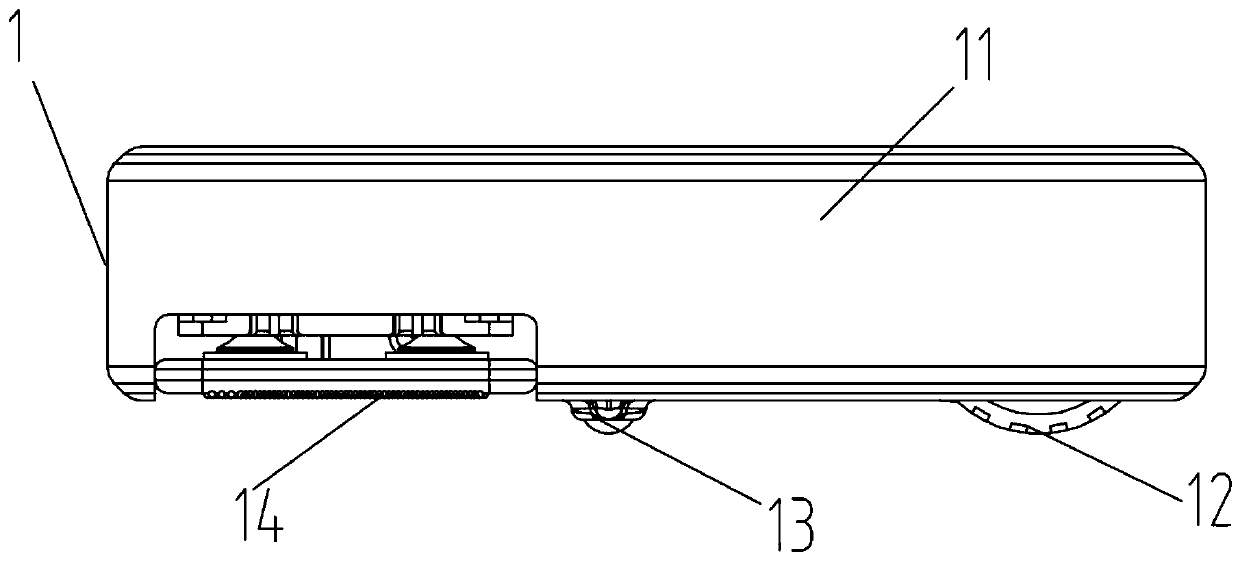

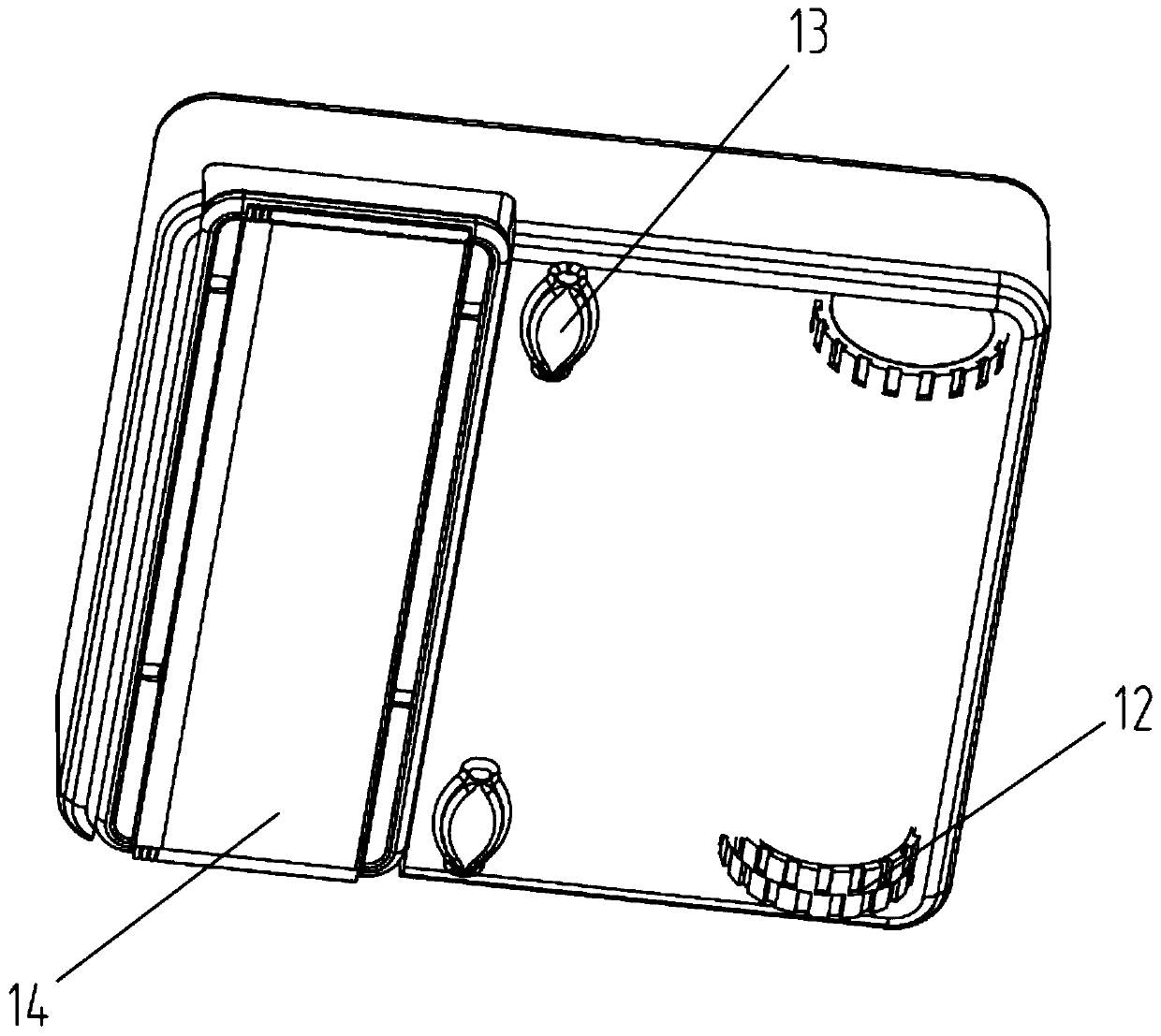

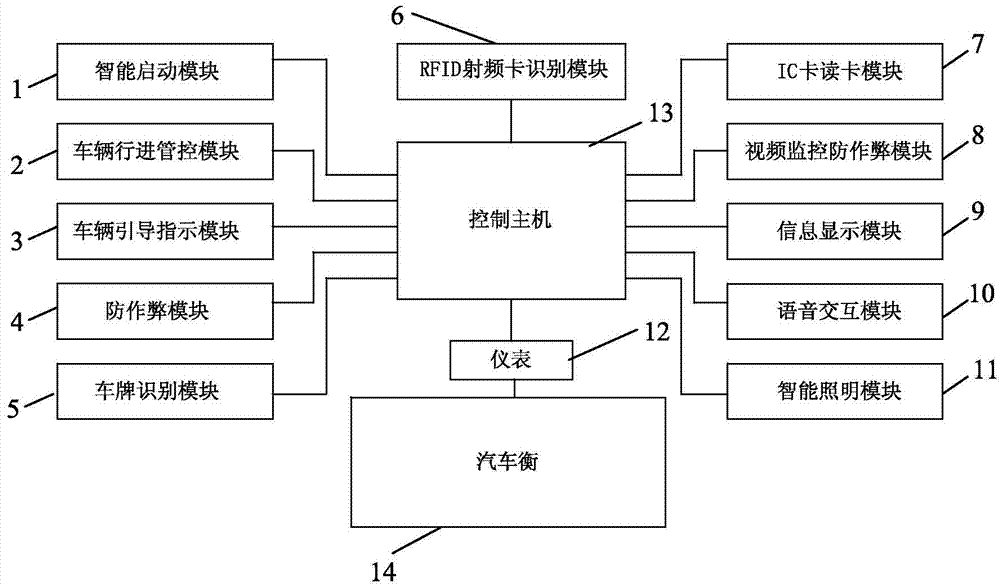

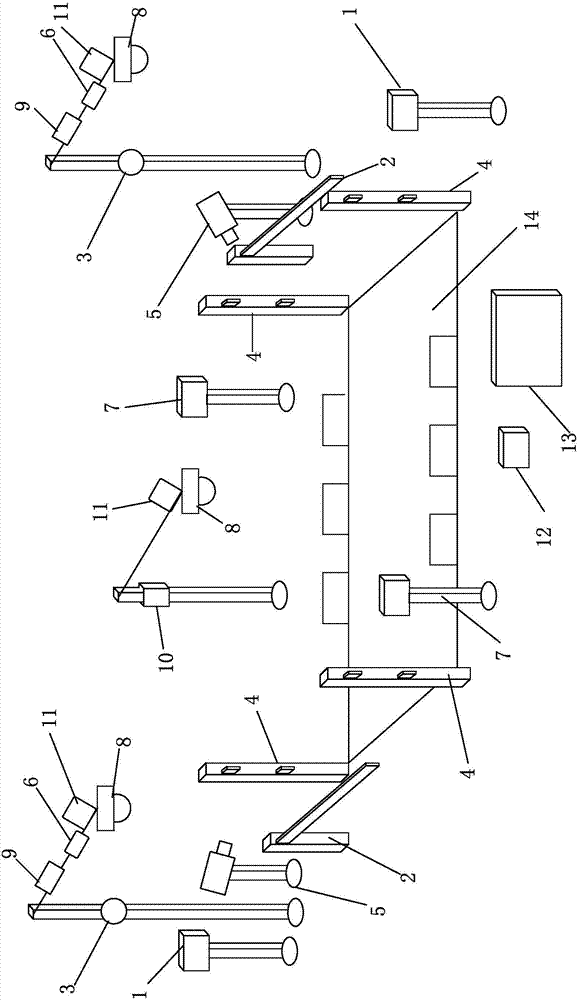

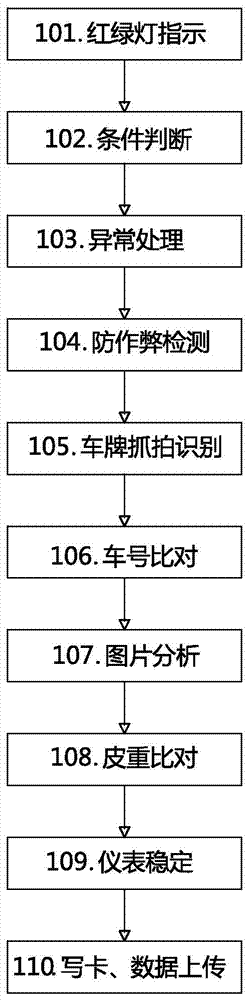

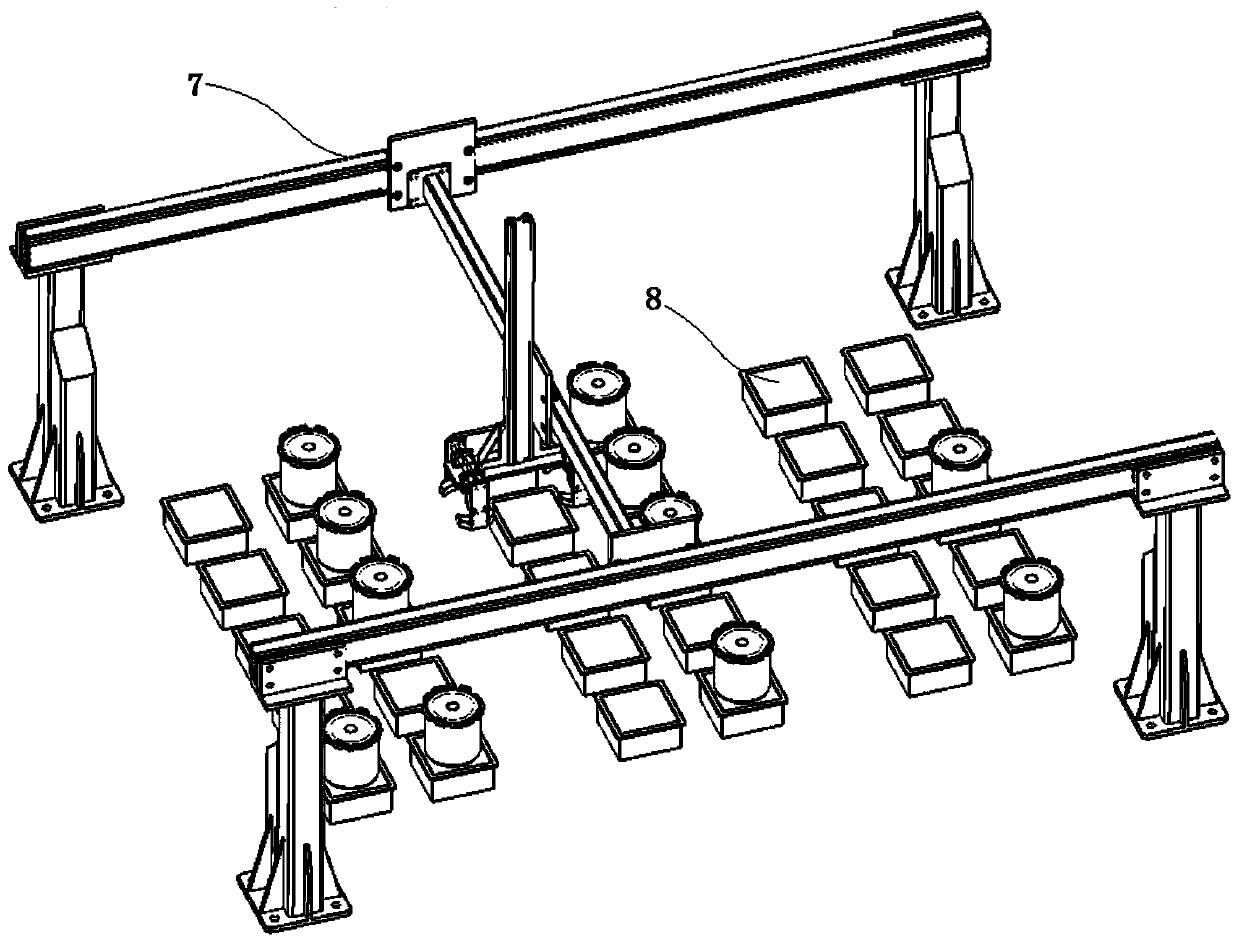

Intelligent unattended operation autoweighing system and method for put-out and put-in of warehouse

ActiveCN103576648AAvoid failureEliminate Tare CheatingProgramme total factory controlVideo monitoringIntelligent lighting

The invention discloses an intelligent unattended operation autoweighing system and method for put-out and put-in of a warehouse and relates to the field of industrial metrology, automatic control and the Internet of Things. The system comprises an intelligent starting module, a vehicle running management module, a vehicle guide indication module, an anti-cheating module, a vehicle license plate recognition module, an RFID radio frequency card recognition module, an IC card reading module, a video monitoring ant-cheating module, an information display module, a voice interaction module, an intelligent lighting module, an instrument module and a control host. Through the RFID technology and the automatic detection and analysis technology, automatic recognition of vehicle numbers, weighing information verification, precise positioning of vehicles, personnel and vehicle cheating supervision, snapshot picture analysis, precise value reading of instruments and the like are achieved in the motor truck scale weighing process, unattended operation autoweighing of a motor truck scale is achieved with the advanced weighing method and the advanced control process, manual participation is reduced, and accuracy, reliability and efficiency of the motor truck scale weighing are improved.

Owner:JINAN JINZHONG ELECTRONICS SCALE +1

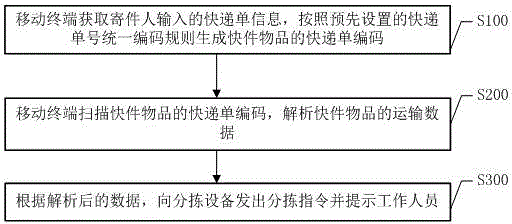

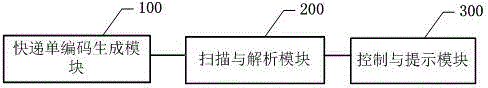

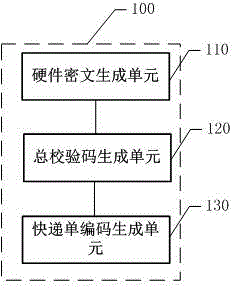

Unified coding-based express delivery object sorting method and system

InactiveCN104907259AExpress sorting is convenientConducive to express delivery managementSortingComputer science

The invention discloses a unified coding-based express delivery object sorting method and system. The method comprises by a mobile terminal, acquiring express wayexpense information input by a sender, generating an express wayexpense code of an express delivery object according to a preset express wayexpense number unified coding rule, scanning the express wayexpense code of the express delivery object by the mobile terminal, carrying out analysis on transport data of the express delivery object by the mobile terminal, and transmitting a sorting instruction to a sorting device according to the analyzed data and giving a prompt for a worker. A courier prints an express wayexpense produced based on the unified coding rule on site, and through craning of the express wayexpense, data such as a logistics enterprise and addressee information are fast identified and ID of the next sorting device is identified in an express delivery object sorting process so that express delivery object sorting and staged automatic settlement of a cost of the related process are convenient, express delivery object management is promoted, artificial participation is reduced and a sorting speed is improved.

Owner:深圳深若科技有限公司

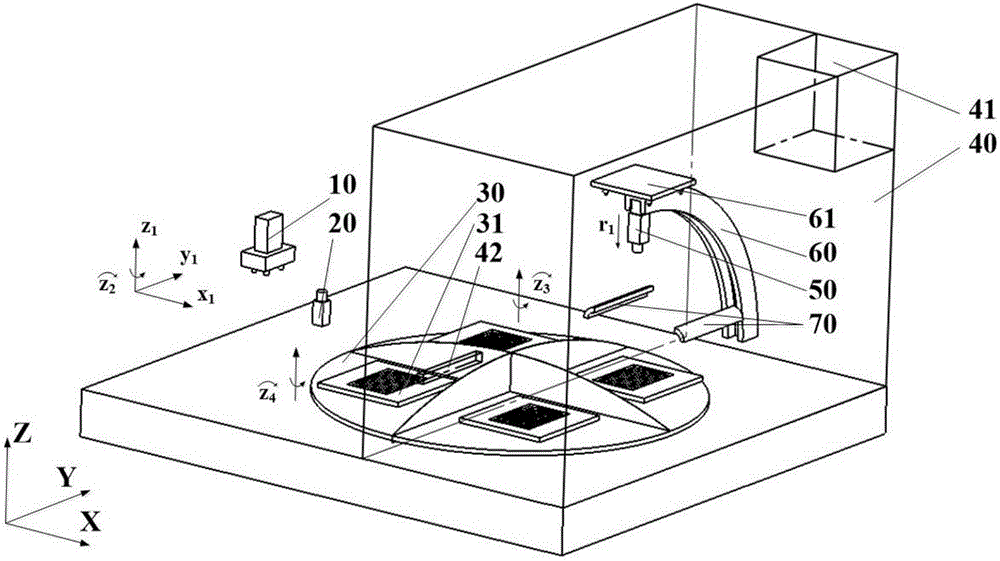

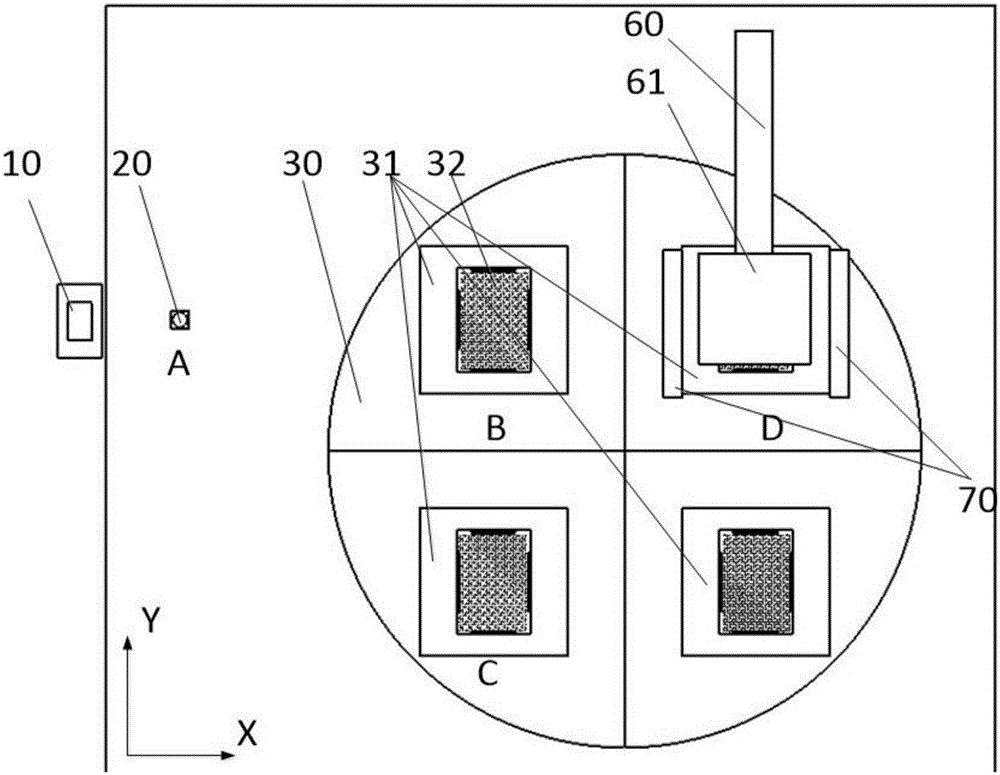

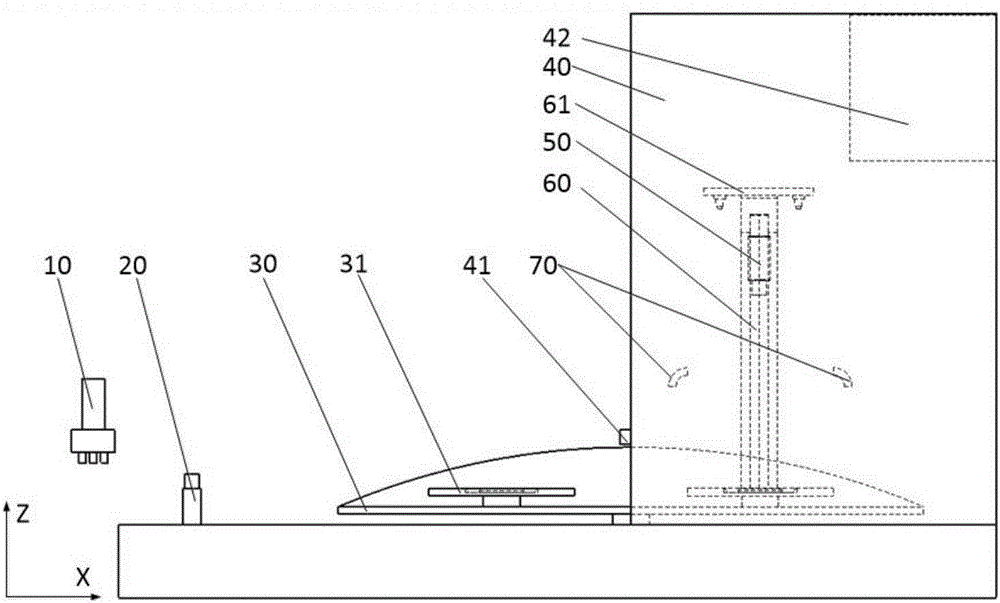

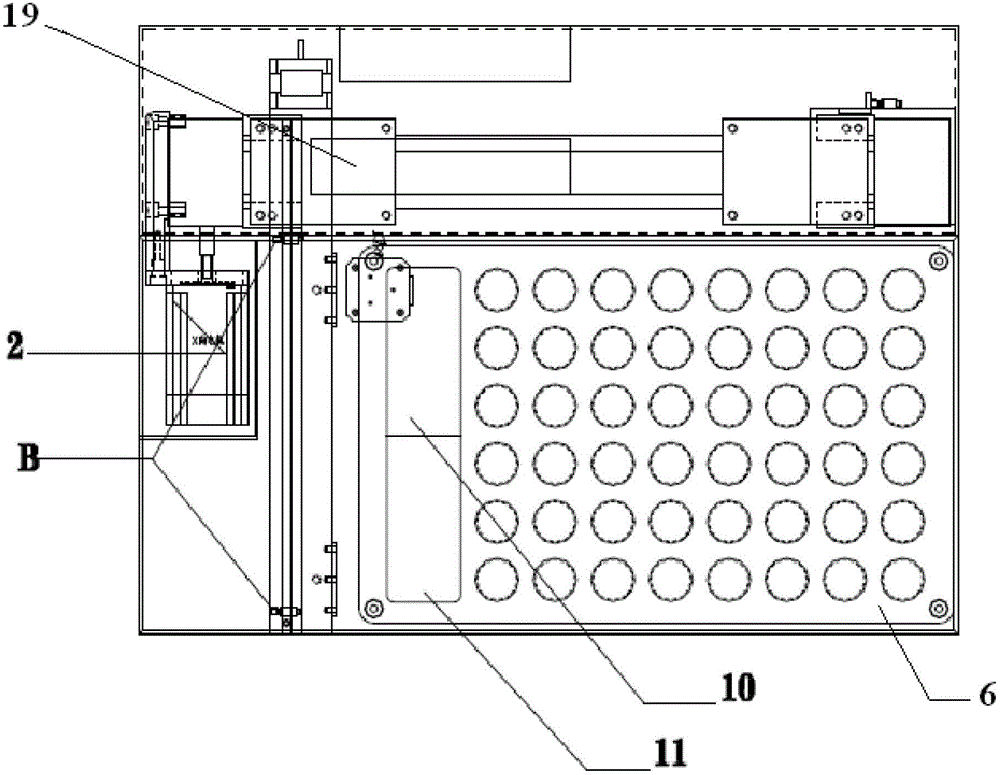

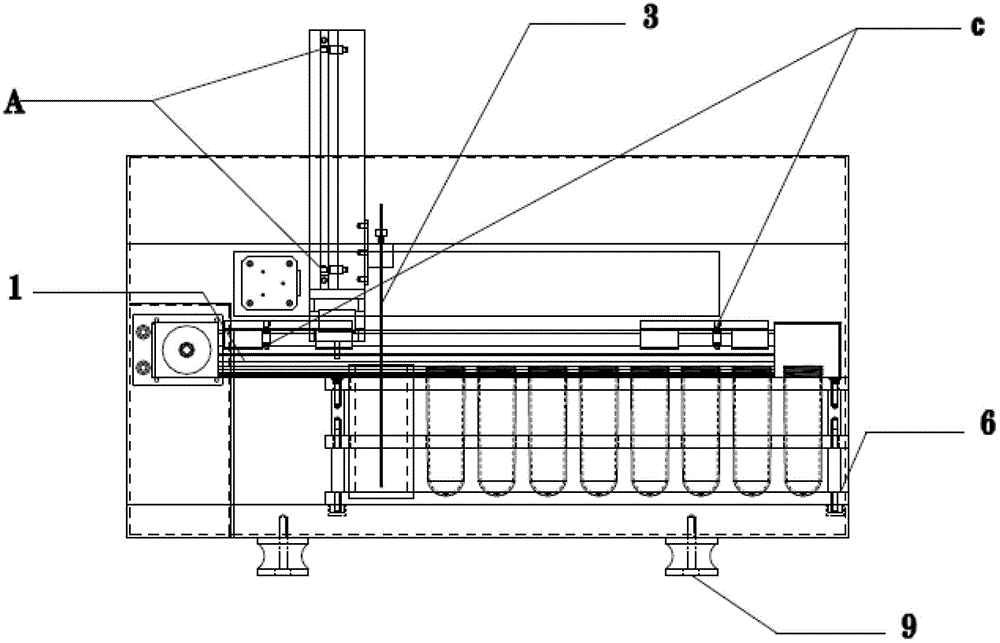

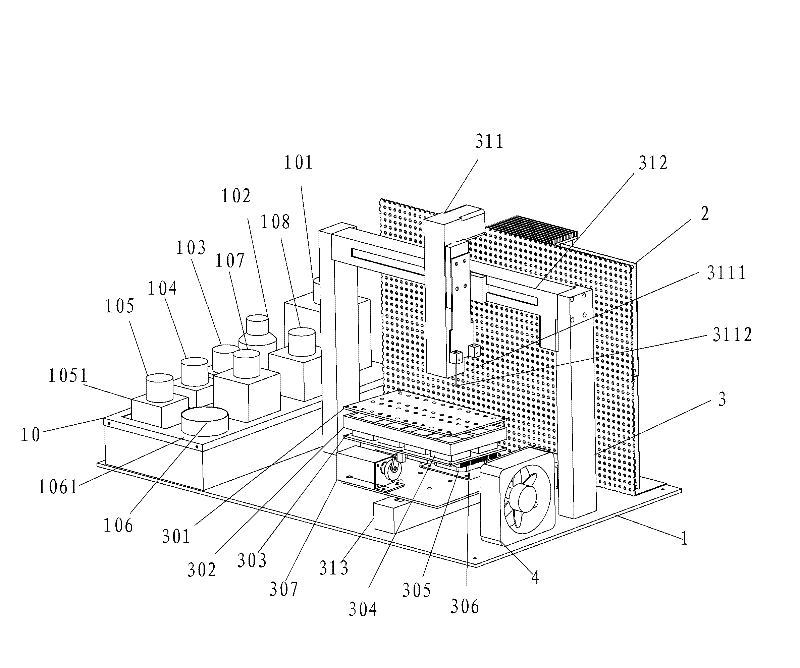

Multi-station single-vision AOI (automatic optic inspection) detection platform and detection method for flexible displays screens

ActiveCN106814087AImprove operation convenienceImprove detection accuracyOptically investigating flaws/contaminationEngineeringFlexible electronics

The invention belongs to the field of flexible electronic product detection associated equipment and discloses a multi-station single-vision AOI (automatic optic inspection) detection platform for flexible displays screens. The platform comprises a feeding and discharging manipulator, an up looking camera, a detection bottom board, an outer cover, a camera guide rail frame, a detection camera, a light emitting component and the like. The feeding and discharging manipulator and the up looking camera are matched mutually to guarantee that to-be-detected flexible display screens are correctly put in detection plates on the detection bottom board. The outer cover is used for providing a hermetical space for detection conditions. The camera guide rail frame and the detection camera are matched mutually to realize high-precision acquisition of front images and lateral images in different angles of the flexible display screens under the action of rotation of the detection plates. The invention further discloses a corresponding detection method. By the multi-station single-vision AOI detection platform and the detection method for the flexible displays screens, a whole multi-station flexible display screen detection process can be executed through one camera. In addition, compared with existing equipment, the platform has advantages of high precision, high efficiency, convenience in operation, high reliability, high adaptability and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

JMX (Java Management Extensions)-based customization real-time monitoring and automatic exception handling system and method

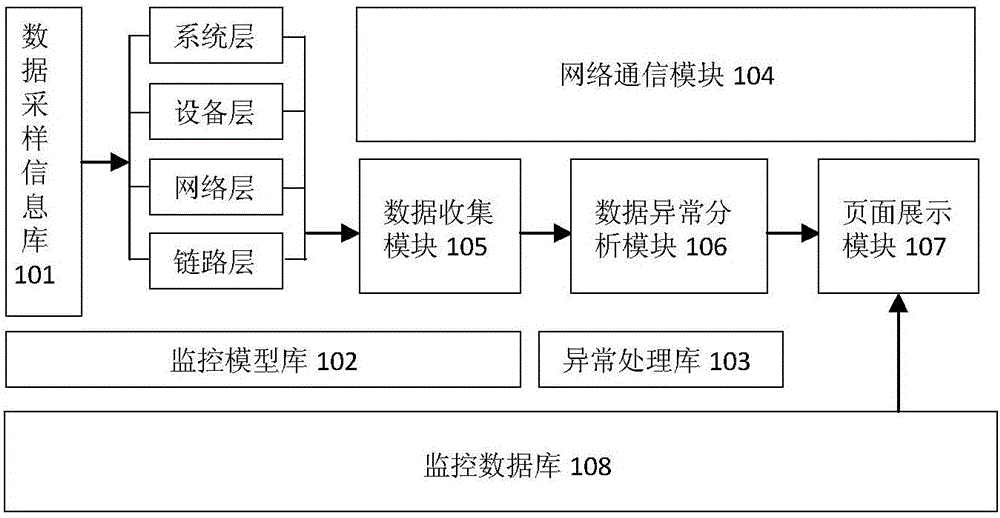

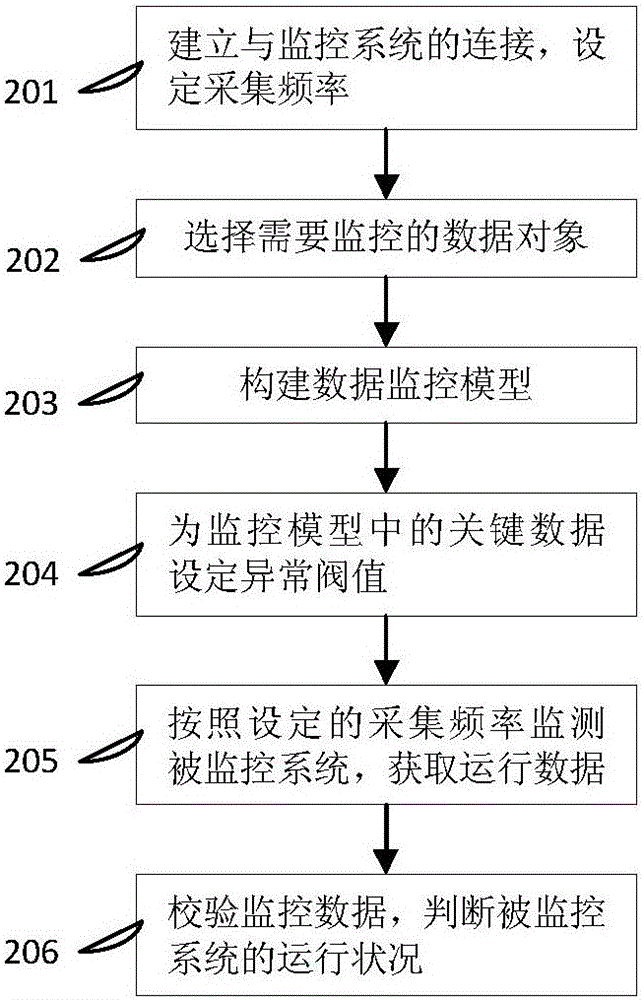

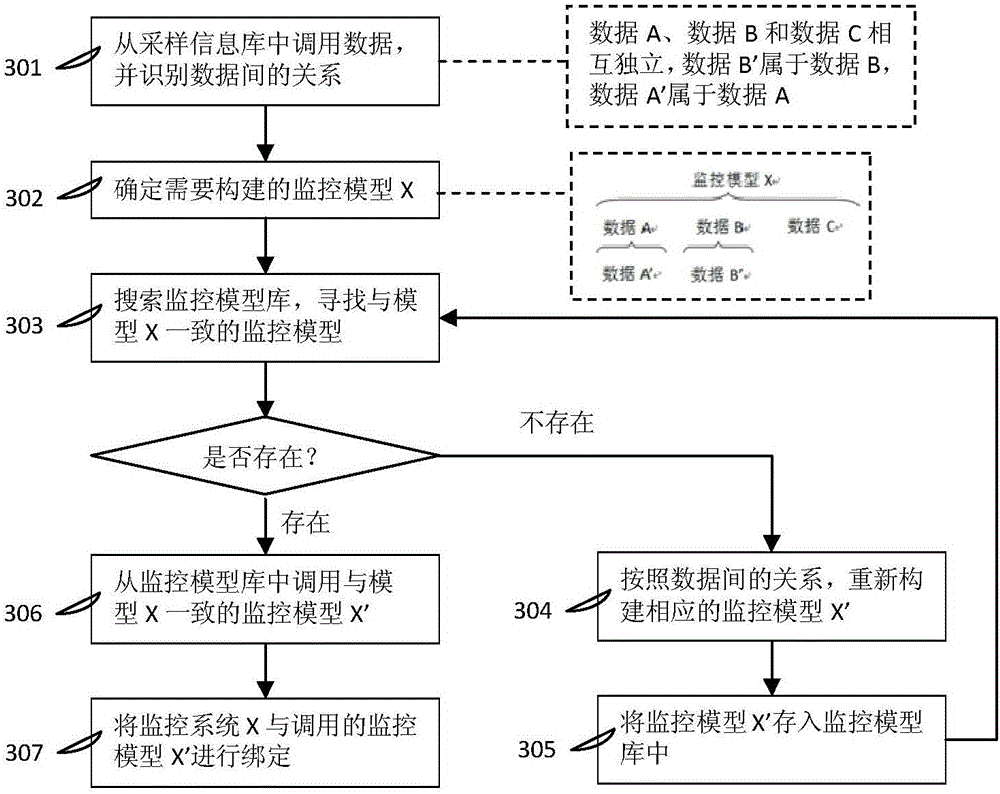

ActiveCN105071969AImprove work efficiencyRealize managementHardware monitoringData switching networksData transmissionCollections data

The invention discloses a JMX (Java Management Extensions)-based customization real-time monitoring and automatic exception handling system. The JMX-based customization real-time monitoring and automatic exception handling system comprises a data sampling information library, a monitoring model library, an exception handling library, a network communication module, a data collection module, a data exception handling analysis module, a page presentation module and a monitoring database, wherein monitored systems are used for starting a JMX access port, and establish remote access connection between the monitoring system and the monitored systems; the data sampling information library is a warehouse for storing data sample information; the monitoring model library is a warehouse for storing monitoring models corresponding to all the monitored systems; the exception handling library is a warehouse for storing exception handling methods and flows; the network communication module is used for constructing and managing network data transmission between the monitoring system and each monitored system, and maintaining normal network communication between the monitoring system and all the monitored system; and the monitoring database is used for storing data monitored and acquired by the real-time data collection module.

Owner:FOCUS TECH

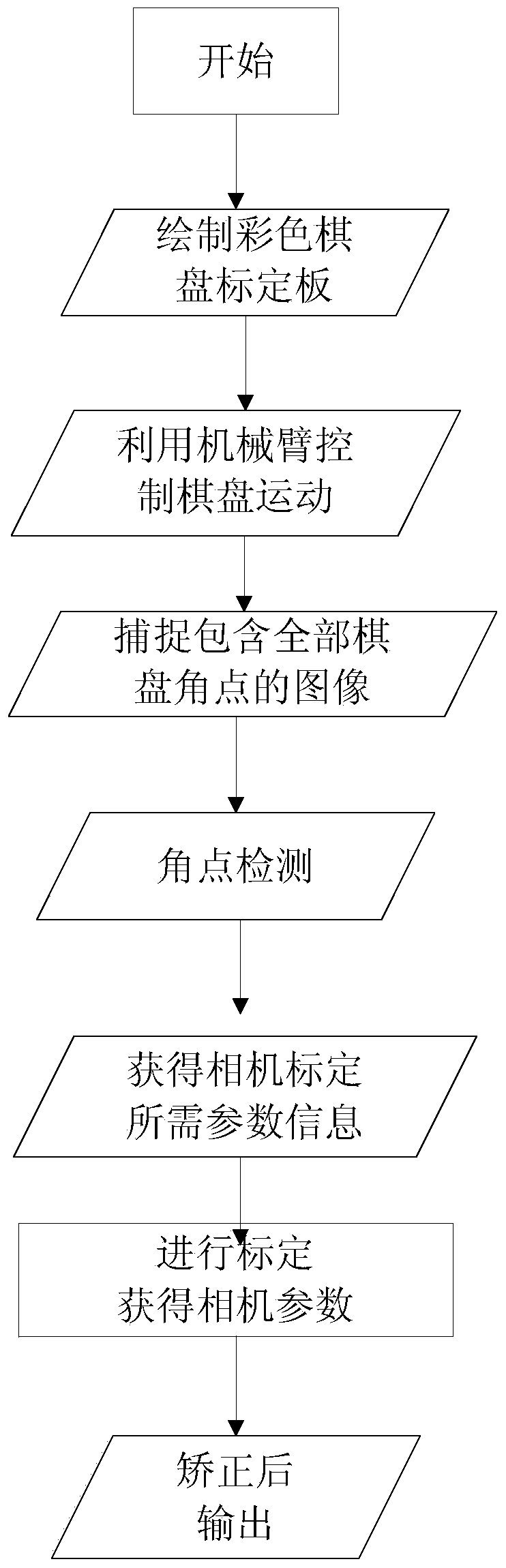

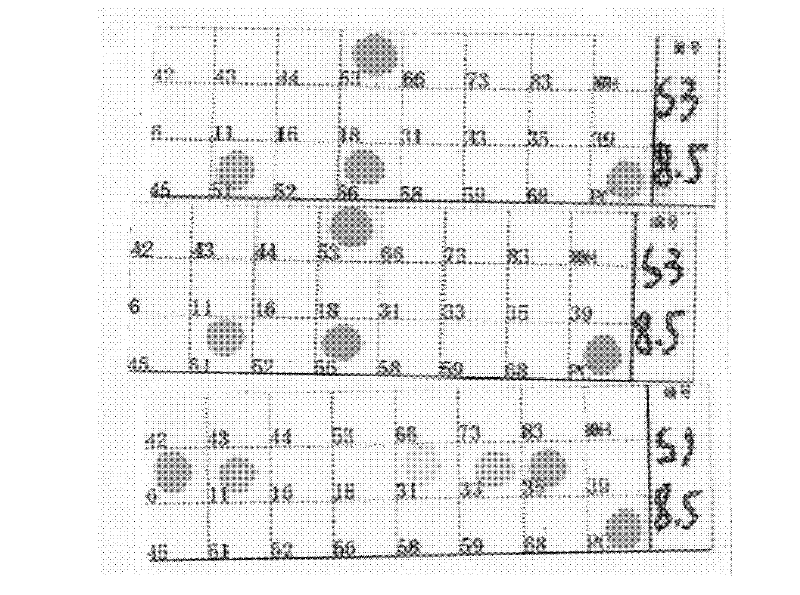

Full-automatic camera parameter calibration method based on colored calibration board

InactiveCN103679729AReduce manual involvementImprove calibration accuracyImage analysis3D modellingCamera auto-calibrationCorner detection

The invention provides a full-automatic camera parameter calibration method based on a colored calibration board. The method includes the following steps that firstly, the colored chess calibration board is drawn, wherein four neighborhoods of each corner are a combination of different colors; secondly, the movement of the colored chess calibration board is controlled by a mechanical arm to set presetting bits and capture calibration images; thirdly, corner detection is carried out according to the calibrated images obtained in the second step; fourthly, fake corners are removed according to whether 'color codes' of the corners are in a 'color code' library of the calibration board or not; fifthly, all parameters for camera calibration are obtained based on space coordinates of the true corners obtained in the fourth step and pixel coordinates of the true corners in the calibration image; sixthly, the camera parameters are acquired to complete camera calibration.

Owner:PLA SECOND ARTILLERY ENGINEERING UNIVERSITY

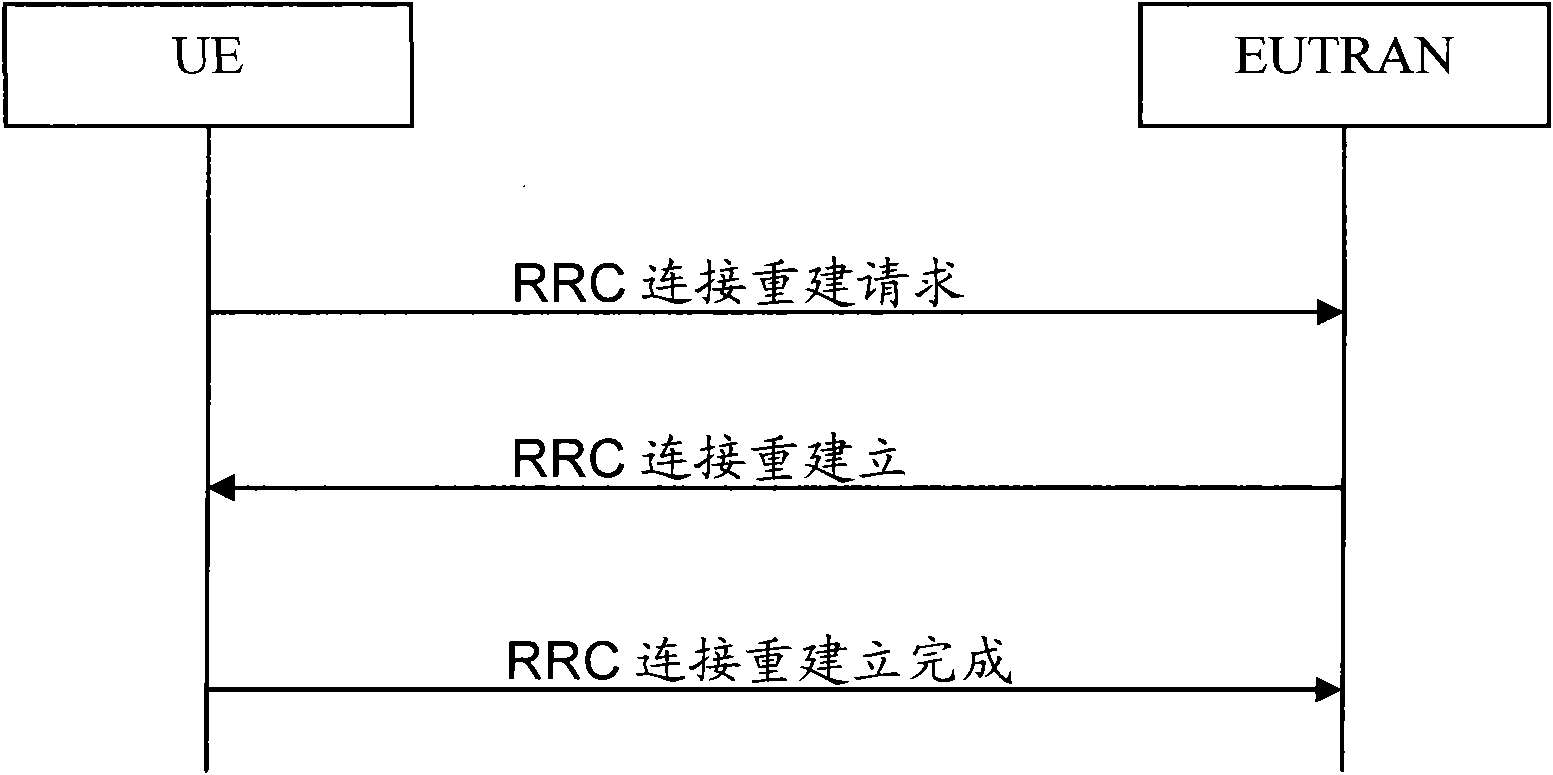

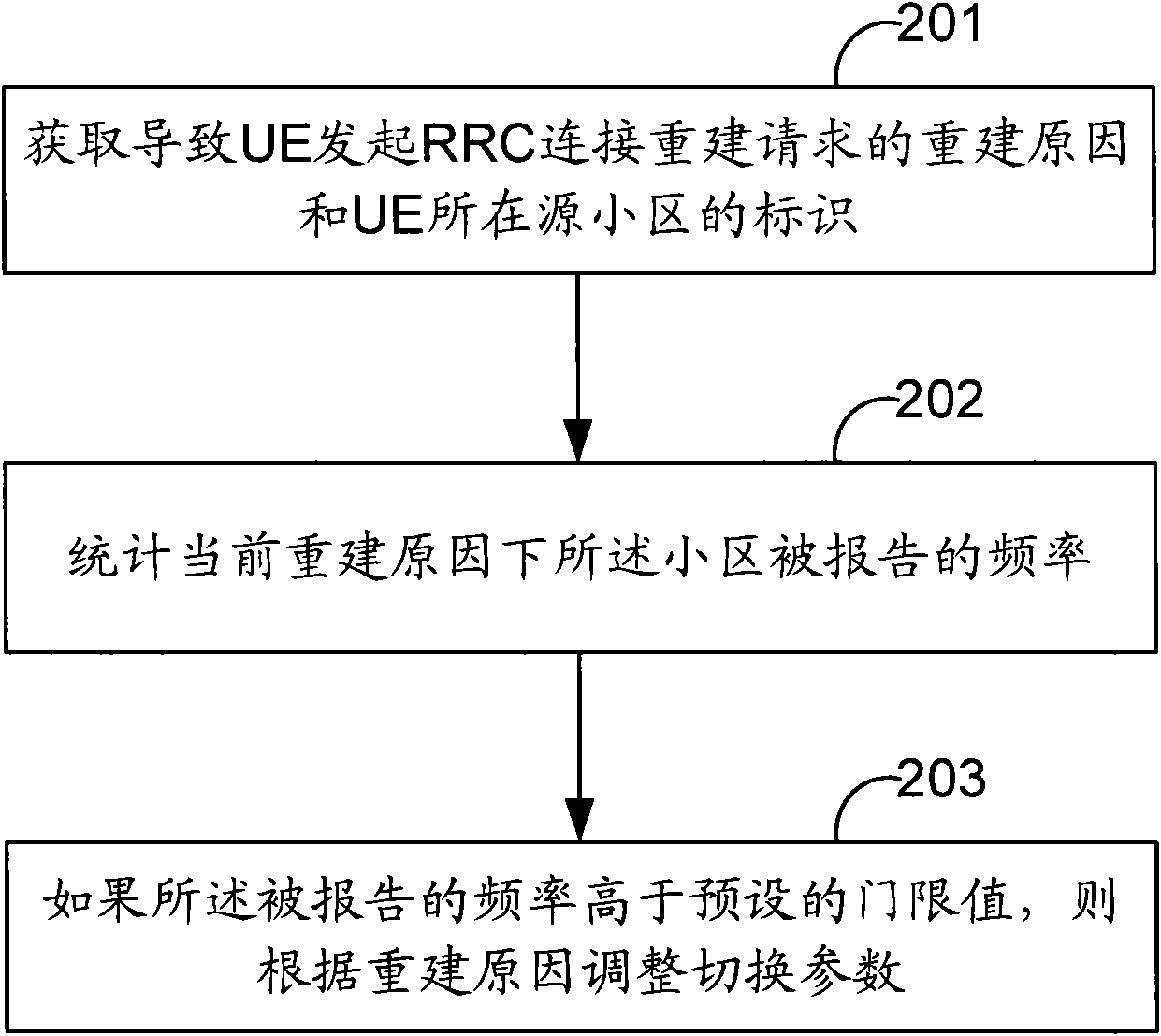

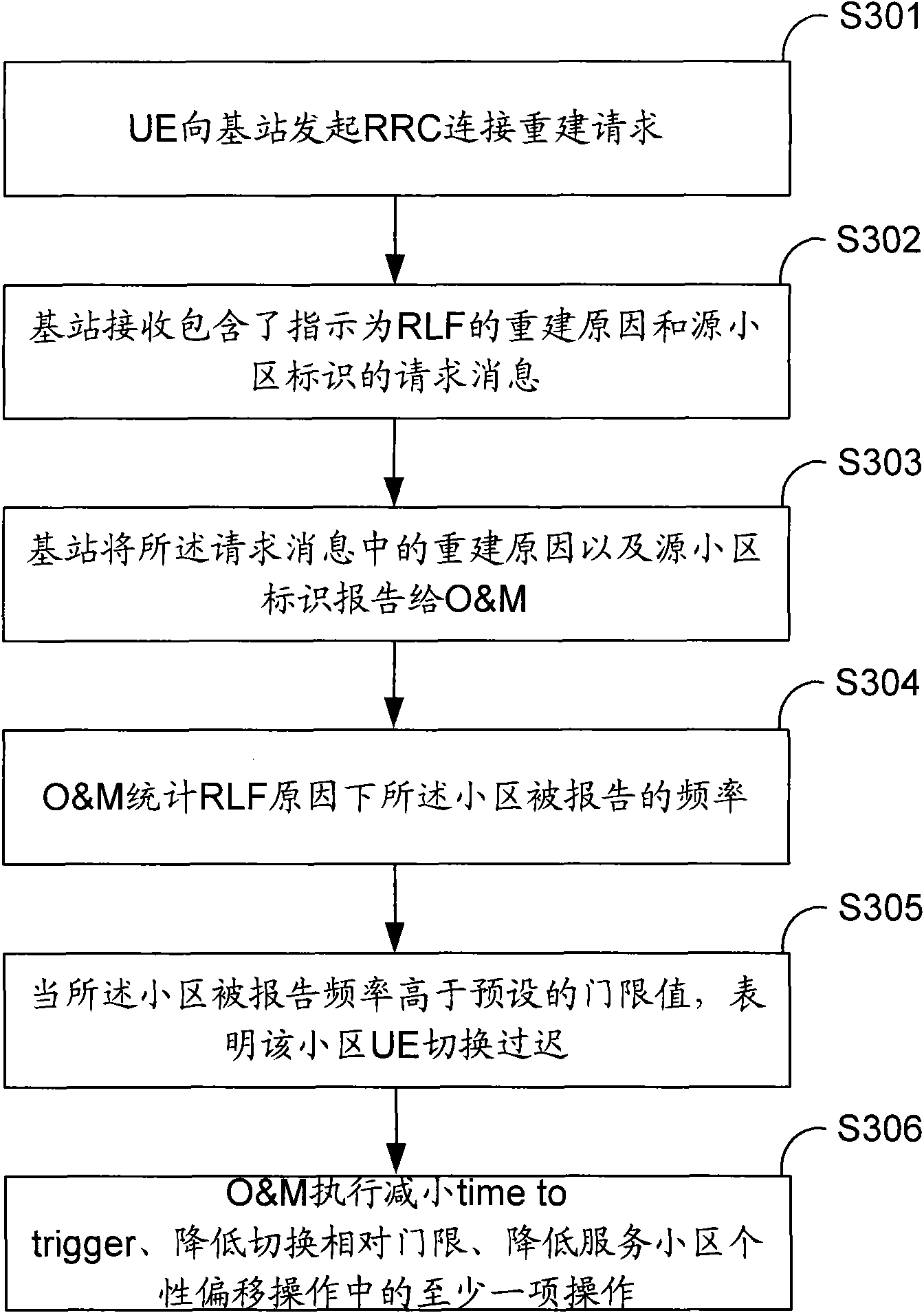

Method, device and system for realizing self-optimization of switching parameter

InactiveCN101848476AAchieve self-optimizationReduce manual involvementWireless communicationOperational costsComputer science

The invention relates to a method, a device and a system for realizing self-optimization of a switching parameter. The method comprises the following steps of: acquiring a reestablishment reason for UE to initiate RRC connection reestablishment request and a mark of a source cell of the UE; counting the reported frequency of the cell over the current reestablishment reason; and if the reported frequency is higher than a preset threshold, correspondingly adjusting the switching parameter according to the reestablishment reason. The invention shows that the method, the device and the system can realize self-optimization of the switching parameter, reduce the human intervention of the network planning and the operation and maintenance and lower the establishment cost and the operation cost for the network.

Owner:CHINA ACAD OF TELECOMM TECH

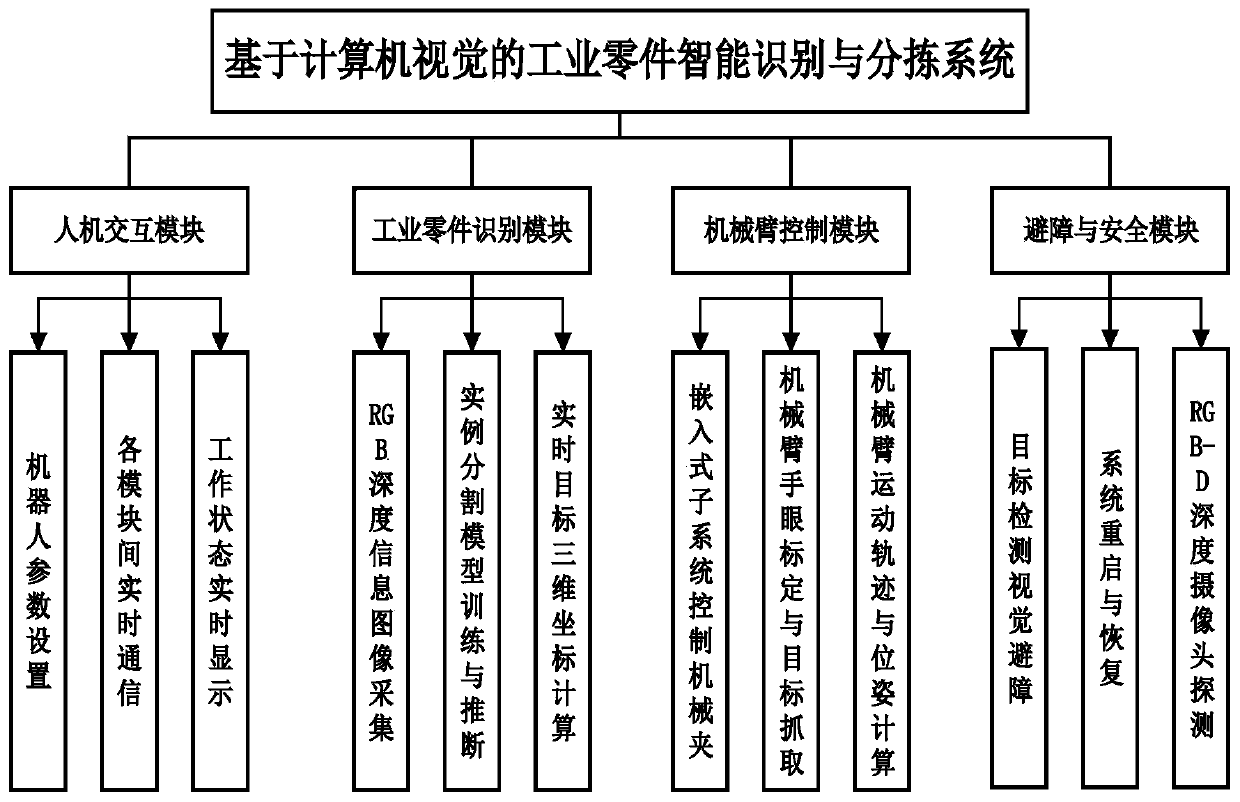

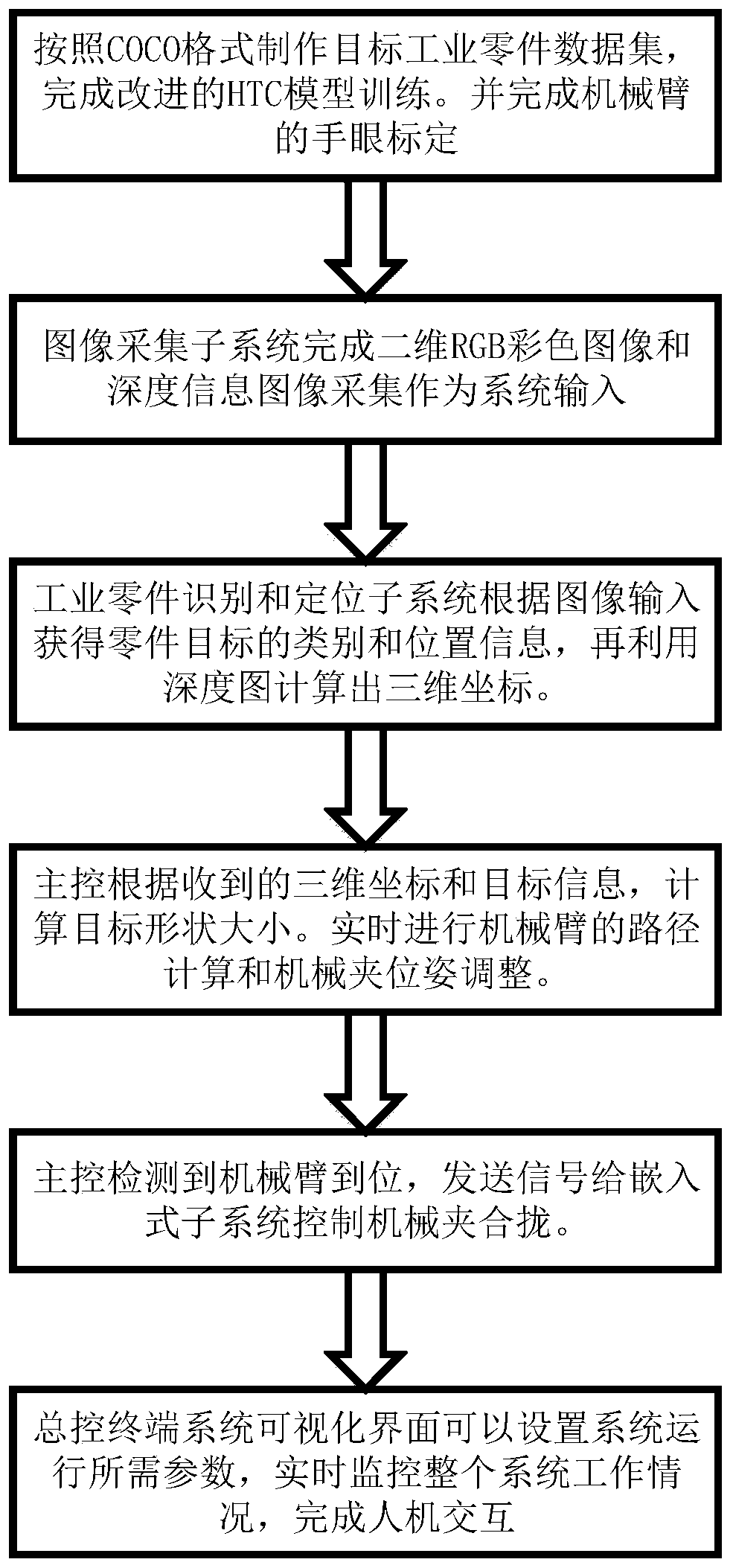

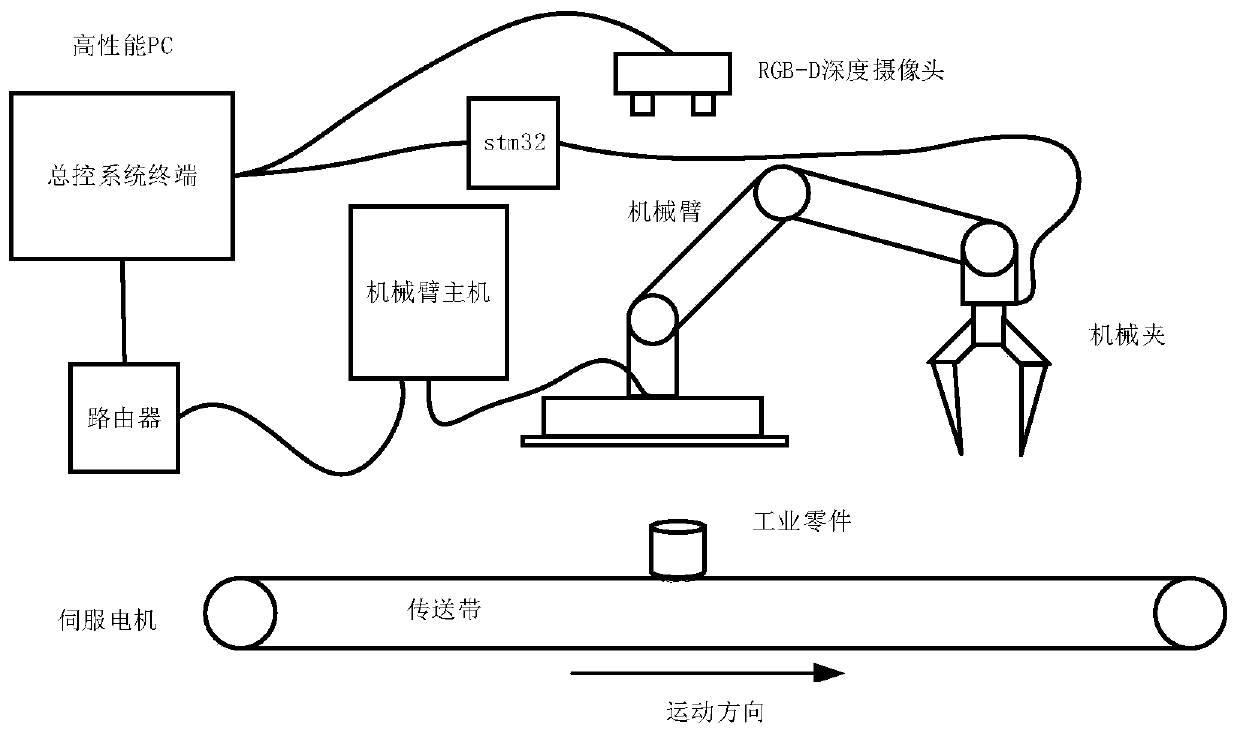

Industrial part intelligent identification and sorting system based on computer vision

PendingCN111421539AIncrease the number ofEasy to classifyProgramme-controlled manipulatorSortingColor imageControl system

The invention provides an industrial part intelligent identification and sorting system based on computer vision. An image collector collects a two-dimensional color image and a depth information image and outputs the two-dimensional color image and the depth information image to a master control system terminal, the master control system terminal extracts the size and position information of a target in a production environment as classification features and inputs the classification features to a locally trained instance segmentation model HTC for target identification and positioning so asto obtain the position information of the target, the path planning of a mechanical arm is completed, and the posture of a mechanical clamp is determined according to the shape and size of the target;and the task of the mechanical arm and the mechanical clamp is interrupted or changed in real time according to the interaction information received in real time from the mechanical arm host and themechanical clamp host. According to the invention, the use of the industrial robot is simplified, the operation difficulty of a user is reduced, and meanwhile, the working efficiency of cooperative sorting between robots is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

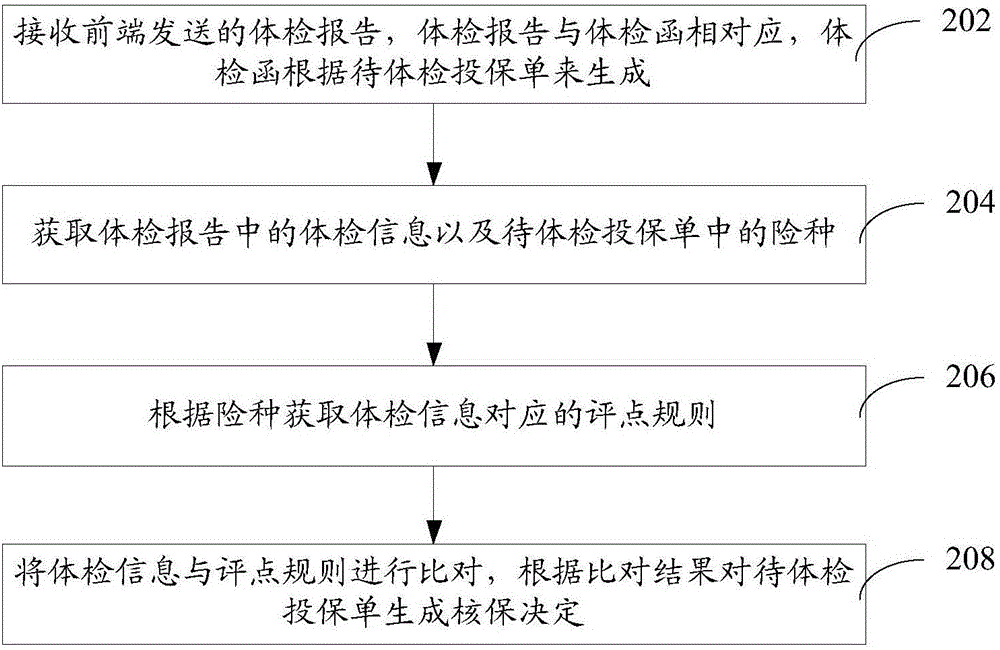

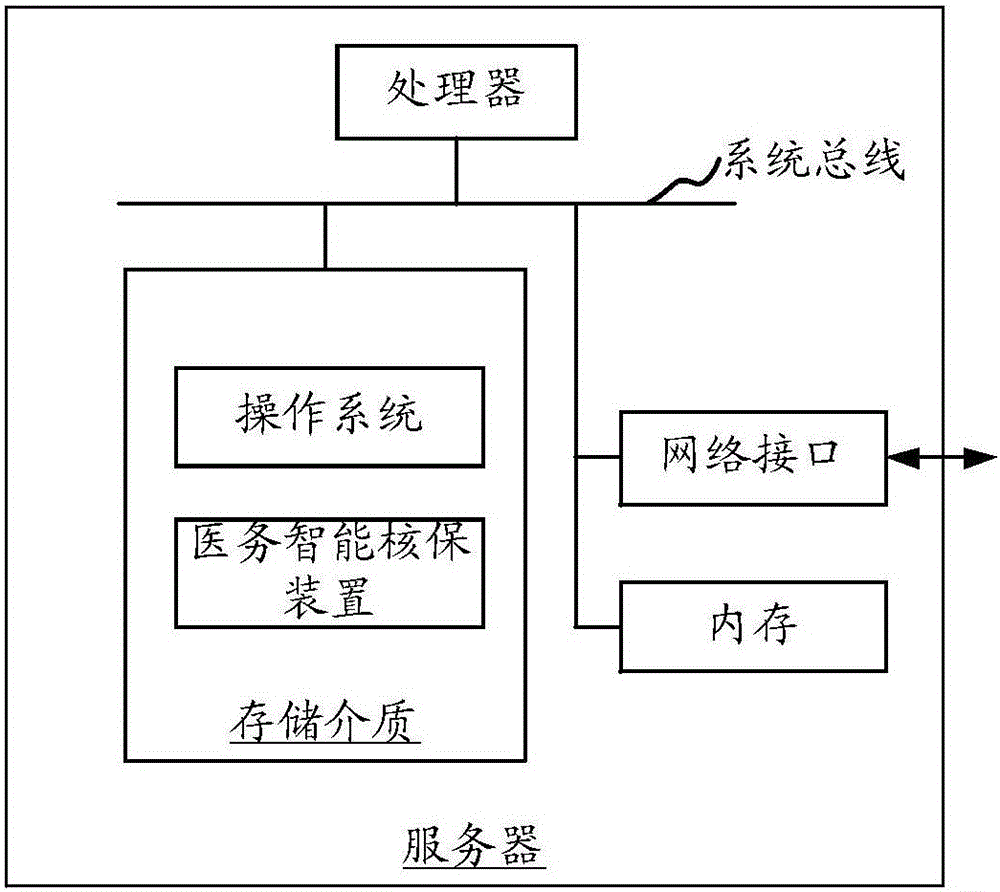

Medical affair intelligent insurance checking method and system

InactiveCN105809549AReduce manual involvementImprove underwriting efficiencyFinanceMedicineHealth check

The invention relates to a medical affair intelligent insurance checking method and system. The method comprises the following steps: receiving a health check-up report sent by a front end, wherein the health check-up report is corresponding to a health check-up letter, and the health check-up letter is generated according to an insurance application needing health check-up; obtaining health check-up information in the health check-up report and an insurance type in the insurance application needing the health check-up; according to the insurance type, obtaining evaluation rules corresponding to the health check-up information; and comparing the health check-up information with the evaluation rules, and according to a comparison result, generating an insurance checking decision for the insurance application needing the health check-up. By using the method provided by the invention, the insurance checking efficiency of insurance applications receiving health check-up letters can be effectively improved.

Owner:PING AN TECH (SHENZHEN) CO LTD

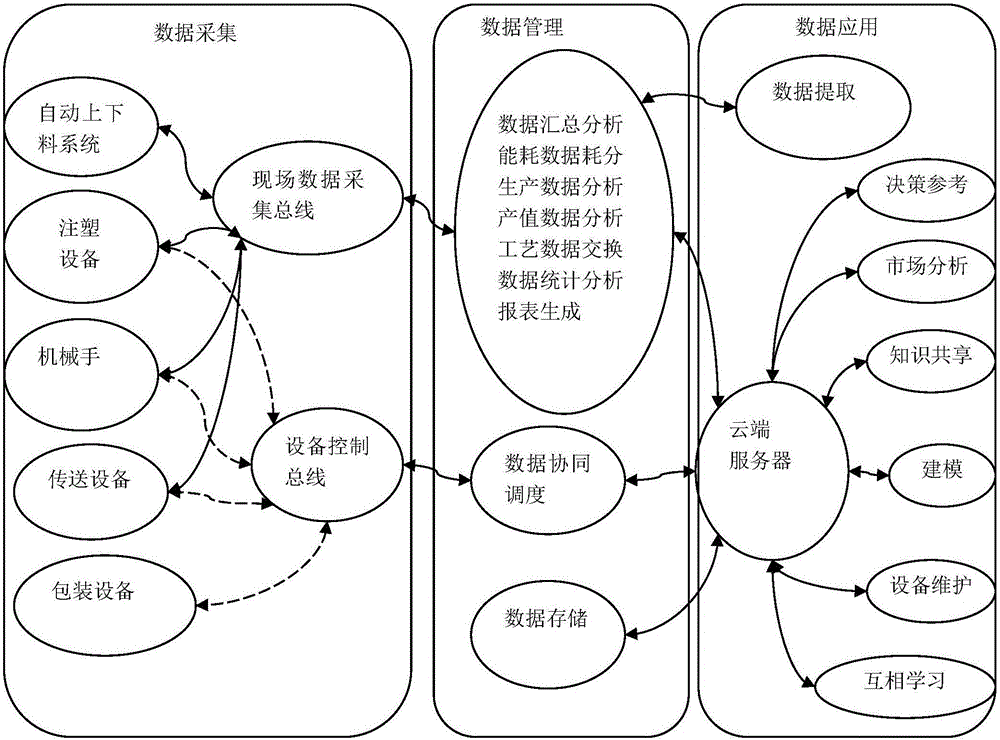

Automatic injection-molding production system and intelligent production method

ActiveCN104991533AIntelligent maintenanceReduce manual involvementTotal factory controlProgramme total factory controlSensing dataData file

The invention discloses an automatic injection-molding production system and an intelligent production method. The production system comprises a cloud server, a central control system, an automatic feeding and blanking system, injection molding devices, mechanical arms, a conveyer system, and a packaging device. The automatic feeding and blanking system, the injection molding devices, the mechanical arms, the conveyer system, the packaging device and the central control system are connected by a field bus. The central control system is used for receiving sensing data fed back by the automatic feeding and blanking system, the injection molding devices and the mechanical arms, sending the sensing data to the cloud server and performing optimization scheduling control on the corresponding devices. The cloud server is used for extracting and analyzing the sensing data sent by the central control system to form a corresponding data file, generating an optimization control decision of the corresponding devices, and sending the optimization control decision to the central control system. By adopting the system and the method of the invention, intelligent injection-molding production can be carried out, manual participation is greatly reduced, and the production efficiency is improved. The system and the method can be widely used in the industry of automatic injection-molding production.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

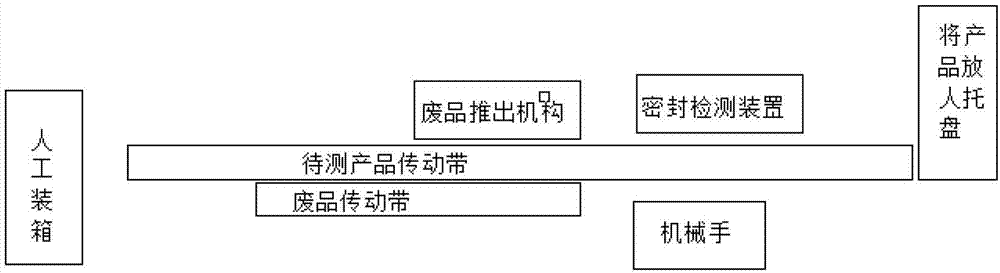

Seal detecting production line

InactiveCN103196636ANot destroyedEasy to grabMeasurement of fluid loss/gain rateProduction lineProgrammable logic controller

The invention discloses a seal detecting production line. The seal detecting production line comprises a working platform, a conveying belt for products to be tested, a waste conveying belt, a seal detecting device, a mechanical arm, and a waste pushing mechanism. The mechanical arm is used for grabbing the products to be tested and enabling the products to be tested to pass in and out the seal detecting device. The waste pushing mechanism is used for enabling tested sub-quality products to be pushed into the waste conveying belt from the conveying belt for the products to be tested. The seal detecting production line enables the mechanical arm, the simple seal detecting device, and the product conveying belt to be combined together in an organic mode, a programmable logic controller (PLC) is utilized for controlling a working time sequence of each unit, and automation degree and system reliability are improved. The products to be tested can be effectively protected form being damaged, grabbing of the mechanical arm depends on the opening and the closing of an executor at the tail end, and the mechanical arm not only is suitable for grabbing canning products, box-packed products, and bottled products, but also can be used for grabbing bagged products, and is strong in generality.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

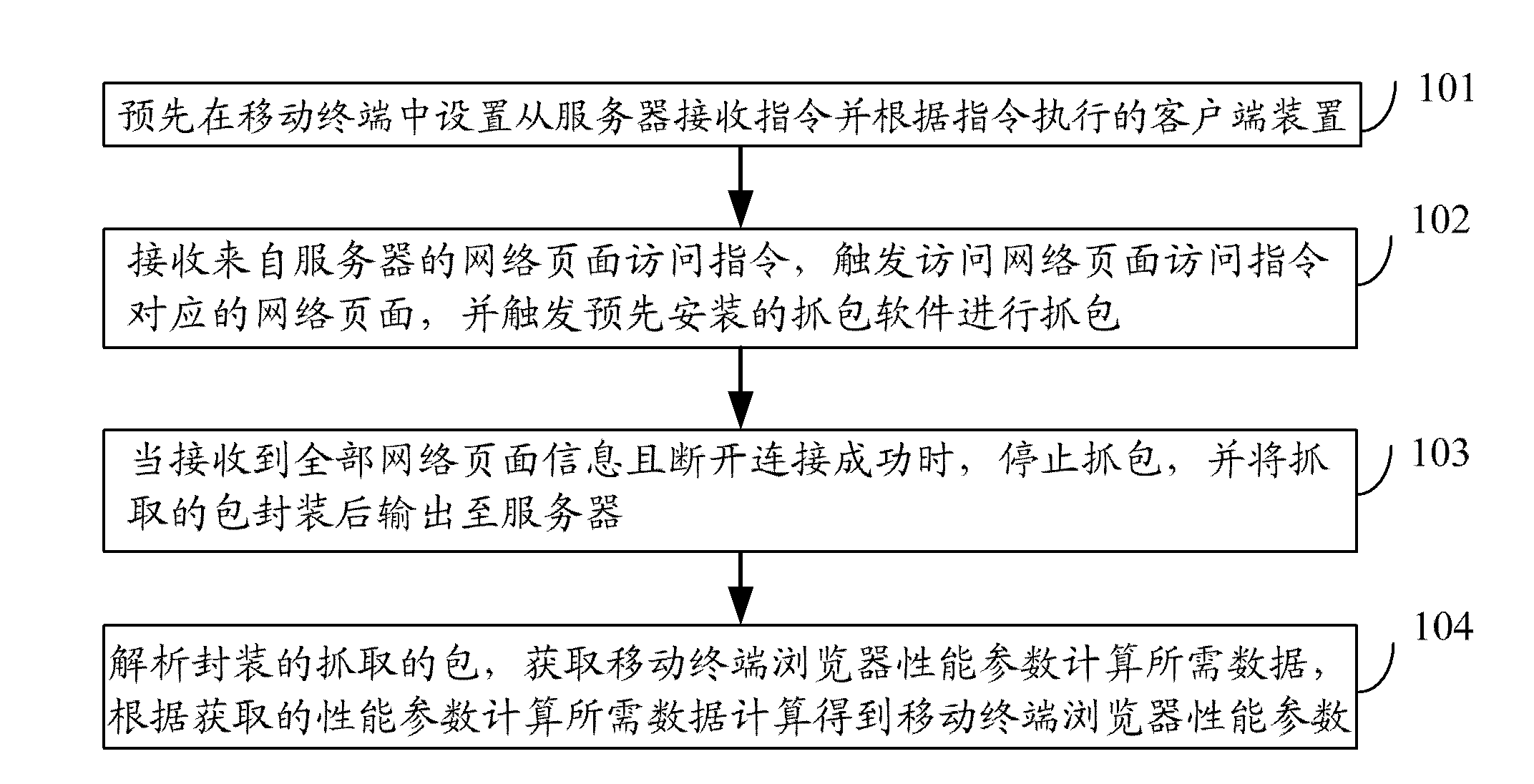

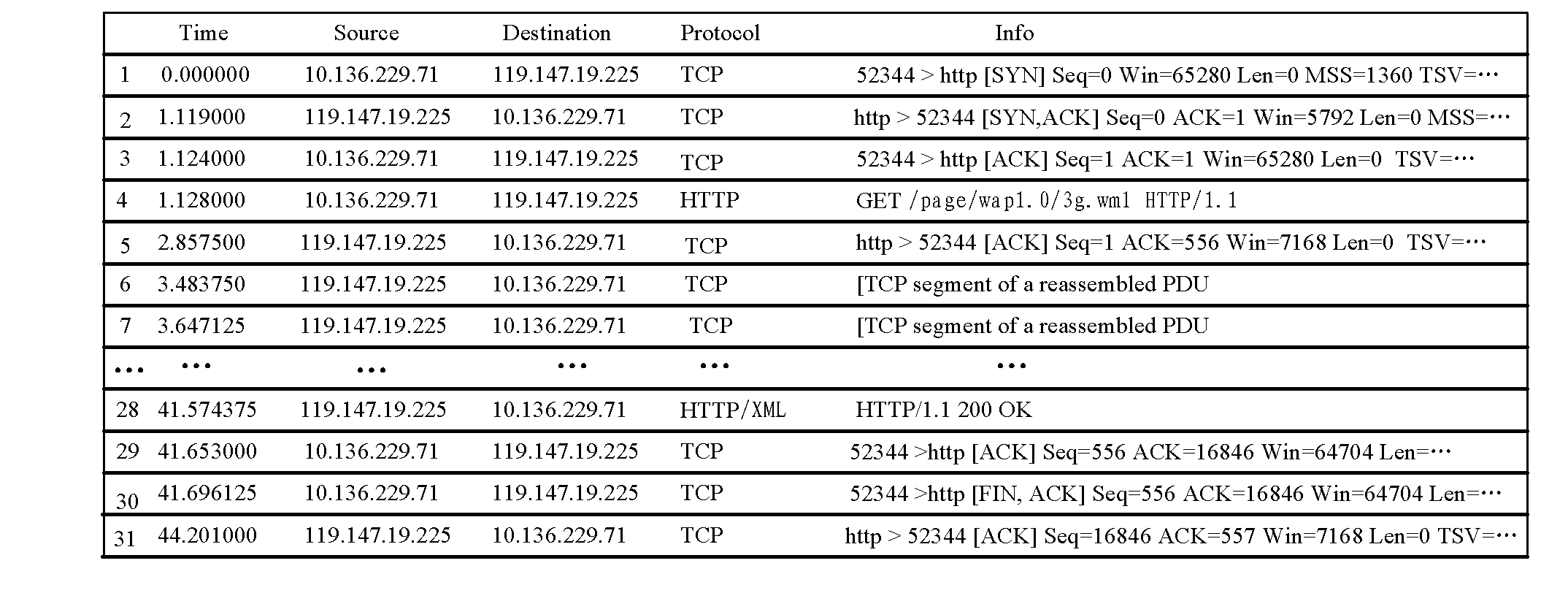

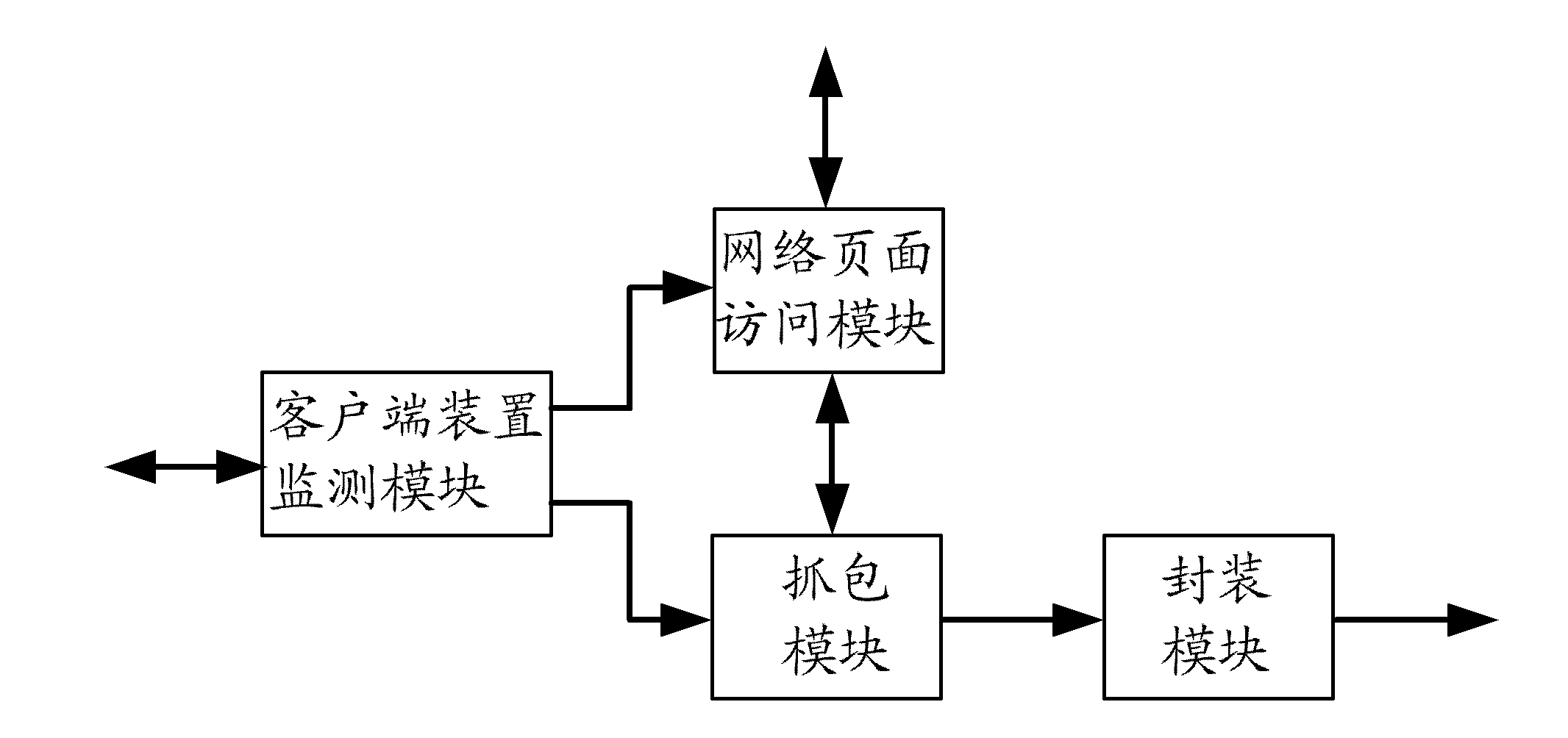

Method, device and system for acquiring performance parameters of browser of mobile terminal

ActiveCN102761456AImprove reliabilityAvoid time errorData switching networksDependabilityClient-side

The invention discloses a method, a device and a system for acquiring performance parameters of a browser of a mobile terminal. The method includes setting a client device for receiving instructions from a server and executing the instructions in the mobile terminal in advance; receiving a network page access instruction from the server, triggering access to a network page corresponding to the network page access instruction and triggering packet capturing software installed in advance to capture a packet; outputting the captured packet to the server after the captured packet is encapsulated; and analyzing the captured encapsulated packet, acquiring data required for computing the performance parameters of the browser of the mobile terminal and computing to obtain the performance parameters of the browser of the mobile terminal. By the aid of the method, the device and the system, reliability of the acquired performance parameters of the browser of the mobile terminal can be improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

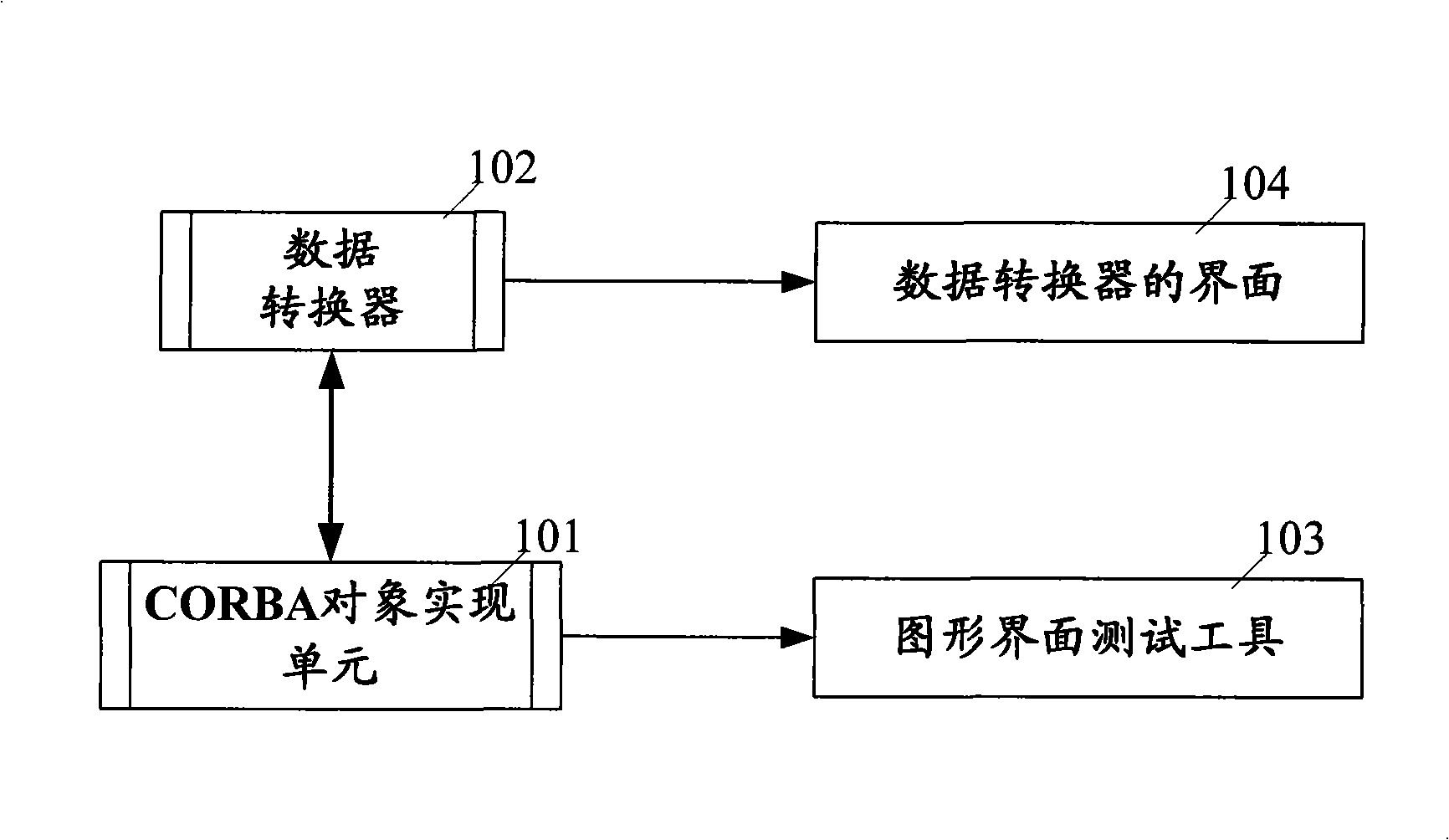

Software system test method and apparatus

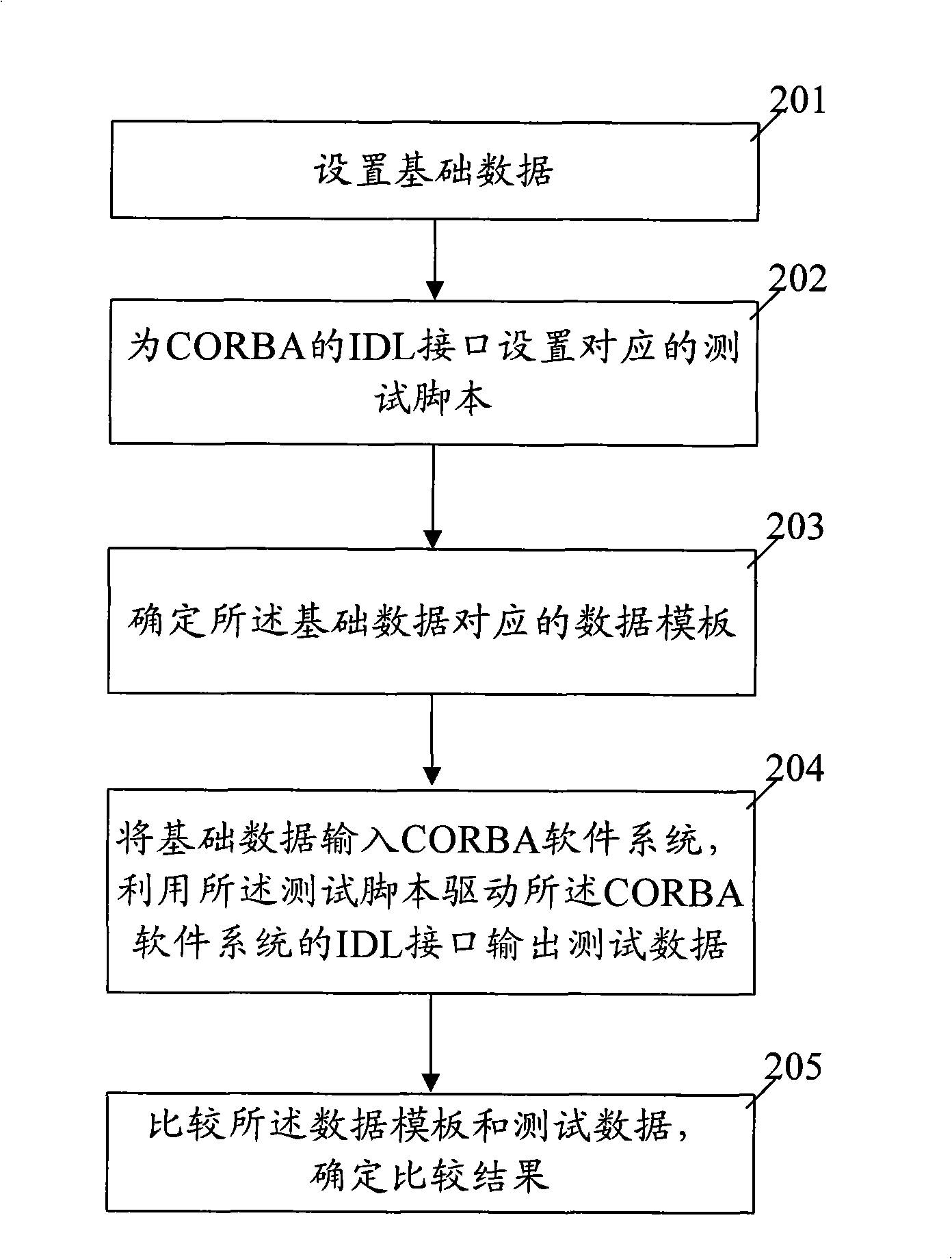

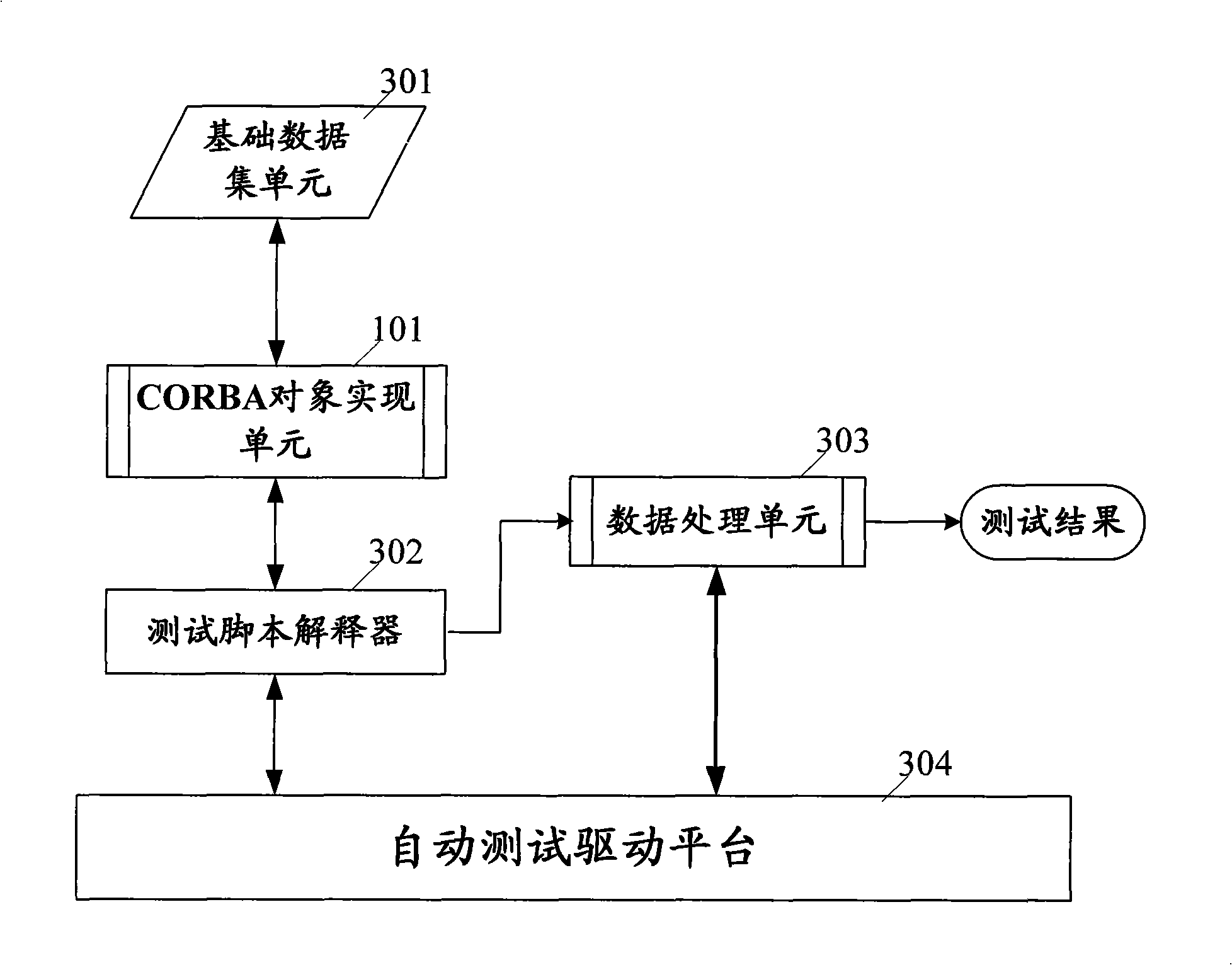

InactiveCN101266570AImplement testImprove test efficiencySoftware testing/debuggingTest scriptData set

The invention discloses a testing method and the device for the software system, being compliant in the software system based on the common object request broker architecture(CORBA), the method comprises: setting a base data; setting a corresponding testing script for the IDL interface of the CORBA; determining a data templet according to the base data; when testing, the base data is inputted to the CORBA software system, the IDL interface of the CORBA software system outputs a testing data driven by the testing script; comparing the data templet and the testing data, determining the comparing result. The testing device comprises: a base data collecting unit, a testing script interpreter using the testing script to drive the IDL interface, and a data processing unit for comparing the data templet and the testing data. The invention uses a separating mechanism implemented by the IDL interface definition of the CORBA and the IDL interface to implement the auto testing of the software in a script driving way, which can enhance the testing efficiency and reduce the testing cost.

Owner:GLOBAL INNOVATION AGGREGATORS LLC

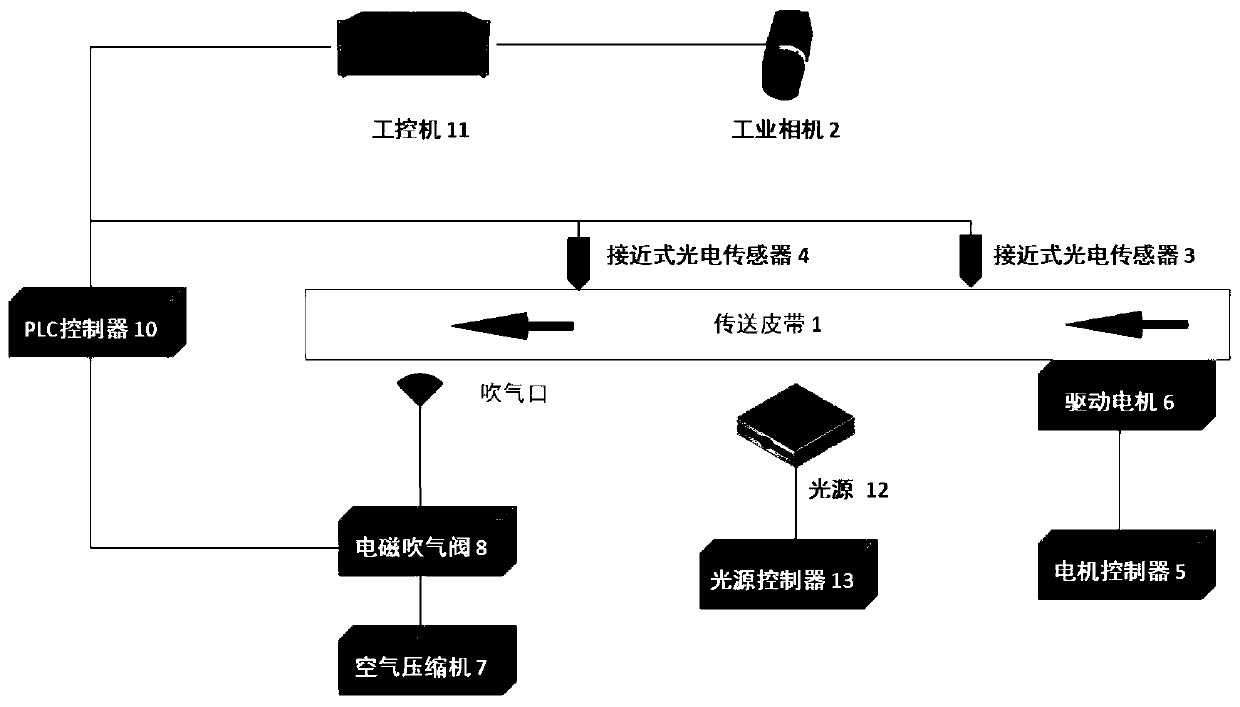

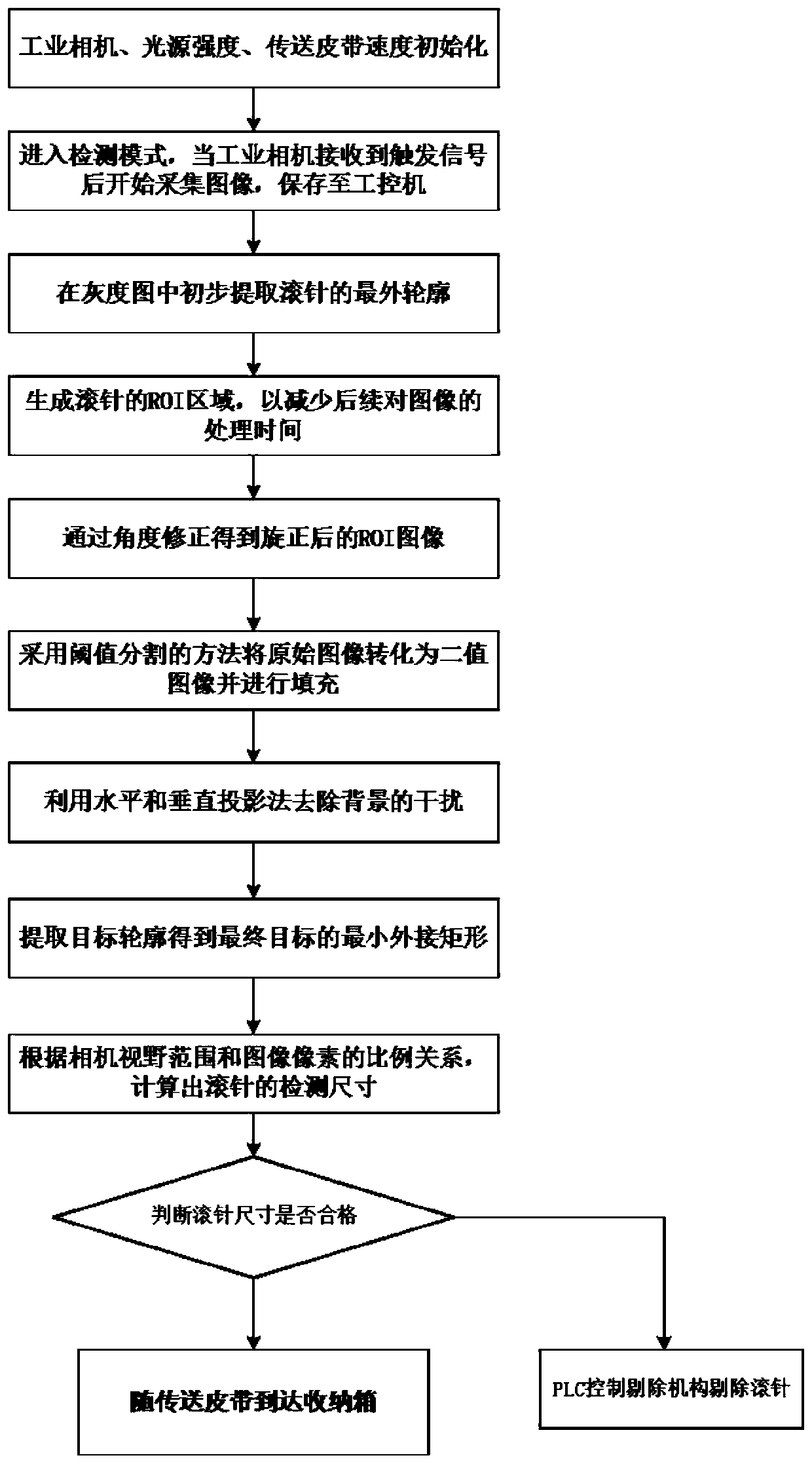

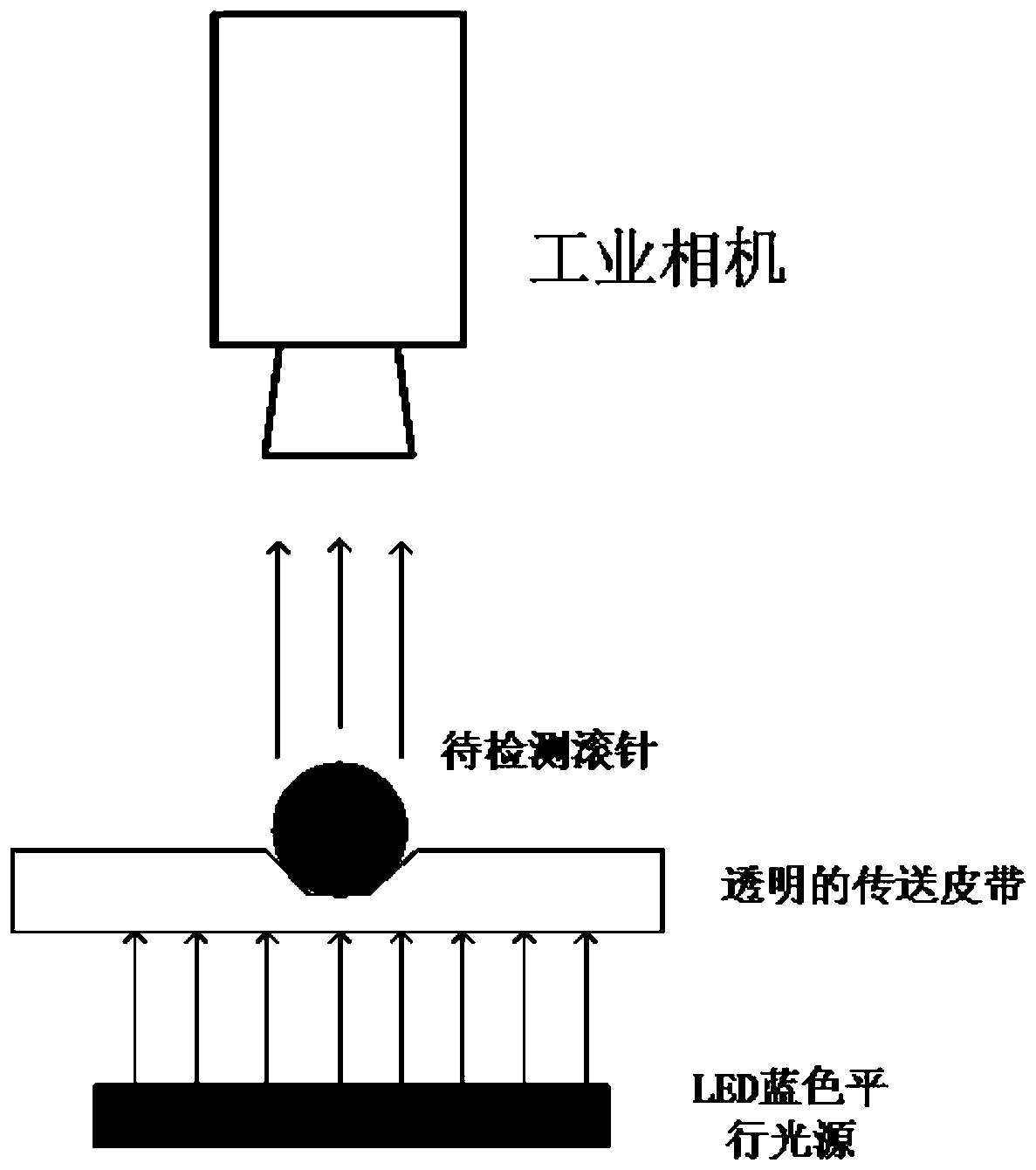

Bearing roller pin size detection system and method based on machine vision

The invention discloses a bearing roller pin size detection system and method based on machine vision. A single low-cost 2D camera is used for collecting images. An industrial camera is used to acquire the images. The acquired images are stored in an industrial personal computer. The industrial personal computer processes the images. Background interference is removed from the processed images byusing horizontal and vertical projection methods, angle correction is performed on an extracted ROI area. A ROI image is converted into a binary image by using a threshold segmentation method, and filling is performed to ensure that an internal color of a contour of a roller pin is white. Contour extraction is performed on the processed image. A detection size of the roller pin is calculated according to a proportional relation between a visual field range of the camera and an image pixel, the roller pin with a qualified size arrives at a storage box along with a transmission belt, and for theroller pin with a unqualified size, an elimination signal is sent to PLC by the industrial personal computer, and an elimination mechanism is controlled to eliminate the roller pin through the PLC. The roller pins moving on an assembly line are detected and removed in real time.

Owner:JIANGNAN UNIV

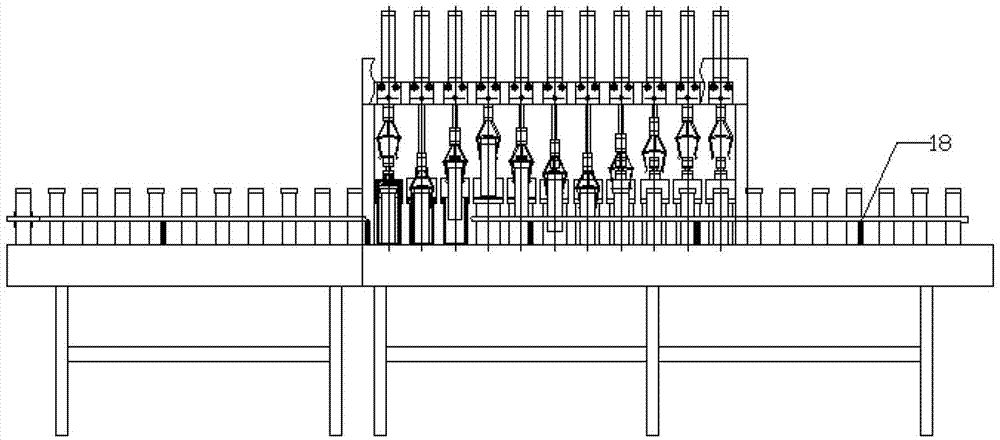

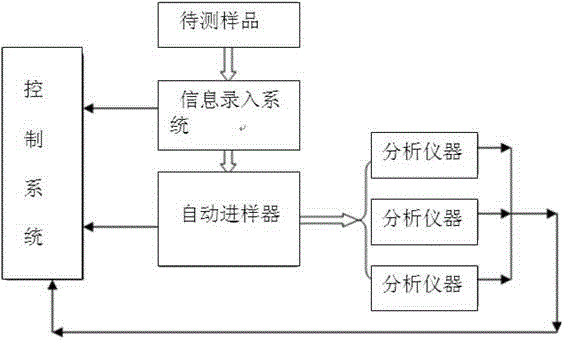

Automatic sample injector and sample injection testing system

InactiveCN102879595AFully automatedRealize unmanned managementMaterial analysisAutosamplerTest sample

The invention discloses an automatic sample injector which is used for provides a sample to be tested for an analytic instrument in test sample analysis process. The sample injector comprises a sample bottle, a sample bottle support, a sample injection needle, a mechanical arm and a control system. The sample bottle is used for containing the sample to be tested. The sample bottle support is used for supporting the sample bottle. The sample injection needle is used for acquiring the sample to be tested and delivers the sample to be tested to the analytic instrument through a sample sending pipeline. The mechanical arm is used for mounting the sample injection needle and can move in a certain space, so that positioning of the sample injection needle at different positions is achieved. The control system controls the mechanical arm to move and controls sampling of the sample injection needle. Therefore, manual replacement of the sample to be tested is not required in test sample analysis, and accordingly sample injection efficiency is improved. Based on the sample injector, the invention further comprises a sample injection testing system comprising the automatic sample injector and the analytic instrument, and automation and unattended management of a laboratory in sample injection testing process are achieved.

Owner:LIHE TECH (HUNAN) CO LTD

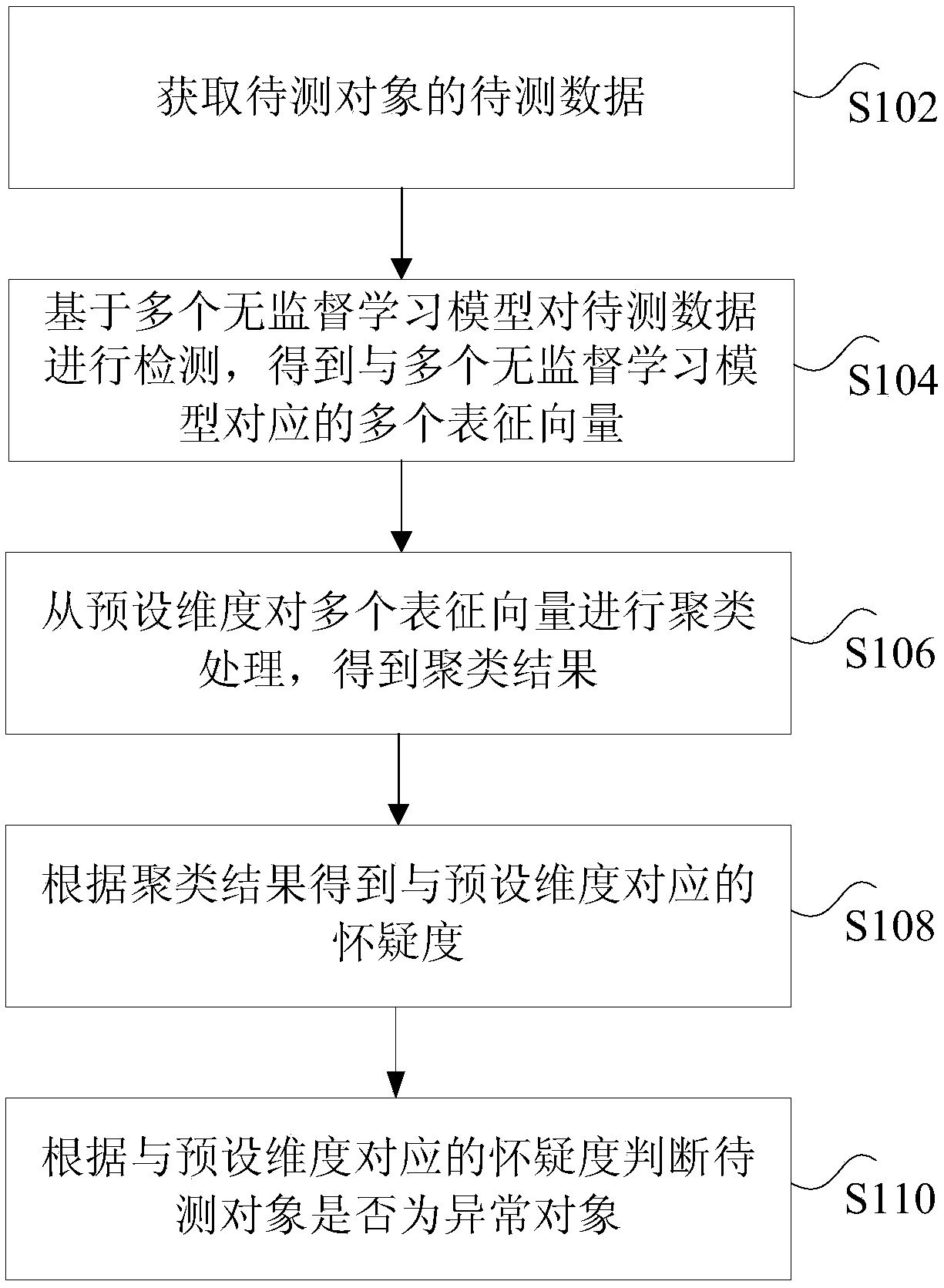

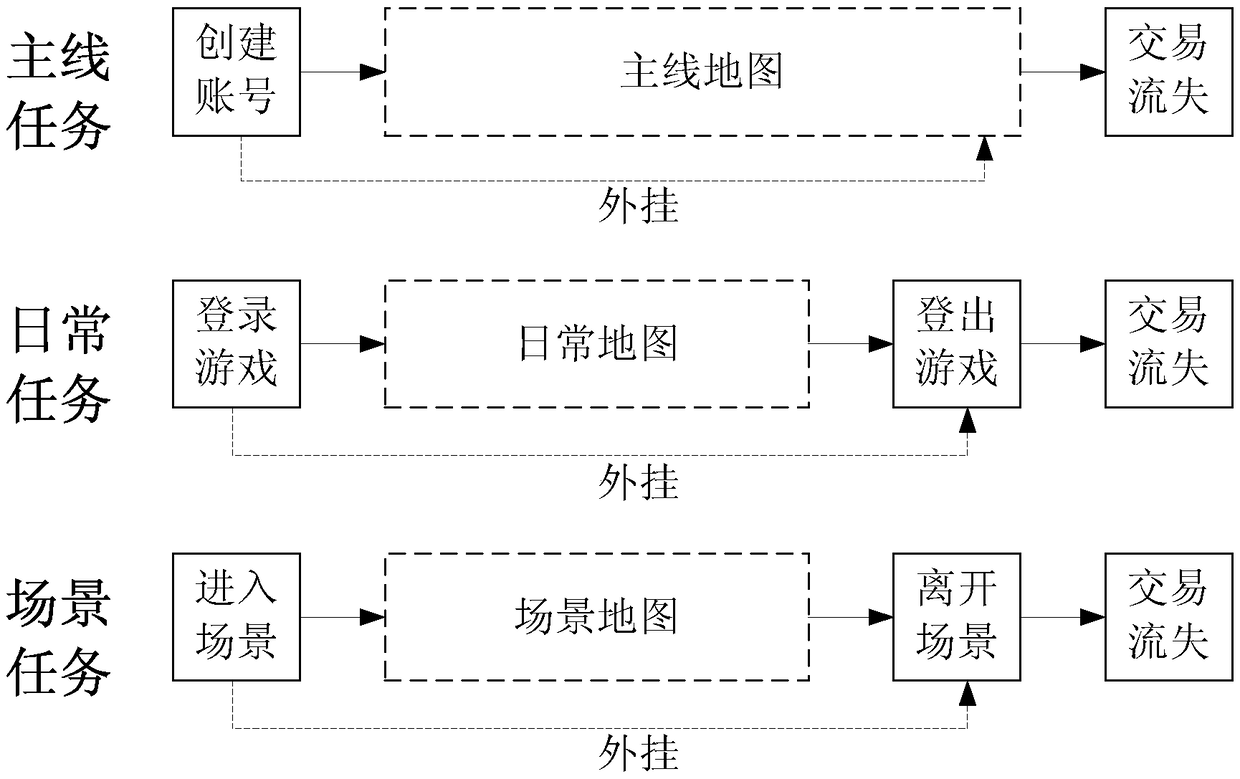

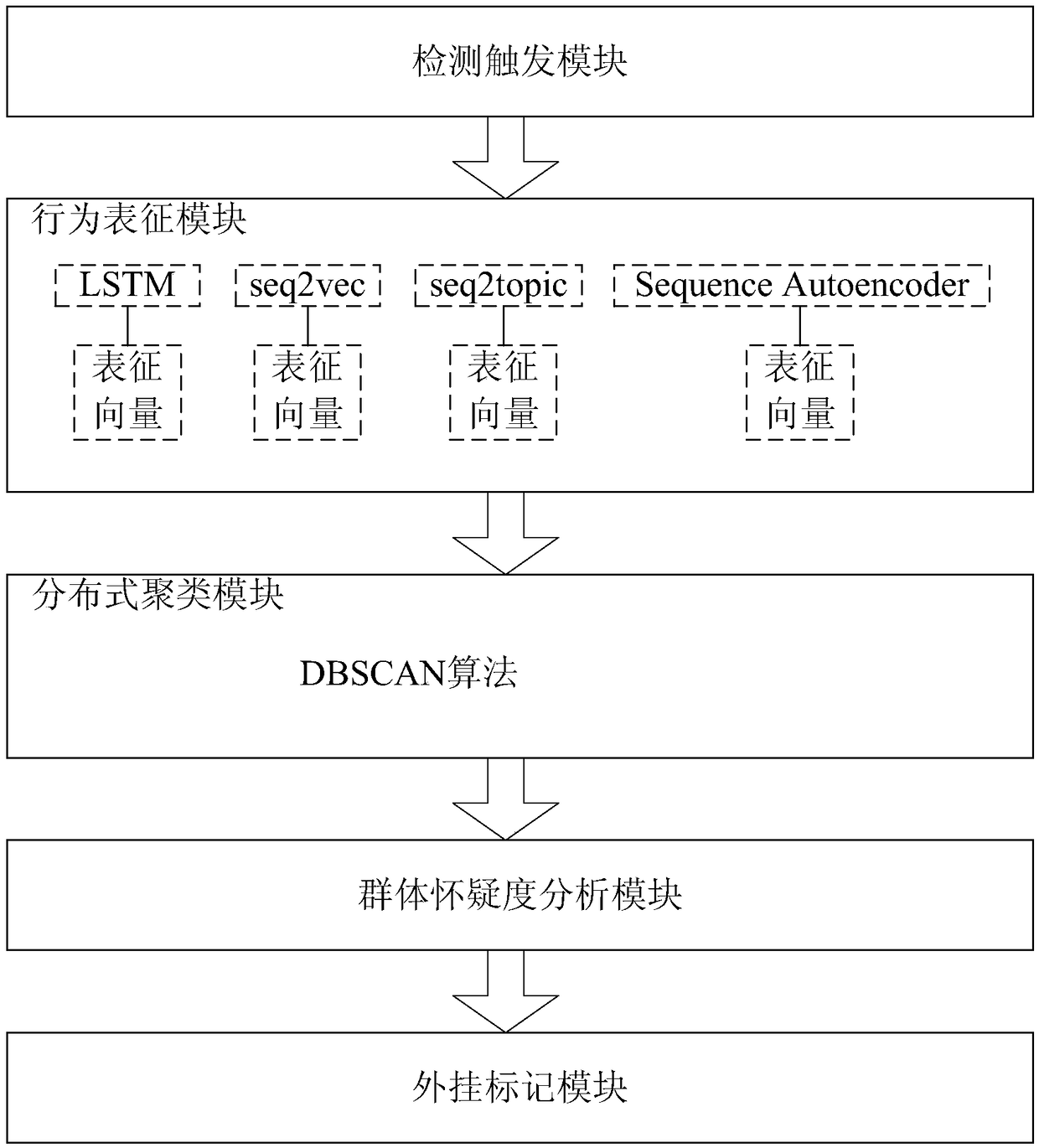

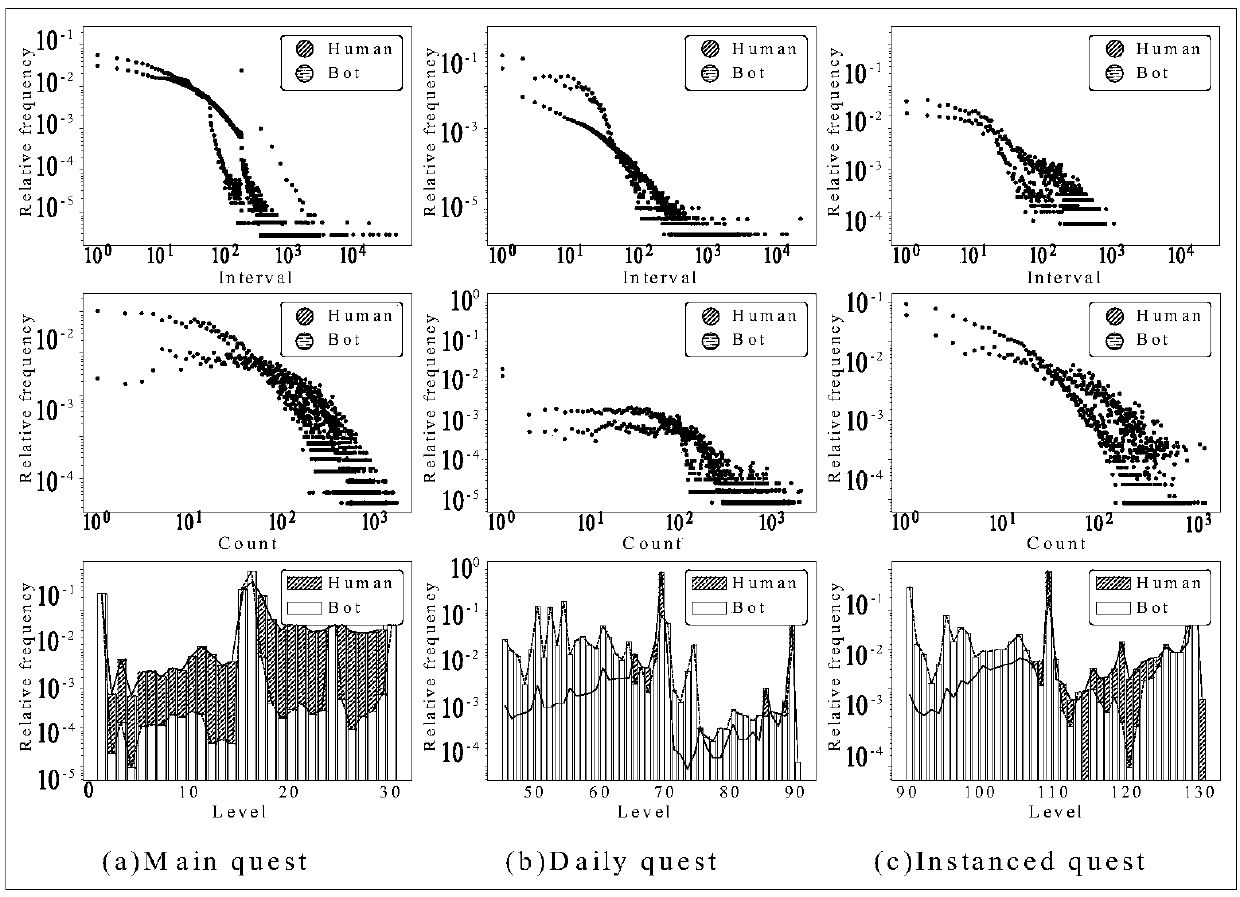

Method, device and terminal for detecting game hanging

The invention discloses a method, device and terminal for detecting game plug-in. The method comprises the following steps of: acquiring data to be detected of an object to be detected; detecting datato be detected based on a plurality of unsupervised learning models to obtain a plurality of characterization vectors corresponding to the plurality of unsupervised learning models, wherein the plurality of unsupervised learning models are used for training data of a plurality of objects to obtain a plurality of characterization vectors; carrying out clustering processing on a plurality of characterization vectors from a preset dimension to obtain a clustering result; obtaining the doubt degree corresponding to the preset dimension according to the clustering result; and judging whether the object to be detected is an abnormal object or not according to the doubt degree corresponding to the preset dimension, wherein the abnormal object has a plug-in behavior. The method, device and terminal for detecting game plug-in solves the technical problem of low accuracy of detecting the game plug-in in the prior art.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

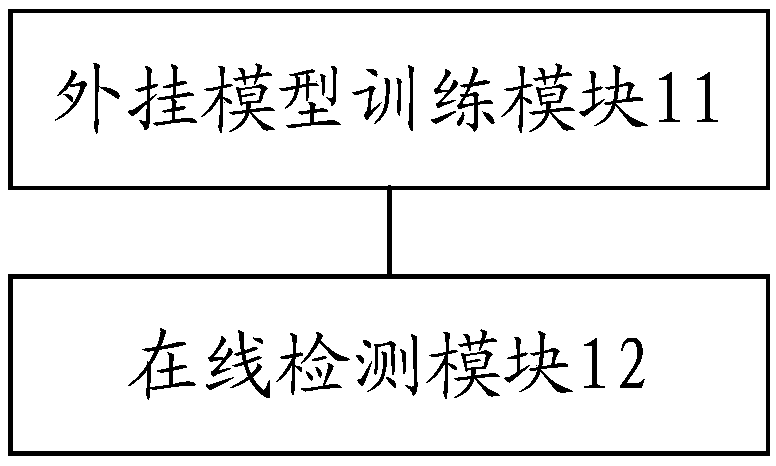

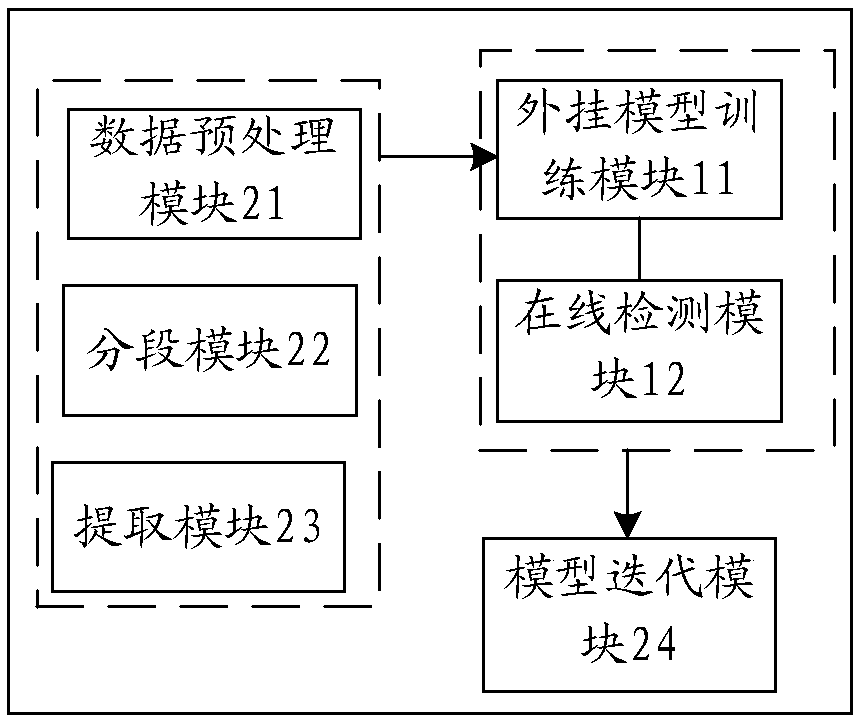

Method and system for detecting plug-ins in games, electronic device and storage medium

The invention discloses a method and a system for detecting plug-ins in games, an electronic device and a storage medium. The system comprises a plug-in model training module and an online detection module. The plug-in model training module is used for training a player behavior sequence to determine a target plug-in detection model, and the target plug-in detection model outputs the probability of a to-be-detected target player being a plug-in player; the online detection module connected with the plug-in model training module is used for acquiring the probability of the target player being the plug-in player according to the target plug-in detection model and a newly-input player behavior sequence of the target player, and determining whether or not the target player is the plug-in player according to the probability of the target player being the plug-in player. By the method and the system, the technical problems of low efficiency and accuracy in game plug-in detection in the related art are solved.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

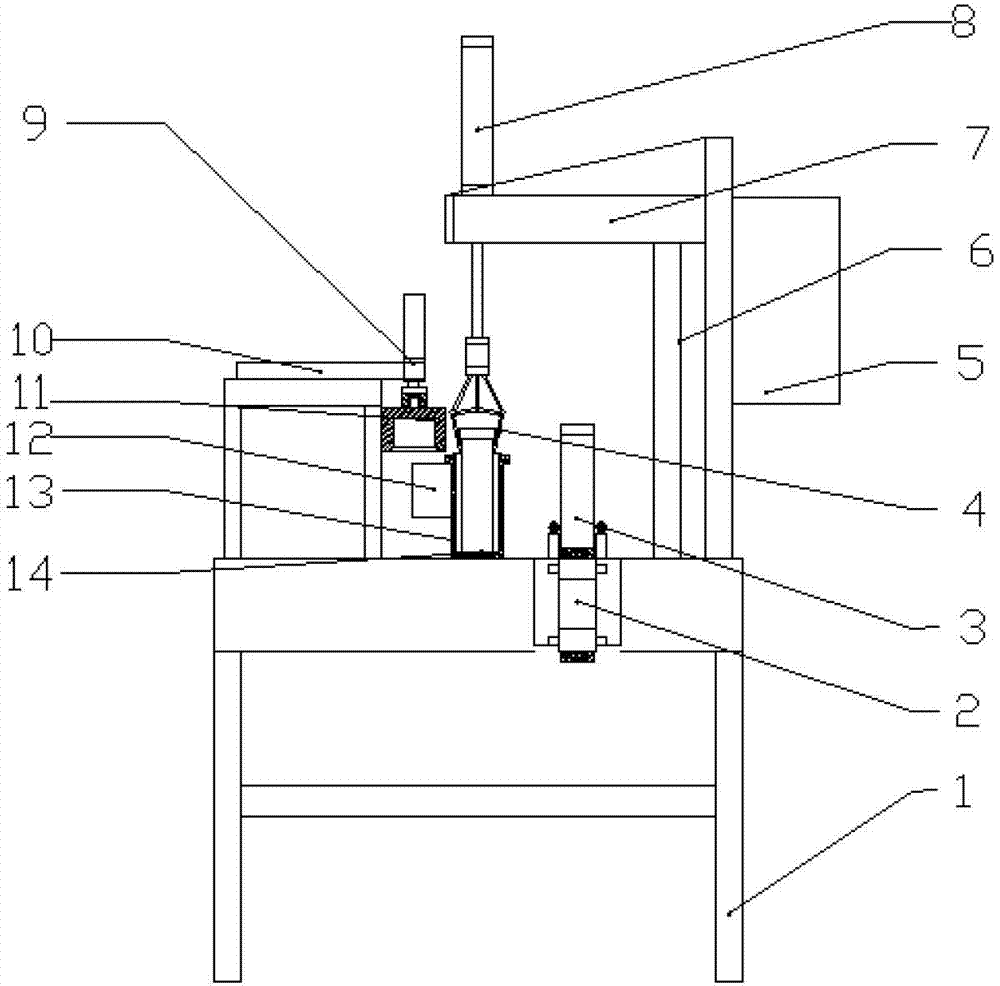

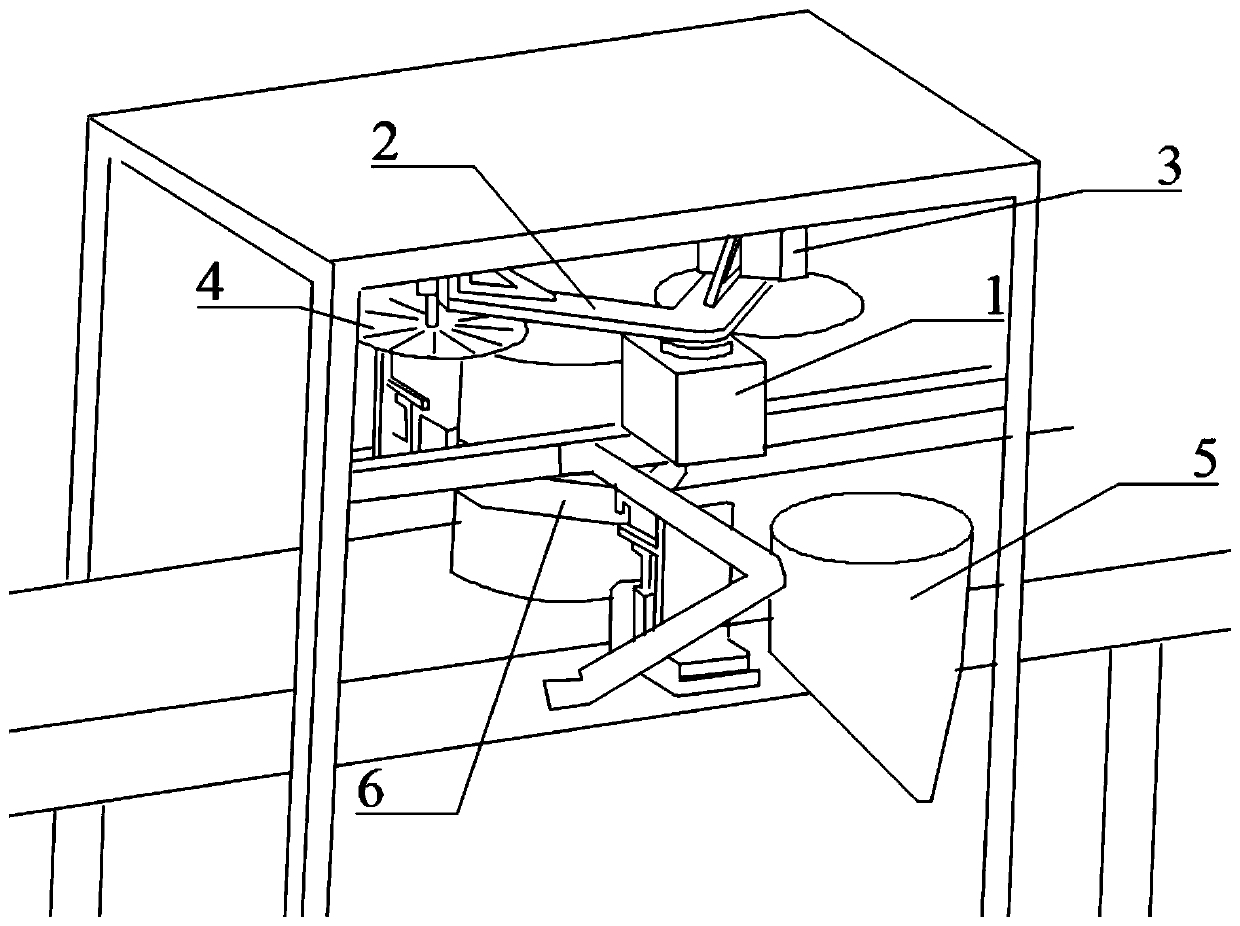

Full-automatic hybridization appliance

ActiveCN102533525APromote the "civilization"Promote "civilianization"Bioreactor/fermenter combinationsBiological substance pretreatmentsHybridization reactionEngineering

The invention discloses a full-automatic hybridization appliance, which comprises a hybridization platform, a machine frame and a back plate. The machine frame and the back plate are fixed on the hybridization platform which is provided with a reagent supply device and a reagent preheating device, wherein the reagent supply device is matched with the reagent preheating device. The machine frame is provided with a hybridization reaction box, a feeding device for feeding reagent in the reagent supply box into the reaction box, an X-axis synchronous belt mechanism for driving the feeding device to reciprocate along the X-axis direction, a Z-axis synchronous belt mechanism for driving the feeding device to reciprocate along the Z-axis direction and a Y-axis synchronous belt mechanism for driving the hybridization reaction box to reciprocate along the Y-axis direction. The full-automatic hybridization appliance can achieve full-automatic operation of steps of washing, hybridizing, enzyme incubation, developing and the like in the gene chip operation technology, is low in manual participation, can greatly reduce production cost and effectively pushes generalized and wide application of gene chips.

Owner:亚能生物技术(深圳)有限公司

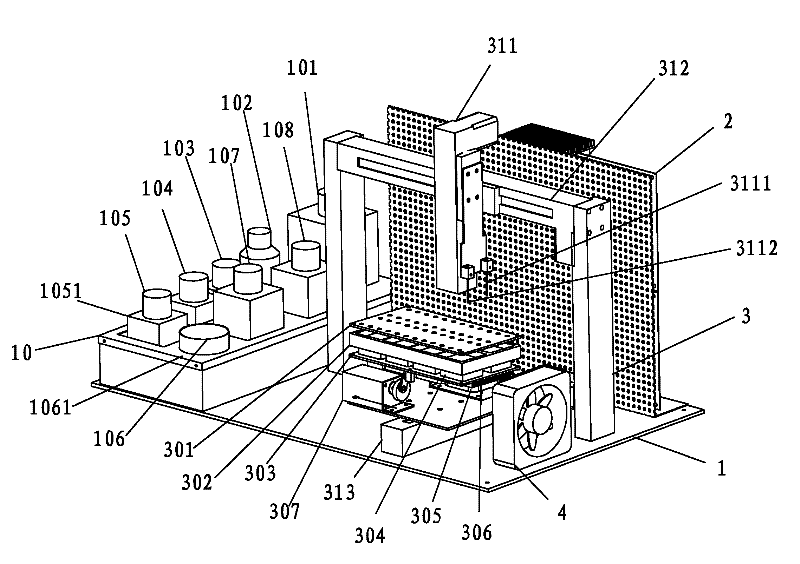

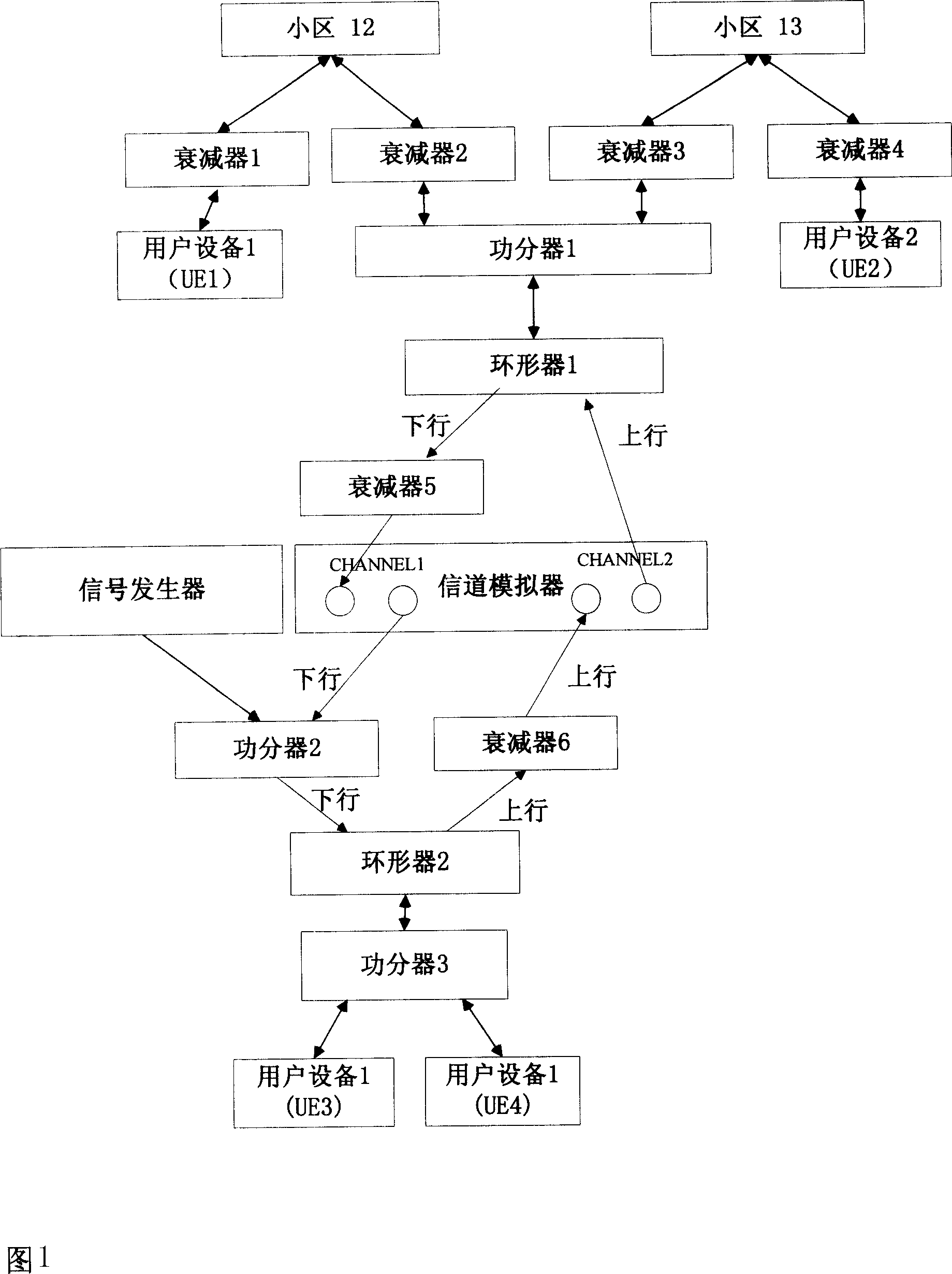

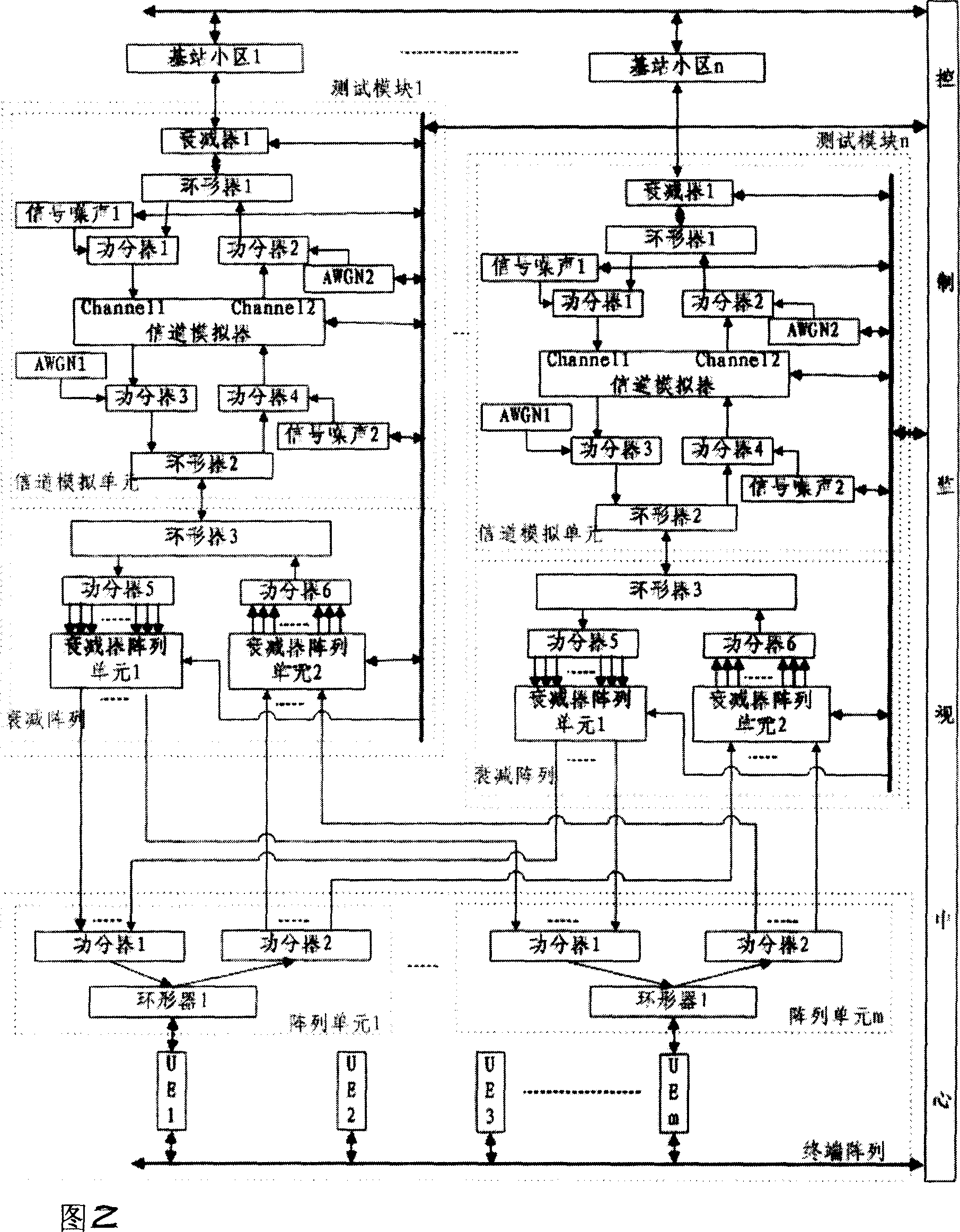

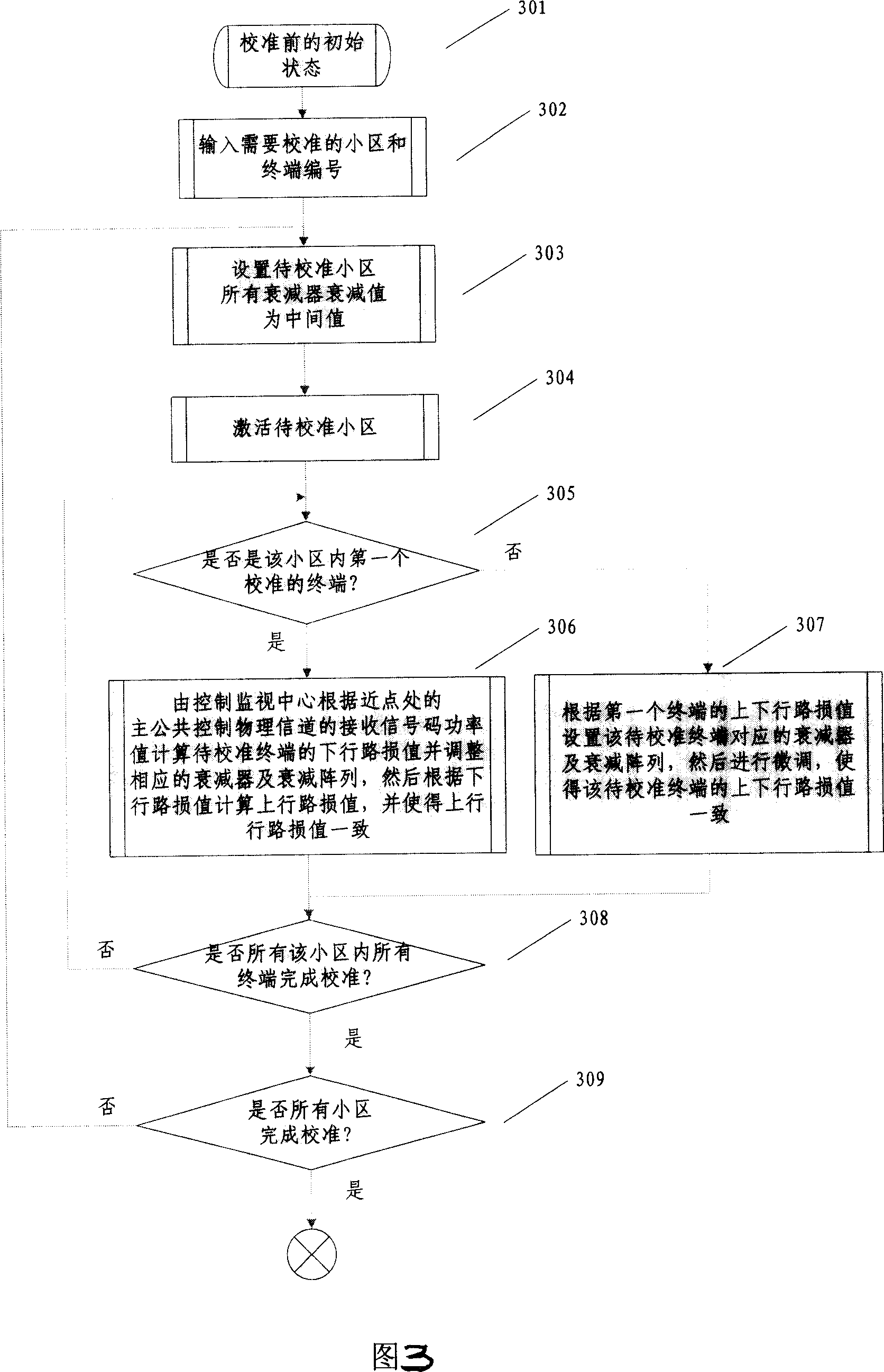

An automatic test method and device of the radio resource management performance

ActiveCN101056446AAutomateReduce manual involvementRadio/inductive link selection arrangementsTransmission monitoringUltrasound attenuationRadio resource management

The invention relates to an automatic testing method and device in a PRM performance test, the method soloves disadvantages of errors and law efficiency when testing in a manually constructed testing entironment. The device includes one or more channel simulation units, one or more attenuation arraies, one or more terminal array units, a control monitoring centre which provides an interface for users to programme test scripts based on testing examples, for outside, and controls adjustable devices via a standard interface, for inside. A testing method corresponding to the device is proposed, which comprises an automatic aligning step and an automatic testing step which are performed by the control monitoring centre according to a receiving signal code power value of a main common control physical channel at a near point and a characteristic that uplink and downlink path loss are symmetrical. The technic of the invention completely replaces manually testing manner in a current technic, is capable of simulating an actual circumstance of a network more accurately and factually, and performing a test with multi-RRM algorithm interaction.

Owner:DATANG MOBILE COMM EQUIP CO LTD

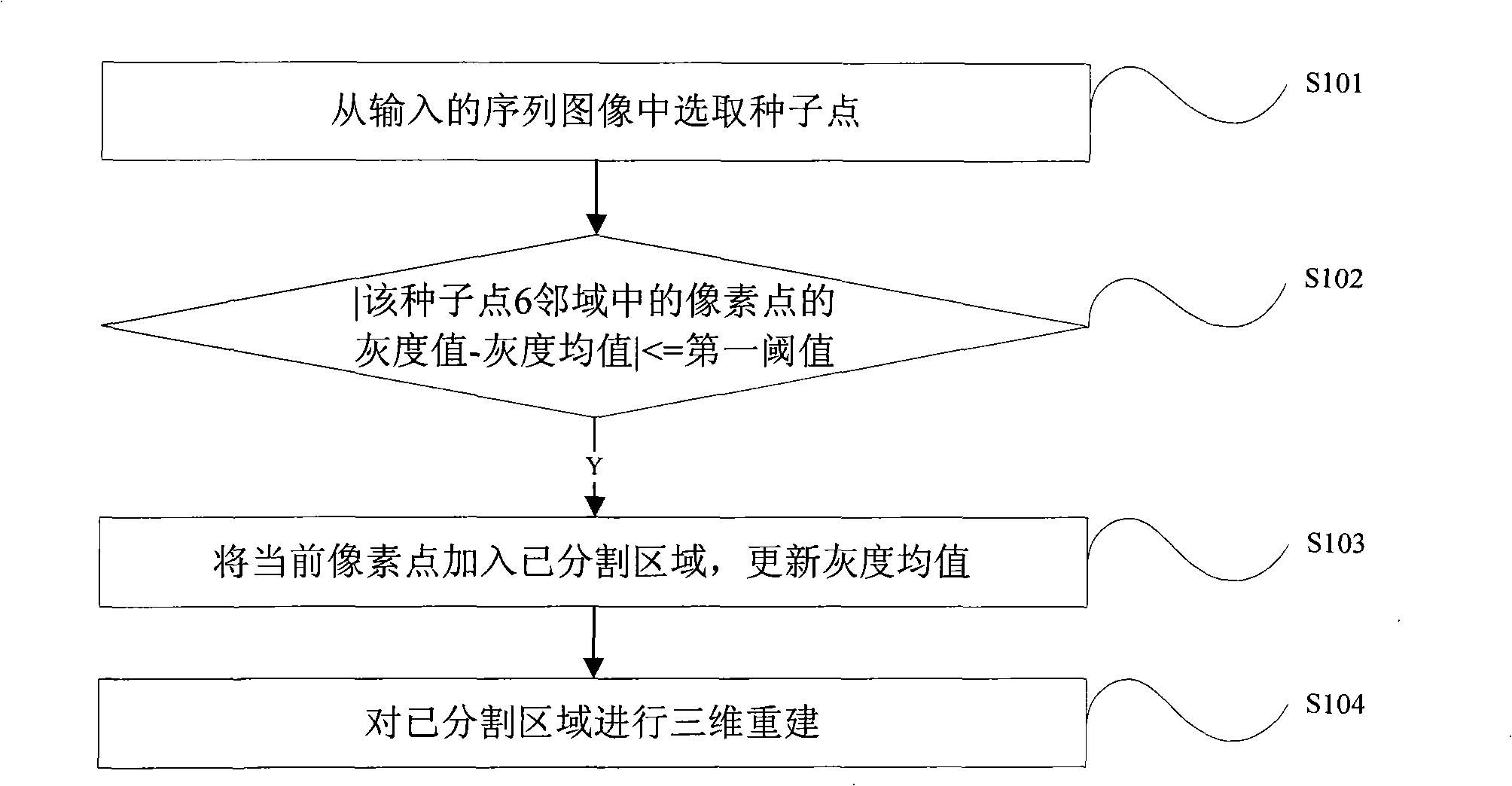

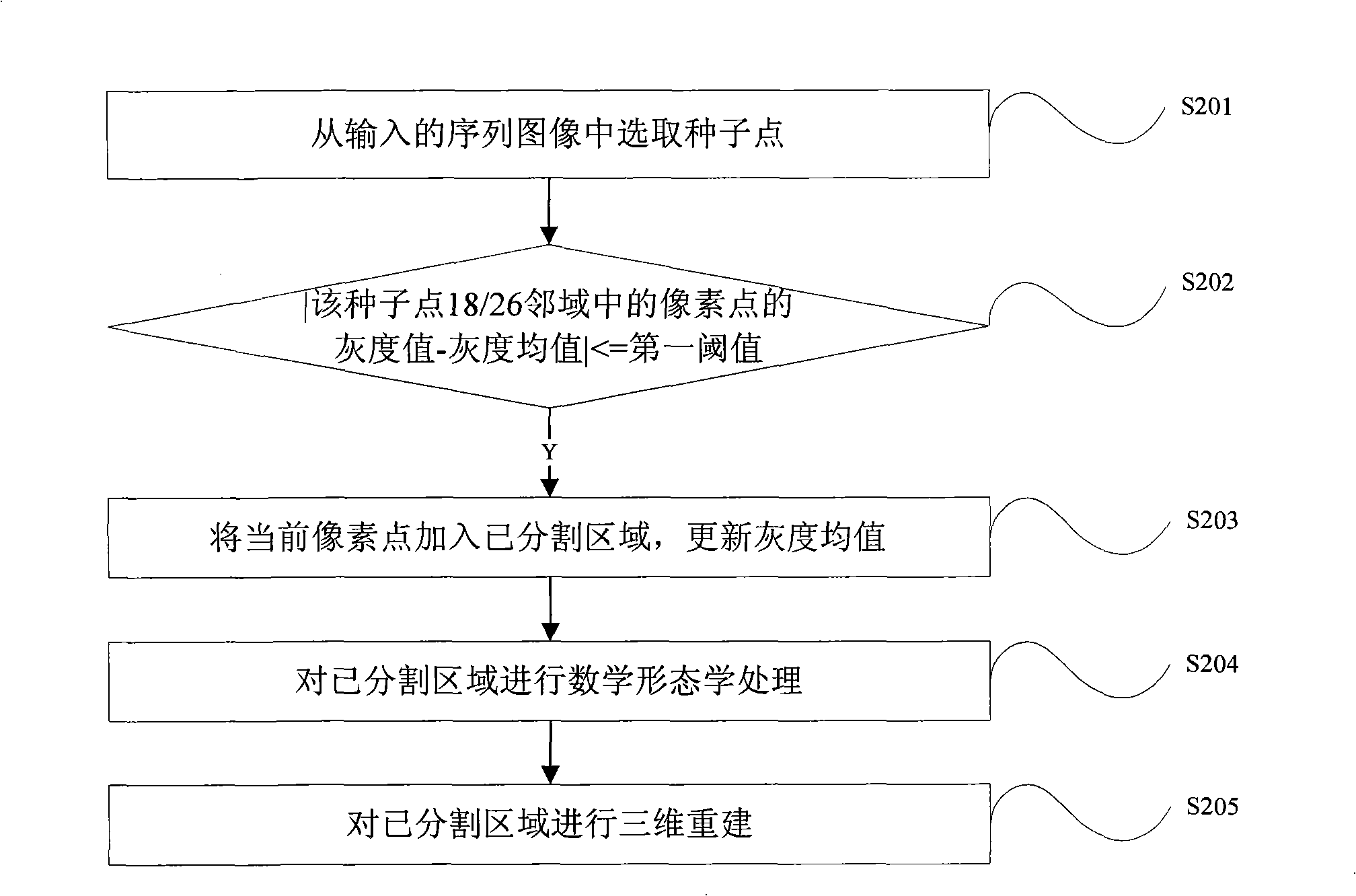

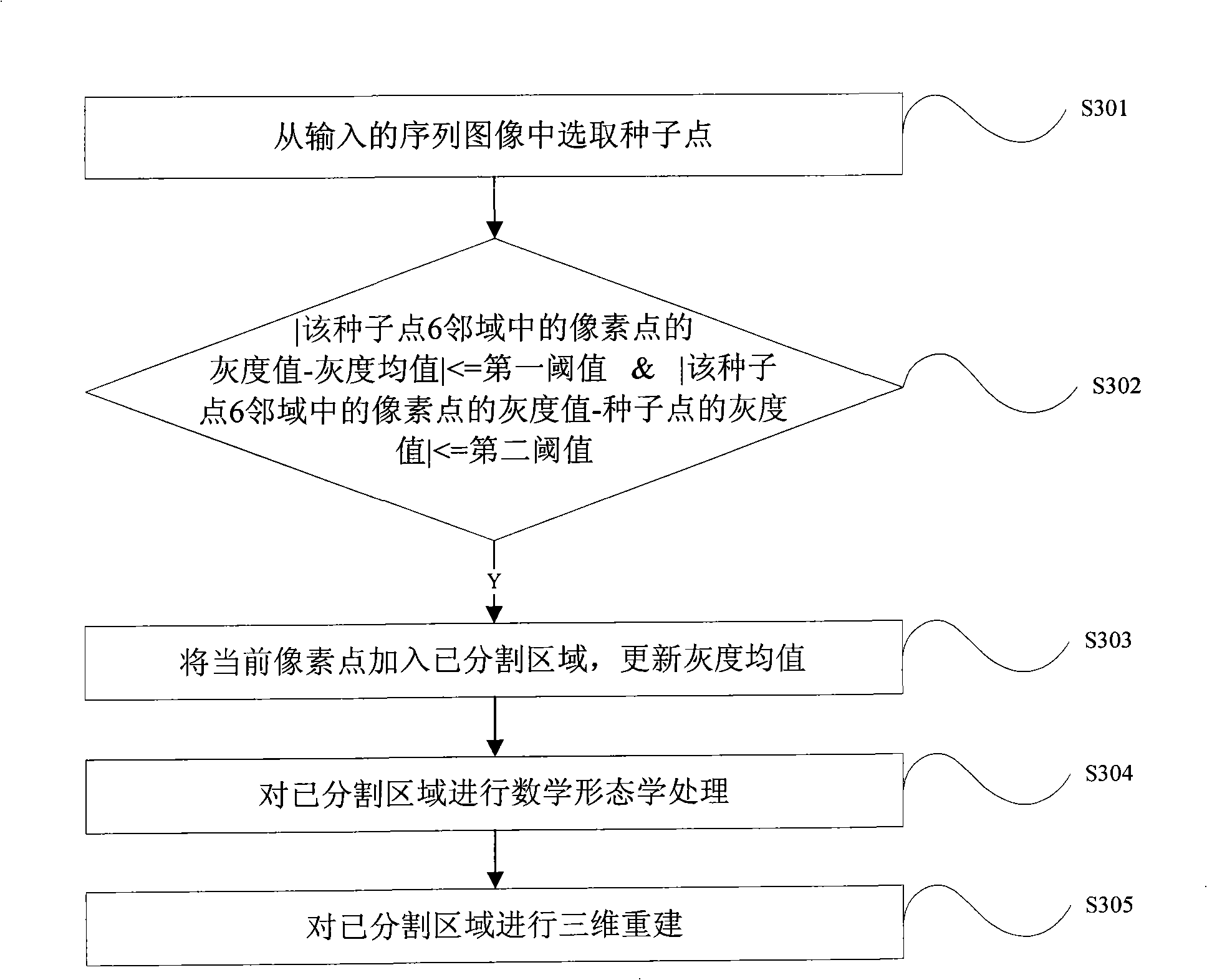

Method and apparatus for three-dimensional visualization of sequence image

InactiveCN101256670AReduce manual involvementFast imagingImage enhancementDiagnosticsPattern recognitionThree dimensional model

The invention relates to a method and a device for sequence image three-dimensional visualization, which chooses a seed point from input sequence image, adds the pixel to a divided region when the absolute value of the difference value between the gray value of the pixel in the three-dimensional neighborhood of the seed point and the mean gray of the divided region is less than or equal to a first threshold value, then carries out three-dimensional reconstruction with the pixels in the divided region. According to the method and device for sequence image three-dimensional visualization of the invention, which chooses a seed point from sequence image, determines whether the absolute value of the difference value between the gray value of the pixel in the three-dimensional neighborhood of the seed point and the mean gray of the divided region is less than or equal to the first threshold value, and adds the pixel to the divided region if it is true. Since the invention carries out the comparison based on the mean gray of the divided region, and carries out the judgment in the three-dimensional region of the seed pixel point, thus it is easier to construct the three-dimensional model for image, it needs few persons to take part in, and it is rapid and convenient for imaging.

Owner:SOUTH CHINA NORMAL UNIVERSITY +1

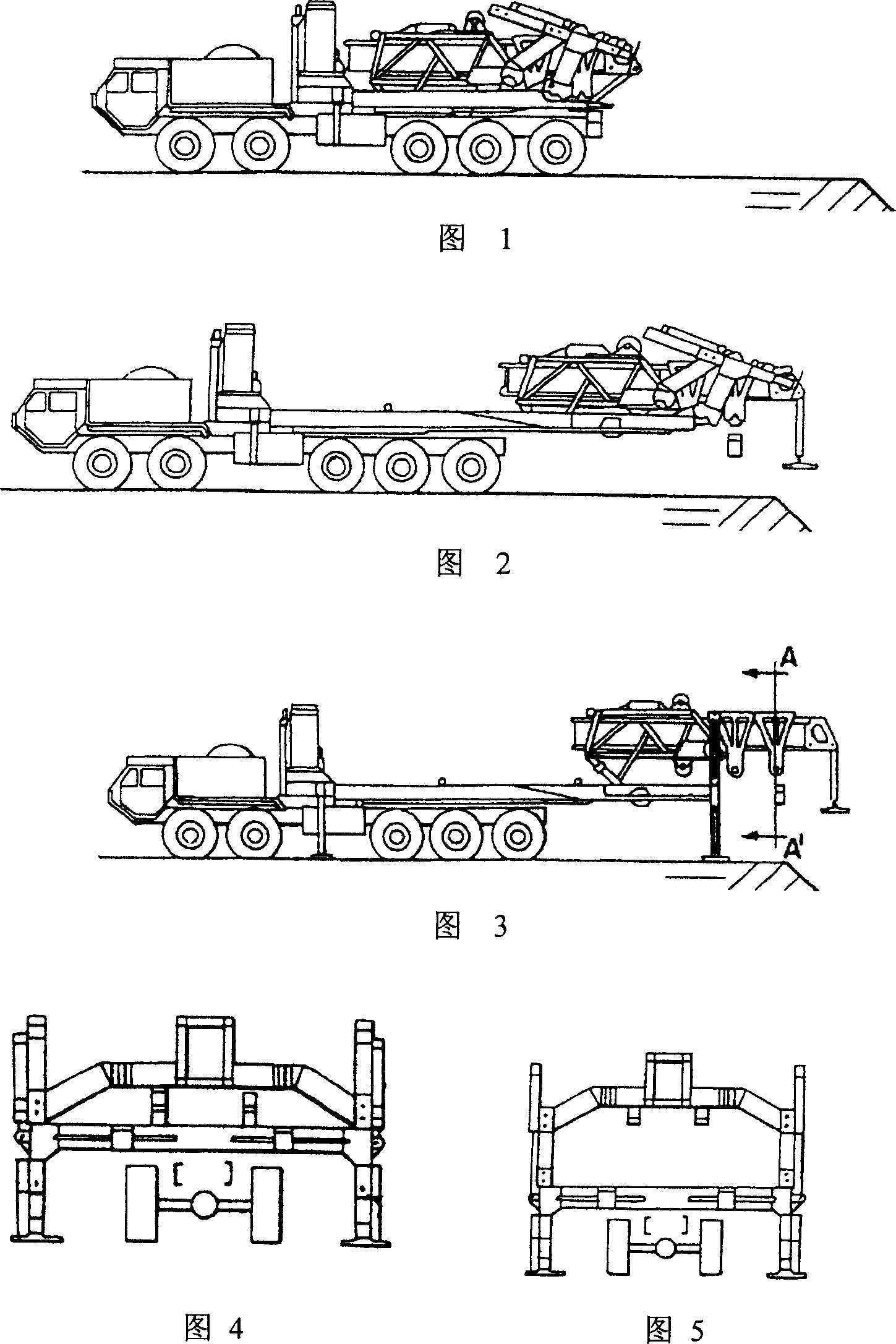

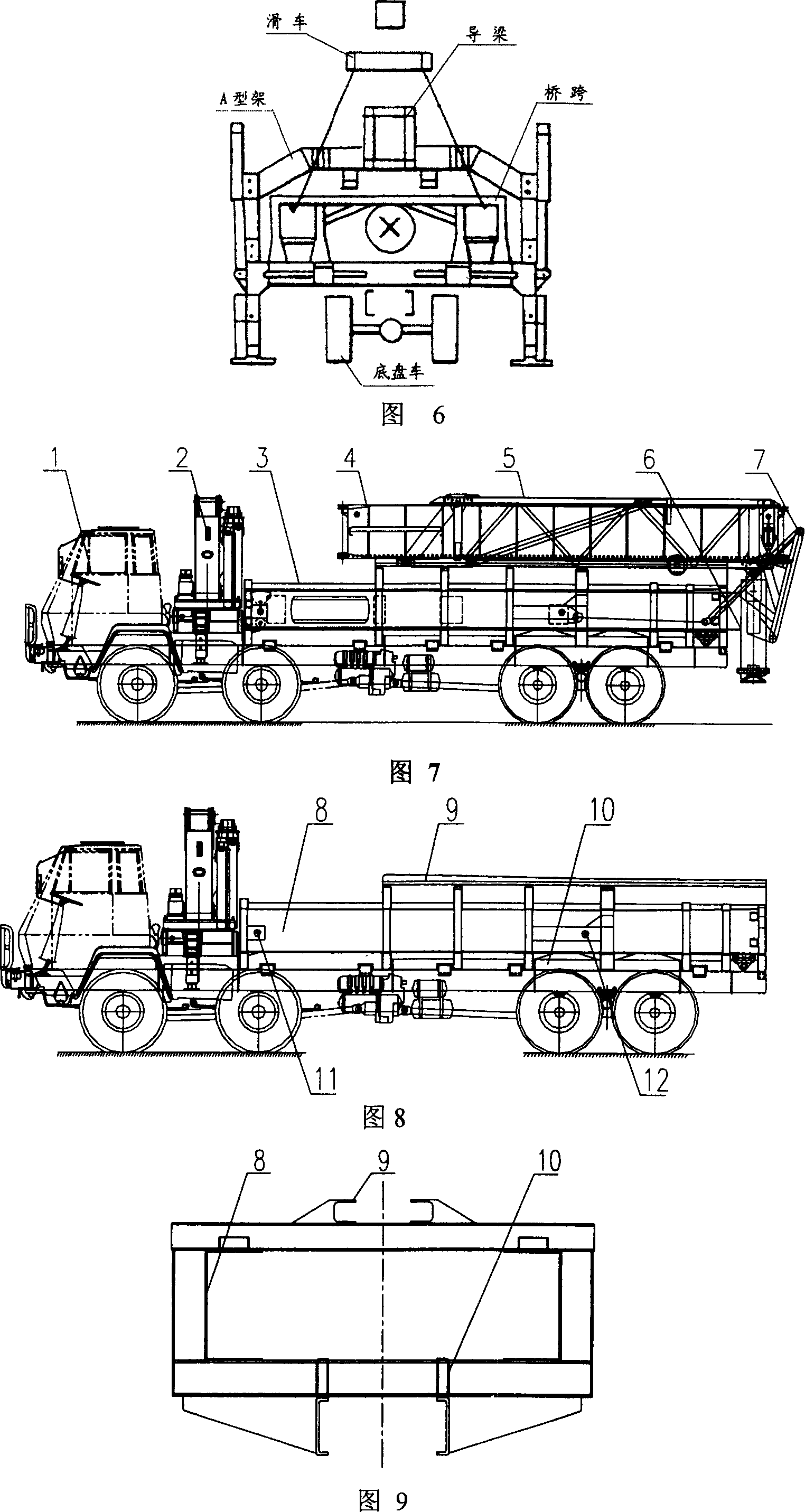

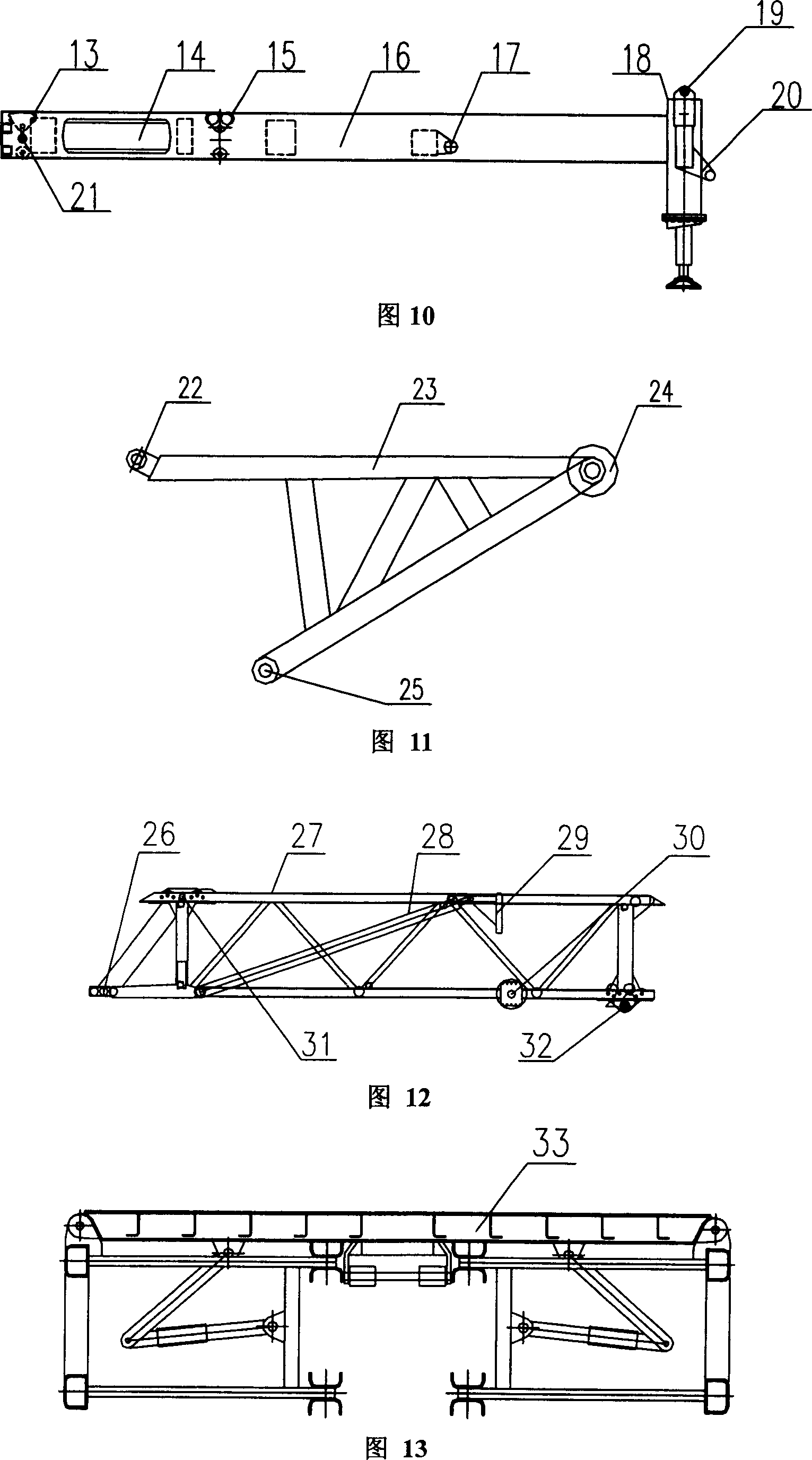

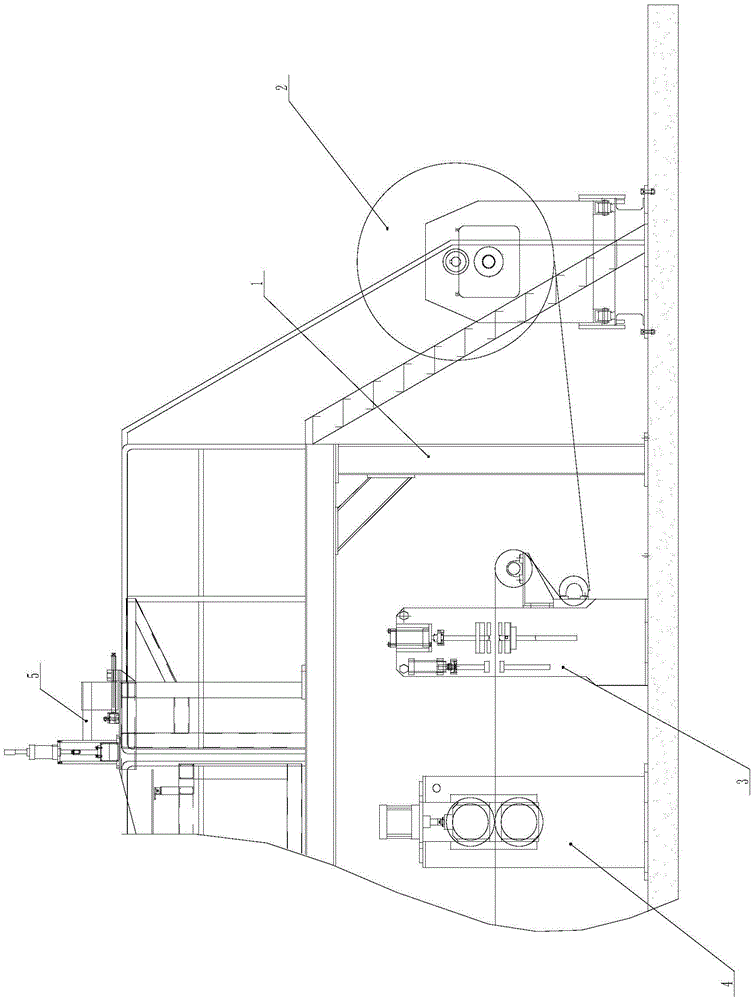

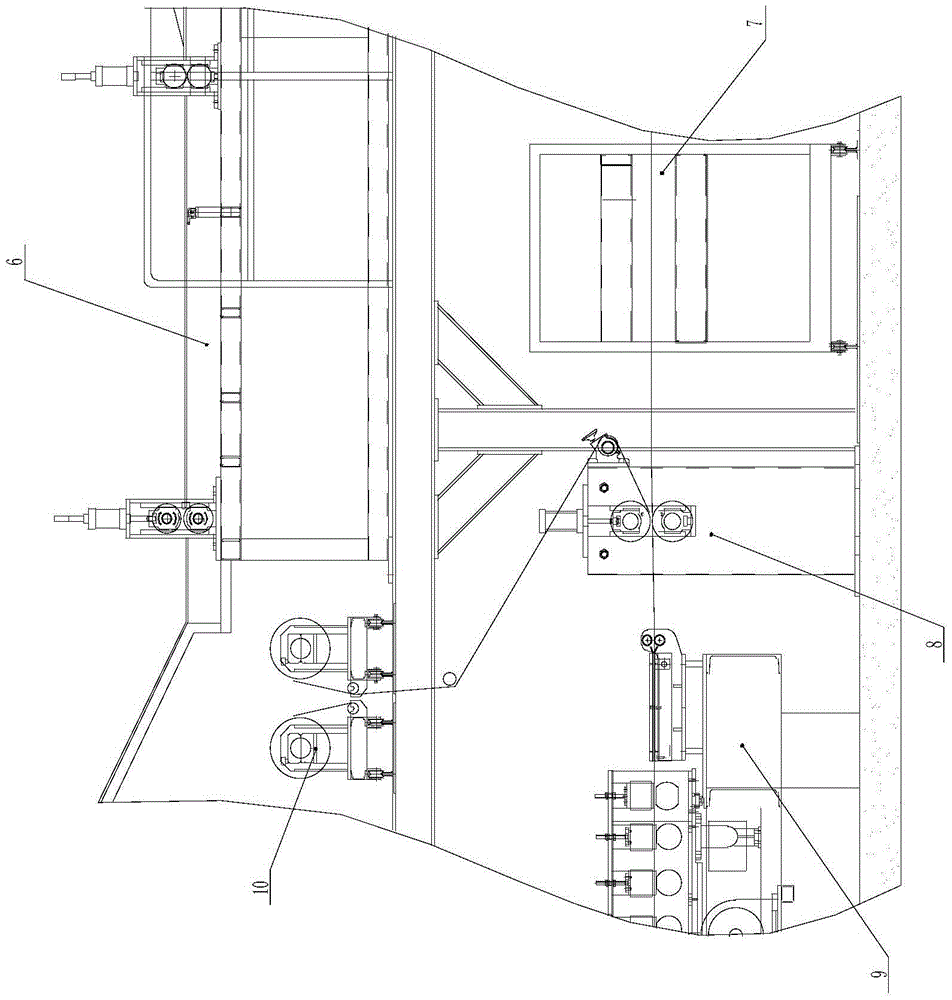

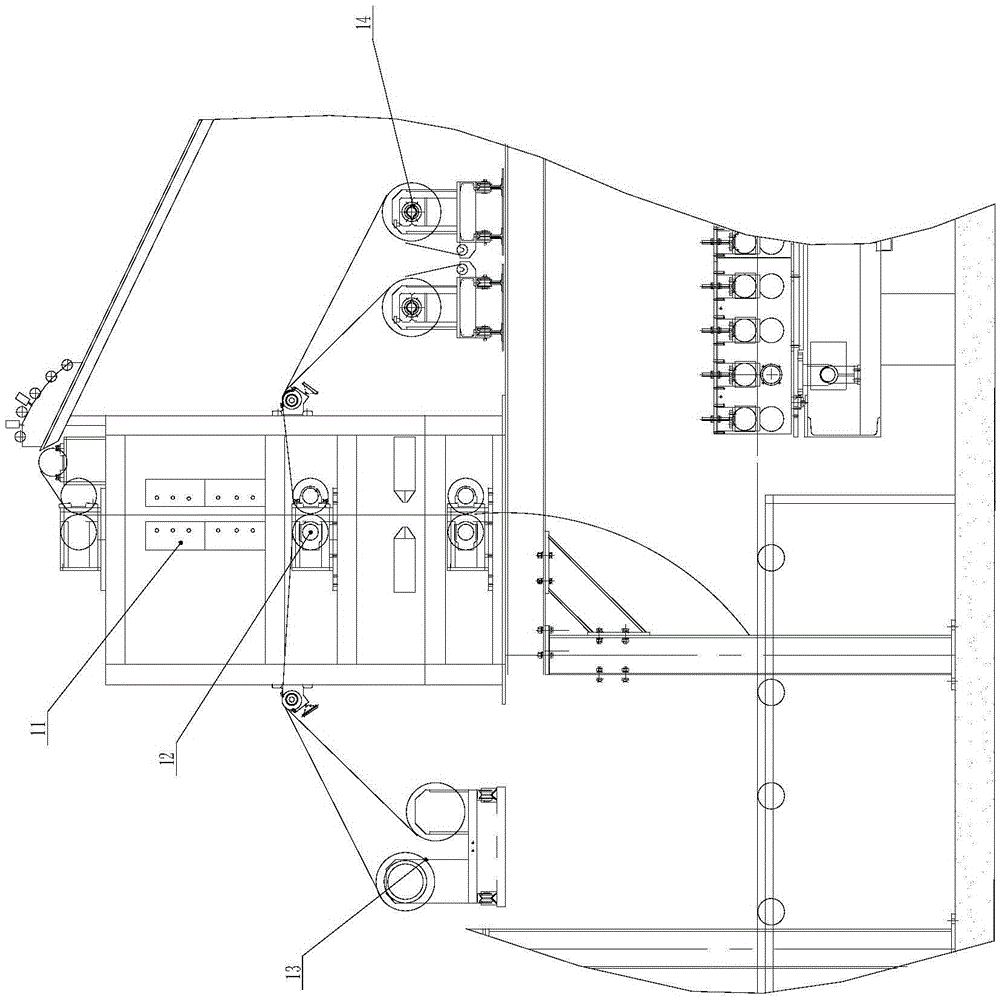

Longspan bridge erecting apparatus and erecting method thereof

InactiveCN100999895ASingle functionImprove reliabilityPortable bridgeBridge erection/assemblyArm foldingLong span

The long span bridge erecting apparatus and process belongs to the field of traffic technology, and is especially suitable for constructing military long span bridge in wartime. The long span bridge erecting apparatus consists of chassis, arm folding crane, erecting platform, leading-in girder unit, leading-in girder sheath, movable stand, chassis frame and bridge section. The long span bridge erecting apparatus has lowered erecting height, convenient transportation, composite structure and high reliability. The present invention has short construction period, low operation plane and relatively simple construction and other advantages.

Owner:邹煜 +7

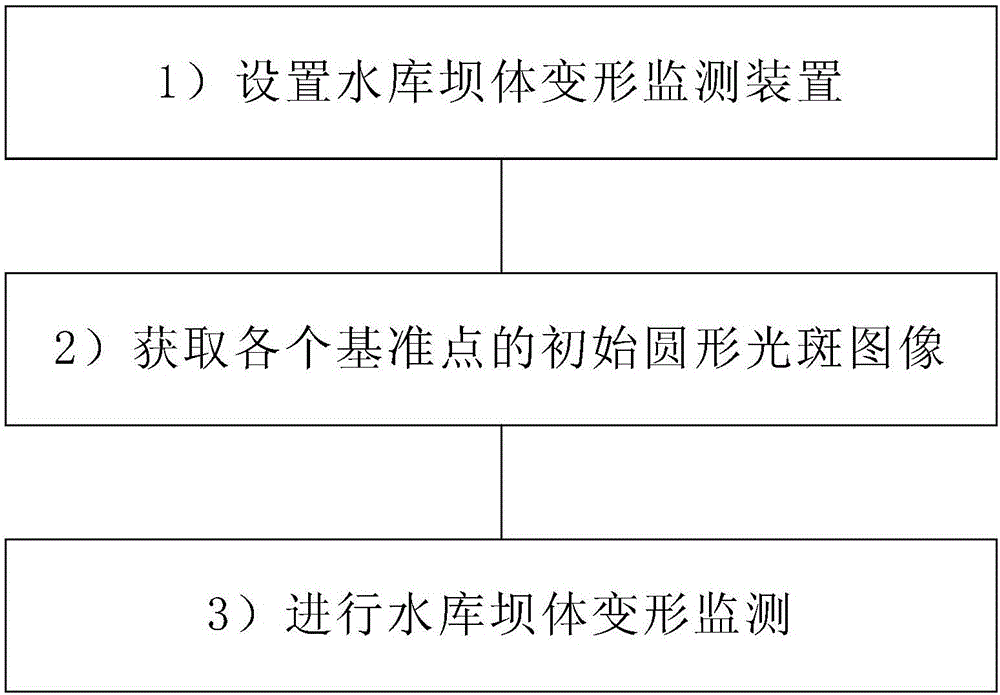

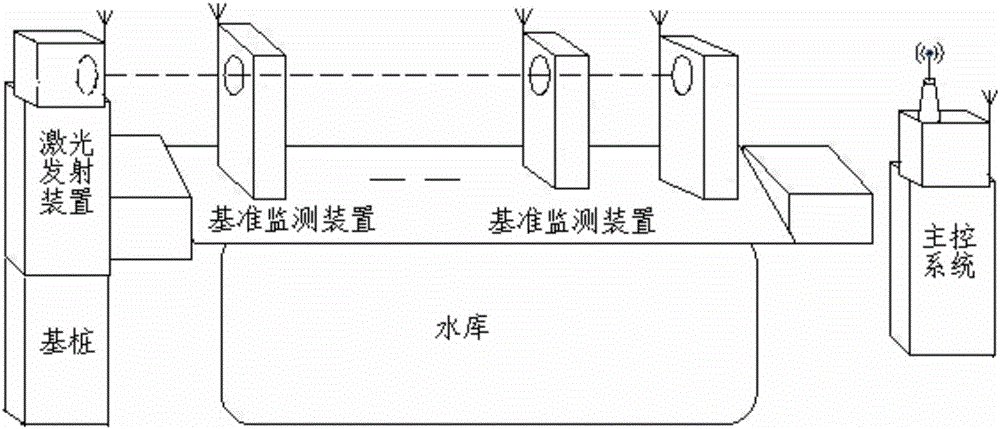

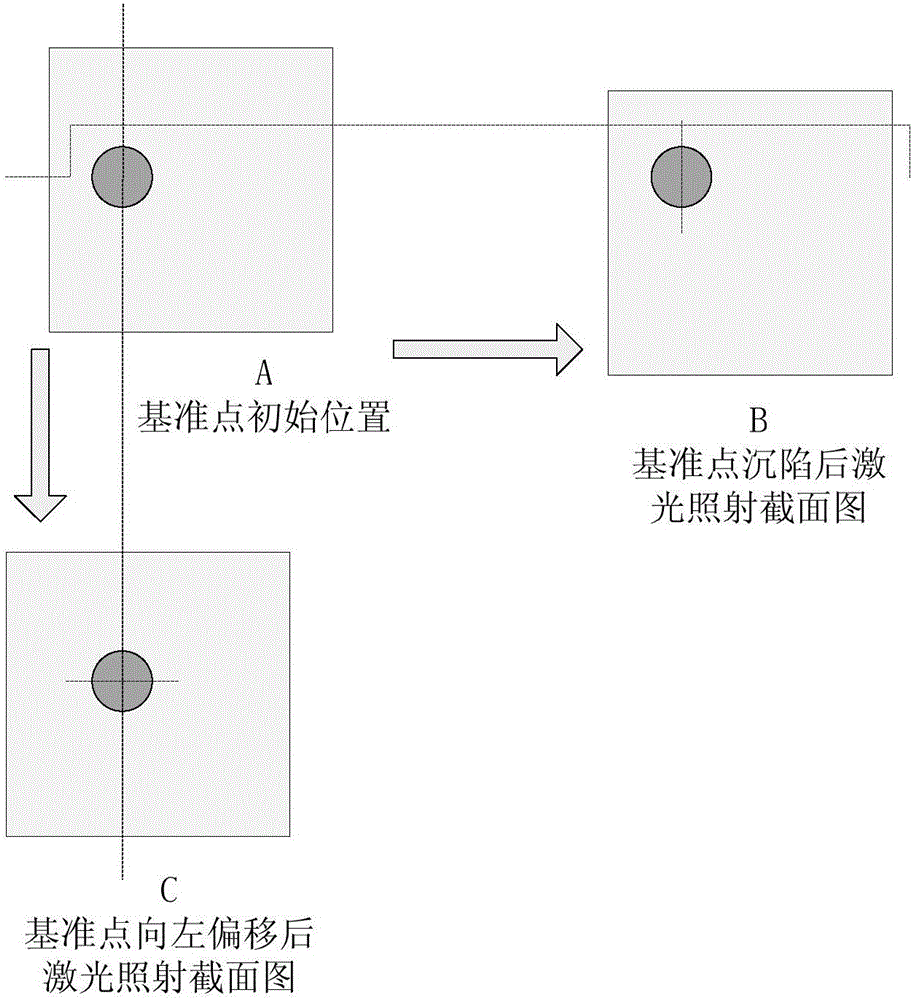

Reservoir dam deformation monitoring method and system

InactiveCN106595506AHigh measurement accuracyRealize automatic monitoring functionUsing optical meansLight spotControl system

The invention relates to a reservoir dam deformation monitoring method and system. The monitoring method includes the following steps that: 1) a reservoir dam deformation monitoring device is set; 2) the initial circular light spot images of each reference point are obtained; and 3) reservoir dam deformation monitoring is carried out. The reservoir dam deformation monitoring system includes a laser emitting device, reference point detecting devices and a main control system; the laser emitting device is arranged at one end of a dam and is used for emitting collimating laser light adopted as a reference line; a plurality of reference points with equal intervals are arranged one a ray with the laser emitting device adopted as an end point; one reference point detecting device is arranged at each reference point; the reference point detecting devices are used for detecting the subsidence and horizontal displacement of the dam; and the main control system is connected with the laser emitting device and the reference point detecting devices through a wireless communication mode and is used for transmitting detection commands, receiving detected data and performing analysis processing on the detected data. With the reservoir dam deformation monitoring method and system of the invention adopted, the automatic detection of the subsidence and horizontal displacement of the dam can be realized, the measurement accuracy of the reservoir dam is improved, and monitoring costs can be reduced.

Owner:UNIV OF JINAN

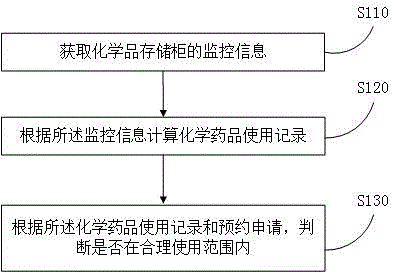

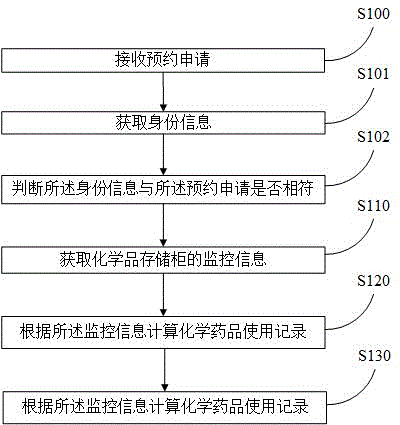

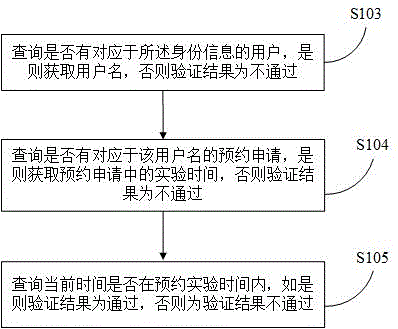

Chemical medicine management method and chemical medicine storage cabinet

PendingCN106779392AAccelerate the speed of receiptImprove management efficiencyEnclosures/chambersResourcesReal-time dataApproaches of management

The invention provides a chemical medicine management method. The method comprises the following steps that: collecting real-time data, wherein the real-time data comprises one of cabinet door state information, chemical medicine information and weight information or the combination of several of the above information; according to the real-time data, generating monitoring information; and sending the monitoring information to a management server. By use of the method, the problems of large space occupation, high cost, difficulty in supervision and low efficiency in an existing chemical medicine management technology are solved, and the chemical medicine management method which can accurately manage chemical medicines and is low in cost and high in management efficiency is provided. The invention also provides a chemical medicine storage cabinet and a chemical medicine management system.

Owner:SOUTH CHINA UNIV OF TECH +1

Continuous and automatic production line for aluminum honeycomb composite boards and continuous production process

InactiveCN105538870AFit tightlyReduce manual involvementLamination plant layoutLaminationProduction lineAluminum honeycomb

The invention discloses a continuous and automatic production line for aluminum honeycomb composite boards. The continuous and automatic production line comprises a rack, an aluminum honeycomb core layer forming unit, an upper-layer board forming unit, a lower-layer board forming unit and a composite forming unit. The aluminum honeycomb core layer forming unit achieves automation of splicing, stretching and unfolding aluminum honeycomb core strips into aluminum honeycomb core layers and coating the aluminum honeycomb core layers with polymeric membranes in advance, the upper-layer board forming unit and the lower-layer board forming unit are used for unreeling upper-layer boards and lower-layer boards and coating the upper-layer boards and the lower-layer boards with polymeric membranes in advance respectively, and finally the three layers are compounded on the composite forming unit. The aluminum honeycomb composite boards can be continuously produced through the continuous production line, capacity is improved, the quality of the formed aluminum honeycomb composite boards is consistent, and the thickness is uniform.

Owner:张家港市弘扬机械设备有限公司

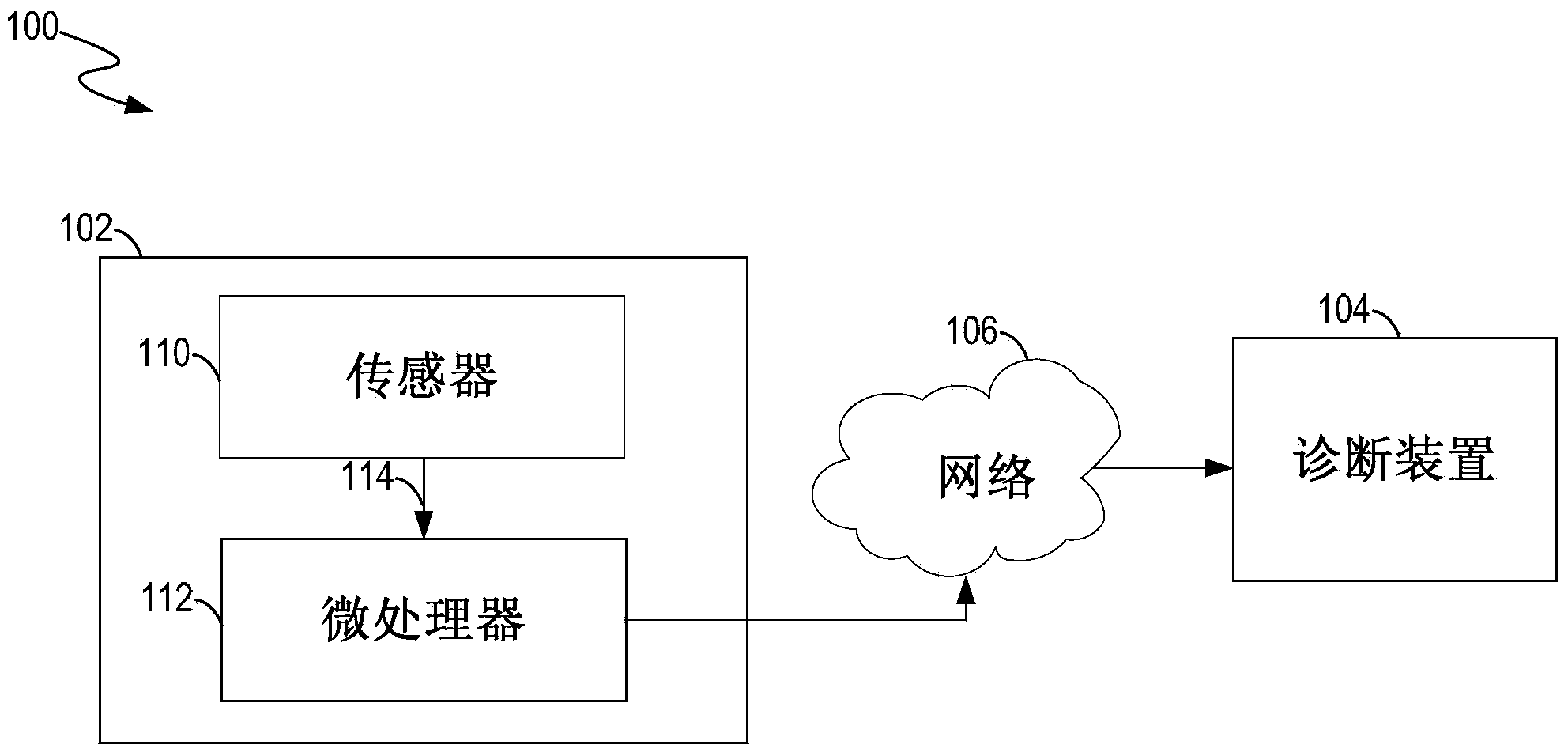

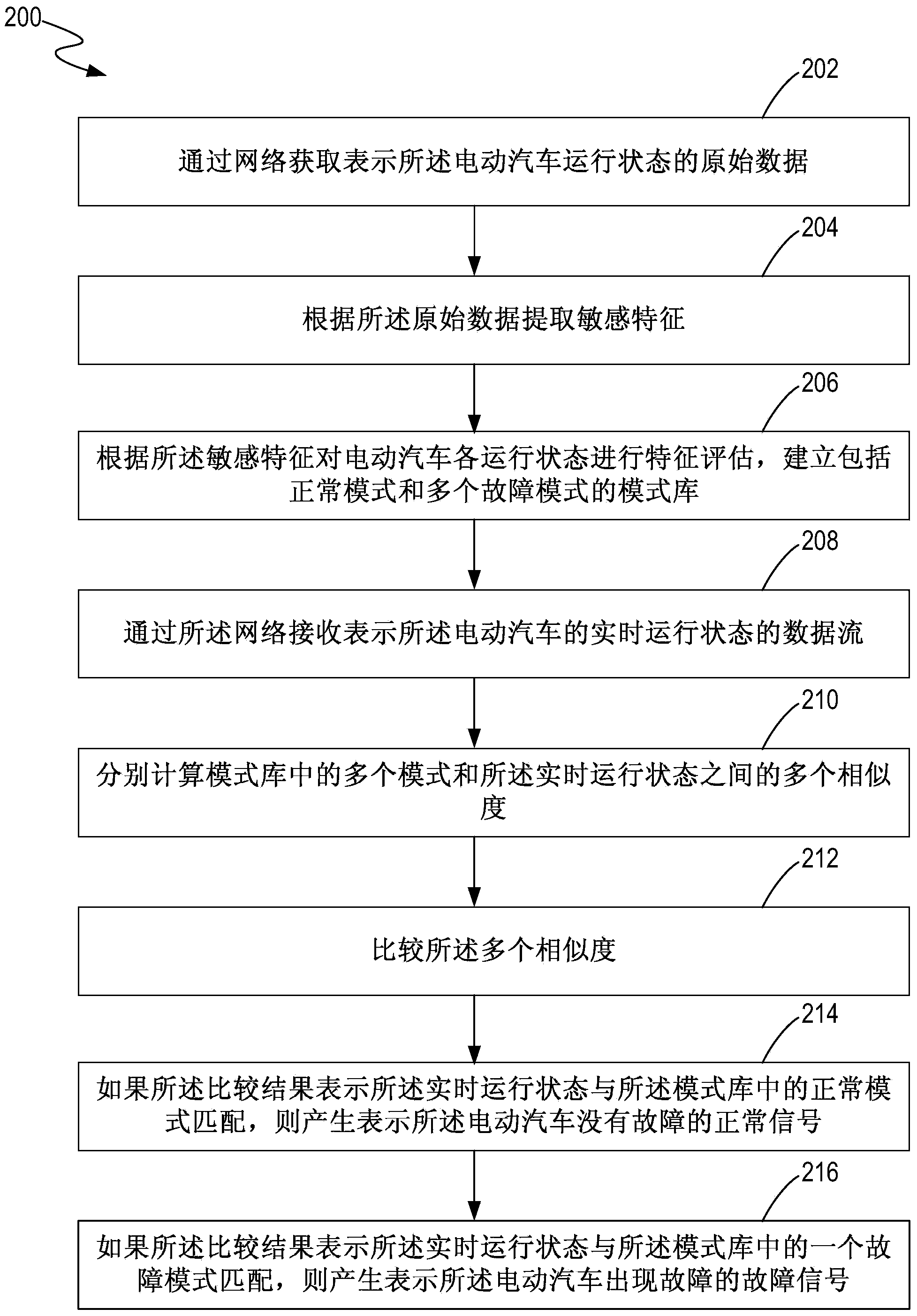

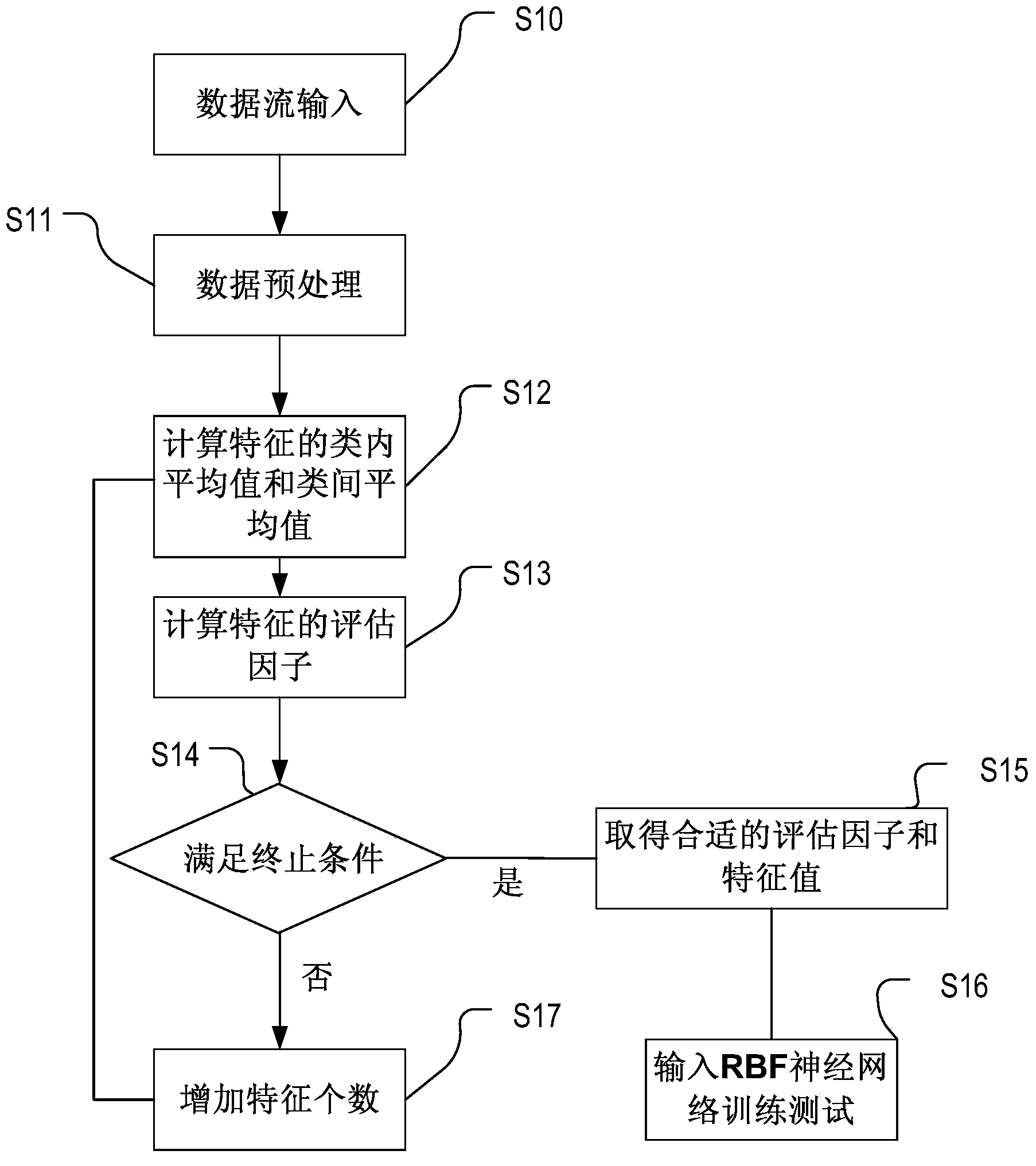

Diagnosis method and device of electric car

ActiveCN103838229AAchieving real-time forecastRealize automation and intelligence of fault detectionElectric testing/monitoringDiagnosis methodsNormal mode

The invention discloses a diagnosis method and device of an electric car. The diagnosis method comprises the steps that mode sensitive features are extracted according to state data flow expressing the operation states of the electric car; feature evaluation is carried out on the operation states of the electric car according to the mode sensitive features; a mode bank comprising the normal mode and a plurality of fault modes is built according a result of the feature evaluation; multiple similarities between the multiple modes in the mode bank and the data flow expressing the real-time operation states of the electric car are calculated and compared; a fault warning signal is generated according to the comparison result. The diagnosis method and device of the electric car achieve real-time forecast of faults, improve the efficiency, and provide basis for remote diagnosis decision making of the electric car. Meanwhile, manual participation is reduced, and potential safety hazard generated by labor is avoided.

Owner:WUHAN UNIV OF TECH

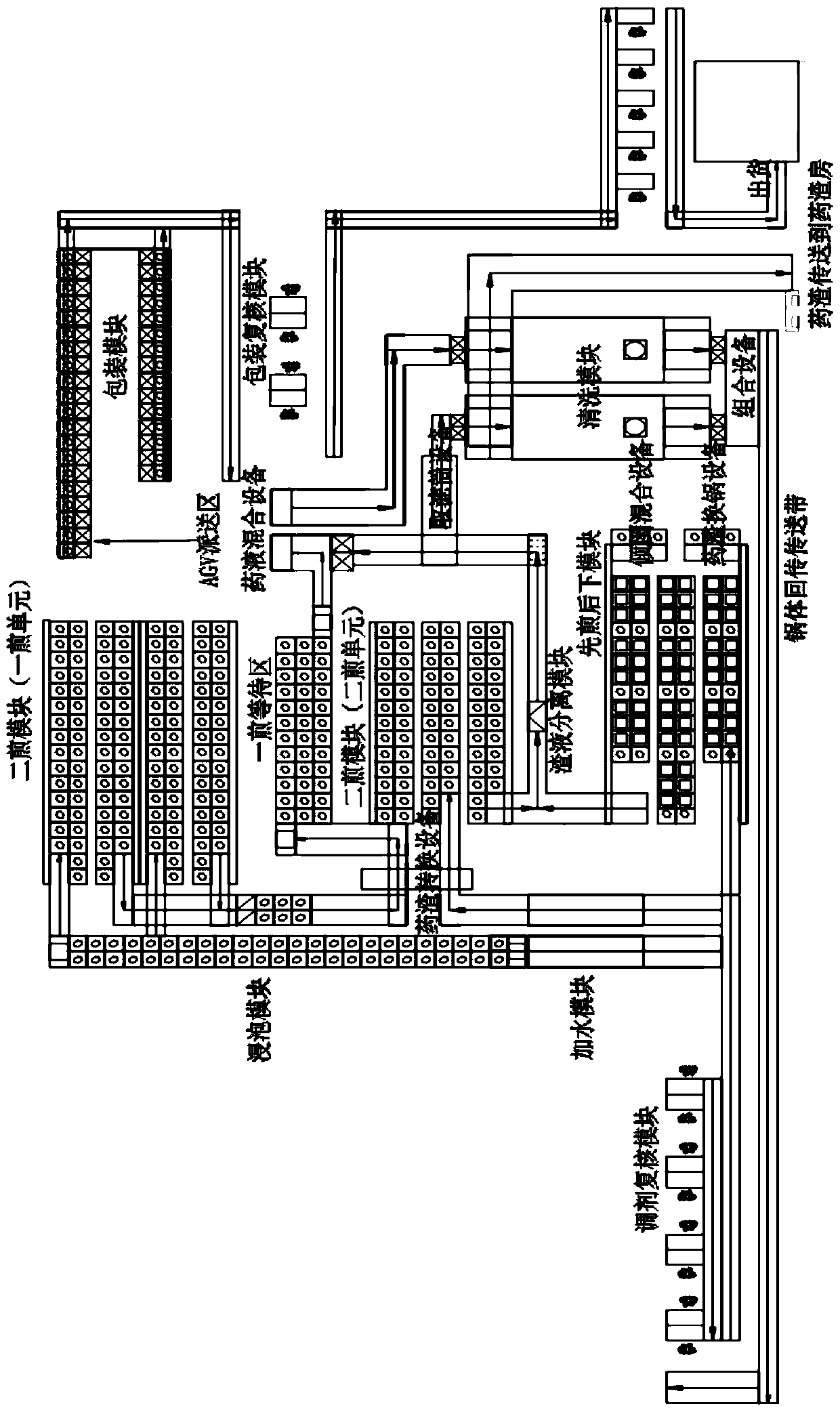

Intelligent decoction system for traditional Chinese medicines

ActiveCN110386273AImprove playbackQuality improvementPharmaceutical product form changePackaging automatic controlEngineeringChinese drug

The invention discloses an intelligent decoction system for traditional Chinese medicines. A dispensing re-check module, a water adding module, a soaking module, a two-decoction module, a residue-solution separation module, a medicine solution mixing module, a packaging module, a packaging re-check module and a cleaning module are sequentially distributed in a conveying direction; the dispensing re-check module, the water adding module, the soaking module, the two-decoction module, the residue-solution separation module, the medicine solution mixing module, the packaging module, the packagingre-check module and the cleaning module are in signal communication with a central control module separately; the two-decoction module comprises a first-decoction unit and a second-decoction unit; andthe medicine solution mixing module is used for mixing medicine solutions in a first-decoction outer bucket and a second-decoction outer bucket, which are separated from the residue-solution separation module. The intelligent decoction system for traditional Chinese medicines automatically completes a two-decoction process for the traditional Chinese medicines, reduces the manual participation, and increases the production efficiency.

Owner:KANGMEI PHARMA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com