Patents

Literature

154results about How to "Good accuracy retention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

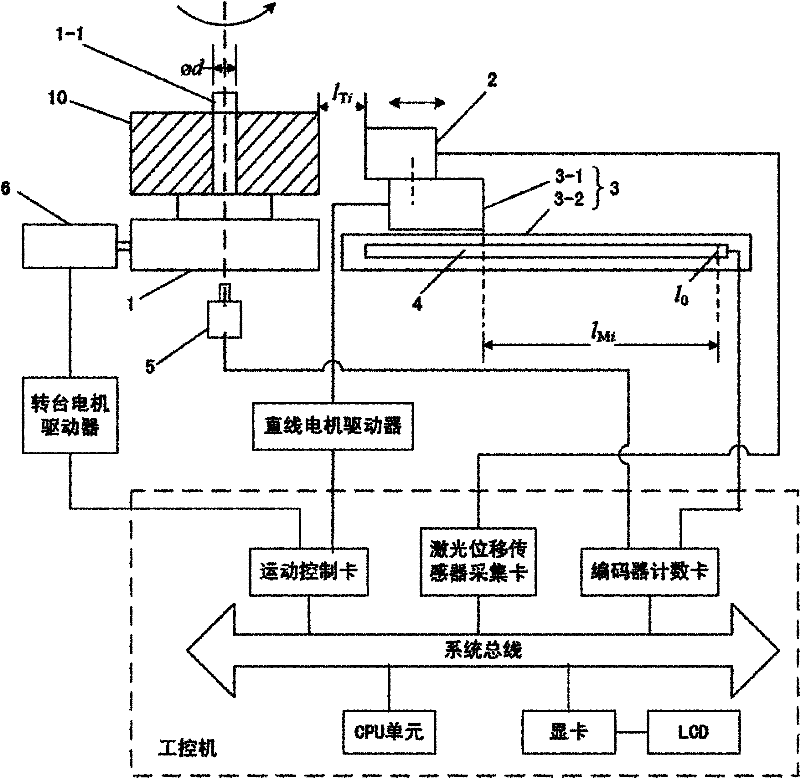

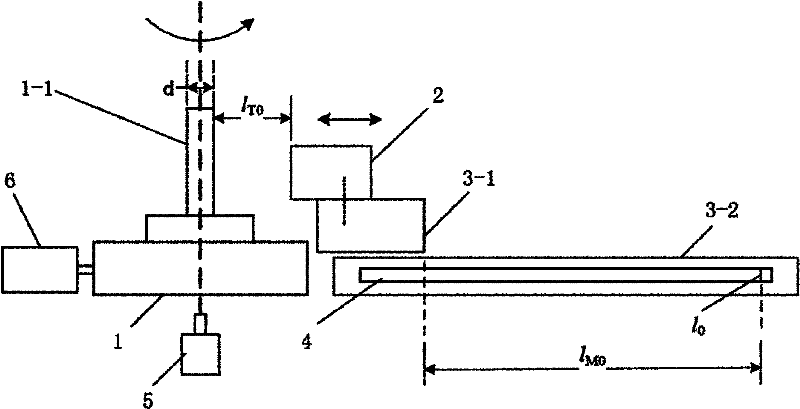

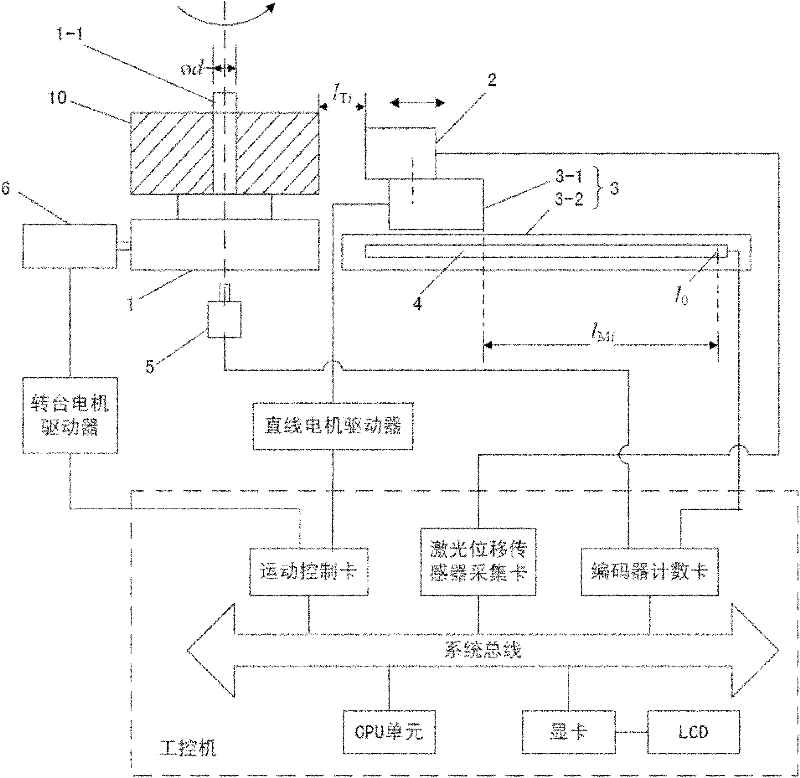

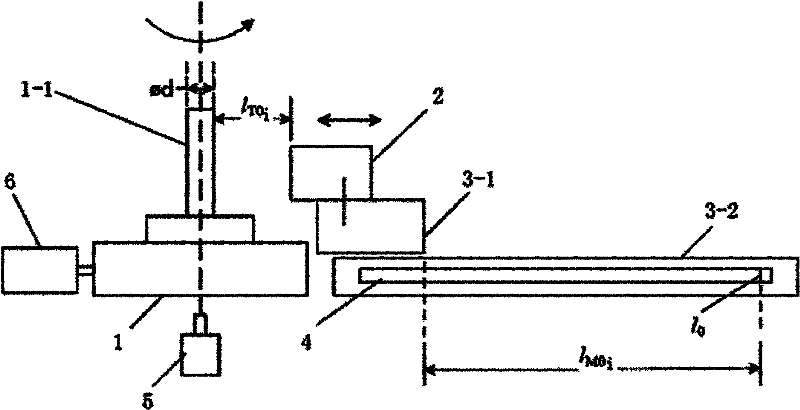

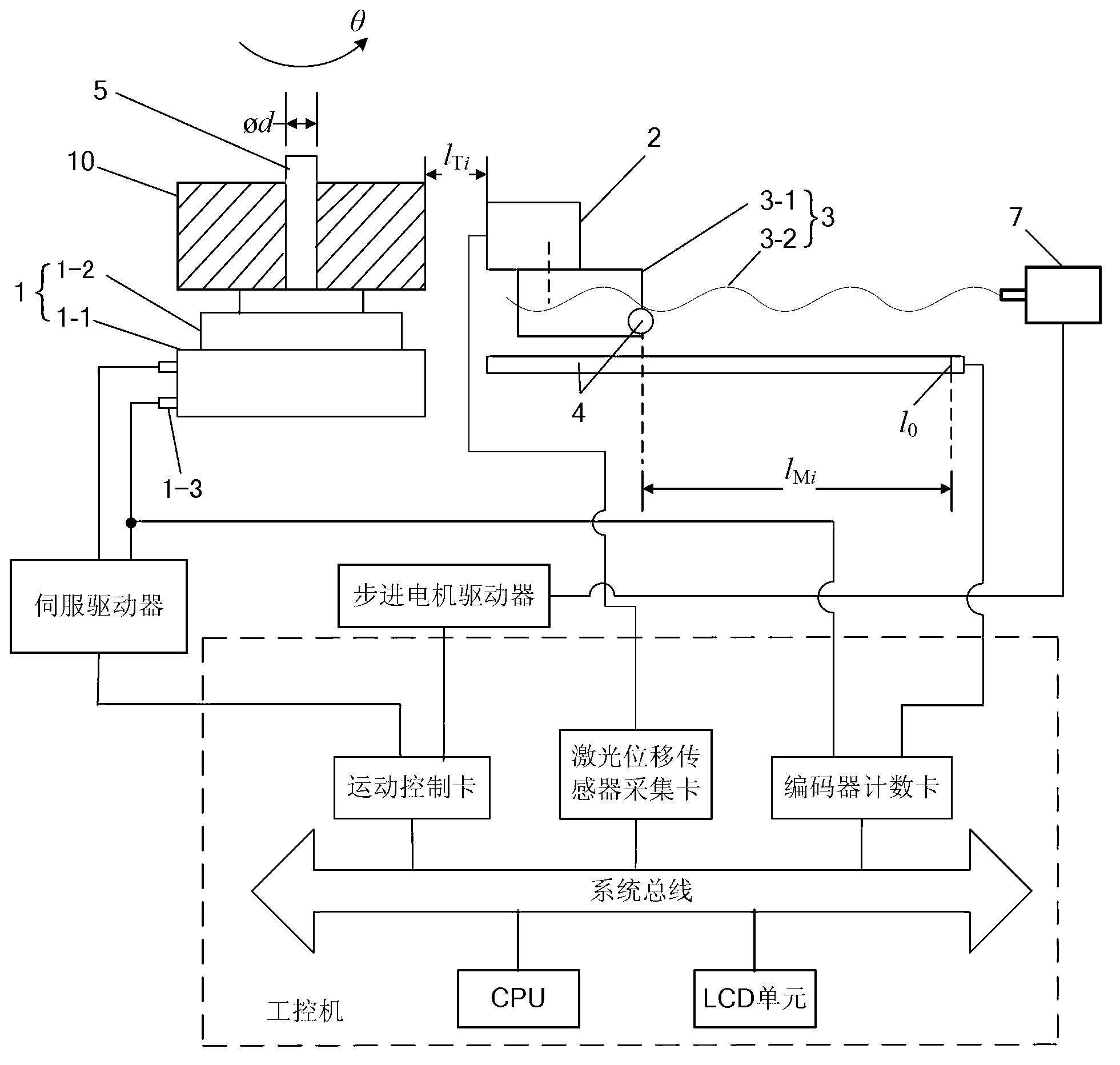

Device for detecting cam profile

InactiveCN102147238AThere is no transmission gapHigh dynamic stiffnessUsing optical meansNumerical controlElectric machine

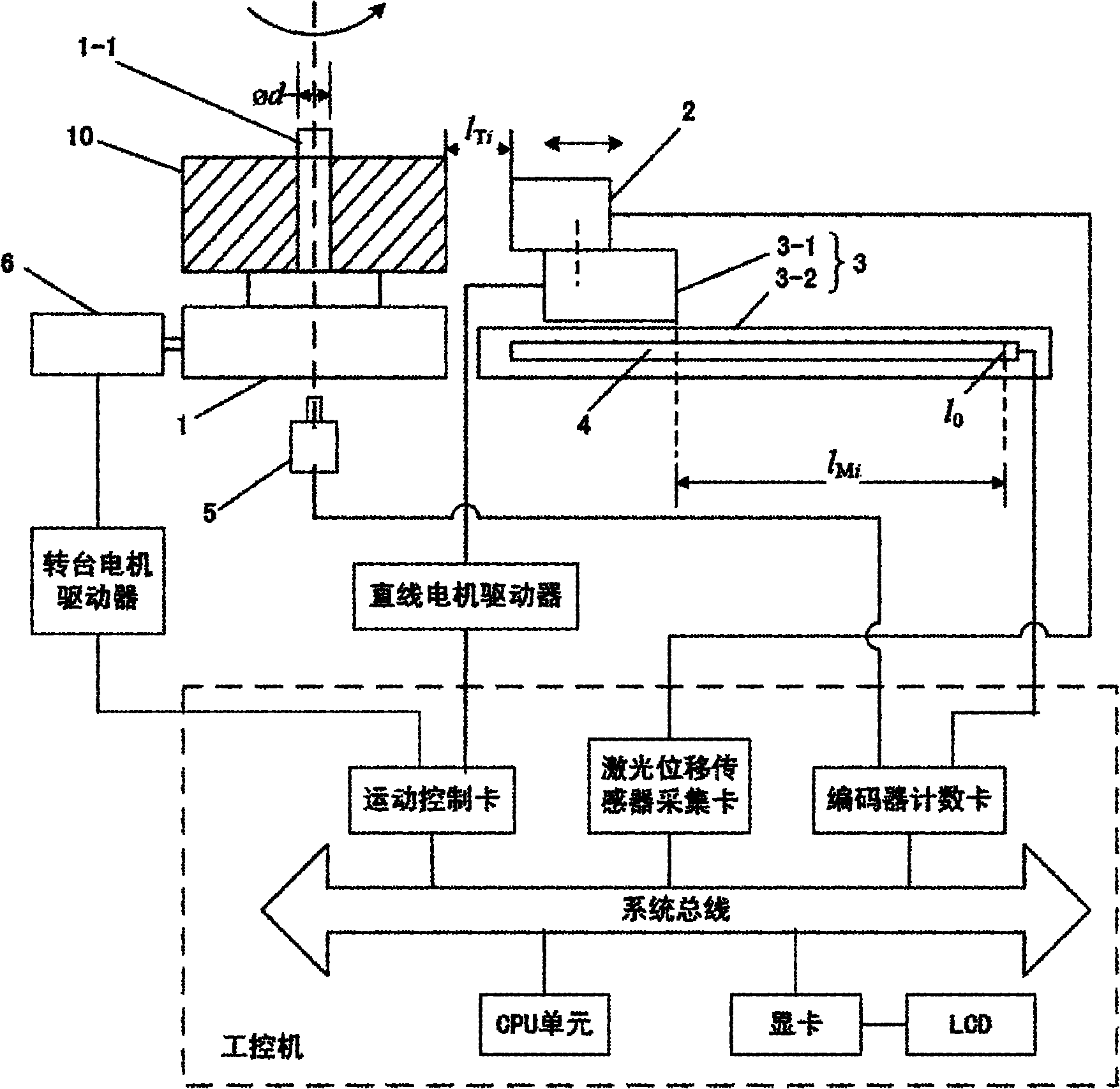

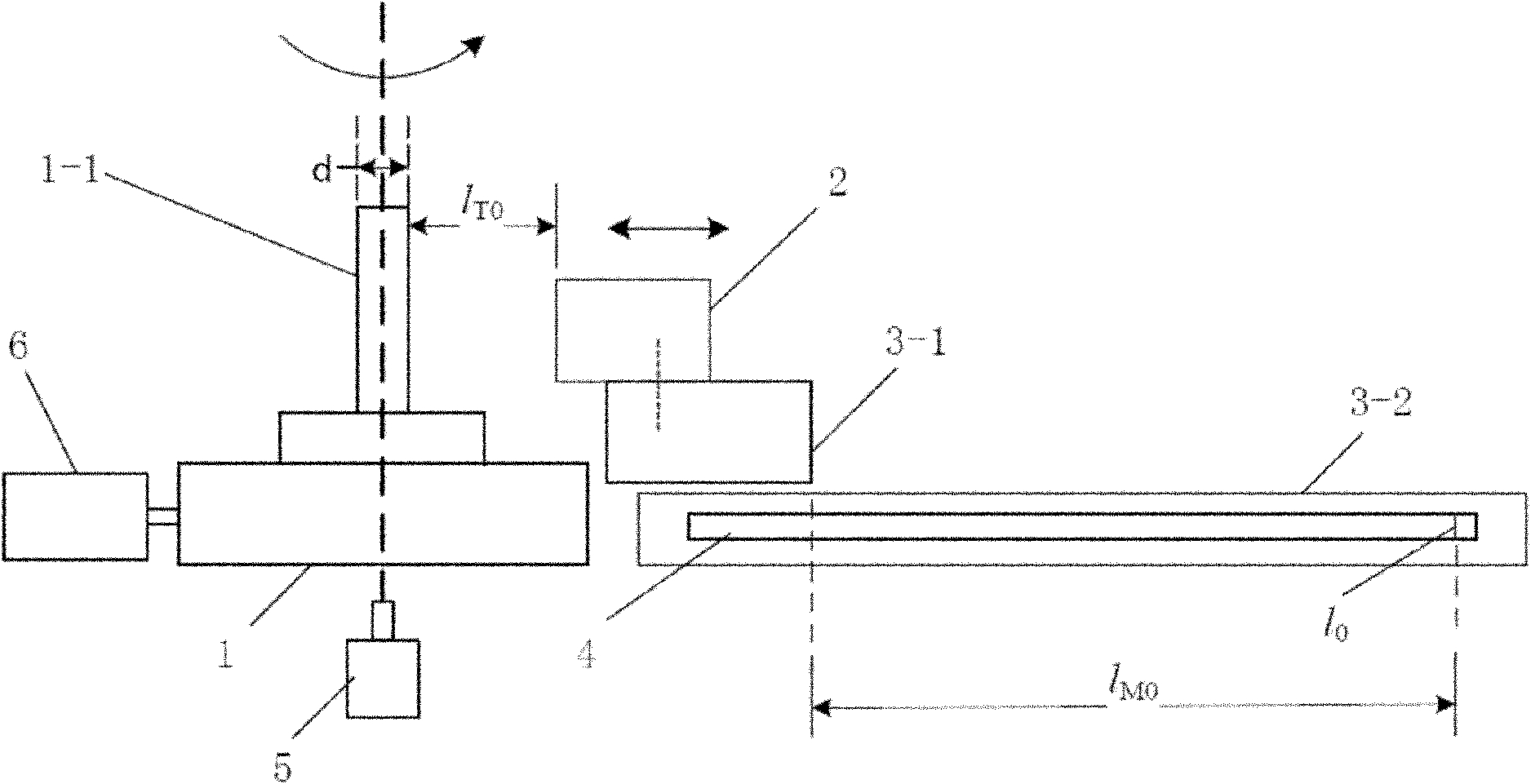

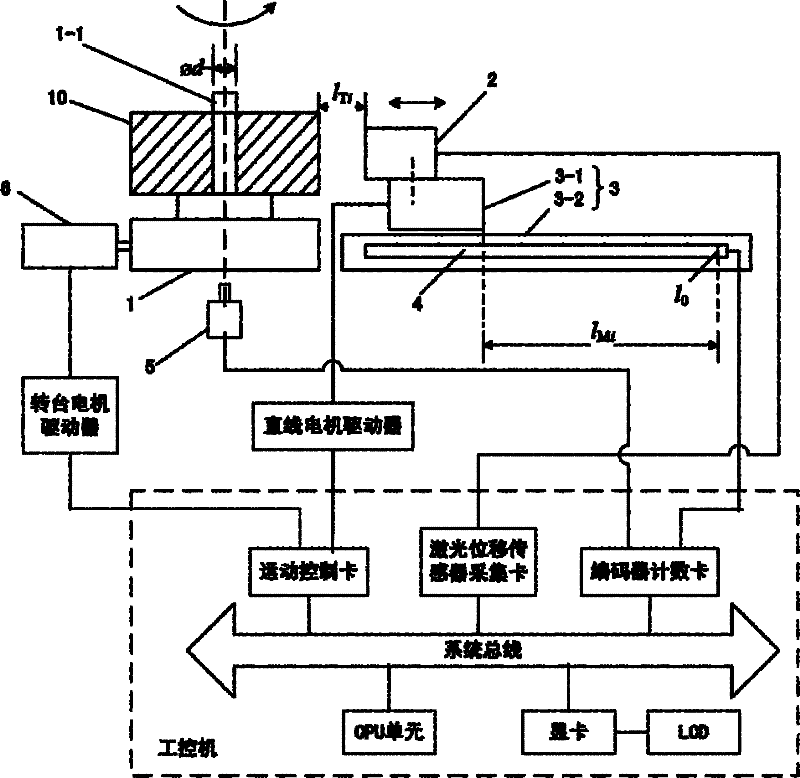

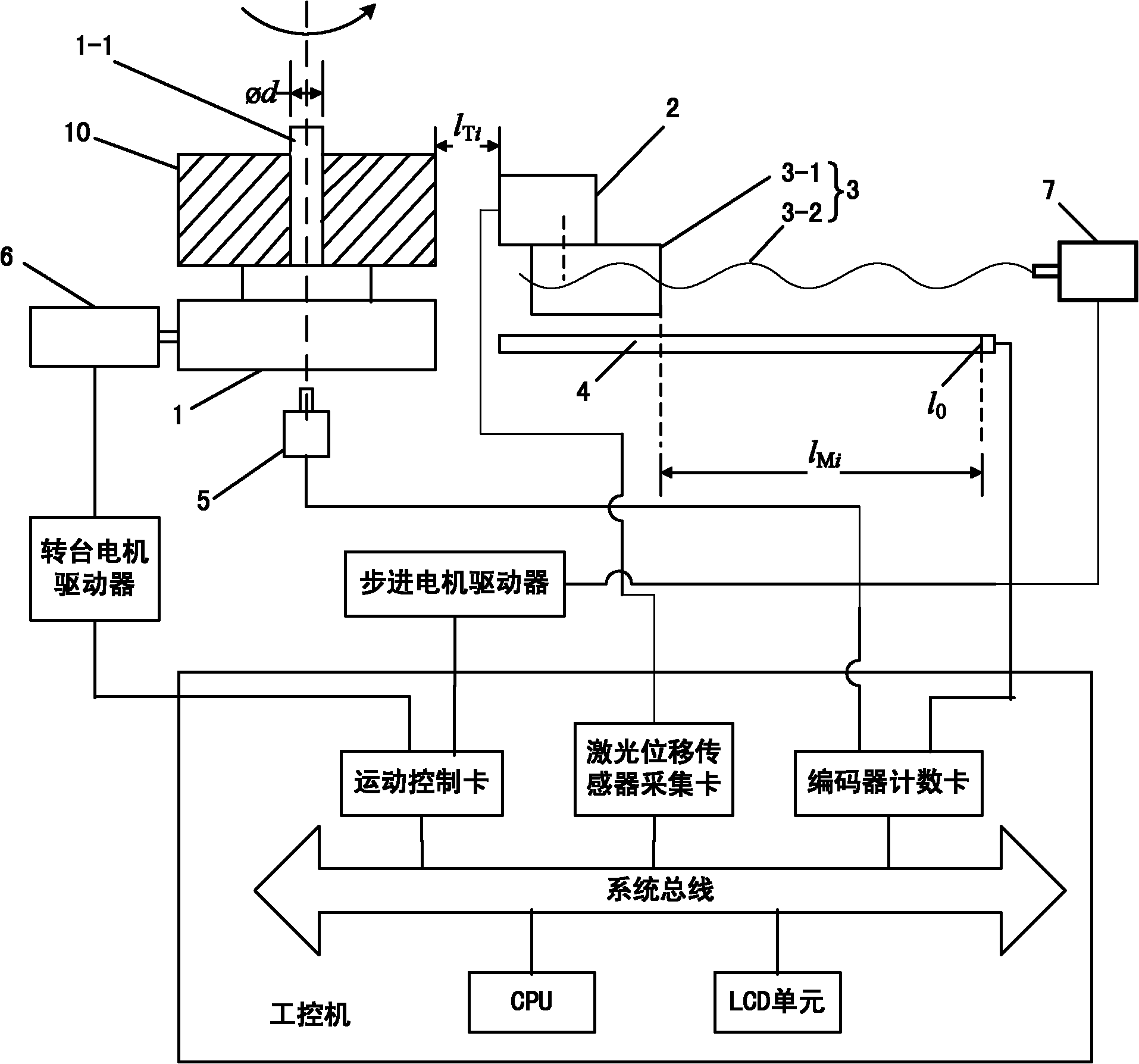

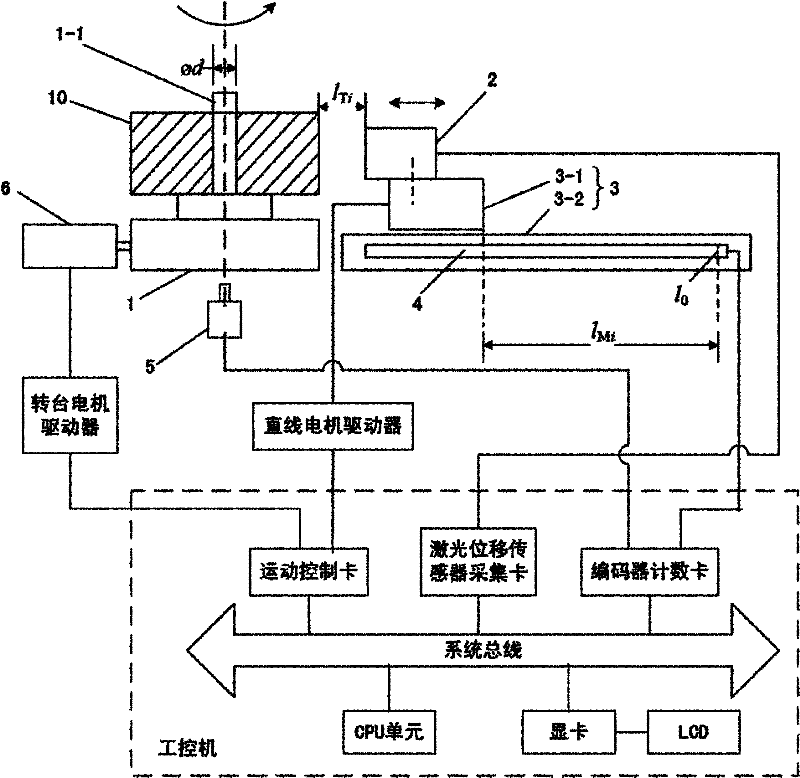

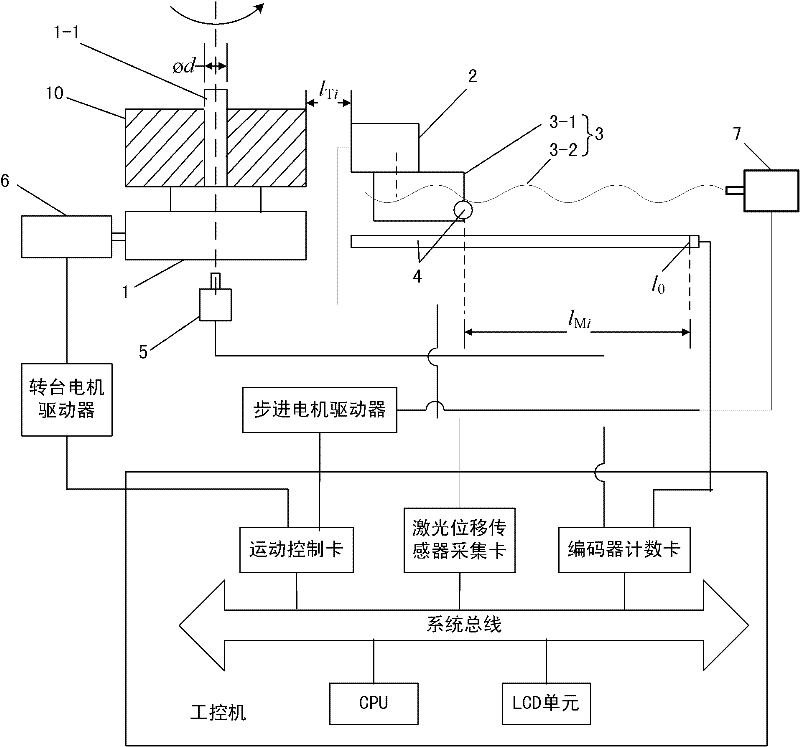

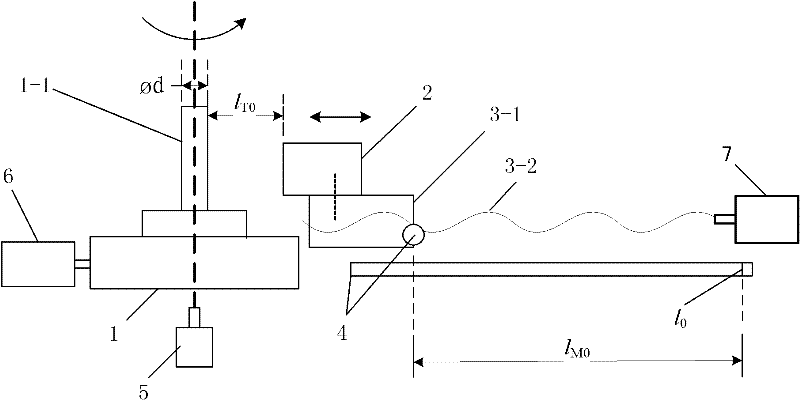

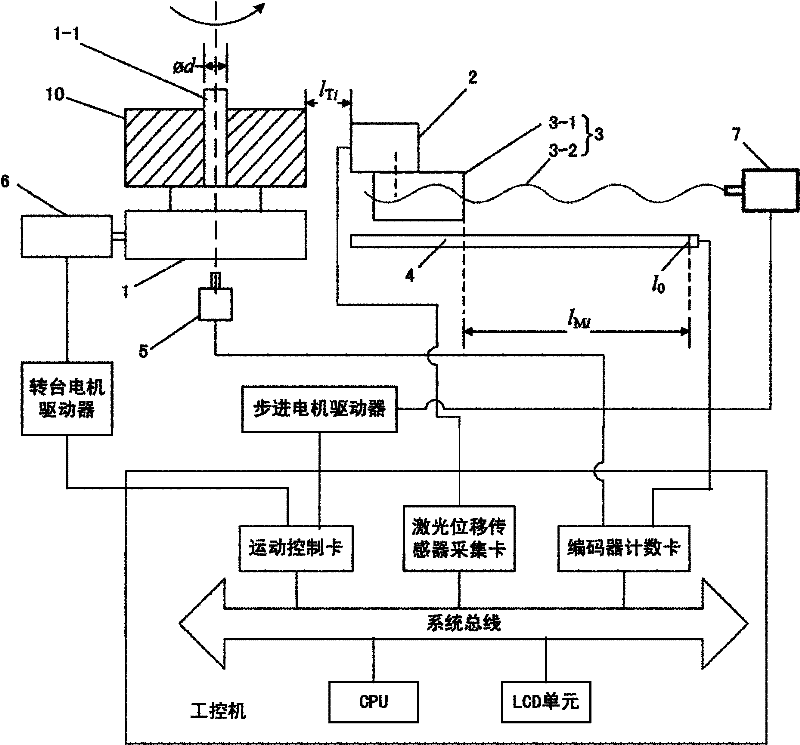

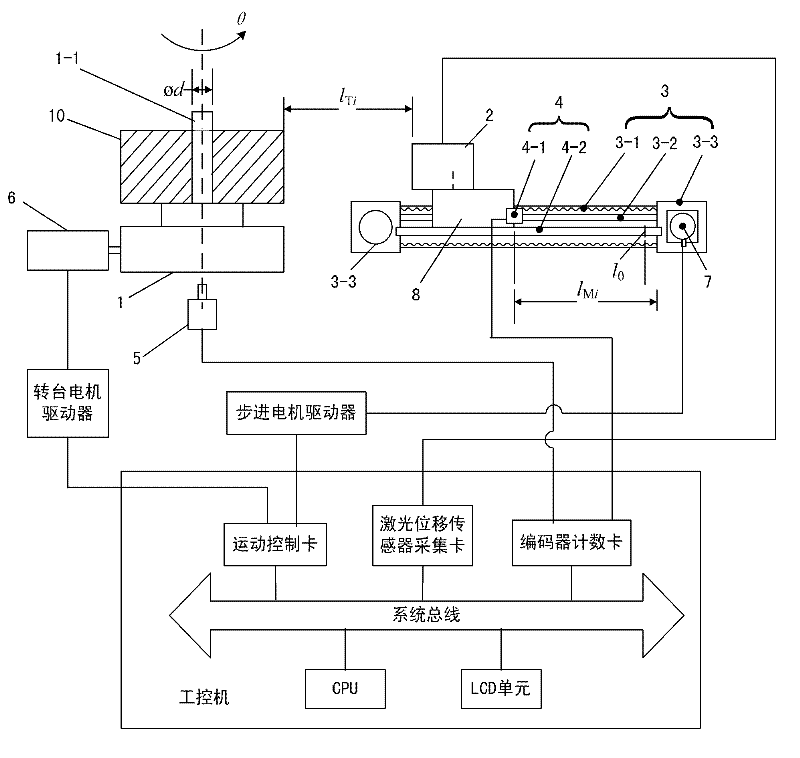

The invention provides a device for detecting cam profiles, which has the advantages of simple structure, high detection precision and higher efficiency. The device comprises a numerical control turntable, a linear motor, a laser measuring head, a grating scale displacement sensor, an encoder and an industrial personal computer, wherein the numerical control turntable is used for driving the cam to horizontally and coaxially rotate around a vertical mandrel; the linear motor is horizontally arranged on one side of the numerical control turntable; the laser measuring head is arranged on the active cell of the linear motor and at one side of the cam; the grating scale displacement sensor is used for measuring the horizontal displacement of the active cell; the encoder is used for detecting the rotation angle of the cam; and the industrial personal computer controls the numerical control turntable and the linear motor to act and obtains the outer profile data of the cam according to data measured by the laser measuring head, the grating scale displacement sensor and the encoder.

Owner:CHANGZHOU INST OF TECH

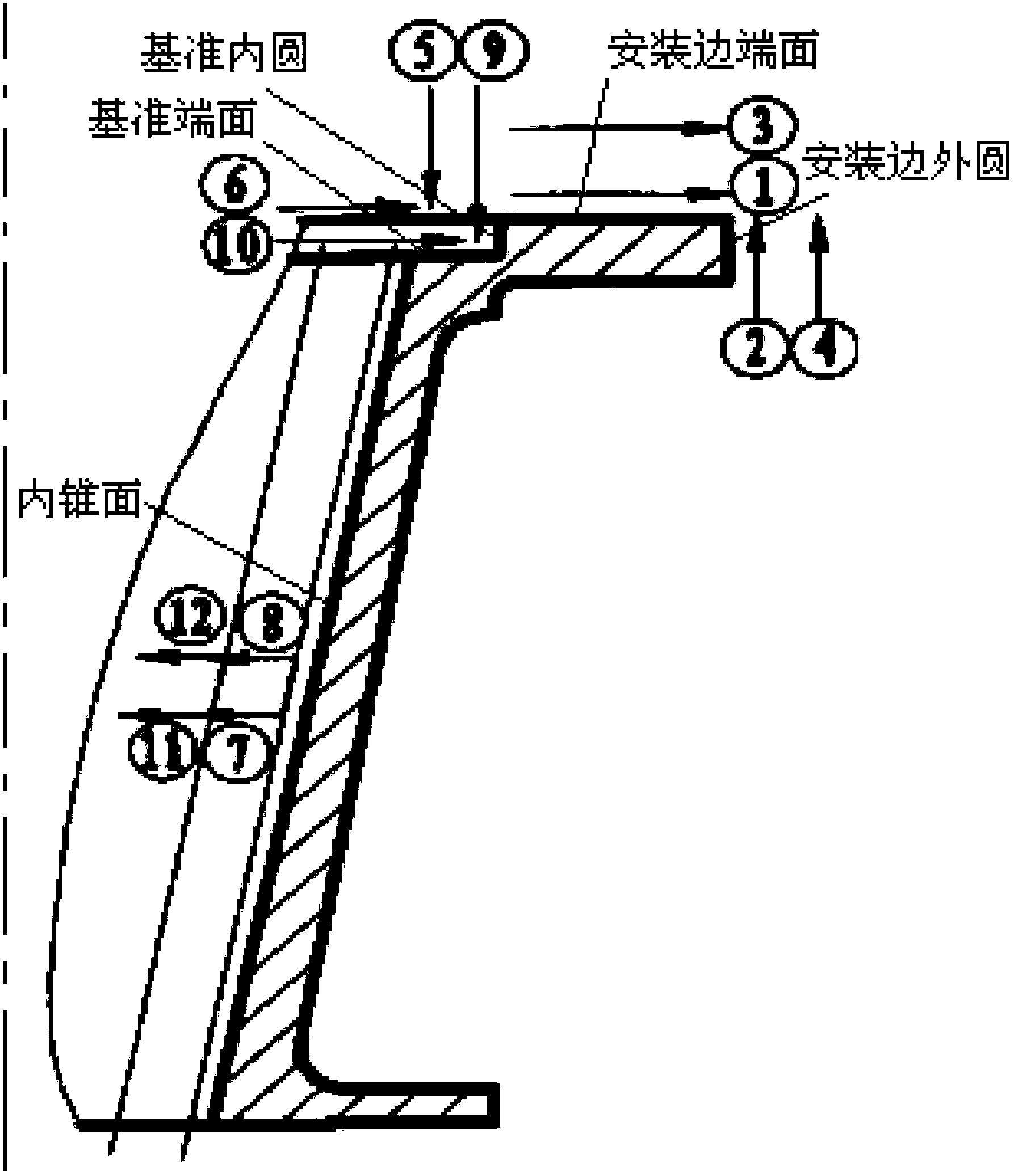

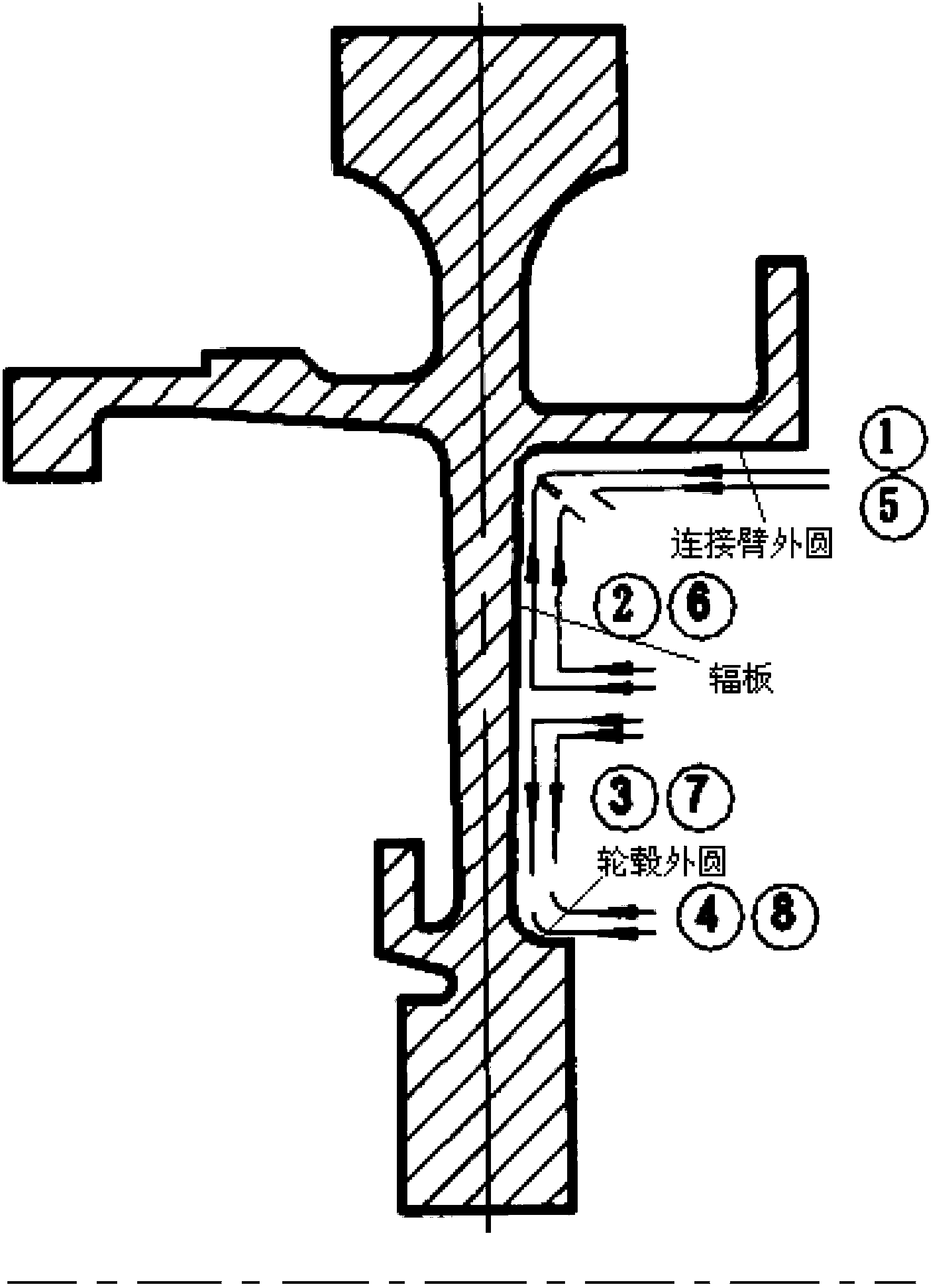

Cutting and feeding path planning method applied to mechanical machining of metal components

InactiveCN103481044AReduce distortionImprove assembly accuracyAutomatic control devicesPeak valueThermal treatment

The invention provides a cutting and feeding path planning method applied to mechanical machining of metal components, which aims at planning a machining technique of easily-deformed metal components to be machined. The cutting and feeding path planning method applied to the mechanical machining of the metal components is characterized in that the requirements are as follows: according to the design structure, the precision requirement and the size of blank machining allowance of a component, the machining times of each surface and the machining sequence of all machining surfaces of the component are arranged, and a cutting direction and a feeding direction of a cutter in each cutting process are arranged. According to the cutting and feeding path planning method applied to the mechanical machining of the metal components, which are provided by the invention, the peak value of residual stress of the interior of the machined component is remarkably reduced, the state of the component is improved, the precision retainability is good, a thermal treatment process for removing the internal residual stress is simplified or eliminated, the work efficiency is improved, the cost is reduced, and an expectable larger economical value and an expectable social value are provided.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

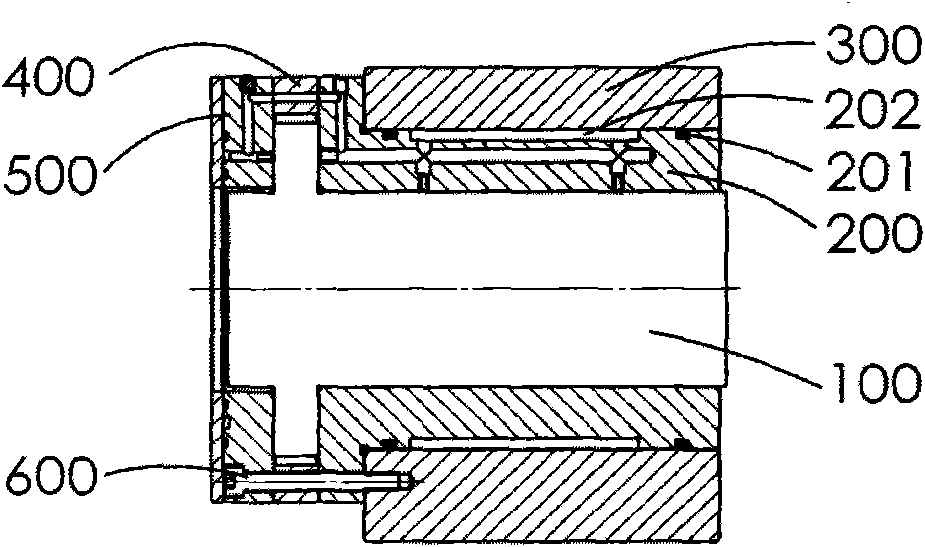

Dynamic and static pressure ceramic sliding bearing lubricated by water or water-based lubricating liquid

ActiveCN101718297AImprove wear resistanceAccelerated corrosionBearing componentsSliding contact bearingsWater basedCarrying capacity

The invention discloses a dynamic and static pressure ceramic sliding bearing lubricated by water or water-based lubricating liquid, which comprises a bearing sleeve, wherein a flange is arranged at one end of the bearing sleeve, and external threads are arranged at the other end of the bearing sleeve; a ceramic shaft sleeve is assembled at the outer layer of the bearing sleeve; a ceramic shaft bushing which comprises a special liquid cavity and a liquid hole structure is arranged outside the ceramic shaft sleeve; a shaft bushing sleeve with the special liquid cavity and the liquid hole structure is assembled at the outer layer of the ceramic shaft bushing; and the bearing of the invention also comprises a bearing end cover, wherein a ceramic ring is assembled at the inner end of the bearing end cover, and internal threads matched with the external threads of the bearing sleeve are arranged on the inner ring of the bearing end cover. The bearing of the invention can improve the wear resistance and the corrosion resistance, can operate in the poor water condition where sandy solid particles are contained, can be lubricated by the water-based lubricating liquid formed by adding other additives into water or water-based liquid; at the same time, the bearing has larger carrying capacity and rigidity, and can ensure a safe and stable operating state, thereby greatly prolonging the operation life.

Owner:TIANJIN UNIV

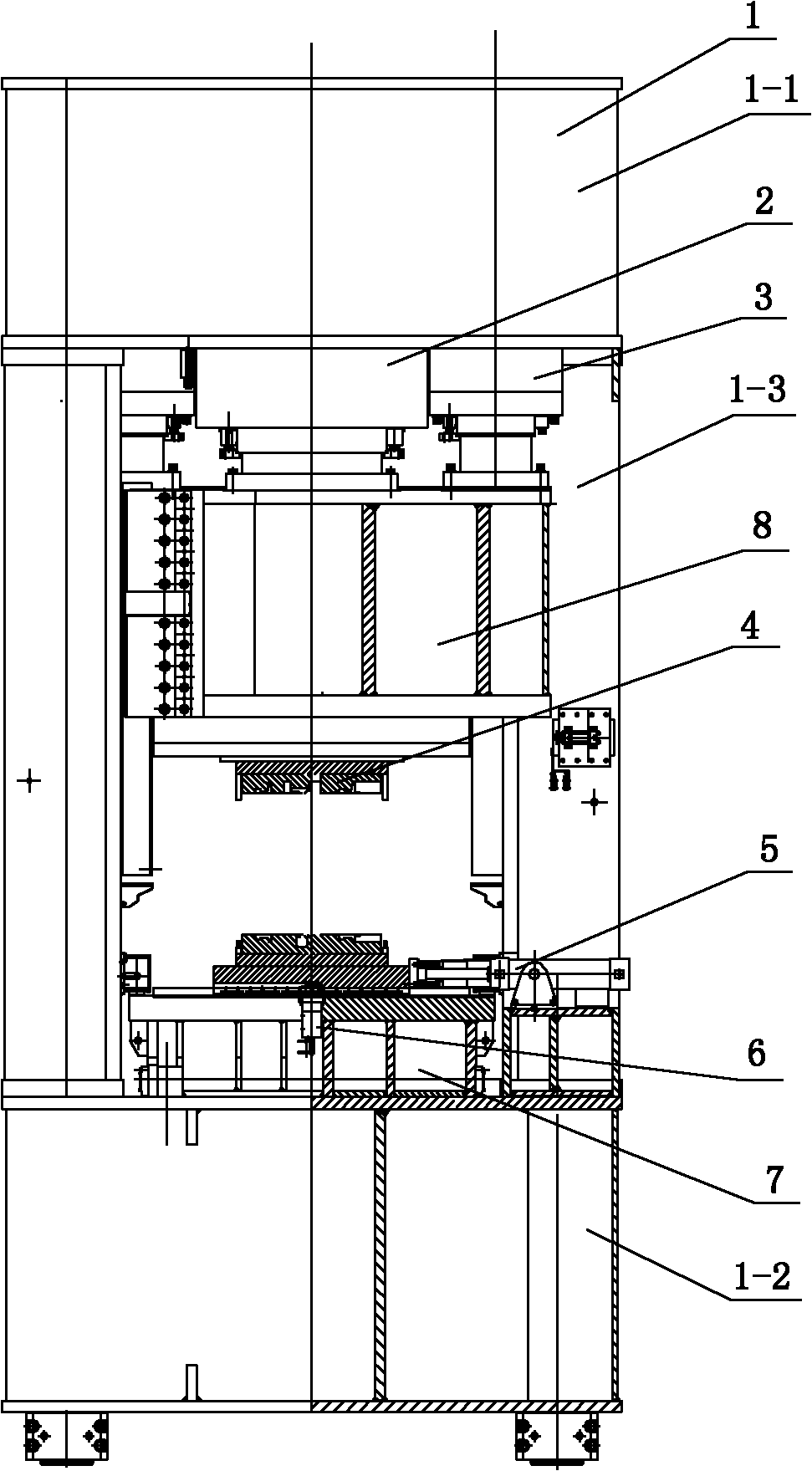

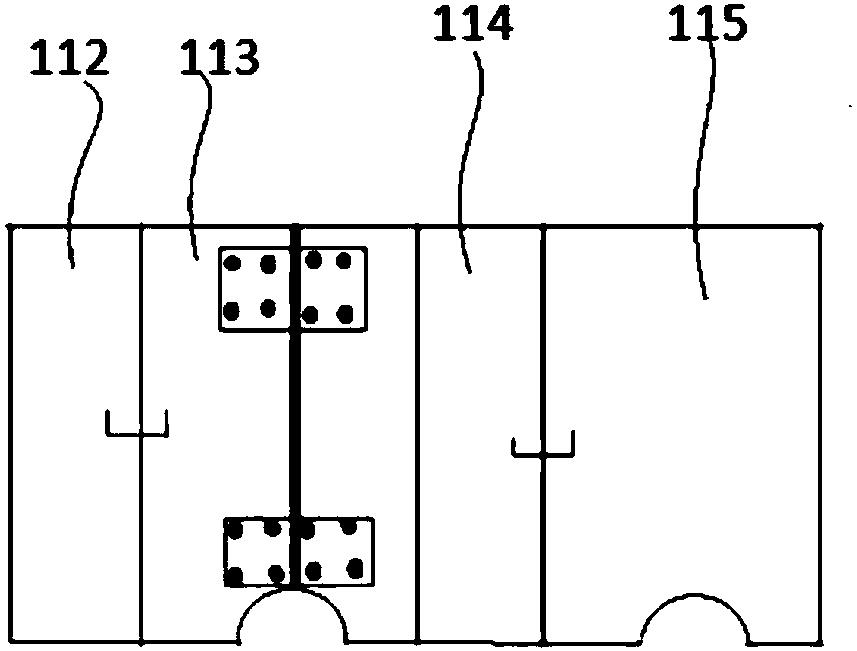

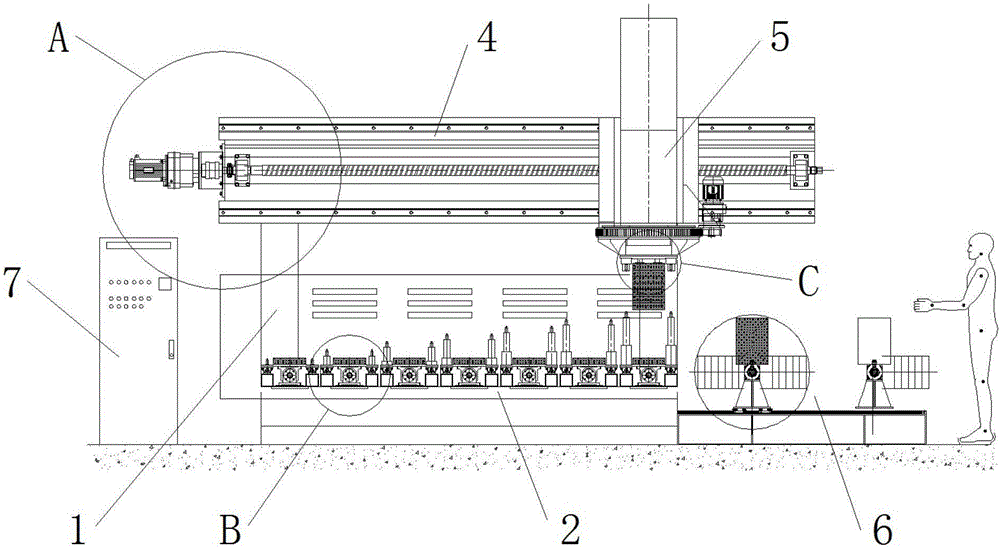

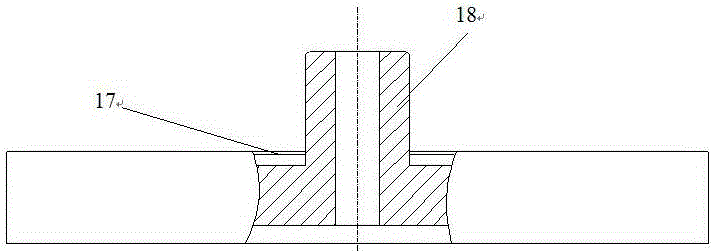

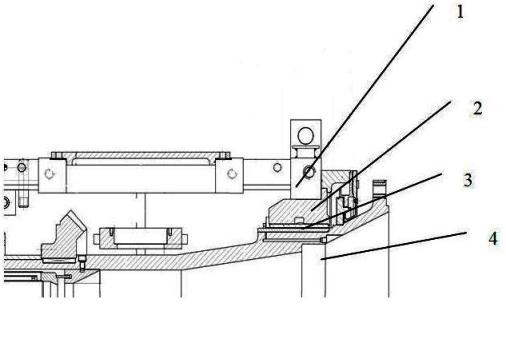

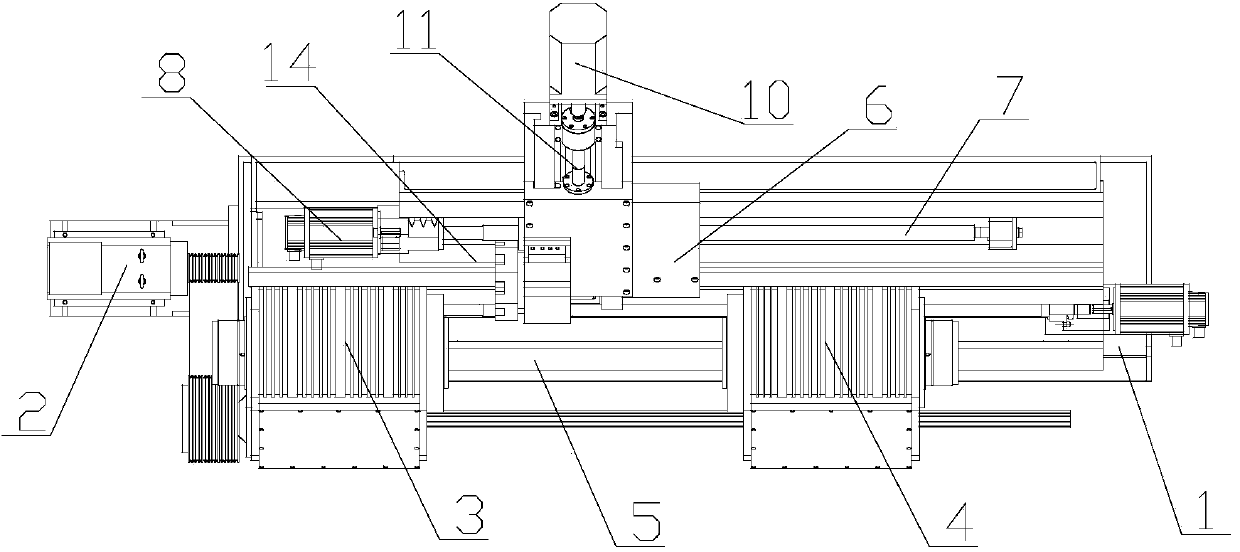

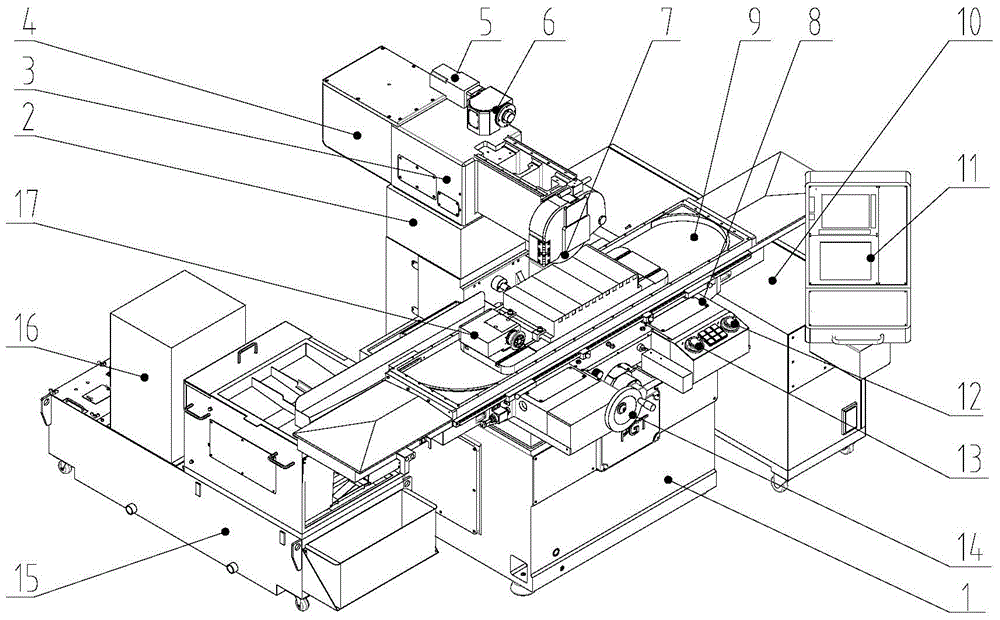

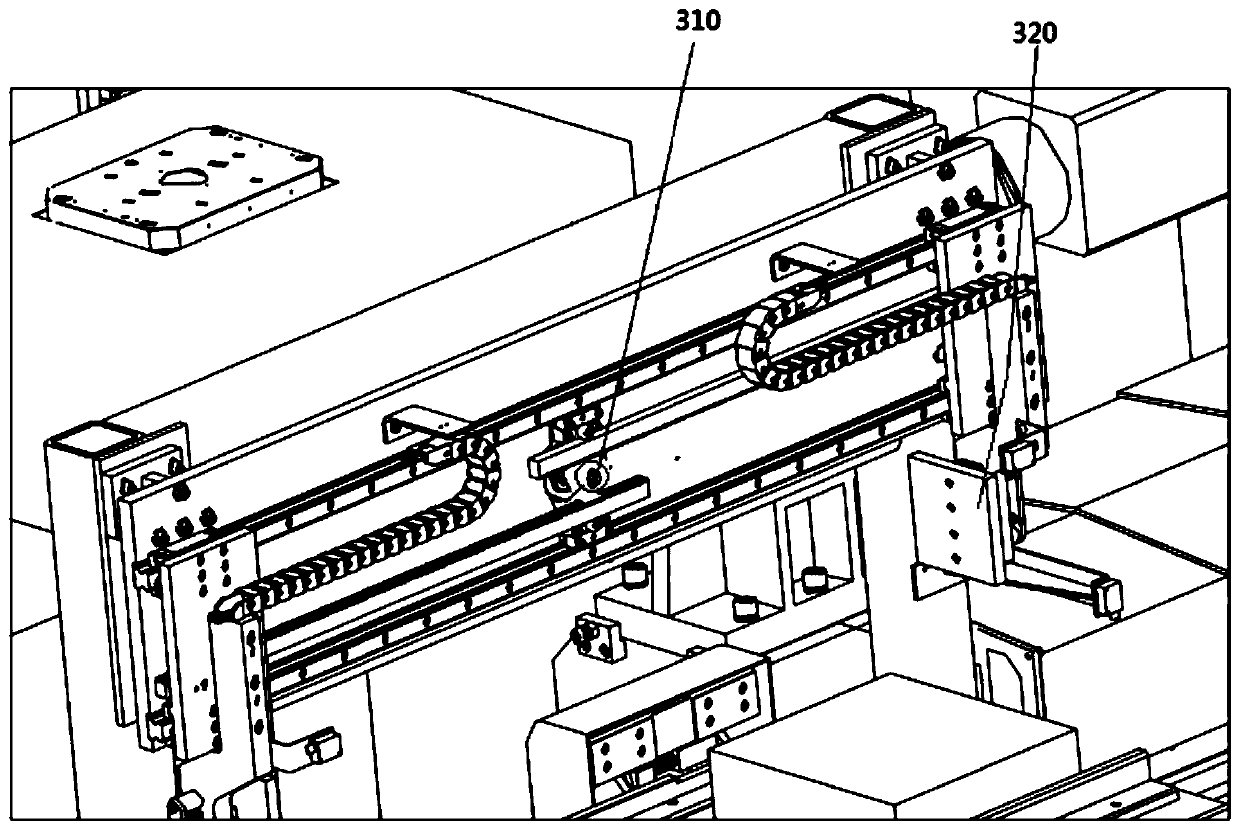

Precision forging process production line for steel rail turnout

ActiveCN102114518AGood accuracy retentionAvoid deformationRailway componentsForging/hammering/pressing machinesCompression moldingProduction line

The invention relates to a precision forging process production line for a steel rail turnout, which is characterized in that the precision forging process production line comprises a steel rail turnout precision forging press, a heating furnace, a normalizing furnace, a steel rail forward conveying device, an automatic steel rail feeding mechanism and an automatic steel rail blanking mechanism; a steel rail transversely-conveying trolley is arranged between the automatic steel rail feeding mechanism and the automatic steel rail blanking mechanism; a transversal motion guide rail and a transmission gear rack are arranged under the steel rail transversely-conveying trolley; a plurality of steel rail precision feeding devices and a servomotor are arranged on the steel rail transversely-conveying trolley; and an electric cabinet used for controlling the operation of the whole production line is arranged on the outer side of the automatic steel rail feeding mechanism. The precision forging process production line has the advantages as follows: the production line is suitable for hot compression molding technology of various AT (abbreviation for Pinyin of 'short-type cross section') steel rail turnouts, and all devices and mechanisms of the production line can achieve automation control without manual intervention, so that time and labor are saved, the labor intensity of operators is reduced, the processing period of the steel rail turnout is shortened, the production cost is lowered, the machining precision and the qualification rate of the steel rail are improved, and the requirement of high-quality steel rail can be satisfied further.

Owner:TIANJIN TIANDUAN PRESS CO LTD

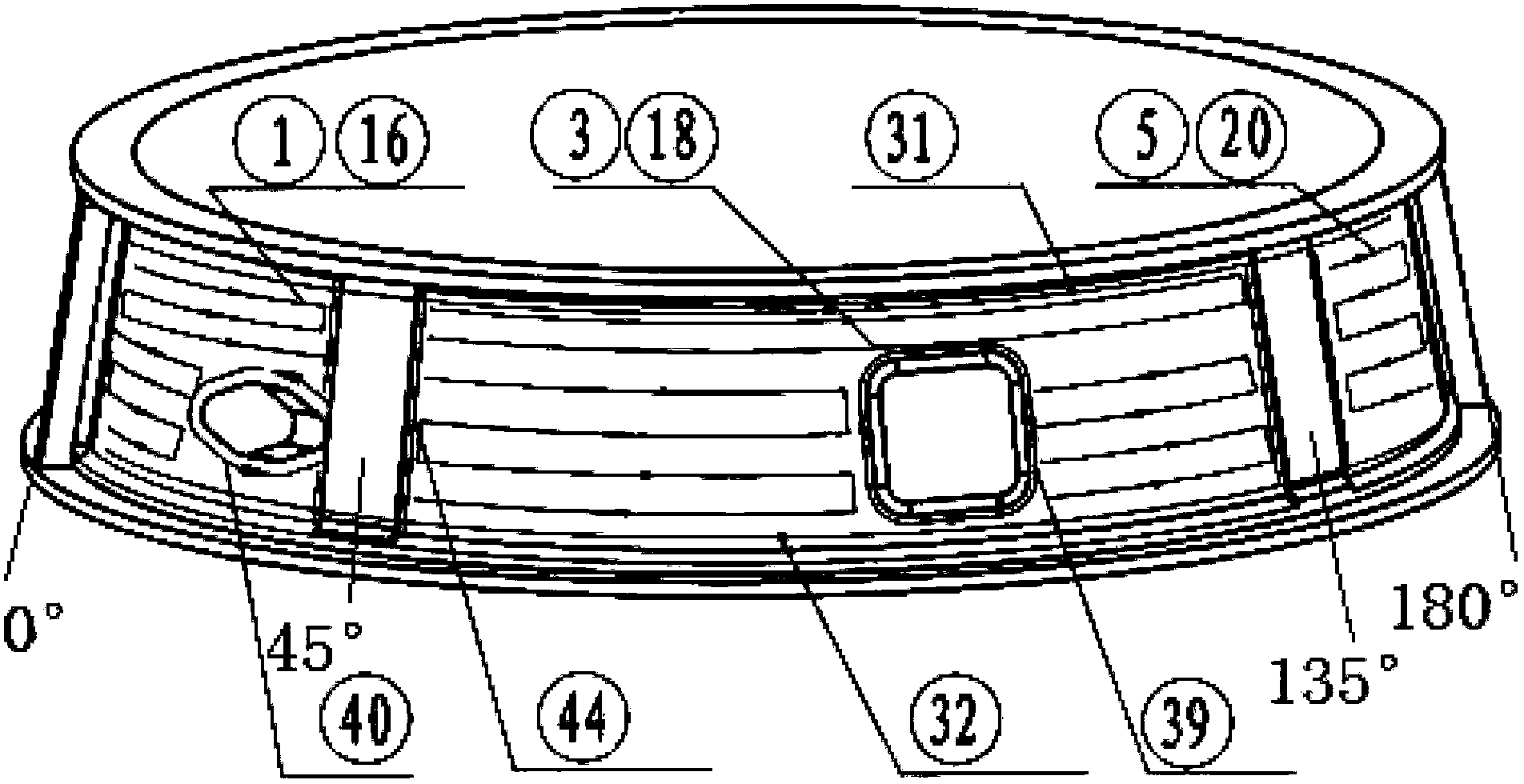

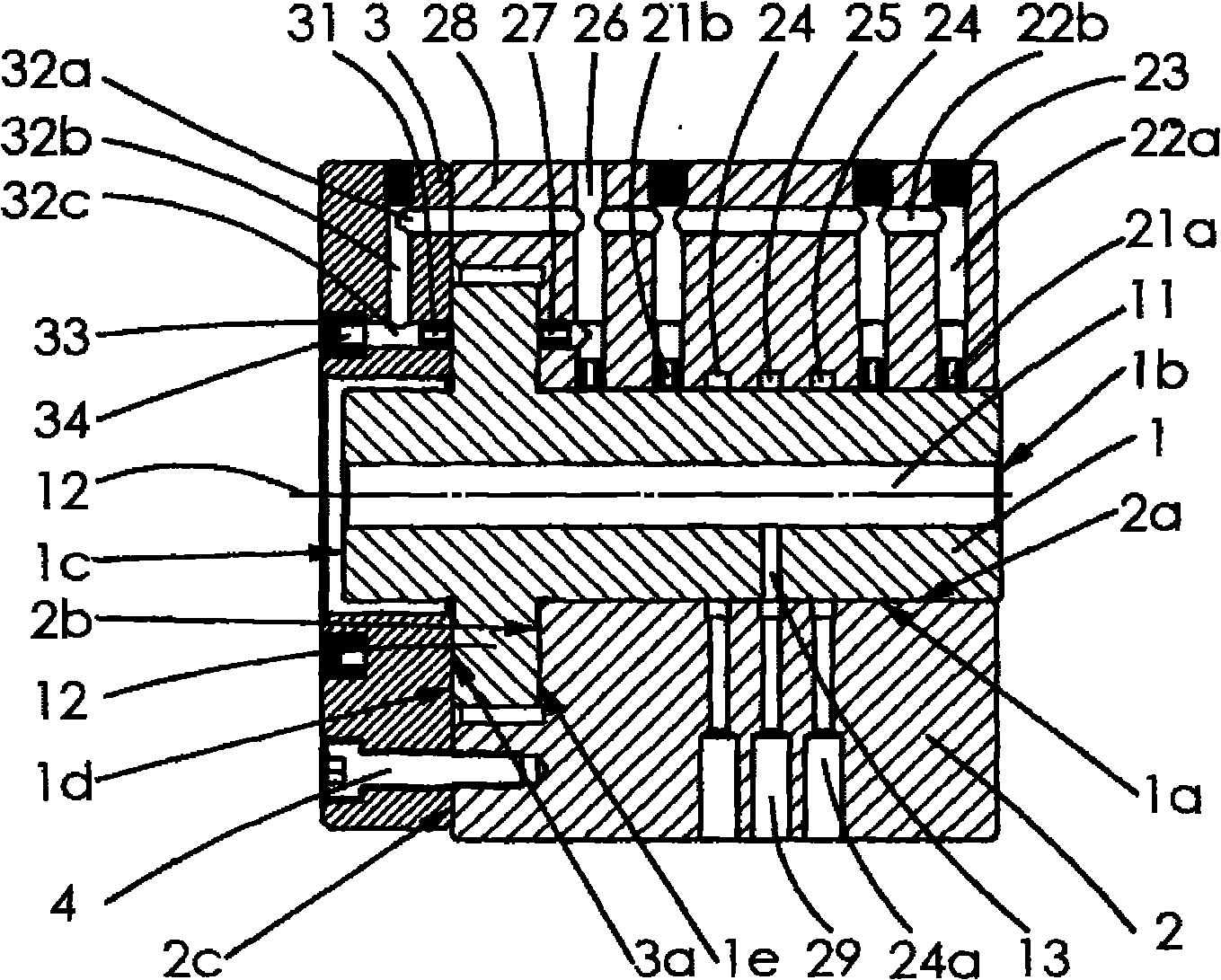

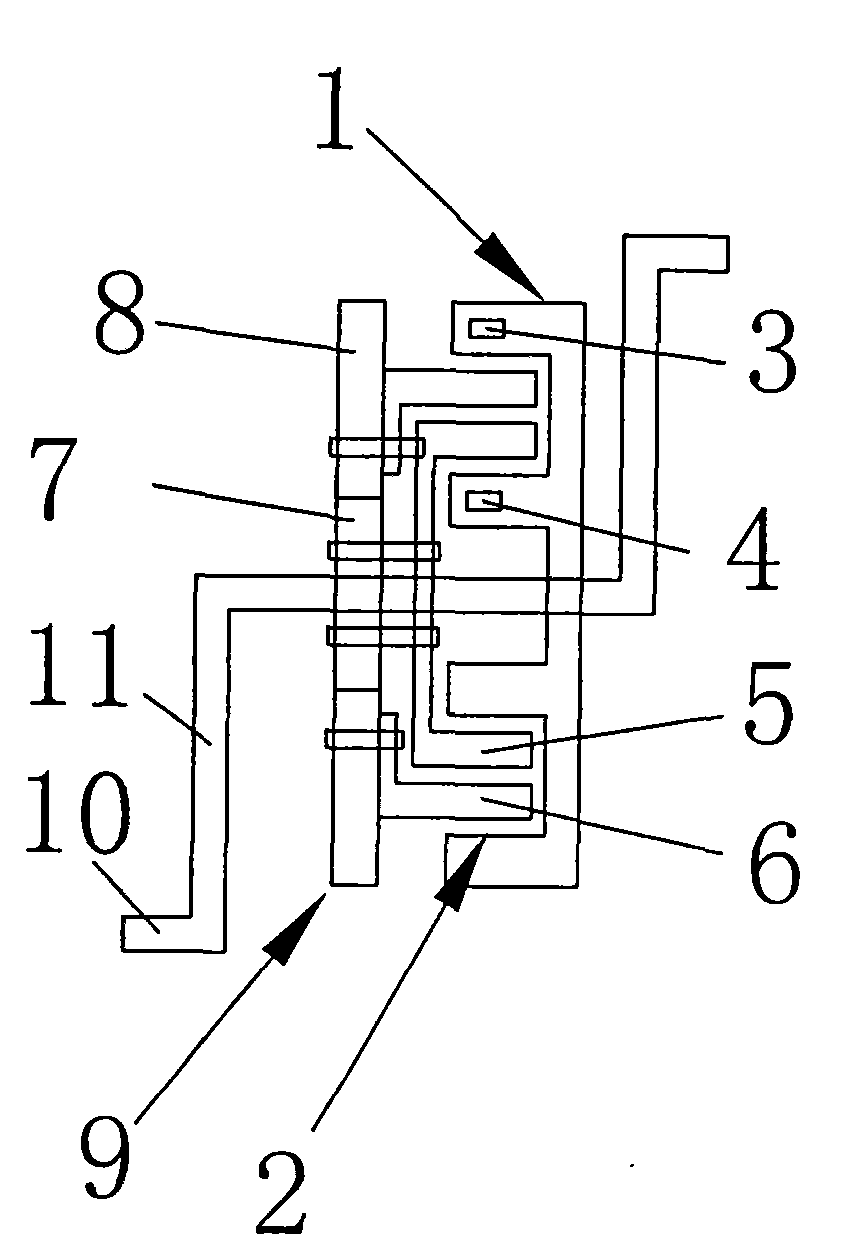

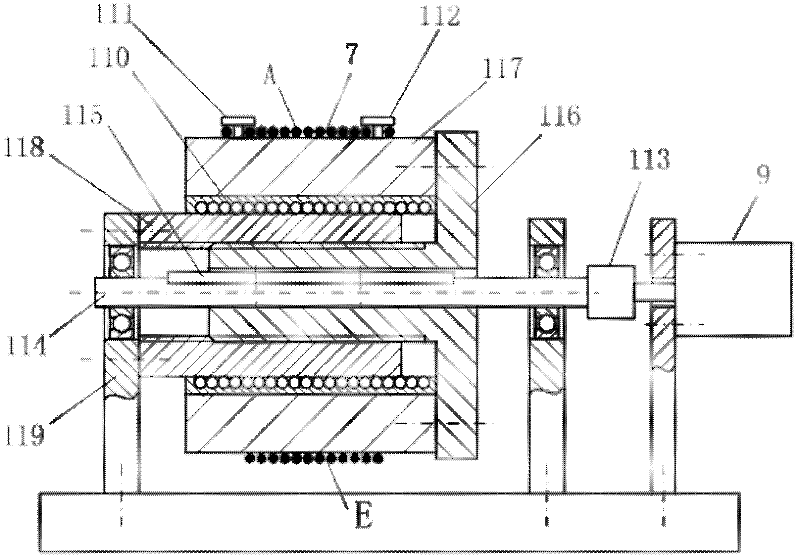

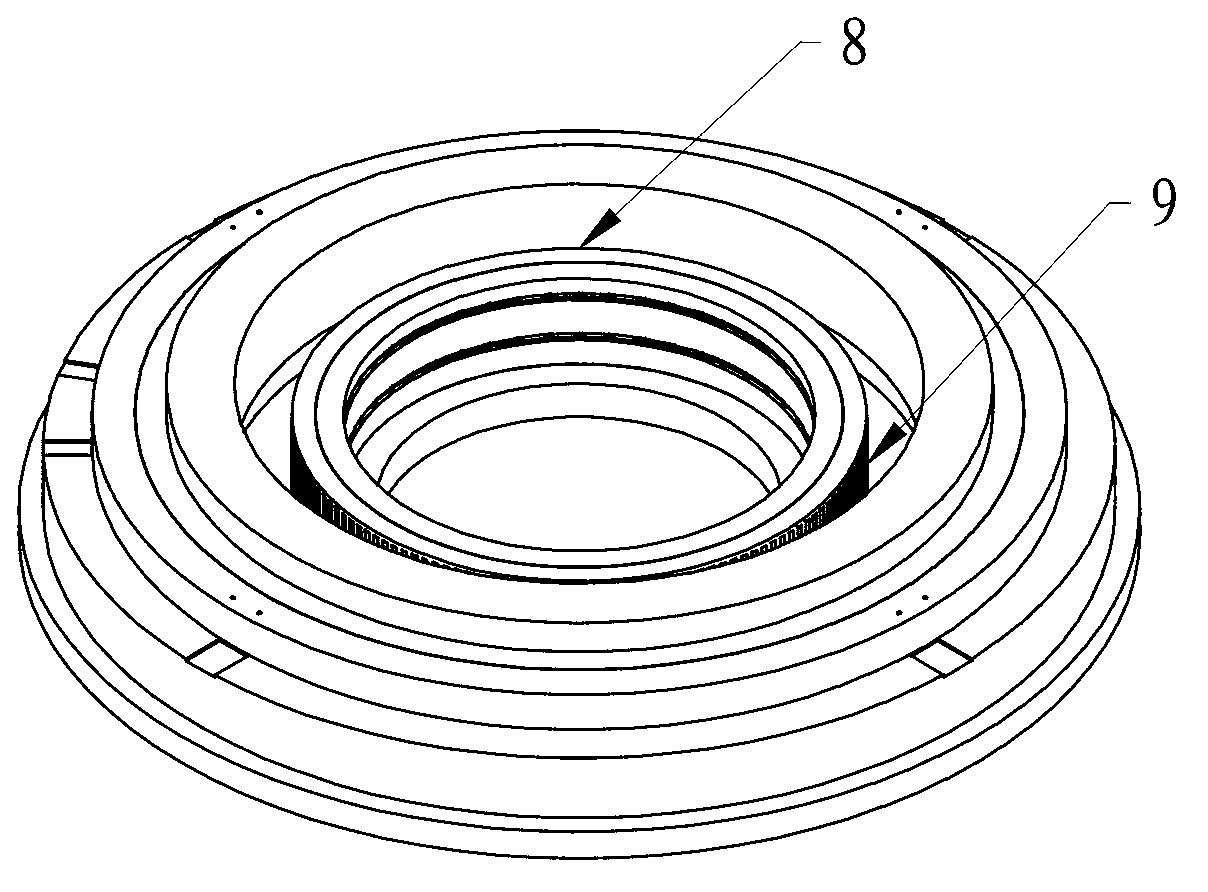

High-precision micro-miniature air static-pressure rotary table

ActiveCN104625765AReduce in quantityIntersection spacing increasedLarge fixed membersDynamic balanceEngineering

The invention provides a high-precision micro-miniature air static-pressure rotary table. According to the high-precision micro-miniature air static-pressure rotary table, the problems that as for a current common-use high-precision micro-miniature air static-pressure rotary table, the number of constituting parts is large, the quite high precision requirement can not be met easily, dynamic balance can not be achieved easily, the size of a whole system is large, and particularly, the height is large are solved; the problems that due to the common-use mode of decreasing the overall height of the rotary table, stability is low, and the capacity for bearing the capsizing moment is low are solved; the production cost problem caused when a plurality of working faces of a shaft sleeve and a shaft need to be machined in the rotary table machining production process is solved. The high-precision micro-miniature air static-pressure rotary table comprises a rotary table machine base, a conical air floating shaft sleeve, a main shaft system and a rotary table motor. According to the high-precision micro-miniature air static-pressure rotary table, the working faces, needing to be machined in the rotary table production process, of the shaft sleeve and a shaft are two corresponding conical surfaces, the number of the working faces is decreased to a certain degree compared with the original high-precision micro-miniature air static-pressure rotary table, and the production cost is reduced. The high-precision micro-miniature air static-pressure rotary table has the advantages of being easy to assemble, good in precision retentivity and the like, and can be used on multi-machining-mode precise and ultra-precision machining equipment.

Owner:HARBIN INST OF TECH

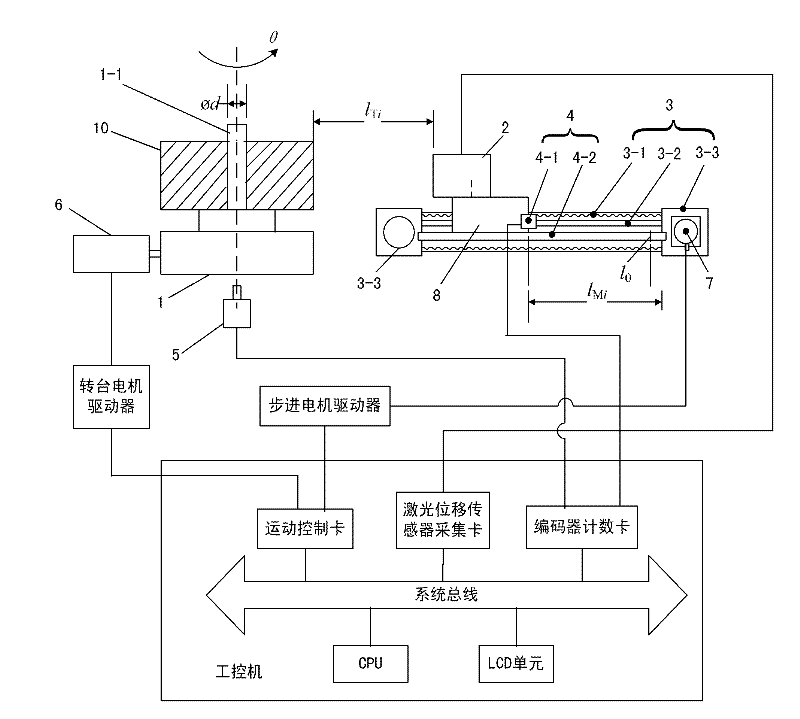

Device for detecting cam profile

InactiveCN102147238BThere is no transmission gapHigh dynamic stiffnessUsing optical meansNumerical controlActive cell

The invention provides a device for detecting cam profiles, which has the advantages of simple structure, high detection precision and higher efficiency. The device comprises a numerical control turntable, a linear motor, a laser measuring head, a grating scale displacement sensor, an encoder and an industrial personal computer, wherein the numerical control turntable is used for driving the cam to horizontally and coaxially rotate around a vertical mandrel; the linear motor is horizontally arranged on one side of the numerical control turntable; the laser measuring head is arranged on the active cell of the linear motor and at one side of the cam; the grating scale displacement sensor is used for measuring the horizontal displacement of the active cell; the encoder is used for detecting the rotation angle of the cam; and the industrial personal computer controls the numerical control turntable and the linear motor to act and obtains the outer profile data of the cam according to datameasured by the laser measuring head, the grating scale displacement sensor and the encoder.

Owner:CHANGZHOU INST OF TECH

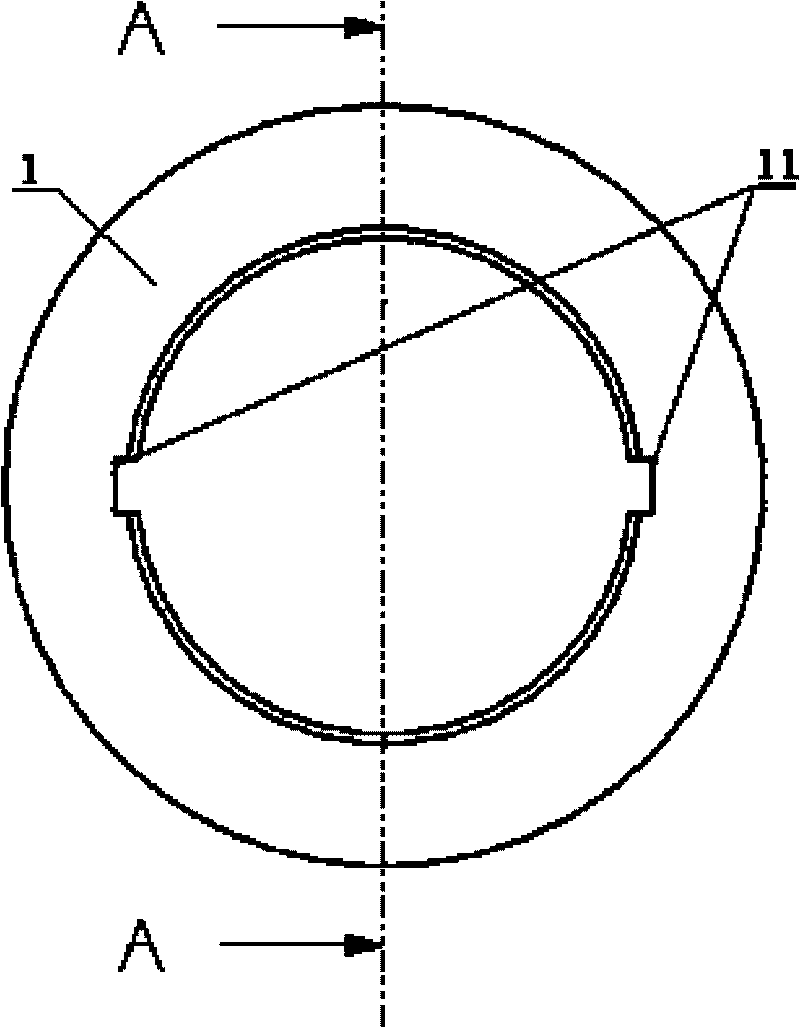

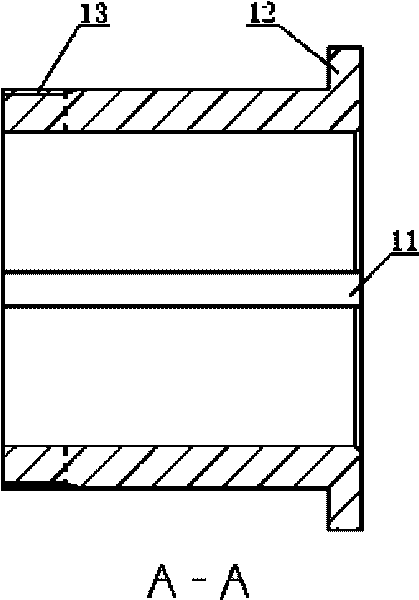

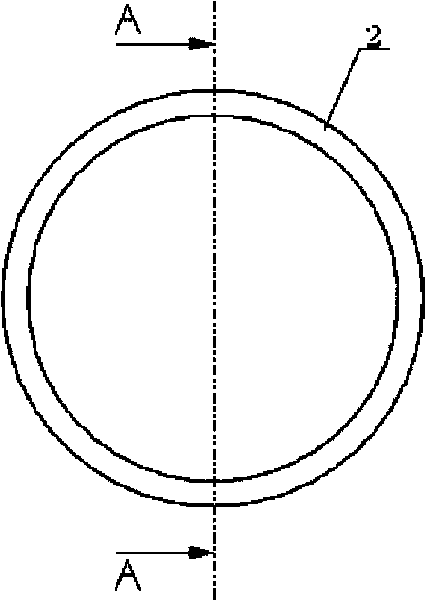

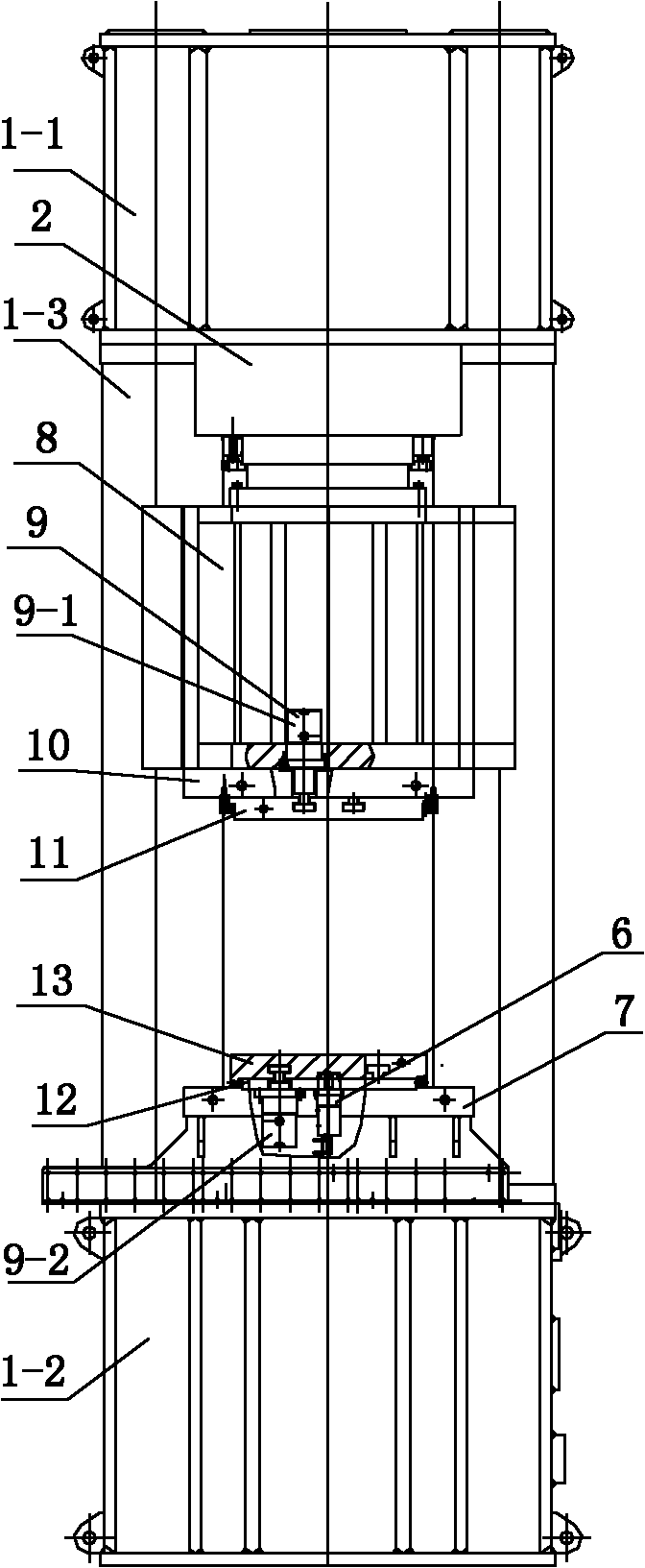

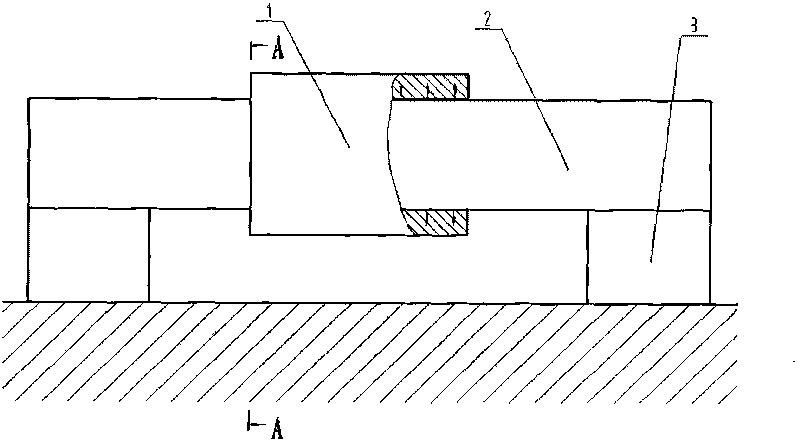

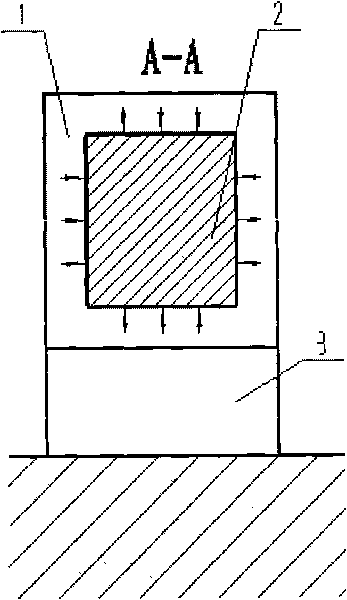

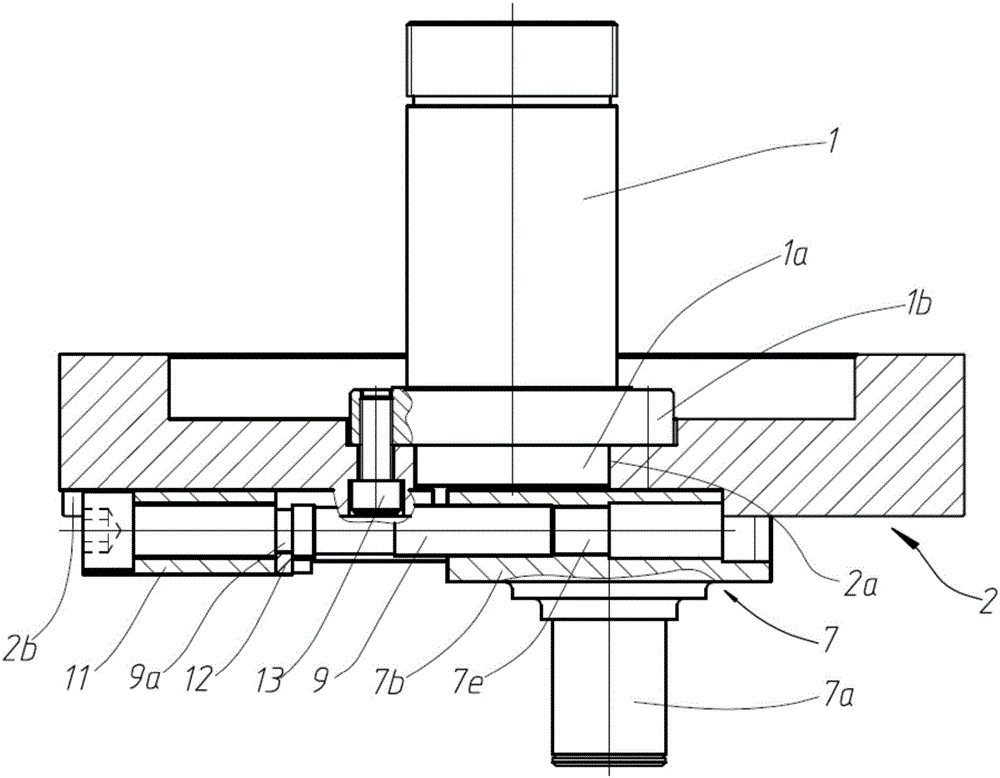

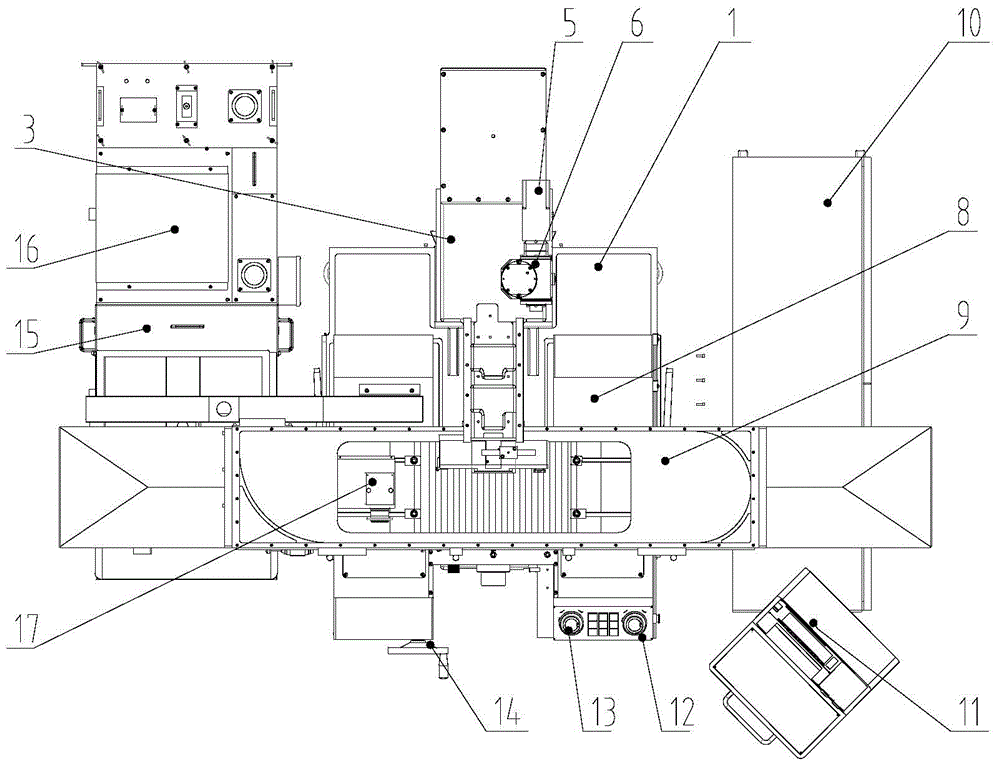

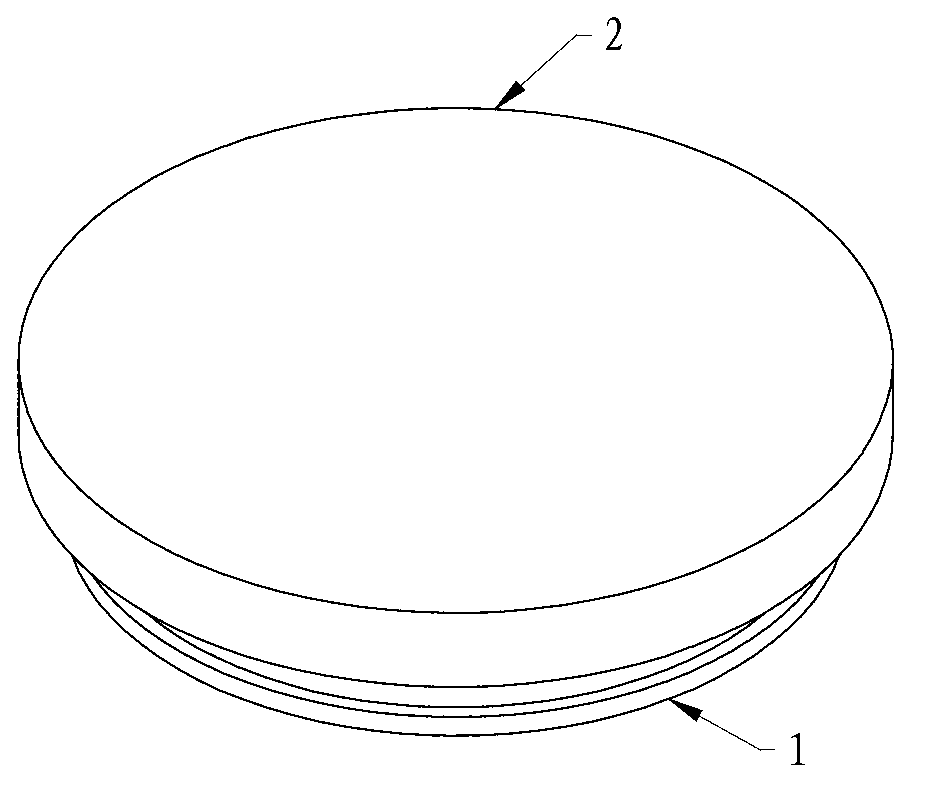

Ultrahigh-precision aerostatic bearing main shaft system

InactiveCN102179532AReduce in quantitySimple structureMetal-working apparatusThrust bearingMechanical engineering

The invention discloses an ultrahigh-precision aerostatic bearing main shaft system comprising a rotating shaft (1), a main shaft box (2) and a main shaft box end cover (3), wherein the rotating shaft (1) is installed in the main shaft box (2), is supported by means of an aerostatic bearing and rotates relative to the main shaft box (2), and the aerostatic bearing is integrated in the main shaft box (2) and is integrated with the main shaft box, therefore, a simplest structure is realized. The main shaft box (2) is internally provided with a thrust boss (28) and an axial air film gap for connecting the main shaft box end cover (3) and forming a thrust bearing. The inner surface (2a) of the main hole cavity of the main shaft box (2) is provided with a vacuum annular groove (25) which is arranged between two air exhaust grooves (24), the main shaft box (2) is provided with a vacuum port (29) which forms a connected vacuum air path together with a radial hole (13) and a central hole (11)which are arranged in the rotating shaft (1), and when installed on the end face of the rotating shaft, a vacuum chuck can be used for absorbing workpieces.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

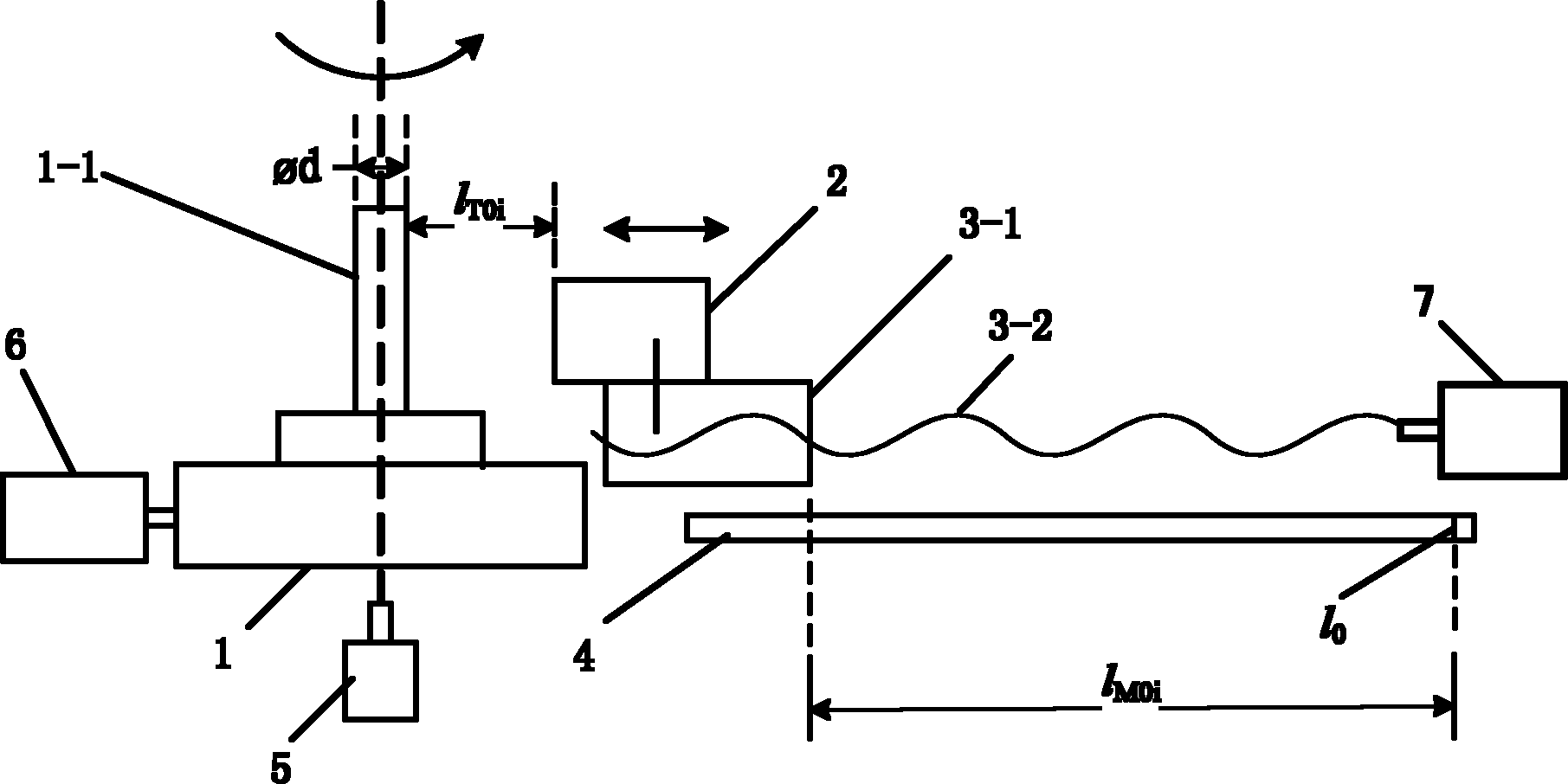

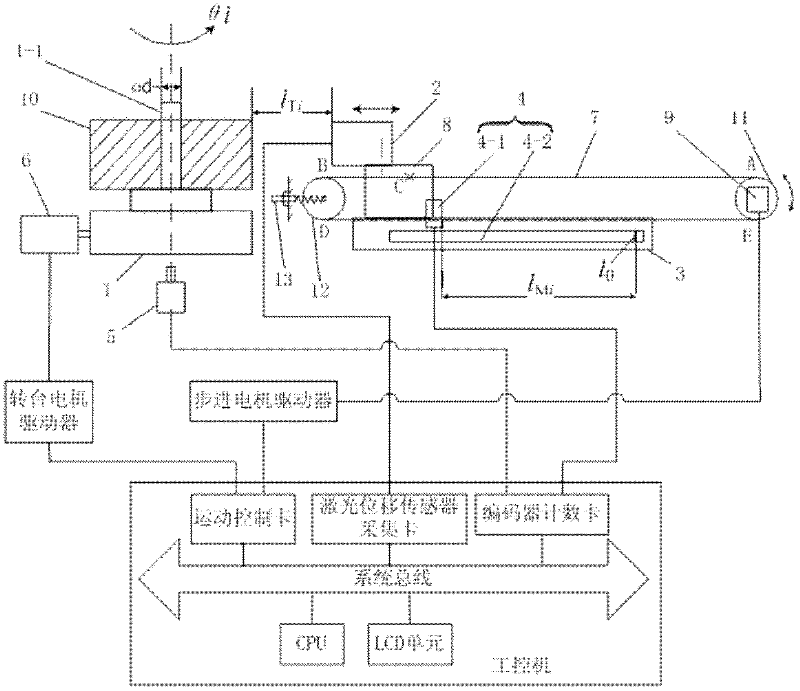

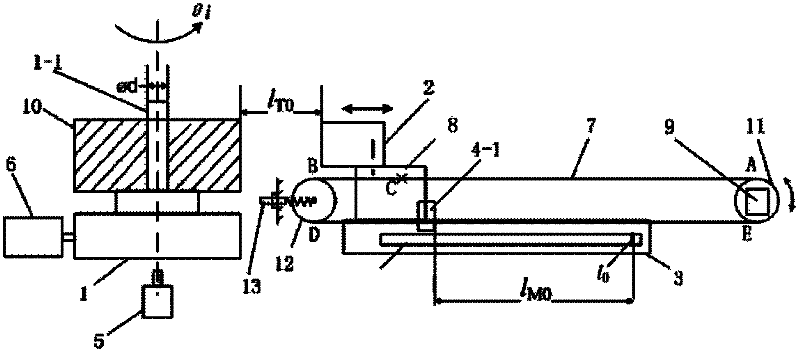

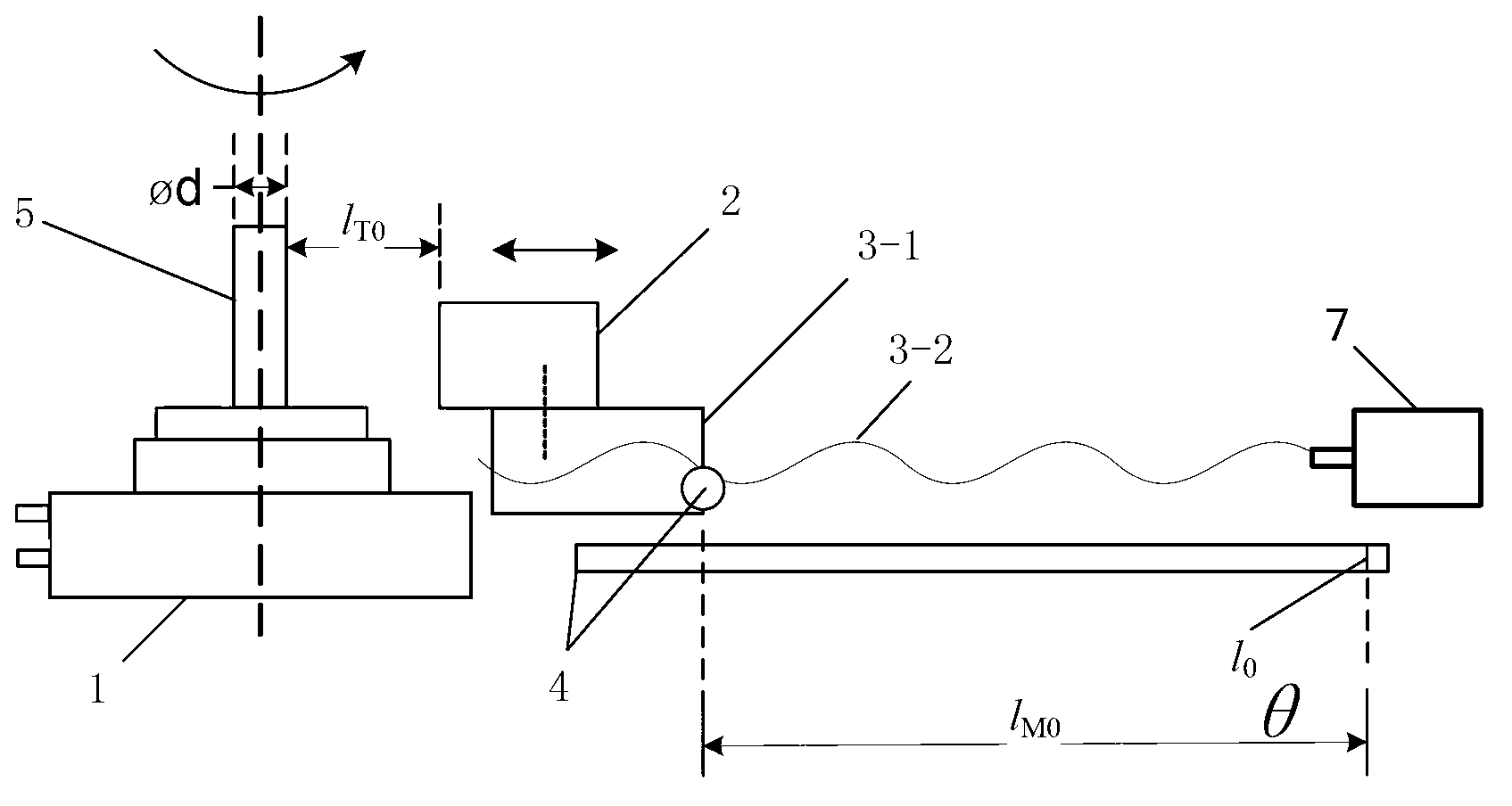

Detection method for cam outline detection system

The invention provides a detection method for a cam outline detection system which has a simple structure and high detection precision and efficiency. The adopted cam outline detection system comprises a numerically controlled rotary table, a screw rod and nut pair, a laser measurement head, a grating bar displacement sensor, an encoder and an industrial control computer; the numerically controlled rotary table is used for driving a cam to horizontally and coaxially rotate around a vertical mandrel; the screw rod and nut pair is horizontally arranged on one side of the numerically controlled rotary table; the laser measurement head is arranged on a movable nut of the screw rod and nut pair and positioned on one side of the cam; the grating bar displacement sensor is used for measuring the horizontal displacement value of the movable nut; the encoder is used for detecting a rotary angle of the cam; and the industrial control computer controls the operation of the numerically controlled rotary table and the screw rod and nut pair, and obtains data of the outer outline of the cam according to data measured by the laser measurement head, the grating bar displacement sensor and the encoder.

Owner:CHANGZHOU INST OF TECH

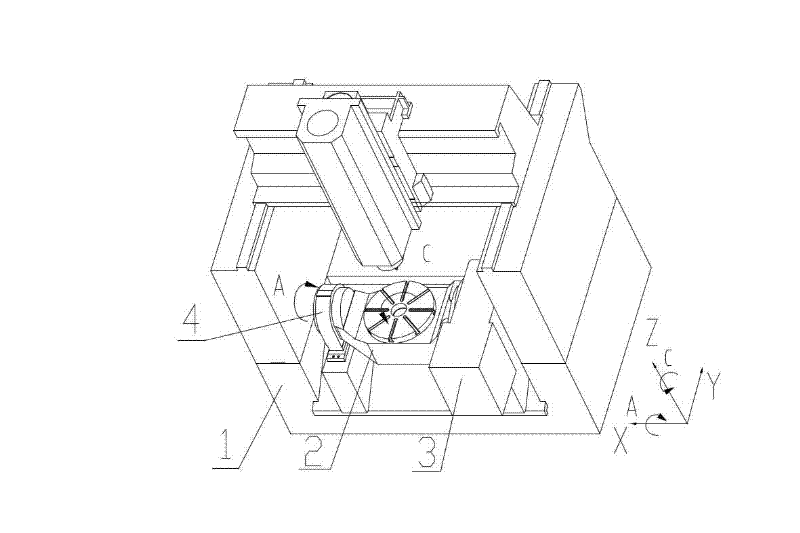

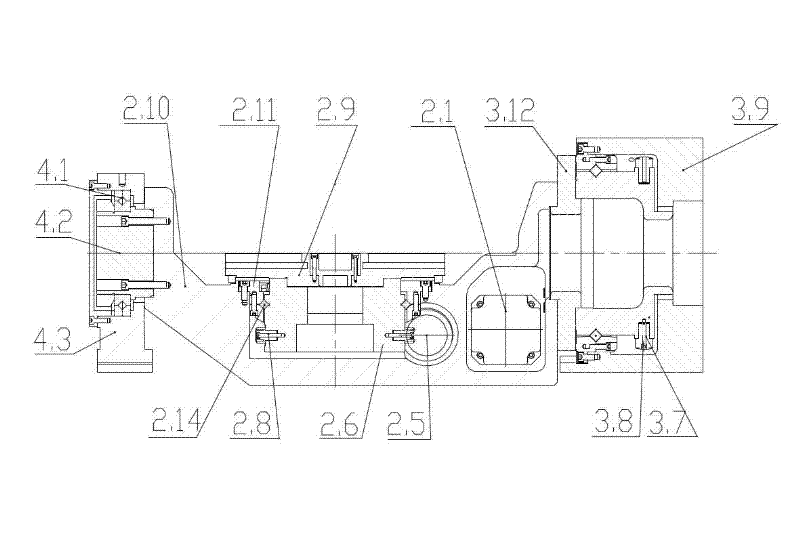

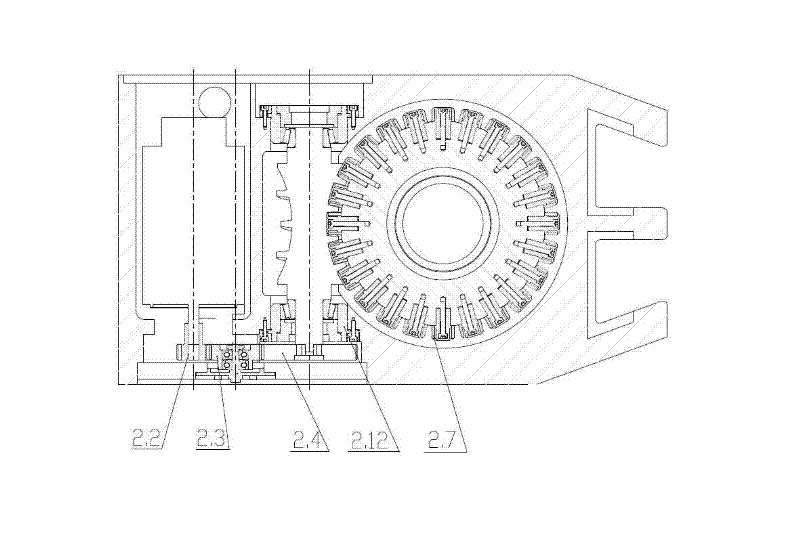

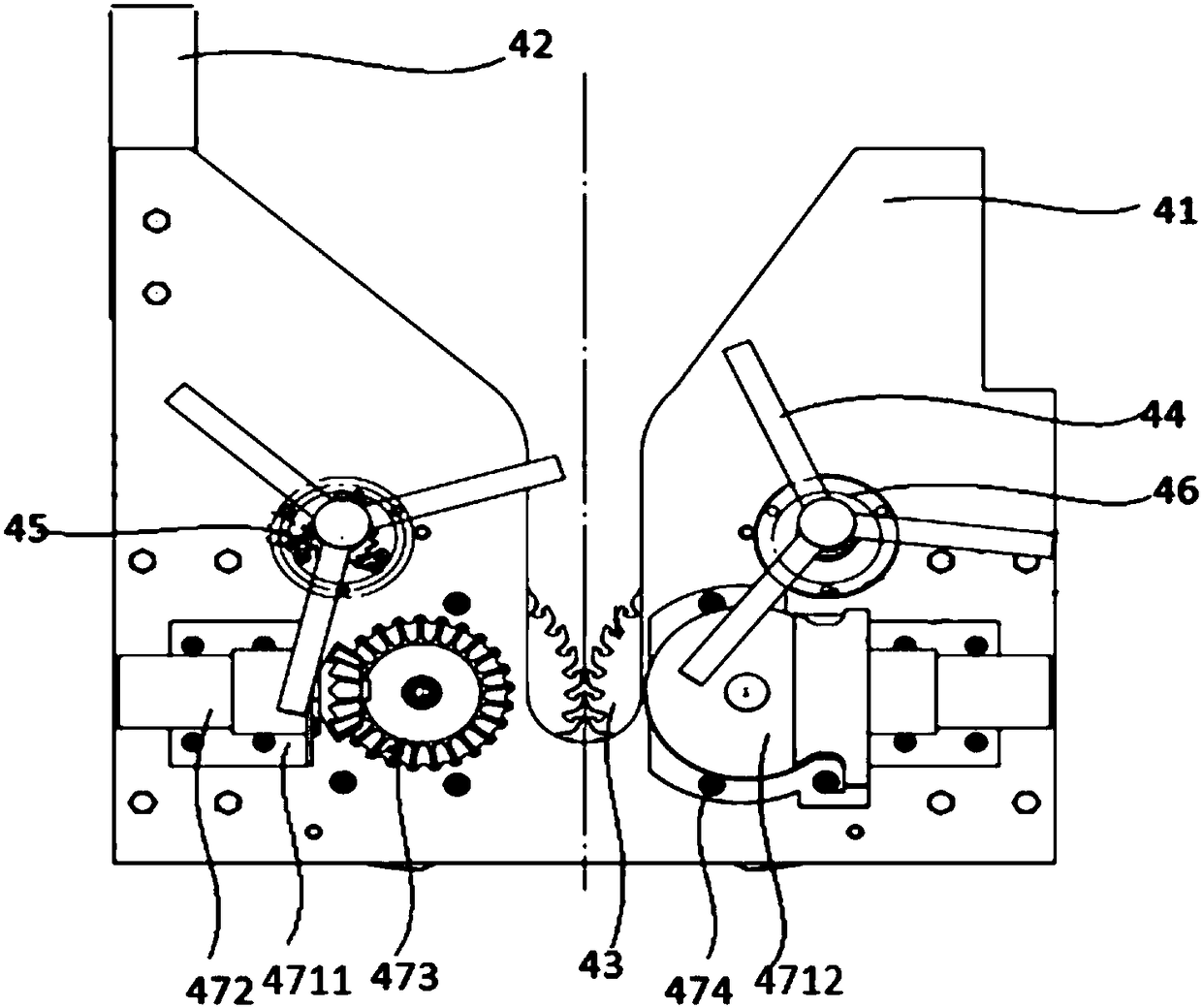

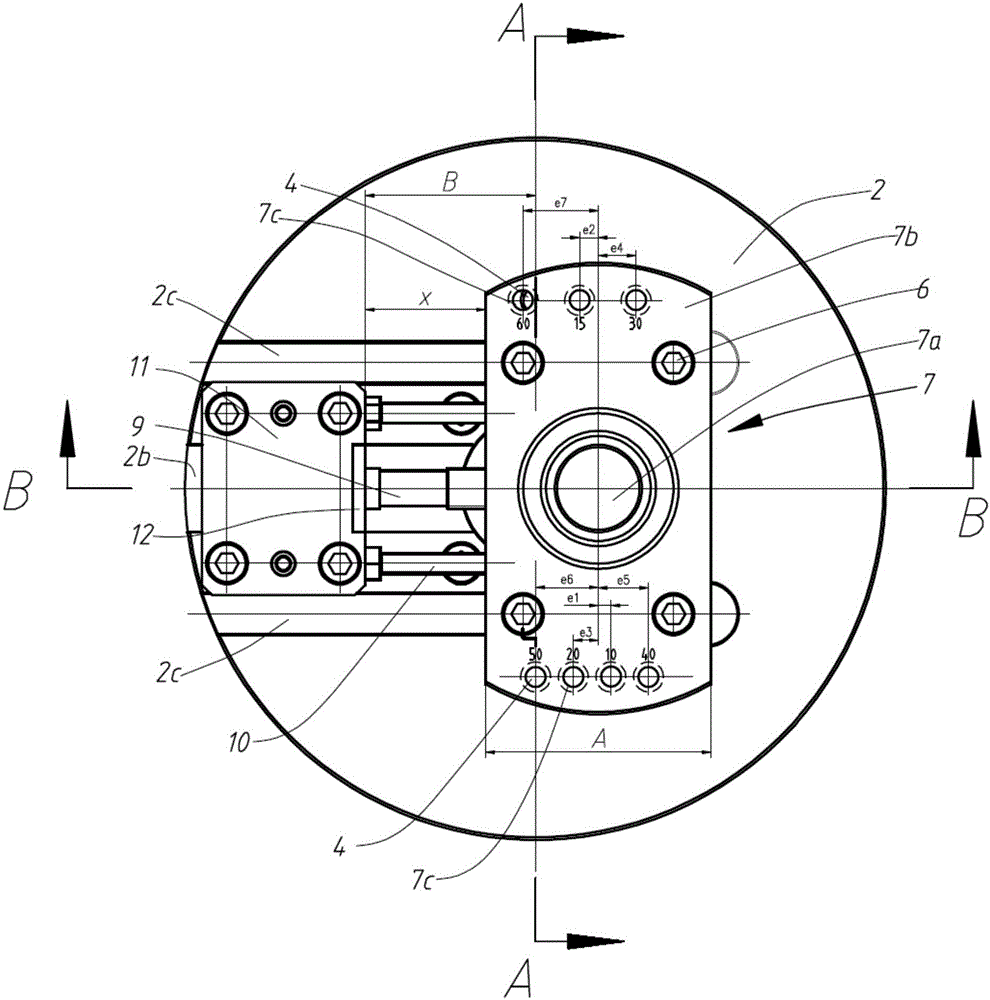

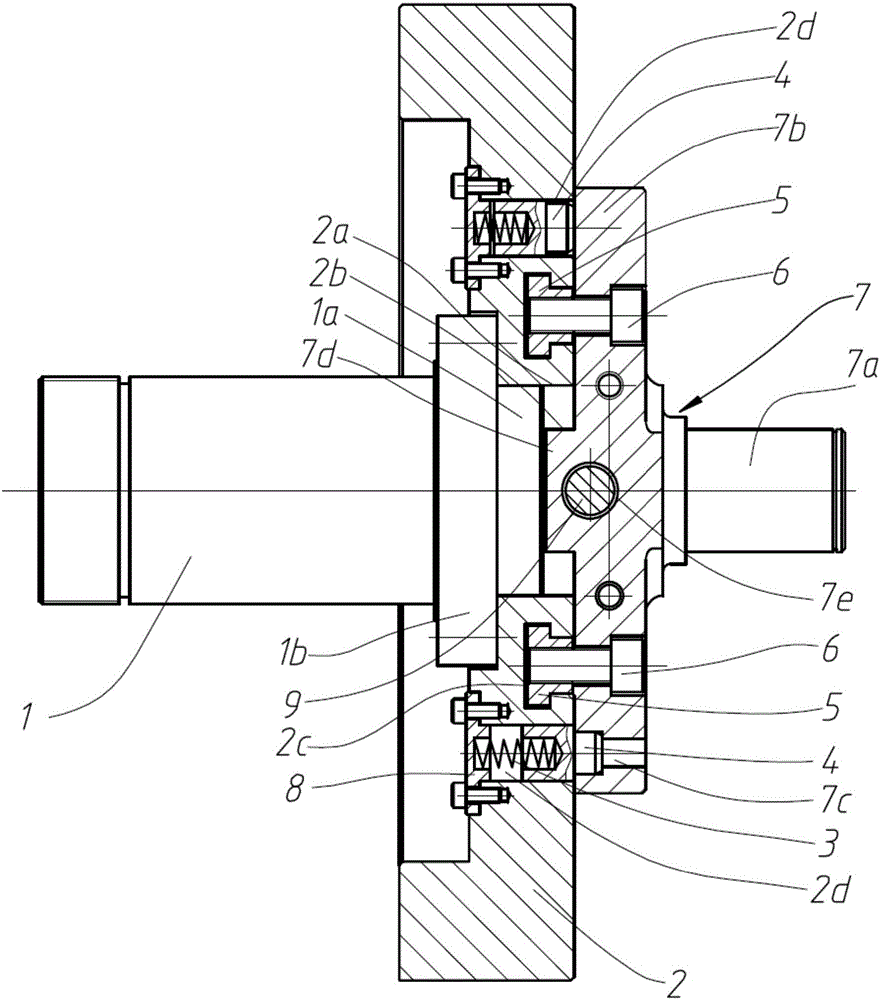

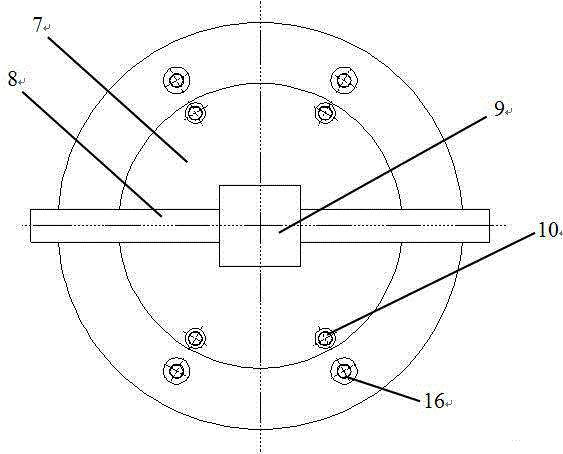

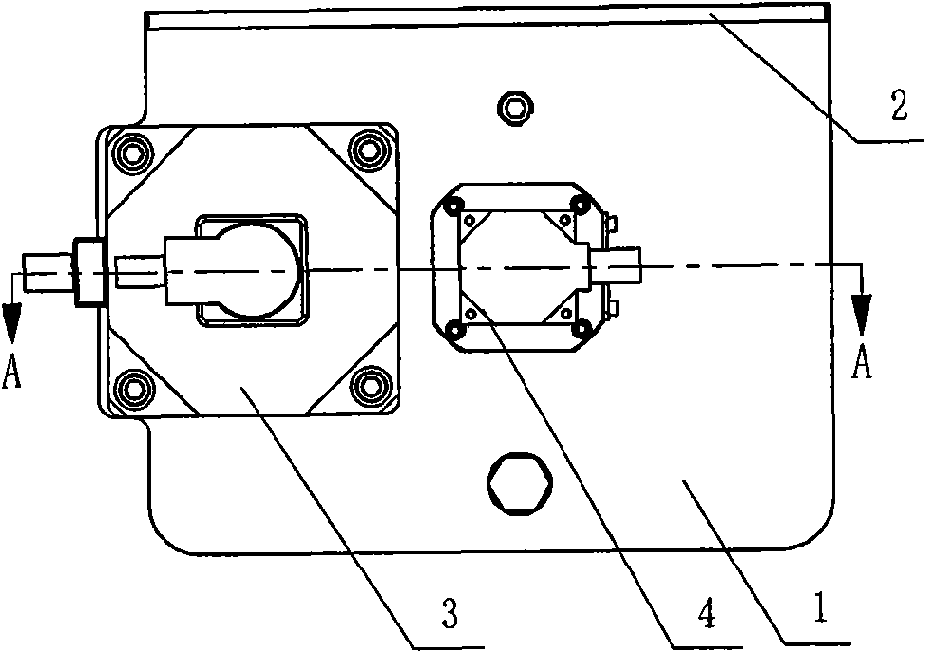

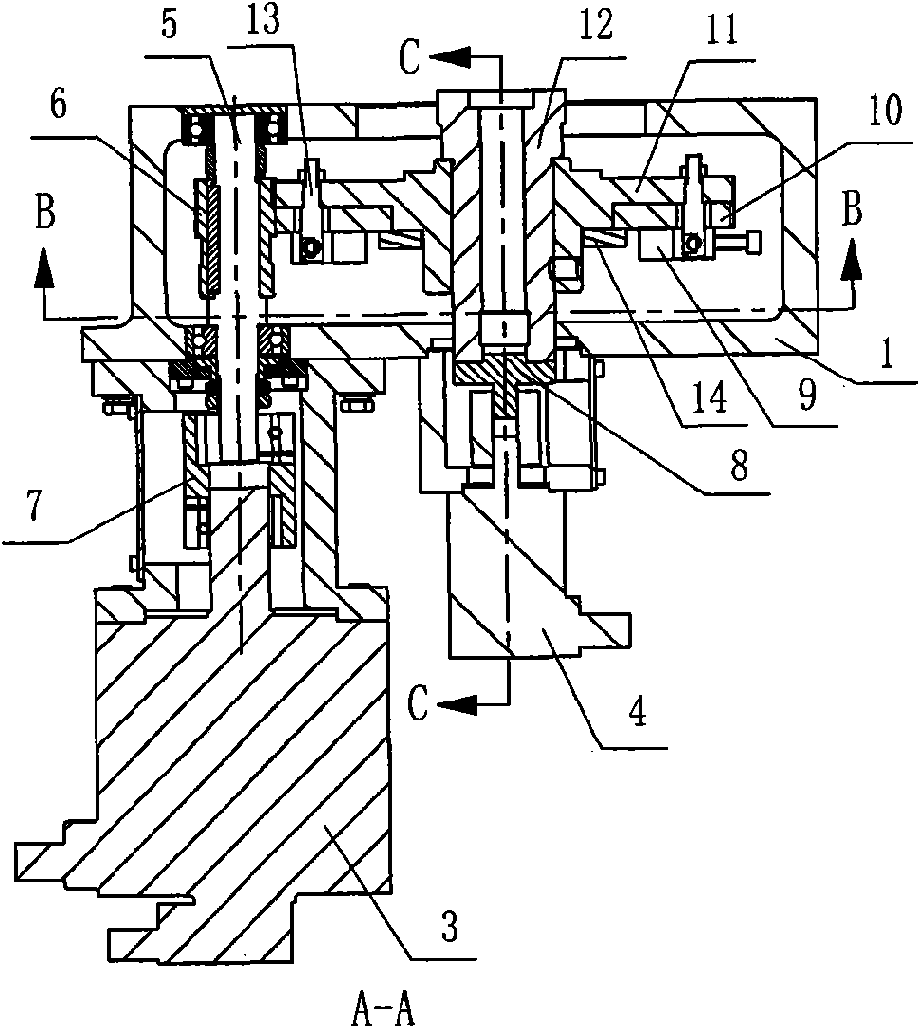

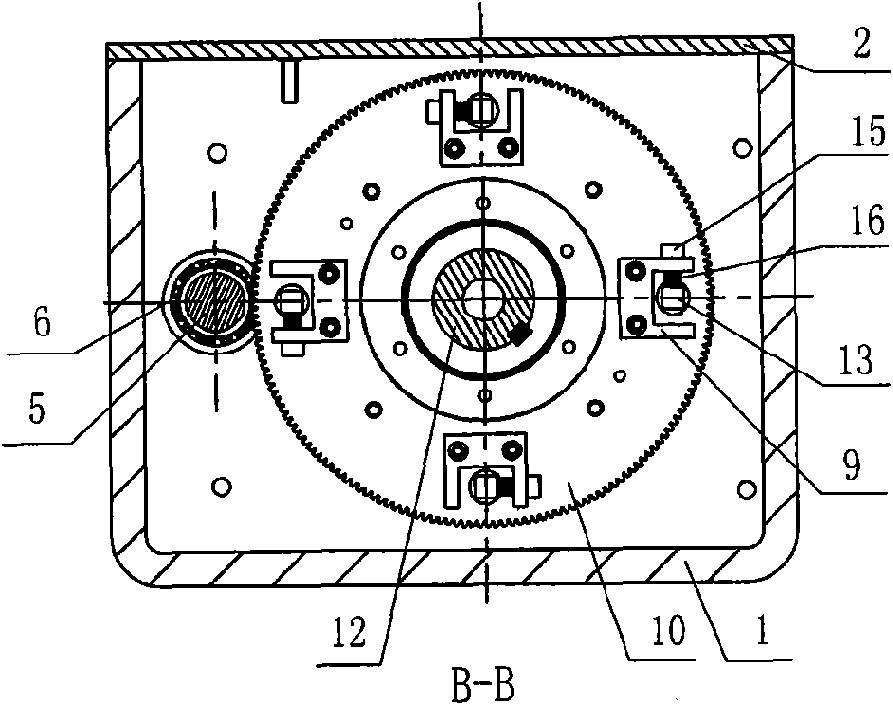

Mechanical type numerical control double-shaft turntable device

ActiveCN102240910AEliminate backlashEasy processing and assemblyLarge fixed membersCamMechanical engineering

The invention relates to a mechanical type numerical control double-shaft turntable device which comprises a turntable C shaft, an A shaft driving end and an A shaft support end, wherein by being matched with a bore bearing of an A shaft, two ends of the turntable C shaft are respectively fixed on the A shaft driving end and the A shaft support end. The A shaft driving end and the turntable C shaft are respectively used for driving the A shaft to rotate by virtue of respective servo motors, transmission gear retarding mechanisms and cam pair retarding and clearance-eliminating mechanisms. An eccentric mechanism can be used for adjusting a gear centre distance, thereby realizing the gear back lash between transmission parts of the A and C shafts. The eccentric mechanism can be used for adjusting a cam pair centre distance, thereby realizing the back lash between cam input and cam output shafts of the A and C shafts. The A and C shafts can be indexed, positioned and self-locked at any angle. The mechanical type numerical control double-shaft turntable device can be used for eliminating a reverse clearance of the numerical control double-shaft turntable under the effect of adjustment. The mechanical type numerical control double-shaft turntable device is conveniently processed and assembled and is good in precision-keeping property.

Owner:通用技术集团沈阳机床有限责任公司

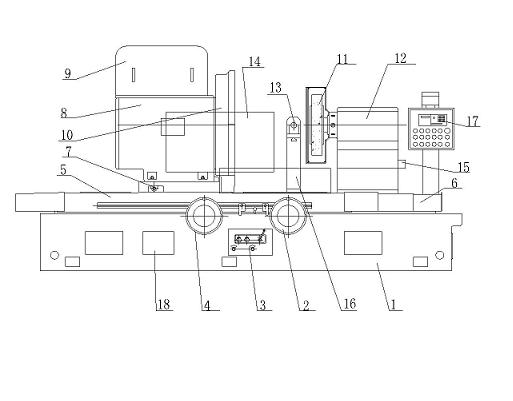

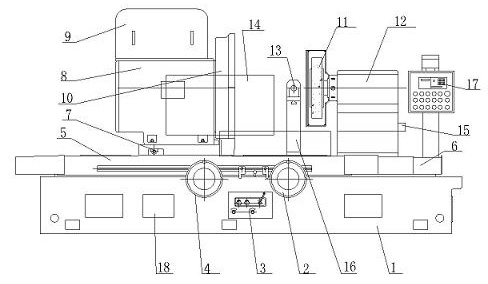

Cylindrical grinding machine for bearing ring

InactiveCN102179735ASimple structureStatic strongRevolution surface grinding machinesAbrasive surface conditioning devicesElectrical controlEngineering

The invention discloses a cylindrical grinding machine for a bearing ring. The cylindrical grinding machine comprises a machine body, a reciprocating operating platform, a grinding wheel shaft box, a workpiece shaft box, a longitudinal feed mechanism, a transverse feed mechanism, a grinding wheel dresser, a hydraulic system, a lubricating system, a cooling system and an electrical control system, wherein the reciprocating operating platform, the longitudinal feed mechanism and the transverse feed mechanism are arranged on the machine body; the grinding wheel shaft box is arranged on the machine body on the rear side of the reciprocating operating platform; a grinding wheel is arranged on the grinding wheel shaft box; the grinding wheel dresser is arranged on the reciprocating operating platform through a grinding wheel dresser seat; the workpiece shaft box is arranged on the reciprocating operating platform; the hydraulic system, the lubricating system and the electrical control system are arranged in the machine body; and the cooling system is arranged on the rear side of the machine body. The cylindrical grinding machine for the bearing ring has a simple structure, high static and dynamic rigidity, high vibration resistance, a high vibration reduction property, high precision retaining ability, a small number of faults, long service life and attractive appearance, is accurately positioned, lightly frictionally worn and easy to operate and maintain, saves energy, and is environment-friendly and safe.

Owner:大连沃飞亚装备制造有限公司

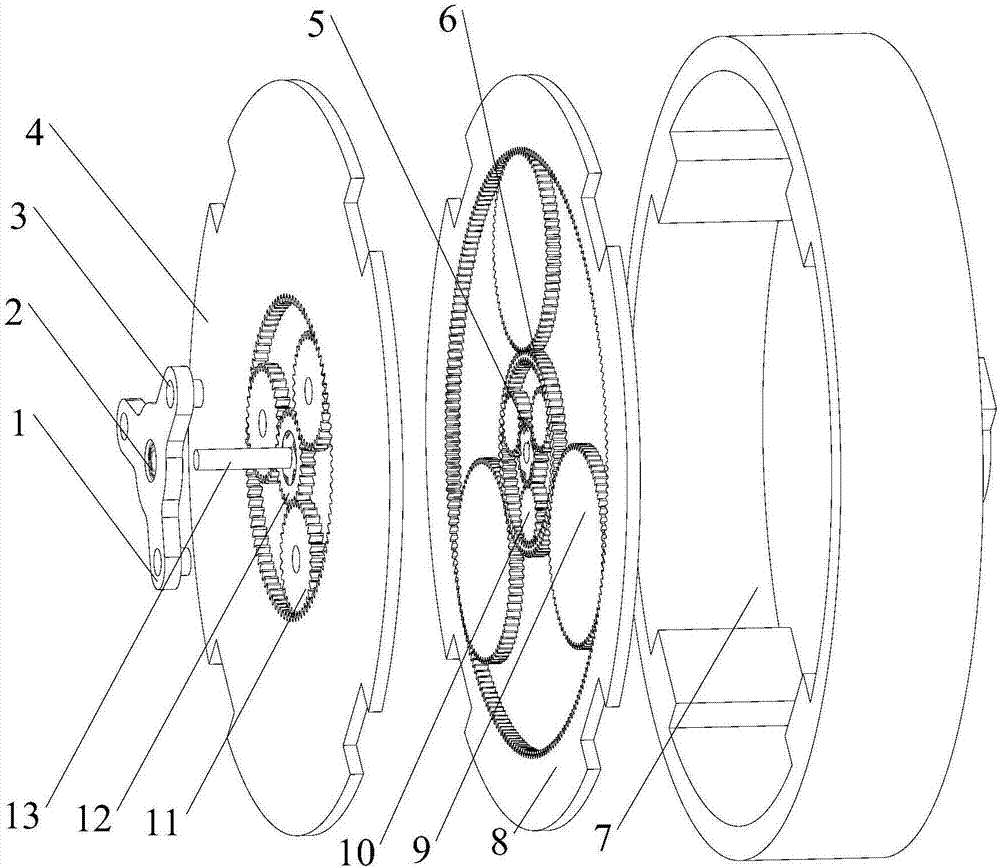

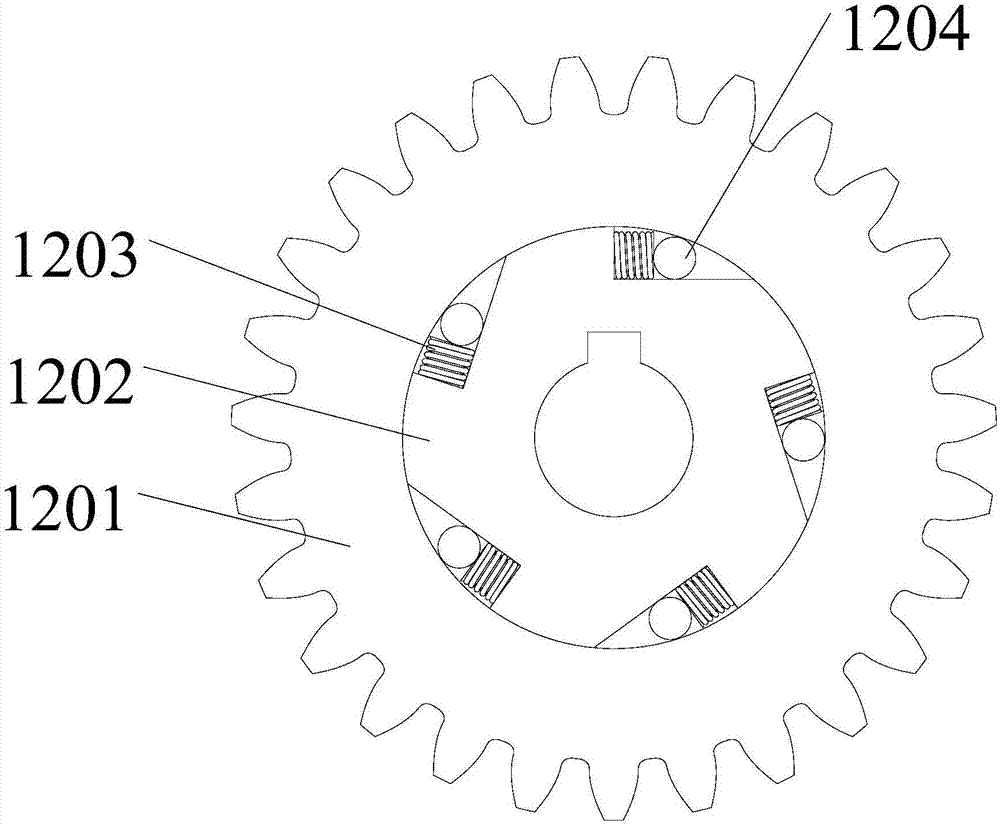

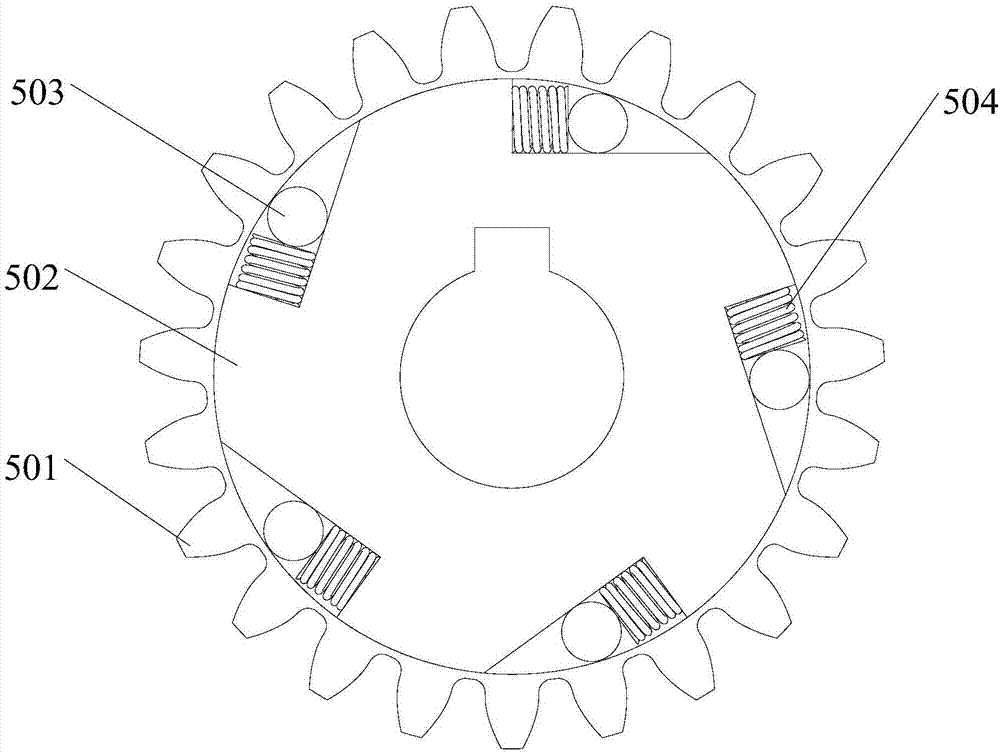

Nested planetary reducer converting reciprocating motion into unidirectional motion

InactiveCN107327544AWide speed rangeGood accuracy retentionMechanical actuated clutchesToothed gearingsBall bearingReciprocating motion

The invention discloses a nested planetary reducer converting reciprocating motion into unidirectional motion. The nested planetary reducer comprises a front overrun clutch, a rear overrun clutch, a composite gear, an output end cover, a planet carrier, a deep groove ball bearing, a front outer gear ring, a rear outer gear ring, rear outer-side planet wheels, rear inner-side planet wheels, front planet wheels and an input shaft. When motion is input clockwise, the front overrun clutch is subjected to engagement and drives the output end cover to output motion counterclockwise after primary direction changing. When motion is input counterclockwise, the rear overrun clutch is subjected to engagement, after the direction of a rear nested planetary transmission mechanism is changed twice, motion is output counterclockwise, and finally, the purpose of converting reciprocating motion into unidirectional motion is achieved. The nested planetary reducer integrates direction changing with speed changing, the complexity, caused by a reversing device, of a transmission system is reduced, and in addition, the nested planetary reducer is large in transmission, flexible in structure, high in smoothness and good in precision retaining ability.

Owner:ANHUI UNIV OF SCI & TECH

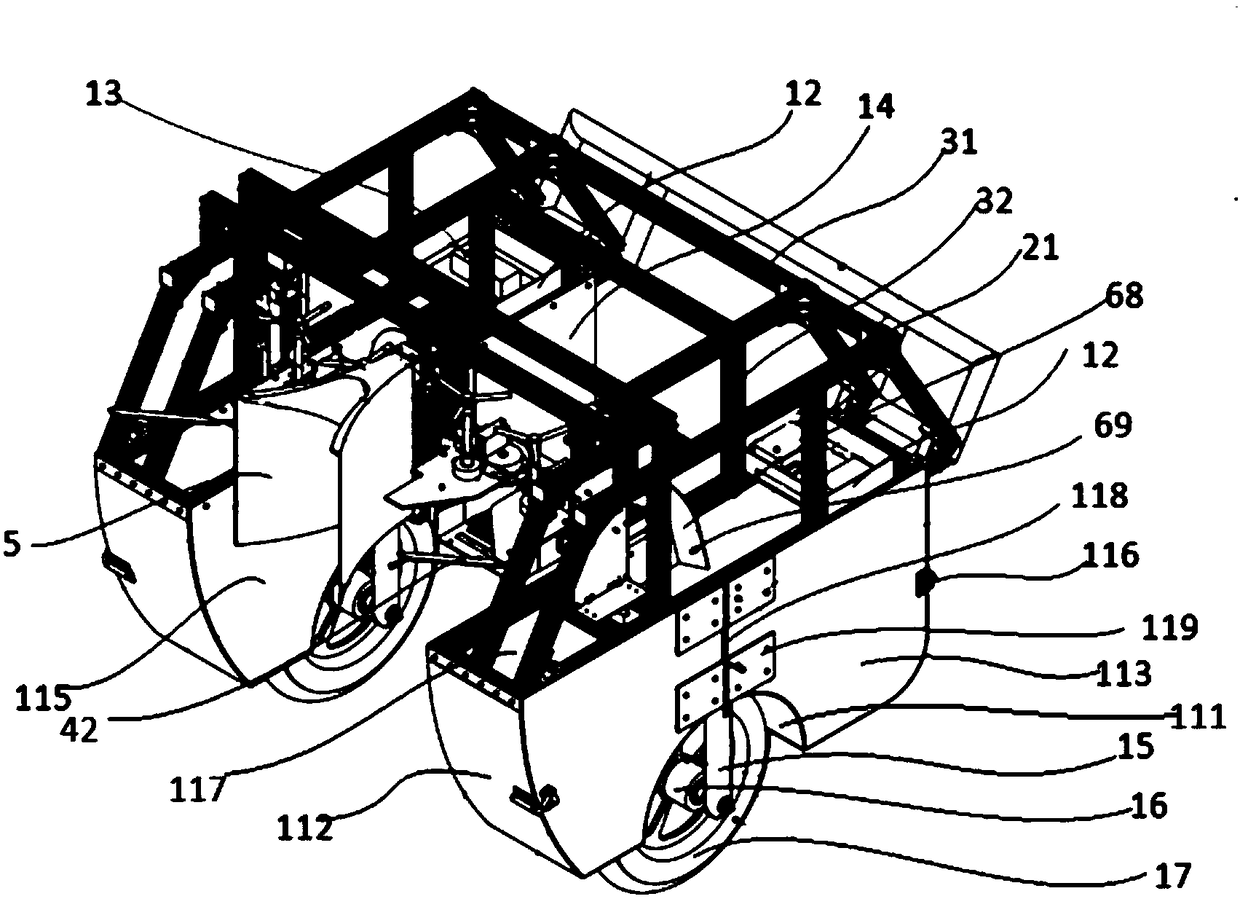

Rapid pineapple harvester

InactiveCN108207318AGood accuracy retentionGood synchronizationPicking devicesAgricultural engineering

The invention discloses a rapid pineapple harvester. The rapid pineapple harvester mainly comprises a first collection module, a second collection module, a connection module, a cutting module, a leafpressing block and a lifting mechanism. The first collection module is connected with the second collection module through the connection module. The cutting module is used for cutting off stems of pineapples. The leaf pressing block is used for pressing down leaves of the pineapples. The lifting mechanism is used for adjusting the height of the cutting module. The rapid pineapple harvester has the advantages of capability of accurately harvesting the complete pineapples at a high speed, simple and reliable structure, simplicity and convenience in operation, low cost, high practicability andwide application range.

Owner:CHONGQING UNIV

Detection method of cam contour detection device

InactiveCN102175181BNo mechanical wearThere is no transmission gapUsing optical meansComputer hardwareElectric machine

The invention provides a detection method of a cam contour detection device which has the advantages of simple structure and high detection accuracy and efficiency. The cam contour detection device which is adopted by the detection method provided by the invention comprises a digital control rotary table, a linear motor, a laser measuring head, a grating ruler displacement sensor, an encoder and an industrial personal computer, wherein the digital control rotary table is used for driving a cam to be horizontally and coaxially rotated around a vertical mandrel; the linear motor is horizontallyarranged at one side of the digital control rotary table; the laser measuring head is arranged on the rotor of the linear motor and at one side of the cam; the grating ruler displacement sensor is used for measuring the horizontal displacement of the rotor; the encoder is used for detecting the rotation angle of the cam; and the industrial personal computer controls the motion of the digital control rotary table and the linear motor and obtains the outer contour data of the cam according to the data which is obtained by the laser measuring head, the grating ruler displacement sensor and the encoder.

Owner:CHANGZHOU INST OF TECH

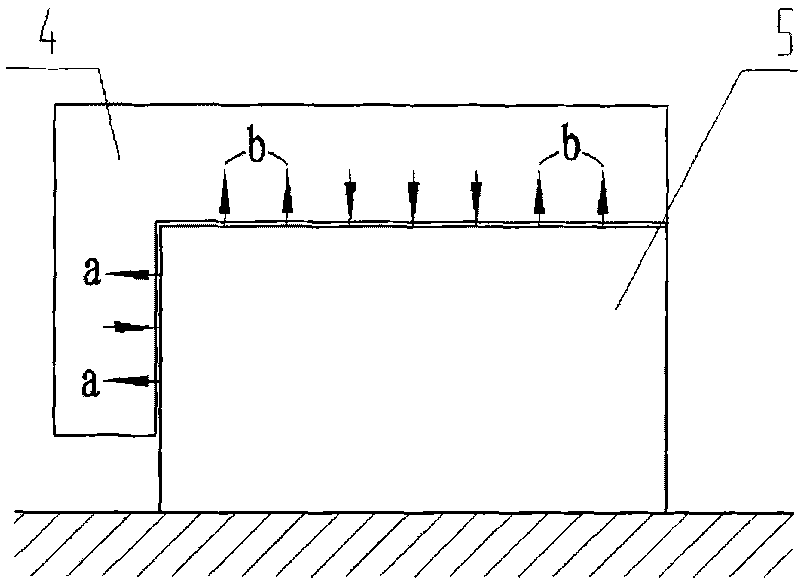

Vacuum negative pressure gas-static super-precision guide rail

InactiveCN101737426AGuidance accuracy influenceGood accuracy retentionBearingsEngineeringProduct gas

The invention discloses a vacuum negative pressure gas-static super-precision guide rail structure, which belongs to the technical field of precision measurement, super-precision machining, micro machinery, nano technology and the like. A guide rail is fixed on the upper surface of a base through a guide rail cushion; a slide block encircles the guide rail, and a compressed air film gap is formed between the two lateral surfaces of the guide rail and the inner lateral surface of the slide block so as to form a static air floating state; and the lower bottom surface of the slide block is provided with a compressed air flow pore and a vacuum cavity, and a vacuum adsorption airflow hole is formed in the slide block. The guide rail structure is characterized in that the slide block has a symmetrical closed structure according to design, and the vacuum cavity and the slide block have the same symmetrical centre line; the compressed air film gap is formed between the slide block and the upper surface of the base; the size of the gap between the upper surface of the guide rail and the inner upper surface of the slide block is c, and the size of the gap between the lower surface of the guide rail and the inner lower surface of the slide block is d; and the c and the d are not smaller than the deformation amount caused by weight of the guide rail. The guide rail has the advantages of high guide precision, good precision retention and high rigidity.

Owner:BEIJING UNIV OF TECH

Numerical control system for detecting cam contours

InactiveCN102122144BReduce loadSmall precision retentionUsing optical meansNumerical controlEngineeringPersonal computer

The invention provides a numerical control system for detecting cam contours, which has a simple structure, high precision and high efficiency. The numerical control system comprises a numerical control turntable, a screw rod nut pair, a laser measuring head, a grating scale displacement sensor, an encoder and an industrial personal computer, wherein the numerical control turntable is used for driving a cam to horizontally and coaxially rotate around a vertical mandrel; the screw rod nut pair is horizontally arranged on one side of the numerical control turntable; the laser measuring head is arranged on a movable nut of the screw rod nut pair and is positioned on one side of the cam; the grating scale displacement sensor is used for measuring the horizontal displacement of the movable nut; the encoder is used for detecting the rotation angle of the cam; and the industrial personal computer is used for controlling the numerical control turntable and the screw rod nut pair to act and acquiring external contour data of the cam according to data acquired by the measurement of the laser measuring head, the grating scale displacement sensor and the encoder.

Owner:CHANGZHOU INST OF TECH

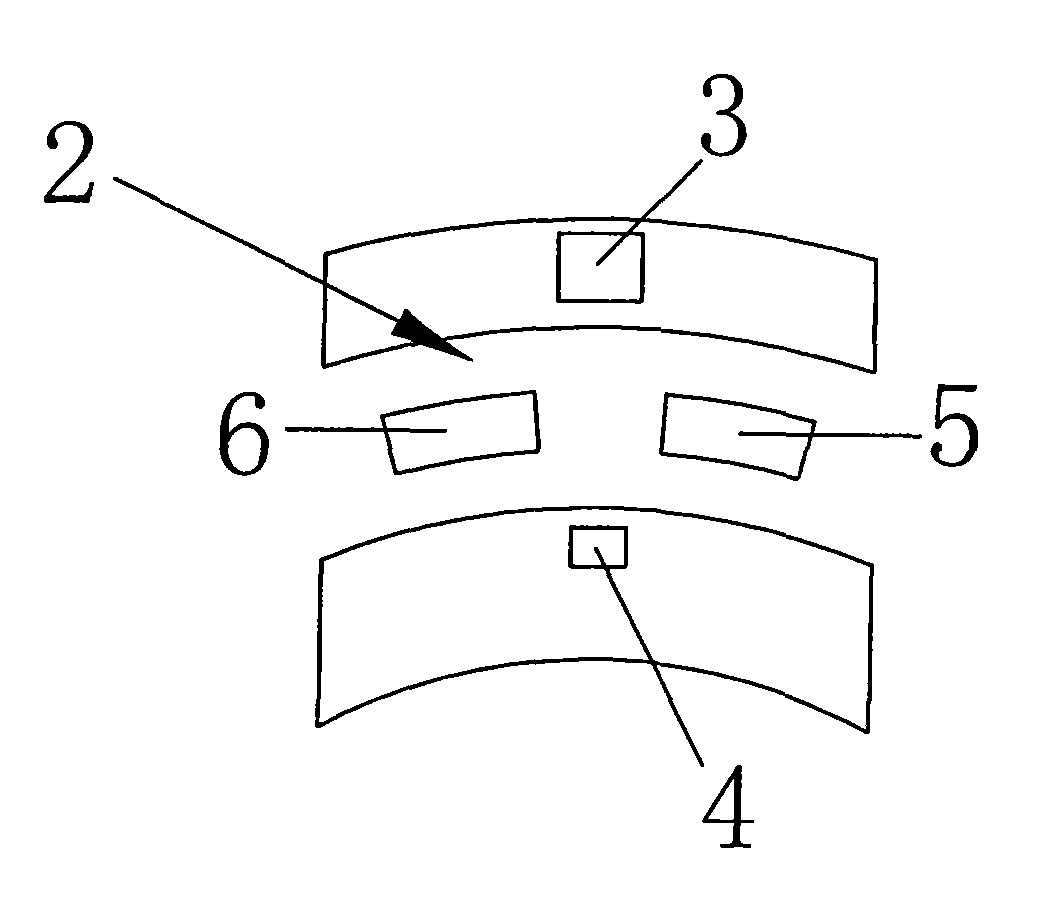

Moment-assistant sensor for single magnetic pole electric bicycle

InactiveCN101592539AReduce in quantitySimple structureVehicle transmissionConverting sensor output electrically/magneticallyHall elementMagnetic poles

The invention relates to a moment-assistant sensor for a single magnetic pole electric bicycle, which comprises a fixed disk fixed nearby a middle shaft of the electric bicycle and is characterized in that the fixed disk is provided with a passage, two sides of the passage are provided with a magnet and a Hall element capable of sensing magnetic field changes respectively, the Hall element is connected with a Hall circuit, the tooth ends of an internal tooth and an external tooth are inserted into the passage, a gap between the internal tooth and the external tooth is changeable, the depths inserted into the passage of the tooth ends exceed the position of a magnetic field, the internal tooth is fixedly connected with an inner disk of a faceplate, the external tooth is fixedly connected with an outer disk of the faceplate, the inner disk is positioned in the outer disk, the inner disk is connected with the outer disk through a driving spring, the outer disk is connected with a real wheel driving chain, and the inner disk is connected with a pedal crank for driving the inner disk to rotate. The moment-assistant sensor has small quantity of components and parts and a simple structure, and can greatly reduce the product cost; besides, a single Hall circuit has small power consumption current and can be connected with a controller of the electric bicycle directly.

Owner:南京奥敏传感技术有限公司

Numerical control system for contour detection of cam

InactiveCN102200762BHigh speedHigh precisionUsing optical meansNumerical controlLaser rangingGrating

Owner:丁仕燕

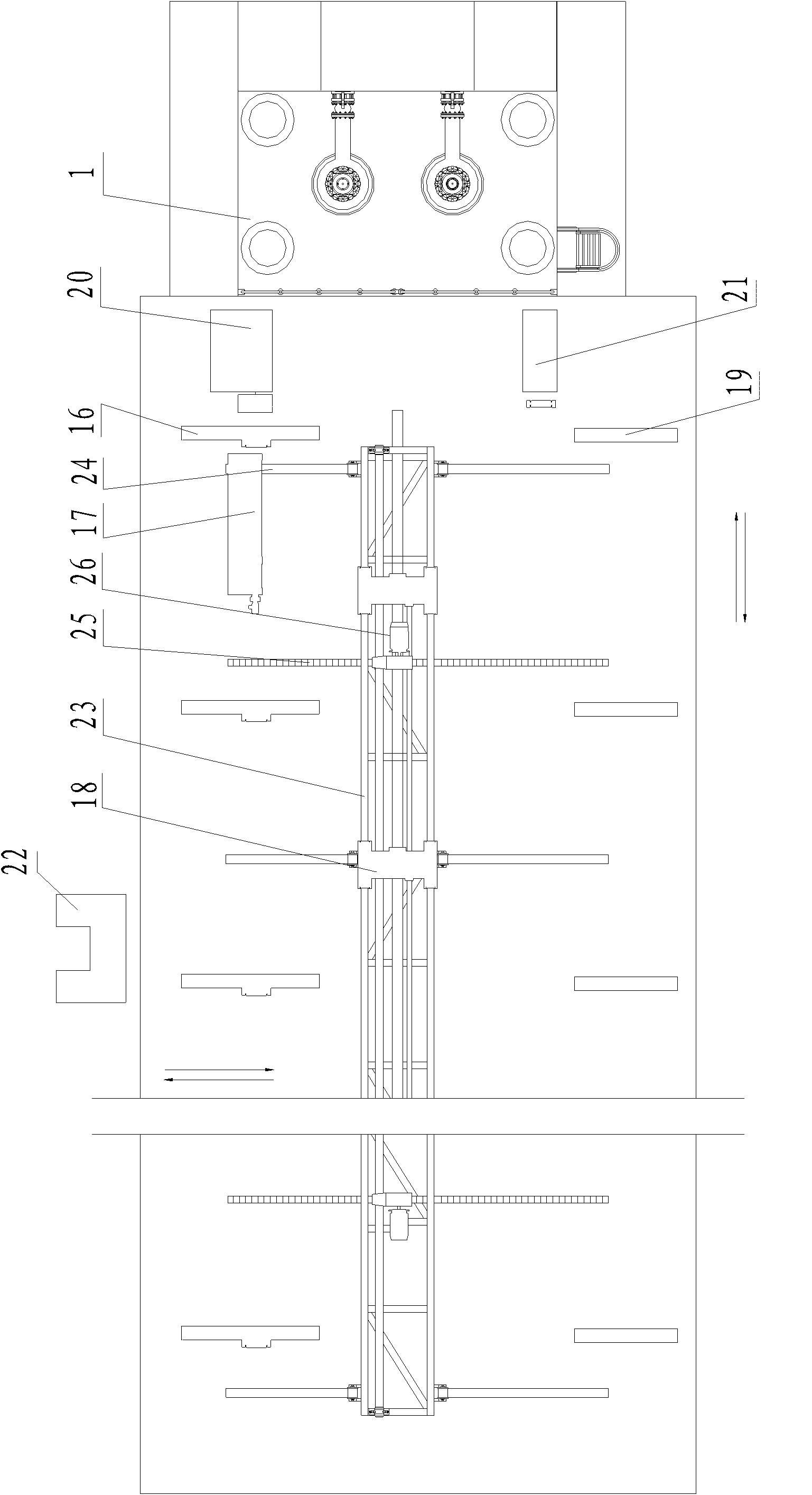

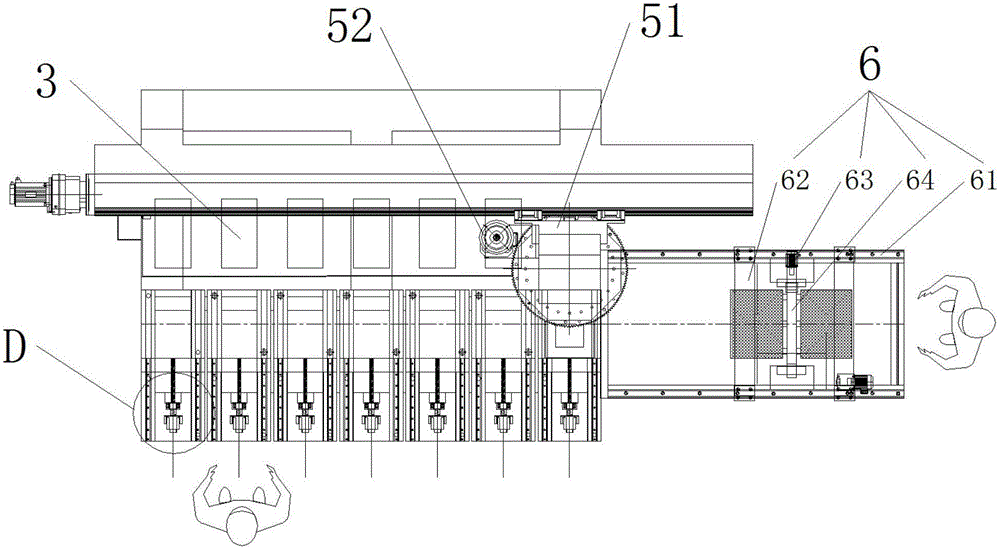

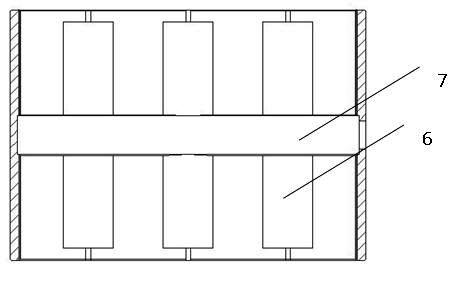

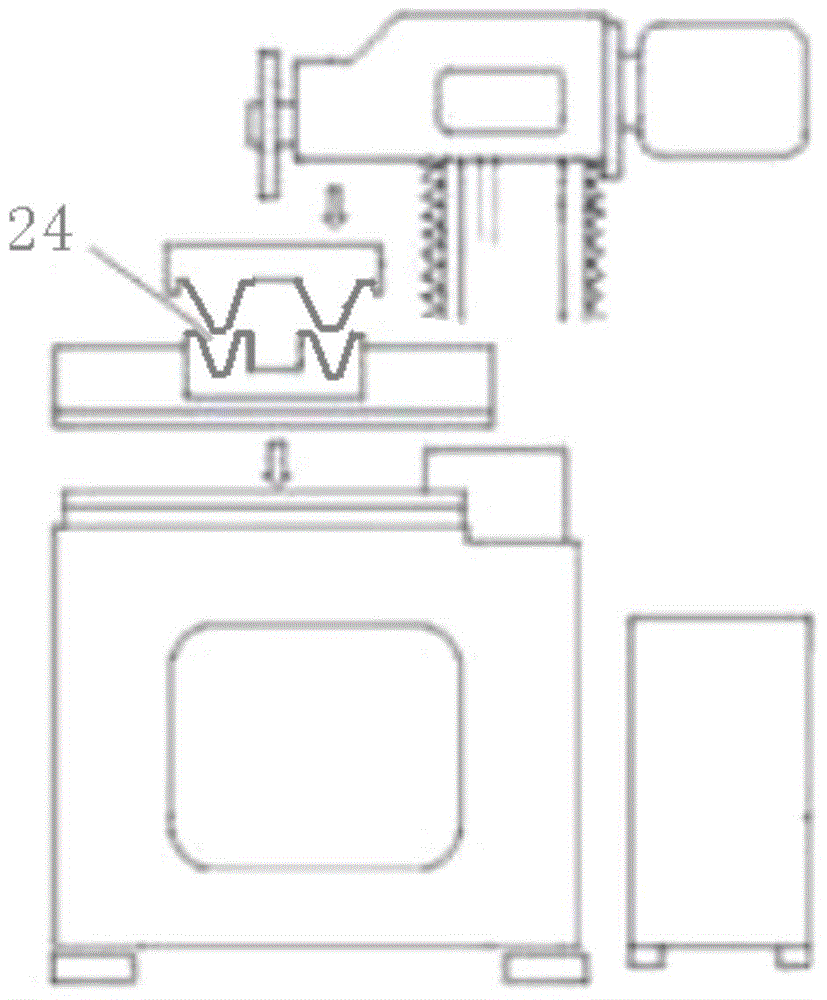

Multi-station digital pasting system for lost foam and pasting method of multi-station digital pasting system

ActiveCN105909639ASimplify equipment structureSimplify the installation processLiquid surface applicatorsMaterial gluingNumerical controlState of art

The invention discloses a multi-station digital pasting system for a lost foam and a pasting method of the multi-station digital pasting system. The multi-station digital pasting system mainly comprises a main rack, numerical control sliding table devices, a pasting system, a transverse movement driving system, a lifting rotating table, a main pouring gate pasting position changing device and an electric system connected with all the parts; by using the system, continuous pasting of a plurality of stations and automatic pouring gate pasting can be realized at one time, and corresponding moulds can be automatically switched according to the combination demand of templates to mount different templates; and compared with the prior art, the pasting system and method are high in automation degree and are used for reducing the cost while reducing the labor intensity of workers, and not only improving the pasting quality of the templates of the lost foam, but also remarkably increasing the pasting efficiency of the templates so as to have a considerable promotional value in the current trend of enterprise technological innovation transformation.

Owner:CMCU ENG

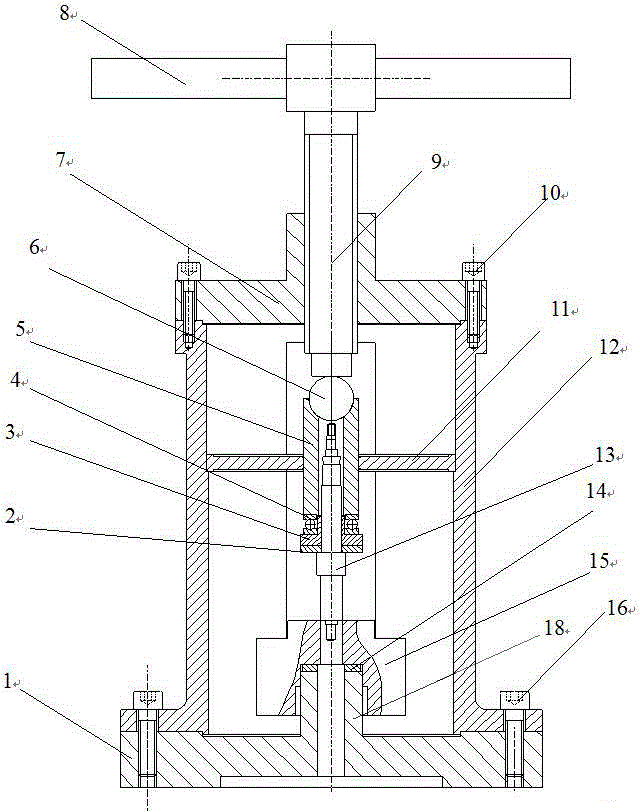

Step and stepless regulation device and regulation method for eccentricity of eccentric shaft

ActiveCN106000851AAvoid the influence of human factorsEasy to operateMechanical vibrations separationCircular discDrive shaft

The invention discloses a step and stepless regulation device for eccentricity of an eccentric shaft. The step and stepless regulation device comprises a driving shaft, a round disc, a shaft disc, an eccentricity step positioning device and an eccentricity regulation device. Step eccentricity positioning is realized in the mode that one of two spring pins in positioning pin holes symmetrically formed in the round disc up and down is aligned with and inserted into a certain eccentric pin hole in the shat disc, and stepless eccentricity regulation is achieved when the spring pin is inserted into the eccentric pin hole in a non-aligned mode. Guiding is realized through sliding matching of a rectangular groove in the round disc and a rectangular boss on the shaft disc, and regulation is realized through fastening connection or disconnection of two T-shaped grooves in the round disc and the shaft disc through T-shaped nuts and fastening screws. The operation of inserting and pulling out a positioning pin is avoided through step eccentricity positioning with the spring pins, operation is simple and rapid, the regulation accuracy of eccentricity is guaranteed through the position and size precision of each positioning pin hole, the repeatability is good, and the regulation range is wide. The step and stepless regulation device for eccentricity of the eccentric shaft can be used for driving of a slider-crank mechanism and a sine excitation mechanism or other application occasions needing adjustable eccentricity.

Owner:JIANGSU UNIV OF SCI & TECH

Continuous no-impact automatic uniform-load press-fitting device

ActiveCN104942565ARealize the guidance functionAvoid direct contactMetal working apparatusThrust bearingSteel ball

The invention provides a continuous no-impact automatic uniform-load press-fitting device which comprises a base, a press-fitting gasket, a bearing support sleeve, a sleeve, a gland, a driving screw, a support cylinder, a support gasket and a guide disk. The support cylinder, the gland and the base are positioned through spigots, a hole-cup drawing is arranged in a base positioning boss, the driving screw is screwed into the gland, the guide disk is arranged on the positioning spigot of the support cylinder in a clamped mode, the sleeve is put into a center hole of the guide disk and presses a thrust bearing, and a shaft is arranged in a center hole of the sleeve in a sleeved mode. The screw is rotated to be fed in a slow, no-impact and continuous mode, and press-fitting is achieved. The sleeve and the guide disk are arranged to conduct centering and guiding; the thrust bearing is arranged, so that direct contact between a workpiece and the driving screw is avoided, and the workpiece which is subjected to press-fitting is pressed in through straight line pressure; a steel ball is arranged to eliminate offset loading force. By means of the continuous no-impact automatic uniform-load press-fitting device, the problem of shaft hole interference fitting can be solved, and the situation that incline, misalignment and scuffing of the workpiece happen in the press-fitting process can be avoided. The continuous no-impact automatic uniform-load press-fitting device is simple in structure, reliable in work and capable of achieving the fitting work of shaft hole parts in a large interference magnitude and high accuracy mode.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

Internal grinding machine for bearing ring

InactiveCN102179736ASimple structureImprove rigidityRevolution surface grinding machinesAbrasive surface conditioning devicesControl systemElectrical control

The invention discloses an internal grinding machine for a bearing ring, comprising a machine body, a reciprocating work table, a workpiece axle box, a grinding wheel dresser, a grinding wheel head assembly, an operational panel, a hydraulic system, an electrical control system and a cooling system; the reciprocating work table is arranged on the machine body, the workpiece axle box is arranged at the upper part of the left end of the machine body, the grinding wheel dresser is fixed at the rear side on the machine body, the grinding wheel head assembly is arranged on the reciprocating work table, the operational panel is arranged above the right side of the machine body, the hydraulic system and the electrical control system are arranged inside the machine body, the cooling system is arranged at the rear end of the machine body. The internal grinding machine for the bearing ring has a simple structure, the rigidity of the internal grinding machine in a static state or a dynamic state is remarkably enhanced, the friction resistance is low, the wear is light, the precision retentivity is good, the vibration-damping and vibration-resisting performance is strong, the control is easy, the cutting amount adjustment is convenient, the size control is more intuitive, the maintenance is easier owning to standardization of spare parts, and the service life of the machine is longer.

Owner:大连沃飞亚装备制造有限公司

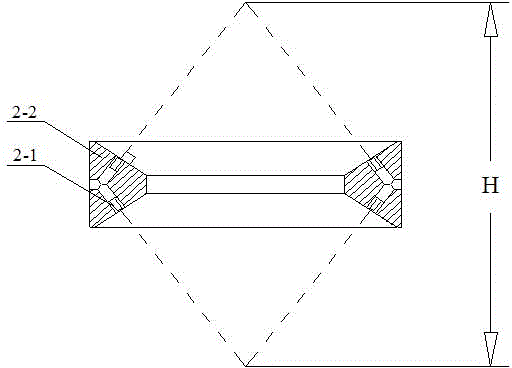

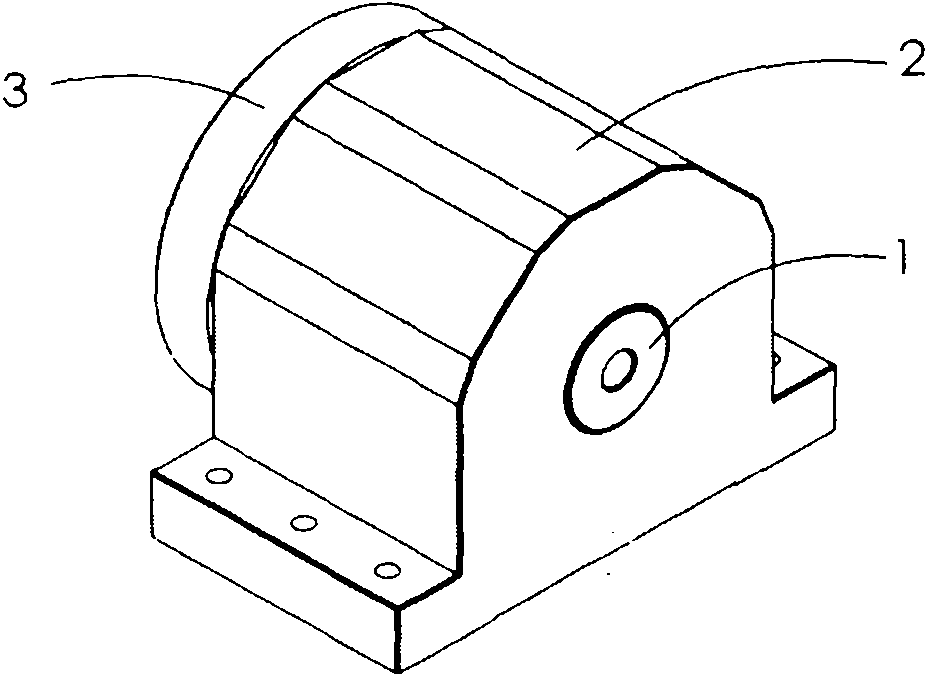

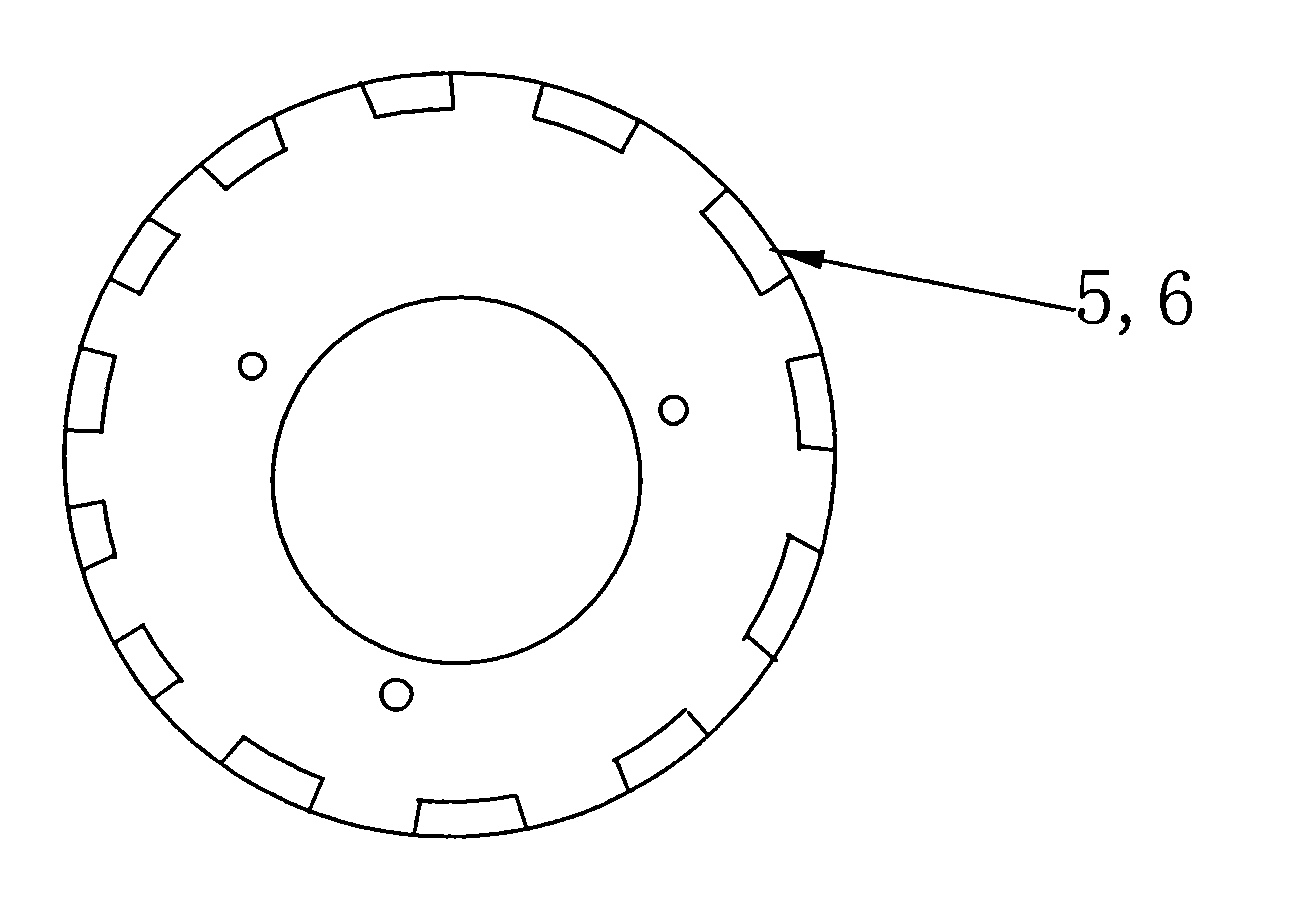

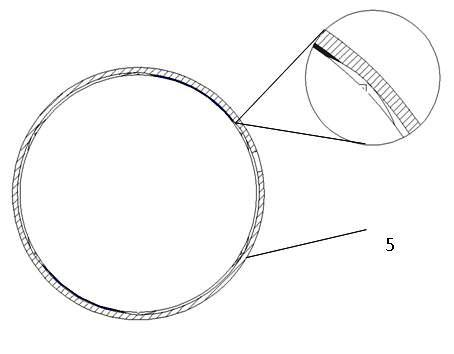

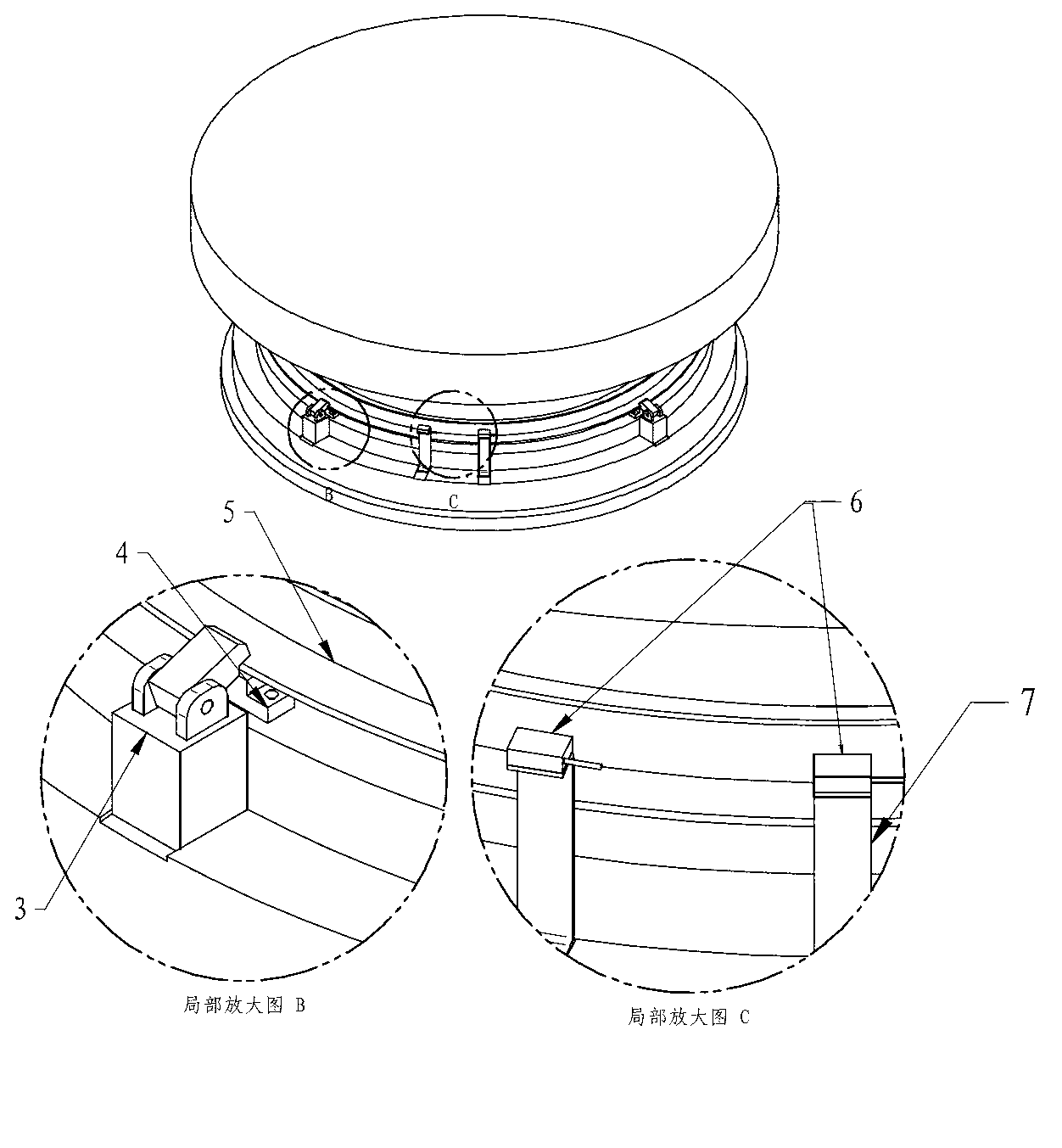

Laying head using dynamic-static pressure oil film bearing

InactiveCN102430593AExtend your lifeGood accuracy retentionSliding contact bearingsFlexible work arrangmentsOil filmPetroleum engineering

The invention provides a laying head using a dynamic-static pressure oil film bearing. The laying head comprises a support structure, a support bearing, a dynamic-static pressure oil film bearing device and a rotor, wherein the rotor is fixed on the support structure through the dynamic-static pressure oil film bearing device and the support bearing, the dynamic-static pressure oil film bearing device adopts the oil film bearing with an all-round structure, a plurality of grooves are arranged on the surface on the inner side of the oil film bearing, an oil cavity with different depths is formed between the oil film bearing and the rotor, when a system works, the rotor floats up under the action of a layer of pressure oil film, the rotor is suspended between the bearings when a motor is not driven, and mechanical friction and abrasion are avoided, therefore the service life of each bearing is further prolonged and good precision retentivity is realized.

Owner:汉威广园(广州)机械设备有限公司

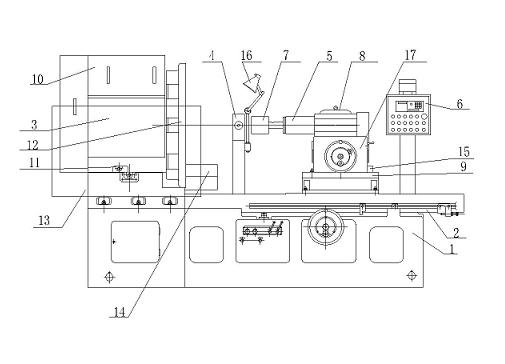

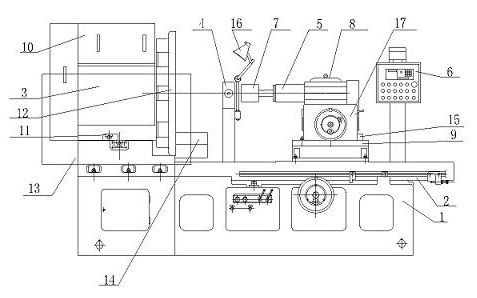

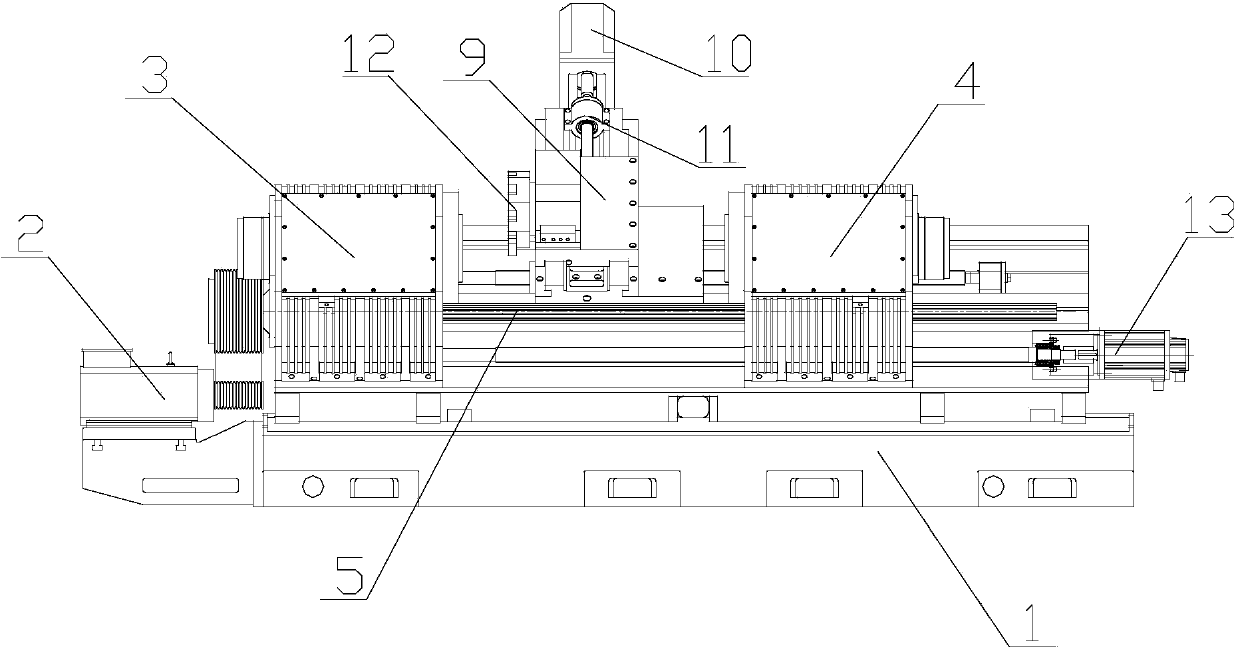

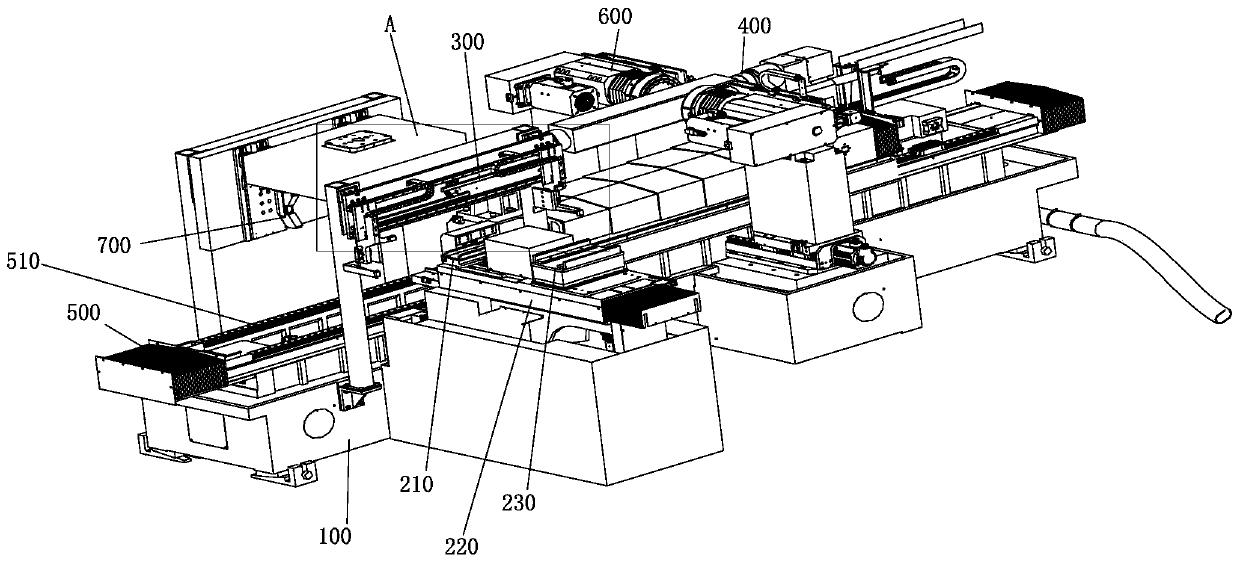

Synchronous double-spindle-box numerically controlled lathe

InactiveCN104190954AReduce coefficient of frictionIncrease coefficient of frictionAutomatic/semiautomatic turning machinesBall screwLong axis

The invention discloses a synchronous double-spindle-box numerically controlled lathe. The synchronous double-spindle-box numerically controlled lathe comprises a lathe body and a main motor arranged on one side of the lathe body, wherein a left spindle box and a right spindle box are arranged at the two ends of the lathe body, a synchronous shaft is arranged between the left spindle box and the right spindle box, the lathe body is provided with a lathe saddle, the lathe saddle is provided with a ball screw a, a servo driving motor a is arranged on one side of the lathe saddle, a middle supporting plate is arranged on the lathe saddle, a servo driving motor b is arranged on one side of the middle supporting plate, a ball screw b is arranged in the middle supporting plate, and an electric tool tower is arranged on the middle supporting plate. When the lathe machines a long-axis-class workpiece, the two ends of the workpiece can be clamped and rotate synchronously, multiple times of machining can be carried out on the workpiece through one time of clamping, and production efficiency is improved. Thus, the dimensional accuracy of the workpiece is guaranteed, the automation degree is high, the productivity efficiency is improved by 6-8 times, and the labor cost is largely reduced.

Owner:LIUAN RUIPU NC MACHINERY

Gapless transmission device of numerical control contour grinder

ActiveCN101683719AEliminate backlashSmooth transmissionGrinding drivesGrinding machinesDrive shaftCoupling

The invention relates to a gapless transmission device of a numerical control contour grinder, belonging to the field of grinder parts. The prior transmission devices of non-circular inner-aperture grinders have the defects of large space occupation, high cost, large energy consumption, poor precision, short service life and incapability of rotating forward and backward. The invention adopts a gearbox form comprising a gearbox body, a box cover, a motor and an encoder, wherein a rotary shaft used as a driving shaft and a main shaft used as a driven shaft are arranged on the box body; the rotary shaft is fixedly sheathed with a small gear, and the main shaft is sheathed with two large gears engaged with the small gear, wherein one large gear is fixed together with the main shaft, and the other is movably sheathed on the main shaft. The tooth surfaces of the two large gears are staggered by an angle staggering mechanism and are closely attached to the tooth surface of the small gear. Theencoder is connected with the main shaft through a shaft coupling and is connected with a numerical control system through a signal wire. The invention has stable transmission and favorable precisionkeeping and can rotate forward and backward continuously.

Owner:绍兴松菱机床有限公司

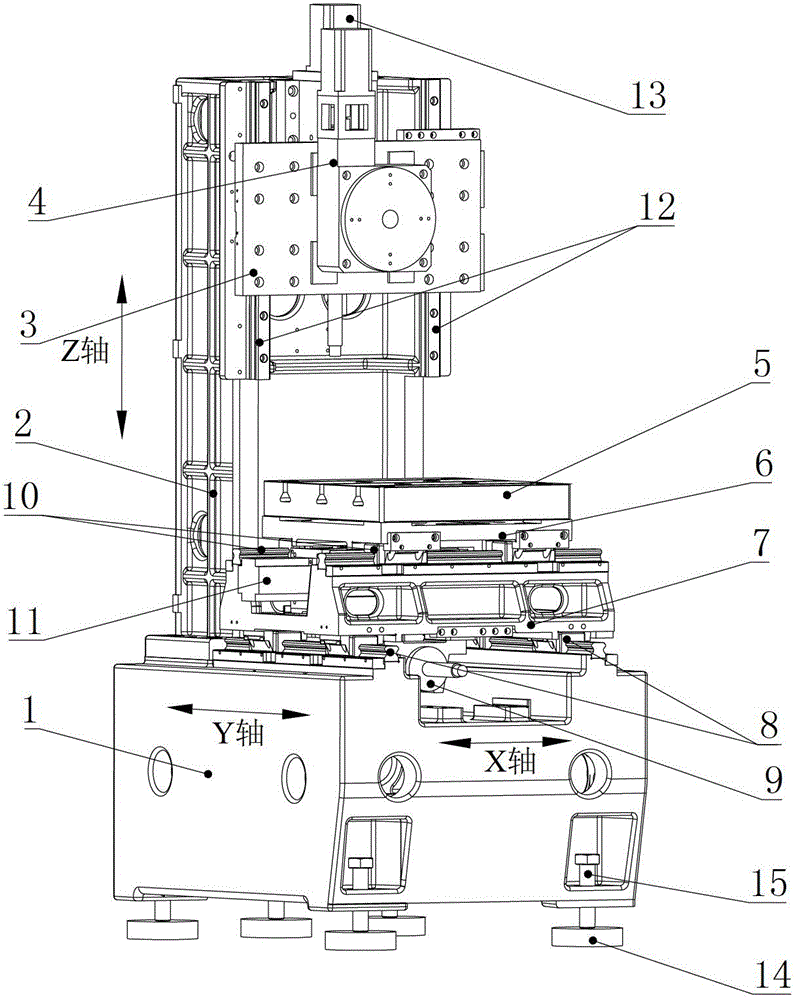

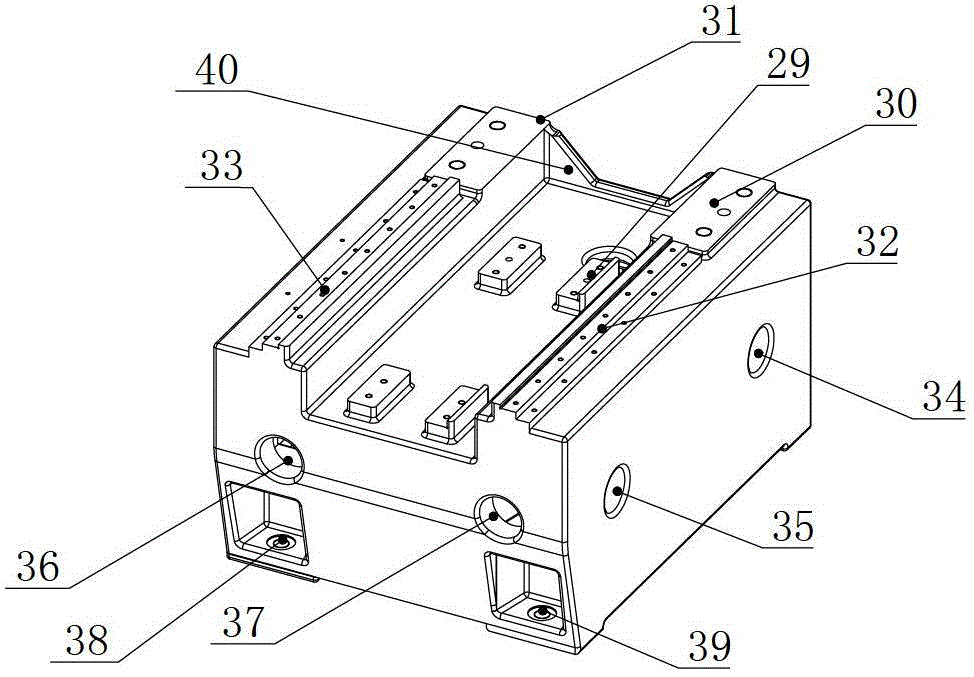

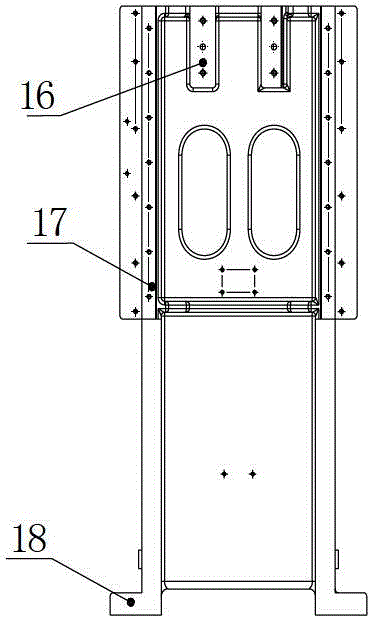

Four-axis linkage machine tool

InactiveCN102909568AGood accuracy retentionCompact structureLarge fixed membersEngineeringSlide plate

The invention provides a four-axis linkage machine tool which comprises a machine tool body, a stand column, a middle sliding plate, an upper sliding plate, a workbench, a Z-axis sliding plate and a B-axis index table, wherein the middle sliding plate is arranged on the machine tool body by Y-axis guide rail sliding blocks; the upper sliding plate is arranged on the middle sliding plate by X-axis guide rail sliding blocks; the Z-axis sliding plate is arranged on the stand column by Z-axis guide rail sliding blocks; the B-axis index table is fixedly arranged on the Z-axis sliding plate; and the workbench is fixed on the upper sliding plate. The height of the machine tool is less than 1400mm, the width of the machine tool is less than 600mm, and the length of the machine tool is less than 800mm. A machine tool assembling assembly has the advantages of compact structure and small land occupation. A box-type stand column structure and a machine tool body in the shape of the Chinese character ''AO'' (concave) have the advantages of good structure rigidity and small stress deformation. The B-axis index table is connected to the box-type stand column by the Z-axis sliding plate, and each component is convenient to disassemble and assemble.

Owner:DIMON BEIJING CNC TECH

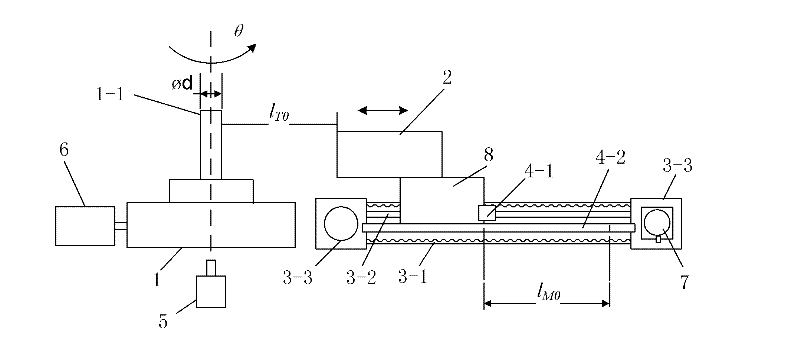

Cam Profile Detection System Driven by Wire Rope

The invention provides a cam contour detection system which is driven by a wire rope and has simple structure, high detection precision and high efficiency. The system comprises the following parts: a numerical control rotary table used for driving a cam to carry out horizontal coaxial rotation around a vertical mandrel, a guide rail which is provided at one side of the numerical control rotary table horizontally, a slide block provided on the guide rail, a laser range finding head which is provided on the slide block and at one side of the cam, a raster ruler displacement sensor used for measuring horizontal displacement amount of the laser range finding head, an encoder used for detecting a rotation angle of the cam, a wire storage cylinder assembly and a directive wheel which are provided at two sides of the slide block respectively, a wire rope which is elastically sleeved on the wire storage cylinder assembly and the directive wheel, and is fixedly connected to slide block, and an industrial control computer. The wire storage cylinder assembly is in transmission connection with a stepping motor. The industrial control computer controls movement of the numerical control rotarytable and the stepping motor, and calculates outer contour data of the cam according to data measured by the laser range finding head, the raster ruler displacement sensor and the encoder.

Owner:CHANGZHOU INST OF TECH

Cam profile detection system based on direct driving motor

The invention provides a cam profile detection system based on a direct driving motor, and the cam profile detection system is simple in structure and high in detection precision and efficiency. The system comprises the direct driving motor, a mandrel, a feed screw nut pair, a laser measurement head, a grating ruler displacement sensor, a circular grating and an industrial personal computer, wherein the mandrel is coaxially and fixedly arranged on the rotor of the direct driving motor and is used for driving a cam to coaxially rotate synchronously; the feed screw nut pair is horizontally arranged at one side of the cam; the laser measurement head is arranged on the movable nut of the feed screw nut pair; the grating ruler displacement sensor is used for measuring the horizontal displacement amount of the movable nut; the circular grating is arranged in the fixed seat of the direct driving motor and is used for detecting the rotation angle of the rotor; and the industrial personal computer controls actions of the direct driving motor and the feed screw nut pair, and obtains outer profile data of the cam according to data obtained by the laser measurement head, the grating ruler displacement sensor and the circular grating.

Owner:CHANGZHOU INST OF TECH

Small and medium-sized plane form grinding machine tool

InactiveCN104476345AImprove rigidityImprove stabilityGrinding drivesAbrasive surface conditioning devicesDisplay deviceReducer

The invention discloses a small and medium-sized plane form grinding machine tool. A vertical shaft upright column is mounted at the rear part of a tool body; a water cooler is mounted behind a water tank; a display is mounted in front of the upper part of an electric cabinet; a grinding head is mounted at the upper end of the vertical shaft upright column; a Y-axis lead screw is mounted inside the vertical shaft upright column; a spindle motor is mounted inside the grinding head; a counter weight is mounted at the rear end of the grinding head; a Y-axis speed reducer matched with the Y-axis lead screw is mounted at the upper part of the grinding head; a Y-axis servo motor matched with the Y-axis speed reducer is mounted at the front end of the Y-axis speed reducer; an abrasive wheel is mounted at the front end of the grinding head; a Z-axis lead screw, a Z-axis servo motor and a Z-axis speed reducer are mounted inside the tool body; according to the grinding head and the vertical shaft upright column of the machine tool, overall vertical movement feeding is realized, and the rigidity and the accuracy stability are high; the grinding capacity of the plane form grinding machine tool is greatly improved, the grinding amount is large, and the accuracy retention is high; the machining stability of a plane grinder is improved. The grinding range of the plane grinder is expanded, and the machine tool is high in accuracy, high in steady mobility and long in service life.

Owner:XIAN PGT PRECISION MACHINERY

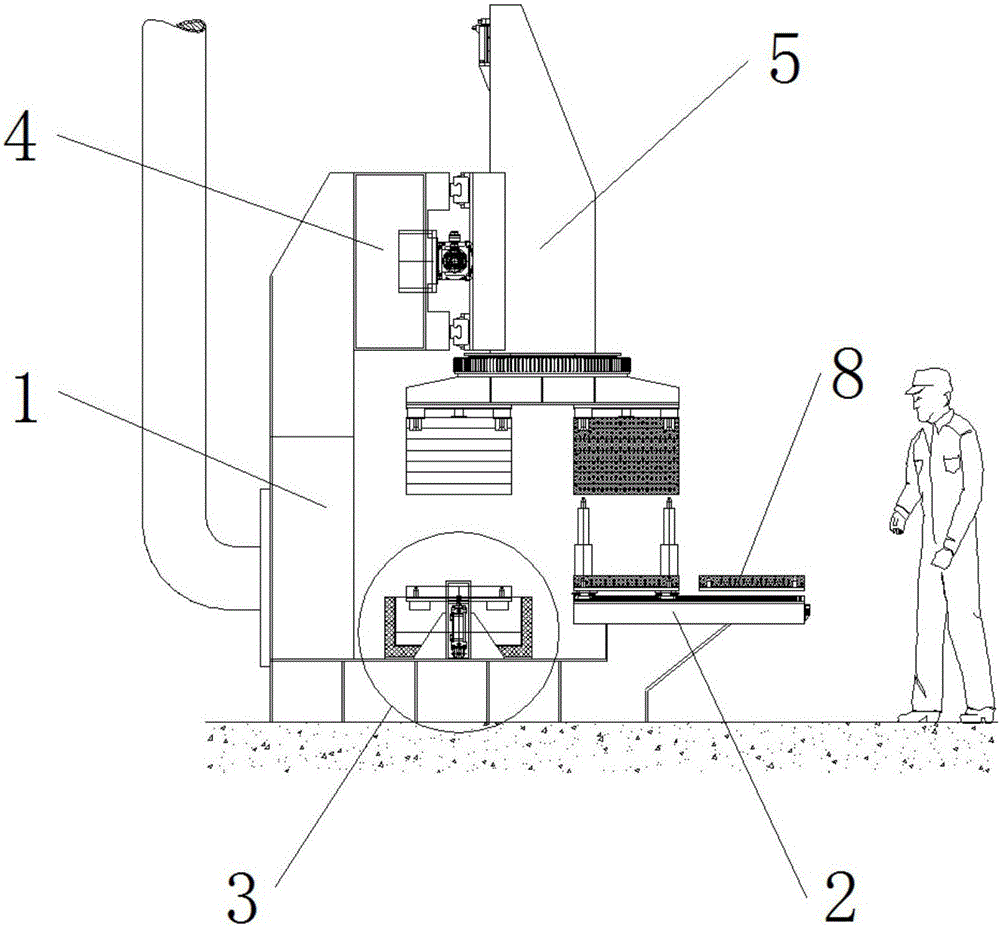

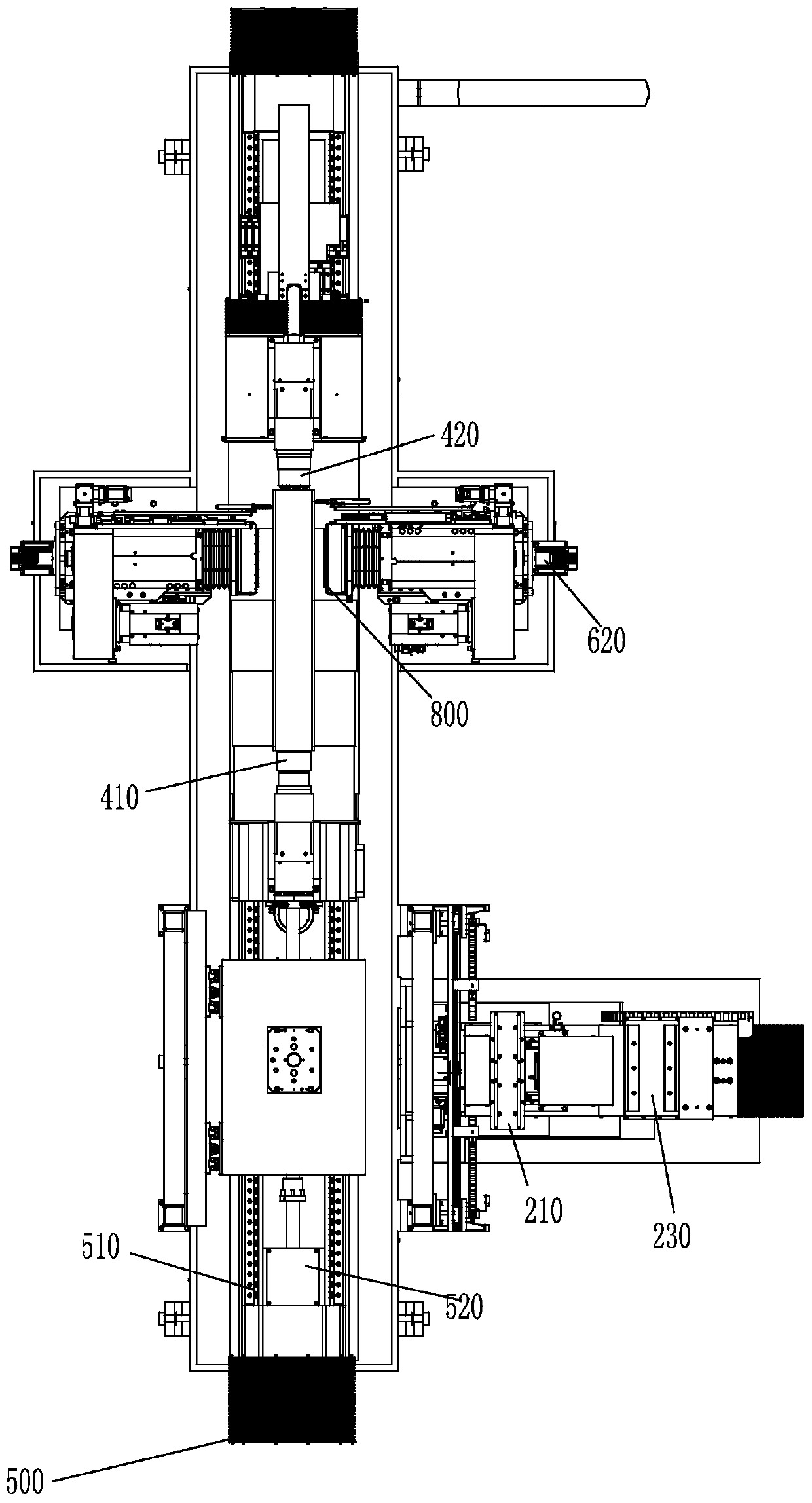

Combined fully-automatic crystal rod grinding and polishing integrated machine

PendingCN111168495AGood accuracy retentionReduce processing timePolishing machinesRevolution surface grinding machinesEngineeringMachine

The invention discloses a combined fully-automatic crystal rod grinding and polishing integrated machine. The machine comprises a base, a feeding component and a discharging component which are used for feeding and discharging crystal rods, a crystal rod centering mechanism arranged on the base and used for realizing the crystal rod centering, a crystal rod clamping component arranged on the baseand used for clamping the crystal rods to move, a crystal rod longitudinal driving mechanism arranged on the base and used for driving the crystal rod clamping component to move in the longitudinal direction, a grinding and polishing head corresponding to a grinding and polishing station, and an adapter manipulator arranged on the base and used for transferring the processed crystal rods to the discharging component; the grinding and polishing head is driven by the grinding and polishing driving mechanism; and the number of the grinding and polishing head is the two groups, and the grinding and polishing heads are arranged correspondingly left and right. The machine has concentrated processing procedures, high workpiece accuracy retainability, and high processing efficiency, shortens silicon rod processing time, and reduces device costs. The machine is suitable for popularization and use.

Owner:QINGDAO GAOCE TECH CO LTD

Large-moment direct-drive plane rotary platform device

InactiveCN102794755AEliminate Symptoms of Low AccuracyReduce precision errorWork benchesHydraulic cylinderWorking environment

The invention belongs to the technical field of an operation platform and relates to a large-moment direct-drive plane rotary platform device. A base, a core shaft, a coil winding, a hydraulic cylinder, a hydraulic seat, a reading head seat and a reading head are fixed through bolts to integrally form a stator; a rotor is formed by a tabletop, a hydraulic sheet, a magnet yoke and a magnetic railing ruler; the stator is coupled with the rotor through a bearing and is fixed in an inner ring of the bearing by a bolt; the rotor is fixed on an outer ring of the bearing by a bolt; glue is filled into the coiling winding to be encapsulated, and magnetic steel is stuck on the magnet yoke by glue; stamp gum is coated on the back face of the magnetic railing ruler, and magnetic railing rule is directly adhered to the tabletop; the hydraulic cylinder and the hydraulic seat are sequentially fixed on the base; the hydraulic sheet is fixed between the hydraulic seat and a pressing head of the hydraulic cylinder of the tabletop; the reading head and the reading head seat are sequentially fixed on the base; the coil winding is uniformly wound and fixed on the core shaft; and the magnetic railing ruler is fixed on the side face of the tabletop. The large-moment direct-drive plane rotary platform device disclosed by the invention has the advantages of simple structure, easiness in control, large moment, stability in rotation, high positioning precision, long service life and friendly working environment.

Owner:青岛同日电机有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com