Small and medium-sized plane form grinding machine tool

A form grinding, small and medium-sized technology, which is applied to the parts of grinding machine tools, machine tools suitable for grinding workpiece planes, grinding machines, etc. Requirements, machining accuracy and grinding range are limited to low-end processing, and can not meet the processing requirements of high-end customers for parts, so as to achieve the effect of improving grinding range, improving rigidity and large grinding amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

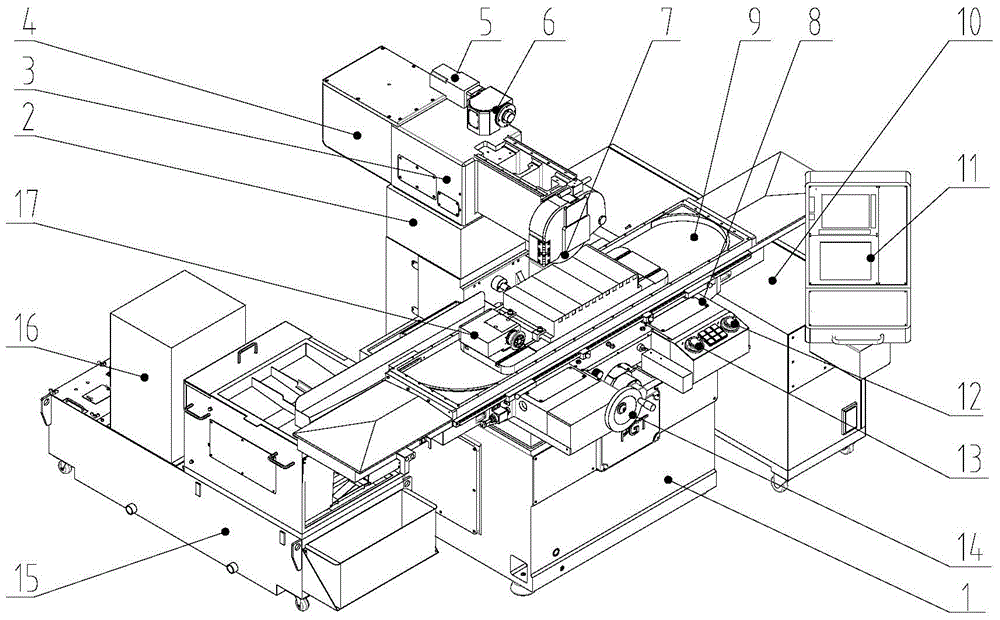

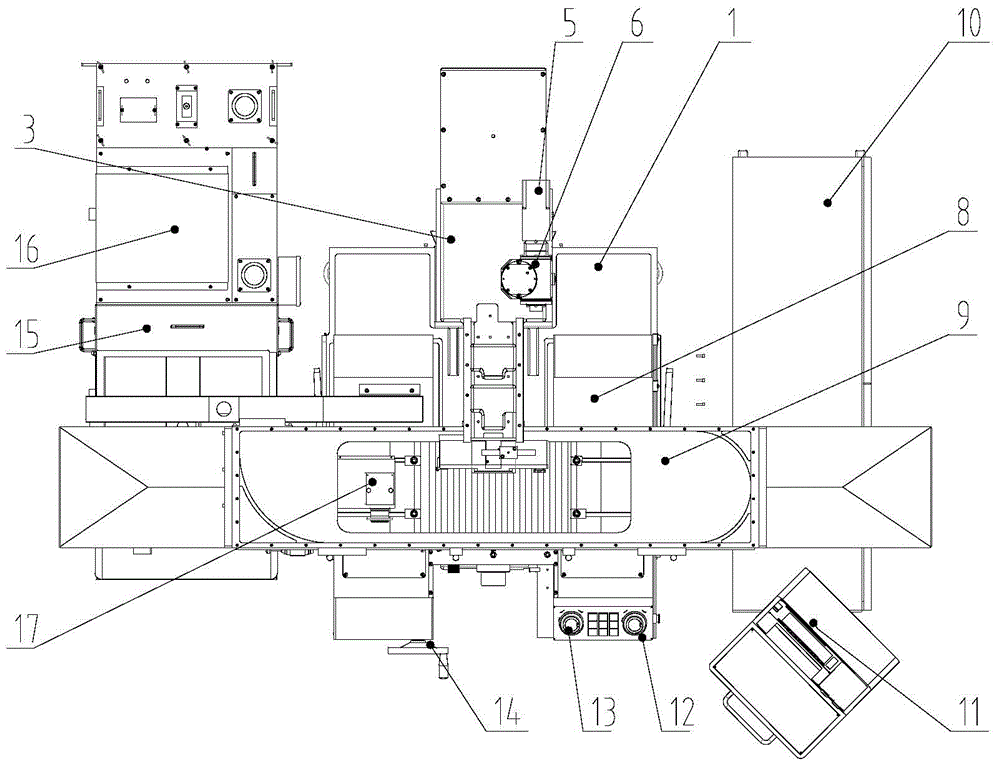

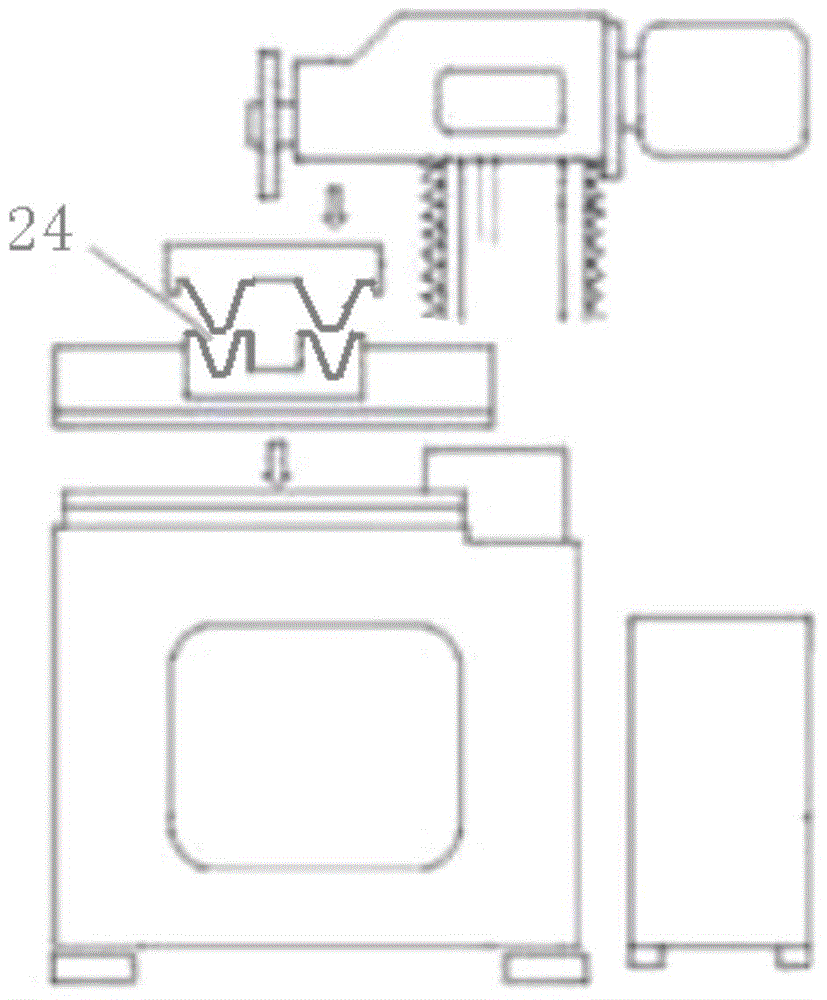

[0037] like Figure 1-6 As shown, a small and medium-sized surface forming grinding machine tool described in the embodiment of the present invention, the machine tool includes: a bed 1, an electric cabinet 10 is installed on the right side of the bed 1, and a Electric cabinet 15, the upper and lower shaft columns 2 are installed at the rear of the bed 1; the water cooler 16 is installed at the rear of the water tank 15; There is a grinding head 3, and a Y-axis screw rod 19 is installed inside the upper and lower shaft columns 2; a spindle motor 23 is installed inside the grinding head 3, and a counterweight 4 is installed at the rear end of the grinding head 3, and the grinding head 3. A Y-axis reducer 6 matching with the Y-axis screw rod 19 is installed on the upper part. A matching Y-axis servo motor 5 is installed at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com