A control method of a circumferential and axial hybrid phase-distributed switched reluctance motor

A technology of axial hybrid and reluctance motors, which is applied in the direction of AC motor control, control systems, electrical components, etc., can solve the problems of reducing the number of active poles, increasing the number of control components, and not being able to increase the number of phases arbitrarily, so as to improve torque ripple and noise, increasing the number of phases, and the effect of smooth motor operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

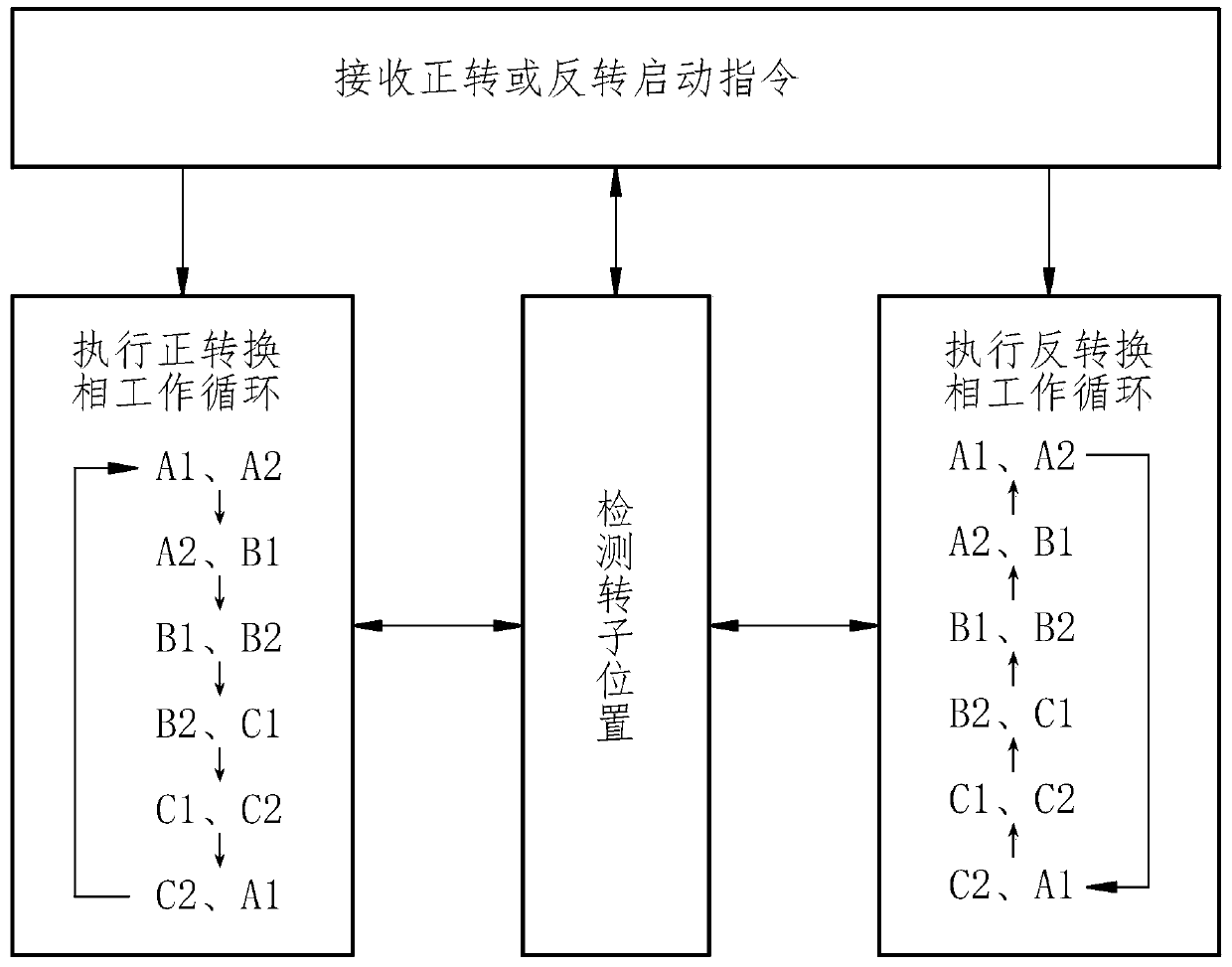

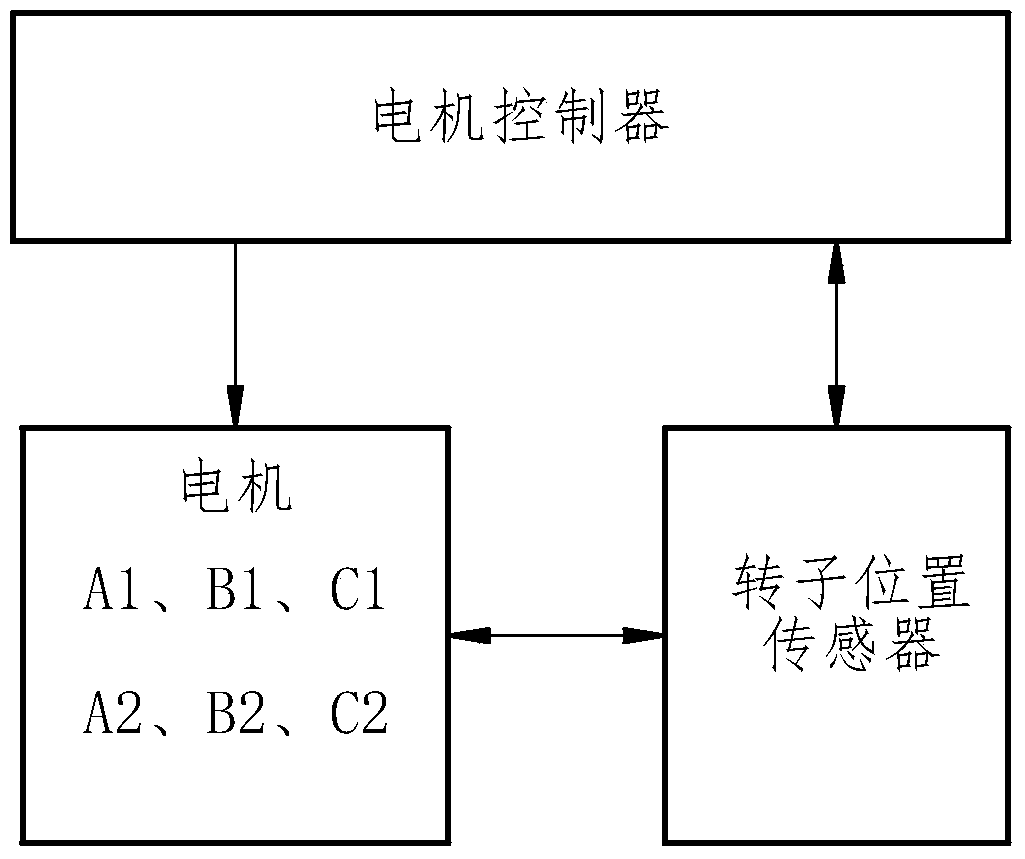

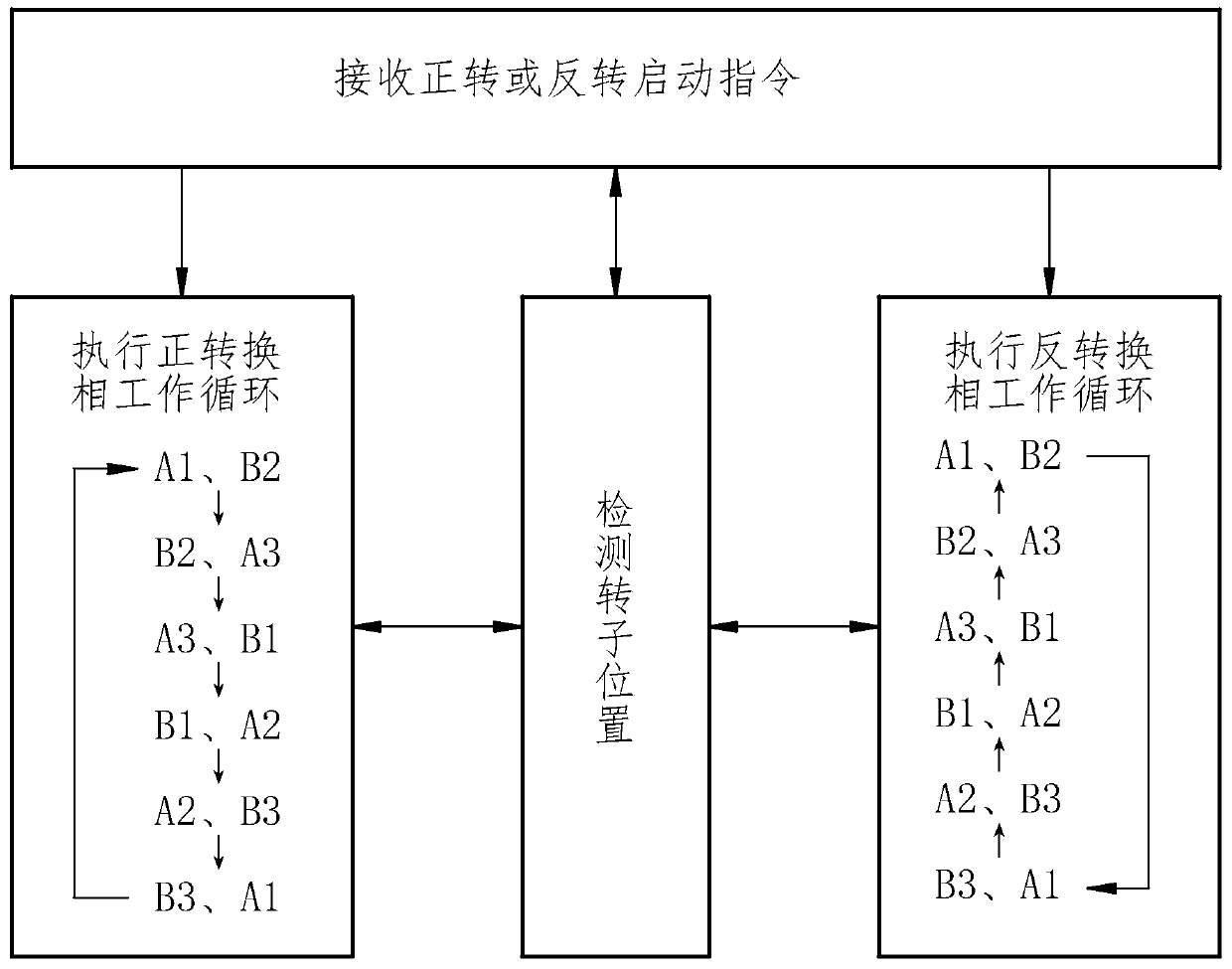

[0020] in figure 1 , figure 2 In the first embodiment shown, a method for controlling a circumferential and axial mixed phase switched reluctance motor, the circumferential and axial mixed phase switched reluctance motor has a 2×3 phase structure with two stator cores The phase windings are respectively defined as A1 phase, B1 phase, C1 phase and A2 phase, B2 phase, C2 phase, including the following steps: the motor controller receives the forward or reverse start command; the rotor position sensor detects the rotor position, and the rotor position The information is fed back to the motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com