Manufacturing method for seamless steel tube for large-caliber high-pressure boiler

A technology for high-pressure boilers and seamless steel pipes, which is used in manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of long processing cycle, complex production equipment, large wall thickness unevenness, etc. High geometric accuracy and good product surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

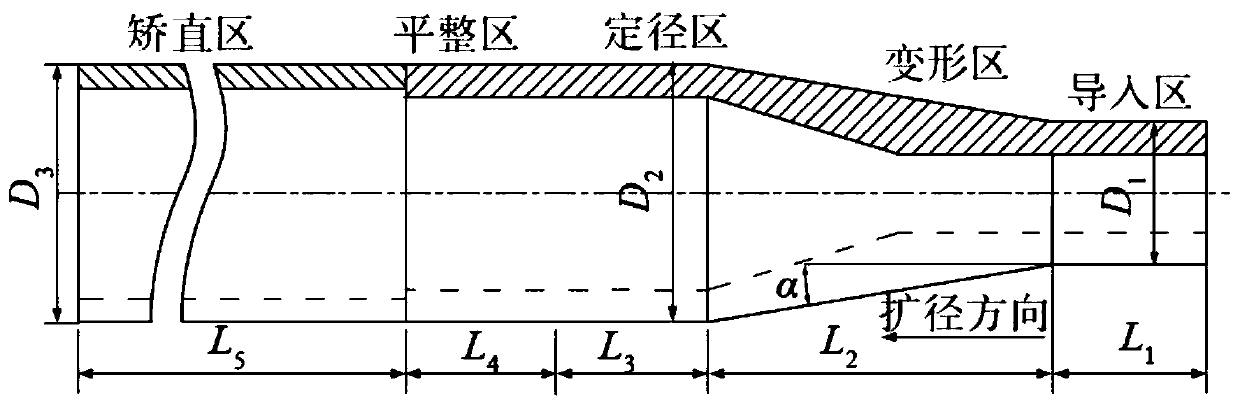

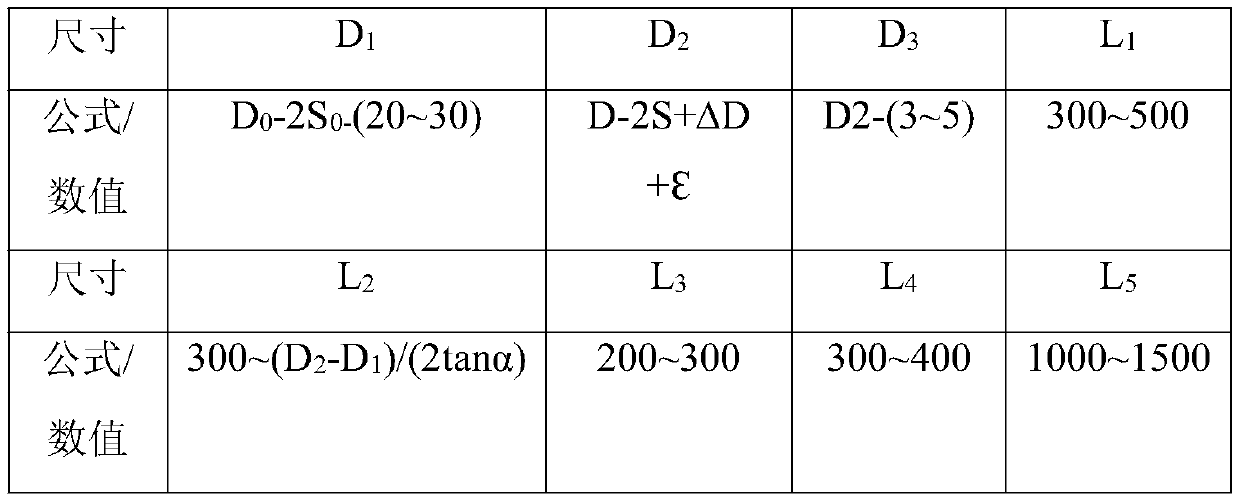

Method used

Image

Examples

Embodiment 1

[0039] In this example, the material of the finished pipe is 10Cr9Mo1VNbN (P91), the outer diameter is 1168.4mm, the nominal wall thickness is 49mm, and the length is greater than 5m. The tolerance is ±10%, the straightness is less than 1.5mm / m, the ellipticity is less than 1.0% of the average diameter, and the performance meets the requirements of GB5310-2017, so the following steps are used for production:

[0040] (1) heating the continuous casting slab with a diameter of 600mm in an annular heating furnace;

[0041] (2) Perforate the heated continuous casting slab with an 820 two-roll cross-rolling piercer, and the outer diameter after the perforation is 790mm;

[0042] (3) Carry out hot-rolled pipe processing with 820 two-roller precision cross-rolling mill, the barren pipe outer diameter that forms after hot-rolling is 813mm, outer diameter deviation ± 1%, nominal wall thickness 54mm, wall thickness deviation ± 10%;

[0043] (4) Straighten and finish the waste pipe so t...

Embodiment 2

[0068] In this embodiment, the material of the finished pipe is 12Cr2MoG (P22), the outer diameter is 1219.2mm, the nominal wall thickness is 28mm, and the length is greater than 6m. The technical agreement requires that the outer diameter tolerance is -3~7mm, the inner diameter tolerance is -2~6mm, and the wall thickness tolerance ±10%, straightness is less than 1.5mm / m, ellipticity is less than 1.0% of the average diameter, the performance meets the requirements of GB5310-2017, and the following steps are used for production:

[0069] (1) heating the continuous casting slab with a diameter of 600mm in an annular heating furnace;

[0070] (2) Perforate the heated continuous casting slab with an 820 two-roll cross-rolling piercer, and the outer diameter after the perforation is 790mm;

[0071] (3) Carry out hot-rolled tube processing with 820 two-roller precision cross-rolling machine, the barren tube outer diameter that forms after hot-rolling is 823mm, outer diameter deviati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com