Patents

Literature

44results about How to "No surface cracks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Porcelainized fireproof and heat insulation foamed silicone rubber and preparation method thereof

The invention discloses porcelainized fireproof and heat insulation foamed silicone rubber and a preparation method thereof. The rubber comprises the following raw materials in parts by weight: 100 parts of base rubber, 10 to 60 parts of porcelain forming filler, 0.1 to 0.5 part of a platinum catalyst, 0.5 to 1.5 parts of silicone oil, 2 to 10 parts of a foaming agent, 0.1 to 0.5 part of a vulcanizing agent, and 0.1 to 0.4 part of a vulcanization accelerator. The foamed silicone rubber has good ceramic effect, does not have surface cracks, is hard in texture, keeps a complete foam structure, ensures that the volume retention rate is 85% or higher, and is excellent in fireproof performance.

Owner:WUHU YANGZHAN NEW MATERIAL TECH SERVICE CO LTD

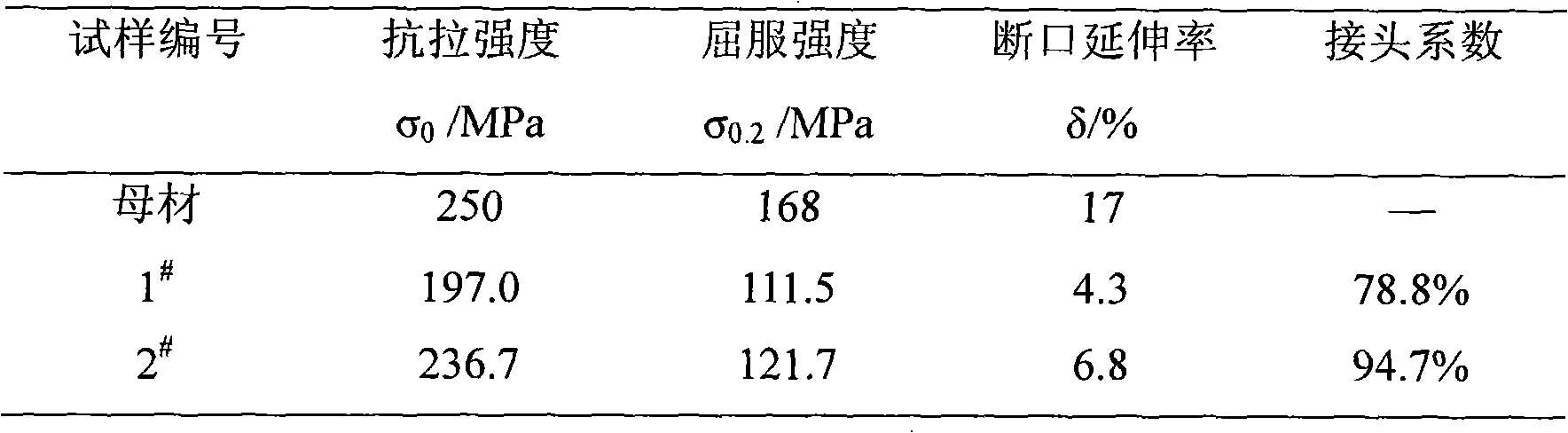

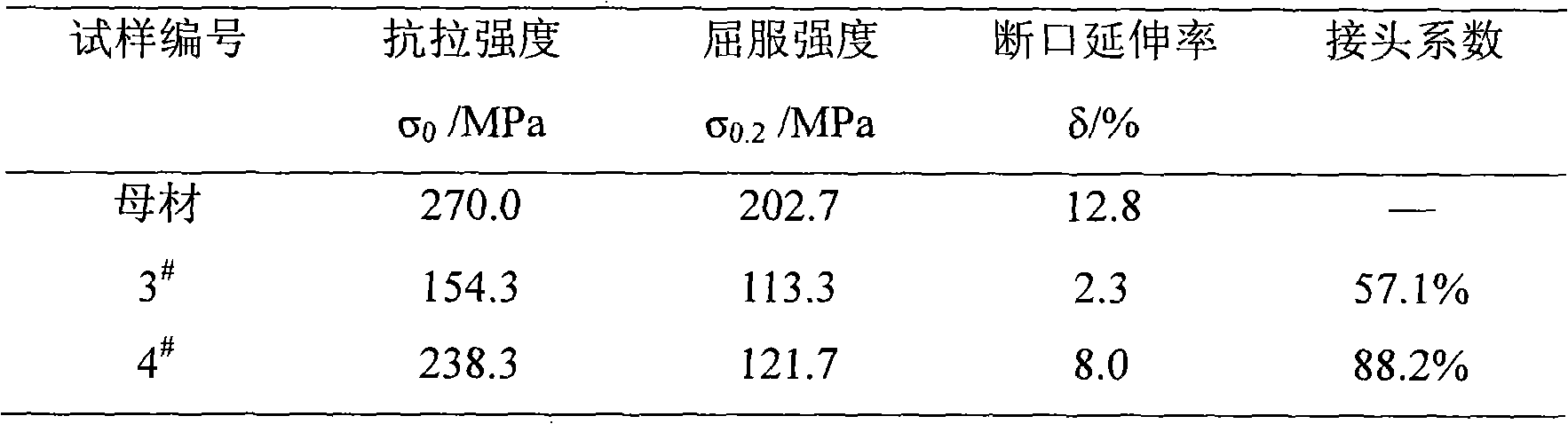

Friction stir welding method of medium plate AZ AZ1 magnesium alloy

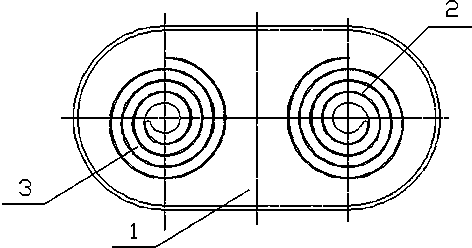

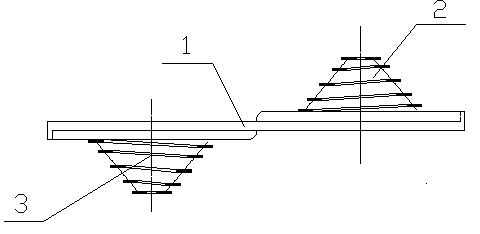

InactiveCN101885109ABeautiful shapeNo surface cracksNon-electric welding apparatusMaterials processingFrustum

The invention relates to a friction stir welding method of a medium plate AZ AZ1 magnesium alloy, belongs to the technical field of welding process used in material processing projects, and particularly provides a friction stir welding method of a 10 to 20-millimeter-thick AZ31 magnesium alloy. The welding inclined angle of a stirring head is 2.5 to 3 DEG, the pressing depth is 0.1 to 0.2 millimeter, the rotation speed is 600 to 1,400r / min, and the welding speed is 100 to 200 mm / min; the shaft shoulder of the stirring head is concave and a stirring pin is frustum-shaped and spiral; the diameter of the shaft shoulder of the stirring head is 28 to 35 millimeters; the diameter of the root part of the stirring pin is 10.3 to 15.1 millimeters, and the diameter of the end part of the stirring pin is 7.8 to 9.3 millimeters; and the length of the stirring pin is 9.6 to 19.5 millimeter. By selecting reasonable welding parameters, the obtained joint is formed elegantly, the maximum tensile strength is up to 94.7 percent of that of a parent metal, and the well welding of the medium plate AZ AZ1 magnesium alloy.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

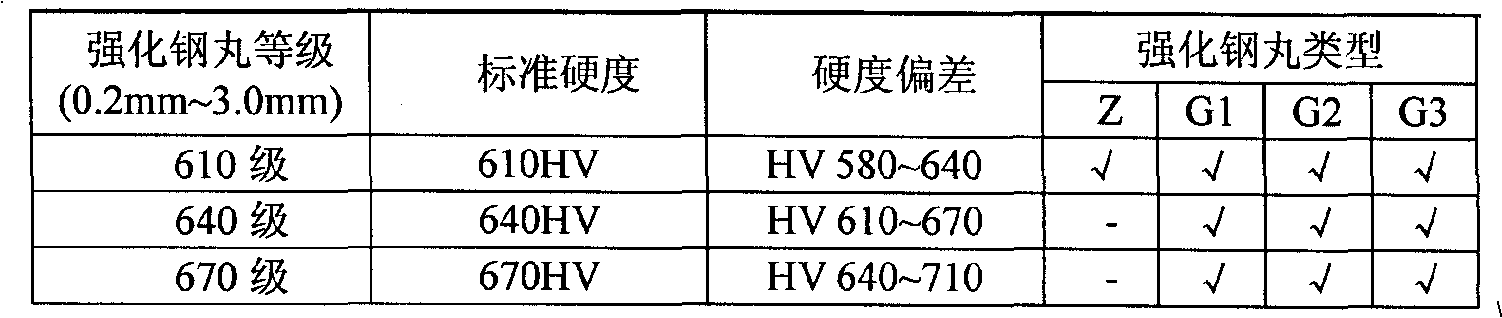

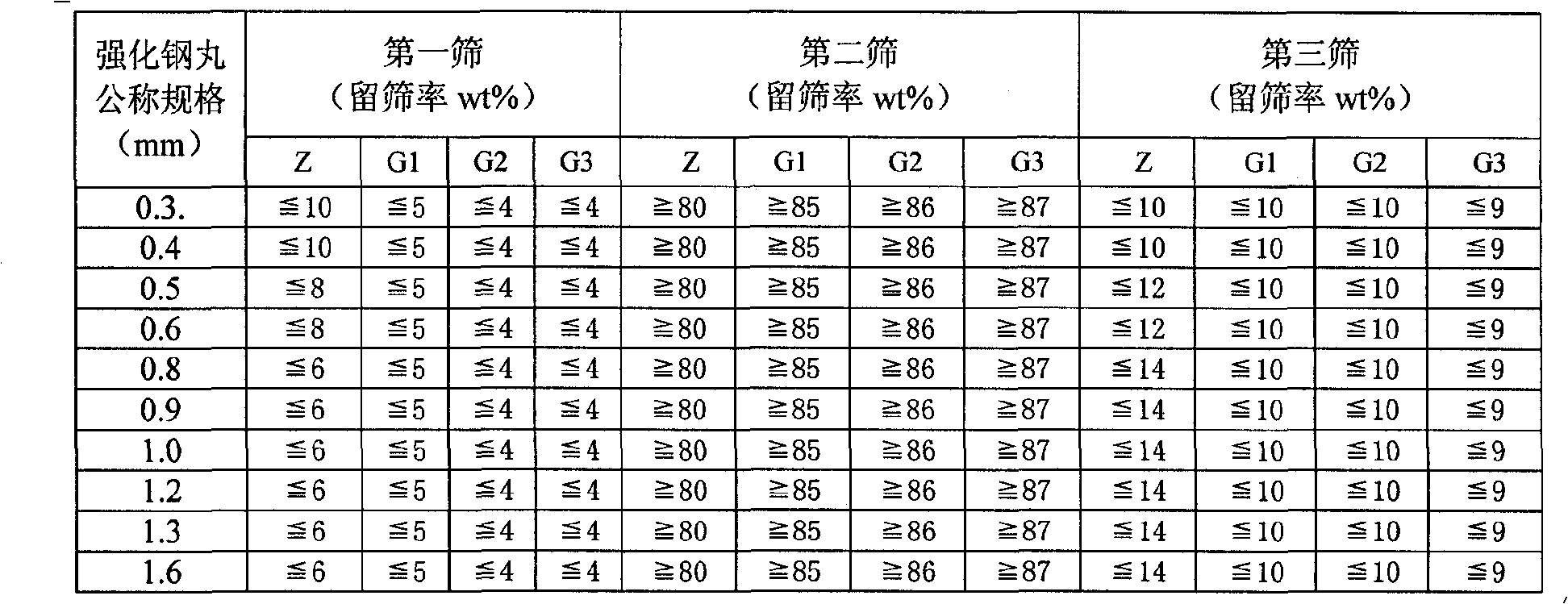

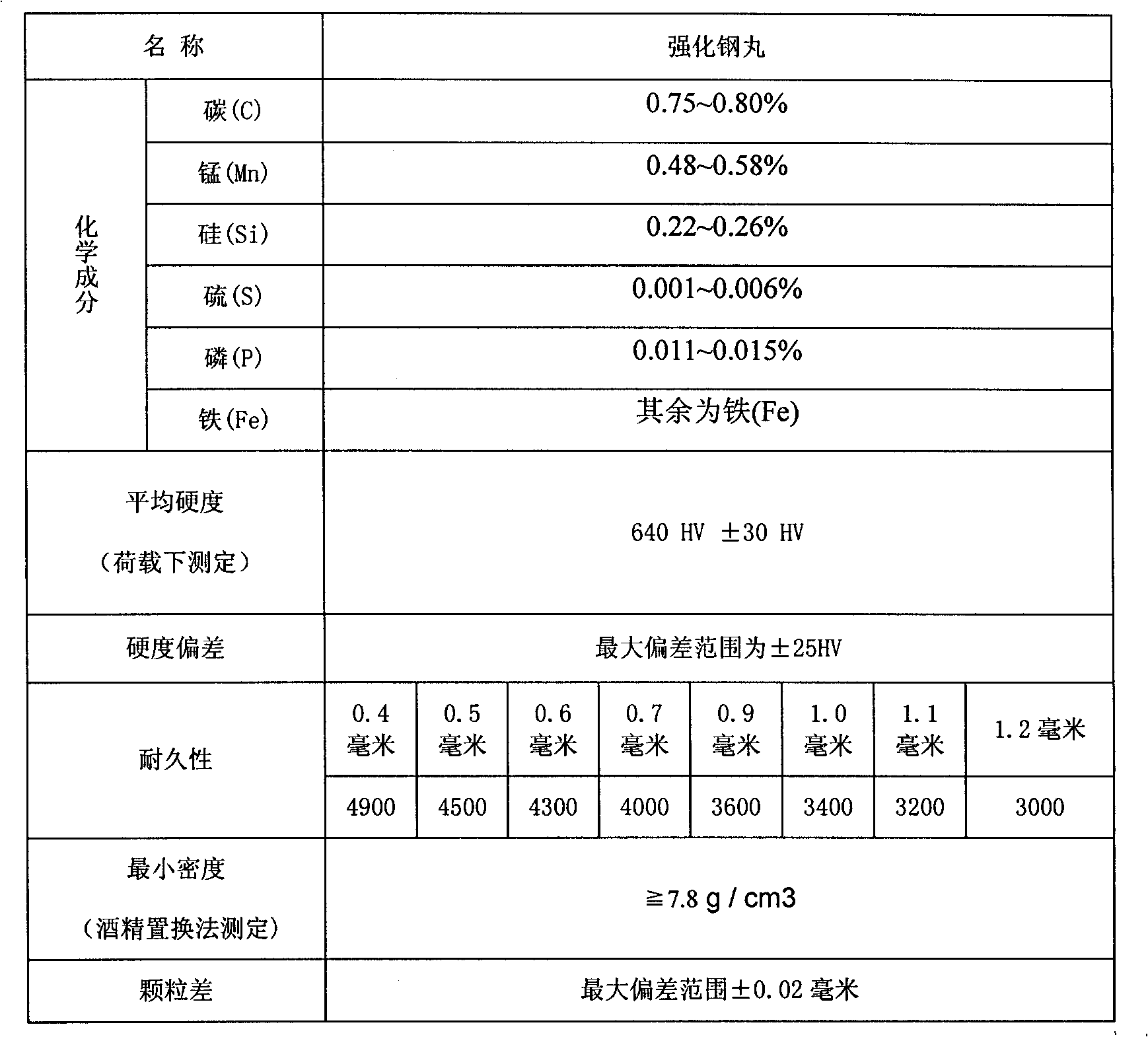

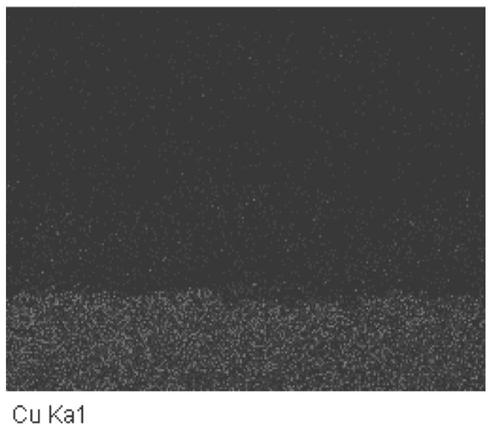

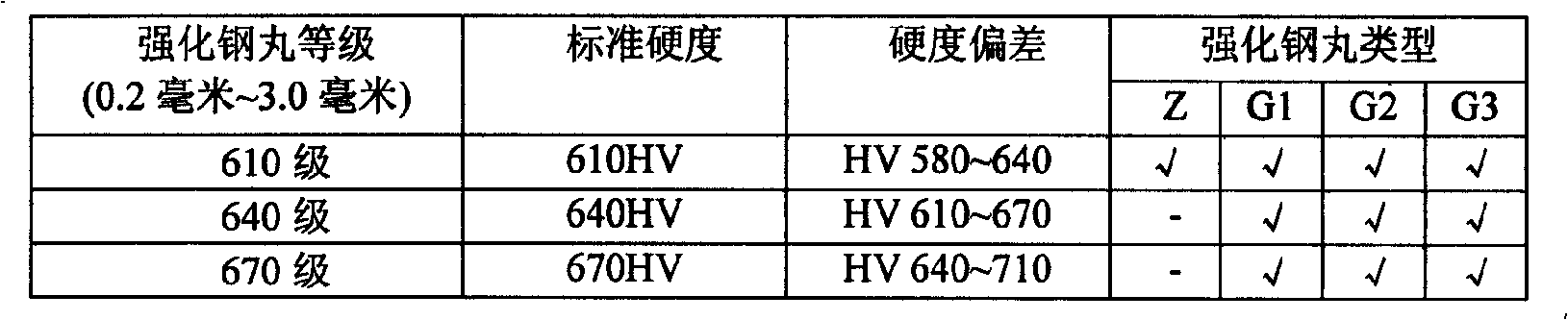

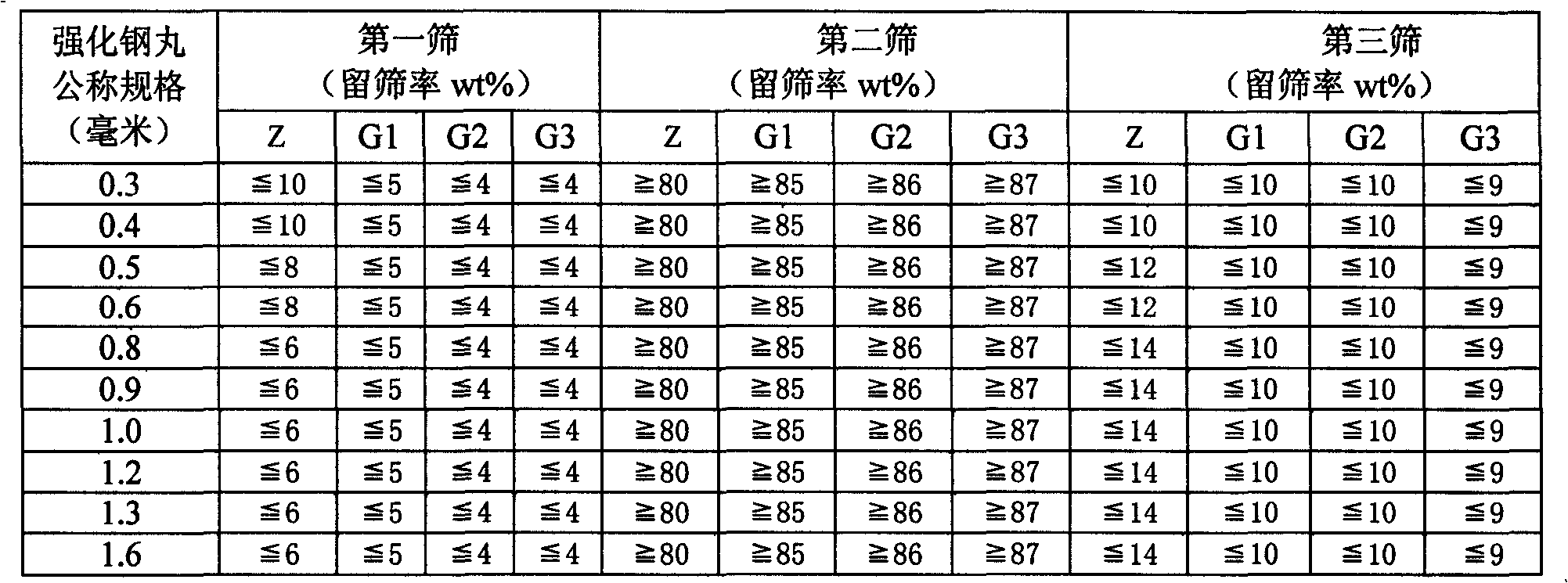

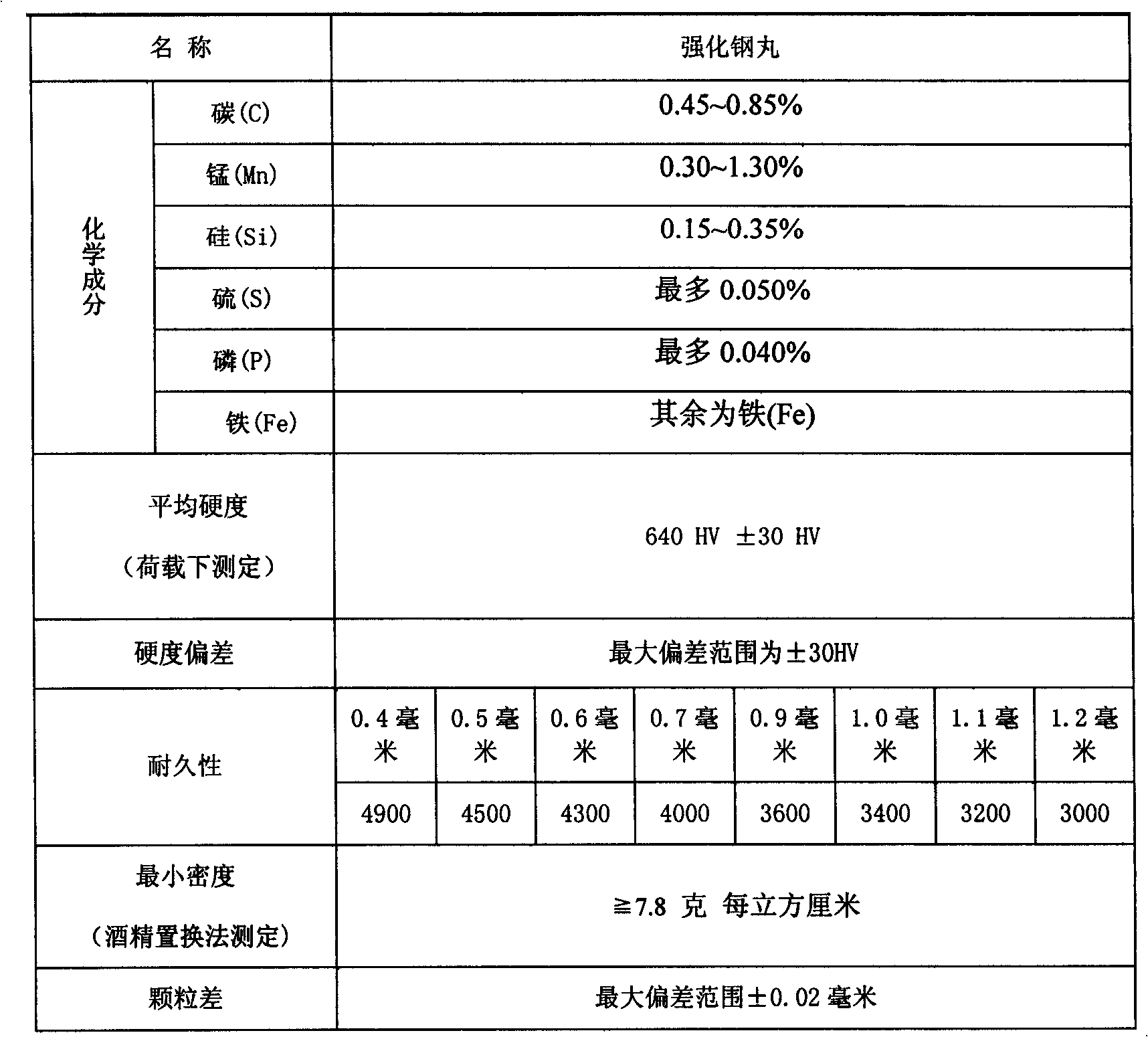

Strengthened steel pill

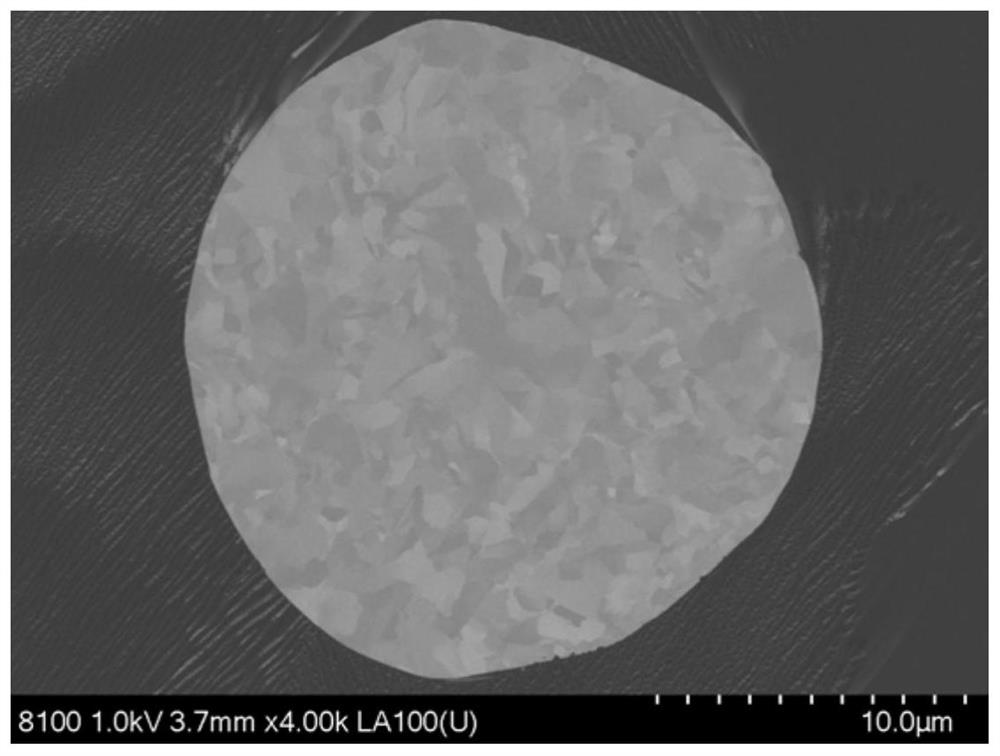

The invention provides strengthening steel shot, and relates to a metal product, in particular to blast shot used for metal surface treatment. The steel shot is characterized in that the steel shot comprises the following components by the weight percentage as follows: 0.45 to 0.85 percent of carbon, 0.30 to 1.30 percent of manganese, 0.15 to 0.35 percent of silicon, sulfur less than or equal to 0.050 percent, and phosphorus less than or equal to 0.040 percent, with iron and inevitable impurities in balancing amount; the average hardness determined under a load is 640HV plus or minus 30HV, and the hardness deviation range is plus or minus 25HV. The strengthening steel shot has the advantages of high consistency of the proportion between the density and elements, smaller hardness deviation ratio, no hollow core and surface crack phenomena, small surface shape difference, high surface strength and good durability. Furthermore, the strengthening steel shot is particularly suitable for surface treatment of high-level workpieces.

Owner:江苏新大奇金属材料科技有限公司

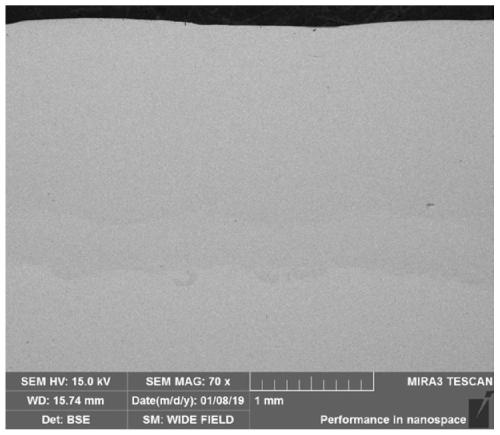

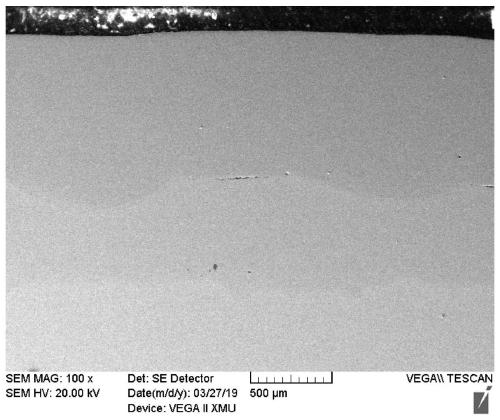

Metal-based material for preparation of crystallizer or tuyere as well as preparation method of metal-based material

ActiveCN110144582AImprove high temperature wear resistanceLower perfect fitMetallic material coating processesSurface engineeringAlloy

The invention discloses a metal-based material for the preparation of a crystallizer or a tuyere and belongs to the technical field of surface engineering. According to the metal-based material, a transition layer is innovatively arranged between a Cu or Cu alloy matrix and a high-abrasion-resistance working layer by the adoption of a metallurgical bonding method, and made of at least one of pureCo metal, pure Ni metal, pure Cr metal, pure Cu metal, pure Mo metal, pure Ag metal and a NiCr or MCrAlY alloy; through the transition layer, the functions of improving the laser absorption rate, lowering the matrix heat conductivity, and lowering the dilution rate can be achieved; due to the existence of the transition layer, the thickness of the working layer can be adjusted within a range of 0.01-3 mm and the formation of surface cracks can be avoided; furthermore, the ratio of the thickness of the transition layer to that of the high-abrasion-resistance working layer is 1:(1-3), so that the perfect bonding of the transition layer and the high-abrasion-resistance working layer can be guaranteed within the ratio range; the formation of a high-abrasion-resistance coating or coating product which is free of surface cracks and subjected to metallurgical bonding on the Cu or Cu alloy matrix can be improved; the reliability of the crystallizer or the tuyere can be improved; and the service life of the crystallizer or the tuyere can be prolonged.

Owner:XI AN JIAOTONG UNIV

Method for producing molybdenum electrode bar by means of precision forging

The invention discloses a method for producing a molybdenum electrode bar by means of precision forging. The method includes the steps of molybdenum powder selection, bar blank pressing, molybdenum bar blank sintering, straightening and forging. The problem that the specifications of the molybdenum bar blanks are unmatched with the forging means in the prior art is solved, and the molybdenum electrode bar produced by the method is uniform in size and quality and free of burrs and surface cracks.

Owner:JINDUICHENG MOLYBDENUM CO LTD

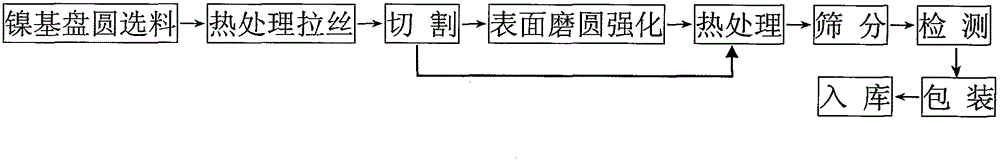

Preparation method of strengthened steel pill

InactiveCN101337317AHigh densityHigh consistency of element ratioAbrasion apparatusInvestigating material hardnessHigh surfaceVolumetric Mass Density

A method for manufacturing a reinforced steel shot relates to a method for manufacturing metal products, particularly to a method for manufacturing the reinforced steel shot used for the metal surface treatment. The method for manufacturing the reinforced steel shot comprises the following process flow: selecting a material, drawing wires, cutting, screening, detecting and storing; or selecting a material, drawing wires, cutting, rounding and reinforcing the surface, screening, detecting, and storing. Since the reinforced steel shot is made of a sectional material, namely a spring steel wire, which is in accordance with requirements of the elementary composition proportion and the hardness deviation range, the density and the consistence of element proportion of the reinforced steel shot are high. Since a novel process is adopted, the reinforced steel shot has the advantages of no occurrence of hollow and surface cracking phenomena, small difference of surface shapes, high surface strength and long service life. The produced reinforced steel shot by using the method is particularly suitable for the high-end workpiece surface treatment.

Owner:CSIC DALIAN NEW MATERIALS CO LTD

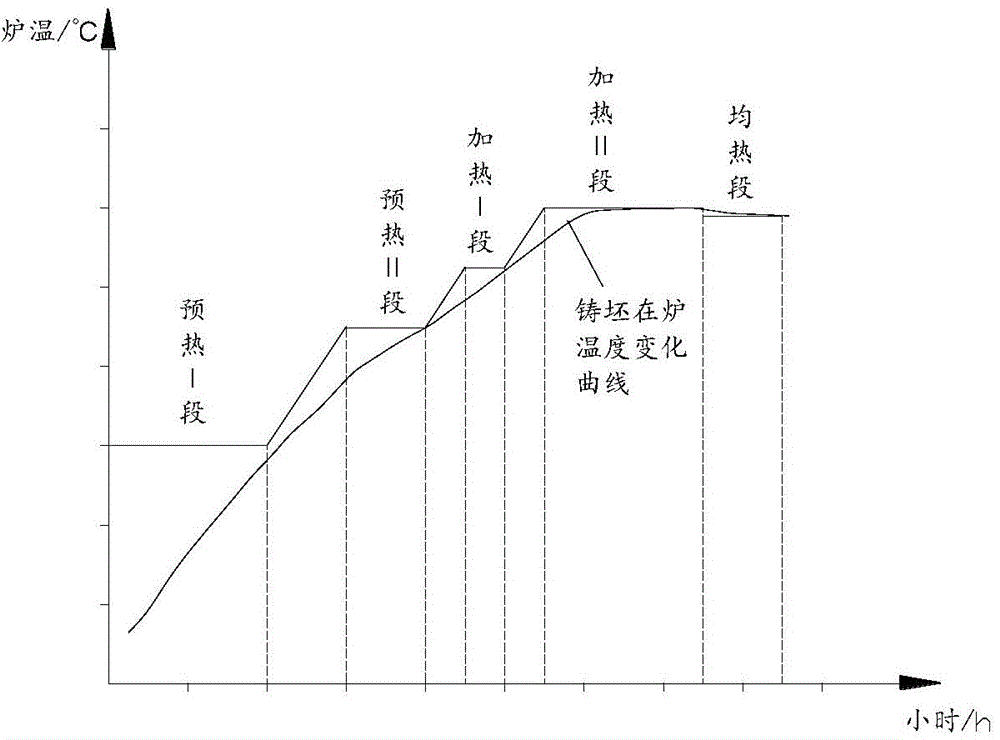

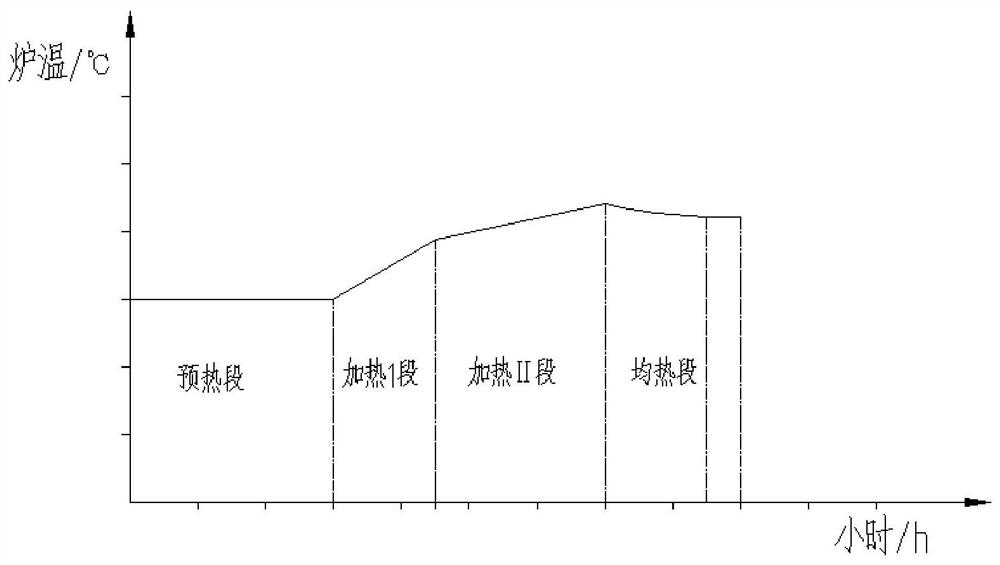

Cold-charge heating method of bearing steel continuous casting billet

ActiveCN104313298AInhomogeneity qualifiedNo overheatingFurnace typesHeat treatment furnacesCarbideContinuous casting

The invention discloses a cold-charge heating method of a bearing steel continuous casting billet, which comprises a preheating section I, a preheating section II, a heating section I, a heating section II and a soaking section. On the premise of not generating overburning and surface crack and ensuring the carbide uniformity to reach the standard, the method satisfies the cold-charge heating and rolling production of the bearing steel continuous casting billet.

Owner:SHANDONG IRON & STEEL CO LTD

Corrosion-resistant high-strength support/hanger assembly and manufacturing technology thereof

ActiveCN105042191AGood plastic deformation stabilityUniform materialPipe supportsManufacturing technologyEngineering

The invention discloses a corrosion-resistant high-strength support / hanger assembly. The support / hanger assembly comprises a tube clamp and a connecting part arranged at the lower end part of the tube clamp, wherein the tube clamp comprises two clamp pliers which are in the same shape and are symmetrically arranged; each clamp plier comprises a connecting end, a circular arc section and a clamping section; the connecting ends of the two clamping pliers are connected together in a rotating manner; the arc mouth ends of the circular arc sections of the two clap pliers are oppositely arranged; fastening holes are respectively formed in the clamping sections of the two clamp pliers, and the two fastening holes correspond to each other. The invention further discloses a manufacturing technology of the corrosion-resistant high-strength support / hanger assembly. The support / hanger assembly disclosed by the invention is simple and reasonable in tube clamp structure, scientific in design, high in strength, hardness and toughness, resistant to acid and alkaline corrosion, not liable to deform under high temperature and high pressure, and long in service life.

Owner:BEIDELI ENERGY EQUIP JIANGSU CO LTD

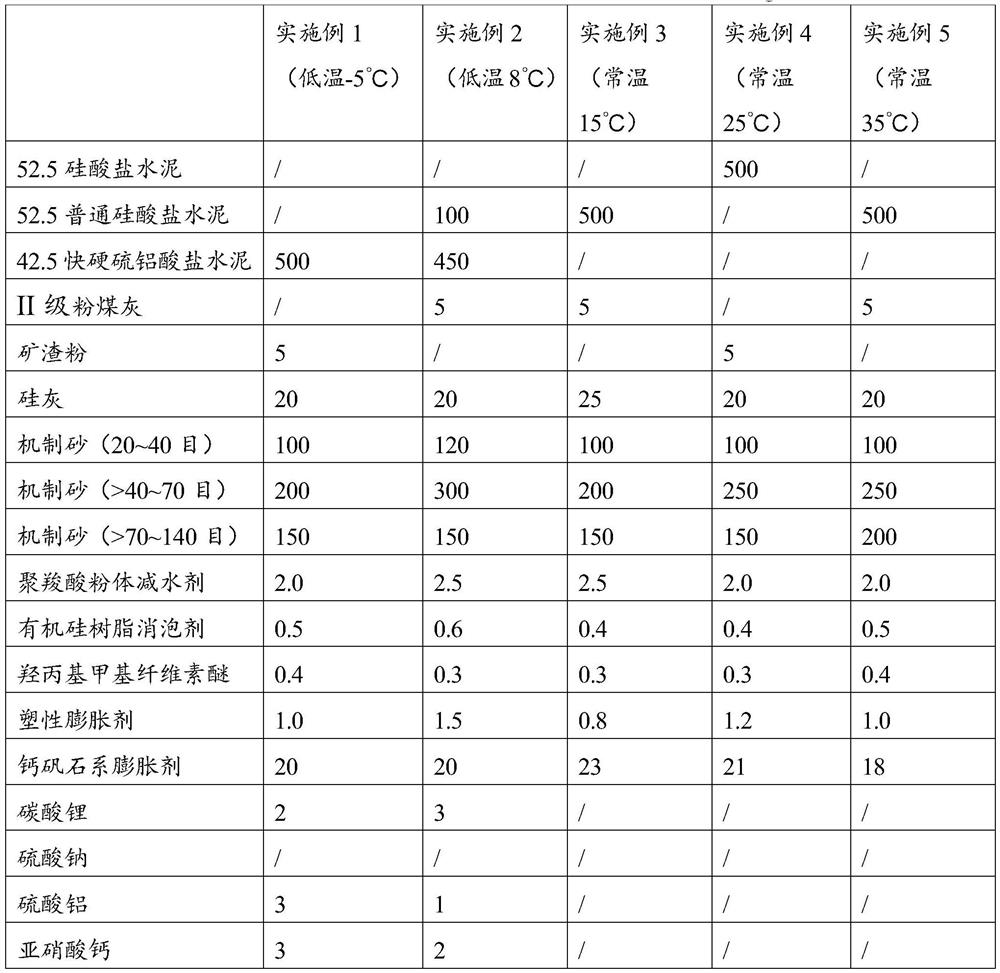

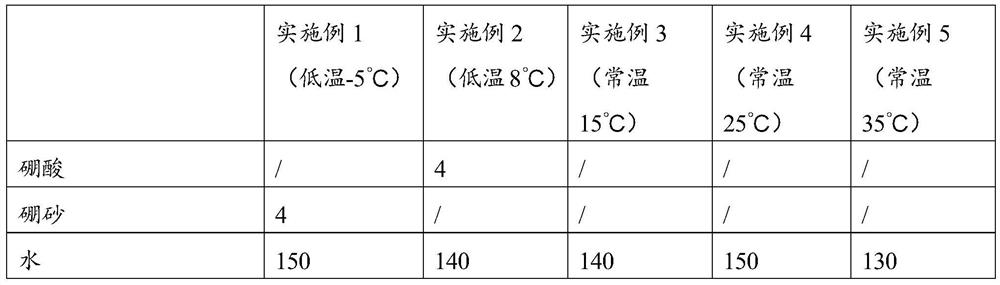

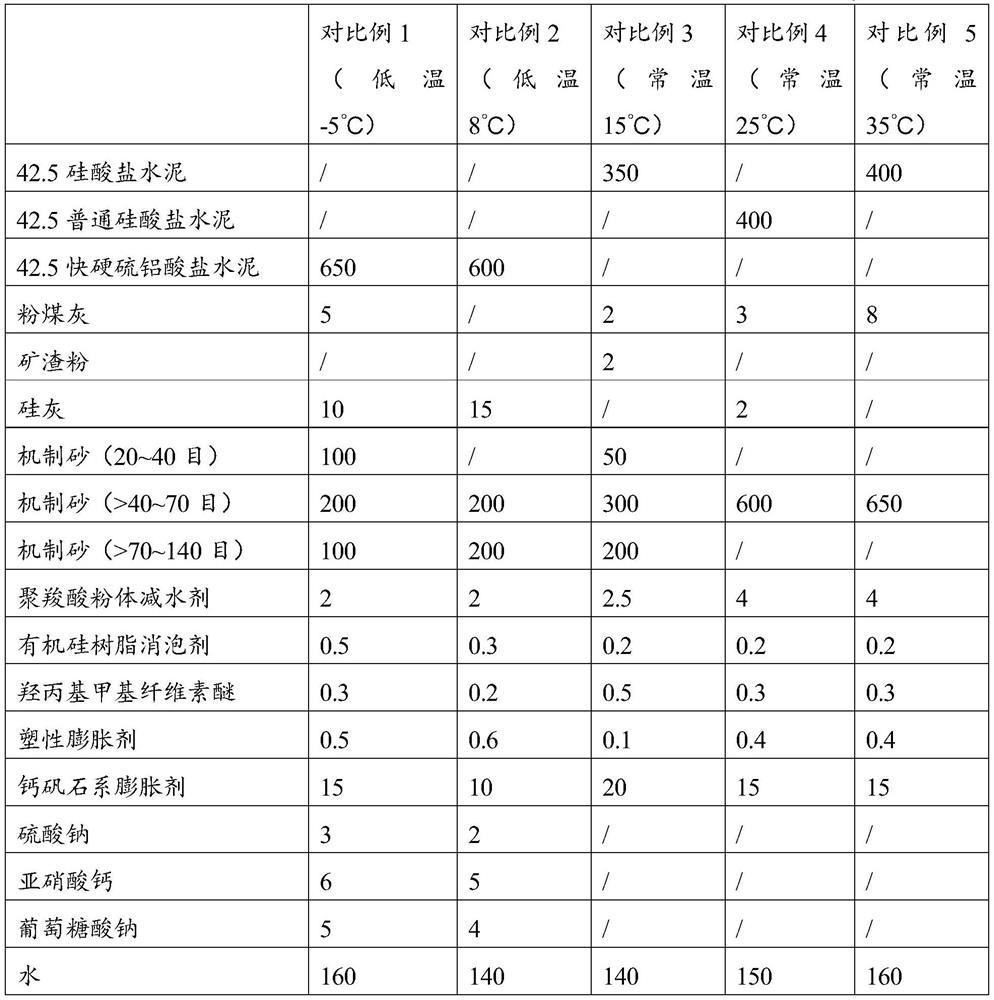

Sleeve grouting material for steel bar connection and preparation method and application thereof

The invention provides a sleeve grouting material for steel bar connection and a preparation method and application thereof.The sleeve grouting material is composed of a component A and a component B.The component A is dry powder and comprises, by mass, 400-600 parts of cement, 10-40 parts of mineral admixture, 400-600 parts of sand, 0.2-3.0 parts of plastic expanding agent, 15-25 parts of expanding agent, 1-3 parts of water reducing agent, 0.2-1.0 part of defoaming agent, 0.1-1.0 part of stabilizer, 0-10 parts of antifreezing agent, 0-5 parts of an early strength agent, and 0-5 parts of a retarder; and the component B is water and comprises, in parts by mass, 120-170 parts of water. The sleeve grouting material has the characteristics of high fluidity, micro-expansion, high strength andthe like, and can be suitable for construction at different temperatures (-5 to 10 DEG C) and normal temperature (higher than 10 DEG C).

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +2

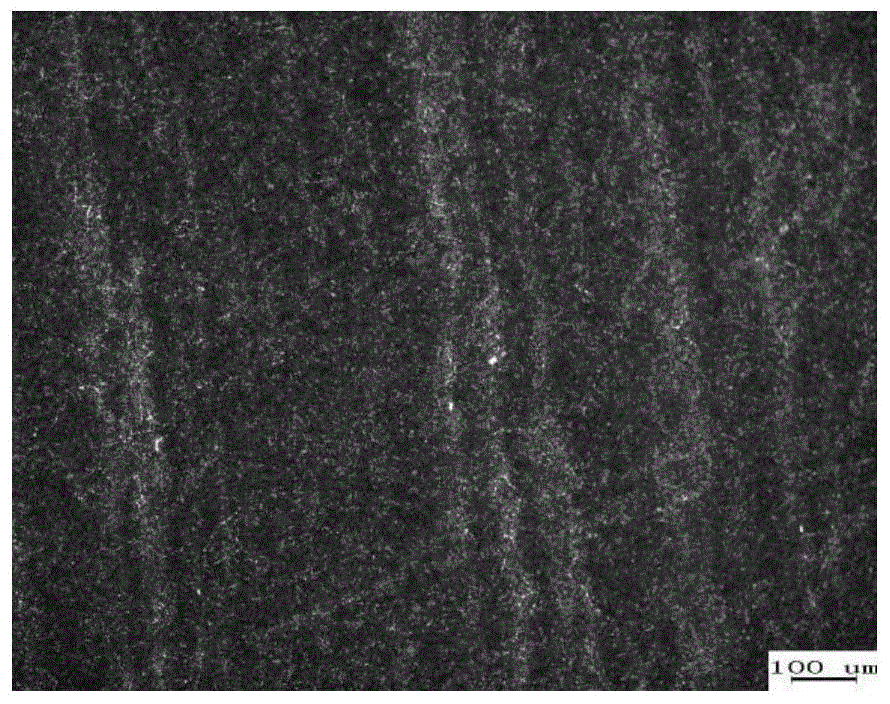

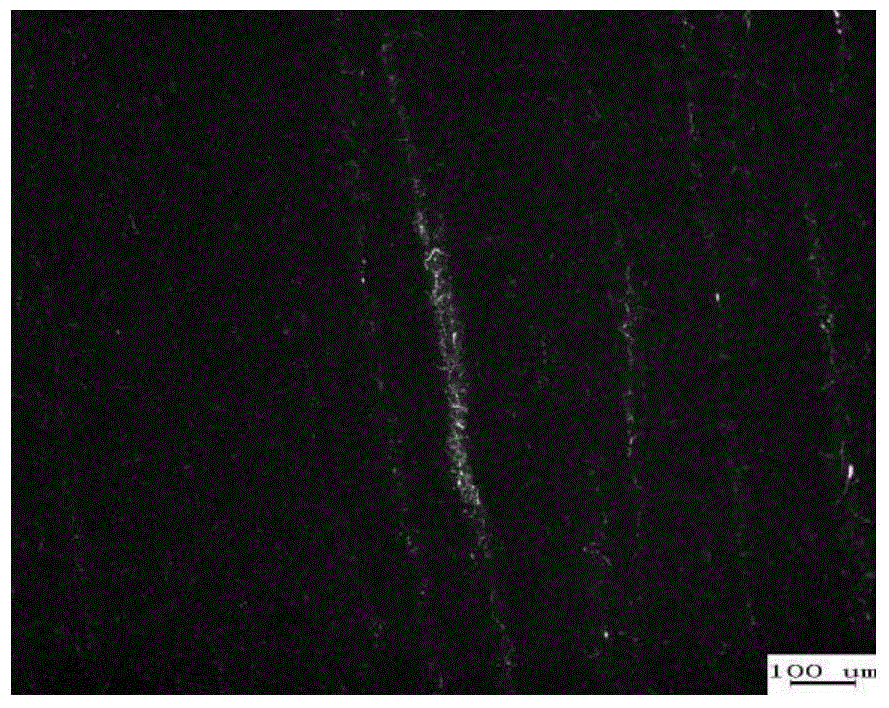

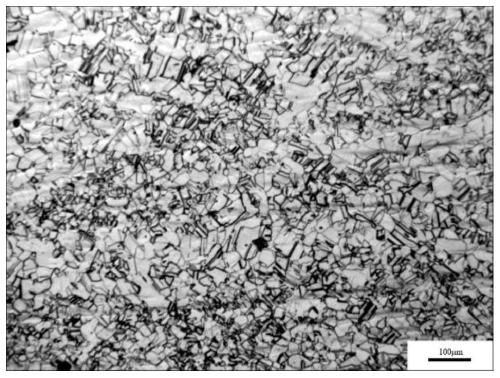

Cold rolling and annealing preparation method of high-tungsten high-cobalt nickel alloy ultra-fine grain panel

The invention relates to a cold rolling and annealing preparation method of a high-tungsten high-cobalt nickel alloy ultra-fine grain panel, and belongs to the technical field of metal materials. An alloy is prepared from the components in percentage by weight: 25 to 45 percent of tungsten, 15 to 25 percent of cobalt, and the balance nickel and residual elements. The method comprises the preparation processes of adopting a cold rolling and annealing alternate repeating deformation path, wherein the cold-rolling deformation amount per pass is 20 to 45 percent, and the cold-rolling deformation amount of the last pass is larger than or equal to 25 percent; and annealing a panel veneer cold-rolled per pass in the middle, wherein the annealing temperature is 850 to 1100 DEG C, and the annealingtime is 30 to 150min. According to the cold rolling and annealing preparation method of the high-tungsten high-cobalt nickel alloy ultra-fine grain panel provided by the invention, the high-tungstenhigh-cobalt nickel alloy ultra-fine grain panel is prepared through a cold rolling and annealing way; and the obtained panel is uniform in deformation, has no defect such as surface cracks, has a tinyinner grain structure with the grain size grade being not lower than 7 grade, has an ideal microscopic structure and an excellent mechanical property in each direction, has a grain size grade difference not exceeding 2 grades, has the ductility reaching to 76 percent, the tensile strength reaching to 995MPa and the yield strength reaching to 588MPa, and is capable of meeting the requirements of multiple product production processes such as follow-up die forging, rocking-rolling, punching and spinning on the panel.

Owner:UNIV OF SCI & TECH BEIJING

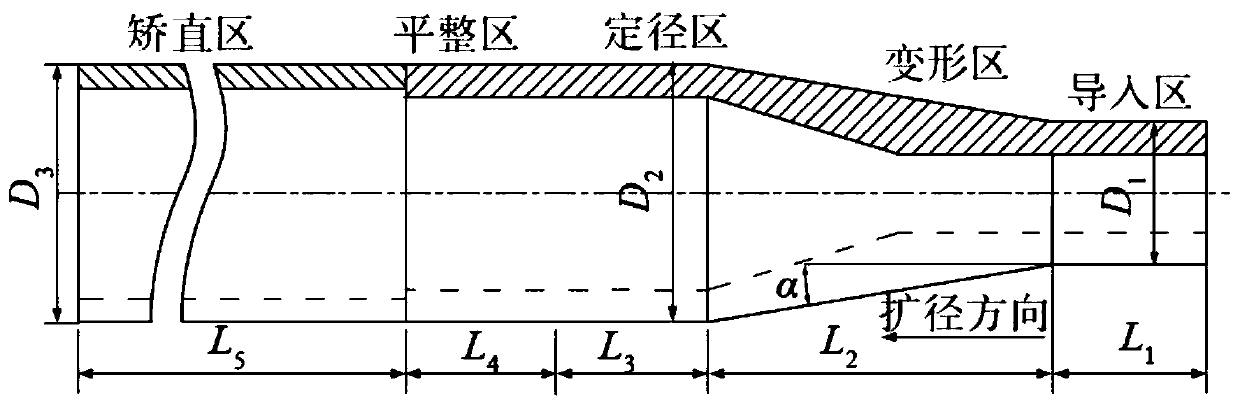

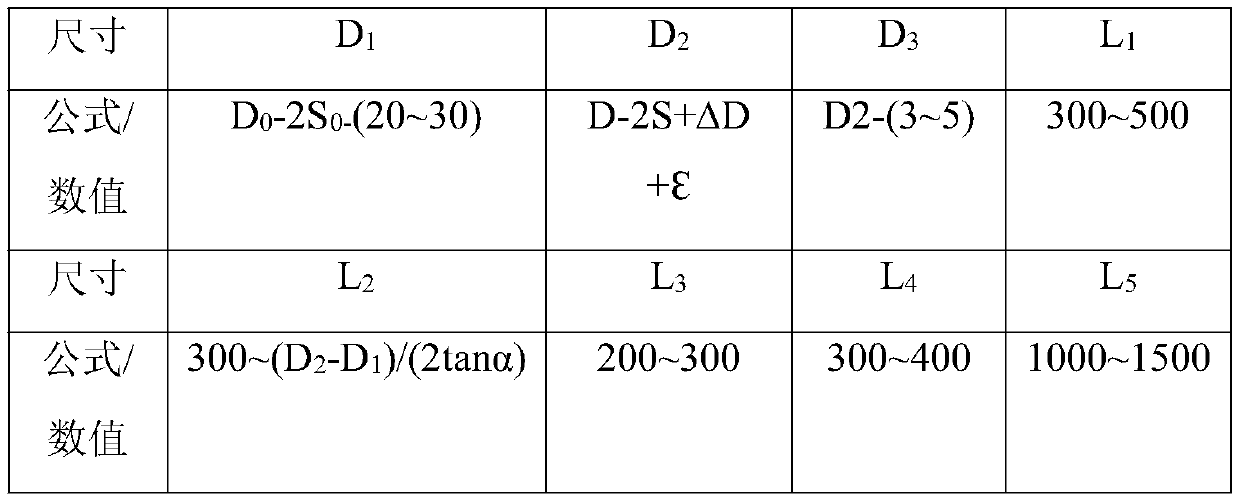

Manufacturing method for seamless steel tube for large-caliber high-pressure boiler

ActiveCN110711777AWide range of sizesFulfil requirementsShaping toolsMeasuring devicesMechanical engineeringMaterials science

The invention provides a manufacturing method for a seamless steel tube for a large-caliber high-pressure boiler. After an 820 oblique rolling unit is used for perforating, a pierced billet is rolled,an intermediate-frequency heat expanding unit is used for expanding, heat treatment is conducted, and a hydraulic straightener and a six-roller straightener are utilized for two-step straightening and circle tidying. The high-pressure boiler seamless steel tube manufactured through the method can reach following indexes that the outer diameter is 840-1,220 mm, the wall thickness is 25-120 mm, andthe maximum length is 14 mm; and the outer diameter tolerance is + / -1.0%, the inner diameter tolerance is + / -0.75%, the wall thickness tolerance is + / -10%, the straightness is smaller than 1.5 mm / m,and the ovality is smaller than 1.0% of the average diameter.

Owner:DEXIN STEEL PIPE CHINA

Method for directly loading casting blank of thick plate containing microalloy elements

InactiveCN103341607AAvoiding cold bend cracking problemsImprove cold bending performance pass rateRare earthPerformance index

The invention provides a method for directly loading a casting blank of a thick plate containing microalloy elements. The method comprises the steps that the content of Mn and S in steel is controlled, the casting blank gets out of a casting machine to be strongly cooled in an on-line mode, the temperature when the casting blank gets out of a straightening section is controlled, the cooling rate and the cooling time when the casting blank gets out of a strongly-cooling section are controlled, then air cooling is conducted on the casting blank, the casting blank is cut for the first time and the second time along a conveying roller and then enters a heating furnace after the size is fixed, and the surface temperature before the casting blank enters the heating furnace is controlled. The measures that rare earth is added in liquid steel in the smelting process and the oxygen content in the liquid steel is controlled at the same time can be adopted. According to the method, existing devices and processes are fully utilized, investment does not need to be increased, operation is easy, the problems of cold bending and cracking of directly-loaded rolled metal containing the microalloy elements can be solved, qualified rate of the cold bending performance of steel plates is improved, combustion consumption of the heating furnace is reduced, oxidation burning loss of the casting blank is reduced, the capacity of the heating furnace is improved, surface cracks do not exist on the steel plates which are rolled, and all performance indexes meet the standard requirement.

Owner:ANGANG STEEL CO LTD

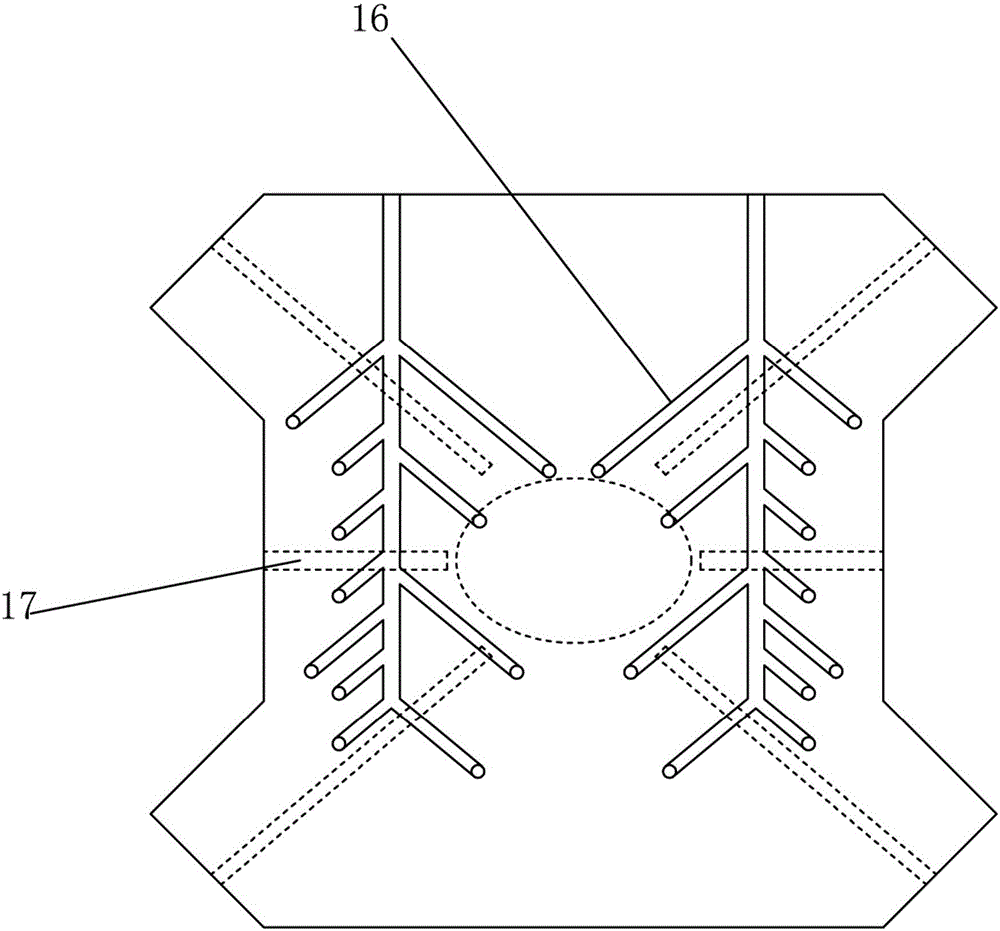

Metal die device, die-casting method and die-cast articles

InactiveCN1096906CNo casting wrinklesNo surface cracksFoundry mouldsFoundry coresRare-earth elementDie casting

The present invention provides a kind of metallic mold scheme and the die casting method for magnesium alloy using the same that the metallic mold scheme is applied to die casting for magnesium alloy or metal injection molding. The invention is characterized that it provides a plurality of vertical gates and configured with horizontal runners from vertical runners to each gates; and, the distances of non-gating portion between neighbored gates are set to under 10 mm except that the product design was not allowed for this setting. The die casting method using the disclosed metallic mold scheme can be applied to thin-wall die casting, especially for the thin-wall die casting with thickness under 1.5 mm or for the alloy casting containing silicon, rare earth elements, calcium. The die casting product from the invented method will have no wrinkles, surface cracks, insufficient filling, and without mold adherence.

Owner:MITSUI MINING & SMELTING CO LTD

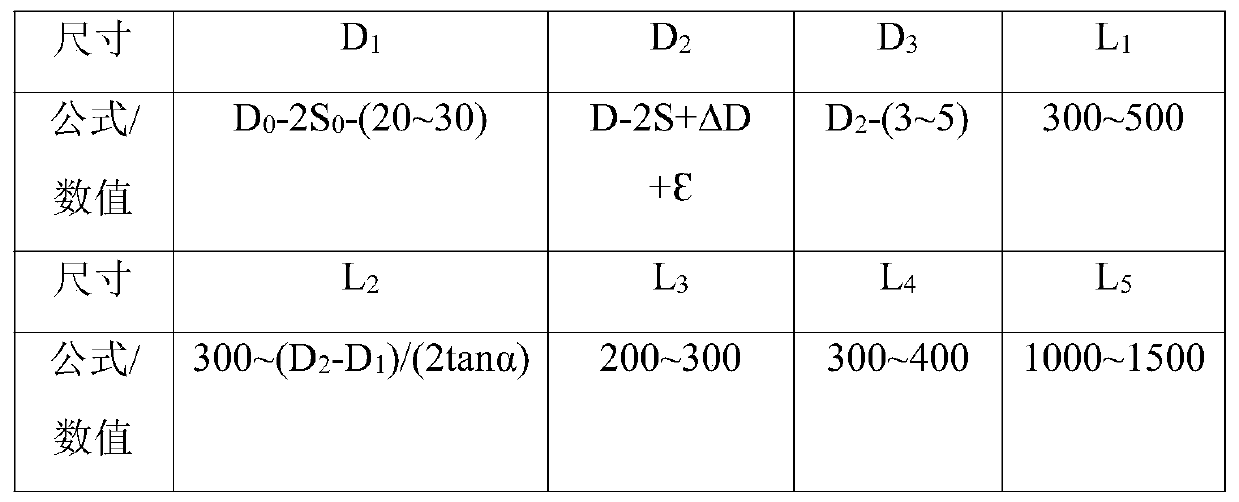

Large section gear steel continuous casting round billet heating process

The invention discloses a large section gear steel continuous casting round billet (the diameter Phi of a section is 650 mm) heating process. The process comprises a preheating section, a heating section I, a heating section II and a soaking section. On the premise of not generating overburning and surface cracks, the large section gear steel continuous casting round billet heating process is designed to meet heating and rolling production of the large section gear steel continuous casting round billet, thereby meeting a demand of a gear steel user on grain size greater than or equal to 6.0 grade and a banded structure smaller than or equal to 2.5 grade.

Owner:SHANDONG IRON & STEEL CO LTD

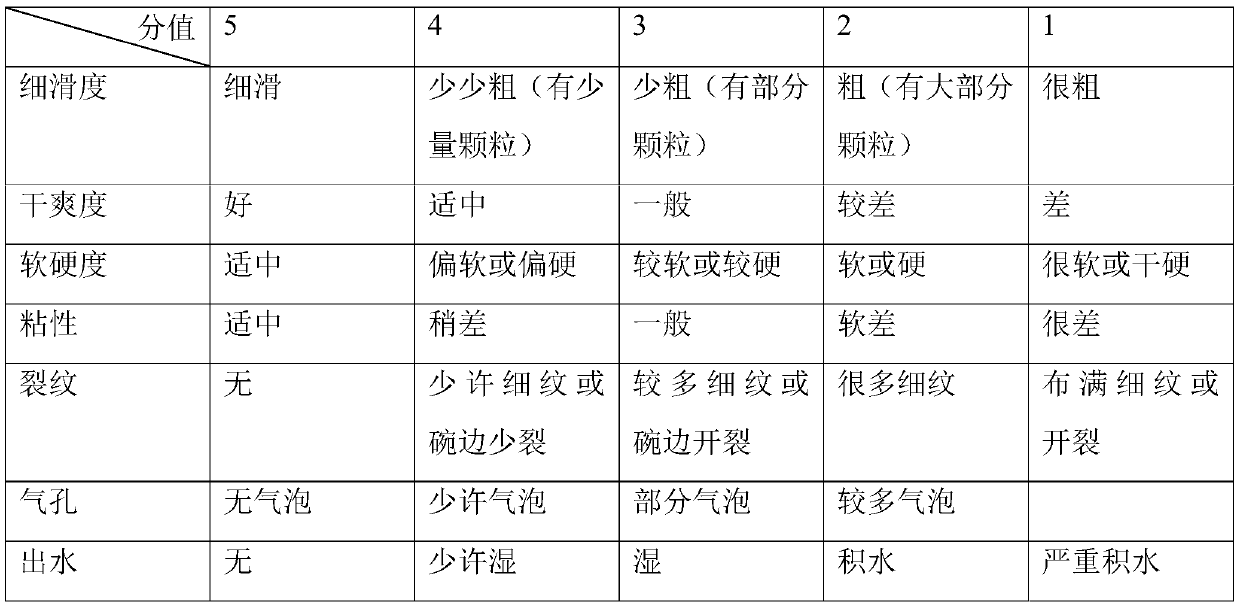

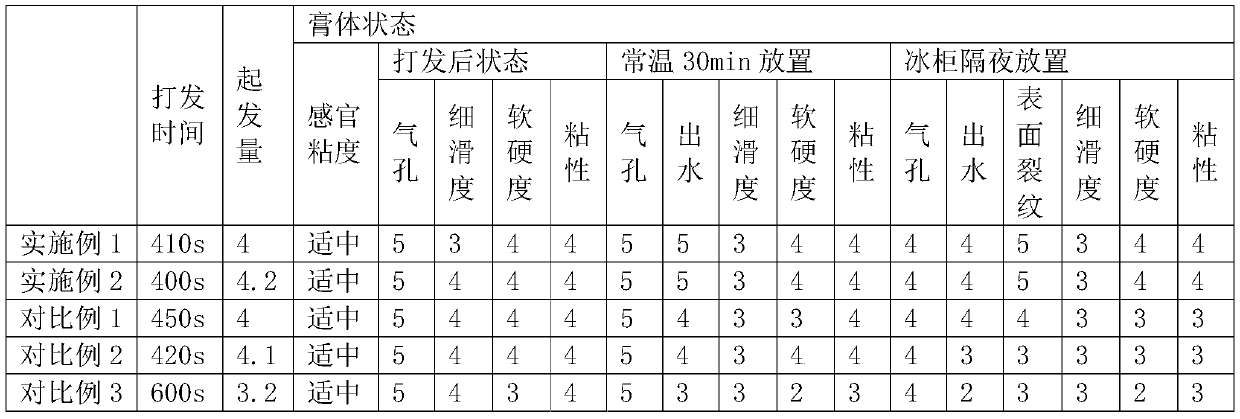

Double-plant-based coconut milk non-dairy cream and preparation method thereof

InactiveCN111616224AStrong natural coconut fragrancePure and soft tasteEdible oils/fats ingredientsEdible oils/fats production/working-upBiotechnologyVegetable oil

The invention discloses double-plant-based coconut milk non-dairy cream and a preparation method thereof. The double-plant-based coconut milk non-dairy cream comprises the following components in percentage by weight: 22%-28% of sugar, 10%-18% of vegetable fat, 3%-6% of coconut milk, 1%-1.8% of an emulsifier, 0.2%-1.2% of a thickener, 0.01%-0.5% of a stabilizer, 0.08%-0.5% of table salt, 0-0.5% ofedible essence and the balance of drinking water. The coconut milk and the vegetable fat are combined to prepare the double-plant-based cream, and the double-plant-based cream has rich natural coconut fragrance, tastes pure and soft, contains a proper amount of fat, a large amount of vegetable proteins and nutrient substances, and meets diversified taste requirements on the market. The double-plant-based coconut milk non-dairy cream prepared by the preparation method has the advantages of strong coconut fragrance, good whipping performance and good stability, and is suitable for industrial production.

Owner:增城市金点食品有限公司

Antimony-containing yield-strength 350MPa-level high-corrosion hot rolled H-shaped steel and production method thereof

InactiveCN108251764ALower yield strengthImprove solubilityProcess efficiency improvementManganeseImpurity

The invention provides antimony-containing yield-strength 350MPa-level high-corrosion hot rolled H-shaped steel and a production method thereof. The H-shaped steel is prepared from the chemical ingredients in percentage by mass: 0.06 to 0.15% of carbon, 0.20 to 0.55% of silicon, 1.00 to 1.45% of manganese, smaller than or equal to 0.025% of phosphorus, smaller than or equal to 0.015% of sulphur, 0.030 to 0.150% of vanadium, 0.050 to 0.090% of antimony, 0.9 to 2.20% of chromium and the balance of trace impurities of iron residues. Compared to the prior art, according to the invention, the H-shaped steel produced by the production method has yield strength of over 380Mpa, toughness at a low temperature of -40 DEG C of over 100J and has excellent toughness of resisting to low temperature impact. The antimony-containing yield-strength 350MPa-level high-corrosion hot rolled H-shaped steel can meet a condition that when the antimony-containing yield-strength 350MPa-level high-corrosion hot rolled H-shaped steel is totally immersed for 24 hours in solution with sulfuric acid concentration of 20% at a temperature of 25 DEG C, a relative corrosion rate with Q345B is smaller than or equal to10%; and compared with common weathering resistant steel, the antimony-containing yield-strength 350MPa-level high-corrosion hot rolled H-shaped steel is obviously improved in product surface quality.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Sea salt-cheese milk-containing non-dairy cream and preparation method thereof

PendingCN110463781AUnique Sea Salt Cheese FlavorMeet the needs of diverse tastesEdible oils/fats ingredientsEdible oils/fats production/working-upVegetable oilAdditive ingredient

The invention discloses a sea salt-cheese milk-containing non-dairy cream and a preparation method thereof, wherein the sea salt-cheese milk-containing non-dairy cream is composed of the following rawmaterials by the weight percentage: 22%-28% of sugar, 12%-18% of vegetable oil, 1%-5% of milk fat, 1%-5% of cheese, 1%-4% of condensed milk, 1.0%-1.8% of an emulsifier, 0.3%-1.2% of a thickener, 0.05%-0.2% of a stabilizer, 0%-0.1% of a coloring agent, 0.08%-0.5% of sea salt, 0%-0.5% of an edible essence, and water added to make the total amount to 100%. The sea salt and cheese ingredients are added on the basis of milk fat-containing non-dairy cream, so that the sea salt-cheese milk-containing non-dairy cream has unique sea salt and cheese flavor, meets the diversified taste demand on the market, has good comprehensive performance and good stability after standing, and is also suitable for industrial production and transportation.

Owner:ZENGCHENG LEGO FOODS CO LTD

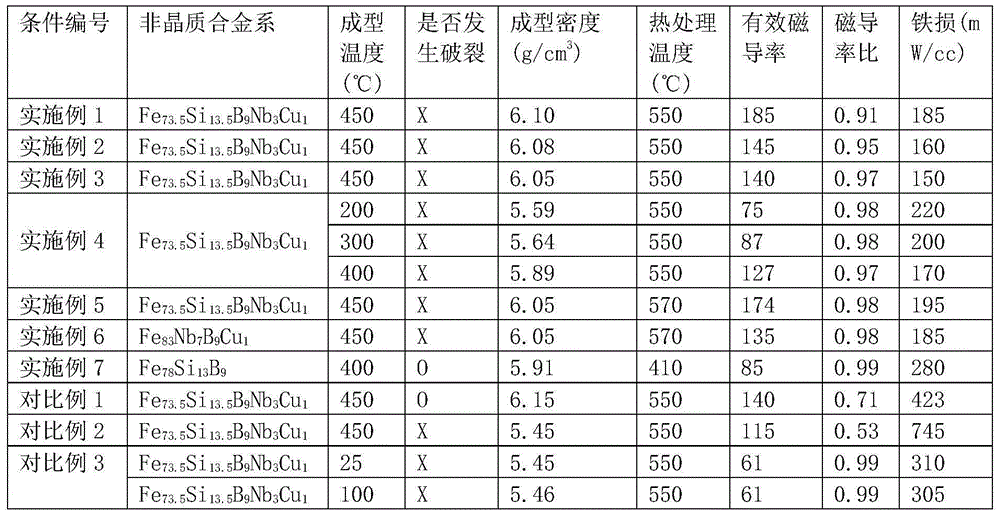

High-permeability amorphous compressed powder core by means of high-temperature molding, and method for preparing same

InactiveCN104884196ASmall change in effective permeabilitySmall changes in magnetic permeabilityTransportation and packagingMetal-working apparatusO-Phosphoric AcidPolyimide

Owner:裵恩英

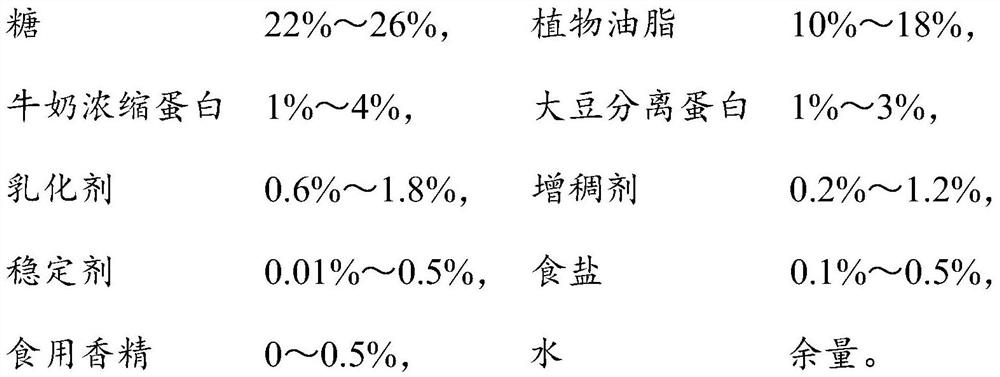

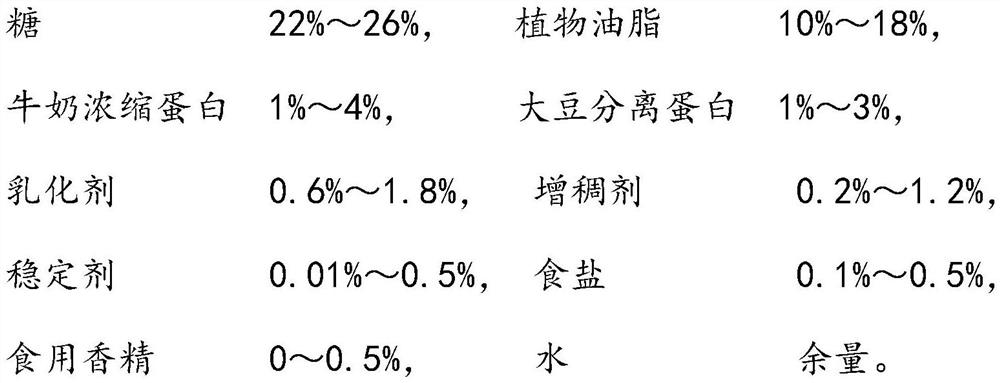

High-protein non-dairy cream and preparation method thereof

InactiveCN111616226AImprovement ingredientsImprove immunityEdible oils/fats ingredientsEdible oils/fats production/working-upBiotechnologyAnimal science

The invention discloses high-protein non-dairy cream and a preparation method thereof. The high-protein non-dairy cream is composed of the following components in percentage by weight: 22%-26% of sugar, 10%-18% of vegetable fat, 1%-4% of milk protein concentrate, 1%-3% of soy isolate protein, 0.6%-1.8% of emulsifier, 0.2%-1.2% of thickener, 0.01%-0.5% of stabilizer, 0.1%-0.5% of salt and 0-0.5% ofedible essence and the balance of water. The milk protein concentrate and the soybean protein isolate are combined with the vegetable oil, so that the high-protein non-dairy cream has high protein, and meets diversified taste requirements on the market. The high-protein non-dairy cream prepared by the preparation method disclosed by the invention is good in whipping performance; the whipped creamis relatively good in stability, and after being refrigerated overnight, the whipped cream has no pores or surface cracks, and maintains favorable smoothness, glossiness, hardness and viscosity.

Owner:增城市金点食品有限公司

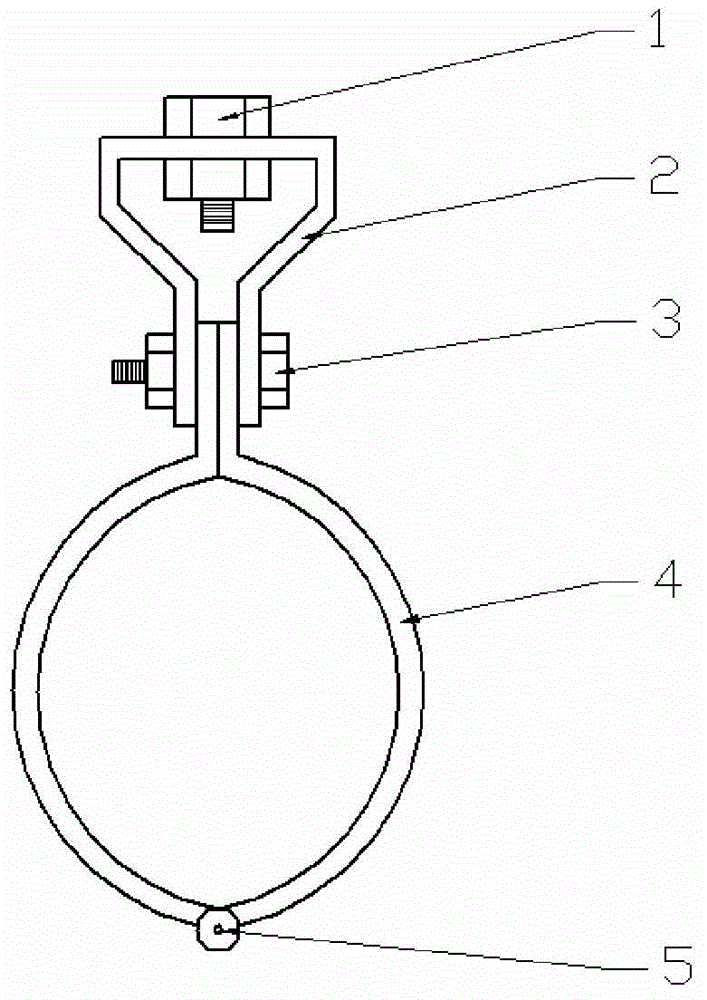

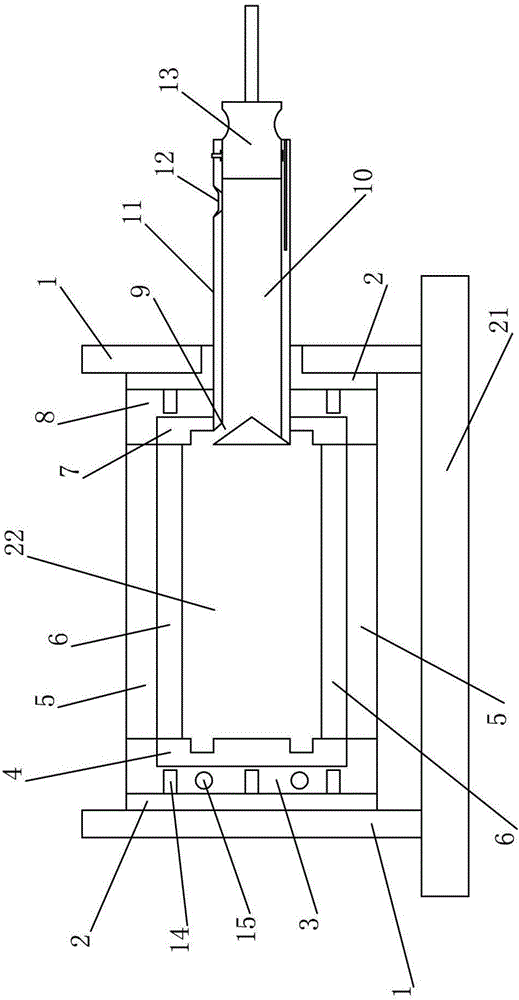

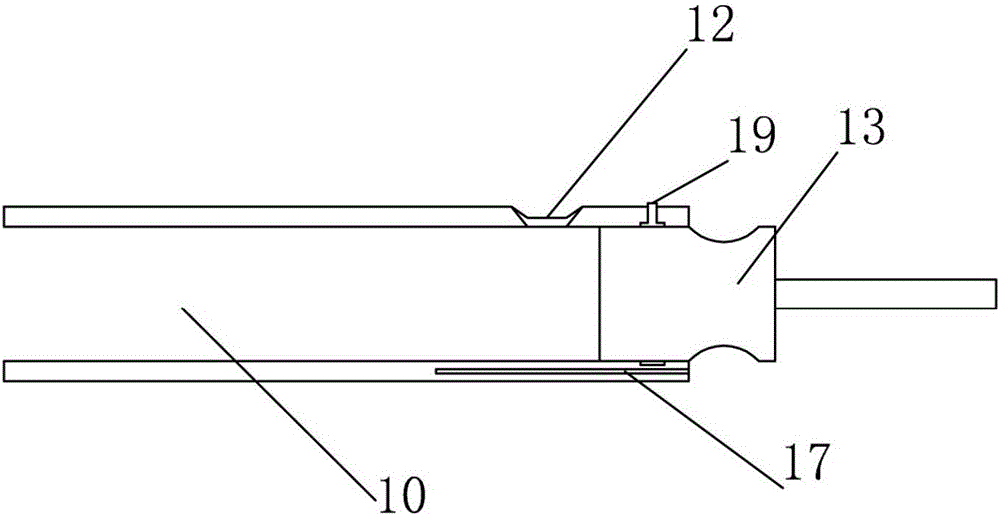

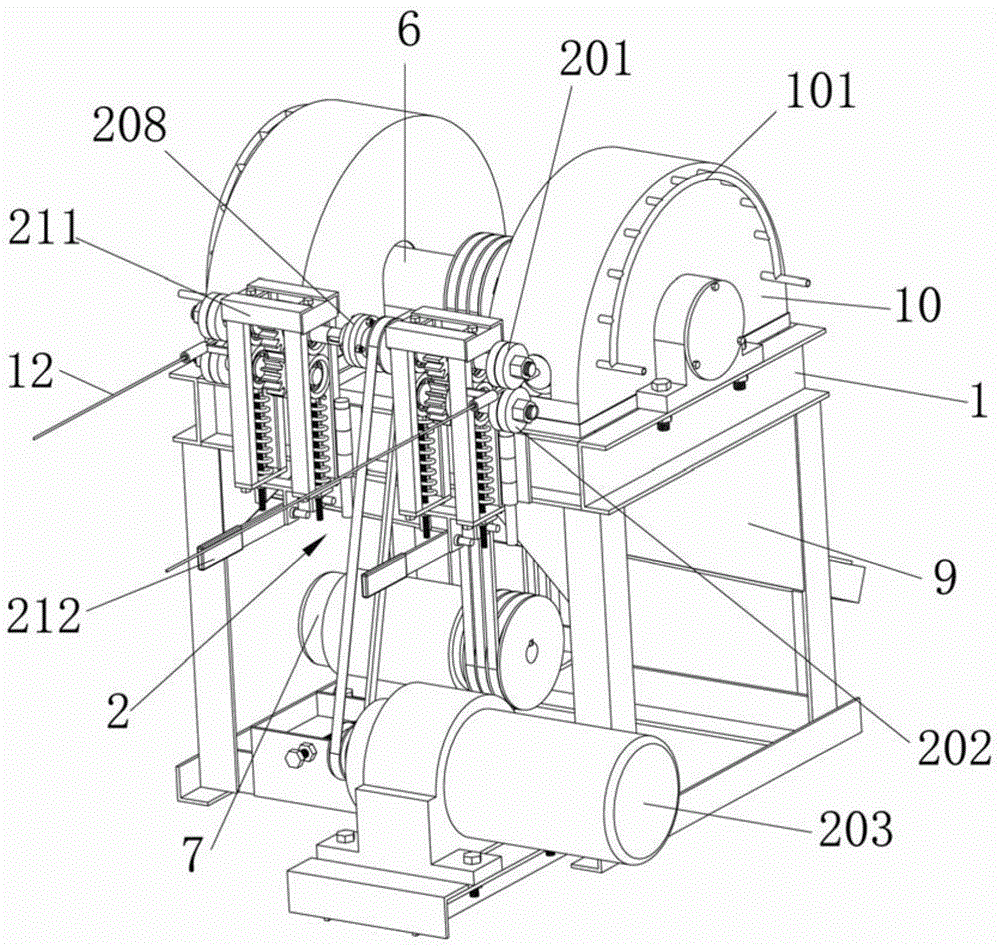

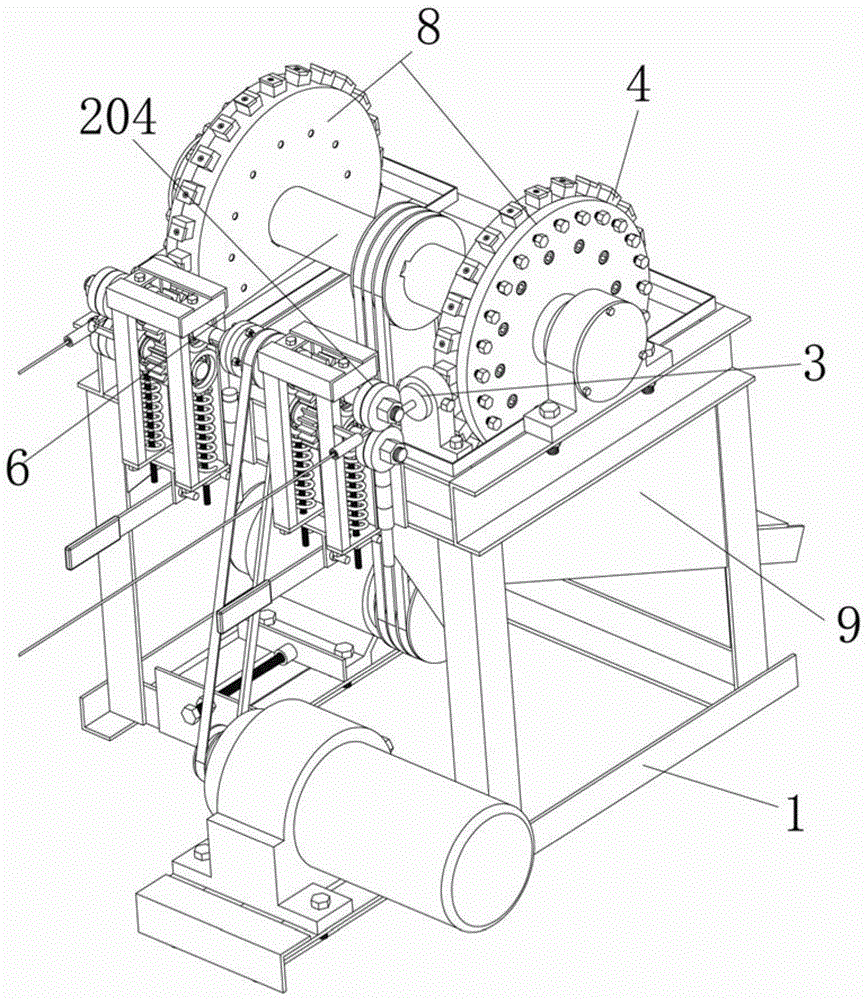

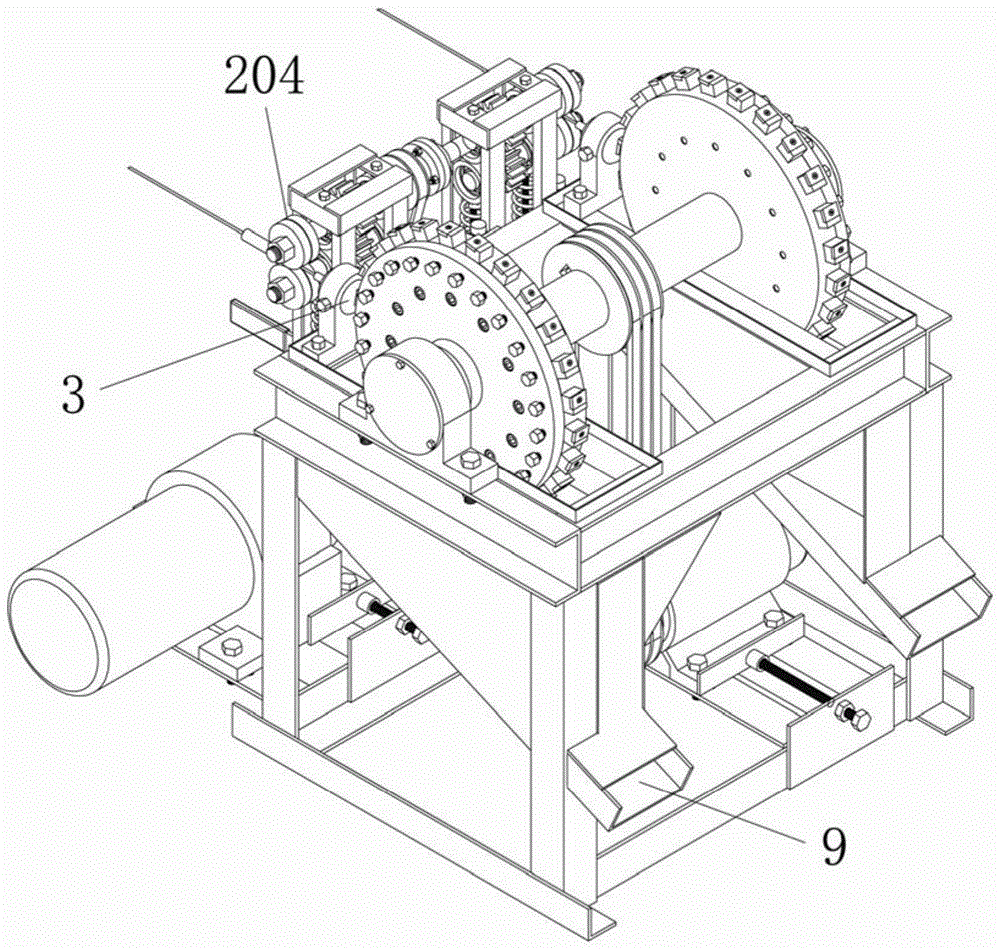

Squirrel cage motor rotor die casting device and method

InactiveCN105772673ANo casting cracksNo surface cracksManufacturing cage rotorsManufacturing stator/rotor bodiesDie castingEngineering

The invention discloses a squirrel cage motor rotor die casting device and method. The die casting device comprises a die casting machine and a melting furnace. The die casting machine is formed through the inserting and splicing combination of a movable die assembly, two replaceable die assemblies, a fixed die assembly and a pressure chamber die. The movable die assembly, the replaceable die assemblies and the fixed die assembly are sequentially arranged. The tail end of the pressure chamber die penetrates the fixed die assembly and makes contact with a closed cavity. A supporting frame is arranged below the movable die assembly. The defects of casting cracks, surface cracks, poor filling, die sticking and the like are avoided for products subjected to die casting, the vibration present value of the products meets the R-level regulation in IEC34-14(1996), and the level R is higher than the level N regulated by Y-series motor technique conditions by one level.

Owner:商学永

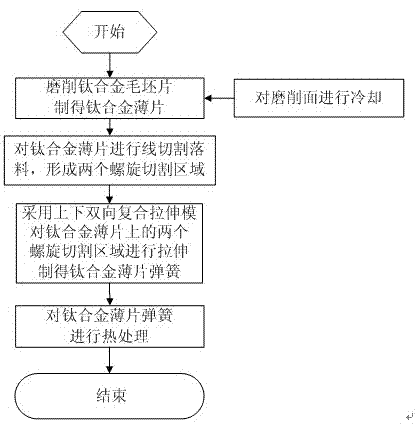

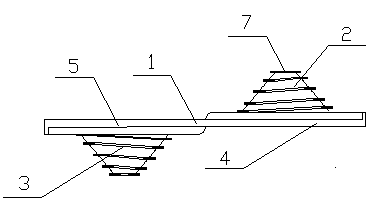

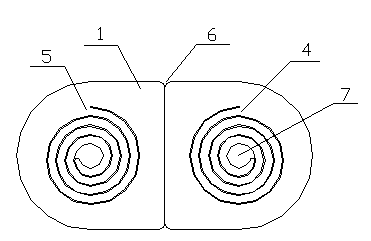

Method for manufacturing titanium alloy sheet springs for smart drill pipes

ActiveCN102847770AHigh dimensional accuracySmall deformation coefficientShaping toolsNumerical controlUltimate tensile strength

The invention provides a method for manufacturing titanium alloy sheet springs for smart drill pipes. The method includes machining titanium alloy blank sheets, cooling ground edges of the blank sheets to obtain high-glossiness titanium alloy sheets, blanking the sheets by linear cutting, drawing the sheets by an upwards and downwards two-way composite drawing die to obtain titanium alloy sheet springs, and finally treating the titanium alloy sheet springs by heat so that strength of the titanium alloy sheet springs meets requirements. Compared with the existing process for manufacturing the titanium alloy sheet springs, the method has the advantages that the titanium alloy sheet springs for the smart drill pipes, manufactured by the method, are high in surface glossiness, free of concealed surface cracks, free of fatigue breakage, are durable and firm; the dimension precision of the springs is increased and enough tensile strength is guaranteed by means of numerical-control linear cutting blanking; and by one-step forming carried out by the two-way drawing die, deformation coefficient of the springs can be reduced to the utmost extent, yield of finished products of the springs can be increased greatly, batch production is facilitated, and production efficiency is increased remarkably.

Owner:扬州恒旺热交换器有限公司

A kind of high-performance bonded platinum alloy fine material for encapsulation and preparation method thereof

ActiveCN113322394BGuaranteed StrengthNo segregationSemiconductor/solid-state device detailsSolid-state devicesDevice materialThermal softening

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

GH4033 high-accuracy hexagonal steel sectional material composite forming method

The invention discloses a GH4033 high-accuracy hexagonal steel sectional material composite forming method. A cold-rolling and cold-drawing composite forming process is mainly adopted to replace cold-draw forming in a traditional process. The process method mainly includes the steps of pretreatment, cold rolling, cold draw, solid solution treatment and the like, operation is simple, and the cost is low. According to a GH4033 hexagonal steel sectional material prepared through the method, the surface of the material is free of cracks, scratches and brittle failure, the surface smoothness is good, the dimensional accuracy reaches the 12th grade, the surface roughness reaches the degree of Ra<=0.8 [mu]m, the surface of the steel material is free of defects, and the using requirements of an aircraft can be met.

Owner:宝武特冶航研科技有限公司

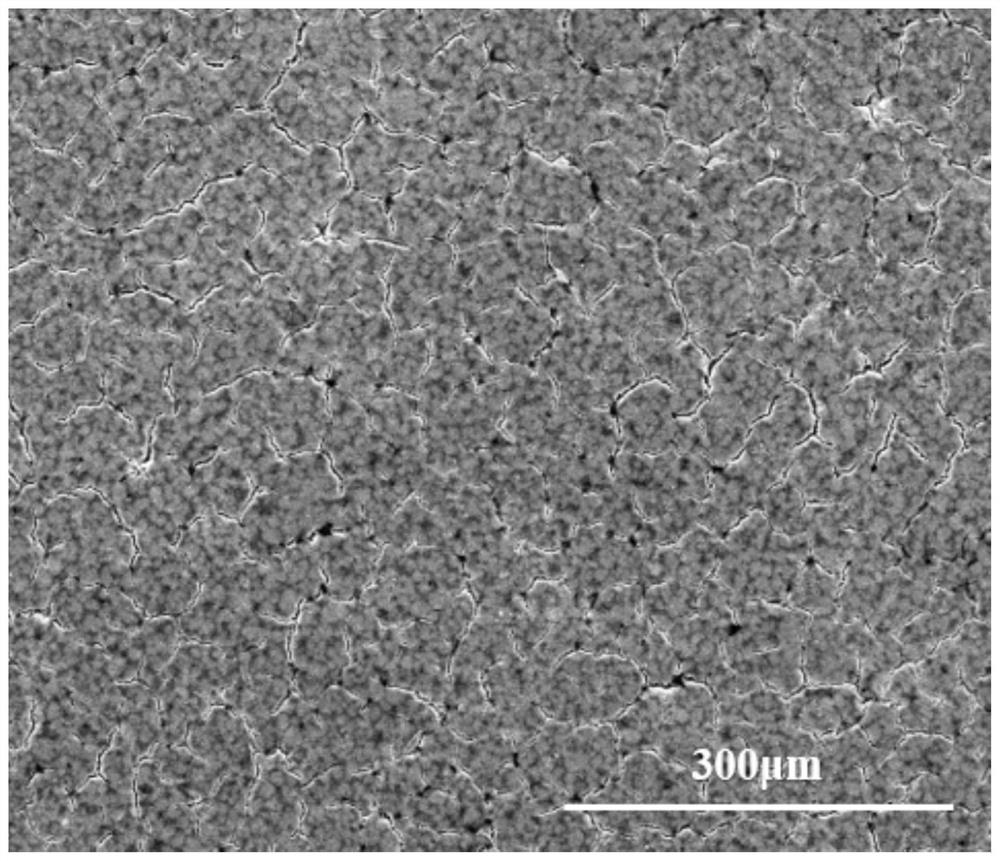

Method for preparing porous material from short metal fibers

Owner:SOUTH CHINA UNIV OF TECH

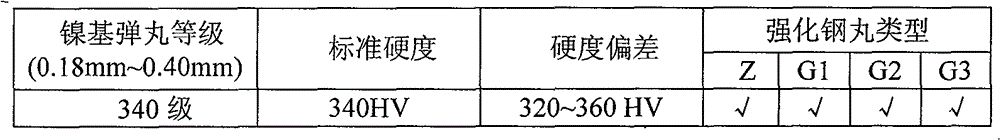

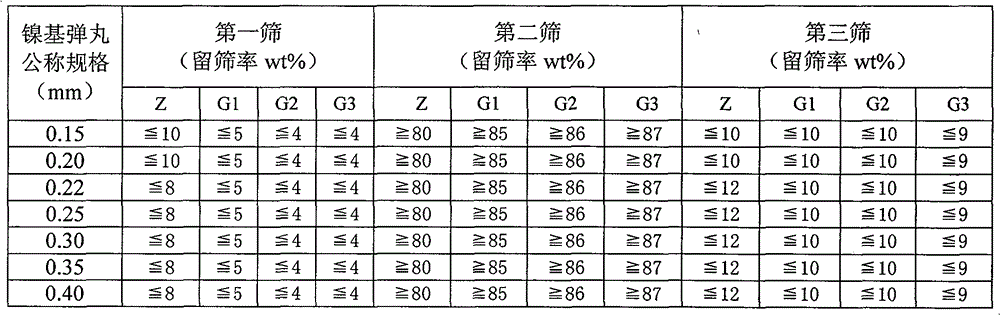

Nickel base projectile and preparation method thereof

A nickel base projectile and a preparation method thereof. The product is mainly used in surface strengthening of high-end nickel base components for aerospace, aircraft turbine blade and nuclear power component. The nickel base projectile comprises 75.25-83.25% of nickel, 14.75-22.75% of chrome, and the balance of iron and unavoidable impurities. The product has a tested average hardness of 340HV+ / - 20HV in load; and the product is prepared by a method comprising steps of: material selection for nickel base wire rod, heat treatment wire drawing, cutting, surface grinding hardening, heat treatment, screening, detection, packaging and storage.

Owner:DAFENG DAQI METAL GRINDING MATERIAL

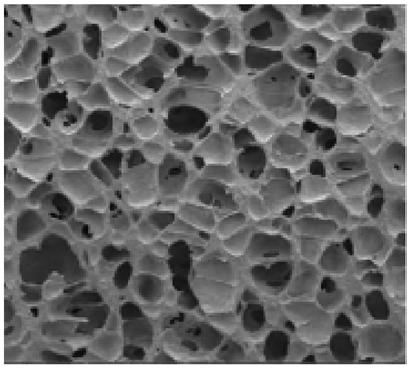

Preparation method of foamed silicone rubber

The invention relates to a preparation method of foamed silicone rubber, and belongs to the field of material preparation. The preparation method is characterized by comprising the following steps of:weighing 100g of rubber compound prepared from methyl vinyl silicone rubber, carrying out mill mixing in a two-roll mixing mill at a room temperature, wrapping rolls with silicone rubber, then adding10-60g of glass fiber powder, a platinum catalyst, 0.2-1.0g of hydrogen-containing silicone oil, and 0-0.8g of hydroxy silicone oil; mixing evenly, and discharging a sheet; and flatly paving, puttingin an aging testing machine for vulcanization, simultaneously foaming, setting the temperature to be 240 DEG C and time to be 5 minutes, and completing the preparation of the foamed silicone rubber.The fire-retardant foamed silicone rubber which can be ceramized at a high temperature is prepared by vulcanization carried out through hydrosilylation reaction and foaming carried out through siliconhydrogen dehydrogenation reaction. After the foamed silicone rubber is fired at the temperature of 1000 DEG C for 30rain, the foamed silicone rubber has good ceramicization effect and hard texture without surface cracks, the cellular structure is kept perfectly, the volume retention rate is above 85%, and the fireproof performance is excellent.

Owner:常馨尹

Casting method for Q1100D ultrahigh-strength steel

PendingCN114346194AGood billet surface qualityImprove surface qualityMetallurgyMechanical engineering

The invention aims to provide a Q1100D ultrahigh-strength steel casting method, which mainly adopts technical measures from casting of a casting machine, avoids surface cracks of an ultrahigh-strength steel casting blank, improves the center segregation control level of the ultrahigh-strength steel casting blank, and achieves the purpose of ensuring that all performances of a steel plate rolled by the casting blank are qualified.

Owner:BAOTOU IRON & STEEL GRP

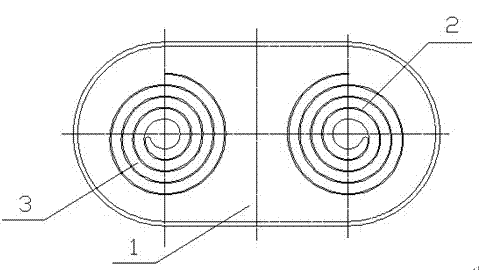

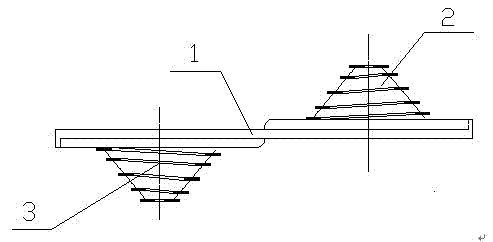

Bidirectional disconnection type titanium alloy sheet spring

InactiveCN102797780ASimple and reasonable structureEasy to manufactureDrilling rodsDrilling casingsBatch productionDrilling system

The invention relates to a bidirectional disconnection type titanium alloy sheet spring, belonging to the technical field of springs. The bidirectional disconnection type titanium alloy sheet spring comprises a titanium alloy sheet and is characterized in that the titanium alloy sheet is provided with an upper spiral cutting region and a lower spiral cutting region, wherein the upper spiral cutting region and the lower spiral cutting region are respectively provided with an upper spiral spring and a lower spiral spring. The bidirectional disconnection type titanium alloy sheet spring disclosed by the invention is of a reasonable and simple structure, is easy to produce and manufacture, and has good usability. Compared with the traditional titanium alloy sheet spring, the bidirectional disconnection type titanium alloy sheet spring disclosed by the invention has the advantages of high surface glossiness, no hidden surface crack, no fatigue break, and durability in use; and the spring is high in the size precision and tensile strength; the bidirectional disconnection type titanium alloy sheet spring is molded at one time through a bidirectional compound stretch drawing die, the deformation coefficient of the spring is reduced to a very small range, the yield of finished product of the spring is greatly improved, the batch production is facilitated, the production efficiency is remarkably improved, and the requirements of the titanium alloy sheet spring for an intelligent drilling rod in a vertical drilling system can be met.

Owner:扬州恒旺五金机械有限公司

Method for manufacturing titanium alloy sheet springs for smart drill pipes

InactiveCN102847770BHigh dimensional accuracySmall deformation coefficientShaping toolsNumerical controlTitanium alloy

The invention provides a method for manufacturing titanium alloy sheet springs for smart drill pipes. The method includes machining titanium alloy blank sheets, cooling ground edges of the blank sheets to obtain high-glossiness titanium alloy sheets, blanking the sheets by linear cutting, drawing the sheets by an upwards and downwards two-way composite drawing die to obtain titanium alloy sheet springs, and finally treating the titanium alloy sheet springs by heat so that strength of the titanium alloy sheet springs meets requirements. Compared with the existing process for manufacturing the titanium alloy sheet springs, the method has the advantages that the titanium alloy sheet springs for the smart drill pipes, manufactured by the method, are high in surface glossiness, free of concealed surface cracks, free of fatigue breakage, are durable and firm; the dimension precision of the springs is increased and enough tensile strength is guaranteed by means of numerical-control linear cutting blanking; and by one-step forming carried out by the two-way drawing die, deformation coefficient of the springs can be reduced to the utmost extent, yield of finished products of the springs can be increased greatly, batch production is facilitated, and production efficiency is increased remarkably.

Owner:扬州恒旺热交换器有限公司

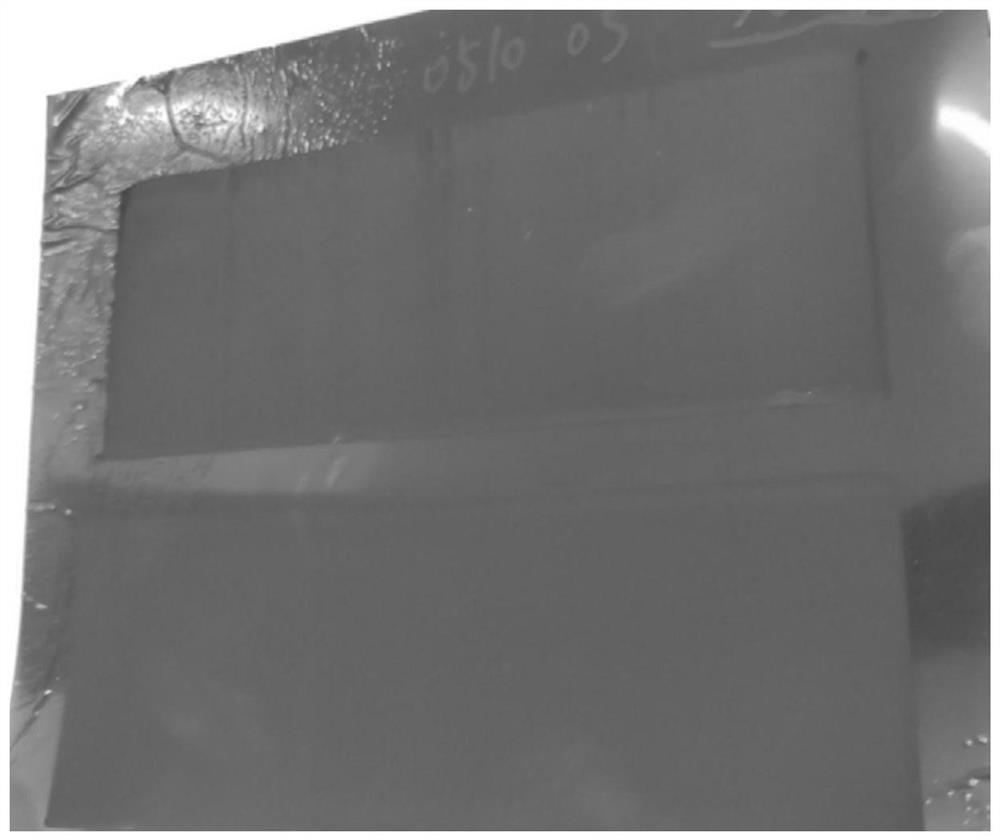

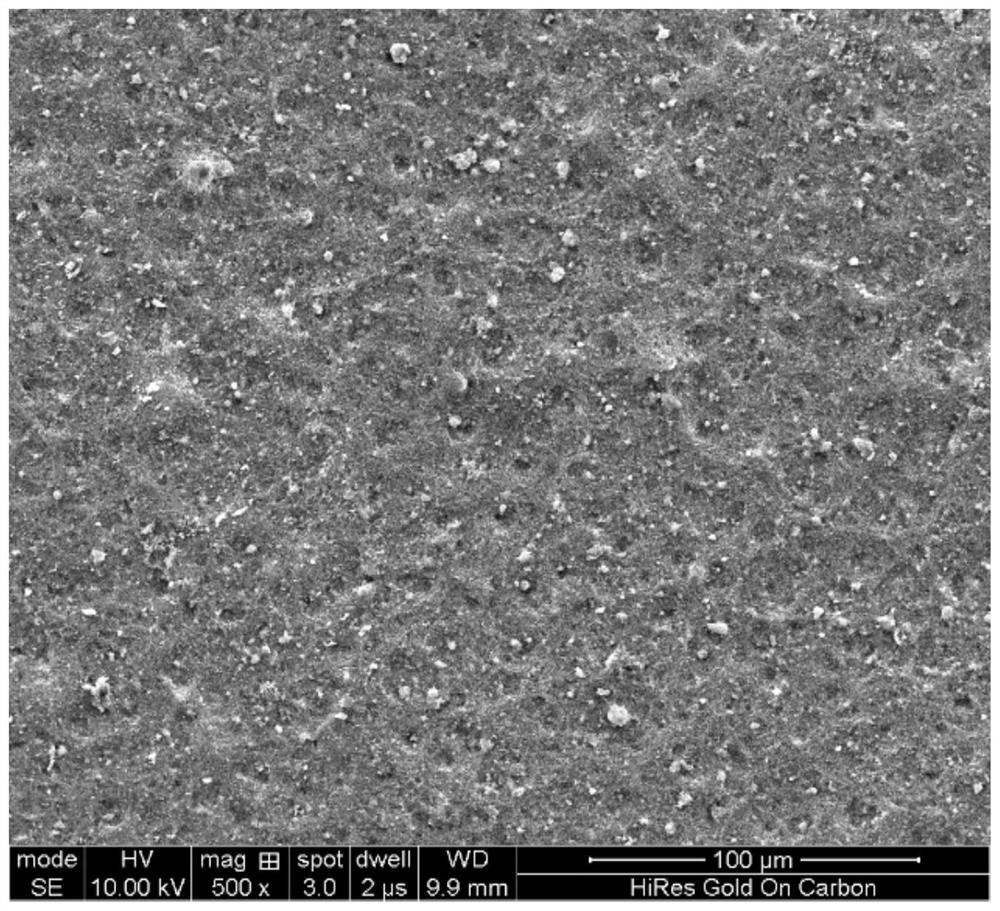

Flawless proton exchange membrane directly coated with catalyst as well as preparation method and application of flawless proton exchange membrane

PendingCN114243033ATo fill the technical gap of preparationFill technology gapsCell electrodesPtru catalystPhysical chemistry

The invention relates to the technical field of fuel cell catalyst layer preparation, in particular to a flawless proton exchange membrane directly coated with a catalyst and a preparation method and application thereof. The preparation method comprises the following steps: mixing a perfluorosulfonic acid solution, normal propyl alcohol and deionized water to obtain dispersion liquid; wetting a catalyst with deionized water, then mixing the catalyst with the dispersion liquid, and carrying out ultrasonic dispersion treatment to form primary dispersion catalyst slurry; performing high-shear dispersion on the primary dispersed catalyst slurry to obtain secondary dispersed catalyst slurry; and finally, carrying out single-layer coating by adopting a blade coating process to obtain the flawless proton exchange membrane directly coated with the catalyst. Compared with the prior art, the fuel cell catalyst layer manufactured by the method is uniform in thickness, good in consistency and free of surface cracks, catalyst layers with different thicknesses can be manufactured according to different catalyst feeding amounts, and the method is suitable for production of domestic fuel cell membrane electrodes.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com