Cylindrical grinding machine for bearing ring

A cylindrical grinding machine and bearing ring technology, which is applied to grinding machines, grinding machine parts, and machine tools designed for grinding the rotating surface of workpieces, etc., can solve the problems of large transmission clearance, low service life and long downtime, etc. The effect of strong static and dynamic rigidity, good precision retention and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

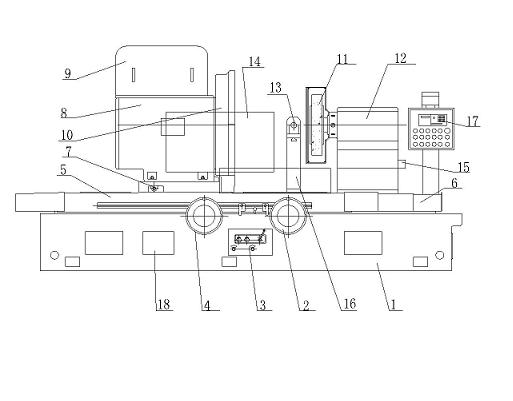

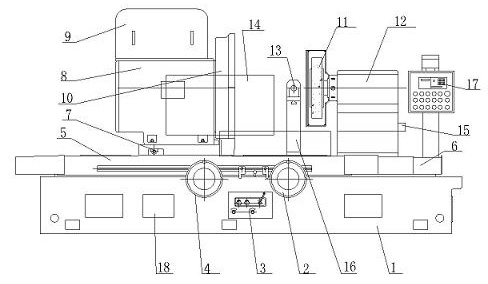

[0017] As shown in Figure 1, the bearing ring cylindrical grinding machine includes a bed 1, a reciprocating table 5, a grinding wheel axle box 12, a workpiece axle box 8, a longitudinal feed mechanism 4, a transverse feed mechanism 2, a grinding wheel dresser 13, a hydraulic system, lubrication system, cooling system and electrical control system, the reciprocating table 5, the longitudinal feed mechanism 4 and the transverse feed mechanism 2 are installed on the bed 1, and the grinding wheel axle box 12 is installed on the bed at the rear side of the reciprocating table 5 1, the grinding wheel 11 is installed on the grinding wheel axle box 12, the grinding wheel dresser 13 is installed on the reciprocating worktable 5 through the grinding wheel dresser seat 16, the workpiece axle box 8 is set on the reciprocating workbench 5, the hydraulic system, lubrication system and electrical The control system is installed in the bed, the cooling system is set on the back side of the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com