Intelligent unattended operation autoweighing system and method for put-out and put-in of warehouse

A technology of automatic metering and in-out storage, applied in the field of metering, can solve the problems of inadequate supervision means, difficult to find, unstable value, etc., to prevent remote control cheating and sensor failures, eliminate the phenomenon of human input errors, and ensure authenticity. Effects of Sexuality and Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

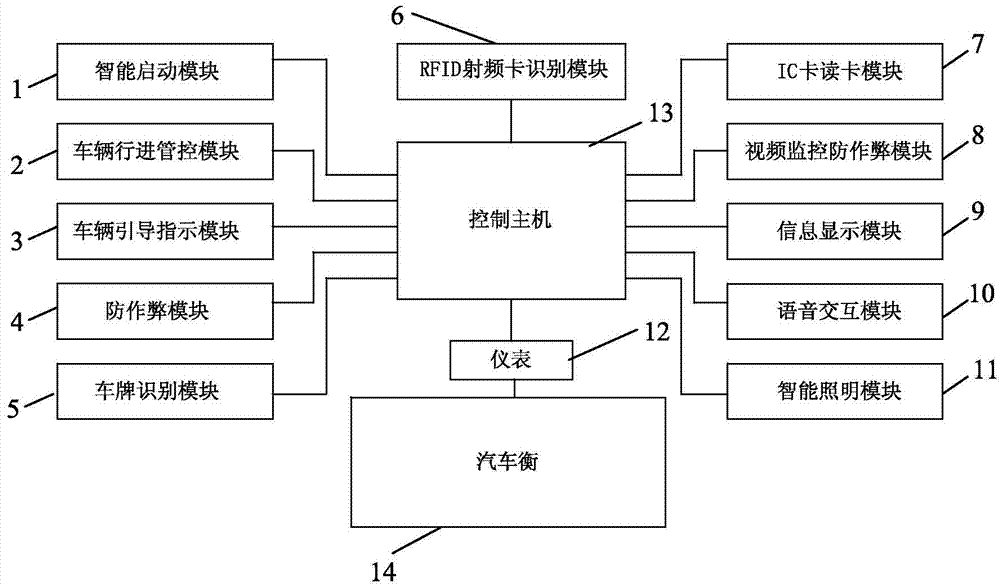

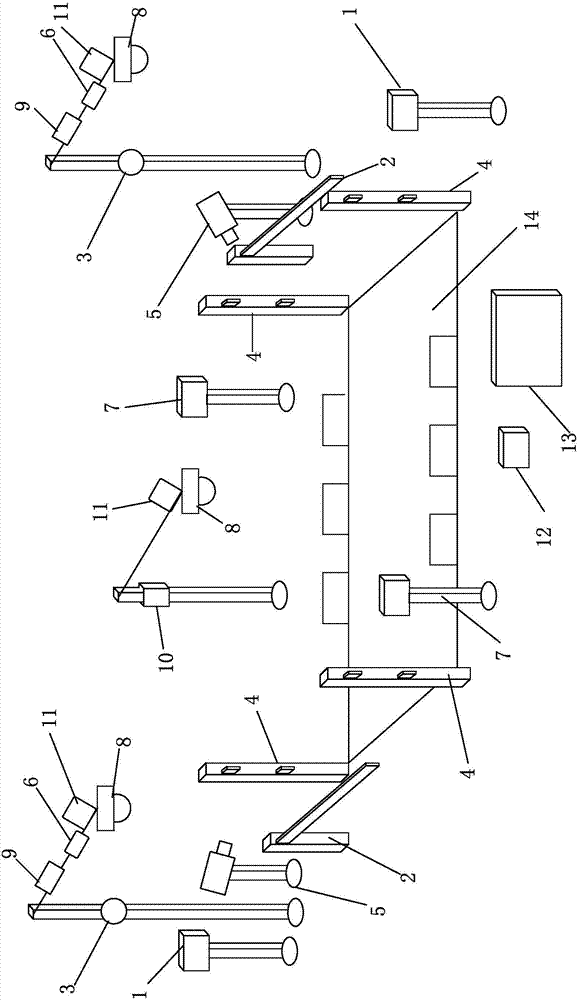

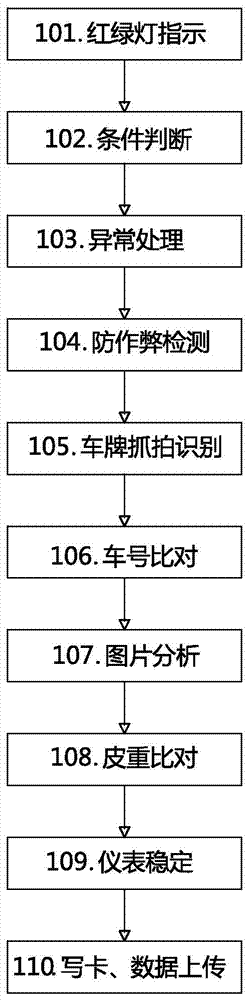

[0052] Such as figure 1 with figure 2 As shown, an intelligent unattended automatic metering system for entering and leaving the warehouse of the present invention includes an intelligent start module 1, a vehicle travel management module 2, a vehicle guidance and indication module 3, an anti-cheating module 4, a license plate recognition module 5, and an RFID radio frequency card Identification module 6, IC card reading module 7, video surveillance anti-cheating module 8, information display module 9, voice interaction module 10, intelligent lighting module 11, instrument module 12 and control host 13.

[0053] The intelligent starting module 1 is arranged on the side of the entrance and exit of the truck scale, and is set with an IP address and communicates with the control host 13 through the RJ45 interface, and is used to start the vehicle travel management module 2 to control the vehicle on the truck scale.

[0054] The vehicle travel management module 2 includes barrie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com