Patents

Literature

5474 results about "Binary image" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A binary image is a digital image that has only two possible values for each pixel. Typically, the two colors used for a binary image are black and white. The color used for the object(s) in the image is the foreground color while the rest of the image is the background color. In the document-scanning industry, this is often referred to as "bi-tonal".

Method and system operative to process color image data

ActiveUS8600158B2Television system detailsCharacter and pattern recognitionPattern recognitionColor image

A method and system operative to process color image data are disclosed. In one embodiment, the method can comprise the steps of receiving color image data, determining the color ranges to be applied to the color image data, assigning each of the pixel positions in the image data a color range, assigning a different spatial binary pattern to each color range, and assigning each of the pixel positions a binary output pixel value that corresponds to the spatial binary pattern assigned to the color range assigned to that pixel position. The resulting binary image data can be written to a file for subsequent storage, transmission, processing, or retrieval and rendering. In other embodiments, a system can be made operative to accomplish the same.

Owner:HAND HELD PRODS

Method and system operative to process monochrome image data

A method and system operative to process monochrome image data are disclosed. In one embodiment, the method can comprise the steps of receiving monochrome image data, segmenting the input pixel values into pixel value ranges, assigning pixel positions in the lowest pixel value range an output pixel value of a first binary value, assigning pixel positions in the highest pixel value range an output pixel value of a second binary value, wherein the first and second binary values are different, and assigning pixel positions in intermediate pixel value ranges output pixel values that correspond to a spatial binary pattern. The resulting binary image data can be written to a file for subsequent storage, transmission, processing, or retrieval and rendering. In further embodiments, a system can be made operative to accomplish the same.

Owner:HAND HELD PRODS

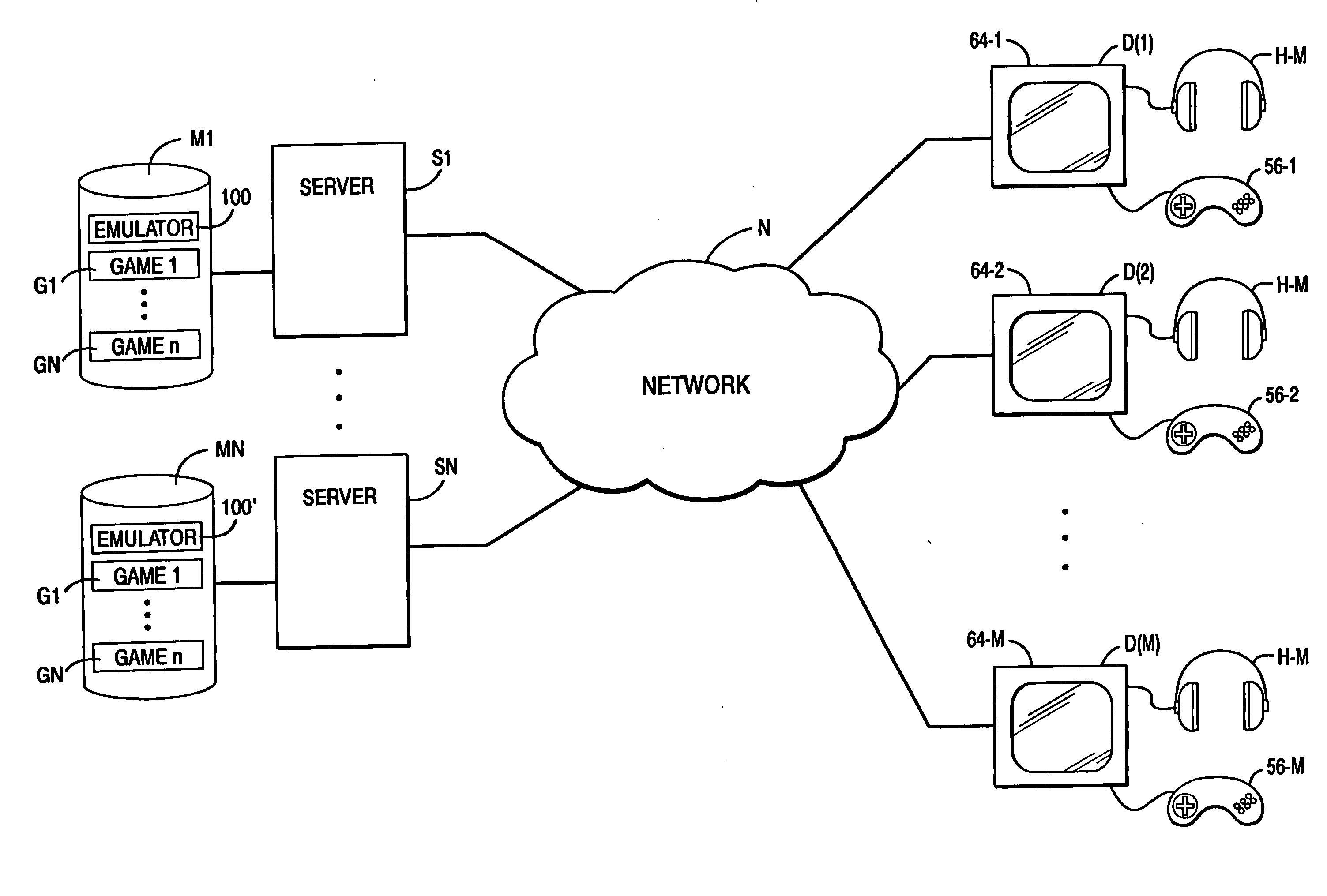

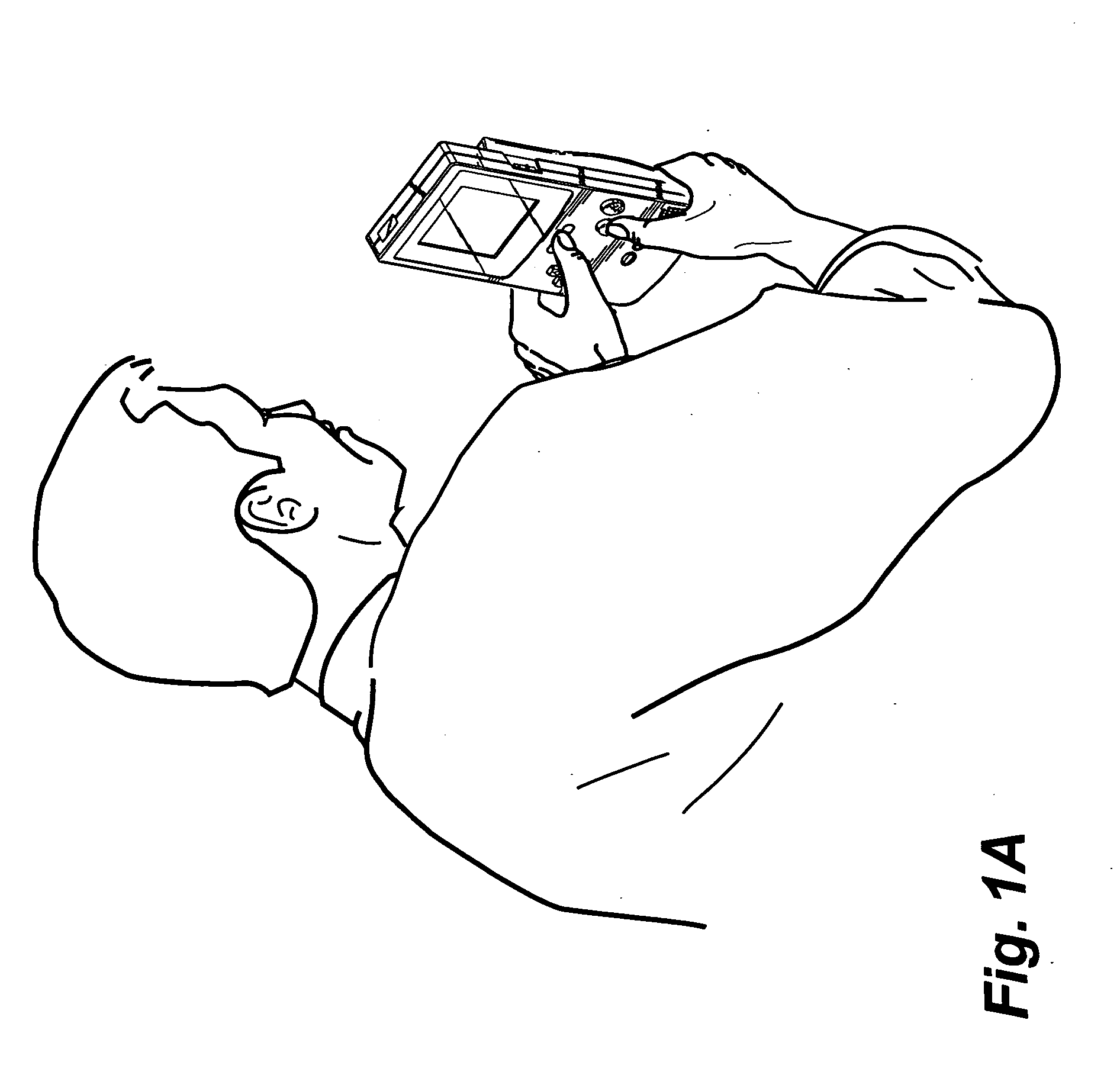

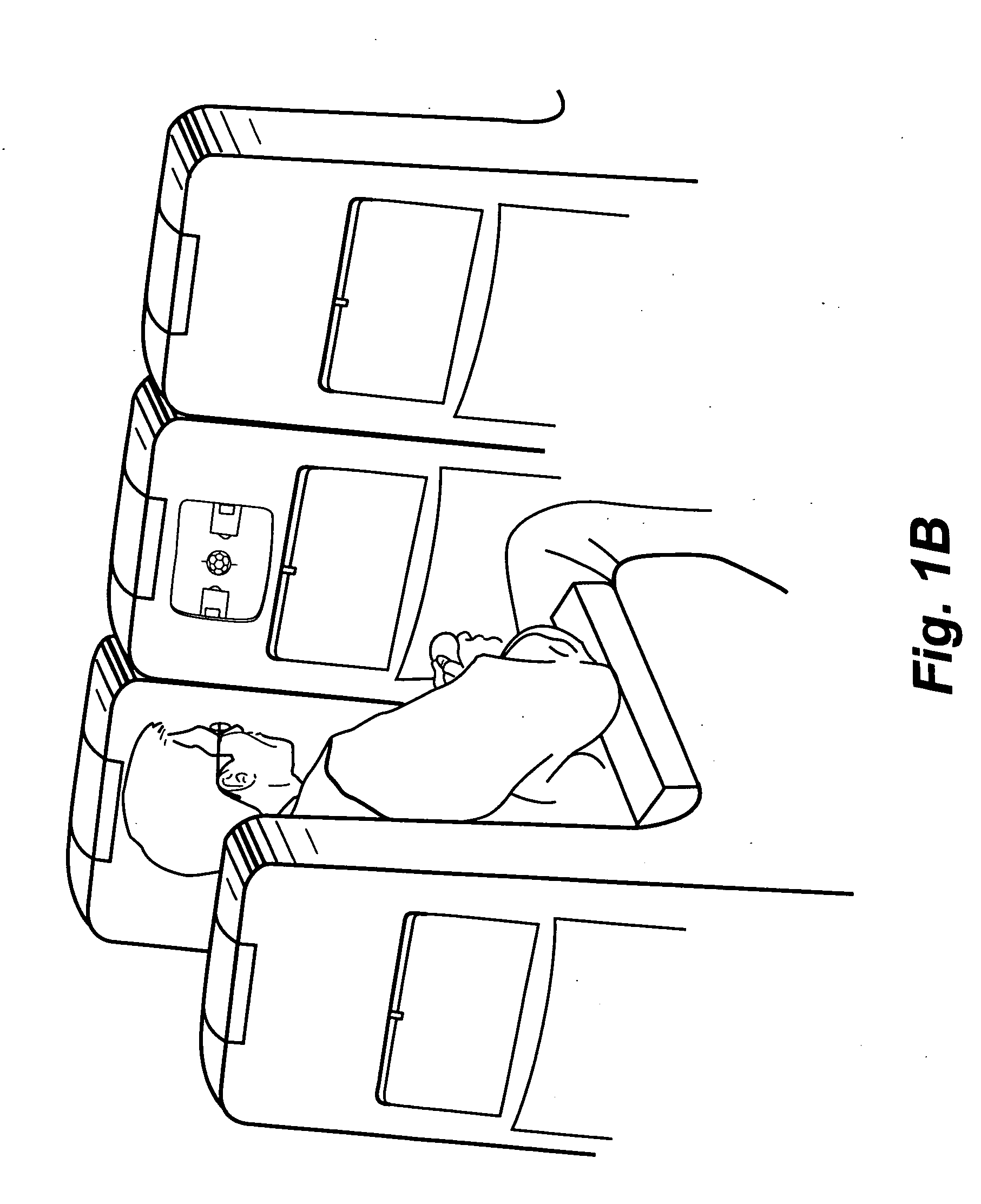

Video game distribution network

InactiveUS6884171B2Keep them occupied and happyVideo gamesSpecial data processing applicationsSoftware emulationInteractive video

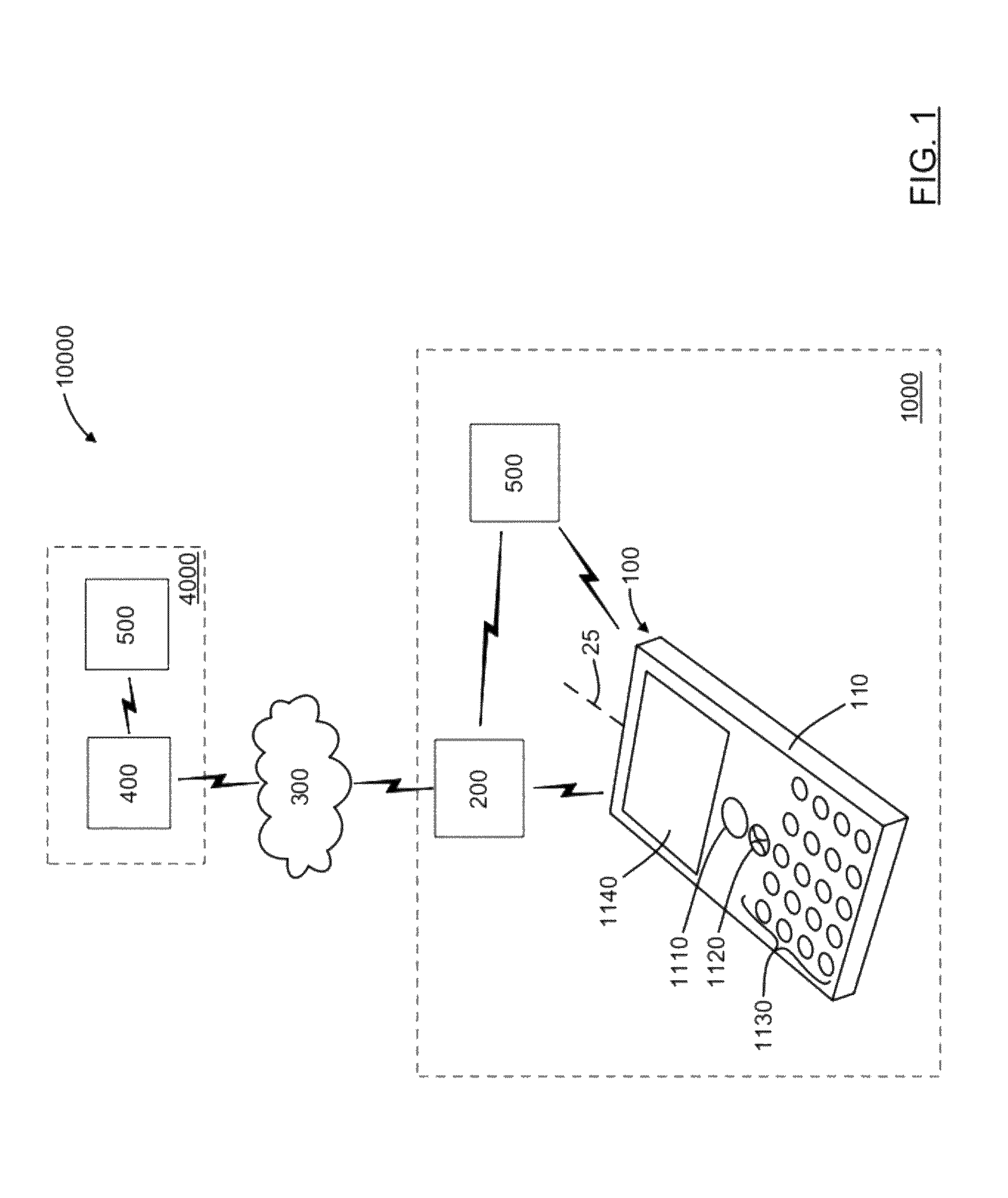

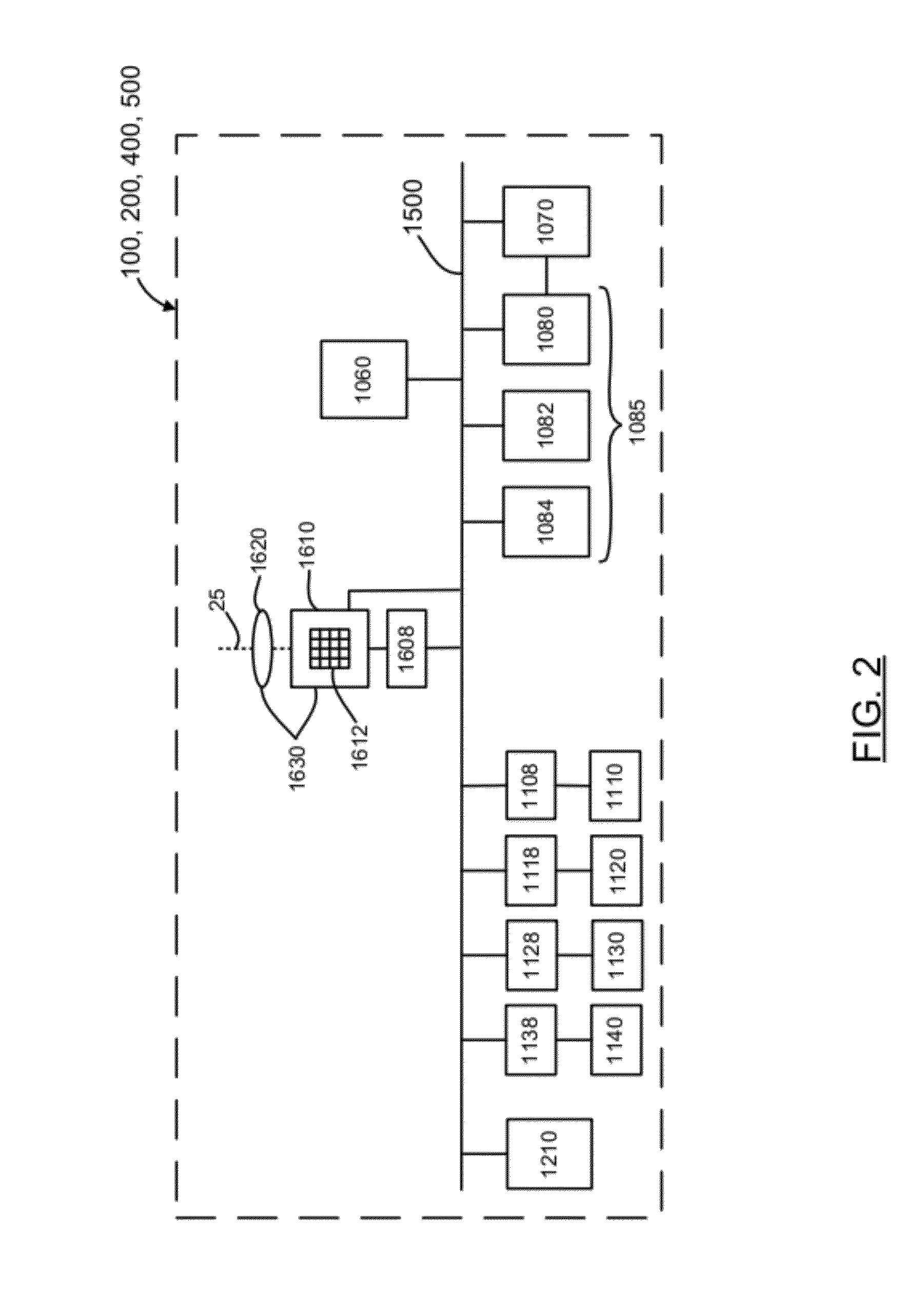

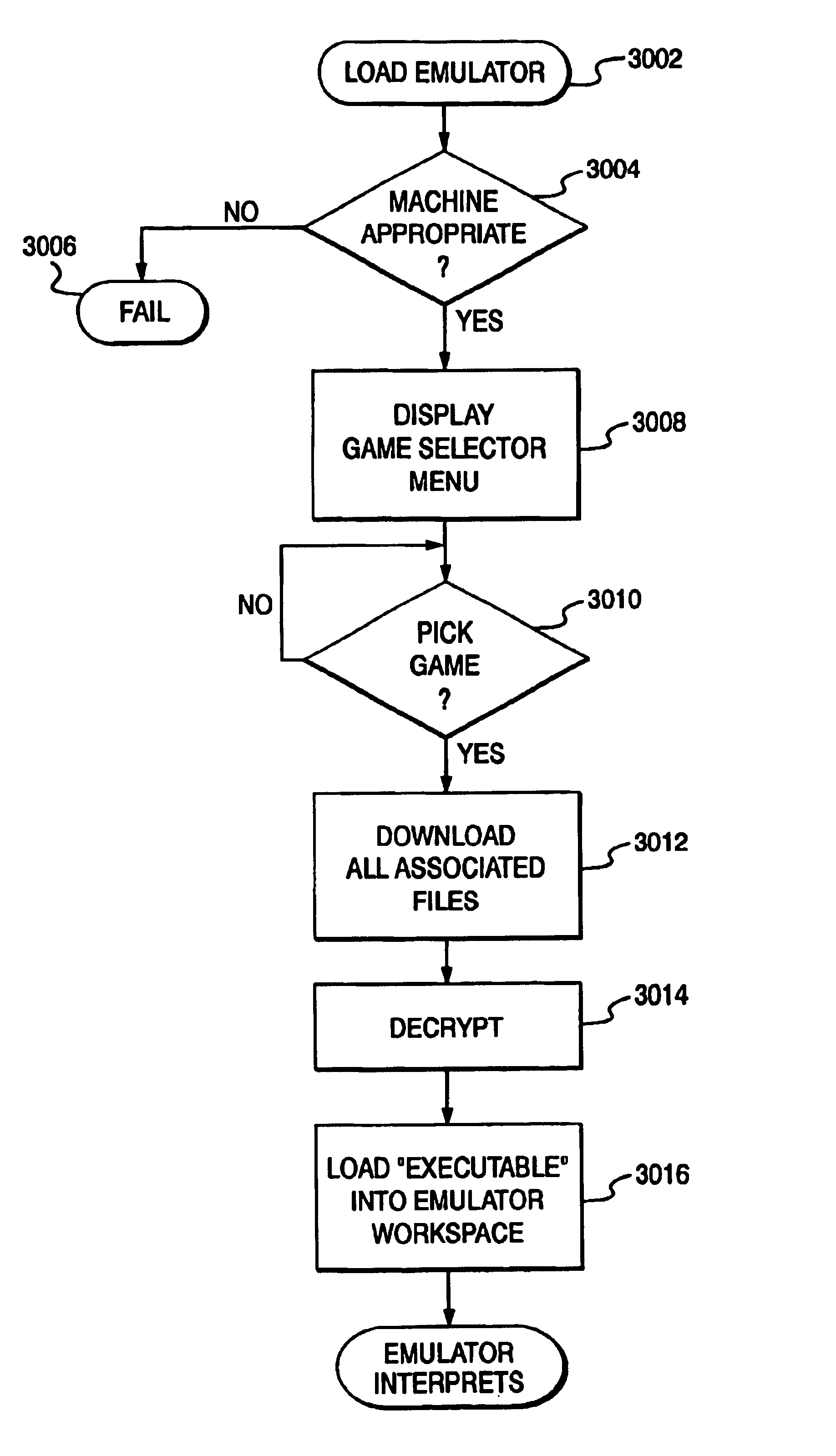

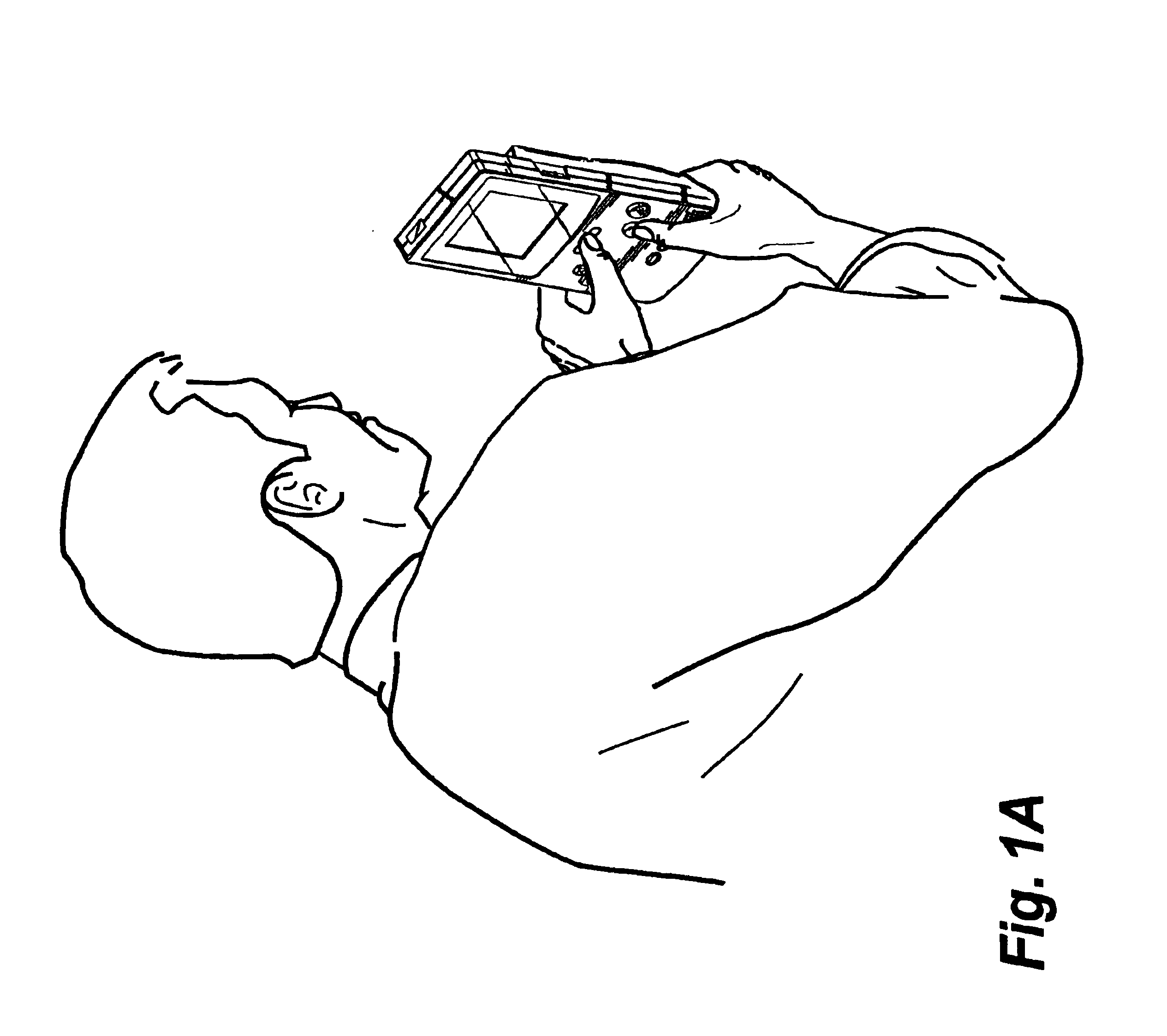

A video game distribution network for use in airlines, trains, hotels, cruise ships, set top boxes, cable television systems, satellite and other wireless systems or other communications systems, distributes special purpose game binary image files to general purpose computing / display devices. Software emulators running on the general purpose computing / display devices model the game source platform and interpret and / or compile the game files to provide interactive video game play. Software emulators for emulating a handheld video game platform such as GAME BOY®, GAME BOY COLOR® and / or GAME BOY ADVANCE® on a low-capability target platform (e.g., a seat-back display for airline or train use, a personal digital assistant, a cell phone) may provide any number of features and optimizations to provide high quality graphics and sound that nearly duplicates the game playing experience on the native platform.

Owner:NINTENDO CO LTD

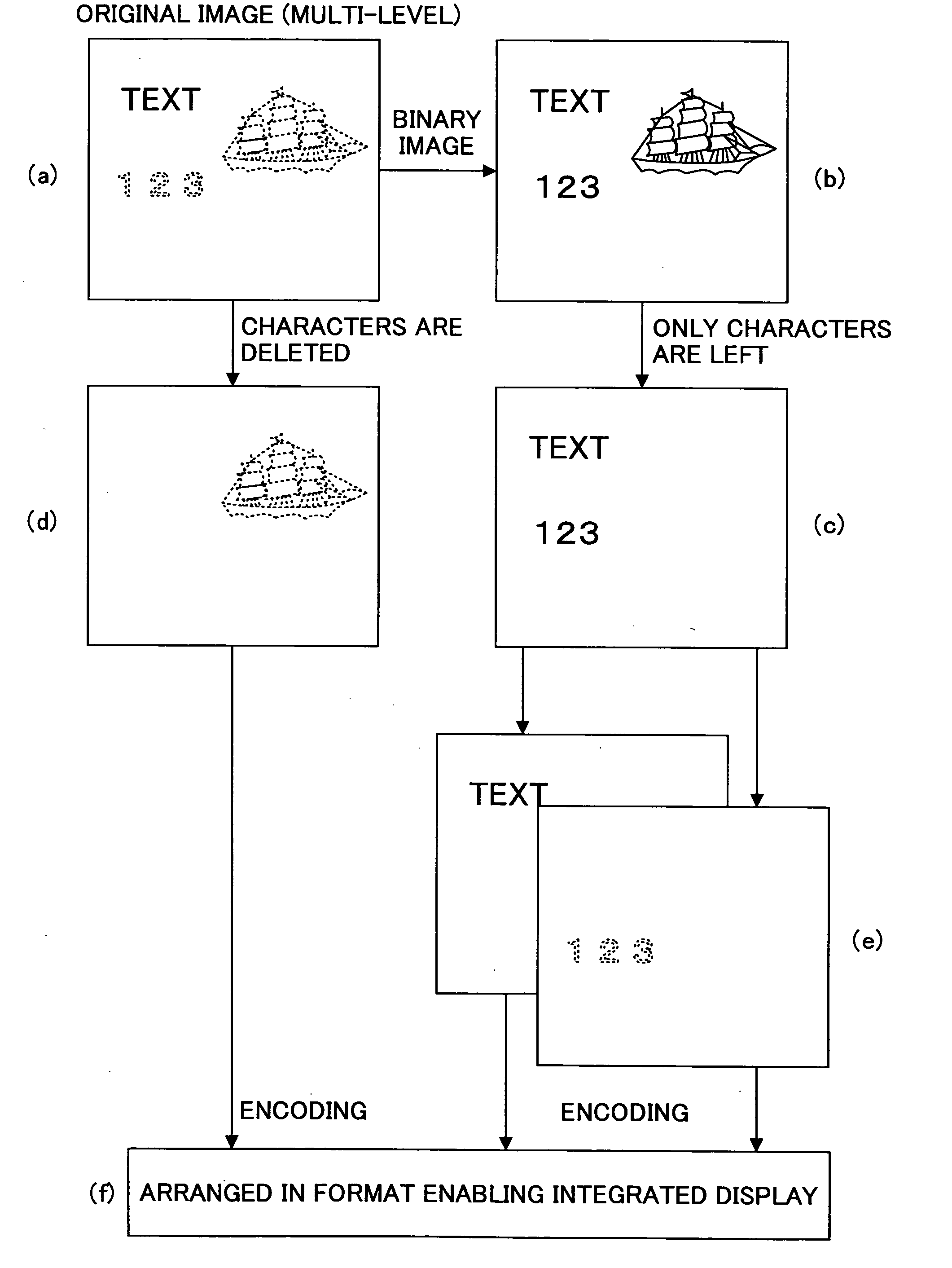

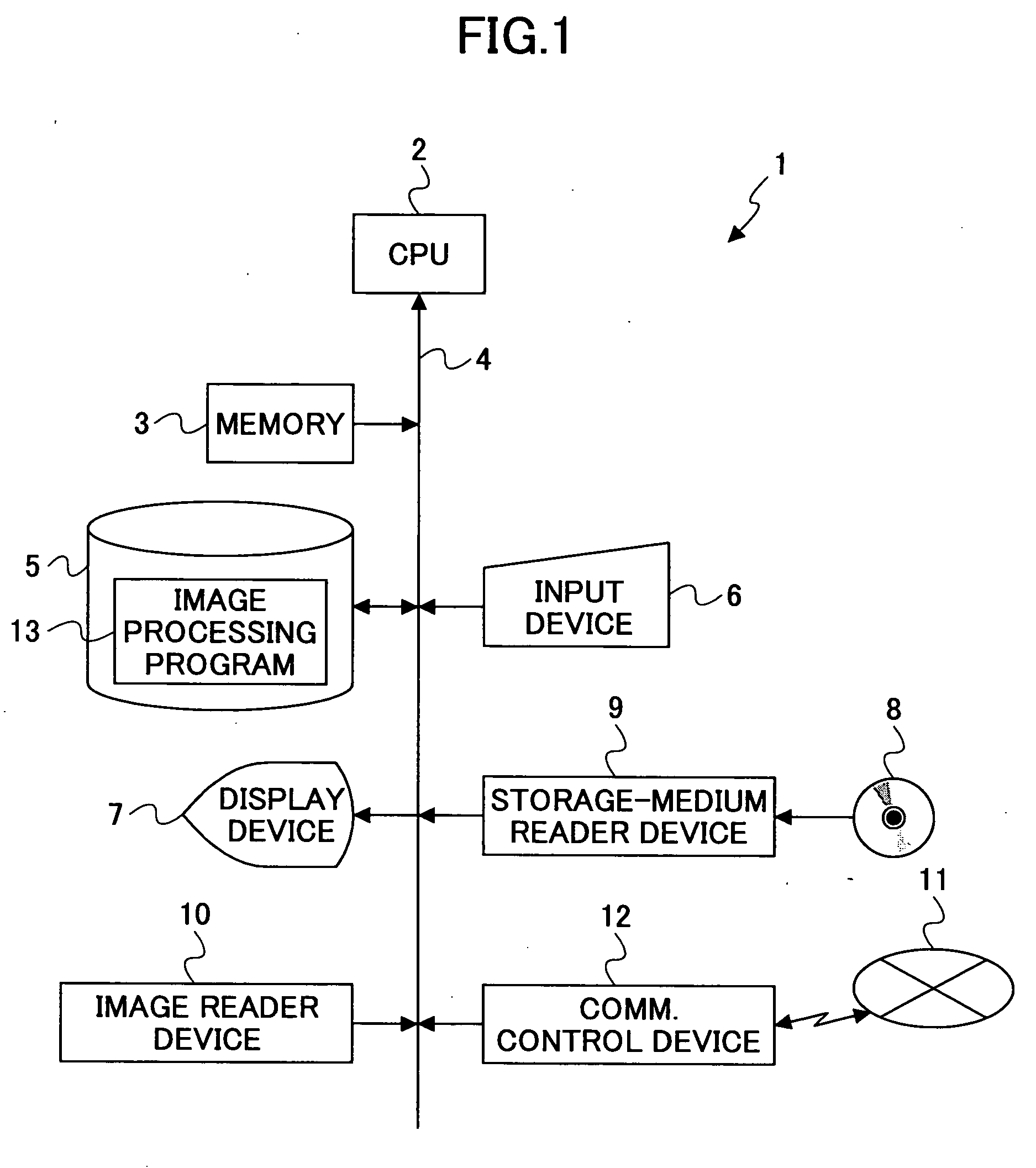

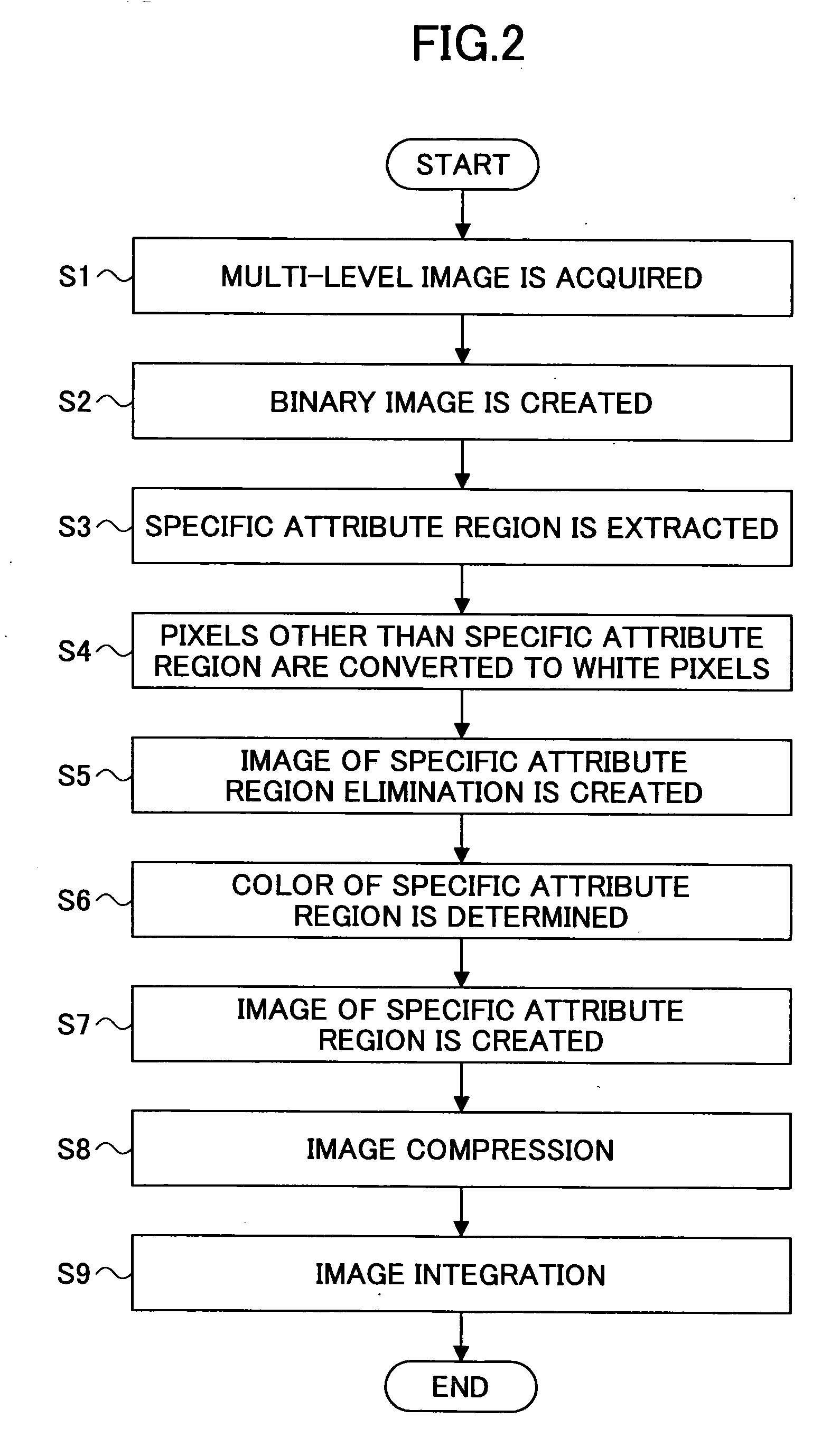

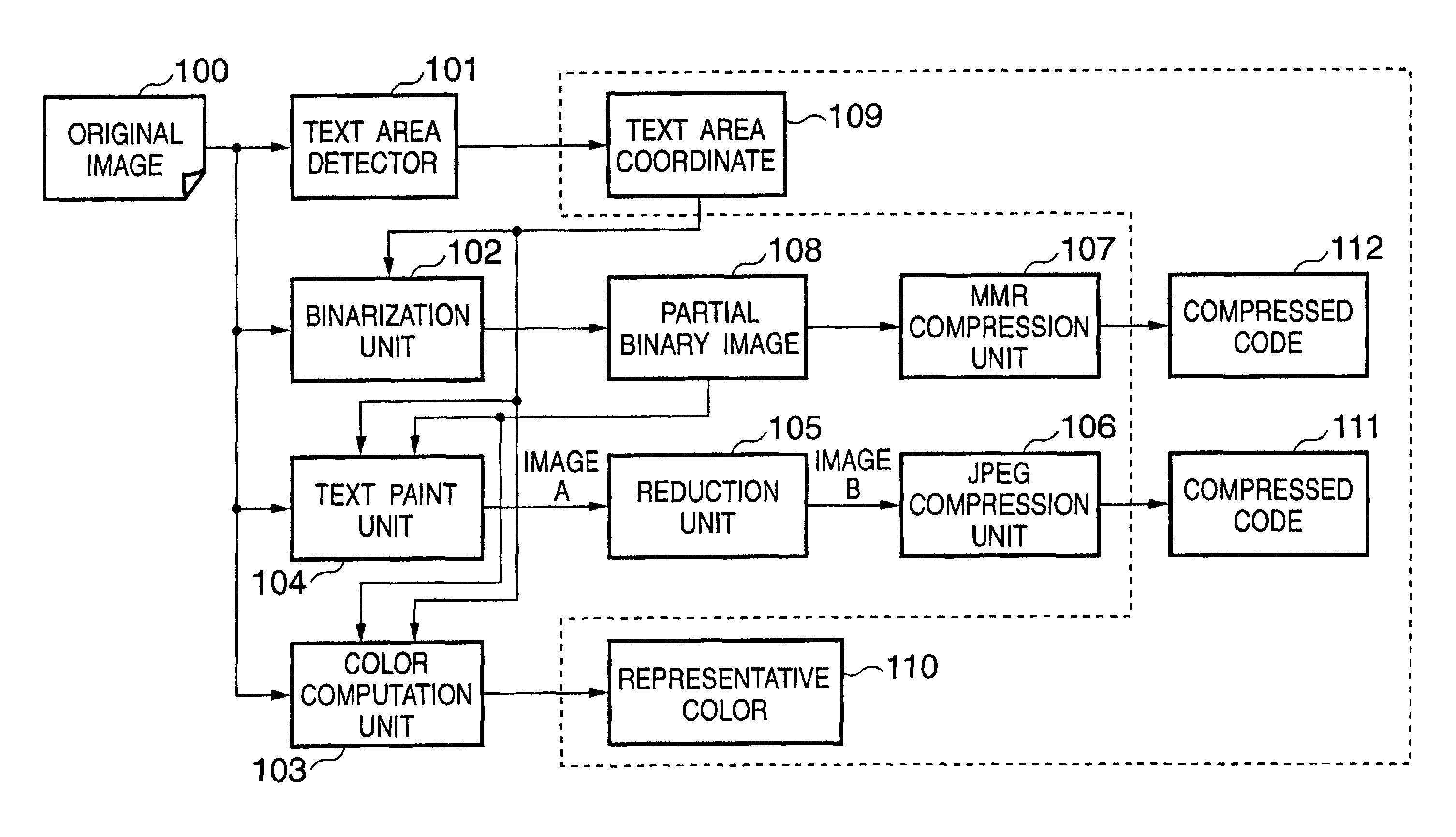

Image processing apparatus, image processing program, and storage medium

InactiveUS20050180645A1Reduce file sizeReduce image qualityCharacter and pattern recognitionPictoral communicationImaging processingImage code

An image processing apparatus comprises a unit acquiring a multi-level image as a processing-object image, a unit acquiring a binary image which is created based on the multi-level image, a unit extracting a specific attribute region which is a region with a specific attribute from the multi-level image, a unit changing pixels other than the specific attribute region in the binary image to white pixels, a unit creating a multi-level image in which the pixels of the specific attribute region are changed by a background color, a unit determining a color of the specific attribute region, a unit creating an image of the specific attribute region having the color determined, an image coding unit carrying out compression coding of two or more images which are created respectively, and a unit creating an integrated file in which the coded images are integrated.

Owner:RICOH KK

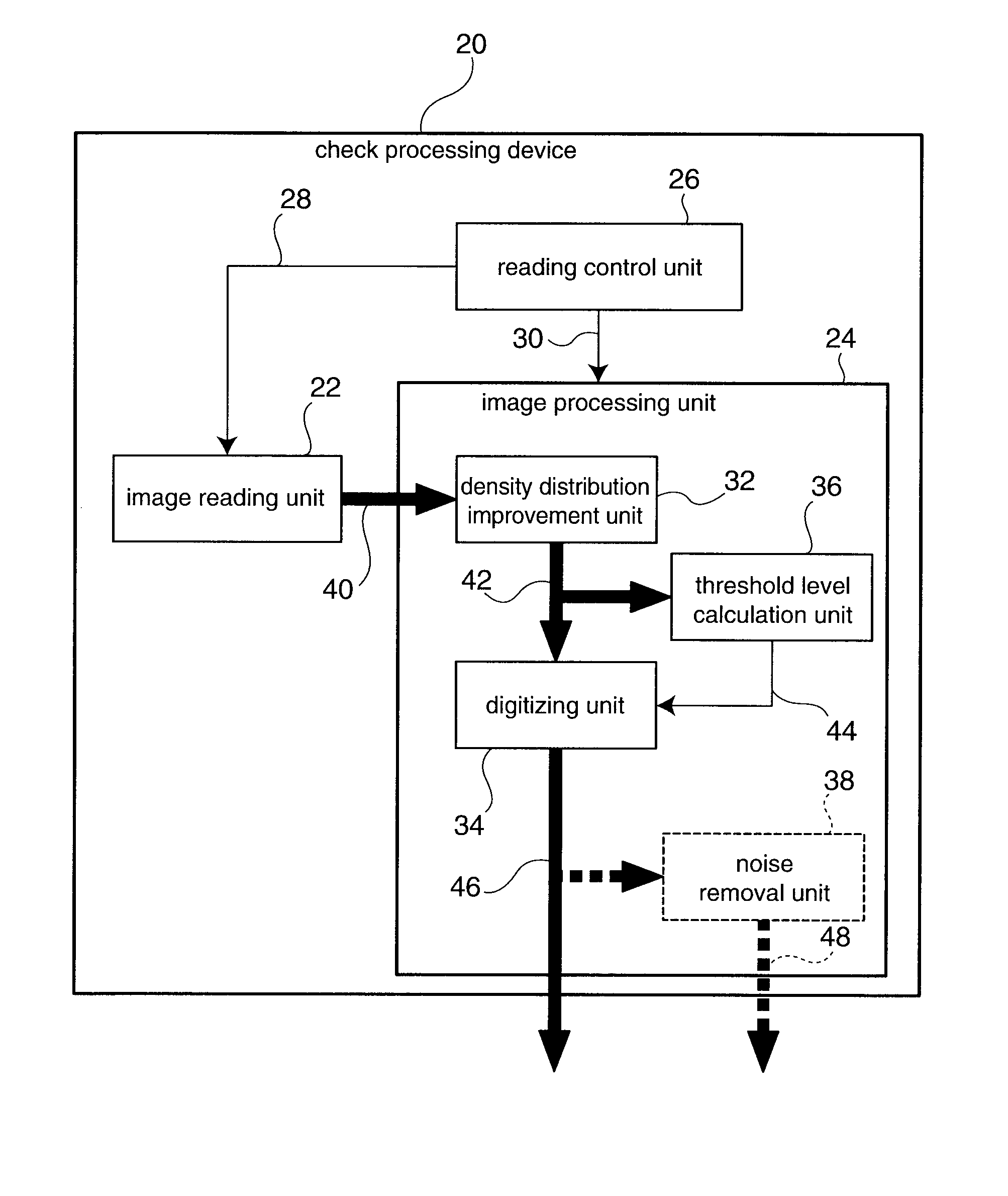

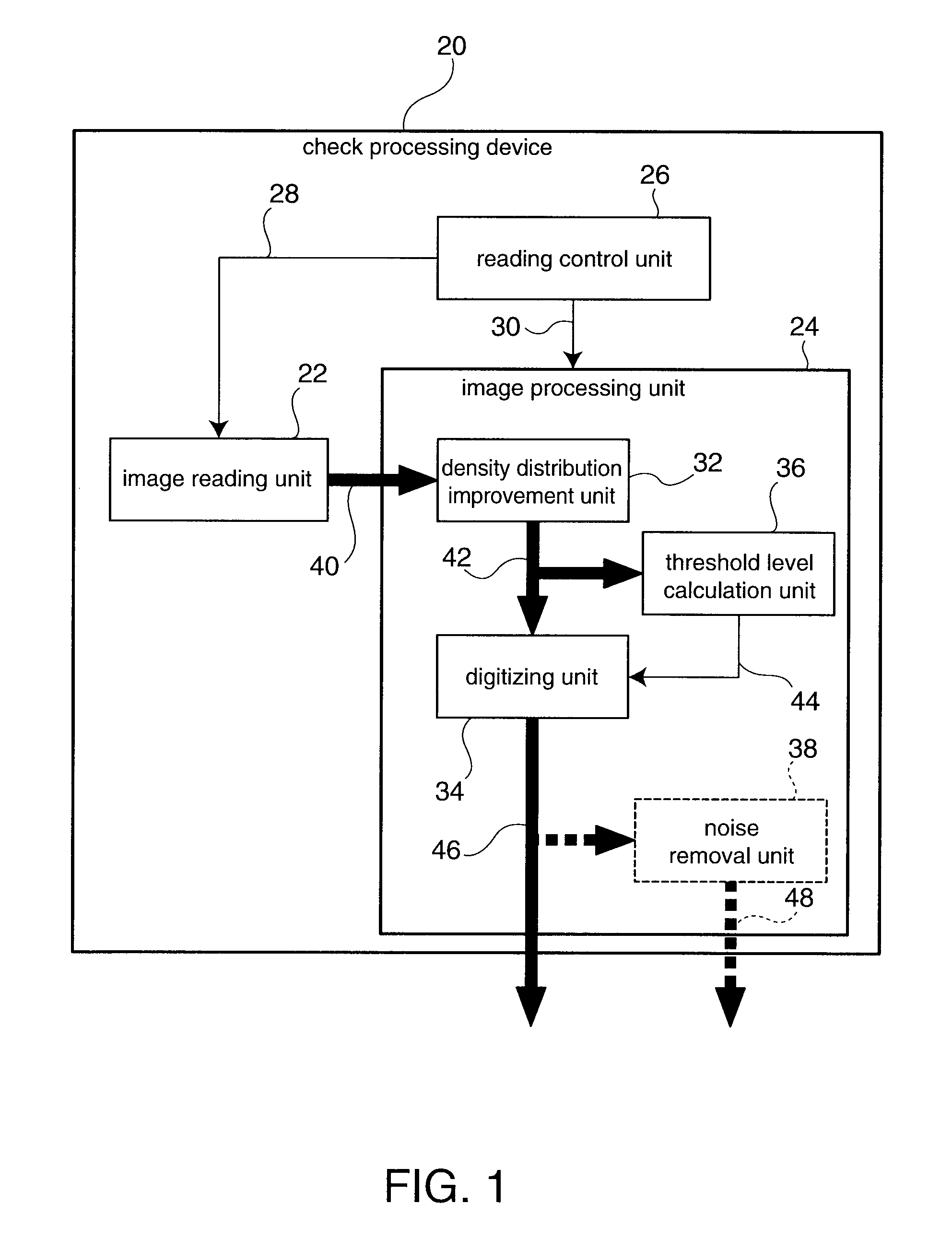

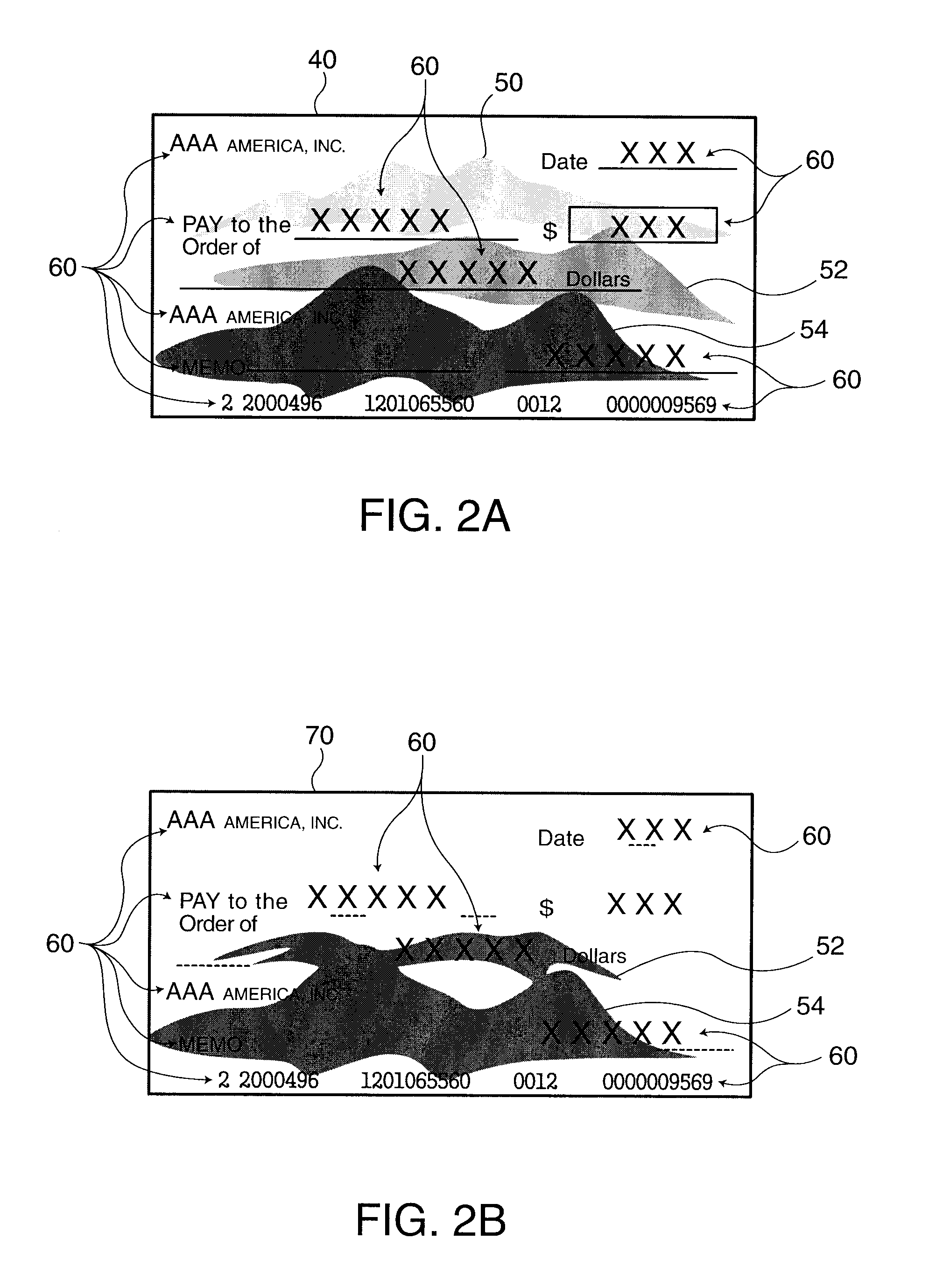

Image Processing Apparatus And Image Processing Method

InactiveUS20070019243A1Improve accuracyImage enhancementCharacter and pattern recognitionImaging processingDensity distribution

Background images are removed and only the desired payment information is extracted from a grayscale image of a check or similar financial instrument. A density distribution improvement process applied to grayscale raw image data 40 acquired by scanning a check corrects the density distribution of the raw image data 40 to separate the density range of the desired payment information from the density range of the background image. Image sharpening or contrast enhancement can be used as the density distribution improvement method. A threshold level 44 for clearly separating the payment information from the background image is then calculated from the characteristics of the density distribution of the grayscale improved image data 42 acquired by the density distribution improvement process. Histograms of the density distributions are used to determine the characteristics of the density distribution. The improved image data 42 is then converted to binary image data 46 using the threshold level 44. Most of the background image is white and most of the desired payment information is black in the binary image data 46.

Owner:SEIKO EPSON CORP

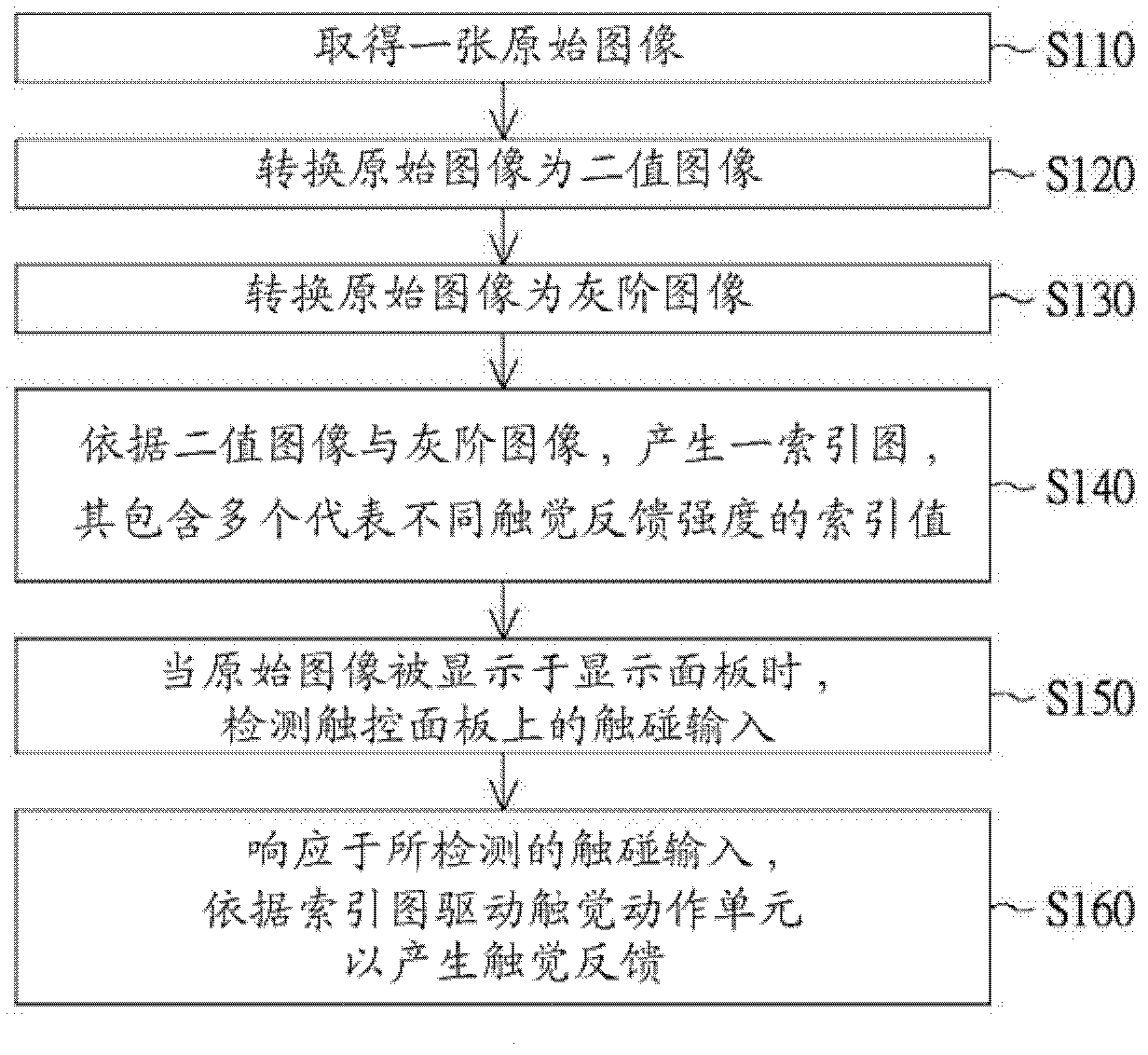

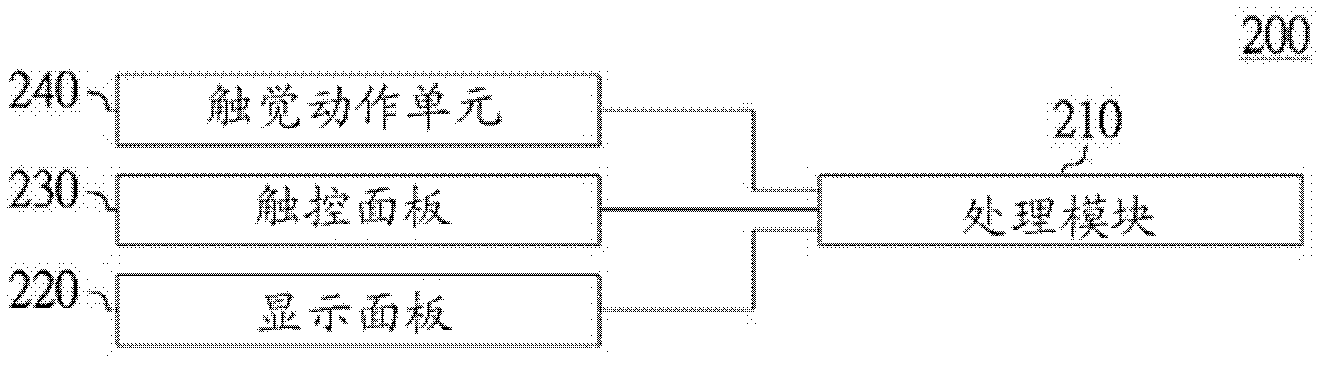

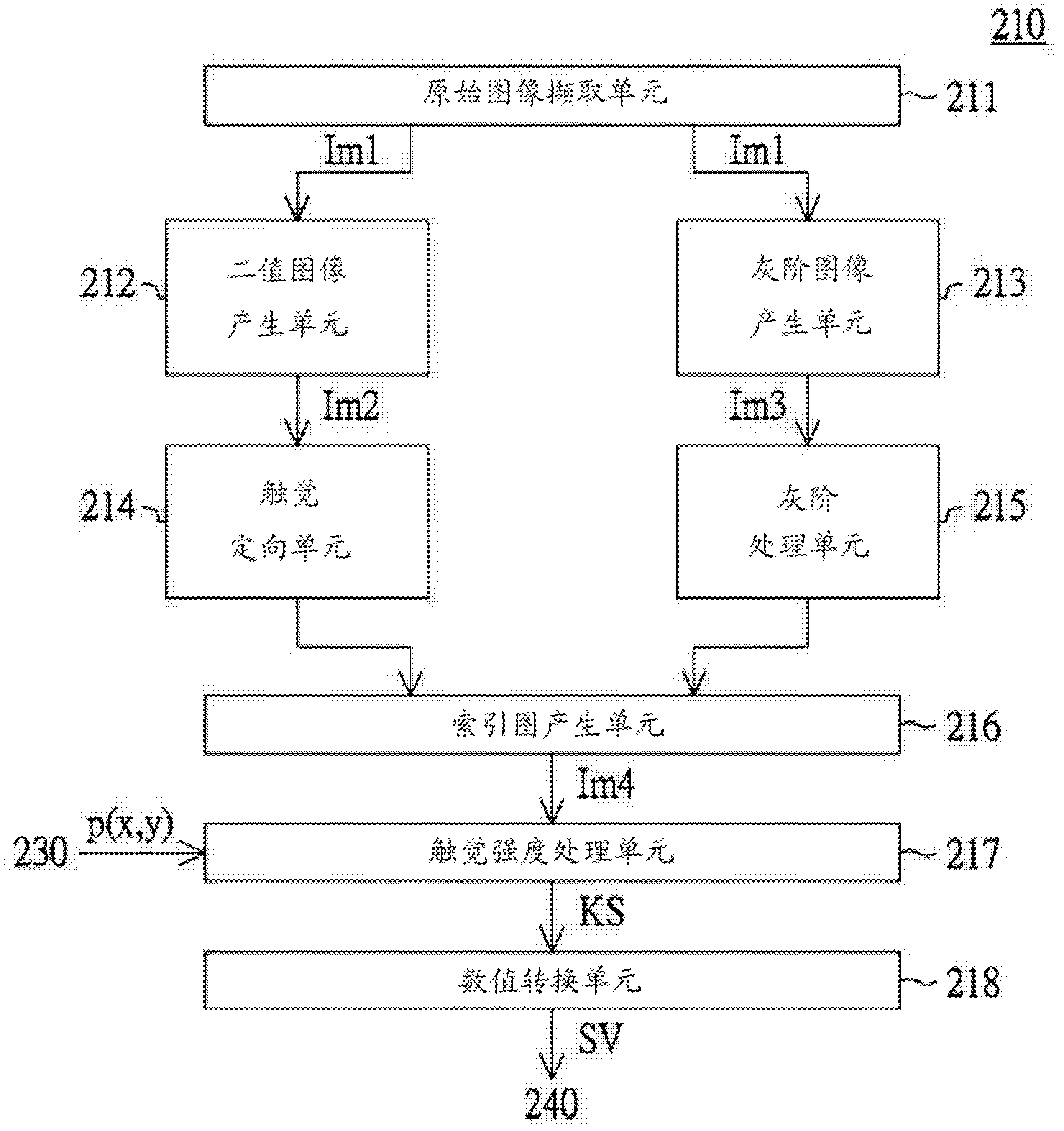

Method and electronic device for tactile feedback

InactiveCN102841677AImprove operational convenienceInput/output for user-computer interactionCharacter and pattern recognitionGray levelBiological activation

A method and an electronic device for tactile feedback are provided. The tactile feedback comprises a plurality of steps. An original image is input and converted to a binary image which includes a first grayscale value and a second grayscale value. The original image is converted to a grayscale image at least including a third grayscale value between the first grayscale value and the second grayscale value. An index map is generated according to the binary image and the grayscale image. The index map includes a plurality of index values indicative of different strengths for tactile feedback. A touch input on a touch panel is detected when the original image is displayed on a display panel. In response to the detected touch input, a tactile activation unit is driven to generate tactile feedback according to the index map.

Owner:QUANTA COMPUTER INC

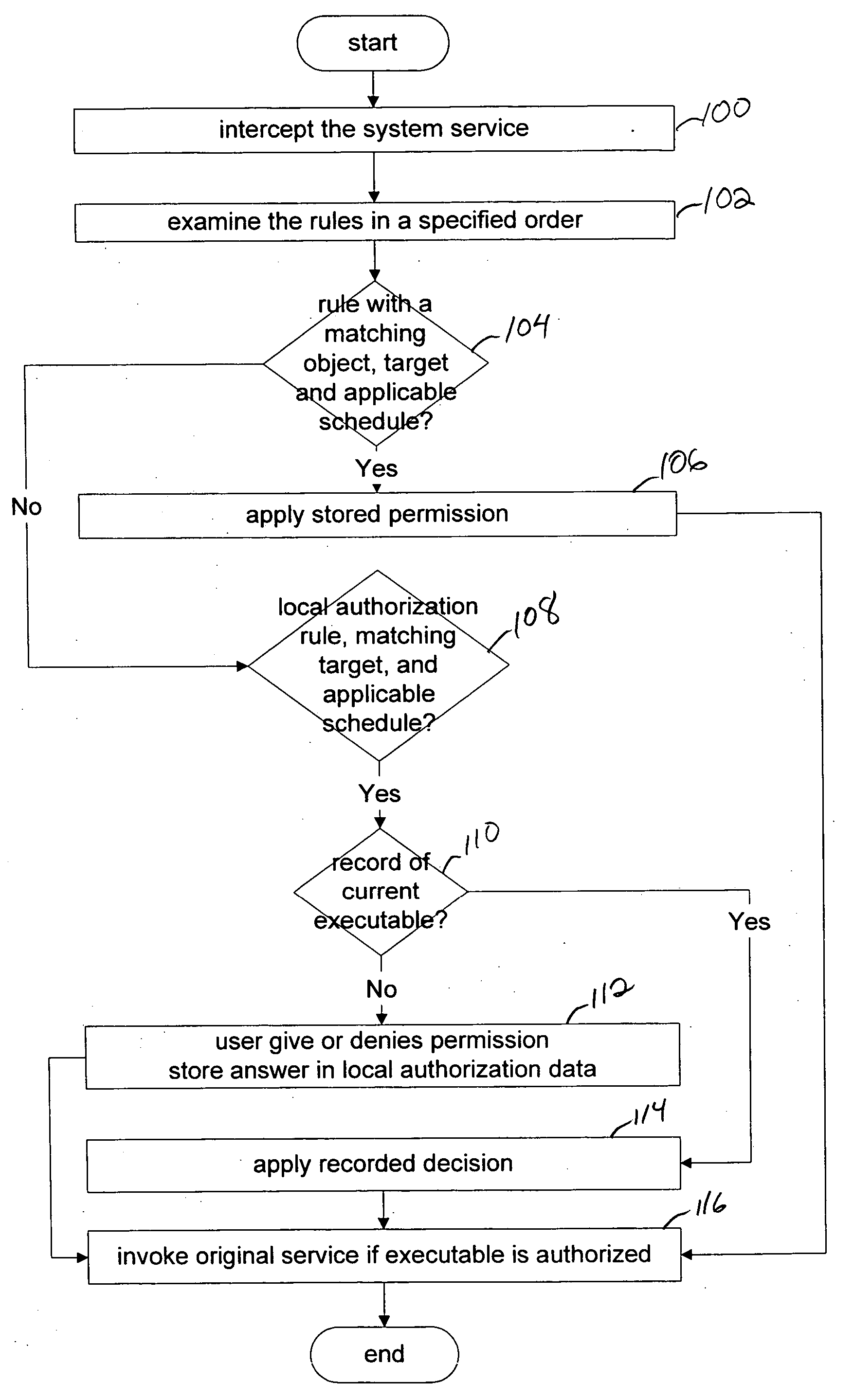

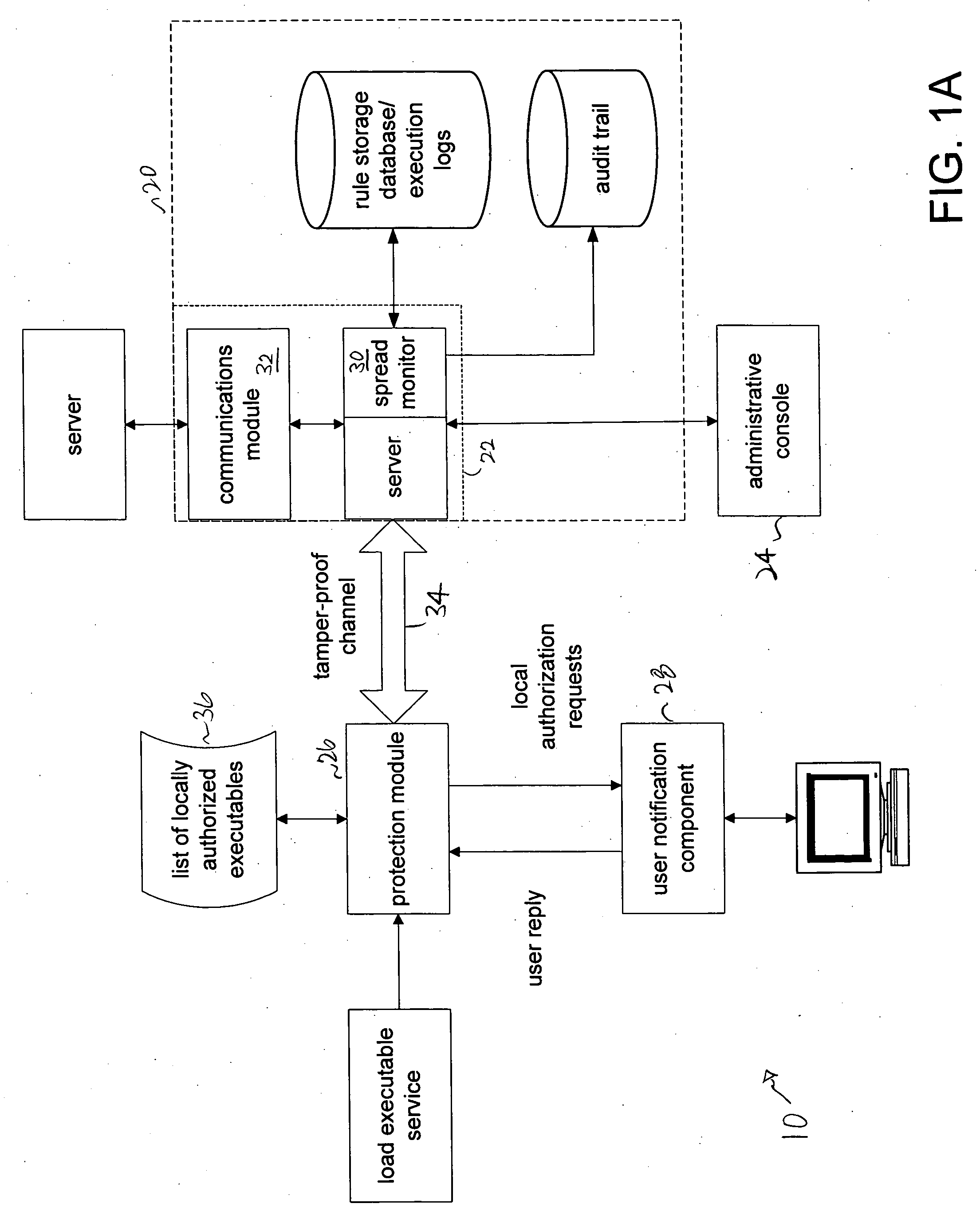

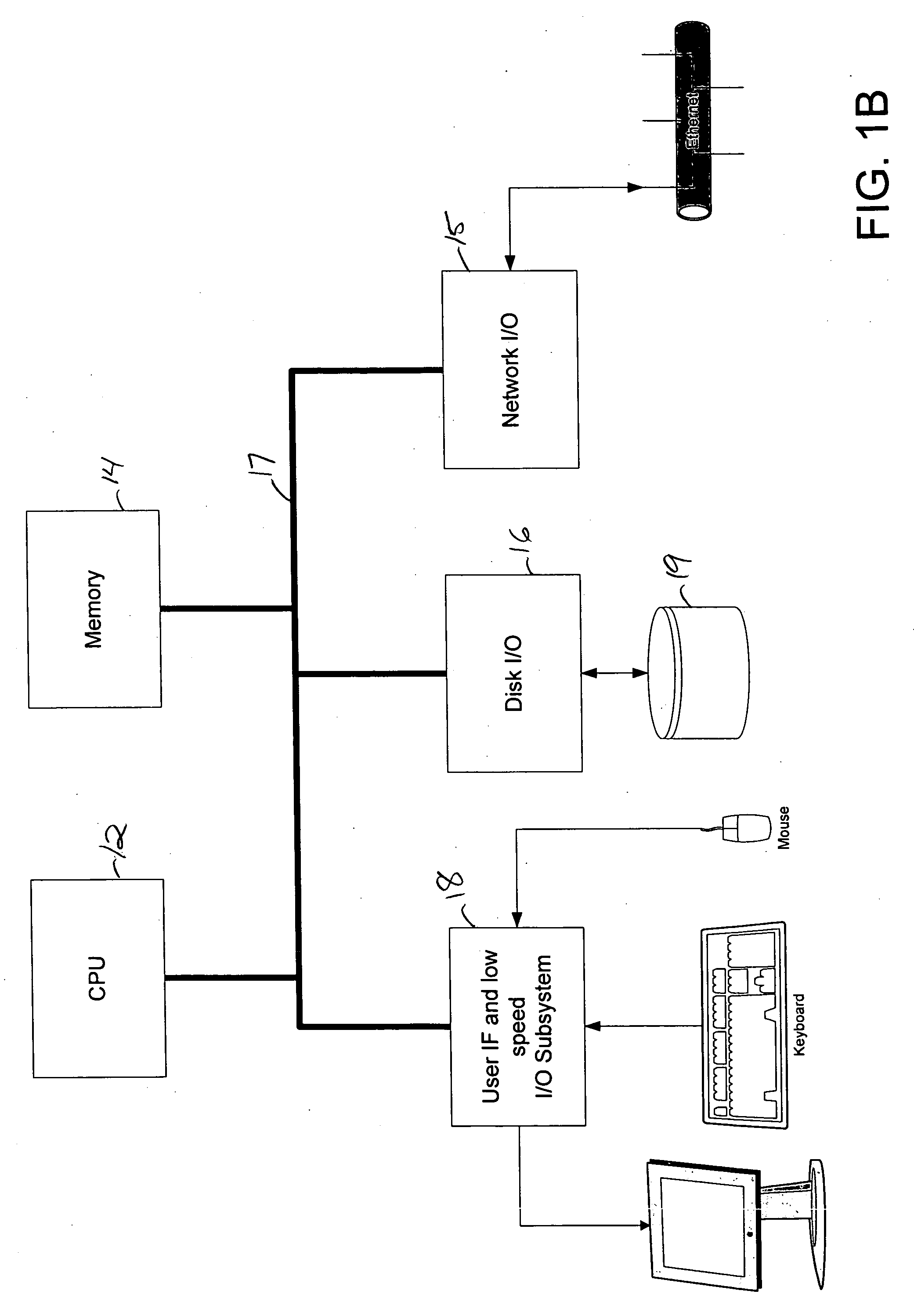

On-line centralized and local authorization of executable files

ActiveUS20050262558A1Reduce in quantityMemory loss protectionDigital data processing detailsComputerized systemAuthorization

Owner:IVANTI INC

Video game distribution network

InactiveUS20050130744A1Video gamesSpecial data processing applicationsSoftware emulationInteractive video

A video game distribution network for use in airlines, trains, hotels, cruise ships, set top boxes, cable television systems, satellite and other wireless systems or other communications systems, distributes special purpose game binary image files to general purpose computing / display devices. Software emulators running on the general purpose computing / display devices model the game source platform and interpret and / or compile the game files to provide interactive video game play. Software emulators for emulating a handheld video game platform such as GAME BOY®, GAME BOY COLOR® and / or GAME BOY ADVANCE® on a low-capability target platform (e.g., a seat-back display for airline or train use, a personal digital assistant, a cell phone) may provide any number of features and optimizations to provide high quality graphics and sound that nearly duplicates the game playing experience on the native platform.

Owner:NINTENDO CO LTD

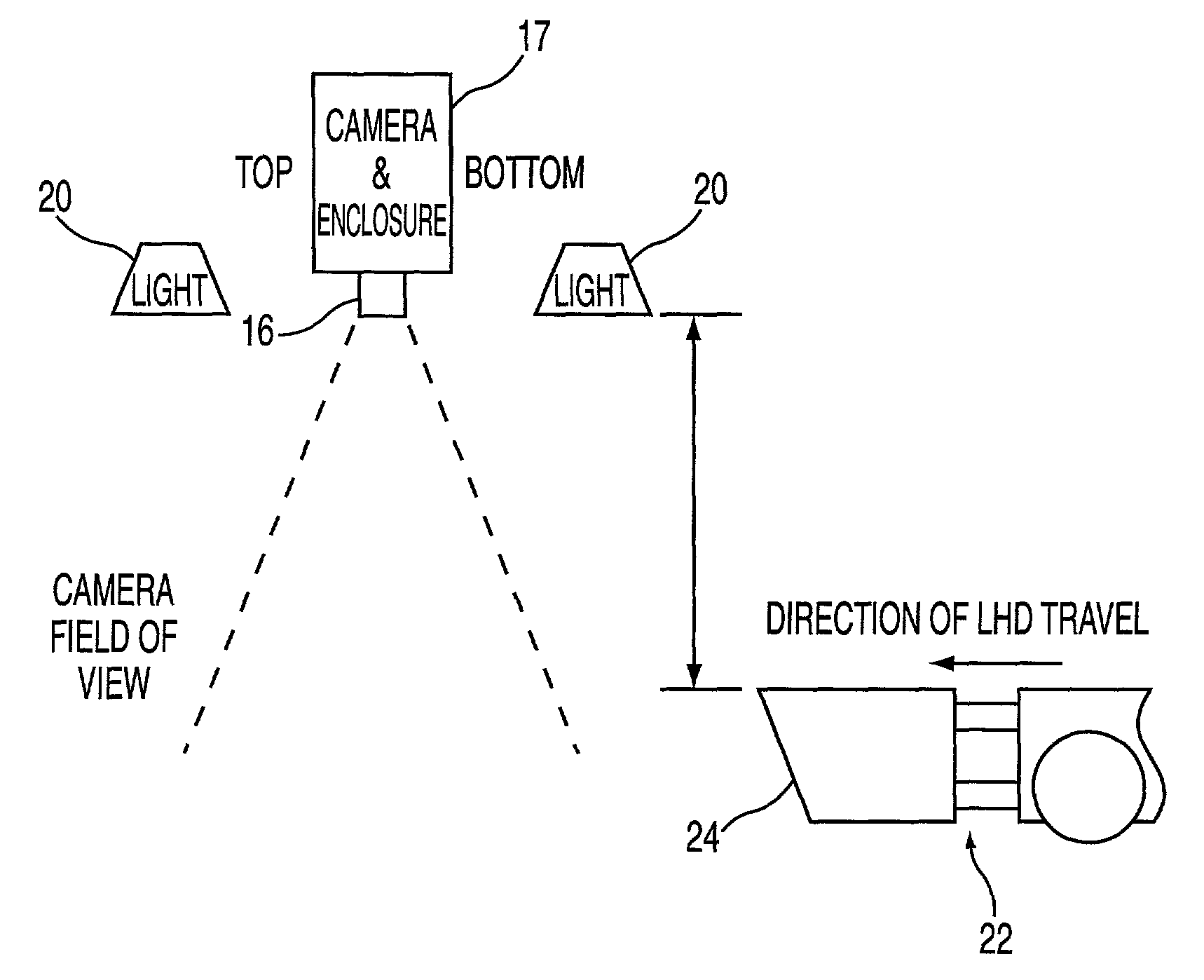

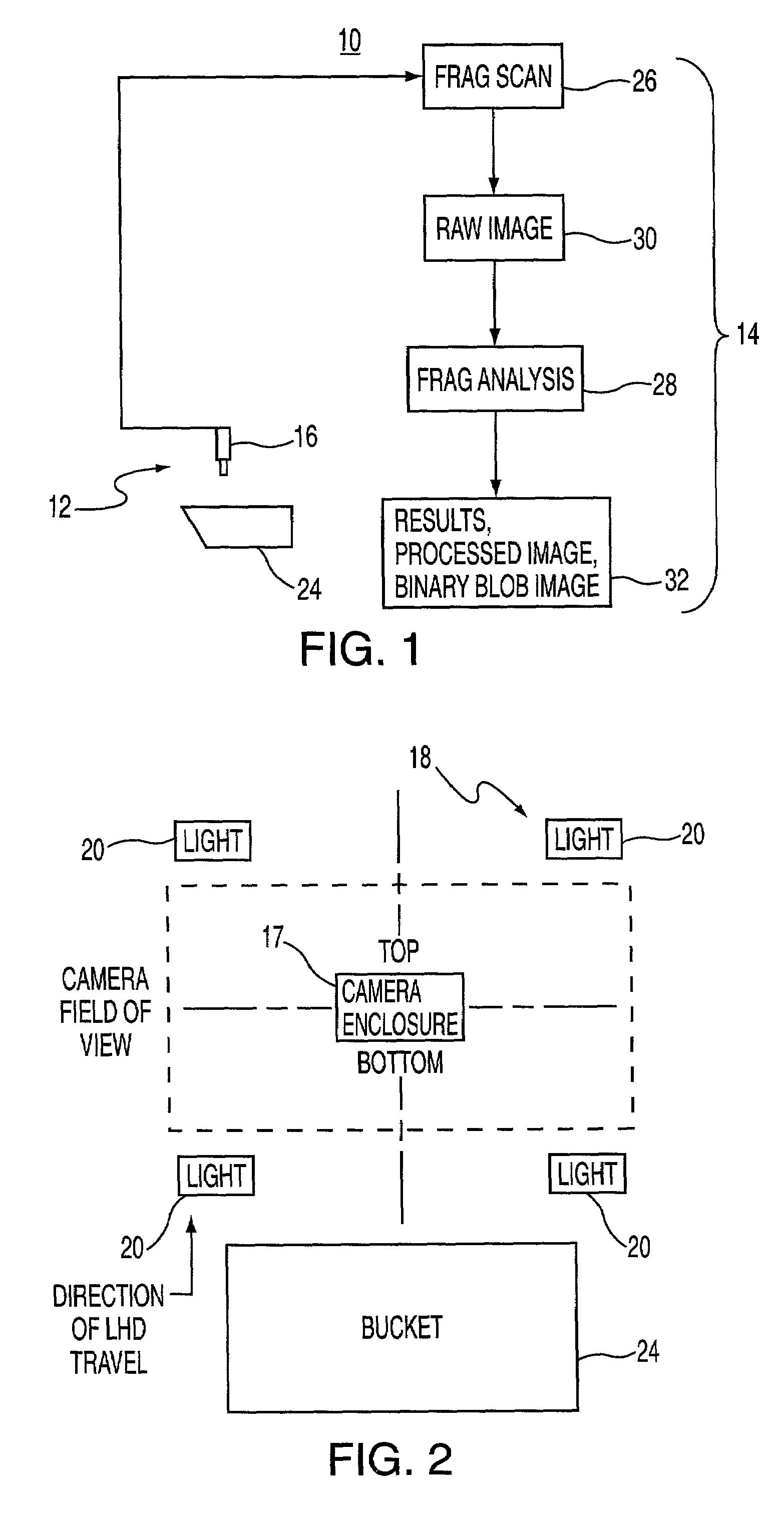

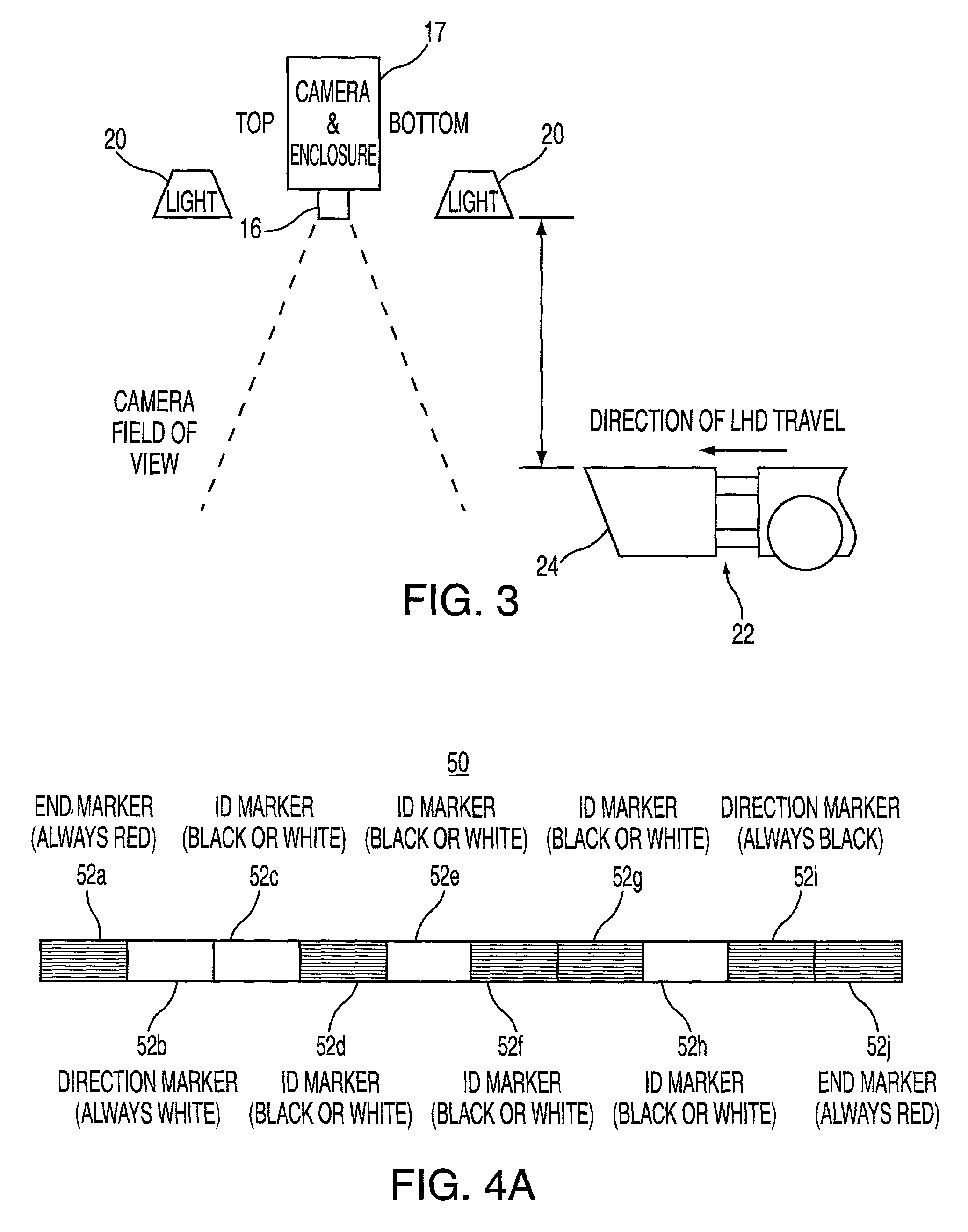

Rock fragmentation analysis system

A rock fragmentation analysis system is provided for analyzing blasted rock (or other fragmented particles) to assess quality of a blast for efficient processing of subsequent operations in a mine, a quarry, etc. The system includes a hardware system and an image processing system. The hardware system includes a camera and a lighting system. The lighting system illuminates an area of the mine, quarry, etc. where a load haul dump (LHD) vehicle passes through. Once the LHD vehicle passes through the illuminated area, the camera provides video signals of scoop-top view images of the LHD vehicle to the image processing system via known communication means, such as hard-wired and wireless. The image processing system receives the video signals, captures the scoop-top view images, evaluates the images for subsequent fragmentation analysis, and performs the rock fragmentation analysis. The image processing system performs these functions using several software modules. Two such software modules are the Fragmentation Scanning (FragScan™) and the Fragmentation Analysis (FragAnalysis™) software modules. The FragScan software module scans the video signals until it captures a valid image for analysis by the FragAnalysis software module. Once the FragScan triggers on the image, a raw image and other details corresponding to the captured image are buffered for subsequent rock fragmentation analysis by the FragAnalysis software module. The rock fragmentation analysis is designed to estimate the major diameter of each rock visible in the image. The overall size distribution of the rocks in the image is output by the FragAnalysis software module, and the corresponding input image and the binary blob image, i.e., the processed image, are stored by the image processing system.

Owner:INCO

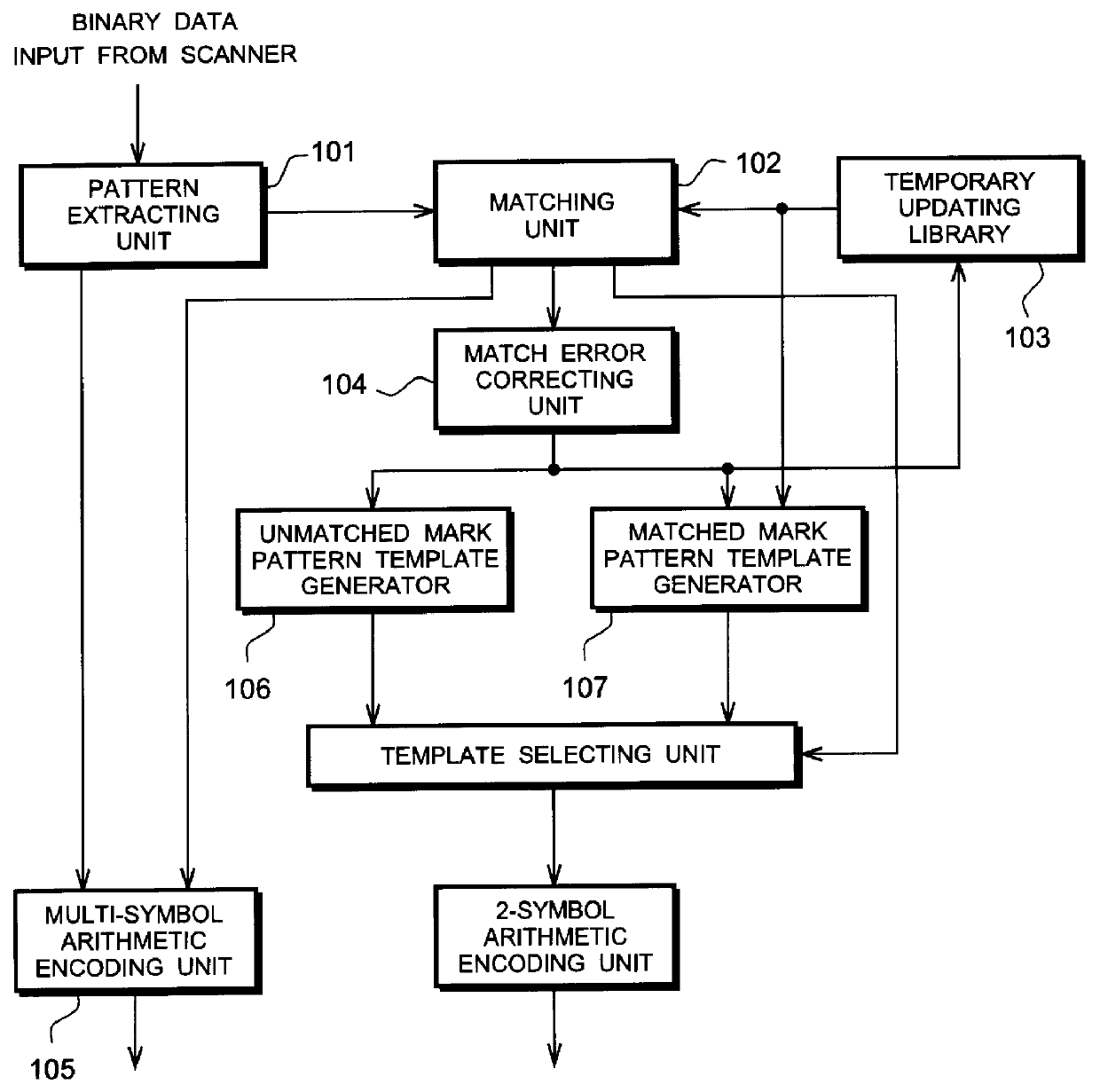

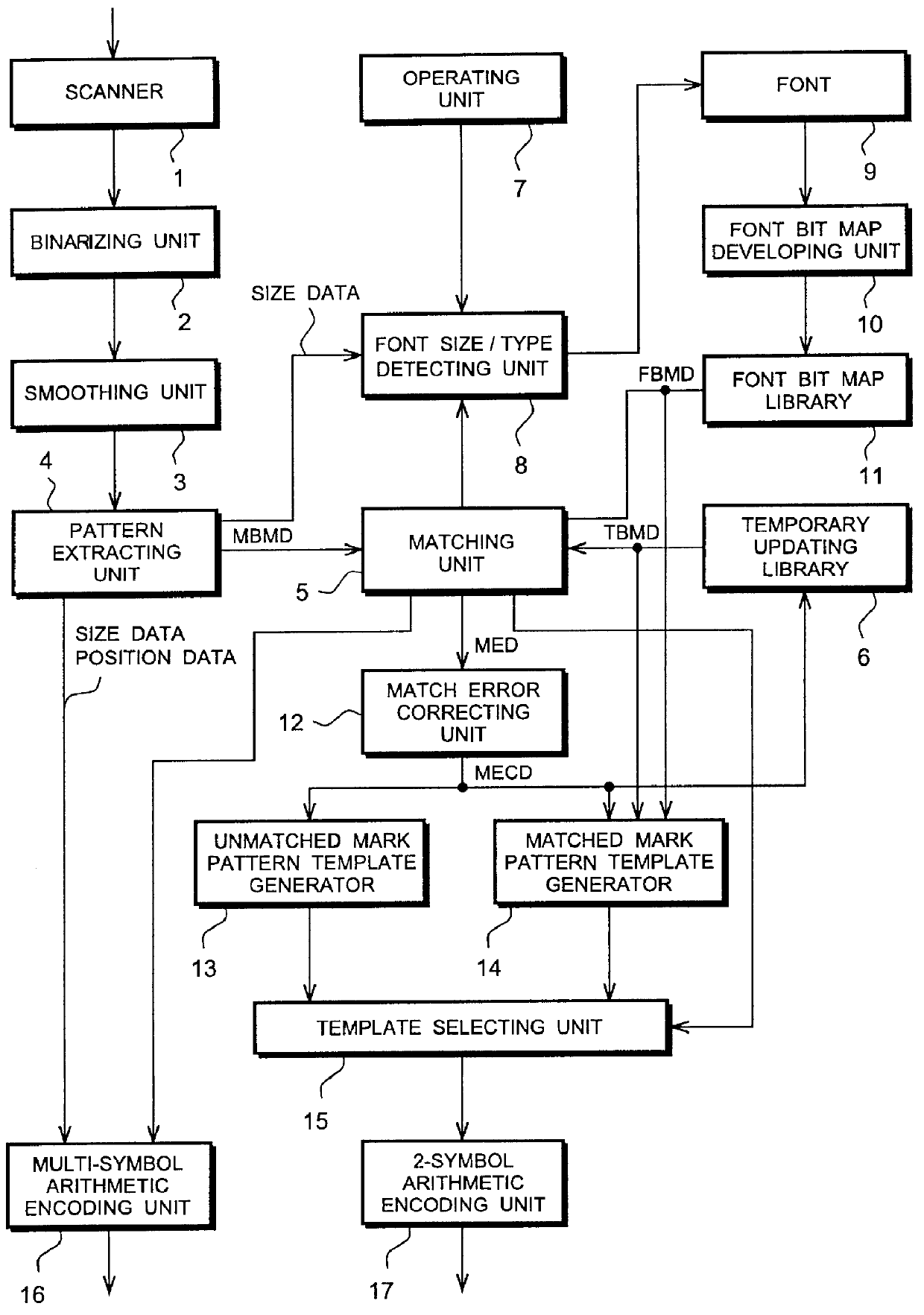

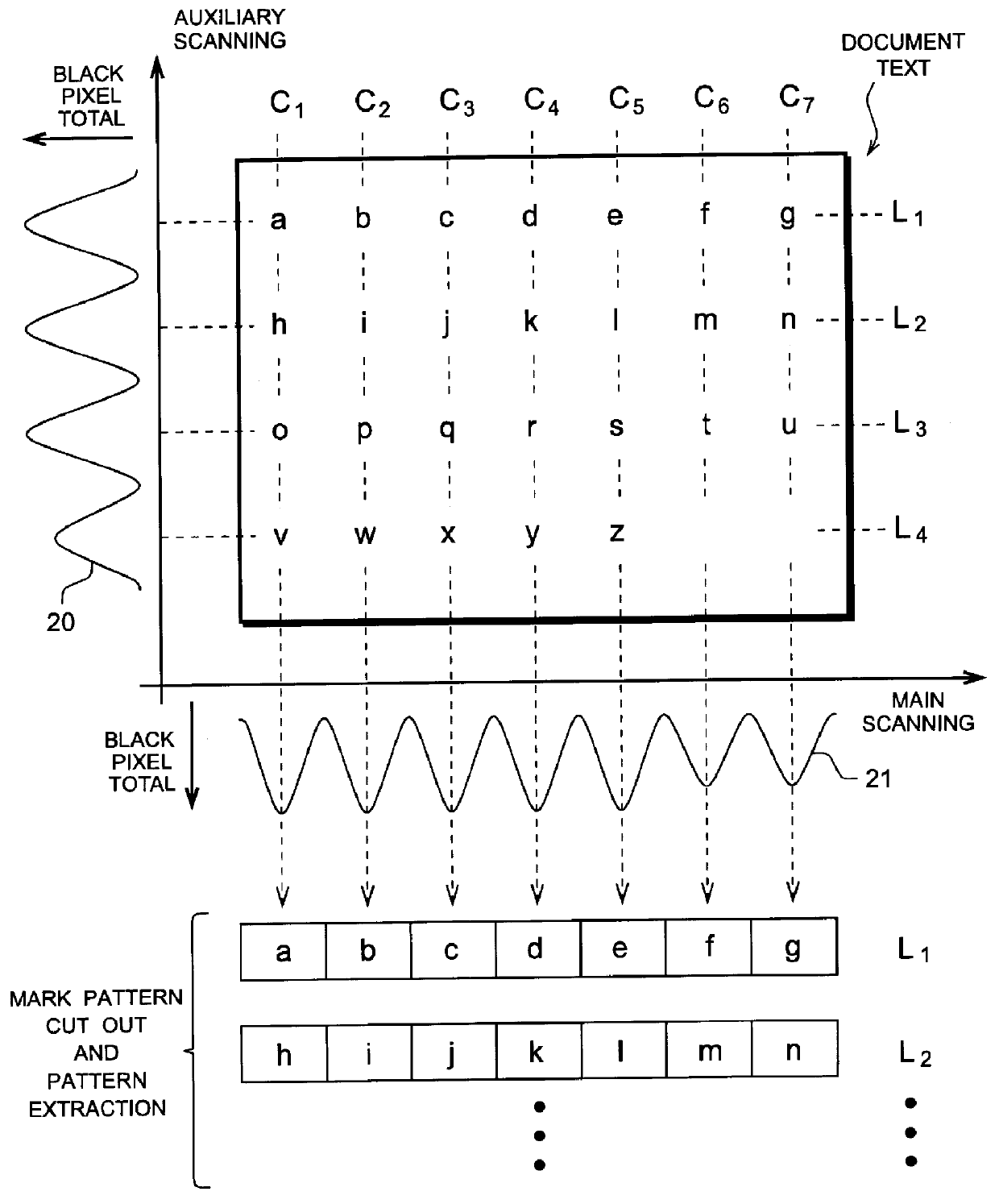

Method and apparatus for compressing binary data using pattern matching encoding

InactiveUS6016361AImprove image qualityAvoid wasteful pattern registrationImage analysisCode conversionPattern recognitionImaging quality

In a method and an apparatus for pattern matching encoding disclosed a font bit map library is provided separately from a temporary updating library, in which temporary bit map pattern data capable of being updated according to a character pattern cut out from input binary image data is stored. In the font bit map library is stored font bit map library pattern data of an input character pattern font or a font designated by the user. A pattern matching process on the character pattern, is executed by comparing the character pattern with temporary bit map pattern data and font bit map pattern data. The character pattern is newly registered in the temporary updating library, when it is judged as being matched with only the temporary bit map pattern or as being matched with neither of the temporary bit map pattern or the font bit map pattern. It is possible to improve data compressibility without sacrifice in image quality.

Owner:NEC CORP

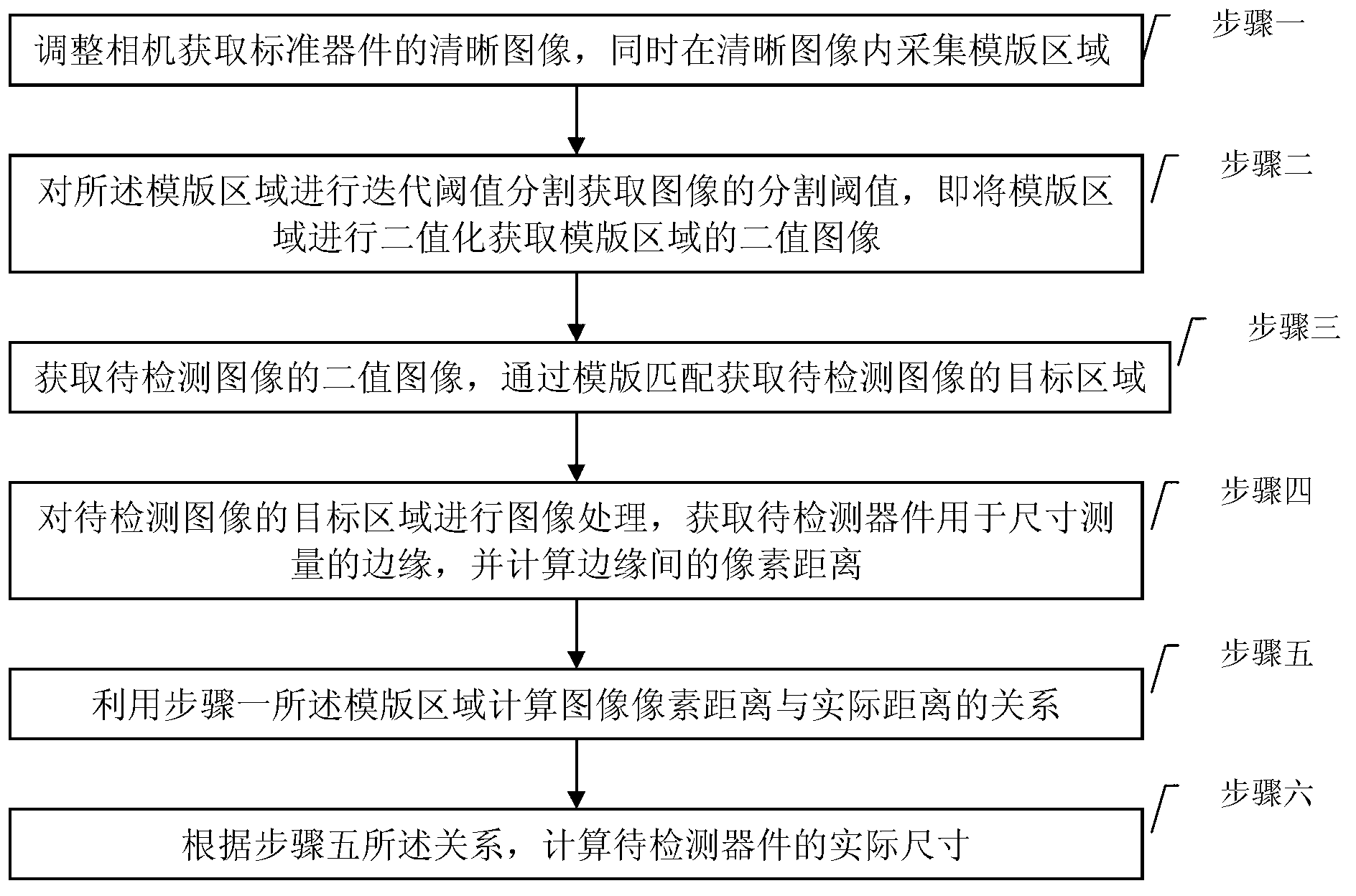

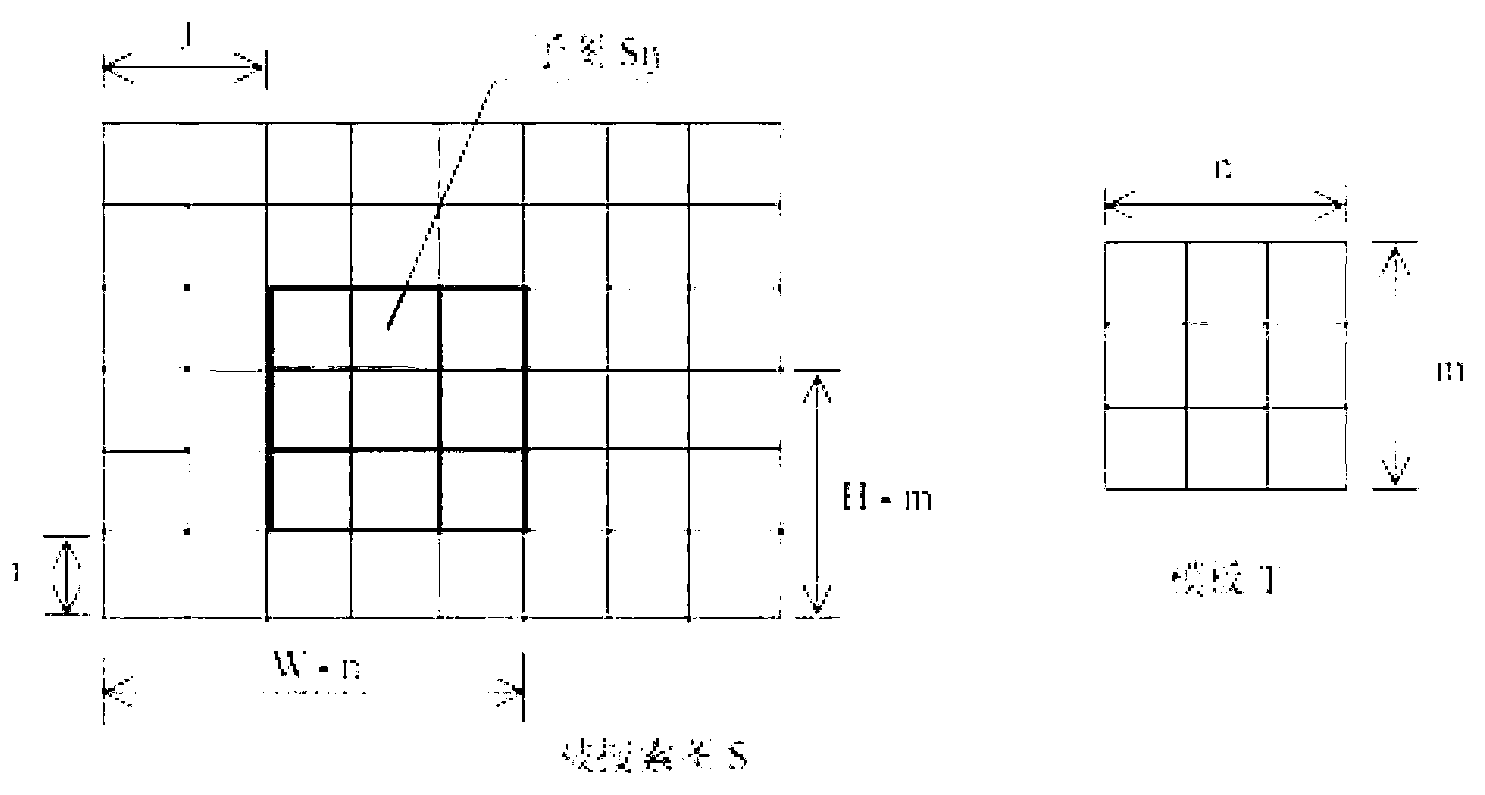

Machine-vision-based online dimensional measurement method of precise instrument

ActiveCN103292701ALower requirementImprove Pixel AccuracyUsing optical meansTemplate matchingImaging processing

A machine-vision-based online dimensional measurement method of precise instruments relates to a machine-vision-based dimensional measurement method and solves the problem of high-precision requirements on workpiece measurement in modern industry. The method comprises the steps of adjusting a camera to obtain a clear image of a standard instrument and meanwhile collecting a template area inside the clear image; performing iterative threshold segmentation on the template area to obtain the segmented threshold of the image, namely, binarizing the template area to obtain a binary image of the template area; obtaining a binary image of an image to be measured, and obtaining a target area of the image to be measured through template matching; performing image processing on the target area of the image to be measured to obtain the edges of an instrument to be measured, which is used for dimensional measurement, and calculating the pixel distances among the edges; calculating the relation between the pixel distances and the actual distances of the image; and calculating out the actual dimension of the instrument to be measured. The machine-vision-based online dimensional measurement method of precise instruments can be widely applied to the machine vision dimensional measurement of the precise instruments.

Owner:宁波智能装备研究院有限公司

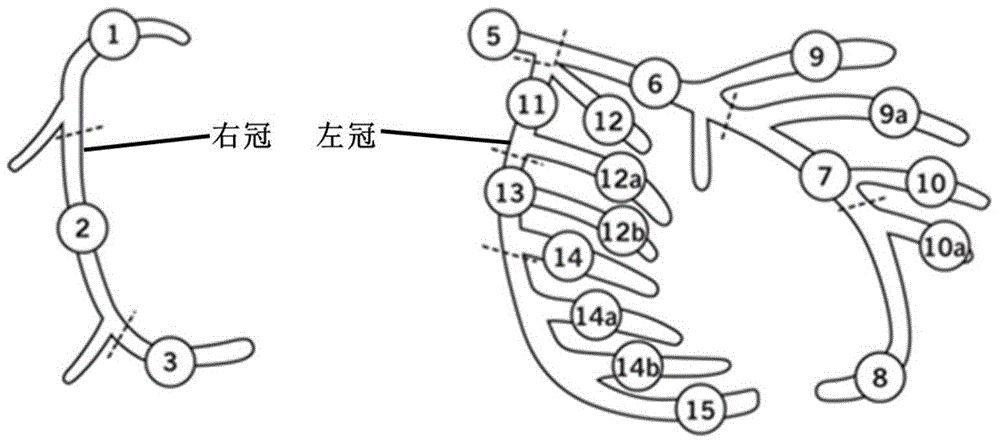

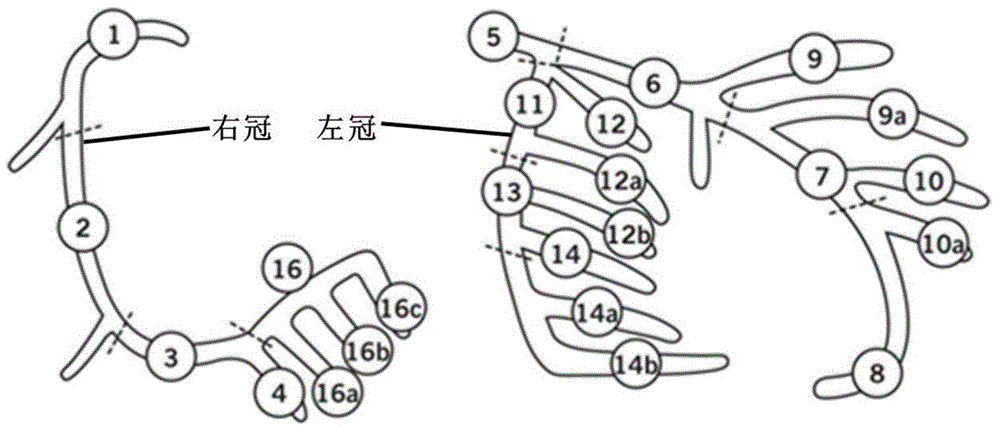

SYNTAX automatic scoring method based on coronary angiogram image segmentation

InactiveCN104867147AReduce workloadShorten the timeImage enhancementImage analysisUltrasound attenuationCoronary arterial tree

An SYNTAX automatic scoring method based on coronary angiogram image segmentation segments and extracts a coronary arterial tree and central line based on coronary angiogram images of a patient and employs a blood vessel side branch separation, reconnection and K main curve method, and generates a binary image of the coronary arterial tree The blood vessel segment numbers are automatically matched based on the SYNTAX scoring standard by employing a central line direction tracking method, and coronary artery pathological changes and adverse characteristics are identified and scored by selecting a coronary left (right) advantageous type in combination with the width attenuation degree of the cross section of the blood vessel and the curvature change of the center line, and the scores are calculated to give a reasonable score result to allow a doctor to employ optimal operation scheme. The method overcomes the problems of great computation amount, tedious calculating steps, complex scoring standard and long calculating time of artificial calculating SYNTAX scoring in conventional clinics.

Owner:BEIJING UNIV OF TECH

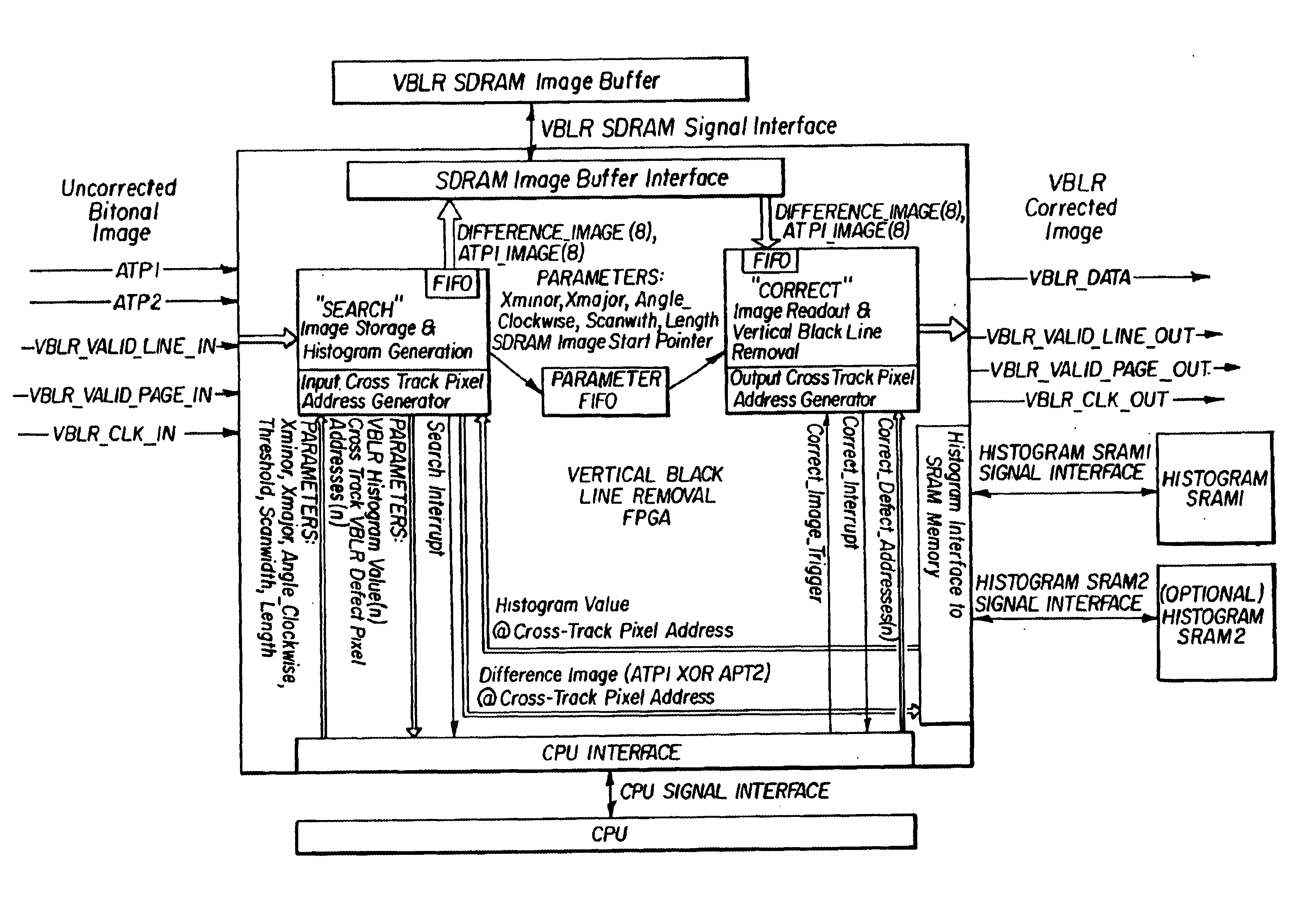

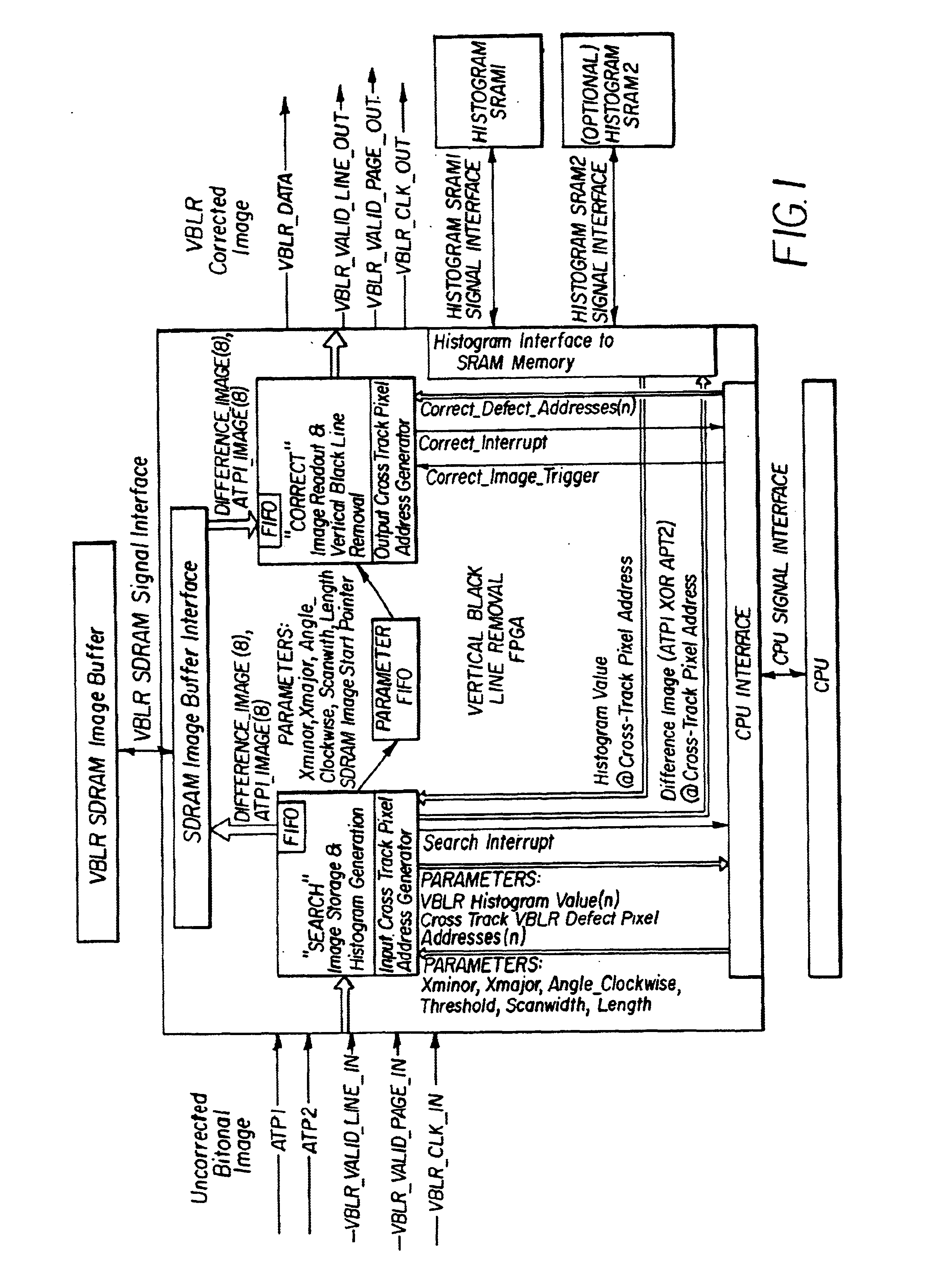

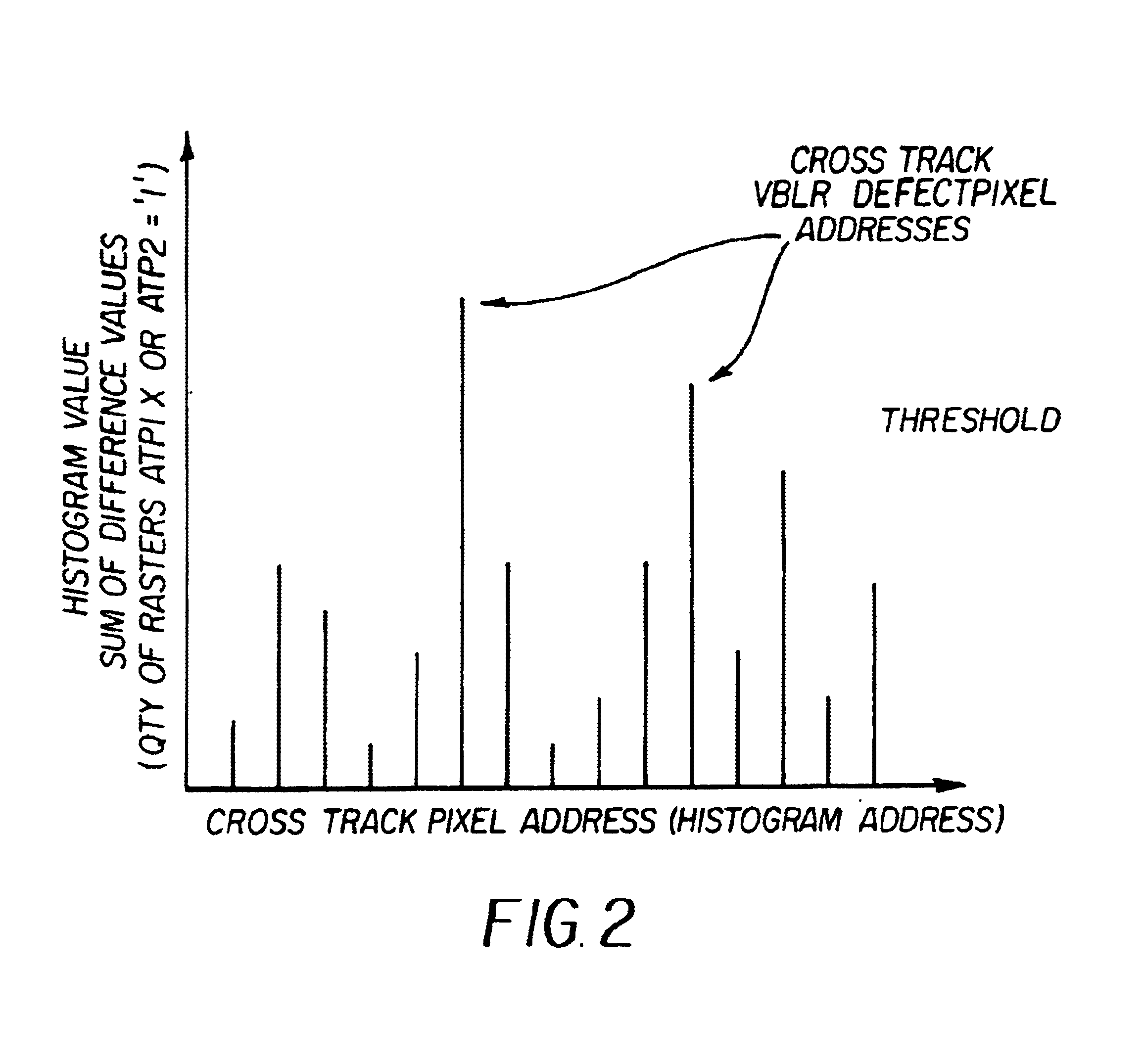

Vertical black line removal implementation

ActiveUS6873728B2Easy to optimizeEfficient implementationImage enhancementColor signal processing circuitsComputer graphics (images)Imaging equipment

A vertical black line removal system (VBLR) is adapted to remove unwanted vertical lines produced on scanned document images by dust or other particles on the imaging apparatus. The VBLR system, placed in a document scanner after the binarization equipment, creates a stored histogram table including the difference values of “1” or “0” for the first and second image data. A vertical black line search processor compares each histogram value in the histogram table with a predetermined threshold value such that when the histogram value is greater than the threshold value the histogram value and the image address indicating the location of defect are stored in memory. An image readout then creates a corrected image by comparing each original image address with the stored defect image addresses so that when there is not a match with defect image addresses the first binary image value is output, and when the addresses are equal the difference value is analyzed for a “1” or “0” to determine when the first or second image data is to be output.

Owner:KODAK ALARIS INC

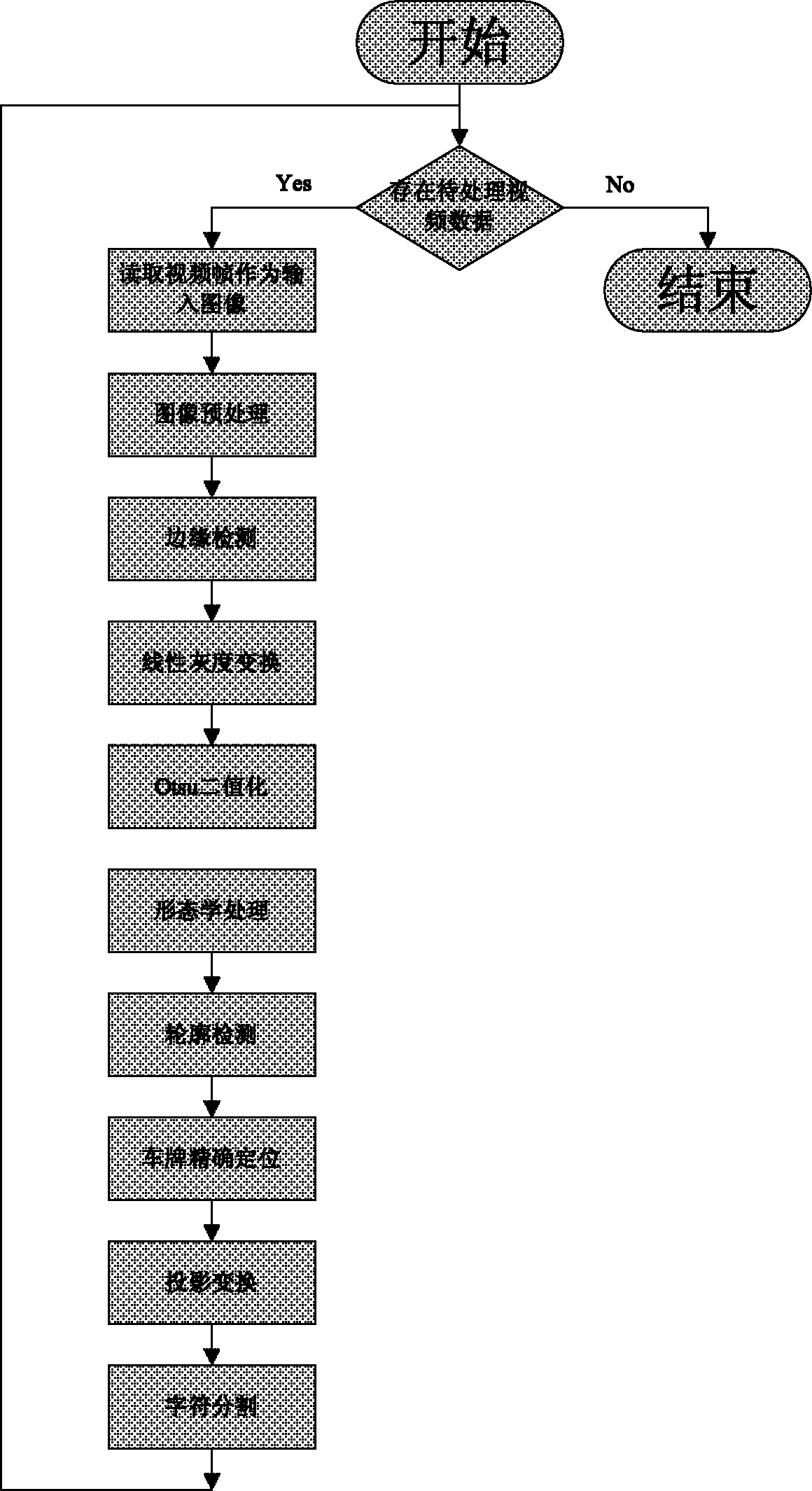

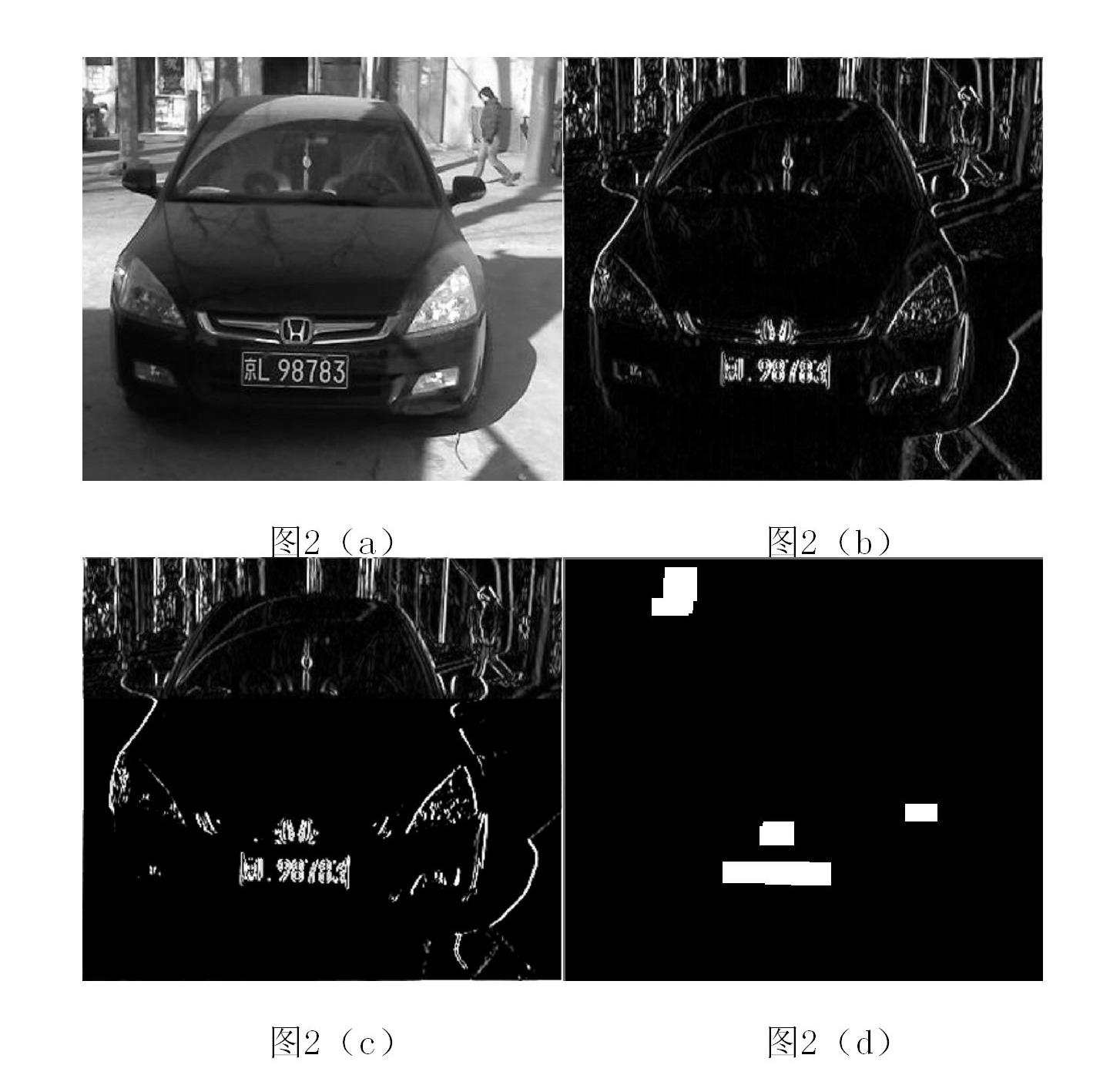

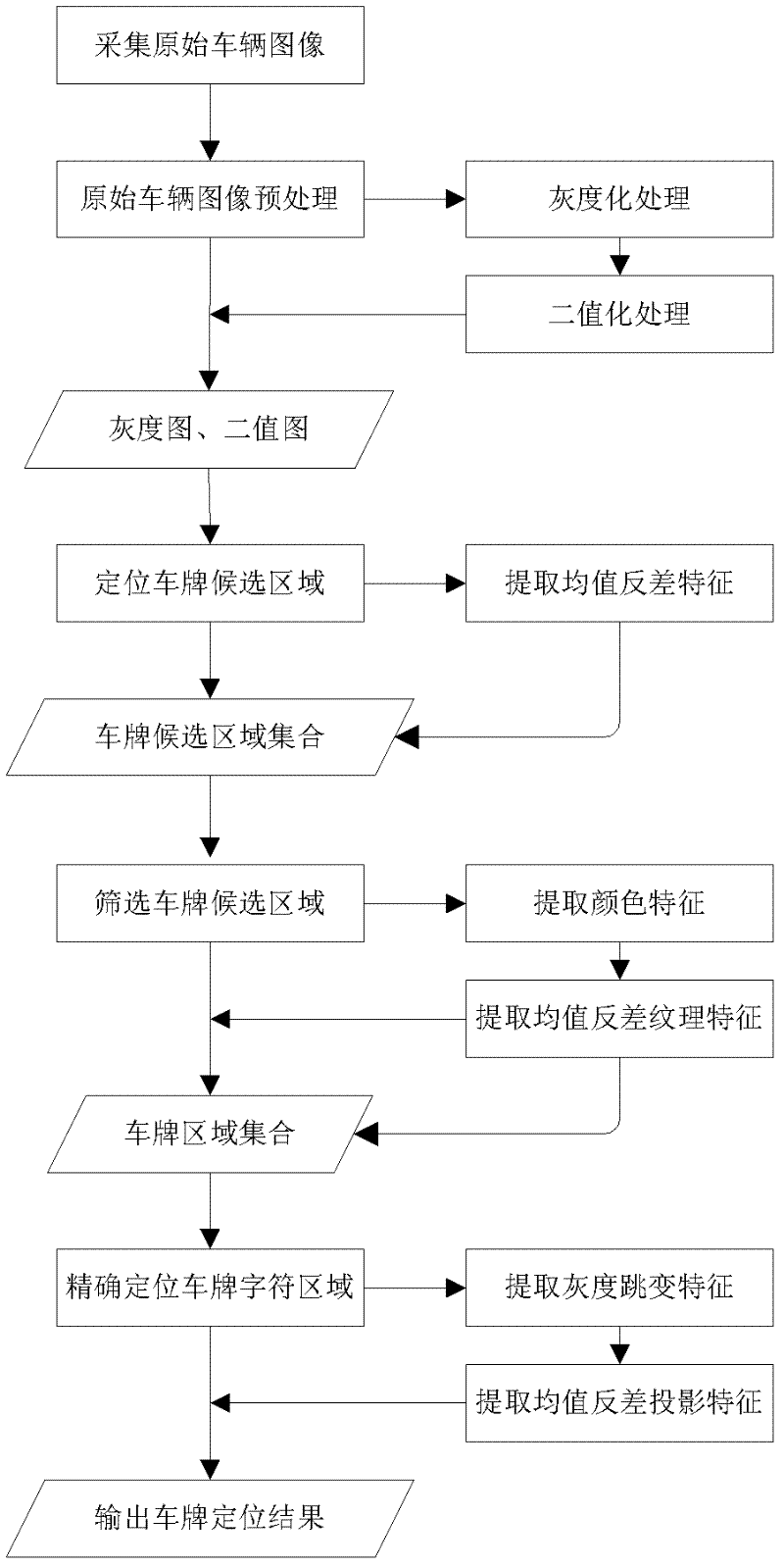

Detection method for vehicle license plate real-time positioning character segmentation

InactiveCN101789080AColor requirements are not highDoes not occupy memory resourcesCharacter and pattern recognitionVideo monitoringSignal-to-noise ratio (imaging)

The invention relates to a detection method for vehicle license plate real-time positioning character segmentation in the technical field of video monitoring, which comprises the following steps of: obtaining a video frame from image acquisition equipment; carrying out image preprocessing; increasing a signal-to-noise ratio; carrying out grey scale transformation; computing a threshold value by adopting an Otsu binarization method and converting a vehicle image into a binary image; firstly carrying out closed operation by using a structural element with the size of length pixels, separating a communicated region at a fine position and smoothing burrs appearing on the edge of the region; carrying out contour detection; and carrying out license plate region accurate positioning: accurately segmenting out each character. The invention has lower requirements for image color, a large amount of system memory resources of a computer can not occupied, the operational speed is quickened after an input image is converted into a grey-scale image, the accurate position of each character can be rapidly found, and each character is segmented out by applying an image shearing method.

Owner:SHANGHAI JIAO TONG UNIV

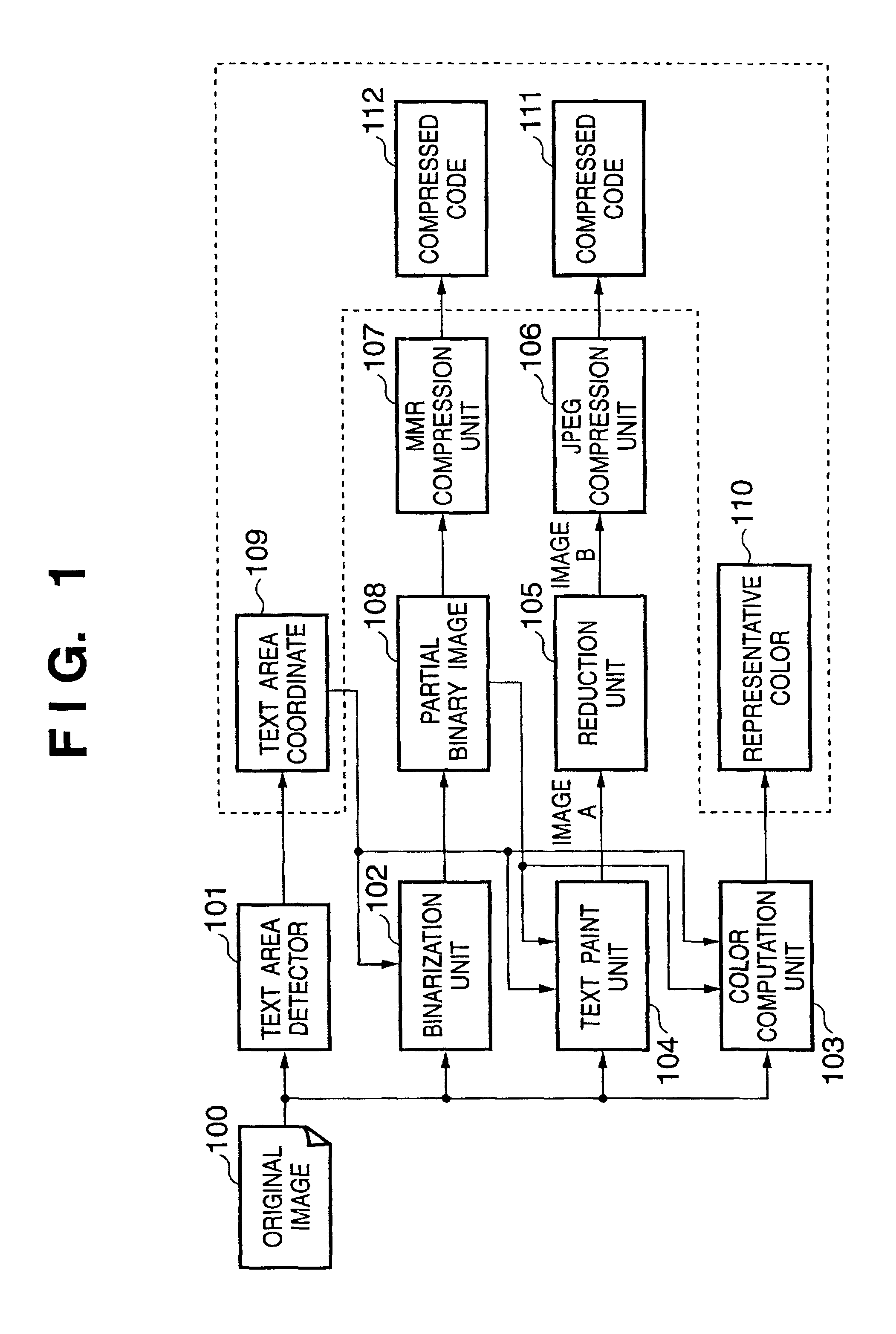

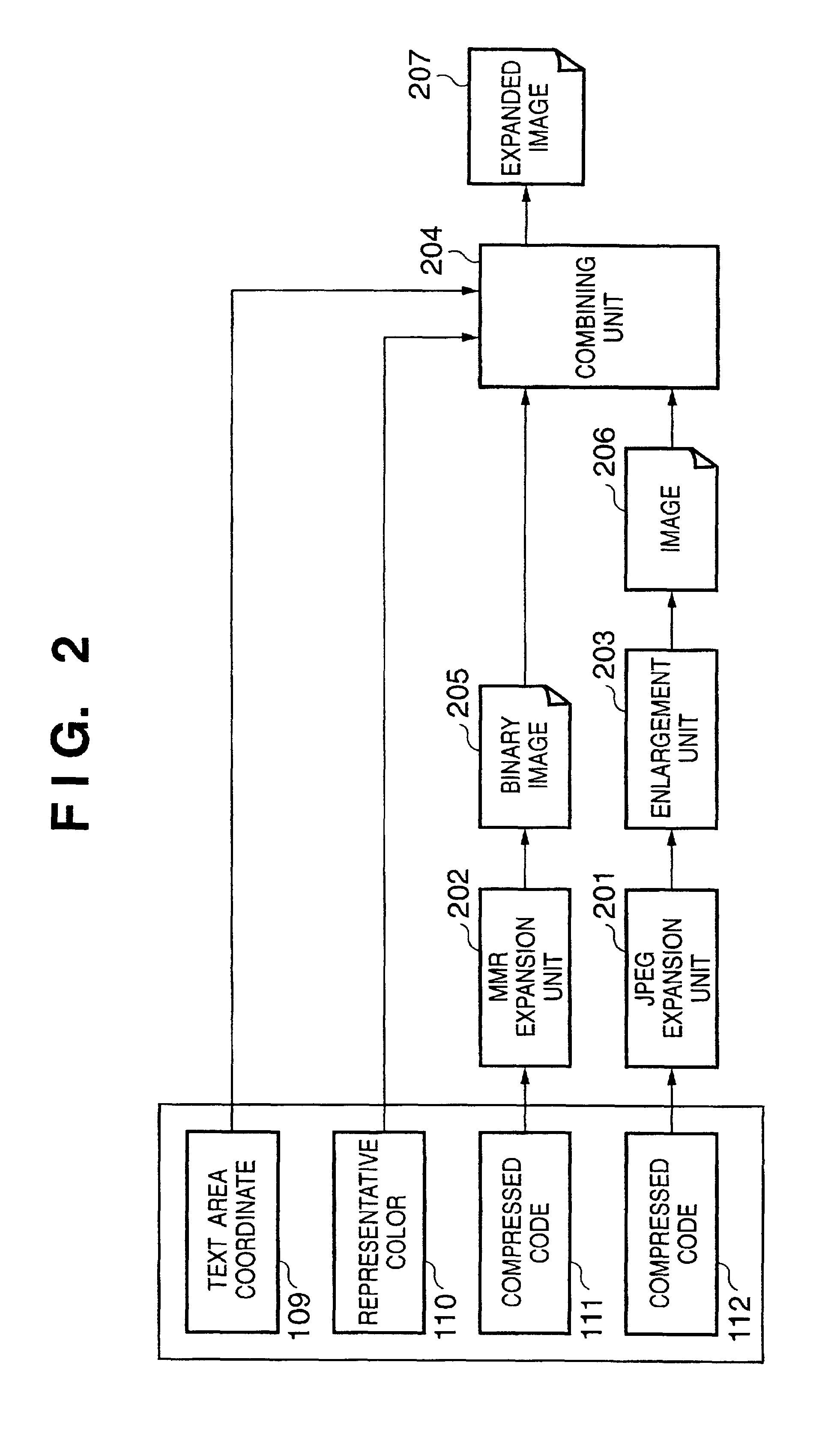

Image processing apparatus and method

ActiveUS7133565B2Efficient compressionImprove image qualityCharacter and pattern recognitionImage codingImaging processingImaging quality

This invention has as its object to provide an image processing apparatus and method which can efficiently compress an image while maintaining high image quality, and a storage medium for implementing the method. To accomplish this, an apparatus has a text area detector (101) for extracting a text area from multi-valued image data, and generating text area coordinate data (109) as position data of the text area, a binarization unit (102) for generating binary image data (108) by binarizing multi-valued image data of the text area, a color computation unit (103) for generating text color data (110) by computing a representative color of the text area, a text paint unit (104) for generating non-text multi-valued image data A by converting multi-valued image data of the text area using multi-valued image data of an area other than text, a reduction unit (105) for generating reduced non-text multi-valued image data by lowering the resolution of the non-text multi-valued image data, a JPEG compression unit (106) for compressing the non-text multi-valued image data by JPEG, and an MMR compression unit for compressing the binary image data of the text area by MMR.

Owner:CANON KK

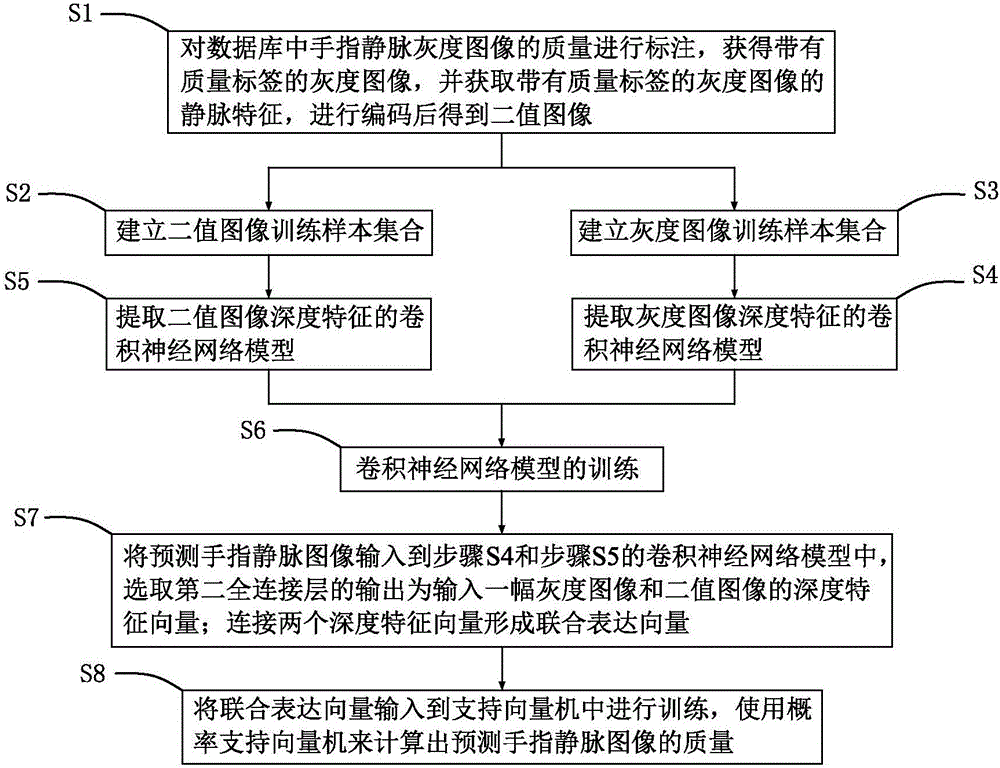

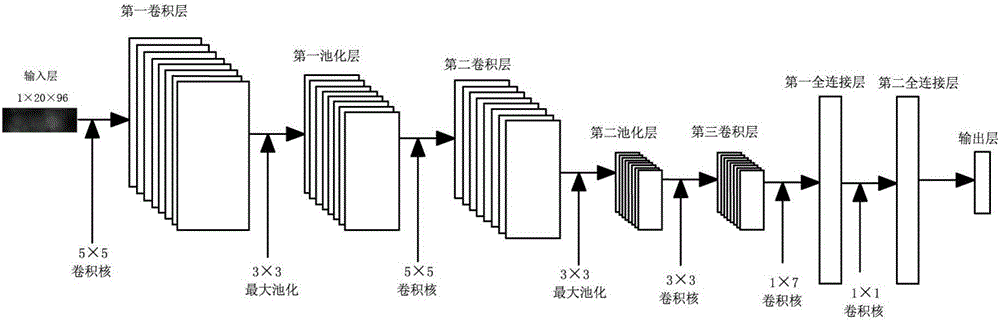

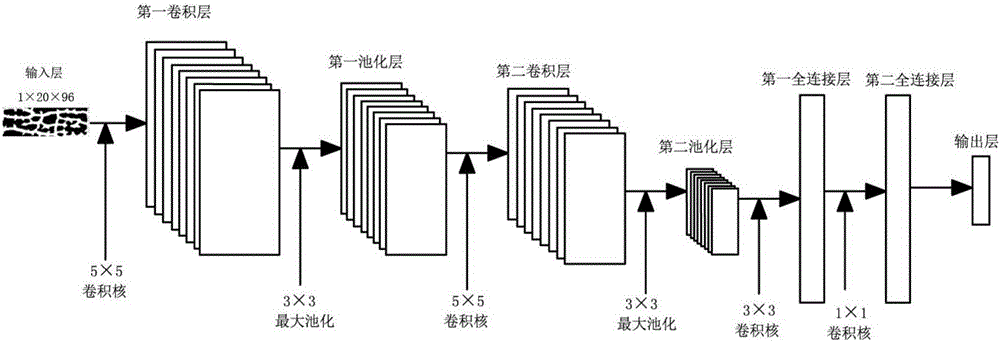

Finger-vein image quality evaluation method and system based on convolutional neural network

ActiveCN106326886AEasy to identifyHigh precisionNeural architecturesMatching and classificationSupport vector machineFeature vector

The invention provides a finger-vein image quality evaluation method and system based on a convolutional neural network. The method includes: labeling the quality of finger-vein gray images, building a training sample set, and using the training sample set to train the convolutional neural network; inputting one optional gray image and a binary image into trained models, selecting the output of second full connection layers in two convolutional neural network models as the depth feature vectors of the input gray image and the binary image; connecting the two depth feature vectors to form a united expression vector, inputting the united expression vector into a support vector machine for training, and using a probability support vector machine to calculate the quality of a predicted finger-vein image. By the evaluation method and system, finger-vein image quality evaluation precision can be increased to a large extent, and the identification performance of a certification system can be improved.

Owner:重庆金融科技研究院 +1

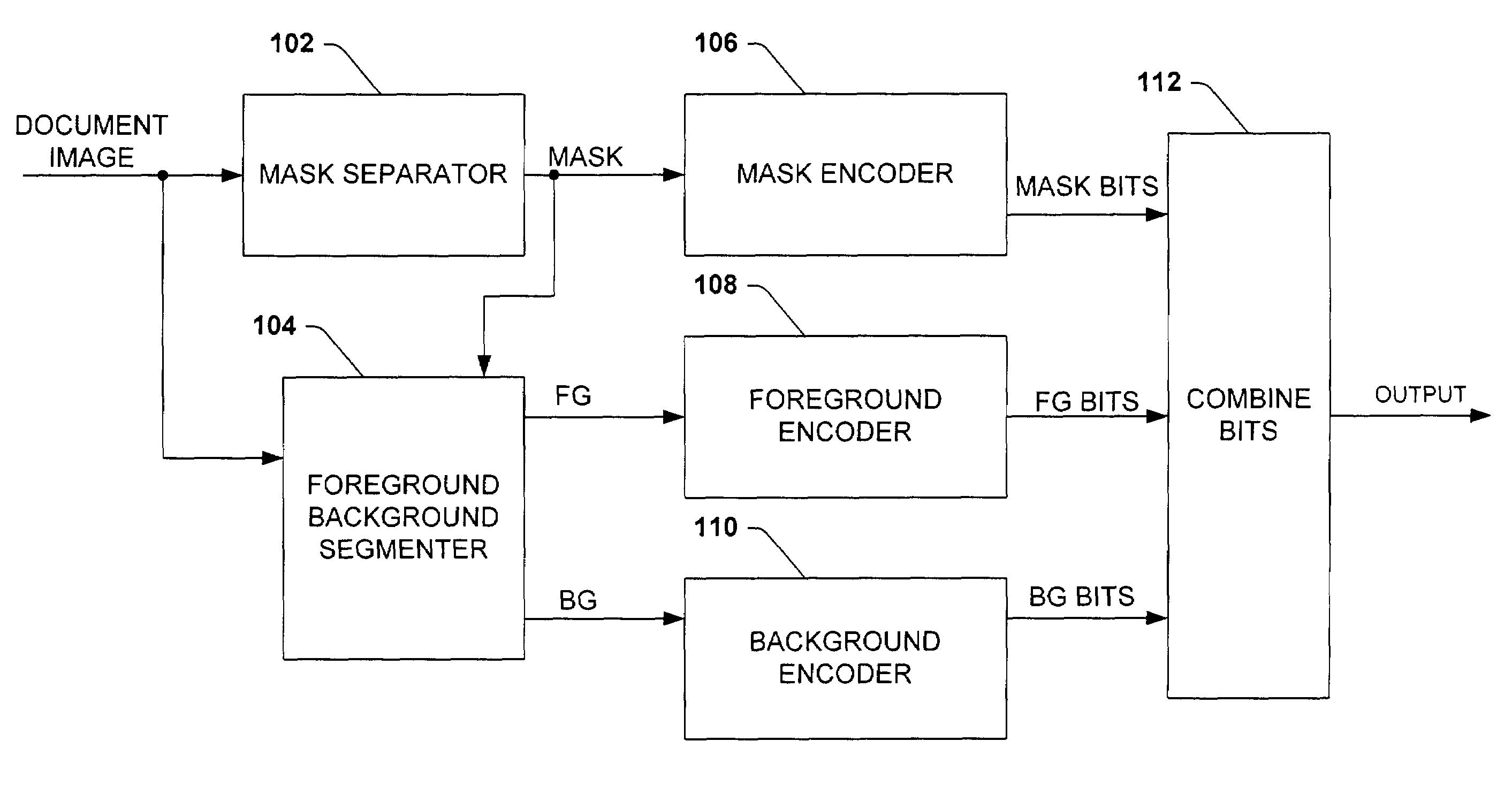

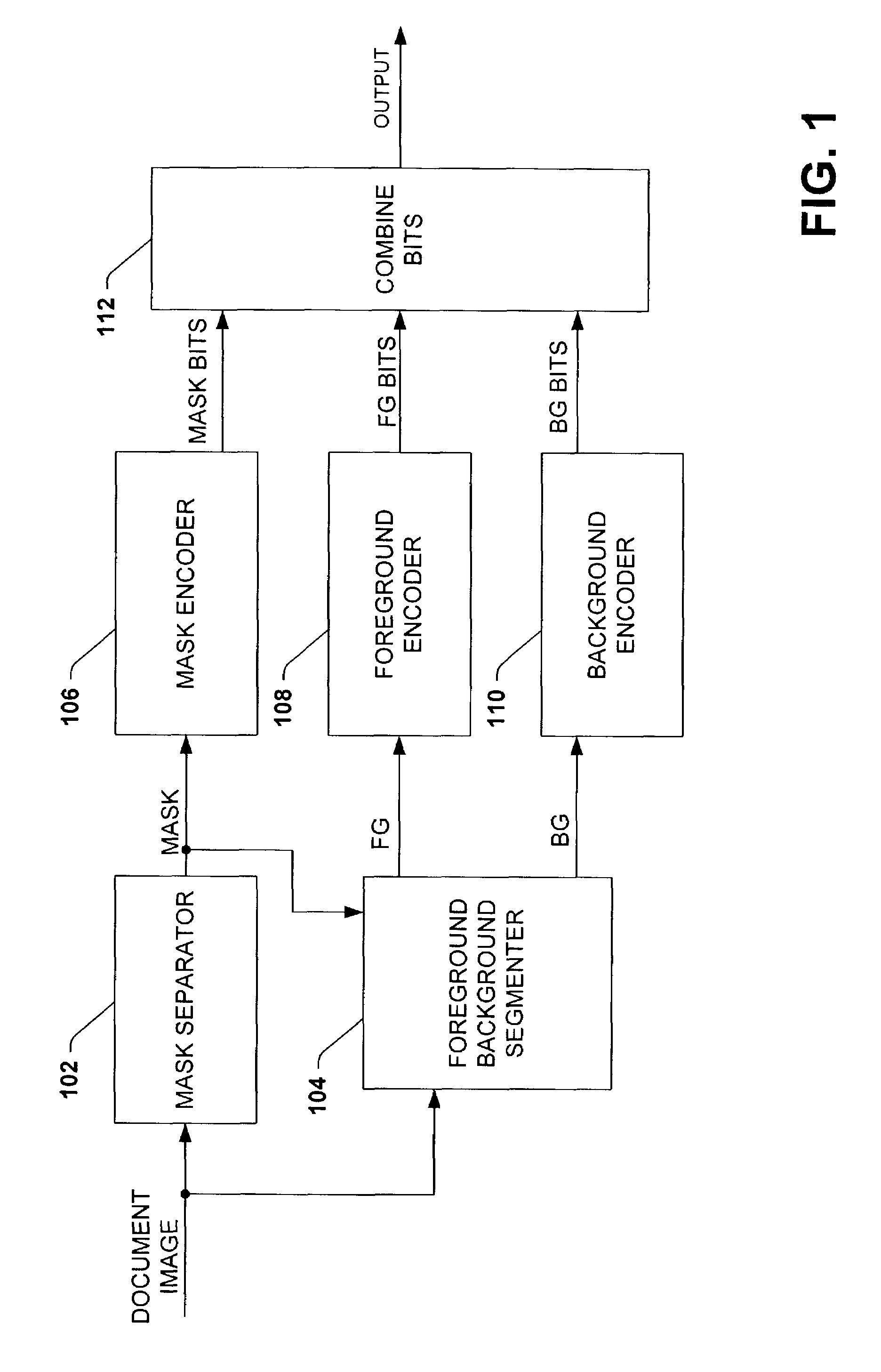

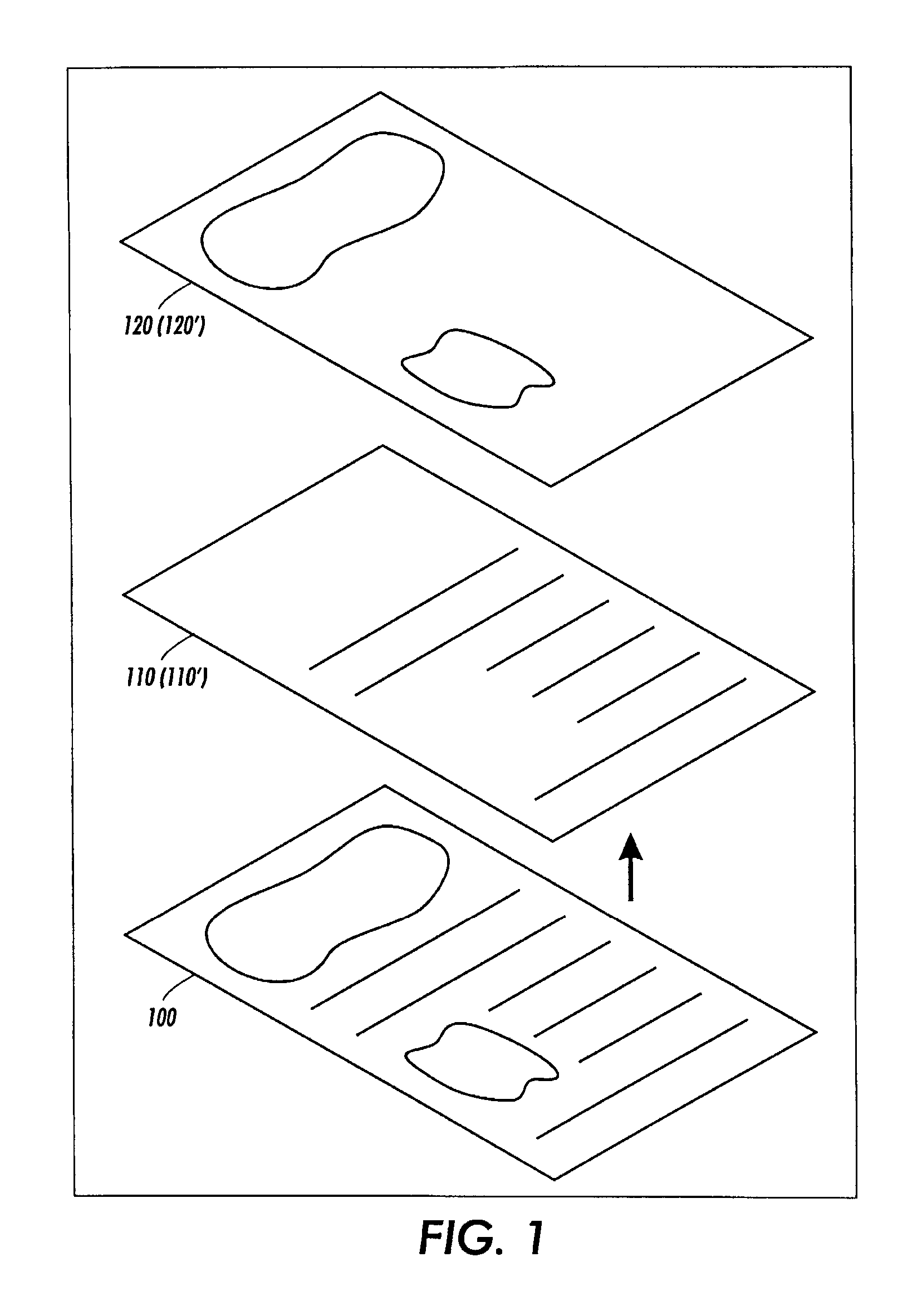

Segmented layered image system

InactiveUS7120297B2Estimate degradedEnhance the imageCharacter and pattern recognitionPictoral communicationPattern recognitionComputer graphics (images)

Systems and methods for encoding and decoding document images are disclosed. Document images are segmented into multiple layers according to a mask. The multiple layers are non-binary. The respective layers can then be processed and compressed separately in order to achieve better compression of the document image overall. A mask is generated from a document image. The mask is generated so as to reduce an estimate of compression for the combined size of the mask and multiple layers of the document image. The mask is then employed to segment the document image into the multiple layers. The mask determines or allocates pixels of the document image into respective layers. The mask and the multiple layers are processed and encoded separately so as to improve compression of the document image overall and to improve the speed of so doing. The multiple layers are non-binary images and can, for example, comprise a foreground image and a background image.

Owner:MICROSOFT TECH LICENSING LLC

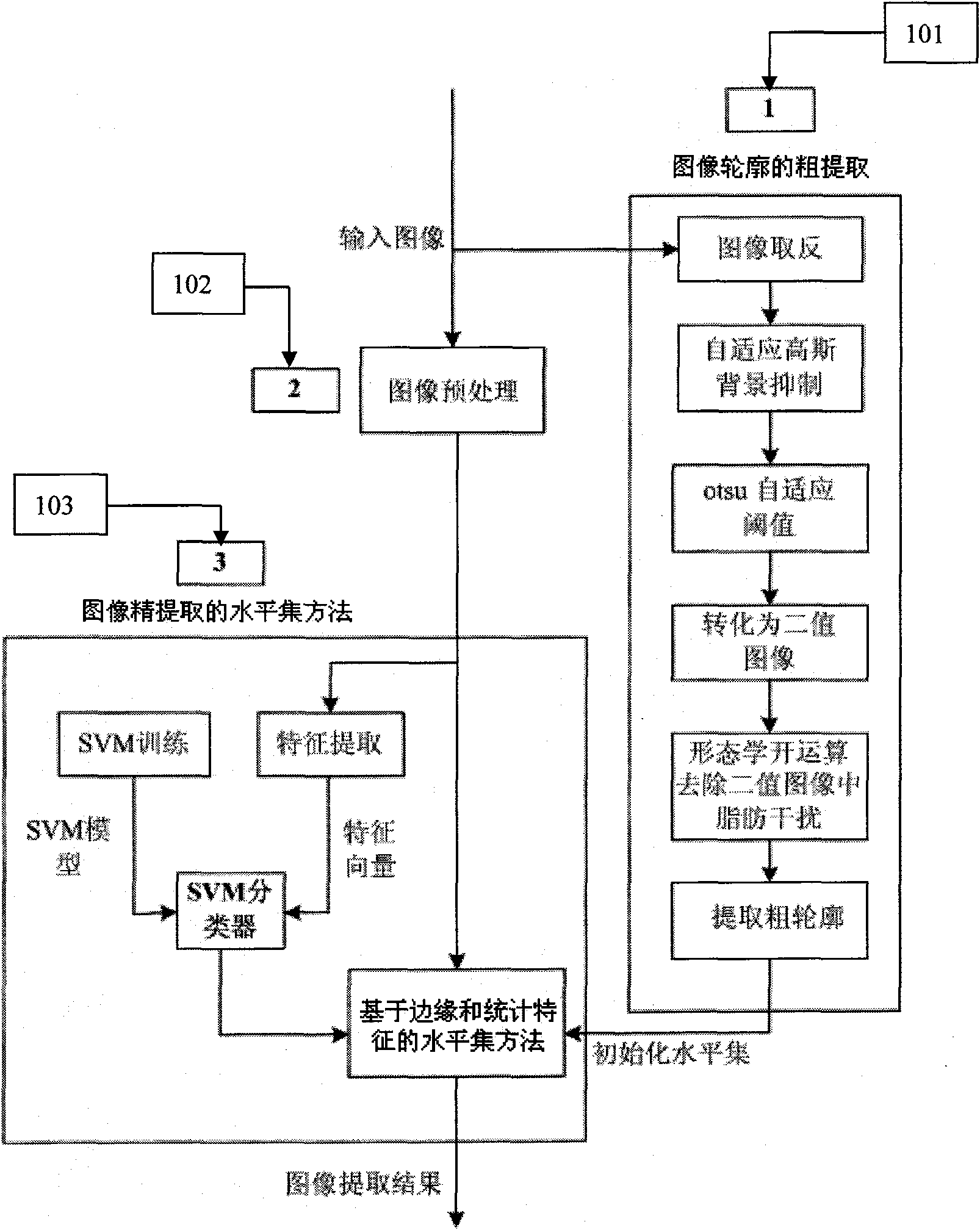

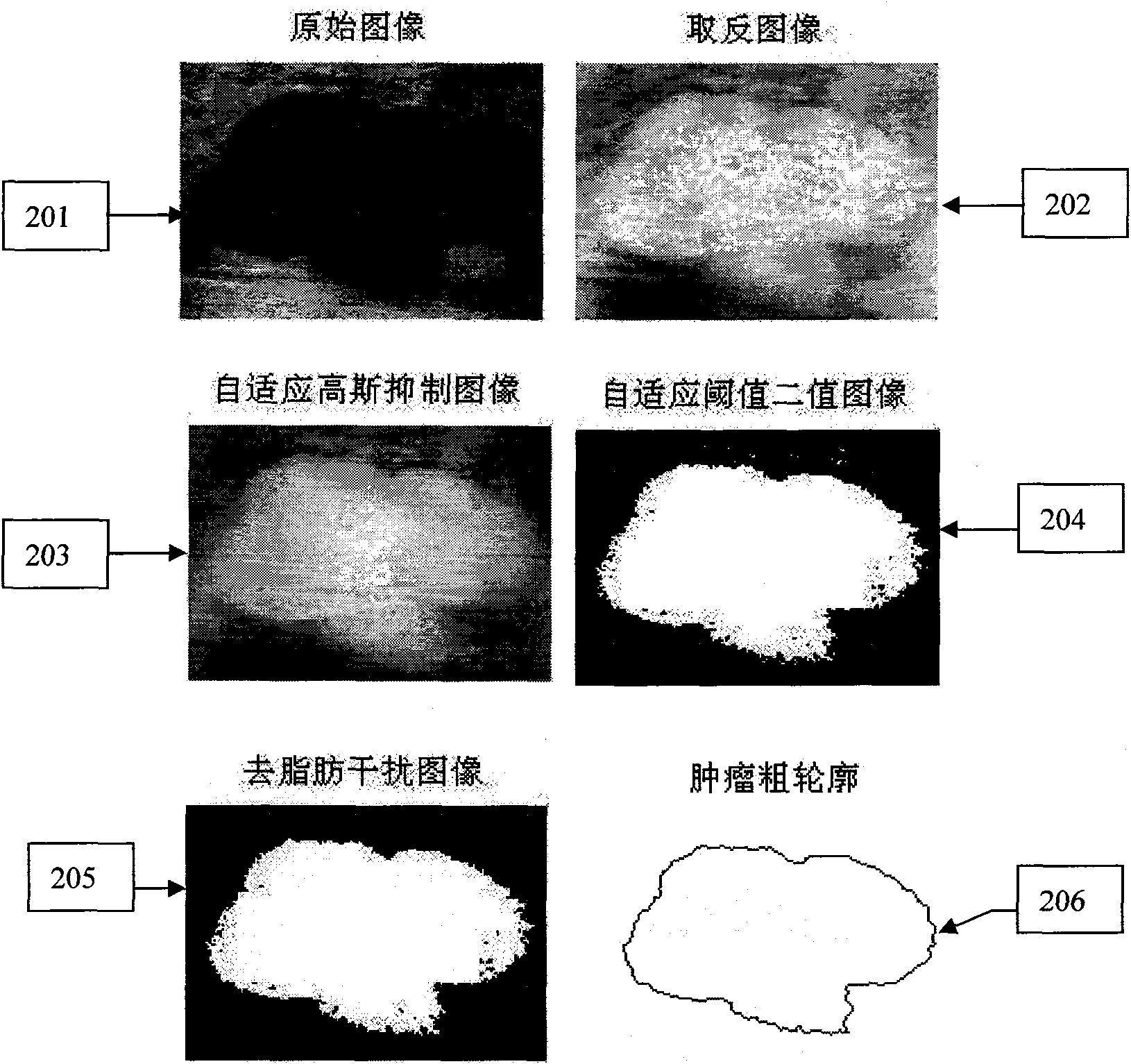

Method for outline extraction of level set medical ultrasonic image area based on edge and statistical characteristic

The invention provides a method for the outline automatic extraction of a level set medical ultrasonic image area based on an edge and a statistical characteristic, aiming at the characteristics of low contrast degree and small signal-to-noise ratio of medical ultrasonic images and designing a method for the outline extraction of the level set area based on the edge and the statistical characteristic. The method comprises three steps of: 1, carrying out area outline coarse extraction, completing image inverse extraction and self-adapting Gaussian function background suppression, applying otsu image automatic threshold algorithm to convert the image into a binary image, and carrying out image degreasing interference operation and closed area outline extraction work; 2, adopting a selectivity aeolotropy medical ultrasonic image smoothing algorithm to pre-treat an original image; and 3, carrying out the precise extraction of the level set image area based on the edge and the statistical characteristic. Experimental results indicate that compared with the prior method, the method of the invention can obtain a more precise partition result.

Owner:HARBIN INST OF TECH

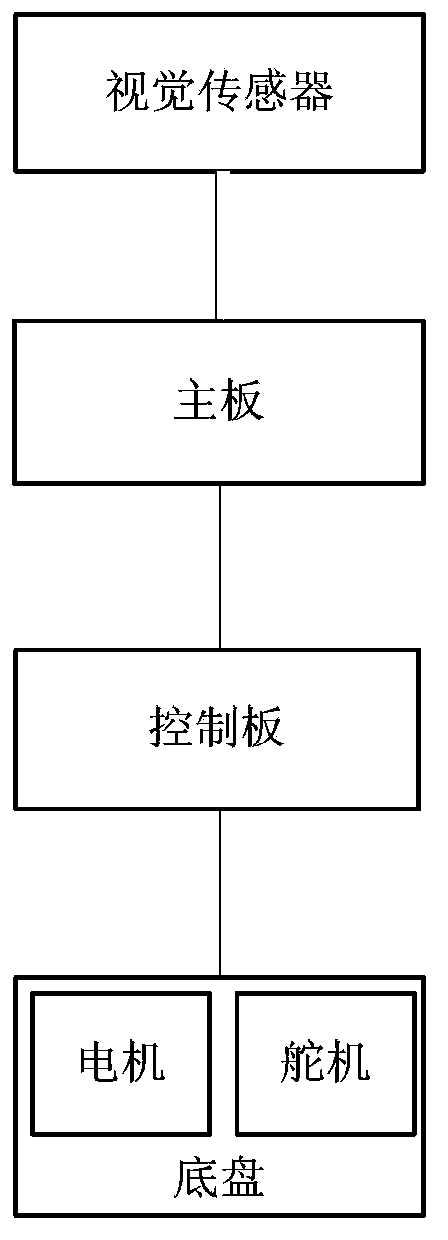

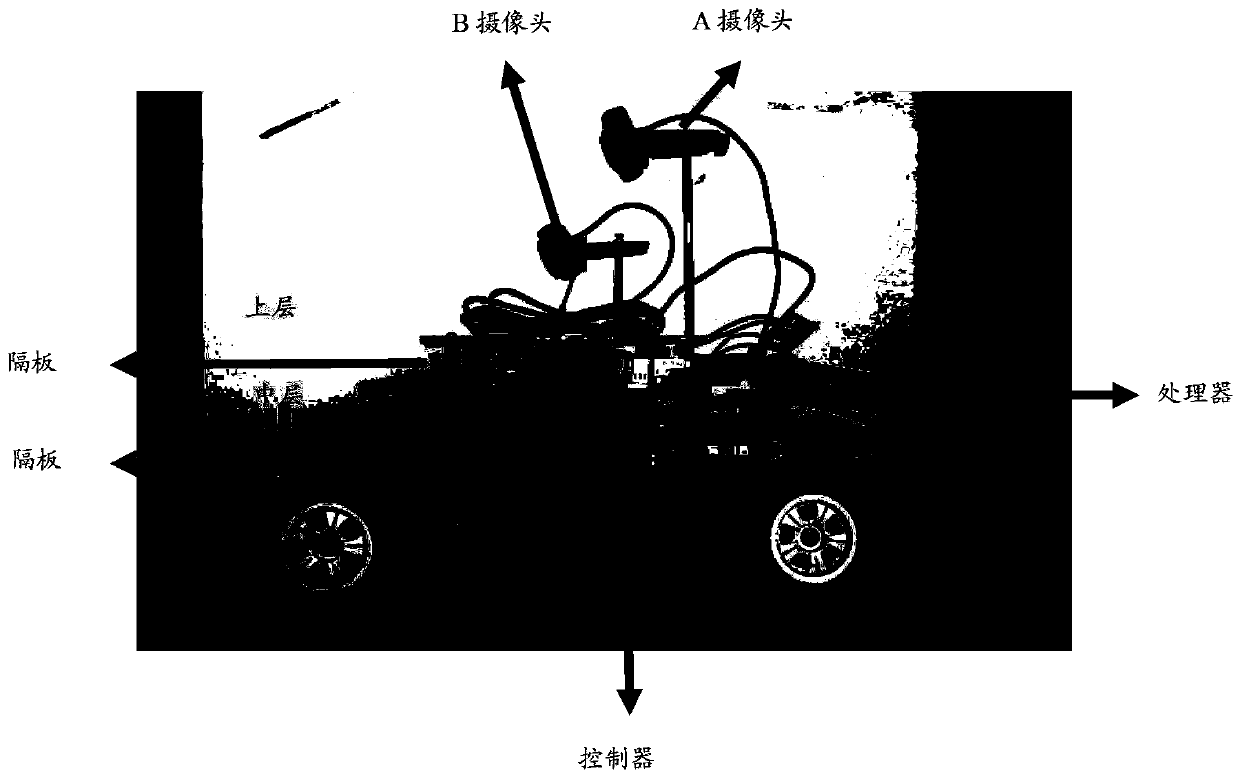

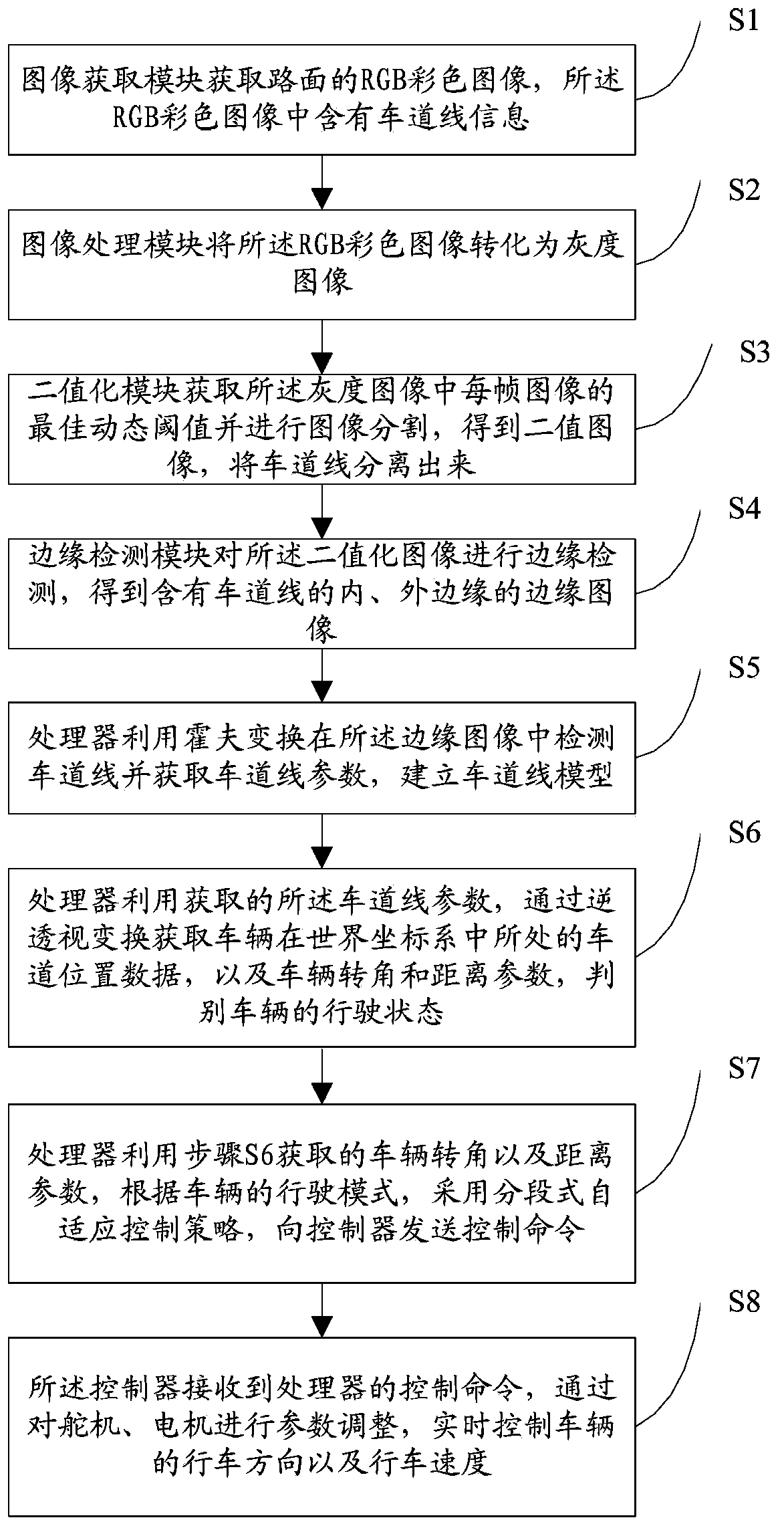

Vehicle line walking method and system based on machine vision

InactiveCN103389733AProminent featuresSmooth rideCharacter and pattern recognitionPosition/course control in two dimensionsColor imageRoad surface

The invention provides a vehicle line walking method and system based on machine vision. The line walking method comprises the following steps: an image acquisition module acquires an RGB color image of a road surface; an image processing module converts the RGB color image into a grayscale image; a binarization module obtains a binarization image to separate a lane line; an edge detection module obtains an edge image containing an inner edge and an outer edge of the lane line; a processor acquires parameters of the lane line to establish a lane line model, acquires lane position data of a vehicle in a world coordinate system through inversely perspective conversion, and determines a driving mode of the vehicle according to road surface image information; parameter adjustment of a steering engine and a motor can be realized by using acquired vehicle corner parameters and distance parameters, adopting the driving mode of the vehicle, and utilizing a sectional adaptive control strategy so as to realize real-time control of driving directions and driving speed of the vehicle. According to the method and system, provided by the invention, the line walking speed in the driving process of the vehicle can be increased, the line walking can be completed within the time of 10 milliseconds, and the stability in the driving process of the vehicle is strong.

Owner:CHONGQING ACADEMY OF SCI & TECH

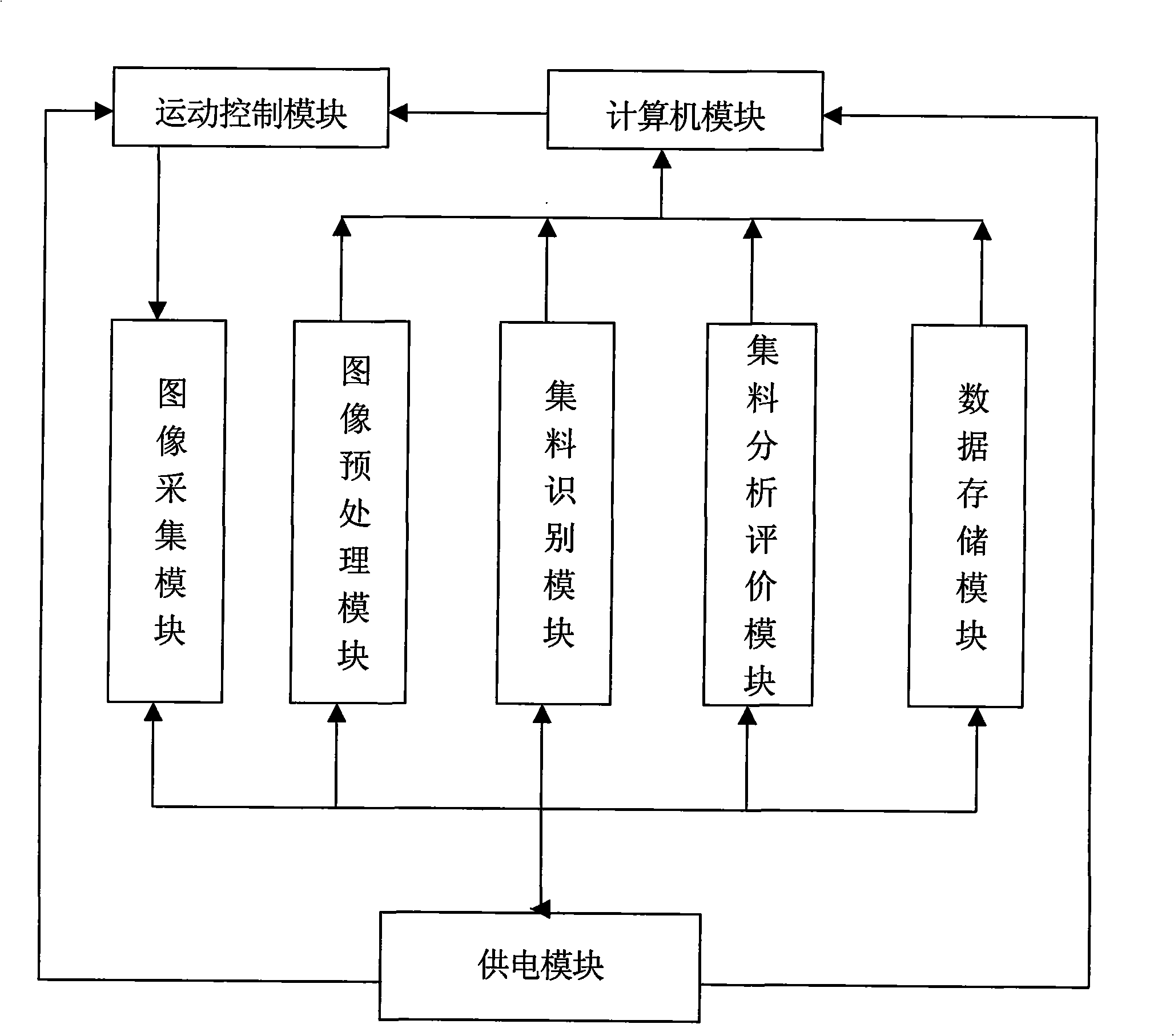

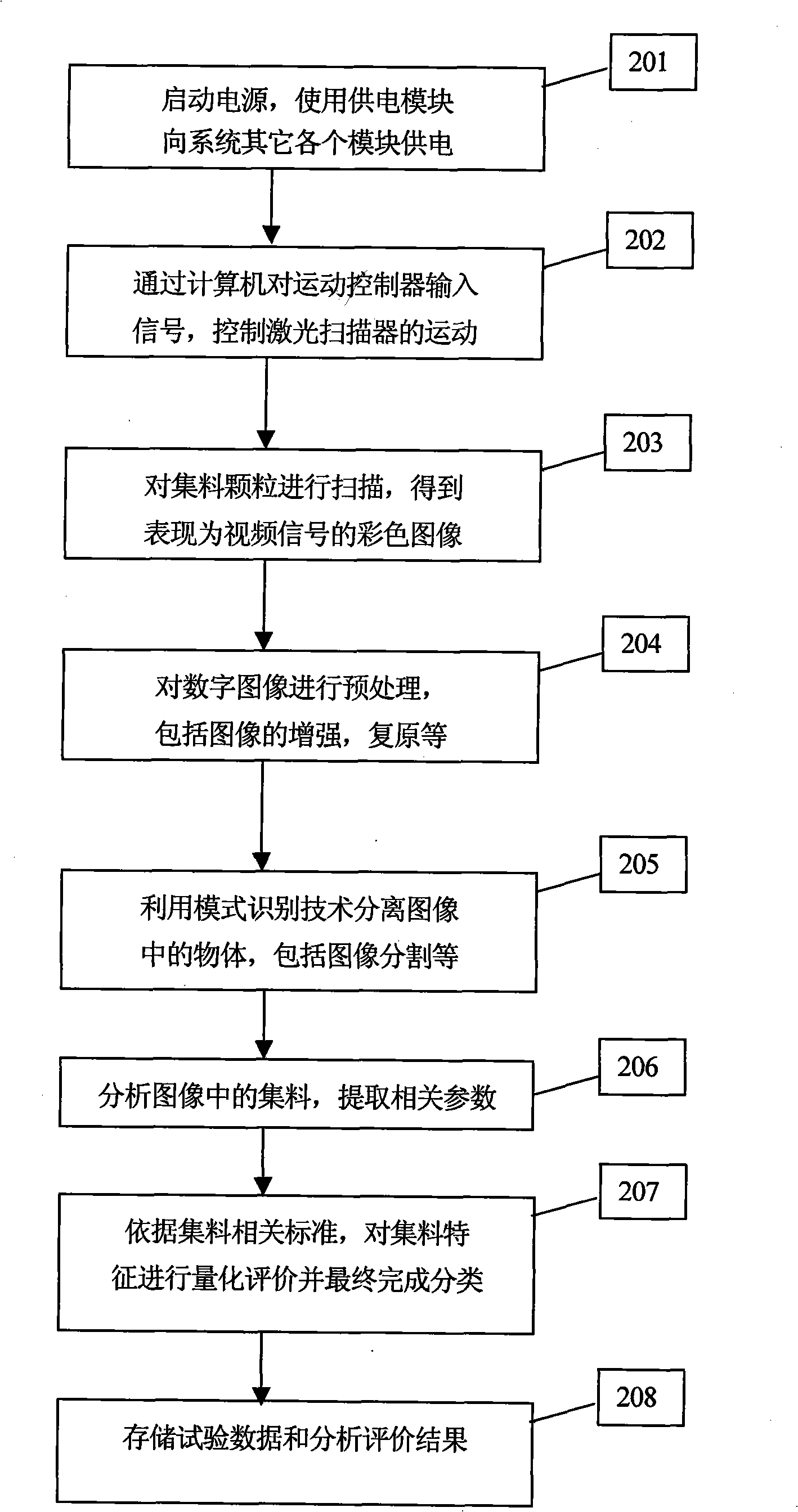

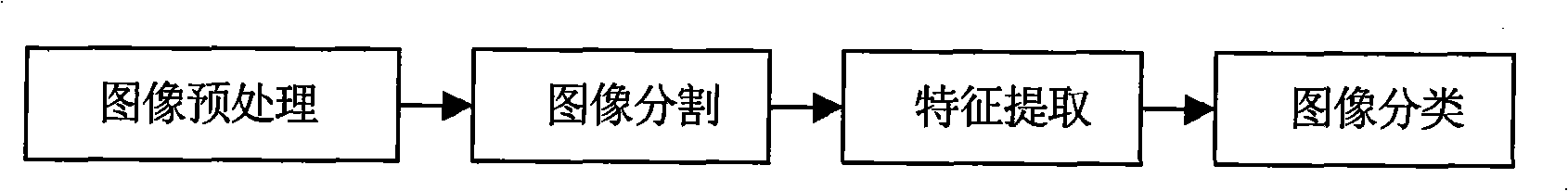

Method and system for evaluating aggregate digital image

InactiveCN101354241AGuaranteed accuracyAccurately obtainedImage analysisCharacter and pattern recognitionLaser scanningMotion controller

The invention discloses an aggregate digital image assessment system which comprises a motion control module, a computer module, an image acquisition module and a power supply module, an image preprocessing module, an aggregate identity module, an aggregate analysis and evaluation module and a data storage module. The assessment method includes that: a computer sends an instruction to a motion controller for controlling the linear sliding of a laser scanner; a CCD camera takes a picture of aggregate on a scanning board and transforms the image to a digital image; the digital image is transformed to a grey-scale map, And an edge detecting operator is utilized for carrying out image enhancement and restoration to the transformed grey-scale map so as to transform the grey-scale map to a binary image; the aggregate in the binary image is projected and the image of the aggregate in the binary image is detected and separated; IPP image processing and analysis software is used for calculating the three-dimensional coordinate of the surface of the aggregate; quantitative assessment category is carried out to the characteristics of the aggregate to obtain the gradation, the shape, the corner angle and the texture of the aggregate; the computer stores experimental data as well as analysis and assessment results. The aggregate digital image assessment system of the invention can be used for analysis and assessment of the aggregate.

Owner:CHANGAN UNIV

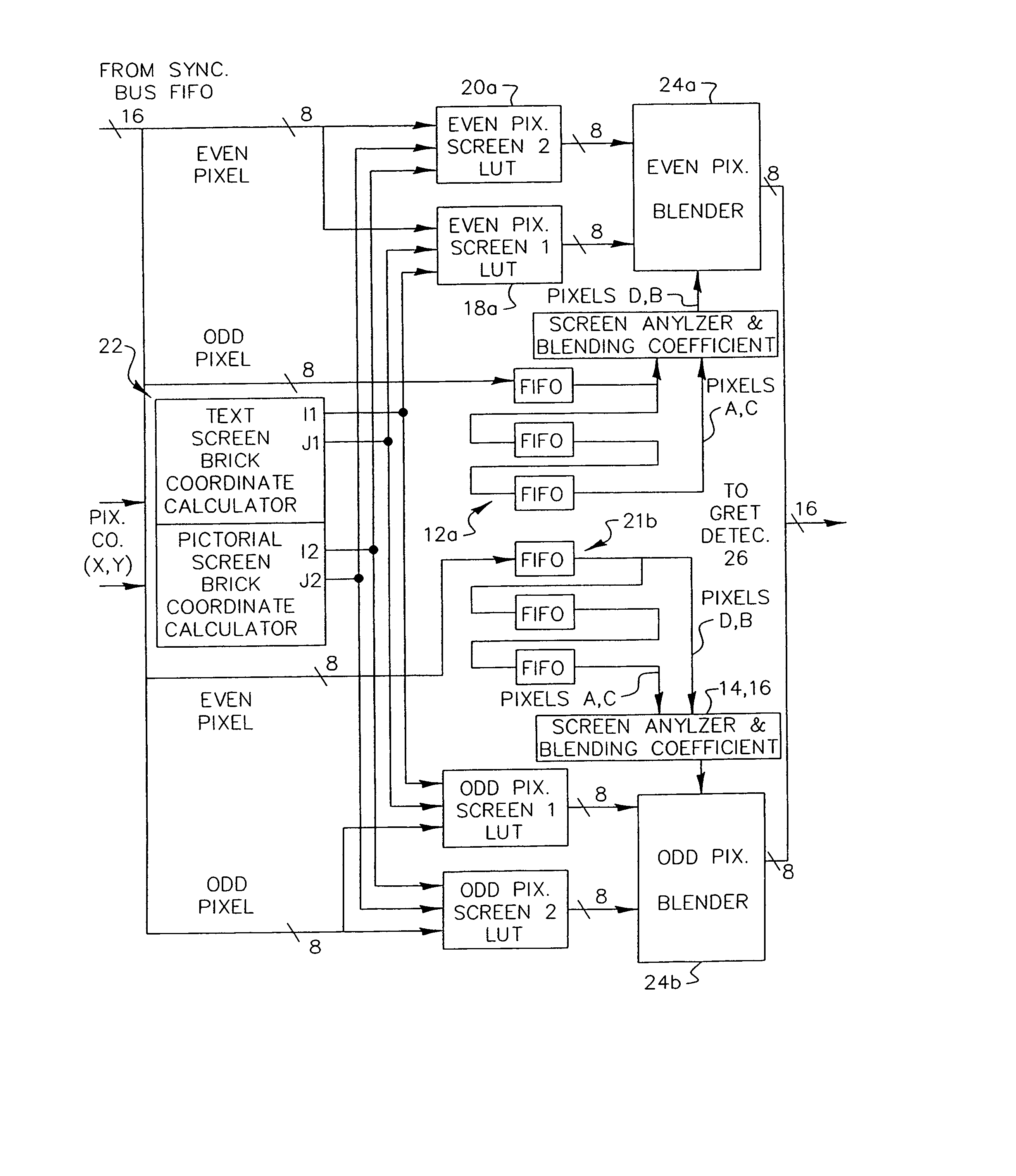

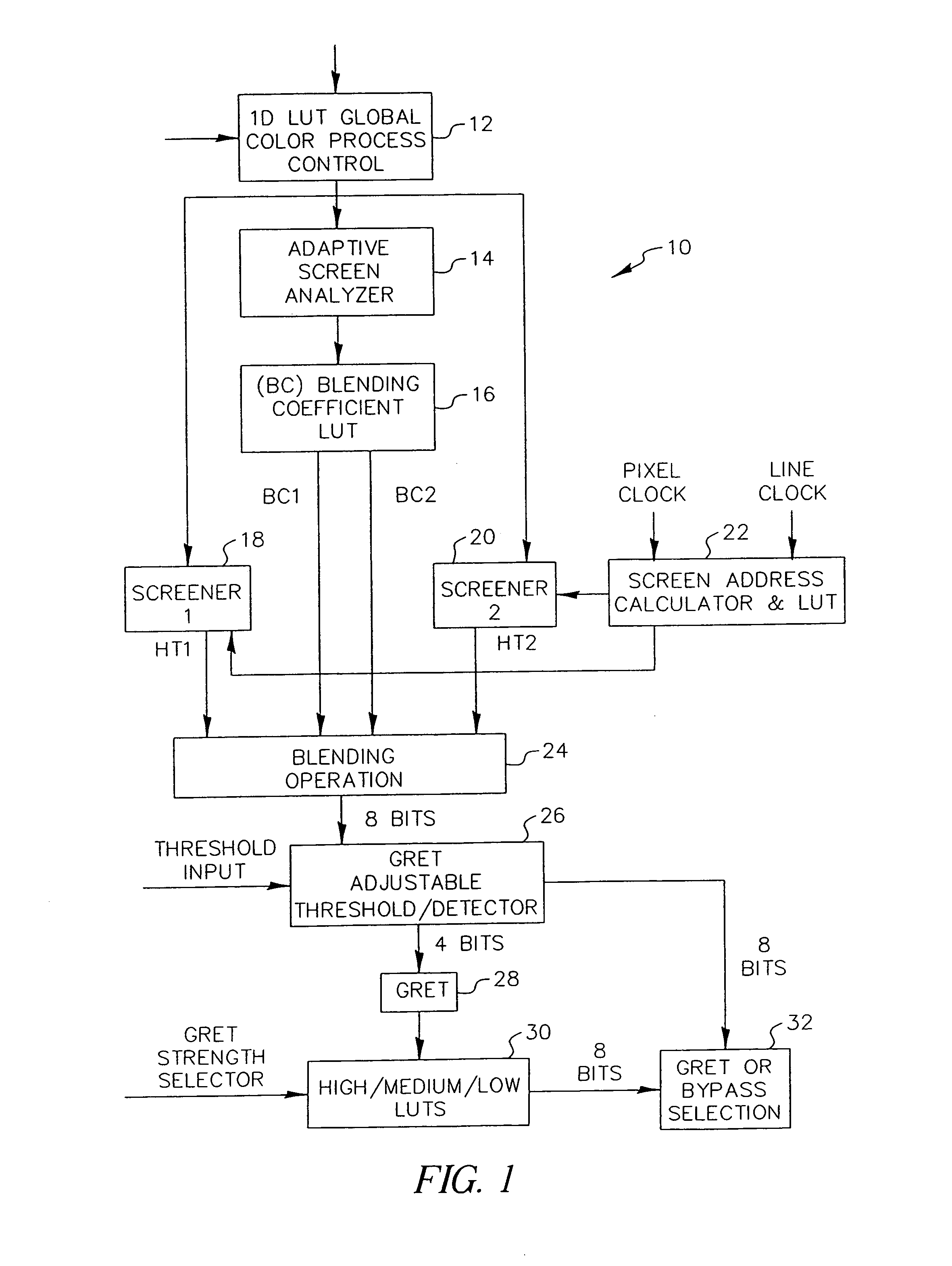

Edge enhancement of gray level images

InactiveUS7079287B1Reduce aliasingImage enhancementCharacter and pattern recognitionAnti-aliasingGray level

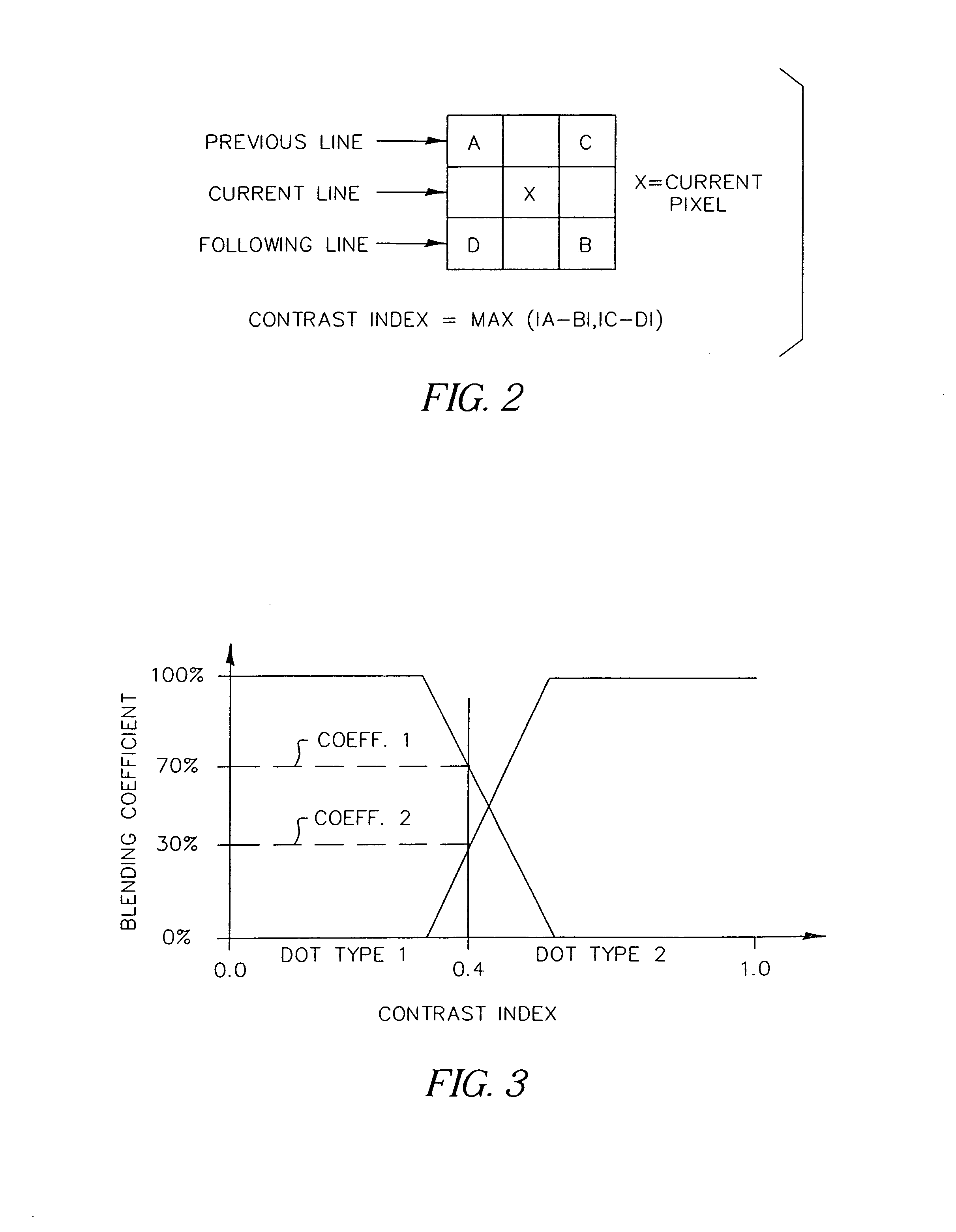

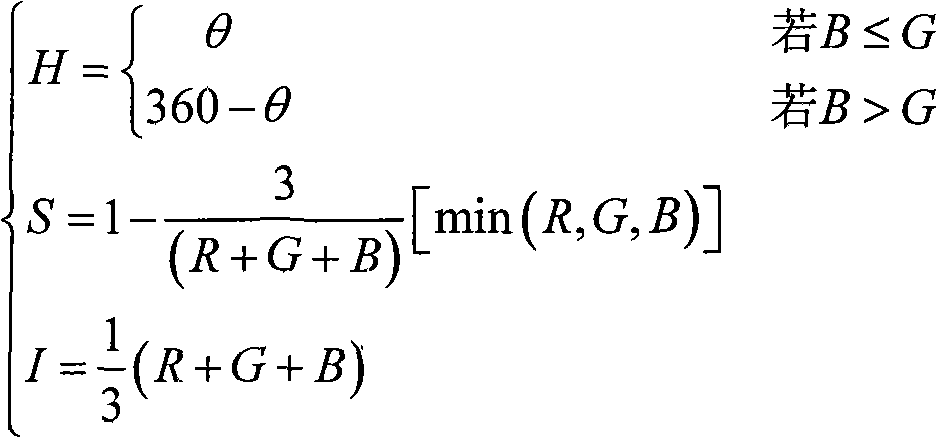

A method and apparatus for processing gray level image data. Gray level image data is subjected to plural separate halftone screen processing to form plural separate halftone processed screen gray level image data. The current pixel is also analyzed for contrast index. In response to analysis of the contrast index blending coefficients for processing of the halftone screen modified image data is made. The respective halftone outputs of the screen processings are multiplied by the respective blending coefficient. The resulting blended halftone gray value of the current pixel as well as neighboring pixels are then subjected to a threshold criterion test to determine if this represents a substantially binary image file such as might occur in a saturated text image file. The blended halftone gray value data for the current pixel is subjected to gray level edge enhancement processing to replace certain binary pixels adjacent an edge to reduce anti-aliasing effects. A signal resulting from the threshold criterion test is used to determine whether there is output to the printer or display of an edge enhanced version of the current blended halftone pixel or a pixel value representing the blended halftone pixel.

Owner:MONUMENT PEAK VENTURES LLC

License plate positioning method incorporating color, size and texture characteristic

InactiveCN101334836AReduce dependenceEasy to separateRoad vehicles traffic controlCharacter and pattern recognitionImaging processingMathematical morphology

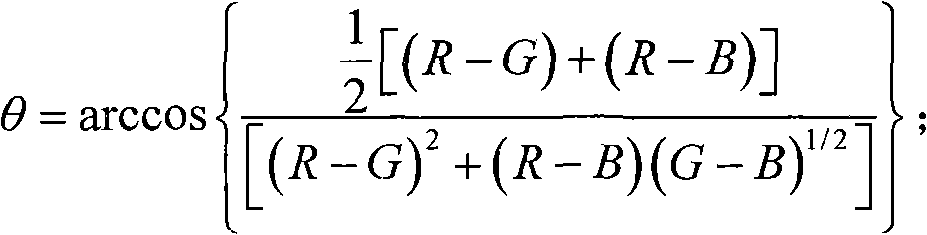

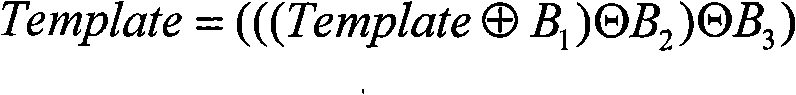

The invention belongs to the image processing technique field and particularly relates to the license plate identifying technique and further to a license plate locating method under a complex background. Firstly, a license plate original image of RBG format is converted into HSI format to realize the separation between color information and brightness information; then the obtained saturation component chart and brightness component chart are binarized; then pixels of the original image are classified according to the color information of the license plate and a license plate locating template binary image can be obtained according to the classification results and a mathematical morphology computing is adopted to remove noise from the license plate locating template binary image; then a region growing method is adopted to extract each communication zone of the license plate locating template binary image and an inspection to the license plate size is also carried out, and the communication zones passing the size inspection become candidate license plate zones; the Hough transformation is adopted to correct inclined license plates and then license plate vertical texture characteristics are adopted to further inspect each candidate license plate zone so as to remove the fake candidate zones. The adoption of the invention can effectively enhance the universality and the locating accuracy of the system.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

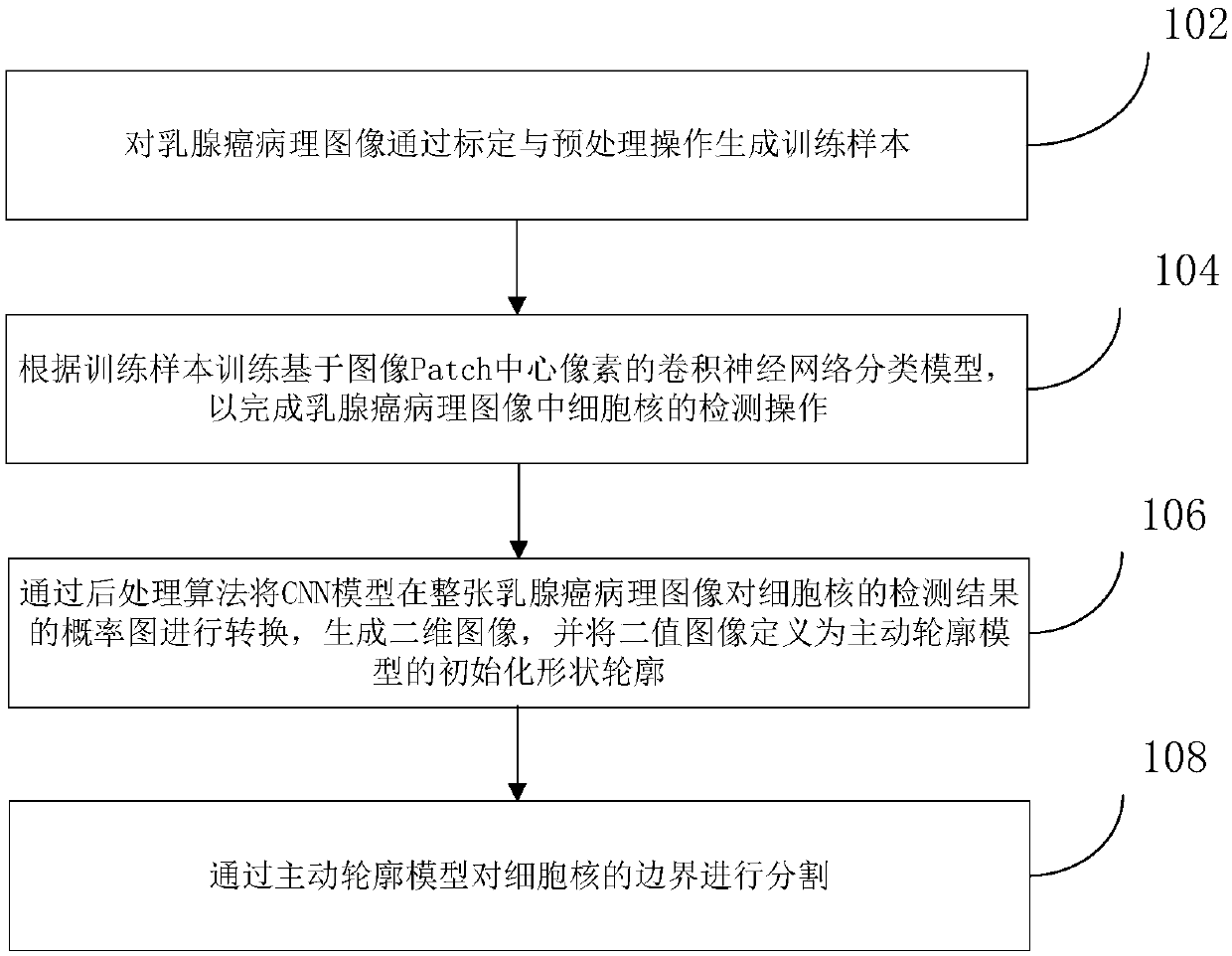

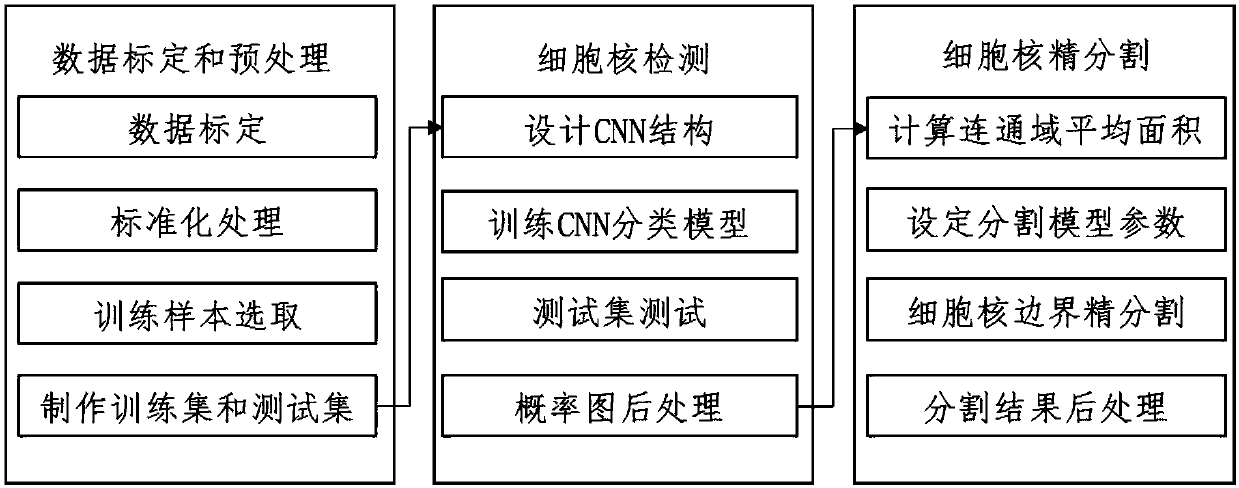

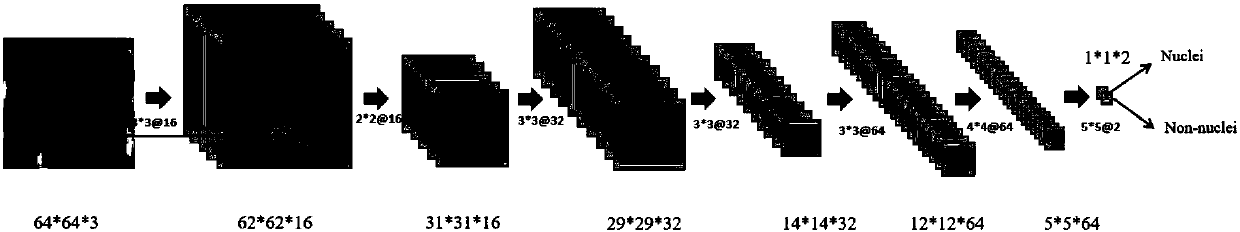

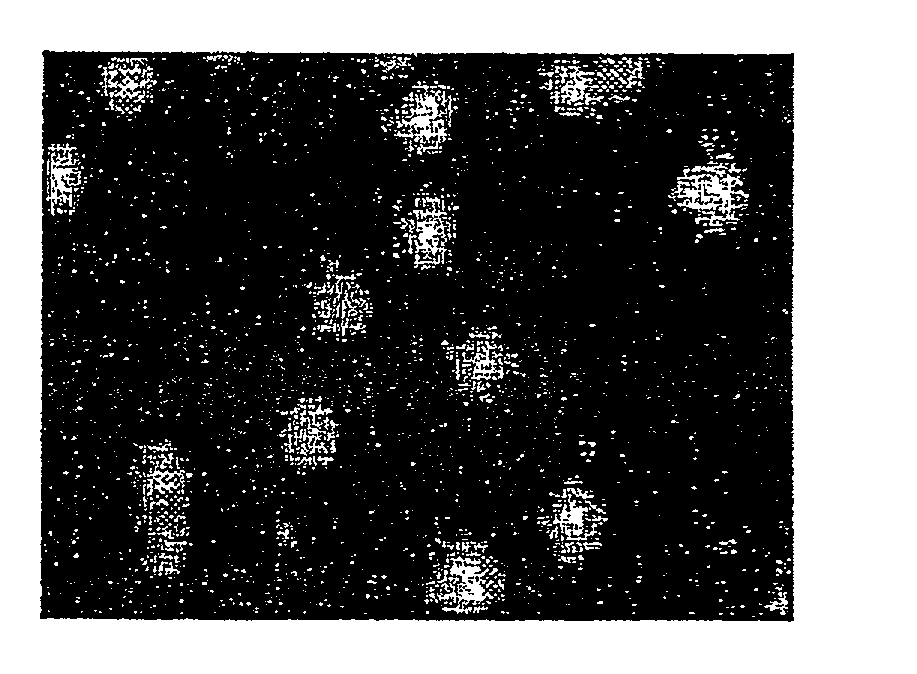

Method and device for segmentation of breast cancer pathologic image

The present invention discloses a method for segmentation of a breast cancer pathologic image. There are three main modules consisting of data preprocessing, cell nucleus detection and cell nucleus boundary refinement segmentation. Pathology experts perform artificial calibration of a cell nucleus boundary, the pathologic image is subjected to standardization processing to eliminate dying difference, a training sample based on a cell nucleus pixel, and a cell nucleus boundary pixel and a background pixel is made to train a convolutional neural network classifier and achieve a classifier basedon a Patch image center pixel. A trained convolutional neural network model is detected on the whole pathologic image to output a probability graph, a postprocessing algorithm is employed to generatea binary image as an initialized shape outline of an active outline model, and the active outline model is employed to perform refinement segmentation of the cell nucleus boundary. The method and thedevice for segmentation of the breast cancer pathologic image are high in segmentation accuracy, and can achieve the algorithm for segmentation of overlapped cells in the breast cancer pathologic image. The present invention further discloses a device for segmentation of a breast cancer pathologic image.

Owner:BEIHANG UNIV

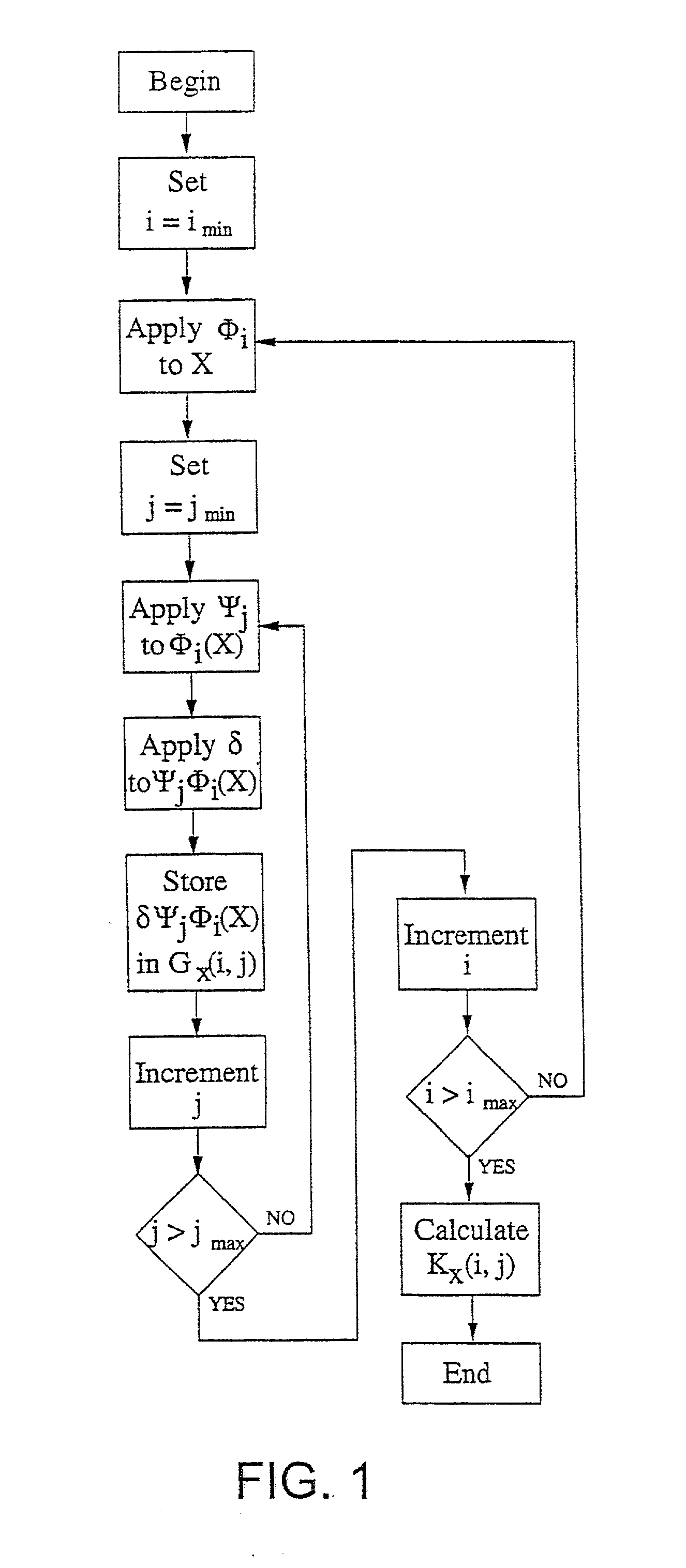

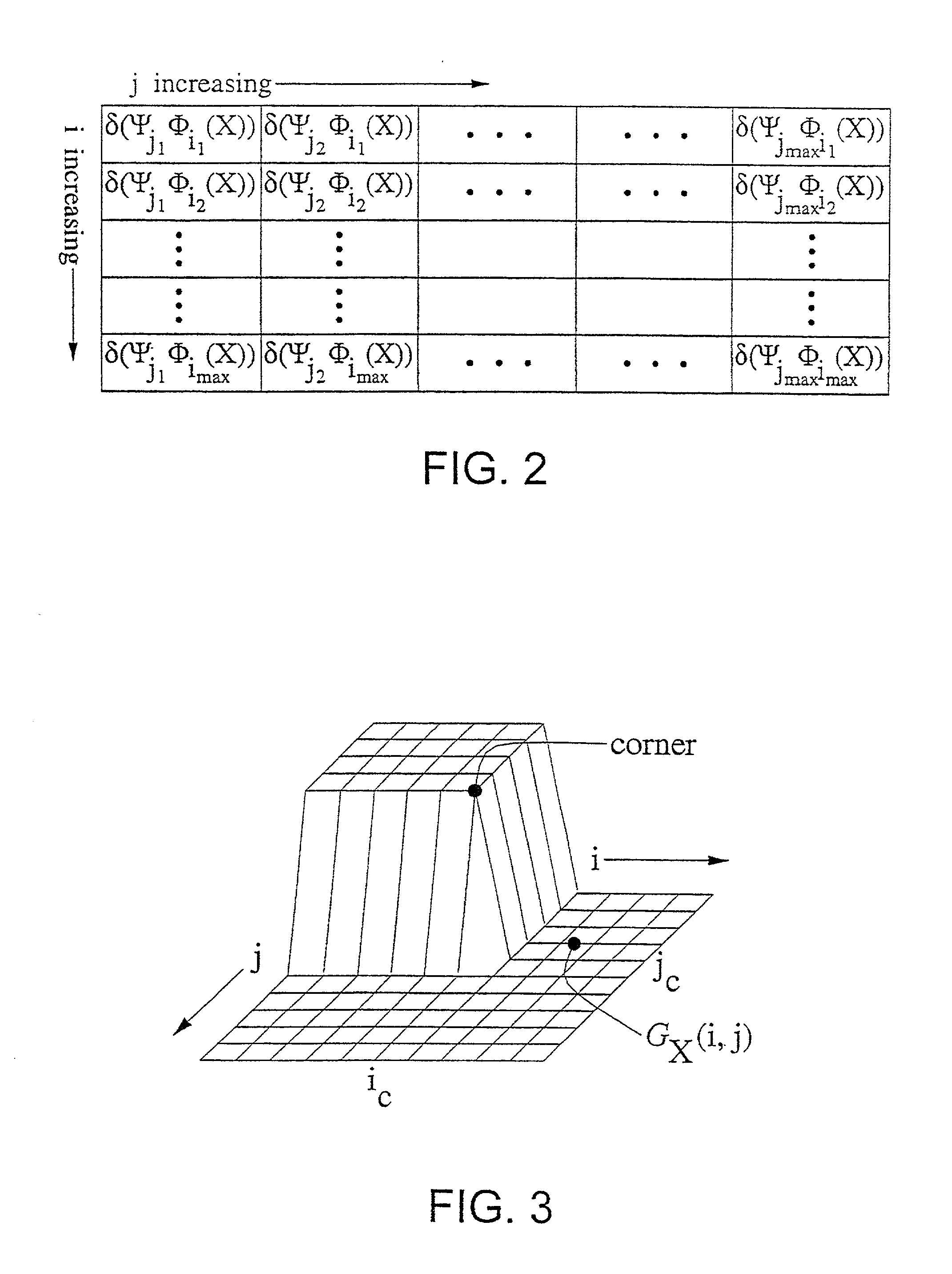

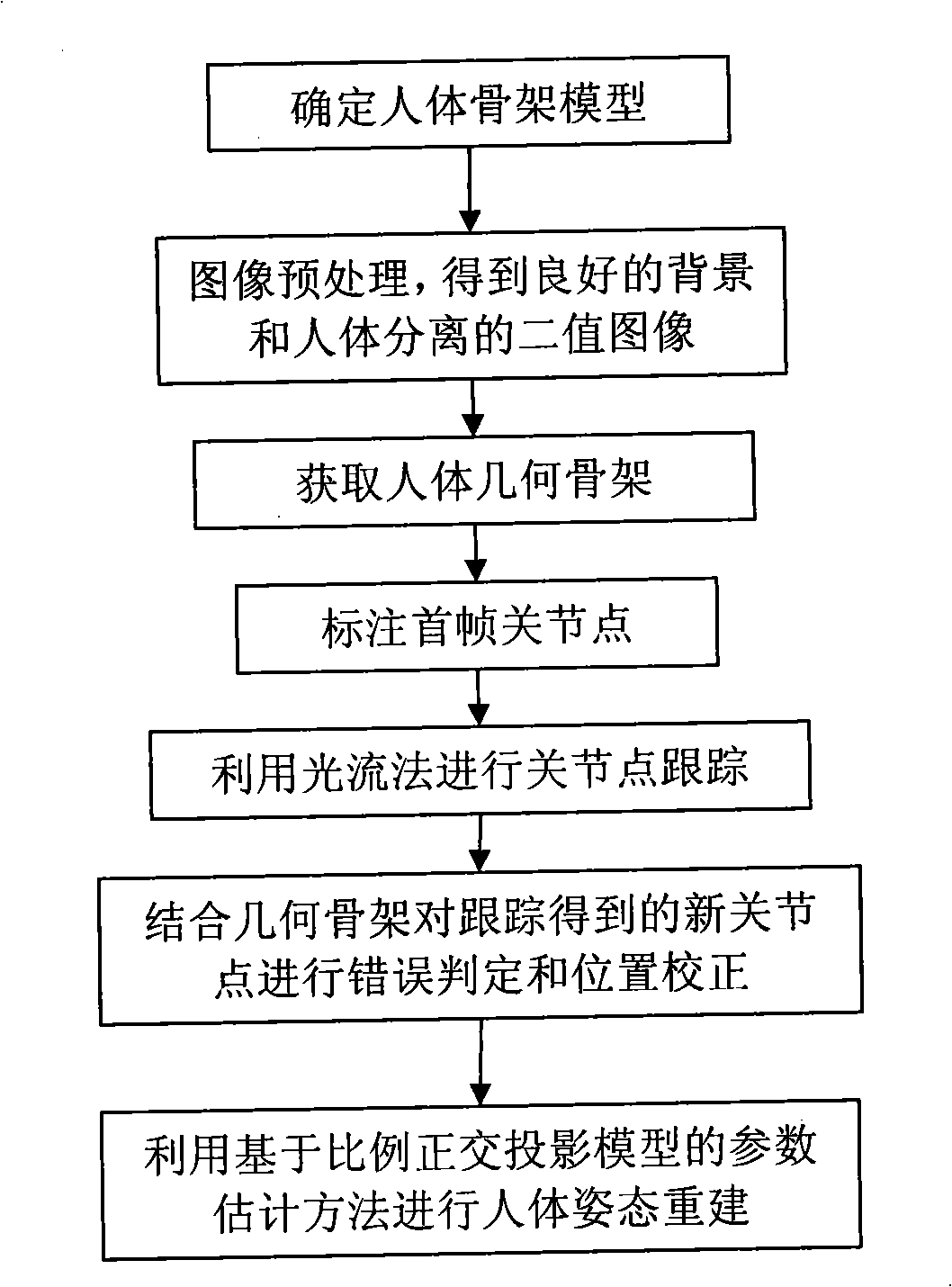

Method for image texture analysis

A method and apparatus for image texture analysis in which the image is mapped into a first set of binary representation by a monotonically varying operator, such as a threshold operator. Each binary representation in the first set of binary representations is mapped to a further set of binary representations using a second monotonically varying operator, such as a spatial operator. The result of the two mappings is a matrix of binary image representations. Each binary image representation is allocated a scalar value to form an array of scalar values which may be analysed to identify defined texture characteristics.

Owner:UNIVERSITY OF ADELAIDE +9

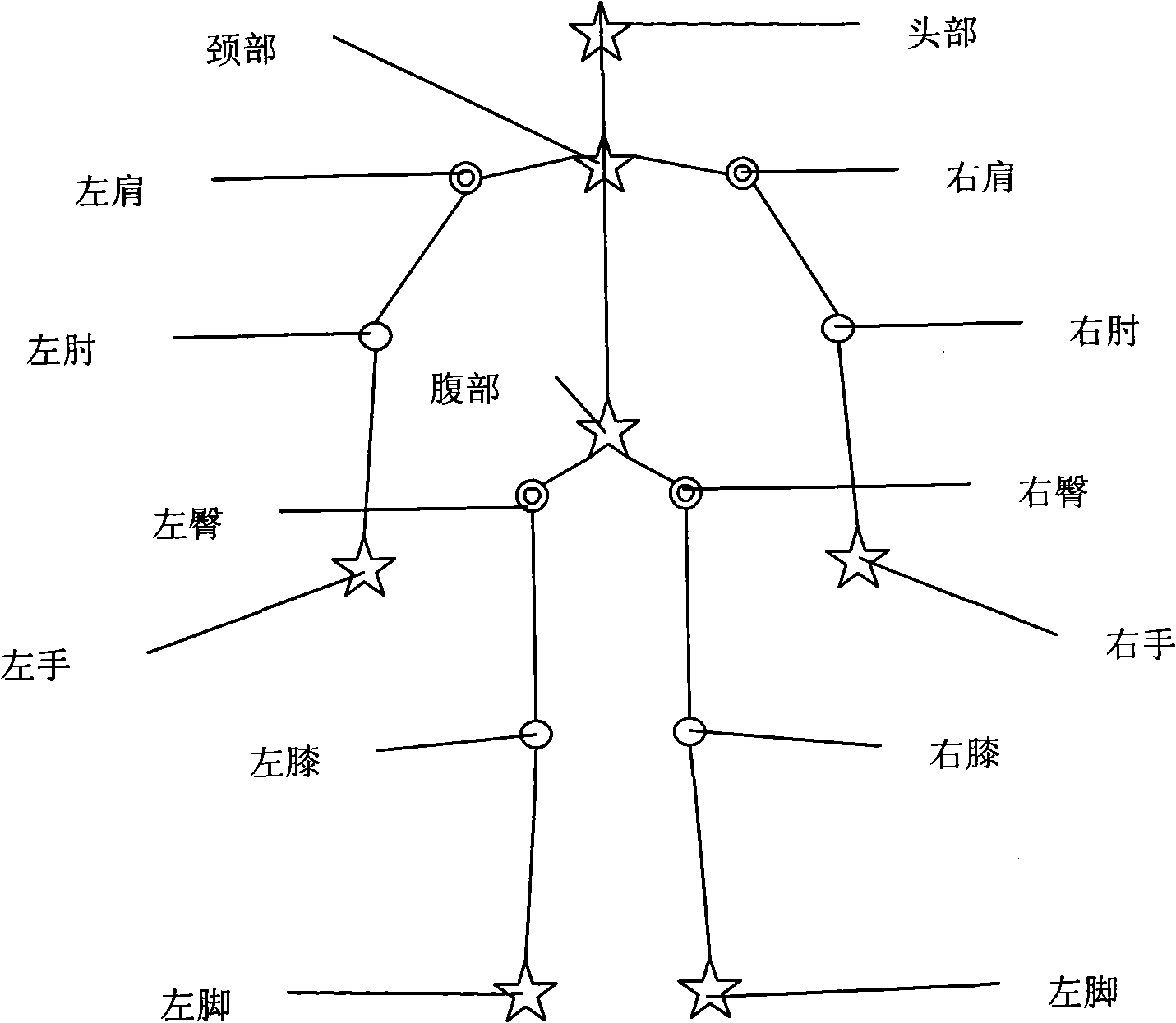

Human body posture reconstruction method based on geometry backbone

InactiveCN101246602AImprove accuracyImprove operational efficiencyCharacter and pattern recognitionDiagnostic recording/measuringHuman bodyNODAL

The present invention provides a reconstruction method of human posture based on the geometrical skeleton, including:determining human skeleton pattern; obtaining 3D human skeleton pattern, pre-processing image; obtaining bianry image of separation of the background and the human; acquiring human geometrical skeleton; obtaining linear geometrical skeleton; labelling articulare of the start frame; bonding the manual labelling articulare on the geometrical skeleton, shortening the initial error; tracing the articulare by light stream method; obtaining the new position by the light stream method; processing error judgement and position correction to the new articulare obtained by the trace with the combined geometrical skeleton; processing line correction calculated by the light stream method; re-constructing the human posture; converting the two-dimensinal coordinate of the articulare to the 3D skeleton pattern by the parameter evaluating method of the proportion orthogonal projection model. The invention improves accuracy of the posture reconstruction, obtaining a high processing efficiency, capable of processing stable and effect human posture reconstruction in the intelligent video monitor system.

Owner:DONGHUA UNIV

Reformatting binary image data to generate smaller compressed image data size

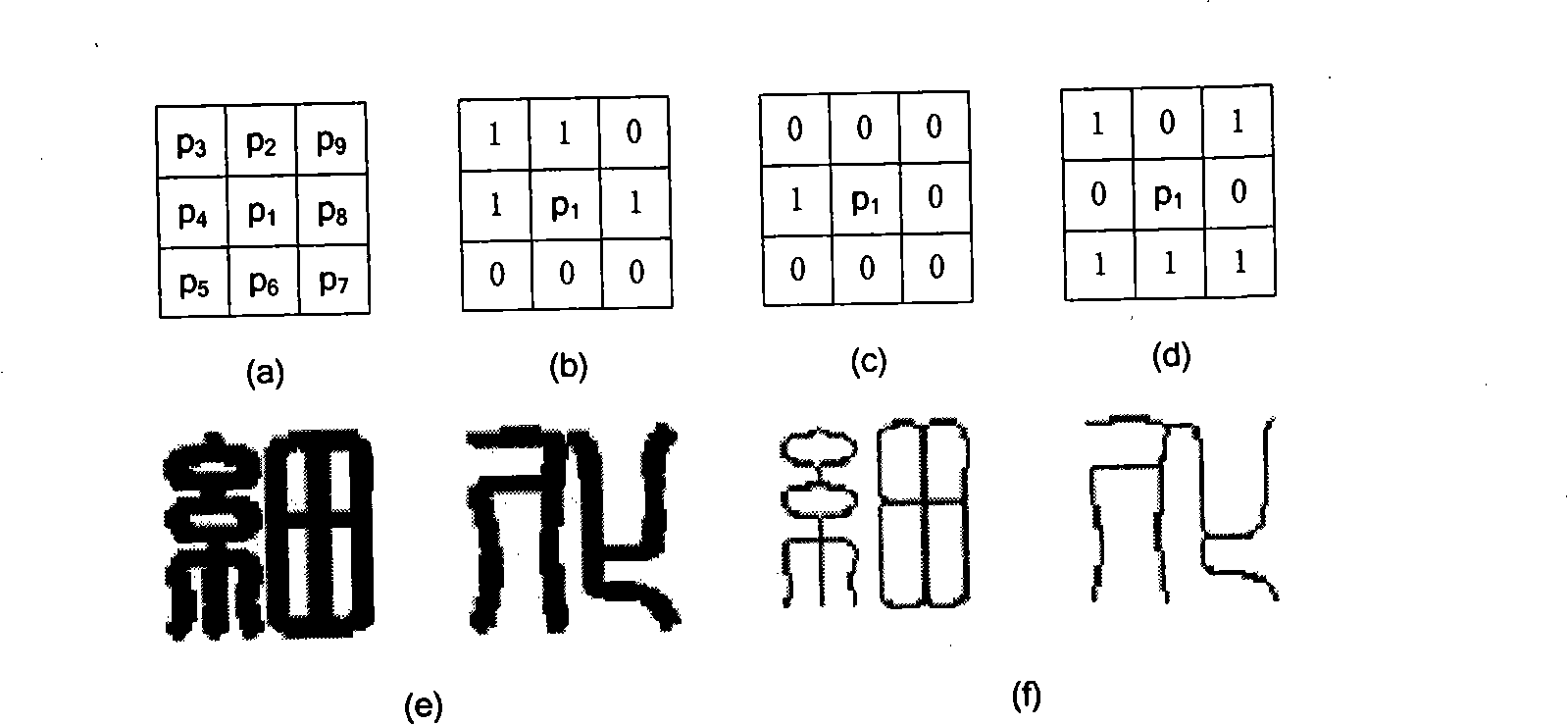

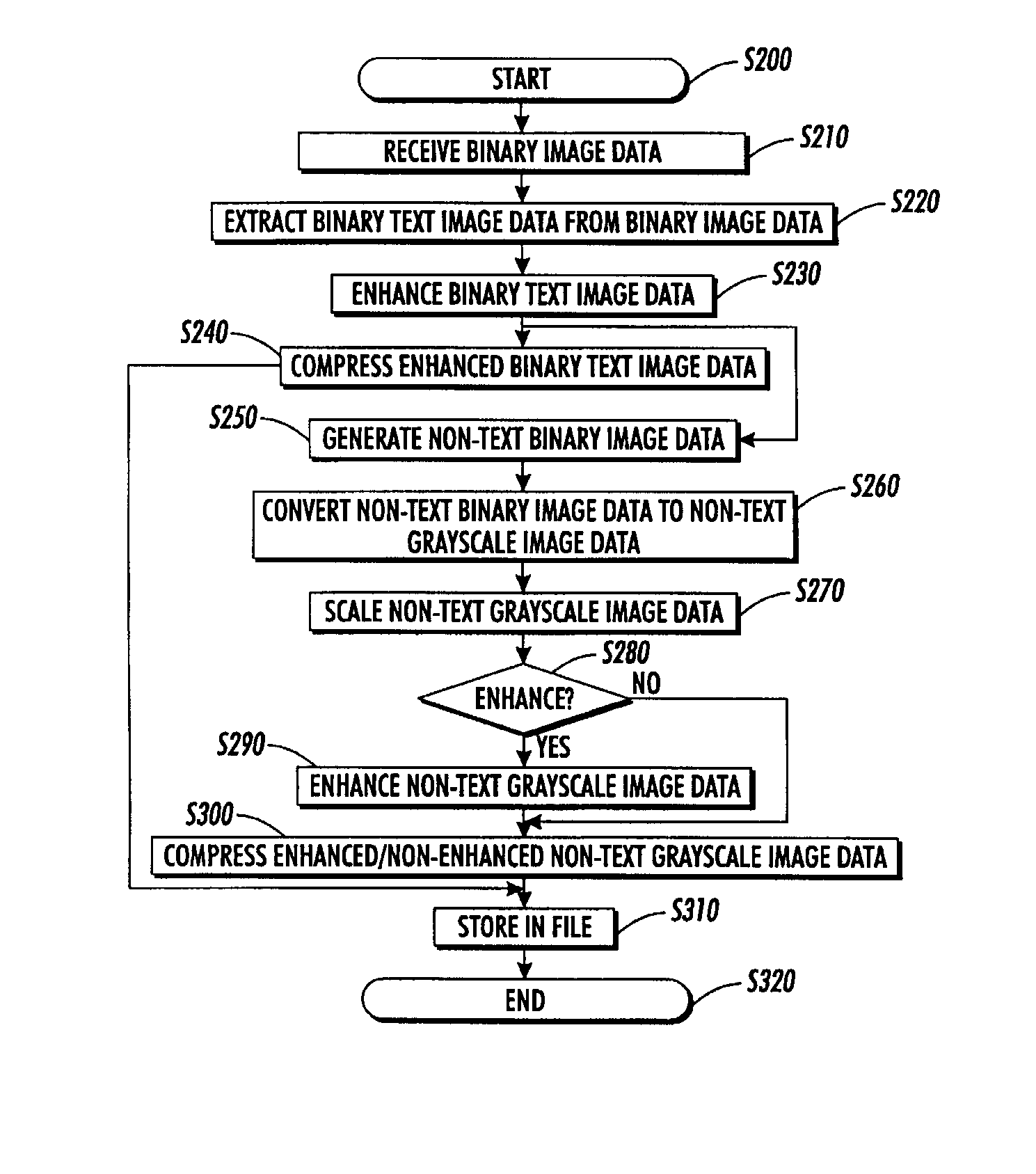

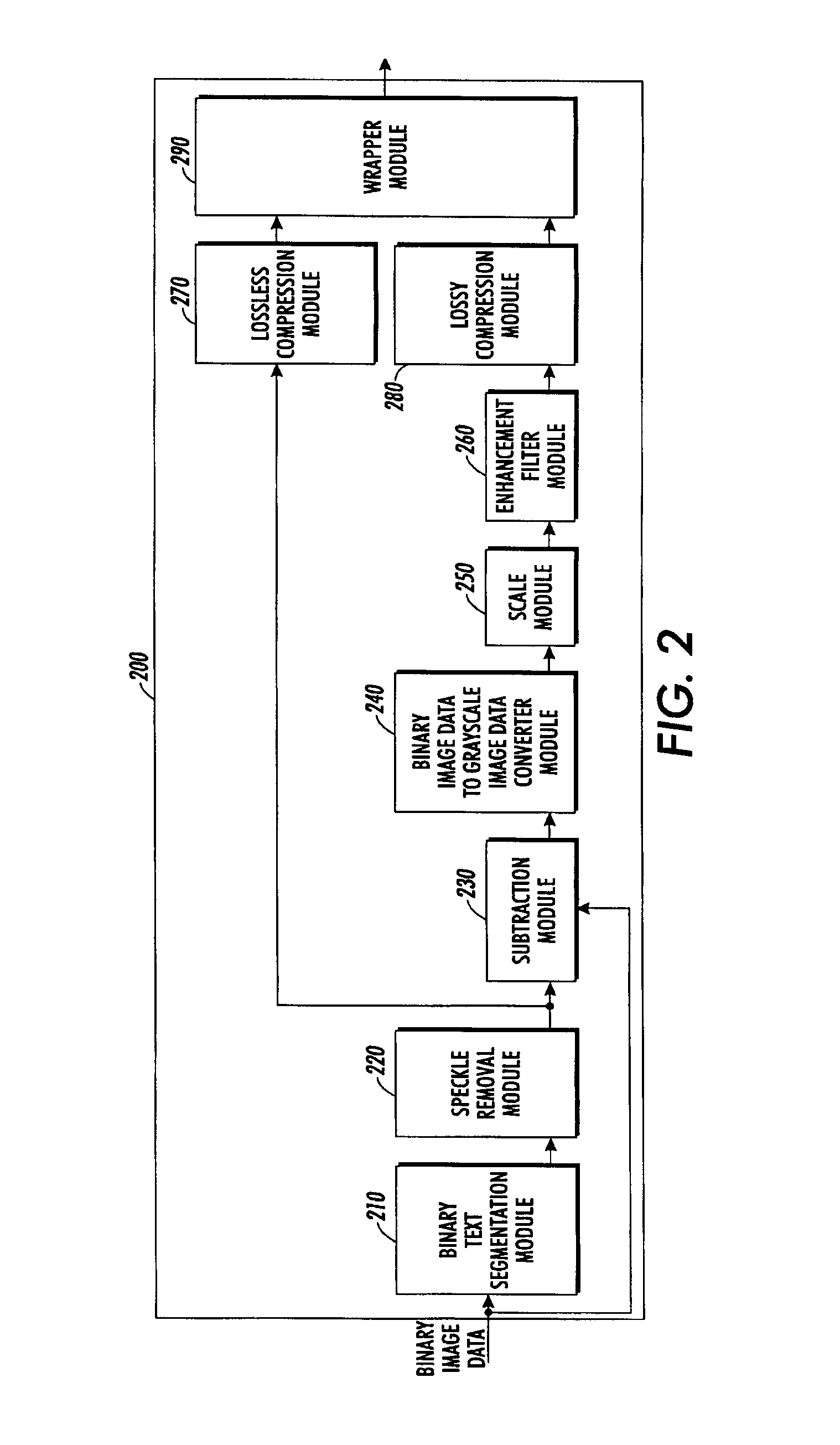

InactiveUS20050244060A1Stable changeEnhancing binary image data image dataCharacter and pattern recognitionPulse conversionComputer visionImaging data

In various exemplary embodiments, systems include a segmentor to segment text binary image data to a first plane. A subtractor subtracts text binary image from binary image data to generate a non-text binary image data in a second plane. A converter converts non-text binary image data in the second plane into non-text gray scale image data in the second plane. A first compressor compresses the text gray scale image data in the first plane. A second compressor compresses the non-text gray scale mage in the second plane.

Owner:XEROX CORP

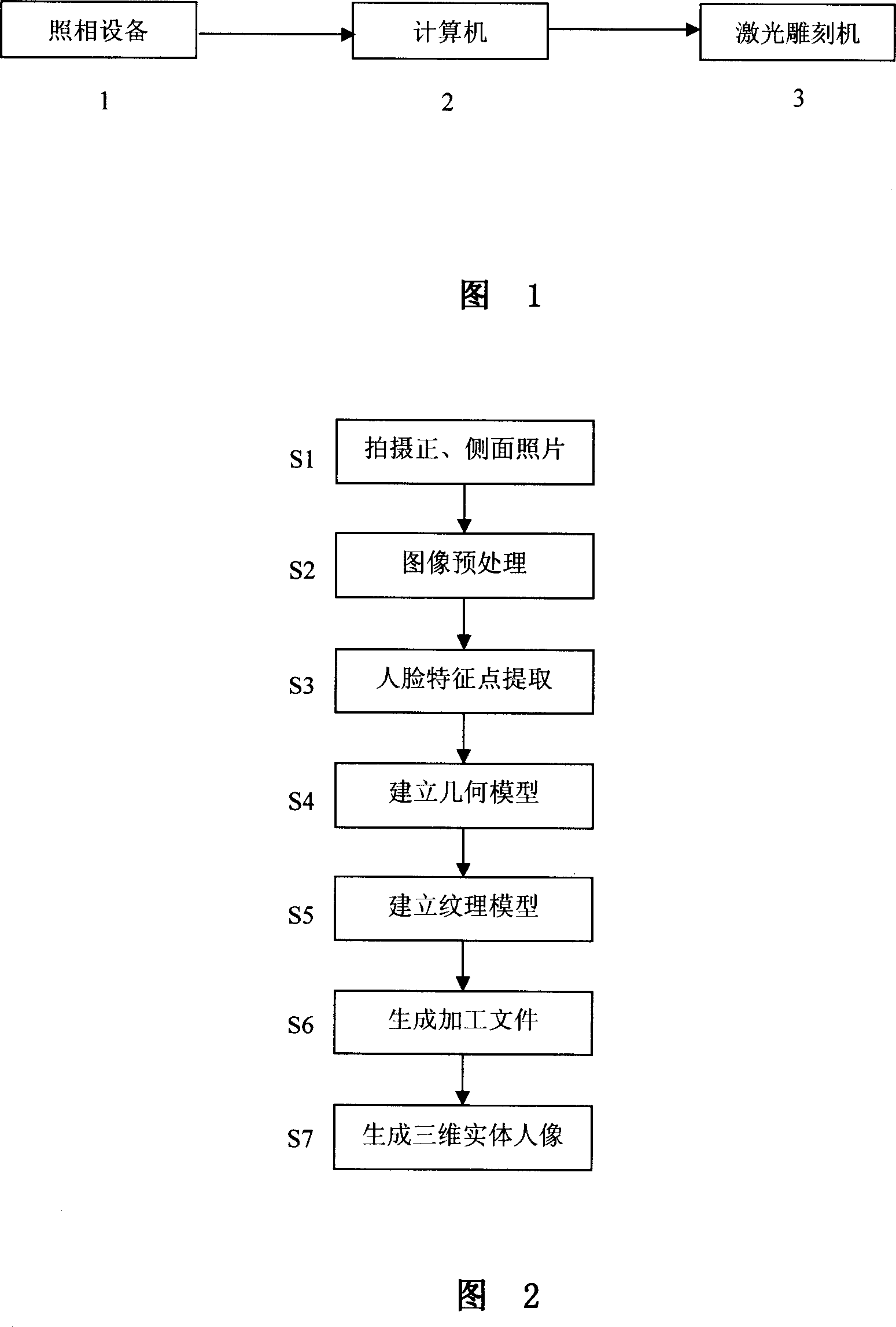

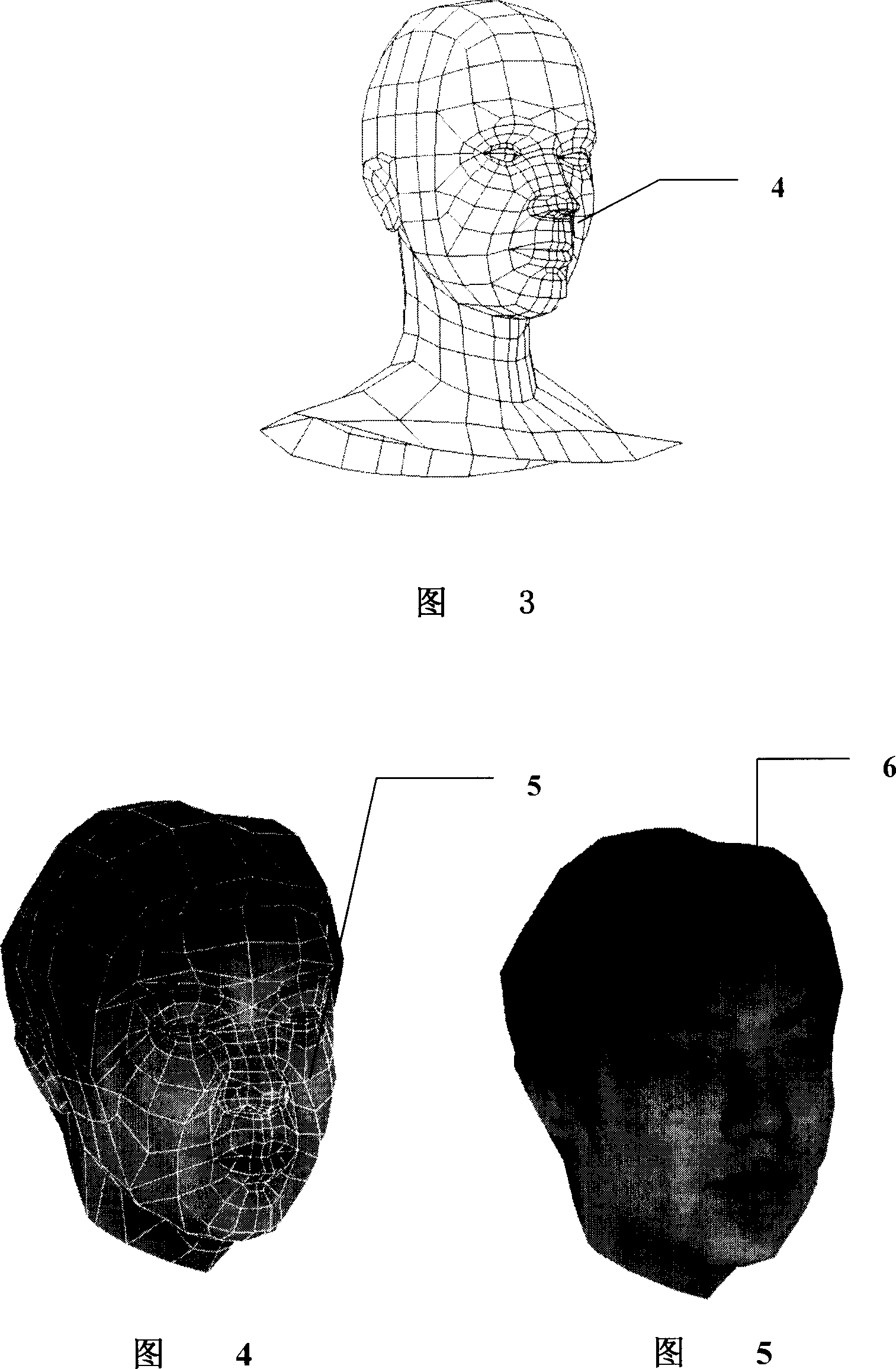

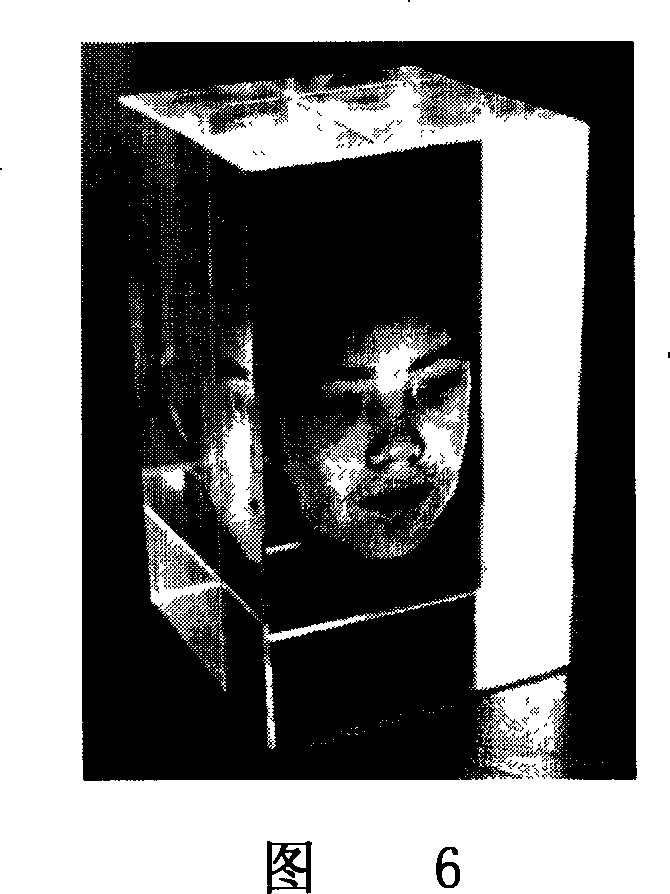

Three-dimensional portrait photograph system and realizing method thereof

InactiveCN101082765AHard textureNew Visual EnjoymentPrintersProjectorsContinuous toneLaser engraving

The invention discloses a three-dimensional portrait shooting system and realizing method, which comprises the following steps: using common camera to shoot positive and lateral photos of portrait; adopting computer visual algorism to acquire three-dimensional geometrical model of head; projecting the photo as texture on the three-dimensional mould according to the projecting relationship of photo and geometrical model; obtaining the three-dimensional portrait model with photo-grade true sense; using spatial semi-tone method to modulate the space of texture grey image continuously; printing binary image approaching three-dimensional image on the visual observing effect in the artificial crystal through laser carving machine; forming the three-dimensional entity head portrait with true sense.

Owner:高宏 +1

Multi-character characteristic fused license plate positioning method

InactiveCN102375982AImprove versatilityImprove real-time performanceCharacter and pattern recognitionColor imagePattern recognition

The invention discloses a multi-character characteristic fused license plate positioning method. The method comprises the following steps of: (1) performing color image graying processing on an original vehicle image, storing as a gray image, and then performing binarization processing on the gray image to obtain a binary image of the vehicle image; (2) extracting a license plate candidate region; (3) removing the candidate region which does not meet a license plate region condition through the color characteristic and texture characteristic of the license plate candidate region to obtain a license plate region; and (4) accurately positioning a license plate, and obtaining upper, lower, left and right boundaries of a character region in the license plate by using the gray skip characteristic of characters of the license plate region. In the method, the character characteristic of the license plate region is fully utilized, the defect that the conventional license plate positioning method more depends on the shape characteristic and edge characteristic of a license plate frame is overcome, extremely high positioning accuracy is also guaranteed under the condition of a blurry license plate frame, and a division result more meets an observation result of human eyes. The method is intuitive, simple and fast and has better instantaneity.

Owner:HUAZHONG UNIV OF SCI & TECH

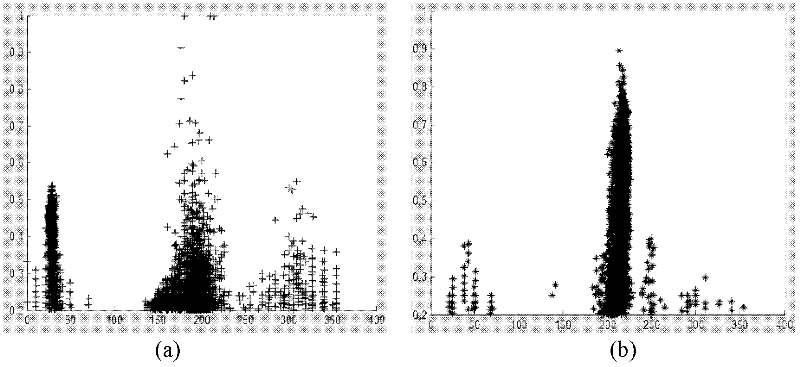

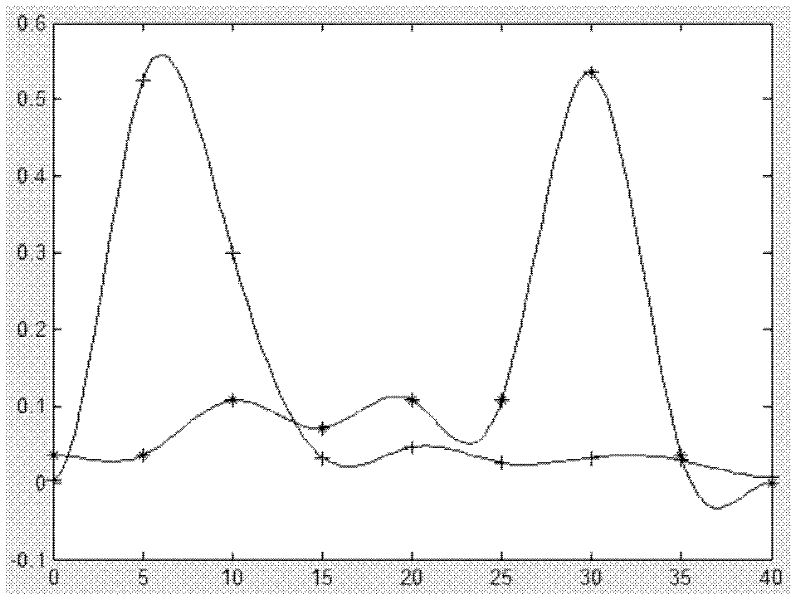

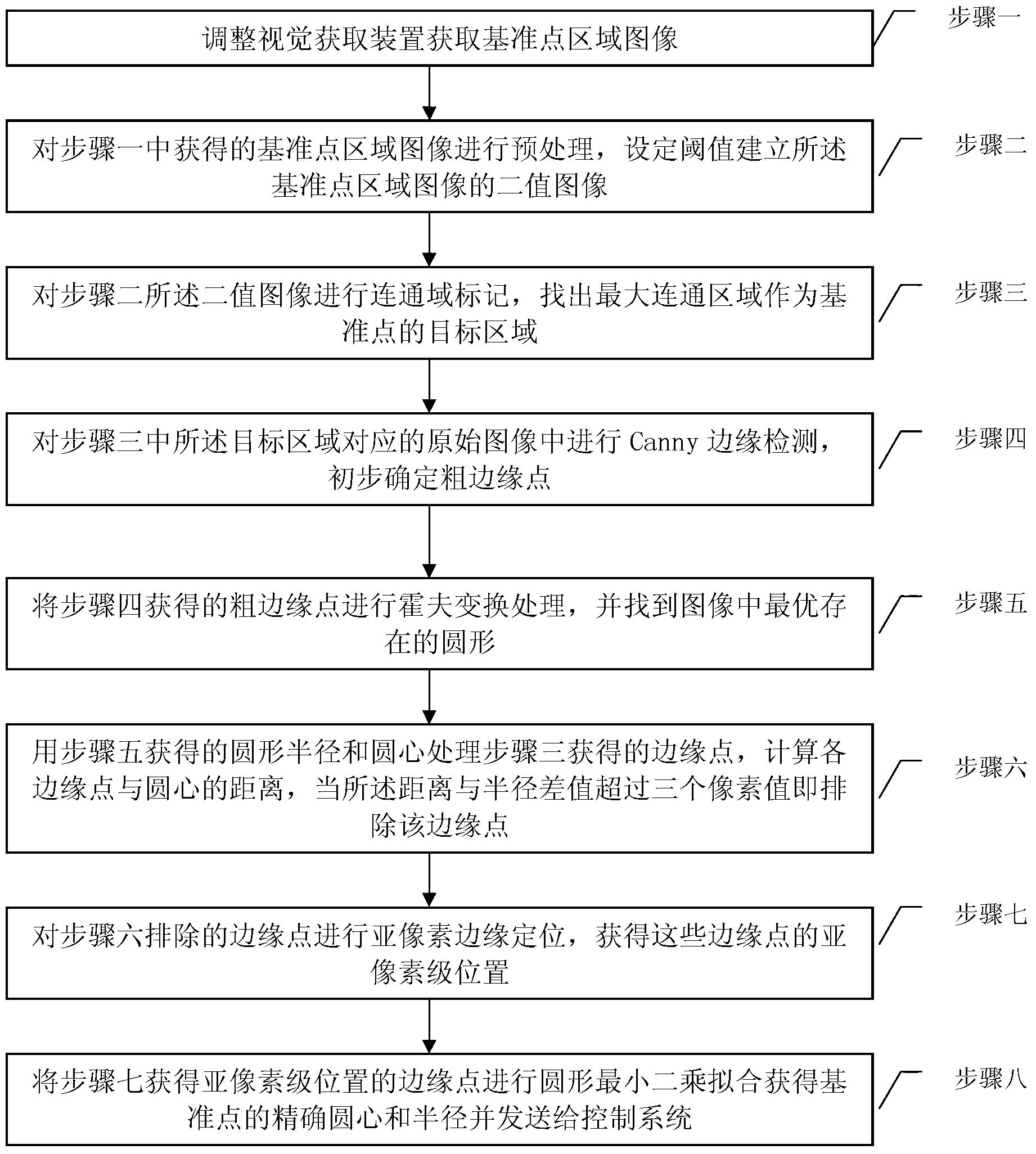

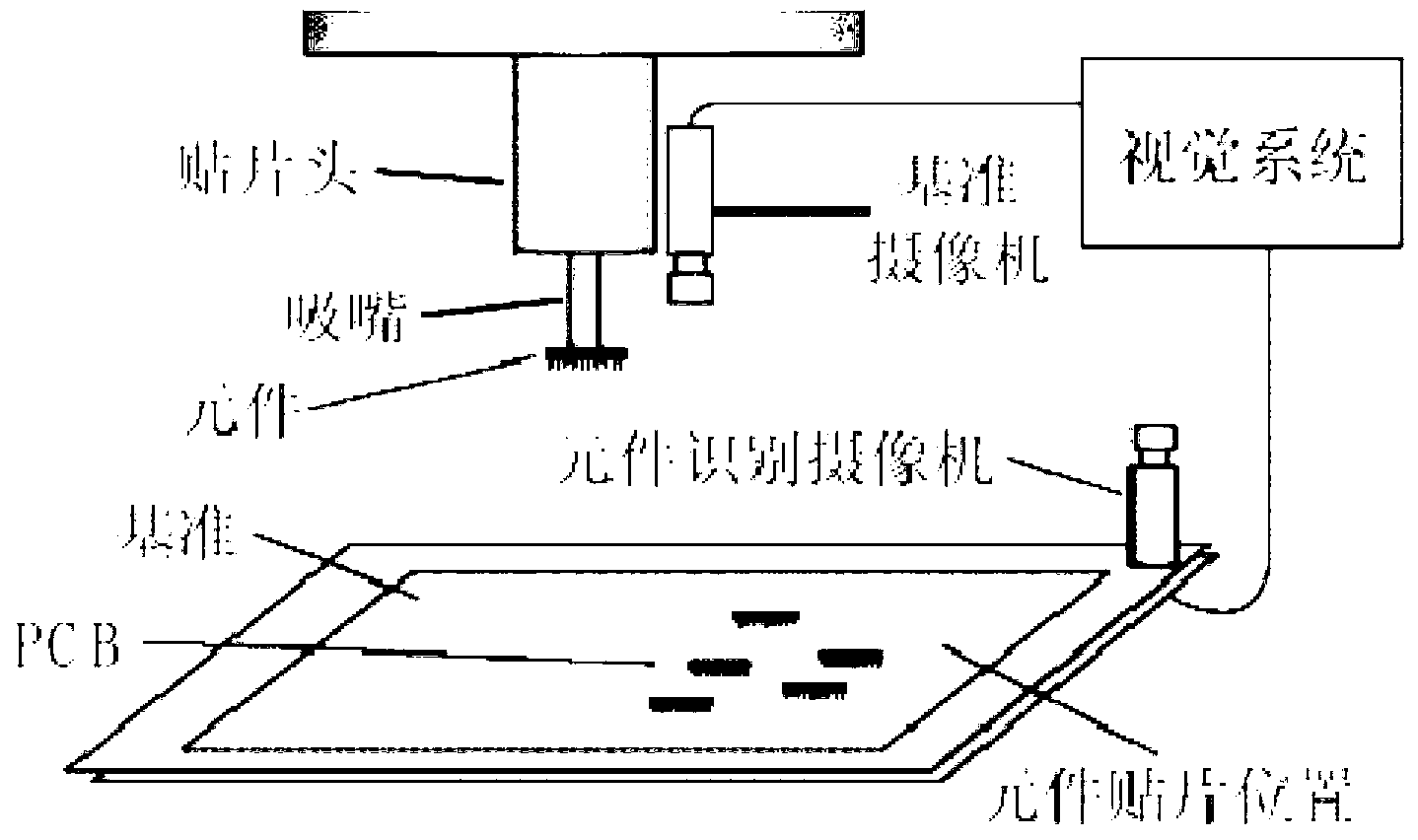

Datum point positioning method based on machine vision

InactiveCN103235939ALow hardware system requirementsLow Optical Equipment RequirementsImage analysisCharacter and pattern recognitionHough transformImaging processing

The invention relates to a datum point positioning method based on machine vision, which belongs to the field of image processing and aims to solve the problems of poor datum point positioning accuracy and high cost of surface mounting equipment. The method comprises the following steps that a vision obtaining device is adjusted to obtain a datum point regional image; the image is preprocessed, and a threshold is set to establish a binary image; connected region labeling is performed on the binary image, so as to find out the largest connected region as a target region of a datum point; Canny edge detection is performed on an original image, so as to preliminarily determine coarse edge points; Hough transformation processing is performed on the coarse edge points, and an optimal existing circle in the image is found out; the distance between each edge point and the center of the circle is calculated; the position of a sub-pixel level of the edge point is obtained; and circular least-square fit is performed on the edge point in the position of the sub-pixel level, and then an accurate center and radius of the datum point are obtained and sent to a control system. The datum point positioning method can be widely applied to accurate positioning of the datum point.

Owner:HARBIN INST OF TECH

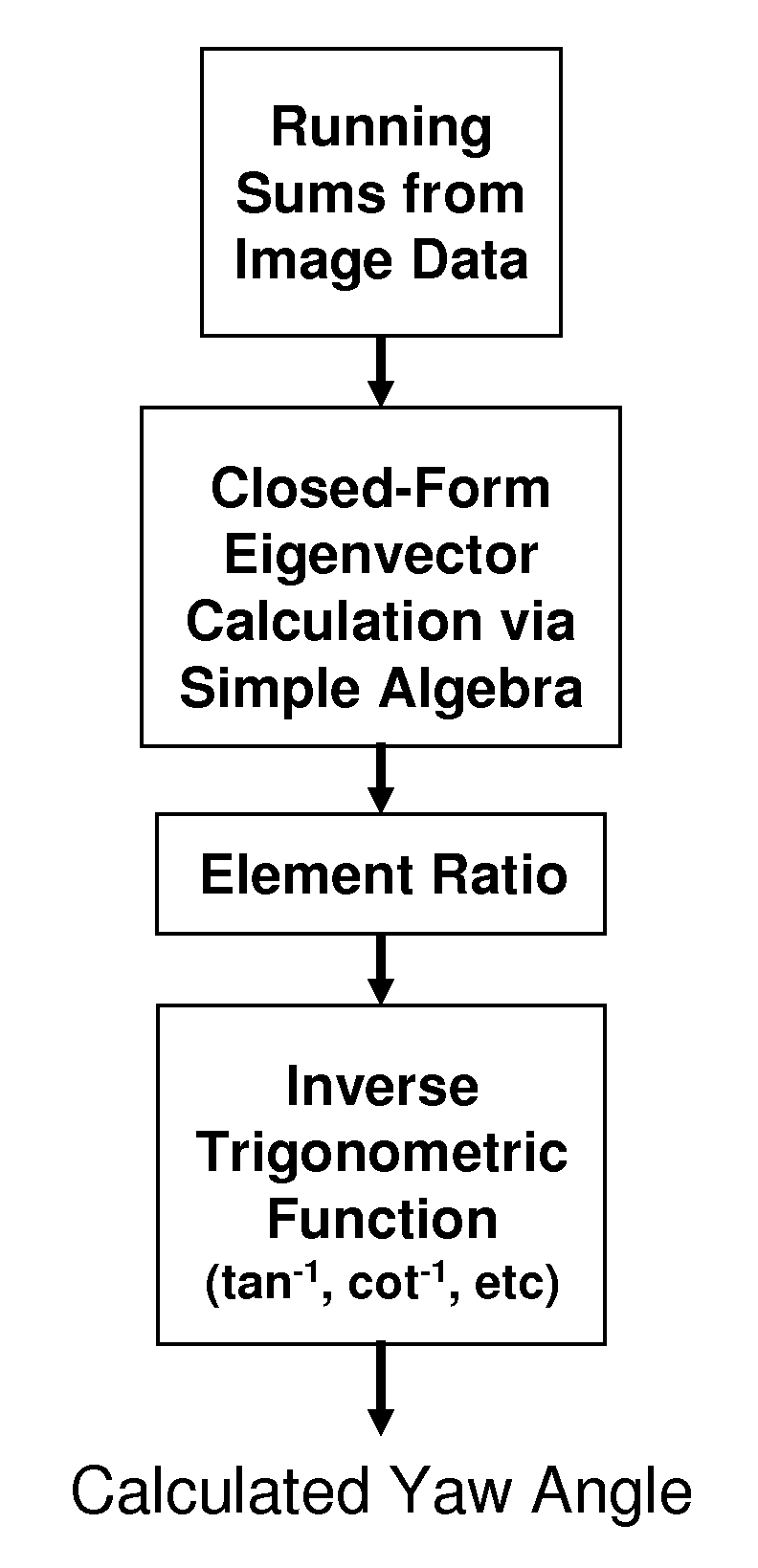

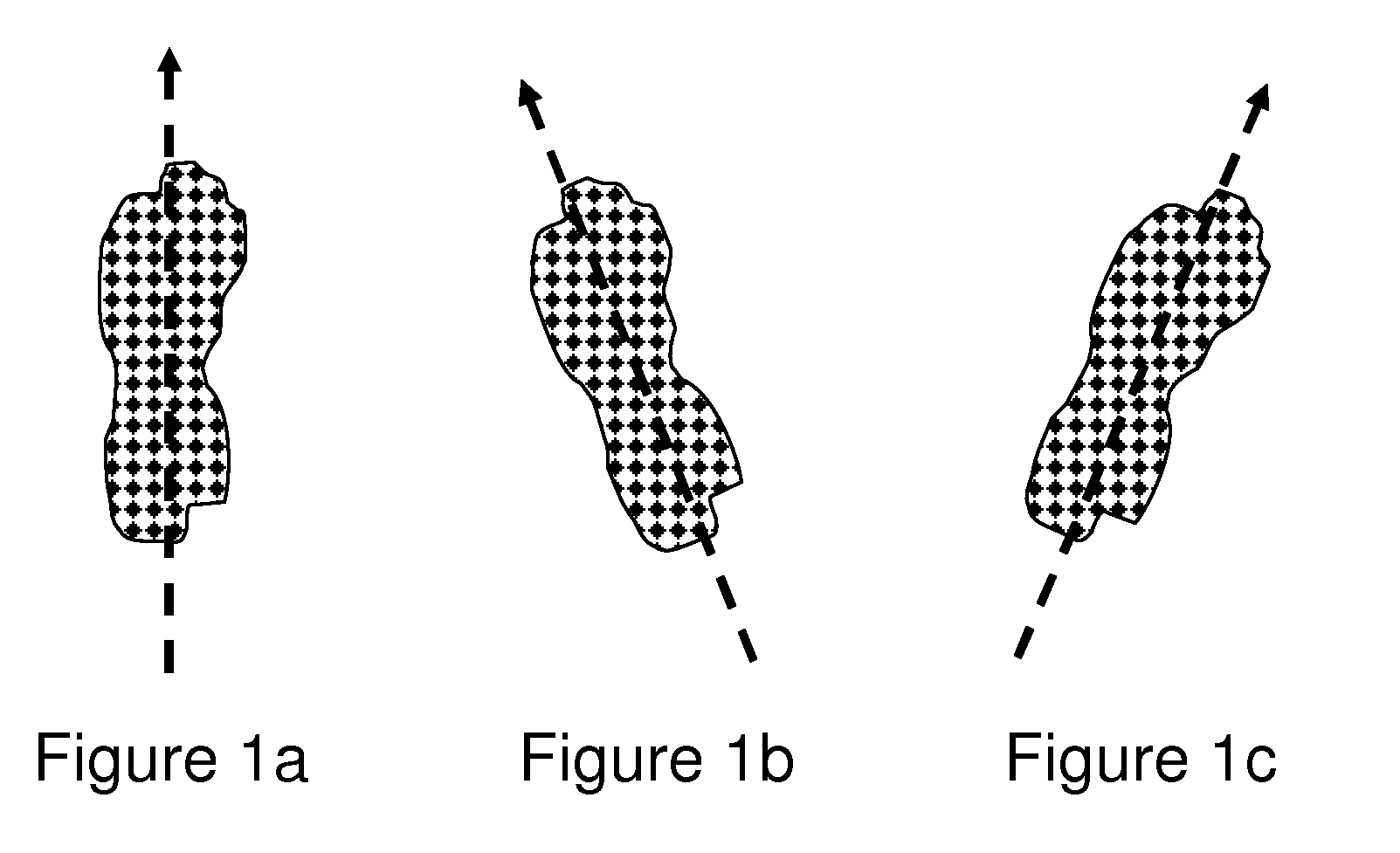

High-performance closed-form single-scan calculation of oblong-shape rotation angles from binary images of arbitrary size using running sums

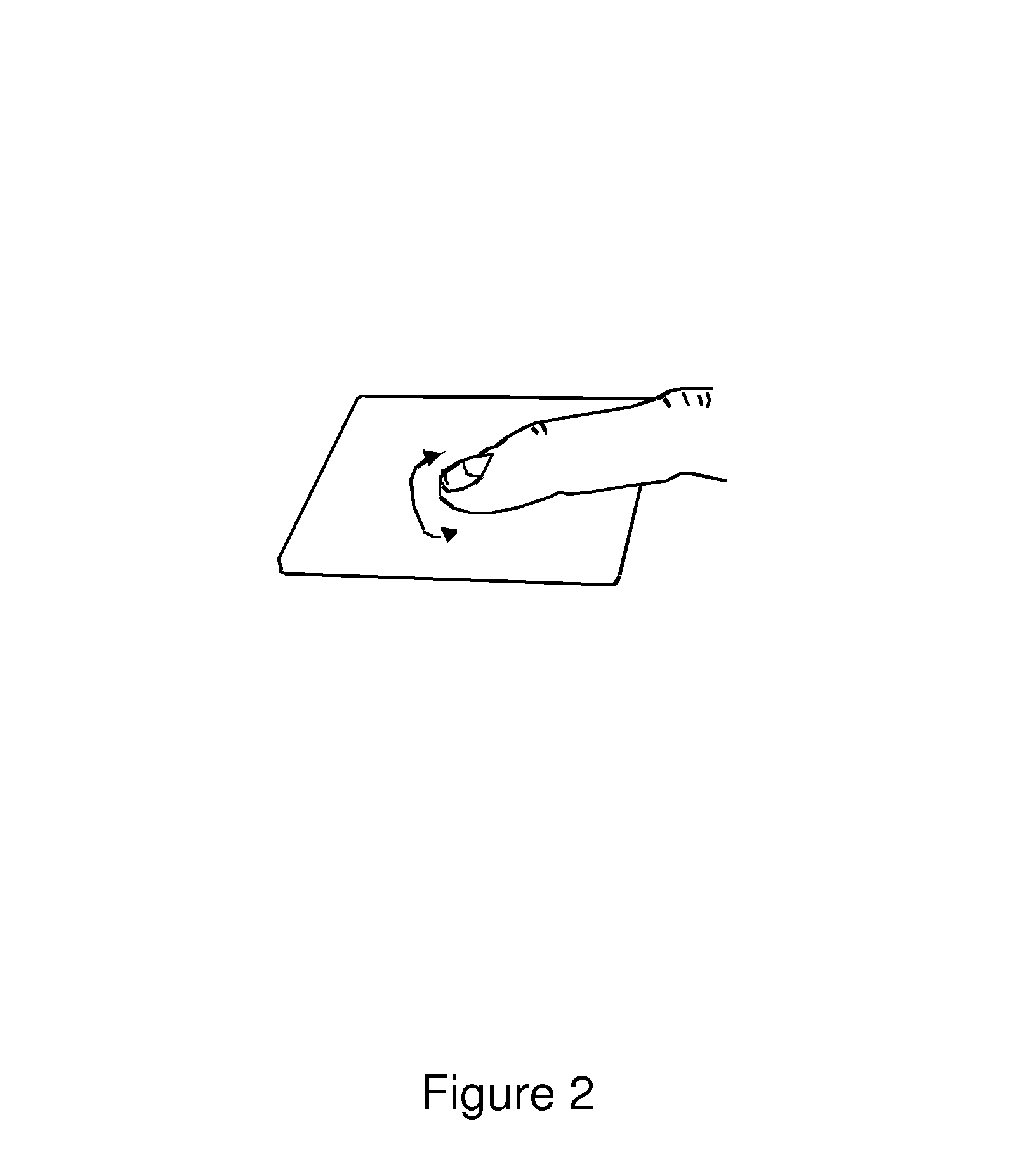

A method for performing a high-performance closed-form single-scan calculation of oblong-shape rotation angles from binary images of arbitrary size on a processor using running sums is disclosed. Running sums are calculated and stored throughout each scan, and the results are obtained in closed form by simple post-scan computation. An algorithmic embodiment may execute on one or more hardware processors with limited or constrained computation power, available instruction cycles, available memory, etc. Exemplary hardware processors are found in one or more CPUs of a desktop, laptop, tablet, or handheld computing device, and may be an embedded processor or a signal processor chip. The resulting method may be used for touch or optical user interfaces, real-time image recognition, real-time machine vision, and other purposes.

Owner:NRI R&D PATENT LICENSING LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com