Porcelainized fireproof and heat insulation foamed silicone rubber and preparation method thereof

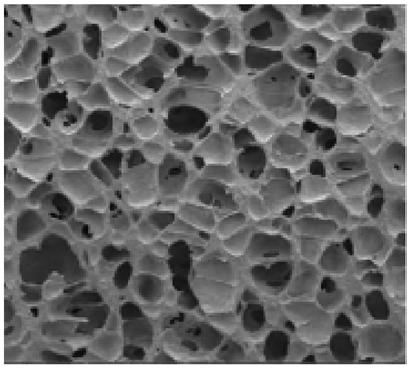

A silicone rubber and foam technology, applied in the field of foam silicone rubber, can solve the problems of easily reducing other properties of silicone rubber foam materials, accelerating rubber aging, etc., and achieve the prospect of large-scale production, ideal foam structure, and intact cell structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Composition of raw materials (parts by weight): base rubber: 100 parts of mixed rubber prepared by methyl vinyl silicone rubber, porcelain filler: 40 parts of glass fiber powder, pore diameter of 1000 mesh, mass fraction of 2.85×10 -6 0.5 parts of platinum-divinyl-tetramethyldisiloxane complex and 1 part of silicone oil: the hydroxyl mass fraction of hydroxy silicone oil is 0.17%, and the viscosity is 750mm at 25°C 2 / s0.2 parts, the mass fraction of hydrogen in hydrogen-containing silicone oil is 1%, and the viscosity is 100mm at 25°C 2 / s0.8 parts, foaming agent: 5 parts of dinitrosopentamethylenetetramine, 0.5 parts of vulcanizing agent: take 2,4-dichlorobenzoyl peroxide, di-tert-butylperoxycumylbenzene Mix according to the molar ratio of 1:1, auxiliary vulcanization agent: 0.33 parts of TAIC, and weigh the raw materials according to the number of parts for later use.

[0023] (1) Rubber mixing: Weigh 100g of methyl vinyl silicone rubber and 40g of aluminum hydroxid...

Embodiment 2

[0027] Composition of raw materials (parts by weight): base rubber: 100 parts of mixed rubber prepared by methyl vinyl silicone rubber, porcelain filler: 40 parts of glass fiber powder, pore diameter of 1000 mesh, mass fraction of 2.28×10 -6 0.5 parts of vinyl siloxane chelate of chloroplatinic acid, 1 part of silicone oil: wherein the hydroxyl mass fraction of hydroxy silicone oil is 0.17%, and the viscosity is 750mm at 25°C 2 / s0.5 parts, the mass fraction of hydrogen in hydrogen-containing silicone oil is 1%, and the viscosity is 110mm at 25°C 2 / s 0.5 parts, foaming agent: 8 parts of dinitrosopentamethylenetetramine, 0.5 parts of vulcanizing agent: take di-tert-butyl cumene peroxide and dicumyl peroxide in molar ratio 2: 3 Mixing, co-vulcanizing agent: 0.25 parts of TAIC, weigh the raw materials according to the number of parts for later use.

[0028] (1) Rubber mixing: Weigh 100g of methyl vinyl silicone rubber and 40g of aluminum hydroxide powder and mix them evenly in ...

Embodiment 3

[0032] Composition of raw materials (parts by weight): base rubber: 100 parts of mixed rubber prepared by methyl vinyl silicone rubber, porcelain filler: 40 parts of glass fiber powder, pore diameter of 1000 mesh, mass fraction of 3.42×10 -6 0.5 parts of platinum-divinyl-tetramethyldisiloxane complex, 1.0 parts of silicone oil: the hydroxyl mass fraction of hydroxy silicone oil is 0.17%, and the viscosity is 750mm at 25°C 2 / s0.4 parts, the mass fraction of hydrogen in hydrogen-containing silicone oil is 1%, and the viscosity is 110mm at 25°C 2 / s0.6 parts, foaming agent: 8 parts of dinitrosopentamethylenetetramine, 0.8 parts of vulcanizing agent: take 2,4-dichlorobenzoyl peroxide, di-tert-butylperoxycumylbenzene Mix with dicumyl peroxide at a molar ratio of 1:2:3, vulcanizing agent: 0.33 parts of TAIC, weigh the raw materials according to the number of parts for later use.

[0033] (1) Rubber mixing: Weigh 100g of methyl vinyl silicone rubber and 40g of aluminum hydroxide pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com