Nested planetary reducer converting reciprocating motion into unidirectional motion

A technology of planetary reducer and reciprocating motion, which is applied in one-way clutches, mechanical drive clutches, clutches, etc., can solve the problems of increased cumulative error of the transmission system, small speed regulation range, and poor accuracy retention, and achieves good accuracy retention , wide range of speed regulation, excellent structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is further described below:

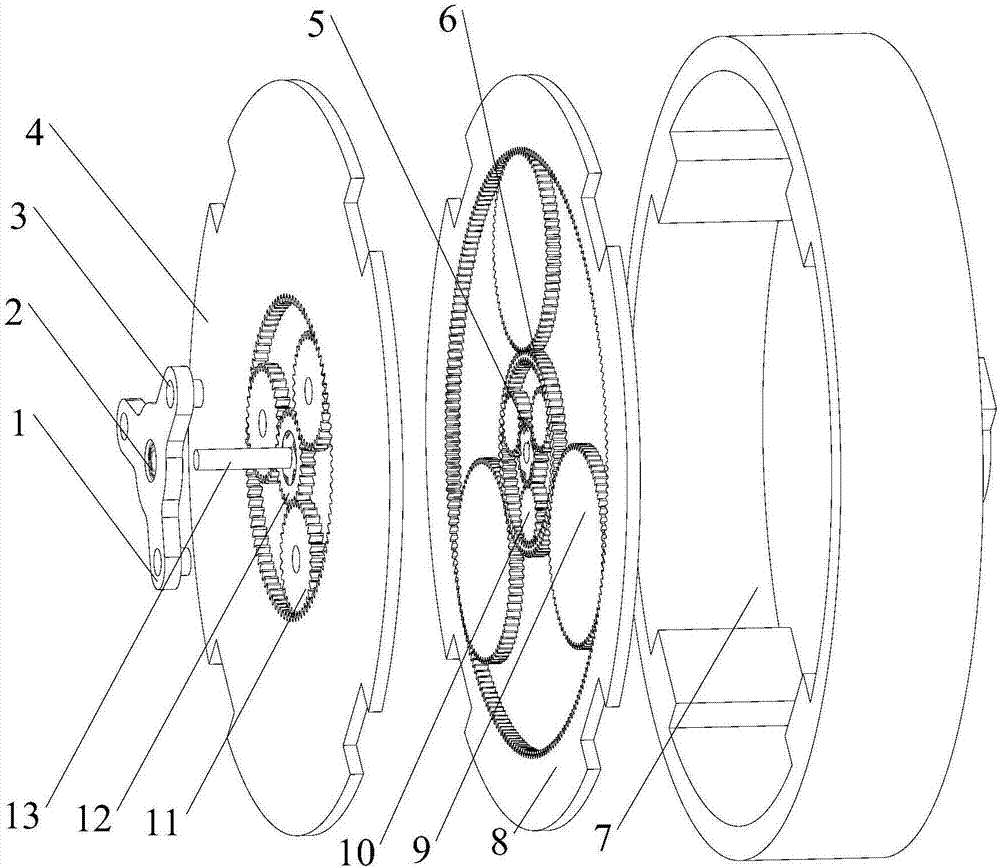

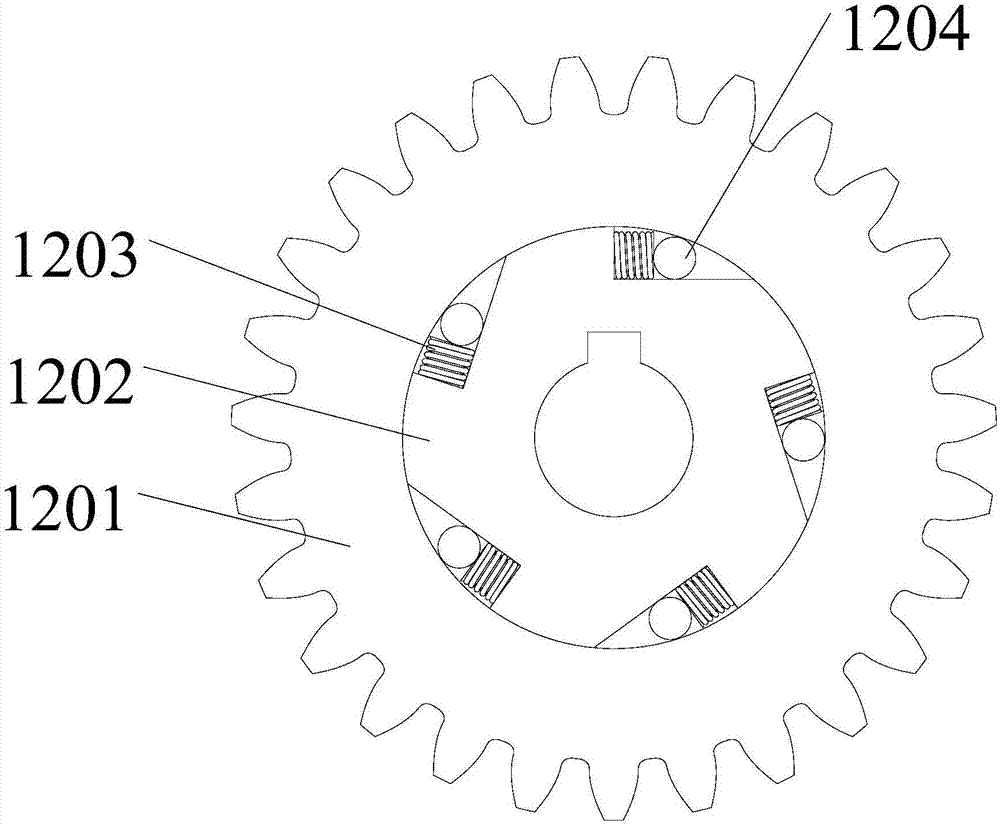

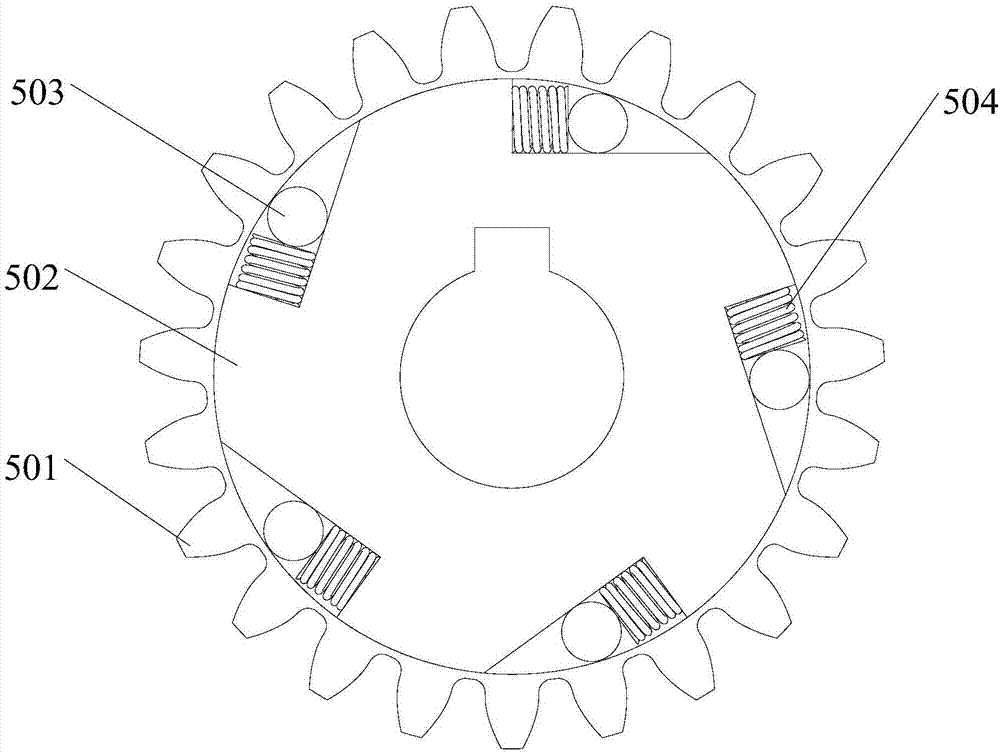

[0021] combine figure 1 , figure 2 , image 3 , Figure 4 , a nested planetary reducer structure that converts reciprocating motion into one-way motion, including front row overrunning clutch 12, rear row overrunning clutch 5, compound gear 6, output end cover 7, planet carrier 1, deep groove ball Bearing 2 , front row outer ring gear 4 , rear row outer ring gear 8 , rear row outer planetary gear 9 , rear row inner planetary gear 10 , front row planetary gear 11 , input shaft 13 and fixed pin shaft 3 . When the motion is input through the input shaft 13 in a clockwise direction, since the installation direction of the front overrunning clutch 12 and the rear overrunning clutch 5 is opposite, at this time the rear overrunning clutch 5 is in a disengaged state, and the front overrunning clutch 12 is engaged. Drive the output end cover 7 backward to output the movement in a counterclockwise direction; when the moveme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com