Seal detecting production line

A sealing detection and production line technology, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement and measuring the acceleration and deceleration rate of fluid, etc., can solve the problems of inability to batch detection, low detection efficiency and high missed detection rate, and achieve reduction of The link of manual participation, strong versatility, and the effect of improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Describe the present invention below in conjunction with specific embodiment:

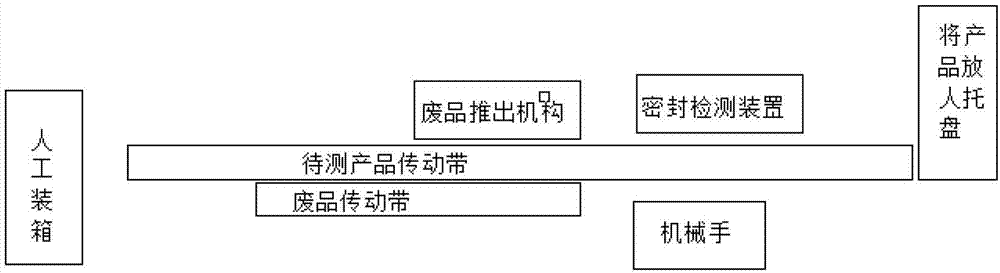

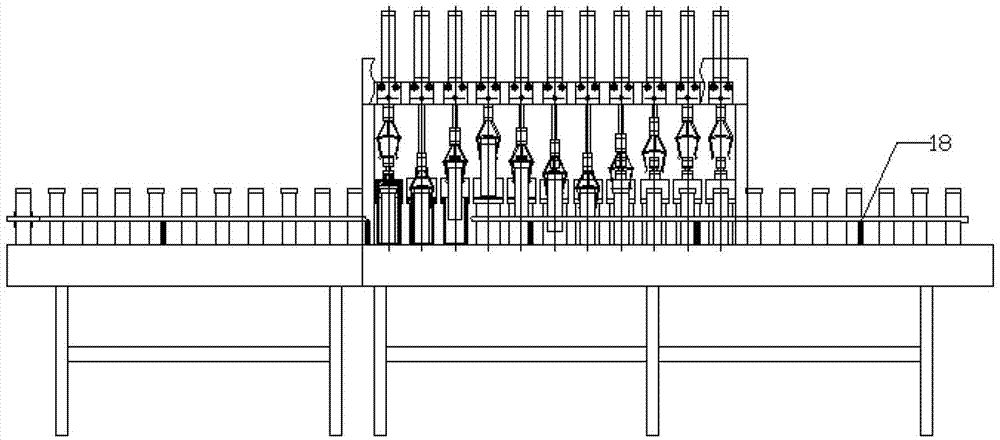

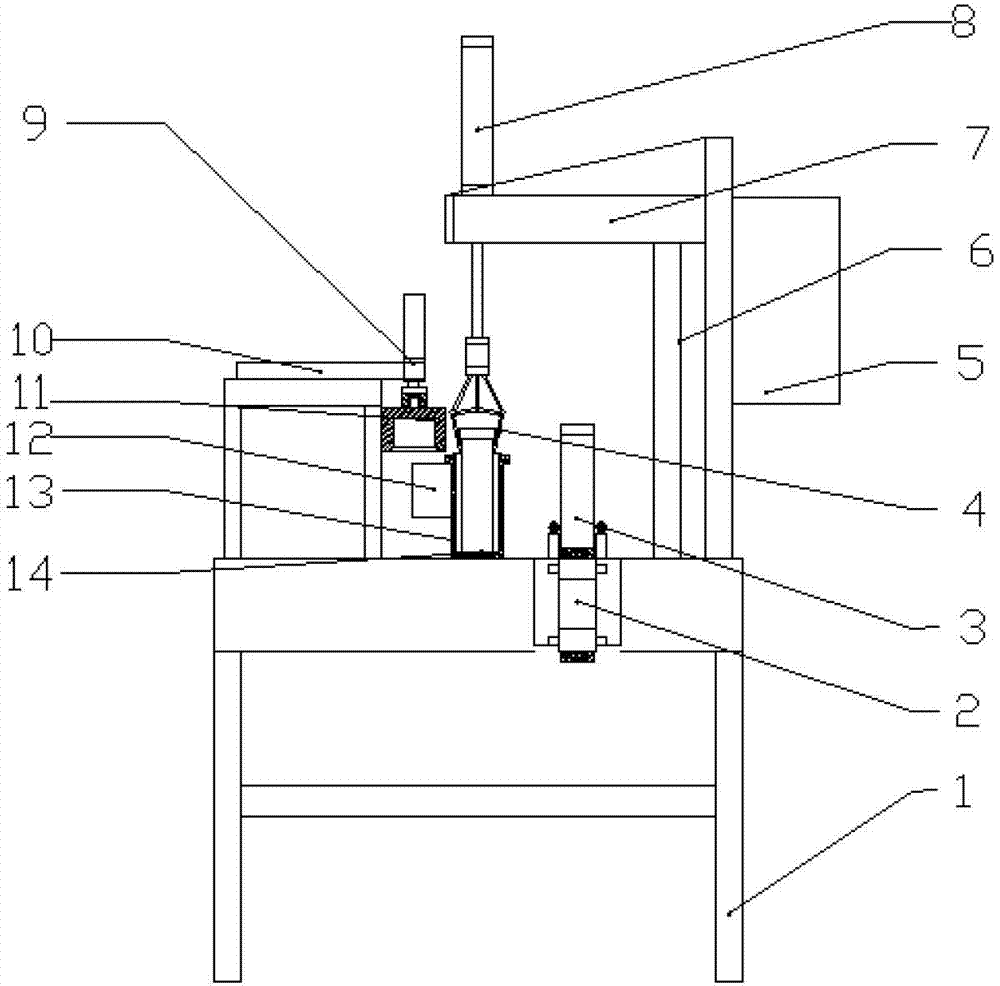

[0020] Refer to attached figure 1 , the seal detection production line in this embodiment includes a workbench and five work units fixed on the workbench: a conveyor belt 2 for products to be tested, a manipulator, a seal detection device, a waste product pushing mechanism and a waste product conveyor belt. The product-to-be-tested conveyor belt 2 traverses the entire inspection production line, and product guardrails 18 are fixed on both sides thereof, which can play a role in restricting the position of the product to be tested. One side of the product conveyor belt 2 to be tested is in order from right to left: a sealing detection device and a waste product pushing mechanism; The seal detection device is facing the manipulator. The manipulator is used for grabbing the product to be detected on the product conveyor belt 2 into and out of the seal detection device.

[0021] The sealing d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com