Hydraulic clamping device for special-shaped workpiece

A hydraulic clamping, special-shaped technology, applied in positioning devices, metal processing machinery parts, clamping and other directions, can solve the problems of wasting materials and labor hours, and achieve a wide range of effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The working mode of the present invention will be further described below in conjunction with the accompanying drawings.

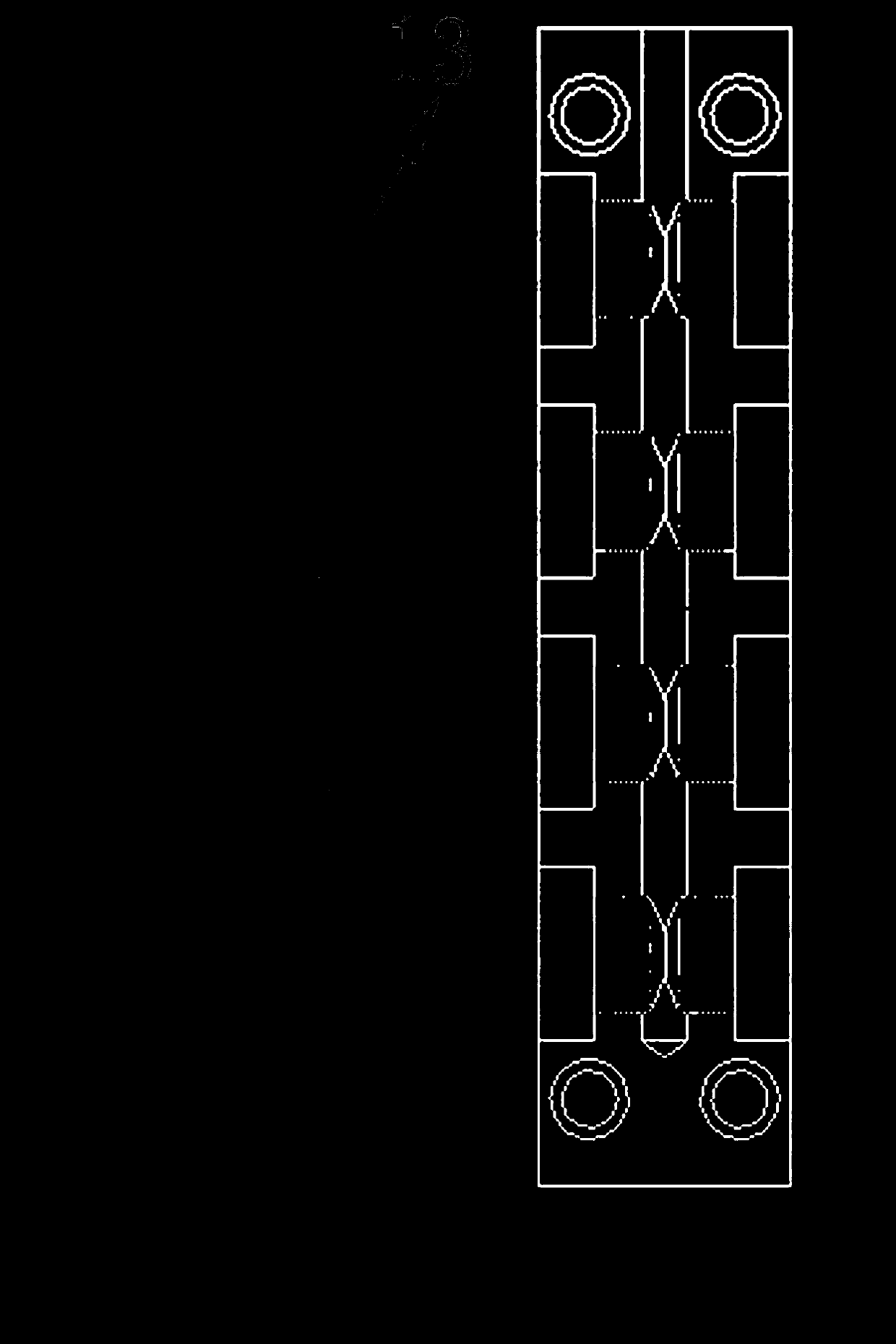

[0016] Such as figure 2 , image 3 As shown, the external threaded single-acting hydraulic cylinder-13 is connected to the oil passages 6, 8, and 11 through threads, and is used to clamp the single-acting piston rod-5.

[0017] The first step: if figure 1 As shown, the swimming matrix hydraulic cylinder cooperates with the base through the dovetail groove and moves longitudinally on the base through the thread transmission of the screw rod. According to the size of the workpiece to be clamped, the opening size of the fixture is determined by adjusting the screw rod-1. Use other tools to place the special-shaped workpiece in the middle of the fixture, and pass low-pressure hydraulic oil into the fixed matrix cylinder-10 through the oil circuit control part to push the piston rod out and make each piston rod contact with the outer wall of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com