Patents

Literature

665results about How to "Hard texture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

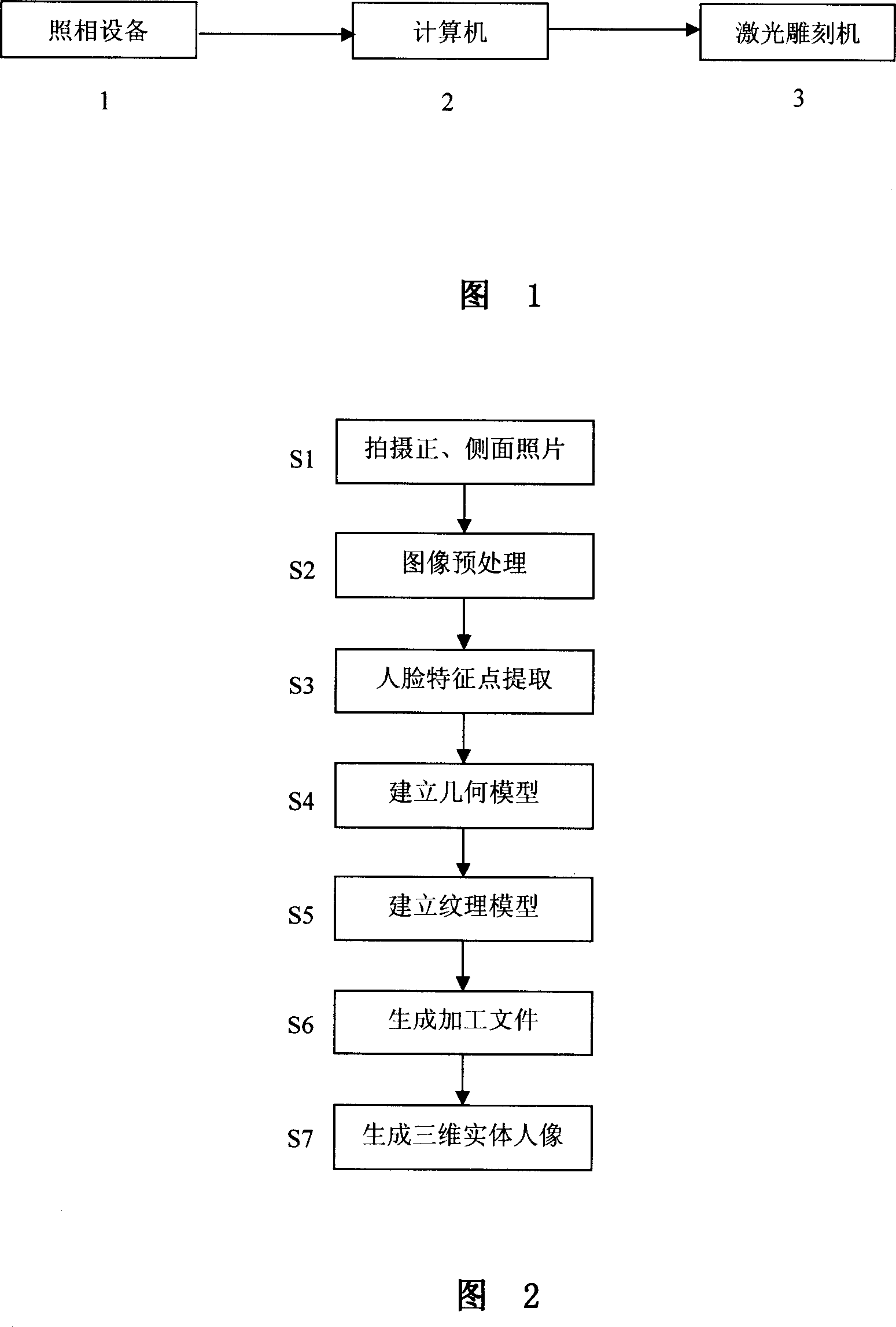

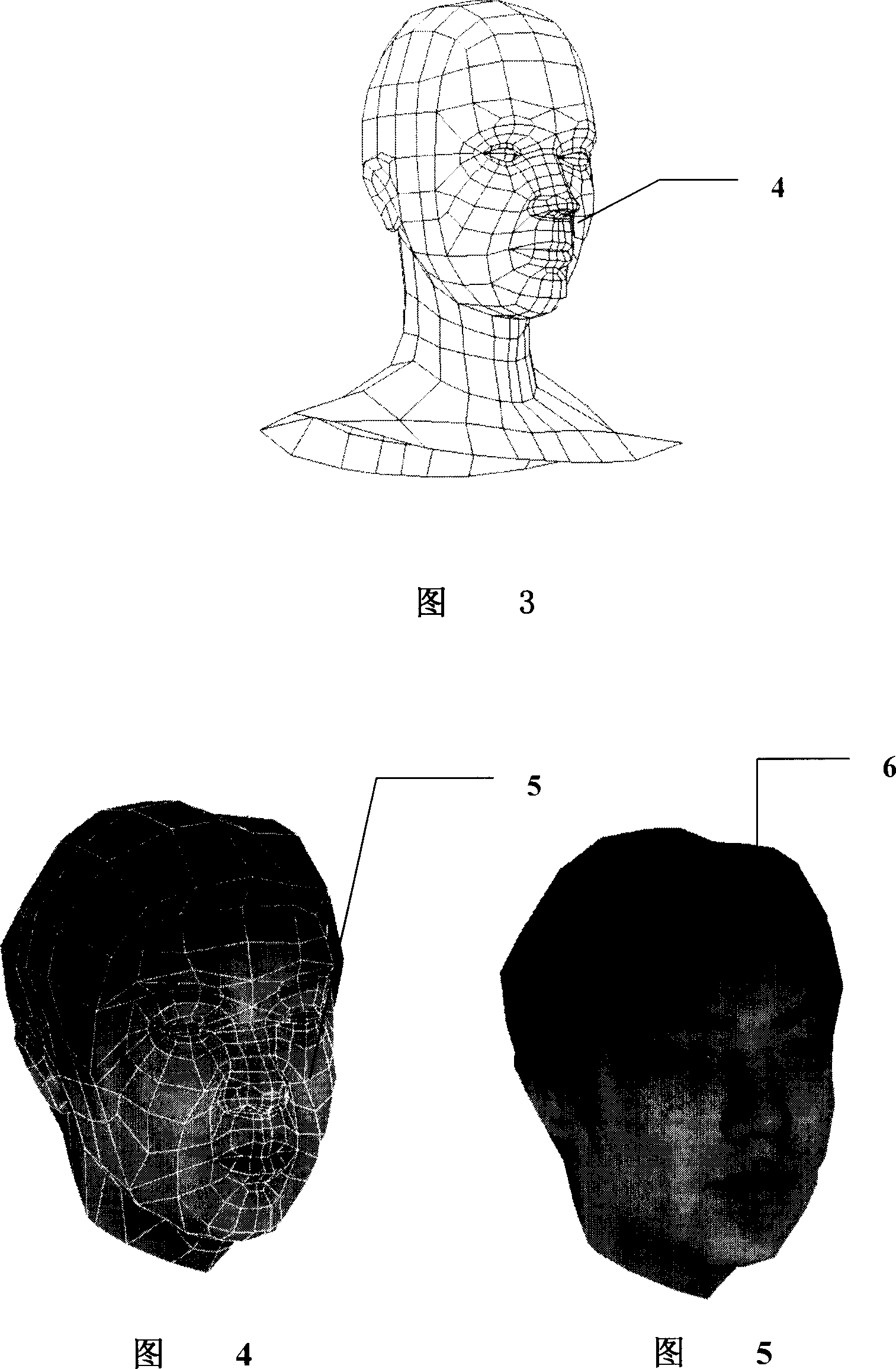

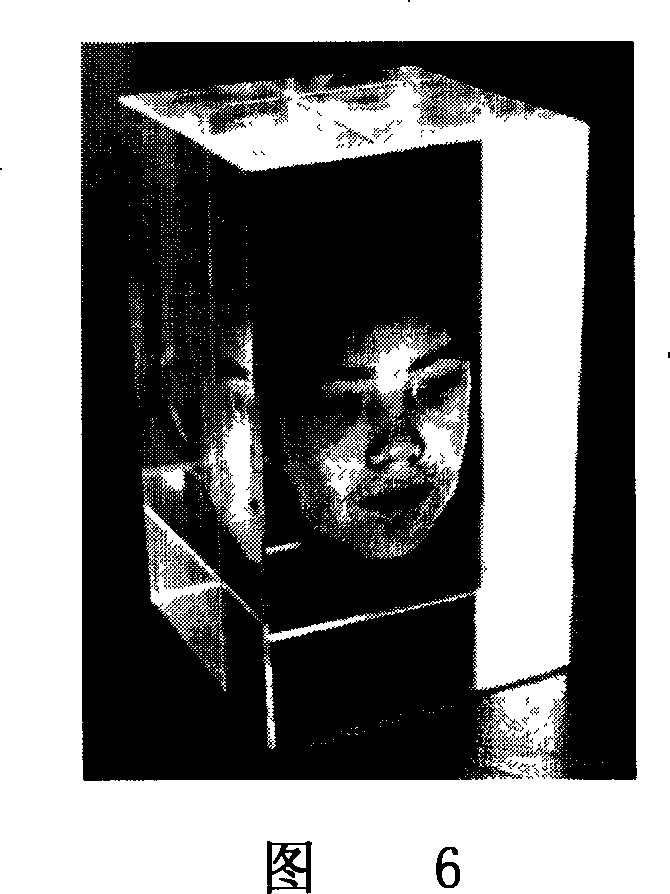

Three-dimensional portrait photograph system and realizing method thereof

InactiveCN101082765AHard textureNew Visual EnjoymentPrintersProjectorsContinuous toneLaser engraving

The invention discloses a three-dimensional portrait shooting system and realizing method, which comprises the following steps: using common camera to shoot positive and lateral photos of portrait; adopting computer visual algorism to acquire three-dimensional geometrical model of head; projecting the photo as texture on the three-dimensional mould according to the projecting relationship of photo and geometrical model; obtaining the three-dimensional portrait model with photo-grade true sense; using spatial semi-tone method to modulate the space of texture grey image continuously; printing binary image approaching three-dimensional image on the visual observing effect in the artificial crystal through laser carving machine; forming the three-dimensional entity head portrait with true sense.

Owner:高宏 +1

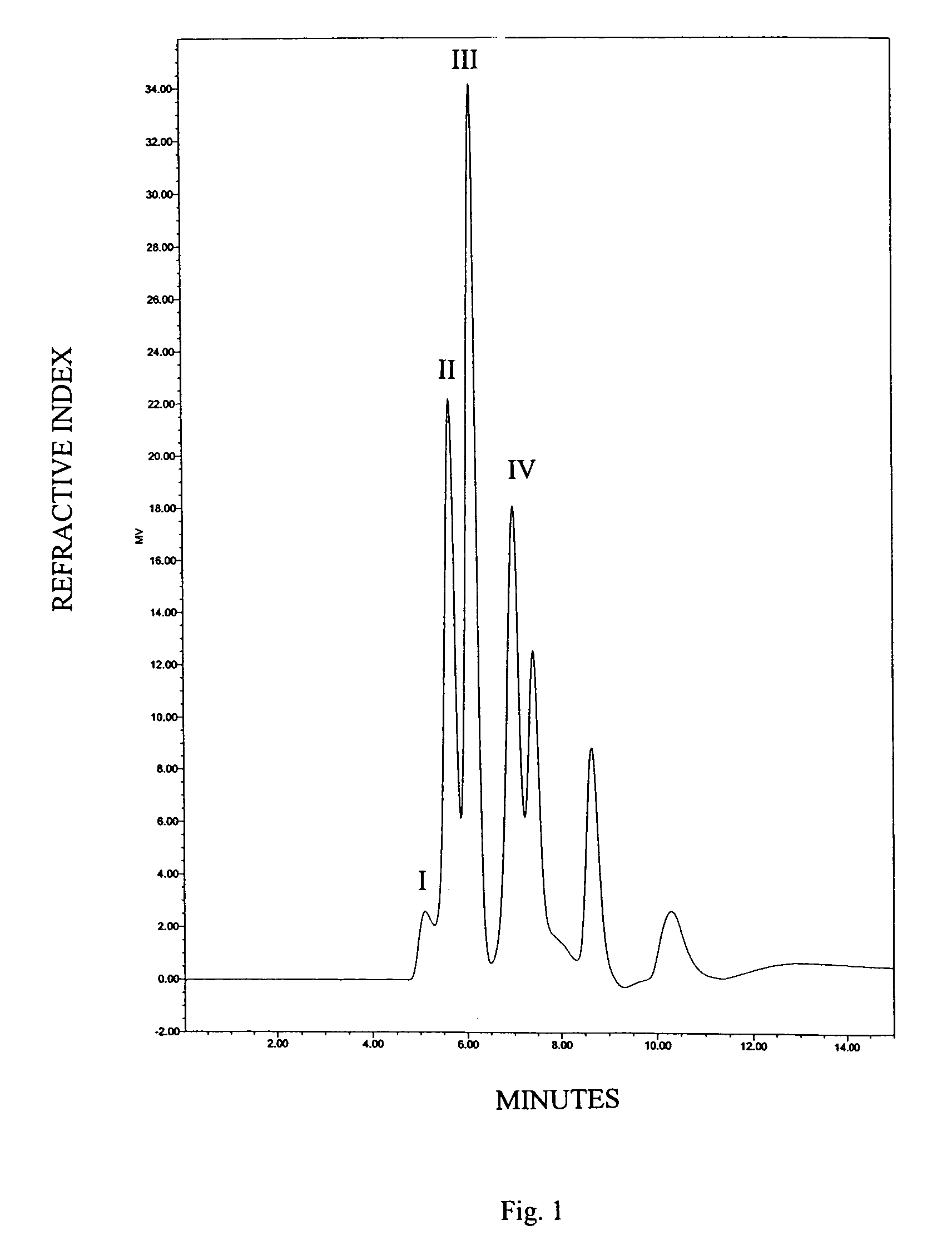

High pH antiperspirant compositions of enhanced efficacy

InactiveUS7087220B2Good curative effectIncrease valueCosmetic preparationsToilet preparationsIrritationStrontium

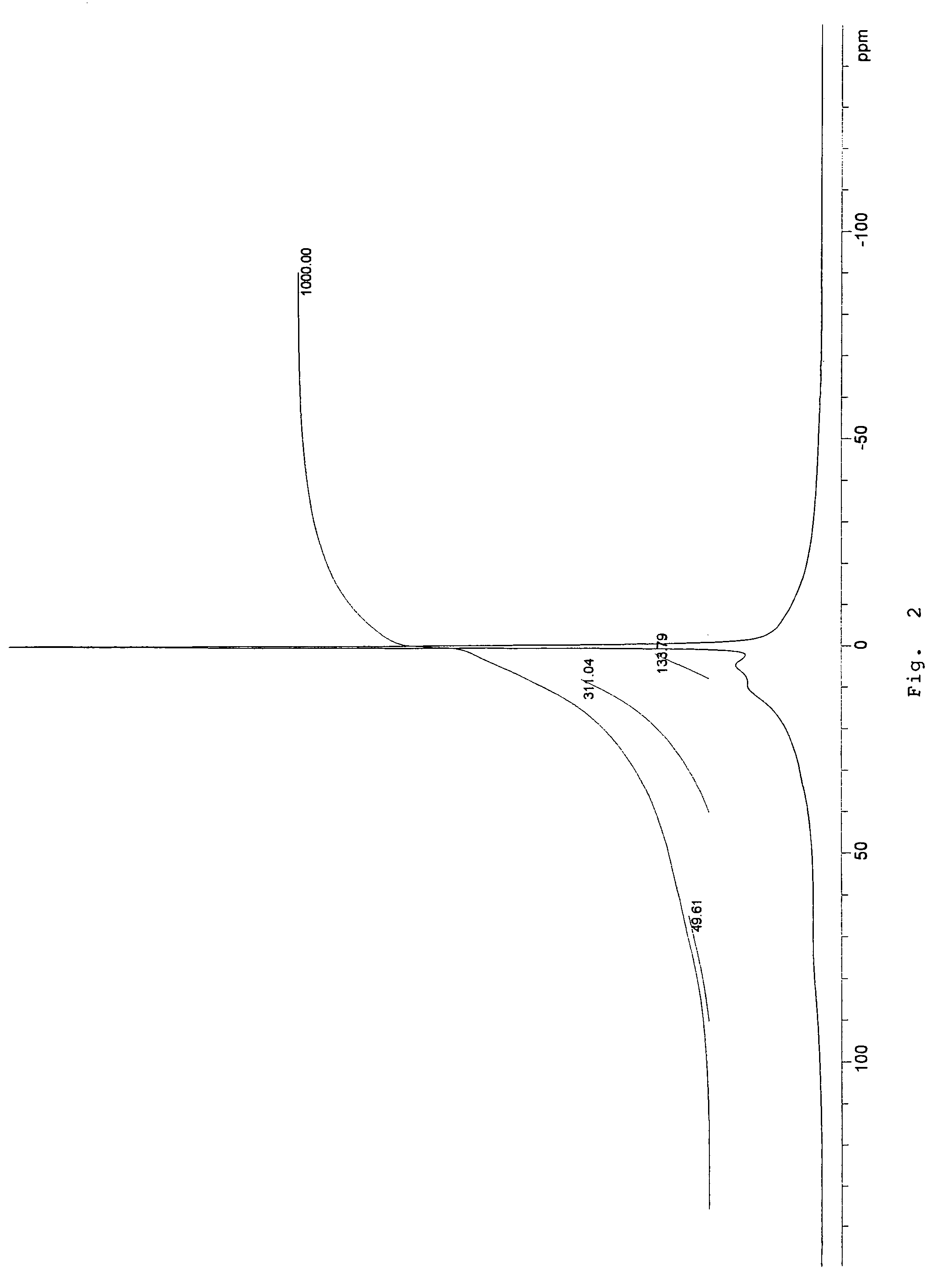

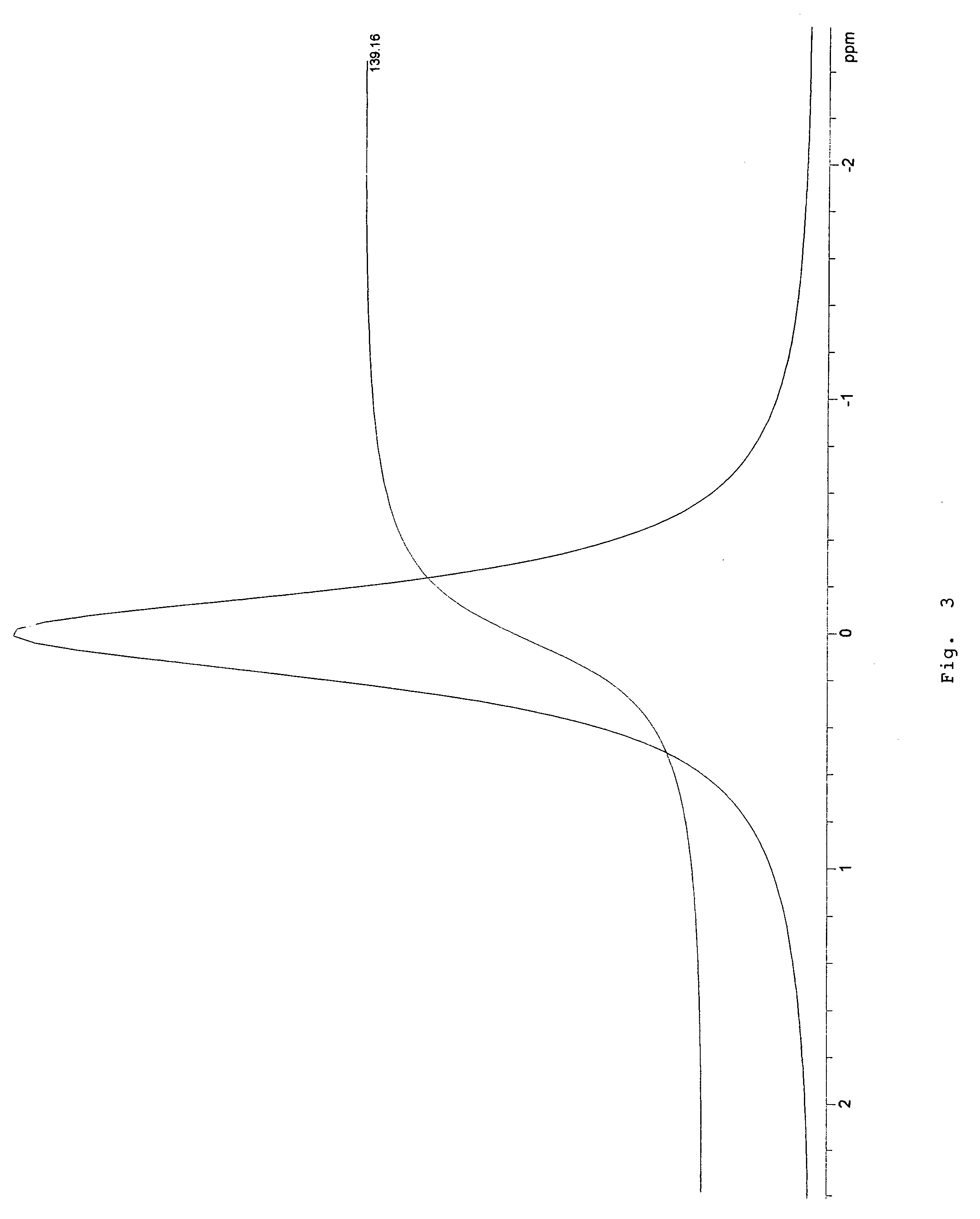

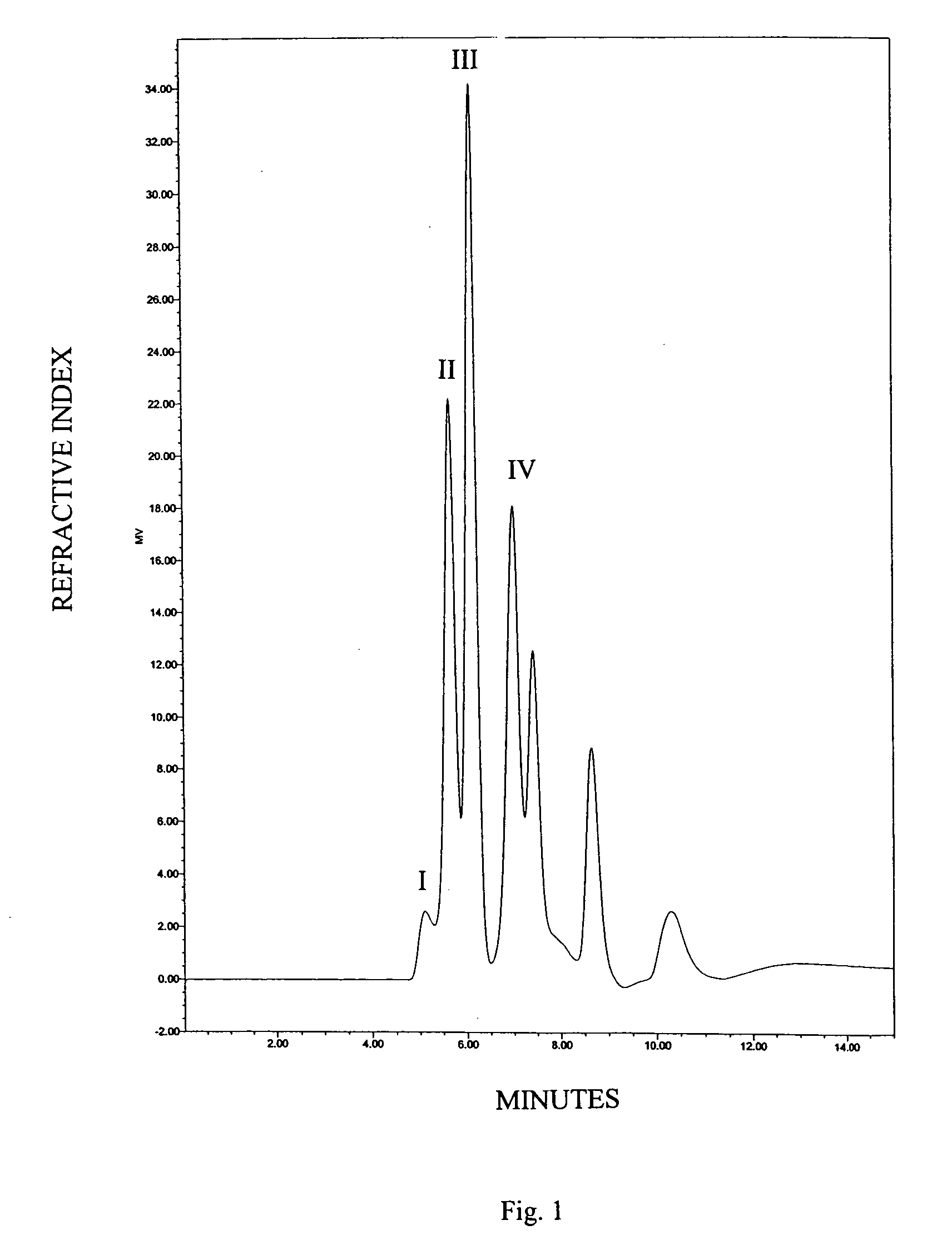

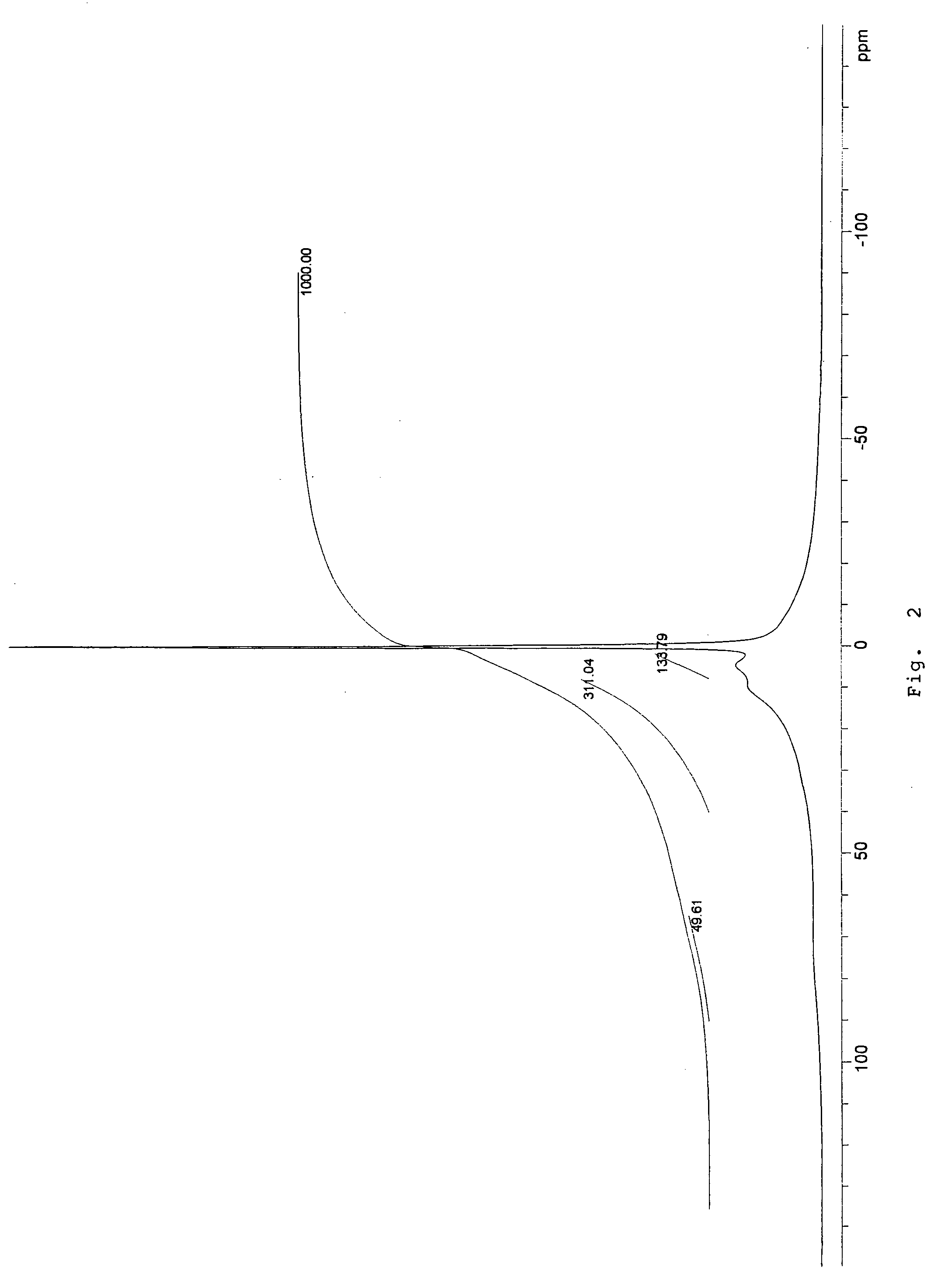

Aluminum and aluminum-zirconium antiperspirant compositions of enhanced efficacy and a pH value of at least 3.5 are provided that are made by reaction with insoluble, strongly alkaline strontium or calcium salts. The aluminum and aluminum-zirconium strontium or calcium compositions show high pH values with characteristic HPLC Band III to Band II ratios of at least 0.5. The basic aluminum halohydrate (or nitrate) solutions typically have aluminum to anion ratio of less that 1.9. The solution compositions are stable with respect to both HPLC Band III to Band II ratio and viscosity at concentrations of about 20% to about 40% by weight of anhydrous solid. The solid state compositions form hard sticks with low irritation, at low metal to chloride ratios of about 0.9 to about 1.2.

Owner:SUMMIT RES LAB

Multiple-aperture carbon granule air purification agent and preparation method thereof

ActiveCN101947433AReasonable designImprove adsorption capacityGas treatmentOther chemical processesSorbentFar infrared

The invention relates to a multiple-aperture carbon granule air purification agent and a preparation method thereof, belonging to the technical field of air purification agents. The multiple-aperture carbon granule air purification agent is prepared from carbon powder, attapulgite, sepiolite, zeolite, cationic surfactant, pore-forming material and bamboo vinegar. The multiple-aperture carbon granule air purification agent has reasonable design. After the carbon powder (containing plant charcoal and active carbon), and nanometer mineral matters of attapulgite, sepiolite, zeolite, and the like are treated, the adsorptive capacity of the original plant charcoal is improved by more than 5 times, the adsorptive capacity of the active carbon is improved by more than twice, and the added cationic surfactant and bamboo vinegar increase the effects of sterilization and bacteriostasis. Compared with other adsorbents in the prior art, the air purification agent still has higher adsorption capacity even in higher temperature and lower adsorbate partial pressure, and remains the functions of releasing negative ions and far infrareds of the plant charcoal at the same time, and the prepared granule has rigid characters without dust and does not pollute contactants and a human body.

Owner:ZHEJIANG JIANZHONG BAMBOO IND

High pH antiperspirant compositions of enhanced efficacy

InactiveUS20050265939A1Good curative effectGreat enhanced efficacyCosmetic preparationsToilet preparationsAntiperspirantsIrritation

Aluminum and aluminum-zirconium antiperspirant compositions of enhanced efficacy and a pH value of at least 3.5 are provided that are made by reaction with insoluble, strongly alkaline strontium or calcium salts. The aluminum and aluminum-zirconium strontium or calcium compositions show high pH values with characteristic HPLC Band III to Band II ratios of at least 0.5. The basic aluminum halohydrate (or nitrate) solutions typically have aluminum to anion ratio of less that 1.9. The solution compositions are stable with respect to both HPLC Band III to Band II ratio and viscosity at concentrations of about 20% to about 40% by weight of anhydrous solid. The solid state compositions form hard sticks with low irritation, at low metal to chloride ratios of about 0.9 to about 1.2.

Owner:SUMMIT RES LAB

Soy protein gel and method of producing the same

ActiveUS20100311950A1Novel propertySoft textureDepsipeptidesPeptide preparation methodsEnzymeIngested food

It is intended to provide a soy protein gel which has such gel properties that have never been obtained hitherto and is excellent in taste and color tone, and a soy protein food taking advantage of the gel properties. It has been found out that gel properties can be modified at an extremely elevated level and thus the desired soy protein gel can be obtained by preparing a gel by using a soy protein material in which the lipophilic protein content is reduced and conducting the gelation with the utilization of not only heat but also the action of a protein crosslinking enzyme.

Owner:FUJI OIL CO LTD

Polymer lithium ion battery core outer package forming material

InactiveCN102431239AImprove shielding effectNot easy to peel offSynthetic resin layered productsMetal layered productsHigh resistancePolyvinyl alcohol

The invention provides a polymer lithium ion battery core outer package forming material, and aims at providing a battery core outer package forming material with the advantages that the blocking performance is very high, the cold punching forming performance is good, and puncture resistance, electrolyte resistance stability and organic solvent and high-volatile substance resistance can be realized. An outer resistance layer lamination layer body is formed by at least one layer of heat resistance resin film: any one material from polyethylene glycol terephthalate (PET), biaxially oriented polyamide (BOPA) and polyethylene naphthalate (PEN) or coexistence of two materials from PET, BOPA and PEN through co-extrusion compounding, aluminum foils in a resistance permeation layer lamination body at least comprise 0.9 weight percent to 1.5 weight percent of Fe, a high-resistance layer lamination body comprises a base layer, a function layer and a hot sealing layer, the base layer is a co-polymer film formed by paired compounding or the combination of at least two kinds of film substrates in polystyrene (PP), chlorinated polypropylene (CPP), polyurethane (PE), PET, polyamide (PA) or metaxylylene diamine (MPE) elastic body polymer blends, polyvinyl dichloride (PVDC), ethylene vinyl silane (EVOH), PEN and transpeptidase (GT), and a high-resistance water-resistance modified polyvinyl acetate (PVA) coating film is respectively coated on the co-polymer film substrate. The polymer lithium ion battery core outer package forming material revolutionarily solves the electrolyte resistance stability problem.

Owner:刘继福

Confectionery product comprising agglomerated oil powder

InactiveUS20150157040A1Pleasant consumption experienceEasy to industrializeMilk preparationConfectioneryCross-linkAdditive ingredient

The invention relates to the use of oil powder and milk powders for the preparation of solid confectionery products wherein the oil powder is granulated together with the milk powder and other powder ingredients and then pressure agglomerated; to solid confectionery products comprising pressure agglomerated powder ingredients including an oil powder and a milk powder, wherein the oil powder comprises an inner core comprising an oil and an outer shell comprising a cross-linked emulsifier and to processes for the preparation thereof.

Owner:NESTEC SA

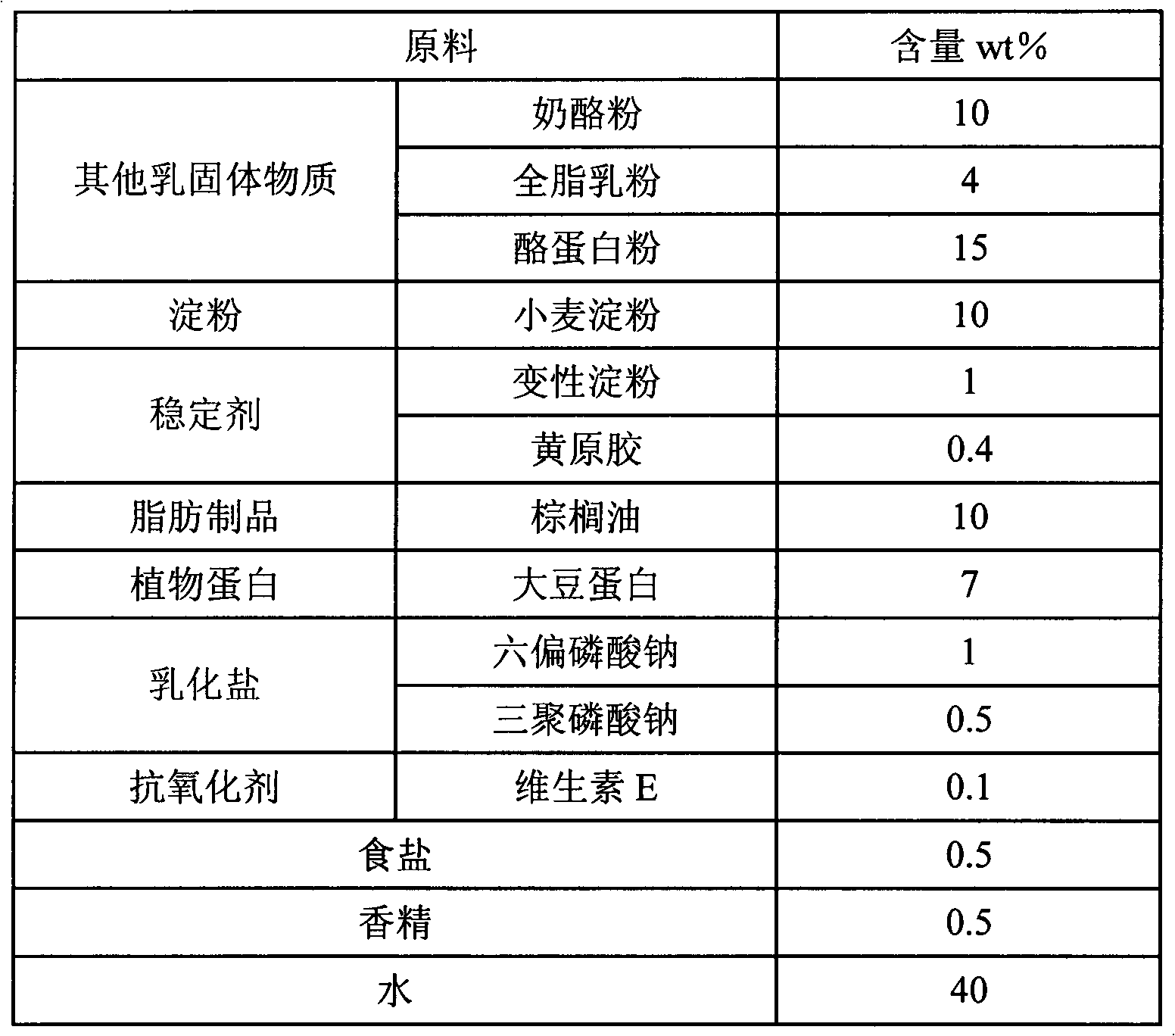

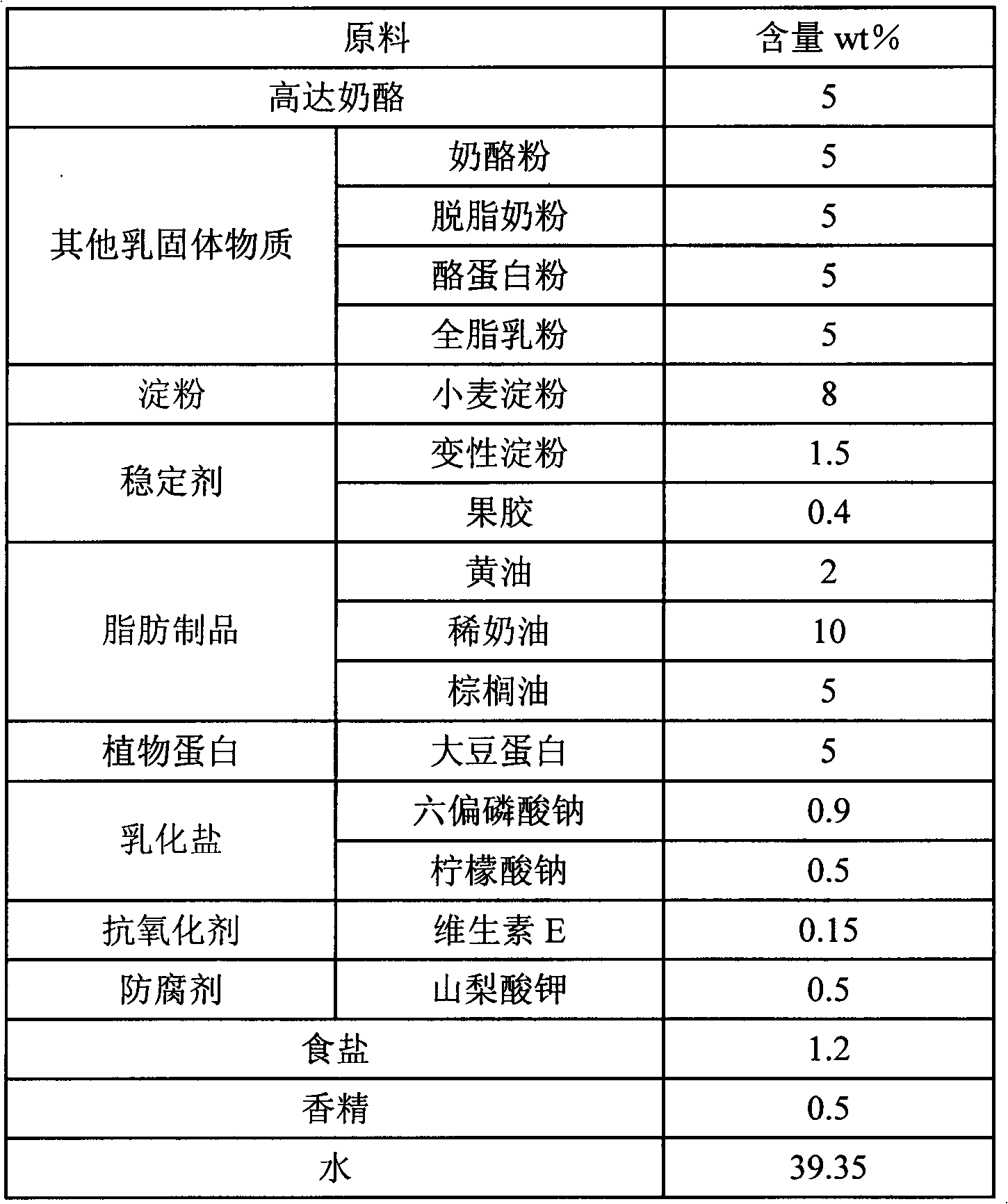

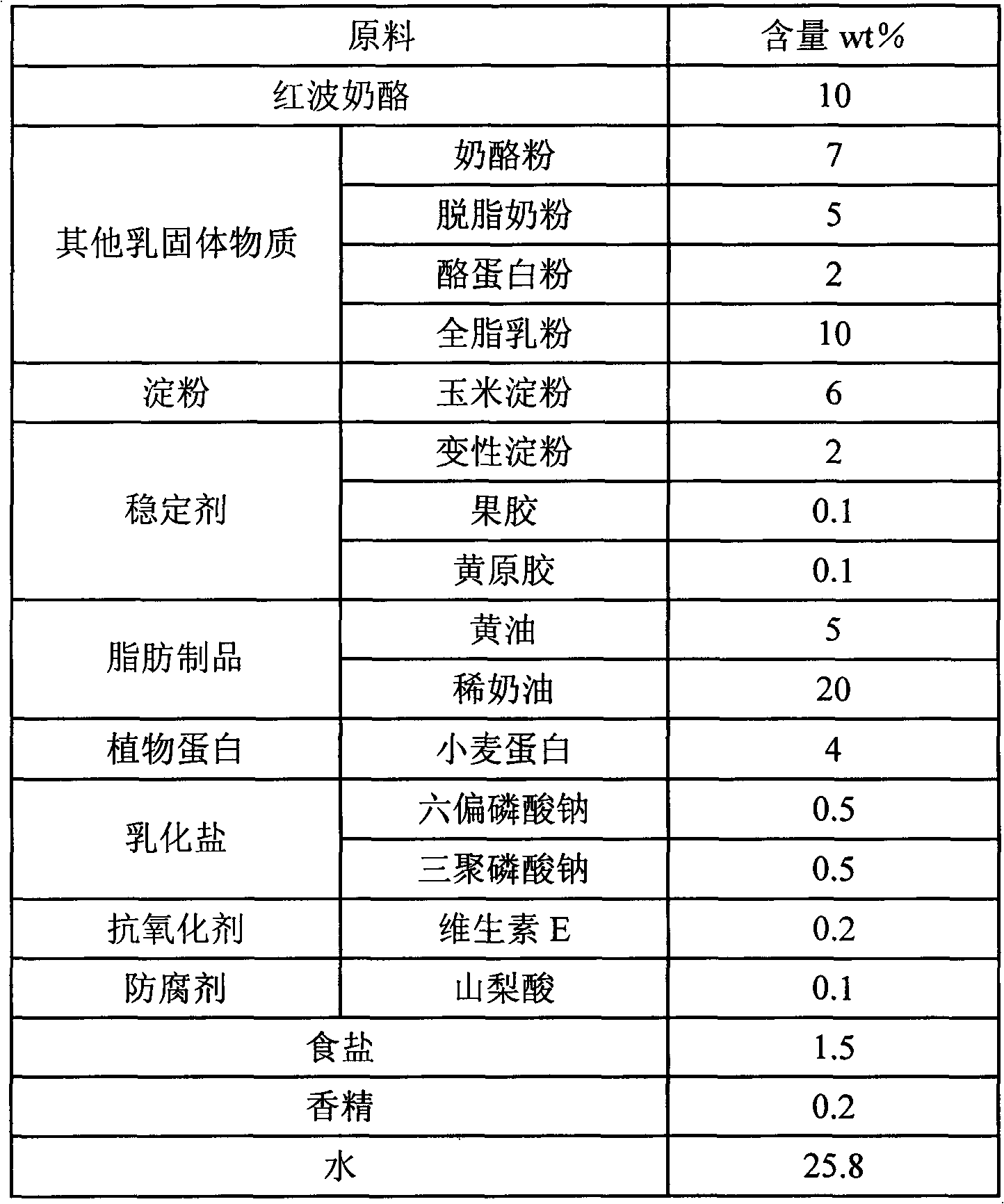

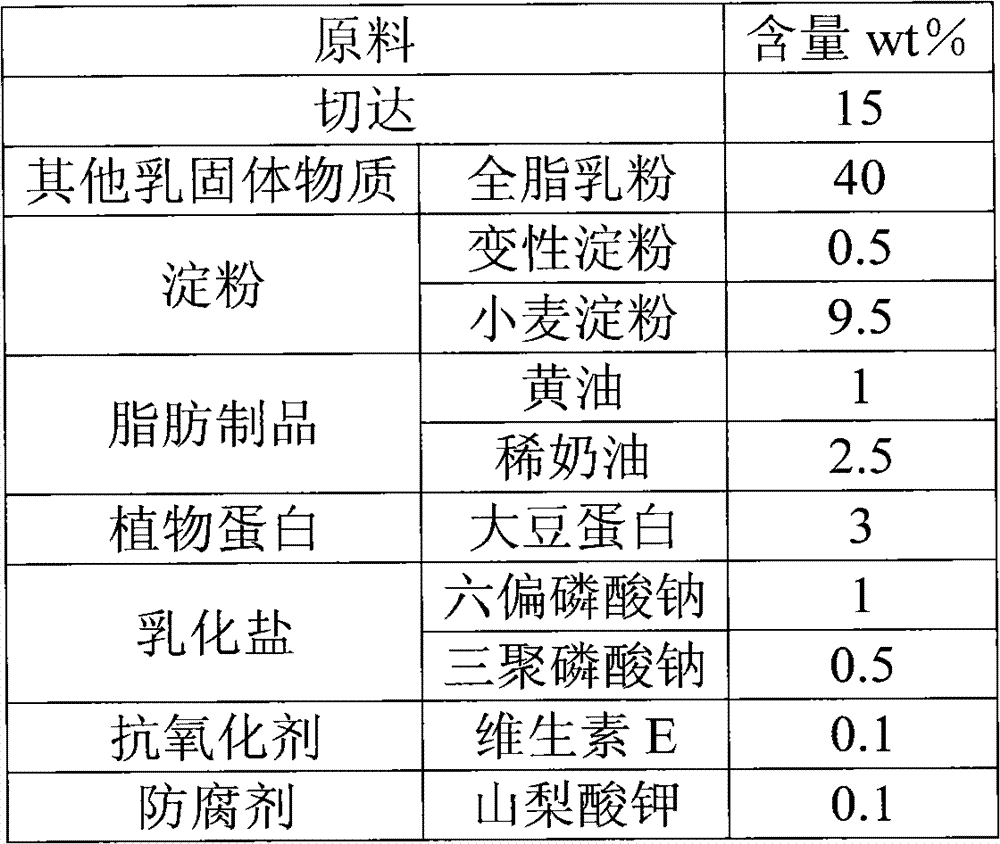

Normal-temperature processed cheese and preparation method thereof

The invention discloses normal-temperature processed cheese and a preparation method thereof. The normal-temperature processed cheese comprises the following components in percentage by weight: 0 to 15 percent of natural cheese, 10 to 25 percent of fat product, 10 to 33 percent of other milk solid substance except the natural cheese and the fat product, 4 to 12 percent of starch, 0.6 to 2.7 percent of stabilizer, 3 to 7 percent of plant protein, 0.1 to 0.2 percent of antioxidant, 1 to 1.8 percent of emulsifying salt and 25.8 to 40 percent of water. The normal-temperature processed cheese can keep the original characteristic flavor and functional properties in normal-temperature shelf life.

Owner:上海光明奶酪黄油有限公司

Preparation method for asphalt concrete with conduction function

InactiveCN101215124ALow costAlleviate problems such as insufficient aggregateSolid waste managementForeign matterMaterials preparation

The invention relates to a process for preparing asphaltic concrete with conducting function, which is characterized in that the process includes the procedures of 1), preliminary treatment of aggregates, which means washing away the foreign matters of the steel slag with water. 2), raw materials preparation, which means that the percentage by weight of each component is that rough aggregates is 55%-80%, fine aggregates is 13%-30%, mineral filler is 7%-15%, the rough aggregates, fine aggregates and mineral filler are selected to reserve as aggregates, consumption of asphalt cement is 6%-8% of the weight of the aggregates, consumption of fabric stabilizer is 0.1%-0.5% of the gross weight of the aggregates and the asphalt cement, consumption of conducting material is 10-30% of the weight of the asphalt cement, and gradation design of SMA mixture is employed. 3), mixture blending, which means charging fractionally and blending multitime, the temperature is kept not lower 150 DEG C when molding. The preparing process has simple technique and low cost. The prepared asphaltic concrete has good conducting function and pavement using property.

Owner:WUHAN UNIV OF TECH

Meat alternative

InactiveUS20050112271A1Texture can be alteredHigh in proteinProteins working-up by texturisingVegetable proteins working-upNutritive valuesSlurry

A meat alternative, having from about 65% to about 85% by weight of a hydrated plant protein source and from about 15% to about 35% by weight of a meat protein source, is formed by mechanically or chemically extracting collagen into a slurry of the meat and water, the collagen supporting the plant protein in the final product to create a pleasing texture and flavor. Dietary fiber is optionally added to retain moisture and increase nutritional value of the meat alternative. Additional gelling agents may be added to increase support for the plant protein, enhancing the product's texture. Optionally, additional plant or animal based flavorings are added to enhance the flavor and coloring agents may be added to enhance the visual aspects of the product. Nutraceuticals may be added to enhance the nutritional value.

Owner:PICKARSKI RON

Soy protein gel and method of producing the same

ActiveUS8304522B2Soft textureSmooth slide down the throatPeptide preparation methodsDepsipeptidesEnzymeColor tone

It is intended to provide a soy protein gel which has such gel properties that have never been obtained hitherto and is excellent in taste and color tone, and a soy protein food taking advantage of the gel properties. It has been found out that gel properties can be modified at an extremely elevated level and thus the desired soy protein gel can be obtained by preparing a gel by using a soy protein material in which the lipophilic protein content is reduced and conducting the gelation with the utilization of not only heat but also the action of a protein crosslinking enzyme.

Owner:FUJI OIL CO LTD

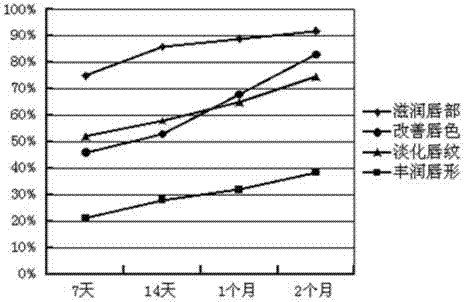

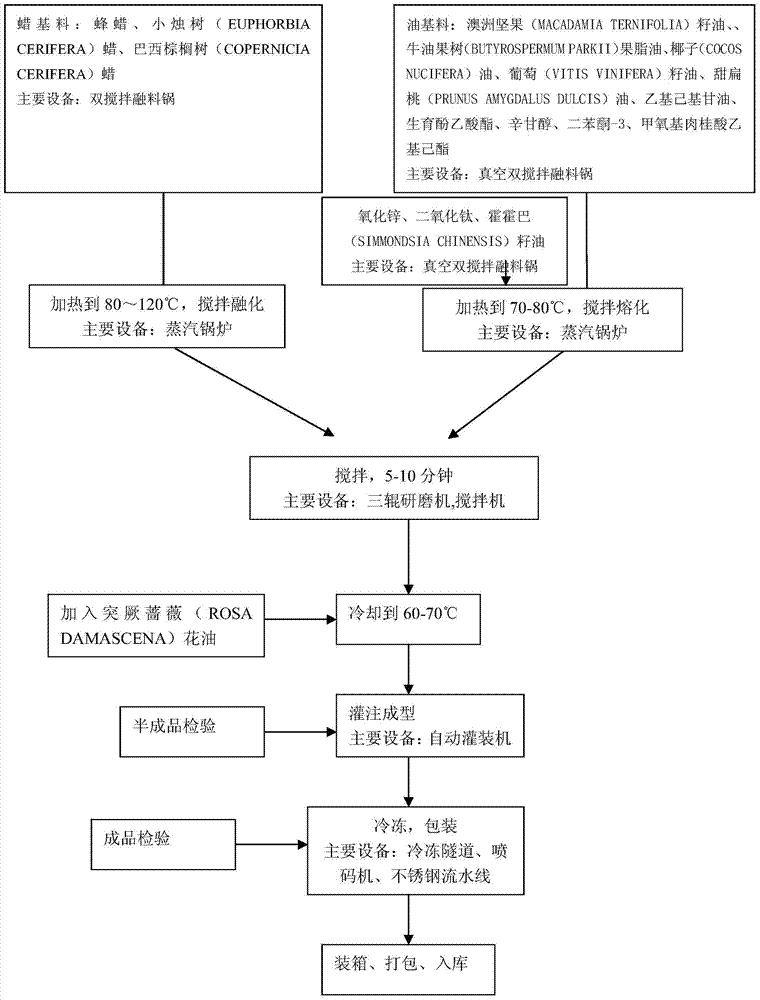

Plant essence type rouge allure lipstick

InactiveCN103494739AGood whitening effectImprove permeabilityCosmetic preparationsMake-upCaprylyl GlycolAdditive ingredient

The invention discloses a plant essence type rouge allure lipstick which comprises an emollient, a sun protection agent, a thickening agent and an aromatic, wherein the emollient comprises macadimia nut seed oil, simmondsia chinensis seed oil, butyrspermum parkii, tocopheryl acetate, coconut oil, grape seed oil, prunus amygdalus dulcis oil, caprylyl glycol and ethylhexylglycerin; the sun protection agent comprises benzophenone-3, 2-ethylhexyl4-methoxycinnamate, zinc oxide and titanium dioxide; the thickening agent comprises beewax, candelilla wax and copernicia cerifera wax; the aromatic comprises Tujue rose flower oil. According to the plant essence rouge allure lipstick, natural plant ingredients are prepared into natural cosmetics, and effective sun protection ingredients are added, the SPF (Sun Protection Factor) value reaches 15 and PA++, and the tender and lovely skin of the lip is protected from being hurt by ultraviolet rays.

Owner:JOTM DAILY CHEM HANGZHOU CO LTD

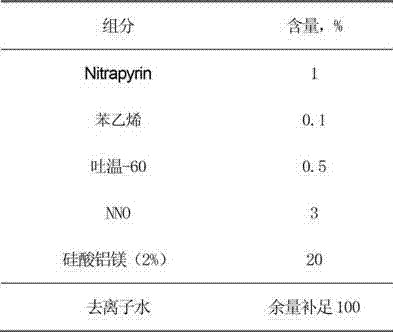

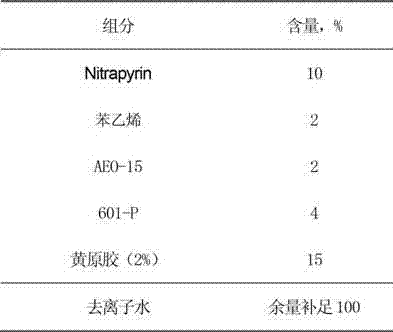

Nitrogen fertilizer stabilizer composition and preparation method thereof

InactiveCN103044137AImprove efficiencyImprove compatibilityFertilizer mixturesNitrapyrinNitrogen fertilizer

The invention discloses a nitrogen fertilizer stabilizer composition. The nitrogen fertilizer stabilizer composition comprises the following components in part by weight: 1-60 parts of nitrapyrin, 1-15 parts of wall material, 2-10 parts of emulsifier, 0.05-0.3 parts of viscosity regulator, 2-10 parts of dispersing agent and 0.1-100 parts of water. The invention further provides a preparation method of the nitrogen fertilizer stabilizer composition. The preparation method of the nitrogen fertilizer stabilizer composition comprises the following steps of: heating and melting active components, adding the macromolecular wall material, and stirring uniformly; adding a mother liquid containing the active components and the wall material into an emulsifier-containing water solution under a shearing condition, and emulsifying into an oil-in-water state; and controlling grain size as required, wherein the nitrogen fertilizer stabilizer composition can be in a liquid or solid state; and liquid drops containing the active components react with water molecules to form the macromolecular wall material. Through addition of a nitrapyrin product, the nitrogen fertilizer stabilizer composition can improve the using efficiency of an ordinary nitrogen fertilizer by decreasing nitrogen leaching and denitrification, is good in compatibility with a variety of fertilizers, pesticides, weedicides and bactericides, and can be mixed therewith for application.

Owner:南通联农佳田作物科技有限公司

Reflective colored vibration deceleration marking composition, and construction method and application thereof

InactiveCN105111896AFast curingDoes not affect normal drivingTraffic signalsRoad signsWear resistantAdhesive

The invention relates to a reflective colored vibration deceleration marking composition, and a construction method and application thereof. The reflective colored vibration deceleration marking composition is characterized by comprising the following main raw materials by weight: 5 to 80% of an adhesive, 0.2 to 60% of a curing agent, 10 to 50% of wear resistant aggregate, 5 to 50% of a reflective material, 10 to 40% of an anti-slip material, 0 to 10% of a promoter, 5 to 20% of pigment, 1 to 30% of a diluent or solvent and 5 to 60% of an inorganic and organic filling material. The reflective colored vibration deceleration marking composition is applied to traffic safety facility signs and can be directly casted on traffic accident blackspots like the square of a highway toll station, the entry of a bridge and a tunnel, a continuous downhill of a road, a curve and a sharp turn of the road, intersections and crossroads of the road and slippery positions of a wet pavement and on pavements needing deceleration of automobiles, e.g., places in front of gates of schools, hospitals and government agencies.

Owner:王健懿

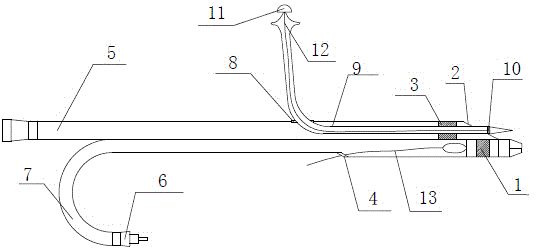

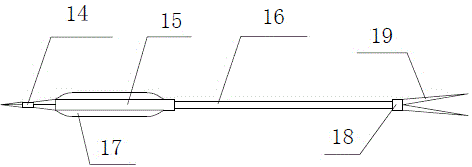

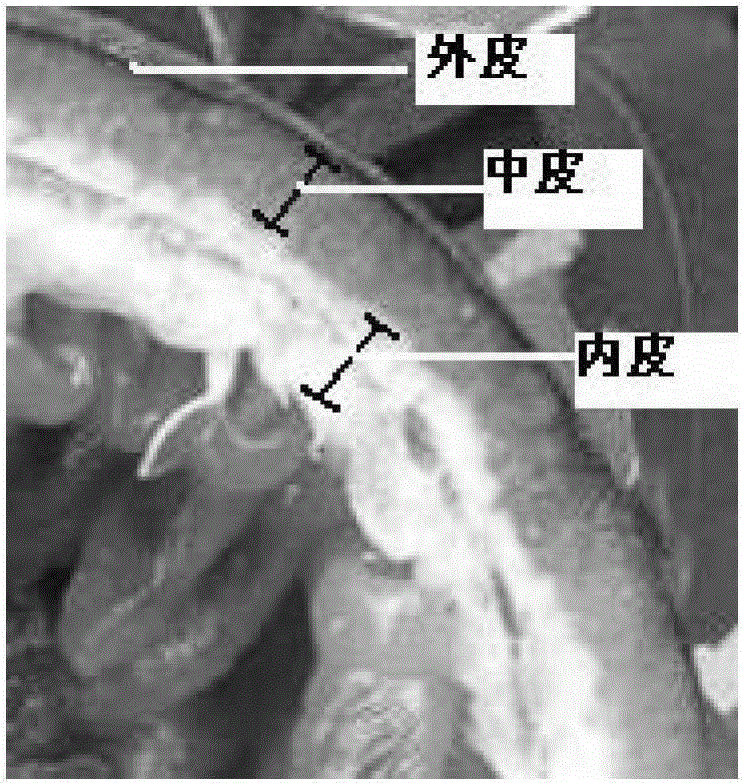

Instrument for arterial occlusion lesion treating and application thereof

ActiveCN104161548AImprove handlingStrong penetrating powerGuide wiresSurgeryCoronary arteriesArterial occlusions

The invention discloses an instrument for arterial occlusion lesion treating and the application thereof. The instrument comprises a vascular ultrasound catheter, a treating micro catheter and a treating guiding line. The vascular ultrasound catheter and the treating micro catheter are integrally connected in parallel. One part of the treating guiding line is placed in the treating micro catheter, and the other part of the treating guiding line penetrates out of the treating micro catheter from a side wall outlet. According to the instrument, the vascular ultrasound catheter and the treating micro catheter are integrally connected in parallel, a double-cavity micro catheter is used for adjusting the treating guiding line to enter a vessel true lumen, thrombus is sucked out through the treating guiding line, and post-operation hidden danger is removed through one-time curing. The problem that in an intervention recanalization treating operation of blocking of coronary arteries, peripheral arteries and other organ pipelines, a treating guiding line cannot enter a true lumen easily is solved.

Owner:马永红

Special feed for rex rabbit

InactiveCN101167532AMeet nutritional needsNutritional diversityFood processingAnimal feeding stuffVegetable oilAdditive ingredient

The invention relates to a special feed for beaver rabbits, which is characterized in that granules which are made from raw materials as grass meal 30-50 parts by weight, corn 20-30 parts by weight, soya bean waste 15-20 parts by weight, bran 13-18 parts by weight, fish meal 2 parts by weight, animals and vegetable oil 1.5 part by weight, yeast 2 parts by weight, methionine 0.4 part by weight, lysine 0.25 part by weight, table salt 0.4-0.5 part by weight, and vitamin complex additive electrolytic multivitamin 0.5 part by weight. The invention has comprehensive nutrition and is compositely processed into the granules by multiple raw materials, thereby various nutrient contents are mutually supplemented, and the nutritional requirements of growth, development, breeding and lactation of the beaver rabbits and the like in different physiological steps are capable of being met. The invention has the advantages of low cost and high survival rate of the beaver rabbits. The invention is particularly suitable for the physiological demand of the beaver rabbits, the crop rate of the first grade fur is above 95 percent, and the benefits are capable of achieving the best state.

Owner:周洪科

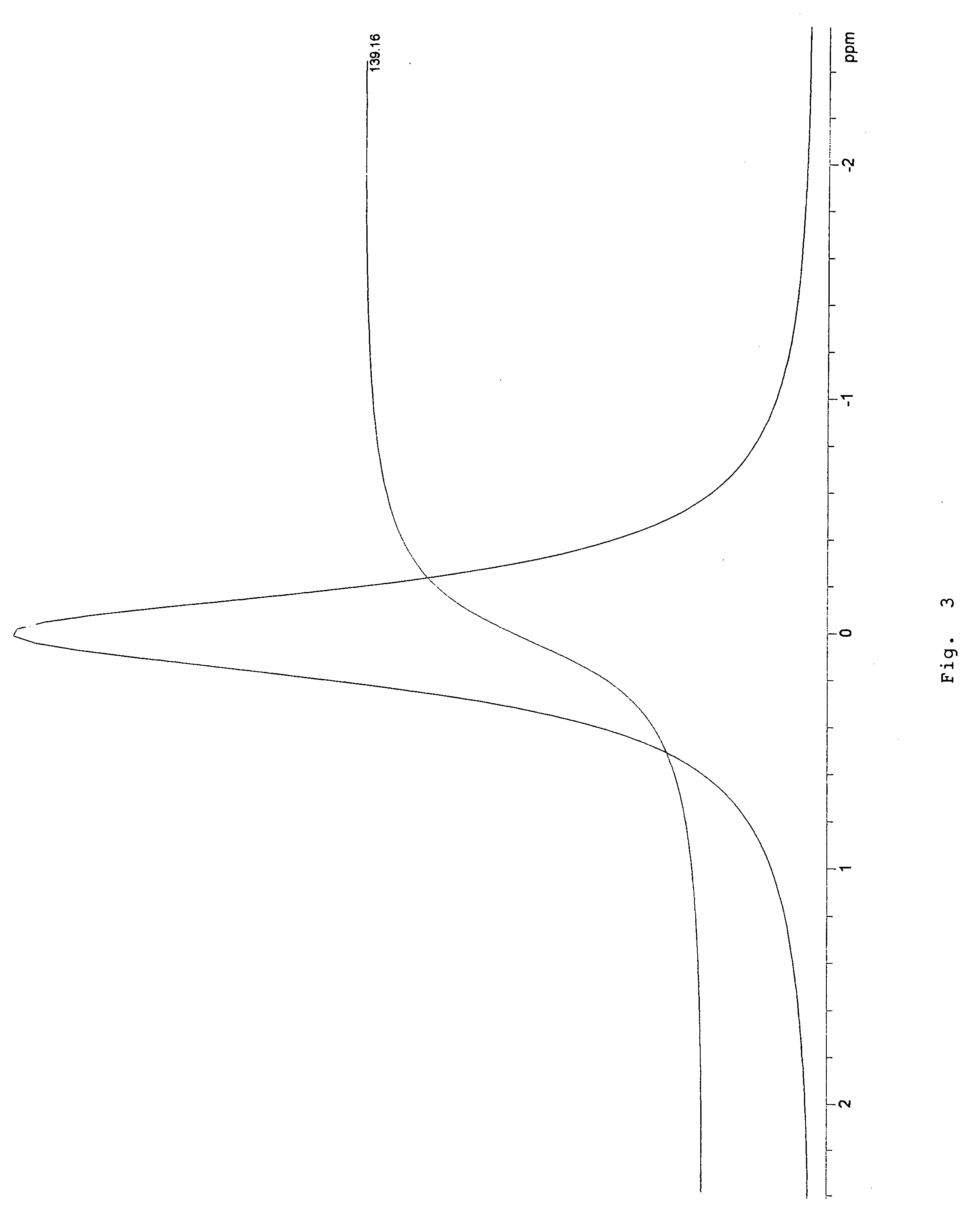

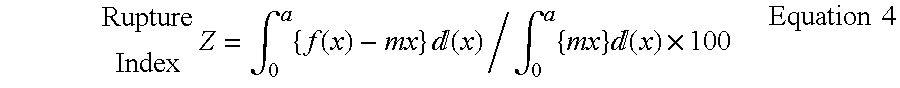

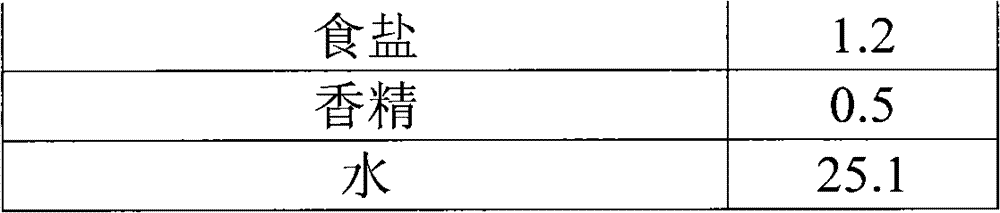

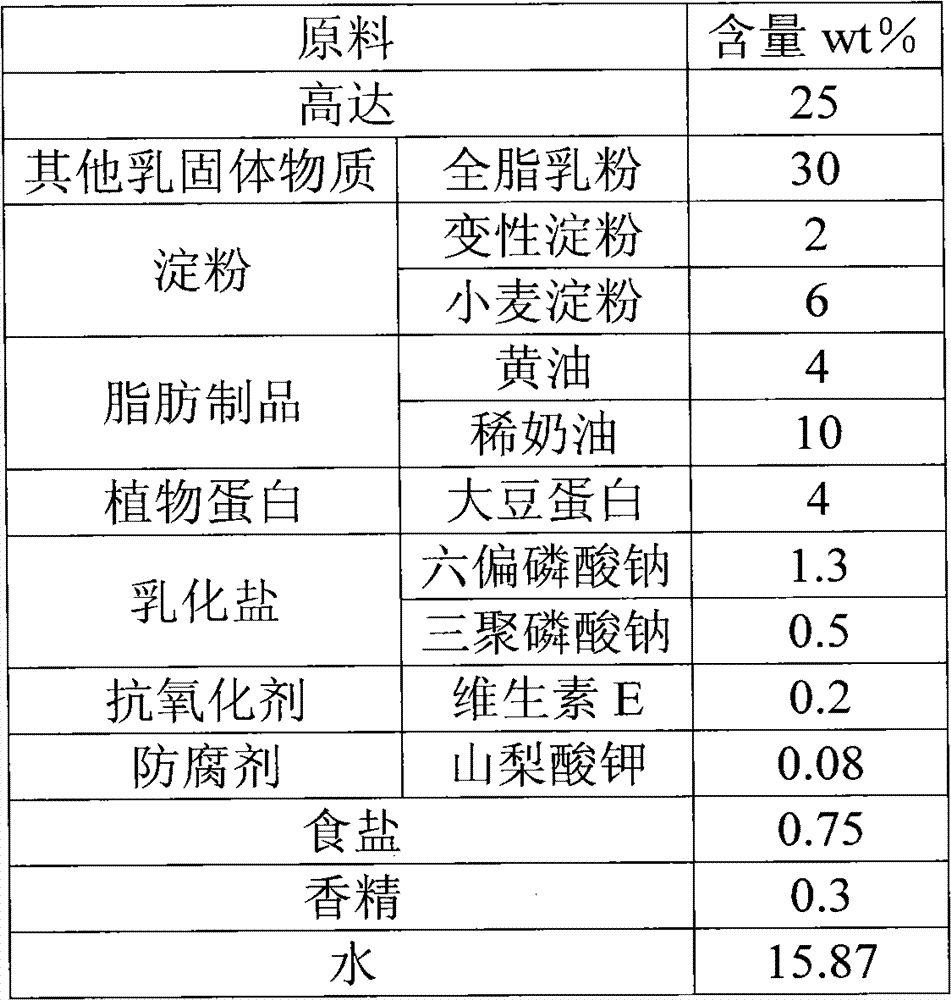

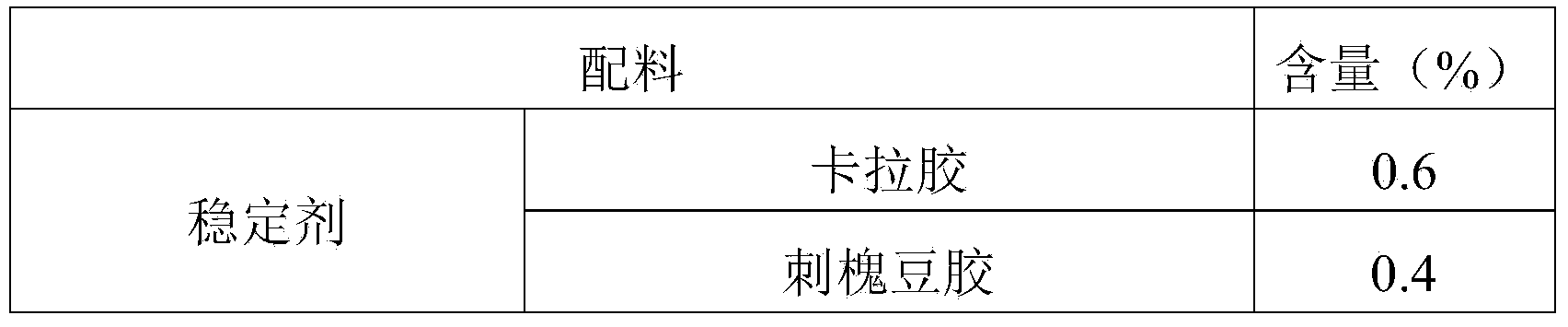

Processed cheese stored in room temperature and method for preparing same

The invention discloses a processed cheese stored in the room temperature and a method for preparing the same. The processed cheese stored in the room temperature comprises the materials of, 15% to 60% of natural cheeses, 2% to 14% of fat products, 3% to 40% of other milk solids other than the natural cheeses and the fat products, 4% to 10% of starch, 3% to 7% of vegetable protein, 0.1% to 0.5% of antioxidants, 1.5% to 2.5% of emulsifying salt and 13% to 25% of water, wherein the percentages are the mass percentages that each material accounts for the total material amount; and the emulsifying salt is phosphate. According to the processed cheese stored in the room temperature and the method for preparing the same, the processed cheese can be stored in the room temperature and has at least a 4-month shelf life, and the situation that current state market cheeses can be only refrigerated is broken, so that the cheese market promotion is facilitated; the processed cheese has mild flavor and can maintain original characteristic flavors and functional characteristics of classical cheeses; the texture is hard, and the processed cheese can be packed into flexible and various snack forms.

Owner:BRIGHT DAIRY & FOOD

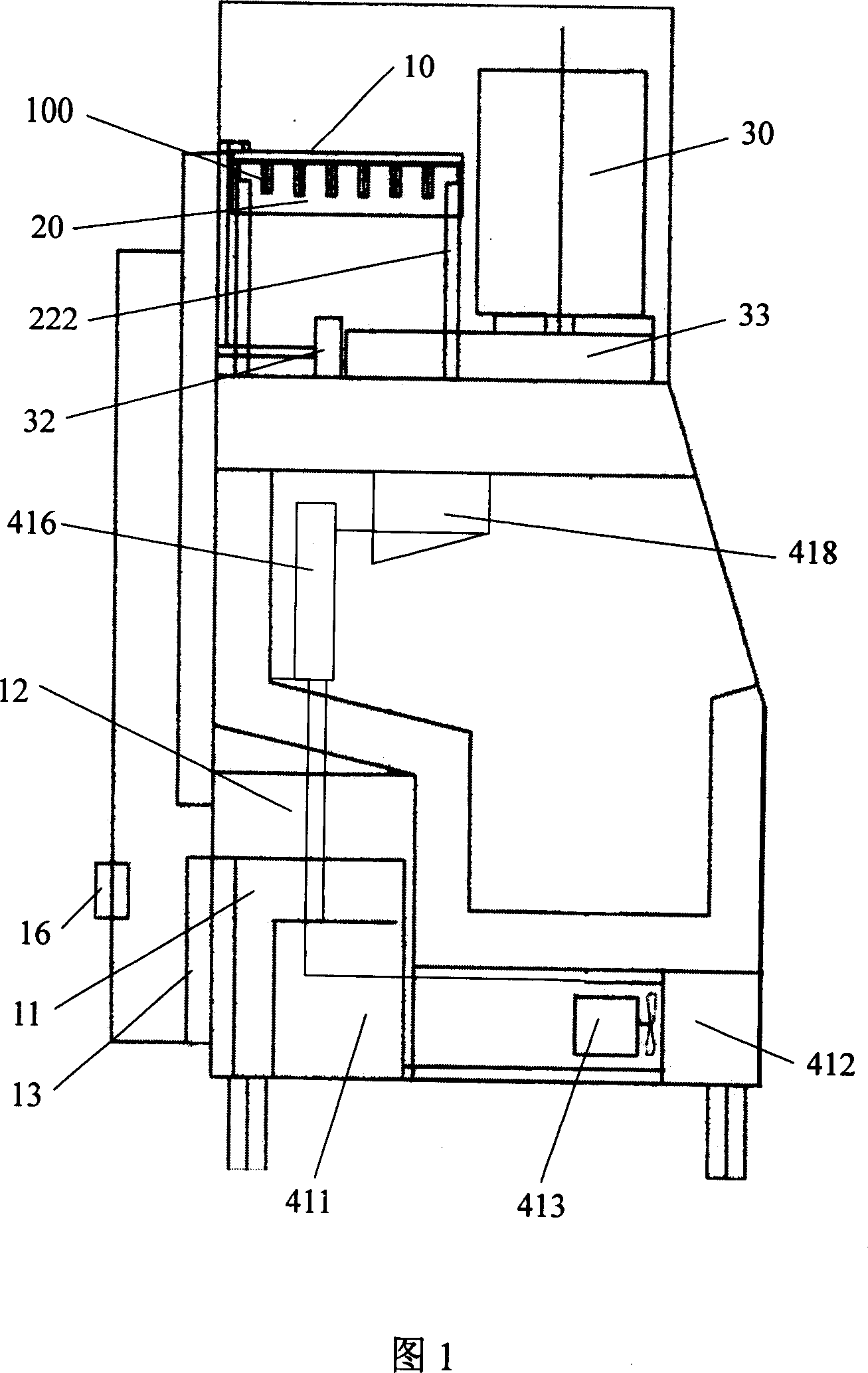

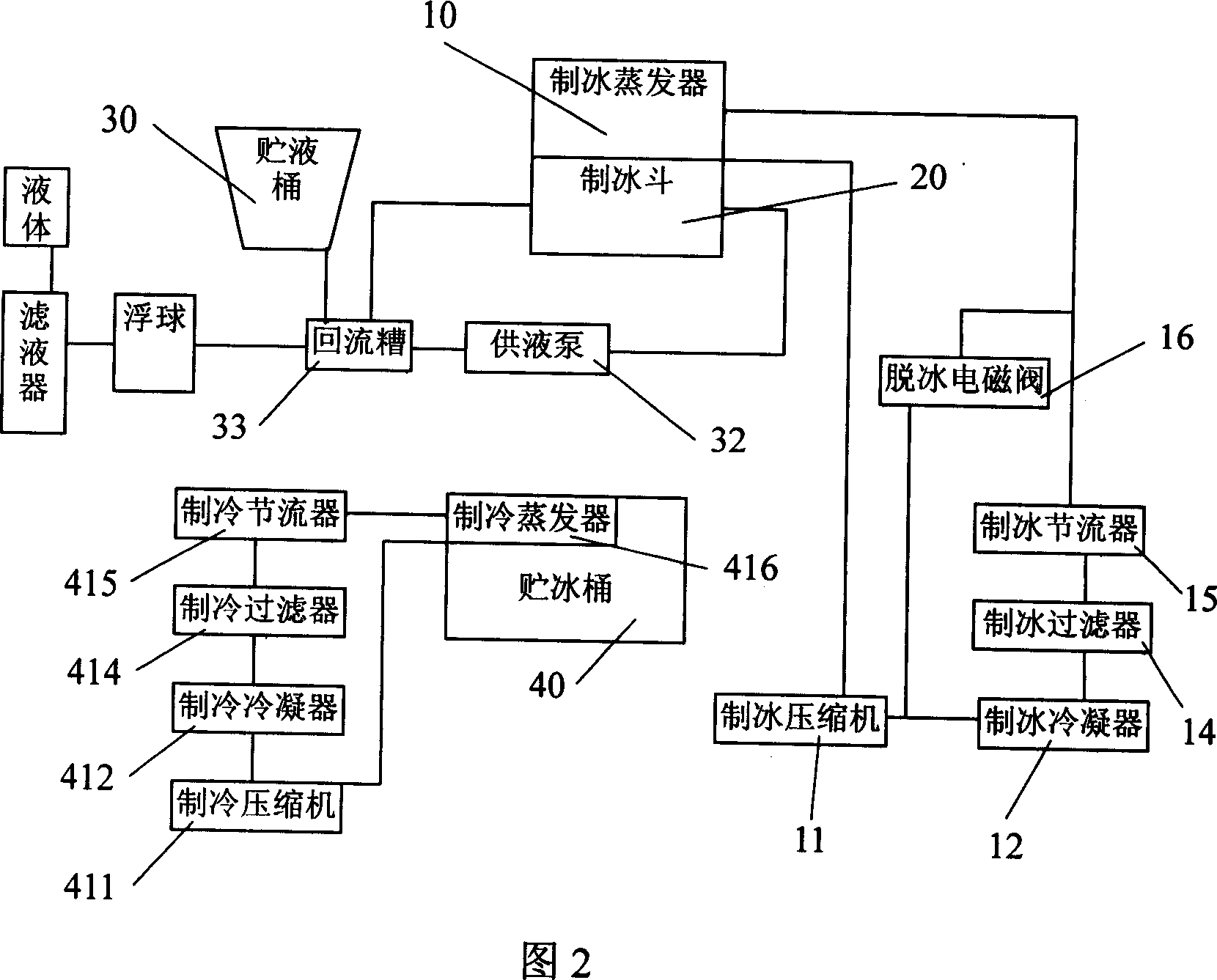

Multifunction ice-making machine

InactiveCN1936465AHard textureEasy to replaceLighting and heating apparatusIce productionIce storageControl system

This invention relates to a multifunction icing machine including an icing device, an icing bin and its drive device, a solution supply system, an ice storage device and a control device, in which, the icing device includes an evaporator, the icing bin is placed under the evaporator and many evaporating posts are protruded downward from the evaporator corresponding to the bin, which rises driven by the drive unit to let the posts plug into the middle part of the icing bin from top to bottom for icing, the icing raw material is one of the following ones: clean water, syrup, tea or coffee. The solution in the icing bin is condensed and iced from inside to outside by plugging the icing posts into the bin and solution generated from deicing is kept in the hole of a middle of ice grains and iced after breaking away from the evaporation automatically to avoid concreting to one with adjacent ice grains in the ice storage drum.

Owner:徐文焕

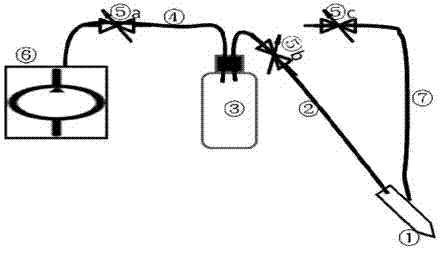

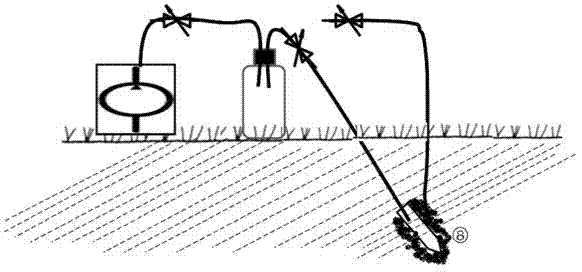

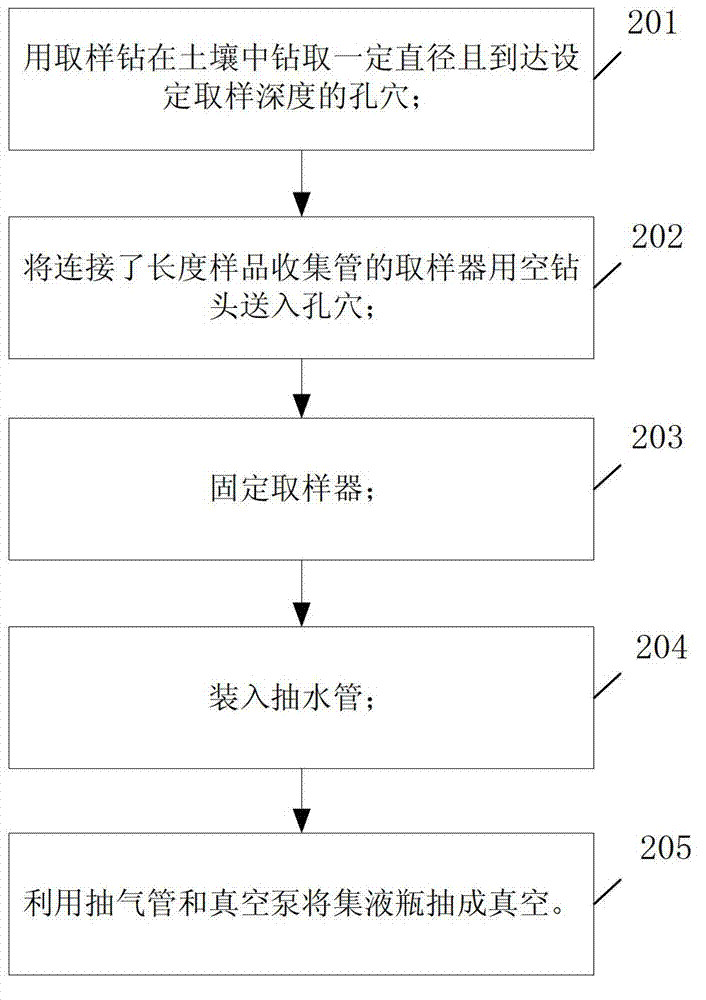

System and method for soil solution sampling

InactiveCN102759463AGuaranteed continuous useHard textureWithdrawing sample devicesSoil scienceBottle

An embodiment of the invention provides a system and a method for soil solution sampling. The system and the method can resist cold frost heaving and melting contraction and be used for soil solution continuous sampling in a high and cold area during the frost heaving in winter and the melting contraction in spring. The embodiment provides a soil solution sampling device system which comprises a sampling device, a sample collecting pipe and a liquid collection bottle. The sampling device is formed by materials which are hard in texture and good in water and solution penetrating property, and when the device system is used, the sampling device is embedded in soil and connected with the liquid collection bottle on the earth's surface through the sample collecting pipe.

Owner:BEIJING NORMAL UNIVERSITY

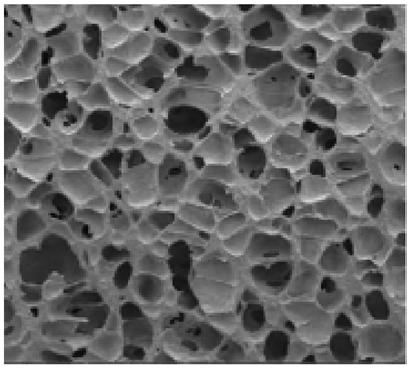

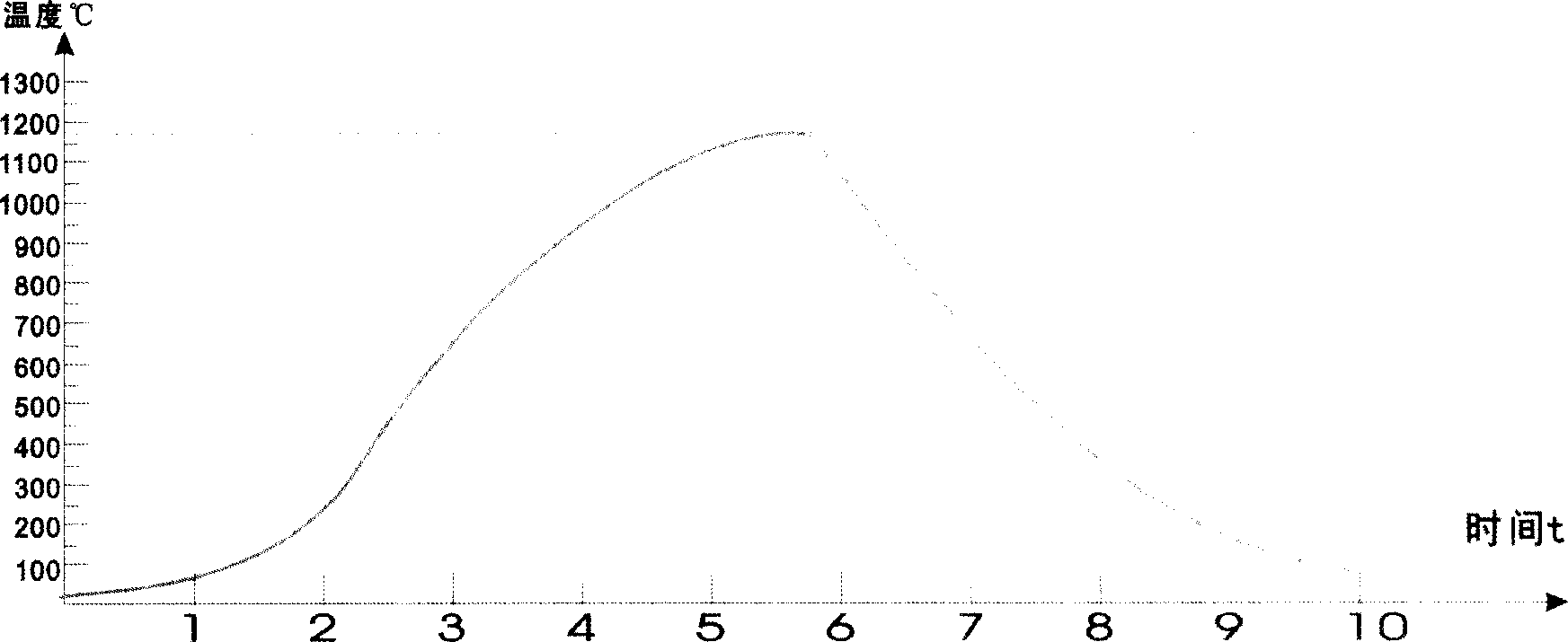

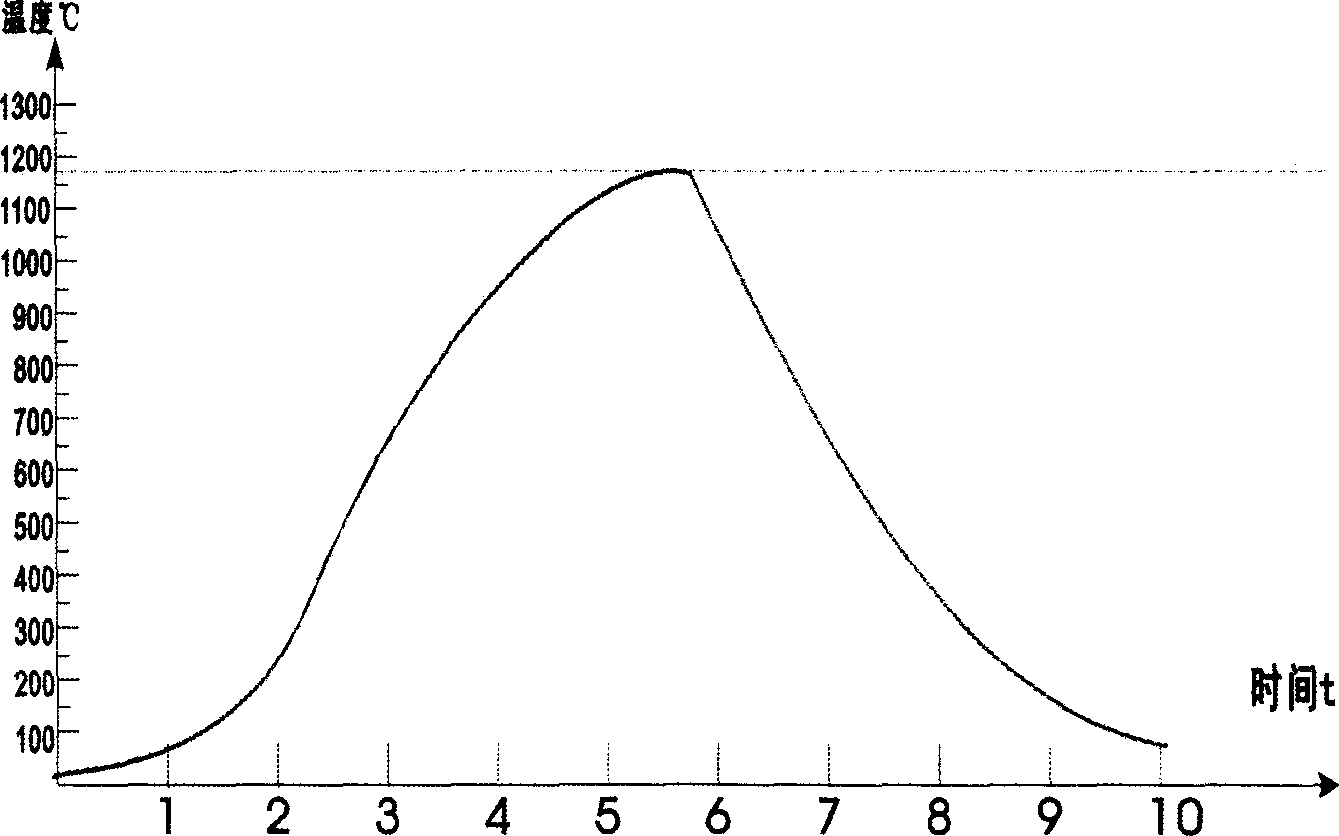

Porcelainized fireproof and heat insulation foamed silicone rubber and preparation method thereof

The invention discloses porcelainized fireproof and heat insulation foamed silicone rubber and a preparation method thereof. The rubber comprises the following raw materials in parts by weight: 100 parts of base rubber, 10 to 60 parts of porcelain forming filler, 0.1 to 0.5 part of a platinum catalyst, 0.5 to 1.5 parts of silicone oil, 2 to 10 parts of a foaming agent, 0.1 to 0.5 part of a vulcanizing agent, and 0.1 to 0.4 part of a vulcanization accelerator. The foamed silicone rubber has good ceramic effect, does not have surface cracks, is hard in texture, keeps a complete foam structure, ensures that the volume retention rate is 85% or higher, and is excellent in fireproof performance.

Owner:WUHU YANGZHAN NEW MATERIAL TECH SERVICE CO LTD

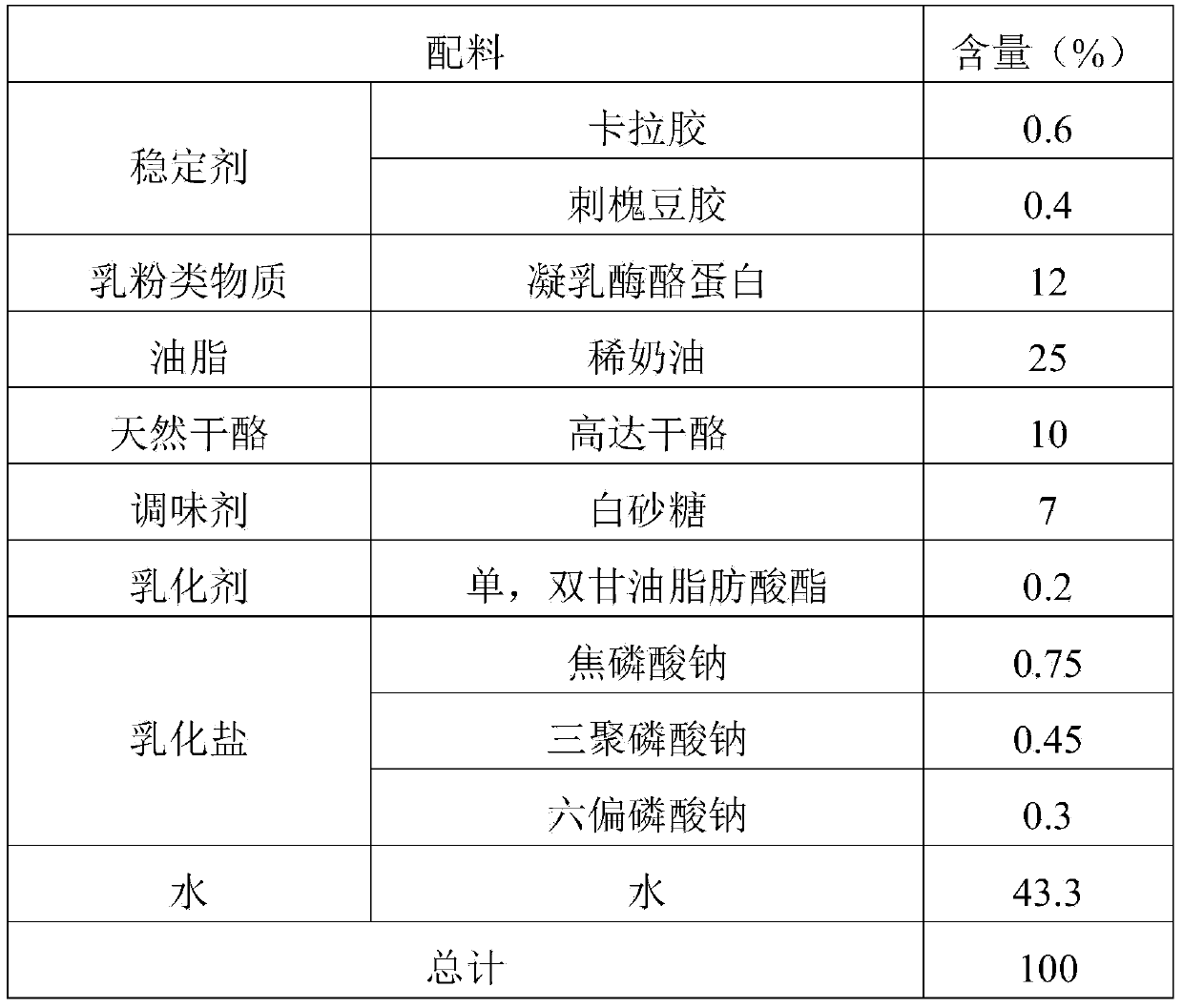

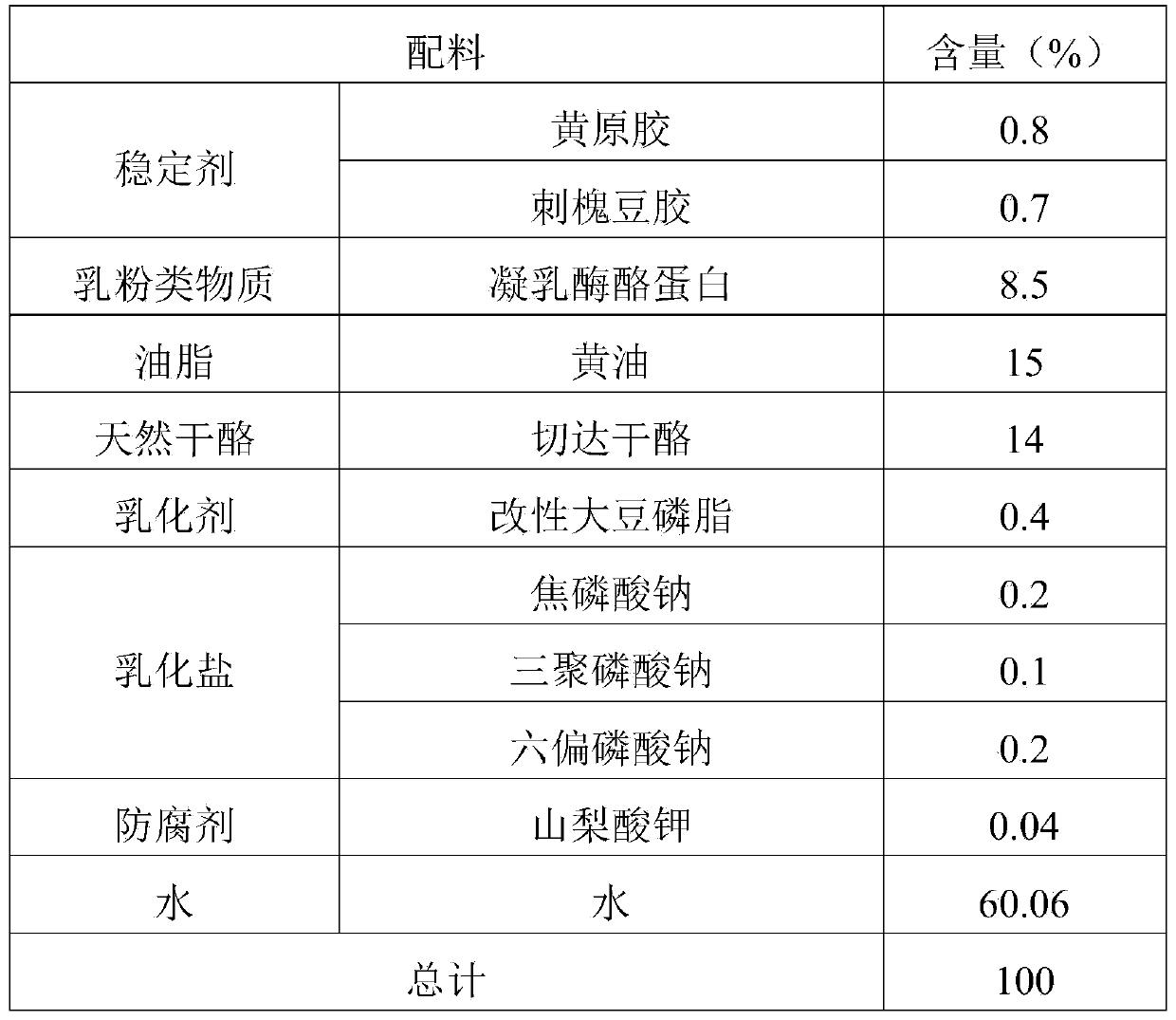

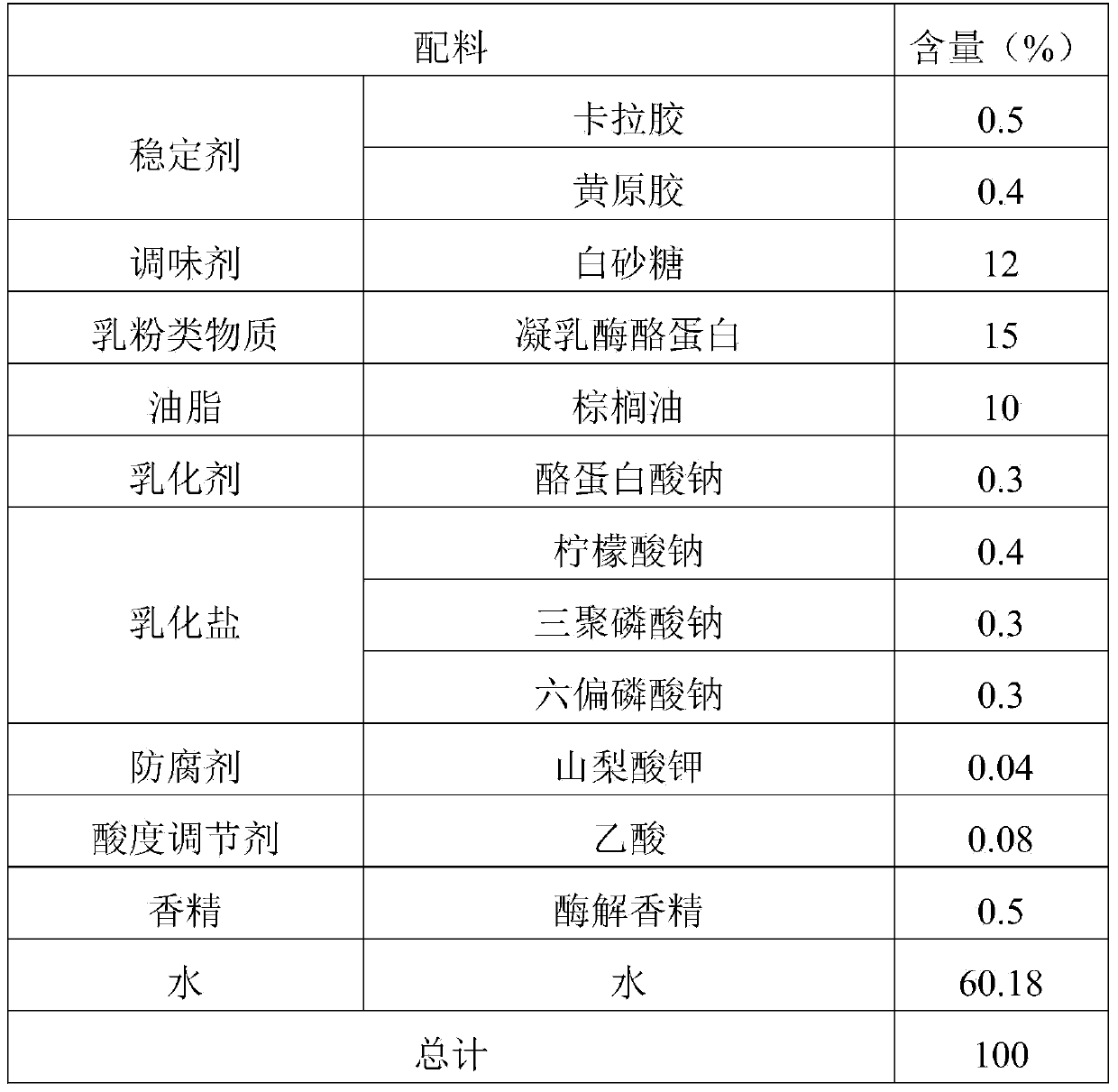

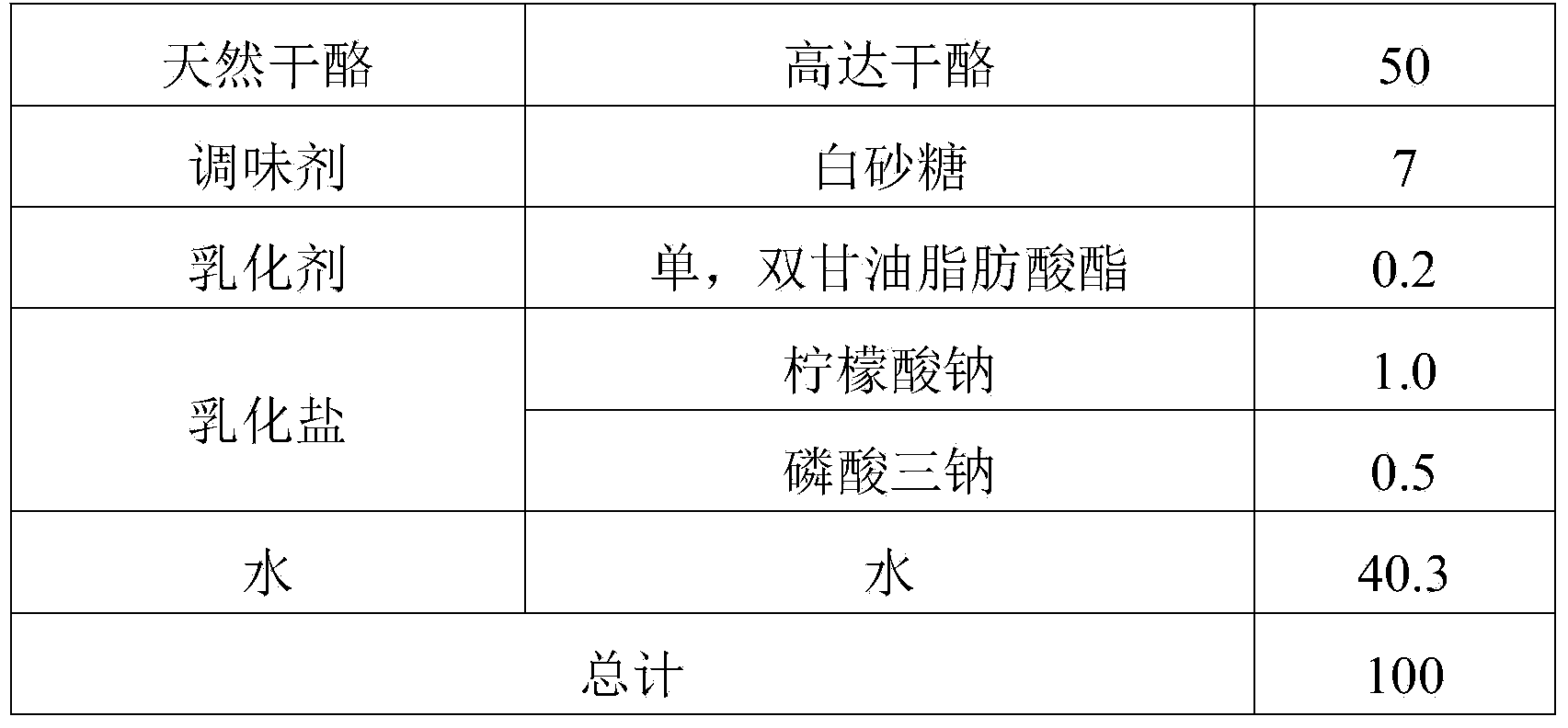

Normal-temperature cheese food and preparation method thereof

The invention discloses normal-temperature cheese food and a preparation method thereof. The preparation method comprises the following steps of (1) uniformly mixing a stabilizing agent, a milk powder substance, an emulsifier and emulsified salt to obtain a mixture A; (2) uniformly mixing grease, the mixture A and water, and performing stirring heating to realize sterilization and emulsification; (3) performing homogenization; (4) performing pouring, cooling and molding; and (5) drying the product until the moisture content is 8-35 percent by mass, and packaging the product. According to the normal-temperature cheese food, the shortcomings of oil and water separating, texture granulation and unstable quality are overcome; the normal-temperature cheese food can be stored and sold under normal temperature; meanwhile, the normal-temperature cheese food serving as leisure food is favorable for popularization of the cheese culture in China.

Owner:BRIGHT DAIRY & FOOD

Functional ceramic wine set

The invention belongs to the technical field of ceramic manufacturing, relates to a functional ceramic wine set and particularly relates to a functional ceramic wine set which is capable of emitting negative oxygen ions and far infrared rays for a long time, converting molecular groups and potentials of wine and regulating the pH value of wine. The functional ceramic wine set is characterized by being mainly prepared from 20% of hexacyclic stone, 18-22% of medical stone, 16-18% of tourmaline, 8-10% of zeolite, 13% of clay, 6-8% of lithium feldspar, 3-5% of quartz and 8-12% of diatomite. The functional ceramic wine set is brownish red in appearance, has the functions of emitting negative oxygen ions and far infrared rays for a long time, inhibiting and killing bacteria, removing traces of harmful substances in wine, regulating aldehydes in wine and improving the taste of wine and is capable of changing wine qualitatively.

Owner:TANGSHAN LIXIONG FENGHUI MATERIAL SCI & TECH CO LTD

Passion fruit juice and preparation method thereof

ActiveCN105167041AHard textureRough tasteFood ingredient for microbe protectionFood preparationBiotechnologyFruit juice

The present invention discloses a passion fruit juice and a preparation method thereof. The preparation method includes the following steps: selecting and washing passion fruits, air-drying, conducting a first freezing, steaming fruits, conducting a second freezing, peeling, thawing, pulping and filtering, and seasoning and filling. By conducting a combined technology of air-drying, freezing, fruit steaming and freezing, an efficient method for removing the skins of passion fruits is achieved, and by using the middle skins, inner skins, pulp and juice of passion fruits, the fruit juice which is sour, sweet, tasty, and rich in nutrition is obtained; and the production method is simple, economical and environmentally friendly, suitable for large-scale industrialized production, and relatively low in production costs.

Owner:谭强

Ceramic tile and its preparing process

The invention discloses a kind of ceramic tile and its manufacture craft. It relates to a kind of ceramic tile used for building fitment and its manufacturer craft. The ceramic tile includes following weight percents of raw material to be fired: Jin'an pottery clay 50% - 70%, Hushan pottery clay 10% - 25%, and bamboo carbon powder 15% - 35%. The ceramic tile manufactured through the technological project of the invention has such effects as moisture-proof, bacteriostasis and environmental purification. The ceramic tile manufactured through the craft has high intensity and rigidity, and can greatly save raw materials. It can be widely used in ceramic tile industry.

Owner:汤建华

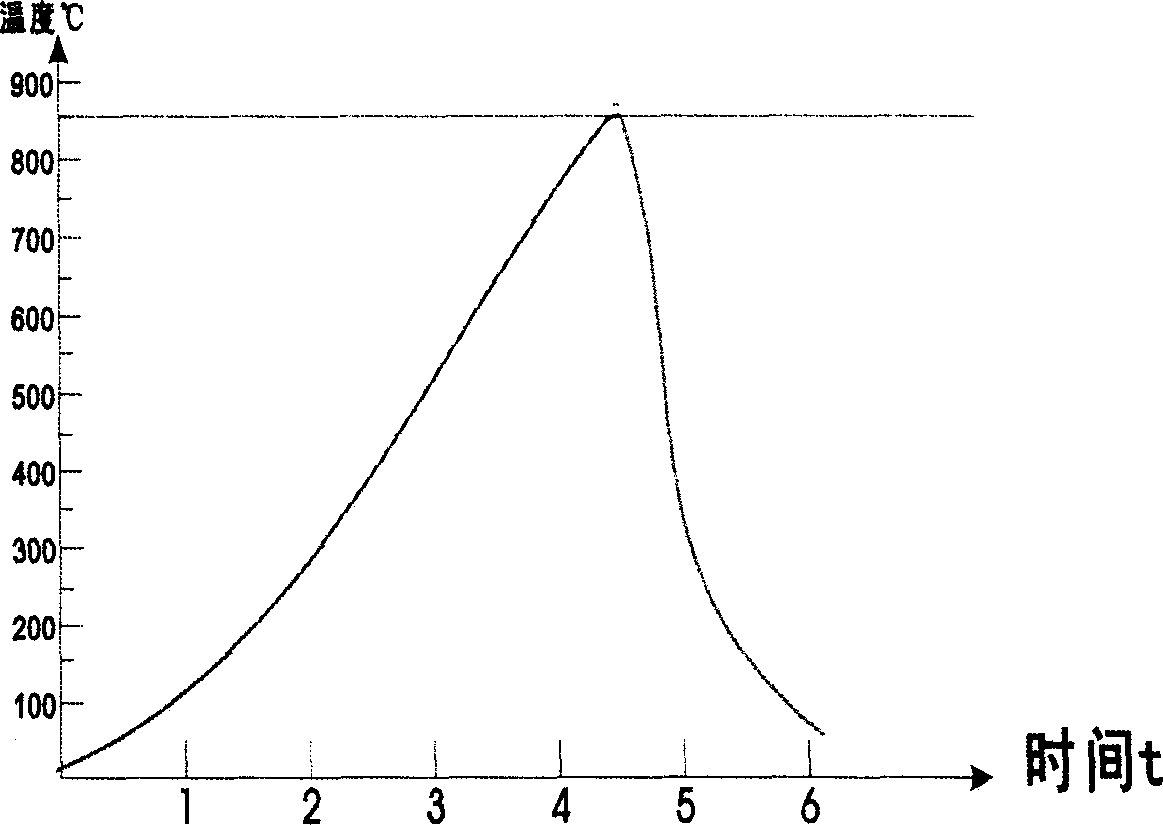

Pine nut shell gas-phase adsorption active carbon and preparation method thereof

InactiveCN103566901AHard textureModerate proportionOther chemical processesDispersed particle separationGas phaseOxygen

The invention relates to pine nut shell gas-phase adsorption active carbon, which is prepared from the following raw materials in parts by weight: 150 to 160 parts of pine nut shell, 3 to 4 parts of graphene, 10 to 15 parts of attapulgite, 8 to 10 parts of ferric trichloride, 8 to 10 parts of sodium perborate, 10 to 15 parts of citric acid, 4 to 5 parts of modified diatomite and an appropriate amount of water. The pine nut shell is adopted as a raw material to produce the active carbon. The pine nut shell has hard texture and moderate specific gravity and is likely to form a fine pore structure after being carbonized at a high temperature, the weaknesses of a traditional method can be overcome and the active carbon is suitable for the gas adsorption; by adopting the attapulgite, a sterilizing, deodorizing, moisture absorbing and mildew preventing functions can be achieved and organisms can be catalyzed and decomposed; by utilizing the ferric trichloride, oxidization and desulphurization can be realized; due to addition of the sodium perborate, the oxidization decoloring function be realized and ecological oxygen can be realized; and the pine nut shell gas-phase adsorption active carbon is safe, healthy, low in cost and particularly suitable for purifying the air of a living environment.

Owner:BENGBU HUAFANG FILTER

Inorganic nano antibacterial polypropylene water-feeding pipe and method for making same

InactiveCN1699459AImprove corrosion resistanceEasy hot melt connectionRigid pipesMildewPolypropylene

The invention relates to an inorganic nano antibacterial polypropylene water-feeding pipe, wherein the pipes is composed of modified polypropylene with charged inorganic nano antimicrobial agent. The pipes can be used for cold and hot water pipeline system in construction, The material can eradicate several dozens of bacterial in the water supply pipe, such as bacteria, fungus, mildew.

Owner:金德管业集团有限公司

Dumpling flour and production method thereof

The invention relates to a dumpling flour and a production method thereof. Complex additive is added to wheat flour which is the main raw material. The dumpling flour is produced by mixing proper amount of complex additive and the processed and ground wheat flour. The complex additive is produced by combining a guar gum, VC, CMC(thickening agent), compound enzyme agent and starch by a certain proportion, which ensures that the actions of all the components can suit well with each other. The color and luster, taste and boiling fastness of made dumplings are greatly improved by adding the complex additive to different flours. Compared with control samples, the dumpling flour has obvious advantages in color and luster, transparency of dumpling wrapper and taste, for cooked dumplings, the soup is clear and the wrapper is not broken before eating.

Owner:郑州天地人面粉实业有限公司

Preparation method of composite coated water retaining and slowly-releasing urea

ActiveCN105315096ASimple processEase of industrial productionFertilizer mixturesOrganic solventComposite film

The invention provides a preparation method of composite envelope water retaining and slowly-releasing urea. The water retaining and slowly-releasing urea of a dual-layer film structure is formed with large granular urea as a kernel, a chitosan-polyving akohol composite film as an inner coating layer and a water-retaining agent as an outer coating layer, and the water retaining and slowly-releasing urea has excellent water retaining and nutrient slowly releasing properties. The method is characterized by comprising the steps that the large granular urea with the diameter of 2-5 mm is put into a coating device, the urea rolls in the coating device and is heated to be 80-100 DEG C, chitosan-polyving akohol coating fluid is sprayed to the surface of the urea, the water-retaining agent of the grain size of 0.075 mm is added, epoxy chloropropane with the concentration of 0.5% is sprayed by a spraying gun with the intensity of pressure larger than or equal to 0.4 MPa for the surface cross-linking reaction, and finished fertilizers are obtained after drying is performed. The water retaining and slowly-releasing urea is simple in production process, low in investment cost, and easy in industrial production. No organic solvent is used in the production process, and secondary pollution caused by using organic solvents is avoided accordingly.

Owner:ZHONGKAI UNIV OF AGRI & ENG

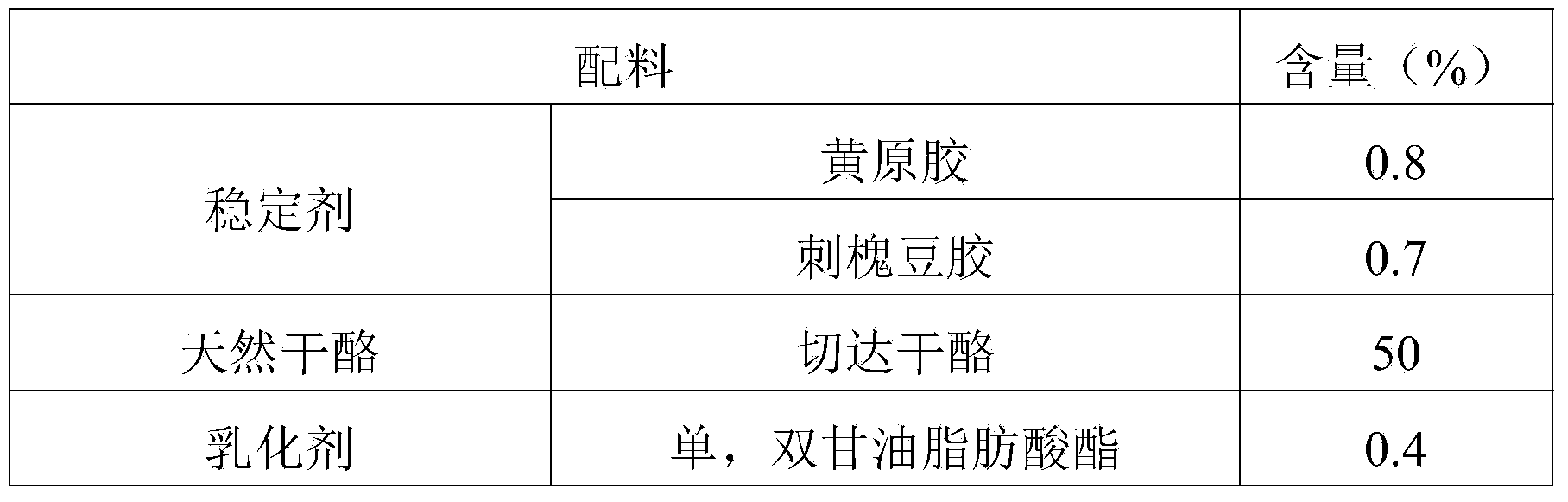

Normal-temperature processed cheese and preparation method thereof

The invention discloses normal-temperature processed cheese and a preparation method thereof. The preparation method comprises the following steps: S1, (1) uniformly mixing a stabilizer and an emulsifier to obtain a mixture A, adding the mixture A into water, performing stirring and heating until materials are uniform to obtain a mixture B, and (2) melting natural cheese, emulsifying salt and the water by heating to obtain a mixture C, wherein the step (1) and the step (2) can be carried out in a random order, and the addition amount of the water in the step (1) accounts for 40-90 percent of the total addition amount of the water; S2, uniformly mixing the mixture B and the mixture C, and performing heating, sterilization and uniform stirring; S3, performing homogenizing; S4, performing pouring, cooling and molding; S5, performing drying until the water content is 9-40 percent, and performing packaging to obtain the normal-temperature processed cheese. According to the normal-temperature processed cheese provided by the invention, the defects of oil separation, water separation, granulation and instable quality are overcome. The normal-temperature processed cheese can be stored and sold at normal temperature.

Owner:BRIGHT DAIRY & FOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com