Double stator-rotor multiple-pole switching reluctance motor

A switched reluctance, stator and rotor technology, applied in the direction of magnetic circuit rotating parts, electrical components, electromechanical devices, etc., can solve the problem of no progress in switched reluctance motors, and achieve increased control difficulty, increased cost, and high noise and vibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

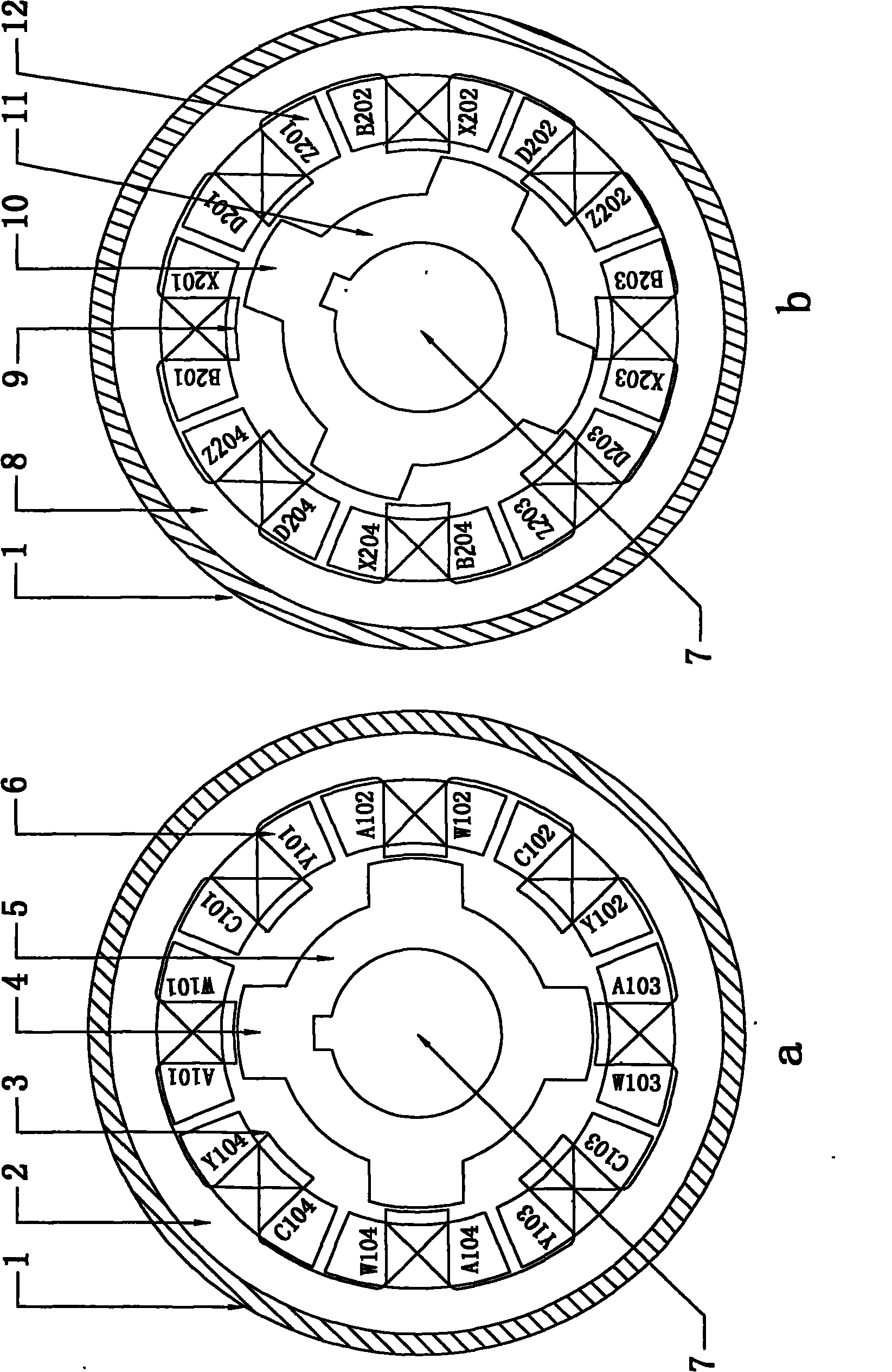

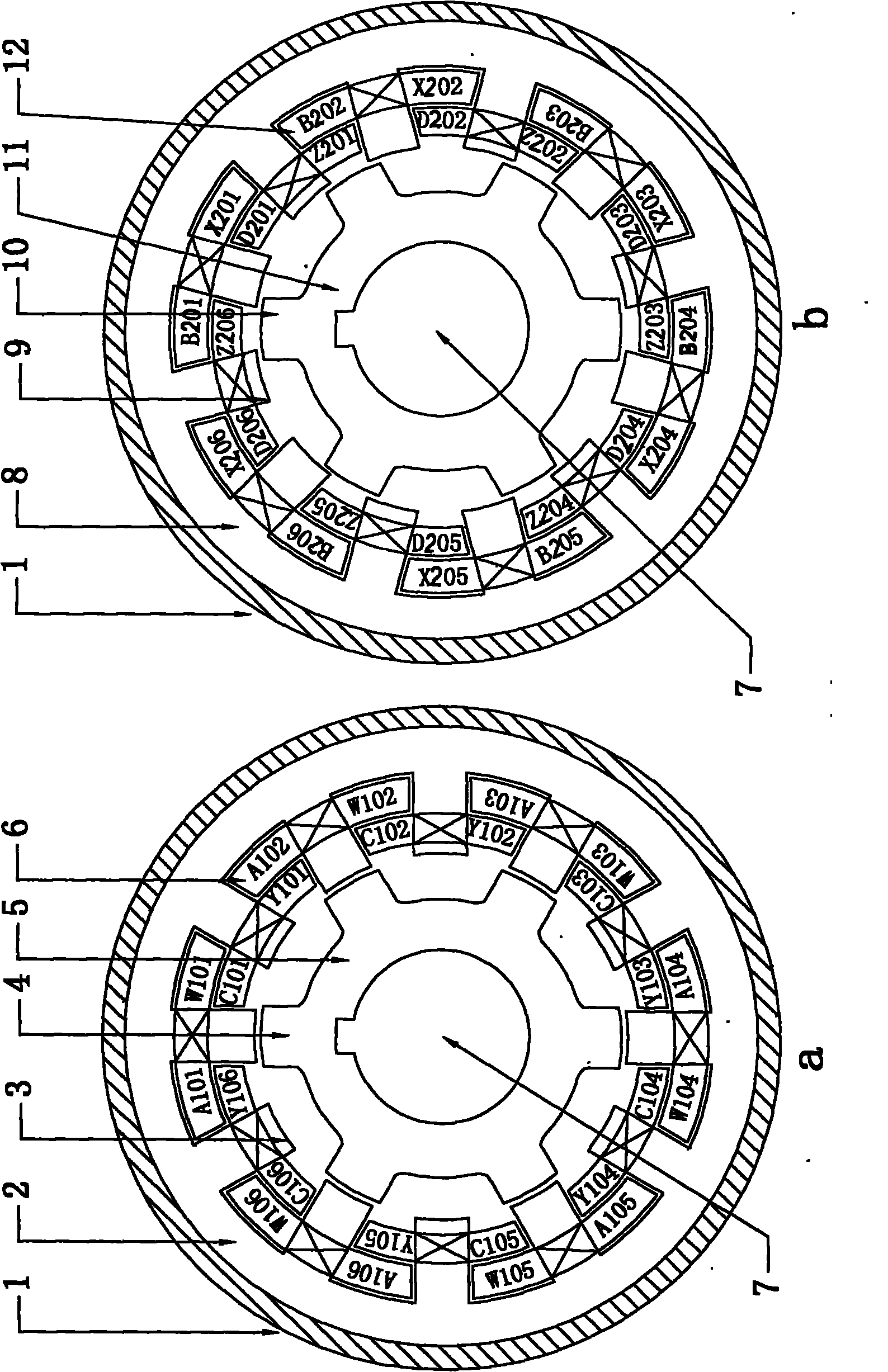

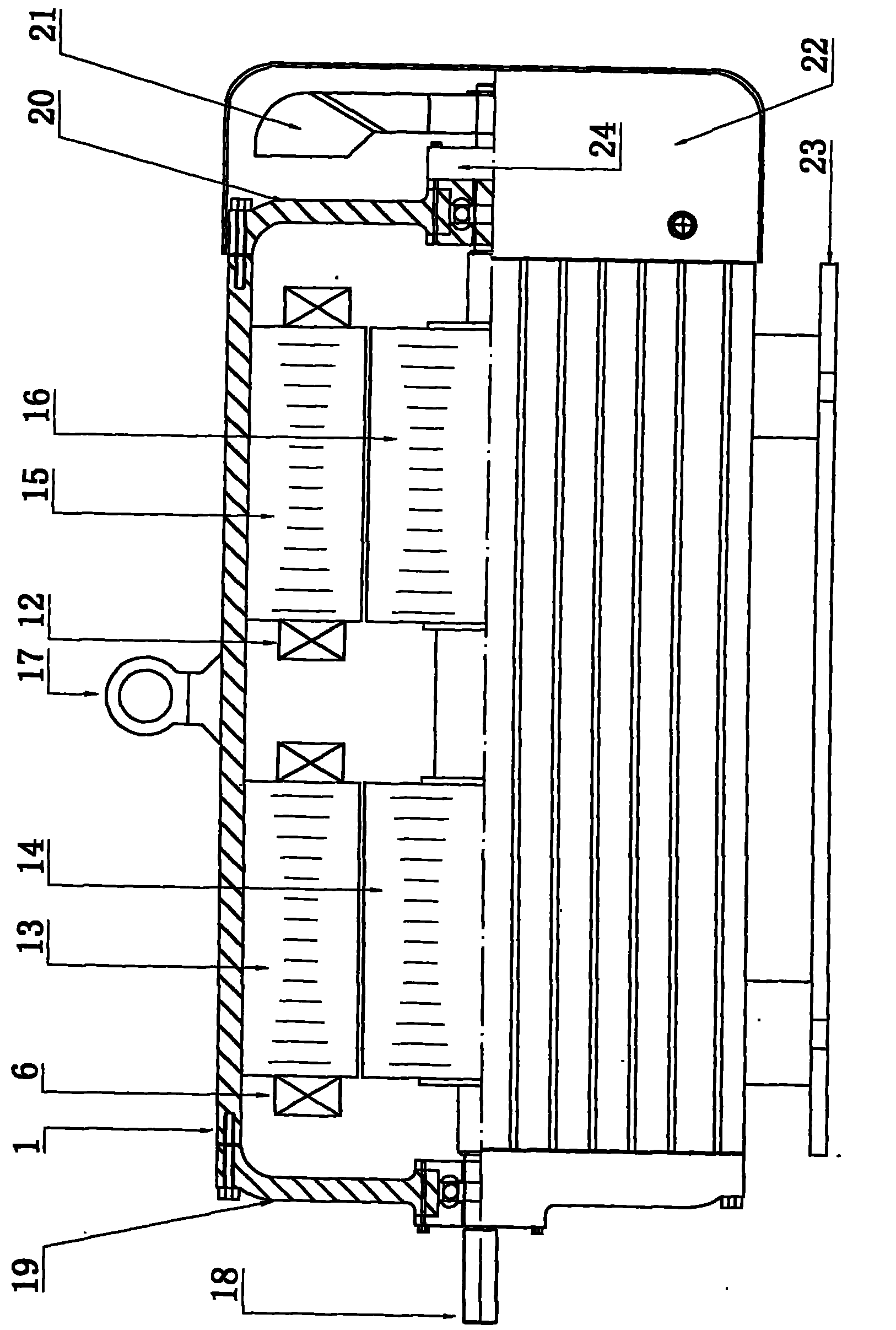

[0037] A dual-stator-rotor double-pole switched reluctance motor, comprising a motor casing 1 placed on a base 23, a motor shaft 18, and a stator and a rotor of a double-salient pole structure laminated by silicon steel sheets (see image 3 ). The middle part of the motor housing 1 is provided with a motor suspension ring 17; the two ends of the motor shaft 18 are respectively provided with a front end cover 19 and a rear end cover 20, and a rotor is arranged between the front end cover 19 and the rear end cover 20; Cover 22, the rear fan 21 is set in the wind cover 22; the sensor 24 is arranged between the rear fan 21 and the rear end cover 20; the stator and rotor cores are composed of two sections, and the length and diameter of the two sections of stator and rotor cores are equal ; Two sets of concentrated windings or layered windings are respectively installed on the two sections of stator teeth, and the armature windings on the two teeth of the same phase of each set of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com