Vacuum negative pressure gas-static super-precision guide rail

A gas static pressure, vacuum negative pressure technology, applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of low slider stiffness, poor guide rail precision retention, inability to ensure thermal symmetry, etc., to achieve high stiffness and precision maintenance. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

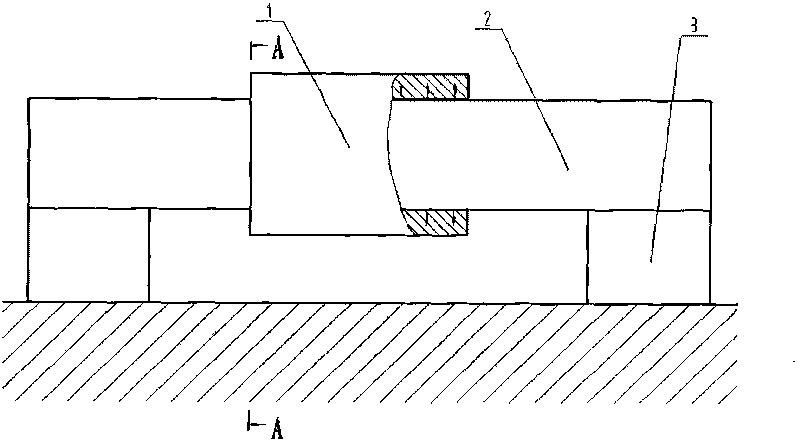

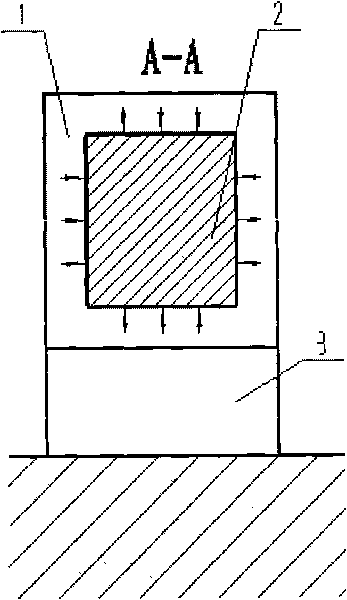

[0033] Attached below Figure 4a , Figure 4b , Figure 4c The present invention is described further:

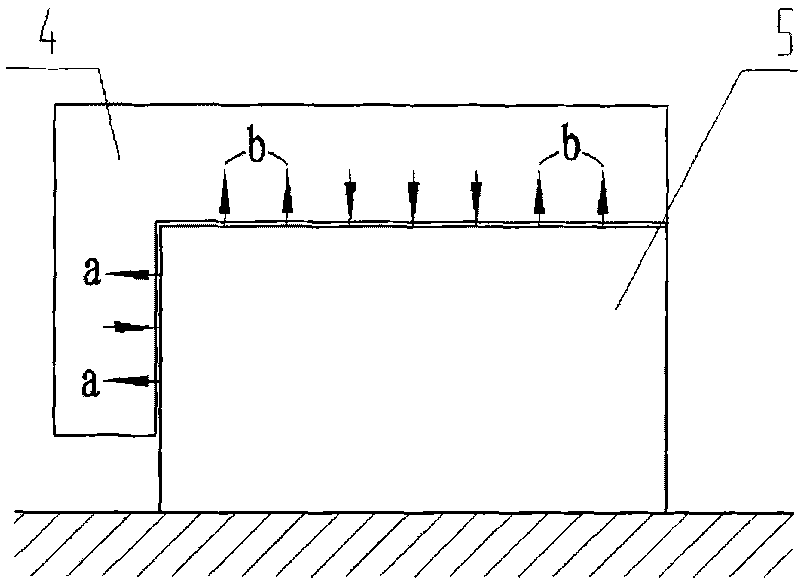

[0034] Guide rail structure description: The guide rail 11 is fixed on the upper surface of the base through the guide rail pad 12; the slider 10 is surrounded by the guide rail 11, and the fixed gaps e and f are maintained between the two sides of the guide rail 11 and the inner surface of the slider; the slider 10 is air-floated On the upper surface of the base, there is a vacuum chamber 13 on the lower bottom surface of the slider 10, and a fixed gap k is maintained between the slider 10 and the upper surface of the base; the gap size between the upper surface of the guide rail 11 and the inner upper surface of the slider 10 is designed as c, the gap dimension between the lower surface of the guide rail 11 and the inner lower surface of the slider 10 is designed as d.

[0035]The working principle of the guide rail: the slider 10 moves along the X-axis, the rotation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com